Page 1

PRELIMINARY

Firelite Wireless Sensor Network

LS10036-000FL-E

User Manual

Document LS10036-000FL-E

10/10/FLite

P/N LS10036-000FL-E:FLRev ECN FLECN

FL

Page 2

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property

insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote notification capability—can provide early warn ing of a developing fire.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire.

An emergency communication system—typically made up of

an automatic fire alarm system (as described above) and a life

safety communication system that may include an autonomous

control unit (ACU), local operating console (LOC), voice communication, and other various interoperable communication methods—can broadcast a mass notification message. Such a

system, however, does not assure protection against property

damage or loss of life resulting from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premises following

the recommendations of the current edition of the Nati onal Fire

Protection Association Standard 72 (NFPA 72), manufacturer's

recommendations, State and local codes, and the

recommendations contained in the Guide for Proper Use of

System Smoke Detectors, which is made available at no charge

to all installing dealers. This document can be found at http://

www.systemsenso r.com/appguides/. A study by the Federal

Emergency Management Agency (an agency of the United

States government) indicated that smoke detectors may not go

off in as many as 35% of all fires. While fire alarm systems are

designed to provide early warning against fire, they do not

guarantee warning or protection against fire. A fire alarm system

may not provide timely or adequate warning, or simply may not

function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a first-floor

or basement fire.

Particles of combustion or “smoke” from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls, chimneys, even wet or humid areas may inhibit particle or smoke

flow.

• Smoke particles may become “cold,” stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown aw a y from de tectors by air

outlets, such as air conditioning vents.

• Smoke particles may be drawn into air returns before reaching the detector.

The amount of “smoke” present may be insufficient to alarm

smoke detectors. Smoke detectors are designe d to alarm at various levels of smoke density. If such density levels are not created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sens ing

limitations. Detectors that have photoelectronic sensing chambers tend to detect smoldering fires better than flaming fires,

which have little visible smoke. Detectors that have ionizing-type

sensing chambers tend to detect fast-flaming fires bette r than

smoldering fires. Because fires develop in different ways and

are often unpredictable in their growth, neither type of detector is

necessarily best and a given type of detector may not provide

adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children playing with matches

(especially in bedrooms), smoking in bed, and violent explosions

(caused by escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and alarm

only when heat on their sensors increases at a predetermined

rate or reaches a predetermined level. Rate-of-rise heat detectors may be subject to reduced sensitivity over time. For this

reason, the rate-of-rise feature of each detector shoul d be tested

at least once per year by a qualified fire protection specialist.

Heat detectors are designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the system for

the connection of alarm transmission wiring, communications,

signaling, and/or power. If detectors are not so located, a developing fire may damage the alarm system, compromising it s ability to report a fire.

Audible warning devices such as bells, horns, strobes,

speakers and displays may not alert people if these devices

are located on the other side of closed or partly open doors or

are located on another floor of a building. Any warning device

may fail to alert people with a disability or those who have

recently consumed drugs, alcohol, or medication. Please note

that:

• An emergency communication system may take priority over

a fire alarm system in the event of a life safety emergency.

• Voice messaging systems must be designed to meet intelligibility requirements as defined by NFPA, local codes, and

Authorities Having Jurisdiction (AHJ).

• Language and instructional requirements must be clearly disseminated on any local displays.

• Strobes can, under certain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have sh own that certain people, even when they he ar

a fire alarm signal, do not respond to or comprehend the

meaning of the signal. Audible devices, such as horns and

bells, can have different tonal patterns and frequencies. It is

the property owner's responsibility to conduct fire drills and

other training exercises to make people aware of fire alarm

signals and instruct them on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause

temporary or permanent hearing loss.

A life safety system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries have

been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control panel. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premises to a central monitoring station may be out of service or temporarily disabled. For added protection against telephone line

failure, backup radio transmission systems are recommended.

The most common cause of life safety system malfunction is

inadequate maintenance. To keep t he entire life safety sys tem in

excellent working order , ongoing mai ntenance is required per the

manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be followed. Environments with large amounts of dus t, dirt, or hig h air

velocity require more frequent maintenance. A maintenance

agreement should be arranged through the local manufacturer's

representative. Maintenance should be scheduled monthl y or as

required by National and/or local fire codes and should be performed by authorized professional life saftety system installers

only . Adequate written reco rds of all inspe ctions should be kept.

Limit-D-1-2013

2 PRELIMINARY: Firelite Wireless Sensor Network — P/N LS10036-000FL-E:N0 10/10/2013

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is

energized. Do not attempt to install, service, or operate this

unit until manuals are read and understood.

CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or

deletion of system components, or after any modification,

repair or adjustment to system hardware or wiring. All components, circuits, system operations, or sof tware functions known

to be affected by a change must be 100% tested. In addit ion,

to ensure that other operations are not inadvertently affected,

at least 10% of initiating devices that are not directly affected

by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º

C/32-120º F and at a relative humidity 93% ± 2% RH (noncondensing) at 32°C ± 2°C (90°F ± 3°F). However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with

a normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all initia ting and indicating device loops. Most devices cannot tol erate more than a

10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subject ed to light ning induced transients. Although no system is completely

immune from lightning transients and interference, proper

grounding will reduce susceptibility. Overhead or outside aerial

wiring is not recommended, due to an increased susceptibility

to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Overtightening may damage threads, resulting in reduced terminal

contact pressure and difficulty wit h screw terminal removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the

body. Use static suppressive packaging to protect electronic

assemblies removed from the unit.

Follow the instructions in the inst al lati on, opera ting, and pr ogramming manuals. These instructions must be followed to

avoid damage to the control panel and associated equipment.

FACP operation and rel iability depend upon prop er inst allatio n.

Precau-D1-9-2005

HARSH™, NIS™, and NOTI•FIRE•NET™ are all trademarks; and Acclimate® Plus, FlashScan®, NION®, NOTIFIER®, ONYX®, ONYXWorks®, UniNet®,

VeriFire®, and VIEW® are all registered trademarks of Honeywell International Inc.HARSH™ is a trademark; and Acclimate®, FlashScan®, NION®, and

VIEW® are all registered trademarks of Honeywell International Inc. MULTI-NET™, Multi-Net Manager™, Unimode Network™, Unimode Network

Manager™, and Uni-Tility™ are trademarks of Tyco Integrated Security. Echelon® is a registered trademark and LonWorks™ is a trademark of Echelon

Corporation. ARCNET® is a registered trademark of Datapoint Corporation. Microsoft® and Windows® are registered trademarks of the Microsoft

Corporation.

©2013 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

PRELIMINARY: Firelite Wireless Sensor Network — P/N LS10036-000FL-E:N0 10/10/2013 3

Page 4

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make

frequent upgrades to the embedded software in our products. To ensure that you are installing and programming the latest

features, we strongly recommend that you download the most current version of software for each product prior to

commissioning any system. Contact Technical Support with any questions about software and the appropriate version for a

specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about our

online Help or printed manuals, you can email us.

Please include the following information:

•Product name and version number (if applicable)

•Printed manual or online Help

•Topic Title (for online Help)

•Page number (for printed manual)

•Brief description of content you think should be improved or corrected

•Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact Technical

Services.

4 PRELIMINARY: Firelite Wireless Sensor Network — P/N LS10036-000FL-E:N0 10/10/2013

Page 5

Table of Contents

Section 1: About This Guide ..................................................................................................10

1.1: Purpose ........................................................................................................................................................10

1.2: Assumed Knowledge...................................................................................................................................10

1.2.1: Additional References .......................................................................................................................10

1.3: Site Survey...................................................................................................................................................10

1.4: Abbreviations and Meanings.......................................................................................................................11

Section 2: W-GATE.................................................................................................................12

2.1: Description...................................................................................................................................................12

2.2: Agency Approvals .......................................................................................................................................12

2.2.1: FCC....................................................................................................................................................12

2.3: Specifications...............................................................................................................................................13

2.3.1: Environmental Specification .............................................................................................................13

2.4: Installing W-GATE ......................................................................................................................................13

2.4.1: Before Installing................................................................................................................................13

2.5: Mounting & Wiring.....................................................................................................................................14

2.5.1: Mounting ...........................................................................................................................................14

2.5.2: Wiring................................................................................................................................................16

2.5.3: W-GATE Powered from SLC ...........................................................................................................17

2.5.4: W-GATE Powered from an External +24VDC source .....................................................................18

2.6: Configuration and Programming.................................................................................................................19

2.6.1: Without a PC-based Configuration Tool...........................................................................................19

Create a New Profile ............................................................................................................................19

Assign a Previously Created Profile Using a Distributor.....................................................................20

Removing a Profile...............................................................................................................................20

Create Mesh Network................................................................................................ ...........................20

2.6.2: With a PC-based Configuration Tool................................................................................................21

Assign Profile with PC Tools....................................................................................... ........................21

Removing Profile with PC Tools .........................................................................................................22

Mesh Formation with PC Tools ............................................................ ...............................................23

2.6.3: Profile Distribution............................................................................................................................23

2.6.4: SLC Configuration ............................................................................................................................24

2.7: Operations....................................................................................................................................................25

2.7.1: W-GATE Modes of Operation..........................................................................................................25

Start Up............................................... .................................. .................................. ..............................25

Factory Default...................................... .................................. .............................................................25

Profile Configured................................................................................................................................25

Mesh Formation....................................................................................................................................26

Initial Mesh Optimization.............................................................. ................................. ......................26

Normal Mode............................................................................................... .........................................26

Rescue Mode........................................................................................................................................26

Mesh Optimization...............................................................................................................................27

Bootloader ............................................................................................................................................27

2.7.2: Magnet Sensor Activations................................................................................................................27

Profile Magnetic Sensor.......................................................................................................................27

Mesh Formation Magnetic Sensor..................................... .................................. .................................27

2.7.3: LED Indications.................................................................................................................................27

2.7.4: Lock/Unlock W-GATE .....................................................................................................................31

Lock/Unlock W-GATE through PC tools............................................................................................31

Password Reset.....................................................................................................................................31

2.7.5: Weak Link Trouble Reporting...........................................................................................................32

Disabling Trouble Reporting at the W-GATE Using PC Tools...........................................................32

2.7.6: Collapse Network Command.............................................................................................................33

Collapsing Mesh Network Using PC Tools.........................................................................................33

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 5

Page 6

Table of Contents

2.7.7: Silence Network Command...............................................................................................................34

Silencing Mesh Network Using PC Tools............................................................................................34

2.7.8: Multiple Wireless Sensor Network Installation Restrictions.............................................................35

2.7.9: Avoiding RF Interference..................................................................................................................35

Section 3: Wireless Display Driver (W-DIS-D)......................................................................36

3.1: Description...................................................................................................................................................36

3.2: Agency Approvals ......................................................................................................................................37

3.2.1: FCC....................................................................................................................................................37

3.3: Specifications...............................................................................................................................................37

W-DIS-D...............................................................................................................................................37

ANN-80 ................................................................................................................................................38

3.3.1: Environmental Specification .............................................................................................................38

3.4: Features........................................................................................................................................................38

W-DIS-D...............................................................................................................................................38

Listed to UL standard ANSI/UL 864 edition. ......................................................................................38

ANN-80 ................................................................................................................................................38

3.5: Mounting & Wiring......................................................................................................................................39

3.5.1: Mounting W-DIS-D...........................................................................................................................39

3.5.2: Wiring................................................................................................................................................41

3.5.3: ANN-80 .............................................................................................................................................41

Mounting ..............................................................................................................................................41

Wiring ..................................................................................................................................................41

3.6: W-DIS-D Configuration...............................................................................................................................42

3.6.1: Assigning Profiles..............................................................................................................................42

Assign Profile with PC Tools...............................................................................................................42

Assigning a Profile to a W-DIS-D with W-GATE or Distributor........................................................43

3.6.2: Mesh Formation.................................................................................................................................43

3.6.3: Removing Profiles .............................................................................................................................44

Restoring a W-DIS-D to Factory Default Without Using the PC-based Configuration Tool..............44

Restoring a W-DIS-D to Factory Default with the PC-based Configuration Tool...............................44

3.7: ANN-80 Configuration................................................................................................................................45

3.8: W-DIS-D Operations ...................................................................................................................................46

3.8.1: W-DIS-D Operations.........................................................................................................................46

Modes of Operation Not in a Mesh Network.......................................................................................46

Modes of Operation as a Mesh Participant...........................................................................................47

SLC Operation......................................................................................................................................47

3.8.2: W-DIS-D LED Indications................................................................................................................47

3.8.3: Switches.............................................................................................................................................51

3.9: ANN-80 Operations.....................................................................................................................................52

3.9.1: Buttons and Switches.........................................................................................................................52

3.9.2: Visual Indicators................................................................................................................................53

3.9.3: Audible Indicators .............................................................................................................................54

3.9.4: Event Messaging................................................................................................................................54

LCD UI Not in Network.......................................................................................................................54

Mesh Formation In Progress.................................................................................................................54

Low Battery Event................................................................................................................................55

Trouble Jamming Event..........................................................................................................

Duplicate Address.................................................................................................................................55

Degraded Connection ...........................................................................................................................56

System Initialization.............................................................................................................................56

System Normal .....................................................................................................................................56

Tamper Event........................................................................................................................................56

Weak Link ............................................................................................................................................57

Key Bus Trouble...................................................................................................................................57

Capacity Exceeded................................................................................................................................57

Maximum Gateways.............................................................................................................................57

..............55

6 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 7

Table of Contents

3.9.5: Clearing messages.............................................................................................................................57

3.9.6: LED Indications.................................................................................................................................58

Section 4: Devices..................................................................................................................60

4.1: Description...................................................................................................................................................60

Subsystem Overview.................................................... ................................. .......................................60

4.2: Agency Approvals......................................................................................................................................60

4.2.1: FCC....................................................................................................................................................60

4.3: Specifications...............................................................................................................................................61

4.4: Installing Devices ........................................................................................................................................61

4.5: Mounting & Wiring.....................................................................................................................................61

4.6: Configuration and Programming.................................................................................................................61

4.6.1: Assigning Profiles .............................................................................................................................62

Assigning Profile Using PC Tools .......................................................................................................62

Assigning a Profile to a Detector with a W-GATE or Distributor.................................................. .....63

4.6.2: Distributor Mode ...............................................................................................................................64

