Page 1

TST... and TST...-R

p

Smart Tem

ELEC. TEMPERATURE SWITCHES/TRANSMITTERS

GENERAL INFORMATION

Honeywell FEMA's TST and TST...R series thermostats

require adjustment (configuration and parameterization) in

only two modes (the basic mode and the expert mode) and

are suitable for the precision-adjustment and monitoring of

medium temperatures in the fields of plant construction,

fluidics, process technology, and pneumatics, as well as in

the monitoring and control of furnaces, heating units, and

process temperatures, as well as for applications in the

field of frost protection.

These thermostats provide sufficient accuracy (0.5% of the

final value) for measurement monitoring in many laboratory

applications. Models with built-on sensors for a temperature range of -50...+200 °C and models with an external sensor for a temperature range of -50...+400 °C are

available. Customized PT1000 precision class-A sensors

(conforming to DIN 60 751) can also be employed in the

aforementioned temperature ranges.

INSTALLATION INSTRUCTIONS

TECHNICAL DATA

Housing polybutylene terephthalate

Ambient temperature -20...+60 °C

Storage temperature -35...+80 °C

Temp. of medium -50...+50 °C, -50...200 °C,

Relative humidity 0...95%, non-condensing

Accuracy, total 0.5% of FSO (full-scale output)

Medium temp. drift 0.3% / 10 K

Parts in contact with medium

Process connections G½" external thread

Electrical connection

Both series 2 5-prong A-coded M12 plugs

TST...-R series additional 3-prong B-coded

Protection class II as per EN 60335-1 (when

Protection rating IP65 as per EN 60529

Climate class C as per DIN EN 60654

Power supply 14...36 Vdc (> 50 °C,

EMC as per EN 61326/A1

Switch outputs configurable as N.O./N.C.

Switching difference (SP and RP) configurable

Relay output (TST..-R-Version)

Contact type 1 switch-over contact

Min. electrical lifetime 250,000 switching cycles

Switching performance, gold (AgSnO

AC1 (resistive) 1.5 VA (24 Vdc / 60 mA,

AC15 (inductive) unsuitable

Max. switch-on current 60 mA for < 5 ms

Min. switching performance 50 mW (> 5 V or > 2 mA)

Switching performance, silver (AgSnO

AC1 (resistive) 690 VA (230 Vac / 3 A)

AC15 (inductive) 230 VA (230 Vac / 1 A)

Max. switch-on current 30 A for < 5 ms

Min. switching performance 500 mW (> 12 V or

Diagnostic output (warning output on plug 2)

Max. load 20 mA / 14...36 Vdc

Transmitter output (analog output)

Voltage/current 0...10 V / 4...20 mA or

Transient response approx. 300 ms

-50...+400 °C (dependent on

model)

as per DIN IEC 60947-5-2

M12 plug as per DIN EN

50044

installed accordingly)

max. 30 Vdc), max. 100 mA

high-side/low-side or as pushpull / inverted push-pull

switches

max. 250 mA / 14...36 Vdc

+Au) contacts

2

230 Vac / 6.5 mA)

) contacts

2

(for cos φ < 0.7: 10 A)

> 10 mA)

10...0 V / 20...4 mA

(config. in expert mode)

® U.S. Registered Trademark

Copyright © 2003 Honeywell Inc. MU1B-0248GE51 R0903

All Rights Reserved 7157 672

Page 2

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

A

A

SERIES

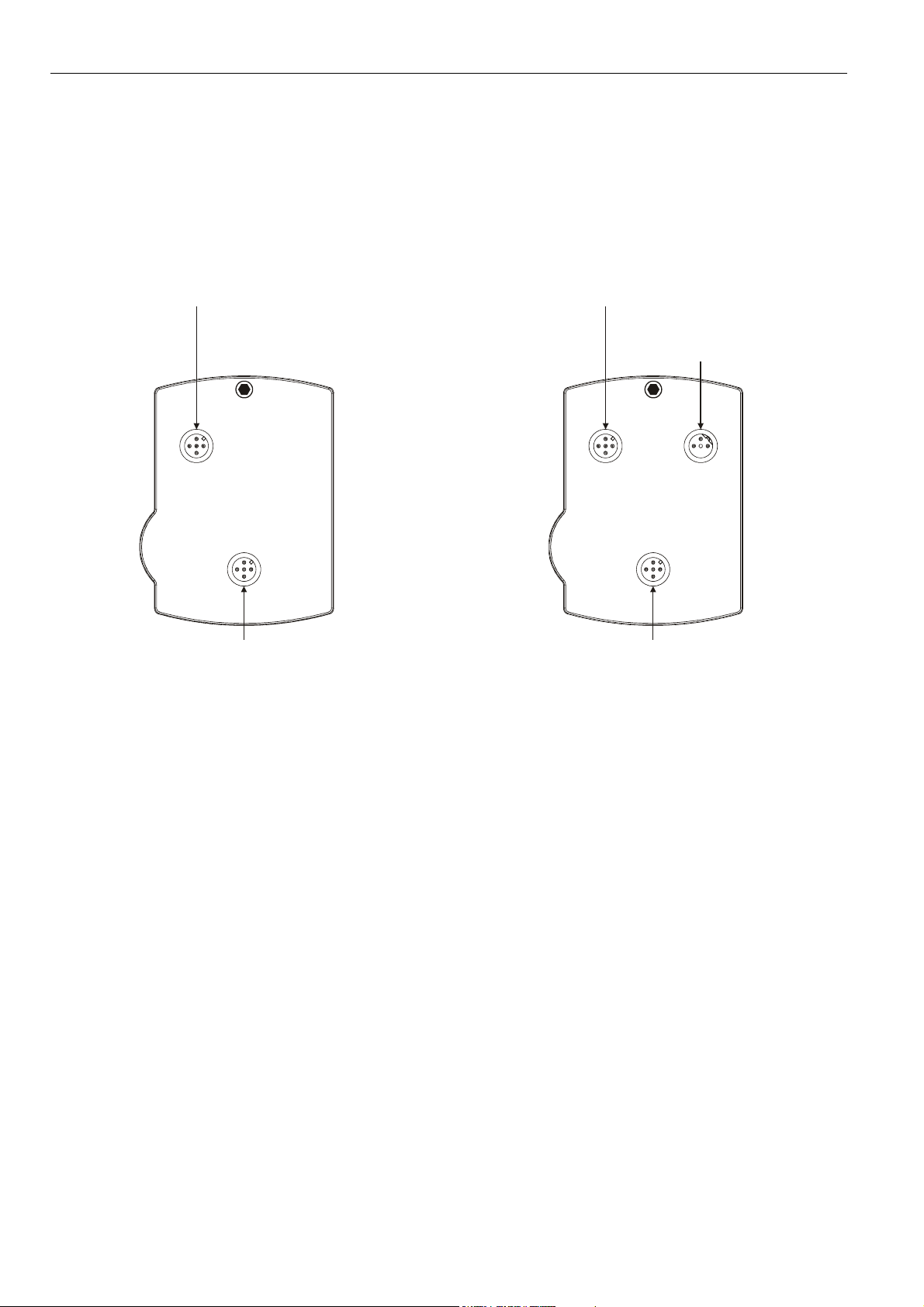

The electronic temperature switches/transmitters are available in two series, TST... and TST...-R, easily distinguishable by the

number of M12 plugs present on the rear side.

TST... Series

The devices of this series provide both switching and

transmitting functionality.

plug 2:

power supply,

OUT, and WARN

plug 1:

power supply,

OUT1, and OUT2

Fig. 1. TST... Series, rear view of housing

TST...-R Series

Like TST... Series devices, the devices of this series provide

switching and transmitting, but also relaying functionality.

plug 2:

power supply,

OUT, and WARN

plug 3:

switch-over

contact relay

plug 1:

power supply,

OUT1, and OUT2

Fig. 2. TST...-R Series, rear view of housing

Two switching outputs (OUT1 and OUT2) are located on a 5prong, A-coded (as per DIN IEC 60947-5-2) M12 plug (plug

1), which you can also use to connect the power supply. You

can configure the two switching outputs as normally-open /

normally-closed high-side/low-side or push-pull / inverted

push-pull switches (see also Table 3 on page 8).

An analog output (AOUT) and a warning output (WARN) are

likewise located on a 5-prong, A-coded (as per DIN IEC

60947-5-2) M12 plug (plug 2), which you can also use to connect the power supply. You can configure the analog output

as either a 0...10 V / 10...0 V analog output or as a 4...20 mA

/ 20...4 mA analog output. The warning output provides feedback about the device's error status (see also section "Technical Data on the WARN Output" on page 6 and section

"Error Codes" on page 8).

Two switching outputs (OUT1 and OUT2) are located on a 5prong, A-coded (as per DIN IEC 60947-5-2) M12 plug (plug

1), which you can also use to connect the power supply. You

can configure the two switching outputs as normally-open /

normally-closed high-side/low-side or push-pull / inverted

push-pull switches (see also Table 3 on page 8).

An analog output (AOUT) and a warning output (WARN) are

likewise located on a 5-prong, A-coded (as per DIN IEC

60947-5-2) M12 plug (plug 2), which you can also use to connect the power supply. You can configure the analog output

as either a 0...10 V / 10...0 V analog output or as a 4...20 mA

/ 20...4 mA analog output. The warning output provides feedback about the device's error status (see also section "Technical Data on the WARN Output" on page 6 and section

"Error Codes" on page 8).

A switch-over contact relay output is located on a 3-prong, Bcoded M12 plug (plug 3), for which a 4-prong M12 angle

junction box with pre-attached cable is available as an

accessory. You can configure this relay output to be coupled

with either OUT1 or OUT2 or with the warning output. If you

configure OUT2 as a warning output, the relay output will

then likewise function as a warning output (see also section

"Pin Assignment of Plug 3" on page 4). You cannot configure

the relay output as a normally-open or normally-closed

switch.

MU1B-0248GE51 R0903 2

Page 3

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

IMPORTANT

The switching performance of the gold (AgSn0

µ

m]) switch-over contacts of the relay located on plug 3

must not be exceeded insofar as doing so will degrade

the contacts, making them unusable for the specified min.

switching performance; thereafter, the switching performance for silver (AgSnO

Da" on page 1) will apply.

) contacts (see "Technical

2

+Au [5

2

Temperature Ranges

For both series, versions of these devices are available for

the following temperature ranges (see Table 7 on page 19).

• devices with built-on sensor: -50...+50 °C,

• devices with built-on sensor and neck tube:

-50...+200 °C,

• devices with external sensor: -50...+200 °C and

-50...+400 °C.

BEFORE INSTALLATION

IMPORTANT

Installation is to be performed only by qualified personnel.

IMPORTANT

In order to comply with protection rating IP65, unused

M12 plugs must be capped (using the caps available as

accessories). The caps included in the shipment provide

protection against contamination during transportation,

only.

IMPORTANT

Regardless of the current operating mode (basic mode /

expert mode), all changes to output values take effect

immediately (except when OUT1[2] is configured as a

N.O./N.C. high-side/low-side or push-pull / inverted pushpull switch, in which case changes take effect only after

the EDIT symbol has been extinguished). However, they

will be stored permanently only if confirmed (via SAVE).

CAUTION

To avoid electrical shock or damage to the device,

you must ensure that all of the device's connections

are without voltage before attempting to detach plugs

and cables.

