Page 1

APPLICATION

The V5197A is a firing rate valve used to provide variable

flow control of air, natural gas, liquefied petroleum (LP), and

manufactured gases. The V5197A is actuated by a firing rate

motor that can be mounted directly on the valve. The V5197A

is not applicable as a safety shutoff valve.

V5197A

Firing Rate Gas Valve

PRODUCT DATA

FEATURES

• Used with air, natural, manufactured or liquefied

petroleum (LP) gases.

• For modulating applications that do not require final

shutoff service of firing rate valve.

• Two valve body types (small and large) applicable to

seven pipe sizes:

• Small body type for 3/4 in. (19 mm), 1 in. (25 mm),

1-1/4 in. (32 mm), 1-1/2 in. (38 mm) and 2 in. (51 mm)

pipes, NPT or ISO 7 threads.

• Large body type for 2 in. (51 mm), 2-1/2 in. (64 mm)

and 3 in. (76 mm) pipes, NPT or ISO 7 threads.

• Two downstream 1/4 in. NPT threaded pressure taps

available.

• Accepts C6097 Pressure Switch mounted directly to

flange (downstream pressure tap only).

• Unpainted cast aluminum body.

• Suitable for electric or pneumatic operators with the

appropriate linkage.

• May be used with manufacturers own linkage and

drive motor.

• Flow adjustment screw on bottom of valve controls

maximum flow.

• Visual position indicator.

The V5197A is specially designed to provide fine control

of gas flow in applications where a high turn down ratio is

required.

The maximum flow adjustment screw on the bottom of the

valve allows adjusting the maximum flow of gas through the

V5197 while maintaining the linear modulating characteristics

and stroke.

The V5197A is part of the Honeywell Integrated Valve Train

System that allows gas train components to be directly bolted

together.

® U.S. Registered Trademark

Copyright © 2003 Honeywell International Inc.

All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 5

Checkout and Operation .................................................. 8

Service Information .......................................................... 8

65-0247-2

Page 2

V5197A FIRING RATE GAS VALVE

SPECIFICATIONS

IMPORTANT

The specifications in this publication do not

include normal manufacturing tolerances; therefore,

an individual unit may not exactly match the

specifications listed. Also, this product is tested

and calibrated under closely controlled conditions,

and some minor differences in performance can be

expected if those conditions are changed.

Models:

V5197A1003: Small body.

V5197A1011: Large body.

Type of Gas: Air, natural, manufactured, mixed or liquefied

petroleum (LP) gases only.

Pipe Size of the gas train: 3/4 in. (19 mm), 1 in. (25 mm),

1-1/4 in. (32 mm), 1-1/2 in. (38 mm), 2 in. (51 mm),

2-1/2 in. (64 mm), 3 in. (76 mm).

Pressure Rating: Maximum operating pressure of 15 psi

(1 Bar).

