Page 1

1

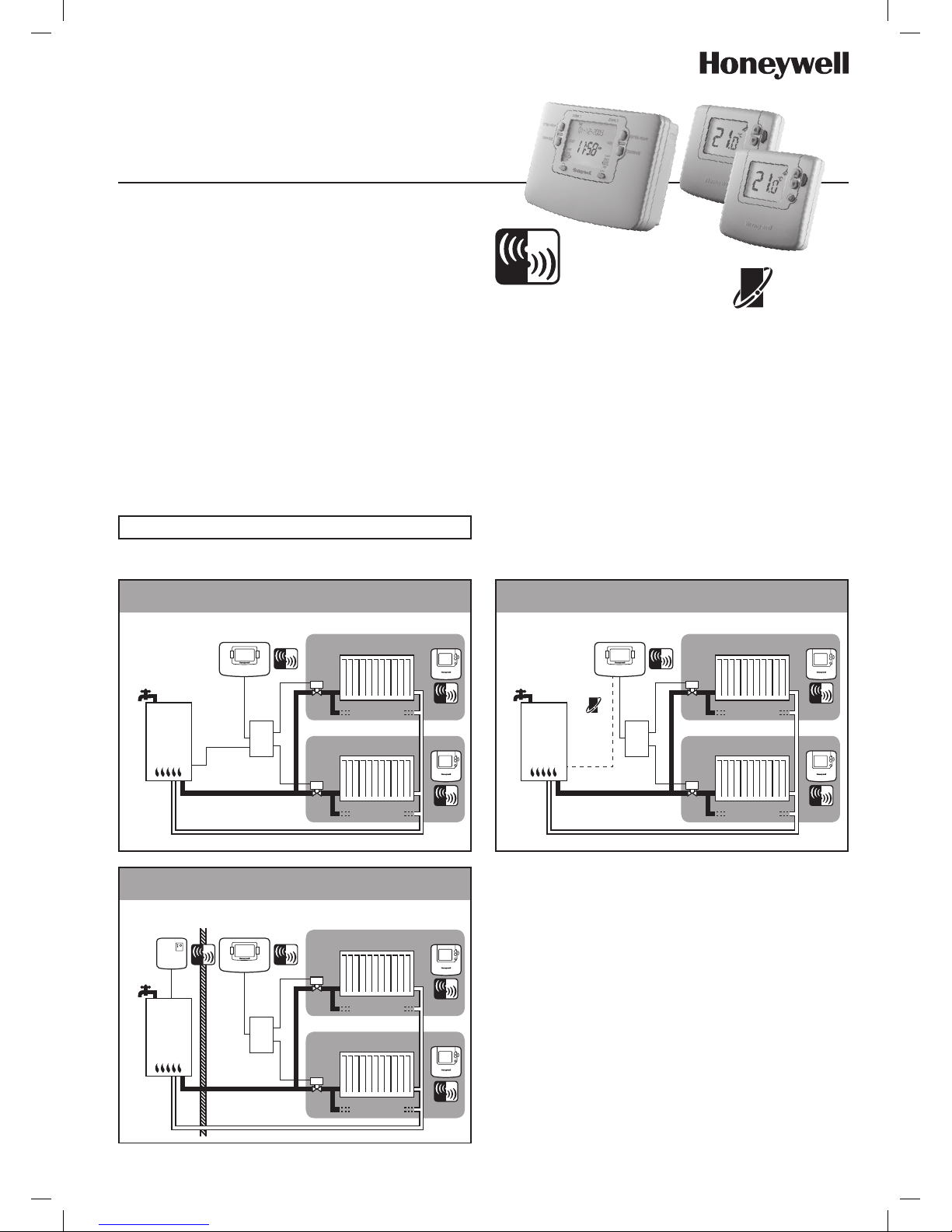

95-3 Wireless room thermostats, wired valves, wireless

TPI boiler control

95-1 Wireless room thermostats, wired valves, wired TPI

boiler control

95-2 Wireless room thermostats, wired valves, OpenTherm 2

wire boiler control

Y9520Z Sundial RF² Pack 5

INSTALLATION INSTRUCTIONS

50047644-006 A

Application

This pack provides a wireless control solution for adding 2 wireless room

thermostats to heating systems, in order to split the heating system

into 2 separate zones and ensure compliance with the latest Building

Regulations.

Pack Contents & Product Descriptions

1 x ST9520C1005 Wireless enabled 7 day programmer with 2

output control relays for switching boilers, pumps

and zone valves in heating systems. It requires

permanent mains 230Vac power.

2 x DTS92E1020 Wireless digital room thermostat with energy

saving ECO function. It operates on 2 x AA alkaline

batteries, giving a battery life of at least 2 years

under typical operating conditions.

2 x table stand for DT92E (optional)

Other Honeywell products, not supplied in this pack, may be required

for a complete installation, depending on the application. For example

BDR91T1004 relay box. See Schematic System Layouts (below) or refer

to www.honeywelluk.com for full details.

Schematic System Layouts

System Operation

DT92E and ST9520C use 2-way communication on an 868MHz radio

frequency (RF) band to control the heating system.

ST9520C operates as the control hub of the system and the DT92E

thermostats are free to be positioned in suitable locations in the 2

separate heating zones.

This functionality is ideal for upgrading existing systems without a room

thermostat to ensure compliance with Building Regulations. It is also ideal

for refurbished systems, where running mains cable from the programmer

to the thermostats and back to the boiler is difficult or impractical.

There are various options for how to connect to the boiler. The simplest

is a direct 230Vac connection. If the boiler supports OpenTherm

communications technology, it is possible to control it using a 2-wire

connection from the ST9520C OpenTherm terminals. If the boiler is

located remotely, it is possible to send the switching signal from the

ST9520C to a remote located BDR91T relay box.

2-way wireless

communication

Honeywell

Sundial RF² is a registered

trademark of Honeywell Inc.

OpenTherm®

communication

V4043H

ZONE 1

ZONE 2

V4043H

Radiator(s)

Radiator(s)

DT92E

DT92E

ST9520C

Junction

Box

Junction

Box

Junction

Box

Hot Water

V4043H

ZONE 1

ZONE 2

V4043H

Radiator(s)

Radiator(s)

DT92E

DT92E

ST9520C

Boiler

Hot Water

BDR91T

V4043H

ZONE 1

ZONE 2

V4043H

Radiator(s)

Radiator(s)

DT92E

DT92E

ST9520C

Boiler

Hot Water

OpenTherm®

2-wire connection

This document is to be left with the user

Page 2

2

The RF link between the Room Thermostats (DT92E) and the Zone

Programmer (ST9520C) in Honeywell system packs is pre-configured

at the factory and therefore all units should be installed at the same site.

• Ifproducts fromindividual systempacks areseparated, ormixed

with other pre-configured system packs during installation, or a

faulty unit is being replaced, the desired units must be specially

configured to allow them to communicate with each other. This

process is called Binding. Please refer to section 6 Binding / Re-

binding Procedure.

• DT92E or ST9520Cwillnotcommunicate with other RF products

that use different frequencies or communications protocols.

• TheDT92E roomthermostatrequires nopower sourceotherthan

the batteries provided.

• The ST9520C Programmer requires a permanent 230V~ supply.

• The ST9520C Programmer should be installed and powered up

before commencing installation on the DT92E room thermostats.

• IfcontrollingtheboilerviaanOpenThermconnection,theST9520C

must be configured to provide this form of output (see Section

4 System Configuration)

• Ifthe boilerisbeingswitchedusingaremote relaybox(BDR91T)

the relay box is not supplied in this pack and will require to be bound

to ST9520C (see Section 6 Binding / Re-binding Procedure)