Before installing the device and connecting the wiring, check

to ensure that you are installing the proper device version.

See section "Manufacturer's Plate" on page 6).

Thermostats equipped with an external sensor (TST...EPT...)

are secured to a wall or wiring box by means of a retainer

(see Fig. 69 on page 18).

External sensors (P2-TVS...) are screwed directly into the

pipe via a G½" process connection. Using the M8 plug accompanying the shipment, they are then connected electrically to the TST200E... or TST400E... thermostats via a

sensor cable.

IMPORTANT

In order to avoid damage, never attempt to fasten the

device by rotating the housing. Mount the process connection using a suitable hexagonal wrench. Mounting is to

be performed by skilled personnel, only! The cable length

must not exceed 3 m. Use only PT1000-A sensors; otherwise, the specified accuracy of 0.5% for the entire device

cannot be guaranteed. The devices can be mounted in

any orientation desired, however, for optimal legibility of

the display, it is recommended that they be mounted in a

vertical orientation. For optimal legibility of the display,

but also to allow for more-flexible installation, the housing

can be rotated on the sensor by approx. 320°.

Electrical Connection

All wiring must comply with applicable electrical codes and

local ordinances (e.g. in Germany, in accordance with VDE

regulations). To prevent damage to the device, the voltage at

OUT1[2] must not exceed 36 Vdc. Refer to job or manufacturer's drawings for details.

IMPORTANT

In order to comply with protection class II, the auxiliary

power source must be reliably separated from the network power supply circuits as per DIN VDE 0106, part

101. When correspondingly installed, the device complies

with protection class II.

The connections for plugs 1 and 2 are protected against

short-circuiting and incorrect polarity.

NOTE: No tampering with the device is allowed. Opening

the device will invalidate the warranty.

NOTE: The devices must always be provided with power

via either plug 1 and/or plug 2. It is sufficient to

connect the power supply via one of these two

plugs. However, in the event that power is

supplied via both of these plugs, it must have the

same polarity and potential.

INSTALLATION

Dimensions

The housing (without process connection or plugs) has

dimensions of 98 x 70 x 60 mm. The overall dimensions

depend upon the number of plugs/cables and the sensor

type. See also Fig. 72 on page 23.

Mounting and Orientation

Thermostats equipped with a built-on sensor

(TST050...0200...) are screwed directly into the pipe via a

G½" process connection.

Pin Assignment of Plug 1

All versions of both series come equipped with plug 1, an Acoded, five-prong M12 plug (see Fig. 3).

Fig. 3. A-coded M12 plug

MU1B-0248GE51 R09033

Page 4

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

Plug 1 has the following pin assignment:

1. Power supply (14...36 Vdc)

2. OUT2: an open-collector output which can be configured

as an N.O./N.C. high-side/low-side or as a push-pull /

inverted push-pull switch (see also Table 3 on page 8).

3. 0 volt

4. OUT1: an open-collector output which can be configured

as an N.O./N.C. high-side/low-side or as a push-pull /

inverted push-pull switch (see also Table 3 on page 8).

5. Programming interface

NOTE: The voltage provided by OUT1[2] can be as much

as 2.5 V lower than the device's power supply.

Thus, assuming a power supply voltage of e.g.

14 V and that the voltage at OUT1[2] is logical

"high," then: 14 V ≥ "high" ≥ 11.5 V. Assuming that

the voltage is logical "low," then: 2.5 V ≥ "low" ≥

0 V.

Pin Assignment of Plug 2

All versions of both series come equipped with plug 2, an Acoded, 5-prong M12 plug (see Fig. 3).

Plug 2 has the following pin assignment:

1. Power supply (14...36 Vdc)

2. WARN ("WARN" output; max. current load: 20 mA)

3. 0 volt

4. AOUT (which can be configured as a 0...10 V / 10...0 V

output or as a 4...20 mA / 20...4 mA output, max. R

when configured as a current output = 500 Ω)

5. Programming interface

L

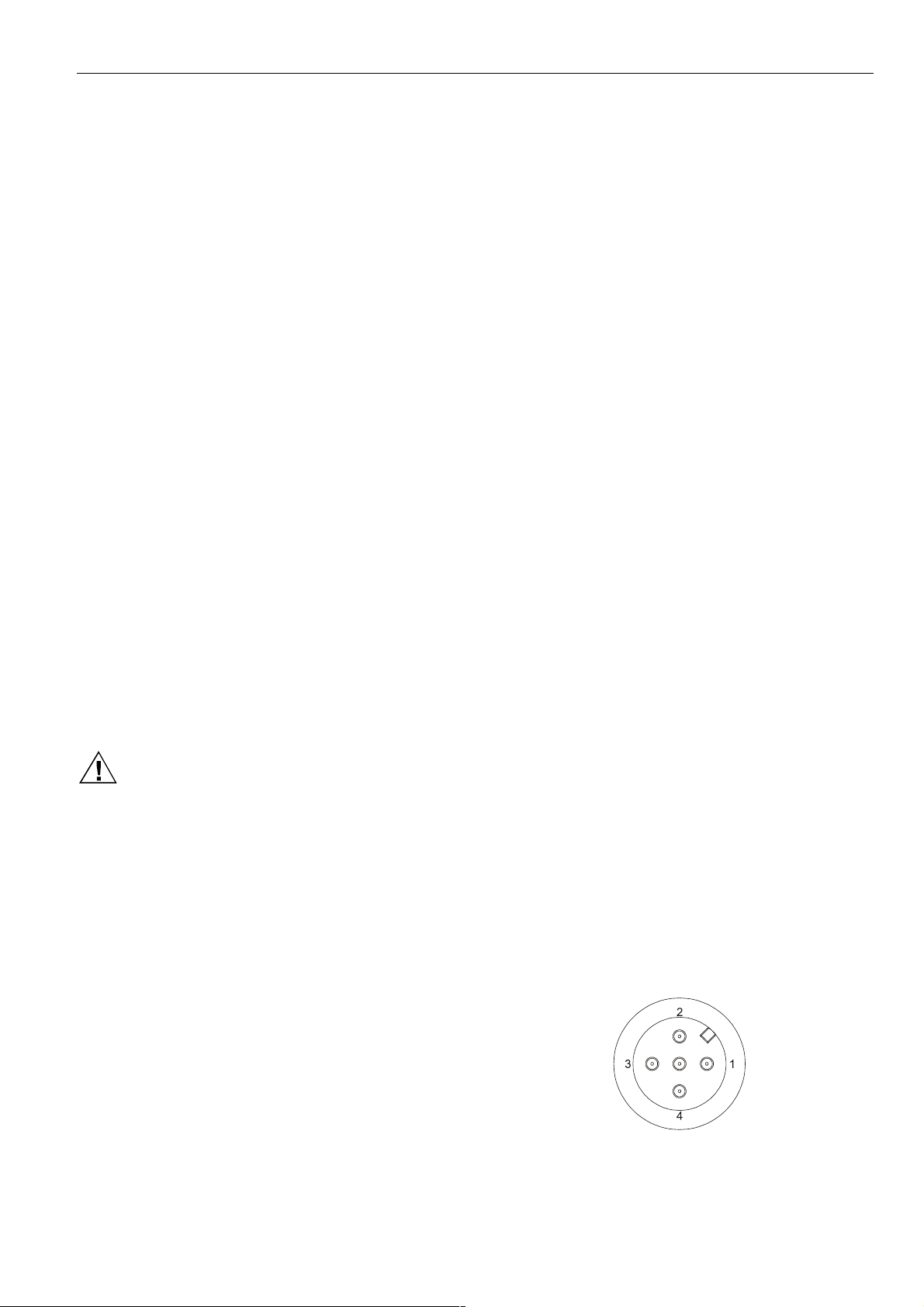

Pin Assignment of Plug 3

All versions of the PST...-R series come equipped with plug

3, a B-coded, three-prong M12 plug (see Fig. 4).

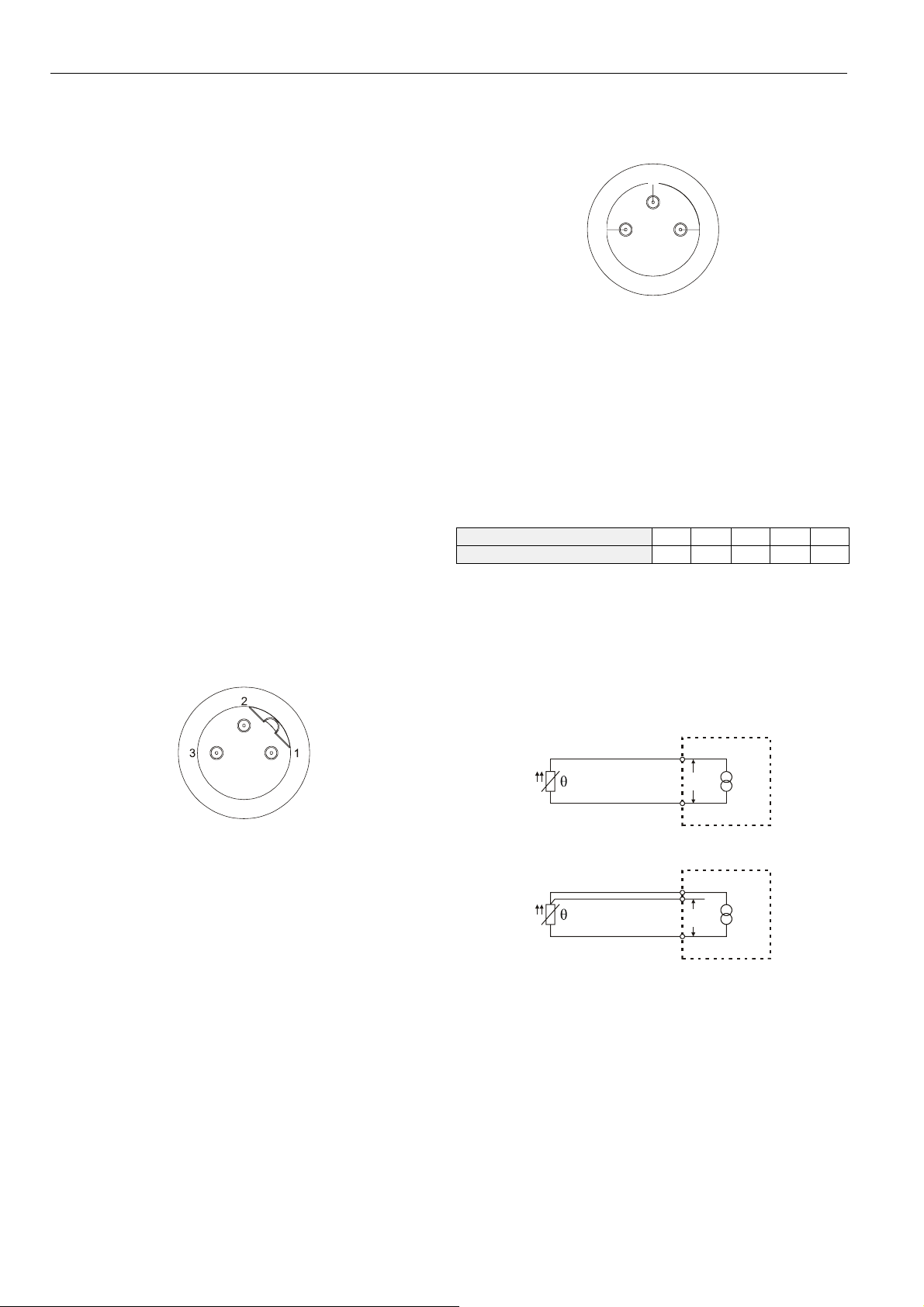

Connecting the Sensor

Each sensor is equipped with a 3-prong M8 plug (see Fig. 5).

