Page 1

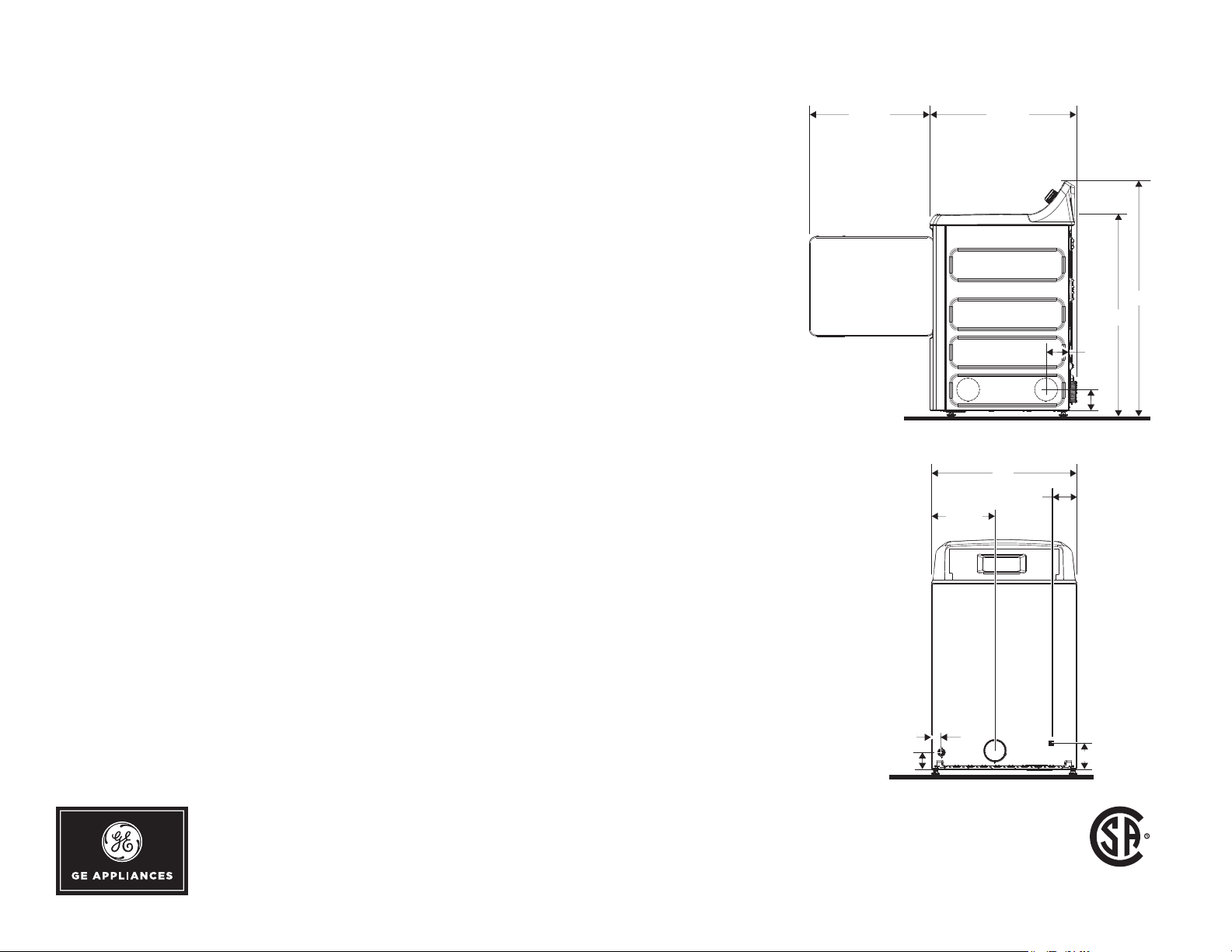

HTX21GASKWW

22 1/2"

26 3/4"

4"

1 3/4"

3 1/4"

4 1/4"

37 1/2"

44"

27"

5"

POWER CORD 4 1/2"

11 3/4"

SIDE VIEW

REAR VIEW

27"

5"

POWER CORD 4 1/2"

11 3/4"

REAR VIEW

Hotpoint

DRYER DIMENSIONS (IN INCHES)

EXHAUST OPTIONS: 3-way via rear, left and bottom. Dryer is shipped exhausted to the

rear. Alternate exhausting knockouts are supplied.

CIRCUIT REQUIREMENTS: An individual properly-grounded branch circuit, with a

three-prong grounding-type receptacle, protected by a 15- or 20-amp circuit breaker or a

time-delay fuse is required.