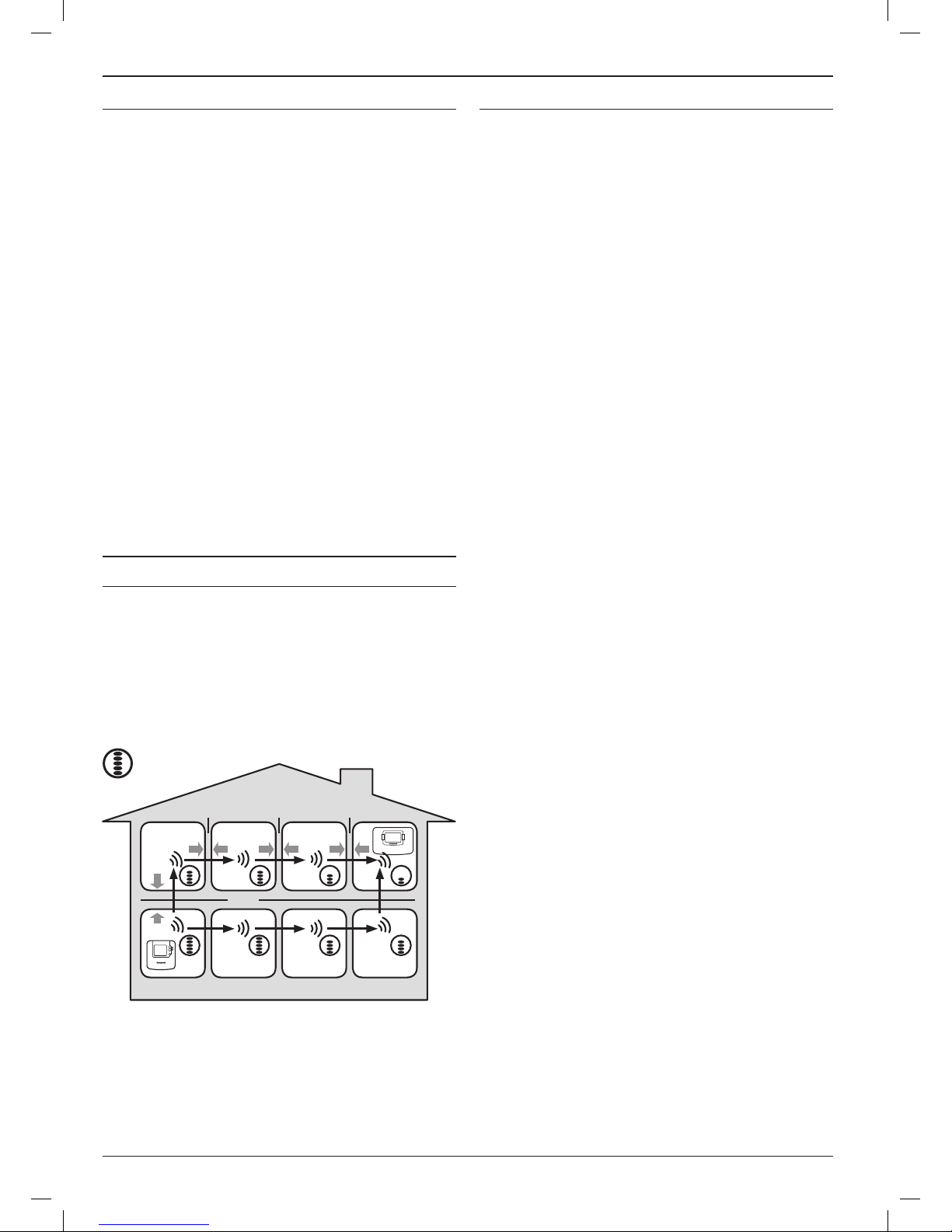

Within a typical house two RF products should communicate reliably

within a 30m range. It is important to take into consideration that walls

and ceilings will reduce the RF signal. The strength of the RF signal

reaching the Programmer depends on the number of walls and

ceilings separating it from the room thermostat, as well as the building

construction - the diagram below illustrates an example of typical

signal strength reduction. Walls and ceilings reinforced with steel or

plasterboard walls lined with metal foil reduce the RF signal significantly

more.

RF Signal Propagation

Installation Notes Installation Sequence: Step by Step

Typical example of Building Fabric Signal losses

= Signal Strength

Wall Wall Wall

Ceiling

Max. Signal Length 30 metres

Section Page

1 INSTALLING THE ST9520C PROGRAMMER

1.1 Mounting ST9520C .................................................................. 3

1.2 ST9520C Mounting options ..................................................... 3

1.3 Wiring ST9520C ....................................................................... 3

1.4 ST9520C Final Assembly ......................................................... 3

1.5 ST9520C Internal Wiring .......................................................... 4

1.6 Wiring Diagrams ...................................................................... 4

1.7 Replacing Other Time Controls ............................................... 5

1.8 Powering Up ST9520C ............................................................ 5

2 INSTALLING THE DT92E ROOM THERMOSTAT

2.1 Locating DT92E ....................................................................... 6

2.2 Powering Up DT92E ................................................................ 6

2.3 DT92E Signal Strength Test ..................................................... 6

2.4 Mounting DT92E ...................................................................... 7

2.5 Separating DT92E from its Mounting Plate .............................. 7

3 INSTALLING THE BDR91T WIRELESS RELAY BOX

3.1 Locating the BDR91T............................................................... 8

3.2 BDR91T Mounting Options ...................................................... 8

3.3 Wiring BDR91T ........................................................................ 8

3.4 BDR91T Final Assembly .......................................................... 8

4 SYSTEM CONFIGURATION: ST9520C

4.1 ST9520C Installer Modes......................................................... 9

4.2 Boiler Service Reminder / Shut-down Feature ......................... 9

4.3 Installer Setup ........................................................................ 10

4.4 Installer Setup Flowchart ....................................................... 11

4.5 OpenTherm Setup and Information Display .......................... 11

4.6 Set Service ............................................................................. 12

4.7 Change PIN ........................................................................... 14

4.8 What the User Will See When a Service is Due ..................... 14

4.9 Resetting the Service Timer Function .................................... 14

5 SYSTEM CONFIGURATION: DT92E

5.1 DT92E Installer Mode ............................................................ 15

6 BINDING / RE-BINDING PROCEDURE

6.1 Binding................................................................................... 16

6.2 ST9520C Guided Binding Menu ............................................ 16

6.3 Replacing Devices or Changing the Application .................. 16

6.4 Binding Menu Display............................................................ 17

6.5 How to Bind DT92E to ST9520C ............................................ 17

6.6 How to Bind BDR91T to ST9520C ......................................... 18

6.7 How to Test BDR91T Signal Strength .................................... 19

7 COMMISSIONING THE SYSTEM

7.1 System Test Checklist ............................................................ 20

7.1 Completion Checklist ............................................................. 20

Page 3

3

For best performance, install in an open space. Leave at least 30cm

distance from any metal objects including pipes and the boiler housing.

After locating the DT92E room thermostats, use the Signal Strength

Test shown on Page 7 to determine if there is a reception problem.

If problems persist, it is recommended that this metal wallbox is

replaced by an equivalent plastic wallbox.

The Programmer should be mounted at a level where the display can

be seen clearly, (compliance with Building Regulations part M requires

a height of 1.2m from the floor) and the ambient temperature is within

the range of 0 to 40°C. The ST9520C is for use in normal domestic

environments.

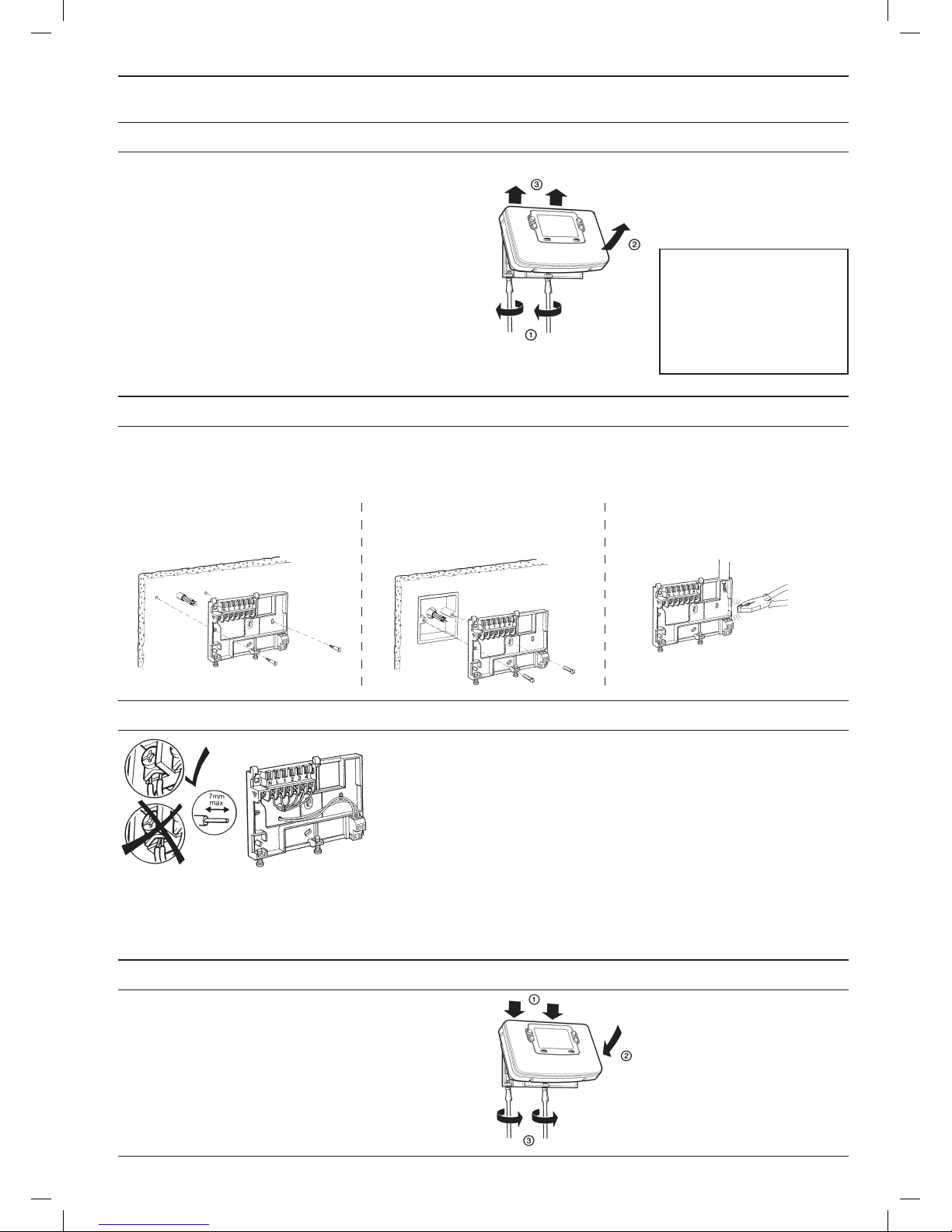

To remove the unit from the wall-plate,

slacken the two securing screws at the

bottom of ST9520C and hinge the unit

up to separate the two halves.

