Page 1

Model 10811A/B

Errata

Title & Document Type: 10811A/B Quartz Crystal Oscillator Operating &

Service Manual

Manual Part Number: 10811-90002

Serial Prefixes: 2028

Revision Date: August 1980

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-Packard's former test and measurement, semiconductor products and chemical analysis businesses are now part of Agilent Technologies.

Changes to this Manual

No changes have been made to this manual, with the exception of correcting the odd

spelling and grammatical errors. In some places original photographs may be replaced

or augmented with modern digital photographs. (it’s weird looking at an old BW HP

manual and seeing a color photograph… still gets me)

All pages are scan at 600 DPI and in some cases (schematics) scaled down to fit

8½x11 page. If you wish to print on 11x17 or larger just print the page and scale to fit.

About this Manual

This manual is reproduced from scans of an original document, which is then converted

using my own custom designed OCR software, and then edited in Microsoft

®

Word 2003.

This means that what you see here is not a scan of a scan/copy with text overlays.

OCR errors may exist and as such the user of this document should take care and use

common sense when referencing this documentation.

Copyright Notice

This documentation is © Copyright 1980 Hewlett Packard and © Copyright 2006, Jack Hudler, hpdocs@hudler.org.

Permission to use and redistribute this documentation for non-commercial and internal

corporate purposes is hereby granted, free of charge.

Any redistribution of this documentation or its derivates must include this copyright

notice.

You may not sell this documentation or its derivations without written consent.

You may modify this documentation as necessary, but you may not sell derivative works

based on it.

You may include this documentation with the equipment/hardware on which it is used

for the purposes of selling the equipment/hardware. If you advertise that a copy of this

documentation is included in the sale, you must state that is for “Free”.

Meaning if you want to gratuitously toss in a copy of the manual on an eBay sale, it’s ok

with me as long as you state it’s for free. No you can’t sell a digital archive of manuals

and say it includes a free copy of this documentation. You must give it away with

equipment.

I think you get the spirit of the copyright; it takes a lot of hours to scan and replicate a

manual. I just want this used in the spirit in which is it given.

Agilent if you have questions or wish to include this in your archive, please email me.

Page 2

Model 10811A/B

Page Intentionally Left Blank

Page 3

Model 10811A/B

Page 4

Model 10811A/B

10811A/B

QUARTZ CRYSTAL OSCILLATOR

OPERATING AND SERVICE MANUAL

SERIAL PREFIX: 2028

This manual applies to Hewlett-Packard Model 10811 A/B Oscillators with serial prefix number 2028.

Also covers oscillators with HP Part Numbers 1081160101 and 10811-60105.

OTHER SERIAL PREFIXES

For serial prefixes above 2028, a "Manual Change" sheet is included with this manual.

First Edition - August 1980

©Copyright 1980

by

HEWLETT-PACKARD COMPANY

5301 Stevens Creek Blvd.

Santa Clara, CA 95050

All Rights Reserved

MANUAL PART NUMBER 10811-90002 Microfiche Part Number 10811-90003

Page 5

Model 10811A/B

TABLE OF CONTENTS

I. GENERAL INFORMATION ..................................................................................2

1-1. INTRODUCTION....................................................................................................2

1-4. SPECIFICATIONS ................................................................................................. 2

1-6. SAFETY CONSIDERATIONS................................................................................2

1-8. INSTRUMENTS COVERED BY THIS MANUAL...................................................2

1-13. DESCRIPTION.......................................................................................................4

1-19. HP Part Number 10811-60101 and 10811-60105 ..........................................4

1-22. RECOMMENDED TEST EQUIPMENT .................................................................4

II. INSTALLATION..................................................................................................6

2-1. INTRODUCTION....................................................................................................6

2-3. INITIAL INSPECTION............................................................................................6

2-5. PREPARATION FOR USE .................................................................................... 6

2-6. Power Requirements.......................................................................................6

2-10. Single Source Regulated Power Supply .........................................................7

2-12. ELECTRONIC FREQUENCY CONTROL (EFC)...................................................7

2-16. 10 MHz FREQUENCY OUTPUT SIGNAL ......................................................7

2-18. OVEN MONITOR OUTPUT...................................................................................8

2-20. MATING CONNECTORS AND MOUNTING ......................................................... 8

2-23. INSTALLATION INSTRUCTIONS...................................................................9

2-25. INSTALLATION INSTRUCTIONS (HP INSTRUMENT) ...................................... 10

2-28. OPERATING ENVIRONMENT ............................................................................10

2-34. STORAGE AND SHIPMENT ............................................................................... 11

2-35. Environment ..................................................................................................11

2-37. PACKAGING........................................................................................................ 11

2-38. Original Packaging ........................................................................................11

2-40. Other Packaging............................................................................................11

III. OPERATION ....................................................................................................12

3-1. INTRODUCTION..................................................................................................12

3-3. BASIC POWER-UP DESCRIPTION.................................................................... 12

3-7. FREQUENCY ADJUSTMENT .............................................................................12

3-9. FREQUENCY ADJUSTMENT PROCEDURE ..................................................... 12

3-10. ACCURACY VS ADJUSTMENT INTERVAL.......................................................13

IV. OPERATIONAL VERIFICATION ........................................................................16

4-1. INTRODUCTION..................................................................................................16

4-3. OPERATIONAL VERIFICATION ......................................................................... 16

4-5. EQUIPMENT REQUIRED....................................................................................16

4-7. TEST RECORD ...................................................................................................16

4-13. OPTIONAL CONTROLLERS AND COUNTERS................................................. 21

4-14. Optional Controllers....................................................................................... 21

4-16. Optional Counters..........................................................................................22

V. ADJUSTMENTS ...............................................................................................25

5-1. INTRODUCTION..................................................................................................25

5-3. EQUIPMENT REQUIRED....................................................................................25

5-5. FACTORY SELECTED COMPONENTS.............................................................25

5-7. ADJUSTMENT LOCATION .................................................................................25

5-9. SAFETY CONSIDERATIONS..............................................................................25

5-11. OSCILLATOR FREQUENCY ADJUSTMENT .....................................................25

5-13. Offset Calculation: .........................................................................................26

5-14. OUTPUT AMPLITUDE ADJUSTMENT ...............................................................27

Page 6

Model 10811A/B

VI. REPLACEABLE PARTS.................................................................................... 29

6-1. INTRODUCTION..................................................................................................29

6-3. ORDERING INFORMATION ...............................................................................29

6-5. HP PART NUMBER ORGANIZATION ................................................................29

6-7. Component Parts and Materials ..........................................................................30

6-10. GENERAL USAGE PARTS .................................................................................31

6-12. Specific Instrument Parts ..................................................................................... 31

6-14. Factory Selected Parts......................................................................................... 31

6-20. REPLACEABLE PARTS LIST LAYOUT..............................................................31

VII. MANUAL CHANGES........................................................................................ 37

7-1. INTRODUCTION..................................................................................................37

7-3. MANUAL CHANGES ...........................................................................................37

7-5. NEWER INSTRUMENTS.....................................................................................37

VIII. SERVICE.................................................................................................... 39

8-1. INTRODUCTION..................................................................................................39

8-3. SCHEMATIC DIAGRAM SYMBOLS AND REFERENCE DESIGNATORS ........ 39

8-5. REFERENCE DESIGNATORS............................................................................39

8-6. Theory of Operation.......................................................................................39

8-8. OVERALL BLOCK DIAGRAM THEORY .............................................................39

8-13. MAIN OSCILLATOR THEORY OF OPERATION................................................42

8-18. ELECTRONIC FREQUENCY CONTROL (EFC).................................................43

8-20. AUTOMATIC GAIN CONTROL (AGC) ................................................................ 44

8-23. RF OUTPUT IMPEDANCE MATCHING AND OUTPUT BUFFER......................45

8-25. VOLT AGE REFERENCES (5.7V AND 6.4V) .....................................................45

8-27. OVEN HEATER AND CONTROLLER THEORY................................................. 46

8-35. PRECISION VOLTAGE REFERENCE................................................................47

8-37. OVEN CONTROLLER TURN-ON CURRENT LIMITING .................................... 47

8-39. HEATER TRANSISTOR BALANCE ....................................................................48

8-41. REPAIR AND TROUBLESHOOTING.................................................................. 49

8-42. Inspection ......................................................................................................49

8-44. REPAIR................................................................................................................49

8-45. Printed Circuit Component Replacement......................................................49

8-47. Replacing Integrated Circuits ........................................................................49

8-50. TROUBLESHOOTING.........................................................................................50

8-57. DISASSEMBLY FOR TROUBLESHOOTING AND REPAIR...............................51

8-61. SPECIAL TEST CONNECTOR FOR 10811A ..................................................... 52

8-65. SPECIAL CABLE FOR THE 10811 B.................................................................. 53

8-67. SPECIAL PARTS REPLACEMENT CONSIDERATIONS ................................... 53

8-69. OVEN CONTROLLER TROUBLESHOOTING....................................................55

8-70. General..........................................................................................................55

8-74. Normal Operation ..........................................................................................56

8-76. TROUBLESHOOTING.........................................................................................56

8-80. Troubleshooting Cautions..............................................................................56

8-82. Flex Damage .................................................................................................56

8-84. OSCILLATOR TROUBLESHOOTING.................................................................58

8-86. NORMAL OPERATION .......................................................................................58

8-88. OSCILLATOR TROUBLESHOOTING TECHNIQUES ........................................ 58

8-92. TROUBLESHOOTING INFORMATION...............................................................59

Page 7

Model 10811A/B

LIST OF TABLES

Table 1-1. Specifications Table .............................................................................................................. 3

Table 1-2. Recommended Test Equipment ...........................................................................................5

Table 2-1. Input Voltages/Voltage Coefficients ...................................................................................... 6

Table 3-1. Accuracy vs Adjustment......................................................................................................14

Table 4-1. Operational Verification Descriptions..................................................................................17

Table 4-2. Operation Verification Procedure........................................................................................18