4

1

Fig. 5. Pin assignment of the sensor's M8 plug

In the event that you would like to connect a two-wire PT1000

sensor to the device (see Fig. 6), you must (in the expert

mode) correspondingly configure the device.

If you choose to use a two-wire sensor connection, you must

take into account that the fact that the device does not automatically compensate for the wire resistance; rather, the wire

resistance will fully affect the measuring results (see Table 1

for information on the resistance given a 10-meter-long [both

ways] connection wire made of copper).

Table 1. Cross-section and resistance of conductor

wire cross-section (mm2)

wire resistance (Ω)

However, it is possible to adjust the device in order to compensate for this resistance (see section "Balancing the

Device" on page 14). The temperature can thus be balanced

within a range of ±5 °C.

An additional option is to employ a three-wire sensor connection (see Fig. 7). However, the prerequisite for this is that

all three lines have identical properties and be exposed to the

same temperatures.

3

0.14 0.22 0.5 0.75 1.5

2.55 1.62 0.71 0.48 0.24

Fig. 4. B-coded M12 plug

NOTE: If inductive components are to be connected to the

switch-over contact relay, it must be prevented

from causing harmful interference or over-voltage.

Plug 3 has the following pin assignment:

1. common

2. N.C. (normally-closed)

3. N.O. (normally-open)

NOTE: The cable for connecting the relay is available as

an accessory. Its green/yellow grounding terminal

(PE) is not connected to the device (protection

class II).

MU1B-0248GE51 R0903 4

3

PT1000

U

1

Fig. 6. Two-wire configuration

4

PT1000

3

U

1

Fig. 7. Three-wire configuration

Page 5

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

Technical Data on OUT1 and OUT2

• Max. current load per output: 250 mA.

• At the switch output, the voltage can diminish by as

much as 2.5 V.

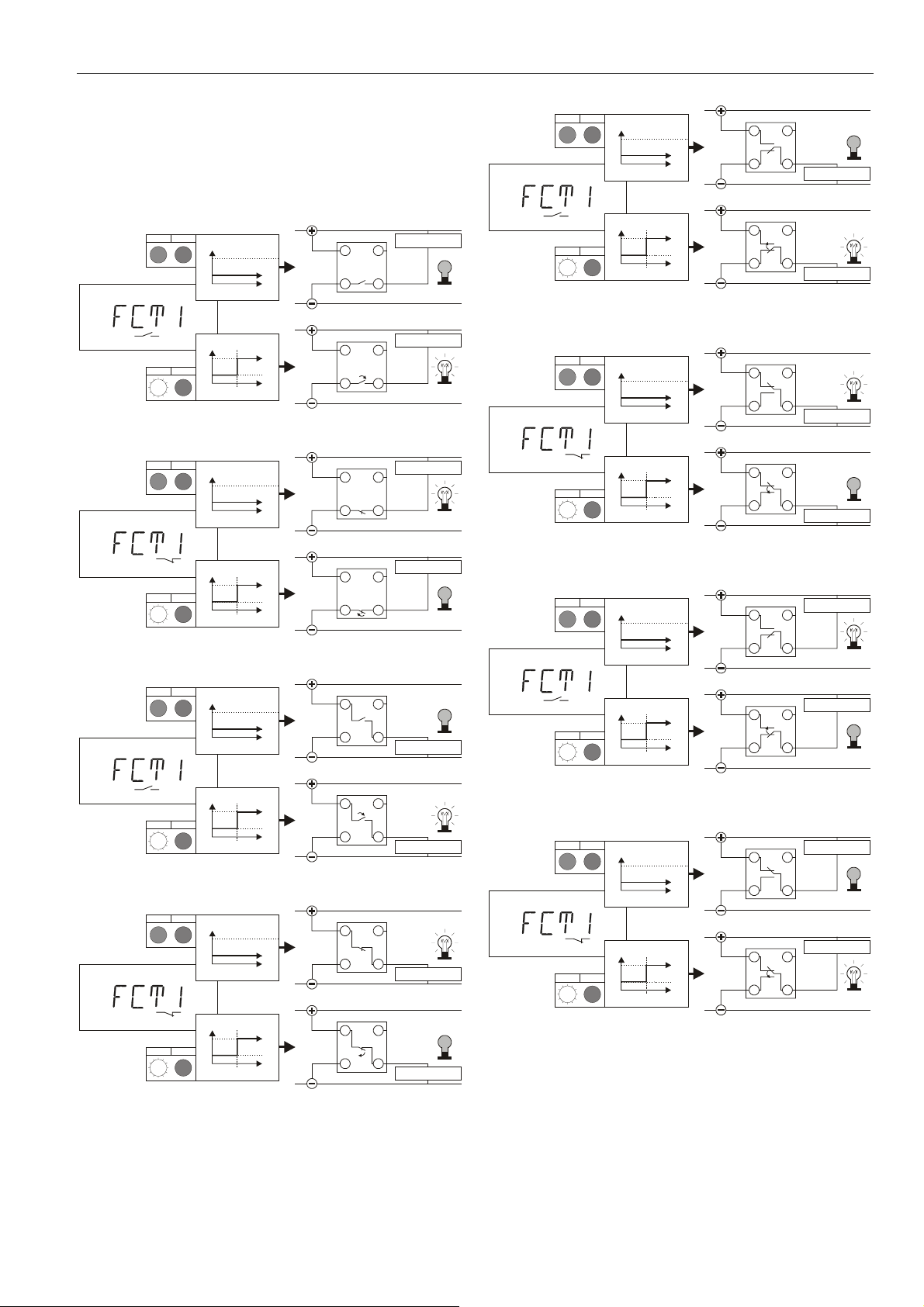

Example software configurations for e.g. OUT 1 are

presented in Fig. 8 through Fig. 15.

greengreen

21

EXPERT

ZERO

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

Fig. 8. OUT1 as a normally-open low-side switch

greengreen

21

EXPERT

ZERO

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

Fig. 9. OUT1 as a normally-closed low-side switch

greengreen

21

EXPERT

ON

OFF

OUT1

P

plug 1

1 2

3 4

plug 1

1 2

3 4

plug 1

1 2

3 4

plug 1

1 2

3 4

plug 1

314

(max. 250 mA)

OUT1

(max. 250 mA)

OUT1

(max. 250 mA)

OUT1

(max. 250 mA)

OUT1

2

OUT1

(max. 250 mA)

load

load

load

load

load

EXPERT

ZERO

FSO

greengreen

21

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

plug 1

1 2

3 4

plug 1

1 2

3 4

OUT1

load

(max. 250 mA)

OUT1

load

(max. 250 mA)

Fig. 12. OUT1 as a push-pull switch with load connected

to 0 V

EXPERT

ZERO

FSO

greengreen

21

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

plug 1

1 2

3 4

plug 1

1 2

3 4

OUT1

load

(max. 250 mA)

OUT1

load

(max. 250 mA)

Fig. 13. OUT1 as an inverted push-pull switch with load

connected to 0 V

load

(max. 250 mA)

OUT1

load

(max. 250 mA)

OUT1

EXPERT

ZERO

FSO

greengreen

21

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

plug 1

1 2

3 4

plug 1

1 2

3 4

FSO

OUT1

ON

greenorange

OFF

21

SP/RP

P

plug 1

2

314

Fig. 10. OUT1 as a normally-open high-side switch

EXPERT

FSO

greengreen

21

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

plug 1

2

314

plug 1

2

314

Fig. 11. OUT1 as a normally-closed high-side switch

OUT1

load

(max. 250 mA)

OUT1

load

(max. 250 mA)

OUT1

load

(max. 250 mA)

Fig. 14. OUT1 as a push-pull switch with load connected

to the power supply

load

(max. 250 mA)

OUT1

load

(max. 250 mA)

OUT1

EXPERT

ZERO

FSO

greengreen

21

greenorange

21

ON

OFF

ON

OFF

OUT1

OUT1

SP/RP

P

P

plug 1

1 2

3 4

plug 1

1 2

3 4

Fig. 15. OUT1 as an inverted push-pull switch with load

connected to the power supply

When OUT1[2] are configured as high-side switches, then

logical "high" is switched to the corresponding output. When

configured as low-side switches, logical "low" is switched to

the corresponding output as soon as it becomes active. In

MU1B-0248GE51 R09035

Page 6

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

the default shipping setting, OUT1[2] are configured as

normally-open low-side open-collector switches (see Fig. 8).

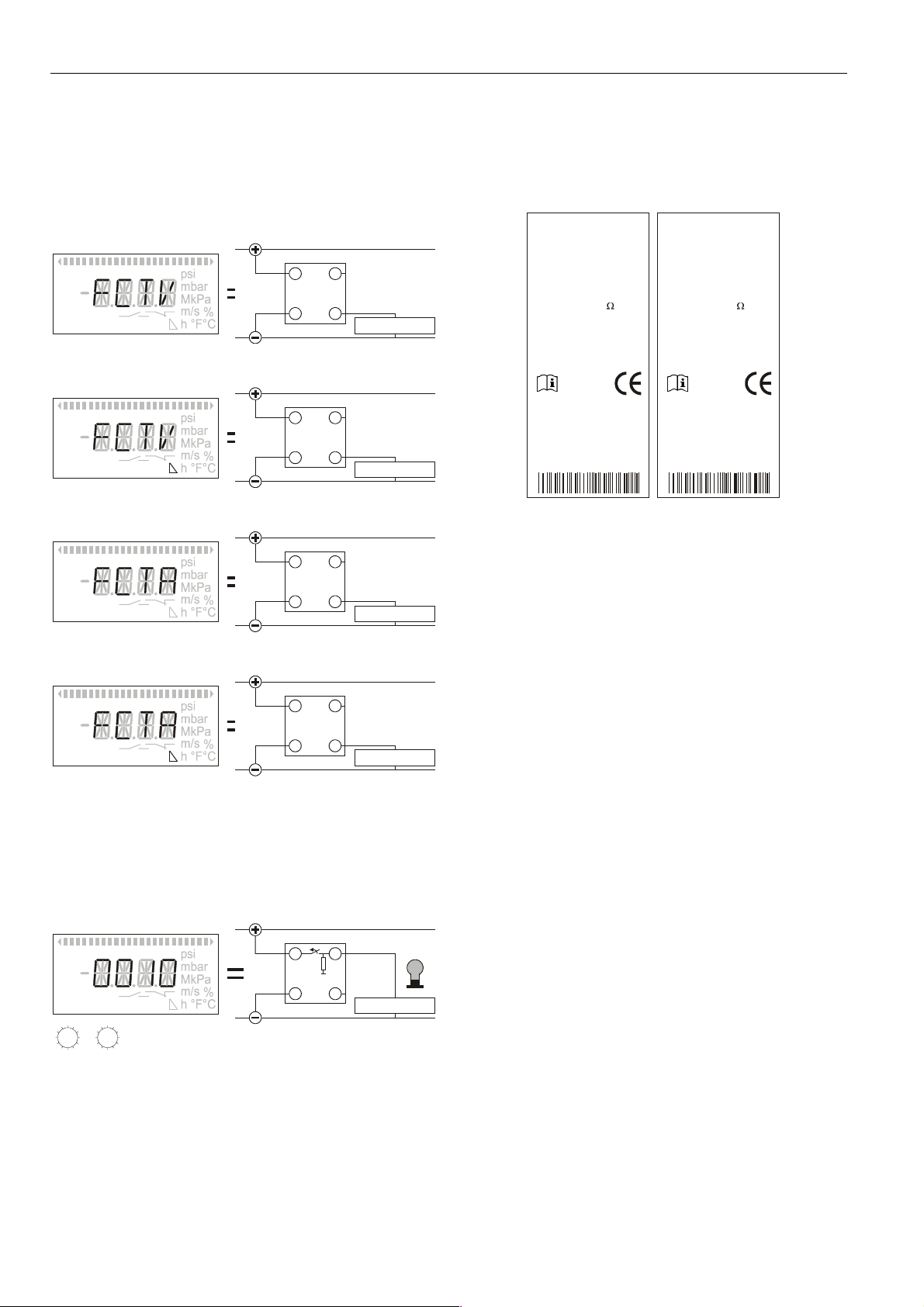

Technical Data on the Analog Output (AOUT)

• configurable either as a 0...10 V / 10...0 V output or as a

4...20 mA / 20...4 mA output.

