Page 1

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

CLEMCO SUPPLIED AIR RESPIRATOR

MODEL 60 HP

O.M. 10533

MC FILE NUMBER:

DATE OF ISSUE:

REVISION:

690-0985

09/85

K, 05/15/98

WARNING

Do not proceed with

these instructions until

you have READ the

orange cover of this

MANUAL and YOU

UNDERSTAND its

NOTICE

This supplied air respirator conforms to all NIOSH

specifications and standards and carries NIOSH

approval. As manufactured, this respirator complies

only with those foreign approvals that accept NIOSH

certification. Specifically , it has not been manuf actured

to European CE standards and does not carry the

European CE-mark.

© CLEMCO INDUSTRIES CORP.

One Cable Car Drive

Washington, MO 63090

Phone (636) 239-4300

Fax (636) 239-0788

®

content.* These

WARNINGS are

included for the health

and safety of the

operator and those in

the immediate vicinity.

*If you are using a Clemco

Distributor Parts and Maintenance

Guide refer to the orange warnings

insert preceding the Index before

continuing with the following

instructions.

Page 2

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Clemco Industries Corp.

Washington, Missouri USA

(314) 239-0300

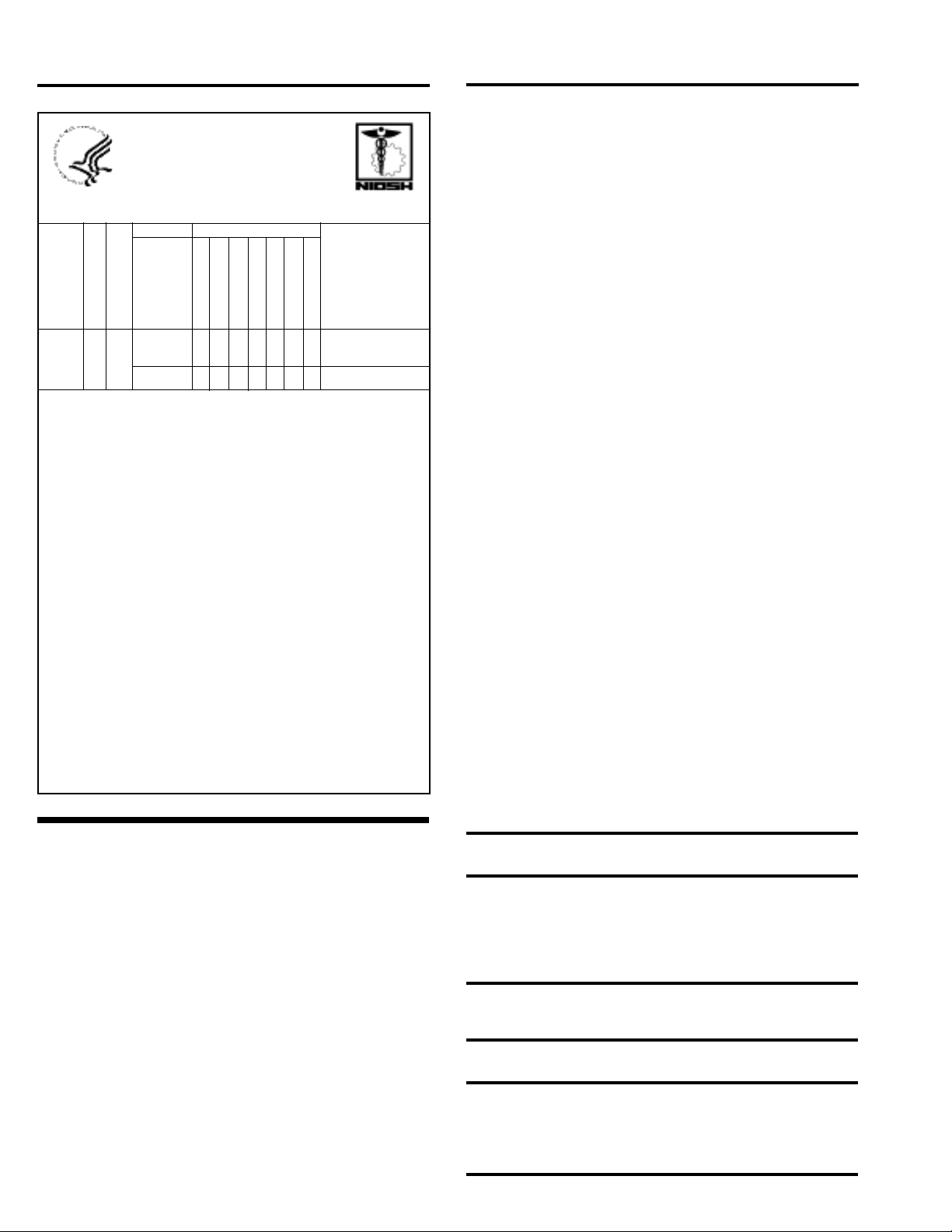

TYPE C AND CE CONTINUOUS FLOW SUPPLIED-AIR RESPIRATOR IS APPROVED

TC#

19C-130

1 PROTECTION

SA-Supplied -air

2 CAUTIONS AND LIMITATIONS

B-Not for use in atmospheres immediately dangerous to life or

health.

C-Do not exceed maximum use concentrations established by

regulatory standards.

D-Air-line respirators can be used only when the respirators are

supplied with respirable air meeting the requirements of

CGA G-7.1 Grade D or higher quality.

E-Use only the pressure ranges and hose lengths specified

in the user's instructions.

J- Failure to properly use and maintain this product could

result in injury or death.

M-All approved respirators shall be selected, fitted, used, and

maintained in accordance with MSHA, OSHA, and other

applicable regulations.

N-Never substitute, modify, add, or omit parts. Use only exact

replacement parts in the configuration as specified by the

manufacturer.

O-Refer to users instructions, and/or maintenance manuals for

information on use and maintenance of these respirators.

S-Special or critical users instructions, and/or specific use

limitations apply. Refer to instruction manual before donning.