Table 4-3. 5316A Program Codes........................................................................................................22

Table 4-4. Operational Verification Record ..........................................................................................24

Table 6-1. Replaceable Parts ...............................................................................................................32

Table 6-1. Replaceable Parts (Continued)...........................................................................................34

Table 6-2. Manufacturers Code List ..................................................................................................... 35

Table 8-1. Temperature Set Resistor List.............................................................................................54

Table 8-2. Oven Controller Troubleshooting Tree................................................................................57

Table 8-3. Oven Circuit Voltages·.........................................................................................................61

Table 8-4. Oscillator Section Normal Voltages (see Notes 1, 2, 3)...................................................... 61

LIST OF FIGURES

Figure 1-1. 10811A and 108118 Oscillators...........................................................................................1

Figure 2-1. Single Source Regulated Power Supply..............................................................................7

Figure 2-3. 10811A Supply and Output Connections............................................................................ 8

Figure 2-4. 10811B Supply and Output Connections............................................................................9

Figure 2-5. Mechanical Mounting Dimensions.....................................................................................10

Figure 3-1. Oscillator Adjustment Set-Up............................................................................................. 13

Figure 4-1. BASIC Program..................................................................................................................21

Figure 4-2. HPL Program......................................................................................................................21

Figure 5-1. Oscillator Adjustment Setup ..............................................................................................26

Figure 5-2. 10811A Amplitude Adjustment Set-up............................................................................... 27

Figure 5-3. 108118 Amplitude Adj Set-up ............................................................................................ 28

Figure 8-1. Schematic Diagram Notes................................................................................................. 40

Figure 8-2. 10811A/B Overall Block Diagram.......................................................................................41

Figure 8-3A. Basic Colpitts- Type Oscillator.........................................................................................42

Figure 8-3B. Main Oscillator Schematic Design...................................................................................42

Figure 8-4. Mode Suppression............................................................................................................. 43

Figure 8-5. Frequency Tuning Circuit...................................................................................................43

Figure 8-6. EFC ....................................................................................................................................44

Figure 8-7. Automatic Gain Control (AGC)...........................................................................................44

Figure 8-8. Output Amplifiers ...............................................................................................................45

Figure 8-9. Voltage References............................................................................................................46

Figure 8-10. Oven Control Circuits....................................................................................................... 47

Figure 8-11. Turn-on Current Limit Circuit............................................................................................48

Figure 8-12. Heater Transistor Balance Circuit. ................................................................................... 48

Figure 8-13. 10811A/B Special Test Connector................................................................................... 52

Figure 8-14. Oven Controller Block Diagram....................................................................................... 55

Figure 8-15. Oven Controller Schematic Diagram............................................................................... 64

Page 8

Model 10811A/B

PREFACE

This manual is designed to present the information required by the user to effectively operate and maintain the 10811A/B Quartz Crystal Oscillator.

In limiting the depth of coverage of this manual, a certain amount of previous knowledge on the part of the

reader must be assumed. A variety of additional related documentation is available. These materials

address the specific areas of interest, and should be used whenever necessary to supplement this

manual. Users unfamiliar with precision time keeping and frequency standards, for example, may wish to

refer to the 10811A/B Documentation Map for further information.

The following references can provide additional information about the theory and use of precision frequency sources and quartz oscillators.

1. Application Note 52-1 Hewlett-Packard Fundamentals of Time and Frequency Standards.

2. Application Note 52-2 Hewlett-Packard Time Keeping and Frequency Calibration.

3. Application Note 200-2 Hewlett-Packard Fundamentals of Quartz Oscillators.

U.S. National Bureau of Standards, Monograph 140, Time and Frequency Theory and

4.

Fundamentals available from:

Superintendent of Documents

U. S. Government Printing Office

Washington

5. In 1990 the NIST replaced the Monograph 140 document with this interim collection of

documents

The 10811A/B Quartz Crystal Oscillator has two manuals available. The Operating Instruction

Manual is supplied with the oscillator and is intended for the user that desires only operating

information. The Operating and Service Manual is a complete document containing both

operating and servicing information. The Operating and Service Manual (This manual) is not

supplied with the oscillator, but is available by ordering HP Part No. 10811-90002 (of course

they won’t sell you one). The Operating Instructions Manual is a duplication of Sections I, II,

and III of the Operating and Service Manual. Any references in the Operating Instructions

Manual to Sections IV, V, VI, VII, and VIII should be considered references to the Operating

and Service Manual.

, D.C. 20402

NIST/TN1-339 or visit time NIST Time and Frequency Publication Database.

10811A/B Documentation Map

Page 9

Model 10811A/B

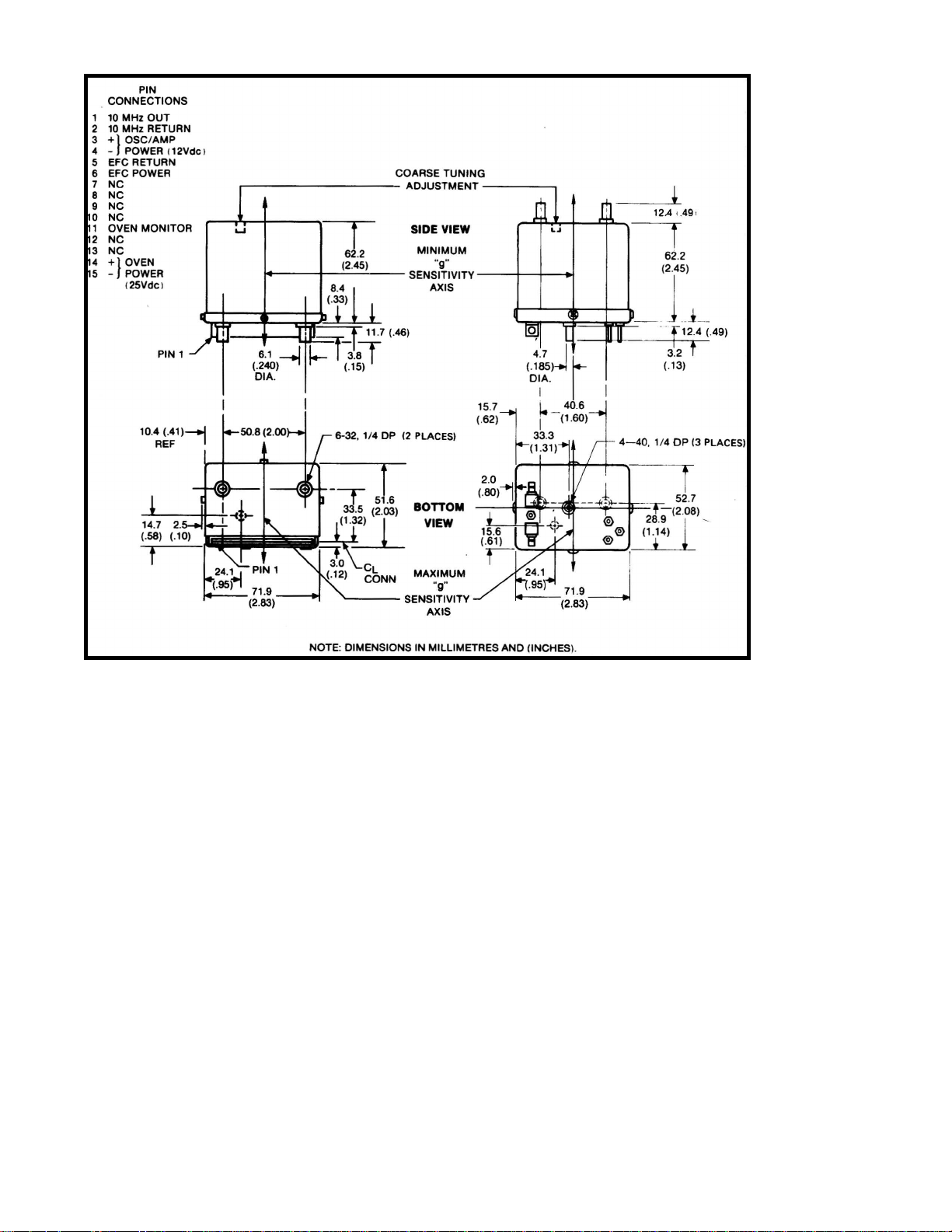

Figure 1-1. 10811A and 108118 Oscillators

1

Page 10

Model 10811A/B

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION

1-2. This manual provides information pertaining to the installation, operation, testing, adjustment, and

maintenance of the HP Model 10811A/B Quartz Crystal Oscillator.

and 10811B.

1-3. This manual is divided into eight sections, each covering a particular topic. The topics by section

number are shown below. Sections I, II, III appear in the Operating Instructions Manual. Sections

I through VIII appear in the Operating and Service Manual.

Section Topic

I General Information

II Installation

III Operation

IV Performance Tests

V Adjustments

VI Replaceable Parts

VII Manual Changes

VIII Service

Figure 1-1 shows the 10811A

1-4. SPECIFICATIONS

1-5. Specifications are listed in Table 1-1. These specifications are the performance standards or

limits against which the oscillator may be tested.

1-6. SAFETY CONSIDERATIONS

1-7. The Model 10811A/B Component Oscillator is a Safety Class III product and must be powered

from a source which is electrically isolated from the mains (line circuits). Safety information

pertinent to the operation and servicing of this instrument is included in the appropriate sections

of this manual.

1-8. INSTRUMENTS COVERED BY THIS MANUAL

1-9. Attached to the instrument is a serial number plate. The serial number is in the form 0000A00000.

It is in two parts; the first four digits and the letter are the serial prefix and the last five are the

suffix. The prefix is the same for all identical instruments; it changes only when a change is made

to the instrument. The suffix, however, is assigned sequentially and is different for each

instrument. The contents of this manual apply to instruments with the serial number prefix(es)

listed under Serial Prefix on the title page.