• max. R

EXPERT EDIT ATT

WARN

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

AOUT

when configured as a current output = 500 Ω.

L

plug 2

1

2

3

AOUT

4

0...10 V

Fig. 16. AOUT as a 0...10 V analog output

plug 2

EXPERT EDIT ATT

WARN

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

AOUT INV

1

2

3

AOUT

4

10...0 V

Fig. 17. AOUT as a 10...0 V analog output

plug 2

EXPERT EDIT ATT

WARN

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

AOUT

1

2

4

AOUT

4...20 mA

L

R max. 500

Ω

3

Fig. 18. AOUT as a 4...20 mA analog output

plug 2

EXPERT EDIT ATT

WARN

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

AOUT INV

1

2

4

AOUT

20...4 mA

R max. 500

L

Ω

3

Fig. 19. AOUT as a 20...4 mA analog output

Technical Data on the WARN Output

• maximum current load: 20 mA

the device does not recognize any error, the WARN output

will remain inactive, and is switched to the power supply.

Manufacturer's Plate

The manufacturer's plate contains important technical data.

TST050G12100

-50...+50 °C

14...36 (> 50 °C: 14...30) Vdc

100mA

I of OUT1[2]: 250 mA

max

Analog Out:

0...10V max. 1mA

4...20mA max. 500

IP65 0138

F.-Nr.: 00577410005

FEMA Regelgeräte

Honeywell AG

D-71101 Schönaich

Made in Germany

www.honeywell.de\fema

TST050G12100-R

-50...+50 °C

14...36 (>50 °C: 14...30) Vdc

100mA

I of OUT1[2]: 250 mA

max

Analog Out:

0...10V max. 1mA

4...20mA max. 500

Relays:

AC1: max. 690VA

AC15: max. 230VA

IP65 0138

F.-Nr.: 00577410001

FEMA Regelgeräte

Honeywell AG

D-71101 Schönaich

Made in Germany

www.honeywell.de\fema

Fig. 21. Manufacturer's plate / TST... and TST...-R series

The manufacturer's plate identifies the device model in the

topmost line and below that the following information:

• the nominal temperature range,

• the permissible power supply,

• the max. permissible current load at OUT1[2],

• the max. permissible current load of and max.

permissible resistance at the analog output,

• the date code,

• the manufacturing number, and

• an information symbol referring the installer to these

Installation Instructions.

Hardware Features

All configuration and parameterization data is stored in the

device.

Regardless of the current operating mode (basic or expert

mode), changed parameters and configurations become

immediately effective, but are permanently stored in the

device's memory only after confirmation via SAVE.

The WARN output (pin 2) is not configurable; rather, it is

permanently wired as a high-side switch. See Fig. 20.

EXPERT EDIT ATT

WAR N

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

plug 2

1 2

10 k

τ

internal

3

4

WARN

load

(max. 20 mA, 14...36 Vdc)

12

Fig. 20. WARN output (permanent high-side)

When the device recognizes an error (see section "Error

Codes" on page 8), the WARN output will become active and

is switched (via a pull-down resistor) to 0 V (logical "low). If

MU1B-0248GE51 R0903 6

In the event of a power loss, only permanently stored values

will be again available once power has been restored.

Unstored parameters and configurations are lost! In the event

of a power loss during the transfer of data into device's

memory (via SAVE), data may be lost.

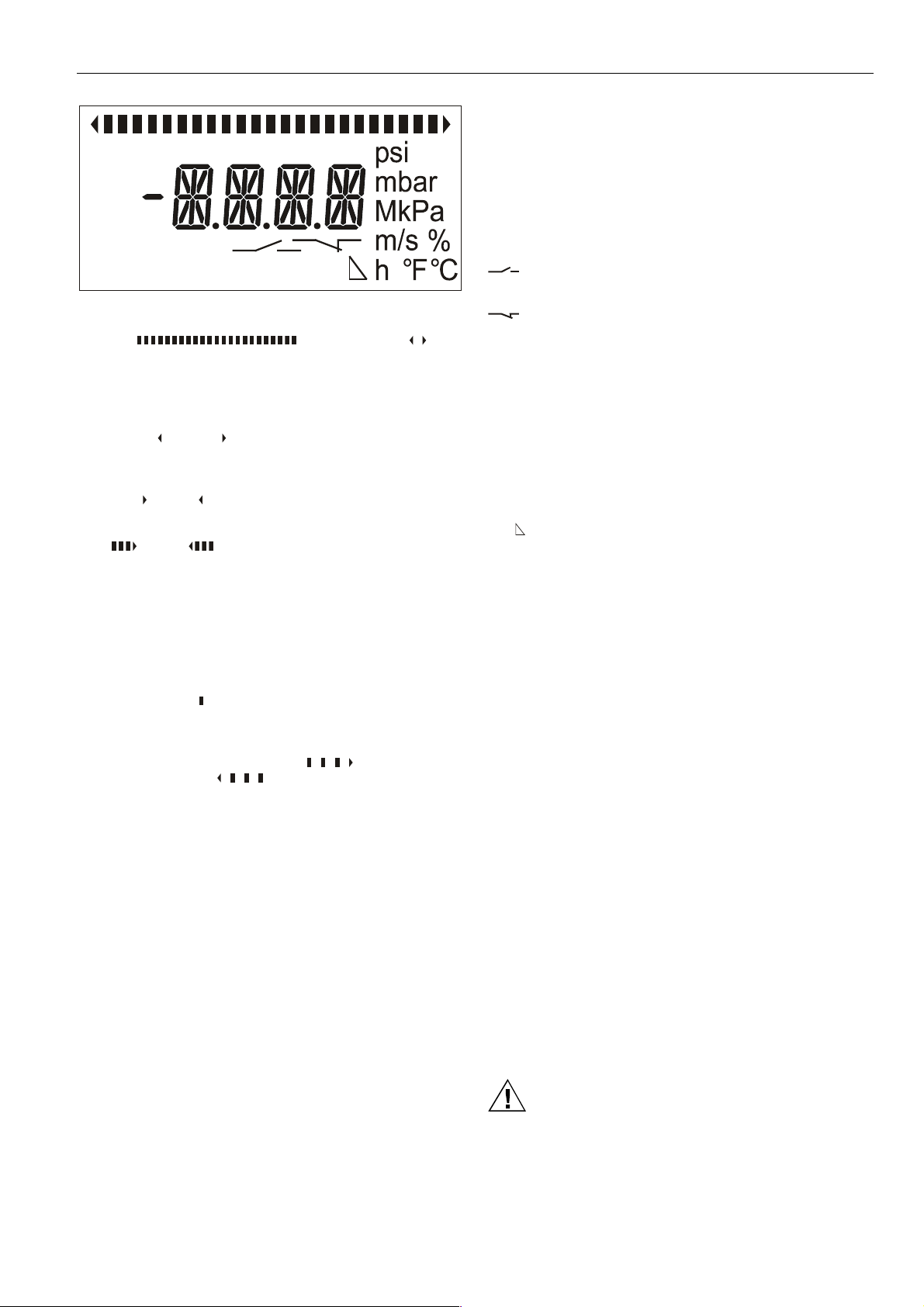

LCD Display Screen

The LCD display screen (see Fig. 22) features a four-digit

display, three decimal points, and a minus sign.

NOTE: When cleaning the display screen, use no harsh

cleaning agents.

In addition to the four-digit numeric display, the LCD display

screen can also present numerous additional symbols useful

in operating the device:

Page 7

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

EXPERT EDIT ATT

WARN

WIN

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

Fig. 22. LCD display screen

Bargraph (

The bar graph (at the top of the screen) consists of several

individual segments. The trend display (to the left and right of

the bar graph) consists of two arrowheads.

• When the device is displaying the current temperature,

the left (

to indicate dropping or rising temperature.

• While an output is being parameterized (in the basic

mode) to act as a max. or min. temperature monitor, the

right (

• When an output is being configured (in the expert mode)

to act as a max. or min. temperature monitor, the right

(

three segments of the bar graph will appear.

• When the device is displaying the current temperature,

the number of segments of the bar graph proportional to

the current temperature will appear. Thus, if the current

temperature is equal to the min. measurable temperature, no segments will be displayed; if the current

temperature is equal to the device's max. measurable

temperature, all of the segments will be displayed.

• When parameterizing the device, a single segment of

the bar graph (

to the set value.

• When viewing the max./min temperature or the time

elapsed since the max./min temperature were registered,

the max. drag indicator symbol (

indicator symbol (

EDIT

After the EDIT symbol has been made to appear (see

sections "Setting Parameters in the Basic Mode" on page 12

and "Configuring in the Expert Mode" on page 15), values (in

the basic mode) or units (in the expert mode) can be

changed by rotating and pressing the RPB (rotary/push

button).

Units

You may choose from among the following temperature units:

• °C

• °F.

Settings

These symbols appear during parameterization /

configuration.

ATT Switch-ON/OFF delay (in seconds)

EXPERT Expert mode (enabling the user to change

WARN Warning / alarm

) or right ( ) arrowhead (respectively) will appear

) or left ( ) arrowhead (respectively) will appear.

) or left ( ) arrowhead (respectively) together with

) will appear at a position corresponding

measurement units, switch-points, etc.)

) and Trend Display ( )

) or min. drag

), respectively, is displayed.