1

INSTALLING THE ST9520C PROGRAMMER

1.1 Mounting ST9520C

CAUTION

Isolate power supply and make

safe before wiring the unit to

prevent electric shock and

equipment damage. Installation

should be carried out by a qualified

electrician or competent heating

engineer.

Recommended clearance distances:

Above wallplate: 110mm

Below wallplate: 100mm

Left/right of wallplate: 10mm

a. Surface mounting concealed wiring b. Flush switchbox

Fixing holes are spaced to suit

BS4662 requirements

c. Surface mounting with

surface wiring in mini trunking

Clip the unit onto the hinges on the top of the wallplate and hinge down

into position. Tighten the two securing screws using a screwdriver.

Switch on the power – the unit will now be operating according to the

built-in programme.

Note: the ST9520C is supplied with a factory set clock for faster

installation.

Refer to Y9520Z User Guide for programming details.

Ensure the mounting surface is supporting and fully covers the wiring wall-plate.

ALL WIRING MUST BE IN ACCORDANCE WITH IEE REGULATIONS.

THIS UNIT IS FOR FIXED WIRING ONLY.

A switch, having contact separation of at least 3mm in all poles must be

incorporated in the fixed wiring as a means of disconnecting the supply.

The unit is a Class II (double insulated) device. A parking terminal is

provided for external earth continuity.

The system must be appropriately fused. A fuse rated at no more than 3

Amps should be installed.

The unit has 4 knockouts for surface wiring. Care must be taken to

ensure that the cable or mini-trunking completely fills the knockout hole

without leaving any gaps.

If the OpenTherm 2 wire connection is used, maintain as large a separation

as possible between these wires and any mains voltage wiring.

EMC compliance considerations

Keep AC mains supply/load cables separate from signal wiring.

Refer to Code of Practice standards EN61000-5-1 and -2 for guidance.

1.2 ST9520C Mounting Options

1.3 Wiring ST9520C

1.4 ST9520C Final Assembly

Page 4

4

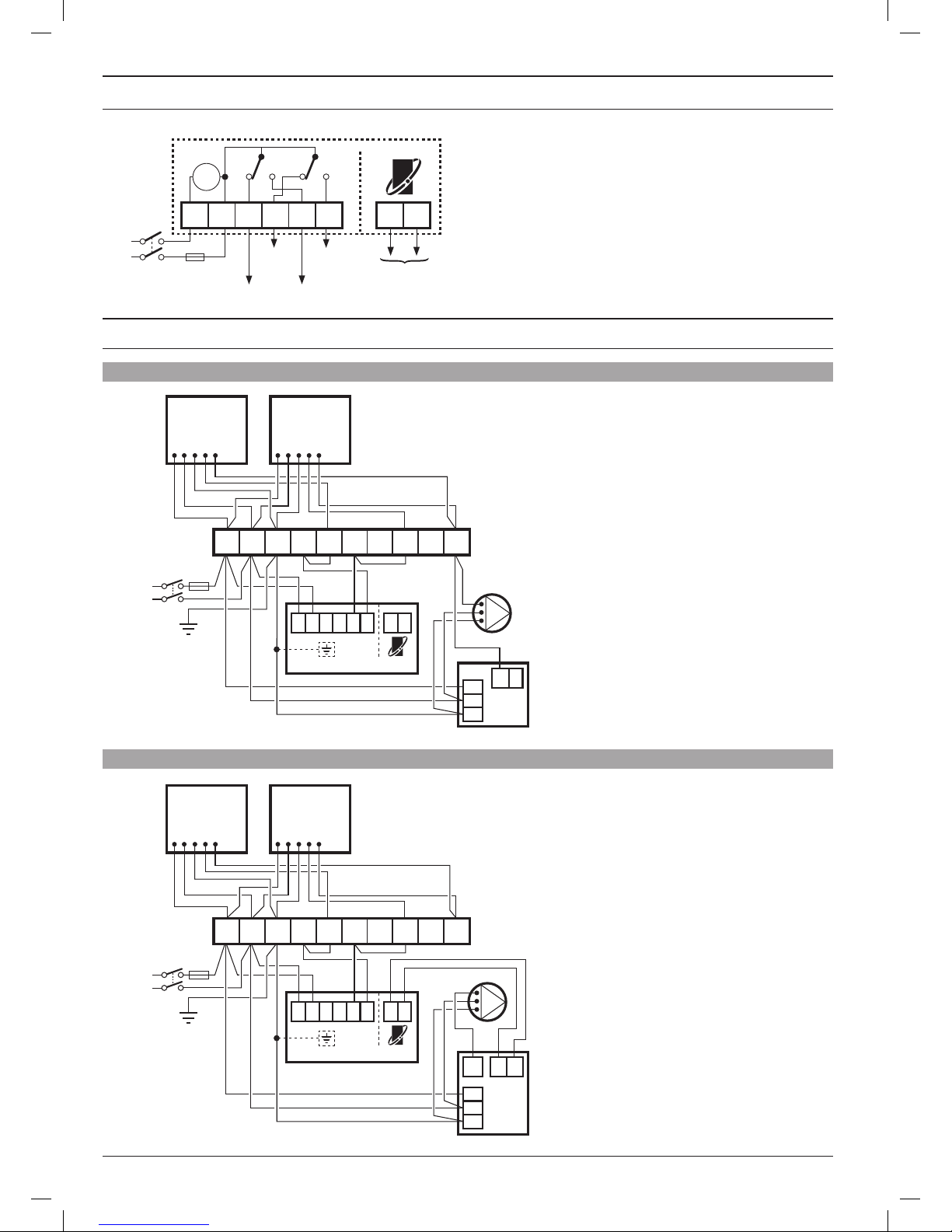

Notes

1. DT92E is completely wireless and so is not shown connected on

these wiring diagrams.

2. The ST9520C is a Class II (double insulated) device. A parking

terminal is provided for earth wiring continuity, if required.

3. The OpenTherm boiler connection (diagram 95-2) is a low voltage

polarity-free connection and is not for 230V~ mains voltages.

4. The BDR91T Relay Box (diagrams 95-3) requires a permanent

230V~ supply.

1.6 Wiring Diagrams

1.5 ST9520C Internal Wiring

Clock

N L 1 2 3 4

3 AMPS MAX

Zone1

OFF

Zone2

OFF

Zone1

ON

Zone2

ON

N

L

OFF ON OFF ON

230V~

50...60Hz

A B

OpenTherm low voltage

output to boiler.

NOT MAINS

95-1 Wireless room thermostat, wired valves, wired TPI boiler control

95-2 Wireless room thermostat, wired valves, OpenTherm 2 wire boiler control

V4043H

2 PORT ZONE VALVE

ZONE 2

BLUE

G/YELLOW

BROWN

ORANGE

GREY

V4043H

2 PORT ZONE VALVE

ZONE 1

BLUE

G/YELLOW

BROWN

ORANGE

GREY

3 AMPS

MAX

L

N

230V~

50...60Hz

BOILER

PUMP

L

N

E

ST9520C

*NOTE 2

N

L 1 2 3 4AB

T1

L

N

E

1 2 3 4 5 6 7 8 9 10

V4043H

2 PORT ZONE VALVE

ZONE 2

BLUE

G/YELLOW

BROWN

ORANGE

GREY

V4043H

2 PORT ZONE VALVE

ZONE 1

BLUE

G/YELLOW

BROWN

ORANGE

GREY

3 AMPS

MAX

L

N

230V~

50...60Hz

BOILER

PUMP

L

N

E

ST9520C

*NOTE 2

N

L 1 2 3 4AB

T1

T2

PL

L

N

E

1 2 3 4 5 6 7 8 9 10

Additional notes

a. Orange wires from zone valves are ‘parked’ for

convenience.

b. Pump live is taken from boiler. If boiler does not

provide this output, connect live input to pump from

terminal 10

Page 5

5

95-3 Wireless room thermostat, wired valves, wireless TPI boiler control

Check the unit powers up correctly and that the display does not remain blank.

ST9520C must be powered up before the DT92E thermostats are installed, so that the signal strength tests can be conducted.