GAS DRYER ELECTRIC RATING: 120V, 60Hz, 6 Amp

GAS (BTU/HR): 22,000. Factory-equipped for natural gas. Tested for LP gas. LP gas

supply requires an optional conversion kit. Check installation instructions for correct kit

and have a qualified gas technician install a conversion kit. See dryer ducting information

for proper installation.

INSTALLAT ION INFO RMATION: For complete information, see installation instructions

packed with product for current dimensional data.

SPECIAL INSTALLATION REQUIREMENTS ALCOVE OR CLOSET INSTALLATION:

- If your dryer is approved for installation in an alcove or closet, it will be stated on a label

on the dryer back.

- The dryer MUST be exhausted to the outside.

- Minimum clearances between dryer cabinet and adjacent walls or other surfaces are:

0" either side, 1" front, top and rear

- Closet doors must be louvered or otherwise ventilated and must contain a minimum of 60

sq. in. of open area equally distributed. If this closet contains both a washer and a dryer,

doors must contain a minimum of 120 sq. in. of open area equally distributed.

- No other fuel-burning appliance shall be installed in the same closet with a gas dryer.

BATHROOM OR BEDROOM INSTALLATION:

- The dryer MUST be exhausted to the outdoors.

- The installation must conform with the local codes, or in the absence of local codes, with

the National Electric Code and National Fuel Gas Code, ANSI Z223 for gas dryers.

MINIMUM CLEARANCES OTHER THAN ALCOVE OR CLOSET INSTALLATION:

Minimum clearances to combustible surfaces 0" both sides, 1" rear

®

6.2 cu. ft. capacity aluminized alloy gas dryer

For answers to your Monogram, GE Café™ Series, GE Profile™ Series or

GE Appliances product questions, visit our website at geappliances.com

or call GE Answer Center® Service, 800.626.2000.