ONLY IN THE FOLLOWING CONFIGURATIONS:

Components

1

MODEL

PROTECTION

APL

SA

x 10506 Helmet

Alternates

x 04440 Flow Regulator

x 04410 Flow Regulator

x 04411 Flow Regulator

x 21422 Cont. Flow Conn.

x 04397 Hose 25 Ft.

x 04415 Hose 50 Ft.

x 04398 Hose 100 Ft.

2

Cautions and

Limitations

B C D E J N O S

Page 1

3. Periodic training.

4. Periodic environmental monitoring.

5. Respirator-fit testing.

6. Maintenance, inspection cleaning, and

storage of the respirators.

7. Selection of the proper NIOSH-approved

respirator.

1.1.3 For safe use of the respirator, it is essential that

the user be properly instructed in its use and maintenance.

This manual must be made available to all users of the

respirator. [Reference OSHA Regulations 1910.134.] Read

the entire manual before installing or operating the equipment.

1.1.4 The respirator must be supplied with respirable air

meeting requirements described herein. It is the responsibility of the owner to provide quality breathing-air to the

respirator, and to establish a program to ensure that the

respirator is properly used and maintained.

1.1.5 The following manuals are available for accessories that may be used in conjunction with the Apollo

Respirator.

Description Manual No.

CAT Cool-Air Tube 08956

CCT Climate Control Tube 08850

CPF Particulate Air Filter 04143

ABL 4021 CarbonMonoxide Alarm 21457

1.2 Hazard Alerts

1.2.1 Clemco uses signal words, based on ANSI Z535.2-

1991, to alert the user of a potentially hazardous situation

that may be encountered while operating this equipment.

ANSI’s definitions of the signal words are as follows:

1.0 INTRODUCTION

1.1 Scope of manual

1.1.1 This manual covers setup, operation, mainte-

nance, replacement parts, and important warnings for safe

operation of the Clemco Apollo 60 HP Supplied-Air Respirator.

1.1.2 OSHA requires the employer to establish a comprehensive respiratory protection program per regulations

29 CFR 1910.134(a)(b) and 29 CFR 1926.103, to include

the following:

1. Program coordination by a designated

responsible individual.

2. Evaluation of each worker’s ability to perform

the work while wearing a respirator.

! NOTICE

“Notice” is used to indicate a statement of company policy as the message relates directly or

indirectly to the safety of personnel or protection

of property.

! CAUTION

“Caution” is used to indicate a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Page 3

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

! WARNING

“Warning” is used to indicate a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

! DANGER

Page 2

toxic or hazardous dust is not restricted to blast

operators. There may be an equal or greater

danger after the blasting process due to lingering

airborne dust particles, and especially from dust

generated during cleanup activity. Heavy metal

paint, asbestos, sand or other silica, and other

toxic material dusts will cause serious lung disease or death without the use of properly designed, and maintained NIOSH-approved, supplied-air respirator equipment by blasting operators and all personnel within the work site area.

Lead poisoning can cause death. OSHA has stated

that the permissible exposure limit of lead is 50

micrograms per cubic meter of air (50 µg/m3),

averaged over an 8-hour workday.

“Danger” is used to indicate an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

1.3 Respiratory and Health Alerts

! WARNING

TOXIC DUST POISONING

Research by the Occupational Safety and Health

Administration (OSHA) has discovered potential

risks of lead and other heavy metal poisoning to

unprotected abrasive blasting operators and other

personnel who may be exposed to toxic dust in

the abrasive blasting vicinity. Toxic dust is produced primarily by the removal and breakdown of

lead or other heavy metal coatings during abrasive blasting.

The breakdown of toxic coatings and hazardous

abrasive causes the contaminants to become

airborne. Breathing toxic dust from lead or other

heavy metal coatings may cause health and life

threatening toxic poisoning and can damage vital

organs. Breathing hazardous dust produced from

silica abrasive may cause delayed life threatening respiratory disease such as silicosis.

Lead is one of several toxic dusts that may be

present in an abrasive blasting operation. It is

imperative that blasting contractors identify all

material being removed by blasting, and obtain

material safety data sheets (MSDS) for the blasting abrasive prior to blasting. It is the responsibility of the employer to identify all airborne contaminants in the blast vicinity, and ensure they do

not exceed the permissible exposure limit (PEL)

Ref. 29 CFR 1910.1000 and 29 CFR 1926.62. Thorough examinations should be made by an industrial hygienist or other qualified professional to

identify all contaminants generated by blasting

and in the blasting vicinity.

Exposure to dangerous levels of lead or other

The Apollo supplied-air respirator system is approved by NIOSH as a Type-CE, continuous-flow,

abrasive blast, supplied-air respirator, in accordance with title 42 CFR Part 84. The NIOSH recognized assigned protection factor (APF) for any

supplied-air respirator equipped with a loosefitting hood or helmet and operated in a continuous flow mode is 25, based upon the NIOSH

Respirator Decision Logic (Pub. No. 87-108). In

other words, any Type-CE respirator should be

used only in atmospheres in which the contaminant level does not exceed 25 times the permissible exposure limit. However, in its Memorandum for Regional Administrators dated August

30, 1995, OSHA has stated that select individual

Type-CE continuous-flow, abrasive blast, supplied-air respirator models that pass stringent

tests conducted by independent third party testing laboratories will be granted APF values higher

than the NIOSH recognized 25. Clemco contracted

with Los Alamos National Laboratory to conduct

the independent testing. Based upon the results

of these tests, OSHA will treat the Apollo Supplied-Air Respirator (NIOSH Approval TC-19C-

130) as having an APF of 1000 times the permissible exposure limit, or 50,000 µg/m3 when used in

lead removal applications.

The employer must provide and maintain appropriate approved respirators, in addition to providing operator training and employing required

work site safety practices.

To avoid any potential danger of respiratory injury, approved, supplied-air respirators must be

worn at all times in the presence of any type of

dust. The respirator must be maintained as described herein. Improper use of any respirator

may cause life threatening respiratory disease,

and immediate poisoning from toxic dust. Respirators should be removed only after the ambient

air has been tested with a dust monitor, and found

to be safe to breathe.