1-10. An instrument manufactured after the printing of this manual may have a serial number prefix that

is not listed on the title page. This unlisted serial number prefix indicates the instrument is

different than those described in this manual. The manual for this new instrument is accompanied

by a yellow Manual Changes supplement. This supplement contains "change information" that

explains how to adapt the manual to the newer instrument.

1-11. In addition to change information, the supplement may contain information for correcting errors in

the manual. To keep this manual as current and accurate as possible, Hewlett Packard

recommends that you periodically request the latest Manual Changes supplement. The

supplement for this manual is identified with the manual print date and part number, both of which

appear on the manual title page. Complimentary copies of the supplement are available from

Hewlett-Packard.

2

Page 11

Table 1-1. Specifications Table

Model 10811A/B

Frequency Stability

of Terms)

Long Term (Aging Rate): <5 X 10

after 24-hour warm-up. See Note 1.

-7

<1 X 10

Short Term: Refer to tables and figures

above.

/year for continuous operation.

: (See Definition

-10

/day

Environmental Sensitivity:

Temperature: <4.5 X 10-9 over a -55°C to

71°C range. <2.5 X 1071 °c range.

Operating:-55°C to +71 °C.

Storage: -55°C to X85°C.

Load: <5 X 10

ohm load. <5 X 10

1KΩ load.

-10

Power Supplies:

Oscillator Supply: <2 X 10

change. <100μv ripple and noise required.

Oven Supply: <1 X 10<30 mv ripple and noise required.

Gravitational Field: <4 X 10

shift (turn-over).

Magnetic Field: <-90 dBc sidebands due

to 0.1 millitesla (1 Gauss) rms at 100 Hz.

Humidity (typical): 1 X 10

40°C.

Shock (survival): 30g, 11ms, ½ sinewave.

Altitude (typical): 2 X 10-9 for 0 to 50,000 ft.

Warmup

10 min. after turn-on within 5 X 10-9 of final

value, at 25°C and 20 Vdc. See Notes 1 &

2.

9

over a O°C to

for a ±10% change in 50

-10

for a ±25% change in

-10

for 1%

10

for 10% change.

-9

for 2g static

-9

for 95% RH at

Adjustment

Coarse Frequency Range: >±1 X 10-6 (±

10 Hz) with 18 turn control.

Elec. Frequency Control (EFC): ≥1 X 10

(1 Hz) total, control range -5 Vdc to +5 Vdc.

Output

Frequency: 10 MHz

Voltage: 0.55 ± 0.05 V rms into 50 ohm.

1V rms ±20%, into 1K ohm.

Harmonic Distortion: Down more than 25

dB from output.

Spurious Phase Modulation: Down more

than 100 dB from output (discrete

sidebands 10 Hz to 25 kHz).

Power Requirements

Oscillator Circuit: 11.0 to 13.5 Vdc. 30

mA typical. 40 mA max.

Oven Circuit: 20 to 30 V dc; turn on load

is 42 ohm minimum. Steady-state power

drops to a typical value of 2.0W at 25°C in

still air with 20 Vdc applied.

Connectors

10811A: Mates with CINCH 250-15-30-210

(HP 1251-0160) or equivalent (not

supplied).

10811B: Solder terminals and 5MB Snapon connectors. Mates with Cablewave

Systems, Inc. #700156 or equivalent (not

supplied).

Accessories Available:

Service Manual: HP 10811-90002: (not

supplied). This Manual.

Size:

72 mm X 52 mm X 62 mm, (see Figure

1). (2-13/16" X 2-1/32" X 2-7/16", 14 cu.

-7

in.).

Weight: 0.31 kg (11 oz.)

Definition of Terms

Long-Term Frequency Stability is de-

fined as the absolute value (magnitude)

of the fractional frequency change with

time. An observation time sufficiently

long to reduce the effects of random

noise to an insignificant value is implied.

Frequency changes due to

environmental effects must be

considered separately.

Time Domain Stability

deviation) is defined as the two-sample

deviation of fractional frequency

fluctuations due to random noise in the

oscillator. The measurement bandwidth

is 100 kHz.

Frequency Domain Stability is defined

as the single sideband phase noise-tosignal ratio per Hertz of bandwidth (a

power spectral density). This ratio is

analogous to a spectrum analyzer

display of the carrier versus either

phase modulation sideband.

See "NBS-Monograph 140" for

measurement details.

σ

(τ) (Allan

γ

Notes:

1. For oscillator off-time less than 24 hours.

2. Final value is defined as frequency 24 hours after turn-on.

*Specifications describe the instrument's warranted performance. Supplemental characteristics are

intended to provide information useful in applying the instrument by giving TYPICAL or NOMINAL, but

non warranted performance parameters. Definition of terms is provided at the end of the specification

section.

3

Page 12

Model 10811A/B

1-12. For information concerning a serial prefix that is not listed on the title page or in the Manual

Changes supplement, contact your nearest Hewlett-Packard office.

1-13. DESCRIPTION

1-14. The HP Model 10811A/B Quartz Crystal Oscillator is an extremely stable, compact, low power

source of 10 MHz. The 10811 A/B has a very fast warm-up time, exhibits excellent temperature

characteristics and has low phase noise and power consumption.

-6

1-15. The 10811A/B has the ability to be adjusted over a range of 20 Hz (2 X 10

sensitive enough to allow adjustment to better than 0.1 Hz (1 X 10

controlled electronically over a 1 Hz (1 X 10

-7

) range with an externally applied voltage to the EFC.

-8

). The frequency can also be

1-16 The 10811A/B is field repairable, thus allowing the oscillator to be quickly placed back into

service.

1-17. The 10811A/B requires two external power supplies. The power supply requirements are listed in

Section II.

1-18. The 10811A and 10811B are identical, except for the connections. The 10811A uses a standard

15 pin printed circuit connector. The 10811B uses filtered-feedthrough terminals for power and

oven monitor, and 5MB subminiature rf snap-on connections for the 10 MHz output and EFC.

1-19. HP Part Number 10811-60101 and 10811-60105

1-20. The 10811-60101 is a 10811A in which phase noise, magnetic field and 2g turn-over are not

specified. The 10811-60101 is physically identical to the 10811A.

-9

1-21. The 10811-60105 is a 10811-60101 with specifications of <1.5 X 10

short-term stability for a 1-second averaging time. The 10811-60105 is physically identical to the

10811A.

for aging and <1 X 10

), yet the control is

-11

for

1-22. RECOMMENDED TEST EQUIPMENT

1-23. The test equipment required to maintain the Model 10811A/B is listed in Table 1-2. Other

equipment may be substituted if it meets or exceeds the critical specifications listed in the table.

4

Page 13

Model 10811A/B

1

0

/day

(Op

Table 1-2. Recommended Test Equipment

INSTRUMENT REQUIRED CHARACTERISTICS MODEL NO.

1. Frequency Analyzer* Phase noise measurement at 10 MHz 5390 5390A* cannot measure 10811 specs above 10 Hz

2. Frequency Counter** 10 MHz range, HP-IB programmable, 2 ns 5345A** resolution

3. Computing Controller** HP-IB compatible 9835A or 9825A **

4. Frequency Reference Short term stability ≤5x10

Long term stability <5x10

-12

/second 5065A, 5061A

-

tion 004),

or 105A/B***

5. Sampling Voltmeter ±3% accuracy at 10 MHz 3406A

6. General Purpose Bandwidth ≥ 10 MHz 1740A Oscilloscope

7. Frequency Doubler Operates at 10 MHz 10515A

8. Mixer Amplifier** 10 MHz Mixer/50 dB gain K79-59992A**

9. Spectrum Analyzer 10 MHz/70 dB range 8552B/8553B

10. Power Supply 480 mA @ 20V (2 required) 6215A

11. DC Voltmeter Any HP type digital or analog

12. Torque Screwdriver 2-30 inch-lb. (0.2 to 3.4 newton meters) 8730-0012

13. Feedthru Termination 50 ohms 11046B

14. BNC to Miniature Use for 10811B Only 05060-6116 Coax Adapter

15. Test Connector For testing 1 0811A See para. 8-61 *Not needed if items 2, 3, 4 are available. **Not needed if HP 5390A Frequency Stability Analyzer is available. ***If a 105A/B is used, its performance must be verified.

5

Page 14

Model 10811A/B

SECTION II

INSTALLATION

2-1. INTRODUCTION

2-2. This section contains installation instructions for the 10811 A/B Quartz Crystal Oscillator. Also

included is information about initial inspection and damage claims, preparation for using the

oscillator, and packaging, storage and shipment.

2-3. INITIAL INSPECTION

2-4. Inspect the shipping container for damage. If the shipping container or cushioning material is

damaged, it should be kept until the contents of the shipment have been checked for

completeness and the oscillator has been checked mechanically and electrically. The contents of

the shipment should be as shown in

are given in Section IV. If the contents are incomplete or if there is mechanical damage or defect,

or if the oscillator does not pass the Performance Tests, notify the nearest Hewlett-Packard office.

If the shipping container is damaged, or the cushioning material shows signs of stress, notify the

carrier as well as the Hewlett-Packard office. Keep the shipping materials for the carrier's

inspection. The HP office will arrange for repair or replacement at HP option without waiting for

the claim settlement.

Figure 1-1; procedures for checking electrical performance

2-5. PREPARATION FOR USE

2-6. Power Requirements

2-7. The 10811A/B requires two power sources. One supplies power to the oscillator circuitry and the

other supplies power to the oven heaters.

effect of a change in these voltages on the output frequency.

Table 2-1. Input Voltages/Voltage Coefficients

Input Circuit

Oscillator/

Amplifier

Oven Controller

2-8. Both the 10811A and 10811 B have separate ground return paths for each section (oscillator and

oven circuits). Both grounds may be tied together or operated at any reasonable difference in

potential. Note the oscillator supply ground and 10 MHz output have a common ground return.

The outer housing for both oscillators is tied to this ground point. The 10811 B filtered

feedthrough grounds are also tied to the outer housing.

