Page 1

HP 10842 Rack

Reference Guide

December 2002 (Second Edition)

Part Number 284358-002

Page 2

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions

contained herein. The information in this document is provided “as is” without warranty of

any kind and is subject to change without notice. The warranties for HP products are set forth

in the express limited warranty statements accompanying such products. Nothing herein

should be construed as constituting an additional warranty.

HP 10842 Rack Reference Guide

December 2002 (Second Edition)

Part Number 284358-002

Page 3

Contents

About This Guide

Important Safety Information ...........................................................................................vii

Symbols on Equipment..................................................................................................... vii

Rack Stability..................................................................................................................... ix

Symbols in Text.................................................................................................................ix

Getting Help........................................................................................................................ x

Technical Support ........................................................................................................ x

HP Website................................................................................................................... x

Authorized Reseller..................................................................................................... xi

Reader’s Comments........................................................................................................... xi

Chapter 1

Overview

HP 10842 Rack................................................................................................................ 1-1

Rack Options ...................................................................................................................1-3

Delivery Considerations ..................................................................................................1-5

Installation Sequence Summary.......................................................................................1-5

Installation Service ..........................................................................................................1-6

HP 10842 Rack Reference Guide iii

Page 4

Contents

Chapter 2

Configuration Factors

Rack Configuration Software.......................................................................................... 2-1

Rack Builder Online Modes of Operation ................................................................ 2-1

Rack Builder Online Features................................................................................... 2-2

Rules for Component Placement..................................................................................... 2-3

Additional Considerations............................................................................................... 2-3

Optimum Environment.................................................................................................... 2-5

Space Requirements.................................................................................................. 2-5

Power Requirements................................................................................................. 2-5

Grounding Requirements.......................................................................................... 2-6

Temperature Requirements....................................................................................... 2-7

Airflow Requirements .............................................................................................. 2-8

Chapter 3

Preparing the Rack

Required Tools................................................................................................................ 3-2

Checking the Hardware................................................................................................... 3-2

Removing the Rack Doors .............................................................................................. 3-3

Removing the Side Panels............................................................................................... 3-7

Stabilizing the Rack ........................................................................................................ 3-8

Standalone Racks...................................................................................................... 3-8

Multiple Racks........................................................................................................ 3-10

Server/Storage vs. Switching Configurations ............................................................... 3-10

Chapter 4

Installing Components in the Rack

General Guidelines.......................................................................................................... 4-2

Component Installation Overview .................................................................................. 4-3

Using the Template ......................................................................................................... 4-4

Installing the Cage Nuts.................................................................................................. 4-5

Preparing and Installing Rack-Mountable Rails ............................................................. 4-6

Preparing the Adjustable Fixed Rails ....................................................................... 4-6

Installing the Adjustable Fixed Rails........................................................................ 4-7

Preparing the Sliding Rails....................................................................................... 4-9

Installing the Sliding Rails...................................................................................... 4-13

Preparing the Component.............................................................................................. 4-14

Adjustable Fixed Rails............................................................................................ 4-14

iv HP 10842 Rack Reference Guide

Page 5

Sliding Rails............................................................................................................ 4-15

Cable Management Arm Bracket............................................................................ 4-16

Installing the Components into the Rack.......................................................................4-17

Installing a Component into a Rack with Adjustable Fixed Rails...........................4-17

Installing a Component into a Rack with Sliding Rails ..........................................4-17

Installing the Cable Management Arm ...................................................................4-19

Connecting the Cables and Power Cord.................................................................. 4-21

Routing the Cables.........................................................................................................4-22

Chapter 5

Specifications

Appendix A

Electrostatic Discharge

Grounding Methods........................................................................................................ A-2

Appendix B

Transportation Instructions

Transportation Methods.................................................................................................. B-1

Air Transport............................................................................................................ B-1

Land Transport......................................................................................................... B-2

Sea Transport ........................................................................................................... B-2

Delivery Services............................................................................................................ B-2

Inside Rack Delivery Service................................................................................... B-2

Expedited Rack Delivery Service ............................................................................ B-3

Shipping/Delivery Considerations ........................................................................... B-4

Contents

Index

HP 10842 Rack Reference Guide v

Page 6

This guide provides step-by-step instructions for installation and reference

information for operation for the HP 10842 Rack.

Important Safety Information

Before installing this product, read the Important Safety Information document

included with the server.

Symbols on Equipment

The following symbols may be placed on equipment to indicate the presence of

potentially hazardous conditions:

WARNING: This symbol, in conjunction with any of the following symbols,

indicates the presence of a potential hazard. The potential for injury exists if

warnings are not observed. Consult your documentation for specific details.

This symbol indicates the presence of hazardous energy circuits or electric

shock hazards. Refer all servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure. Refer all maintenance, upgrades, and servicing to

qualified personnel.

About This Guide

HP 10842 Rack Reference Guide vii

Page 7

About This Guide

Weight in kg

Weight in lb

This symbol indicates the presence of electric shock hazards. The area

contains no user or field serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure.

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors into this

receptacle.

This symbol indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow the

surface to cool before touching.

These symbols, on power supplies or systems, indicate that the

equipment is supplied by multiple sources of power.

WARNING: To reduce the risk of injury from electric shock,

remove all power cords to completely disconnect power from the

system.

This symbol indicates that the component exceeds the recommended

weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manual material handling.

viii HP 10842 Rack Reference Guide

Page 8

Rack Stability

WARNING: To reduce the risk of personal injury or damage to the equipment,

be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if

more than one component is extended for any reason.

Symbols in Text

These symbols may be found in the text of this guide. They have the following

meanings.

WARNING: Text set off in this manner indicates that failure to follow directions

in the warning could result in bodily harm or loss of life.

About This Guide

CAUTION: Text set off in this manner indicates that failure to follow directions could

result in damage to equipment or loss of information.

IMPORTANT: Text set off in this manner presents essential information to explain a concept

or complete a task.

NOTE: Text set off in this manner presents additional information to emphasize or supplement

important points of the main text.

HP 10842 Rack Reference Guide ix

Page 9

About This Guide

Getting Help

If you have a problem and have exhausted the information in this guide, you can get

further information and other help in the following locations.

Technical Support

In North America, call the HP Technical Support Phone Center at 1-800-652-6672.

This service is available 24 hours a day, 7 days a week. For continuous quality

improvement, calls may be recorded or monitored. Outside North America, call the

nearest HP Technical Support Phone Center. Telephone numbers for worldwide

Technical Support Centers are listed on the HP website,

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

• Product serial number

• Product model name and number

• Applicable error messages

www.hp.com.

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

HP Website

The HP website has information on this product as well as the latest drivers and flash

ROM images. You can access the HP website at

x HP 10842 Rack Reference Guide

www.hp.com.

Page 10

Authorized Reseller

For the name of your nearest authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• Elsewhere, see the HP website for locations and telephone numbers.

Reader’s Comments

HP welcomes your comments on this guide. Please send your comments and

suggestions by e-mail to

ServerDocumentation@hp.com.

About This Guide

HP 10842 Rack Reference Guide xi

Page 11

As computer systems have evolved in size and complexity, managing them has

become a critical concern. By centralizing your equipment in a HP 10000 Series rack,

the efficiency and accessibility of your system can be increased dramatically.

The 10000 Series racks are designed to house rack-mountable products on industrystandard 19-inch (48.26-cm) wide rails. Using rack-mountable products allows you to

decrease the footprint required to house your existing hardware while still providing

expansion capability.

Racks and rack-mountable components are typically described using

U measurements. For example, one U is 44.45 mm (1.75 inches) high.

