Page 1

YP7999A1000 ControLinks™ Fuel

Air Ratio Control Panel

INSTALLATION INSTRUCTIONS

FEATURES

• Pre-wired and ready to install

• Includes the R7999A control, wiring subbase and

S7999D1048 touchscreen display

• Commission, monitor and control ControLinks through

the touchscreen interface

• Fuel selector switch

• Alarm light

• Reset button

• Unit shutdown / Emergency stop button

•Auto/manual switch

• Manual operation potentiometer

• S7999D touchscreen display is Modbus ready

APPLICATION

The Honeywell YP7999A1000 ControLinks Fuel Air Ratio

Control Panel is a packaged, pre-wired panel that includes the

R7999A ControLinks controller for linkageless fuel/air ratio

control. The included S7999D color touchscreen interface

allows commissioning of the ControLinks system as well as

monitoring and control, all with user-friendly menus. On board

selector switches, buttons and alarm lights are included for

customer convenience. The ML7999A2001 universal direct

coupled actuators are purchased separately.

This document provides installation instructions and operation

information. Other applicable publications are:

— 65-0238, R7999 ControLinks Controller

— 65-0240, Q7999A ControLinks Universal Wiring Sub-

base

— 65-0239, ML7999A Universal Parallel-Positioning

Actuator

— 65-0321, S7999D1048 System Display

SPECIFICATIONS

Electrical Ratings

100 – 120 Vac, 50/60 Hz, 3 Amps

For individual ratings, see component literature for details.

Environmental Ratings

Enclosure: NEMA 12.

For individual ratings, see component literature for details.

Humidity

Install the panel where the relative humidity never reaches the

saturation point. The relay module inside the panel is

designed to operate in a maximum 85 percent relative

humidity continuous, non-condensing, moisture environment.

Vibration

Do not install the panel where it could be subjected to vibra-

tion in excess of 0.5G continuous maximum vibration.

General

Overall panel size: 24 in. high x 24 in. wide x 8 in. deep

(excluding door and door mounted components)

Panel weight: approx. 64 pounds

Mounting holes are 0.44 in. typical diameter, 18 in. on center.

66-2060-01

Page 2

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

WARNING

WARNING

CAUTION

WARNING

Approvals

Components are individually approved by the nationally rec-

ognized agencies. Please see component literature for

details. The panel has UL 508A flame control panel

approval. Panel is assembled and wired to the UL Standards.

INSTALLATION

When Installing This Product…

1. Read these instructions and the appropriate product lit-

erature carefully. Failure to follow them could damage

the product or cause a hazardous condition.

2. Refer to the installation manuals and wiring diagrams

provided with this panel for the embedded products.

3. Check the ratings given in the instructions and on the

product to make sure that the product is suitable for your

application.

4. Installer must be a trained, experienced combustion service technician.

5. Disconnect the power supply before beginning installation to prevent electrical shock and equipment damage.

More than one disconnect may be involved.

6. All wiring must comply with the National Electric Code

(NEC) and any applicable local electrical codes, ordinances and regulations.

7. After installation is complete, check out product operation as provided in the appropriate product installation

instructions.

Fire or Explosion Hazard. Can cause severe injury,

death or property damage.

To prevent possible hazardous burner operation, verify

safety requirements each time a controller is installed

on a burner.

WIRING

Electrical Connections

1. Refer to the appropriate product data sheet for details.

2. Wire size and length will vary, depending on the compo-

nent. Refer to the component literature for specific wire

lengths, sizes and type recommendations.

3. Wire according to specifications, following all local ordinances and requirements.

4. Field knockouts are required for the wiring. When drilling holes, take care to protect the electronics from metal

pieces and debris.

IMPORTANT

Run line voltage and low voltage wiring in separate

conduit to avoid signal interference.

Carefully check field wiring and terminal designations in this document and the associated wiring diagram. They are different from those of the individual

components.

Panel Inspection

After mounting and wiring, but before powering the panel,

inspect all internal panel wire connections. Each panel is fully

tested at the factory; however, wires may loosen during transit.

Verify that all internal wire connections are secure from the

Q7999 subbase to the components mounted on the door and

the S7999D touchscreen interface.

Final Wiring Check and Static Checkout

All wiring shall be in accordance with the National Electric

Codes (NEC) and local electrical codes.

1. Check the power supply circuit. The voltage and frequency must match the specification listed.

2. Check wiring terminations and routing to ensure proper

connections.