WIN Window monitor (for monitoring a temperature

OUT1 Output 1

OUT2 Output 2

SP Switch-point or, in the case of monitoring a

RP Reverse switch-point or, in the case of monitoring

AOUT Analog output (if the current temperature is

ZERO Zero-point of the analog output. Also, it appears if

FSO Full-Scale Output, i.e. upper limit of the analog

INV

See also sections "Sequence of Display Screens in Basic

Mode" on page 10 and "Overview of Parameterization and

Configuration" on page 20, where you will find an explanation

of when the various different screens will appear and for

additional information on the meanings of the individual

symbols.

range)

temperature window (WIN), the upper or lower

temperature limit

a temperature window (WIN), the upper or lower

temperature limit

OUT1[2] configured to be an N.O. switch (FSO or

ZERO also displayed) or as push-pull switch (FSO

and ZERO also displayed)

OUT1[2] configured to be an N.C. switch (FSO or

ZERO also displayed) or as inverted push-pull

switch (FSO and ZERO also displayed)

outside of the span, the AOUT symbol will not be

visible on the screen)

OUT1[2] has been configured to be a low-side

switch (i.e. the device switches logical "low" to the

output)

output. Also, it appears if OUT1[2] has been configured to be a high-side switch (i.e. the device

switches logical "high" to the output)

Inversion of the analog signal (i.e. output is then

configured as 10...0 V or 20...4 mA instead of as

0...10 V or 4...20 mA, respectively)

Time-Out Function

The time-out represents a 1-minute period during which the

device will remain in the basic mode or expert mode (as the

case may be) without automatically reverting to the display

state (whereupon already-changed but not-yet-saved values

will be lost). During the time-out, any manipulation of the RPB

will restart the internal clock, thus prolonging the time-out for

an additional 1 minute and allowing the user to continue

parameterization and/or configuration.

IMPORTANT

If the user allows (by not manipulating the RPB for 1

minute) the time-out to completely elapse, the device will

automatically revert to the display state (i.e. show the

current temperature), and already-changed but not-yetsaved values will be lost.

However, when the device is in the expert mode, the

time-out is enabled only as long as no configuration has

been changed. I.e. changing a configuration disables the

time-out function.

Recognition of Implausible Settings

CAUTION

The software automatically recognizes implausible settings of

SP, RP, ZERO, and FSO. The last-set value takes

MU1B-0248GE51 R09037

Page 8

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

precedence over the first-set value. Thus, upon permanently

storing the last-set value, the first-set value will be shifted

right up to the second-set value, as necessary.

In the case of an implausible setting, the corresponding LED

(for OUT1 or OUT2, as the case may be) will light up red.

When this setting is then stored, the value of the other output

(OUT 2 or OUT1, as the case may be) will be automatically

shifted. If your parameterizations are plausible, the red LED

is extinguished and the current switching status is displayed.

Plausible parameterizations are explained below.

Parameterizing the Device to Act as a Switch

When configuring an output as a max. temperature monitor,

SP must be greater than RP; further, a predefined min.

difference between SP and RP must be observed. If this condition is not observed, the corresponding LED will turn red,

and upon permanently storing the settings, the other value

(SP or RP, respectively) will be shifted; SP will then be equal

to RP. The LED will remain red until the min. difference is set.

When configuring an output as a min. temperature monitor,

SP must be less than RP; further, a predefined min.

difference between SP and RP must be observed. If this condition is not observed, the corresponding LED will turn red,

and upon permanently storing the settings, the other value

(SP or RP, respectively) will be shifted; SP will then be equal

to RP. The LED will remain red until the min. difference is set.

CAUTION

After setting the switch-point or reverse switch-point of an

output to act as a min. or max. temperature monitor and after

storing this configuration, you must check if the corresponding switch-points indeed have the desired values and

that the red LED has been extinguished.

NOTE: When configuring an output to act as a window

monitor (WIN), the only restriction applying to the

relative values of SP and RP is that the min.

difference be observed. SP can be greater or less

than RP.

Parameterizing the Analog Output

When configuring the analog output in order to define a span

(i.e. that portion of the device's total measuring range which

is of particular interest to you), FSO minus ZERO must be

greater than or equal to 30% of the device's total measuring

range. If this is not the case, no error is displayed; rather, the

first-set value (i.e. FSO or ZERO, as the case may be) will be

automatically shifted, as necessary.

or 10 V, as the case may be; when configured as FCTA, it is

limited to 4 mA or 20 mA, as the case may be.

Indicator LEDs

The condition (status) of the switch outputs is indicated by

means of two LEDs located below the display screen. These

two LEDs can display three different colors having the

following meanings:

• Orange: The corresponding output is active.

• Green: The corresponding output is not active (if

specified as a WARN output, "green" likewise means

that the WARN output is not active)

• When editing (EDIT) SP/RP, only the LED of that output

being edited is illuminated; in the event of implausible

values for RP and/or SP, the corresponding LED will

light up red.

• If both indicator lights are illuminated red and the

"WARN" symbol appears: WARN mode.

• If both indicator lights are illuminated, but the "WARN"

symbol does not appear: Implausible RP/SP for both

outputs.

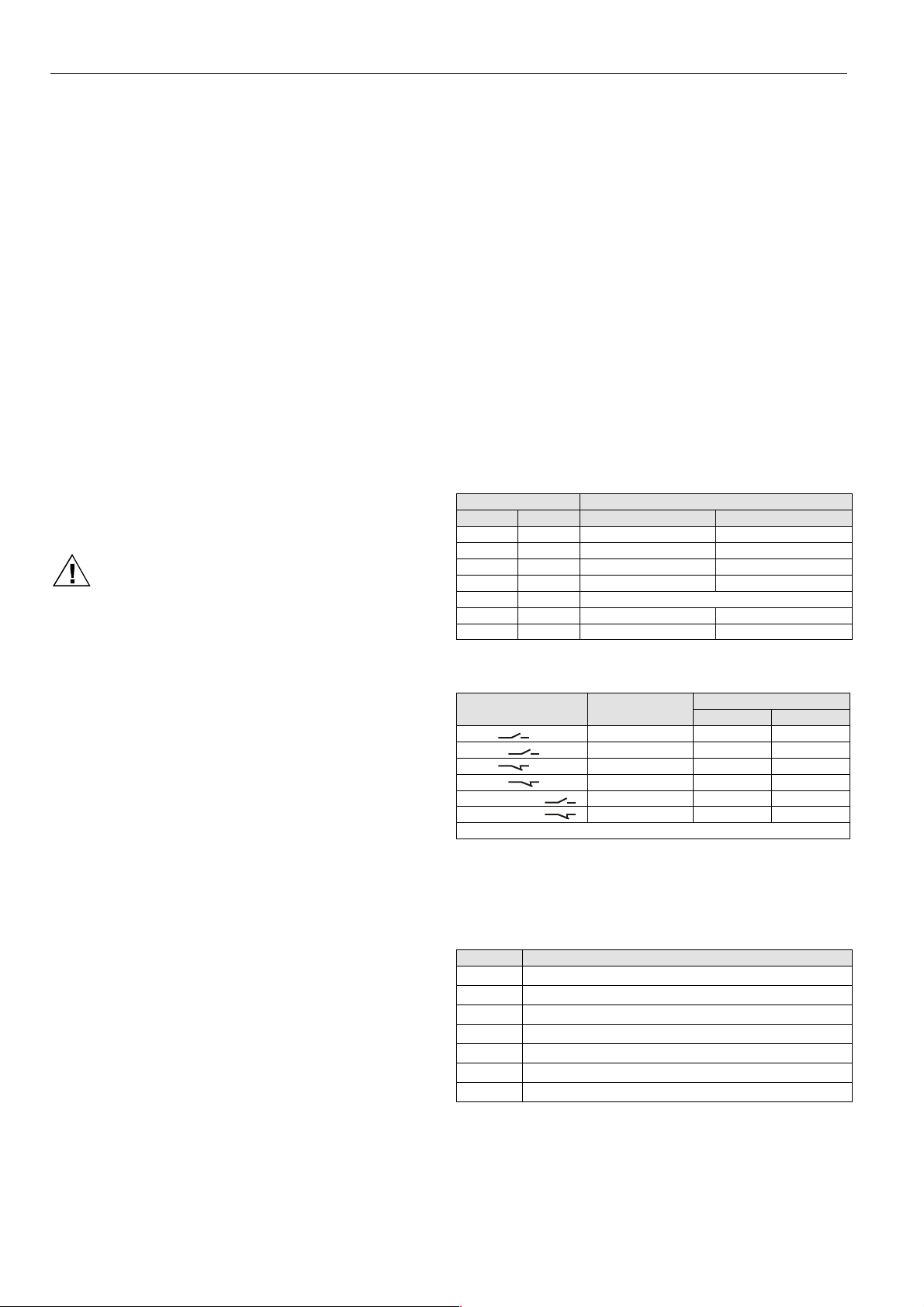

Table 2. Meaning of LED indicators

LED status meaning

LED 1 LED 2 OUT1 status OUT2 status

orange orange active active

green green inactive inactive

orange green active inactive

green orange inactive active

red red error (WARN) or 2x implausible

red -- implausible --

-- red -- implausible

Table 3. Potential of outputs in dependence upon their

symbols in

display

FSO, N.O. high-side "high" floating

ZERO, N.O. low-side "low" floating

FSO, N.C. high-side floating "high"

ZERO, N.C. low-side floating "low"

ZERO, FSO, push-pull "high" "low"

ZERO, FSO, inv. push-pull "low" "high"

N.O. = normally-open; N.C. = normally closed

configuration and status

configuration

active inactive

output signal

Error Codes

A number of different error codes can appear in the display,

serving to indicate a variety of faulty states.

NOTE: The specified accuracy refers to the respective

temperature range. E.g. at FSO minus ZERO =

50%, the accuracy then amounts to 1% of the

correspondingly narrower range.

NOTE: After shifting the value of ZERO, the value of FSO

must be checked and vice-versa.

If the current measured temperature is outside of the

selected span (i.e. either below ZERO or above FSO), the

AOUT symbol will not be visible on the screen and the

current temperature will be displayed. When configured (in

the expert mode) as FCTV, the analog signal is limited to 0 V

MU1B-0248GE51 R0903 8

Table 4. Error codes

text meaning

***1 sensor failure

**1* power supply voltage too low

*1** excessively low ambient temperature

*2** excessively high ambient temperature

1*** OUT1 is overloaded

2*** OUT2 is overloaded

3*** OUT1 and OUT2 both overloaded

Page 9

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

Rotary/Push Button (RPB)

Pushing the RPB: Pushing the RPB (rotary/push button)

confirms (in certain cases: rejects) the selections you have

made.

Rotating the Rotary/Push Button: When the EDIT symbol

has been called up, rotating the RPB (CW or CCW)

individual ticks increases or decreases (as the case may be)

the given displayed value. Otherwise, rotating the RPB

sweeps through a sequence of screens.

Possible Settings

Switching Delay ("ATT" Symbol)

The user can employ a convenient function to mask shortterm temperature fluctuations and peaks: the switching delay.

The switching delay can be set to values in the range of

1...3600 seconds. Any subsequent variation in temperature

which does not have the set minimum duration will still be

shown in the display and will be registered by the drag

indicator, but will nonetheless be unable to trigger a switch.

This delay can be applied to the switch-on behavior (

the switch-off behavior, (

), or to both ( ).

),

Locking/Unlocking the Device

Defining a Non-Zero Code

NOTE: The following explanations assume that the device

In order to prevent the unauthorized changing of parameters

and configurations, the user can define a 4-digit, non-zero

code (without a minus sign, and having a value of between

0001 and 9999). This is done by going through the expert

mode's sequence of screens until reaching the screen

shown in Fig. 54.