2-9. In order to maintain the high spectral purity of the 10811A/B output signal, the supply voltages

must be relatively clean. The supply ripple and noise on the 12-volt line (oscillator supply) must

be kept below 100 µV rms and the 20-volt line (oven supply) ripple and noise must be kept below

30 mV rms with both measured in the 10 Hz to 25 kHz range. A 1% change of the 12-volt supply

(oscillator) will cause ≤2

(oven) will cause a ≤1

Required

Voltage

11.0-13.5V dc

Noise <100 µV

20-30V dc 10% <1 X 10

Power drops to steady state value (≈2W)

within 10 min. at 25°C with 20V dc applied.

X 10

-10

X 10

Required Current/Power

30 mA typical, 40 mA max.

Turn on load is 43 ohms minimum

-10

change in output frequency. A 10% change in the 20-volt line

change in output frequency.

Table 2-1 lists the required supply voltages and the

Voltage Coefficients

Voltage

Change

1% <2 X 10

Frequency

Change

-10

-10

6

Page 15

Model 10811A/B

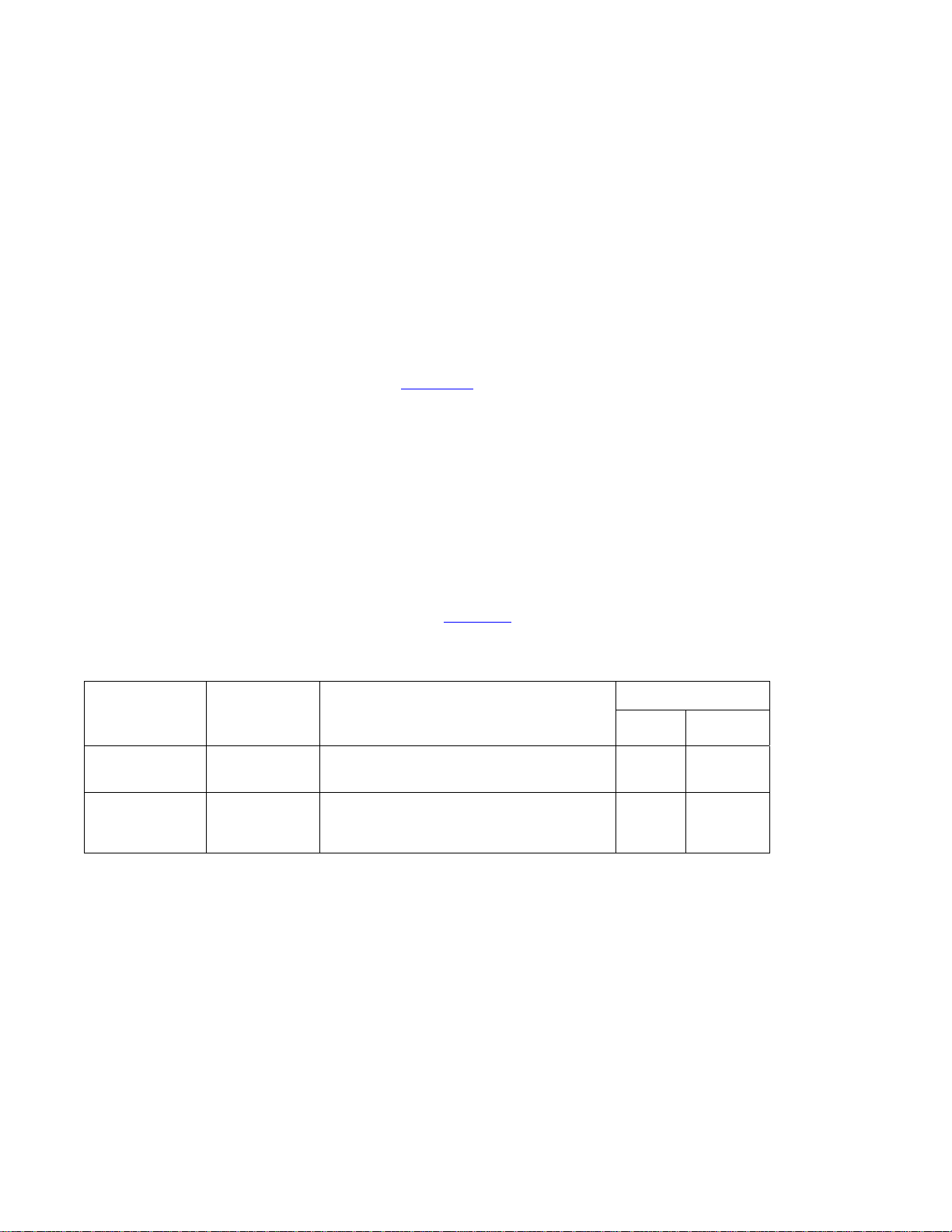

2-10. Single Source Regulated Power Supply

2-11. A single source of +20 to +30V dc with 10% regulation may be used to power both the oven and

oscillator amplifier circuits if a simple IC regulator is used. A suggested circuit is shown in Figure

2-1. The resistor and capacitor connected to terminals 3 and 4 of the IC minimize ripple and noise

in the regulated output.

Figure 2-1. Single Source Regulated Power Supply

2-12. ELECTRONIC FREQUENCY CONTROL (EFC)

2-13. The EFC allows the oscillator to be tuned over a 1 Hz range (1 x 10-7) by applying -5 to +5 volts

to the EFC input. As the EFC voltage goes positive the output frequency will go lower. Conversely,

as the EFC voltage goes negative, the output frequency will go higher.

2-14. Since noise on the EFC line affects the oscillator's stability (noise appears as FM on the output),

care must be taken to ensure that a relatively noise free EFC voltage source is used. The noise

level must be kept below 100 µV to maintain good stability performance.

2-15. The EFC input should be connected to oscillator circuit ground if not used. A shorting plug (1250-

0911) is supplied with 10811B for this purpose. The EFC input on the 10811A should be

grounded at the printed circuit connector by wiring pins 5 and 6 together.

2-16. 10 MHz FREQUENCY OUTPUT SIGNAL

2-17. The 10 MHz output is ac coupled from a source impedance of approximately 50 ohms. The signal

level is .55 ±.05 into a 50 ohms load or 1-volt ±20% into a 1 K ohm load.

7

Page 16

Model 10811A/B

2-18. OVEN MONITOR OUTPUT

2-19. The OVEN MONITOR OUTPUT is an indicator of oven warm-up. At initial turn-on (warmup) the

oven monitor will go to approximately 1.5 volts BELOW the oven power supply voltage. After the

oven cuts back, the output will drop to approximately 3.5 volts (at 25°C). The output impedance of

this circuit is 10,000 ohms.

Figure 2-2 shows an oven monitor LED indicator circuit.

Figure 2-2. Oven Monitor LED Circuit

2-20. MATING CONNECTORS AND MOUNTING

2-21. The 10811A Oscillator requires a 15-pin printed circuit connector. The recommended connector is

the CINCH 250-15-30-210 (HP 1251-0160). The 10811A can be secured with two 6-32 screws,

1/4-inch long.

the mechanical mounting dimension for the 10811A and 10811B.

Figure 2-3 shows the power supply connection for the 10811A. Figure 2-5 shows

8

Figure 2-3. 10811A Supply and Output Connections

Page 17

Model 10811A/B

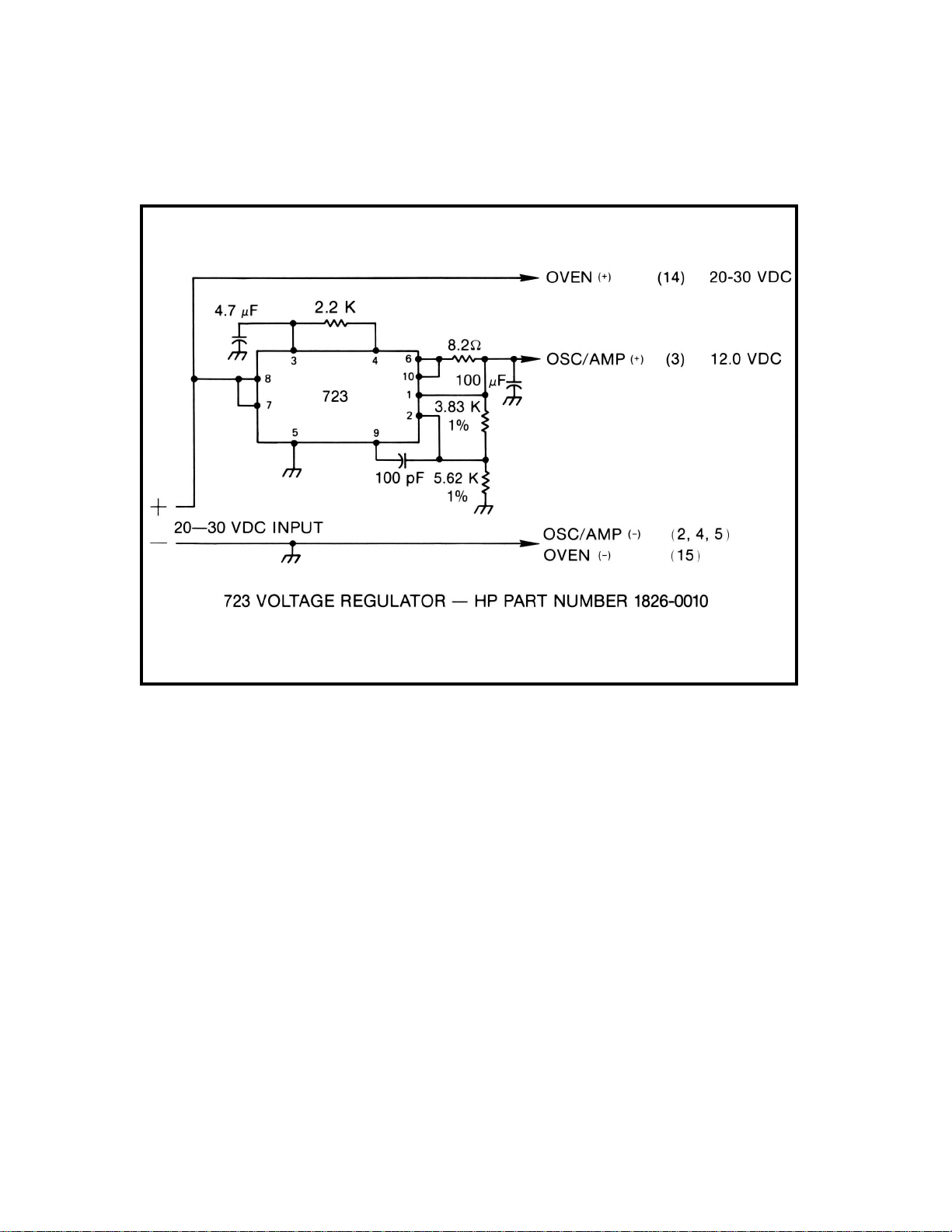

2-22. The 10811 B Oscillator uses solder terminals with filtered feedthrough capacitors for power and

oven monitor outputs and 5MB subminiature rf snap-on connectors for the 10 MHz output and