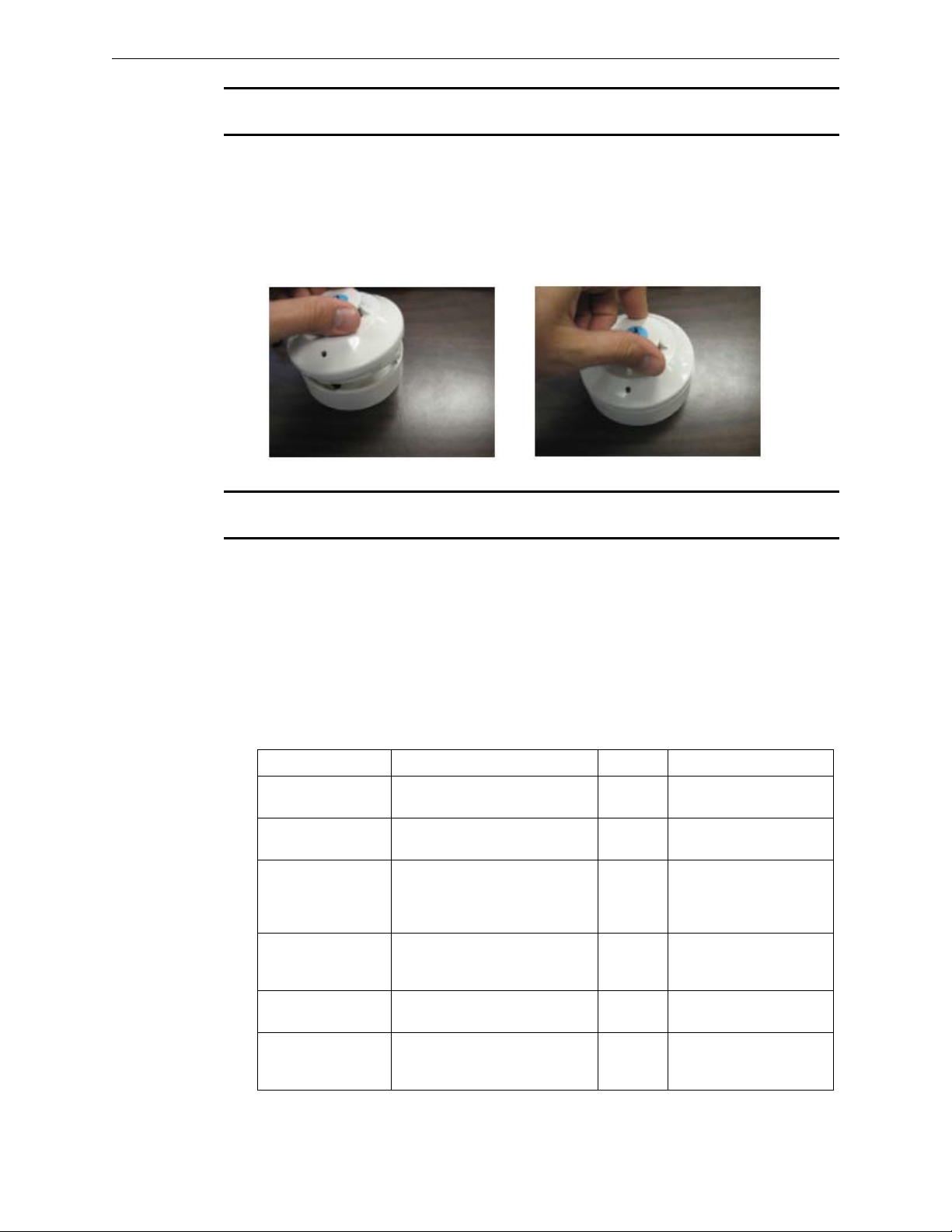

Converting a Device into a Distributor ................................................................................................64

Converting a Distributor Back into a Device.......................................................................................65

4.6.3: Mesh Formation.................................................................................................................................65

4.6.4: Restoring a Device to Factory Default..............................................................................................65

Removing Profiles Without PC-based Configuration Tool..................................................................65

Removing a Profile with PC Tools.......................................................................................................66

4.7: Device Operations .......................................................................................................................................66

4.7.1: Modes of Operation...........................................................................................................................66

Factory Default...................................... .................................. .............................................................66

Profile Assigned ...................................................................................................................................66

Bootloader ............................................................................................................................................67

Distributor.............................................................................................................................................67

Mesh Participant...................................................................................................................................67

4.7.2: LED Indications.................................................................................................................................67

Section 5: USB Adapter..........................................................................................................72

5.1: Introduction..................................................................................................................................................72

5.2: Agency Approvals......................................................................................................................................72

5.2.1: FCC....................................................................................................................................................72

5.3: Specifications...............................................................................................................................................73

5.3.1: Electrical Specifications...................................................................................................................73

5.3.2: Serial Communication Specification................................................................................................73

5.3.3: Mechanical Specifications................................................................................................................73

5.3.4: Environmental Specifications............................................................................................................73

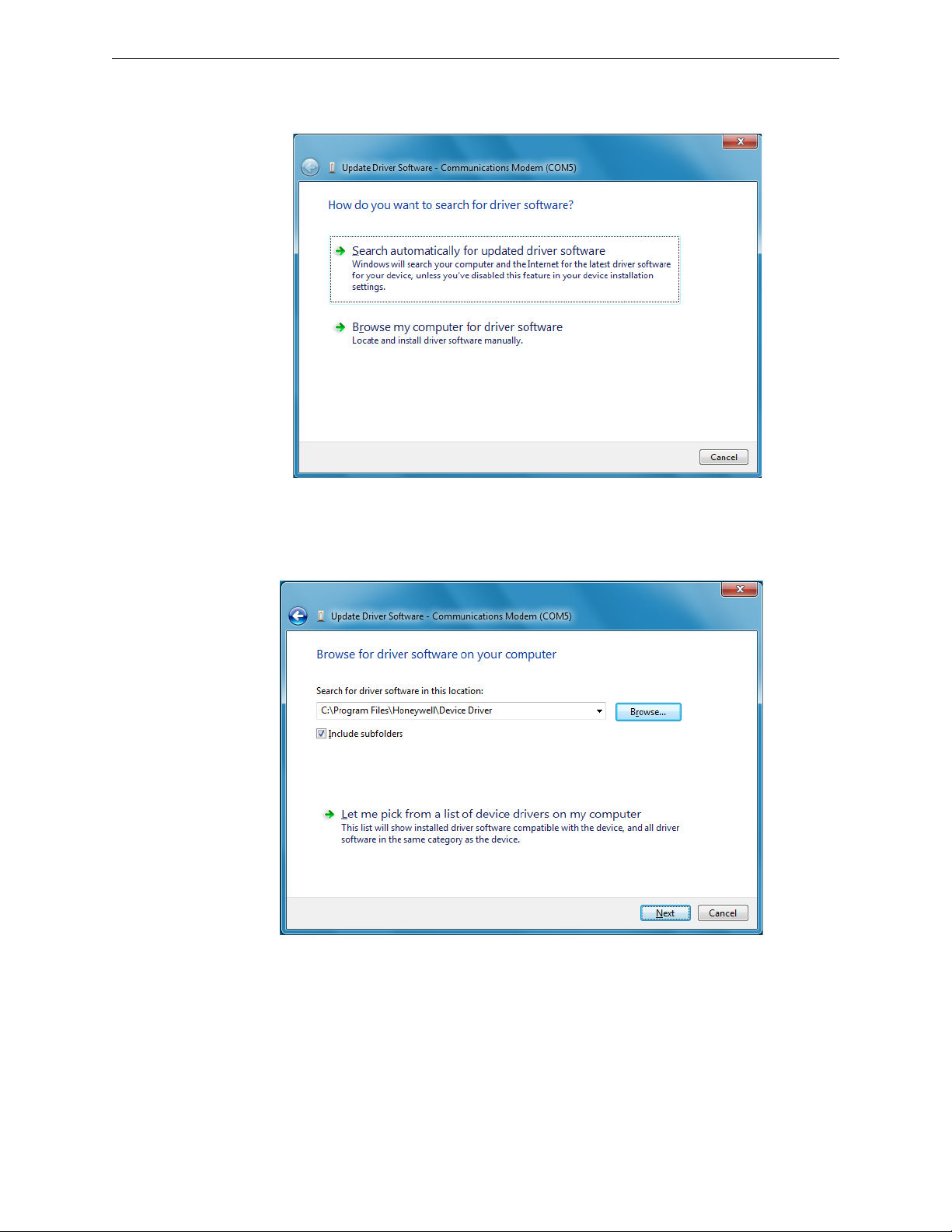

5.4: Driver Installation........................................................................................................................................74

Appendix A: Site Survey........................................................................................................78

A.1: Description..................................................................................................................................................78

A.1.1: Conducting Site Survey at the Job Site ............................................................................................78

Link Quality Test.............................................. .................................. ..................................................78

Results of Link Test..............................................................................................................................79

Link Quality Test and RF Scan Test....................................................................................................80

Conduct a Link Test .............................................................................................................................80

Results of Link Test..............................................................................................................................81

Results of RF Scan Test .......................................................................................................................81

Appendix B: PC tools.............................................................................................................82

B.1: Description..................................................................................................................................................82

B.1.1: Launching PC Tools .........................................................................................................................82

B.1.2: Creating Jobsite.................................................................................................................................83

B.1.3: Opening Jobsite.................................................................................................................................84

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 7

Page 8

Table of Contents

Appendix C: Troubleshooting and Testing..........................................................................86

C.1: Troubleshooting...........................................................................................................................................86

C.2: Testing W-GATE and Devices ....................................................................................................................86

C.2.1: Testing LED Indications...................................................................................................................86

C.3: Testing Wireless Network...........................................................................................................................86

C.3.1: Network Topology............................................................................................................................87

Parent-Child Devices............................................................................................................................87

Orphan Devices ....................................................................................................................................87

Class A Compliance .............................................................. ...............................................................87

C.3.2: History Events...................................................................................................................................88

C.3.3: Network Snapshots ...........................................................................................................................88

C.3.4: Network Statistics.............................................................................................................................88

C.3.5: Device Attributes ..............................................................................................................................88

Index ........................................................................................................................................90

8 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 9

Table of Contents

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 9

Page 10

About This Guide Purpose

Section 1: About This Guide

1.1 Purpose

The Firelite Wireless Sensor Network user’s manual provides an overview of the following:

• Wireless fire alarm system

• Instructions for installing and configuring the wireless devi ces

• Information on monitoring the status of the wireless devices

• Removal and replacement procedures of the W-GATE and W-DIS-D

• Testing, maintenance and firmware upgrade information of the W-GATE and W-DIS-D.

1.2 Assumed Knowledge

The document is created with the assumption that all users are familiar with working on a PC and

laptop for configuration purposes. Installers should be familiar with the Fire Alarm and Related

Service Standards.

The terminology and level of details of this document reflect this assumption.

1.2.1 Additional References

Model Description Manual

W-SD355 Wireless LiteSpeed

W-SD355T Wireless LiteSpeed

W-H355R Wireless LiteSpeed Heat

W-H355 Wireless LiteSpeed Heat

W-MMF Monitor Module W-MMF Wireless Monitor Module. Manual Part

1.3 Site Survey

A site survey is recommended to assess and qualify the site prior to installing the Wireless Fire

Alarm system. The site survey utility allows you to perform the Link quality test and radio frequency (RF) assessment of the site. This information is used for site qualification, maximum device

spacing identification, and configuring the network. This helps to optimize the reliability and performance of the wireless network in the wireless fire alarm system. Conduct a site survey, and

ensure there are no obstructions for using RF communications. For more information on a site survey, refer to Appendix A:, "Site Survey".

Detector, Photo

Detector, Photo/Heat

sensorHeat, Rate Of Rise

135

sensor Heat, Fixed

Temp135

W-SD355 and W-SD355T Intelligent Wireless

Photoelectric Smoke Sensors.

Manual part number for the above devices- I564081-000

W-H355R and W-H355 and Intelligent Wireless

Temperature Sensors.

Manual part number for the above devices- I564082-000

number - I56-4083-000

10 PRELIMINARY: Firelite Wireless Sensor Network — P/N LS10036-000FL-E:N0 10/09/2013

Page 11

Abbreviations and Meanings About This Guide

1.4 Abbreviations and Meanings

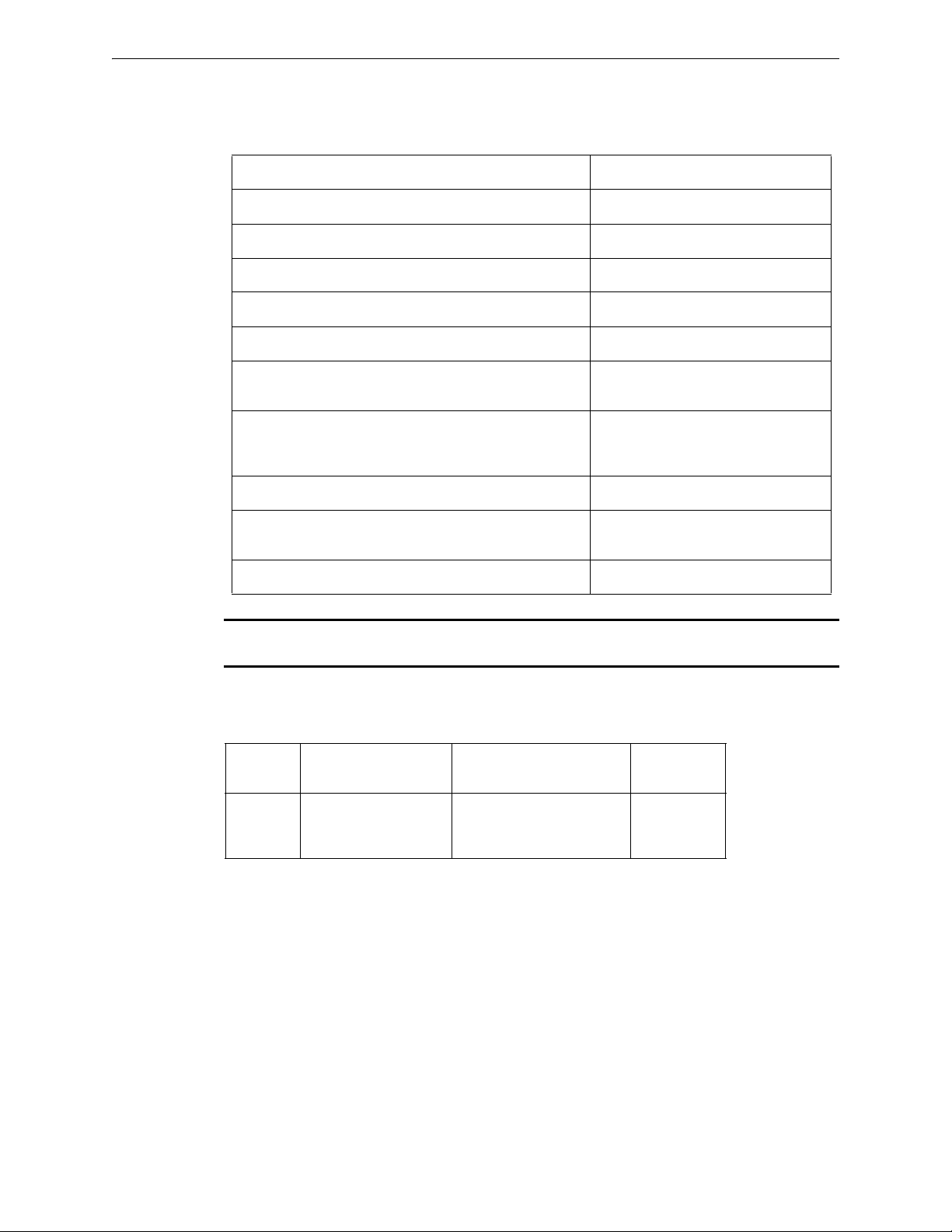

The following table lists the abbreviations and their definitions used in this manual.

Abbreviation Definition

AHJ Authority Having Jurisdiction

ANSI American National Standards Institute

dBm Milli Decibel

FACP Fire Alarm control Panel

FCC Federal Communications Commission

ISM Industrial, Scientific and Medical Radio

LCD Liquid Crystal Display

LED Light Emitting Diode

mA Milliampere

MHz Megahertz

NFPA National Fire Protection Association

PC Personal Computer

RF Radio Frequency

SLC Signaling Line Circuit

UI User Interface

UL Underwriters Labaratories

W-DIS-D Wireless Display Driver

W-GATE Wireless Gateway

Bands.