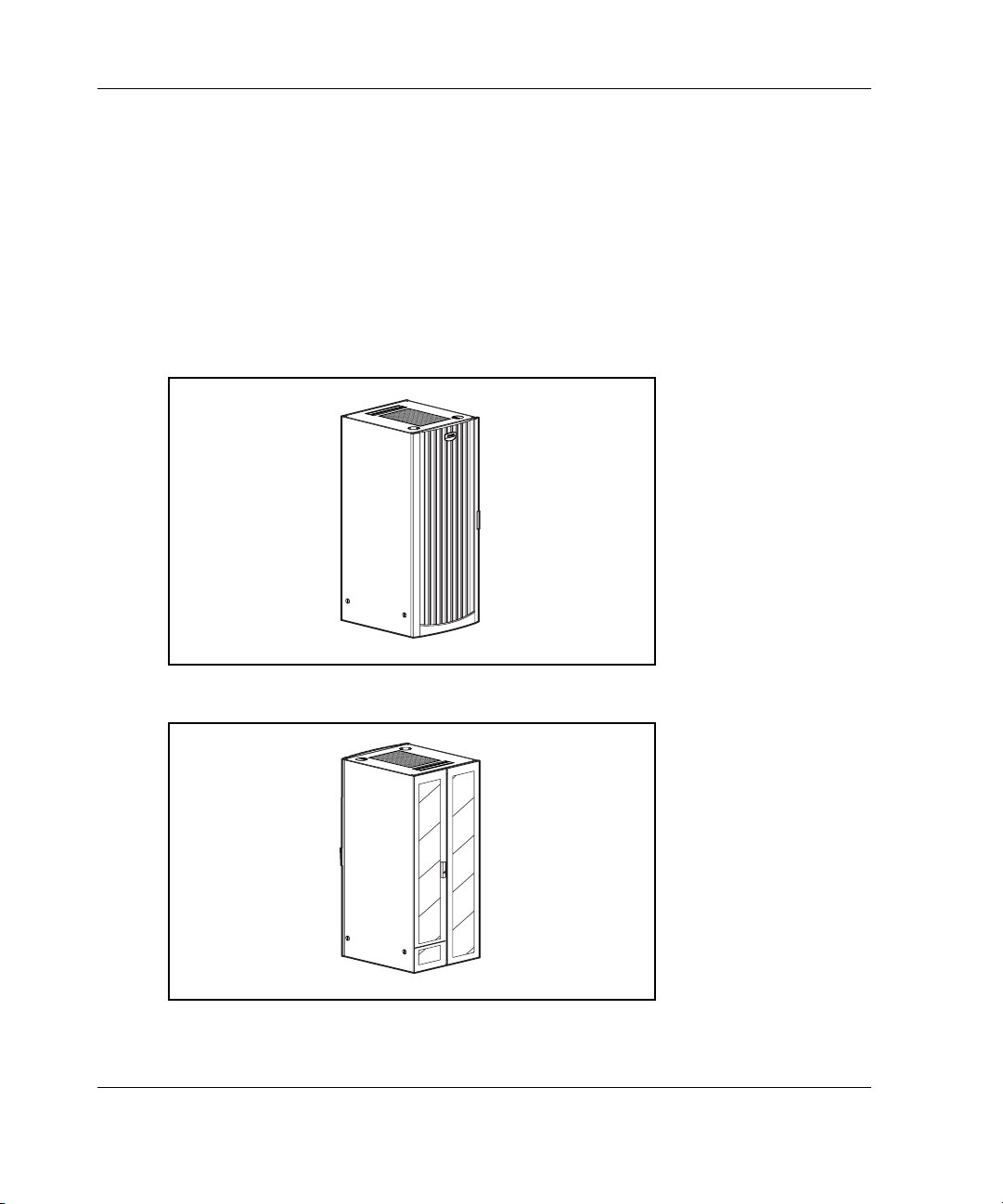

HP 10842 Rack

The HP 10842 rack is a 800 x 1000 mm 42U rack that arrives in a server/storage

configuration with internal mounting rails that are front justified, allowing the

customer room in the rear of the rack for cable routing.

1

Overview

The 10842 rack offers the following features:

• Perforated front door, solid side panels (optional), and split rear perforated doors

• Cable access panel that allows routing and cable management

• Perforated rack top with egress slot

HP 10842 Rack Reference Guide 1-1

Page 12

Overview

• Interchangeable front and rear doors that allow the rack to be used in

server/storage or switching applications

NOTE: Customers wanting to utilize the 10842 rack exclusively for switching devices,

such as routers and switches, have two options:

• Interchange the front and rear doors to make use of the mounting rail front

justification, allowing room in the front of the rack for cabling.

• Move the front vertical rails back allowing the switching devices to be mounted on

both front and rear sets of internal mounting rails.

Figure 1-1: 10842 rack

Figure 1-2: Dual-opening perforated rear doors

1-2 HP 10842 Rack Reference Guide

Page 13

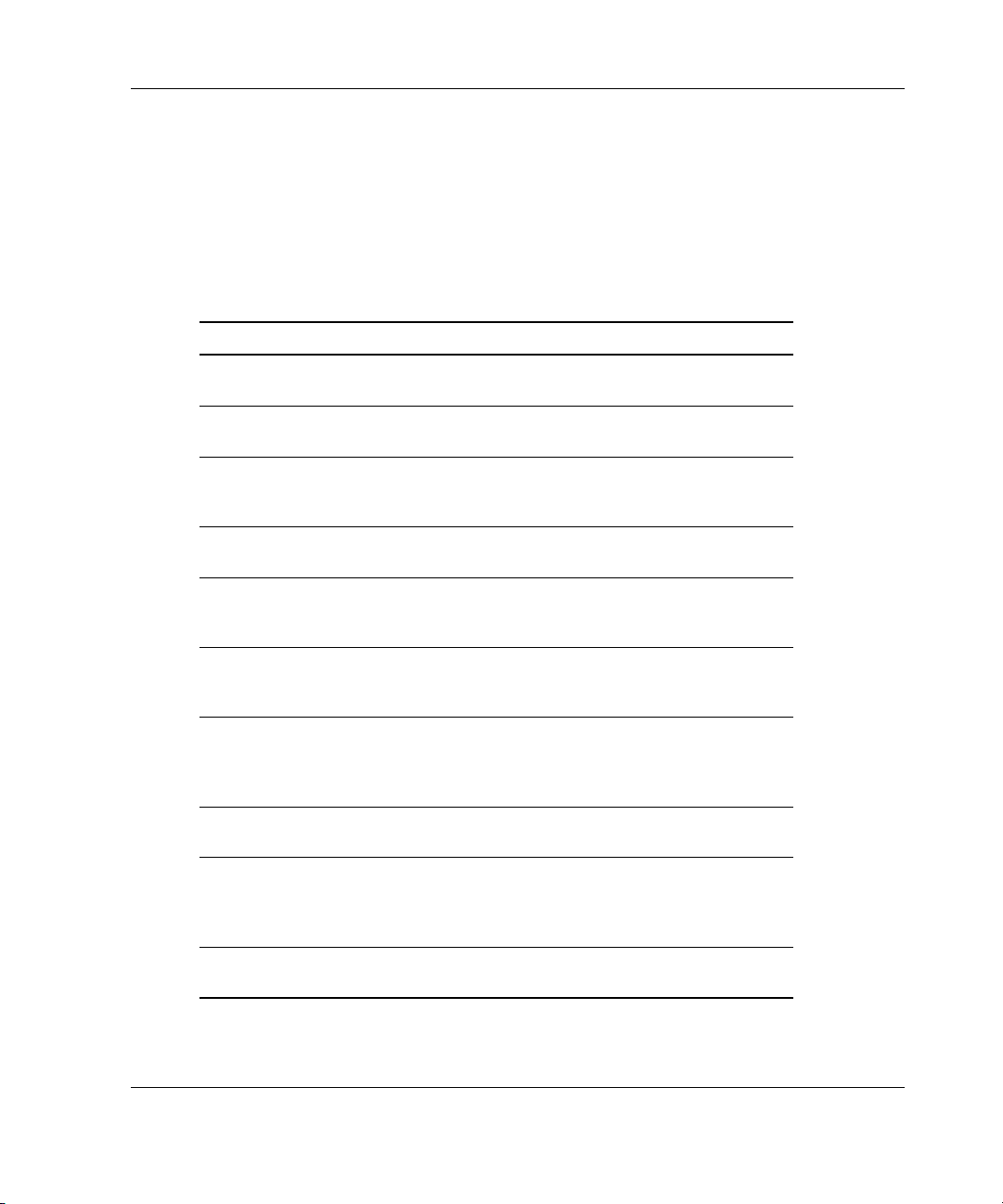

Rack Options

In addition to the standard rack, HP also provides rack options to complement or to

complete your rack solution. The following list is only a sampling of the many rack

option kits available. For more information, refer to the HP website,

Table 1-1: Rack Options

Option Description

Side Panels Rack Option Kit Provides enclosures for the sides of

Stabilizer Rack Option Kit Increases the stability of free-

Ballast Option Kit Provides rack stability when heavy

Rack Option Baying Kit Joins multiple racks of the same

Rack Option Offset Baying Kit Joins multiple racks of different

Fan (110V/220V) Rack Option Kit Enhances natural convection

Ground Bonding Rack Option Kit Reduces electromagnetic emissions

Monitor/Utility Shelf Rack Option Kit Holds a monitor or other rack

Server Console Switch Kit Provides a programmable switch

Networking Cable and Recessed

Rail Management Kits

Overview

www.hp.com.