• The text "CODE" then means that a code has not yet

• The text "LOCK" then means that a code has already

Assuming that the text "CODE" has appeared, you must now

press the RPB in order to confirm that you do indeed wish to

define a code. "0000" will then appear in the display.

The desired code must now be defined by sequentially

rotating (to select) and pressing (to confirm) the RPB for

each digit of the desired code (which must be a 4-digit

number between 0001 and 9999). After the fourth digit of the

desired code has been defined, the text "LOCK" will appear.

You should then rotate the RPB CW one tick, whereupon the

"EXIT" screen (Fig. 55) will appear. After confirming this by

pressing the RPB, the device will re-enter the basic mode,

and the 1-minute grace period will immediately become

effective (see also section "Time-Out Function" on page 7).

If a non-zero code has been defined, the following will apply:

• If the 1-minute grace period is allowed to elapse, or

• if the device is turned OFF and then ON again,

is still in the default shipping setting (i.e. "EXPN" =

not locked for configuration). Otherwise, see

section "Locking the Device for Configuration

("EXPN" -> "EXPL")" on page 9.

been defined and that the user is free to define one.

been defined and, moreover, that the device has already

been locked.

the device will immediately become locked for parameterization and configuration. It is then no longer possible

to make changes to parameters or configurations without first

unlocking the device; rather, parameters can then be viewed,

only. Thus, a parameter can be selected (and will also be

displayed), but after pressing the RPB, instead of the value

changing, the text "LOCK" will appear in the screen for 1

second, after which the unchanged value will re-appear.

In order to be able to again change parameters, it is

necessary to unlock the device (also section "Unlocking a

Locked Device" below).

Unlocking a Locked Device

A device locked for parameterization and configuration can

be unlocked by inputting the correct code. This is done by

going through the basic mode's sequence of screens (Fig. 26

to Fig. 37) and stopping at the last screen, in which the text

"CODE" (instead of "EXP") will appear, thus prompting the

user to input the correct code. You must now press the RPB

in order to confirm that you wish to input the code. "-- -- -- --"

will appear in the display.

The correct code must now be inputted by sequentially

rotating (as appropriate) and pressing the RPB for each digit

of the code (which must be a 4-digit number between 0001

and 9999).

If you have inputted the incorrect code, the device will remain

in the basic mode and display the text "CODE".

Inputting the correct code will place the device into the expert

mode. The 1-minute grace period will then immediately

become effective again. The user then has the option of

either remaining in the expert mode (where configurations

can be viewed and changed) or of entering the basic mode.

Defining No Code (CODE = 0000)

Defining (and permanently storing) a code of 0000 (which is

the default shipping setting) means that that the device will

under no circumstances ever become locked. If, while in the

expert mode, any parameters / configurations are then

changed but not permanently stored (via SAVE), the device

will nevertheless remain in the expert mode until either a

SAVE or a REST (for "restore") is performed.

Locking the Device for Configuration ("EXPN" -> "EXPL")

It is possible to lock the device for configuration; thereafter, it

is still possible to enter the expert mode, but it is impossible

to make any changes while there. To do this, it is necessary

to change the default shipping setting of "EXPN" to "EXPL".

This can be done during the power-up sequence as follows:

1. Immediately after the power is turned ON, press and

hold down (for approx. 5 seconds) the RPB until the

software version is displayed.

2. Now rotate the RPB CW and go through the sequence of

screens until you reach a screen displaying either "EXP"

(indicating that as yet no code [CODE = 0000] had been

defined) or "CODE" (indicating that a non-zero code has

already been defined). If "EXP" appears, you can enter

the expert mode and press the RPB to proceed

immediately to step 3. If "CODE" appears, you must first

input the correct code in order to enter the expert mode,

press the RPB, and then proceed to the step 3.

MU1B-0248GE51 R09039

Page 10

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

3. Rotate the RPB CW until you come to a screen

displaying either "CODE" (indicating that as yet no code

[CODE = 0000] had been defined) or "LOCK" (indicating

that a non-zero code has already been defined).

Regardless, you must now press the RPB. You can now

either input the same (old) code or define a new code.

4. The very next screen to appear will display either

"EXPN" or "EXPL" (see Table 5 for the code-dependent

meaning of this text; the first line is the default shipping

setting). Changing "EXPN" to "EXPL" locks the device

for configuration. Changing "EXPL" to "EXPN" unlocks

the device for configuration.

Table 5. Code-dependent meaning of text at power-up

code text

0000 EXPN unlocked unlocked

0000 EXPL unlocked locked

≠0000 EXPN locked unlocked

≠0000 EXPL locked locked

Lost/Forgotten Code

In the event that you have lost or forgotten your code, you

can also unlock the device by means of the master code

obtained from Honeywell (when contacting Honeywell, please

state your device's serial number).

parameterization

(basic mode)

configuration

(expert mode)

Operating Sequence

If the user does not manipulate the RPB for 30 seconds, and

if "LED-" has been set (in the expert mode), the LCD display

screen's backlighting will be shut off automatically (see Fig.

25). If (in the expert mode) "LED+" has been set, the LCD

display screen's backlighting will remain on permanently.

Sequence of Display Screens in Basic Mode

When in the basic mode, rotating the RPB one tick CW at a

time results in the presentation, in the following sequence

(see Fig. 26 to Fig. 37), of all of the individual screens

available in this mode. At any time, you may rotate the RPB

CCW to go back to earlier screens in the reverse sequence.

Fig. 24. LCD display screen after power-up

Fig. 25. LCD display screen 30 s after last manipulation

Power Up

After power has been supplied, the backlighting is activated,

thus illuminating the LCD display, and all of the symbols

appear. Further, the two LEDs are illuminated for one second

(see Fig. 23).

EXPERT EDIT ATT

WARN

WIN

OUT2

OUT1 SPRP

AOUT ZERO FSO INV

Fig. 23. LCD display screen and LEDs on power-up

Basic Mode

After one second, the display goes into the so-called basic

mode. The basic mode is used to display and change (i.e. to

parameterize) SP/RP, ZERO, and FSO, to set the switching

delay, to view/reset the drag (min./max.) temperature

indicators, and to enter the expert mode.

In the first screen (see example in Fig. 24), the current

temperature (as a digital value and bar graph), the corresponding temperature unit, and the trend (increasing /

decreasing temperature) are displayed.

Display state: If the user does not manipulate the RPB for

60 seconds, regardless of the current screen, the LCD

display screen will revert to the first screen displaying the

temperature.

The values displayed in the following examples are valid for

devices of the PST...-R series, which was chosen because it

embodies the full range of possible functions. In the case of

devices of the PST... series, symbols referring to the relay

output will be displayed, but the text "NAPL" ("not

applicable") will appear in the text display.

Fig. 26. First screen displayed in the basic mode

After rotating the RPB one tick CW, the next screen, with

information about the switch-point (SP) of output 1, will be

displayed (see example in Fig. 27; in this case, OUT1 has

been configured as an N.O. high-side switch and as a max.

temperature monitor with a switch-point of 30 °C).

MU1B-0248GE51 R0903 10

Page 11

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

A

A

has been configured as an N.O. low-side switch for window

monitoring, with a reverse switch-point of 32 °C).

OUT1 SP

FSO

Fig. 27. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the reverse switch-point (RP) of output 1,

will be displayed (see example in Fig. 28; in this case, OUT1

has been configured as an N.O. high-side switch and as a

max. temperature monitor with a reverse switch-point of 20

°C).

OUT1 RP

FSO

Fig. 28. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information on the switching delay for OUT1, will be

displayed (see example in Fig. 29; in this case, the switching

delay has been switched OFF).

WIN

OUT2

RP

ZERO

Fig. 31. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the switching delay for OUT2, will be

displayed (see example in Fig. 32; in this case, a switching

delay of 520 seconds has been configured).

TT

OUT2

Fig. 32. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the zero-point (ZERO) of the analog output,

will be displayed (see example in Fig. 33; in this case, the

analog output has been configured with a ZERO of -10 °C).

TT

OUT1

Fig. 29. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the switch-point (SP) of output 2, will be

displayed (see example in Fig. 30; in this case, OUT2 has

been configured as an N.O. low-side switch for window

monitoring, with a switch-point of 35 °C).

WIN

OUT2

SP

ZERO

Fig. 30. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the reverse switch-point (RP) of output 2,

will be displayed (see example in Fig. 31; in this case, OUT2

AOUT ZERO

Fig. 33. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the upper limit (FSO) of the analog output's

measuring range, will be displayed (see example in Fig. 34;

in this case, the analog output has been configured with an

FSO of +140 °C).

AOUT FSO

Fig. 34. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the min. temperature (recorded by the drag

indicator) will be displayed (see example in Fig. 35; in this

case, the lowest temperature recorded was 15 °C).

MU1B-0248GE51 R090311

Page 12

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

Setting Parameters in the Basic Mode

If the device has been locked for parameterization, you will

be unable to do more than view values.

After having unlocked the device (see section "Unlocking a

Fig. 35. Next screen after rotating the RPB

If you now press the RPB, the EDIT symbol will appear,

whereupon you can make the drag indicator's timer appear

by rotating the RPB one tick CW. The timer displays how

long ago (in hours) the min. temperature occurred (e.g. "1.38

h" means that it occurred 1 hour and 38 minutes ago).

Rotating the RPB another tick CW and then pressing it will

reset the timer.

Locked Device"), however, you will be able to change values.

To change a particular value (after unlocking), the display

screen must first be made to present the desired parameter

by going through the sequence of screens listed above until

the corresponding screen is reached (see example in Fig.

38).

NOTE: Immediately after power-on, and until the timer has

been reset, the timer function is not available (and

the text "NAVL" will appear in the display).

After rotating the RPB another tick CW, the next screen, with

information about the max. temperature (recorded by the

drag indicator) will be displayed (see example in Fig. 36; in

this case, the highest temperature recorded was 28 °C).

Fig. 36. Next screen after rotating the RPB

If you now press the RPB, the EDIT symbol will appear,

whereupon you can make the drag indicator's timer appear

by rotating the RPB one tick CW. The timer displays how

long ago (in hours) the max. temperature occurred (e.g. "0.44

h" means that it occurred 44 minutes ago). Rotating the RPB

another tick CW and then pressing it will reset the timer.

NOTE: Immediately after power-on, and until the timer has

been reset, the timer function is not available (and

the text "NAVL" will appear in the display).

After rotating the RPB another tick CW, the next and final

screen will be displayed (see Fig. 37).

OUT1 SP

FSO

Fig. 38. Displaying the desired parameter to be edited

Press the RPB. The screen remains unchanged except that

the EDIT symbol appears (see Fig. 39).

OUT1 SP

FSO

Fig. 39. Display screen after appearance of EDIT symbol

If the RPB is now rotated CW or CCW, the value will correspondingly rise or drop in increments / decrements which

depend upon the model (see example in Fig. 40).

Fig. 37. Final screen after rotating the RPB

The final screen will display either "EXP" or " CODE" (see

section "Unlocking a Locked Device" on how to input the

code).

Upon reaching this final screen, you can return to any one of

the previous screens by rotating the RPB individual ticks

CCW. The previous screens will then be again displayed,

though in the reverse order.