Toxic dust poisoning may also occur by eating,

drinking, or smoking in a contaminated area, or

by eating, drinking, or smoking in a non-hazardous area before thorough washing of hands and

face. Do not eat, drink or smoke in the blast area.

Thoroughly wash hands and face to remove contaminants before eating, drinking, or smoking

outside the blast area.

Page 4

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 3

This manual does not contain all the health and

safety requirements regarding toxic and hazardous dust exposure. Obtain copies of the OSHA

regulations and consult a safety professional

and/or industrial hygienist for complete requirements.

Within this manual we refer to hazardous or contaminated environments. These environments can

be any place around the blast area that could

contain toxic or hazardous dust.

If these warnings are not completely understood,

or if further information is required, contact a

local OSHA office. If any personnel in the abrasive blasting vicinity cannot read or comprehend

these warnings and the entire content of this

instructional material, assign a qualified person

to instruct them.

Additional information on abrasive blasting hazards titled “Preventing Silicosis and Death From

Sandblasting”, Publication No. 92-102, is available from:

Publications Dissemination, DSDTT

National Institute for Occupational Safety and Health

4676 Columbia Parkway

Cincinnati, OH 45226 (513) 533-8287

1.5.1 Air pressure at the point of attachment (the point

of attachment is where the respirator supply hose is

connected to the respirable air source) must be maintained at pressures between the minimum pressure as

shown in the table in Section 4.2.4 and the maximum of

100 psi.

! WARNING

Failure to maintain the minimum pressure at the

point of attachment may reduce air flow below the

minimum flow required by OSHA. Reduced air

flow may result in ingress of hazardous toxic

dust, subjecting the user to immediate health and

life threatening poisoning and subsequent respiratory disease.

1.5.2 Use no more than 12 sections of respirator hose to

obtain a total maximum length of up to 300 feet, as noted

in the table in Section 4.2.4.

1.4 Cautions and Limitations

1.4.1 Not for use in atmospheres immediately danger-

ous to life or health.

1.4.2 Do not exceed maximum use concentrations established by regulatory standards.

1.4.3 Air-line respirators can be used only when the

respirators are supplied with respirable air meeting the

requirements of CGA G-7.1 for Grade D or higher quality.

1.4.4 Use only the pressure ranges and hose lengths

specified in the instruction manual.

1.4.5 Failure to properly use and maintain this product

could result in injury or death.

1.4.6 All approved respirators shall be selected, fitted,

used, and maintained in accordance with MSHA, OSHA,

and other applicable regulations.

1.4.7 Never substitute, modify, add, or omit parts. Use

only exact replacement parts in the configuration as specified by the manufacturer.

1.5.3 The respirator is designed for specific use in

abrasive blasting applications. Do not use in other operations such as painting or welding.

1.6 Protection

1.6.1 Assigned Protection Factor (APF): The NIOSH

recognized assigned protection factor for any Type-CE

respirator (the Apollo respirator is a Type-CE respirator) is

25 times the permissible exposure limit (PEL). In other

words, CE respirators should be used only in atmospheres

in which the contaminant level does not exceed 25 times

the PEL. However, based upon the results of independent

testing, OSHA will treat the Apollo Supplied-Air Respirator

as having an APF of 1000 times the PEL when used in lead

removal applications.

1.6.2 Head: The respirator protects the wearer’s head

and neck from impact and from abrasion caused by rebounding abrasive. The respirator meets physical requirements for industrial head protection as stated in ANSI

Z89.1-1997 as a Type I Class G protective helmet.

1.6.3 Face: The Apollo 60 inner lens meets impact and

penetration requirements under ANSI Z87.1-1989.

1.4.8 Refer to users instructions, and/or maintenance

manuals for information on use and maintenance of these

respirators.

1.5 Special Use Limitations

1.6.4 Eyes: Apollo respirators do not provide primary

eye protection. Wear approved eye protection with the

respirator.

1.6.5 Hearing: Noise generated by the Apollo respirator

and measured inside the helmet do not exceed 80 deci-

Page 5

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 4

bels. (42 CFR part 84.140) When any exterior noise

causes the internal noise level to exceed 80 decibels, the

user must wear additional hearing protection. A variety of

hearing protectors can be worn with the respirator.

1.7 Description

1.7.1 The Clemco Apollo 60 Supplied-Air Respirator is

approved by the National Institute of Occupational Safety

and Health (NIOSH).

! WARNING

OSHA/NIOSH approval applies only when this

supplied-air respirator is used as a complete

system. Do not make any non-approved modification, deletion, or substitution. Non-approved

components voids the NIOSH approval and may

permit ingress of toxic and hazardous dust, and

result in toxic poisoning and respiratory disease.

1.7.2 The respirator comes with one of four air control

devices that permit safe, comfortable blast cleaning under

various conditions.

• Constant-Flow Connector (CFC): Provides non-adjustable volume of supplied air, within the cfm range required

by OSHA.

• Air Control Valve (ACV): Enables the user to adjust

the volume of supplied air, within the cfm range required by

OSHA. It is for use in areas where the air temperature is

comfortable.

• Cool-Air Tube (CAT): Used in warm climates to enable

the user to adjust supplied air to cooler temperatures.

• Climate Control Tube (CCT): Enables the user to adjust

supplied air to warmer or cooler temperatures.

1.7.3 Low Pressure Conversion Kit: This optional accessory kit contains parts and instructions to convert the

Apollo 60 HP, (respirator for use with Grade “D” Compressed Air) to Apollo 60 LP (respirator for use with

ambient air pump). The kit is listed in Section 10.1.

