Page 1

V5825B

Small Linear Valve / PN25

DH Compact Valve

PRODUCT DATA

FEATURES

• Pressure-balanced kvs 1.0...10 m3/hr

• Normally-closed valve

• Supplied with manual adjustment cap for start-up

• Small size

• Threaded and welding connection sets

• Bronze body, stainless steel trim

• Low seat leakage rate

• Metal-to-metal seating for long life span

GENERAL

Single-seated 2-way valves for modulating control of hot /

chilled water in heating, ventilating, and air conditioning

systems.

These valves are designed especially for flow control in

hydraulic systems with high temperatures and pressures,

such as district heating systems. It can also be used in

combination with M6410/M7410 (300 N) actuators as well as

with ML7430/35 and ML6435 (400 N) actuators.

• Easy mounting of direct-coupled electric actuators

• Approval per DIN EN 14597

SPECIFICATIONS

Action valve is closed by its spring

Nominal pressure rating PN25

Rangeability 50:1

Leakage rate: max. 0.05% of k

Characteristic split characteristic / linear - equal

percentage

Stroke 6.5 mm

Close-off pressure 0...1600 kPa with 300 N actuator

Valve body

End connections

Material

Trim

Seat

Plug

Stem

Packing EPDM, O-ring

Medium water; glycol/water mixture

Medium temperature 2...130 °C

Dimensions See Fig. 2 on page 4

0...2500 kPa with 400 N actuator

external thread per ISO 228/1

red bronze (DIN 1705)

stainless steel (W.-No. 1.4305)

stainless steel (W.-No. 1.4305)

stainless steel (W.-No. 1.4305)

(max. 50% glycol per VDI 2035)