MU1B-0248GE51 R0903 12

OUT1 SP

FSO

Fig. 40. Display screen after increasing value of desired

parameter

After the desired value has been reached, again pressing the

RPB will cause the following screen to appear (see Fig. 41).

However, if no values have been changed, it is not necessary

to save.

Page 13

EDIT

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

OUT1 SP

FSO

Fig. 41. Display screen after pressing the RPB: SAVE

You now have only two choices: You can either accept or

reject the new value.

• Accept: Pushing the RPB now means that you want to

permanently save the new value.

• Reject: Rotating the rotary/press button one tick CCW

will cause the next screen to appear (see Fig. 42).

EDIT

OUT1 SP

FSO

Fig. 42. Next screen after rotating back the RPB

If you now press the RPB, the new values will be rejected,

and the former values will be reinstated in the permanent

memory.

Fig. 43. First screen displayed in the expert mode

After rotating the RPB one tick CW, the next screen, with

information about the function of output 1, will be displayed

(see Fig. 44; in this case, OUT1 has been configured as an

N.O. low-side switch).

Fig. 44. Function display for OUT1 in expert mode

After rotating the RPB another tick CW, the next screen, with

information about the configuration of output 2, will be

displayed (see Fig. 45; in this case, OUT2 has been configured as a temperature window monitor).

NOTE: In contrast to the other functions which can be

parameterized in the basic mode, when adjusting

the switching delay, after pressing the RPB, it is

necessary to make a further specification, namely

whether the switching delay should apply to the

switch-on behavior (

), or to both ( ).

(

), the switch-off behavior

Sequence of Screens in Expert Mode

When in the expert mode, rotating the RPB individual ticks

results in the presentation in a sequence of all of the

individual screens of this mode. At any time, the sequence

can be halted by pressing the RPB, whereupon parameters

can be redefined/reconfigured by rotating the RPB. The

values displayed in the following figures are examples.

In the first screen, the configuration of output 1 is displayed

(see example in Fig. 43; in this case, OUT1 has been configured as a max. temperature monitor).

Fig. 45. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the function of output 2, will be displayed

(see Fig. 48; in this case, OUT2 has been configured as an

N.C. high-side switch).

Fig. 46. Function display for OUT2 in expert mode

After rotating the RPB another tick CW, the next screen, with

information about the function of the analog voltage output

MU1B-0248GE51 R090313

Page 14

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

(FCTV) or analog current output (FCTA), will be displayed

(see Fig. 47).

Fig. 47. Next screen after rotating the RPB

The "V" means that the analog output is configured for

0...10 V. By causing the INV

symbol to appear, this can be

changed to 10...0 V.

The "A" means that the analog output is configured for

4...20 mA. By causing the INV

symbol to appear, this can

be changed to 20...4 mA.

After rotating the RPB another tick CW, the next screen, with

information about the switch-over contact relay, will be

displayed (see example in Fig. 48; in this case, the relay has

been coupled with OUT1).

Fig. 48. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about the unit of temperature, will be displayed

(see Fig. 49). In this example, the device has been

configured for °C.

To balance the device, proceed as follows:

1. Immediately after turning ON the power (i.e. during the

power-up sequence), press and hold down (for approx. 5

seconds) the RPB until the software version is displayed.

Enter the expert mode and select SET0.

2. Rotate the RPB until the actual temperature is displayed.

If you wish to return the device to its original factory settings,

you must rotate the RPB until the left (

) and right ( ) trend

arrow heads appear simultaneously.

After rotating the RPB another tick CW, the next screen, with

information about the given sensor connection (two-wire or

three-wire, as the case may be) will be displayed (see also

section "Connecting the Sensor" on page 4). In this case,

(see example in Fig. 51), a three-wire sensor has been connected (this is the default setting). To change this configuration, see section "Reconfiguring the Sensor Connection" below.

EXPERT

Fig. 51. Next screen after rotating the RPB

Reconfiguring the Sensor Connection

The reconfiguration of the device to correspond to the given

sensor connection is a hidden function, and can be carried

out only immediately after switching ON the device and while

in the expert mode.

To reconfigure the device, you must turn OFF. Immediately

after turning the device back ON, press and hold down the

RPB for approx. 5 seconds, after which the software version

will appear in the display. You must then enter the expert

mode and choose "WIR2" or "WIR3", as appropriate.

Fig. 49. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen will

be displayed (see example in Fig. 50).

EXPERT

Fig. 50. Next screen after rotating the RPB

After pressing the RPB, the current measured temperature

will be displayed. If this temperature deviates from the actual

temperature, you should balance the device. See section

"Balancing the Device" below).

Balancing the Device

Balancing is a hidden function which can be carried out only

immediately after switching the device on and while in the

expert mode.

After rotating the RPB another tick CW, the next screen, with

information about adjusting the display backlighting, will be

displayed (see Fig. 53). In this example, the LED has been

set to remain ON permanently (+).

EXPERT

Fig. 52. Next screen after rotating the RPB

After rotating the RPB another tick CW, the next screen, with

information about simulation modes, will be displayed (see

Fig. 53). In this example, the simulation mode has been

turned OFF.

EXPERT

Fig. 53. Next screen after rotating the RPB

MU1B-0248GE51 R0903 14

Page 15

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

See also section "Configuring and Executing a Simulation"

on page 17 for an explanation of how to configure and

execute simulation modes.

After rotating the RPB another tick CW, the next screen, with

information about the code or lock, will be displayed (see Fig.

54). If no code has been set (i.e. code = 0000), the left

display will appear; if a code has been set (i.e. code = 0001

to 9999), the right display will appear.

Fig. 54. Next screen after rotating the RPB

After rotating the RPB another tick CW, the final screen of

the expert mode will be displayed (see Fig. 55).

Fig. 57. Display screen after appearance of EDIT symbol

If the user now again presses the RPB, the screen will revert

to its appearance in Fig. 56. If, however, the RPB is rotated

CW or CCW, different configuration options (in this example:

°F instead of °C) will appear accordingly.

Fig. 58. Display screen after selecting a different unit

If the user now again presses the RPB, the screen will revert

to its appearance in Fig. 56, though with a new unit (namely:

°F). If, however, the RPB is instead rotated to the end of the

sequence, the "EXIT" screen will appear (see Fig. 59).

Fig. 55. Final screen after rotating the RPB

You can return to any of the previous screens by rotating the

RPB individual ticks CCW. The previous screens will be

again displayed, though in the reverse order.

NOTE: If, while in the expert mode, no configuration is

changed, following the time-out (one minute), the

device will revert to the basic mode.

NOTE: If, while in the expert mode, a value is changed,

the device will remain at that position of the

sequence of screens until the user defines a value

via either "SAVE" or "REST."

Configuring in the Expert Mode

The screen must be made to present the desired parameter

by going through the sequence of screens listed above until

the corresponding screen is reached (see example in Fig.

56).

Fig. 56. Displaying the desired parameter to be edited

Fig. 59. Display screen after rotating the RPB to the end

of the display sequence

You can now press the RPB to confirm that you want to exit

the editing sequence, and then rotate the RPB CW or CCW

(as the case may be) until either "SAVE" (see Fig. 60) or

"REST" (see Fig. 61) appears in the screen.

Fig. 60. Display screen after rotating the RPB to "SAVE"

You now have only two choices: You can either accept or

reject the new parameters. Pushing the RPB now means that

you want to permanently save the new parameters. Rotating

the rotary/press button one tick CW will cause the next

screen to appear (see Fig. 61).

Press the RPB. The screen remains unchanged except that

the EDIT symbol now appears (see example in Fig. 57).

Fig. 61. Display screen after rotating the RPB to "REST"

If the user now presses the RPB, the new values will be

rejected, and the former values will be reinstated in the

MU1B-0248GE51 R090315

Page 16

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

e

t

e

t

e

t

permanent memory. Following either the "REST" or "SAVE"

screen, the device will revert to the basic mode.

Example Configurations in the Expert Mode

NOTE: When configuring an output as a max. or min.

temperature monitor or window monitor (WIN), it

may occur that the LED of the corresponding

output will light up red. This indicates that the

software has assigned SP and RP implausible

values (e.g. SP = RP). In this case, you will have

to enter the basic mode and change the values of

SP and/or RP so that the red LED is extinguished.

Furthermore, the red LED also lights up when the

current temperature is displayed in the basic mode

or when the settings are implausible.

Configuration of an Output as a Max. Temperature Monitor

When one of its output has been configured as a max. temperature monitor, the device serves to monitor and act upon

changes of temperature relative to a pre-selected upper limit

(SP). The corresponding output will then switch as soon as

this upper limit is exceeded. On the basis of this switching

process, a controller could then e.g. reduce the temperature.

As soon as the temperature drops below the reverse switchpoint (RP), the output will revert to its initial state. Thus, the

switching process is triggered when the temperature rises

above SP, while the reverse switching process is triggered

when the temperature drops below RP!

increase the temperature. As soon as the temperature rises

above the reverse switch-point (RP), the device will revert to

its initial state. Thus, the switching process is triggered when

the temperature drops below SP, while the reverse switching

process is triggered when the temperature rises above RP!

emperature

RP

e.g. +5 °C

SP

e.g. +20 °C

= active

= inactive

tim

Fig. 64. Min. temperature monitor

Example:

EXPERT

SPRP

emperature

SP

e.g. +35 °C

RP

e.g. +28 °C

= active

= inactive

tim

Fig. 62. Max. temperature monitor

Example:

EXPERT

SPRP

Fig. 63. OUT1 configured as a max. temperature monitor

Configuration of an Output as a Min. Temperature Monitor

When one of its output has been configured as a min. temperature monitor, the device serves to monitor and act upon

changes of temperature relative to a pre-selected lower limit

(SP). The corresponding output will then switch as soon as

the temperature drops below the set min. value. On the basis

of this switching process, a controller could then e.g.

Fig. 65. OUT1 configured as a min. temperature monitor

Configuration of an Output as a Window Monitor

When one of its outputs has been configured as a window

monitor, the device serves to monitor and act upon changes

of temperature beyond a pre-selected range. The corresponding output will then switch as soon as the temperature leaves the set range. On the basis of this switching

process, a controller could then e.g. increase or decrease the

temperature, as appropriate. As soon as the temperature

returns to the pre-selected range, the device will revert to its

initial state. Thus, the switching process is triggered when the

temperature leaves the pre-selected range, though with a

certain degree of hysteresis (in order to prevent uncontrolled

switching on the part of the temperature controller).

emperature

RP or SP

e.g. +40 °C

SP or RP

e.g. +30 °C

= active

= inactive

internal

hysteresis

internal

hysteresis

tim

Fig. 66. WIN temperature monitor

MU1B-0248GE51 R0903 16

Page 17

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

Fig. 67. OUT1 configured as a "WIN" monitor

display screen will display information and the two LED's

will light up / change color / go out just as though the

temperature were actually changing. As long as the

simulation is running, the text "SIM1" will be displayed

every ten seconds for five seconds. After a while

(approx. 30 minutes), the simulation mode is deactivated

automatically.

NOTE: When configuring an output as a window monitor

(WIN), the only restriction applying to the relative

values of SP and RP is that the min. difference be

observed. SP can be greater or less than RP.

Configuring and Executing a Simulation

There are two simulation modes: SIM1 and SIM2.