the rack

standing racks

equipment is installed, removed, or

accessed within the rack

series, height, and depth

series with the same height but

different depths

cooling by increasing the airflow in

the rack

that may be given off by electric

components operating within the

rack

components

panel with connection hardware

used to switch a keyboard, monitor,

and mouse among multiple servers

Routes and organizes cables within

the rack

continued

HP 10842 Rack Reference Guide 1-3

Page 14

Overview

Table 1-1: Rack Options continued

Option Description

Cable Management D-Ring Rack

Option Kit

25-inch Rail Adapter Option Kit Allows the inner rack rails to

1U Keyboard Drawer Option Kit Holds and conceals a keyboard

100 Kilo Sliding Shelf Rack Option

Kit

TFT5600 Rackmount Keyboard and

Monitor (RKM) Kit

TFT5000R Flat Panel Monitor

Rackmount Kit

Depth Adjustable Fixed Rail Kit Provides rails that can be adjusted

Shock Pallet Spares Kit Transports configured racks

Rack Door Cushion Spares Kit Provides padding between the rack

Helps with cable management

accommodate third-party rack

options

Allows easy access to various rack

components

Rack-mountable 1U keyboard and

flat panel monitor on a drawer with

room in the rear to add a switchbox

Rack-mountable 2U flat panel

monitor

to various depths

unit and its front and rear doors

HP also offers several rack-mountable power products. For complete information

about these products, see the HP website,

www.hp.com.

Contact the nearest HP authorized reseller or service provider for information about

ordering rack option kits. For the name of the nearest HP authorized reseller, refer to

“About This Guide.”

1-4 HP 10842 Rack Reference Guide

Page 15

Delivery Considerations

The following list is only a sampling of the many delivery considerations available.

For more information, visit the Best Practices Web page at

When preparing to receive palletized racks, consider the following:

• The dock door at the receiving site has to accommodate the height and width of

palletized racks.

IMPORTANT: The 42U-palletized rack is approximately 216.87 cm (85.38 inches) high

and does not fit through a standard-height door.

• Do not lay a rack on its side, because the sheet metal can become distorted.

• Transport a rack as far into the building as possible while it is still on the pallet.

Ideally, move the palletized rack to its final destination before removing the rack

from the pallet, or removing any of the packaging.

Installation Sequence Summary

Overview

www.hp.com.

The following is a recommended sequence of events for the most efficient

installation of your rack and components.

1. Download the Rack Builder Online software from the HP website and install it

on your system. Using the Rack Builder Online software, plan the rack

component location and installation sequence.

2. Select a location to set up your rack. This location should be as close as possible

to the permanent site for your rack.

3. Remove the packaging from the rack and verify the hardware contents.

4. Remove any doors and panels from the rack to provide easy access.

5. Stabilize the rack.

6. Bay multiple racks together.

7. Install products such as Power Distribution Units (PDUs) or switch boxes in

sidewall locations.

HP 10842 Rack Reference Guide 1-5

Page 16

Overview

8. Install products such as Uninterruptible Power System (UPS) units starting from

the bottom of the rack.

9. Install the appropriate support rails and/or tray for the first rack-mountable

component.

10. Install the first individual component.

11. Attach a cable management arm, if required.

12. Attach the appropriate cables and power cords to the component, being sure to

adhere to all cautions and warnings.

13. Install the remaining components in the appropriate sequence.

14. Reinstall any doors and panels.

15. Power up and configure the system.

Installation Service

In the United States, HP can make arrangements to have your rack system installed

by qualified guaranteed service providers. This installation service covers the entire

hardware installation sequence, from unpacking the components to cable routing and

running a test of the system. For more information on HP support, refer to “About

This Guide.”

1-6 HP 10842 Rack Reference Guide

Page 17

Configuration Factors

Before populating your new rack, it is important to plan the placement of each

component. Factors of each component, such as weight, accessibility, power,

temperature, and airflow requirements, affect installation order and component

placement in the rack.

Rack Configuration Software

To help you plan your rack configuration more efficiently, HP provides Rack Builder

Online, the browser-based rack configuration tool. The latest version of the software

is available at

Rack Builder Online Modes of Operation

The Rack Builder Online software has two modes of operation:

www.hp.com.

2

• Help Me Build It Mode—Includes a simple interview session to help determine

your rack and component needs, as well as the necessary power products and

rack assembly devices needed to complete the final rack assembly

• Let Me Build It Mode—Lets you select the individual devices that are required

for your configuration

HP 10842 Rack Reference Guide 2-1

Page 18

Configuration Factors

Rack Builder Online Features

The Rack Builder Online software offers the following features.

• Multiple-Rack Configuration—Allows up to six racks to be viewed and

configured onscreen in one session

• Graphics—Uses graphical representations of the systems to illustrate the U

height that each component occupies

• Labeling—Aids in rack maintenance and configuration by allowing individual

racks and components within a rack to be labeled

• Drag & Drop—Allows the graphics of devices in a multiple-rack configuration

to be dragged and dropped between racks

• Reports—Provides reports on rack configuration labeling and rack suite graphics

for configurations that include multiple racks

• Third-Party Support—Allows you to define and add third-party products

If you are planning a new rack, use Rack Builder Online to view your rack as you

build it. Then print out a report and use it as your shopping list. After your rack

configuration is in place, use Rack Builder Online to assist you in maintenance and

upgrades.

Refer to the documentation accompanying Rack Builder Online for installation and

use of the software features.

2-2 HP 10842 Rack Reference Guide

Page 19

Rules for Component Placement

The following rules apply to the physical placement of components in the rack.

• Weight—Sort all components by weight, placing the heaviest components at the

bottom of the rack.

• Balance—Be sure to balance the weight load between racks, placing the heaviest

components at the bottom. For example, if you have several UPS units and

several servers, do not put all of the UPS units into one rack—distribute them

evenly in the bottom positions of each rack.

• Server Console Switch—Position the switch box on the side of the rack above

the keyboard, or mount it behind the keyboard.

• CRT Monitor—Position the monitor topmost within the rack.

• Rack Mountable Flat Panel Monitor—Select a position to accommodate the

desired viewing height (a minimum of 4Us above the keyboard tray).

Additional Considerations

Configuration Factors

The following are additional items to consider, based on your specific rack

configuration.

• Power—If a UPS is installed, do not exceed its output rating. Be sure to review

the installation instructions provided with each component for important cautions

and warnings.

• PDUs—Install PDUs before installing other components.

• Height—The height of the rack and of rack-mountable components is measured

in U increments. When you are configuring your rack installation, remember that

the total U measurement of the components you want to install cannot exceed the

stated U height of the rack.

• Keyboard—The rack keyboard requires prior installation of a 1U Keyboard

Drawer Rack Option Kit.

HP 10842 Rack Reference Guide 2-3

Page 20

Configuration Factors

• Monitor—The monitor requires installation of a Monitor/Utility Shelf Rack

Option Kit unless you are using a rack-mountable flat panel monitor.