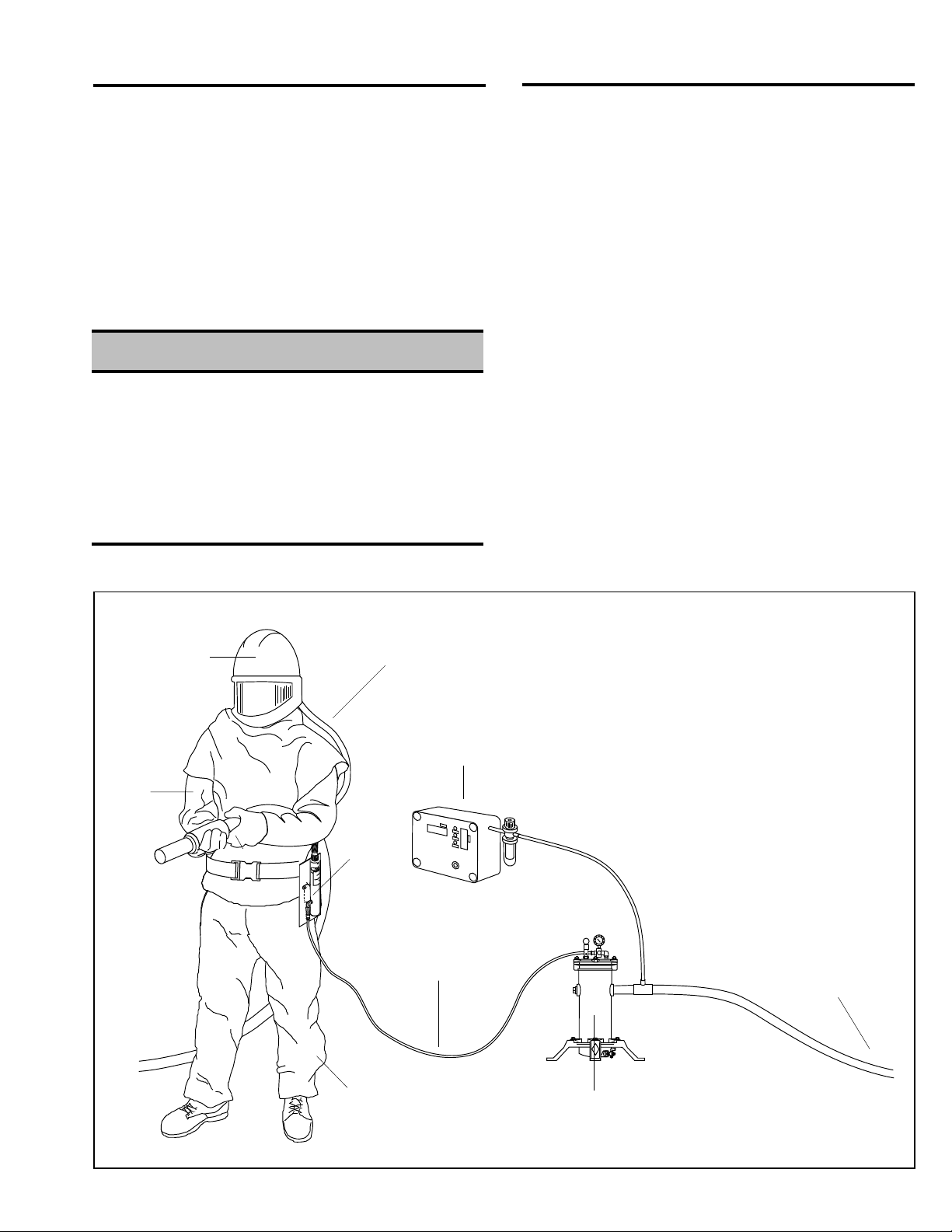

Apollo 60

Supplied-Air

Respirator

Blast

Suit

Gloves

Breathing-Air

Tube Assembly

Climate

Control

Tube

Blast Suit

Carbon

Monoxide

Alarm

Respirator

Supply Hose

CPF-20

Particulate

Filter

General Arrangement

of Operator Safety

and Comfort Components

Breathing-Air

Source

Figure 1.

Page 6

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

2.0 INSPECTION

! NOTICE

A Clemco respirator hose must be used with the

Apollo Respirator. If one is not available, it must

be ordered from an authorized distributor of

Clemco products. Hoses are not included with

respirators, because blast operators often are

assigned personal respirators, while using common respirator hoses.

2.1 Component Checklist

2.1.1 Make sure that all the respirator components are

present. Each respirator box should contain the following:

• Helmet with chin strap, suspension and cape

attached

• Breathing tube assembly

• One of the following air control devices with belt:

Constant-Flow Connector

Air Control Valve

Cool-Air Tube

Climate-Control Tube

• Disconnect adaptor assembly

NOTE: Respirator hose (one or more alternate hoses)

must be ordered separately.

Page 5

3.2.1 The lens system is an important part of the respi-

rator assembly. The helmet is supplied with an inner lens,

secured by a thick rubber gasket. Held in place on top of

the inner lens by the window frame are up to five perforated

outer lenses.

3.2.2 Check that the inner lens is in place. (See Section

9.1)

3.2.3 The perforated outer lenses are secured to the

helmet by the window frame. As one lens becomes frosted

during blasting, it can be torn off to expose the next lens.

Check that the perforated outer lenses are in place. (See

Section 9.2)

3.3 Belt

3.3.1 Using the spring clip attached to the Constant-

Flow Connector, attach the connector to the belt slide. This

step is not required with alternate air control devices,

because the Air Control Valve is furnished with a hook-on

belt clip, and belts are attached to Cool Air Tubes and

Climate Control Tubes.

3.4 Breathing Tube Assembly

3.4.1 Attach the red end of the breathing tube to the

threaded air inlet fitting at the back of the helmet.

3.4.2 Attach the swivel connector on the black end, to

the Constant-Flow Connector, or alternate air control

device.

2.1.2 When all of these components are present, prepare the respirator for operation per Section 3.0.

3.0 PREPARATION

3.1 Adjust Helmet Suspension per Section 6.2.

3.2 Lens Assembly

! WARNING

Never use the respirator without the fixed inner

lens and perforated outer lenses in place. The

fixed lens provides support for the window gasket. If the gasket is not adequately supported,

leaks can occur which could permit entry of toxic

and hazardous dust or abrasive into the helmet.

! WARNING

The red end of the breathing tube must attach to

the helmet, and the black end to the ConstantFlow Connector or alternate air control valve.