3. Follow any system checkout recommendations for individual components as found in the component literature.

4. Restore power to the panel.

Electrical Shock Hazard. Can cause serious injury,

death or equipment damage.

Disconnect the power supply before beginning wiring

to prevent electrical shock, equipment and control

damage. More than one disconnect may be involved.

Ground Connection

Earth ground is required for proper operation of the

ControLinks system. The earth ground must be capable of

conducting enough current to blow the fuse or breaker in the

event of an internal short. Ensure the panel is bonded to a

substantial earth ground. Make sure that mechanically

tightened joints along the ground path are free of

nonconductive coatings and protected against corrosion on

mating surfaces.

66-2060—01 2

Test each limit and interlock to ensure system

operates correctly as defined in the 7800 Series

“Checkout and Test” document (Form #65-0229).

Explosion and Electrical Shock Hazard.

Can cause serious injury, death or equipment

damage.

1. Close all manual fuel shutoff valves before starting

these tests.

2. Use extreme care while testing the system. Line voltage

is present on most terminal connections when power is

on.

3. Replace all limits and interlocks that are not operating

properly. Do not bypass limit and interlocks.

Page 3

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

TROUBLESHOOTING

System Diagnostics

The S7999D touchscreen interface indicates the current fault and keeps a fault history log. The R7999 ControLinks control and

the ML7999A Universal Parallel-Positioning Actuator also have LED fault blink codes. Refer to the appropriate product instruction

sheet for further troubleshooting information and diagnostic codes.