PRELIMINARY: Firelite Wireless Sensor Network — P/N LS10036-000FL-E:N0 10/09/2013 11

Page 12

W-GATE Description

Section 2: W-GATE

2.1 Description

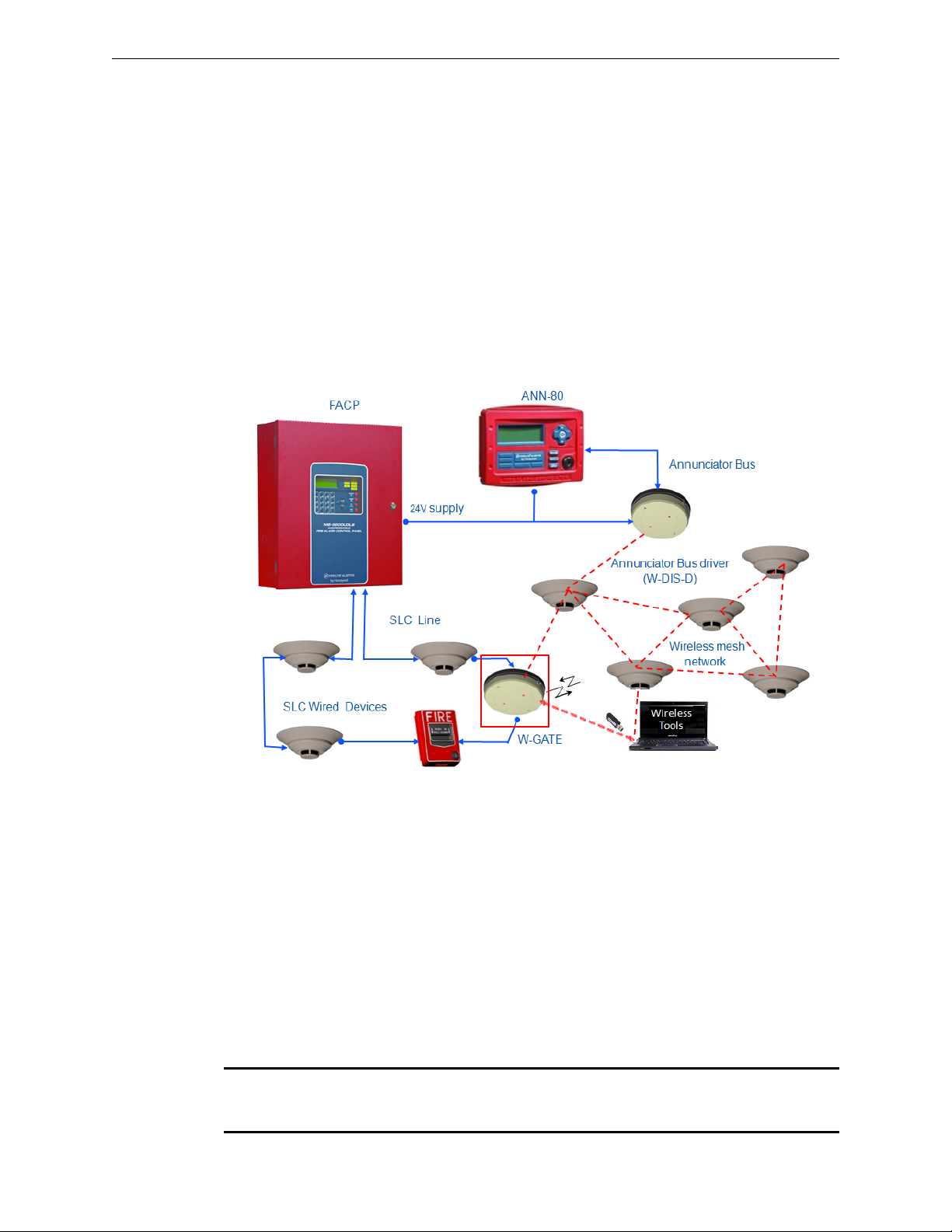

The W-GATE is a device in a wireless fire system that acts as a bridge between fire alarm control

panels and wireless fire devices. All wireless fire devices communicate with the W-GATE over the

wireless network formed by the devices and the W-GATE.

The Wireless Sensor Network includes a W-DIS-D (Wireless Display Driver). The W-DIS-D and

ANN-80 are required for the display of wireless specific events. W-DIS-D and ANN-80 are

explained in detail in Chapter 3.

The W-GATE is powered by either the SLC loop or from any ext ernal 24VDC UL listed power

supply. The W-GATE uses LiteSpeed proto col on the SLC to communicate with the panel and a

proprietary wireless protocol to communicate with wireless fire devices. The following graphic is

an illustration of the components of the Firelite Wireless Sensor Network.

Figure 2.1 Firelite Wireless Sensor Network

2.2 Agency Approvals

2.2.1 FCC

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

FCC ID PV3WFSGW

WARNING: CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY THE

MANUFACTURER COULD VOID THE USER’S AUTHORITY TO OPERATE THE EQUIPMENT.

12 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 13

Specifications W-GATE

2.3 Specifications

Following are the specifications of the W-GATE.

Specifications Data

External Supply Electrical Ratings 18V-30V

SLC Electrical Ratings 15V-30V

Maximum current when using the external supply 40mA

Maximum current when using the SLC power supply 24mA

Maximum SLC Resistance 50 Ohms

Minimum signal strength level needed at the receiver for a

primary path with weak link trouble reporting enabled.

Minimum signal strength level needed at the receiver for a

secondary path or primary path with weak link trouble

reporting disabled.

Maximum ambient noise level -90dBm*

Maximum RF Power Output +17dBm (Tx power level without

Radio Frequency Lower ISM Band (915MHz).

NOTE: Devices that do not meet the minimum signal strength or have an ambient noise level

that exceeds the limit are not allowed to join the mesh network.

2.3.1 Environmental Specification

System

W-GATE 0°C-49°C / 32°F-120°F -10°C- 60°C / 14°F-140°F 10 to 93% RH

Operating

Temperature

Storage

Temperature

-50dBm

Must be 15 dBm higher than the noise

floor down to a minimum of -87dBm*

antenna)

Humidity

Non-

condensing

2.4 Installing W-GATE

2.4.1 Before Installing

Choose a location for the W-GATE that is clean, dry, and vibration-free. The area should be readily

accessible with sufficient room to easily install and maintain the W-GATE. Metal obstructions

impede the radio frequency communication and should be avoided. Carefully unpack the system

and inspect for shipping damage if any. All wiring must comply with the national and local codes

for fire alarm systems.

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 13

Page 14

W-GATE Mounting & Wiring

2.5 Mounting & Wiring

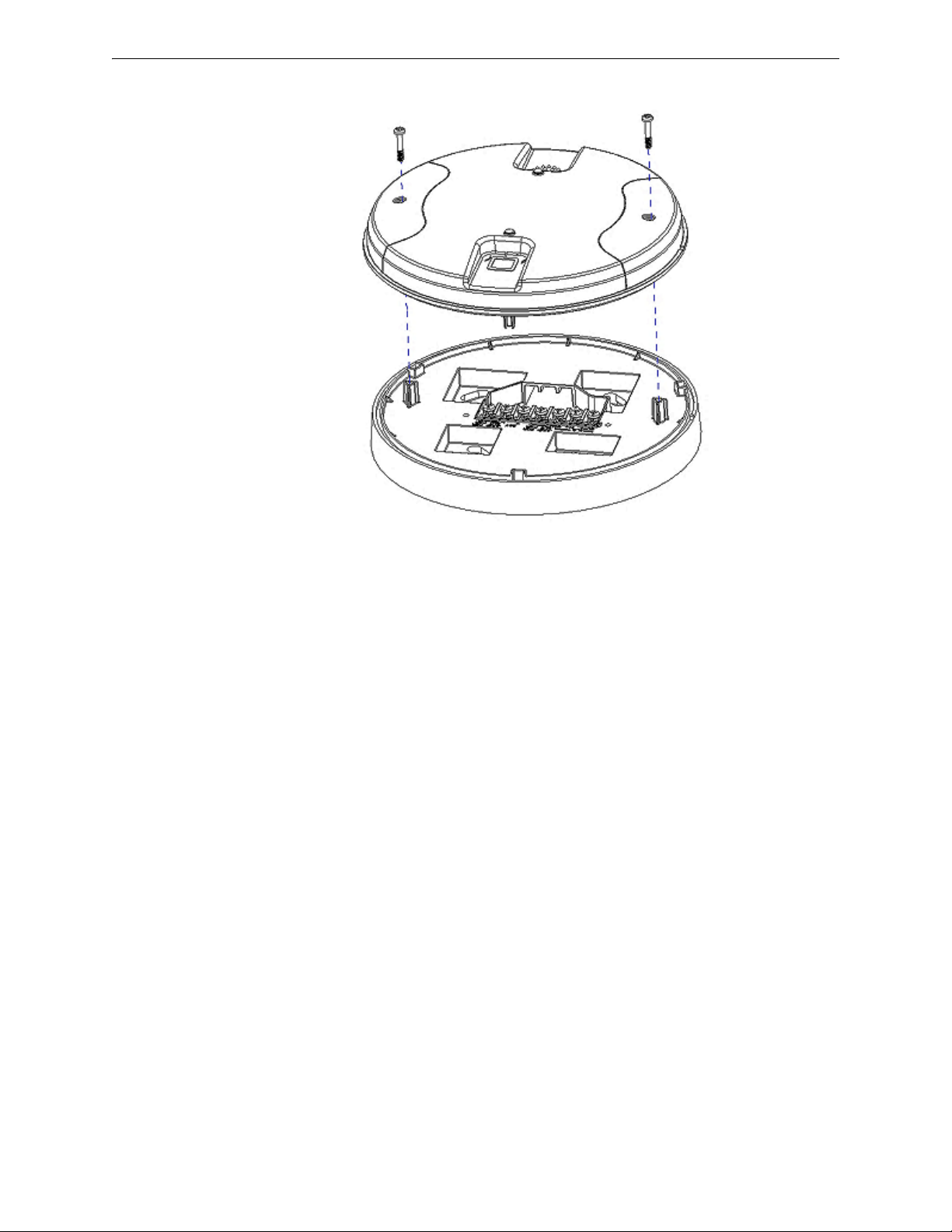

2.5.1 Mounting

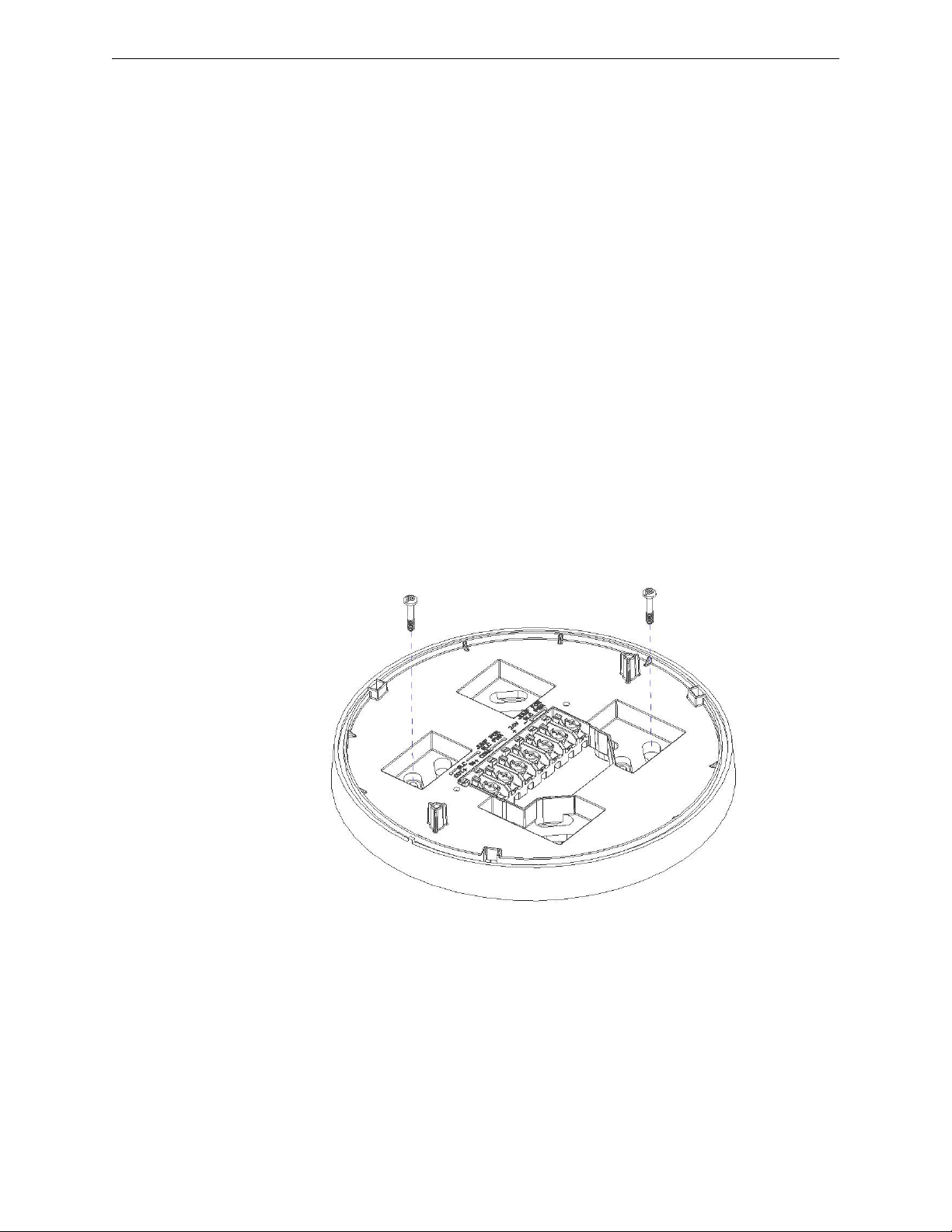

The W-GATE has two major pieces, the cover and the mounting plate. The mounting plate is

mounted to the wall or ceiling, and field wiring is connected to it. The cover contains the PC board

and is fastened to the mounting plate once the wiring is connected.

Mount the mounting plate directly to an electrical box on the ceiling or wall. The plate mounts

directly to 4˝ square (with and without plaster ring), 4˝ octagon, 3 1/2˝octagon, single gang or double gang junction boxes. If an electrical box is not available, the mounting plate can be mounted to

any flat surface and the wiring can be connected via the knockout points in the mounting plate.

To mount the W-GATE, do the following:

1. Pull the wiring through the opening in the mounting plate.

2. Mount the mounting plate to the junction box or ceiling. See figure 2.2.

3. Connect field wiring to the terminals, as described in section 2.5.2, "Wiring".

4. Connect necessary jumpers where applicable, as described in section 2.5.3, "W-GATE

Powered from SLC".

