Page 1

WT8840 TRADE WATER HEATER CONTROLS

WARNING

CAUTION

WARNING

WARNING

Perform Gas Leak Test

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Check for gas leaks with soap and water

solution any time work is done on a gas system.

Water Damage Hazard.

Can damage electrical components in the

WT8840.

Do not spray soap and water solution on the

WT8840 housing. Do not use an excessive

amount of soap and water to perform the gas

leak test.

Gas Leak Test

1. Paint pipe connections upstream of the water

heater control with a rich soap and water

solution. Bubbles indicate a gas leak.

2. If a leak is detected, tighten the pipe connection.

3.

Stand clear of the burner while lighting to prevent

injury caused from hidden leaks that could cause

flashback in the appliance burner compartment.

4. With the burner in operation, paint the pipe

joints (including adapters) and the control inlet

and outlet with a rich soap and water solution.

5. If another leak is detected, tighten the adapter

screw, joints, and pipe connections.

6. Replace the part(s) if a leak cannot be stopped.

Check the gas input and burner

flow rate

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly:

1. Do not exceed input rating stamped on

appliance nameplate or manufacturer

recommended burner orifice pressure for

size of orifice(s) used. Follow instructions of

appliance manufacturer.

2. IF CHECKING GAS INPUT BY CLOCKING

GAS METER: Make certain there is no gas

flow through the meter other than to the

appliance being checked. Other appliances

must remain off with the pilots extinguished

(or that consumption must be deducted

from the meter reading). Convert flow rate to

Btuh as described in form number 70-2602,

Gas Controls Handbook, and compare to

Btuh input rating on appliance nameplate.

3. IF CHECKING GAS INPUT WITH

MANOMETER: Make sure the manual gas

shutoff switch is in the OFF position before

removing outlet pressure tap plug to connect

the manometer (pressure gauge). Also, move

the manual gas shutoff switch to the OFF

position when removing the gauge and

replacing the plug. Also shut off gas supply

before disconnecting manometer and

replacing plug. Repeat Gas Leak Test at plug

with main burner operating.

Procedure to check the gas input

and burner flow rate

1.

Check the full rate manifold pressure listed on

the appliance nameplate. Water heater control

full rate outlet pressure should match this rating.

2. With burner operating, check the water heater

control flow rate using the meter clocking

method or check pressure using a manometer

connected to the outlet pressure tap on the

water heater control. See Fig. 5.

MAINTENANCE

Fire or Explosion Hazard. Can cause severe

injury, death or property damage.

Do not attempt to take apart or clean the gas

valve inside the WT8840 control. Improper

cleaning or reassembly can cause gas leakage.

The maintenance program should include regular

checkout of the control as outlined in the Startup and

Checkout section, and the control system as described

in the appliance manufacturer literature.

Maintenance frequency must be determined individually

for each application. Some considerations are:

1. Cycling frequency. Appliances that may cycle

10,000 times annually should be checked

monthly.

2. Intermittent use. Appliances that are used

seasonally should be checked before shutdown

and again before the next use.

3. Consequence of unexpected shutdown. Where

the cost of an unexpected shutdown would be

high, the system should be checked more often.

4. Dusty, wet or corrosive environment. Since these

environments can cause the control to

deteriorate more rapidly, the system should be

checked more often.

The system should be replaced if:

• It does not perform properly on checkout or

troubleshooting.

• The control is likely to have operated for more

than 150,000 cycles.

• The control is wet or looks as if it has been wet.

TROUBLESHOOTING

Troubleshooting With Status

Indicator Assistance

1. Pilot burner must be lit. If not, push and hold

Pilot knob and light pilot with piezo. Error code

will be displayed when thermopile heats up.

Error code can be recognized by counting the

number of flashes of the status indicator after a

three second pause. One single flash (with set

point knob in PILOT position) indicates that the

control is in normal operation.

2. Observe status indicator on control; check and

repair the system as noted in Table 3 on page 6.

Flash codes are displayed with a three-second

delay between cycles. A continuous solid light

indicates system shutdown when knob is turned

from a temperature setting to OFF position.

When the solid light is present, the pilot and

5 34-00013EF—03

Page 2

WT8840 TRADE WATER HEATER CONTROLS

main valve will not hold. When the status

indicator goes out, the user can restart the

system. (Approximate shutdown time is one

minute.)

3. After status indicator analysis and appliance

repair is complete, turn device knob to OFF, wait

until the indicator goes out, then perform

lighting procedure.

4. Status indicator light should be in normal mode

(1 flash) with the knob in the PILOT position.

Turn the device knob past the water temperature

in the tank should turn on the main burner. The

Status indicator light will strobe every three

seconds when there is a call for heat.

5. In the event of multiple failure codes, the next

failure code follows the previous failure code by

approximately three seconds with higher flash

count first.