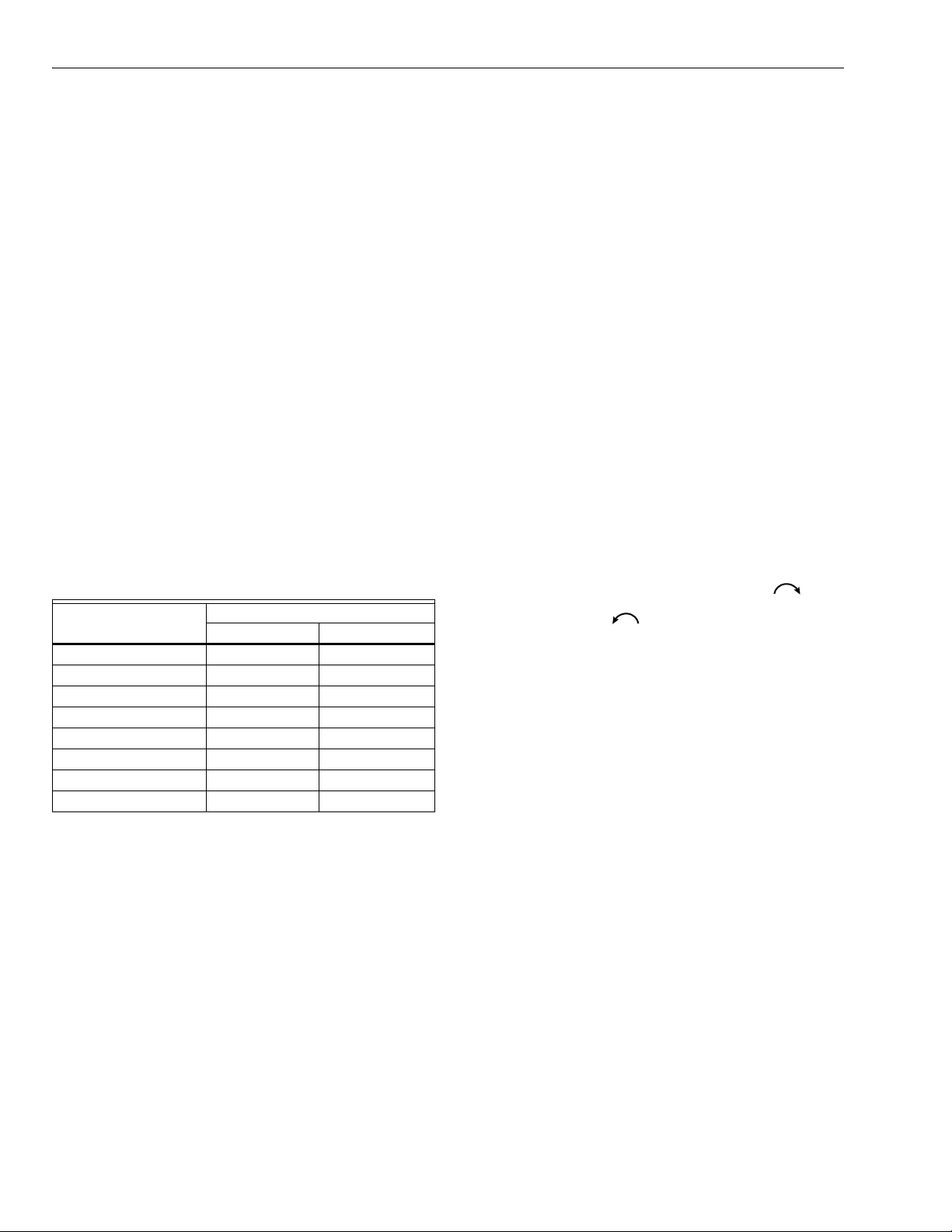

Maximum Valve Capacities: SCFH gas: 0.64 sp. gr. at

1 in. wc pressure drop across valve (flow limit adjustment

set at 100% open). See Table 1.

(natural gas at 0.64 sp.gr.) at 1 in. w.c. (2.5 mBar)

Pipe Size in in. (mm)

3/4 (19) 2450 69

1 (25) 3080 87

1-1/4 (32) 4430 125

1-1/2 (38) 5010 142

2 (51)—small body 5480 155

2 (51)—large body 12,600 356

2-1/2 (64) 14,800 419

3 (76) 16,900 478

a

Standard cubic feet per hour (SCFH) and standard cubic

meters per hour (SCMH) listed. For other gases, multiply the

listed capacity by the square root of (0.64 divided by the

specific gravity of the other gas).