• Server Console Switch—If a switch box is configured, use the CPU-to-Switch

cable included with the server. The standard distance between the switch box and

the keyboard, monitor, and/or mouse can vary by 3-, 7-, 12-, 20- and 40-foot

(91.44-, 213.36-, 365.76-, 609.6-, and 1219.2-cm) lengths. Optional Plenumrated KVM cables are available in 20- and 40-foot (609.6- and 1219.2-cm)

lengths.

NOTE: National Electrical Regulations governing the installation of building wiring require

that an appropriate cable, meeting fire-safety standards, be used any time cabling is

routed:

• Through an overhead drop-ceiling

• Under a computer room’s raised flooring

• From room to room

• From floor to floor

Be sure that the cable jacket or sleeving is made of material that does not burn easily and

does not exude toxic fumes when exposed to heat. Be sure that the cable you have

selected is appropriate for your installation site. If you require U.S. plenum-rated (CL2P)

cable, please contact your local HP authorized reseller to obtain the following options:

• 149363-B21—20-foot (609.6-cm) plenum cable

• 149364-B21—40-foot (1219.2-cm) plenum cable

• Rack Option Baying Kit—The number of baying kits needed to join a series of

racks is one less than the number of racks in the suite.

• Rack Option Offset Baying Kit—This kit joins multiple racks of different

series with the same height but different depths.

• Sidewall Panels—Only one set of sidewall panels is required for each row of

bayed racks.

• Stabilizing Feet—A stand-alone rack requires stabilizing feet.

2-4 HP 10842 Rack Reference Guide

Page 21

Optimum Environment

Specific requirements for space, power, temperature, and airflow must be met to

provide optimum performance with minimum maintenance for your rack

environment.

Space Requirements

When deciding where to place your rack:

• At least 122 cm (48 inches) of clearance is needed all the way around the pallet

and above the rack to allow the removal of packing materials.

• At least 86 cm (34 inches) of clearance is needed in front of the rack to allow the

door to open all the way.

• At least 75 cm (30 inches) of clearance is needed in the rear of the rack to

provide access to components.

• At least 38 cm (15 inches) of clearance is needed around a power supply to

facilitate servicing.

Configuration Factors

Power Requirements

WARNING: To reduce the risk of personal injury, fire, or damage to the

equipment, do not overload the AC supply branch circuit that provides power

to the rack. Consult the electrical authority having jurisdiction over your

facility wiring and installation requirements.

When planning for power distribution requirements for your rack configuration:

• The power load must be balanced between available AC supply branch circuits.

• The overall system AC current load must not exceed 80 percent of the branch

circuit AC current rating.

• If a UPS is used, the load should not exceed 80 percent of the marked electrical

current rating of the UPS.

HP 10842 Rack Reference Guide 2-5

Page 22

Configuration Factors

CAUTION: To reduce the risk of damage to the equipment, verify that all AC voltage

selector switches are set correctly to match your local AC line voltage

(115V or 230V). If the AC voltage selector switch is not properly set, your

components will be damaged when power is applied.

The installation of this equipment shall be in accordance with local/regional electrical

regulations governing the installation of Information Technology Equipment by

licensed electricians. This equipment is designed to operate in installations covered

by the National Electric Code (ANSI/NFPA-70, 1993) and the code for Protection of

Electronic Computer/Data Processing Equipment (NFPA-75, 1992).

For electrical power ratings on options, refer to the product’s rating label or user

documentation supplied with that option.

Grounding Requirements

For proper operation and safety, all powered rack-mountable components are

required to be properly grounded in accordance with NFPA 70-1993, Article 250. All

power distribution devices, branch wiring, and receptacles must be listed as

grounding-type devices.

When using power strips for electrical distribution, make sure that ground integrity is

maintained for each connection made. Plug each component into a reliably grounded

outlet.

WARNING: To reduce the risk of electric shock or damage to your equipment,

do not disable the power cord grounding feature. This equipment is designed

to be connected to a grounded (earthed) power outlet that is easily accessible

and located as close as possible to the equipment. The grounding plug is an

important safety feature.

2-6 HP 10842 Rack Reference Guide

Page 23

Temperature Requirements

For safe and reliable operation of equipment, locate the system in a well-ventilated,

climate-controlled environment.

Configuration Factors

The HP Maximum Recommended Ambient Operating Temperature (T

) for most

MRA

server products is 95°F (35°C). Therefore, the temperature in the room where the

rack is located should not exceed 95°F (35°C).

The operating temperature inside the rack is always higher than the room

temperature, and is dependent on the configuration of equipment in your rack. Check

the T

for each piece of equipment before installation.

MRA

The maximum internal rack temperature for your configuration should not exceed the

values in the following table.

Table 2-1: Rack Internal Temperature Maximums

Equipment Included Maximum Internal Rack Temperature

HP rack-mountable servers 95°F/35°C

HP rack-mountable options 104°F/40°C

HP PDUs 122°F/50°C

Other manufacturers’ options See other manufacturers’ specifications

CAUTION: To reduce the risk of damage to the equipment when installing

third-party options:

• Make sure that the option equipment does not impede airflow to the

rack-mountable products already installed in the rack, nor increase the internal

rack temperature beyond the maximum rating specified by HP.

• Make sure that the manufacturer’s Maximum Recommended Ambient Operating

Temperature for the option equipment is not exceeded when the option

equipment is installed in a HP rack.

HP 10842 Rack Reference Guide 2-7

Page 24

Configuration Factors

Airflow Requirements

HP rack-mountable products typically draw in cool air through the front and exhaust

warm air out through the rear of the rack. The front door of the rack, therefore, must

be adequately ventilated to allow ambient room air to enter the rack, and the rear

door must be adequately ventilated to allow the warm air to escape the rack. Do not

block the ventilation apertures.

Fan Kits

If additional cooling is required, fan kits can be used to draw heated air from the rear

of the rack, out through the top.

Blanking Panels

If the front of the rack is not completely filled with components, the remaining gaps

between the components can cause changes in the airflow that adversely affect

cooling within the rack. Cover these gaps with blanking panels.

2-8 HP 10842 Rack Reference Guide

Page 25

This chapter discusses the following topics:

• Required tools

• Checking the hardware

• Removing the rack doors

• Removing the side panels

• Stabilizing the rack

— Standalone racks

— Multiple racks

• Server/storage vs. switching configurations

3

Preparing the Rack

HP 10842 Rack Reference Guide 3-1

Page 26

Preparing the Rack

Required Tools

You need the following tools to install your rack components:

• Flat-bladed screwdriver

• Phillips screwdrivers—#1, #2, and #3

• Torx screwdrivers—T-10, T-15, T-25, and T-30

• Adjustable wrench

• Allen wrench

• Cage nut fitting tool (included with the rack-mounting hardware kit)

For comfort and efficiency while setting up your rack and installing the components,

use battery-powered screwdrivers.

Checking the Hardware

After unpacking the rack and its components, locate the HP Rack Kit Components

List that was shipped with your rack. Be sure that you received all the listed

components.

IMPORTANT: You will typically have extra fasteners after completing your rack configuration

and component installation. Retain the extra fasteners for future use.

3-2 HP 10842 Rack Reference Guide

Page 27

Removing the Rack Doors

To provide access to all sides of the rack while you are installing the various

components, first remove the rack doors. If your rack has side panels, also remove

them before installing mounting brackets and other hardware.

To remove the rack front door:

1. Unlock the door (1) and press the handle release button down (2) until the handle

pops out.

2. Lift the handle up and out to open the door (3).

3

Preparing the Rack

1

2

Figure 3-1: Opening the rack front door

HP 10842 Rack Reference Guide 3-3

Page 28

Preparing the Rack

3. Lift up the top hinge pin (1).

4. Tilt the door out (2) and lift the door away from the rack to remove it from the

bottom hinge bracket. Store the front door in an upright position, taking care to

protect it from damage.

2

Figure 3-2: Removing the rack front door

1

3-4 HP 10842 Rack Reference Guide

Page 29

To remove the rack rear doors:

1. Rotate the rack rear door handle to the right (1).

2. Pull the rack rear door handle to open the rack rear doors (2).

1

2

Figure 3-3: Opening the rack rear doors

Preparing the Rack

HP 10842 Rack Reference Guide 3-5

Page 30

Preparing the Rack

3. Open the hinge brackets by pulling up on the top hinge bracket and down on the

bottom hinge bracket for each rear door (1).