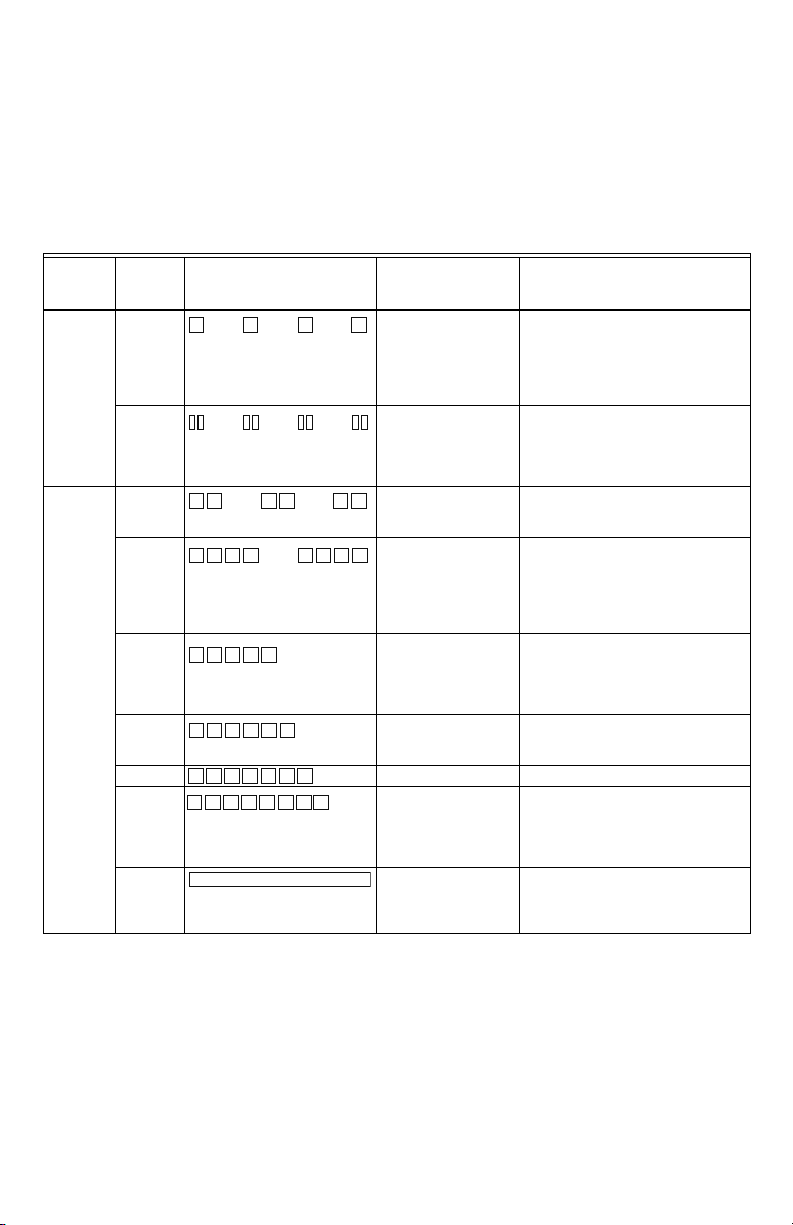

Table 3. Troubleshooting with status light visual indication.

LED

Error

**

Normal

operation.

No action

required.

Action

required.

Code

1 flash

every 3

seconds

Strobe

every 3

seconds

2 flashes Low thermopile

4 flashes Temperature cut-out

5 flashes Water temperature

6 flashes Tank leakage

Number of LED Flashes*Detected Failure Recommended Action

Not an error;

indicates the

electronics is holding

the Pilot Valve open

and the Main Valve

closed.

Not an error;

indicates call for heat

during normal

operation, Main valve

open.

voltage; main valve

not turned ON.

limit reached.

sensor failure.

detected by

accessory module.

You can now turn the knob to a

desired setpoint temperature. LED

will continue to flash 1 time every 3

seconds while in Idle mode (no call

for heat).

None.

Check thermopile and its

connections. Check pilot flame.

Check the valves and the water

temperature sensor. Reduce the

water temperature setpoint.

Thoroughly check out main valve

operation and water temperature

control before walking away.

Check water temperature sensor

and its connection for open

circuits, shorts, or differences in

resistance between the two sensor

elements.

Control recovers after receiving

message from accessory module.

7 flashes Electronics Failure Replace control module.

8 flashes This is just a warning;

Solid ON Not an error—

*

LED Error Codes are flashed once per second, with a three-second pause between repeating the error code.

**

Maximum two different errors can be displayed simultaneously if more than one error has been detected.

The control does not

see power decaying

with the knob in the

OFF position.

indicates that the

control is in OFF

mode.

