Page 1

Construction

The reverse rinsing actuator comprises:

•Housing

•Ball valve

• Mains cable

Materials

• High quality synthetic material housing

• Nickel-plated brass ball valve

Reverse Rinsing

Reverse rinsing duration when mains electrical operation approximately 25 sec.

Reverse rinsing quantity at 4.0 bar operating pressure:

Filter size Drain connection Reverse rinsing

quantity (litres)

1

/2" + 3/4" DN 50 12

1

/4" DN 70 15

1" + 1

1

/2"+2" DN 70 18

1

DN 65 - 100 DN 100 150

EN0H-1120GE23 R1009 • Subject to change without notice

Z11AS

Reverse rinsing actuator

for fully automatic filter cleaning

Product specification sheet

Application

The Z11AS automatic reverse rinsing actuator provides fully automatic cleaning for all Honeywell reverse rinsing filters, filter combinations, water supply units and water distributor units. The

reverse rinsing intervals are adjustable in sixteen steps between

four minutes and three months. The Z11AS has an emergency

running function in the event of power failure (only when batteries

are fitted) and offers the possibility of manual operation of the

reverse rinsing function. Connection options are available for

differential pressure switching, remote control and remote monitoring.

Special Features

• Pushbuttons give easy setting of intervals

• Pushbutton for manual operation of reverse rinsing

• Digital indicator of time interval set

• Digital indicator of number of reverse rinsing cycles carried

out

• Facility to indicate time remaining before next programmed

reverse rinsing cycle

• Reset button enables resetting of counter

• Settings are maintained even when electrical power fails

• Set during manufacture to 45 day interval

• Can be set to 16 different reverse rinsing intervals

• Automatic battery

• Manufactured with integral electrical suppression

• Additional PG 9 cable entry for connection of remote operation, remote monitoring or differential pressure control

• Can be connected for differential pressure switch, remote

operation or remote monitoring

Range of Application

For fully automatic reverse rinsing of Honeywell filters, filter

combinations and water supply unit.

Technical Data

Mains cable 1.5 metres

Batteries Four LR6-1.5 V-Mignon/AA size

Battery life Approximately 3 years

Water temperature Maximum 70 °C

Time intervals 4 minutes to 3 months

Ambient conditions 5...90 % relative humidity

Protection type IP 55 sprayed water

Protection class 1 DIN VDE 0700 -T1/EN 60335 -1

1)

Batteries are not supplied with the appliance. Batteries are not necessary if automatic run-on in the event of power failure is not required. When batteries are fitted,

the appliance should not be left unplugged for long periods.

1)

run-on if mains supply fails

alkali-manganese batteries

0...60 °C

1)

www.honeywell.com 75

Page 2

Z11AS Reverse rinsing actuator

Method of Operation

The Z11AS opens or closes the ball valve according to the set

time interval. The opening of the ball valve causes a differential

pressure within the filter which activates the reverse rinsing

function. The ball valve closes again at the end of the reverse

rinsing period. Four batteries (not supplied) provide back-up

protection. The batteries close the ball valve if power fails during

reverse rinsing function, thus preventing unwanted water loss.

Options

For filters and filter combinations HS10, F76, F76C, FK76C,

FKN76C, FN76C and FN09 (up to 1996).

Z11AS-1/2A = 230 V, 50/60 Hz, 10 W

Z11AS-1/2B = 24 V, 50/60 Hz, 10 W

Z11AS-1/2Z = 230 V, 50/60 Hz, 10 W with moulded Type 12

From 1997 onwards: Use reverse rinsing actuator Z11AS for

filters and filter combinations HS10S, F76S, F76CS, FK76CS,

FKN76CS, FN76CS and FN09S.

