TP970 and TP9600 Series

Pneumatic Thermostats

ENGINEERING DATA

Contents

Introduction .............................................................................................................................. 2

Fundamentals of

Thermostat Operation .............................................................................................................................. 2

General................................................................................................................. 2

Flapper-Nozzle Operation.................................................................................... 2

Valve Unit Operation ............................................................................................ 2

Low-Capacity, Single-Temperature

TP973A, B and TP9630 A, B

Thermostats .............................................................................................................................. 4

TP970A-D and TP9600A, B

High-Capacity, Single-Temperature

Thermostats .............................................................................................................................. 6

TP971A-C and TP9610A, B

High-Capacity, Dual-Temperature

Thermostats .............................................................................................................................. 7

TP972A and TP9620A High-Capacity,

Heating/Cooling Thermostat .............................................................................................................................. 10

General................................................................................................................. 4

Operation.............................................................................................................. 5

Direct Action.................................................................................................. 5

Reverse Action.............................................................................................. 5

General................................................................................................................. 6

Operation.............................................................................................................. 6

Direct Action.................................................................................................. 6

Reverse Action.............................................................................................. 7

TP971B and TP9610B ......................................................................................... 7

TP971C ................................................................................................................ 7

TP971A and TP9610A ......................................................................................... 7

Daytime Operation ............................................................................................... 8

Nighttime Operation ............................................................................................. 8

Manual DAY Override........................................................................................... 9

General................................................................................................................. 10

Operation.............................................................................................................. 12

TP974A Room

Temperature Sensor .............................................................................................................................. 12

General................................................................................................................. 12

Operation.............................................................................................................. 12

Copyright © 1997 Honeywell Inc. • All Rights Reserved

77-9382-1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

INTRODUCTION

This Engineering Data sheet provides detailed information

on the operation of TP970 and TP9600 Ser ies Pneumatic

Thermostats (Thermostats). These Thermostats use the

force-balance design with high nozzle feedback for stability.

The TP970 and TP9600 Series includes the following

thermostat models:

— TP970A-D and TP9600A, B:

High capacity

Proportional control

Single temperature

— TP971A-C and TP9610A, B:

Dual temperature

Day/night control (automatic switchover through

diaphragm logic)

Two sensing elements

Individual setpoint control

— TP972A and TP9620A, B:

High capacity

Heating/cooling control (automatic switchover

through diaphragm logic)

Two sensing elements (one for heating control,

one for cooling control)

— TP973A, B and TP9630A, B:

Low capacity

Proportional control

Single temperature

— TP974A:

Room temperature sensor

Used as a remote temperature transmitter for the RP920

Pneumatic Controller

This Engineering Data sheet describes the TP973A, B and

TP9630A, B Thermostats first, because they are the

simplest.

FUNDAMENTALS OF THERMOSTAT

OPERATION

General

throttling range (TR) adjustment) has a fixed branchline

pressure (BLP) for each temperature within the temperature

and throttling range settings. The forces within the nozzleflapper-bimetal assembly always seek a balanced condition;

giving the same BLP for the same temperature regardless of

fluctuations in main air or the relative positions of the nozzle,

flapper, and bimetal.

Flapper-Nozzle Operation

Flapper-nozzle operation is generally the same for all TP970

and TP9600 Thermostats. The Thermostat provides a

branchline air pressure that is a function of the ambient

temperature in the room or controlled space. As shown in

Figure 1, the force of the temperature-sensing bimetal acting

on one side of the flapper (Force A) is balanced by the

feedback force of the pilot pressure through the nozzle

acting on the other side of the flapper (Force B).

SETPOINT

THROTTLING RANGE

ADJUSTMENT

FORCE A

FLAPPER

NOZZLE

FORCE B

BIMETAL

IN BALANCED STATE,

FORCE B EQUALS FORCE A

Fig. 1. Flapper-Nozzle-Bimetal Assembly.

The position of the flapper over the nozzle changes and

creates a new pilot pressure when the bimetal force changes

(through temperature or setpoint change). This pilot pressure

feeds into the valve unit, which converts the low-capacity

pilot pressure to a high-capacity branchline change (see the

Valve Unit Operation section). Feedback at the nozzle

regulates the pressure to negate the effect of normal main

air supply fluctuations on the branch line.

Adjusting the throttling (proportioning) range changes the

flapper lever position. Moving the setpoint cam changes the

bimetal operating force and thus the setpoint.

KNOB

CALIBRATION

SCREW

SETPOINT

CAM

C6046

In force-balance design, two forces oppose each other until

they are equal, or balanced. The TP970 and TP9600 Series

Thermostats use the force of the bimetal to close the flapper

over the nozzle and the opposing force of the air pressure in

the nozzle chamber to lift the flapper (see the FlapperNozzle Operation section). When the forces are equal, a

force-balance condition exists.

