Page 1

V5032

Kombi-2-plus

BALANCING AND SHUTOFF VALVE

PRODUCT DATA

CONTENTS

Design...................................................................................1

Materials................................................................................1

Application............................................................................1

Features................................................................................1

Specifications.......................................................................2

Function................................................................................2

Dimensions, kvs-values and Ordering Information ..........2

Accessories..........................................................................3

Connections .......................................................................3

Accessories........................................................................ 3

Measuring equipment.........................................................3

Spare parts.........................................................................3

Flow Data.................................................................... 4 to 11

Influence of Coolants on Flow Values..............................12

Correction Factor f ...........................................................12

Design

The Kombi-2-plus valve consists of:

•

Valve body with pressure test cocks and internal threads

DN10...DN20 to DIN2999 (ISO7) for threaded pipe or copper and precision steel pipe 10...20 mm (see Accessories),

or

•

Valve body DN25...DN80 with pressure test cocks and

internal threads to DIN2999 (ISO7) for threaded pipe

•

Valve insert

•

Blue handwheel with pre-setting dial and display

Materials

•

Valve housing made of red bronze

•

Valve insert and pressure test cocks made of brass

•

O-rings and soft seals made of EPDM

•

Handwheel, pre-setting dial and display made of plastic

Application

The Kombi-2-plus is installed in the return mains of pump

driven warm water heating systems and cold water cooling

systems to regulate the hydronic balance and as shutoff

valve. The Kombi-2-plus has an O-ring spindle seal and is

maintenance free. The valve body can be insulated easily

and is equipped with pressure test cocks for differential pressure or flow measurement.

Further functions can be retrofitted without interrupting operation of the system: draining, filling and automatic regulation

(in combination with a Kombi-3-plus BLACK valve in the supply and a Kombi-Diaphragm Unit).

Features

• Maintenance free spindle with double O-ring sealings

• PTFE seat sealing

• High accuracy of the pre-setting because of individual

adjustment

• Valve body PN16

• Dimensions DN15 to DN40 can be retrofitted with a

Kombi-Diaphragm Unit

• Robust valve body made of corrosion resistant red

bronze

• Availabe in sizes up to DN80

• Visible pre-setting dial with concealed pre-setting

wheel

Copyright © 2002 Honeywell AG • All rights reserved EN0H-0048GE25 R0402

Page 2

KOMBI-2-PLUS (V5032)

Specifications

Medium

Operating temperature

Operating pressure

Differential pressure

vs

(cv)-values

k

NOTE: Differential pressure: Closing pressure for

Kombi-2-plus with installed Kombi-Diaphragm Unit.

Regarding noise generation the conditions, requirements and installation design have to be taken into

account.

Water, water-glycole mixture

2...130°C (36...266°F)

max. 16 bar (232 psi)