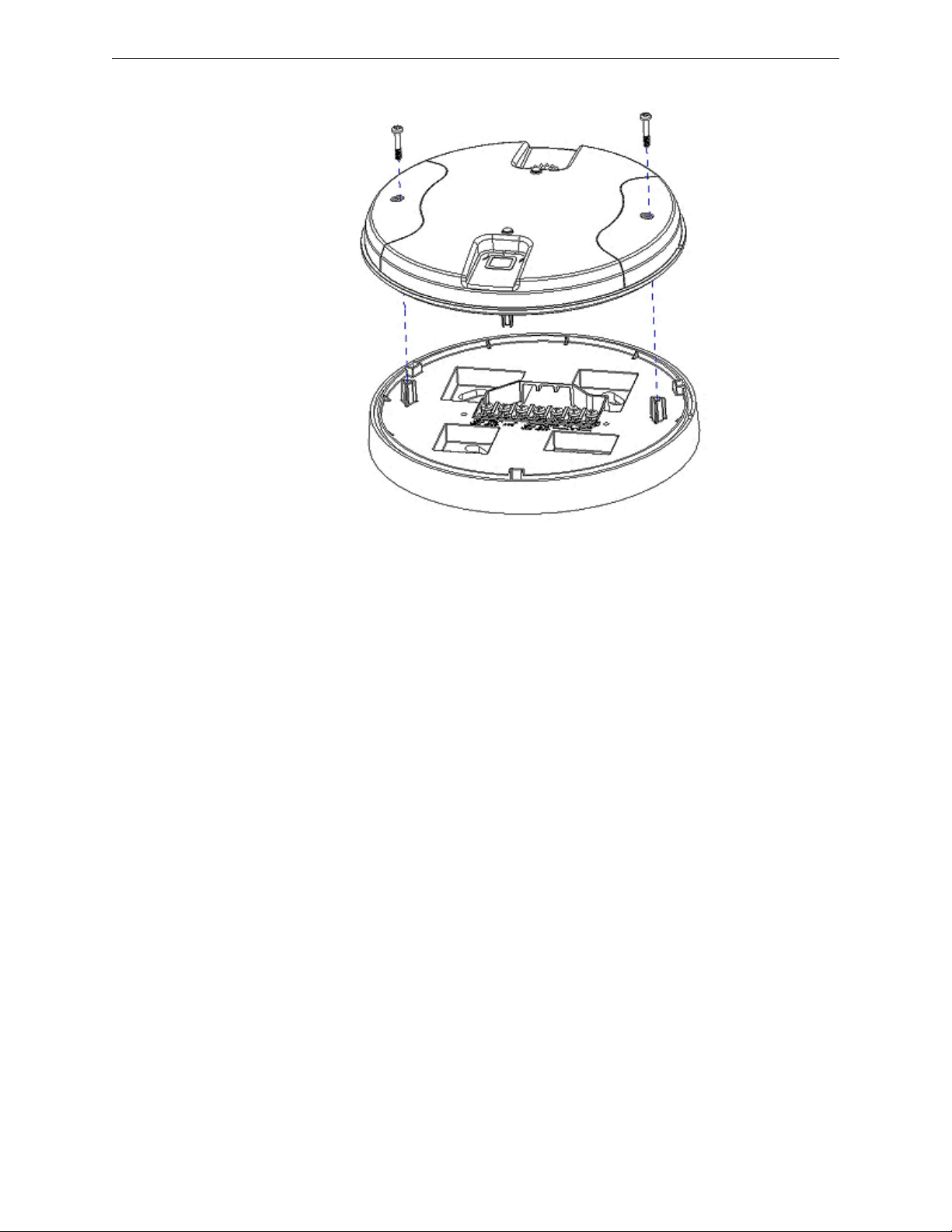

5. To mount the cover, align the locating pins on the cover to the corresponding slots in the

mounting plate. See Figure 2.3, "Cover Attaching to Mounting Plate".

6. Secure the cover by tightening the mounting screws.

Figure 2.2 Mounting Plate

14 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 15

Mounting & Wiring W-GATE

Figure 2.3 Cover Attaching to Mounting Plate

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 15

Page 16

W-GATE Mounting & Wiring

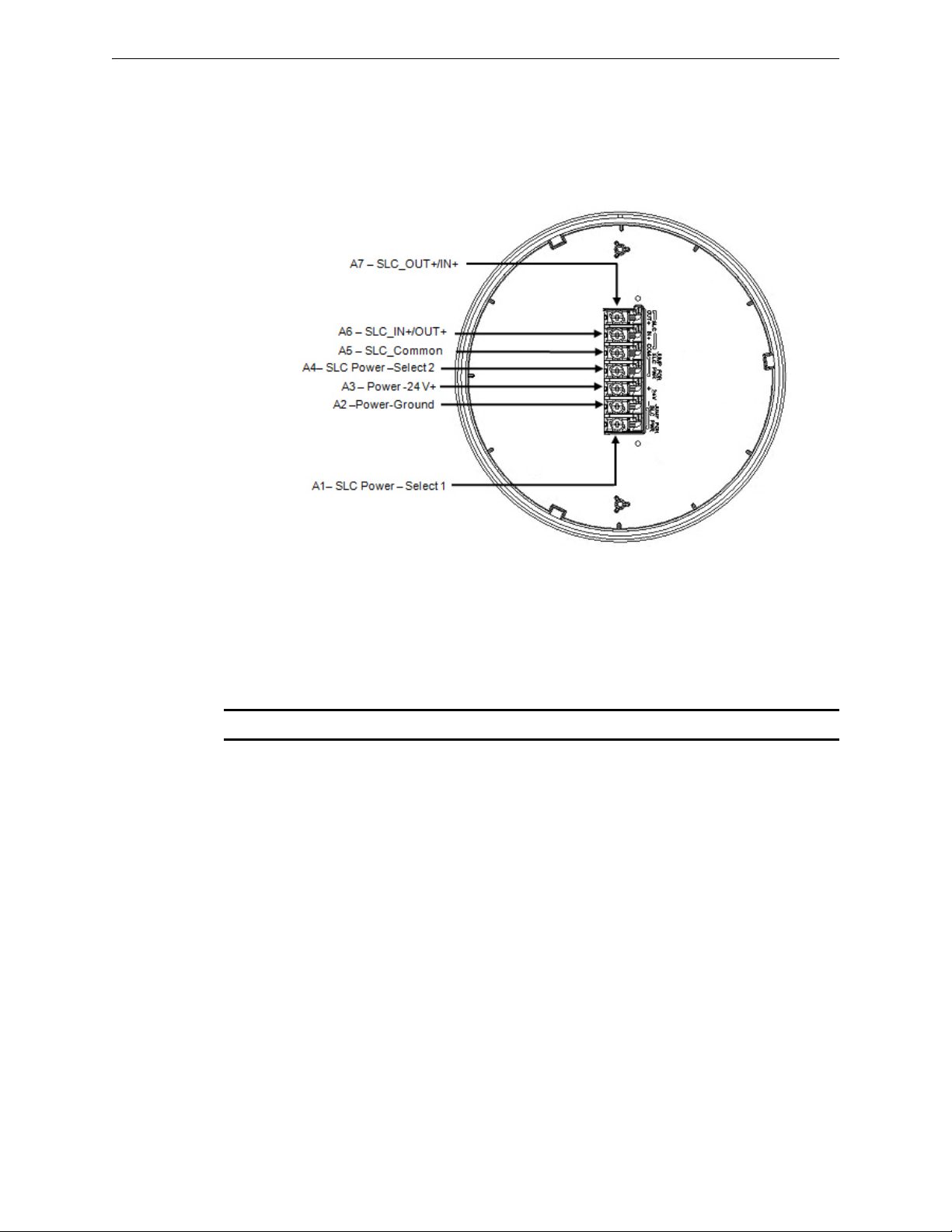

2.5.2 Wiring

• All wiring must be installed in compliance with the National Electrical Code and the local

codes having jurisdiction.

• 12-18 AWG is recommended.

Figure 2.4 (Wiring diagram with terminal descriptions)

For wiring connections, follow this procedure:

• Strip about 3/8” of insulation from the end of the wire.

• Then, to make the wire connection, slide the bare end of the wire und er the appropriate

clamping plate, and tighten the clamping plate screw.

NOTE: Do not loop the wire under the clamping plate.

16 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 17

Mounting & Wiring W-GATE

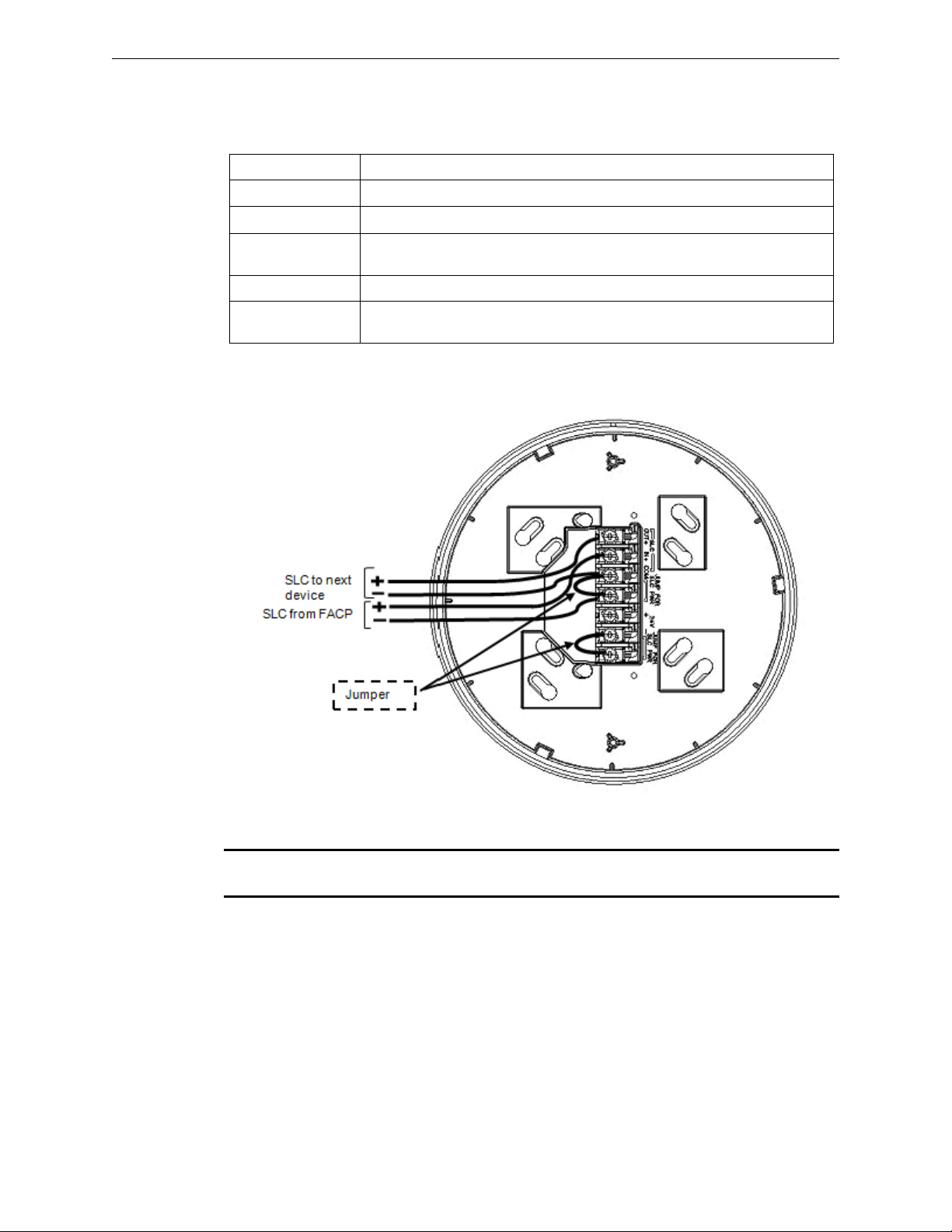

2.5.3 W-GATE Powered from SLC

To power the W-GATE using the signal line circuit, connect it as described in table 2.1 below:

Terminal Pins Description

A5 & A7 SLC Common & SLC Output/Input

A5& A6 SLC Common & SLC Input/Output

A4 & A5 Jumper selection to enable power from the SLC supply (Insert Jumper when using

SLC power)

A3 Unused

A1 & A2 Jumper selection to disable power from the external supply. (Insert Jumper when

using SLC power)

Table 2.1

Figure 2.5 Wiring Connections (W-GATE powered from SLC)

NOTE: It is recommended to use the same wire gauge if there are multiple connections to the

same terminal.

The W-GATE provides isolation of short circuits on the SLC in class A installations, that use the

A6 and A7 connections as an in and out connection. A5 is common for SLC wiring that enters and

leaves. Class B wiring that terminates at the W-GATE can use either the A6 or A7 connection for

the SLC positive. SLC connections are power limited by the panel. An interruption in the SLC that

causes a loss of power at the W-GATE for more than 100ms may result in a trouble condition and

loss of fire protection provided by the wireless devices for up to 15 minutes. Using an external 24V

power source (not SLC power) is recommended for installations that require fire protection in the

presence of short circuits, including class A applications and applications that utilize isolator modules.

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 17

Page 18

W-GATE Mounting & Wiring

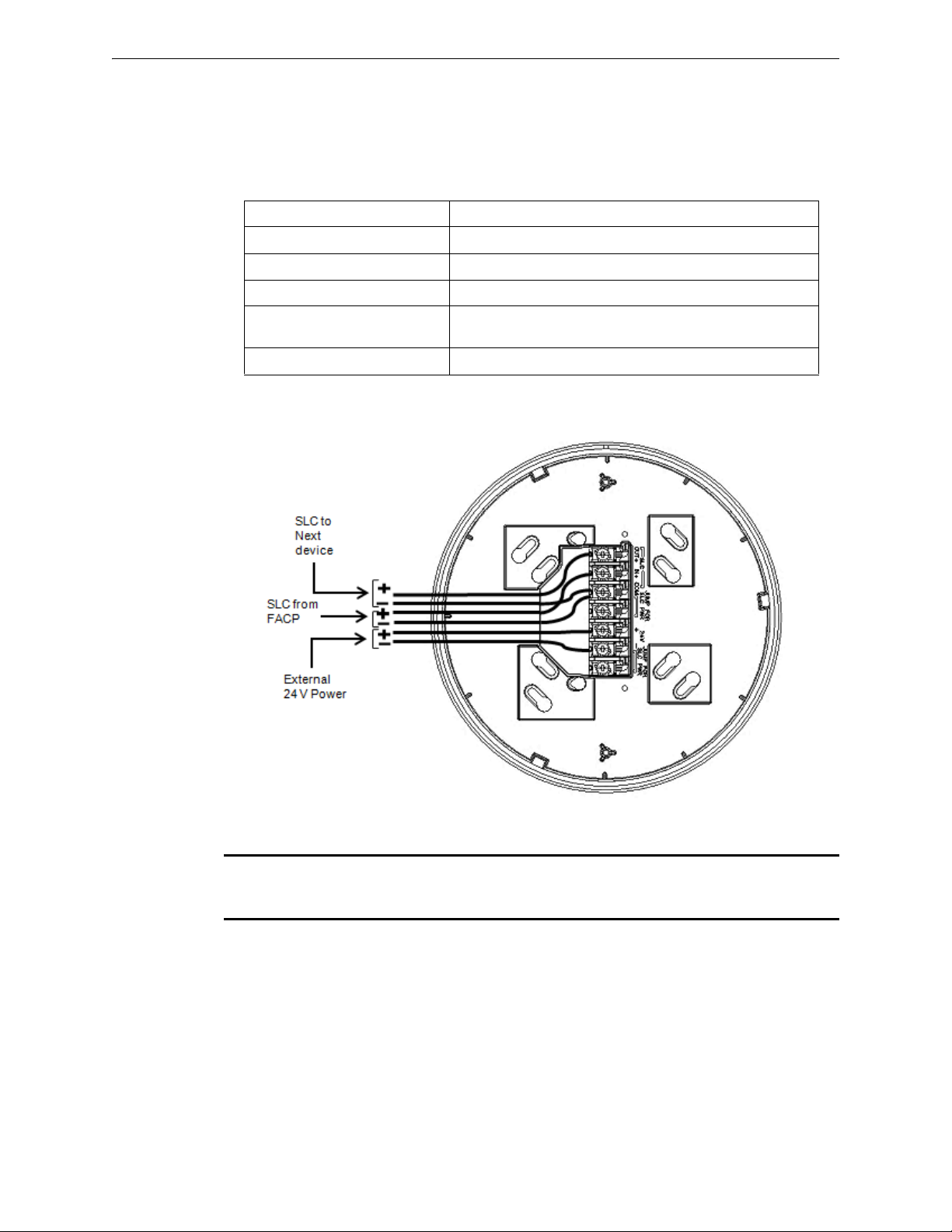

2.5.4 W-GATE Powered from an External +24VDC source

To power the W-GATE using a +24VDC source, connect the W-GATE as described in table 2.2

below.