The throttling range setting and the calibration reference

temperature determine the Thermostat span and calibration

point. At control point the nozzle-flapper-bimetal assembly

(acting through the calibration screw, setpoint cam, and the

77-9382—1

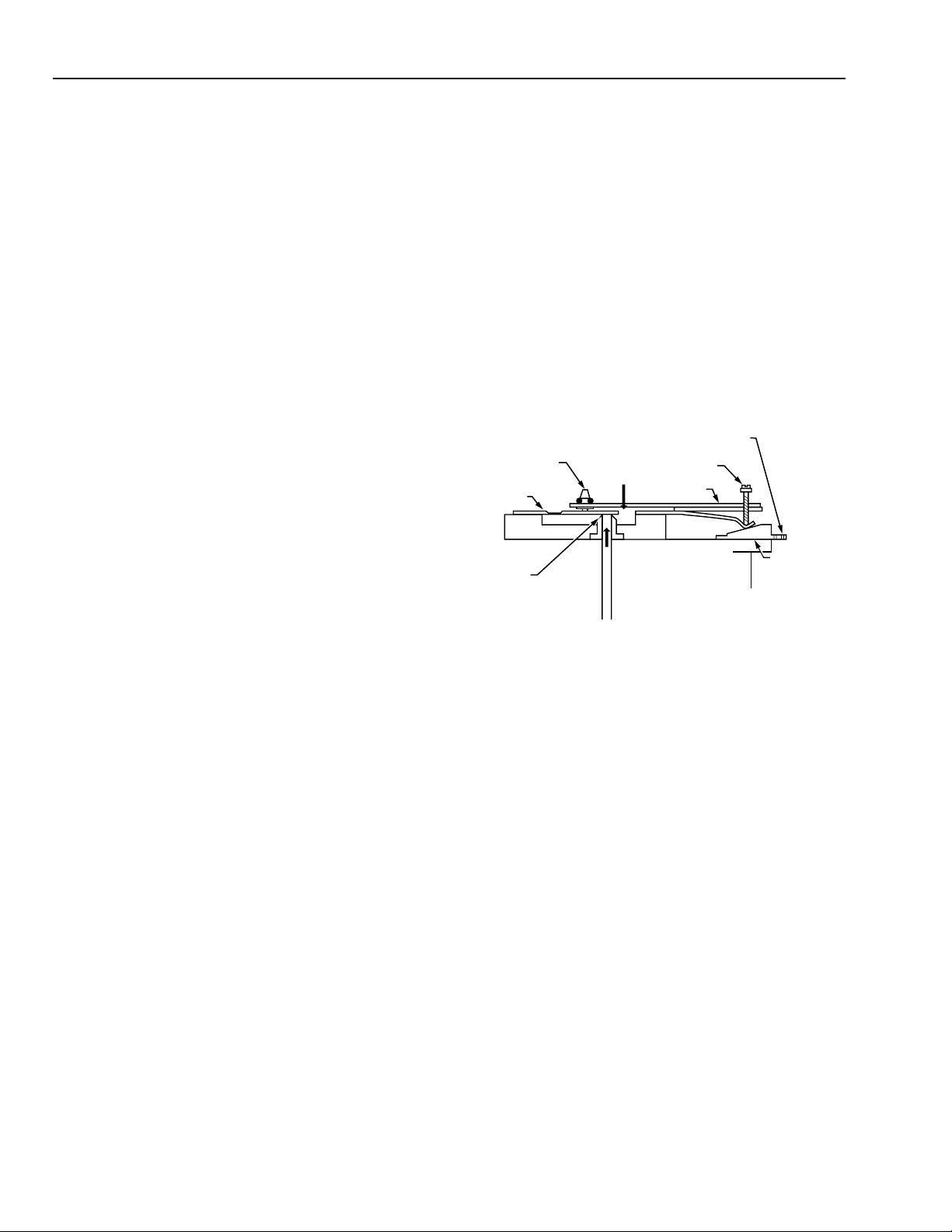

Valve Unit Operation

TP970, TP9600, TP971, TP9610, TP972, and TP9620

Thermostats use force-balance valve units to amplify airflow

and minimize air consumption without loss of required device

capacity. Figure 2 is a cross-section of a TP970 and TP9600

Thermostat showing the relationship of the valve unit to the

bimetal, nozzle, and other components.

2

TP790 AND TP9600 SERIES PNEUMATIC THERMOSTATS

POINT A

EXHAUST AIR

POINT B

MAIN LINE

BRANCH

LINE

PILOT AIR

C6049-1

NOTE: THE SEAL AT POINT A DOES NOT

ALLOW AIR TO EXHAUST.

VALVE

THROTTLING RANGE

ADJUSTMENT

FLAPPER

BLEED

BRANCHLINE

PRESSURE TAP

EXHAUST

BRANCHLINE

CHAMBER

PILOT

PILOT

CHAMBER

Fig. 2. Cross Section of TP970 and TP9600 Thermostat Showing Valve Unit and Airflow.

TP970, TP9600, TP971, TP9610, TP972, and TP9620

Thermostats are designed around a valve unit for flow

amplification rather than conventional pressure amplification.

Branchline chamber and pilot chamber design are such that

branch pressure is equal to nozzle pressure at a higher

capacity.

Figures 3, 4, and 5 are cross-sections of the valve unit only,

showing air passages and the pilot-branch diaphragm

relationship.

Figure 3 shows a valve unit in a strategic or balanced

condition. All the forces are equal; BLP equals the pilot-line

pressure.

No main air enters the branchline chamber and no exhaust

air leaves the branchline chamber. In this static condition,

the valve is sealed at both Points A and B, preventing airflow.