Check valves.

None; wait until LED turns off if you

want to restart the system.

34-00013EF—03 6

Page 3

WT8840 TRADE WATER HEATER CONTROLS

M22535D

TIME (MINUTES)

OUTPUT (mV)

THERMOPILE OUTPUT WITH TIME

500

600

400

300

200

100

0

012345678910

900

800

700

NORMAL RANGE

OUTPUT TOO LOW

Troubleshooting Without Status Indicator Assistance

Follow diagram in Fig. 6.

TROUBLESHOOTING GUIDE WITHOUT STATUS LIGHT

TURN DEVICE KNOB FROM OFF TO

PILOT, PRESS DOWN KNOB AND HOLD,

LIGHT PILOT BY DEPRESSING PIEZO

IGNITION BUTTON, PILOT SHOULD

LIGHT.

– WATER TEMPERATURE IS BELOW

THE CUT-OUT LIMIT

STATUS LIGHT SHOULD FLASH AFTER

1 MINUTE, LED WILL FLASH NORMAL

SINGLE BLINK, RELEASE THE DEVICE

KNOB, PILOT SHOULD REMAIN LIT

YES

YES

CHECK:

• INLET PRESSURE

NO

• MAKE SURE AIR IS BLED OUT OF SYSTEM

• PIEZO SPARKING TO THERMOPILE

• CLOGGED PILOT ORIFICE

• GAS LEAK IN PILOT TUBING CONNECTIONS

CHECK:

• WIRING OF THERMOPILE LEADS

NO

• FLAME COVERAGE OF THERMOPILE

– THERMOPILE OUTPUT IS TOO LOW-RUN

• THERMOPILE OUTPUT CHECK

TURN DEVICE KNOB TO DESIRED

TEMPERATURE SETTING, BURNER WILL

TURN ON ONLY IN ACTIVE CALL FOR

HEAT (WATER TEMPERATURE IS LESS

THAN TEMPERATURE SETTING MINUS

DIFFERENTIAL); LED FLASHES 1 TIME

EVERY 3 SECONDS DURING A CALL

FOR HEAT.

YES

SYSTEM OK

Fig. 6. Troubleshooting without status light.

Thermopile Output Check

1. Turn device knob to OFF.

2. Disconnect thermopile leads.

3. Turn device knob to PILOT, hold down knob to

light pilot burner. Hold the knob down for five or

more minutes.

4. After five minutes, check thermopile output by

connecting the voltmeter to the positive red lead

and negative white lead.

5. Output should be at least 350 mV. (See Fig. 7.)

Connect the 3.6 ohm resistor between the two

thermopile leads, the voltage should be at or

higher than one half of the open circuit voltage.

6. The terminal housing prevents miswiring of

positive and negative leadwires.

7. Flame must envelop thermopile at Hot Junction

(3/8 in. below tip).

8. Keep heat away from cold junction (brass sleeve

of the thermopile) for maximum output.

CHECK:

NO

• EXCESSIVE INLET PRESSURE

• TANK TEMPERATURE IS AT OR CLOSE TO

SET POINT

Fig. 7. Thermopile output.

M29431C

7 34-00013EF—03

Page 4

WT8840 TRADE WATER HEATER CONTROLS

WARNING

WARNING

INSTRUCTIONS TO THE

HOMEOWNER

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. IF YOU SMELL GAS:

• Turn off the gas supply at the appliance

service valve.

• Do not light any appliances in the house.

• Do not touch electrical switches or use the

phone. Leave the building and use a

neighbor’s phone to call your gas

supplier.

• If you cannot reach your gas supplier, call

the fire department.

2. The water heater control must be replaced

in event of any physical damage, tampering,

bent terminals, missing or broken parts,

stripped threads or evidence of exposure to

heat.

Scalding Hazard.

Can cause burns, severe injury or death.

Never move temperature setpoint knob past

the HOT setting without checking water

temperature at the faucet, and readjusting

until comfortably warm to the touch. Consider

the ages and health of all who will come into

contact with heated water.

IMPORTANT

Follow the operating instructions provided by

the manufacturer of your water tank

appliance. The information in this form

describes a typical water heater control

application, but the specific controls used

and the procedures outlined by the

manufacturer of your appliance can differ,

requiring special instructions.

STOP: READ THE

WARNINGS ABOVE.

If the appliance does not turn on when the setpoint

knob is set several degrees above the previous

temperature, follow these instructions:

1. Set the temperature setpoint knob to OFF.

2. Turn off the main gas valve to the appliance.

3. Wait five minutes to clear out any unburned gas.

If you then smell gas, STOP! Follow step 1 in the

warning above. If you DO NOT smell gas,

continue with the next step.

4. Turn on the gas supply to the appliance.

5. Restart the appliance by performing lighting

procedure.