Terminal Pins Devices Powered

A5 & A7 SLC Input/output

A5 & A6 SLC Input/output

A4 Unused

A2 & A3 +24VDC input. Voltage range from 18VDC to 30VDC. Use only

power limited device circuits.

A1 Unused

Table 2.2

Figure 2.6 Wiring Connections -W-GATE Powered from an External +24VDC source

NOTE: Terminal A5 is referenced more than once in the above connections. It is recommended

to use wire of the same gauge for all connections to A5 and use the same wire gauge if there are

multiple connections to the same terminal.

The W-GATE provides isolation of short circuits of the SLC in class A installations that use the A6

and A7 as an in and out connection. A5 is common for in and out SLC wiring. Class B SLC wiring

that terminates at the W-GATE can use either the A6 or A7 connection for the SLC positive. SLC

connections are power limited by the panel. 24VDC must be power limited by the so urce.

18 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 19

Configuration and Programming W-GATE

2.6 Configuration and Programming

The goal of configuring and/or programming the W-GATE is to:

1. Create a profile - A profile is a set of parameters that binds together a W-GATE and the devices

in a mesh network.

2. Distribute the profile to every device that will be a part of the mesh.

3. Form the mesh - The mesh cannot be formed until the profile is assigned to the W-GATE. The

profile contains a mesh ID and, if required, a password, that are used when forming the

associations. Creating and distributing the profile will enable all the devices that have that

profile to form associative links when the mesh is formed. All devices, including the W-GATE,

require a common profile.

This section shows how to configure/program an W-GATE with a profile, how to distribute that

profile to other devices, and how to form all these devices into a mesh. These processes may be performed with or without using PC-based configuration tool.

2.6.1 Without a PC-based Configuration Tool

This section shows the configuration of the W-GATE using only a magnet and a screw driver. For

configuration instructions using the PC-based configuration tool, refer to 2.6.2, "With a PC-based

Configuration Tool".

There are two ways to provide a W-GATE with a profile without using a configuration tool.

• Create a new profile using the W-GATE

• Assign a previously created profile to the W-GATE using a distributor.

Create a New Profile

To create a unique profile in the W-GATE without using the PC-based configuration tool, perform

the following steps.

1. Start with the device powered off. The process is performed during the start-up.

2. Power on the W-GATE using SLC power or external +24V. This can be done either by

attaching the W-GATE to its mounting plate with the terminals already energized, or by

connecting the SLC or external source wiring to a W-GATE that is already installed in its

mounting plate.

3. Verify if the W-GATE is in the factory default state; if it is in the factory default state, both the

LEDs on the W-GATE flash red (double blink) every second for ten seconds. If the LEDs are

yellow, refer to section below on removing a profile.

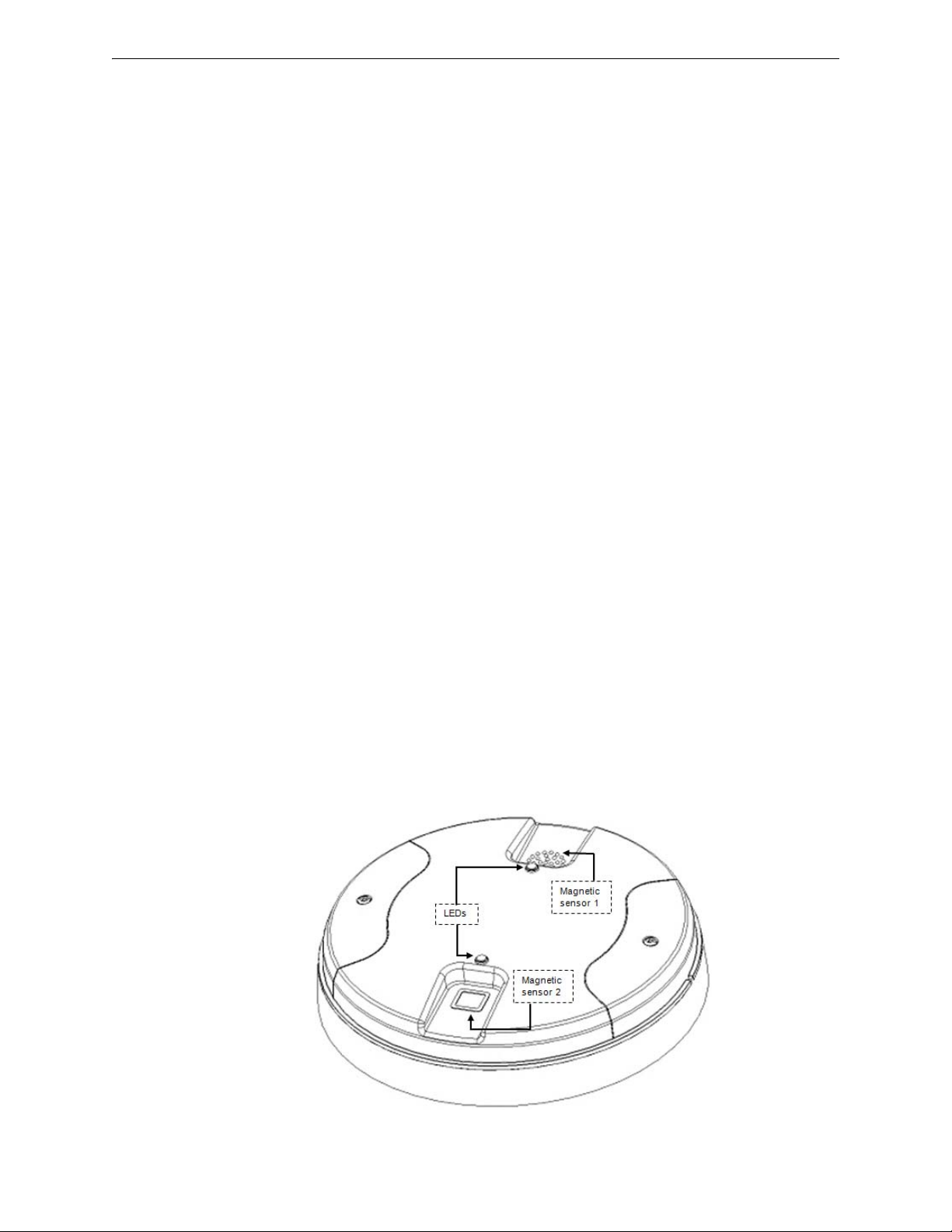

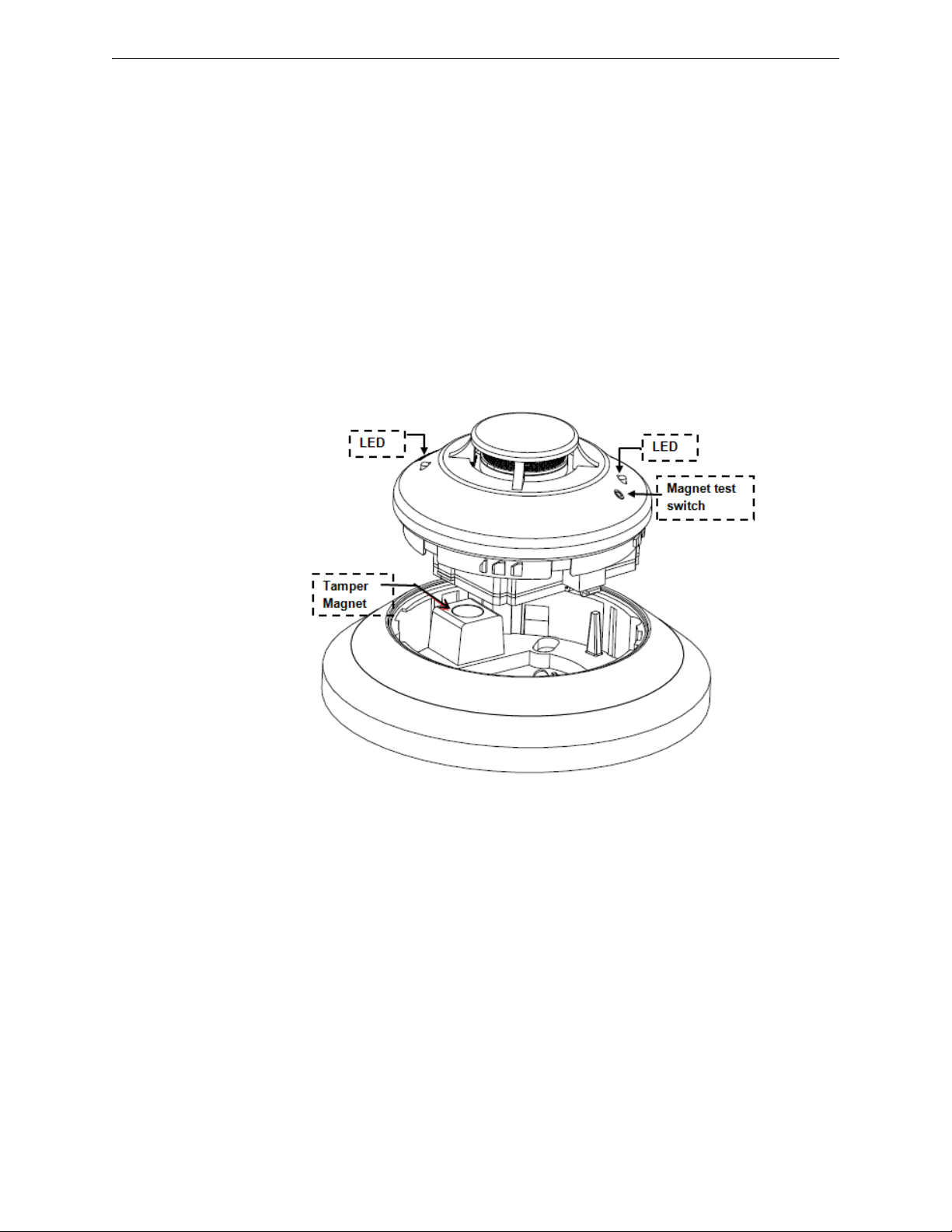

Figure 2.7 W-GATE with LEDs and Magnetic sensors

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 19

Page 20

W-GATE Configuration and Programming

4. Activate either magnetic sensor with a magnet within ten secoands of starting up the W-GATE

while the double red blink is active in the W-GATE. (If you miss this ten-second window,

power down the W-GATE and repeat step 1). The LED next to the magnetic sensor emits a red

light for one second when it is activated.

When the profile is successfully created, the LEDs on the W-GATE emit green light for five seconds (Refer to 2.7.2, "Magnet Sensor Activations" for further information on activating magnetic

sensors). A default profile has been created, containing a mesh ID, and a password. The default

password is ‘12345’ and is needed if the W-GATE is locked by the FACP and later accessed by the

PC-based configuration tool.

Assign a Previously Created Profile Using a Distributor

To assign an existing profile to the W-GATE (as you would do during a replacement), use the WGATE that has the profile, or a device in the mesh that contains the profile, to distribute that profile

to the W-GATE that requires it. Perform the following steps:

1. Ensure that the W-GATE or other mesh device with the profile is set for distribution (Refer to

2.6.3, "Profile Distribution"" or 4.6.2, "Distributor Mode").

2. Start with the device powered off. The process is performed during the start-up.

3. Power on the W-GATE and ensure it is in the factory default state (Refer to steps 1 and 2 in the

above topic, "Create a New Profile").

4. Bring the profile distributor within 20 feet of the W-GATE.

5. Wait until the W-GATE blinks only a single red blink (ten seconds after startup).

6. Use a magnet to activate either of the magnetic sensors. The LED blinks a single red every

half-second indicating that it is searching for a profile.

When the profile is successfully received from the distributor, the LEDs on the W-GATE emit

green light for five seconds. If the profile is rejected, the W-GATE LEDs emit red light for five seconds.

Removing a Profile

To remove the profile from a W-GATE, perform the following steps:

1. Start with the device powered off. The process is performed during the start-up.

2. Power on the W-GATE using SLC power or external +24V. This can be done either by

attaching the W-GATE to its mounting plate with the terminals already energized, or by

connecting the SLC or external source wiring to a W-GATE that is already installed in its

mounting plate.

3. Verify the W-GATE is in the profile modification state; if it is in the profile modification state,

both the LEDs on the W-GATE flash yellow (double blink) every second for ten seconds.

4. Activate both the magnetic sensors within ten seconds of starting up the W-GATE (while the

double yellow blink is active on the W-GATE) or repeat step 1 (If you miss the ten second

window, power down the W-GATE and repeat steps 1 and 2).

The W-GATE LEDs blink green every second for five seconds indicating that the profile is

removed.

Create Mesh Network

Mesh formation forms a wireless communication mesh around the W-GATE. The W-GATE communicates with all devices in range that have a common profile and establishes communication

links with all the devices. Once a device joins the mesh, it acts as a repeater for devices out of the

range of the W-GATE. All devices must be in their final mounting locations prior to initiating the

mesh formation. The mesh formation is initiated and terminated by the W-GATE.