VS

Copyright © 2009 Honeywell Inc. • All rights reserved EN0B-0403GE51 R0709

Page 2

V5825B SMALL LINEAR VALVE / PN25

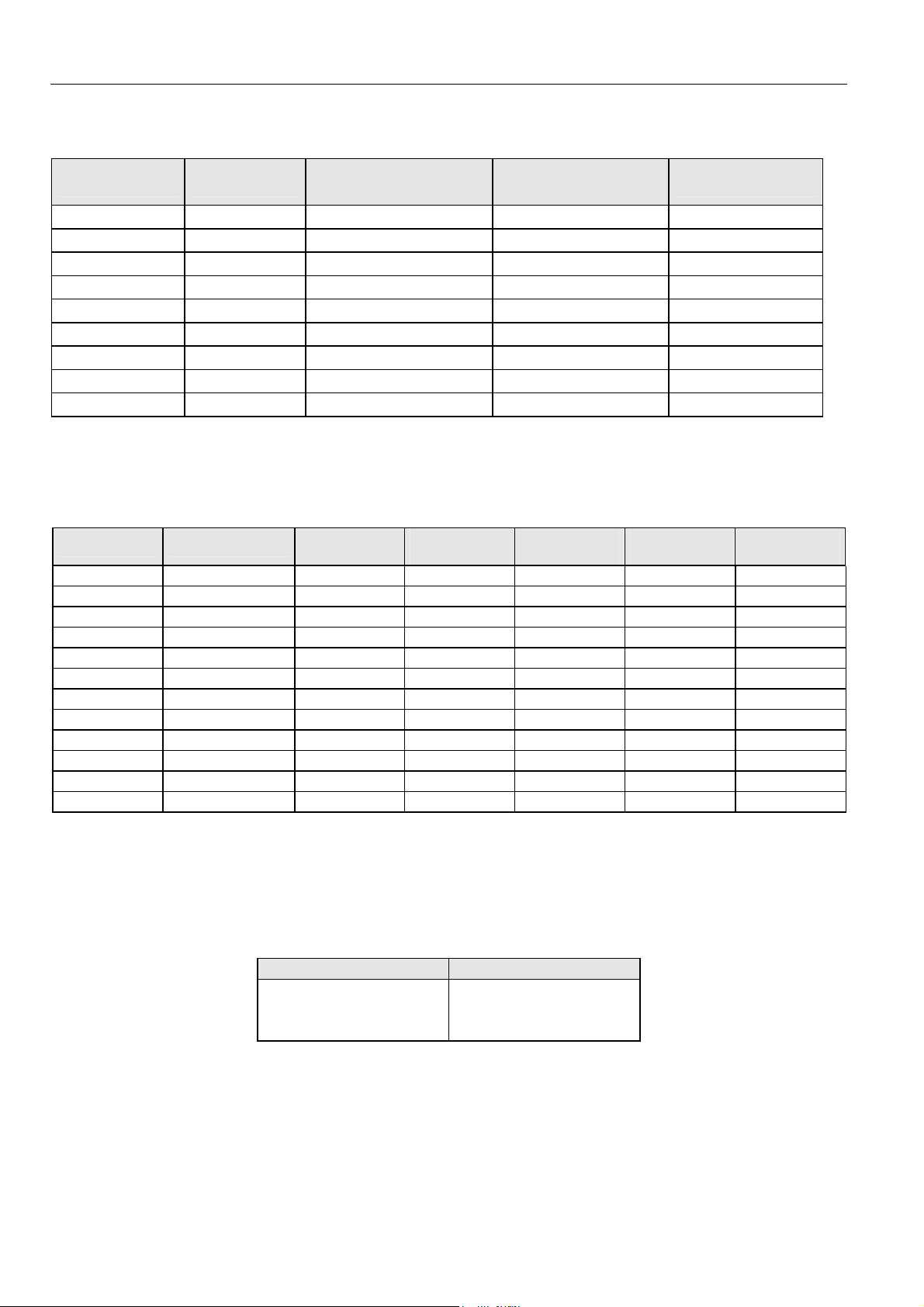

SIZES AND FLOW CAPACITIES

size kVS (m3/h)

DN15 0.25 1600 2500 V5825B1001

DN15 0.40 1600 2500 V5825B1019

DN15 0.63 1600 2500 V5825B1027

DN15 1.0 1600 2500 V5825B1035

DN15 1.6 1600 2500 V5825B1043

DN20 2.5 1600 2500 V5825B1050

DN20 4.0 1600 2500 V5825B1068

DN25 6.3 1600 2500 V5825B1076

DN32 10.0 1600 2500 V5825B1084

close-off pressure (kPa)

with 300 N actuator

close-off pressure (kPa)

with 400 N actuator

order number

ACTUATORS

Suitable electric actuators:

OS no. data sheet

M7410C1015 EN0B-0096GE02 24 Vac - valve cap 300 -

M6410C2031 EN0B-0096GE02 24 Vac - integrated 300 -

M6410C4037 EN0B-0096GE02 24 Vac 2 integrated 300 -

M6410L2031 EN0B-0096GE02 230 Vac - integrated 300 -

M6410L4037 EN0B-0096GE02 230 Vac 2 integrated 300 -

M7410E1028 EN0B-0097GE02 0/2...10 V - valve cap 300 -

M7410E2034 EN0B-0097GE02 0/2...10 V - integrated 300 -

M7410E4030 EN0B-0097GE02 0/2...10 V 2 integrated 300 -

ML6435B1008 EN0B-0259GE51 24 Vac - valve cap 400 stem retract

ML6435B1016 EN0B-0259GE51 230 Vac - valve cap 400 stem retract

ML7430E1005 EN0B-0260GE51 0/2...10 V - integrated 400 -

ML7435E1004 EN0B-0260GE51 0/2...10 V - valve cap 400 stem retract

For further technical information about electric actuators, please consult Honeywell Product Data Sheets.

control

signal

auxiliary

switches

manual

adjustment

stem force

(N)

power failure

position

APPROVAL

NOTE: For V5825B valves in combination with the following actuators, approval according to DIN EN 14597.

Actuator O.S. no. DIN registration no.

ML6435B1008

ML6435B1016

ML7435E1004

EN0B-0403GE51 R0709 2

1F152/08

Page 3

V5825B SMALL LINEAR VALVE / PN25

OPERATION

DH Compact valves V5825B are available in four sizes, from

DN15 through DN32. This description refers to size DN25.

A built-in return spring (4) produces the closing force on the

port A to port B. The valve is supplied with a screwed-on

valve cap for manual operation and for protection of the

1

4

5

2

3

6

AB

1 valve insert

2 valve body

3 valve plug

Fig. 1. DH Compact Valve V5825B, size DN25

(cross-sectional drawing)

4 return spring

5 cone stem boring

6 compensation chamber

system. This allows the system to be filled and set up for the

initial heating / cooling during the building construction phase

without the use of a controller or actuator.

The medium flows through the valve from port A to port B, in

the direction of the arrow mark on the valve body.