6. Set the setpoint knob to the desired setting.

7. If the appliance does not turn on, turn off the

gas supply to the appliance and contact a

qualified service technician for assistance.

8. Allow one minute for thermopile to cool before

re-lighting pilot.

TURNING OFF THE

APPLIANCE

Complete Shutdown

1. Turn de vice kn ob to OFF. Tur n off the gas sup ply

to the appliance. Appliance will completely shut

off.

2. Follow the procedure in the Instructions to the

Homeowner section above to resume normal

operation.

Home and Building Technologies

In the U.S.:

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

® U.S. Registered Trademark

© 2017 Honeywell International Inc.

34-00013EF—03 M.S. Rev. 04-17

Printed in United States

Page 5

Régulateurs de chauffe-eau de

remplacement WT8840

NOTICE D'INSTALLATION

APPLICATION

Le régulateur de chauffe-eau WT8840 est conçu pour

les applications à veilleuse permanente utilisant un

puits d’immersion pour la détection de la température

de l’eau. Tous les modèles WT8840 incluent un

capteur de température à coefficient intégré.

Le WT8840 est alimenté par une thermopile chauffée

par la flamme de la veilleuse permanente. Les

veilleuses CS8840 sont conçues pour fonctionner

avec ce régulateur.

Le puits d’immersion pour la détection de l’eau du

capteur est muni de capteurs à thermistance à

coefficient de température négatif adaptés. Ces

capteurs fournissent un mécanisme avec sécurité

intégrée par lequel le WT8840 peut fournir une

régulation précise de la température de l’eau ainsi

qu’une fonction de limitation de la température de

l’eau (coupure de température ou TCO [Temperature

Cut-Out]).

CARACTÉRISTIQUES

IMPORTANT

Les régulateurs WT8840 sont un

remplacement direct uniquement.

Régulateur de pression : Le réglage du régulateur de

pression de sortie est indiqué sur l'étiquette du

produit.

Plage de pression d'admission :

Voir la plaque signalétique de l'appareil pour la

plage de pression d'admission recommandée.

Pression d'entrée maximale de 0,5 PSI (14,0 po c.e.)

autorisée pour un fonctionnement correct.

Configuration du corps : 90° avec entrée de 1/2 po

et sortie conique inversée de 1/2 po.

Montage : À la verticale uniquement.

Entrée de régulateur :

Tension minimum : 350 mV c.c., circuit ouvert.

Tension maximum : 850 mV c.c., circuit ouvert.

Capacité : Voir le Tableau 1.

Plage de régulation :

Gaz naturel :

Minimum : 30 000 Btuh.

Maximum : 85 000 Btuh.

Plage de température ambiante : 0 à 66 °C

(32 à 150 °F)

Plage de température de fonctionnement :

-18 à 66 °C (0 à 150 °F)*

*La vanne fonctionne à -18 °C (0 °F) mais ses

caractéristiques ne peuvent pas être garanties tant

que la température ambiante n'a pas atteint 0 °C

(32 °F).

Plage de stockage : -40 à 66 °C (-40 à 150 °F)

Humidité : 95 % sans condensation à 40 °C (104 °F)

Homologations :

Cet appareil est certifié par l'Association canadienne

de normalisation (CSA) pour les normes suivantes :

ANSI Z21.20

ANSI Z21.23

ANSI Z21.78

ANSI Z21.87

CAN/CSA-C22.2 N° 199-M89

CAN1-6.6-M78

CSA 4.6

CSA 6.20

Accessoires :

Veilleuse CS8840

Page 6

RÉGULATEURS DE CHAUFFE-EAU DE REMPLACEMENT WT8840

Numéro pièce de rechange Remplace Numéro FEO Remplacement FEO FEO

Réservoir, isolation de 1 po,

colonne d’eau de 4 po

Réservoir, isolation de 2 po,

colonne d’eau de 4 po

Réservoir, isolation de 1 po,

colonne d’eau de 5 po

Réservoir, isolation de 2 po,

colonne d’eau de 5 po

WV8840A1000 222-47463-01A

WV8840A1001 222-47463-01E Bradford White

WV8840A1050 222-47463-02A

WV8840A1051 222-47463-02E Bradford White

WV8840B1042 316910-000

WV8840B1109 316910-000 AOSmith

WV8840B1110 321166-000 AOSmith

WV8840B1059 316910-001

WV8840B1117 316910-001 AOSmith

WV8840B1118 321166-001 AOSmith

239-47463-01*

239-47463-02*

100112336 et

9007884005

100112337 et

9007885005

Bradford White

Bradford White

* Comprend la veilleuse et le joint de la chambre de combustion.

AOSmith

AOSmith

34-00013EF—03 2

Loading...

Loading...