Page 1

Kombi-FC, DN 15

Kombi-FC, DN 25

and DN 40

V5015

Kombi-FC

FLOW CONTROLLER

PRODUCT DATA

Application

Kombi-FC flow controllers are installed in the return of systems with constant volume flows, for example one-pipe systems. They support a hydronic balance by keeping the flow

through consumers at a constant pre-set level even under

changing pressure conditions.

Apart from flow control the Kombi-FC also provides shutoff

and draining functions (see ‘Accessories’). The compact body

design allows installation under restricted space conditions.

Features

• Automatic flow control, infinitely pre-settable up to

000 kg/h

1

• Easy pre-setting of the flow without pipe system cal-

culation

• Leaden sealing of pre-setting possible

• Additional functions shutoff and draining

• Compact design

• Robust, low-noise and flow efficient valve housing

made of corrosion-resistant red bronze

Specifications

Design

The Kombi-FC is made up of:

• Valve housing PN16, DN15, DN25 and DN40 with connection threads, flat sealing. Refer to ‘Accessories’ for

suitable pipe connections

• Valve insert

• Diaphragm unit

• Handwheel

• Union-nuts with sealings

Medium

pH-value

Operating temperature

Operating pressure

Min. differential pressure

Max. differential pressure

Max. Flow

Water or water-glycol mixture

8...9,5

2...130°C (36...266°F)

max. 16 bar (232 psi)

0,2 bar (2,9 psi),

recommended value also see

diagram ‘Flow Characteristic’

2 bar (29 psi)

DN15 1000 kg/h

DN25 2000 kg/h

DN40 4000 kg/h

Materials

• Valve housing made of red bronze

• Valve insert made of brass with EPDM O-rings and soft

sealings

• Diaphragm housing made of stainless steel with membrane made of EPDM

• Handwheel made of blue plastic

• Union-nuts made of nickel-plated brass with EPDM seal-

ings

Copyright © 2002 Honeywell AG • All rights reserved EN0H-0205GE25 R0902

Function

The Kombi-FC control valve is a proportional controller without need of auxiliary energy. Thereby the pressure sensing is

done before and after a throttle, which is adjusted by the

handwheel. At version DN 15 pressure sensing is done internally. At versions DN 25 and DN 40 pressure sensing is done

before the throttle by using pipes or tubes for pressure sensing. Pressure sensing after the throttle is done internally.

The flow is controlled by the differential pressure over the

throttle and kept to a constant, pre-set value.

Page 2

KOMBI-FC (V5015)