Failure to properly attach the tube may increase

noise levels beyond OSHA limits.

3.4.3 Use the strap handle to carry or hang the respira-

tor. Never hold, carry or hang the respirator by the breathing tube. Mishandling the respirator in this manner may

damage the tube or helmet inlet. Any leaks or breaks in the

breathing tube will alter the air flow through the respirator

and affect user’s safety and comfort.

3.5 Respirator Hose

3.5.1 Use the disconnect adaptor assembly to attach

the respirator hose to the Constant-Flow Connector, or

alternate air control device. Using the adaptor provided,

Page 7

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 6

connect the other end of the respirator hose to a respirable

air source. If longer hose is required, it must be a NIOSHapproved Clemco respirator hose extension. Any 25 foot,

50 foot and 100 foot respirator hoses can be added in any

combination to produce the maximum total length as noted

in the table in Section 4.2.4.

4.0 AIR SUPPLY

! WARNING

Air supplied to this respirator system is critical to

the safety of the user. Read this section carefully.

Poor quality air will cause serious respiratory

injury or death to the user. See Toxic Dust Poisoning Warning in Section 1.3.

4.1 Air Quality

4.1.1 The quality of air supplied to the respirator is

extremely critical to the safety of the user. Special care

must also be taken to avoid accidental connection to any

other gas lines; such as, oxygen, acetylene, or nitrogen.

! WARNING

4.1.3 Prior to using the respirator, read the owner’s

manual and all instructions, labels, and warnings relating

to the compressed air source. Take special care to abide

by all warnings from the compressor manufacturer regarding compressor use.

4.1.4 A breathing air type compressor must be used.

The compressor must be equipped with necessary safety

and monitoring devices, plus suitable in-line air filters and

purifying equipment to assure breathing air quality. [Reference OSHA Regulations 29 CFR 1910.134 (d), and 29

CFR 1926.103 (f)].

4.1.5 If an oil-lubricated compressor is used, it must be

equipped with a high-temperature alarm or carbon monoxide (CO) alarm, or both. If only a high-temperature alarm

is used, the air from the compressor must be tested

frequently for the presence of carbon monoxide. [Reference OSHA Regulations 29 CFR 1910.134 (d) and 29 CFR

1926.103 (f)].

4.1.6 Regardless of the air compressor type, precautions must be taken to prevent contaminants from entering

through the compressor intake. The compressor inlet must

be located away from all sources of toxic contaminants

including carbon monoxide, which is found in engine

exhaust, and in any form of combustion. No vehicles

should be allowed near the compressor intake. Contaminants can enter respiratory equipment through the compressor air inlet. This inlet must not be located near any

exhaust system outlet, ventilation flue, or source of fumes

or particles of any kind.

Never connect a breathing air line to an air source

that has not been tested for gas and particulate

contamination. The presence of unacceptable

levels of carbon monoxide (CO) or other gases in

the breathing air will cause death to the user.

! WARNING

Do not use piston type, oil-bath, compressors for

breathing air. These compressors could produce

dangerous levels of carbon monoxide, which will

cause death to the user.

4.1.2 Breathing air used to supply the respirator must be

respirable breathing air and contain no less than 19.5

volume-percent of oxygen. Breathing air shall also meet

the requirements for Grade D or higher quality, as described in Compressed Gas Association Commodity Specification pamphlet G-7.1., titled Commodity Specification

For Air, published by Compressed Gas Association Inc.,

Arlington, VA. (42 CFR Chapter 1).

4.1.7 The precautions described above also apply to

portable compressors. In addition, in the case of enginedriven compressors, precautions must be taken to prevent

engine exhaust gases from entering the air intake of the

compressor. Compressor engine exhaust should be piped

to a location safely downwind from the compressor air

intake. Compressors vary in design and operation; therefore, it is important that users carefully read the

manufacturer’s operation and maintenance instructions

before making modifications.

4.1.8 An appropriate air filter must be installed and

regularly maintained to remove objectionable odors, as

well as oil mist, water, pipe scale and other particulate

matter. Refer to OSHA Regulation 1910.94(6). The Clemco

CPF Air Filter complies with the regulation, and provides

the pressure reducing valve referred to in the regulation.

4.1.9 It is the owner’s and user’s responsibility to check

the air supply. This includes the compressor, carbon

monoxide alarms, air filters, and shut-down devices. An

overheated compressor, or one that is in poor mechanical

condition, may produce carbon monoxide. A carbon

Page 8

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

monoxide removal or conversion system may also be used

to ensure breathing air quality. The maximum allowable

presence of carbon monoxide in Grade D breathing air is

10 parts per million (ppm).

4.2 Air Volume and Pressure

4.2.1 A pressure regulator and gauge must be installed

at the point where the respirator hose is attached to the air

source. The Clemco CPF Filter with regulator meets this

requirement if the inlet pressure does not exceed 125 psi.

See typical installation, Figure 1.

! DANGER

Page 7

Hose Minimum Pressure Setting, psi

Length CFC ACV CCT CAT

25 ft. 65 85 90 90

50 ft. 65 85 90 90

75 ft. 65 85 90 90

100 ft. 65 85 95 95

125 ft. 70 90 95 95

150 ft. 70 90 100 100

175 ft. 70 90 100 100

200 ft. 70 90 100 100

225 ft. 75 95 * *

250 ft. 75 95 * *

275 ft. 75 95 * *

300 ft. 75 95 * *

Do not connect the Apollo Respirator or CPF

Filter, or any other regulator or filter, to bottled air

that does not have a pressure reducing valve that

reduces pressure to maximum of 125 psi (65 to

100 psi for the respirator only). Failure to comply

with this warning will cause devices rated at

lower pressures to explode under the high pressure of bottled air. Such an explosion could cause

severe injury or death.

4.2.2 The respirator must be supplied with 15 cfm (cubic

feet per minute) of Grade D breathing air at 65 to 100 psi

(pounds per square inch). When using an alternate CoolAir Tube or Climate Control Tube, the respirator must be

supplied with 20 cfm of Grade D breathing air at 90 to 100

psi.