CALIBRATION

SCREW

SETPOINT

CAM

SETPOINT

KNOB

C6047-1

VALVE

NOZZLE

BRANCH LINE

BIMETAL

MAIN

LINE

FILTER

RESTRICTOR

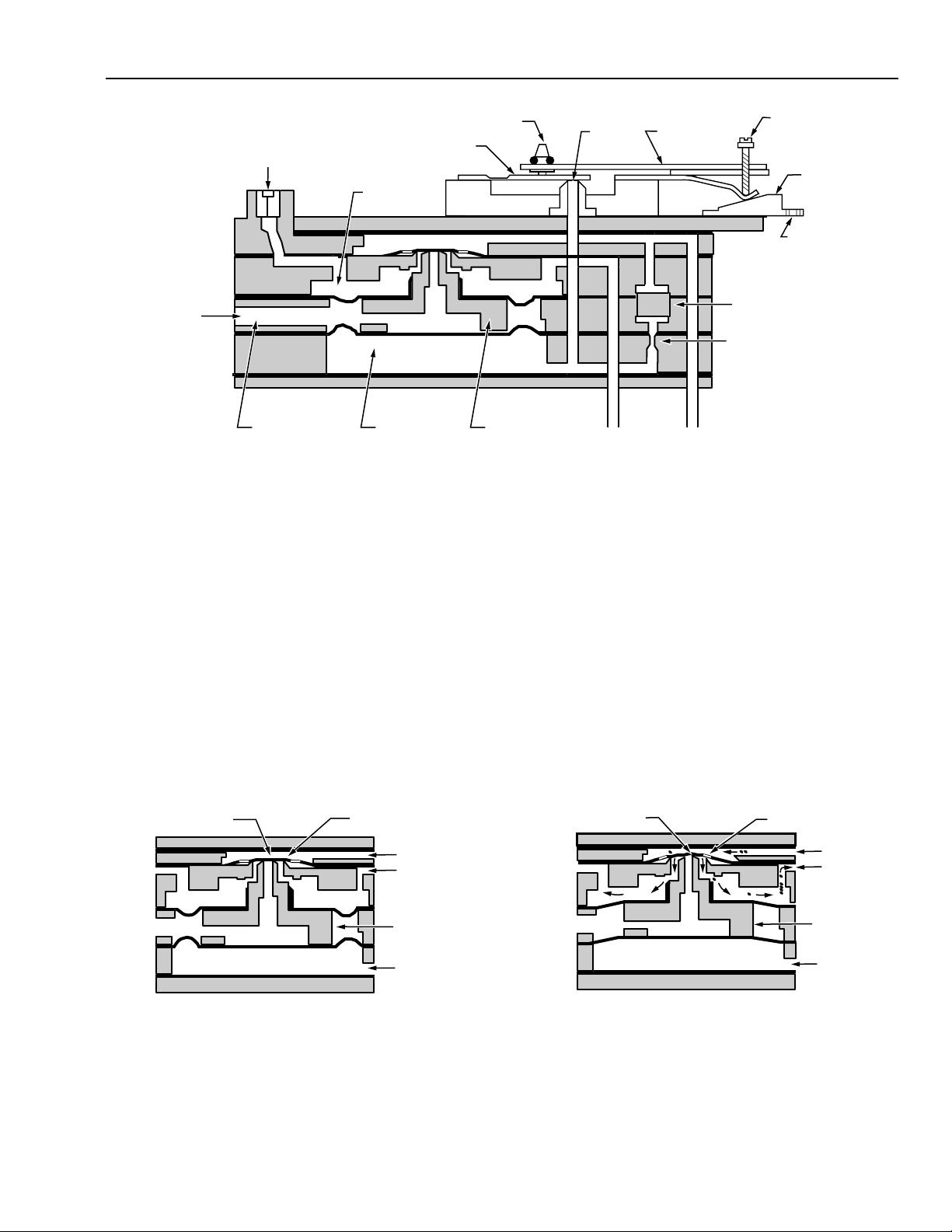

Figure 4 shows the valve unit supplying air to the branch

line. This condition occurs when the bimetal sensing element

forces the Thermostat flapper to ward the nozzle, decreasing

the nozzle-flapper gap and increasing the pilot pressure.

The increased pilot pressure against the pilot diaphragm

overcomes the force of the BLP on the branchline

diaphragm. This change opens the valve unit at Point B,

allowing main air to flow into the branch line. BLP builds until

the pressure against the branch diaphragm again equals the

pressure against the pilot chamber diaphragm. The main

airflow then shuts off, bringing the valve unit into a balanced

condition at a new pressure.

With direct-acting bimetal sensors, a temperature increase

closes the nozzle-flapper gap; with reverse-acting bimetal

sensors, a temperature increase opens the nozzle-flapper

gap. The arrows in the air passages in Figure 4 show the

direction of airflow.

EXHAUST

POINT A

BRANCH

PILOT CHAMBER

POINT B

MAIN LINE

BRANCH

CHAMBER

VALVE

PILOT AIR

Fig. 3. Valve Unit Flow Amplifier in a

Balanced (Static) Condition.

LINE

C6048-1

Fig. 4. Valve Unit Shown with Pilot

Chamber Pressure Increased.

3

77-9382—1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

Figure 5 shows the valve unit bleeding down the BLP. This

condition occurs when the bimetal sensing element relaxes

its force against the flapper, allowing the nozzle-flapper gap

to increase.

POINT A

VALVE

PISTON

EXHAUST

AIR

NOTE: THE SEAL AT POINT A DOES NOT

ALLOW AIR TO EXHAUST.

Fig. 5. Valve Unit Shown with Pilot

Chamber Pressure Decrease.

The reduction in pilot pressure against the pilot diaphragm

allows the BLP to overcome the pressure in the pilot

chamber. This change moves the valve piston down, sealing

off Point B and opening Point A. Branchline air bleeds off

until the pressure against the branchline diaphragm equals

the pressure against the pilot chamber diaphragm. When the

pressures become equal, the exhaust air is shut off at Point

A. The valve unit is again in a balanced condition at the new

pressure. The arrows in the air passages in Figure 5 show

the direction of airflow.