EFC. The 10811 B also has one internally threaded mounting stud on the bottom cover and two

located on the top. The three studs are threaded for 4-40 screws, 1/4-inch deep. These mounting

studs may be used with vibration isolators such as the LORD #J2924-2-1 (HP Part No. 1520-

0094). However, for ease of testing and interfacing, a 6-pin Amphenol connector is attached. If

you wish to use this connector, the following parts are required to build its mate.

Description Quantity HP Part No. Amphenol Part No. Receptacle 1 1251-4297 221-1508

Pin-Female 5 1251-4734 220-883-03

Guide-Pin 2 1251-0597 221-590

If you do not wish to use the Amphenol connector, it may be easily removed. The 5MB connectors mate

to Cablewave Systems, Inc. #700156 or equivalent HP Part No. 1250-0885 (not supplied).

shows the connections for the 10811 B Oscillator.

Figure 2-4

Figure 2-4. 10811B Supply and Output Connections

2-23. INSTALLATION INSTRUCTIONS

2-24. Figure 2-5 shows the mechanical mounting dimensions of the 10811A/B Oscillators for use in

custom installation. Since all quartz oscillators are sensitive to shock, vibration, radiation fields,

and ambient temperature changes, to obtain the best performance from your 10811A/B, these

factors should be taken into consideration. To optimize performance therefore:

1. The 10811A/B should be mounted in an area that has a minimum amount of vibration or shock

accelerations. In addition, the 10811 A/B should be mounted so that the vibrational forces act

along the "minimum G sensitivity" axis shown in

2. The 10811A/B should be mounted as far as possible from transformers or fan motors that radiate electromagnetic fields.

3. The 10811A/B should be mounted away from the main system airflow in order to isolate it as much as possible from ambient temperature changes.

Figure 2-5.

9

Page 18

Model 10811A/B

Figure 2-5. Mechanical Mounting Dimensions

2-25. INSTALLATION INSTRUCTIONS (HP INSTRUMENT)

2-26. The 10811 A may be installed in most Hewlett-Packard instruments that already have a 10544A

or 10544B oscillator or has provisions for it. The 10811A may be exchanged directly without any

circuit change or modification.

2-27. If the instrument does not have a 10544A oscillator installed, but is available as an option, then

the service manual for that instrument should be consulted to see if an oscillator support board

(power supplies) is required. Once the support board is installed, the 10811A can be installed in

place of the 10544A. Consult your nearest sales and service office for more details.

2-28. OPERATING ENVIRONMENT

2-29. TEMPERATURE. The 10811A/B may be operated in temperatures from -55°C to +71°C.

2-30. MAGNETIC FIELDS. Sidebands due to 0.1 milliTelsa (1 Gauss) rms at 100 Hz will be down more

than 90 dB from carrier.

-9

X 10

2-32. ALTITUDE. The frequency change will be typically 2

2-33. SHOCK. The 10811A/B can withstand a shock up to 30 Gs for 11 ms, 1/2 sine wave.

for altitudes up to 15.2 km (50,000 ft.).

10

Page 19

Model 10811A/B

2-34. STORAGE AND SHIPMENT

2-35. Environment

2-36. The 10811A/B may be stored or shipped in environments with the following limits: Temperature ····························· -55°C to +85°C Altitude ······································ 15.2 Km (50,000 feet)

2-37. PACKAGING

2-38. Original Packaging

2-39. Containers and materials identical to those used in factory packaging are available through

Hewlett-Packard offices. If the instrument is being returned to Hewlett-Packard for servicing,

attach a tag indicating the type of service required; return address, model number, and full serial

number. Also, mark the container Fragile to ensure careful handling. In any correspondence, refer

to the instrument by model number and full serial number.

2-40. Other Packaging

2-41. The following general instructions should be used for repacking with commercially available

materials.

1. Wrap instrument in heavy paper or plastic. (If shipping to Hewlett

center, attach tag indicating type of service required; return address, model number, and full

serial number.)

2. Use strong shipping container. A double-wall carton made of 350-pound test material is adequate.

3. Use a layer of shock-absorbing material 70 to 100 mm (3 to 4 inch) thick around all sides of the instrument to provide firm cushioning and prevent movement inside container. Protect control panel with cardboard.

4. Seal shipping container securely.

5. Mark shipping container FRAGILE to insure careful handling.

6. In any correspondence, refer to instrument by model number and full serial number.

-Packard office or service

11

Page 20

Model 10811A/B

SECTION III

OPERATION

3-1. INTRODUCTION

3-2. This section contains operating information including operating characteristics and operating procedure.

3-3. BASIC POWER-UP DESCRIPTION

3-4. The following paragraph is a basic description of the actions occurring when power is applied to

the oscillator. This description assumes the oscillator is at room temperature (25°C).

3-5. When power is applied to the oscillator, 10 MHz will appear at the output. The oven controller

circuit will go into its full warm-up mode. In this mode the maximum heating power is applied to

the oven mass. The oven mass is a metal casting surrounding the oscillator circuits and crystal.

The OVEN MONITOR output will be approximately 1.5 volts below the oven power supply voltage.

In about 10 minutes, the oven will have heated to the proper temperature. The oven controller will

begin to regulate at this temperature, and the OVEN MONITOR will drop to approximately 3.5

volts. It is normal for the oven current to drop momentarily to a low value when the oven

temperature first reaches maximum. This lasts less than second and is a typical circuit action.

3-6. After the first 10 minutes have passed, the oscillator may be initially adjusted using the following

procedure. The oscillator should be readjusted after 24 hours for maximum accuracy. Periodic

adjustment schedule can be determined by the procedure described in

paragraph 3-10.

3-7. FREQUENCY ADJUSTMENT

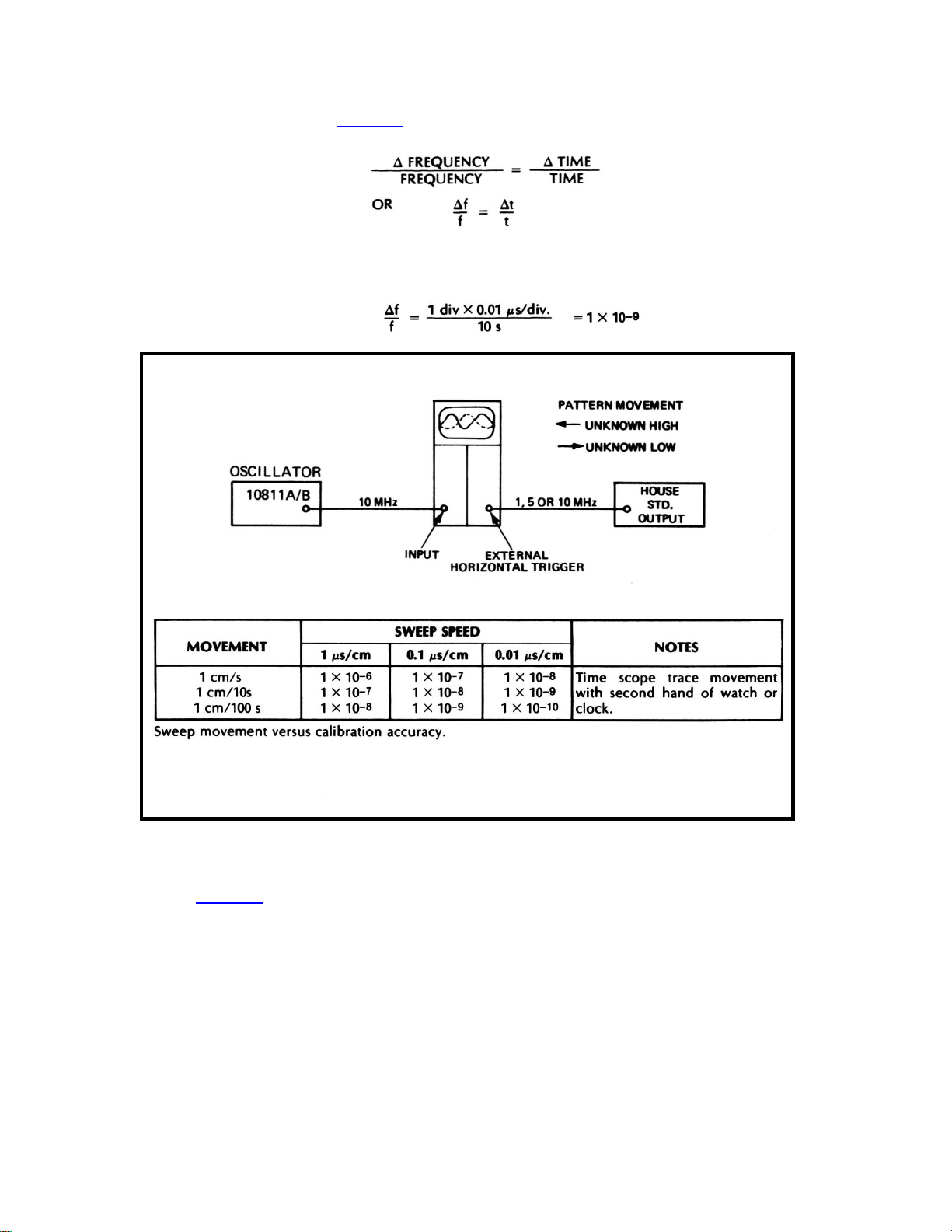

3-8. The frequency adjustment is the only periodic adjustment required. This may be initially adjusted

after 10 minutes of warm-up and then readjusted after 24 hours.