max. 2,0 bar (29 psi) –

see NOTE below

see table on page 2

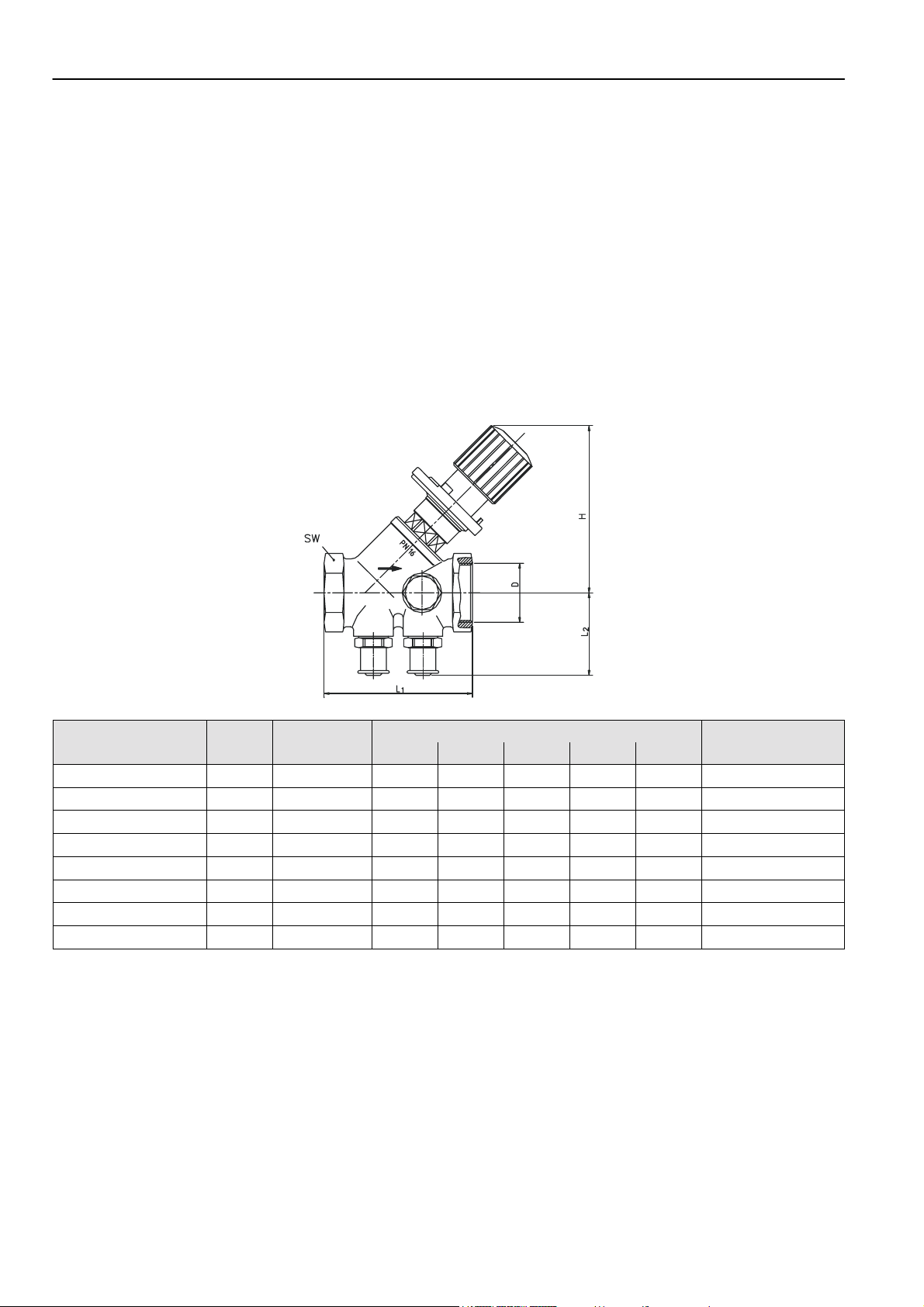

Dimensions, kvs-values and Ordering Information

Function

The hydronic balance is a significant requirement for the

efficient operation of a hydronic heating or cooling installation.

In an unbalanced system under or over provision of hot water

to individual radiators or circuits can occur. Apart from the

correct selection of radiator valves, regulation of individual

circuits is also necessary and in some cases, such as in

DIN 18 380, VOB part C, is required by national standards.

This requirement is met with the shutoff and balancing valve

Kombi-2-plus. The Kombi-2-plus for the return has the functions shutoff, pre-setting, regulation (with diaphragm unit,

accessory), draining and filling (draining adapter, accessory).

Type DN kvs (cv)- Dimensions OS-No.

value D H L

Internal threads 15 2,7 (3,16) Rp1/2” 85 65 41 27 V5032Y0015

Internal threads 20 6,4 (7,49) Rp3/4” 100 75 42 32 V5032Y0015

Internal threads 25 6,8 (7,96) Rp1” 100 90 45 41 V5032Y0015

Internal threads 32 21,0 (24,6) Rp1 1/4” 137 110 46 50 V5032Y0015

Internal threads 40 22,0 (25,7) Rp1 1/2” 137 120 49 55 V5032Y0015

Internal threads 50 38,0 (44,5) Rp2” 158 150 55 70 V5032Y0015

Internal threads 65 47,7 (55,8) Rp2 1/2” 195 180 68 85 V5032Y0015

Internal threads 80 71,0 (83,1) Rp3” 210 200 75 100 V5032Y0015

NOTE: All values in mm if not stated otherwise.

Dimension ‘H’ refers to fully open valve.