The preceding explanation of valve unit operation is very

important to understanding TP970, TP9600, TP971, TP9610,

TP972, and TP9620 operation. As can be seen from Figures

3, 4, and 5, pilot pressure changes affect BLP changes in

the same ratio. There is no pressure gain to amplify errors as

with other pneumatic Thermostats. Still, the main air supply

being switched through the valve unit, provides fast, high

capacity increase and decrease of BLP.

POINT B

MAIN LINE

BRANCH

LINE

VALVE

PILOT AIR

C6050-1

THROTTLING

RANGE

ADJUSTMENT

FLAPPER

BIMETAL

NOZZLE

AIR CONNECTION

FILTER AND

RESTRICTOR

SETPOINT

KNOB

CALIBRATION

SCREW

SETPOINT

CAM

SETPOINT

KNOB

C6051

Fig. 6. Basic TP973 and TP9630 Thermostat.

The TP973 and TP9630 are used on one- or two-pipe

systems. Connections are made to main and branch for twopipe applications (see Fig. 7). The main air connector is

plugged when used on one-pipe applications (Fig. 8). This

causes the Thermostat to operate like any other bleed-type

thermostat with a remote restrictor.

SETPOINT

KNOB

CALIBRATION

SCREW

FLAPPER

THROTTLING RANGE

ADJUSTMENT

BIMETAL

TP973A, B AND TP9630 A, B LOW CAPACITY, SINGLE-TEMPERATURE

THERMOSTA TS

General

The TP973A, B TP9630A, B (Fig. 6) are the simplest

Thermostats in the TP970 and TP9600 Series. Ever y other

model includes the basic TP973 and TP9630 assembly with

additions. Air going to the controlled device from the TP973

and TP9630 passes through an internal restrictor. The

TP973A and TP9630A are direct acting (signal pressure

increases as the temperature increases); the TP973B,

reverse acting (signal pressure increases as the temperature

decreases).

77-9382—1

NOZZLE

NOZZLE

CHAMBER

RESTRICTOR

MAIN LINE

CAM

SLOPE

BRANCH

LINE

BACKPLATE

TO CONTROLLED

DEVICE

SETPOINT

CAM

C6052

Fig. 7. TP973 and TP9630 Operating Section.

4

TP790 AND TP9600 SERIES PNEUMATIC THERMOSTATS

SETPOINT

KNOB

CALIBRATION

SCREW

CAM

SLOPE

BACKPLATE

SETPOINT

CAM

C6053

FLAPPER

NOZZLE

NOZZLE

CHAMBER

RESTRICTOR

MAIN LINE

THROTTLING RANGE

ADJUSTMENT

BIMETAL

TO CONTROLLED

DEVICE

Fig. 8. TP973 and TP9630 Operating

Section—Main Port Capped.

Operation

Direct Action

Refer to Figures 7 and 8. On a temperature rise, the flapper

is forced toward the nozzle by the action of the temperaturesensing bimetal, which reduces the flapper-nozzle gap. The

change in the flapper-nozzle gap allows less air to escape

from the nozzle, thus increasing the pressure in the nozzle

chamber as well as the branch line. The controlled device is

thereby positioned to maintain the controlled space to the

desired temperature.

The Thermostat provides a BLP that is a function of ambient

temperature. The force from the bimetal acting on the flapper

is balanced by the feedback force of the BLP acting on the

opposite side of the flapper through the nozzle. If the

setpoint knob is changed to a new setting, the opposing

forces in the lever system go out of balance and the room

ambient temperature changes to rebalance the lower

system.

For example, if the setpoint cam is moved to a higher

temperature setting, the point of the lever system that rides

the slope of the cam lowers (direct-acting device) due to this

cam slope. As a result, the bimetal reduces its force applied

to the flapper. The reduced force causes the BLP to bleed

down and a heating valve to open. Heat is introduced to the

space until the forces of the bimetal are again in equilibrium

with the opposing force (8 psi [55 kPa] times the area of the

nozzle at the flapper). A reduction in setpoint causes the

reverse to happen.

The calibration screw allows for matching the bimetal start

position with the indicated setting on the setpoint cam to

achieve an 8 psi (55 kPa) BLP at the indicated setpoint.

The TR adjustment (Fig. 9) provides a means for changing

the effective length of the bimetal. When the TR adjustment

is moved over the nozzle, the force from the bimetal is

exerted directly over the nozzle and a narrow TR, or very

high sensitivity, results. For example, a 1°F (0.56°C) change

in temperature results in a 5 psi (34 kPa) BLP change.

When the TR adjustment is moved toward the end of the

bimetal away from the nozzle, the effective force output of

the bimetal is reduced. This reduction requires a greater

temperature change at the bimetal to throttle the flapper over

the nozzle. The result is a wider TR or very low sensitivity; for

instance, a 1°F (0.56°C) change in temperature results in

only a 1 psi (7 kPa) BLP change.

Reverse Action

Refer to Figures 7 and 8. On a temperature rise, the flapper

is forced away from the nozzle by the action of the

temperature-sensing bimetal, which increases the flappernozzle gap. The change in the flapper-nozzle gap allows

more air to escape from the nozzle, thus decreasing the

pressure in the nozzle chamber as well as the branch line.

The controlled device is thereby positioned to maintain the

controlled space to the desired temperature.