4.2.3 The pressure regulator must be adjusted to 65 to

100 psi. Refer to the table in Section 4.2.4 to determine the

minimum pressure, based on the total length of respirator

hose, and choice of air control device. Adjust the pressure

with the respirator hose and respirator attached. If the

regulator is adjusted with static pressure (no air flow),

pressure may drop below the required pressure when the

respirator is connected, and may result in low air flow.

Setting the pressure as instructed will provide a minimum

of 7 cfm to the respirator.

4.2.4 Use the table below to determine the minimum

pressure setting and maximum respirator hose length,

based on the air control device as shown in Section 1.7.2.

* Do not use these control devices at distances greater

than 200 ft.

! WARNING

The compressor must provide adequate output,

and the plumbing between the compressor and

the point of attaching the respirator hose must

have sufficient capacity to supply the volume of

air at the pressure required (as stated in Section

4.2.2). Restricted air flow will cause discomfort to

the user, and may result in ingress of hazardous

and toxic dust, subjecting the user to health and

life threatening toxic poisoning and long term

respiratory disease and death.

5.0 OPERATION

! WARNING

With the respirator on, leave the blast area

immediately if any of the following conditions

occur:

• Any part of the respirator system becomes

damaged.

• Any air monitoring alarm is activated.

• Airflow into the respirator is reduced or

stops.

• Breathing becomes difficult.

• At the first sign of dizziness, nausea, fever,

illness or injury.

• Any contamination is noted by taste, smell

or vision inside the respirator.

• Vision becomes impaired.

• Any irritation is noted.

Page 9

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 8

5.1 Prior to operation, thoroughly inspect and clean

the helmet, breathing tube, respirator hose, air entry ports,

and fittings of all dust and debris. Inspect the helmet

suspension and adjust if necessary per Section 6.2.

5.2 Start the compressor and open the service valve

to pressurize the air supply line.

5.3 Check air pressure at the point of attachment. Set

the pressure between the minimum pressure assigned in

Section 4.2.4 and the maximum of 100 psi. Pressure must

be set with the respirator connected.

5.4 Check all safety, and breathing equipment used in

conjunction with the respirator as recommended by the

manufacturer.

5.5 Check respirator hoses and connections for tightness and leaks.

5.6 Put the respirator on in a clean non-hazardous

environment, free of contaminants, where the air is safe to

breathe. When putting the respirator on or taking it off,

keep it upright to prevent dust and abrasive from falling

inside.

5.7 Position the chin strap so it fits comfortably under

the chin.

5.8 Position the knit cuff on the inner collar so that it fits

snugly around the neck in turtleneck fashion, without any

interference from clothing such as shirt collars. When

correctly positioned the smaller elastic end of the collar

must face up.

5.11 When finished blasting and with cleanup, remove

the respirator in a clean, non-hazardous environment

where the air is safe to breathe.

! WARNING

Do not put the respirator on, or store it in a blast

contaminated environment. Do not remove the

respirator in a contaminated environment except

for emergency evacuation when the use of the

respirator hinders escape.

6.0 ADJUSTMENTS

6.1 Air Control Valve, alternate, Figure 2

Outlet End

(top of unit)

Belt Clip

Pull sleeve down

and turn

to adjust air flow

Higher Lower

! WARNING

Correct placement of the inner collar is critical for

providing the protection for which the respirator

is designed. The collar must be positioned and

maintained without any interference from items

such as hair, facial hair, or shirt collars, between

the collar and user’s neck.

5.9 Pull the cape down to fully extend it and connect

the four elastic straps (two on each side) under the arms,

and tighten using the slides provided.

5.10 Put the belt and control valve on over the cape.

Buckle the belt around the waist, and tighten it by pulling

the belt end through the buckle insert.

Adjustment

Sleeve

Inlet End

(bottom of unit)

Figure 2.

6.1.1 Clemco’s Air Control Valve allows the user to

increase or decrease the volume of breathing-air while

wearing the supplied-air respirator. The valve provides a

range of 7 to 10 cfm of breathing-air when it is supplied with

respirable air as noted in Section 4.0. To regulate the air

supply, pull down and turn the large sleeve on the lower

end of the valve in the desired direction to increase or

decrease the air flow as needed. A soft hissing sound is

normal when the air control valve is in operation as some

air is allowed to escape underneath the sleeve to prevent

the entry of dust into the adjustment mechanism.

Page 10

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 9

6.2 Helmet Suspension Adjustment and Replacement,

Figure 3

White Plastic Tabs

(rear)

Headband

Size Slots

Front Band

Lugs

Button B

Suspension Strap

Button A

Vinyl

Sweatband

White Plastic

Tabs

(front)

Head Band

Tongue

Front Holder

Figure 3.

! WARNING

The suspension maintains a fixed distance between the head and the helmet. It is critical that

the suspension is properly installed, and adjusted as described, to provide maximum head

protection and comfort.

6.2.5 Fasten the vinyl sweatband onto the buttons of the

suspension.

6.2.6 Install the suspension strap before installing the

suspension. Insert the yellow end tabs into the clefts on the

helmet shell. When correctly installed, the strap is between

the suspension and helmet shell and above the ears.

6.2.7 Install the suspension by inserting the four white

plastic tabs into the clefts on the shell. The tabs must fully

seat in their respective locators.

6.2.8 Try the helmet on for fit and readjust if necessary.

6.2.9 Check that the chin strap is in place, then reattach

the cape onto the helmet following the instructions in

Section 9.4.

7.0 MAINTENANCE PROGRAM

7.1 Basic Service

7.1.1 A program for maintenance and care of the respi-

rator must be established based on application, working

conditions, and hazards involved, and include the following basic service.

• Inspection for defects (including a leak check)

• Cleaning and disinfecting

• Repair (service maintenance)

• Storage

Equipment must be properly maintained to retain its original effectiveness. [Reference OSHA Regulations 1910.134

(f)].

7.2 Inspection

6.2.1 Remove the cape from the helmet per Section 9.4.

6.2.2 Remove and discard the old suspension and

suspension strap by extracting the plastic tabs from the

wedge-shaped clefts in the shell.