1

2

L

SW

EN0H-0048GE25 R0402 2 Honeywell AG • All rights reserved

Page 3

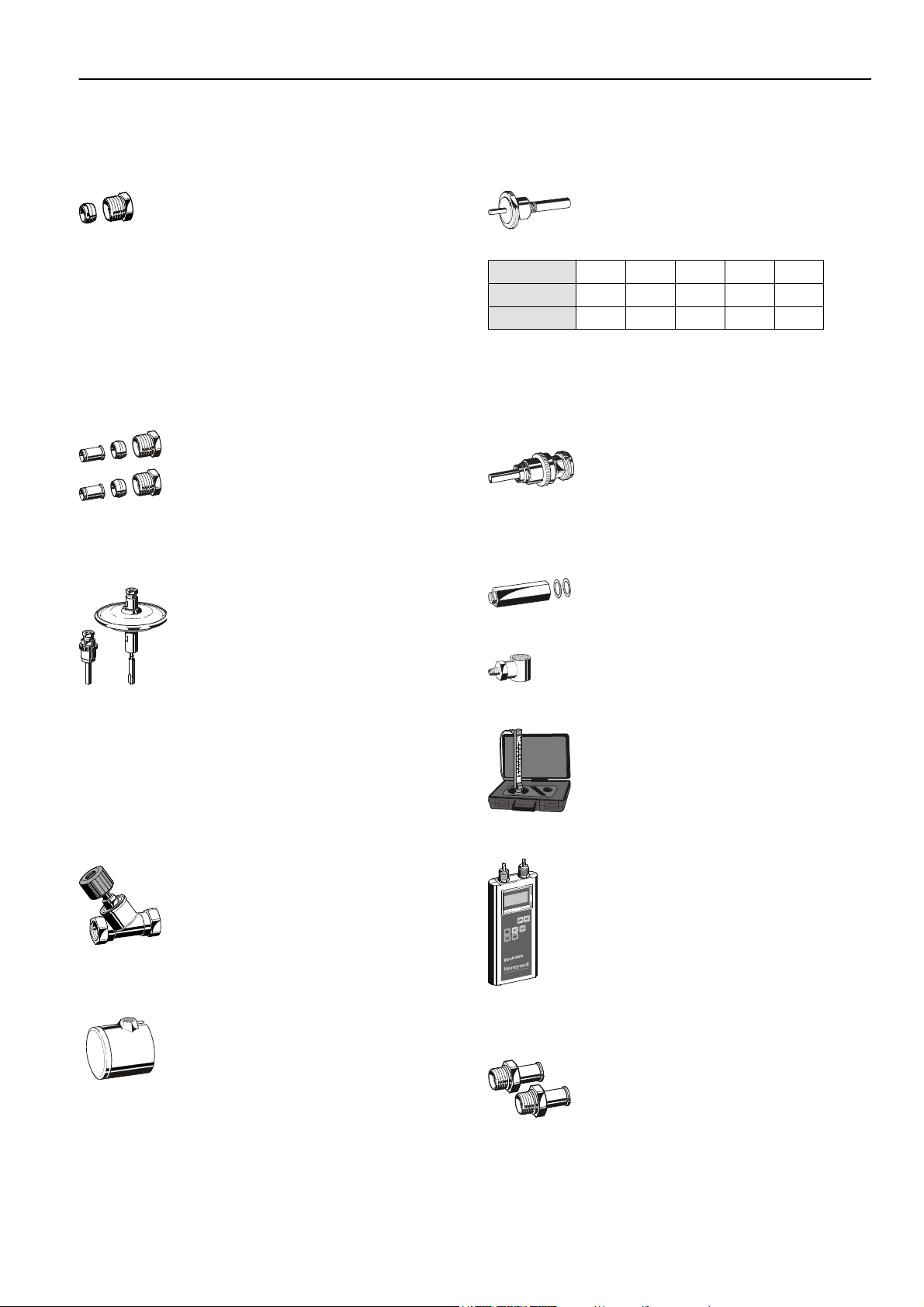

Accessories

Connections

Set of compression ring and nut

1/2” x 10 mm VA650A1210

1/2” x 12 mm VA650A1212

1/2” x 14 mm VA650A1214

1/2” x 15 mm VA650A1215

1/2” x 16 mm VA650A1216

3/4” x 18 mm VA650A2018

3/4” x 22 mm VA650A2022

NOTE: Support inserts have to be used for soft copper and

Set of compression ring, nut and support insert (2 pcs each)

Accessories

Kombi-DU Diaphragm Unit (V5012) for valves DN15...DN40

steel pipe (wall thickness 1 mm).