THROTTLING

BRANCHLINE

PRESSURE

GAGE TAP

FLAPPER

NOZZLE

RANGE

ADJUSTMENT

BIMETAL

BRANCH

LINE

MAIN

LINE

CALIBRATION

SCREW

FILTER

RESTRICTOR

Fig. 9. Cross Section of TP973 and TP9630 Thermostat.

5

SETPOINT

CAM

SETPOINT

KNOB

C6054

77-9382—1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

The Thermostat provides a BLP that is a function of ambient

temperature. The force from the bimetal acting on the flapper

is balanced by the feedback force of the BLP acting on the

opposite side of the flapper through the nozzle. If the

setpoint knob is changed to a new setting, the opposing

forces in the lever system go out of balance and the room

ambient temperature changes to rebalance the lower

system.

For example, if the setpoint cam is moved to a higher

temperature setting, the point of the lever system that rides

the slope of the cam rises (reverse-acting device) due to this

cam slope. As a result, the bimetal increases its force

applied to the flapper. The increased force causes the BLP

to build up and a cooling valve to open. Cooling is introduced

to the space until the forces of the bimetal are again in

equilibrium with the opposing force (8 psi [55 kPa] times the

area of the nozzle at the flapper). A reduction in setpoint

causes the reverse to happen.

The calibration screw allows for matching the bimetal start

position with the indicated setting on the setpoint cam to

achieve an 8 psi (55 kPa) BLP at the indicated setpoint.

The TR adjustment provides a means for changing the

effective length of the bimetal. When the TR adjustment is

moved over the nozzle, the force from the bimetal is exerted

directly over the nozzle and a narrow TR, or very high

sensitivity, results. For example, a 1°F (0.56°C) change in

temperature results in a 5 psi (34 kPa) BLP change.

When the TR adjustment is moved toward the end of the

bimetal away from the nozzle, the effective force output of

the bimetal is reduced. This reduction requires a greater

temperature change at the bimetal to throttle the flapper over

the nozzle. The result is a wider TR or very low sensitivity; for

instance, a 1°F (0.56°C) change in temperature results in

only a 1 psi (7 kPa) BLP change.

BRANCH LINE

PRESSURE GAGE PORT

THROTTLING RANGE

ADJUSTMENT

FLAPPER

VALVE UNIT

BIMETAL

SETPOINT KNOB

NOZZLE

CALIBRATION

SCREW

SETPOINT

KNOB

SETPOINT

CAM

C6055

Fig. 10. TP970 and TP9600 High Capacity

Pilot Operated Thermostat.

NOTE: TP970C1000 (direct acting) and TP970D1008

(reverse acting) Thermostats have extended

throttling ranges of 5 to 20°F (2.5 to 10°C) for

energy conservation applications. The extended

throttling range allows for a Zero Energy Band

(ZEB) between sequenced heating and cooling

modes.

TP970A-D AND TP9600A, B HIGHCAPACITY, SINGLE-TEMPERATURE

THERMOSTA TS

General

The TP970 and TP9600A, B Thermostats (Fig. 10) are the

basic TP973 with a valve unit added for greater capacity to

control valve or damper actuators in heating or cooling

systems.

TP970A, B, C, D and TP9600A, B devices are bimetalelement, pilot-operated, two-pipe, proportioning pneumatic

Thermostats. The TP970A, C and TP9600A are direct acting

(BLP increases as temperature increases). The TP970B, D

and TP9600B are reverse-acting (BLP decreases as

temperature increases).

Operation

Direct Action

Refer to Figure 11. On a temperature rise, the flapper is

forced toward the nozzle by the action of the bimetal. The

force of the bimetal acting on the flapper is balanced by the

feedback force of the pilot pressure in the nozzle chamber

acting in an opposing direction. This action varies the

flapper-nozzle gap, which in turn causes an increased

pressure in the pilot line. The change in pilot pressure is

routed to the flow amplifier that converts the low capacity

pilot pressure signal to a high capacity branchline flow at the

same pressure.

For a more detailed discussion, refer to the Valve Unit

Operation section.

77-9382—1

6

TP790 AND TP9600 SERIES PNEUMATIC THERMOSTATS

SETPOINT KNOB

THROTTLING RANGE

ADJUSTMENT

FLAPPER

NOZZLE

NOZZLE

CHAMBER

RESTRICTOR

MAIN LINE

BIMETAL

CALIBRATION

SCREW

VALVE

UNIT

PILOT LINE

FLOW

AMPLIFIER

BRANCH LINE

SETPOINT

CAM

C6056-1

Fig. 11. Operating Sections of TP970A, C and TP9600A

(Direct Acting).

Reverse Action

Refer to Figure 11. On a temperature rise, the flapper is

forced away from the nozzle by the action of the bimetal. The

force of the bimetal acting on the flapper is balanced by the

feedback force of the pilot pressure in the nozzle chamber

acting in an opposing direction. This action varies the

flapper-nozzle gap, which in turn causes a decreased

pressure in the pilot line. The change in pilot pressure is

routed to the flow amplifier that converts the low capacity

pilot pressure signal to a high capacity branchline flow at the

same pressure.

For a more detailed discussion, refer to the Valve Unit

Operation section.

TP971A-C AND TP9610A, B HIGHCAPACITY, DUAL-TEMPERATURE

TP971A and TP9610A

On the TP971A and TP9610A direct-acting Thermostats (Fig.

