Page 1

TB7220 CommercialPRO™

Programmable Thermostat

FEATURES

• Large, clear display with backlight shows the current

and set temperature and time—even in the dark.

• Menu-driven programming make setup effortless.

• Beautiful ergonomic design is smart and sophisticated

to match your customers’ lifestyle.

• Real-time clock keeps time during power failures and

automatically updates to daylight savings.

• “Saving Changes” notification lets you know when the

schedule changes have been saved.

• Change reminders let you know when to replace the

batteries.

• Holiday Override options allow you to override the

APPLICATION

The TB7220 COMMERCIALPRO™ 7000 Programmable

Thermostat is an effortless, seven-day programmable

thermostat that provides universal system compatibility,

precise comfort control and is easy-to-program.

program schedule, as desired.

• Speedy same-schedule programming—no need to

copy multiple days.

• Armchair programming allows you to remove the

thermostat from the wall for programming.

PRODUCT DATA

The TB7220 provides temperature control for gas, oil, electric

and heat pumps for up to 2 heat, 2 cool systems.

Contents

Application ........................................................................ 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Wiring ............................................................................... 5

Installer Setup .................................................................. 12

Operation .......................................................................... 17

Troubleshooting (Table 11) ............................................... 22

63-2635—2

Page 2

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

SPECIFICATIONS

Thermostat Description: See Table 1.

Electrical Ratings: See Table 2.

Temperature:

Ratings:

Operating Ambient:

TB7220: 0°F to 120°F (-18°C to 49°C).

C7089U, C7189U: 5% to 95%.

Shipping: -30 °F to 150 °F (-34.4°C to 65.6°C).

Display Accuracy: ±1°F (±0.5°C).

Setpoint:

Range:

Heating: 40°F to 90°F (4°C to 32°C).

Cooling: 50°F to 99°F (10°C to 37°C).

Default Settings: See Table 3.

Humidity Ratings (RH, non-condensing):

TB7220 Thermostat: 5% to 90%.

C7089U, C7189U: 5% to 95%.

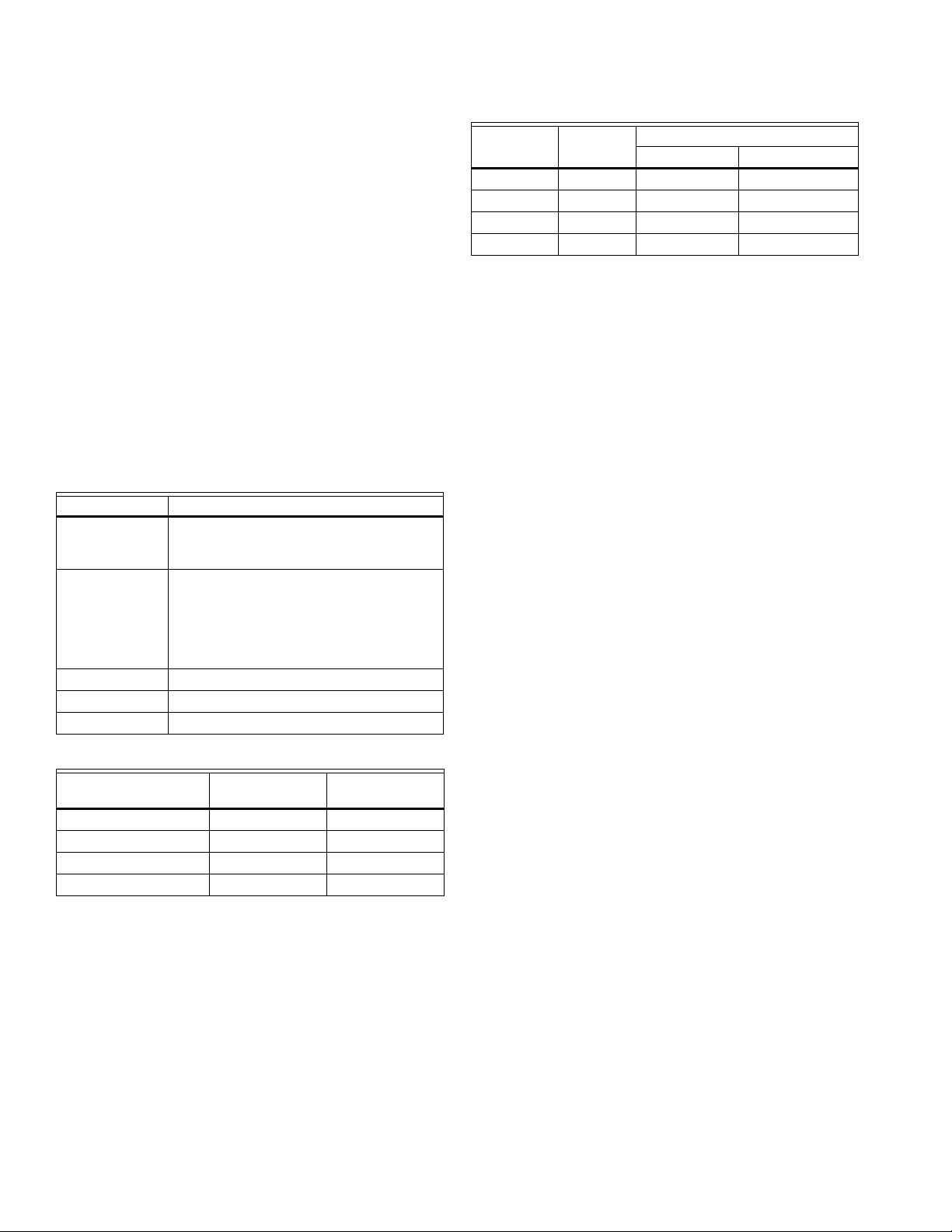

Table 1. Thermostat Description.

Feature Description

Powering

methods

System types

(up to

2 heat/2 cool)

Changeover Manual or Auto changeover selectable

System setting Heat-Off-Cool-Auto

Fan setting Auto-On

Terminal

W (Heating) 20 - 30 Vac 0.02 - 1.0A

Y (Cooling) 20 - 30 Vac 0.02 - 1.0A

G (Fan) 20 - 30 Vac 0.02 - 0.60A

A (Economizer/TOD) 20 - 30 Vac 0.02 - 1.0A

• Battery only

• 24 Vac only

• 24 Vac with battery backup

• Gas or electric heat with air conditioning

• Warm air, hot water, high-efficiency

furnaces, and heat pumps

• Heat only

• Heat only with fan

• Cool only

Table 2. Electrical Ratings

Voltage

(50/60 Hz) Running Current

Table 3. Energy Star Default Program Settings.

Schedule

Period Time

Occ1 8:00am 70°F (21°C) 75°F (24°C)

Unocc1 10:00pm 55°F (10°C) 85°F (29.5°C)

Occ2 — — —

Unocc2 — — —

Cycle Rates (at 50% Load):

Heating: Selectable 1 - 12 cycles per hour.

Cooling: Selectable 1 - 6 cycles per hour.

Interstage Differential:

Droopless control. Once the first stage is running at 90% load,

the thermostat energizes the second stage.

Cool Indication: Displays “Cool On” when Cool is activated.