1/2” x 12 mm VA651A1212

1/2” x 15 mm VA651A1215

1/2” x 16 mm VA651A1216

3/4” x 18 mm VA651A2018

Setting range 0,1...0,3 bar

(1,45...4,35 psi) differential

pressure

Setting range 0,3...0,6 bar

(4,35...8,7 psi) differential

pressure

V5012A0103

V5012A0306

KOMBI-2-PLUS (V5032)

Adapter for actuators with M 30 x 1,5 connection

for valves DN15...DN40 VA2500A001

vs

-values for Kombi-2-plus with installed adapter:

k

DN

kvs-value

cv-value

NOTE: The Kombi-2-plus valve must be pre-set to 1.5 (for

DN15...25) or 1.0 (DN32...40) when used with actuator.

Pump pressure: max. 2 bar (29 psi)

Draining adapter

15 20 25 32 40

1,50 3,50 3,50 5,50 5,50

1,76 4,1 4,1 6,44 6,44

for all sizes VA3500A001

Measuring equipment

Extension piece for pressure test cocks, length 45 mm – for use with

insulated Kombi-2-plus

for all sizes VA2601A008

Measuring adapters (2 pcs)

for all sizes VS3600A008

NOTE: For product information and diagrams see product

data sheet ‘V5012 Kombi-DU’.

The Kombi-2-plus valve must be pre-set to 1.5 (for

DN15...25) or 1.0 (DN32...40) when used with the

Kombi-Diaphragm Unit.

Pump pressure: max. 2 bar (29 psi)

Kombi-3-plus BLACK (V5100) as shutoff valve and Kombi-DU connection point in the s upply

DN15 V5100Y0015

DN20 V5100Y0020

DN25 V5100Y0025

DN32 V5100Y0032

DN40 V5100Y0040

Tamper-proof cap

for valves DN15...DN25 VA2501A010

for valves DN32...DN50 VA2501A032

Flow meter

for all sizes VM200A1001

‘BasicMES’ handheld measuring computer

for all sizes; computer is supplied with case and accessories

Spare parts

Pressure test cocks (2 pcs)