3-9. FREQUENCY ADJUSTMENT PROCEDURE

a. Connect reference frequency standard (multiple or submultiple of 10 MHz) to the EXTERNAL

SYNC INPUT of the oscilloscope.

b. Connect oscillator output (10811A/B) to Channel A. Set the sweep speed to .1 μs/div.

c. Set the oscilloscope to EXTERNAL TRIGGER and adjust the oscilloscope so that its sweep is

synchronized to the reference frequency. The pattern will appear to move.

d. Using an insulated tuning tool, adjust oscillator frequency adjustment (FREQ ADJUST on the

10811AIB) for minimum sideways movement of the oscilloscope pattern.

e. By timing the sideways movement (divisions per second on the oscilloscope), the approximate

offset can be determined based on the oscilloscope sweep speed shown in

Figure 3-1

12

Page 21

Model 10811A/B

f. For example, if the trace moves 1 division in 10 seconds and the sweep speed is 0.01 μs/div., the

oscillator's frequency is 1 x 10

from the calibration,

Table 3-1. The calculation can also be made by the following formula:

-9

different from that of the reference frequency, as can be seen

where Δf/f = offset of the oscillator with respect to the reference standard Δt = the movement of the

oscilloscope pattern (1 div. X .01 μs/div.) = .01, μs t = time required for Δt to occur.

Figure 3-1. Oscillator Adjustment Set-Up

3-10. ACCURACY VS ADJUSTMENT INTERVAL

3-11. Table 3-1 shows the required adjustment interval to maintain a required accuracy. If the aging

rate is known to be 3 x 10

(The specification for aging is <5 X10

can be expected to gradually decrease, and typically will reach 1 X 10

Example:

Known aging rate···········································3 X 10

Maximum allowable error ·····························5 X 10

-10

/day, then a more precise adjustment interval can be determined.

-10

/day, but aging is typically less than this.) The aging rate

-10

/day

-9

-10

/day within 1-year.

13

Page 22

3-12. Find the line on

allowable error (accuracy) on the horizontal axis. Follow the maximum allowable error vertically

until it crosses the oscillator's known aging rate. Move horizontally to the left and read the

minimum calibration interval in days.

Model 10811A/B

Table 3-1 corresponding to the oscillator's aging rate. Then find the maximum

maximum allowable error

known aging rate (per day)

Example:

3-13. From

3-14. The minimum calibration interval may also be determined from the following formula:

-9

5 x 10

3 x 10

(maximum allowable error)

-10

/day (known aging rate) = 16.67 days (~17 days) 3 X 10

Table 3-1, the oscillator should be adjusted approximately every 17 days.

= calibration interval in days

-10

/day (known aging rate)

14

Table 3-1. Accuracy vs Adjustment

Page 23

Model 10811A/B

Page Intentionally Left Blank

15

Page 24

Model 10811A/B

SECTION IV

OPERATIONAL VERIFICATION

4-1. INTRODUCTION

4-2. The tables in this section test the instrument's performance using the specifications of Table 1-1

as the performance standards. All tests can be performed without access to the interior of the

instrument.

4-3. OPERATIONAL VERIFICATION

4-4. The Operational Verification, Table 4-2, can be performed to give a high degree of confidence

that the 10811A/B is operating properly without performing the complete performance tests. The

operational verification should be useful for incoming QA, routine maintenance, and after

instrument repair.

4-5. EQUIPMENT REQUIRED

4-6. Equipment required for the operational verification is listed in the recommended test equipment in

Section I,

given in the table may be substituted for the recommended model(s).

Table 1-2, and in Table 4-1. Any equipment that satisfies the critical specifications

4-7. TEST RECORD

4-8. Results of the Operational Verification, Table 4-2, may be tabulated on the Operational

Verification Record,

4-9. If the 10811A/B Oscillator is to be tested outside its normal installation, a special test connector

may be used for applying power to the oscillator. The connector also has a BNC connector for the

10 MHz output signal. A photo, parts list, and construction information is located in Section VIII.

The connector should be used under the following circumstances:

a. If the 10 MHz output is not easily accessible.

b. If there is a buffer amplifier between the 10811A/B output and the oscillator output jack

on the rear panel of the instrument.

c. Troubleshooting.

d. If testing of the oscillator in its normal installation causes erroneous measurements (e.g.,

fan noise, vibrations, noisy circuits, etc.). If in doubt, use the special test connector.

4-10.

Table 4-1 lists the five sections of the operational verification and their descriptions.

Table 4-4.

16

Page 25

Model 10811A/B

Table 4-1. Operational Verification Descriptions

1. Amplitude (0.55 volts (±0.05 volts/50Ω, 1 volt ± 0.2 volt/1kΩ).

a. Equipment required:

BNC-to-BNC Cable

500 and 1 KΩ loads

3406A AC Voltmeter

2. Harmonic Distortion (-25 dB below 10 MHz output signal).

a. Equipment required:

141T Display Section

8553B Spectrum Analyzer - RF Section

8552B Spectrum Analyzer - IF Section

BNC-to-BNC Cable

3. Spurious Signals - Signals unrelated to the 10 MHz output signal (-100 dB below the 10 MHz

output signal).

NOTE

Due to the complexity of measuring signal 100 dB

below a reference, this procedure will verify that no

spurious signals exist greater than 65 dB below the

normal 10 MHz output signal.

4.

a. Equipment required:

141T Display Section

8553B Spectrum Analyzer - RF Section 8552B

Spectrum Analyzer - IF Section

BNC-to-BNC Cable

5. Short Term Stability (5 X 10

-12

for 1-second averaging; 1 X 10

-11

for 10811-60105).

a. Equipment required:

5065A Rubidium Vapor Frequency Standard

5061A Option 004, or 105A/B, See Table 1-2

HP Model 5390A may be used in place of the following:

10830A Mixer

5345A Electronic Frequency Counter with Option 011

9825A Calculator with 98210A and 98213A or 98214A or 98216A

98034A HP-IB Interface

10515A Doubler

6-Plug AC Power Strip 3

BNC-to-BNC Cables

6. Long Term Stability -<5 X 10

-10

over 24 hours; 1.5 X 10-9/24 hours for 10811-60105.

a. Equipment required:

HP 1740A 100 MHz Oscilloscope,

105A/B Quartz Crystal Oscillator,

5065A Rubidium Frequency Standard, or 5061A Cesium Beam Frequency Standard.

See Table 1-2.

4-11. In the following tests, the power supply voltages to the oscillator are not shown. They are

assumed to be:

Oscillator Circuits ........................................ +12V dc

Oven Circuits ............................................... +20V dc

4-12. Any supply voltages within the specified limits listed in

Table 1-1 may be used and will not affect

the operational verification. The voltages are only reference points and are used throughout this

manual.

17

Page 26

Model 10811A/B

Table 4-2. Operation Verification Procedure

1. Amplitude Test

Procedure:

a. Set the 3406A Voltmeter to the l-volt range.

b. Insert the 3406A Voltmeter probe into the 1 volt jack on the front panel.

c. With the CAL button out, set the 3406A to zero by adjusting the ZERO control on the front

panel.

d. Press the CAL button and adjust the 3406A to read 1V by adjusting the CALIBRATE control

on the front panel.

e. Remove the probe from the 1-volt jack and conned to the 10811A/B output through a 50 ohm

termination.

f. Verify amplitude of 0.55 volts ±0.05 volts. Mark the test card.

g. Remove the 50Ω termination and replace with a 1 kΩ termination.

h. Verify amplitude of 1 volt ±0.2 volt.

2. Harmonic Distortion

a. Set 141T Spectrum Analyzer controls to:

TUNING STABILIZER·········································· OFF

BANDWIDTH ······················································30 kHz

SCAN WIDTH per Division ·································5 MHz/div.

INPUT ATTENUATION ·······································50 dB

VIDEO FILTER ····················································OFF

SCAN TIME ························································· 10 ms/div.

SCAN MODE ······················································INT

SCAN TRIGGER ·················································AUTO

LOG REF LEVEL ················································+10

LOG/LINEAR Switch············································10 dB LOG

b. Connect the output of the 10811A/B to the spectrum analyzer input.

c. Apply power to the oscillator and spectrum analyzer. Allow 10 minutes for oscillator to

stabilize.

d. Adjust Spectrum Analyzer FREQUENCY control so that 10 MHz signal is at left-edge of

display (center frequency, approximately 35 MHz).

e. Adjust LOG REF LEVEL vernier control (right hand knob) so that 10 MHz signal is at top of

display gratitude. Verify that all harmonics of the 10 MHz signal are more than 25 dB down.

Leave spectrum analyzer connected for next test.

3. Spurious Output Signals

a. Use the test setup as described in Test 2.

b. Set the Spectrum Analyzer controls to:

TUNING STABILIZER·········································· OFF

BANDWIDTH ·······················································1 kHz

SCAN WIDTH ······················································.05 MHz

INPUT ATTN························································ 50 dB

LOG REFERENCE ··············································+10 dBm

SCAN TIME··························································0.1 s/div.