Heat Indication: Displays “Heat On” when Heat is activated.

Auxiliary Heat Indication: Displays “Aux. Heat On” when

Auxiliary Heat is activated.

Clock Accuracy: ±1 minute per month.

Finish:

TB7000: Premier White® color.

C7189U Wall Mount Remote Indoor Sensor: Premier White®

color.

T7770A Wall Mount Remote Indoor Sensor: Premier White®

color.

Batteries:

Two replaceable AA alkaline batteries: Power thermostat when

24 Vac common is not used.

Non-replaceable lithium battery with ten-year life: Under nor-

mal conditions holds calendar and time settings.

NOTE: Alkaline batteries keep calendar and time if lithium

battery is no longer functional.

Resistance Characteristics of Remote Sensors:

C7089U Outdoor Sensor: 10K ohm NTC.

C7189U Remote Indoor Sensor: 10K ohm NTC.

C7772 Flush-Mount Remote Indoor Sensor: 20K ohm NTC.

T7770A1006 Wall-Mount Remote Indoor Sensor: 20K ohm

NTC.

T7770A3002 Wall-Mount Remote Indoor Sensor: 10K ohm

NTC.

Setpoints

Heat Cool

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2635—2 2

Page 3

Calibration (TB7220, C7089U, C7189U, T7770A):

No field calibration required.

Mounting Means:

TB7220: Direct wall-mount using mounting screws and

anchors provided. Fits standard vertical or horizontal

2 in. x 4 in. junction box.

C7089U: Mounts outside of living space with mounting clip and

screws provided.

C7189U, T7770A: Mounts directly on the wall using mounting

screws and anchors provided. Fits a vertical 2 x 4 in. junction box.

Cover Plate:

32003796-001 Cover Plate is used to cover marks left on the

wall by the old thermostat.

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

1

LEVEL

BRACKET

LEVEL

5 IN.

(127 MM)

6-7/8 IN. (175 MM)

UP

2

2

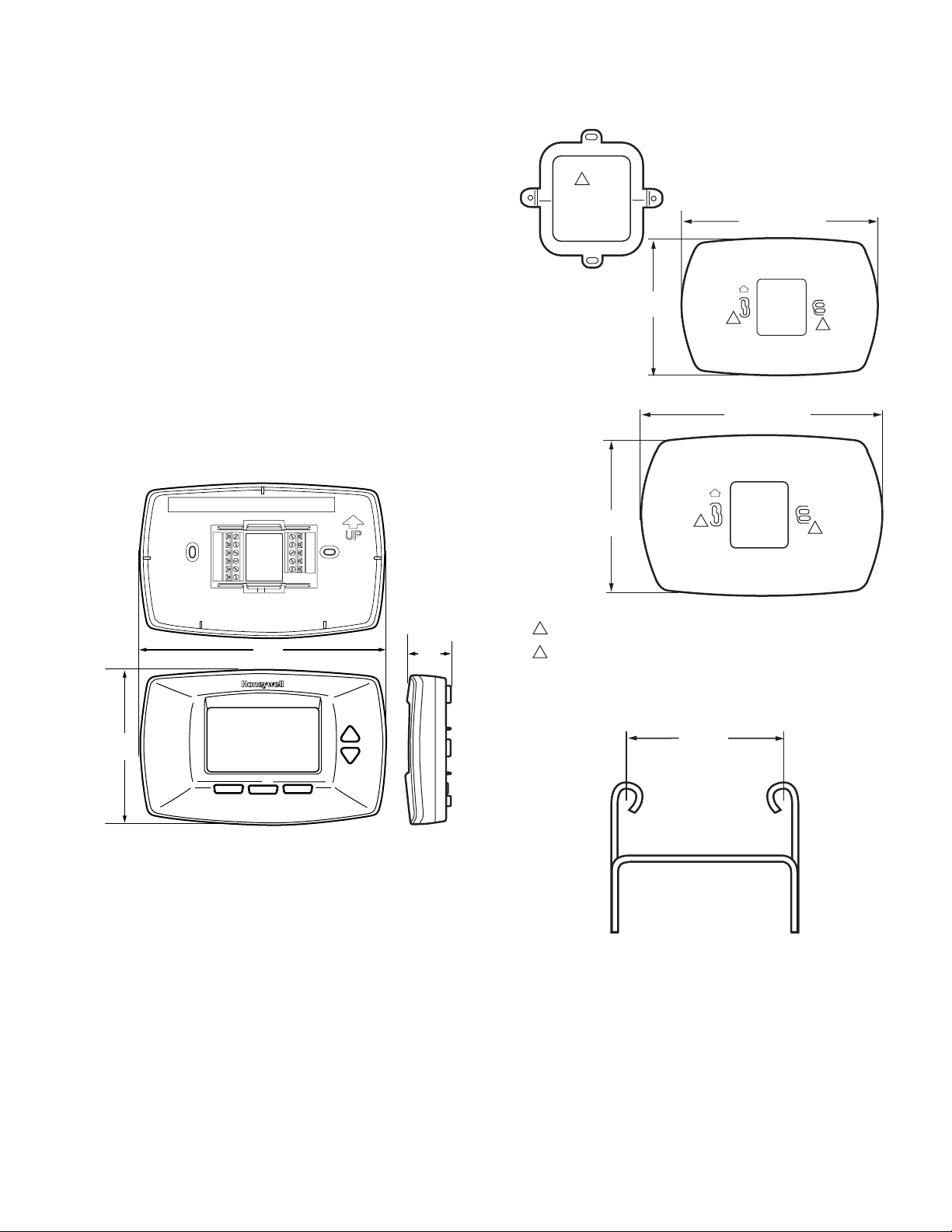

Dimensions:

TB7220 Thermostat: See Fig. 1.

C7089U Outdoor Sensor Mounting Clip: See Fig. 3.

C7189U Remote Indoor Sensor: see Fig. 5.

T7770A: See Fig. 4.

32003796-001 Cover Plate: See Fig. 2.

THERMOSTAT

AND WALLPLATE

6 (152)

3-3/4

(95)

1-3/8

(35)

MEDIUM COVER PLATE

8-5/16 IN. (211 MM)

UP

6 IN.

(152 MM)

1

BRACKET FOR MOUNTING ON JUNCTION BOX NOT INCLUDED

WITH COVER PLATE

2

USE BOTTOM MOUNTING HOLES.

.

2

LARGE COVER PLATE

2

M13669

Fig. 2. 32003796-001 Cover Plate dimensions in in. (mm).

1-1/2 (38)

Fig. 1. TB7220 Thermostat

dimensions in in. (mm).

M13668

M4488

Fig. 3. C7089U Outdoor Sensor Mounting Clip

dimensions in in. (mm).