r

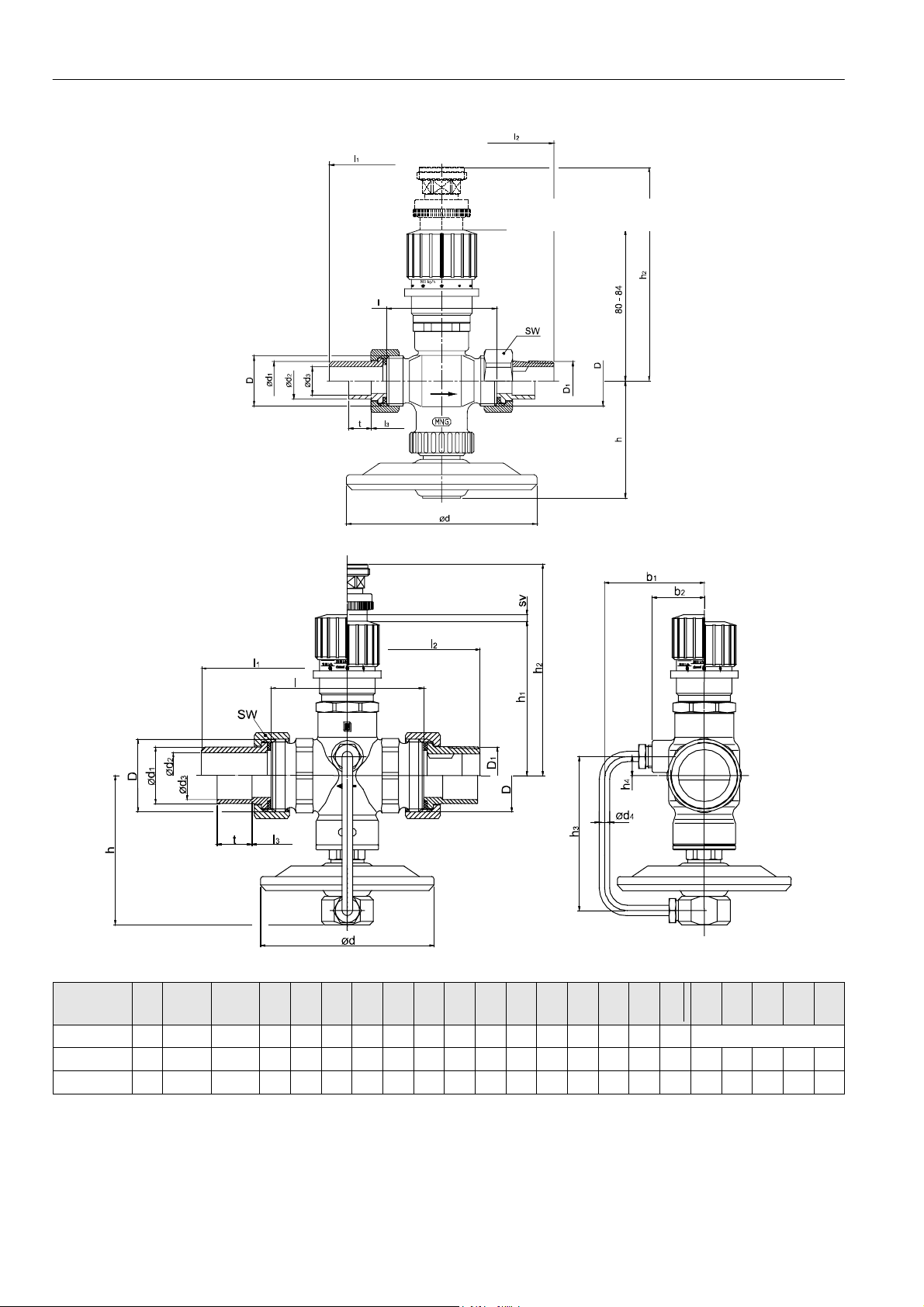

Dimensions

Installed draining adapte

Fig. 1 Dimensions DN15

Fig. 2. Dimensions DN25 and DN40

OS-No. DN D

DIN ISO 228D1DIN 2999

V5015X0015 15 G 3/4 R 1/2 100 20,5 19 15 58 118 118 74 12 30 62 80 116 4 Pressure pipe is installed

V5015X0025 25 G 1 1/4 R 1 100 33 26,4 28 88 168 153 110 20 46 86 89 122 4 6 89 11 58 30

V5015X0040 40 G 1 3/4 R 1 1/2 100 47,5 41 42 113 215 233 135 29 60 88 93 126 7 6 101 21 58 37

NOTE: All dimensions in mm unless otherwise stated.

NOTE: Draining adapters and tailpieces are not supplied with the valve.

EN0H-0205GE25 R0902 2 Honeywell AG • All rights reserved

Ød Ød1 Ød2 Ød3 l l1 l2 l3 t SW h h1 h2 SV Ød4 h3 h4 b1 b2

Page 3

Ordering Information

Order text DN Max. Flow kvs (cv)-value OS-No.

Kombi-FC Flow Controller

Application Examples

KOMBI-FC (V5015)

15 1000 kg/h 2,5 (2,93) V5015X0015

25 2000 kg/h 5,0 (5,85) V5015X0025

40 4000 kg/h 10,0 (11,70) V5015X0040

Fig. 2 Kombi-FC maintains constant flow in single pipe

cooling and heating circuits

Fig. 3. Kombi-FC fitted as a flow rate regulator on fan coil

units

Please Note

• To avoid stone deposit and corrosion the composition of the medium should conform with VDI-Guideline 2035.

• Additives have to be suitalbe for EPDM sealings.

• Mineral oil or any products with mineral oil content in the medium result in heavy swelling and, in most cases, failure of

EPDM sealings.