6.2.3 Unfasten the vinyl sweatband from the two lower,

outside buttons (A and B in Figure 3).

6.2.4 The suspension fits head sizes 6.5 to 8. Head

sizes are marked on the headband slots. Slide the headband

tongue through the front holder until the desired head size

is reached. It is important that the adjustment be made

evenly on both sides. Press the selected slots firmly onto

the lugs on the front band.

7.2.1 Inspect respirators before and after each use.

Inspection shall include a check for tightness of connections and the condition of the lenses, suspension, cape

and elastic parts, breathing tube, respirator hoses and

connectors, Constant-Flow Connector or alternate air control valve or temperature control valve. [Reference OSHA

Regulations 1910.134 (f)(2)].

7.2.2 The respirator hoses, breathing tube, air entry

ports, and fittings must be checked for dust contamination,

and cleaned before making connections.

7.2.3 The helmet suspension is a very important component for maintaining maximum hard hat and respiratory

protection. It must be inspected for fit and wear on a daily

basis, and replaced immediately at the first sign of wear.

(See Section 6.2)

Page 11

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 10

7.2.4 Periodically inspect and clean the foam filter and

screen in the alternate air control valve. Replace the foam

filter at first sign of blockage or deterioration. (See Section

9.8)

7.2.5 The inner collar is a very important factor in

controlling air escape from the helmet and preventing

ingress of dust. The elastic properties of the collar are

intended to provide a snug fit on the user’s neck. The collar

must be replaced before it is stretched to the point where

it no longer fits snugly around the neck.

7.2.6 The outer cape provides protection from rebounding abrasive and from abrasive ingress into the helmet.

Inspect the outer cape frequently for wear. Replace the

cape before holes are worn through, or any wear occurs

that prevents the cape from providing the protection for

which it is intended.

7.3 Cleaning and Disinfecting

7.3.1 Respirators must be cleaned and disinfected as

frequently as necessary to ensure that proper protection is

provided to the wearer. Respirators used by more than one

person must be cleaned and disinfected after each use.

See Section 8.0 for cleaning instructions. [Reference

OSHA Regulations 1910.134 (b)(5); 1910.134 (f)(3)].

store it in a clean, dry place. [Reference OSHA Regulations 1910.134 (f)(5)].

8.0 CLEANING

! CAUTION

Follow washing instructions as described in this

section. Do not use any caustic chemicals or

solvents that may be irritating or harmful to the

user, or which change the properties of the materials used in any part of the respirator.

8.1 Outer Cape

8.1.1 The cape can be machine washed using warm

water and mild detergent. Dry in a clothes dryer at the

lowest temperature setting. Do not dry clean. See Section

9.4 for removal and installation instructions.

8.2 Inner Collar

7.4 Repair (Service Maintenance)

7.4.1 Replacement or repairs shall be done only by

trained persons, using genuine Clemco parts designed for

the respirator. No attempt shall be made to replace components or to make adjustment or repairs beyond the

manufacturer’s recommendations. See Sec. 9.0 for service instructions. [Reference OSHA Regulations 1910.134

(f)(4)].

7.5 Storage

7.5.1 Daily Storage

7.5.1.1 When the respirator is not in use, it must be stored

in a clean, dry area. Hang the respirator by the strap

provided on the top. Do not tuck the cape inside the helmet.

Let the cape hang loose to allow air to circulate, to dry

condensation from the cape and from inside the helmet.

7.5.2 Long-term storage

7.5.2.1 After inspection, cleaning and thorough drying,

and after necessary repairs are made, the cape should be

tucked inside the helmet. The respirator shall then be

placed in a plastic bag and the bag sealed to keep out dust

and moisture. Place the bag in a clearly marked carton and

8.2.1 The removable inner collar should be frequently

washed to remove build-up of dirt that accumulates from

normal perspiration and air moisture. For general hygiene,

daily washing is recommended.

8.2.2 The inner collar may be either washed or replaced

separately or with the outer cape. To wash separately,

unzip the collar and machine wash with warm water and

mild detergent. Tumble dry in a clothes dryer at the lowest

temperature setting. Do not dry clean.

8.3 Sweatband and Suspension

8.3.1 The sweatband, suspension, suspension strap,

and chin strap should be washed using warm water and

mild detergent. See Section 6.2 for removing the suspension.

8.4 Helmet Assembly

8.4.1 The helmet assembly should be wiped clean with

mild detergent and water. DO NOT IMMERSE THE HELMET IN WATER! While this does not permanently dam-

age the helmet, it will require an extended drying period.

8.4.2 Care must be used to prevent abrasive entry when

putting on or removing the respirator and when changing

lenses. Vacuum the inside of the helmet to remove any

abrasive.

Page 12

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

8.4.3 If the acoustical foam on the inside of the helmet

becomes soiled, it can be wiped with a damp cloth or pulled

off and replaced.

8.5 Inner Lens

8.5.1 Inner lenses should be replaced when dirty or

scratched; however mild detergent and water can be used

to clean the inner lens. Volatile solutions such as alcohol,

gasoline or ammonia must not be used to clean this lens.

Allow the lens to air dry; cloth and towels can scratch the

lens surface.

Page 11

Locating Tabs

Perforated Outer Lens

Lens Pull Tab

Window Frame

Inner Lens

Hinge

9.0 SERVICE MAINTENANCE

! CAUTION

Clean the respirator of dust and media before

maintenance. All maintenance must be done in a

clean environment away from dust and media.

Doing so will help prevent ingress of dust and

contaminants.

9.1 Replacing Inner Lens

9.1.1 Unlatch and open the window frame.

9.1.2 Working from inside the helmet, pull up the win-

dow gasket lip and push the gasket and lens out the front

of the window opening.

9.1.3 Remove the old lens from the gasket and replace

with new lens.

9.1.4 Place the new lens and gasket over the window

opening. From the inside of the helmet, work the gasket lip

back onto the helmet.

9.1.5 Smooth out wrinkles in the gasket on the inside of

the helmet.