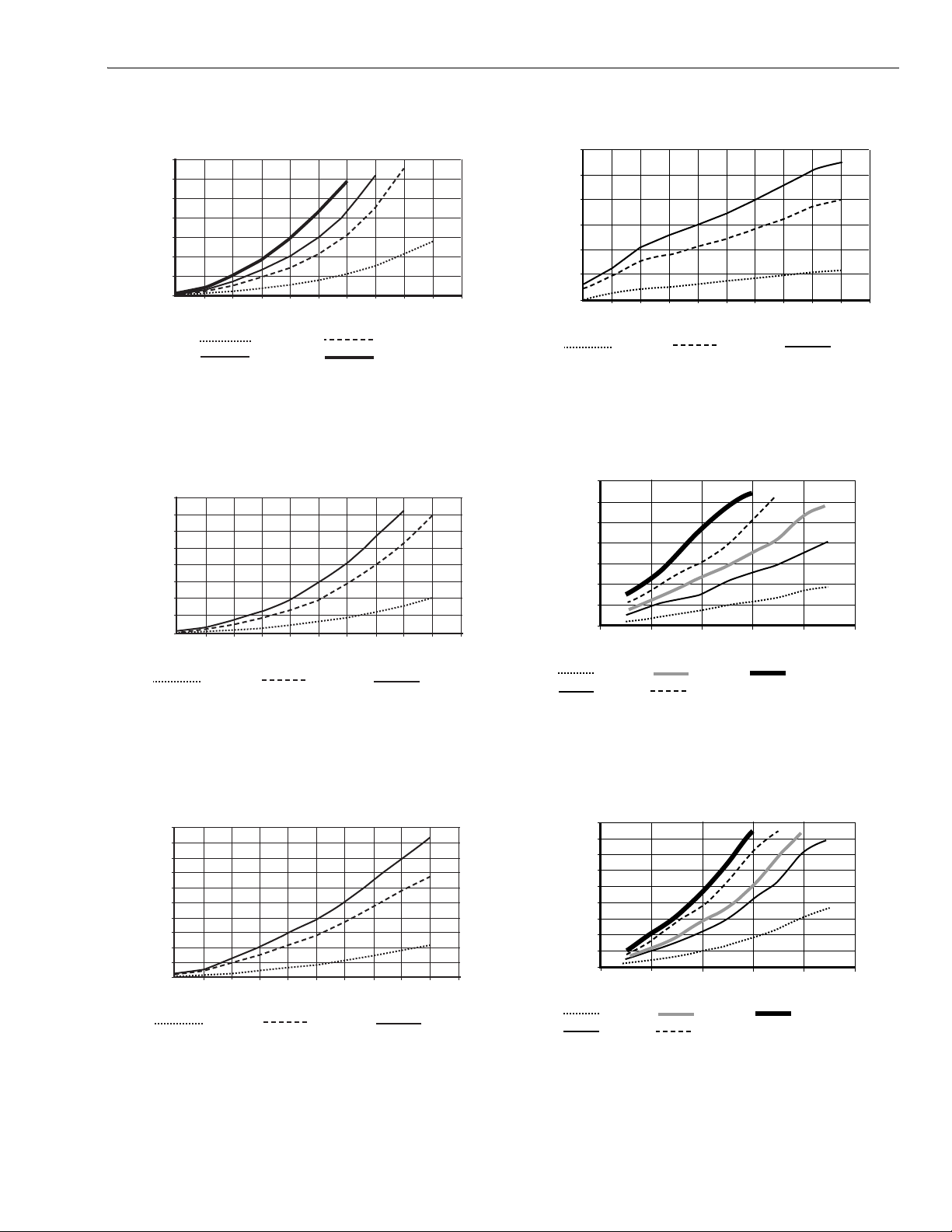

Flow curves: See Fig. 1 through 8.

Table 1. Maximum Flow Capacity

Pressure Drop Across Valve.

Flow Capacity

SCFH SCMH

a

NOTE: The percentage settings listed on the figures refer

to the setting of the flow adjustment screw on the

bottom of the V5197. Pressure drops are shown as

solid, broken or dotted lines on the figures.

Bolt/Nut Fasteners (Provided with the valve):

Small body: 3/8-16 by 1-3/8, Grade 5 bolt. Metric equivalent

M8x1.25x35mm, class 9.8. Tighten to 13 ft-lb (18 N•m).

Large body: 1/2-13 by 2.00, Grade 5 bolt. Metric equivalent

M12x1.75x50mm, class 9.8. Tighten to 25 ft-lb

(34 N•m).

Tapping and plug: Two downstream 1/4 in. NPT taps.

Plugs : 1/4 in. hex socket.

Ambient Operating Temperature Rating: -40°F to +150°F

(-40°C to +66°C).