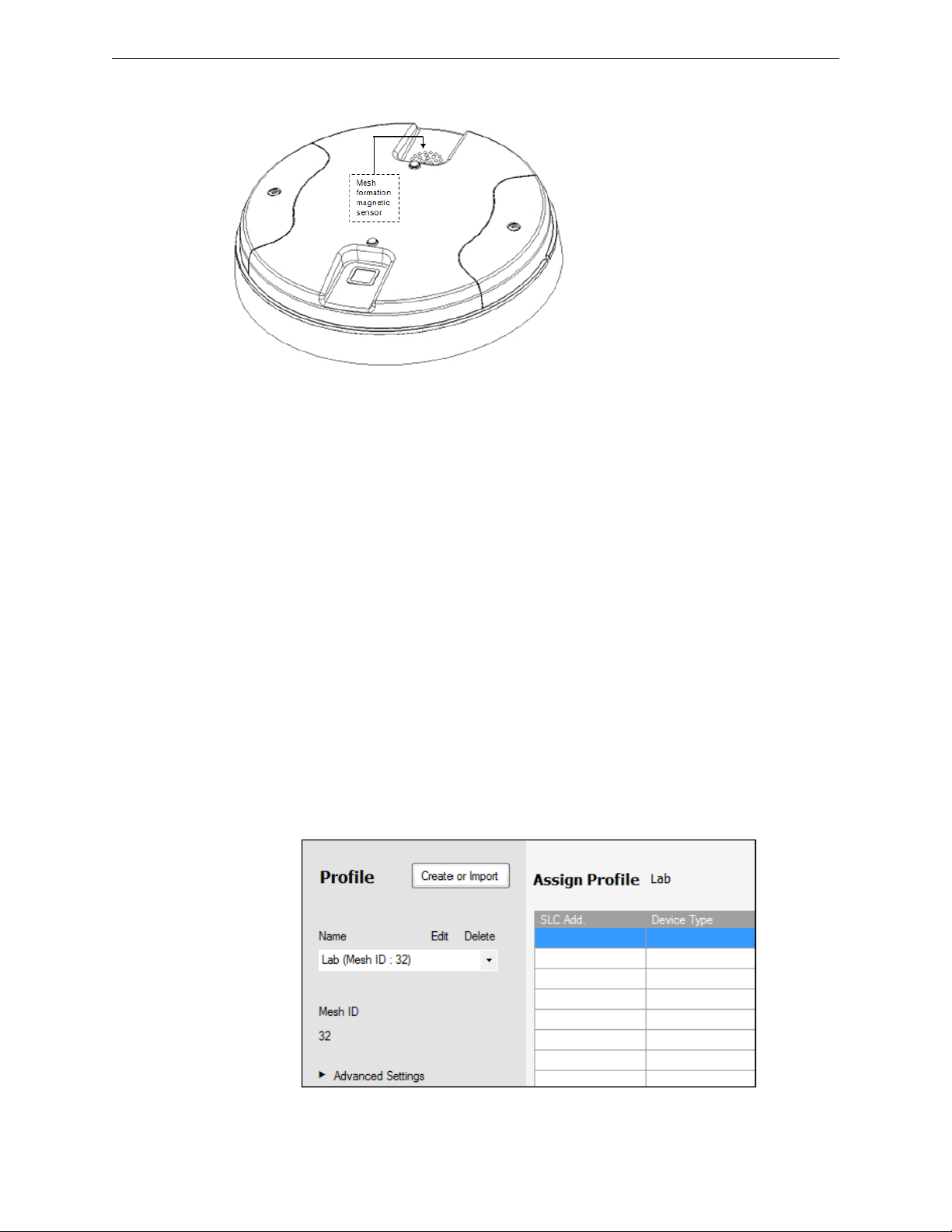

To form a mesh network, ensure that the W-GATE is powered on and contains a profile. (Refer to

2.7.3, "LED Indications" for information on how the W-GATE indicates its status). Activate the

“Mesh Formation” magnet switch on the W-GATE with a magnet.

20 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 21

Configuration and Programming W-GATE

Figure 2.8 Mesh Formation

Magnetic Sensor on a W-GATE

The W-GATE transitions to the mesh formation mode and establishes communication with all the devices containing a

common profile. The blink pattern in WGATE indicates that it is in mesh formation mode.

•At this stage, both the LEDs on the W GATE blinks twice every 3.4 seconds.

•The first blink is green and the second

blink is red when the W-GATE is acting

as a profile distributor and forming the

mesh.

• The first blink is green and the second blink is yellow when the W-GATE is only form ing the

mesh.

Mesh formation typically takes one minute for each device in the mesh. Mesh formation automatically terminates 10 minutes after the last device joins the mesh. The mesh formation can be terminated manually by the user by activating the mesh formation magnetic sensor again.

Once the mesh formation is complete, the network transitions to optimize the mesh. For further

operating instructions, refer to 2.7, "Operations".

2.6.2 With a PC-based Configuration Tool

Assign Profile with PC Tools

To assign a profile to the W-GATE using the PC Tools application, do the following:

1. Connect the W-USB dongle device to your computer. For more information on USB dongle,

refer to Section 5:, "USB Adapter".

2. Launch the PC Tools application. Refer to Appendix B:, "PC tools" to know about launching

the PC Tools application.

3. Go to the Create Mesh Network step.

4. Create a new profile or import an existing profile as required.

5. Select and open the profile to be assigned to the W-GATE from the Name drop-down list in the

left panel.

6. Power on the W-GATE in range of the PC Tools.

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 21

Page 22

W-GATE Configuration and Programming

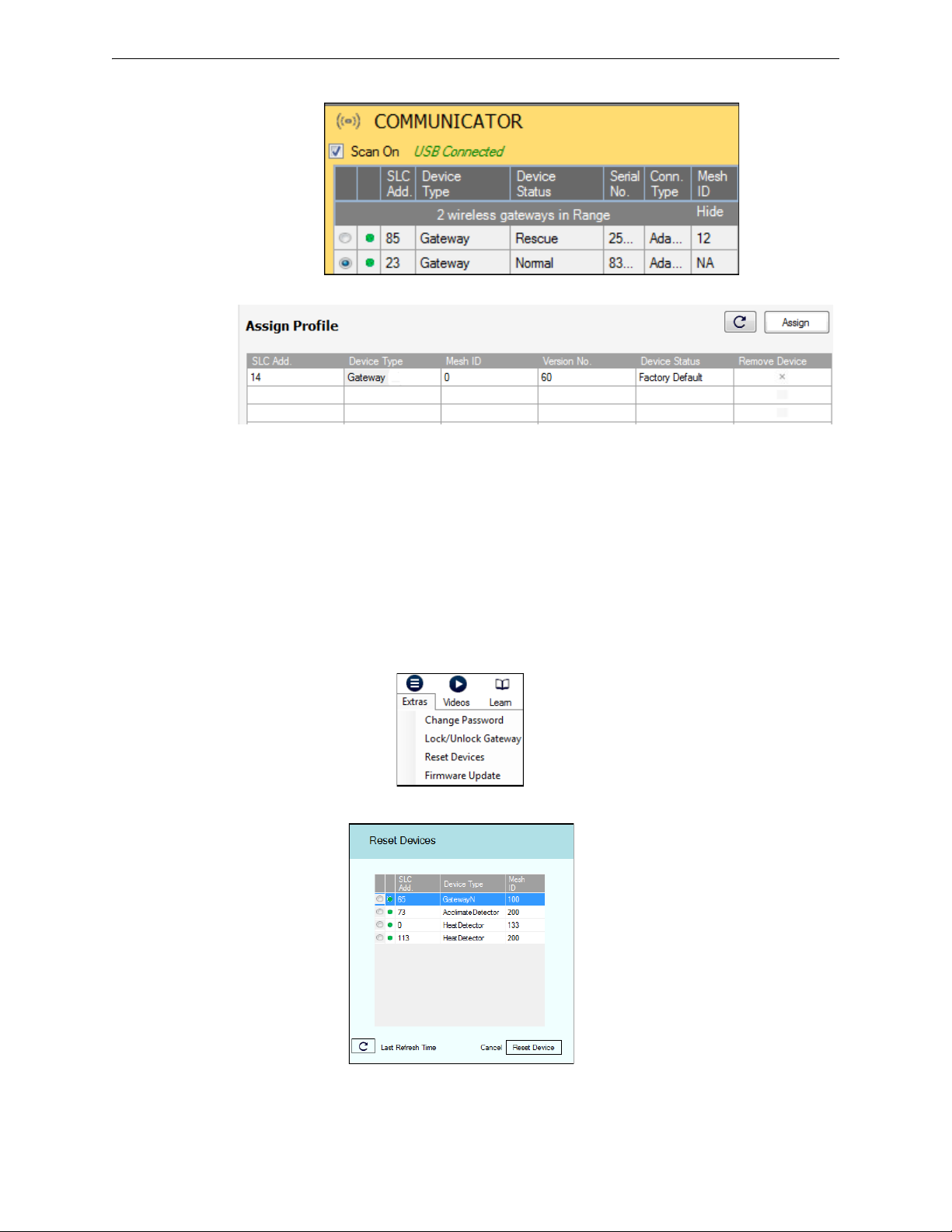

7. Select the W-GATE from the Communicator panel.

8. Click Assign.

The W-GATE is now included in the list of devices with a profile assigned.

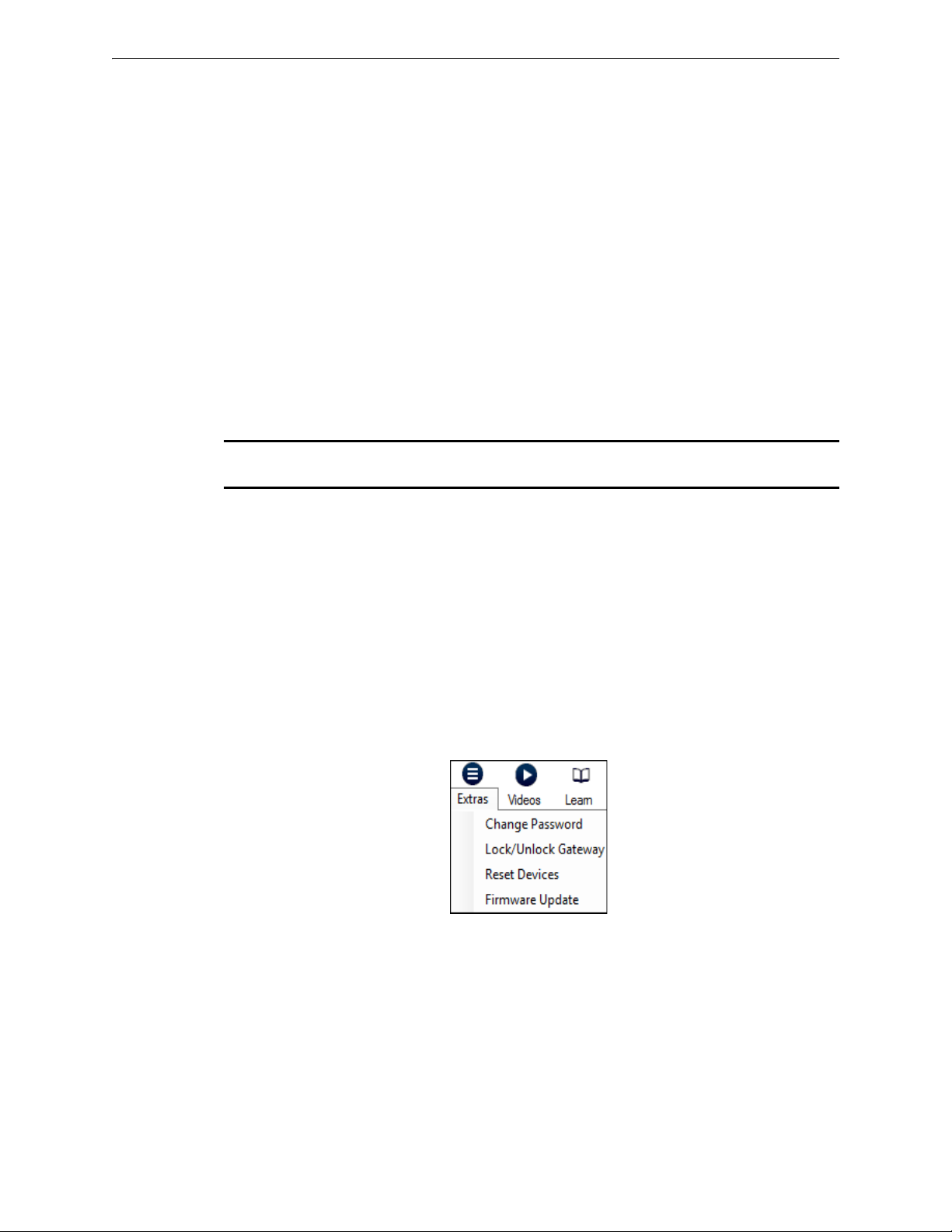

Removing Profile with PC Tools

To remove a profile in a W-GATE using the PC Tools application, do the following:

1. Connect the W-USB dongle device to your computer. For more information on USB dongle,

refer to Section 5:, "USB Adapter".

2. Launch the PC Tools application. Refer to Appendix B:, "PC tools" to know about launching

the PC Tools application.

3. Go to Site Survey , Create Mesh Network, or Diagnostics step.

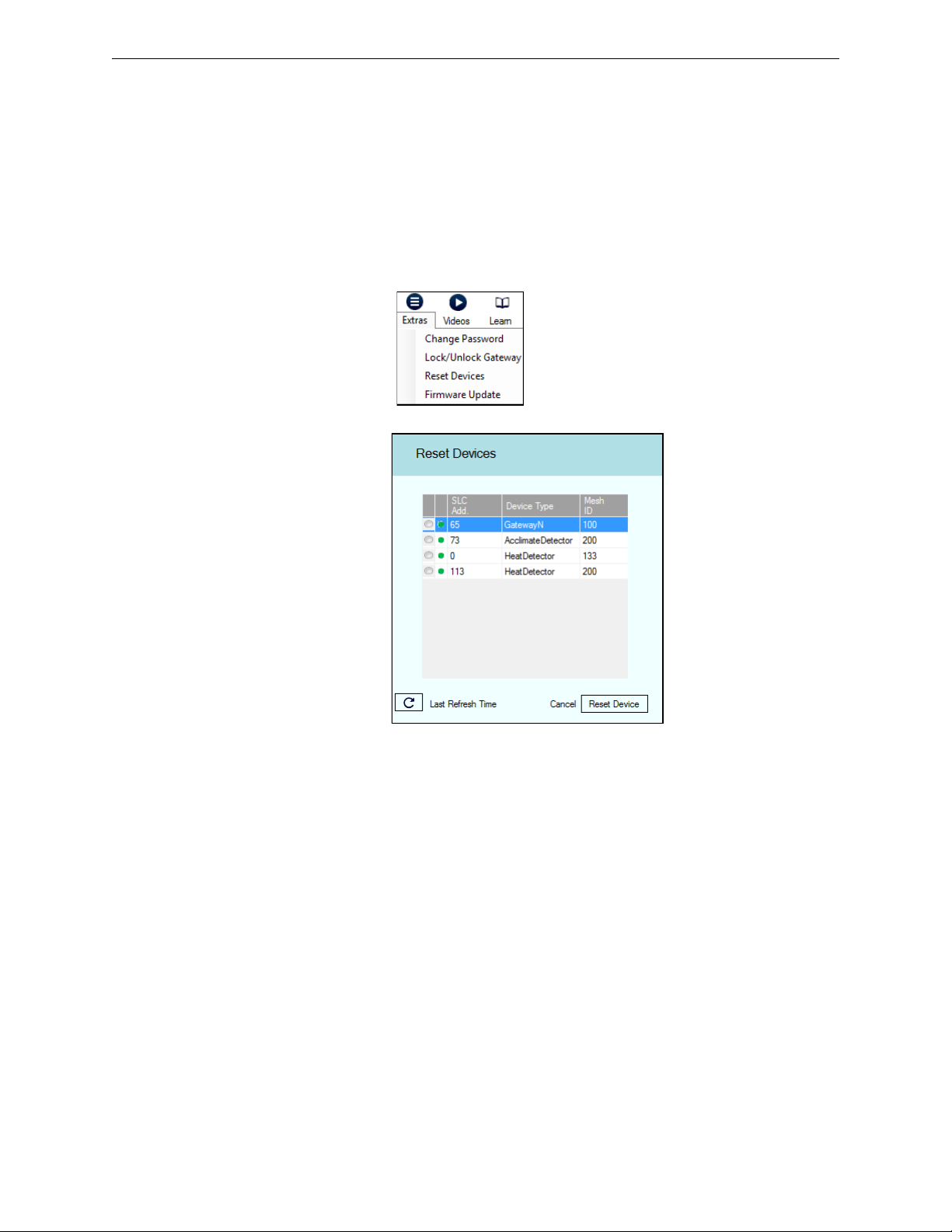

4. Click Extras and select Reset Devices. The Reset Devices screen appears, displaying the W-

GATE and other devices that have a profile assigned.