9.1.6 To maximize the wear life of the inner lens do not

remove the last perforated outer lens. (See Section 9.2)

The respirator must never be used without the inner lens

in place.

9.2 Replacing Perforated Outer Lenses, Figure 4

9.2.1 Up to five outer lenses can be installed at one time.

For maximum visibility, install only enough lenses to last

during a work period.

Lens Replacement

Inner Lens Gasket

Figure 4.

9.2.2 Preparing lenses in the following manner will

permit lenses to be pulled off easily by a user wearing

heavy gloves.

9.2.3 Place up to five lenses on a clean flat surface. Fold

up the tab of each lens except the first and last, so that the

tab of each lens is against the back of the one over it.

9.2.4 Unlatch and open the window frame and remove

all remnants of old lenses.

9.2.5 Pick up the stack of prepared lenses. They will be

installed with the straight side toward the top of the helmet,

and the pull tabs toward the hinged end of the window

frame. See Figure 4.

9.2.6 Drop only the top lens tab through the window

frame opening at the window frame hinge end. The tab of

the bottom lens (inside lens) should not go through the

window frame opening. Placing the lenses in this manner

will prevent unintentional removal of the last perforated

lens and prolong the life of the inner lens. Allow all the

lenses to drop in place between the locating lugs on the

window frame. The lens perforations should line up close

to the window frame opening when the frame is closed and

latched.

9.3 Suspension

9.3.1 To replace and adjust suspension, see Section

6.2.

9.4 Outer Cape

9.4.1 When the cape becomes soiled or requires re-

placement, it can easily be removed as follows.

Page 13

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

Page 12

9.4.2 Separate the Velcro tabs on the back of the cape.

See Figure 5.

Air Inlet

Fitting

Notch

Cape Removal

Velcro Tab

Figure 5.

9.4.3 Slide the ends of the cape to the notch. Continue

sliding one end of the cape out of the groove until the entire

cape is detached from the helmet.

9.4.4 To install the cape, separate the Velcro tabs on the

cape and slide one end into the groove on the bottom edge

of the cape attachment strap at the point where the groove

is notched. Continue sliding the cape around the bottom of

the helmet until the entire cape is completely into the

groove. NOTE! Spraying a non-toxic silicone-base lubricant into the groove will reduce friction and ease assembly.

9.4.5 Join the Velcro tabs at the notch.

9.5 Inner Collar

9.5.1 The inner collar is a very important factor in

controlling air escape from the helmet and preventing

ingress of dust.

closed. When replacing the window frame the acoustical

foam inside the helmet should also be replaced.

9.7 Chin Strap

9.7.1 Replace the chin strap when worn.

9.8 Filter Kit

9.8.1 A filter kit is available for the alternate Air Control

Valve. When the foam filter becomes soiled or deteriorates, pry out the retaining ring with a small screwdriver.

Remove the screen and dirty filter. Replace all three items

with parts supplied in the kit.

10.0 REPLACEMENT PARTS

10.1 Supplied-Air Respirator Systems

and Alternate Accessories

Respirators do not include alternate respirator

hoses shown in Section 10.2. Respirator hose must

be ordered separately.

Item Description Stock No.

(-) Apollo 60 HP Respirator,

w/constant-flow connector................. 21300

(-) Apollo 60 HP Respirator,

w/air control valve.............................. 10505

(-) Apollo 60 HP Respirator,

w/cool-air tube ................................... 10508

(-) Apollo 60 HP Respirator,

w/climate control tube........................ 10509

(-) Air control valve with belt......................... 04440

(-) Cool-air tube with belt .............................. 04410

(-) Climate control tube with belt .................. 04411

(-) Filter kit, air control valve.........................04381

(-) Low pressure conversion kit.

Converts Apollo 60 HP (high pressure)

(Grade “D” Compressed Air)

respirator to LP (low pressure,

ambient air) respirator ....................... 22079

9.5.2 The elastic properties of the collar are intended to

provide a snug fit on the user’s neck. The inner collar must

be replaced before it is stretched to the point where it no

longer fits snug against the neck. The collar unzips from

the outer cape for replacement or washing. See Section

8.2 for cleaning instructions.

9.6 Window Frame

9.6.1 The window frame must be replaced when it

becomes difficult to maintain a seal, or to keep the latch

Page 14

APOLLO 60 HP SUPPLIED-AIR RESPIRATOR

10.2 Supplied-Air Respirator, Figure 6

Item Description Stock No.

1. Constant-flow connector, HP (alternate),

without belt ........................................ 21415

2. Belt assembly, 2" .....................................04430

3. Respirator hose, 3/8" x 25 ft. (alternate),

includes items 6 and 7....................... 04397

4. Respirator hose, 3/8" x 50 ft. (alternate),

includes Items 6 and 7 ...................... 04415

5. Respirator hose, 3/8" x 100 ft. (alternate),

includes items 6 and 7....................... 04398

6. Adaptor, 3/8" hose to 3/8" pipe................00022

7. Union, 3/8" hose to 3/8" hose .................. 01020

8. Disconnect, 1/4" female...........................00025

9. Adaptor, 3/8" hose to 1/4" pipe................01019

10. Acoustical foam kit, sides ........................ 04369

Page 13

11. Gasket, window........................................ 04452

12. Inner lens, .040" package of 5 ................. 04367

13. Outer lens, .0075", perforated,

package of 25....................................04361

14. Window frame kit ..................................... 08741

15. Chin strap................................................. 04460

16. Handle strap............................................. 03623

17. Suspension ..............................................10532

18. Cape attachment strap ............................ 10534

19. Cape with inner collar ..............................04435

20. Breathing tube assembly w/molded ends 21550

21. Washer, breathing tube, package of 6..... 04370

22. Inner collar kit........................................... 08740

23. Window latch kit ....................................... 04368

24. O-Ring, .864" ID x 1.004" OD .................. 21561

(21)

(24)

(2)

(1)

(16)

(23)

(18)

(17)

(20)

(10)

(11) (12) (14)(13)

(15)

(22)

(19)

(8)

(9)

(3, 4, 5)

(6)

(7)

Figure 6.

Loading...

Loading...