The initial signal strength test will verify that both units have each others addresses in their memory, and can therefore communicate. The process of

writing respective addresses into memory is called BINDING.

ST9520C is supplied with its own wiring back-plate. As this is for new or upgraded installations it is recommended this is used, and it MUST be used

for OpenTherm applications (95-3).

ST9520C may mount on the back-plate of existing time controls, but it is likely major wiring changes will be required for compatibility with the plumbing

and controls changes. Refer to the Honeywell Technical Help Desk for advice.

1.8 Powering Up ST9520C

1.7 Replacing Other Time Controls

1.6 Wiring Diagrams (cont.)

Additional notes

a. Orange wires from zone valves are ‘parked’ for

convenience.

b. Pump live is taken from boiler. If pump is located next

to zone valves, take the pump N and E from the 10-way

junction box (terminals 2 & 3 respectively) and the pump

switched Live from terminal 10.

V4043H

2 PORT ZONE VALVE

ZONE 2

BLUE

G/YELLOW

BROWN

ORANGE

GREY

V4043H

2 PORT ZONE VALVE

ZONE 1

BLUE

G/YELLOW

BROWN

ORANGE

GREY

3 AMPS

MAX

5 AMPS

MAX

L

N

L

N

230V~

50...60Hz

230V~

50...60Hz

BOILER

PUMP

L

N

E

ST9520C

BDR91T

*NOTE 2

N

L 1 2 3 4

N

L L

A

B

T1

T2

PL

L

N

E

1 2 3 4 5 6 7 8 9 10

A-B:5(3)A

A-C:5(3)A

A

B C

Page 6

6

This pack contains 2 x DT92E room thermostats for location in each control zone. The DT92E for Zone 1 has

a zone ID label number 1 under the battery cover. The other DT92E has zone ID label 2. These thermostats

must be located in the correct zone to ensure the correct valve is operated in response to their commands.

For best performance, install each DT92E in an open space where it can sense the room temperature, and

where the signal strength is high.

The Room Thermostats can be mounted on a wall or on the optional table stand. Do not mount on metal

wall-boxes.

Leave at least 30cm distance from any metal objects and at least 1 metre from any other electrical equipment.

Select the preferred location and test the Signal Strength before installation.

2

INSTALLING THE DT92E ROOM THERMOSTATS

2.1 Locating DT92E

DT92E is supplied in the pack with the mounting plate separated from the rest of the unit for ease of installation. The next sequence of operations

should be done before mounting DT92E onto its mounting plate.

First hold DT92E between 1 and 2 meters away from ST9520C. To power it up, unclip the battery cover and then remove the paper tab that isolates

the batteries from their contacts. When the display powers up the battery cover should be clipped back on.

Immediately on power up, DT92E will try to communicate and

synchronise with ST9520C. This process may take up to 4 minutes, and

will be indicated by the word ‘Sync’ on the DT92E display.

When ‘Sync’ disappears from the display, DT92E is ready for a test of

the RF signal strength between it and the ST9520C programmer.

Now go to section 2.3 to conduct the Signal Strength Test.

2.2 Powering Up DT92E

1

2

Honeywell 2-way RF communications allows signal strength testing to

ensure DT92E can be positioned in the best possible location.

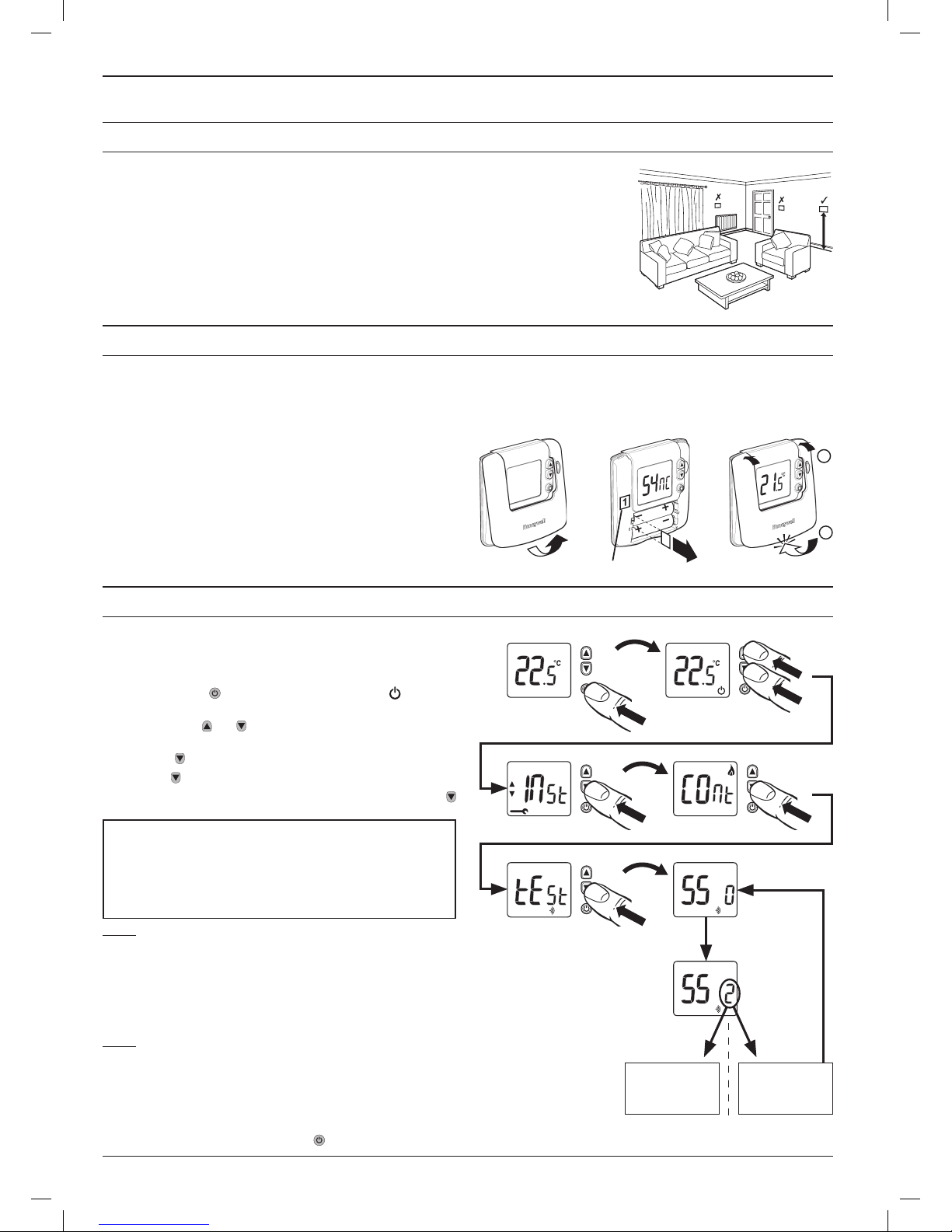

To enter Signal Strength Test:

a. Hold down the button for 2 seconds until the symbol is

displayed.

b. Hold down the

and

buttons together for 3 seconds until ‘Inst’

appears in the display.

c. Press the button (‘Cont’ is now displayed)

d. Hold the button for 3 seconds to enter Test mode.

e. Signal Strength Test is entered from Test mode by holding the

button for 3 seconds, until the display shows ‘SS’.

Step 1

Hold DT92E between 1 and 2 meters away from ST9520C and check the signal strength is high

(3 or more). This confirms the two units are in the condition they left the factory and are bound

together, and you can move to Step 2.

If the signal strength is shown as 0, the units are possibly not bound together. Go to the

section 6 Binding / Rebinding, follow the procedure there, and then repeat the complete

Signal Strength Test sequence.

Step 2

Whilst staying in Signal Strength Test mode, take the DT92E to the preferred location. Wait for

10 seconds and check the signal strength is 3 or more. If so, the DT92E is ready to mount.

If the signal strength is less than 3, re-position the room thermostat within the local area +/- 1 or

2m to see if the signal strength improves. If this fails, try to reduce the range/distance between

the room thermostat and the ST9520C.

2.3 DT92E Signal Strength Test

3 s

2 s

3 s

Poor signal,

reposition Room

Thermostat.

Strong signal,

proceed to

mount the Room

Thermostat.

10 s

= 0, 1, 2= 3, 4, 5

3 s

ST9520C measures the strength of the DT92E signal every 5-10

seconds and will communicate this to DT92E as a number between

0 and 5. The value drops to 0 briefly as each new signal strength

measurement is made.

A signal strength of 3 or more is recommended to ensure reliable

communications.

Exit Signal Strength Test by holding the button for 5 seconds. The DT92E will timeout of this mode after 10 minutes.

Zone ID Number (1 or 2)

1.2m

Page 7

7

2.5 Separating DT92E from its Mounting Plate (if required)

DT92E can be mounted (a) directly on a wall, or (b) on the optional table stand provided.

Wall mounting is recommended as it ensures a position of high signal strength can be maintained.