4. Lift the rear doors off of the hinge brackets and remove them from the rack (2).

Store the rear doors in an upright position, taking care to protect them from

damage.

Figure 3-4: Removing the rack rear doors

2

1

1

3-6 HP 10842 Rack Reference Guide

Page 31

Removing the Side Panels

To remove the side panels:

1. Unlock the two side panel locks securing the side panels to the rack (1).

2. Lift each side panel up to unhook it from the hangers bolted on the rack

frame (2).

3. Remove each side panel from the rack (3). Store the side panels in an upright

position, taking care to protect them from damage.

2

Preparing the Rack

1

3

Figure 3-5: Removing the rack side panels

Instructions for replacing the side panels are given in Side Panel Rack Option Kit

Installation Instructions.

HP 10842 Rack Reference Guide 3-7

Page 32

Preparing the Rack

Stabilizing the Rack

WARNING: The rack allows you to stack computer components on a vertical

rather than a horizontal plane. To reduce the risk of personal injury or damage

to the equipment, you must follow these instructions carefully and heed all

cautions and warnings throughout the installation instructions.

Standalone Racks

If you are installing a single (standalone) rack, make sure that the rack is level and

that the stabilizing feet have been attached, before installing the components. If an

unstable rack is loaded with components, it can become unbalanced and may tip over.

Extending the Leveling Feet

CAUTION: To reduce the risk damage to the casters, make sure that the full weight

of the rack rests on the leveling feet, and not on the casters. The casters are

designed only as an aid in moving the rack into position. They are not designed to

support the weight of the rack and may become damaged if relied on to support the

rack.

The leveling feet, located beside each caster on the rack, unscrew and extend to the

floor, resting in leveling feet bases provided with your rack. These feet support the

rack and help compensate for uneven surfaces.

After positioning the rack in its final location, use an adjustable wrench to extend the

leveling feet to the base until the weight of the rack is fully on the feet and feet bases,

not the casters. This stabilizes the rack for installation of your components.

3-8 HP 10842 Rack Reference Guide

Page 33

Attaching the Stabilizing Feet

WARNING: To reduce the risk of personal injury, you must attach the

stabilizing feet to all standalone (non-bayed) racks.

The Stabilizer Rack Option Kit contains three full-size stabilizing feet that are used

for standalone racks. Attach one stabilizing foot to the front and one to each side of

the rack. Stabilizing feet are not required on the back of a standalone rack.

Preparing the Rack

Figure 3-6: Full-size stabilizing feet attached (top view)

HP 10842 Rack Reference Guide 3-9

Page 34

Preparing the Rack

Multiple Racks

To increase space and stability, 10842 racks can be bayed together by installing the

Rack Option Baying Kit or the Rack Option Offset Baying Kit, depending on the

series, height, and depth.

• Rack Option Baying Kit—Joins multiple racks of the same series, height, and

depth

• Rack Option Offset Baying Kit—Joins multiple racks of different series with

the same height but different depths

Observe the following tips when using multiple-rack configurations:

• Stabilizing feet are optional with bayed racks.

• The number of baying kits needed is one less than the total number of racks.

• Position and install either baying option kit before populating the racks with

components.

• Racks from different series can be bayed together as long as they are the same

height.

Server/Storage vs. Switching Configurations

The 10842 rack offers interchangeable front and rear doors that allow the rack to be

used in server/storage or switching applications. The 42U rack arrives in a

server/storage configuration with internal mounting rails that are front-justified,

providing the customer greater room in the rear of the rack for cable routing.

3-10 HP 10842 Rack Reference Guide

Page 35

4

Installing Components in the Rack

IMPORTANT: It is strongly recommended that you configure your rack using the Rack Builder

Online software before beginning the installation process.

This chapter discusses the following topics:

• General guidelines

• Component installation overview

• Using the template

• Installing the cage nuts

• Preparing and installing rack-mountable rails

• Preparing the component

• Installing the component

HP 10842 Rack Reference Guide 4-1

Page 36

Installing Components in the Rack

General Guidelines

WARNING: To reduce the risk of personal injury, always be sure that the rack

is adequately stabilized before extending a component outside the rack. A rack

may become unstable if more than one component is extended for any reason.

Extend only one component at a time.

WARNING: To reduce the risk of personal injury or damage to the equipment,

always load the heaviest item first from the bottom of the rack up. This makes

the rack bottom-heavy and helps prevent the rack from becoming unstable.

Refer to Chapter 2, “Configuration Factors,” for more information about the

placement of rack-mountable components.

WARNING: To reduce the risk of personal injury or damage to the equipment,

be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if

more than one component is extended for any reason.

CAUTION: To reduce the risk of damage to the equipment when installing

third-party options:

• Be sure the option equipment installed does not impede airflow to the

rack-mountable ProLiant servers or increase the internal rack temperature

beyond the maximum rating specified by HP.

• Be sure that the option equipment installed does not exceed the manufacturer’s

Maximum Recommended Ambient Operating Temperature.

4-2 HP 10842 Rack Reference Guide

Page 37

Observe the general guidelines when installing your components:

• Refer to the user documentation that was shipped with the component for

detailed instructions on installing a specific component or third-party hardware.

• Refer to Appendix A, “Electrostatic Discharge,” before installing components

into the rack.

• Use the configuration prepared with the Rack Builder Online software as a

guideline for installing the components.

• Install the heavier components first from the bottom of the rack up.

• Be sure to balance the weight load between bayed racks. For example, if you

have several UPS units and several servers, do not install all of the UPS units into

one rack. Instead distribute them evenly in the bottom positions of each rack.

• Allow a minimum clearance of 76 cm (30 inches) between the wall and the rear

of the rack to provide adequate access for installation and service.

Component Installation Overview

NOTE: The stabilizer feet should be installed before any component installation.

IMPORTANT: The following installation instructions are for standard installations. For specific

installation instructions, refer to the documentation included with your component.

Installing Components in the Rack

The following steps outline the sequence for installing rack-mountable components

in a rack. You should install zero U devices first, such as PDUs, switch boxes, and

so on.

1. Use the template to measure and mark the rack for correct placement of the

installation hardware.

2. Install the cage nuts into the rack.

3. Prepare and install the adjustable fixed rails, sliding rails, or both.

4. Prepare the component for mounting it into the rack.

5. Install the component into the rack and secure it.

6. Attach the cable management arm to the rack and then to the component.

HP 10842 Rack Reference Guide 4-3

Page 38

Installing Components in the Rack

7. Connect the appropriate cables and power cords, being sure that you adhere to all

cautions and warnings contained in the individual component installation

instructions.

8. Remove the cable access panel and route the cables (using the conduit if present).

Using the Template

Use the template that shipped with your rack-mountable component to mark the

location of the mounting hardware on the mounting rails of the rack.

1. Push back the tabs (marked ★) on the top of the template and place them in the

correct holes in the mounting rails.

2. Match up the hole pattern indicated on the sides of the template with the hole

pattern on the mounting rails.

Be sure you begin measuring in the correct place. If a rack component is already

installed immediately below the planned position of the new component, place the

template on top of the previously installed component against the front mounting

rails.

Figure 4-1: Measuring with the template

4-4 HP 10842 Rack Reference Guide

Page 39

3. Use the front of the template to mark the attachment points for rack-mounting

brackets, rails, components, or cage nuts on the front of the rack.

4. Use the back of the template to mark the attachment points for rack-mounting

brackets, rails, components, or cage nuts on the back of the rack.

Installing the Cage Nuts

Use the cage nut insertion tool to install the cage nuts on the inside of the mounting

rails.

To install the cage nuts:

1. Hook the bottom lip of the cage nut in the square rail perforation.

2. Insert the tip of the insertion tool through the perforation and hook the top lip of

the cage nut.

3. Pull the cage nut through the hole until the top lip snaps into position.

Installing Components in the Rack

Figure 4-2: Installing the cage nuts

HP 10842 Rack Reference Guide 4-5

Page 40

Installing Components in the Rack

Preparing and Installing Rack-Mountable Rails

IMPORTANT: The installation instructions in this section are for standard installations. For

specific installation instructions, please refer to the documentation included with your

component.