for all sizes VA2600A008

VM241A1002

Honeywell AG • All rights reserved 3 EN0H-0048GE25 R0402

Page 4

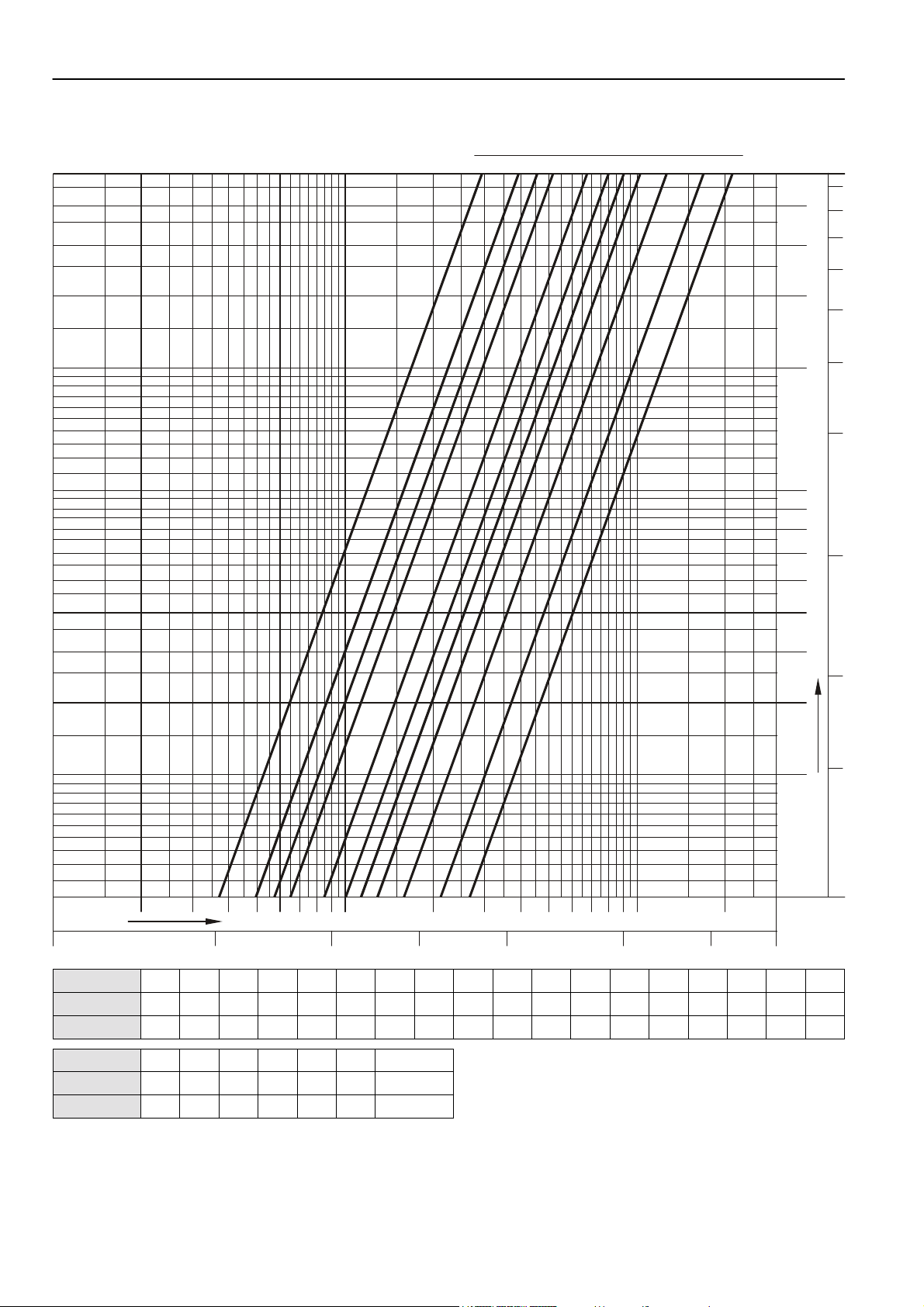

KOMBI-2-PLUS (V5032)

P

Flow Data DN15

0,3

0,6

0,8

re-setting

1,5 2

2,5

7

3,5

4

4,9

0

0

1

31

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

10 2

kg/h

Flow

Pre-setting

kv-value

cv-value

5

4

3

2

r

p

a

o

b

r

a

d

m

P

e

r

u

s

0

s

0

e

r

0

0

1

1

P

356781009245

4

0,025 0,050,0028 0,01 0,5l/sec

0,1

7 8 1000932

6

0,25

3

0,3 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6

0,37 0,43 0,49 0,57 0,65 0,73 0,81 0,88 0,94 1,00 1,05 1,10 1,16 1,22 1,32 1,42 1,57 1,74

0,43 0,50 0,57 0,67 0,76 0,85 0,95 1,03 1,10 1,17 1,23 1,29 1,36 1,43 1,54 1,66 1,84 2,04

5

,

0

3

,

0

.

I

.

S

.

P

5

4

1

,

0

Pre-setting

kv-value

cv-value

3,8 4,0 4,2 4,4 4,6 4,8 4,9 = open

1,92 2,12 2,31 2,49 2,63 2,67 kvs = 2,70

2,25 2,48 2,70 2,91 3,08 3,12 3,16

NOTE: Flow diagram is ONLY valid for valve WITHOUT installed actuator (-adapter) or Kombi-Diaphragm Unit

EN0H-0048GE25 R0402 4 Honeywell AG • All rights reserved

Page 5

Flow Data DN20

P

0,3

0,6

0,8

KOMBI-2-PLUS (V5032)

re-setting

1,5

1

2,5 3

2

3,5

4

51,2 5,9

0

0

1

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

60 100

kg/h

Flow

l/sec

Pre-setting

kv-value

cv-value

5

4

3

2

r

p

a

o

b

r

a

d

m

P

e

r

u

s

0

s

0

e

r

0

0

1

1

P

2 4 5 6 7 8 100093 2 4 5 6 7 8 1000093

0,05

0,10,017

0,25

0,5

1,0

2,5

0,3 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6

0,68 0,72 0,84 0,97 1,10 1,30 1,50 1,70 1,90 2,10 2,30 2,50 2,70 2,91 3,12 3,36 3,60 3,86

0,80 0,84 0,98 1,13 1,29 1,52 1,76 1,99 2,22 2,46 2,69 2,93 3,16 3,40 3,65 3,93 4,21 4,52

5

,

0

3

,

0

.

I

.

