Honeywell VTL120 Installation Instruction

e

n

e

r

g

y

www.energysavingtrust.org.uk

g

n

i

v

a

s

VTL120

Reversible Flow Radiator Thermostat

Installation Instruction

1. Notes and Safety instructions

These products are approved to the

European CEN standard EN215, which

supersedes BS 6284.

Whilst Honeywell takes all reasonable practical

steps to design and manufacture its products to

comply with the requirements of the Health and

Safety at Work Act 1974 all products must be

properly used and purchasers are reminded that

their obligations under the Act are to ensure that

the installation and operation of such products

at a place of work should be safe and without

risk to health.

Honeywell reserves the right at any time and

without notice to change any product or any

information contained in this publication.

1.2 Check list

• Check all connections for securing and leakes.

• Use clean pipework, free from swarf.

• Consider the use of an automatic by-pass

valve (e.g. Honeywell DU145) to ensure the

specification is adherded to.

• Don’t allow heat from blow torch onto body.

• Don’t install the valve in a position which is

subject to draughts, sun radiation or behind

curtains.

• Don’t overtighten the head/body connection,

as the insulating sleeve may become damaged.

2. Location

The thermostat can be fitted in any orientation

with the flow through the body in either

direction.

3. Technical Data

Maximum working pressure 10 bar (140 psi)

Closing time 20 minutes

To ensure that the valve will thermostatically

close the differential pressure must not

exceed 1.0 bar.

Maximum differential pressure to ensure

reliable and quiet operation is 0.2 bar.