Speci fication Revised 5/16

Page 2

HTX21GASKWW

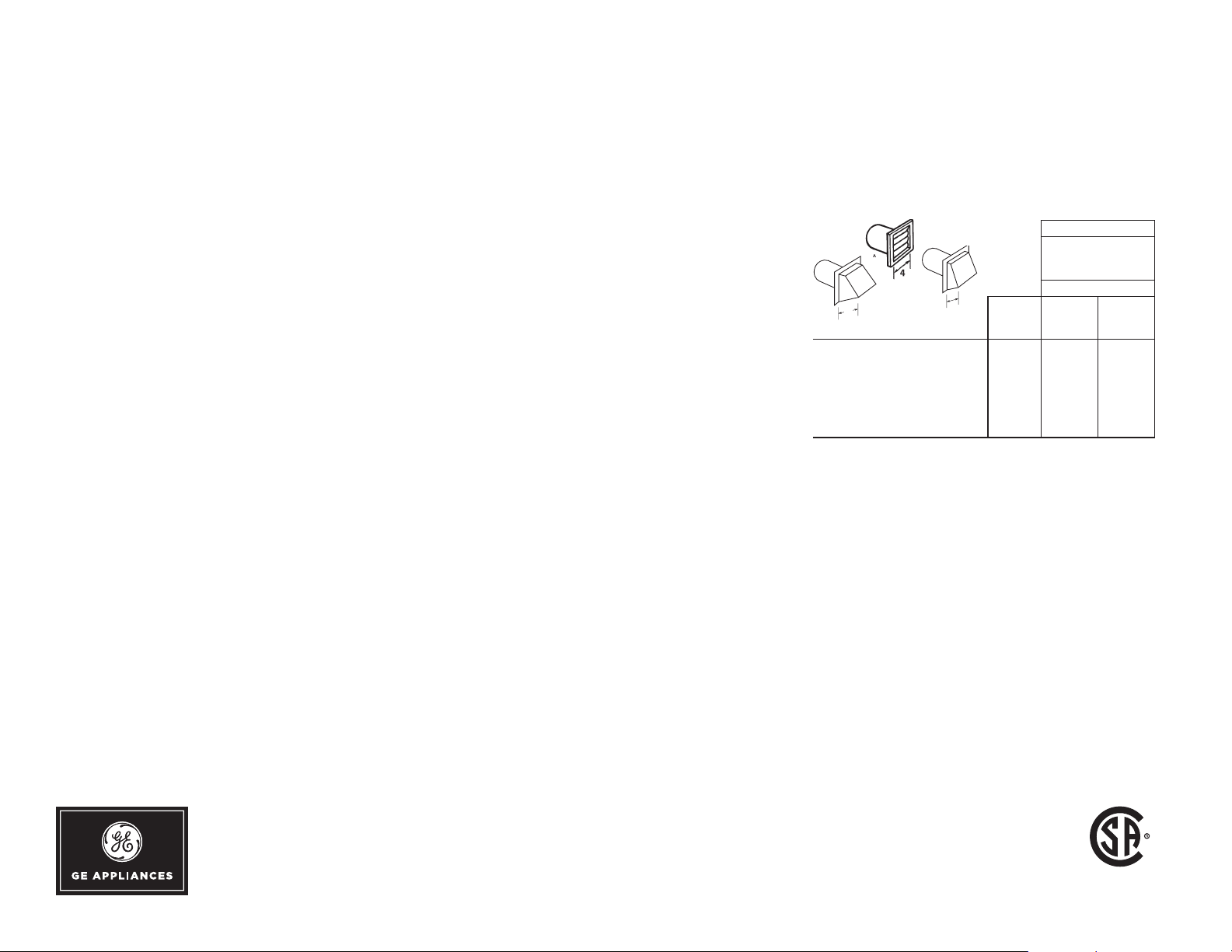

A

B

4

GE Dryer Vent

B

2-1/2

Hotpoint

®

6.2 cu. ft. capacity aluminized alloy gas dryer

For complete information, see installation instructions packed with your

dryer.

DUCTING MATERIALS:

For best performance, this dryer should be vented with 4" diameter all

rigid metal exhaust duct. If rigid metal duct cannot be used, then UL-listed

flexible metal (semi-rigid) ducting can be used (Kit WX08X10077). In

special installations, it may be necessary to connect the dryer to the house

vent using a flexible metal (foil-type) duct. A UL-listed flexible metal (foiltype) duct may be used ONLY in installations where rigid metal or flexible

metal (semi-rigid) ducting cannot be used AND where a 4” diameter can be

maintained throughout the entire length of the transition duct. Please see

installation instruction packed with your dryer for complete instructions

when using f lexible metal (foil type) ducting.

EXHAUST LENGTH CALCULATION:

1. Determine the number of 90° turns needed for your installation. If you

exhaust to the side or bottom of dryer, add one turn.

2. The maximum length of 4' rigid (aluminum or galvanized) duct which

can be tolerated is shown in the table.

A turn of 45° or less may be ignored. Two 45° turns within the duct

length should be treated as a 90° elbow. A turn over 45° should be

treated as a 90° elbow.

Dryers must be exhausted to the outside.

CAUTION: For personal safety do not terminate exhaust into a chimney,

under any enclosed house floor (crawl space), or into an attic, since the

accumulated lint could create a fire hazard or moisture could cause

damage. Never terminate the exhaust into a common duct or plenum with

a kitchen exhaust, since the combination of lint and grease could create a

fire hazard. Exhaust ducts should be terminated in a dampered wall cap

to prevent back drafts, bird nesting, etc. The wall cap must also be located

at least 12" above the ground or any other obstruction with the opening

pointed down.

Dryer exhausting information—use metal

duct only vertical and horizontal ducting

Best performance

Maximum length

A

Number

of 90°

Domestic dryer models

Long Vent 6.0 - 8.0 cu. ft.

capacity electric & gas dryers

(HTX21 and HTX24)

For every extra 90° elbow, reduce the allowable vent system length by 10 ft.

Two 45° elbows will be treated like one 90° elbow.

For the side exhaust installations, add one 90° elbow to the chart.

When calculating the total vent system length, you must add all the straight

portions and elbows of the system (including the transition duct).

Laundry Center length includes factory-installed elbow that does not impact

vent length.

of 4" dia rigid

metal duct

Exhaust hood type

A

turns

0 120 f t. 90 ft.

1 100 ft. 75 ft.

2 85 ft. 65 ft.

3 70 ft. 55 ft.

4 60 ft. 45 ft.

5 55 ft. 35 ft.

4"

opening

opening

B

2-1/2"

Speci fication Revised 5/16

Page 3

HTX21GASKWW

Hotpoint

FEATURES AND BENEFITS

Auto Dry - For clothes that come out feeling and looking

great, this setting monitors air temperature to set the

optimal drying time

Up to 120 ft. venting capability - Provides f lexible

installation

Aluminized alloy drum - Improves energy efficiency and

resists corrosion

3 heat selections - Offer a choice of drying temperatures for

personalized fabric care

Rotary electromechanical controls - Make it simple to set

cycles

Upfront lint filter - Makes cleaning out lint easy

Reverse-a-door - Door opening can be reversed to meet

laundry room needs

Model HTX21GASKWW – White on white

®

6.2 cu. ft. capacity aluminized alloy gas dryer

Speci fication Revised 5/16

Loading...

Loading...