Material: Cast aluminum body, brass and stainless steel

internal parts, NBR seals.

Mounting: Directly bolted to Integrated Valve Train (IVT)

components or IVT adapters.

Mechanical Strength: Group 2.

Maximum flow adjustment (Fig 9):

Located on the bottom of the valve with a 1/4 in. (6 mm)

hex key:

To decrease the maximum flow, turn clockwise ;

to increase the maximum flow, turn

counterclockwise .

Mounting position: Any position.

Dimensions: See Fig. 10 and 11.

Weight:

Small Body—5-1/4 lb (2.4 kg).

Large Body— 11-5/8 lb (5.3 kg).

Accessory: 201391 Shaft Adapter for 3/8 in. (10 mm) round

or square shaft (provided with both small body and large

body valves.

Approvals:

Underwriters Laboratories, Inc. (UL).

CSA.

EN161 Approval requires the use of an EN161-approved

actuator.

CE.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0247—2 2

Page 3

V5197A FIRING RATE GAS VALVE

B

FLOW 0.64 s.g. GAS (cfh)

V5197A1003

0

FLOW 0.64 s.g. GAS (cfh)

V5197A1003

0

M17523B

FLOW 0.64 s.g. GAS (cfh)

V5197A1003

0

B

FLOW 0.64 s.g. GAS (cfh)

V5197A1003

0

FLOW 0.64 s.g. GAS (cfh)

0

V5197A1011

FLOW 0.64 s.g. GAS (cfh)

0

A

V5197A1011

14000

12000

10000

8000

6000

4000

2000

0

0 10203040506070809010

1 INCH

20 INCH

100%

DEGREE OPEN

10 INCH

40 INCH

M17521

Fig. 1. V5197A (small body) flow curves at stated

pressure drops with flow adjustment set at 100%.

16000

14000

12000

10000

8000

6000

4000

2000

0

0 102030405060708090

1 INCH

75%

DEGREE OPEN

10 INCH

20 INCH

M17522B

3000

2500

2000

1500

1000

500

0

0 102030405060708090

1 INCH

25%

DEGREE OPEN

10 INCH

10

20 INCH

M17524

Fig. 4. V5197A (small body) flow curves at stated

pressure drops with flow adjustment set at 25%.

14000

12000

10000

8000

6000

4000

2000

0

10

020406080

1 INCH

5 INCH

25%

DEGREE OPEN

10 INCH

20 INCH

10

40 INCH

M17894A

Fig. 2. V5197A (small body) flow curves at stated

pressure drops with flow adjustment set at 75%.

10000

9000

8000

7000

6000

5000

4000

3000

2000

1000

0 102030405060708090

1 INCH

50%

DEGREE OPEN

10 INCH

20 INCH

Fig. 3. V5197A (small body) flow curves at stated

pressure drops with flow adjustment set at 50%.

Fig. 5. V5197A (large body) flow curves at stated

pressure drops with flow adjustment set at 25%.

18000

16000

14000

12000

10000

8000

6000

4000

2000

10

020406080

1 INCH

5 INCH

50%

DEGREE OPEN

10 INCH

20 INCH

30 INCH

M17895

Fig. 6. V5197A (large body) flow curves at stated

pressure drops with flow adjustment set at 50%.

3 65-0247—2

10

Page 4

V5197A FIRING RATE GAS VALVE

FLOW 0.64 s.g. GAS (cfh)

V5197A1011

0

A

A

4

16000

14000

12000

10000

8000

6000

4000

2000

0

020406080

1 INCH

2 INCH

75%

DEGREE OPEN

5 INCH

10 INCH

20 INCH

Fig. 7. V5197A (large body) flow curves at stated

pressure drops with flow adjustment set at 75%.

V5197A 1011

18000

16000

14000

12000

10000

8000

6000

4000

FLO W 0.64 s.g. G AS (cfh)

2000

100%

M17896

32000109-005 2 in. (51 mm—small body valve only.

32001605-001 2 in. (51 mm)—large body valve only.

32001605-002 2-1/2 in. (64 mm).

32001605-003 3 in. (76 mm).