If the DT92E requires to be separated from its mounting plate, follow the simple steps shown below.

a. For wall mounting, install the mounting plate first, then follow

steps 1, 2 and 3 to hinge the front piece on, as shown in the

diagrams.

b. If the optional table stand is to be used, first assemble the two

pieces together as shown. Next follow steps 1, 2 and 3 to hinge

the DT92E front piece onto its mounting plate, and mount the unit

onto the table stand.

1

2

= N

o

6

3

2.4 Mounting DT92E

2

1

3

Page 8

8

If the heating boiler is located remotely it is possible to control it using a wireless relay box BDR91T1000. This is not supplied in this pack and must

be purchased separately. After installation it must be bound (paired) to the ST9520C timer and then the signal strength should be verified to ensure

the location chosen is suitable.

The BDR91T Relay Box requires a permanent 230V~ supply.

Isolate power supply and make safe before wiring the

unit to prevent electric shock and equipment damage.

Installation should be carried out by a qualified

electrician or competent heating engineer.

For wiring schematics please refer to diagram 95-3 on page 5.

EMC compliance considerations

Keep AC mains supply/load cables separate from signal wiring.

Refer to Code of Practice standards EN61000-5-1 and -2 for guidance.

1

2

< 7mm Ø

> 7mm Ø

a. Mounting on a wall box b. Surface mountingRemoving the BDR91T cover

Replacing the BDR91T coverWire preparation

= M3.5

= N

o

6

1.5-2.5mm²

6mm max.

2

1

For best performance install in an open space. Leave at least 30cm distance from any metal

objects including wall boxes and boiler housing. Do not mount on metal wall boxes.

The BDR91T needs to be positioned in a location where the RF signal strength from ST9520C is

high. The simplest way to identify such a location in advance is to use the signal strength feature

on DT92E, because DT92E can be moved around freely.

a) Remove one DT92E from its mounting plate (section 2.5)

b) Enter signal strength test (section 2.3)

c) Identify a location close to the boiler where the signal strength is 3 or more.

d) After BDR91T is mounted and wired in this location, the signal strength it is receiving can be

verified using its own signal test (section 6.7)

e) Remember to re-attach DT92E to its mounting plate.

Ensure the mounting surface is supporting and fully covers the

backplate and mount to the surface using the screw holes provided.

An alternative pair of mounting holes is also available.

Unclip the front cover and hinge it

away to reveal the wiring backplate.

Insert the hinges and close

the cover until it clips closed

at the bottom.

Ensure only the correct

gauge of wire is used and

tightened securely into the

correct terminal.

NOTE: The BDR91T contains no user serviceable parts. It should be

opened and installed by a qualified installer only.

WARNING: Electrostatic sensitive device! Do not touch the circuit board.

3

INSTALLING THE BDR91T WIRELESS RELAY BOX (IF REQUIRED)

3.2 BDR91T Mounting Options

3.1 Locating the BDR91T

3.3 Wiring BDR91T

3.4 BDR91T Final Assembly

CAUTION

Page 9

9

ST9520C has 4 Installer Modes that enable the product to be customized for the application and for the needs of the User. Each adjustable feature is

called a Parameter, and is represented by a number or letter ID and a value. The Modes are:-

• InstallerSetup

Installer Setup allows features to be adjusted to suit user lifestyles or preferences, for example; backlight operation, automatic time-change, and

selection of the default time programme. It is entered by a combination of button presses.

• OpenTherm Setup (and information display)

This mode allows OpenTherm communications to be enabled, the OpenTherm parameters to be configured, and some OpenTherm data from

the boiler to be displayed.

• SetService

This is where the ST9520C Boiler Service Reminder and Shut-down Features can be set. This mode can only be entered by using a 4 digit PIN

code. The factory supplied default PIN code is 0000

• ChangePIN

This mode allows the 4-digit PIN code to be adjusted. It is itself protected by the PIN code. When the code is changed this new code is used to

enter both SET SERVICE and CHANGE PIN modes.

To Enter & Navigate Around the Installer Modes:

a. Ensure the slider is in the RUN position, then press and hold

and buttons together for 8 seconds. Ignore the ‘NOT VALID’

that is displayed for a few seconds. The message ‘SET UP MENU’

will show briefly, to indicate you have entered the Setup menu. The

LoT™ Display will continue to show messages indicating which

Installer Mode is possible to select, for example ‘SET INSTALLER

OK ?’

b. Use the or buttons to navigate to the correct Installer Mode.

c. Use the button to confirm you wish to enter that particular mode.

To Exit Installer Modes:

You can exit the Installer Modes at any time by moving the slider to the next position and then back again to RUN. Any changes that have been

confirmed will be saved and used.

Note: The Installer Modes and the Setup Menu will exit automatically after 10 minutes if the slider is not moved and no adjustments have been made

in this time.

4

SYSTEM CONFIGURATION: ST9520C

4.1 ST9520C Installer Modes

The ST9520C Programmer has a Service feature that can assist Social Housing Landlords to comply with the requirements of Regulation 36 of the

Gas Safety (Installation & Use) Regulations 1998. It is intended as an aid to compliance but should not be used to replace the Landlord’s existing

Servicing procedures.

The ST9520C performs like a standard 2 Zone programmer. In addition it can automatically provide a Service Reminder and can be set to Shut-down

the heating once the gas Boiler Service becomes overdue. This helps to eliminate the potential for an incident to occur after the Landlord’s Safety

Certificate has expired.

The operation of the Service Feature is flexible. The landlord or installer can set the following:

• Theserviceinterval,indays

• Anadvancereminderforthetenant,bycountingdowndaysuntilserviceisdue

• Acontacttelephonenumbertocalltoarrangetheservice–displayedontheLCDscreen

• Howthetimerwilloperatewhentheserviceintervalhasexpired.

The options include:

1. Continued normal operation with a Reminder message

2. Total shutdown of heating

3. “Prompt” mode – shutdown that will allow repetitive manual over-ride for one hour at a time.

The Service feature is configured from a special Installer Mode called ‘SET SERVICE’. Entry into this mode is only possible by entering a unique 4

digit PIN code.

Note: The ST9520C is supplied from the factory with the Service features DISABLED. They need to be enabled from the Installer Modes. See section

4.6 Set Service for details.

4.2 Boiler Service Reminder / Shut-down Feature

Installer Mode LoT™ Display Message

Installer Setup ‘SET INSTALLER OK ?’

OpenTherm Setup ‘SET OPENTHERM OK ?’

Set Service ‘SET SERVICE OK ?’

Change PIN ‘CHANGE PIN OK ?’

Page 10

10

The system can be set up to operate in a variety of different ways to suit the application, or the user lifestyle or preferences.

This setup is done via the ST9520C Installer Setup. The features that can be adjusted are called Installer Parameters, and are listed in the table below,

along with a description of the options that are possible.

* Not used in this system.

** This parameter by default has a value of 1, unless you change any other parameter, when it will change to 0. Set it to 1 to reset all parameters

back to defaults. Some parameters may not be displayed, depending on the settings made for prior parameters.

INSTALLER PARAMETER Parameter

Number

LoT™ Display

Description

Default

Value

Range of Values Description [LoT™ Display Description]

24hr or am/pm clock display. 1 CLOCK MODE 12 12, 24 12 = am/pm display,

24 = 24hr display

[AM PM]

[24 HOUR]

Configure backlight

operation.

2 BACKLIGHT 2 0, 1, 2 0 = off,

1 = on if button pressed,

2 = on continuously

[NO B-LIGHT]

[B-L DELAY]

[B-LIGHT ON]

Enable/disable auto time

change.

3 AUTO TIME 1 0, 1 0 = disabled,

1 = enabled

[NO CHANGE]

[TIME CHANGE]

1-day or 5/2-day or 7-day

operation.

4 UNIT TYPE 7 1, 5, 7 1 = 1-day operation,

5 = 5/2-day operation,

7 = 7-day operation

[1-DAY]

[5-2 DAY]

[7-DAY]

Number of ON/OFFs per

day.

5 ON PERIODS 3 2, 3 2 = 2 on/offs per day,

3 = 3 on/offs per day

[2 PER DAY]

[3 PER DAY]

Select default time

programme.