12), the daytime bimetal controls the system when the main

air pressure is 13 psi (90 kPa). The nighttime element

controls the system when the main air pressure reaches 18

psi (124 kPa). Models are available with switchover

pressures of 16 to 21 psi (110 to 145 kPa) and 20 to 25 psi

(138 to 172 kPa).

NIGHT BIMETAL

NIGHT THROTTLING

RANGE ADJUSTMENT

DAY THROTTLING

RANGE ADJUSTMENT

THROTTLING RANGE

ADJUSTMENT

FLAPPER

DAY/NIGHT

LOGIC CIRCUIT

Fig. 12. TP971 and TP9610 Day/Night Thermostat.

NIGHT SETPOINT

INDICATOR

DAY BIMETAL

BRANCH LINE

PRESSURE GAGE PORT

BIMETAL

NOZZLE

AIR CONNECTION

FILTER AND

RESTRICTOR

NIGHT SETPOINT

KNOB

DAY

SETPOINT KNOB

CALIBRATION

ADJUSTMENT

NIGHT

SETPOINT CAM

DAY

SETPOINT

KNOB

VALVE UNIT

C6057

THERMOSTATS

The TP971A, B, C and TP9610A, B Thermostats feature day

and night sensing elements with individual setpoint

adjustments for day/night control of heating and air

conditioning systems. The Thermostat cover is removable for

adjusting the nighttime setpoint. All TP971 and TP9610

Thermostats have a manual override lever (DAY/AUTO)

which allows the occupant to change the Thermostat

operation from night cycle to day cycle. The Thermostat can

be made tamper proof by cutting off the manual override

lever with a side cutter. The complete manual override lever

assembly can be removed and replaced if desired (see

TP970 and TP9600 Series Pneumatic Thermostats Service

Data 75-7134).

TP971B and TP9610B

The TP971B and TP9610B are the same as the TP971A and

TP9610A except that they are reverse acting.

TP971C

The TP971C is a direct-acting, three-pipe Thermostat. The

third pipe, a secondary branch line, is a switched line

providing pilot control of auxiliary equipment. Switchover

pressure is 13 psi (90 kPa) for daytime operation and 18 psi

(124 kPa) for nighttime operation. The TP971C is typically

used in conjunction with unit ventilator systems requiring

Day/Night/Warm-up cycles.

The secondary branch line is used with a pneumatic/electric

(P/E) switch to start and stop the supply fan on the night

cycle. The secondary branch line has full main air pressure

on the night cycle and daytime main air pressure on the day

cycle.

7

77-9382—1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

Daytime Operation

Figure 13 shows airflow through the Thermostat during

daytime operation. The main air pressure is at the lower,

daytime operating pressure of 13 psi (90 kPa).

Air enters the Thermostat through the main line, passes

through a screen, then diverts into the valve unit and through

the multistage filter. The arrows in Figure 13 show main air

traveling to Logic Module A, which is closed because the

adjustable spring is set to open only at the higher nighttime

pressure. Main air passes through the integral restrictor, into

the pilot chamber of the valve unit, and in to Logic Module B.

The spring holds Port B1 open because there is no air

pressure against the top of the diaphragm of Logic Module

B. This action allows air to pass through Port B1 to the 13 psi

(90 kPa) (DAY) nozzle-flapper. The Thermostat now operates

on a daytime cycle at the daytime setpoint. The valve unit

operation is identical to that described in the Valve Unit

Operation section.

S

SECONDARY

BRANCH

LOGIC MODULE A

1

Nighttime Operation

In Figure 14, the main air pressure is at 18 psi (124 kPa) for

nighttime operation. The airflow, shown by arrows, is the

same as the daytime cycle up to Logic Module A and Logic

Module B. The main air pressure, 18 psi (124 kPa), is now

enough to overcome the spring-loaded diaphragm in Logic

Module A. Because the manual override lever is in the AUTO

position, the air passes through Logic Module A, and then

through Logic Modules C and D. This air pressure forces the

diaphragm of Logic Module B downward, closing Port B1

and allowing air to pass through Port B2. The airflow then

passes to the 18 psi (124 kPa) (NIGHT) nozzle-flapper. In

this condition, the Thermostat operates on a nighttime cycle.

Valve unit flow amplifier operation is identical to that

described in the Valve Unit Operation section.

DAY/AUTO LEVER

MANUAL DAY

LOGIC

MODULE C

LOGIC

MODULE D

MAIN LINE

SPRING

B BLEED 1

SPRING

LOGIC

MODULE B

S

S

F

FILTER

BRANCH LINE

R

RESTRICTOR

PILOT

CHAMBER

VALVE

UNIT

DOTTED LINES INDICATE THE SECONDARY

1

BRANCH LINE INTEGRAL TO THE TP971C

Fig. 13. TP971 and TP9610 Operation on Day Cycle—Main Air Pressure 13 psi (90 kPa).

BLEED 2

B

DIAPHRAGM

PORT B2

PORT B1

18 PSI (124 kPa)

NIGHT

13 PSI (90 kPa)

DAY

C6058-1

77-9382—1

8

S

SECONDARY

BRANCH

TP790 AND TP9600 SERIES PNEUMATIC THERMOSTATS

DAY/AUTO LEVER

1

LOGIC MODULE A

LOGIC

MODULE C

MANUAL DAY

LOGIC

MODULE D

SPRING

BLEED 1

B

MAIN LINE

S

S

F

FILTER

BRANCH LINE

R

RESTRICTOR

PILOT

CHAMBER

Fig. 14. TP971 and TP9610 Operation on Nighttime Cycle—Main Air Pressure 18 psi (124 kPa).