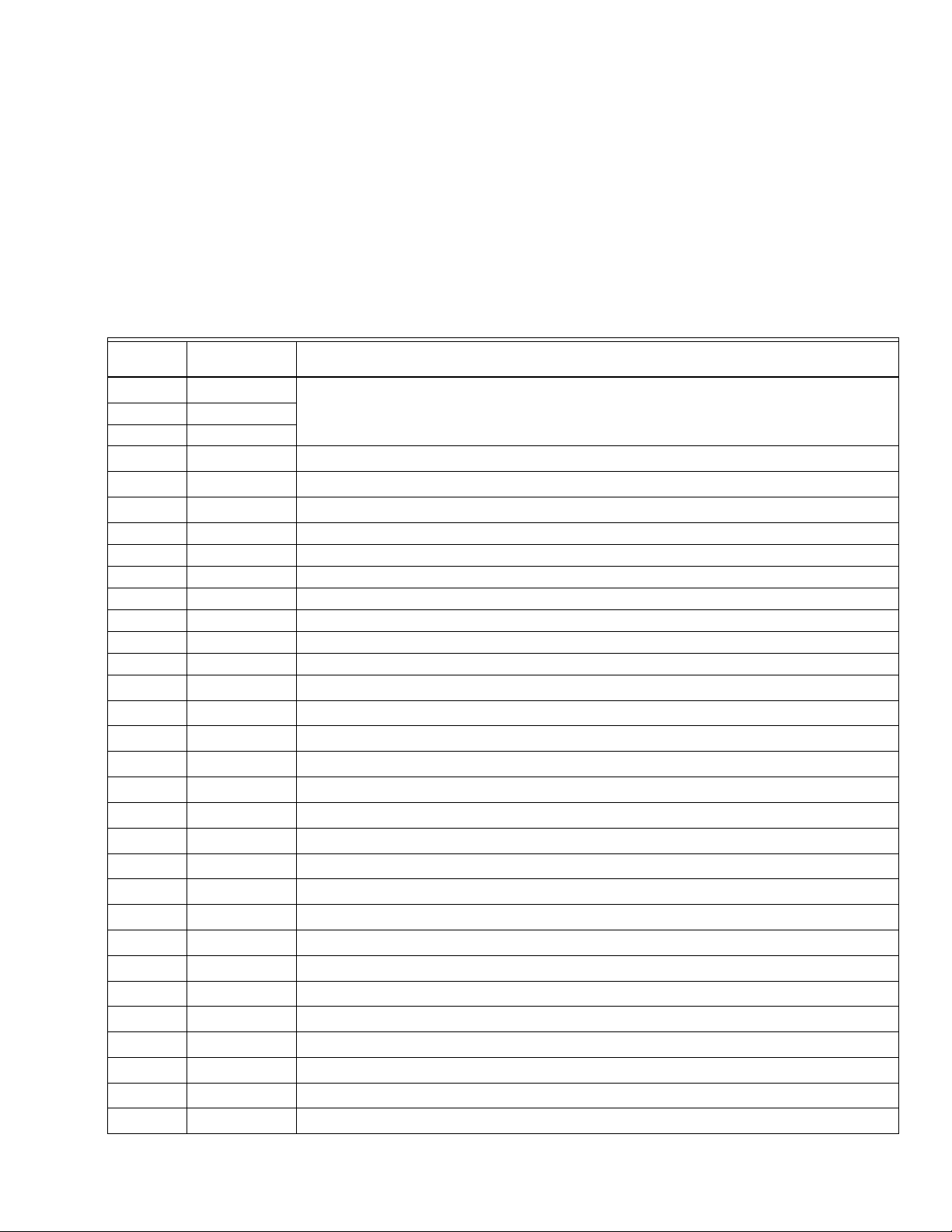

FIELD WIRING

Table 1. Field Wiring and Terminal Designation1.

To Connecting

Terminal #

2

1

2 L2 Panel neutral

GND Panel ground

3

4

3

2

3

GND

9 HFP High Fire Proven output from ControLinks controller to burner control

10 LFP Low Fire Proven output from ControLinks controller to burner control

11 HF High Fire drive command input from burner controller

12 MV Main Valve command input from burner controller

13 LF Low Fire drive command input from burner controller

14 LCI Limit Control Input from burner limit string, including on/off control, LWCO, high-limit, etc…

15 LCO Limit Control Output from ControLinks controller to burner control demand/interlock inputs

3,4

200

3,4

201

3,4

202

3,4

203

3,4

204

3,4

GND

3,4

205

3,4

206

3,4

207

3,4

208

3,4

209

3,4

GND

3,4

210

3,4

211

3,4

212

3,4

213

3,4

214

3,4

GND

Device Description

L1 Panel power 120Vac Power Supply, 3A Max.

L1 power to circuit breaker.

Provide disconnect means and overload protection as required.

L1 L1 customer convenience wire point – provided for 4 actuators – 120Vac, 50/60Hz

L2 L2 customer convenience wire point – provided for 4 actuators

Panel ground GND customer convenience wire point – provided for 4 actuators

DR1 Air Actuator DR1 command input

DR2 Air Actuator DR2 command input

CW Air Actuator potentiometer CW output

S Air Actuator potentiometer S output

CCW Air Actuator potentiometer CCW output

Ground Air Actuator ground

DR1 Fuel 1 Actuator DR1 command input

DR2 Fuel 1 Actuator DR2 command input

CW Fuel 1 Actuator potentiometer CW output

S Fuel 1 Actuator potentiometer S output

CCW Fuel 1 Actuator potentiometer CCW output

Ground Fuel 1 Actuator ground

DR1 Fuel 2 Actuator DR1 command input

DR2 Fuel 2 Actuator DR2 command input

CW Fuel 2 Actuator potentiometer CW output

S Fuel 2 Actuator potentiometer S output

CCW Fuel 2 Actuator potentiometer CCW output

Ground Fuel 2 Actuator ground

3 66-2060—01

Page 4

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

Table 1. Field Wiring and Terminal Designation

1

. (Continued)

To Connecting

Terminal #

3,4

215

3,4

216

3,4

217

3,4

218

3,4

219

3,4

GND

Device Description

DR1 FGR/4th Channel Actuator DR1 command input

DR2 FGR/4th Channel Actuator DR2 command input

CW FGR/4th Channel Actuator potentiometer CW output

S FGR/4th Channel Actuator potentiometer S output

CCW FGR/4th Channel Actuator potentiometer CCW output

Ground FGR/4th Channel Actuator ground

223 XmA+ Auxiliary 4-20mA+ input from Stack/Water temperature sensor (used for low fire hold)

220 XmA- Auxiliary 4-20mA- input from Stack/Water temperature sensor (used for low fire hold)

224 CmA+ 4-20mA+ input from Firing Rate control

225 CmA- 4-20mA- input from Firing Rate control

5

231

5

232

5

228

1

Carefully check field wiring and terminal designations in this document and the associated wiring diagram. They are different

COM 2 A S7999D COM 2 Modbus A / Data + terminal

COM 2 B S7999D COM 2 Modbus B / Data - terminal

COM 2 GND S7999D COM 2 Modbus C / Ground terminal

from those of the individual components.