S

.

P

5

4

1

,

0

Pre-setting

kv-value

cv-value

3,8 4,0 4,2 4,4 4,6 4,8 5,0 5,2 5,4 5,6 5,8 5,9 = open

4,12 4,40 4,69 4,99 5,28 5,57 5,84 6,07 6,26 6,32 6,38 kvs = 6,40

4,82 5,15 5,49 5,84 6,18 6,52 6,83 7,10 7,32 7,39 7,46 7,49

NOTE: Flow diagram is ONLY valid for valve WITHOUT installed actuator (-adapter) or Kombi-Diaphragm Unit

Honeywell AG • All rights reserved 5 EN0H-0048GE25 R0402

Page 6

KOMBI-2-PLUS (V5032)

P

Flow Data DN25

0,3

0,6

0,8

re-setting

1,5

1

2,5 3

2

3,5

4

5,9

51,2

0

0

1

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

60 100

kg/h

Flow

l/sec

Pre-setting

kv-value

cv-value

5

4

3

2

r

p

a

o

b

r

a

d

m

P

e

r

u

s

0

s

0

e

r

0

0

1

1

P

2 4 5 6 7 8 100093 2 4 5 6 7 8 1000093

0,05

0,10,017

0,25

0,5

1,0

2,5

0,3 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6

0,68 0,72 0,84 0,97 1,10 1,30 1,50 1,70 1,90 2,10 2,30 2,50 2,70 2,95 3,20 3,48 3,76 4,05

0,80 0,84 0,98 1,13 1,29 1,52 1,76 1,99 2,22 2,46 2,69 2,93 3,16 3,45 3,74 4,07 4,40 4,74

5

,

0

3

,

0

.

I

.

S

.

P

5

4

1

,

0

Pre-setting

kv-value

cv-value

3,8 4,0 4,2 4,4 4,6 4,8 5,0 5,2 5,4 5,6 5,8 5,9 = open

4,34 4,64 4,94 5,24 5,52 5,80 6,06 6,30 6,50 6,65 6,75 kvs = 6,80

5,08 5,43 5,78 6,13 6,46 6,79 7,09 7,37 7,61 7,78 7,90 7,96

NOTE: Flow diagram is ONLY valid for valve WITHOUT installed actuator (-adapter) or Kombi-Diaphragm Unit

EN0H-0048GE25 R0402 6 Honeywell AG • All rights reserved

Page 7

Flow Data DN32

P

0,5

KOMBI-2-PLUS (V5032)

re-setting

1

1,2

1,5 2

4

5

3

6,5

6

0

0

1

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

100 2

kg/h

Flow

Pre-setting

kv-value

cv-value

5

4

3

2

r

p

a

o

b

r

a

d

m

P

e

r

u

s

0

s

0

e

r

0

0

1

1

P

3 5 6 7 8 10009245

4

0,25 0,50,028 0,1 5,0l/sec

1,0

7 8 10000932

6

2,5

3

0,5 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6 3,8

1,40 1,45 1,55 1,60 2,60 3,70 4,80 5,90 6,50 6,90 7,50 8,30 9,20 10,2 11,2 12,2 13,2 14,1

1,64 1,70 1,81 1,87 3,04 4,33 5,62 6,90 7,61 8,07 8,78 9,71 10,8 11,9 13,1 14,3 15,4 16,5

5

,

0

3

,

0

.

I

.

S

.

P

5

4

1

,

0

Pre-setting

kv-value

cv-value

4,0 4,2 4,4 4,6 4,8 5,0 5,2 5,4 5,6 5,8 6,0 6,2 6,4 6,5 = open

15,0 15,8 16,5 17,1 17,7 18,2 18,6 19,0 19,4 19,7 20,0 20,4 20,8 kvs = 21,0

17,6 18,5 19,3 20,0 20,7 21,3 21,8 22,2 22,7 23,0 23,4 23,9 24,3 24,6

NOTE: Flow diagram is ONLY valid for valve WITHOUT installed actuator (-adapter) or Kombi-Diaphragm Unit

Honeywell AG • All rights reserved 7 EN0H-0048GE25 R0402

Page 8

KOMBI-2-PLUS (V5032)