3 63-2635—2

Page 4

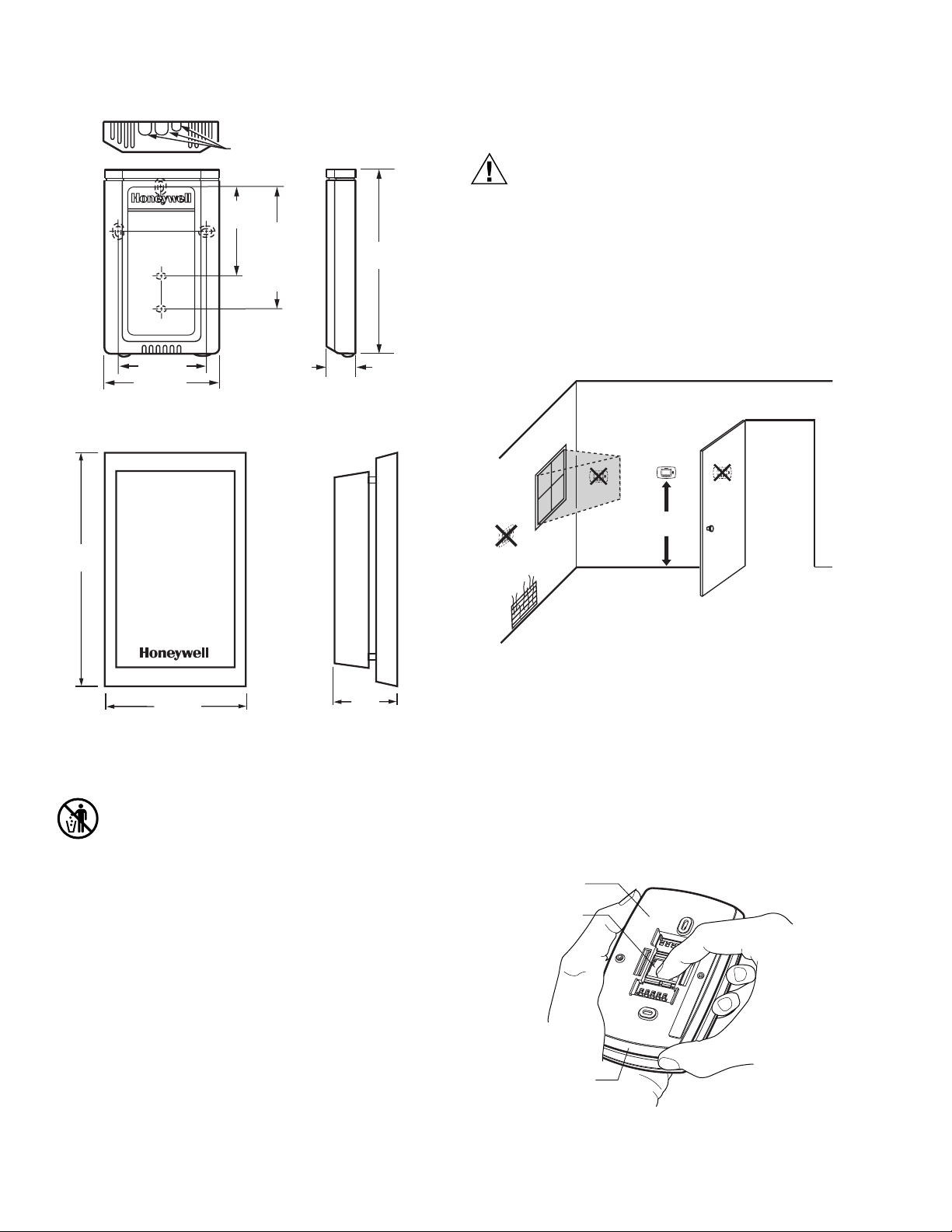

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

KNOCKOUTS FOR

EUROPEAN APPLICATIONS

2-3/8

(60)

STANDARD

UTILITY

CONDUIT

BOX (2 X 4)

MOUNTING

HOLES

5-1/16

(128)

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Select Thermostat Location

Select a location for the thermostat about 5 ft (1.5m) above the

floor in an area with good air circulation at average

temperature. See Fig. 6.

2-3/8 (60)

3-3/16 (80)

15/16

(23)

M22936

Fig. 4. T7770A dimensions in in. (mm).

4-5/8

(117)

1-1/8

(29)

M4465

2-3/4 (70)

FRONT VIEW SIDE VIEW

Fig. 5. C7189U Indoor Sensor dimensions in in. (mm).

NO

M22258

NO

NO

YES

5 FEET

[1.5 METERS]

Fig. 6. Select thermostat location.

Do not install the thermostat where it can be affected by:

— Drafts or dead spots behind doors and in corners.

— Hot or cold air from ducts.

— Radiant heat from sun or appliances.

— Concealed pipes and chimneys.

— Unheated (uncooled) areas such as an outside wall behind

the thermostat.

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash. Dispose of properly.

Contact your local waste management authority

for instructions regarding recycling and the proper

disposal of an old control.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a

hazardous condition.