5. Click to select the W-GATE and click Reset Device to remove the profile.

The profile is removed and the W-GATE is reset to factory default state.

22 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 23

Configuration and Programming W-GATE

Mesh Formation with PC Tools

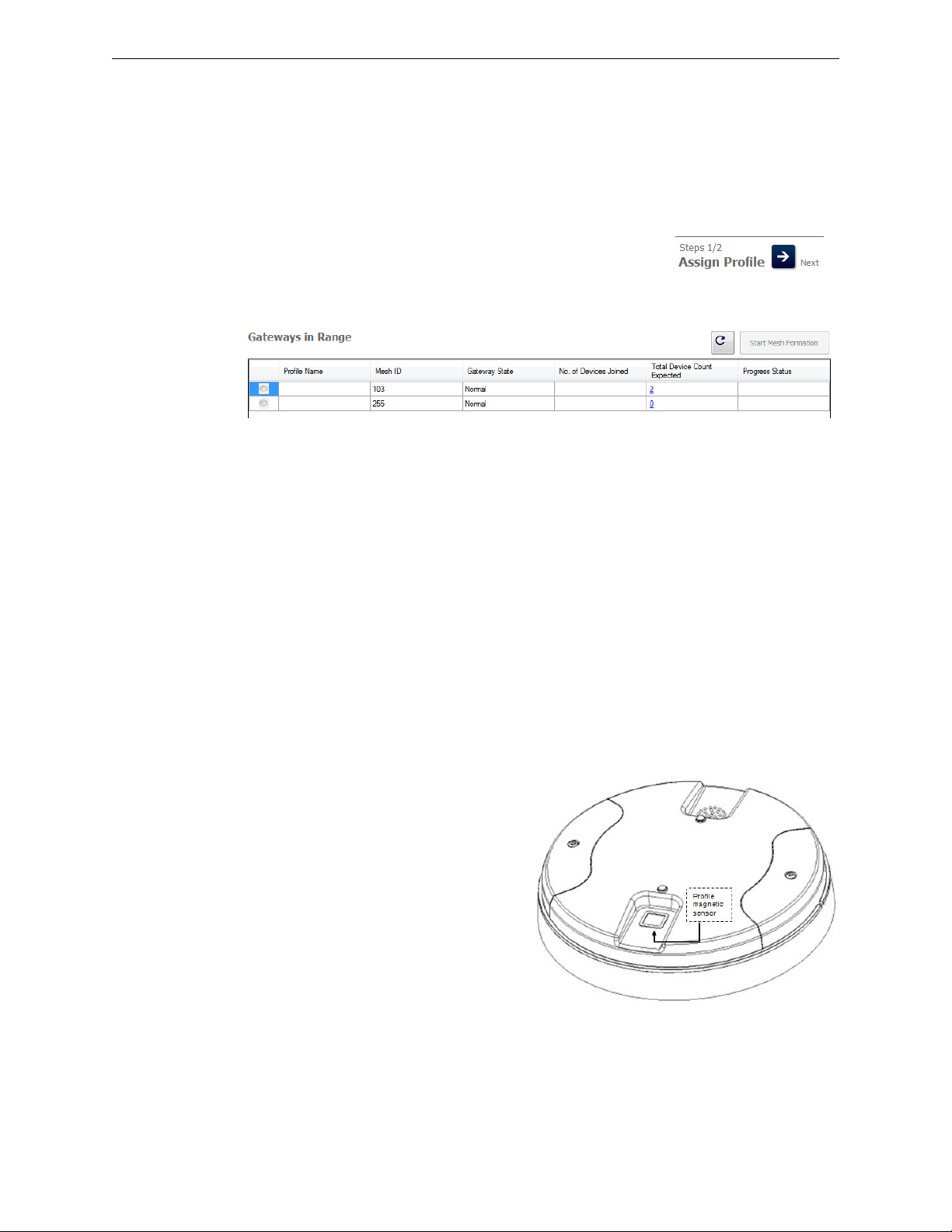

To create a mesh network using the PC Tools, perform the following steps.

1. Connect the W-USB dongle device to your computer. For more information on USB dongle,

refer to Section 5:, "USB Adapter".

2. Launch the PC tools application. Refer to Appendix B:, "PC tools" to know about launching

the PC tools application.

3. Go to Create Mesh Network step.

4. Navigate to the second step of Create Mesh Network by clicking

on top of the screen.

5. Click to select the W-GATE displayed in the Gateways in Range table, and click 'Start Mesh

Formation'.

When the mesh is formed, the tool helps you to track the number of devices that have joined the

mesh, and view the progress. The mesh formation terminates 10 minutes after the last device joins

the mesh. In addition, it can be terminated by the user by clicking Stop Mesh Formation.

Once mesh formation is complete, the network transitions to optimize the mesh. For further operating instructions, refer to 2.7, "Operations".

2.6.3 Profile Distribution

There are two ways to initiate profile distribution from the W-GATE.

• Automatically after creating a profile,

• Activating the profile creating magnetic sensor when it has a profile.

After Creating a Profile

Profile distribution is automatically enabled from the W-GATE after creating a profile. The profile

distribution automatically terminates after 10 minutes.

Activating the Profile Magnetic Sensor When it has a Profile

Activating the profile magnetic sensor while it

has profile will put the W-GATE in a mode of

distributing the profile to any device that

requests a profile. The W-GATE’s LED pattern

will be altered when it is distributing a profile

for easy identification. Profile distribution will

automatically terminate after 10 minutes. For

more information on W-GATE LED patterns,

refer to the table in 2.7.3, "LED Indications".

Figure 2.9 Profile Magnetic

Sensor on a W-GATE

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 23

Page 24

W-GATE Configuration and Programming

2.6.4 SLC Configuration

The W-GATE,

• Communicates with the control panel via the SLC circuit.

• Is a LiteSpeed only device.

• CLIP mode is not supported.

• FACPs have limited support for displaying all troubles from the wireless device, and requires

the use of an ANN-80 for event details. Refer to the appropriate section below for

configuration steps.

Three consecutive SLC addresses are used for a W-GATE. Set the base address using the rotary

dials on the W-GATE prior to installation. Ensure the address and the next two addresses on the

SLC loop are available.

The base address uses the following configuration parameters:

• Module Type: Monitor

• T ype Code Label: Monitor

The W-GATE does not cause any alarms at this address, but the point is used for supervision of the

W-GATE.

The base address +1 uses the following configuration parameters:

• Module Type: Monitor

• T ype Code Label: Tamper

This address is a latching supervisory condition that goes active whenever a wireless detector in the

mesh is removed from its base or a module has its cover plate removed (tamper). This point does

not show the address of the tampered device. The ANN-80 displays the device address information.

The base address +2 uses the following configuration parameters:

• Module Type: Monitor

• T ype Code Label: Trouble Mon

This address is a tracking trouble condition that goes active whenever a wireless device in the mesh

is in a trouble condition. Refer to 3.9.4, "Event Messaging"for the message displayed at the ANN80 for the trouble event.

The specific address and trouble condition is displayed on the ANN-80.

24 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 25

Operations W-GATE

2.7 Operations

2.7.1 W-GATE Modes of Operation

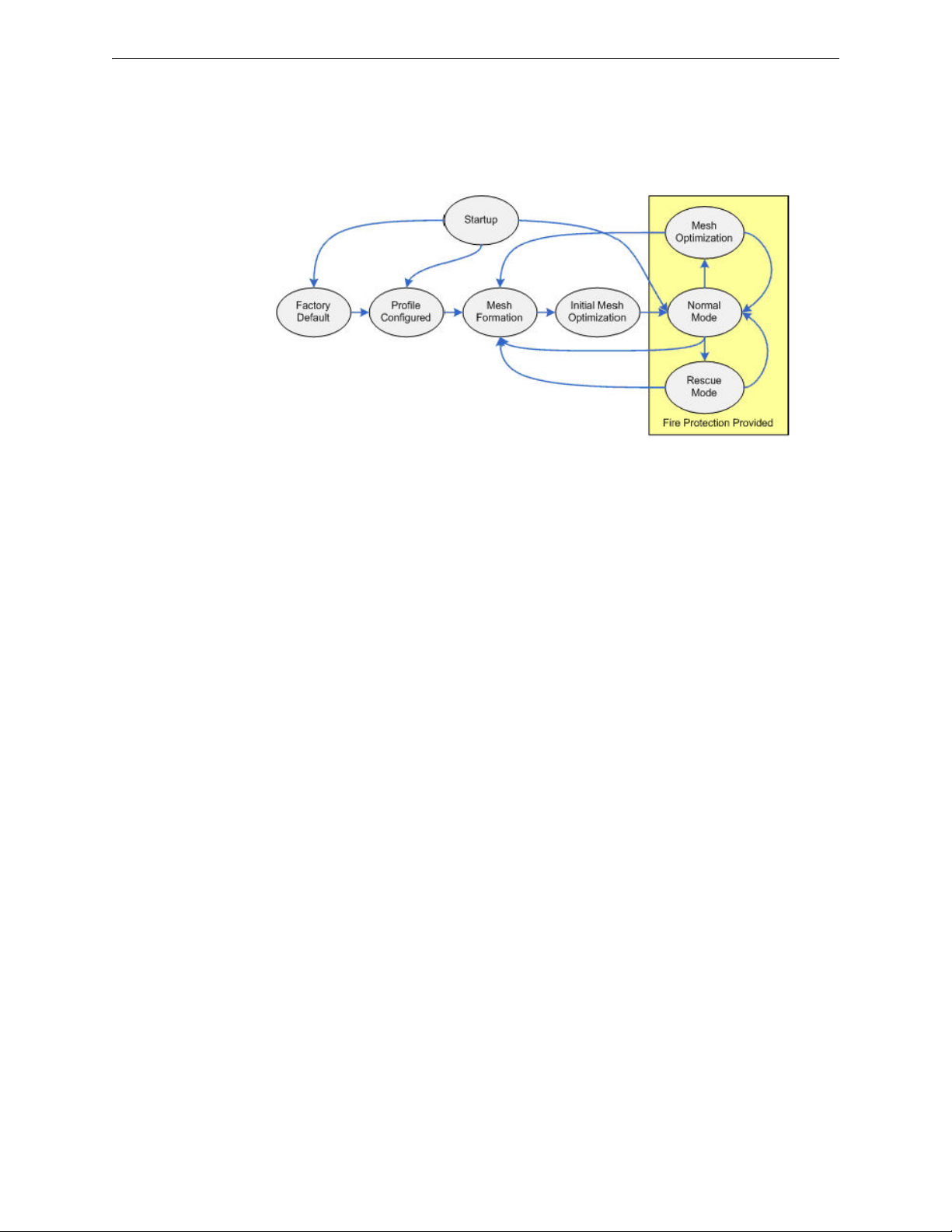

Figure 2.10 W-GATE Modes Of Operation

Start Up

Startup is a temporary mode of operation. It is during the startup mode, that a profile can be created

or removed. The startup period lasts for 10 seconds. If a particular unit contains a profile, the LEDs

blink yellow twice every second. If the unit does not contain a profile, the LEDs blink red twice

every second.

During startup, the W-GATE does not provide fire protection.

After startup, the W-GATE proceeds to the factory default state if a profile was removed or miss-

ing. In the presence of a profile, the W -GATE will proceed to mesh formation if it was previously

part of a mesh network or normal mode if it was not previously part of a mesh network.

The W-GATE does not respond to the panel during startup. All the three SLC addresses will be an

INVALID REPLY.

Factory Default

Factory default is the initial state of the W-GATE. The W-GATE and peripheral devices do not provide any fire protection when they are in factory default mode. The W-GATE does not communicate with wireless devices. The only wireless communication is with the configuration tool. The

configuration tool needs to be within 20 feet of the W-GATE for communication. The W-GATE

needs to be assigned a profile before continuing the installation.

The W-GATE reports “Factory Default” to the communicator display of the PC Tools application.

The W-GATE’s base address will be normal and the supervisory point (base address + 1) will also

be normal. The trouble point (base address + 2) will indicate open circuit.

Profile Configured

The W-GATE enters the profile configured mode after getting assigned a profile from the tool or a

distributor or creating a profile. Profile configured is a temporary mode before the W-GATE transitions to mesh formation or normal mode.

The W-GATE does not provide fire protection in the profile configured mode. The W-GATE

reports “Profile Assigned” to the communicator display of the PC Tools application.

The W-GATE’s base address will be normal and the supervisory point (base address + 1) will also

be normal. The trouble point (base address + 2) will indicate open circuit.

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 25

Page 26

W-GATE Operations

Mesh Formation

The W-GATE must have a profile before entering mesh formation. The W-GA TE and the peripheral

devices do not provide any fire protection in mesh formation. The W-GATE automatically enters

mesh formation in the following ways:

• After creating a profile using the mesh formation sensor.

• After activating the mesh formation sensor with a magnet when the W-GATE contains a

profile.

• Automatically after startup when the W-GATE previously was part of a mesh

• By command from the PC Tools application

A W-GATE in mesh formation mode instructs all d evi ces in the mesh to also transition to mesh formation. The W-GATE and all communicating devices search for new or lost devices with the same

profile to join the network.

If the W-GATE automatically entered mesh formation after startup, then mesh formation terminates

after all existing devices are recovered. If new devices are found or if mesh formation was initiated

by the user, then mesh formation terminates after a period of 10 minutes without any new devices

joining the mesh. At any point Mesh formation can be terminated by user interaction by activating

the magnet sensor again, or by using the PC Tools application.

The W-GATE reports “Mesh Formation” to the communicator display of the PC Tools application.

The W-GATE’s base address will be normal and the supervisory point (base address + 1) will also

be normal. The trouble point (base address + 2) will indicate open circuit.

Initial Mesh Optimization

The initial mesh optimization mode automatically runs after each mesh formation. The W -GATE

and peripheral devices do not provide fire protection during the initial mesh optimization. Mesh

optimization analyzes the signal strengths between devices. The W-GATE designates the primary

and secondary communication paths between devices that provide a redundant path for all transmissions. Mesh Optimization terminates automatically once all devices have a redundant communication path and signal strengths that meet the requirements of primary and secondary

transmission paths. Any device that does not have a redundant path or meet the requirements for

signal strength will report a fault.

The W-GATE reports “Optimization” to the communicator display of the PC tools application.

The W-GATE’s base address will be normal and the supervisory point (base address + 1) will also

be normal. The trouble point (base address + 2) will indicate open circuit.

Normal Mode

Normal mode can be described as a standard operating state. The mesh network is formed, providing fire protection. The mesh network continu o usly searches for additional devices with a matching profile to join the mesh. To avoid interference, the mesh network periodically checks for

adjacent mesh networks created by Honeywell. The W-GATE reports “Normal” to the communicator display of the PC Tools application.