Manual DAY Override

Manual DAY Override is shown in Figure 15. With main air

pressure at the 18 psi (124 kPa) (NIGHT) setting, airflow

applies pressure to Logic Modules A, C, and D. However,

because the DAY/AUTO lever has been manually positioned

to DAY, Logic Module D is shut off, stopping airflow. Air

pressure is bled from Logic Module B through Bleed 2, and

the diaphragm moves up to open Port B1 and close Port B2.

This condition allows an airflow path to the 13 psi (90 kPa)

(DAY) nozzle-flapper and closes the airflow path to the 18

psi (124 kPa) (NIGHT) nozzle-flapper. Thus, the Thermostat

works on a daytime cycle even though the main air supply

pressure is at its normal night cycle main air pressure of 18

psi (124 kPa).

The 18 psi (124 kPa) pressure on the diaphragm of Logic

Module C holds the manual DAY/AUTO lever in position. If

the occupant fails to return the override lever, the lever

returns automatically when the system main air pressure is

reduced to 13 psi (90 kPa). This change returns the

Thermostat to its normal operation and automatic logic

switchover.

The secondary branch line operates with the manual DAY/

AUTO lever position as follows:

1. System in normal daytime operation, 13 psi (90 kPa)

main air pressure (Fig. 13 dotted lines).

2. Move the manual DAY/AUTO lever to the DAY position.

It snaps back to AUTO because there is no air

pressure on logic switch C (Fig. 13).

The secondary branch line is always at the main air pressure

when the system operates in a daytime mode; the P/E switch

contacts are closed and the supply fan is operating.

BLEED 2

VALVE

UNIT

SPRING

LOGIC

MODULE B

1

B

DIAPHRAGM

PORT B2

PORT B1

DOTTED LINES INDICATE THE SECONDARY

BRANCH LINE INTEGRAL TO THE TP971C

18 PSI (124 kPa)

NIGHT

13 PSI (90 kPa)

DAY

C6059-1

During normal nighttime operation conditions (Fig. 14):

1. The system is in normal nighttime operation mode;

main and secondary branchline air pressure is at 18

psi (124 kPa). The secondary branch line is also at 18

psi (124 kPa).

2. Since the P/E switch contacts open at any pressure

over 15 psi (103 kPa), the supply fan is off.

3. The manual DAY/AUTO lever is in the AUTO position

because operation is under normal nighttime

conditions (Fig. 14).

The secondary branch line is at the night main air pressure

of 18 psi (124 kPa) when the system is operating in a normal

nighttime mode. The P/E switch contacts are open and the

supply fan is off because the pressure in the secondary

branch is over 15 psi (103 kPa).

For night occupancy and daytime control:

1. Push the DAY/AUTO switch to the DAY position. This

opens the nozzle-bleed on the secondary branch line

(Fig. 15).

2. The DAY/AUTO lever stays in the DAY position

because of the air pressure on Logic Module C (Fig.

15).

3. The main air pressure in the secondary branch line

bleeds down through the secondary branch nozzle.

The secondary branchline restrictor maintains normal

night system pressure in the rest of the Thermostat.

However, airflow is now diverted to operate the nozzleflapper on the DAY mode sensing element (Fig. 15).

9

77-9382—1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

MAIN LINE

S

SECONDARY

BRANCH

S

S

SPRING

F

FILTER

BRANCH LINE

1

LOGIC MODULE A

B

R

RESTRICTOR

BLEED 1

SB

NOZZLE

PILOT

CHAMBER

Fig. 15. TP971 and TP9610 Operation, DAY/AUTO Lever Manually Set to

DAY Position—Main Air Pressure 18 psi (124 kPa).

When the air supply system returns to its normal daytime

pressure, the DAY/AUTO lever is spring returned to the

AUTO position and the Thermostat returns to normal

operation. The occupant can also return the system to

normal operation by manually switching the DAY/AUTO lever

to AUTO.

LOGIC

MODULE C

VALVE

UNIT

HEATING THROTTLING

RANGE ADJUSTMENT

SPRING

LOGIC

MODULE B

DAY/AUTO LEVER

MANUAL DAY

LOGIC

MODULE D

BLEED 2

B

DIAPHRAGM

PORT B2

PORT B1

1

DOTTED LINES INDICATE THE SECONDARY

BRANCH LINE INTEGRAL TO THE TP971C

HEATING

BIMETAL

HEATING SETPOINT

KNOB FOR TP972A1036

(55-75°F (13-24°C) RANGE)

18 PSI (124 kPa)

NIGHT

13 PSI (90 kPa)

DAY

C6060-1

In the preceding situation, the P/E switch contacts are

closed. This is because the secondary BLP is under 15 psi

(103 kPa); the DAY/AUTO lever is held in the DAY position

by pressure on Logic Module C; and the Thermostat uses its

daytime bimetal because the airflow through Logic Module

D is closed off.

TP972A AND TP9620A HIGH-CAPACITY,

HEATING/COOLING THERMOSTA T

General

The TP972A and TP9620A (Fig. 16) are high-capacity, twopipe, proportioning pneumatic Thermostats with two bimetal

sensing elements.

COOLING THROTTLING

RANGE ADJUSTMENT

THROTTLING RANGE

ADJUSTMENT

FLAPPER

HEATING/COOLING

LOGIC CIRCUIT

THERMOMETER

POST

BRANCH LINE

PRESSURE GAGE PORT

BIMETAL

NOZZLE

COOLING

BIMETAL

AIR CONNECTION

FILTER AND

RESTRICTOR

SETPOINT

KNOB (TAB

REMOVED FOR

TP972A1036)

CALIBRATION

ADJUSTMENT

NIGHT

SETPOINT KNOB

VALVE UNIT

COOLING

SETPOINT

KNOB

C6061-1

Fig. 16. TP972A and TP9620A Cross Section Showing

Adjustments and Modular Construction.