6 DEF PROFILE A A, b, C A = standard,

b = at home,

C = economy

[PROFILE A]

[PROFILE B]

[PROFILE C]

* Set Hot Water Temperature 8 WATER TEMP 60 40 ... 85°C Hot Water Temperature [SET WATER TEMP]

Optimum start 9 OP START 0 0, 1, 2 0 = no optimum start

1 = delayed start

2 = optimum start on

[NO OP-STRT]

[DELAY-STRT]

[OP-STRT ON]

Optimum start limit

(Only available if OP START

set to 2)

10 STRT LIMIT 1 1, 2, 3 1 = 1 hour

2 = 2 hours

3 = 3 hours

[1 HOUR]

[2 HOURS]

[3 HOURS]

Optimum stop 11 OP STOP 0 0, 1 0 = disabled,

1 = enabled

[NO OP-STOP]

[OP-STOP ON]

Frost protection temperature

12 FROST TEMP 5 5 to 16°C Frost protection temperature [SET FROST TEMP]

Minimum ON/OFF time 13 MIN ON-OFF 1 1, 2, 3, 4, 5 minutes Minimum ON/OFF time [SET MIN ON-OFF]

Cycle rate 14 CYCLE RATE 6 3, 6, 9, 12 Number of boiler cycles [SET CYCLE RATE]

Proportional band width 15 PROP BAND 15

(=1.5°C)

15 … 30

(=1.5 ... 3.0°C)

Control proportional band [SET PROP BAND]

Failsafe mode (loss of RF

communications)

16 COMMS LOSS 0 0, 1 0 = off

1 = on 20%

[HEAT OFF]

[20 PERCENT]

** Reset all parameters 20 PROG RESET 1 0, 1 0 = do not reset

1 = default parameters

[RESET OFF]

[RESET ON]

To Enter Installer Setup:

a. Ensure the slider is in the RUN position, then press and hold the and buttons together for 8 seconds. Ignore the ‘NOT VALID’ that is

displayed for a few seconds. The message ‘SET UP MENU’ will show briefly, followed by ‘SET INSTALLER OK ?’

b. Press the button to take you into the Installer Setup Parameter Menu.

c. Parameter 1 is now available to change. This is to allow you to change the clock format from 12 hour AM/PM to 24 hour. At every step, the LoT™

Display will inform you what the parameter means and what option you have selected. The parameter number is shown on the display separated

by a colon from the parameter value.

d. You can change the parameter value by pressing the or buttons. At this point the description in the LoT™ Display will change and the

parameter value will flash. If you press the value will stop flashing and will be saved for use.

e. Press to move to the next parameter available for editing. The parameter number will change accordingly.

f. Keep pressing to step around the list of parameters, and use or buttons to change the parameter value.

g. Any parameter changes that have been confirmed with the button will be saved and used.

To Exit Installer Setup:

You can exit any Installer Mode at any time by moving the slider to the next position and then back again to RUN.

Note: Installer Modes will exit automatically after 10 minutes if the slider is not moved.

4.3 Installer Setup

Application Cycles per hour Minimum on/off time What to change:

Gas boiler 6 1 No changes required, leave at default values

Oil boiler 3 4 Set parameter 13: 1 to 13: 4

Set parameter 14: 6 to 14: 3

Recommendations for Specific Boiler Applications

Page 11

11

4.4 Installer Setup Flowchart

or

LoT™ Display

Parameter

Number

Parameter

Value

4.5 OpenTherm® Setup and Information Display

OpenTherm PARAMETER Parameter IDLoT™ Display

Description

Default

Value

Range of

Values

Description [LoT™ Display Description]

Enable or Disable

OpenTherm

Ot OpenTherm 0 0, 1 0 = disabled

1 = enabled

[DISABLED]

[ENABLED]

Supply water temperature SUPPLY °C ---- 0 – 99 Supply water temperature [SUPPLY °C]

Water pressure PRESSURE ---- 0.0 - 4.0 Water pressure [PRESSURE]

Flame modulation % MODULATION ---- 0 – 100 Flame modulation % [MODULATION]

Central Heating Output

Temperature Limit

CL CH LIMIT 90 40 – 90 * Central heating water temperature limit [SET CH LIMIT]

Enable or Disable

OpenTherm Low Load Mode

LL LOW LOAD 1 0, 1 ** 0 = disabled

1 = enabled

[DISABLED]

[ENABLED]

Reset OpenTherm

parameters to defaults

rS OT RESET 1 0, 1 0 = do not reset

1 = default parameters

[NO RESET]

[RESET]

* this value may be further limited by the boiler

** the boiler may not allow low load operation

Note: When OpenTherm is enabled, BOILER binding is not possible and anything already bound in the BOILER binding slot is deleted (see page 16).

Refer to Honeywell Technical Help Desk for wireless OpenTherm possibilities using the R8810A OpenTherm receiver.

ST9520C has the facility for a direct low voltage communications connection to the boiler using the OpenTherm® protocol. If the boiler supports it,

OpenTherm allows the boiler’s gas valve to be controlled so the amount of heat provided exactly matches the varying demand. By reducing the flow

temperature to a minimum as it leaves the boiler, the return temperature is kept below the dew point (55°C) whenever possible, thus allowing the boiler

to operate in its most efficient condensing mode.

The OpenTherm control can be adjusted by setting some parameters in OpenTherm Setup mode. In addition, as OpenTherm is a communications

protocol, it is possible to view some operating metrics in this mode, such as supply water temperature, pressure, and flame modulation level. These

are shown in the table below.

Page 12

12

To Enter Set OpenTherm Mode:

a. Enter Installer Modes (as described on page

9) and navigate to SET OPENTHERM mode. In

response to the query ‘SET OPENTHERM OK ?’,

press the button to enter SET OPENTHERM.

b. The first OpenTherm parameter ‘Ot’ is now

available to adjust. This allows you to enable

or disable OpenTherm communications. The

parameter ID is shown on the display separated by

a colon from the parameter value. If this parameter

is set=0, OpenTherm will not function and no other

OpenTherm parameters will be accessible.

c. You can change the parameter value by pressing

the or buttons. At this point the description

in the LoT™ Display will change and the parameter

value will flash. If you press the value will stop

flashing and be saved for use.

d. Press to move to the next parameter. If the

parameter is a Display parameter it does not have

an ID code. It cannot be adjusted but will simply

display the information supplied by the boiler.

e. Keep pressing to step around the list of available

parameters, and use or buttons to change

the parameter value, where allowed.

f. Any parameter changes that have been confirmed

with the button will be saved and used.

To Exit Set OpenTherm Mode:

You can exit Set OpenTherm Mode at any time by moving the slider to the next position and then back again to RUN.

4.5 OpenTherm® Setup and Information Display (cont.)

Only if OpenTherm is

enabled (Ot=1) will it be

possible to access the

other parameters

4.6 Set Service

‘SET SERVICE’

PARAMETER

Parameter IDLoT™ Display

Description

Default

Value

Range of

Values

Description [LoT™ Display Description]

Enable or disable service

alarm feature

AL SERV MODE 0 0, 1 0 = disabled

1 = enabled

[DISABLED]

[ENABLED]

Number of days till next

Service

d SERV DAYS 364 001 to

400

001….400

000 = service is overdue

[SET DAY COUNT]

Number of days for

advance warning

Ad DAYS NOTICE 28 0 to 28 0 …28 [SET DAYS NOTICE]

Action taken at time-out to ACTION TYPE 2 0, 1, 2 0 = no action,

1 = switch off,

2 = ‘prompt’ mode

[NO ACTION]

[SWITCH OFF]

[PROMPT MODE]

Number of EXTRA HOUR

button presses allowed in

‘Prompt’ mode

bP 1HR BOOSTS uL uL,

1 to 99

uL = unlimited number,

1…99 = specified number of button

presses, after which unit switches off

[NUM BOOSTS]

Enable telephone call

number display

tC SHOW

PHONE

0 0, 1 0 = disabled

1 = enabled

[DISABLED]

[ENABLED]

Enter contact telephone

STD code

St STD CODE ------- 1 When a or button is first pressed the LoT™ Display

shows a row of dashes which can be adjusted using or

buttons, then verified using the button.

Enter contact telephone

number

nu NUMBER --------- 1 When a or button is first pressed the LoT™ Display

shows a row of dashes which can be adjusted using or

buttons, then verified using the button.

* Reset ‘SET SERVICE’

parameters to default values

rS ALRM RESET 1 0,1 0 = do not reset

1 = default parameters

[NO RESET]

[RESET]

* This parameter by default has a value of 1, unless any other parameter is adjusted, when it will change to 0. Set it to 1 to reset all parameters

back to defaults

Set Service parameters are listed in the table below, along with a description of the options that are possible. Most are only displayed if Service is

enabled i.e. parameter AL is set = 1.

Page 13

13

4.6 Set Service (cont.)

To Enter Set Service Mode:

a. Enter Installer Modes (as described on Page

9) and navigate to SET SERVICE mode.

In

response to the query ‘SET SERVICE OK ?’

press the button to enter SET SERVICE.

b. The message ‘ENTER PIN’ will now be displayed,

along with the 4-digit entry code format 0---. The

first digit will be flashing, to indicate it can be

changed. Use the

or

buttons to set the

first digit, and press to confirm the digit.

c.

At this point the first digit will stop flashing and

the second digit will begin to flash, indicating it

can be changed.

d.

Proceed in this way to enter the 4 digits of the

PIN code. Upon confirming the last digit, if the

PIN was incorrect, the message

‘INVALID’

will be

displayed, and then the whole process will start

again from step b. above.

e. If the PIN was correct, the first SET SERVICE

parameter ‘AL’ will be available to change. This

allows you to enable or disable all the service

alarm features. At every step, the LoT™ Display

will inform you what the parameter means and

what option you have selected. The parameter ID

is usually shown on the display separated by a

colon from the parameter value.

f. You can change the parameter value by

pressing the

or

buttons. At this point the

description in the LoT™ Display will change and

the parameter value will flash. If you press the

value will stop flashing and will be saved for use.

g. Press to move to the next parameter available

for editing. The parameter ID will change

accordingly.

h.