• System has to be flushed thoroughly before initial operation.

• No complaints or costs resulting from non-compliance with above rules will be accepted by Honeywell.

• Please contact us if you should have any special requirements or needs.

Honeywell AG • All rights reserved 3 EN0H-0205GE25 R0902

Page 4

KOMBI-FC (V5015)

Accessories

Brass soldering tailpiece, flat sealing

15 mm, for valves DN15

28 mm, for valves DN25

42 mm, for valves DN40

Steel welding tailpiece, flat sealing

1/2", for valves DN15

1", for valves DN25

1 1/2", for valves DN40

Externally threaded brass tailpiece, flat sealing

1/2", for valves DN15

1", for valves DN25

1 1/2", for valves DN40

Reducing soldering tailpiece

Valve DN25 on copper pipe

22 mm

Valve DN40 on copper pipe

28 mm

Reducing welding tailpiece

Valve DN25 on pipe DN20

Ventil DN40 on pipe DN32

VA5530A015

VA5530A025

VA5530A040

VA5540A015

VA5540A025

VA5540A040

VA5500A015

VA5500A025

VA5500A040

VA5512A020

VA5512A032

VA5511A020

VA5511A032

Draining adapter

VA3500A001

Kombi-3-plus RED (

supply

NOTE: Also see Product Data 'Kombi-3-plus'.

Kombi-3-plus BLACK (V5100) shutoff valve for the supply

NOTE: Also see Product Data 'Kombi-3-plus'.

V5000) measuring and shutoff valve for the

DN15

DN20

DN25

DN32

DN40

DN15

DN20

DN25

DN32

DN40

V5000X0015

V5000X0020

V5000X0025

V5000X0032

V5000X0040

V5100X0015

V5100X0020

V5100X0025

V5100X0032

V5100X0040

Reducing externally threaded tailpiece

Valve DN25 on thread

connection 3/4“

Valve DN40 on thread

connection 1 1/4“

Adapter with union-nut and sealing

For extension valve DN15 on

connection DN20

For extension valve DN25 on

connection DN32

NOTE: Suitable union tailpieces see above.

VA5510A020

VA5510A032

VA2101A020

VA2101A032

'Stop-Ball' ball valve for the supply

DN15

DN20

DN25

DN32

DN40

NOTE: Also see Product Data 'VB550 - Stop-Ball'.

VB550X0015

VB550X0020

VB550X0025

VB550X0032

VB550X0040

EN0H-0205GE25 R0902 4 Honeywell AG • All rights reserved

Page 5

Flow Characteristic

KOMBI-FC (V5015)

Method of Calculation

Given:

Kombi-3-Plus BLACK in the supply and Kombi-FC in the return

Mass flow in circuit: q

Available differential pressure of circuit: ∆p

Required differential pressure of circuit: ∆p

Required:

Dimension Kombi-FC

Differential pressure Kombi-FC

Result:

The nominal size DN25 of valve is choosen dependent on mass flow q

Kombi-FC is set to 1200 kg/h.

Calculation of the differential pressure:

Differential pressure Kombi-3-Plus BLACK, DN25 ∆p

Differential pressure Kombi-FC ∆p

Required differential pressure ∆p

= 271 mbar for Kombi-FC depending to given mass flow qm = 1200 kg/h is within the recom-

v2

mended range of application.

Honeywell AG • All rights reserved 5 EN0H-0205GE25 R0902

= 1200 kg/h

m

= 400 mbar

0

= 100 mbar

v1

= 1200 kg/h in flow characteristic

m

= 29 mbar

v1

= ∆p0 – (∆pv1 + ∆pv1)

v2

= 400 – (29 + 100) mbar

= 271 mbar

Page 6

KOMBI-FC (V5015)

Automation & Control Products

Honeywell AG Phone: (49) 2932 9880

Zu den Ruhrwiesen 3 Fax: (49) 2932 988239

D-59755 Arnsberg-Neheim mng@honeywell.com http://europe.hbc.honeywell.com

EN0H-0205GE25 R0902 6 Subject to change • All rights reserved

Loading...

Loading...