VIDEO FILTER ····················································100 Hz

SCAN MODE ······················································INT

SCAN TRIGGER ·················································AUTO

FREQUENCY······················································· 10 MHz (0-11 MHz RANGE)

c. Adjust FREQUENCY so 10 MHz signal is at center of display. Adjust LOG REF LEVEL so

signal is at top of graticule.

d. Set TUNING STABILIZER switch "on" (up) and reset Spectrum Analyzer controls as follows:

BANDWIDTH ·······················································.03 kHz (30 Hz)

SCAN WIDTH ······················································5 kHz

SCAN TIME··························································10 s/div.

18

Page 27

Model 10811A/B

Table 4-2. Operational Verification Procedure (Continued)

e. Set INTENSITY and PERSISTENCE controls for an easily readable display at the 10 s scan

time.

f. Verify that there are no repeating signals above a level 65 dB below the 10 MHz signal (i.e., no

signals between -64 dB and 0 dB). Allow the analyzer to sweep through several times to verify

that no signals repeat on successive sweeps. Signals greater than -65 dB indicate possible

spurious signals on 10811A/B output. Be sure there is no other equipment nearby that could be

radiating signals into the measurement. Be sure power supplies meet noise specifications as

described in

Table 1-1.

4. Short-Term Stability

NOTE

If the model 5390A frequency stability analyzer is available it should be used in place of the text described below. Follow instructions in the 5390A operating manual to make measurement.

a. Connect the equipment as follows:

NOTE

Arrange the instruments as shown. Keep all signal leads away from

power cords and HP-IB cable. DO NOT FORGET THE 10515A

DOUBLER ON THE 5065A OUTPUT. Connect all ac power to the same

strip so that all ground paths are as short as possible. DO NOT STACK

THE INSTRUMENTS. Use coax for all signal leads.

b. Set the 5345A address to 18:

A5 A4 A3 A2

1 (16) 0 (8) 0 (4) 1 (2) = 18

c. Allow 1-hour warmup to stabilize the test equipment and the 10811A/B.

d. Set the 5345A front panel controls as follows:

FUNCTION ·········································································· FREQ A

GATE TIME ········································································· 1 s

SAMPLE RATE ··································································· max (ccw)

GATE CONTROL INPUT (REAR PANEL) ·························· INTERNAL

A LEVEL ·············································································· PRESET

B LEVEL ·············································································· PRESET

A IMPEDANCE ··································································· 50 ohm

B IMPEDANCE ··································································· 50 ohm

A ATTENUATOR ································································ X1

B A TTENUATOR ······························································· X1

19

Page 28

Model 10811A/B

Table 4-2. Operational Verification Procedure (Continued)

A COUPLING······································································· DC

B COUPLING······································································· DC

A SLOPE··············································································+

B SLOPE ·············································································+

CHECK/COM/SEP ······························································SEP

e. Adjust the 10811A/B to read ≈9.5 Hz (reading must be less than 10 Hz).

NOTE

The display on the 5345A should be changing only in

the .001 Hz or .0001 Hz digits. This represents

frequency deviations of parts in 10

11

and 1012,

respectively.

f. Type the program from Figure 4-1 into the 9835A calculator. (See paragraph 4-13 for use

of other controllers and counters.)

g. Press "RUN". When the program asks for the number of samples, enter "100" and press

CONTINUE.

h. Allow 2 to 3 minutes for the program to finish. Verify a short-term stability of less than 5 X

-12

.

10

NOTE

Measurement of short-term stability is somewhat difficult and exacting.

If the 10811A/B fails this test, be sure no signal sources other than the

test reference are operating near the measurement system, as these

can cause interference with the measurement. Other sources of error

are vi brat ion, nearby electrical equipment, poor shielding, or motors

that can radiate signals into the 10811A/B. The failure to connect the

HC input (to ground) can cause poor frequency stability as can a noisy

voltage being used for the EFC control. If another oscillator is available

(known to be good), verify the accuracy of the measurement system.

This could save considerable troubleshooting time.

Two other possibilities external to the oscillator are the oven and

oscillator power supplies. These must be stable in order for the circuits

to function properly. See

Table 1-1, Specifications, and paragraph 2-6

for power supply noise requirements.

5. Long-Term Stability

NOTE

The 10811A/B will typically take 24 to 48 hours to reach its specified

aging rate after storage or shipment. In some cases, if extreme

environmental conditions were encountered during storage, the

10811A/B could take up to 1-week to achieve its specified aging rate.

a. Connect reference frequency standard (multiple or submultiple of 10 MHz) to the EXTERNAL

SYNC INPUT of the oscilloscope.

b. Connect the output of the 10811A/B to CHANNEL A INPUT. Adjust sweep speed to 0.1 μs/div.

c. Set oscilloscope to EXTERNAL TRIGGER and adjust it so that its sweep is synchronized with

the reference frequency. The oscilloscope pattern will probably be moving.

d. Carefully adjust oscillator frequency control so that pattern on oscilloscope stops. Use a higher

sweep speed on oscilloscope for better resolution.

e. When the oscillator is adjusted as close as possible to frequency, measure the frequency as

described in

paragraph 5-13.

f. Allow the oscillator to remain undisturbed for 48 hours, then again measure the frequency. The

difference between the frequency measured in step e and that measured in this step is the aging

rate per 48 hours and should be less than 1 X 10

hours so that the frequency offset measured will be well in excess of the system resolution. In

many cases the daily aging rate of <5 X 10

-10

-9

. The measurement is allowed to run for 48

per day can be verified in 24 hours.

20

Page 29

Model 10811A/B

Figure 4-1. BASIC Program

4-13. OPTIONAL CONTROLLERS AND COUNTERS

4-14. Optional Controllers

4-15. Figure 4-2 lists the program for the 9825A Calculator.

Figure 4-2. HPL Program

21

Page 30

Model 10811A/B

4-16. Optional Counters

4-17. Table 4-3 shows the program codes set required when using the 5316A counter. Replace line 4

(HPL) or line 40 (BASIC) with the appropriate codes. Be sure the optional counter address is set

to "18".

5316A

(gate time must be set manually to 1 s on the front panel)

Table 4-3. 5316A Program Codes

22

Page 31

Model 10811A/B

Page Intentionally Left Blank

23

Page 32

Model 10811A/B

Table 4-4. Operational Verification Record

24

Page 33

Model 10811A/B

SECTION V

ADJUSTMENTS

5-1. INTRODUCTION

5-2. This section describes the adjustments required to maintain the 10811A/B operating

characteristics within specifications. Adjustments should be made when required, such as after a

performance test failure or when components are replaced that may affect an adjustment.

5-3. EQUIPMENT REQUIRED

5-4. The test equipment required for the adjustment procedure is listed in Table 1-2, Recommended

Test Equipment. Substitute instruments may be used if they meet the critical specifications.

5-5. FACTORY SELECTED COMPONENTS

5-6. Some of the values in the parts lists are selected during manufacturing to meet circuit

requirements. These parts are marked with an asterisk (*) in the parts list and schematic diagrams, with

average value shown.

5-7. ADJUSTMENT LOCATION

5-8. Adjustment locations are identified in this section and in the component locators in Section VIII,

Schematic Diagrams.

5-9. SAFETY CONSIDERATIONS

5-10. This section contains warnings and cautions that must be followed for your protection and to

avoid damage to the equipment.

WARNING

MAINTENANCE DESCRIBED HEREIN IS PERFORMED WITH POWER

SUPPLIED TO THE INSTRUMENT, AND PROTECTIVE COVERS

REMOVED. SUCH MAINTENANCE SHOULD BE PERFORMED ONLY

BY SERVICE-TRAINED PERSONNEL WHO ARE AWARE OF THE

HAZARDS INVOLVED (FOR EXAMPLE, FIRE AND ELECTRICAL

SHOCK). WHERE MAINTENANCE CAN BE PERFORMED WITHOUT

POWER APPLIED, THE POWER SHOULD BE REMOVED.

BEFORE ANY REPAIR IS COMPLETED, ENSURE THAT ALL SAFETY

FEATURES ARE INTACT AND FUNCTIONING, AND THAT ALL

NECESSARY PARTS ARE CONNECTED TO THEIR PROTECTIVE

GROUNDING MEANS.

5-11. OSCILLATOR FREQUENCY ADJUSTMENT

5-12. The following frequency adjustment procedure is the same for both the 10811A and 10811B.

Allow the oscillator to warm up for 24 hours before making this adjustment. See

a. Connect reference frequency standard (multiple or submultiple of 10 MHz) to the EXTERNAL

SYNC INPUT of the oscilloscope. Adjust oscilloscope so that sweep is synchronized with

reference frequency.

Figure 5-1.

25

Page 34

Model 10811A/B

Figure 5-1. Oscillator Adjustment Setup

b. Connect oscillator output to Channel A of the oscilloscope. Adjust sweep speed so pattern

movement can be seen.

c. Adjust oscillator frequency adjustment (FREQ AD) on 10811A/B Crystal Oscillator unit) for

minimum sideways movement of the 10 MHz displayed signal. Increase oscilloscope sweep

speed for greater resolution.

5-13. Offset Calculation:

a. By timing the sideways movement (divisions per second on the oscilloscope), the approximate offset

can be determined based on the oscilloscope sweep speed as shown below.

b. For example, if the trace moves 5 divisions in 10 seconds and the sweep speed is 0.01 μs/div., the

oscillators signal is within 5 X 10-9 of the reference frequency. The calculation can also be made as

follows:

Where:

Δf/f is the normalized frequency difference between the 10811A/B and the reference signal

Δt is the change observed in the oscilloscope

t is the time required for Δt to occur.

26

Page 35

Model 10811A/B

5-14. OUTPUT AMPLITUDE ADJUSTMENT

5-15. The output amplitude is adjusted by the setting of the variable resistor R6 which is in the

feedback of the AGC circuitry. It is not accessible from the outside of the oscillator.

5-16. The following procedure should be used to adjust the output amplitude only if the output level falls

outside the specified level, or repairs have been made to the main oscillator or AGC circuitry.