Keep pressing to step around the list of

parameters, and use or buttons to

change the parameter value.

i.

Any parameter changes that have been

confirmed with the button will be saved and

used

. Some parameters may be made invalid by

a previous parameter setting, and these will be

skipped over in the setting process.

To Exit Set Service Mode:

You can exit Set Service Mode at any time by moving the slider to the next position and then back again to RUN.

or

or

Page 14

14

If you intend to change the PIN code, please ensure you take a note of the new code that you are setting.

The process for changing the current PIN code is as follows:

a. Enter Installer Modes (as described on Page 9) and navigate to CHANGE PIN mode. In response to the query ‘CHANGE PIN OK ?’ press the

button to enter CHANGE PIN mode.

b. The message ‘ENTER PIN’ will now be displayed, along with the 4-digit entry code format 0---. The first digit will be flashing, to indicate it can

be changed. Use the or buttons to set the first digit, and press to confirm the digit.

c. At this point the first digit will stop flashing and the second digit will proceed to flash, indicating it can be changed.

d. Proceed in this way to enter the 4 digits of the old PIN code. Upon confirming the last digit, if the PIN was incorrect, the message ‘INVALID’ will

be displayed, and then the whole process will start again from step b. above.

e. If the PIN was correct the message ‘SET NEW PIN OK ?’ will appear. As before, use the or buttons to set the digits, and the button to

confirm. Upon confirming the final digit, the message ‘PIN SET’ will be displayed, and the new PIN code will be held on the screen for 5 seconds,

to give you time to note it down.

f. After setting the new PIN code, you will be taken back to the SETUP MENU.

If the advance warning has been configured, the screen will flash this message every few seconds, and the User should

telephone to arrange a service call before the final date when the service is due.

If a telephone number has been entered using the ‘SHOW PHONE’ feature, this will be displayed when the advanced

warning period commences.

When the boiler service is overdue the screen will keep flashing the words ‘SERVICE DUE’ every second.

If the NO ACTION option has been selected, the unit will continue to operate as normal and the real time will continue

to be shown.

If the SWITCH OFF or PROMPT Actions have been selected, the ‘SERVICE DUE’ message will flash and the word “OFF”

will appear on the display. The boiler has been switched off to ensure the safety of the User. A service appointment

should be arranged immediately.

In PROMPT operation, the User can obtain limited use of the boiler by pressing the EXTRA HOUR button. Each button

press will allow operation of the boiler for 1 hour at a time, and the screen will display the message ‘On 1h’, as shown.

A service appointment should be arranged immediately.

If a contact telephone number has been programmed into the ST9520C, a message will appear on the LoT™ Display

indicating the number that should be called.

If the Service Timer function is enabled you will be required to reset it after the boiler service has been carried out.

The process for resetting the Service Timer is as follows:

a. Enter Installer Modes (as described on page 9) and navigate to SET SERVICE mode. In response to the query ‘SET SERVICE OK ?’ press the

button to enter SET SERVICE mode.

b. If you no longer require the Service Timer, disable it by setting parameter AL to 0 and confirm with the button.

c. If you still require the Service Timer, set the number of days until the next service is due using parameter d and confirm with the button.

d. Whilst in SET SERVICE mode, use the opportunity to change any other service parameters if required.

e. Exit by moving the slider to the next position and back again to RUN.

4.8 What the User Will See When a Service is Due

4.9 Resetting the Service Timer Function

4.7 Change PIN

Page 15

15

Like ST9520C, DT92E also has an Installer Mode to enable it to be

customized for the application. Each adjustable feature is called a

Parameter, and is represented by a letter ID and a value on the display,

as shown.

The Parameters are listed in the table below:-

To Enter Installer Mode:

a. Hold the button for 2 seconds until

DT92E is in standby mode

b.

Hold and buttons for 3 seconds

until the word ‘Inst’ appears on the

display

c. Press the button

The first parameter is now ready to be

changed

To Select a Parameter:

Use the and buttons to move from one

parameter to the next. Stop at the Parameter

you wish to change.

To Change a Parameter:

Use the button to select the parameter

value, then the and buttons to change

the value. Confirm the change by pressing

the button again to take you back to the

parameter.

To Exit Installer Mode:

Hold the button for 3 seconds to exit

Installer Mode.

Note: The Installer Mode will exit automatically after 10 minutes if no adjustments have

been made in this time.

5

SYSTEM CONFIGURATION: DT92E

5.1 DT92E Installer Mode

INSTALLER PARAMETER Parameter Default Value Range of Values Description

Temperature measurement offset t0 0 -3 to 3°C Offset to measured temperature

Upper setpoint limit uL 35 21 to 35°C Upper set temperature limit in °C

Lower setpoint limit LL 5 5 to 21°C Lower set temperature limit in °C

Energy saving ECO setpoint ES 18 5 to 35°C Energy saving ECO set temperature in °C

Reset parameters to factory settings FS 1 0, 1 Parameter will be set to 0 if any of the other

parameter values have been changed. Set to 1

to get back to factory settings.

3 s

2 s

3 s

Parameter Value

Page 16

16

2-way RF devices that communicate with each other achieve this through having each others unique addresses written in their memories. This allows

each device to know which other device to communicate with. The process of writing these addresses is known as Binding.

All devices in the pack are pre-bound at the factory. The binding operation is only required if:

- any of the system components are replaced

- pre-bound system pack components have been mismatched

- additional components are required for the application, e.g. BDR91T relay box for remote boiler application 95-3. In this case the

BDR91T must be bound to the ST9520C as a BOILER CONTROL (see section 6.6).

The ST9520C is the communications ‘hub’ of the entire system, so other RF devices are bound to it and not to each other. ST9520C has a special

‘Guided Binding Menu’ that allows you to bind other devices to it in a logical way. Devices are bound into special ‘slots’ and there are rules governing

what can be bound into which slot. This ensures binding errors are minimised and applications are correctly set up. When in ‘Guided Binding Menu’

the and buttons are used to navigate around.

Sensor binding (refer to section 6.5 for sequence of steps)

It is possible to bind 2 sensors to ST9520C in separate binding slots, a DT92E thermostat for Zone 1 and a DT92E thermostat for Zone 2. If the display

shows dashes it means there is nothing already bound in the slot. If the display shows ‘bnd’ it means there is something already bound.

Control and boiler binding (refer to section 6.6 for sequence of steps)

Once a valid sensor is bound, it is then possible to bind an output device, such as a BDR91T relay box. If this is to control remote zone valves for the

heating zones, then use the CONTROL binding slots. In the special case of controlling a remote boiler, use the special BOILER binding slot. When

this is bound, the Guided Binding Menu then allows a signal strength test to be initiated (refer to section 6.7 for sequence of steps).

Binding table by application

General Binding Notes

• Tobind2devicestogether,BOTHmustbeputintoBindingMode.

• Withbothdevicesinbindingmode,youmustsendthebindingsignalfromonedevicetotheother:

- To bind a sensor, the signal is sent from the sensor.

- To bind an output device, the signal is sent from the ST9520C.

6

BINDING / RE-BINDING PROCEDURE

6.1 Binding

6.2 ST9520C Guided Binding Menu

6.3 Guidance for Replacing Devices or Changing the Application

Situation Binding Action

1. Replacing faulty DT92E • BindnewsensoroverpreviousbindinginSENSORslot.

2. Replacing faulty BDR91T • BindnewBDR91ToverpreviousBDR91TinCONTROLorBOILERslotand

remove faulty BDR91T from system.

3. Reconfiguring system by adding or removing BDR91T • IfremovingBDR91T,cancelbindinginthatCONTROLorBOILERslot.

• IfaddingBDR91T,bindintovacantCONTROLorBOILERslot.

Note: if a sensor is removed, the binding for any output device associated with that sensor will be cancelled.