2. Check ratings given in instructions and on the product to

ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

63-2635—2 4

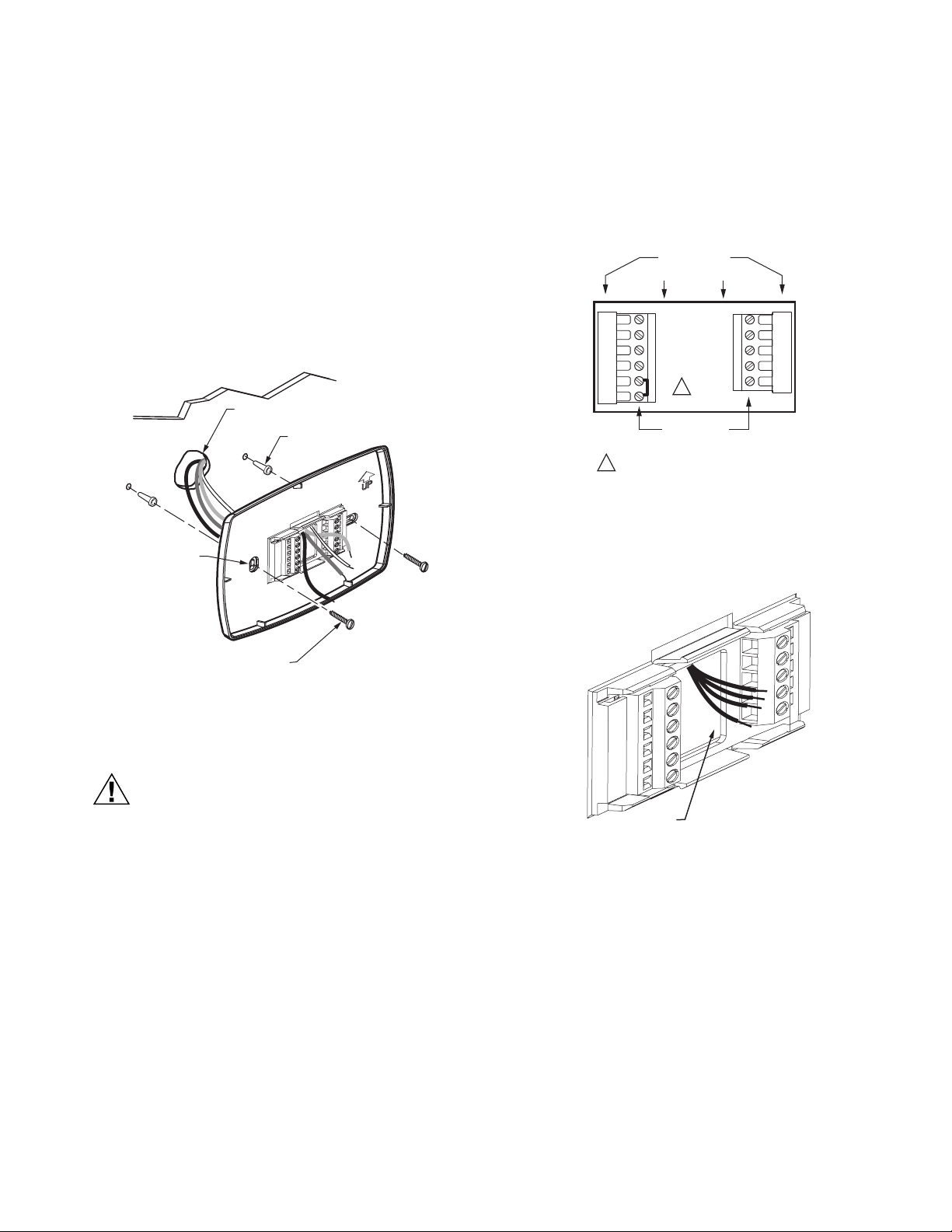

Separate Wallplate from Thermostat

1. Separate the wallplate from the thermostat. See Fig. 7.

WALLPLATE

WIRE HOLE

THERMOSTAT

M22267

Fig. 7. Separate wallplate from thermostat.

Page 5

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Install Wallplate (See Fig. 8)

Mount the thermostat horizontally on the wall:

1. Pull the wires through the wire hole on the wallplate.

2. Position the wallplate on the wall with the arrow pointing

up. Level the wallplate for appearance only.

3. Use a pencil to mark the mounting holes.

4. Remove the wallplate from the wall and drill two 3/16 in.

holes in the wall (if drywall) as marked. For firmer

material such as plaster, drill two 7/32 in. holes. Tap the

wall anchors (provided) into the drilled holes until flush

with the wall.

5. Pull the wires through the wire hole on the wallplate and

position the wallplate over the wall anchors.

6. Insert the mounting screws into the wall anchors and

tighten.

WALL

WIRES THROUGH WALL

AND WIRE SLOT

WALL

ANCHORS (2)

MOUNTING

HOLES

NOTES:

— Refer to Table 5 for terminal designation

descriptions.

— See Fig. 12 through 21 for wiring diagrams for

specific equipment applications.

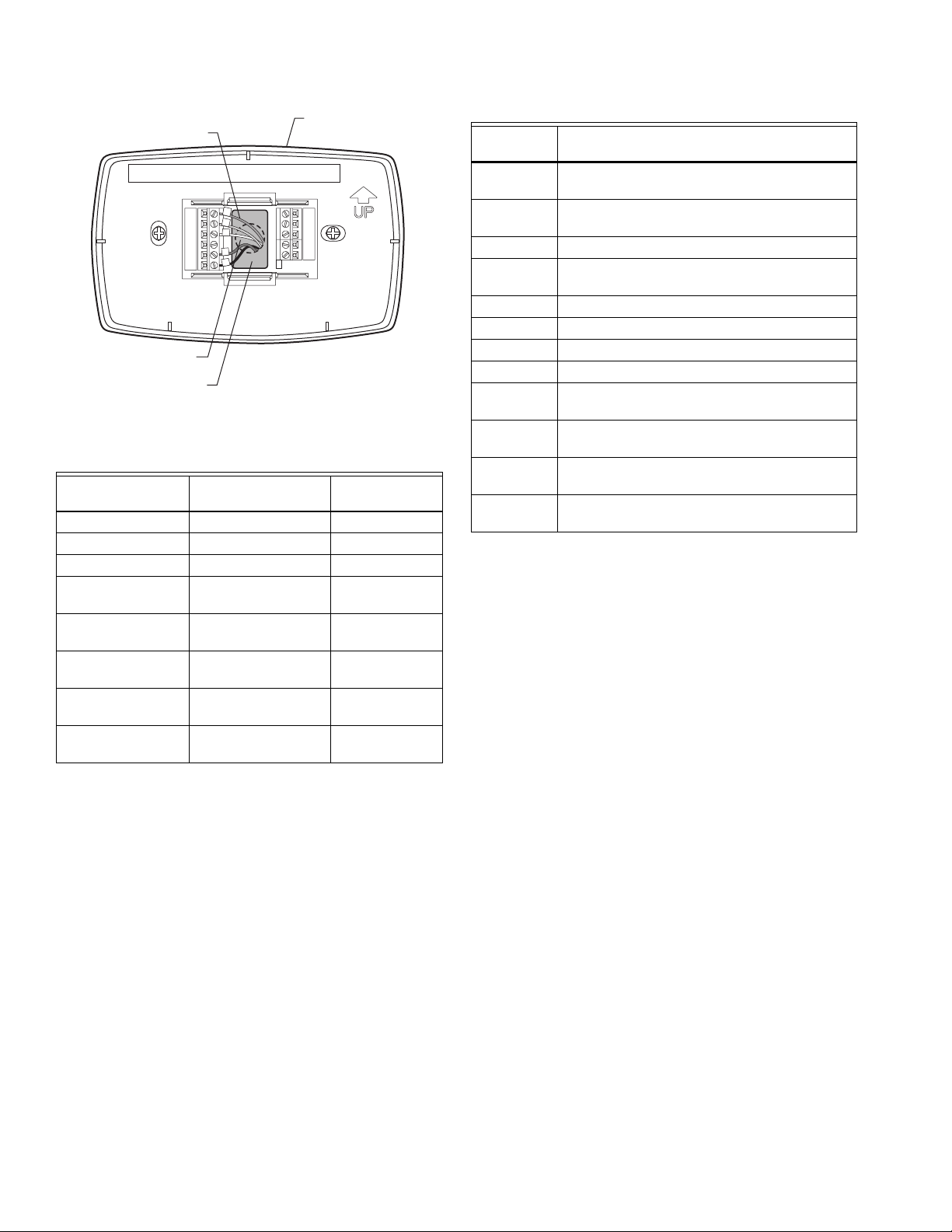

1. Select set of terminal identifications that correspond to

your system type (conventional or heat pump). See Fig. 9.

HEAT PUMP

CONVENTIONAL

1

SCREW

W2

Y2

S1

S2

W1

Y2

A

S1

S2

M13663

C

G

Y

O/B

RC

R

1

C

G

Y

W

RC

R

TERMINALS

FACTORY INSTALLED JUMPER.

Fig. 9. Terminal identifications for system type.

2. Loosen screw terminals used for the application.

3. Insert the wires into the terminal block and tighten each

screw terminal. See Fig. 10.

MOUNTING

SCREWS (2)

Fig. 8. Install wallplate.

WIRING

CAUTION

Electrical Shock Hazard.

Can cause electrical shock or equipment damage.

Disconnect power supply before connecting wiring.

IMPORTANT

— All wiring must agree with applicable codes,

ordinances and regulations.

— Use 18 gauge thermostat wire. Shielded cable is not

required.

M13665

M13666

WIRE HOLE

Fig. 10. Insert wires into terminal block.

4. Push excess wire back into the wall opening and restrict

wires to the shaded area. See Fig. 11.