1. Remove oscillator from instrument.

WARNING

THE OSCILLATOR'S INTERNAL OVEN MASS TEMPERATURE MAY

BE AS HIGH AS 85°C (185°F). TO AVOID SERIOUS BURNS DO NOT

REMOVE OSCILLATOR CIRCUITS AND/OR OVEN MASS ASSEMBLY

FROM THE OUTER HOUSING UNTIL THE OSCILLATOR HAS

SUFFICIENTLY COOLED (APPROXIMATELY 1 HOUR WITH BOTTOM

COVER AND FOAM INSULATOR REMOVED). THE OUTER HOUSING

TEMPERATURE IS NOT A RELIABLE INDICATION OF THE INTERNAL

TEMPERATURE.

2. Remove bottom cover and allow oscillator to cool (if previously operated). To remove cover:

a. For the 10811A, remove the three screws securing the bottom cover. Remove the two screws

securing the P.c. edge connector to the outer can. Remove the top foam insulator to expose

the oscillator circuits.

CAUTION

DO NOT pull the oscillator out of the outer

housing by pulling on the P.C. edge

connector or flex circuit!!

b. For the 10811B remove the four

screws securing the bottom

cover. Disconnect the bottom

cover flex circuit from the seven

pin connector.

3. Once the oscillator is cool enough to

handle, remove the oscillator assembly by

pushing on the tuning capacitor (top of

oscillator) with a long, small diameter tool

until the oscillator assembly can be

removed freely.

NOTE

Under no circumstances should the oven

circuit be operated with the oven mass

removed from the outer housing. To do so

will cause damage to components inside the

oven mass.

4. Obtain HP Model 6215A Power Supply or

equivalent. Preset power supply to 12V dc.

Turn off power supply before proceeding

to next step.

Figure 5-2. 10811A Amplitude Adjustment Set-up

27

Page 36

5. For the 10811A, connect Model 6215A Power

Supply to pins 2 Hand 3 (+) of a 15 pin printed

circuit connector.

a. Insert the 10811A P.c. edge connector

into the 15 pin P.c. connector. (See

Section VIII for a special 10811 A test

connector.)

b. Connect pin 1 of the 15 pin pc connector

through a 50Ω termination (use pin 2 as

ground) to a 3406A Sampling Voltmeter.

Figure 5-2. Do not apply power to

See

the oven circuits.

c. For the 10811B, reconnect the flex

circuit attached to the bottom cover and

connect the 6215A as shown in

Figure

5-3. DO NOT APPLY POWER TO THE

OVEN CIRCUITS. A Micon to BNC

adaptor is available for the 10 MHz

output (HP Part Number 05060-6116).

d. For both 10811A and B, turn on the

6215A power supply and adjust R6 AGC

control for .55V rms ±50 mV as read on

the 3406A Sampling Voltmeter. R6 is

accessible through the small hole in the

side of the oven mass.

6. Turn off the 6215A power supply and reassemble the oscillator.

Model 10811A/B

Figure 5-3. 108118 Amplitude Adj Set-up

28

Page 37

Model 10811A/B

SECTION VI

REPLACEABLE PARTS

6-1. INTRODUCTION

6-2. This section contains information for ordering replacement parts. Table 6-1 lists parts in

alphanumerical order of their reference designators and indicates the description and HP Part

Number of each part, together with any applicable notes. The table includes the following

information.

a. Description of part (see abbreviations below).

b. Typical manufacturer of the part in a five-digit code; see list of manufacturers in

c. Manufacturer's part number.

d. Total quantity used in the instrument (Qty column).

6-3. ORDERING INFORMATION

6-4. To obtain replacement parts, address order of inquiry to your local Hewlett-Packard Sales and

Service Office (see lists at rear of this manual for addresses). Identify parts by their Hewlett

Packard part numbers.

Table 6-2.

a. Instrument model number.

b. Instrument serial number.

c. Description of the part.

d. Function and location of the part.

e. Check digit.

f. Quantity required.

6-5. HP PART NUMBER ORGANIZATION

6-6. The following is a general description of the HP part number system.

29

Page 38

Model 10811A/B

g

A

6-7. Component Parts and Materials

6-8. Generally, the prefix of HP part numbers identifies the type of device. Eight-digit part numbers are

used, where the four-digit prefix identifies the type of component, part, or material and the four-digit suffix

indicates the specific type. Following is a list of some of the more commonly used prefixes for component

parts. The list includes HP manufactured parts and purchased parts.

Prefix Component Part Material

0121- Capacitors, Variable (mechanical)

0122- Capacitors, Voltage Variable (semiconductor)

0140- Capacitors, Fixed

01500160- Capacitors, Fixed

0180- Capacitors, Fixed Electrolytic

0330- Insulatin

0340- Insulators, Formed

0370- Knobs, Control

0380- Crystals

04700490- Relays

0510- Fasteners

0674- through 0778- Resistors, Fixed (non wire wound)

0811- through 0831- Resistors (wire wound)

1200- Sockets for components

1205- Heat Sinks

1250- Connectors (RF and related parts)

1251- Connectors (non RF and related parts)

1410- Bearings and Bushings

1420- Batteries

1820- Monolithic Digital Integrated Circuits

1826- Monolithic Linear Integrated Circuits

1850- Transistors, Germanium PNP

1851- Transistors, Germanium NPN

1853- Transistors, Silicon PNP

1854- Transistors, Silicon NPN

1855- Field-Effect- Transistors

1900- through 1912- Diodes

1920- through 1952- Vacuum Tubes

1990- Semiconductor Photosensitive and Light-emitting Diodes

3100- through 3106- Switches

8120- Cables

9100- Transformers, Coils, Chokes, Inductors, and Filters

6-9. For example, 1854-0037, 1854-0221 and 1851-0192 are all NPN transistors. The first two are

silicon and the last is germanium.

Capacitors, Fixed,

Materials

dhesives

30

Page 39

Model 10811A/B

6-10. GENERAL USAGE PARTS

6-11. The following list gives the prefixes for HP manufactured parts used in several instruments, e.g.,

side frames, feet, top and bottom covers, etc. These are eight-digit part numbers with the fourdigit prefix identifying the type of parts as shown below:

Type of Part P/N Suffix

Sheet Metal 5000- to 5019Machined 5020- to 5039Molded 5040- to 5059Assembly 5060- to 5079

Component 5080- to 5099

6-12. Specific Instrument Parts

6-13. These are HP manufactured parts for use in individual instruments or series of instruments. For

these parts, the prefix indicates the instrument and the suffix indicates the type of part. For

example, 05328-60001 is an assembly used in the 5328A. Following is a list of suffixes commonly

used.

Type of Part

Sheet Metal -00000 to -00499

Machined -20000 to -20499

Molded -40000 to -40499

Assembly -60000 to -60499

Component -80000 to -80299

Documentation -90000 to -90249

P/N Suffix

6-14. Factory Selected Parts

6-15. Some of the values in the parts list are selected during manufacture to meet circuit requirements.

These parts are marked with an asterisk (*) in the parts list and schematic diagrams, with average

values shown.

6-16. The 10811A/B Oscillator contains only one factory selected part which is R20 OVEN

TEMPERATURE SET resistor. This resistor is supplied with the crystal, should the crystal require

replacement.

Table 8-1 lists the various resistors and their corresponding part numbers.

6-20. REPLACEABLE PARTS LIST LAYOUT

6-21. The 10811A and 10811 B Oscillators are identical internally, except that the 10811 B has had the

15-pin pc edge connector removed and a 7-pin connector (11) placed on the board for the 10811

B bottom cover flex circuit (see

Thus the parts lists for the circuit boards are identical. The parts lists are set up in the following

manner:

1. 10811A and 10811B Circuit Board Components and Miscellaneous Parts.

2. 10811A and 10811B Transistor Mounting Hardware.

3. 10811A and 10811B Oven Mass Assembly and covers.

4. 10811A Mechanical Parts (Housing).

5. 10811B Mechanical Parts (Housing).

Figure 8-15). The only other difference is the outer housings.

31

Page 40

Table 6-1. Replaceable Parts

Model 10811A/B

Reference

Designation

10811-60001 3 1 CIRCUIT BOARD COMPONENTS 10811A/B 28480 10811-60001

C1 0121-0511 6 1 TUNING CAPACITOR 28480 0121-0511

C2 0160-0576 5 11 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C3 0160-5109 0 1 CAPACITOR-FXD 15pF ±5% 50VDC CER 0±30 28480 0160-5109

C4 0160-0576 5 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C5 0160-0576 5 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C6 0160-4935 8 CAPACITOR-FXD 510pF ±1% 100VDC CER 72982 8121-100-COGO-511F

C7 0160-0576 5 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C8 0160-5110 3 1 CAPACITOR-FXD 62pF ±1% 50VDC CER 0±30 28480 0160-5110

C9 0160-0576 5 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C10 0160-3874 2 2 CAPACITO R-FXD 10pF ±.5PF 200VDC CER 28480 0160-3874

C11 0160-0576 S CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160.0576

Cl2 0160-4512 7 2 CAPACITOR-FXD 120pF ±5% 200VDC CER 51642 200-200-NP0-121J

C13 0160-3479 7 3 CAPACITO R-FXD .01uF ±20% 100VDC CER 28480 0160-3879

C14 0160-0576 5 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C15 0180-2617 1 1 CAPACITOR-FXD 6.8uF +.10% 35VDC TA 25085 D6R8G81B35K

C16 0160-0576 5 CAPACITOR-FXD .1uF ±20% 50VDC CER 28480 0160-0576

C17 0160-3874 2 CAPACITOR-FXD 10pF ±.5pF 200VDC CER 28480 0160-3874

C18 0160-4947 2 1 28480 0160-4947

C19 0160-3879 7 CAPACITOR-FXD .01uF ±20% 100VDC CER 28480 0160- 387 9

C20 0160-3879 7 CAPACITOR-FXD .01uF +.20% 100VDC CER 28480 0160-3879

C21 0160-0576 5 CAPACITOR-FXD .1uF +.20% 50VDC CER 28480 0160-0576