2

The circuit protection incorporated into this control panel is designed to serve as supplemental protection only. It is the responsibility of the end user to provide appropriate protection on the service to this control panel. Refer to the National Electric Code

and UL standard 1077 for more information on this subject. Use 16 AWG MTW wire.

3

Low voltage wire to the firing rate actuators must be run in separate conduit. Line voltage wiring to actuators may be obtained

from terminals 4, 2 and GND or provided by customer. Run line voltage wires in separate conduit. Refer to the ML7999A product sheet for details.

4

Connect the shield ground of the ML7999A actuator(s) to the earth ground strip provided in the Q7999 universal subbase, on

the low voltage side. Connect the shield at the controller end only. Refer to the ML7999A product sheet for details.

5

COM 2 on the S7999D is wired to field terminals for customer use. Customer may wire an existing Modbus-capable RM78xxL

burner control and/or Modbus-enabled UDC2500/3200/3500 controls in a daisy-chain fashion to the customer terminals for display on the S7999D. Refer to the S7999D, S7800A or S7810M and UDC control product manuals for further information on wiring and S7999D display set-up.

6

Installation, operation and maintenance shall conform with National Fire Protection Association standards, national and local

codes and authorities having jurisdiction.

7

For detailed device wiring information, refer to the R7999, Q7999A, ML7999A and S7999D1048 product sheets.

66-2060—01 4

Page 5

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

TWIST TO START

PUSH TO STOP

M34890

24 (610)

24

(610)

MANUAL

OPERATOR

5K OHMS

MANUAL

AUTO

SS103

CONTROL

CONTROLINKS

RESET

CONTROLINKS

ALARM

LT104 PB114

FUEL

SS104

WARNING

ADVERTISEMENT

P9100

Fig. 1. Panel front dimensions in in. (mm).

Table 2. Wire Code.

Function Color AWG

120 VAC (HOT) RED 16 (MTW)

120 VAC (NEUTRAL) WHITE 16 (MTW)

GROUND GREEN 16 (MTW)

DRY CONTACTS YELLOW 16 (MTW)

VDC BLUE 16 (MTW)

24 VAC BROWN 16 (MTW)

TYPE K THERMOCOUPLE YELLOW/RED 20 (POLYVINYL)

FSG RESET/CONTROLINKS RESET/POTENTIOMETER BELDEN 8760 18 AWG TWISTED PAIR

ACTUATOR INTERFACE BELDEN 9535 24 AWG, 5 CONDUCTOR

DISPLAY TO TERMINAL STRIP BELDEN 9535 24 AWG, 5 CONDUCTOR

DISPLAY COM1 & COM2 (FROM TERM STRIP TO DEVICES) BELDEN 8770 18 AWG, 3 CONDUCTOR

TEMP CTRL MODBUS BELDEN 8770 18 AWG, 3 CONDUCTOR

5 66-2060—01

Page 6

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

M34891

Fig. 2. Wiring diagram (part 1).

66-2060—01 6

Page 7

(L) (N)

M34892

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

Fig. 3. Wiring diagram (part 2).

Wiring Diagram Key Wiring Notes

Indicates terminals and wiring in control panel

(main terminal block).

Indicates external wiring.

Indicates terminals in valves.

Indicates component terminals.

1. The circuit protection incorporated into this control

panel is designed to serve as supplemental protection

only. It is the responsibility of the end user to provide

appropriate protection on the service to this control

panel. Refer to the National Electric Code and UL Standard 1077 for more information.

2. Wire to the firing rate actuator must be run in separate

conduit.

7 66-2060—01

Page 8

YP7999A1000 CONTROLINKS™ FUEL AIR RATIO CONTROL PANEL

21 (533)

21

(533)

3A

FU100

FU121

.5A

1

FUEL/AIR

CONTROL

SPARE

SPARE

SPARE

SPARE

SPARE

SPARE

M34893

SPARE

3. Ground shield to subbase earth ground screw on low

voltage side of subbase.

4. Installation, operation, and maintenance shall conform

with National Fire Protection Association standards,

national and local codes, and authorities having jurisdiction.

Fig. 4. Equipment mounting panel dimensions in in. (mm).

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2013 Honeywell International Inc.

66-2060—01 M.S. 06-13

Printed in United States

Loading...

Loading...