Rescue Mode

During normal mode, when a device loses communication to the network, the W-GATE triggers

rescue mode in all communicating devices. All devices in communication continue to provide fire

protection during rescue mode, but also searches for a lost or added device. The rescue mode terminates automatically 6 minutes after the last device is rescued and returns to the normal mode. The

W-GATE reports “Rescue” to the communicator display of the PC Tools application.

26 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

Page 27

Operations W-GATE

Mesh Optimization

In addition to the initial mesh optimization, the routine executes after any restoration of communication to a device or to recover from a link failure (class A fault). Mesh optimization that occurs

during the normal mode does not generate a trouble and provides fire protection from all devices

that are participating in the mesh communication. The W-GATE reports “Optimization” to the communicator display of the PC Tools application.

Bootloader

The W-GATE enters the bootloader mode when it is being updated using the PC Tools application.

The W-GATE does not communicate with the FACP during bootloader mode. The W-GATE

reports “Bootloader” to the communicator display of the PC Tools application.

2.7.2 Magnet Sensor Activations

Profile Magnetic Sensor

The profile magnetic sensor (Figure 2.9, "Profile Magnetic Sensor on a W-GATE") is used to create

a unique profile on startup. It can also be used to start profile distribution for a W-GATE that contains a profile. The LED next to the profile magnet sensor emits solid red light for ½ a second

when the sensor is activated.

Mesh Formation Magnetic Sensor

The mesh formation magnetic sensor (Figure 2.8, "Mesh Formation Magnetic Sensor on a WGATE") toggles the W-GATE, in and out of mesh formation mode. The initial activation of the sensor puts the W-GATE in mesh formation mode (as long as it contains a profile). A subsequent activation of the magnetic sensor toggles the W-GATE out of mesh formation and into the initial mesh

optimization and normal mode. The W-GATE can be placed back into mesh formation by activating the magnet sensor once again. The Mesh formation magnetic sensor can also be used to create

a profile on startup for a W-GATE that does not already contain a profile.

The LED next to the mesh formation magnetic sensor emits solid red light for ½ a second when the

sensor is activated.

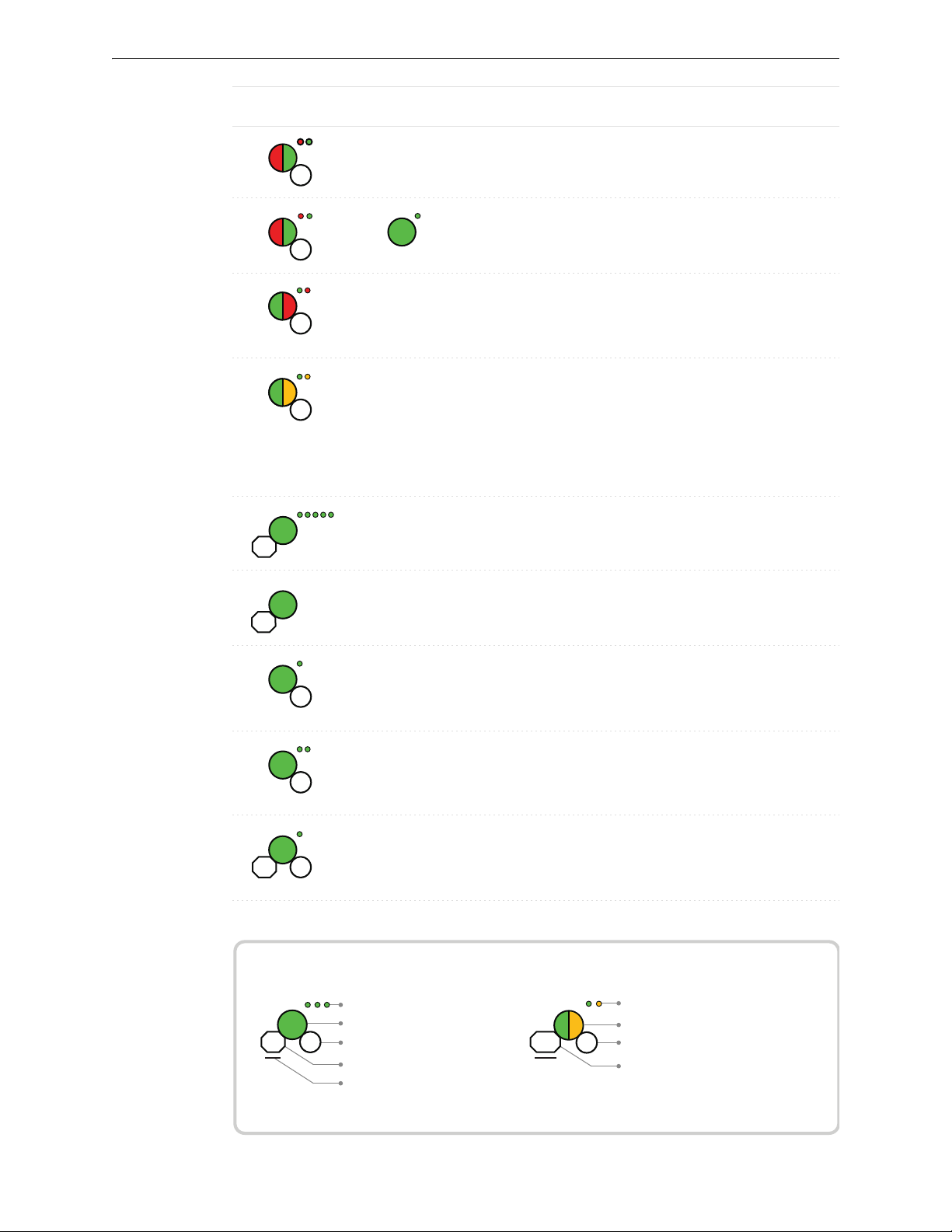

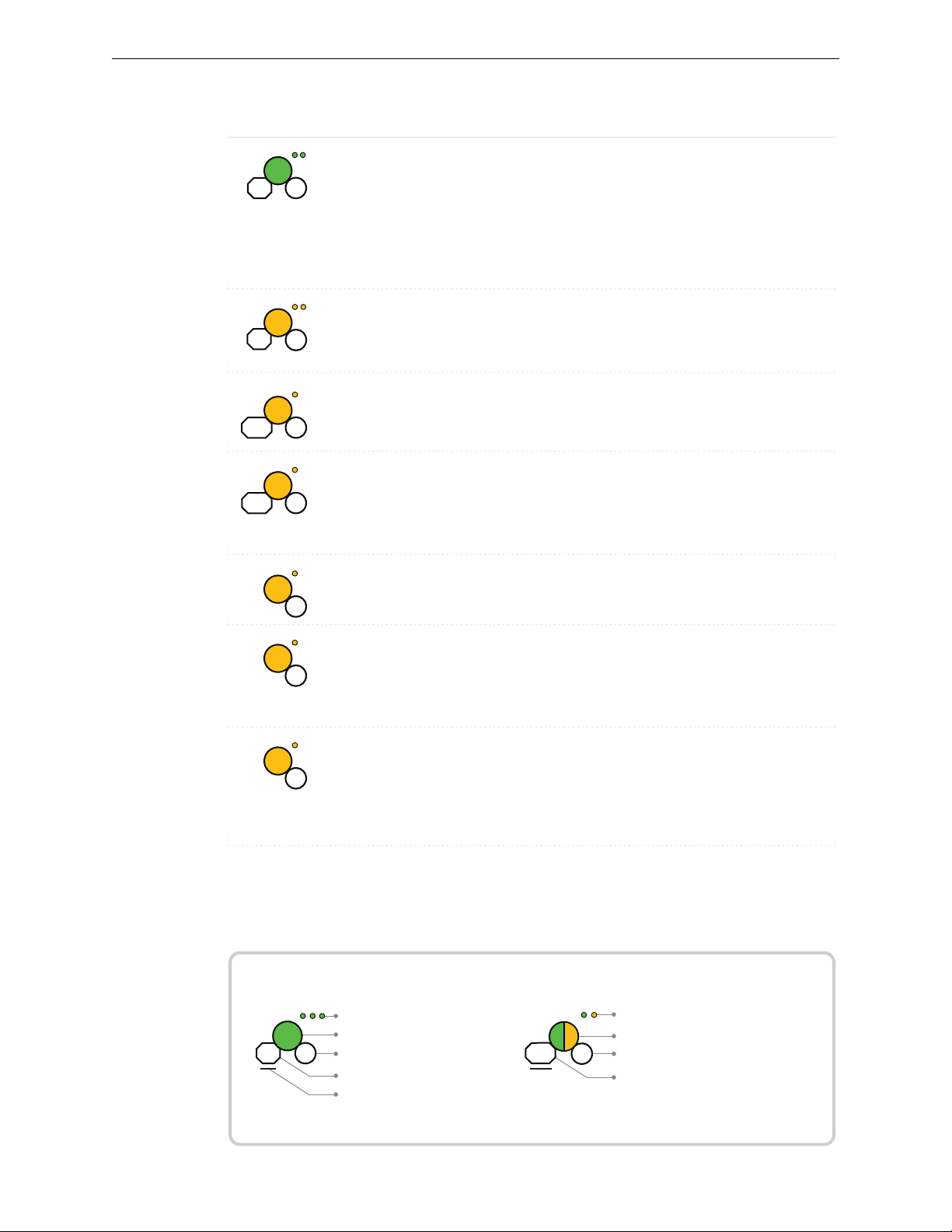

2.7.3 LED Indications

The two LEDs on the W-GATE blink in the same pattern to allow the LED to be viewed from any

angle. The LED indications are provided in the table below.

PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013 27

Page 28

W-GATE Operations

Duration of LED state

All units are in seconds. Minute is indicated by M.

Example:

Legend

LED color

No. of blinks

Interval between blink patterns

Approximate duration

Will transition to next state after

30 min (approx)

First blink is green. Second is yellow

Two blinks in this pattern

7 sec between blink patterns

7

M

30

Condition Action Required

Device is ready to update

LED Pattern

Prole removed Gateway has returned to the

factory default state

Mesh formation Gateway is forming the

mesh & looking for

devices that are not in the

mesh

Wait until all devices join

the mesh, and then

terminate mesh formation

Use PC based conguration tool to initiate the

download

Mesh formation

with prole

distribution

Gateway is forming the

mesh & looking for

devices that are not in the

mesh. The gateway is also

distributing a prole to

any device that requests a

prole

Wait until all devices join

the mesh, and then

terminate mesh formation

App

erase

App

loading

New application code is

being downloaded

7

7

2

5

14

14

Normal Mode /

Background

mesh optimization

Normal operation of the

gateway

Normal Mode/Background mesh

optimization with

prole distribution

Normal operation of the

gateway. The gateway is also

distributing a prole to any

device that requests a prole

Prole accepted

Gateway is now prole

assigned

5

Rescue Mode Gateway and the mesh

network are searching for any

device that is not in the mesh

network with the same prole

7

6

M

Bootloader

5

28 PRELIMINARY: Firelite Wireless Sensor Network P/N LS10036-000FL-E:N0 10/10/2013

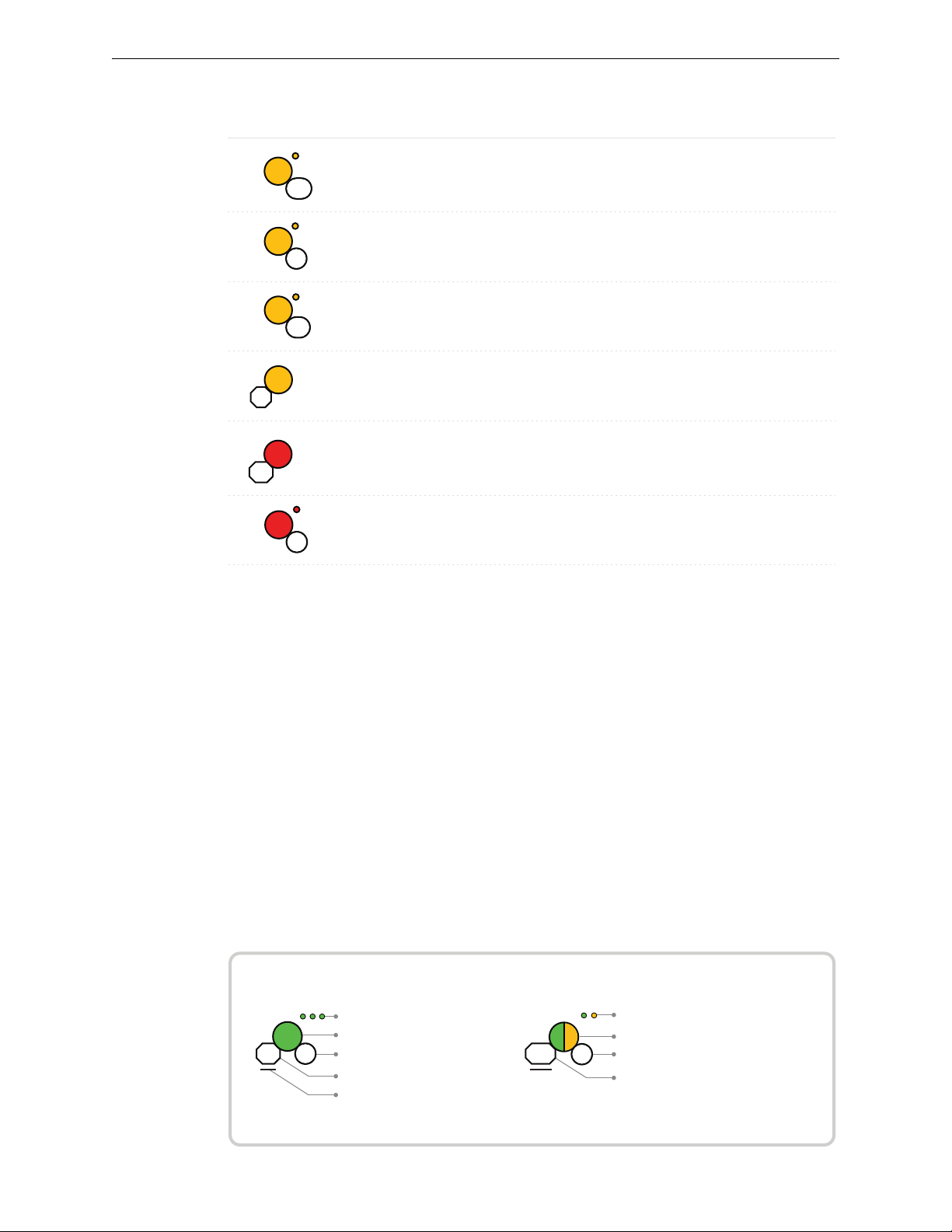

Page 29

Operations W-GATE

Duration of LED state

All units are in seconds. Minute is indicated by M.

Example:

Legend

LED color

No. of blinks

Interval between blink patterns

Approximate duration

Will transition to next state after

30 min (approx)

First blink is green. Second is yellow

Two blinks in this pattern

7 sec between blink patterns

7

M

30

7

Rescue Mode

with prole

distribution

Gateway and the mesh

network are searching for

any device that is not in

the mesh network with the

same prole. The gateway

is also distributing a prole

to any device that requests

a prole

Prole assigned;

pending hall sensor

activations

starting up with a prole Activate both hall sensors

simultaneously within 10

seconds to remove a

prole

1st mesh

optimization

Mesh is formed and

initializing

Ensure all devices in the