These are two types of rack-mountable rails:

• Adjustable fixed rails

• Sliding rails

Preparing the Adjustable Fixed Rails

Components mounted with adjustable fixed rails are typically designed to slide into

the rack one time for initial installation.

1. Loosen the wing nuts (1) and extend the brackets to the desired length (2) for

each adjustable rail.

1

2

Figure 4-3: Adjusting the fixed rails

2. Tighten the wing nuts slightly to stabilize the rail-mounting brackets during

installation.

4-6 HP 10842 Rack Reference Guide

Page 41

Installing the Adjustable Fixed Rails

To install the adjustable fixed rails:

1. Insert at least one screw through each rack-mounting rail, securing the adjustable

fixed rail to the front of the rack.

NOTE: After installing your components, insert at least one more screw into each

adjustable rail for additional support.

Installing Components in the Rack

Figure 4-4: Securing the adjustable fixed rails to the

front of the rack

HP 10842 Rack Reference Guide 4-7

Page 42

Installing Components in the Rack

2. Insert at least one screw through the rail-mounting bracket and into the cage nuts

installed earlier, securing the adjustable fixed rail to the rear of the rack.

NOTE: After installing your components, insert at least one more screw into each

adjustable rail for additional support.

Figure 4-5: Securing the adjustable fixed rails to the

rear of the rack

3. Retighten the wing nuts on the adjustable fixed rails.

The adjustable fixed rails are now ready for installation of your components.

4-8 HP 10842 Rack Reference Guide

Page 43

Preparing the Sliding Rails

Components mounted with this type of rail are designed for frequent accessibility,

maintenance, or both.

1. Extend the component rail until the component rail release latch clicks (1).

2. Hold down the component rail release latch (2) and completely remove the

component rail from the sliding rail assembly.

NOTE: You will attach the component rails to the component before you insert the unit

into the rack.

Installing Components in the Rack

2

1

Figure 4-6: Removing the component rails from the

sliding rail assembly

HP 10842 Rack Reference Guide 4-9

Page 44

Installing Components in the Rack

3. After removing the component rail, attach the sliding rail assembly to the rackmounting brackets. Note the orientation of the rack-mounting brackets:

a. The front flange (1) has alignment tabs.

b. The back flange (2) is designed to install flush against the rack.

1

Figure 4-7: Rack-mounting brackets

2

4-10 HP 10842 Rack Reference Guide

Page 45

Installing Components in the Rack

4. Note the orientation of the sliding rail assembly:

a. The front of the sliding rail assembly (1) allows the inner slide to move

forward on ball bearings.

b. The back of the sliding rail assembly (2) has a stop for the inner slide.

NOTE: While matching fronts, lay one rack-mounting bracket and one sliding rail

assembly together so that the screw holes are aligned.

2

1

Figure 4-8: Orienting the sliding rail assembly

5. Extend the inner slide in the sliding rail assembly until the screw holes in the

rack-mounting bracket and the sliding rail assembly are aligned (1). (Refer to

Figure 4-9.) Secure the sliding rail assembly to the rack-mounting bracket by

inserting one 8-32 x 3/8 screw into each of the three exposed holes, two near the

rear and one near the front of the sliding rail assembly.

6. Adjust the inner slide until you can access another screw hole (2) and insert one

8-32 x 3/8 screw. (Refer to Figure 4-9.)

HP 10842 Rack Reference Guide 4-11

Page 46

Installing Components in the Rack

7. Adjust the inner slide again and insert the last 8-32 x 3/8 screw (3) into the

exposed hole.

1

2

3

Figure 4-9: Attaching the sliding rail assembly to the

rack-mounting brackets.

Repeat the steps 4 through 7 for the other sliding rail. The sliding rails are now ready

for installation.

4-12 HP 10842 Rack Reference Guide

Page 47

Installing the Sliding Rails

To install the sliding rails:

1. Align and secure the front of each sliding rail to the front of the rack with two

M6 x 16 screws.

NOTE: The tabs on the front of the sliding rails help you align them correctly with the

mounting rails.

Installing Components in the Rack

Figure 4-10: Securing the front of the sliding rails

HP 10842 Rack Reference Guide 4-13

Page 48

Installing Components in the Rack

2. Align the rear of each sliding rail with the cage nuts on the rear of the rack and

secure them with two M6 x 16 screws.

Figure 4-11: Securing the rear of the sliding rails

Preparing the Component

This section contains general instructions for preparing a typical rack-mountable

component for installation. Refer to the documentation that ships with each

component for complete installation instructions.

Adjustable Fixed Rails

If the component mounts with adjustable fixed rails, typically there is nothing

additional to install on the component before inserting it into the rack.

4-14 HP 10842 Rack Reference Guide

Page 49

Sliding Rails

For a sliding rail installation, you need to install the component rails on the

component before you can insert it into the rack.

To install the component rails on the component:

1. Locate the component rails that you set aside when they were removed from the

sliding rail assemblies.

2. Use three 8-32 x 3/8 screws to install each component rail on the side of the

component.

Installing Components in the Rack

Figure 4-12: Attaching the component rails to the

component

HP 10842 Rack Reference Guide 4-15

Page 50

Installing Components in the Rack

Cable Management Arm Bracket

If the component uses a cable management arm, use two 6-32 x ¼ screws to attach

the bracket that supports the cable management arm.

NOTE: The cable management arm is installed after the component is installed into the rack.

Figure 4-13: Attaching the cable management arm

bracket to the component

4-16 HP 10842 Rack Reference Guide

Page 51

Installing Components in the Rack

Installing the Components into the Rack

After all rack-mounting hardware has been installed on the component, you can insert

it into the rack.

WARNING: Components can be very heavy. To reduce the risk of personal

injury or damage to the equipment:

• Remove all pluggable power supplies and modules to reduce the weight of

the product before lifting it.

• Observe local occupational health and safety requirements and guidelines

for manual material handling.

• Get help to lift and stabilize the product during installation or removal,

especially when the product is not fastened to the rails.

• The product is unstable when it is not fastened to the rails during

installation into or removal from the rack.

Installing a Component into a Rack with Adjustable Fixed Rails

To install a component into a rack with adjustable fixed rails:

With the unit well supported, lift the component up and slide it into place along the

adjustable fixed rails you installed in the rack.

Installing a Component into a Rack with Sliding Rails

IMPORTANT: Read and adhere to the cautions and warnings in this section.

To install a component into a rack with sliding rails:

1. Fully extend the sliding rails.

2. With the unit well supported, lift it up and align the component rails on the

component with the sliding rails secured to the rack.

HP 10842 Rack Reference Guide 4-17

Page 52

Installing Components in the Rack

3. Press in the component rail release latches on either side of the component and

slide the unit all the way back into the rack.

NOTE: The first time you slide the component into the rack, you may have to apply some

pressure to loosen the ball bearings. After that, the ball bearings should slide easily.

I

0

Figure 4-14: Inserting the component into the rack

4. Using the cage nuts, tighten the thumbscrews on the front of the unit to secure it

to the rack.

4-18 HP 10842 Rack Reference Guide

Page 53

Installing the Cable Management Arm

To install the cable management arm:

1. Extend the cable management arm and bend the hinged bracket to the right.

2. Use two M6 x 12 Phillips screws to attach the cable management arm to the

bracket you installed on the component.

Installing Components in the Rack

Figure 4-15: Attaching the cable management arm to

the bracket

HP 10842 Rack Reference Guide 4-19

Page 54

Installing Components in the Rack

3. Align the screw-retaining plate behind the rack-mounting rail at the rear of the

rack and attach the cable management arm to the rail with two 10-32 x 5/8

screws.

NOTE: As you slide the unit in and out of the front of the rack, the cable management

arm collapses and extends so that the cables remain connected to the unit and stay

untangled.