P

Flow Data DN40

re-setting

6

0,5 6,5

1

1,2

1,5 2

3

5

4

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

0

0

1

1

9

8

0

,

7

1

6

100 2

kg/h

Flow

Pre-setting

kv-value

cv-value

5

4

3

2

r

p

a

o

b

r

a

d

m

P

e

r

u

s

0

s

0

e

r

0

0

1

1

P

3 5 6 7 8 10009245

4

0,25 0,50,028 0,1 5,0l/sec

1,0

7 8 10000932

6

2,5

3

0,5 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6 3,8

1,40 1,45 1,55 1,60 2,60 3,70 4,80 5,90 6,50 6,90 7,50 8,30 9,20 10,2 11,2 12,2 13,2 14,1

1,64 1,70 1,81 1,87 3,04 4,33 5,62 6,90 7,61 8,07 8,78 9,71 10,8 11,9 13,1 14,3 15,4 16,5

5

,

0

3

,

0

.

I

.

S

.

P

5

4

1

,

0

Pre-setting

kv-value

cv-value

4,0 4,2 4,4 4,6 4,8 5,0 5,2 5,4 5,6 5,8 6,0 6,2 6,4 6,5 = open

15,0 15,8 16,5 17,1 17,7 18,2 18,6 19,0 19,4 19,7 20,0 20,8 21,6 kvs = 22,0

17,6 18,5 19,3 20,0 20,7 21,3 21,8 22,2 22,7 23,0 23,4 24,3 25,3 25,7

NOTE: Flow diagram is ONLY valid for valve WITHOUT installed actuator (-adapter) or Kombi-Diaphragm Unit

EN0H-0048GE25 R0402 8 Honeywell AG • All rights reserved

Page 9

Flow Data DN50

P

KOMBI-2-PLUS (V5032)

re-setting

1

1,5

2

2,5 3

3,5

4

57

7,9

0

0

1

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

100

Flow

Pre-setting

kv-value

cv-value

5

4

3

2

r

p

a

o

b

r

a

d

P

m

e

r

u

s

0

s

0

e

r

0

0

1

1

P

4kg/h

2

3 5 6 7 8 10009 2 4 5 6 7 8 10000932

0,25

0,50,028 0,1 5,0l/sec

1,0

2,5

3

1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6 3,8 4,0 4,2 4,4

0,80 1,25 1,88 2,72 3,78 5,10 6,68 8,54 10,7 13,0 15,6 18,7 21,0 22,8 24,3 25,4 26,4 27,2

0,94 1,46 2,20 3,18 4,42 5,97 7,82 9,99 12,5 15,2 18,3 21,9 24,6 26,7 28,4 29,7 30,9 31,8

5

,

0

3

,

0

.

I

.

S

.

P

5

4

1

,

0

Pre-setting

kv-value

cv-value

4,6 4,8 5,0 5,2 5,4 5,6 5,8 6,0 6,2 6,4 6,6 6,8 7,0 7,2 7,4 7,6 7,9 = open

28,0 28,8 29,5 30,2 31,0 31,7 32,4 33,0 33,6 34,1 34,6 35,0 35,4 35,8 36,2 36,8 kvs = 38,0

32,8 33,7 34,5 35,3 36,3 37,1 37,9 38,6 39,3 39,9 40,5 41,0 41,4 41,9 42,4 43,1 44,5

Honeywell AG • All rights reserved 9 EN0H-0048GE25 R0402

Page 10

KOMBI-2-PLUS (V5032)

P

Flow Data DN65

re-setting

1,5 2 3 41

5

67,9

0

0

1

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

100

kg/h

Flow

Pre-setting

kv-value

cv-value

5

4

3

2

r

a

b

m

0

1

3 2 4 5 6 7 8 100009324563

2 4 5 6 7 8 1000

9

0,25 0,50,028 0,1 5,0l/sec

1,0

2,5

10,0

1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6 3,8 4,0 4,2 4,4

1,40 1,50 2,50 3,50 4,50 5,50 7,70 10,0 12,2 14,5 16,7 19,0 21,3 23,7 26,0 28,3 30,1 31,9

1,64 1,76 2,93 4,10 5,27 6,44 9,01 11,7 14,3 17,0 19,5 22,2 24,9 27,7 30,4 33,1 35,2 37,3

5

,

0

3

,

0

.