The flow rate is limited by the setting of the valve plug (3),

which is positioned either using the manually adjustable valve

cap or by an actuator. Maximum stroke means maximum flow

rate.

In order to be able to close precisely against high pressure

differences, the valve compensates pressure differences by

means of a cone stem boring (5) connecting to a compensation chamber (6).

Some specific actuators automatically retract the stem in the

event of a power failure in order to close the valve and stop

the flow of medium (refer to section "Actuators" on page 2).

INSTALLATION

When installing the valve, ensure that the flow direction

corresponds with the arrow direction on the valve body (see

Installation Instructions MU1B-0224GE51).

• The valve must not be mounted with the stem pointing

below the horizontal.

• The valve should be installed stress-free.

External threaded or welding connection sets are available

(refer to section "Accessories" on page 5).

• The installation of a strainer is strongly recommended; in

district heating systems, it is obligatory.

• Make sure that water hammers are avoided.

• For pressure test, the valve (with actuator) must be open.

• The adjustment cap must be removed from the valve only

when an actuator is fitted.

• The water must not contain more than 50% glycol

according to VDI 2035 requirements.

MAINTENANCE

In case of leakage or heavy soiling of the valve, the complete

valve insert (1) can be replaced (see section "Spare Parts" on

page 6).

EN0B-0403GE51 R0709

3

Page 4

V5825B SMALL LINEAR VALVE / PN25

DIMENSIONS

Valve V5825B

valve

normally

closed

max. 6.5

18

11. 5

fmax

c

g

d

e

Fig. 2. V5825B Dimensions (mm)

threaded connection welding connectionDN a

b

b* a2 b* a1

15 G¾" 65 125 R½" 175

20 G1" 70 138 R¾" 184

25 G1¼" 75 154 R1" 180

32 G1½" 100 192 R1¼" 264

a

dimensions in mm

16∅

20∅

27∅

32∅

a2

a1

b

b*

c d e f g

59 18 35 77 270

67 18 36 85 280

69 23 46 87 280

89 25 57 107 300

EN0B-0403GE51 R0709

4

Page 5

V5825B SMALL LINEAR VALVE / PN25

ACCESSORIES

Connection Sets

For threaded connections according to ISO 7/1 for steel pipes or malleable iron, refer to Fig. 3 (ACS-...T) or Fig. 4 (ACS-...W).

a

Fig. 3. External threaded connection

Two connection sets are necessary

connection pipe size DN order no. connection set description a b c

external

thread

welding

R½"

R¾"

R1"

R1¼"

½"

¾"

1"

1¼"

15

20

25

32

15

20

25

32

b

ACS-15T

ACS-20T

ACS-25T

ACS-32T

ACS-15W

ACS-20W

ACS-25W

ACS-32W

a c

Fig. 4. Welding connection

threaded connection

(consisting of 1 union nut,

1 tailpiece, and 1 gasket)

welding connection

(consisting of 1 union nut,

1 tailpiece, and 1 gasket)

G¾"

G1"

G1¼"

G1½"

G¾"

G1"

G1¼"

G1½"

R½"

R¾"

R1"

R1¼"

-

-

-

-

-

-

-

-

16∅

20∅

27∅

32∅

EN0B-0403GE51 R0709

5

Page 6

V5825B SMALL LINEAR VALVE / PN25

SPARE PARTS

Table 1. Valve inserts

kvs order no.

0.25 0903809

0.40 0903810

0.63 0903811

1.0 0903812

1.6 0903813

2.5 0903814

4.0 0903815

6.3 0903816

10.0 0903817

Table 2. Adapter for Salina

valve type to

be replaced

V5872B1003 V5825B1001 0.25 AK15-15

V5872B1011 V5825B1019 0.40 AK15-15

V5872B1029 V5825B1027 0.63 AK15-15

V5872B1037 V5825B1035 1.0 AK15-15

V5872B1045 V5825B1043 1.6 AK15-15

V5872B1052 V5825B1050 2.5 AK20-15

V5872B1060 V5825B1068 4.0 AK20-25

V5872B1078 V5825B1076 6.3 AK25-25

V5872B1086 V5825B1084 10.0 n.a.

NOTE: The valve adapter kit contains all of the components

required to replace one V5872B valve with the

V5825B.

new valve

model

kvs

order no. of valve

adapter kit

Fig. 5. Typical valve insert

Fig. 6. Valve adapter

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0403GE51 R0709

Loading...

Loading...