5. Plug the wall opening with nonflammable insulation to

prevent drafts from affecting the thermostat.

5 63-2635—2

Page 6

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

WIRE

WALL OPENING

SHADED AREA

WALLPLATE

M22266

Fig. 11. Restrict wires to shaded area of wire hole.

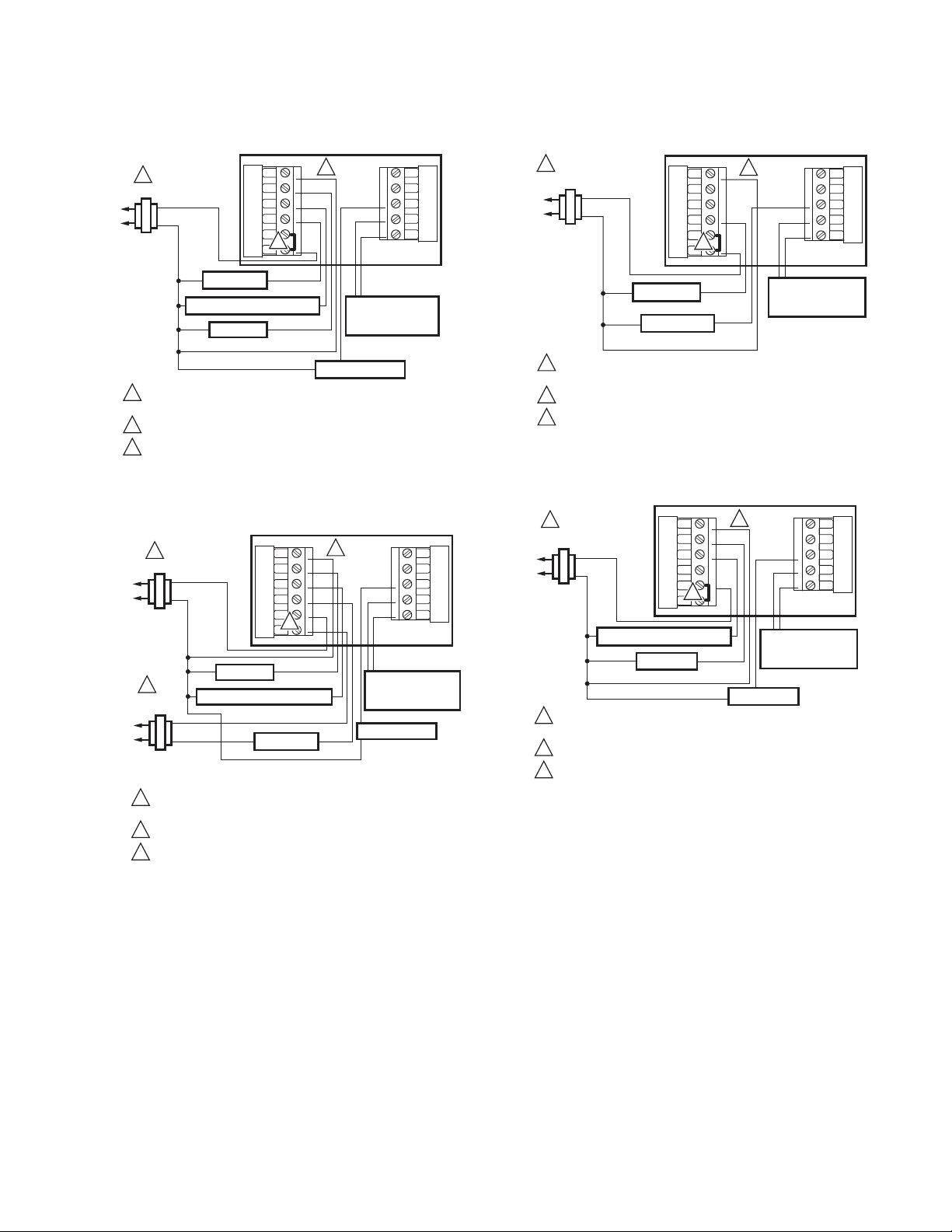

Table 4. Wiring Diagrams.

System Type

Wallplate Terminal

Identifications

Wiring Diagram

Standard Heat/Cool Conventional 12, 13

Heat Only Conventional 14

Cool only Conventional 15

Standard Multistage

Conventional 16, 17

up to 2 Heat/2 Cool

Heat Pump

Heat Pump 18, 19

(No Auxiliary Heat)

Heat Pump

Heat Pump 20, 21

(with Auxiliary Heat)

Multiple T7770A

— 26, 27, 28

Sensors

Multiple C7189U

—29

Sensors

Figure

Table 5. Terminal Designation Descriptions.

Terminal

Designation Description

Rc

(see Note 1)

R

(see Note 1)

Power for cooling—connect to secondary side

of cooling system transformer.

Power for heating—connect to secondary side

of heating system transformer.

Y Compressor output.

C

(see Note 2)

Common wire from secondary side of cooling

system transformer.

W Heat relay.

GFan relay.

W2 Second stage heat relay.

Y2 Second stage cooling.

O/B

Changeover valve for heat pumps.

(see Note 3)

A

(see Note 4)

S1

Economizer/Time-Of-Day (TOD) output—

powered via R terminal.

Optional outdoor or indoor remote sensor.

(See Note 5)

S2

Optional outdoor or indoor remote sensor.

(See Note 5)

NOTES:

1. When used in a single-transformer system, leave

metal jumper wire in place between Rc and R. If

used on a two-transformer system, remove metal

jumper wire between Rc and R.

2. Common wire is optional when thermostat is used

with batteries. When using separate transformers

for heating and cooling, the common must come

from the cooling transformer.

3. If thermostat is configured for a heat pump in the

Installer Setup, configure changeover valve for

cool (O-factory setting) or heat (B).

4. Reference economizer literature for wiring details.

When set for economizer operation, the A terminal

provides the occupancy signal. (Power indicates

occupied.)

5. Sensor wires must have a cable separate from the

thermostat control cable.

63-2635—2 6

Terminal “A” Wiring Details for Economizers

— Wire the A terminal to the W7212 “N” terminal, or the

W7459 “TR” terminal.

— When using dual transformers at the thermostat, the cooling

transformer must power the economizer.

— The A signal is powered from the R terminal and energizes

the economizer to signal occupied status and drive the

damper to the set minimum position.

Page 7

Conventional System Wiring

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

3

1

L1

(HOT)

24 VAC

L2

HEAT RELAY

COMPRESSOR CONTACTOR

FAN RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

3

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

C

G

Y

W

RC

2

R

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

ECONOMIZER

M23011

Fig. 12. Typical wiring of single transformer 1H/1C system.

1

L1

(HOT)

L2

COOLING

TRANSFORMER

1

L1

(HOT)

L2

HEATING

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

REMOVE FACTORY INSTALLED JUMPER.

3

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. WHEN USED, THE COMMON MUST CONNECT

TO THE COOLING TRANSFORMER SECONDARY.

24 VAC

FAN RELAY

COMPRESSOR CONTACTOR

24 VAC

HEAT RELAY

3

C

G

Y

W

RC

2

R

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

ECONOMIZER

M23012

1

L1

(HOT)

L2

24 VAC

HEAT RELAY

ECONOMIZER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

3

WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS

OPTIONAL.