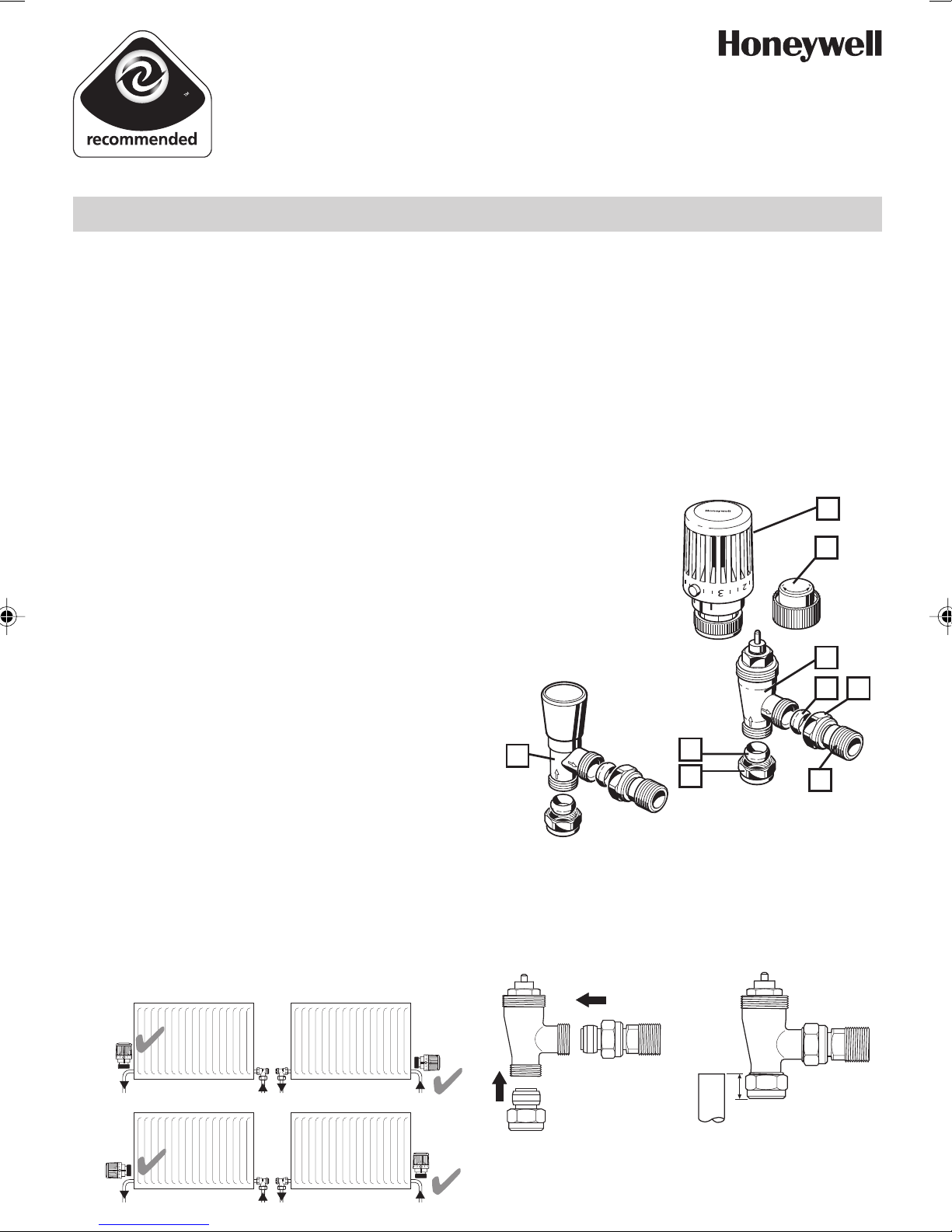

4. Component parts

1

1 Wheelhead

2 Decorators Cap

2

3 Valve body

4 Tail piece

5 Olive

6 Nut

7 Lockshield valve

3

5

7

5

6

4

5. Installation

5.1 Fitting - valve connections

1. Fit the connection fittings to the valve.

2. Cut copper tube to entry depth of 10 mm.

6

EB-VTL120; 04 100 50 001 000

10 mm

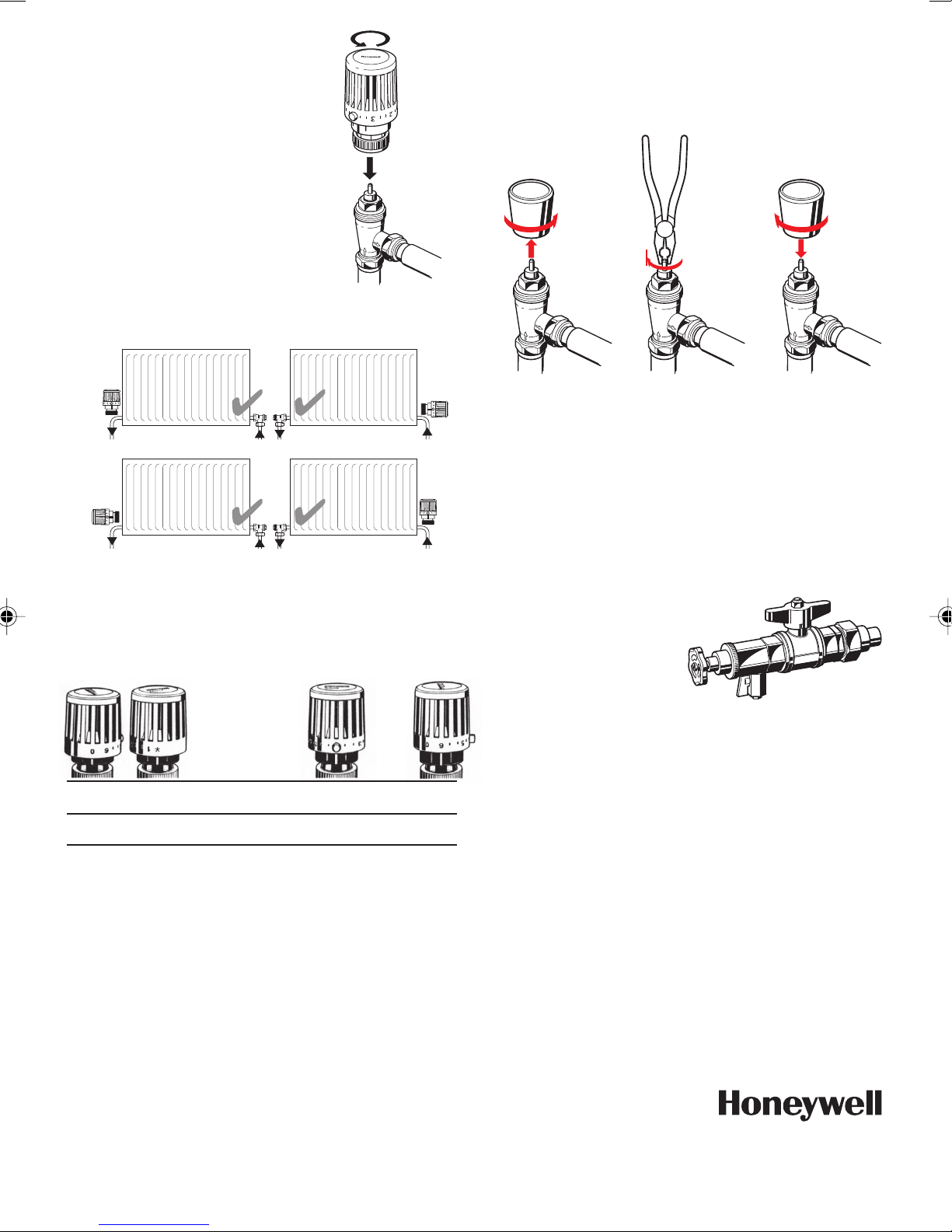

5.2 Head to body

1.Turn head to open position.

2.Position head so indicator is

facing user.

3.Screw on head, ensuring lugs

and slots engage as collar

is tightened.

5.3 Lockshield valve

1.Install the lockshield valve opposite from

thermostat

6. Adjustment / Setting of thermostat

The VT117E is adjustable by turning the top

anti-clockwise to increase temperature setting

or clockwise to decrease temperature setting.

7. To shut off the lockshield valve

1.Unscrew and remove cover cap.

2.Turn the spindle clockwise till stop by using a

pliers

3.Fit cover cap.

8. Service

8.1 Decorator cap

When removing the radiator for any reason

the decorators cap supplied with the valve

should be used to isolate the flow.

8.2 Servicing

Use the service tool VA8200A001 for cleaning

or replacement of the valve seating without

draining the system.

For further informations

see seperate manual.

0

123 ● 56

*

closed 6°C 8°C 12°C 16°C 20°C 23°C 26°C

These temperatures are for guideance only

and are based on horizontal mounting on the

flow pipe. If the radiator thermostat is installed

in any other direction then the temperature will

vary by 1°C to 2°C.

Note: Heating can freeze when thermostats

with zero position are set at position „0“.

Honeywell Control Systems Ltd.

Honeywell House

Arlington Business Park

Bracknell, Berkshire RG12 1EB

Phone: 01344 656000

Fax: 01344 656240

9. Disposal

Observe the local requirements regarding

correct waste recycling/disposal.

www.honeywelluk.com

EN3H-0315GE25R1105

Loading...

Loading...