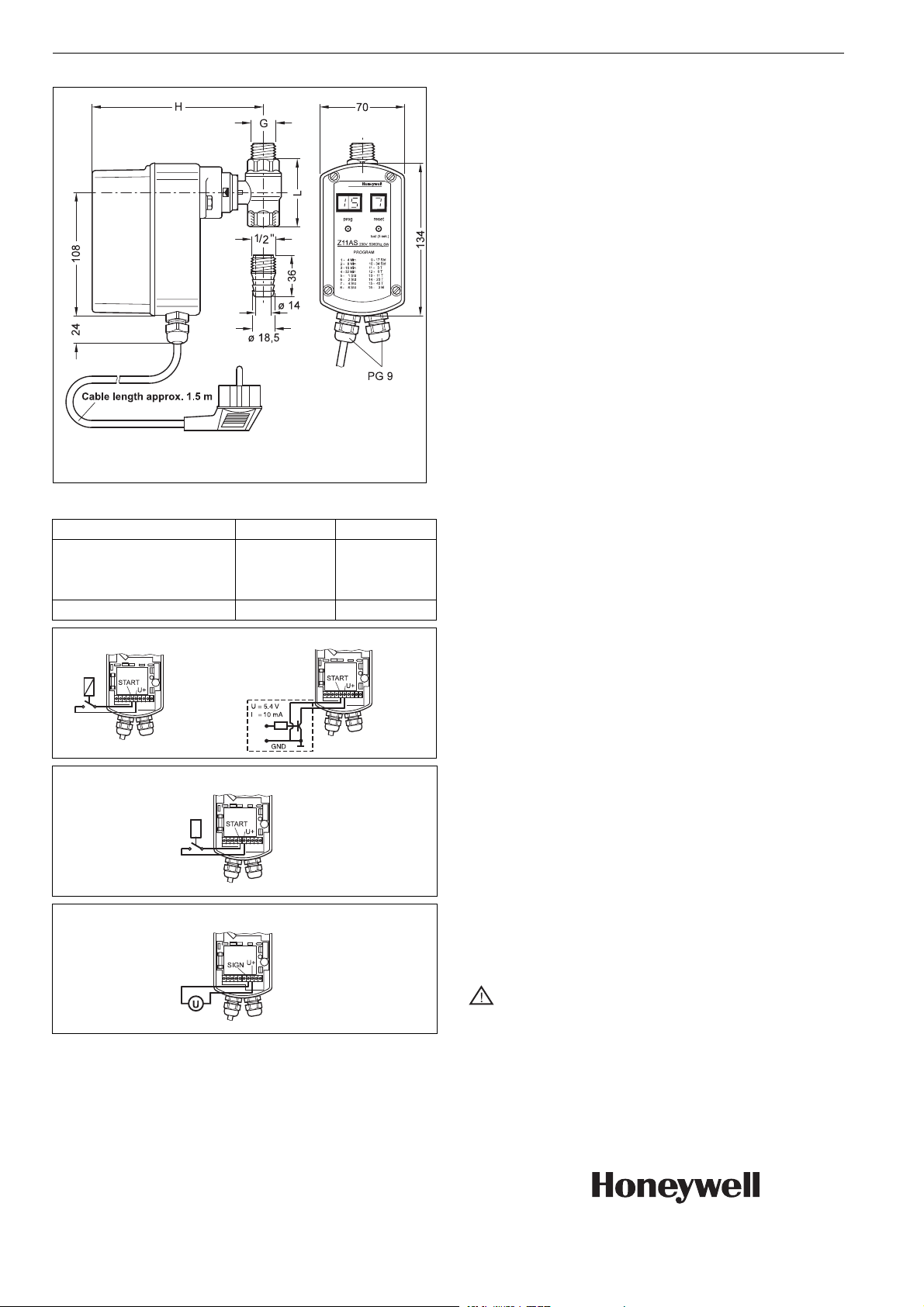

For filters with flanges F76-F and F76S-F

Filter size R R 1/2" - R 2" DN 65 - 100

G

1

/2"1"

H mm 150 160

Lmm5981

Weight approx. kg 1,2 1,7

Remote control (analogous) (digital)

Differential pressure switch

Remote monitoring

Z11AS-1A = 230 V, 50/60 Hz, 10 W

Z11AS-1B = 24 V, 50/60 Hz, 10 W

Z11AS-1Z = 230 V, 50/60 Hz, 10 W with moulded Type 12

Additional connection options

The Z11AS can be remotely actuated by:

a) A volt-free switching circuit

b) Via an open-collector output.

In both cases the minimium holding period is one second.

Reverse rinsing occurs when the inputs “Start” and “U+” have

been separated.

The reverse rinsing function can be actuated according to

demand using the DDS76 differential pressure switch with

voltage free switching. It is recommended that the differential

pressure be set to 1.0 bar. Operation occurs when the inputs

“Start” and “U+” have been separated, that is, after the differential pressure has fallen below the set value. Through this it is

guaranteed that a maximum quantity of water is available for

reverse rinsing. If reverse rinsing starts immediately irrespective

of the duration of the differential pressure signal, then the inputs

should be connected instead to “U+” and “SIGN”.

The DDS76 differential pressure switch can only be used

where F76 / F76S / F76S-F fine filters are also installed.

For remote monitoring of the open/closed position of the ball

valve the installation of a building management system with 0 to

10 V input is recommended. The maximum current is 10 mA.

With a current of 0.5 V the ball valve is open and with a value

between 5 V and 6 V the ball valve is closed.

with moulded Schuko electrical plug

without electrical plug

electrical plug for Switzerland

with moulded Schuko electrical plug

without electrical plug

electrical plug for Switzerland

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Rolle, Z.A. La

Pièce 16, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1120GE23 R1009

Subject to change without notice

© 2009 Honeywell GmbH

Loading...

Loading...