3

C

G

Y

W

RC

2

R

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

Fig. 14. Typical hookup of heat-only system.

2

3

C

G

Y

W

RC

R

ECONOMIZER

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

1

L1

(HOT)

24 VAC

L2

COMPRESSOR CONTACTOR

FAN RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

3

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

Fig. 15. Typical hookup of cool-only system.

SENSOR

M23013

M23015

Fig. 13. Typical hookup of dual transformer 1H/1C system.

7 63-2635—2

Page 8

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

1

L1

(HOT)

24 VAC

L2

COOL RELAY 1

HEAT RELAY 1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

3

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

COOL RELAY 2

FAN RELAY

3

C

G

Y

W

RC

2

R

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

HEAT RELAY 2

ECONOMIZER

M23016

Fig. 16. Typical hookup of single transformer multistage

system (up to 2H/2C).

Heat Pump System Wiring

3

1

L1

(HOT)

L2

TRANSFORMER

TRANSFORMER

24 VAC

COOLING

FAN RELAY

1

L1

(HOT)

L2

HEATING

1

2

3

COOL RELAY 1

24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

REMOVE FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. WHEN USED, THE COMMON MUST CONNECT

TO THE COOLING TRANSFORMER SECONDARY.

HEAT RELAY 1

C

G

Y

W

RC

2

R

COOL RELAY 2

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

HEAT RELAY 2

ECONOMIZER

M23017

Fig. 17. Typical hookup of dual transformer multistage

system (up to 2H/2C).

L1

(HOT)

2

FAN RELAY

3

OUTDOOR/INDOOR

ECONOMIZER

W1

Y2

A

S1

S2

TEMPERATURE

SENSOR

5

M23018

24 VAC

L2

1

CHANGEOVER VALVE

COMPRESSOR CONTACTOR

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

3

IS OPTIONAL.

4

"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

5

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

C

G

Y

O/B

4

RC

R

Fig. 18. Typical hookup of single-stage heat pump with no

auxiliary heat (1H/1C).

L1

(HOT)

24 VAC

L2

1

FAN RELAY

COMPRESSOR 1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

3

IS OPTIONAL.

4

"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

5

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

C

G

Y

O/B

4

RC

R

CHANGEOVER VALVE

2

COMPRESSOR 2

3

OUTDOOR/INDOOR

W1

Y2

A

S1

S2

TEMPERATURE

SENSOR

ECONOMIZER

5

M23019

Fig. 19. Typical hookup of multistage heat pump with no

auxiliary heat (2H/2C).

63-2635—2 8

Page 9

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

L1

(HOT)

24 VAC

L2

1

COMPRESSOR CONTACTOR

FAN RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

3

IS OPTIONAL.

4

"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

5

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

C

G

Y

O/B

4

RC

2

R

CHANGEOVER VALVE

ECONOMIZER

3

OUTDOOR/INDOOR

TEMPERATURE

AUXILIARY HEAT RELAY

SENSOR

W1

Y2

A

S1

S2

5

M23020

Fig. 20. Typical hookup of single-stage heat pump with

auxiliary heat (2H/1C).

POWER THE THERMOSTAT

You can choose from three methods to power the thermostat:

• Batteries only (AAA alkaline).

• 24 Vac direct connection only.

• 24 Vac direct connection with battery backup (AAA alkaline).

Wiring 24 Vac Common

• Single-Transformer System—Connect the common side of

the transformer to the C screw terminal of the thermostat

wallplate. Leave the metal jumper wire in place between Rc

and R.

• Two-Transformer System—Connect the common side of

the cooling transformer to the C screw terminal of the

thermostat wallplate. Remove the metal jumper wire

between Rc and R.

Installing Batteries

1. Install two AA alkaline batteries on the back of the thermostat as marked. See Fig. 22.

BATTERIES (2)

BATTERY HOLDER

L1

(HOT)

24 VAC

L2

1

CHANGEOVER VALVE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

3

IS OPTIONAL.

4

"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

5

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

C

G

Y

O/B

4

RC

R

COMPRESSOR 1

FAN RELAY

COMPRESSOR 2

3

2

OUTDOOR/INDOOR

AUXILIARY HEAT RELAY

ECONOMIZER

W1

Y2

A

S1

S2

TEMPERATURE

SENSOR

Fig. 21. Typical hookup of multistage heat pump

with auxiliary heat (3H/2C).

5

M23021

BACK OF THERMOSTAT

M22259

Fig. 22. Installing batteries.

2. Locate and remove tab labeled Remove. See Fig. 23.

IMPORTANT

This tab must be removed in order to set the real-time

clock.

REMOVE

TAB

INSTALLATION

REMOVE DURING

INSTALLATION

REMOVE DURING

M22260

Fig. 23. Remove tab labeled REMOVE from

thermostat back.

9 63-2635—2

Page 10

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Locate and Mount C7089U Outdoor Temperature Sensor (Optional)

Mount the sensor where (see Fig. 24):

• cannot tamper with settings.

• there is good air circulation.

• it can measure true outdoor ambient temperature.

• surface is flat.

• wire distance between C7089U and thermostat is less than

200 feet.

Do not mount the sensor:

• in direct sunlight.

• where hot or cold air blows on the sensor. Discharge line

from an outdoor compressor unit, vent or fan causes

inaccurate temperature readings.

• where snow, ice or debris can cover it.

Use the following steps to mount the sensor:

1. Remove the sensor from the mounting clip.

2. Mark the area on the location selected for mounting the

sensor mounting clip.

3. Mount the clip.

Wire C7089U Outdoor Sensor

CAUTION

Electrical Interference (Noise) Hazard.

Can cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lighting ballasts and

large power distribution panels.

Use shielded cable to reduce interference when

rerouting is not possible.

1. Wire C7089U Outdoor Sensor to S1 and S2 terminals on

the thermostat. If leadwire provided is not long enough

(60 in.), run a cable to a hole at C7089U location.

a. Using color-coded, 18-gauge thermostat wire is

recommended. For example of general wiring of

2. Mount C7089U in its mounting clip.

3. Plug wiring hole using nonhardening caulk or putty.

C7089U, see Fig. 25.

1

C7089

WIRING HOLE

THROUGH

STRUCTURE

2

M7514

Fig. 24. Typical locations for C7089U Outdoor Sensor.

1

USE APPROPRIATE MOUNTING MEANS FOR THE

TYPE OF STRUCTURE.

2

PLUG WIRING HOLE WITH NON-HARDENING CAULK

OR PUTTY.

M13664

Fig. 25. Wire C7089U Outdoor Sensor to the thermostat.

Locate and Mount T7770A or C7189U Remote Indoor Temperature Sensor (Optional)

Locate and mount the sensor in the same fashion as the

thermostat. See the Select Thermostat Location section.

Consider the following as well:

1. Be sure wire distance between sensor and thermostat is

less than 200 feet.

2. Mark the area on the wall selected for mounting the

sensor or junction box.

3. Sensor wire must be separate from the thermostat cable.

4. Run wire cable to a hole at the selected wall location.

5. Pull approximately three inches of wire through the

opening.

NOTE: Color-coded, 18-gauge wire is recommended.