Figure 4-16: Attaching the cable management arm to

the rack

4. Secure any cables that you connect to the component to this arm.

4-20 HP 10842 Rack Reference Guide

Page 55

Connecting the Cables and Power Cord

To connect the cables and power cord:

1. Connect appropriate cables to the component.

2. Connect the power cord by doing the following:

a. Remove the label covering the AC power outlet.

b. Set the input voltage selection switch to the appropriate position.

c. Connect the AC power cord to the unit.

Installing Components in the Rack

Figure 4-17: Connecting the AC power cord to the

component

HP 10842 Rack Reference Guide 4-21

Page 56

Installing Components in the Rack

Routing the Cables

To route the cables:

1. Extend the cable management arm; then bundle the cables and the power cord.

2. Secure the cables to the cable management arm with the fasteners provided.

NOTE: Leave enough slack in the cables so that you can bend the cable management

arm easily.

3. Route the bundled cables over the top of the cable management arm and down

the conduit, if present.

Figure 4-18: Routing the cables for server/storage

applications

4-22 HP 10842 Rack Reference Guide

Page 57

Installing Components in the Rack

4. Remove the cable access panel, if present:

NOTE: The cable access panel can be removed from the left rear door.

a. Rotate the handle to the right.

b. Pull the handle to open the doors (1).

c. Release the cable access panel hinges (2) and then unscrew the two

fasteners (3). Retain the fasteners and hinge brackets for later steps.

d. Remove the cable access panel from the hinge bracket (4). Store the panel in

an upright position, taking care to protect it from damage.

3

3

4

1

2

Figure 4-19: Removing the cable access panel

HP 10842 Rack Reference Guide 4-23

Page 58

Installing Components in the Rack

WARNING: To reduce the risk of electrical shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an

important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

• When using an optional power distribution device, make sure that the

ground integrity is maintained for each connection by plugging each

component into a reliable grounded outlet.

CAUTION: To reduce the risk of damage to the equipment, verify that all AC voltage

selector switches are set to match your local AC line voltage (115V or 230V). If the

AC voltage selector switches are not properly set, your components will be damaged

when power is supplied.

5. After all cables and power cords have been routed to their power destinations,

connect the power cords to a main power switch such as a properly rated Power

Distribution Unit (PDU).

NOTE: If you are not using a PDU, route the power cord directly to a properly rated and

grounded AC wall or floor outlet.

4-24 HP 10842 Rack Reference Guide

Page 59

Specifications

Table 5-1: Model 10842

Dimensions

Cabinet size Height 2000 mm (78.7 inches)

Depth 1000 mm (39.4 inches)

Width 800 mm (31.5 inches)

Shipping size

(with packing materials)

Height 2220 mm (85.4 inches)

Depth 1219 mm (48 inches)

Width 985 mm (38.8 inches)

5

Weight

Operating 115 kg (253 lbs)

Shipping 148 kg (325 lbs)

Loading Static (gross) 907 kg (2000 lbs)

Dynamic (gross) 454 kg (1000 lbs)

HP 10842 Rack Reference Guide 5-1

Page 60

A

Electrostatic Discharge

To prevent damaging the system, be aware of the precautions you need to follow

when setting up the system or handling parts. A discharge of static electricity from a

finger or other conductor may damage system boards or other static-sensitive

devices. This type of damage may reduce the life expectancy of the device.

To prevent electrostatic damage, observe the following precautions:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free

workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or

assembly.

HP 10842 Rack Reference Guide A-1

Page 61

Electrostatic Discharge

Grounding Methods

There are several methods for grounding. Use one or more of the following methods

when handling or installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or

computer chassis. Wrist straps are flexible straps with a minimum of 1 megohm

± 10 percent resistance in the ground cords. To provide proper ground, wear the

strap snug against the skin.

• Use heel straps, toe straps, or boot straps at standing workstations. Wear the

straps on both feet when standing on conductive floors or dissipating floor mats.

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have HP

authorized reseller install the part

NOTE: For more information on static electricity, or assistance with product installation,

contact your HP authorized reseller.

A-2 HP 10842 Rack Reference Guide

Page 62

Transportation Instructions

NOTE: The following section is only a sampling of the many delivery considerations available.

For more information, visit the Best Practices Web page at www.hp.com.

Transportation Methods

Depending on your circumstances and time schedule, there are three transportation

methods for transporting your rack: air, land, and sea.

Air Transport

All racks can be air freighted upright (on a pallet or shock pallet) or horizontally

(in a crate). However, since the 10842 rack has a packaged height of 217 centimeters

(85.4 inches) and the maximum height for air cargo is 218.4 centimeters (86 inches),

only the largest cargo planes can accommodate it upright. If your destination does not

accommodate large cargo planes, the 10842 rack must be air freighted horizontally in

a crate.

B

A passenger plane with cargo space has a height limitation of 160 centimeters

(63 inches). Because a palletized 10622 rack is below this limit, it can readily be

delivered by air. It must be shipped upright on a pallet, and double-stacking is not

allowed.

CAUTION: If your rack is an integrated model, it MUST be transported upright. If

this is not possible, remove all components from the rack and prepare them for

delivery, or choose an alternative transportation method.

HP 10842 Series Reference Guide B-1

Page 63

Transportation Instructions

Because of the dimensions and the weight of the racks, check with carriers for their

limitations before dispatching.

Land Transport

All racks can be shipped by common carriers. Carriers providing air ride capabilities

are preferred. Ship racks upright on their pallets. Do not lay the racks horizontally or

double-stack them. Because of the dimensions and the weight of the racks, please

check with carriers for their restrictions before dispatching.

Sea Transport

All racks can be transported by sea, but it takes four to six weeks for the shipment to

arrive. Ship racks upright on their pallets. Do not lay the racks horizontally or

double-stack them.

Delivery Services

HP provides two methods of delivery for customers in North America: Inside Rack

Delivery Service and Expedited Rack Delivery Service. If you want both Inside Rack

Delivery and Expedited Rack Delivery, you must specify both part numbers on your

purchase order.

Inside Rack Delivery Service

Inside Rack Delivery Service (Part No. 184649-001) is available for receiving sites

that do not have the proper facilities for the standard dock-to-dock delivery, or when

you need delivery to a specific location within a site. The rack is transported as close

as possible to the desired location. If a stairway or a non-accessible doorway is

encountered, the rack is left there.

Highlights

• The palletized rack is unloaded by transportation personnel.

• Transportation personnel provide material-handling equipment.

B-2 HP 10842 Series Reference Guide

Page 64

• The rack is delivered to the desired location within the facility

(see “Limitations”).

• Delivery service is for a single rack.

Limitations

• If shipping a non-integrated rack, door widths and corridors must accept a

99-centimeters x 122-centimeters (39-inches x 48-inches) pallet.

• Door heights and corridors must be at least 2 meters (79 inches) tall to

accommodate the 10842 rack.

• A proper freight elevator must be available for deliveries to upper and lower

floors.

• Transportation personnel will not remove the rack from the shipping pallet.

• Transportation personnel will not remove the pallet or packaging.

Expedited Rack Delivery Service

Expedited Rack Delivery Service (Part No. 184449-001) is available in the rare

instances when air shipment of the rack is required.

Transportation Instructions

Highlights

• Special packaging, such as crating, is provided as required.

• Shipment is made by an air carrier selected by HP.

• Delivery service is for a single rack.

Limitations

• This service is available only in the continental United States, Alaska,

and Hawaii.

• Inside rack delivery is not included.

HP 10842 Series Reference Guide B-3

Writer: Amy L. Laffitte File Name: h-appb Transportation Methods

Codename: Mastiff Part Number: 284358-002 Last Saved On: 10/23/02 1:07 PM

HP CONFIDENTIAL

Page 65

Transportation Instructions

Shipping/Delivery Considerations

The following precautions should be observed when receiving the racks and

components.

• A dock door is needed at the receiving site to accommodate the height and width

of the palletized racks.

• When shipping a rack, the 99-centimeters x 122-centimeters (39-inch x 48-inch)

pallet does not fit through a standard-width internal door, which is about

76.2 centimeters (30 inches) wide.

• The palletized 42U rack is approximately 216 centimeters (85 inches) high and

does not fit through a standard-height door.

• Do not lay the rack horizontally because the sheet metal can become distorted.