The purpose of SIM1 is to allow the user to test his configurations by rotating the RPB (which simulates increasing /

decreasing temperature) and simultaneously observing if the

LED's are lit at the appropriate temperature values and if the

corresponding information (text, symbols) appears in the

display.

The purpose of SIM2 is to allow the user to check the

flawless functioning of downstream devices connected to the

SmartTemp by switching the SmartTemp's outputs ON and

OFF in periodic intervals. Specifically, the user can set the

switch periods of the two outputs (OUT 1 and OUT2) in a

range of from 300 ms to 20 sec (corresponding to a set value

of from 0.0 to 100.0%; see

Table 6. Set value and corresponding switch period

set value switch period

0% approx. 300 ms

1% approx. 500 ms

5% approx. 1 s

10% approx. 2.5 s

50% approx. 10 s

100% approx. 20 s

To set up a simulation mode, proceed as follows:

1. Enter the expert mode.

2. Rotate the RPB CW until "SIM-" appears.

3. Press the RPB. The EDIT symbol will appear.

4. Rotate the RPB CW until SIM1 or SIM2 (as desired)

appears.

5. Press the RPB; the EDIT symbol will disappear.

6. Rotate the RPB CW until the text "EXIT" appears. Press

the RPB to confirm that you wish to exit the expert mode.

It is not necessary to save the simulation mode which

you have just set up – this is done automatically. However, after approx. 30 minutes, the simulation will be

automatically terminated and the device will return to

normal operation.

To execute SIM2, proceed as follows:

1. Immediately after completing the set-up described

above, the device is in the basic mode, and the FSO

(full-scale output) is displayed. Press the RPB; the EDIT

symbol and a value of 100.0% (meaning "max. switching

period") will appear.

2. Set the desired value of between 0.0% (min. switching

period = approx. 300 ms) and 100.0% (max. switching

period = approx. 20 s) by rotating the RPB CW and/or

CCW. OUT1, OUT2, the switch-over contact relay output, the analog output, and also the min./max.

temperature drag indicators will all react as though the

temperature were actually changing. Thus, as long as

the simulation is running, the device's display screen will

display information and the two LED's will light up /

change color / go out just as though the temperature

were actually changing. As long as the simulation is

running, the text "SIM2" will be displayed every ten

seconds for five seconds. After a while (approx. 30

minutes), the simulation mode is deactivated

automatically.

Warn Function

Besides pin 2 of plug 2, which is permanently wired as a

high-side switch serving as a warning output, it is also

possible to configure OUT2 (i.e. pin 2 of plug 1) as a warning

output.

In the event that the power supply voltage drops below a

critical level, or in the event of a sensor defect, operation

outside of the permitted temperature range, or overloading of

OUT1 and OUT2, the two LEDs will both light up red (see

also section "Error Codes" on page 8).

EXPERT

WARN

Fig. 68. OUT2 configured as a warning output

To execute SIM1, proceed as follows:

1. Immediately after completing the set-up described

above, the device is in the basic mode, and the FSO

(full-scale output) is displayed. Press the RPB; the EDIT

symbol will appear.

2. Rotate the RPB CW and/or CCW, thus simulating

increasing/decreasing temperature. OUT1, OUT2, the

switch-over contact relay output, the analog output, and

also the min./max. temperature drag indicators will all

react as though the temperature were actually changing.

Thus, as long as the simulation is running, the device's

MU1B-0248GE51 R090317

Page 18

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

A

FACTORY SETTINGS

feature factory setting

definition max. temperature monitor

function normally-open low-side output

OUT1

OUT2

SP two-thirds of FSO

RP one-third of FSO

ATT OFF

definition temperature window monitoring

function normally-open low-side output

SP two-thirds of FSO

RP one-third of FSO

ATT OFF

function non-inverted (normal, i.e.: 0...10 V)

ZERO lower limit of measuring rangeAOUT

FSO upper limit of measuring range

REL coupled with OUT1

Unit °C

Code 0000 (= no code / unlocked), EXPN

LOST/FORGOTTEN CODE

In the event that you have lost or forgotten your code, you

can also unlock the device by means of the master code

obtained from Honeywell (when contacting Honeywell, please

state your device's serial number).

40

25

8.4

50

20

4.5

5

.

4

44

58

50

80

100

ACCESSORIES

The following accessories are not included in the shipment,

but can be ordered.

M12 Couplings

For Plugs 1+2

For plugs 1+2 (5-prong plug for power supply and switching /

analog outputs):

• ST12-5-G (straight design)

• ST12-5-A (angled design)

For Plug 3

For plug 3 (3-prong relay output of TST...R):

• ST12-4-G (straight design)

• ST12-4-A (angled design)

• ST12-4-GK (straight design with 2-meter-long cable)

• ST12-4-AK (angled design with 2-meter-long cable)

Other Accessories

• AST1 wall mounting set (for attaching the TST...E... for

evaluating external sensors), see Fig. 69

• ST8-3 (3-prong M8 plug as per DIN IEC 60947-5-2 with

screw terminals)

60

Fig. 69. AST1 wall mounting set

Thermowells

Material: Stainless steel 1.4571 / 316L

model A B C D E F screwing

G12-100 105 36 19 14 15 83 G ½" (cylindrical)

G12-250 255 36 19 14 15 233 G ½" (cylindrical)

R12-100 105 36 19 14 15 83 R ½" (conical)

R12-250 255 36 19 14 15 233 R ½" (conical)

N12-100 105 36 19 14 15 83 N ½" (conical NPT)

N12-250 255 36 19 14 15 233 N ½" (conical NPT)

C

E

SW27

B

D

inner screwing for

insertion sensor G 1/2”

8 x 0.7 mm

F

Fig. 70. Dimensions of thermowells

MU1B-0248GE51 R0903 18

Page 19

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

LITERATURE

See also TST... and TST...-R Electronic Temperatur

Switches/Transmitter, Product Data (EN0B-0439 GE51).

Additional information and technical documentation in

electronic format are available under the following URL's:

www.honeywell.de/fema

and

www.fema.biz

MODELS AND TEMPERATURE RANGES

Table 7. Temperature ranges, connections, and models

temperature range

-50...+50 °C 100 built-on, G½" TST050G12100 TST050G12100-R

-50...+50 °C 250 built-on, G½" TST050G12250 TST050G12250-R

-50...+200 °C 100 built-on neck tube, G½" TST200G12100 TST200G12100-R

-50...+200 °C 250 built-on neck tube, G½" TST200G12250 TST200G12250-R

-50...+200 °C n.a. external, w/ cable* TST200EPT1K TST200EPT1K-R

-50...+400 °C n.a. external, w/ cable* TST400EPT1K TST400EPT1K-R

*Sensors not included in delivery.

sensor immersion

depth (mm)

sensor type, connection

switch / transmitter

model

switch / transmitter /

relay model

With the TST200EPT1K and TST400EPT1K, even customized PT1000 class-A sensors can be evaluated in the

aforementioned temperature ranges. PT1000 class-A sensors, only, may be used insofar as the required accuracy of 0.5% will

otherwise not be maintained.

External Sensors

temperature range

-50...+400 °C 100 2,5 m extern, G½" P2-TVS12-400-100 plug included

-50...+400 °C 250 2,5 m extern, G½" P2-TVS12-400-250 plug included

sensor immersion

depth (mm)

line length

sensor type,

connection

model remark

MU1B-0248GE51 R090319

Page 20

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

OVERVIEW OF PARAMETERIZATION AND CONFIGURATION

activity / situation

Current Temperature Is Displayed

current temperature

OUT1 is active

OUT2 is active

AOUT (temp. between ZERO & FSO)

temperature is rising

temperature is dropping

warning

Parameterizing Output 1 [Output 2]

SP

RP

first limit of window (WIN)

second limit of window (WIN)

Configuring Output 1 [Output 2]

max. temperature monitor (SP>RP)

min. temperature monitor (SP<RP)

window monitor (WIN)

output 2 as WARN

N.C. low-side open-collector OUT1[2]

N.O. low-side open-collector OUT1[2]

N.C. high-side open-collector OUT1[2]

N.O. high-side open-collector OUT1[2]

output 1 [2] as "push-pull"

output 1 [2] as inverted "push-pull"

Parameterizing the Analog Output

first limit (ZERO) of range

second limit (FSO) of range

Configuring the Analog Output

0...10 V voltage-controlled output

10...0 V voltage-controlled output

4...20 mA current-control output

20...4 mA current-control output

Configuring the Relay

relay coupled with output 1

relay coupled with output 2

relay configured as alarm output

Configuring Unit

unit EXPERT, °C / °F UNIT NO YES

Parameterizing Switching Delay

delay type (ON or OFF or ON + OFF) OUT1 [2], SP/RP, ATT or or YES NO

minimum duration bar graph, OUT1[2], ATT, s digital value or OFF YES NO

Locking / Unlocking Device Using a Code

unlocked (code = 0000)

locked (code ≠ 0000) - CODE, digital value YES NO

1

The same symbols appearing in the expert mode are also visible in the basic mode, where they indicate the current configuration of the given

output. Exceptions: If an output has been configured to act as a max. / min. monitor, in the basic mode,

1

, OUT1 [OUT2], SP digital value YES NO

, OUT1 [OUT2], RP digital value YES NO

, OUT1 [OUT2], SP digital value YES NO

, OUT1 [OUT2], RP digital value YES NO

EXPERT, SP, RP,

EXPERT, SP, RP,

EXPERT, WIN OUT1 [OUT2] NO YES

EXPERT, WARN OUT2 NO YES

EXPERT,

EXPERT,

EXPERT,

EXPERT,

EXPERT,

EXPERT,

, AOUT, ZERO digital value YES NO

, AOUT, FSO digital value YES NO

EXPERT, AOUT FCTV NO YES

EXPERT, AOUT, INV

EXPERT, AOUT FCTA NO YES

EXPERT, AOUT, INV

EXPERT, OUT1 REL NO YES

EXPERT, OUT2 REL NO YES

EXPERT, WARN REL NO YES

LCD display shows parameters adjustable in

symbols digital values / text basic mode expert mode

, unit digital value - -

OUT1 - - -

OUT2 - - -

AOUT - - -

---

---

WARN digital value NO NO

OUT1 [OUT2] NO YES

OUT1 [OUT2] NO YES

, ZERO FCT1 [FCT2] NO YES

, ZERO FCT1 [FCT2] NO YES

, FSO FCT1 [FCT2] NO YES

, FSO FCT1 [FCT2] NO YES

, ZERO, FSO FCT1 [FCT2] NO YES

, ZERO, FSO FCT1 [FCT2] NO YES

FCTV NO YES

FCTA NO YES

-EXPYESNO

and appear instead of and .

MU1B-0248GE51 R0903 20

Page 21

TST... AND TST...-R ELECTRONIC TEMPERATURE SWITCHES/TRANSMITTERS

OVERVIEW OF PARAMETERIZATION AND CONFIGURATION (CONTINUATION)

activity / situation

Changing Code

device is locked

device is unlocked

Resetting the display lighting

ON continuously

turned OFF

Drag indicator

max. temperature measured , temperature unit (°C / °F)

time since max. temperature , EDIT, h

min. temperature measured , temperature unit (°C / °F)

time since min. temperature , EDIT, h