63-2635—2 10

Page 11

Wire Indoor Sensor

CAUTION

Electrical Interference (Noise) Hazard.

Can cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lighting ballasts and

large power distribution panels.

1. Check Installer Setup Number (ISU) 340 to ensure it is

set to the desired value. (See Table 6.)

2. Wire sensor to S1 and S2 thermostat terminals.

3. Push excess wire back into the hole. Plug the hole using

nonhardening caulk, putty or insulation to prevent drafts

from affecting performance.

4. Remove sensor cover.

5. Mount sensor to the wall or junction box using the

screws and anchors provided.

6. Level the sensor for appearance only. Device functions

correctly even when not level.

7. Install sensor cover.

Sensor Wiring for Temperature Averaging

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

SUBBASE

S1 S2

T7770A1006

TT

T7770A1006

TT

1

THE T7770A3002 IS A 10K OHM SENSOR.

T4 T3

1

T7770A3002

M22934

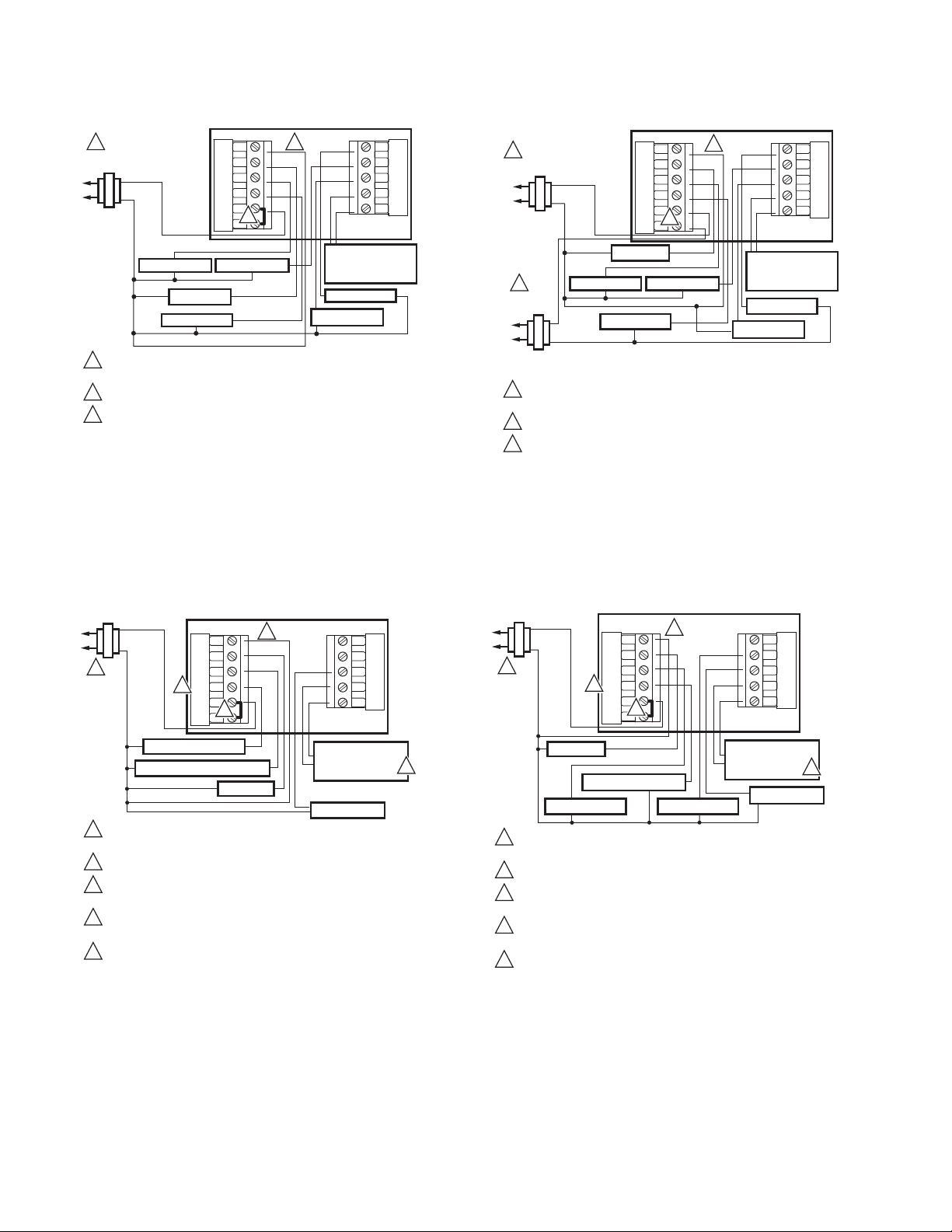

Fig. 28. Wiring two T7770A1006 (20K ohm) Sensors and

one T7770A3002 (10K ohm) sensor to provide a

temperature averaging network

SUBBASE

S1 S2

T7770A

TT

T7770A

TT

T7770A

TT

T7770A

TT

M22831

Fig. 26. Wiring four T7770A1006 (20K ohm) Sensors.

SUBBASE

S1 S2

T4 T3

T4 T3

W2

Y2

1

WIRES MUST HAVE A CABLE SEPARATE FROM

1

THE THERMOSTAT CABLE.

C7189

C7189

C7189 C7189

A

S1

S2

M13667

Fig. 29. Wiring four C7189U (10K ohm) Sensors to provide

a temperature averaging network.

SET CALENDAR AND TIME

This thermostat is designed to, under normal use,

automatically keep current time and day in memory for up to

ten years once the calendar is set. There are two ways to set

the calendar for this thermostat:

Setting Calendar Once Functioning

See steps 1 through 4, in the Advanced Settings section, to set

year, month and day.

T7770A3002

111THE T7770A3002 IS A 10K OHM SENSOR.

T7770A3002

M22933

Fig. 27. Wiring two T7770A3002 (10K ohm) Sensors to

provide a temperature averaging network.

Setting Calendar When First Powered

When first powered, the thermostat proceeds through a

sequence of screens to set the calendar.

— When first powered, the thermostat proceeds through a

sequence of screens to set the calendar. See Fig. 30.

11 63-2635—2

Page 12

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

m

&

an

S

e

C

k

&

e

o

ue

o

Cool

Se

o

m

&

an

an

UseEdit

C

e

o

o

Cool

MONTH

YEAR

Tue

DeSelect Day

System & Fan

FanUseEdit

Schedule

GO BACK BUTTON

GOES BACK TO LAST SETTING

DAY

View

Clock & More

NEXT BUTTON

ADVANCE TO NEXT SETTING

UP AND DOWN

BUTTONS

CHANGES

MONTH,

DAY AND

YEAR

DONE

BUTTON

ADVANCES

TO TIME

SETTING

SCREEN

M22302

Fig. 30. Setting calendar when thermostat is first powered.

3. The Setup Number displays to the center of the screen.

It is a four-digit code beginning with zero. The current

setting is displayed to the right.

NOTE: To cycle through the Setup Numbers, press the up or

down arrow.

T

System Aut

HeatOff

Syste

Fan Aut

F

chedul

t T

loc

Mor

UP AND DOWN BUTTONS

CHANGES TIME

View

Clock & More

DONE BUTTON

ADVANCES TO HOME SCREEN

M22303

Fig. 31. Setting time when thermostat is first powered.