77-9382—1

10

TP790 AND TP9600 SERIES PNEUMATIC THERMOSTATS

The TP972A and TP9620A have one setpoint adjustment

knob that controls both heating and cooling bimetals. Each

bimetal has an independent throttling range adjustment

(Fig. 16). The cooling bimetal of the TP972A and TP9620A

controls when the two-pressure air supply is at the lower of

the two pressures; the heating bimetal of the TP972A and

TP9620A controls when air supply pressure increases to the

higher of the two pressures. Typical values for the twopressure supply systems are 13/18 psi (90/124 kPa),

16/21 psi (110/145 kPa), and 20/25 psi (138/172 kPa).

Figures 17 and 18 are schematic representations of the

TP972A and TP9620A airflow paths for heating and cooling

control. Operation is the same as that for the TP971 and

SPRING

LOGIC

MODULE A

B

BLEED 1

MAIN LINE

S

F

FILTER

R

RESTRICTOR

PILOT

CHAMBER

TP9610 except for the logic modules, the manual override,

and the independent setpoint adjustment. Cooling control

requires a lower pressure in the main air supply. Figure 17

shows the workings and traces the air path within the

TP972A and TP9620A when it is controlling with the cooling

bimetal.

NOTE: The TP972A2036, A2168, and A2176 and TP9620A

limited-control-range Thermostats have separate,

concealed setpoints for heating and cooling and

limit the heating control point to a maximum of

75°F (24°C).

18 PSI (124 kPa)

WINTER

13 PSI (90 kPa)

SUMMER

SPRING

LOGIC

MODULE B

DIAPHRAGM

PORT B2

PORT B1

S

BRANCH LINE

MAIN LINE

S

S

BRANCH LINE

VALVE

UNIT

Fig. 17. TP972A and TP9620A Operation on Cooling Cycle—Main Air Pressure 13 psi (90 kPa).

SPRING

LOGIC

MODULE A

18 PSI (124 kPa)

WINTER

DIAPHRAGM

PORT B2

PORT B1

13 PSI (90 kPa)

SUMMER

F

FILTER

R

RESTRICTOR

B

BLEED 1

PILOT

CHAMBER

VALVE

UNIT

SPRING

LOGIC

MODULE B

C6062-1

C6063-1

Fig. 18. TP972A and TP9620A Operation on Heating Cycle—Main Air Pressure at 18 psi (124 kPa).

11

77-9382—1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

Operation

Main air enters through the main air passage. Filtered air

goes to Logic Module A and into the pilot chamber of the

valve unit flow amplifier (see arrows in Fig. 17). When the air

reaches Logic Module A, it cannot pass because the springloaded diaphragm is adjusted to pass only 18 psi (124 kPa)

of air. In this condition, no air pressure is applied to the

diaphragm of Logic Module B and it stays in the up position,

allowing air to pass from the pilot chamber through Port B1.

This air is routed on to the flapper-nozzle of the cooling

bimetal and the Thermostat operates in a cooling mode. The

spring-loaded diaphragm of Logic Module B stays open until

air pressure is applied from Logic Module A.

When main air enters the Thermostat at 18 psi (124 kPa), as

previously described for the cooling cycle, the spring of

Logic Module A is overcome and air passes through the

Module. The air pressure is applied to the diaphragm of

Logic Module B, closing off Port B1, and opening Port B2.

Now the air is directed to the flapper-nozzle of the heating

bimetal and the Thermostat controls in the heating mode.

TP974A ROOM TEMPERATURE

SENSOR

General

FLAPPER

NOZZLE

EXTERNAL

RESTRICTOR

MAIN

LINE

BIMETAL

FILTER

RESTRICTOR

BACKPLATE

TO

CONTROLLED

DEVICE

C6065

Fig. 20. Cross Section of TP974A—One-Pipe Application.

Operation

Figure 21 shows a TP974A used with a direct-acting

RP920A Controller for control of a normally open heating

valve. A fall in temperature at the TP974A lowers the signal

to the RP920A. The RP920A responds by decreasing the

BLP to the valve to admit more hot water to the heating coil.

TP974A

The TP974A (Fig. 19, 20) is a bimetal-element, proportioning

temperature sensor for either two- or one-pipe applications.

The sensor bimetal is direct acting (signal pressure

increases as the temperature increases). The TP974A is

factory calibrated for 50 to 100°F (10 to 38°C), for a fixed

span of 50°F (28°C). This span is equal to a corresponding

pressure change of 12 psi (83 kPa) for 3 to 15 psi (21 to

103 kPa). The TP974A has no setpoint adjustment and the

TR is factory preset.

FLAPPER

NOZZLE

BRANCH SIGNAL

PRESSURE

(TO INDICATION

GAGE OR CONTROL)

BIMETAL

FILTER

RESTRICTOR

BACKPLATE

MAIN

LINE

C6064

Fig. 19. Cross Section of TP974A—Two-Pipe Application.

M

21

RP920A

SUPPLY N.O.

3

(DA)

Fig. 21. Typical TP974A Operation.

C6066

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

77-9382—177-9382—1 R. F. 10-97

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

12

Loading...

Loading...