Pipe Adapters, BSP:

32000109-006 3/4 in. (19 mm).

32000109-007 1 in. (25 mm).

32000109-008 1-1/4 in. (32 mm).

32000109-009 1-1/2 in. (38 mm).

32000109-010 2 in. (51 mm)—small body valve only.

32001605-004 2 in. (51 mm)—large body valve only.

32001605-005 2-1/2 in. (64 mm).

32001605-006 3 in. (76 mm).

10

4074EYE Bag Assembly (bolts, nuts and washers for large

body valve), supplied.

4074EYF Bag assembly (bolts, nuts and washers for small

body valve), supplied.

4074EYK Bag Assembly (O-rings and tube of lubricant for

small body valve), supplied.

4074EYL Bag Assembly (O-rings and tube of lubricant for

large body valve), supplied.

The following non-part-numbered items are provided with

the valve:

ML7999 Actuator Mounting Bracket

Mounting Bracket Screws

Valve Drive Stem

020406080

DEGREE OPEN

.5 INCH

1 INCH

5 INCH

10 INCH

20 INCH

60 INCH

100

M17897

Fig. 8. V5197A (large body) flow curves at stated

pressure drops with flow adjustment set at 100%.

Accessories:

201391 3/8 in. Shaft Adapter for mounting ML7999A/B to

V5197.

Pipe Adapters, NPT:

32000109-001 3/4 in. (19 mm).

32000109-002 1 in. (25 mm).

32000109-003 1-1/4 in. (32 mm).

32000109-004 1-1/2 in. (38 mm).

FLOW

ADJUSTMENT

Fig. 9. V5197 Flow Adjustment.

M1763

65-0247—2 4

Page 5

V5197A FIRING RATE GAS VALVE

1

)

2

1

6

V

D

S

V

P

I

S

0-5/16

(277)

4-27/32 (123)

2-1/2 (64)

6-7/16 (165)

7-1/8

(181

3-25/3

(96)

M17528

2-11/16

(322)

4-13/16 (122)

4 (102)

9-1/4 (235)

7-15/1

(202)

4-3/4

(121)

M17898

Fig. 10. V5197A Firing Rate Gas Valve (small body), with

mounting bracket (included) and ML7999 Actuator

(not supplied), dimensions in in. (mm).

Fig. 11. V5197A Firing Rate Gas Valve (large body), with

mounting bracket (included) and ML7999 Actuator (not

supplied), dimensions in in. (mm).

INSTALLATION

Installing the Valve Drive Stem in the V5197

When Installing this product…

1. Read these instructions carefully. Be sure to follow

Warning information carefully.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced flame

safeguard control technician.

4. After installation is complete, check out product

operation as provided in these instructions.

1. Place the short end of the Valve Drive Stem in the top of

the V5197 Valve drive so that the square portion of the

drive stem is fully engaged in the square hole in the

valve drive assembly. See Fig. 12.

NOTE: The short end of the Valve Drive Stem is

1 in. (25 mm) in length (measured from the square

portion of the stem); the long end of the Valve

Drive Stem is 1-1/8 in. (35 mm) long.

2. Tighten the valve position indicator setscrew (located

in the valve drive assembly) to a torque setting of

5 inch-pounds (80 inch-ounces/6 kg-cm).

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause explosion, serious injury or death.

1. Turn off gas supply before starting installation.

2. Disconnect power supply for valve actuator

(if applicable) before beginning installation.

More than one disconnection can be involved.

Installation

ALVE

RIVE

TEM

ALVE

OSITION

NDICATOR

ETSCREW

IMPORTANT

Install the valve so the arrow on the valve body

points in the gas flow direction.

M17686

Fig. 12. Inserting the Valve Drive

Stem in the V5197 Valve.

5 65-0247—2

Page 6

V5197A FIRING RATE GAS VALVE

Installing the V5197 in the IVT

Refer to the Integrated Valve Train Installation instructions

(form 66-1099) for complete instructions on mounting a

V5197A in a Honeywell Integrated Valve Train System.

Allow sufficient clearance for assembling the motor and

linkage (if applicable), and for general servicing.