• Transport the rack as far into the building as possible while still on the pallet.

Then remove the rack from the pallet and roll the rack on its casters, being

careful to keep the rack from tipping. Ideally, the palletized rack should be

moved to its final destination and then removed from the pallet.

B-4 HP 10842 Series Reference Guide

Page 66

Index

Symbols and Numbers

100 kilo sliding shelf rack option kit 1-4

1U keyboard drawer rack option kit 1-4

25-inch rail adapter option kit 1-4

A

AC supply branch circuit warning 2-5

adjustable fixed rails

installing into rack 4-7

installing on components 4-14

preparing 4-6

air transport of rack B-1

airflow

blanking panels 1-4

caution 2-7

fan kits 2-8

requirements 2-8

ventilation 2-8

attaching

cable management arm 4-19

cables 4-21

power cords 4-21

authorized reseller xi

authorized, service provider 1-6

B

balance considerations 2-3

ballast rack option kit 1-3

baying offset rack option kit 1-3

baying rack option kit 1-3

Best Practices web page 1-5

blanking panels, using 2-8

boot straps, using A-2

C

cable access panel, removing 4-23

cable management arm, installing 4-20

cable management bracket, installing 4-19

cable management D-ring rack option

kit 1-4

cables

attaching 4-21

length 2-4

routing 4-22

server console switch 2-4

cage nuts, installing 4-5

clearance

around the rack 2-5

between wall and rack 4-3

to unpack 2-5

HP 10842 Rack Reference Guide Index-1

Page 67

Index

component placement considerations 2-3

components

installation guidelines 4-3

installing into rack 4-17

preparing for, required 4-14

configurations

factors 2-1

Rack Builder Online 4-3

rack, planning 2-1

software 2-1

considerations

delivery 1-5

height 2-3

power 2-3

stabilizing feet 2-4

CRT Monitor considerations 2-3

D

definition, U measurement 1-1

delivery

considerations B-4

services, overview B-2

transporting 1-5

depth adjustable fixed rail rack option

kit 1-4

doors 1-1

E

electrostatic discharge See ESD

environment requirements

airflow 2-8

grounding 2-6

power 2-5

space 2-5

temperature 2-7

ESD (electrostatic discharge)

obtaining additional information A-2

precautions A-1

preventing A-1

storing products A-1

transporting products A-1

types of damage from A-1

expedited delivery service B-3

F

fan rack option kit 1-3

features

10842 Rack 1-1

Rack Builder Online 2-1

fixed rails

installing 4-7

prepaing 4-6

flat panel monitor rack mount option kit 1-4

flat panel monitor, positioning 2-3

front door 3-3

G

graphics, Rack Builder Online 2-2

ground bonding rack option kit 1-3

grounding requirements 2-6

grounding straps

specifications A-2

wearing A-2

grounding, methods A-2

guidelines for component installation 4-3

H

hardware shipped with rack 3-2

heel straps, using A-2

Index-2 HP 10842 Rack Reference Guide

Page 68

Index

height, rack configuration

considerations 2-3

Help Me Build It Mode, Rack Builder

Online 2-1

HP authorized service provider 1-4

HP Maximum Recommended Ambient

Operating Temperature 2-7

HP website x

I

inside delivery service B-2

installation

overview of 4-3

service for 1-6

summary sequence of 1-5

tools needed for 3-2

installing

cable management arm 4-19

cable management arm bracket 4-19

cage nuts 4-5

components 4-17

fixed rails 4-7

sliding rails 4-15

zero U devices 4-3

installing components in to rack 4-17

interchangeable front and split rear

doors 1-2

J

joining racks 2-4

M

marking with the template 4-4

Maximum Recommended Ambient

Operating Temperature (TMRA) 2-7

measurements 2-3

modes of operation, Rack Builder

Online 2-1

monitor

placement 2-3

required parts 2-4

monitor/utility shelf rack option kit 1-3

multiple racks

configuring 2-2

stabilizing 3-10

tips 3-10

N

National Electric Code 2-6

National Electrical Regulations 2-4

networking cable and recessed rail

management rack option kit 1-3

O

opening

front door 3-3

rear doors 3-5

optimum environment 2-5

options 1-3

overview 1-1

K

keyboard 2-3

L

labeling, Rack Builder Online 2-2

land transport of rack B-2

Let Me Build It Mode, Rack Builer

Online 2-1

HP 10842 Rack Reference Guide Index-3

P

parts

proper handling A-1

storing A-1

transporting A-1

PDU

installation location 1-5

rack configuration considerations 2-3

planning a rack configuration 2-1

power

Page 69

Index

rack configuration consideration 2-3

requirements 2-5

power cords, attaching 4-21

power distribution unit See PDU

preparing

adjustable fixed rails 4-6

components 4-14

sliding rails 4-15

R

rack

baying 2-4

configuration software 1-5

environment 2-5

hardware list 3-2

joining 2-4

multiple, stabilizing 3-10

option kits 1-3

outside dimensions 2-5

shipping by air B-1

shipping by land B-2

shipping by sea B-2

standalone, stabilizing 3-8

unpacking, space required 2-5

Rack Builder Online

described 4-3

features 2-2

modes of operation 2-1

rack configuration software 2-2

rack configuration utility 1-5

rack door cushion spares kit 1-4

rack kit components list 3-2

rack option

100 kilo sliding shelf kit 1-4

1U keyboard drawer kit 1-4

25-inch rail adapter kit 1-4

ballast kit 1-3

baying kit 1-3

cable management D-ring kit 1-4

depth adjustable fixed rail kit 1-4

door cushion spares kit 1-4

fan kit 1-3

features 1-3

ground bonding kit 1-3

monitor/utility shelf kit 1-3

networking cable and recessed rail

management kit 1-3

offset baying kit 1-3

server console switch kit 1-3

shock pallet spares kit 1-4

side panel kit 1-3

stabilizer kit 1-3

TFT5000R flat panel monitor rackmount

kit 1-4

TFT5600 rackmount keyboard and

monitor kit 1-4

rack spares, shock pallet kit 1-4

rack stability, warning 4-2

rack-mounting brackets, installing 4-11

rails, fixed

installing 4-7

preparing 4-6

rails, sliding

installing 4-13

preparing 4-9

rear doors

opening 3-5

removing 3-6

removing

cable access panel 4-23

front door 3-3

rear doors 3-5

side panels 3-7

replacing side panels 3-7

reports, Rack Builder Online 2-2

requirements

blanking panels 1-4

environment 2-5

grounding 2-6

power 2-5

temperature 2-7

wiring 2-4

routing, cables 4-22

Index-4 HP 10842 Rack Reference Guide

Page 70

Index

S

sea transport of rack B-2

server console rack option kit 1-3

server console switch

placement 2-3

required parts 2-4

server/storage vs. switching 3-10

service for installing racks 1-6

shipping

by air B-1

by land B-2

by sea B-2

receiving B-4

shock pallet spares kit 1-4

side panels

considerations 2-4

removing 3-7

replacing 3-7

side panels rack option kit 1-3

sliding rails

installing on component 4-15

installing on rack 4-13

space required

between wall and rack 4-3

for rack 2-5

stability, warning 4-2

stabilizer rack option kit 1-3

stabilizing

multiple racks 3-10

standalone racks 3-8

stabilizing feet

attaching 3-9

considerations 2-4

standalone racks, stabilizing 3-8

static-safe containers

storing products in A-1

transporting products in A-1

switching configurations 3-10

symbols in text ix

system, preventing electrostatic damage

to A-1

T

technical support x

telephone numbers x, xi

temperature 2-7

template, using 4-4

TFT5000R flat panel monitor rackmount

rack option kit 1-4

TFT5600 rackmount keyboard and monitor

rack option kit 1-4

tools

conductive field service type A-2

required 3-2

transporting rack

by air B-1

by land B-2

by sea B-2

U

UPS 2-3

V

ventilation airflow 2-8

voltage selection switch, caution 2-6

W

websites, HP x

weight considerations 2-3

wiring requirements 2-4

wrist straps

specifications A-2

using A-2

HP 10842 Rack Reference Guide Index-5

Loading...

Loading...