Application Zone 1 Sensor Zone 2 Sensor Zone 1 Control

Output

Zone 2 Control

Output

Boiler

Output

Binding Required

SENSOR SENSOR CONTROL CONTROL BOILER

95-1 DT92E DT92E -- -- -- -- -- -- Supplied pre-bound

95-2 DT92E DT92E -- -- -- -- -- -- Supplied pre-bound

95-3 DT92E DT92E -- -- -- -- BDR91T Bind in BDR91T

Page 17

17

6.5 How to Bind DT92E to ST9520C

SENSOR : means temperature sensor

BOILER : means output device wired to boiler

CONTROL : means output device wired to zone valve

Zone 2

Boiler

Zone 1

bnd : indicates something is already bound in this slot

-- -- : indicates nothing is currently bound in this slot

a. Ensure the ST9520C slider is in the RUN position, then press and hold , and Zone 2 MODE buttons for 8 seconds to access the Guided

Binding Menu. The message ‘BIND MENU’ will show briefly, followed by the binding display.

b. From the Guided Binding Menu, select the Room Temperature SENSOR binding mode. Pay attention to which zone is being bound, Zone 1 or

Zone 2.

c. Refer to the table in Section 6.3 to determine whether you require to cancel any binding. If the display shows dashes it means there is nothing

already bound in the slot. If the display shows ‘bnd’ it means there is something already bound. When in ‘Guided Binding Menu’ the and

buttons are used to navigate around.

d. Any existing binding can be cancelled by holding the button for 8 seconds and the LoT™ Display will say ‘RESET’ for a few seconds.

e. Press the button on ST9520C to put it into binding mode, ready to receive the binding message from the sensor. The display will flash and the

message ‘BINDING’ will be shown to indicate ST9520C is waiting for this message.

f. Now bring DT92E (or its front section, minus mounting plate) to approximately 1 metre from ST9520C.

g. Put DT92E into binding mode as shown.

- Press and hold the button for 2 seconds

- Hold the and buttons for 3 seconds until display shows ‘Inst’

- Press the button and the display shows ‘Cont’

h. If you do not need to cancel existing binding in DT92E (see section 6.3) skip this step and go straight to step i.

- Keep pressing the button until the display shows ‘CLr’

- Press the button to clear existing binding data

- Now put DT92E into binding mode by pressing the button again. The display will show ‘COnt’.

i. Press the button on DT92E to send the binding message to ST9520C. If binding was successful DT92E will exit binding mode, and will show

‘SYnc’ on its display for up to 4 minutes, as communication and synchronisation are established. The ST9520C display will stop flashing, ‘bnd’

will be shown, and the LoT™ Display will say ‘COMPLETE’ for a few seconds.

j. If binding was unsuccessful, repeat step i. If this fails, repeat steps e. to i. again. If binding was successful, proceed to step k.

k. Exit Guided Binding Menu by moving the ST9520C slider to the next position and then back again to RUN (it will exit automatically after 10

minutes if the slider is not moved).

l. Now go to section 2.3 to verify communication by using the Signal Strength check.

2 s

3 s

6.4 Binding Menu Display

Page 18

18

6.6 How to Bind BDR91T to ST9520C

NOTES:

• ItisonlypossibletobindaBDR91Tifbothsensors(DT92E)havealreadybeenboundtothesensorslotsinST9520C.

• BDR91Tcan be boundas aCONTROLdevice, tooperatea zonevalve for example(refer toHoneywellfor supportedapplications)or asa

BOILER control (refer to Binding Table in section 6.2 for details).

a. Ensure the ST9520C slider is in the RUN position, then press and hold , and Zone 2 MODE buttons for 8 seconds to access the Guided

Binding Menu. The message ‘BIND MENU’ will show briefly, followed by the binding display.

b. Refer to the table in Section 6.3 to determine whether you require to cancel any binding. The SENSOR binding slot will be displayed first. Use

the and buttons to navigate to the CONTROL or BOILER binding slots, where ‘CONTROL’ or ‘BOILER’ will appear on the display. If the

display shows dashes it means there is nothing already bound in the slot. If the display shows ‘bnd’ it means there is something already bound.

c. Any existing binding can be cancelled by holding the button for 8 seconds and the LoT™ Display will say ‘RESET’ for a few seconds.

d. Now go to the BDR91T. If you need to cancel any previous binding in BDR91T, hold the button down for 15 seconds. The red light will give a

quick flash every second. Otherwise go to step e.

e. Hold the BDR91T button for 5 seconds until the red light flashes on for 0.5s, off for 0.5s. The BDR91T is now in binding mode awaiting the binding

message from ST9520C.

f. Now press the button on ST9520C to send the binding signal. If binding was successful the ST9520C display will stop flashing, ‘bnd’ will be

shown, and the LoT™ Display will say ‘COMPLETE’ for a few seconds. The flashing red light on BDR91T will also go off.

g. If binding was unsuccessful, repeat step f. if this fails, repeat steps d. to f. again. When binding has succeeded, proceed to step h.

h. Exit Guided Binding Menu by moving the ST9520C slider to the next position and then back again to RUN (it will exit automatically after 10

minutes if the slider is not moved).

i. Now go to section 6.7 to verify communication by using the Signal Strength test.

15 s

0.1s 0.1s 0.1s

0.9s0.9s

5 s

0.5s 0.5s 0.5s

0.5s 0.5s

Page 19

19

Honeywell 2-way RF communications allows signal strength testing to verify BDR91T is positioned in the best possible location.

a. Enter ST9520C Guided Binding Menu (ensure the slider is in the RUN position, then press and hold , and Zone 2 MODE buttons for 8

seconds. The message ‘BIND MENU’ will show briefly, followed by the binding display).

b. Navigate to the Signal Strength Test screen by pressing the button until the message ‘SIGNAL TST OK?’ appears on the display.

c. Press the button to activate the test. The ST9520C will show ‘SIGNAL TST’ and flash ‘SS’ on the display.

d. Go to the BDR91T where the red light will flash several times quickly in succession, repeating every 5 seconds. The number of flashes in each

burst will be between 0 and 5, with 5 representing a strong signal and 0 a weak one.

e. If the signal strength is less than 3, re-position the BDR91T within the local area +/- 1 or 2m to see if the signal strength improves.

f. Signal Strength Test is cancelled by pressing the or buttons on ST9520C or by moving the slider to exit the Guided Binding Menu.

6.7 How to Test BDR91T Signal Strength

Page 20

20

1

Check ST9520C has powered up correctly and the display is not blank. Now set Zone 1 and Zone 2 operating modes to

AUTO.

2

Check both DT92E thermostats have powered up correctly and the displays are not blank.

3

Configure DT92E thermostats as required (see Section 5 for how to do this). Remember to make a note of any changes

in the Configuration Data section of the User Guide.

4

Change the temperature setpoint on both DT92E thermostats to 35°C by pressing the button. (If DT92E is currently off,

hold the button for 2 seconds to take it back to run mode).

5

Now go to ST9520C. With Zone 1 and Zone 2 operating modes set to AUTO, switch Zone 1 and Zone 2 on and off using

the OVERRIDE buttons, to ensure the system is operating correctly.

6

If OpenTherm control has been enabled (application 95-2) go into OpenTherm SETUP mode as explained in section 4.5

and verify the display parameter for the supply water is showing actual values rather than ----. This indicates OpenTherm

communications are functioning.

7

If a BDR91T relay box has been installed (application 95-3), verify it is switching the relay on and off in response to

manual operation of the ST9520C OVERRIDE buttons. The relay status is indicated by the green light on the BDR91T.

8

Check the factory-set day, date, and time are correct and adjust if necessary. Refer to User Guide for details.

9

If required, enter Installer Setup Mode and adjust Installer Parameters to match the lifestyle and needs of the User.

Remember to make a note of these parameter changes in the Configuration Data section of the User Guide.

10

If required, enter Set Service Mode and enable the Boiler Service Reminder, and set the appropriate Service parameters.

11

Set both DT92E thermostats to the temperature required by the User. 20°C is recommended for a living area and 18°C

for a bedroom zone.

7

COMMISSIONING THE SYSTEM

7.1 System Test Checklist

1

Explain the operation of the products to the User, and help them to set their Zone 1 and Zone 2 programmes. ST9520C

has 3 built-in profiles that can be used as a basis for typical User programmes.

2

Explain when the User should contact someone to arrange a Service Visit, and what you have programmed to happen

when the Service is overdue.

3

If required, attach the self-adhesive programme guide label to the underside of the ST9520C cover flap. The label is

supplied in the box.

4

Write the date of installation, your name and telephone number in the space provided in the User Guide, in the section

‘Boiler & System Service Log’.

5

Remember to leave the User Guide and Installation Instructions with the User and remind them to keep them in a safe

place. This forms part of a Home Information Pack.

This product and its associated documentation and packaging are protected by various intellectual property rights belonging to Honeywell

Inc and its subsidiaries and existing under the laws of the UK and other countries. These intellectual and property rights may include patent

applications, registered designs, unregistered designs, registered trade marks, unregistered trade marks and copyrights.

Honeywell reserves the right to modify this document, product and functionality without notice. This document replaces any previously issued

instructions and is only applicable to the product(s) described.

This product has been designed for applications as described within this document. For use outside of the scope as described herein, refer to

Honeywell for guidance. Honeywell cannot be held responsible for misapplication of the product(s) described within this document.

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, ACS-ECC EMEA, Z.A. La

Pièce 16, 1180 Rolle, Switzerland, by its Authorised Representative Honeywell Inc.

50047644-006 A

© 2011 Honeywell International Inc.

Honeywell Control Systems Ltd.

Arlington Business Park,

Bracknell, Berkshire

RG12 1EB

Technical Help Desk: 08457 678999

www.honeywelluk.com

7.2 Completion Checklist

Loading...

Loading...