IMPORTANT

Install the valve so the arrow on the valve body

points in the gas flow direction. Make sure the O-ring

seals (provided) are properly positioned and seated

at the inlet and outlet flange connections.

1. Install the V5197 Valve so the arrow on the valve body

points in the gas flow direction.

NOTE: Normally, the V5197 will be located

downstream of the safety shutoff valve(s) in

the Integrated Valve Train.Refer to form

66-1099 or the following steps.

2. Using the grease packet provided (or equivalent,

general purpose, lithium grease), grease the O-rings

provided with the valve. Make sure the grease is applied

evenly around the O-ring. See Fig. 13.

3. Connect the V5197 Valve to the safety shutoff valve

(SSOV) using three bolts, nuts and lockwashers as

shown in Fig. 13.

NOTE: Tightening torque for nuts/bolts:

• Small body flanges: 13 ft-lb (18 N-m).

• Large body flanges: 25 ft-lb (34 N-m).

4. Connect the pipe adapter to the other end of the V5197

Valve using three bolts, nuts and lockwashers.

5. Assemble the downstream gas piping:

a. Use new, properly reamed, pipe, free from chips.

b. Apply moderate amounts of good quality pipe dope,

resistant to the action of liquid propane (LP) gas,

on the pipe threads. See Fig. 14.

c. Do not thread pipe too far into pipe adapter.

The pipe should end flush with the O-ring sealing

surface of the pipe adapters. Valve distortion or

malfunctions can result from excess pipe in the

valves.

6. Mount the ML7999 Actuator on the V5197 Valve and

secure the actuator to the mounting bracket.

7. Wire the ML7999 Actuator according to instructions

in form no. 65-0239.

8. Restore power to the system.

GREASE

PACKET

GREASE

PACKET

O-RING

PIPE ADAPTER

Fig. 13. Mounting the V5197 Valve in the IVT.

Mounting the ML7999 Mounting Bracket

The ML7999 Actuator and mounting bracket can be installed

in one of four positions, depending on accessibility of the

valve and actuator. See Fig. 15.

VALVE

V5197

O-RING

3 BOLTS ON

EACH SIDE

M17681

1. Choose the actuator and bracket position best suited for

your location and place the mounting bracket over the

drive shaft of the V5197 valve. See Fig. 16.

2. Manually open the V5197 valve for proper alignment of

the ML7999 Actuator.

3. Secure the mounting bracket with the three screws

provided.

65-0247—2 6

Page 7

V5197A FIRING RATE GAS VALVE

INCORRECT:

T

CORRECT: NORMAL

0

7

G

2

S

A

7

FULL THREAD

TWO CLEAN THREADS

WITH MODERATE

AMOUNT OF DOPE

PIPE

ADAPTER

CORRECT

USE PIPE DOPE RESISTANT

1

TO ACTION OF LP GAS.

DISTORTS VALVE SEAT

LOOSE

CHIPS

1

REAM PIPE AND BLOW

OUT CHIPS (TO AVOID

LODGING ON SEAT)

TOO LONG,

EXCESS DOPE

CAN BLOCK DISK

FROM VALVE SEA

PIPE

ADAPTER

INCORRECT:

TOO LONG,

DISTORTS VALVE SEAT

M1641

Fig. 14. Preparing pipes.

Mounting the ML7999 Actuator

1. Insert the shaft adapter and place the actuator over the

shaft. Position and seat the actuator.

ML7999

MOUNTIN

BRACKET

Fig. 15. Possible mounting positions of the

ML7999 Actuator and mounting bracket.

V519

M17682

NOTE: Use the 201391 shaft adapter (included with

the valve) to mount the ML7999 Actuator to the

V5197 Valve drive stem. Place the adapter as

shown in Fig. 16 so that the valve drive shaft is

between the adapter and the four setscrews.

2. Secure the actuator to the mounting bracket using a

bolt, nut and locking washer. See Fig. 17.

CAUTION

Equipment Damage Hazard.

Improper alignment can damage the actuator.