I

p

.

o

S

r

a

.

d

P

P

e

r

u

s

5

0

s

4

0

e

1

r

,

0

0

1

P

Pre-setting

kv-value

cv-value

4,6 4,8 5,0 5,2 5,4 5,6 5,8 6,0 6,2 6,4 6,6 6,8 7,0 7,2 7,4 7,6 7,9 = open

33,6 35,4 37,2 38,6 40,1 41,5 43,0 44,0 44,9 45,4 46,0 46,5 47,0 47,1 47,3 47,4 kvs = 47,7

39,3 41,4 43,5 45,2 46,9 48,6 50,3 51,5 52,5 53,1 53,8 54,4 55,0 55,0 55,3 55,5 55,8

EN0H-0048GE25 R0402 10 Honeywell AG • All rights reserved

Page 11

Flow Data DN80

P

KOMBI-2-PLUS (V5032)

re-setting

1,5 2 3 41

56 7,97

0

0

1

7

,

8

6

8

5

7

0

,

6

4

0

,

5

3

0

,

4

0

,

3

2

0

,

2

0

0

0

0

1

9

8

0

,

7

1

6

100

kg/h

Flow

Pre-setting

kv-value

kv-value

5

4

3

2

r

a

b

m

0

1

3 2 4 5 6 7 8 100009324563

2 4 5 6 7 8 1000

9

0,25 0,50,028 0,1 5,0l/sec

1,0

2,5

10,0

1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6 3,8 4,0 4,2 4,4

2,20 4,20 6,20 8,10 10,1 12,1 15,3 18,5 21,6 24,8 28,0 30,9 33,9 36,8 39,8 42,7 44,9 47,0

2,57 4,91 7,25 9,48 11,8 14,2 17,9 21,6 25,3 29,0 32,8 36,1 39,7 43,1 46,6 50,0 52,5 55,0

5

,

0

3

,

0

.

I

p

.

o

S

r

a

.

d

P

P

e

r

u

s

5

0

s

4

0

e

1

r

,

0

0

1

P

Pre-setting

kv-value

kv-value

4,6 4,8 5,0 5,2 5,4 5,6 5,8 6,0 6,2 6,4 6,6 6,8 7,0 7,2 7,4 7,6 7,9 = open

49,2 51,3 53,5 55,2 57,0 58,7 60,5 62,2 63,4 64,5 65,7 66,8 68,0 68,6 69,2 69,8 kvs = 71,0

57,6 60,0 62,6 64,6 66,7 68,7 70,8 72,8 74,2 75,5 76,9 78,2 79,6 80,3 81,0 81,7 83,1

Honeywell AG • All rights reserved 11 EN0H-0048GE25 R0402

Page 12

KOMBI-2-PLUS (V5032)

Influence of Coolants on Fl ow Va lue s

The flow through a valve is defined by the kv-value. The kv-value is the flow m through a valve in [m³/h] at a differential pressure

of 1 bar (14,5 psi) and is only valid for fluids with a density of σ0 = 1000 kg/m³. This condition is met by water at a temperature of

20°C (68°F). For fluids with another density the following formula can be applied:

Kv

Medium

m

=

p

∆

ρ

Medium

×

ρ

0

Correction Factor f

When the density σ is expressed in t/m³ instead of kg/m³ the correction factor f is the result. The correction factor f can be used

to re-calculate kv-value, pressure drop and flow:

KvKv

Medium

Medium

Normal water 100% 1,000 0,998 0,994 0,988 0,981 0,972

Ethylen glycol 70% 1,052 1,047 1,041 1,033 1,024 1,015

e.g. Antifrogen N 50% 1,086 1,079 1,070 1,061 1,052 1,042

Propylen glycol 70% 1,035 1,029 1,021 1,012 1,002 0,991

e.g. Antifrogen L 50% 1,053 1,044 1,035 1,025 1,014 1,002

0

f

Table 1. Values for correction factor f

water part 5°C (41°F) 20°C (68°F) 35°C (95°F) 50°C (122°F) 65°C (149°F) 80°C (176°F)

Medium

fpp

×∆=∆

0

Correction factor f

Medium

mm

1

×=

1

×=

0

f

Control Products

Honeywell AG Phone: (49) 2932 9880

Zu den Ruhrwiesen 3 Fax: (49) 2932 988239

D-59755 Arnsberg-Neheim mng@honeywell.com http://europe.hbc.honeywell.com

EN0H-0048GE25 R0402 12 Subject to change • All rights reserved

Loading...

Loading...