Align the ML7999 Actuator bottom panel parallel with

the ML7999 mounting bracket (Fig. 18). Failure to do

so will cause undue stress on the actuator motor and

shorten its operating life.

3. Partially tighten the four hub setscrews to ensure that

the actuator seats firmly against the mounting bracket

with the shaft centered in the actuator hub. See note 1

in Fig. 18.

4. Tighten the anti-rotation bolt to the torque

recommendation for the selected bolt/nut.

5. Tighten the hub setscrews against the shaft to a torque

of 60 in-lb (69 kg-cm). See Fig. 17.

M17685

Fig. 16. Attaching the ML7999 Actuator mounting bracket

to the V5197 Valve (valve in the open position).

01391

HAFT

DAPTER

ML7999A/B

ACTUATOR HUB

V5197

DRIVE STEM

7 65-0247—2

Fig. 17. Proper positioning of 201391 shaft adapter

and V5197 drive shaft.

ML7999

SETSCREWS

M2102

Page 8

V5197A FIRING RATE GAS VALVE

)

ML7999

1

HUB

SCREWS

1

V5197

1

ML7999 MUST BE MOUNTED PARALLEL WITH MOUNTING BRACKET.

ANTI-ROTATION

BOLT AND LOCKING

NUT (NOT SUPPLIED

ML7999

MOUNTING

BRACKET

M17683

replaced (see Service Information section). It is recommended

that this test also be included in the scheduled inspection and

maintenance procedures.

NOTE: Additional leakage and closure tests may be required

for other gas train components (for example, safety

shutoff valves [SSOV]).

1. Close the downstream manual gas valve(s).

2. Energize the valve train to apply gas pressure.

3. Test with rich soap and water solution to make sure

there is no leak at any pipe adapter/valve mating

surfaces.

4. Restore the system to normal operation.

Fig. 18. Mounting the ML7999 Actuator

on the V5197 Valve.

CHECKOUT AND OPERATION

Checkout

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause explosion, serious injury or death.

1. Do not allow fuel to accumulate in the combustion

chamber for longer than a few seconds without

igniting. An explosive mixture can result.

2. Do not put the system into service until you have

satisfactorily completed the following Valve Leak

Test, all applicable tests described in the Checkout

section of the instructions for the flame safeguard

control, and any other tests required by the burner

manufacturer.

3. All tests must be performed by a trained,

experienced flame safeguard control technician.

4. Close all manual fuel shutoff valves as soon as

trouble occurs.

After the installation is completed, cycle the valve several

times with the manual fuel shutoff cock closed. Make sure the

valve and actuator function properly. Also perform the Valve

Leak Test before putting the valve into service.

Valve Leak Test

This is a test for checking the leakage tightness of the firing

rate gas valve only. It should be performed only by trained,

experienced flame safeguard control technicians during the

initial startup of the burner system, or whenever the valve is

Operation

A V5197A Firing Rate Gas Valve is operated by an actuator.

The valve opens counterclockwise and closes

clockwise . When closed, the valve does not totally seal

off the gas flow and has no safety shutoff function. For further

information, refer to the actuator instructions.

Make sure that the actuator does not force the V5197 Valve

beyond the limits of the valve stroke (90 degrees). This can

damage or destroy the valve position indicator setscrew.

SERVICE INFORMATION

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause explosion, serious injury or death.

1. Turn off the gas supply and disconnect all electrical

power to the valve actuator before servicing.

2. Properly position and seat the seals in ends of the

valve body to prevent a hazardous gas leak.

Read these instructions and form 66-1099 carefully

for servicing information.

IMPORTANT

Only trained, experienced flame safeguard control

technicians should attempt to service or repair flame

safeguard controls and burner assemblies.

Scheduled Inspection and Maintenance

Set up and follow a schedule for periodic inspection and

maintenance for the burner, all other controls and the valves.

It is recommended that the valve leak test in the Operation

and Checkout section be included in this schedule. Refer to

the instructions for the primary safety control and safety

shutoff valve(s) for more information.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

65-0247—2 G.R. Rev. 06-03 www.honeywell.com

M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...