INSTALLER SETUP

Advanced Settings

The thermostat has advanced settings to match the HVAC

system. These settings can be adjusted to match specific

needs.

M22304

Fig. 32. Entering Installer Setup.

User Settings (Simple Set)

Access to the user settings is obtained as follows:

1. From the main screen, press SYSTEM.

2. Press and hold the center key approximately five sec-

onds.

3. The Setup Number displays to the center of the screen.

It is a four-digit code beginning with zero. The current

setting is displayed to the right.

NOTE: To cycle through the Setup Numbers, press the up or

down arrow.

System Aut

Fan Aut

Heat Off

Syste

F

F

ancelDon

There are two different groups of settings:

— A complete set designed for the installation use.

— A simple set to limit accessibility for typical users.

Installer Settings (Complete Set)

Access to the installer settings is obtained as follows:

1. From the main screen, press SYSTEM.

2. Press and hold the two keys on either side of the center

key for approximately five seconds. (See Fig. 32.)

63-2635—2 12

M22305

Fig. 33. Entering User Setup.

Page 13

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

INSTALLER SETUP NUMBERS (ISU), SETTINGS, AND TESTS (TABLE 6)

Use the Installer System Test to test the heating, cooling and

fan. Refer to the latter portion of Table 6.

IMPORTANT

CAUTION

Equipment Damage Hazard.

Minimum compressor off time is bypassed during

Installer System Test

Avoid cycling compressor quickly.

Table 6. Installer Setup Menu.

Installer

Setup

Number

a

0120

a

0130

a

0140

a

0150

a

0160

0170 System Selection 8 1—1H/1C Conv

0175 TOD/Economizer

0180 Heat Fan Operation 0 0—Fossil

0185 Pre-occupancy

0190 Reversing Valve O/B 0 0—O (O/B On Cool)

0220 Cycles Per Hour

0230 CPH for second

0240 CPH for first stage

0250 CPH for second

a

Setting available for modification in both the Installer and User setup modes.

Installer Setup

Name

Date (Year Upper) 20 20—20xx

Date (Year Lower) 04 00-99 Available year range: 2001 - 2178

Date (Month) 6 1-12

Date (Day) 15 1-31 (Month Dependent)

Schedule Options 4 0—Non-Programmable

output

Purge Duration

(CPH) for first stage

compressor

stage compressor

conventional heat

stage conventional

heat

Default

Setting All Settings Notes

21—21xx

4—Programmable

2—1H/1C HP

3—1H w/o fan

4—1H with fan

6—1C

7—2H/1C HP

8—2H/2C Conv

9—2H/1C Conv

10—1H/2C Conv

11— 2 H / 2 C H P

12—3H/2C HP

0 0—Unused

1—TOD

2—Economizer

1—Electric

0 0—no duration

1—one hour

2—two hours

3—three hours

1—B (O/B On Heat)

3 1-6 Only shown for system with cool stages. Selection in this

3 1-6 Only shown if two stages of cool selected.

5 1-12 Only shown if system is conventional with heat stages.

5 1-12 Only shown with at least two stages conventional heat or

NOTE: Unless otherwise noted, setup items are accessible

Available year range: 2001 - 2178

Economizer energizes A during a call for cool.

TOD energizes A during Occupied period, and deenergizes A during Unoccupied.

Only shown for conventional system with heat stages and

fan capability selected. If heat pump is selected, fan

defaults to electric.

Shown only if system has fan and schedule programmable.

Pre-occupancy purge enabled by nonzero duration (and

sends economizer to minimum position).

Only shown with heat pump system selected.

stage changes default CPH of second stage cool.

Selection in this stage changes default CPH of second

stage heat.

2H/1C heat pump selected.

Use Installer System Test to test heating, cooling and

fan. The setting chosen for System Type (ISU 0170)

can prevent some System Test Numbers from

appearing.

through only the Installer setup and not the User

setup.

13 63-2635—2

Page 14

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Table 6. Installer Setup Menu. (Continued)

Installer

Setup

Number

0260 CPH for third Stage

Installer Setup

Name

Default

Setting All Settings Notes

9 1-12 Only shown if 3H/2C heat pump is selected.

Heat

0270 CPH for Auxiliary

Heat

0280 Continuous

Backlight

0300 Changeover 1 0—Manual

9 1-12 Only shown if multi-stage heat pump is selected (heat

pump with more heat than cool stages).

0 0—No

1—Yes

Always shown. If AC power not present the option is

overridden and normal backlight operation occurs.

Only shown if system has both heat and cool stages.

1—Auto

0310 Deadband 3°F

(2°C)

2 (1.5)—2°F (1.5°C)

3 (2.0)—3°F (2.0°C)

Only shown if Automatic Changeover Selected

4 (2.5)—4°F (2.5°C)

5 (3.0)—5°F (3.0°C)

6 (3.5)—6°F (3.5°C)

7 (4.0)—7°F (4.0°C)

8 (4.5)—8°F (4.5°C)

9 (5.0)—9°F (5.0°C)

a

0320

0330

Temperature

Indication Scale

a

Daylight Saving 2 0—Disabled

0 0—°F

1—°C

1—Enabled (US 1987)

2—Enabled (US 2007)

3—Enabled (Europe)

0340 Remote

Temperature Sensor

0 0—None

1—Outdoor for Display

2—Outdoor for Control

3—Remote 10K Indoor

Averaging would not include on-board sensor. It is

accomplished by series/parallel combinations.

2 applies only to Heat Pump applications (allowing

compressor lockout while displaying temperature).

4—Remote 20K Indoor

0350 Heat Pump

Compressor Lockout

0 0—None

15(-9.5)—15°F (-9.5°C)

20(-6.5)—20°F (-6.5°C)

25(-4.0)—25°F (-4.0°C)

30(-1.0)—30°F (-1.0°C)

Only shown for heat pump systems with more heat stages

than cool selected and remote sensor selection is outdoor

for control.

Must enforce a dead band between this and Auxiliary

Lockout

35(1.5)—35°F (1.5°C)

40(4.5)—40°F (4.5°C)

45(7.0)—45°F (7.0°C)

0360 Heat Pump Auxiliary

Lockout

0 0—None

40(4.5)—40°F (4.5°C)

45(7.0)—45°F (7.0°C)

50(10.0)—50°F (10.0°C)

55(13.0)—55°F (13.0°C)

Only shown for heat pump systems with more heat stages

than cool selected and remote sensor selection is outdoor

for control.

Must enforce a dead band between this and Heat Pump

Compressor Lockout.

60(15.5)—60°F (15.5°C)

0535 Temporary Occupied

Duration Limit

3 0—no duration

1—one hour

0 means no limit

2—two hours

3—three hours

4—four hours

a

0540

Number of Periods 4 2—2 Periods

4—4 Periods

Does not appear if Non-programmable is chosen.

Applies to all days of the week. With 2 selected the “Cancel

Period” option does not appear on the display.

0580 Minimum

Compressor Off

Time

50—Off

2—2 minutes

3—3 minutes

Only shown if system has cool stages.

4—4 minutes

5—5 minutes

0600 Heat Temperature

90 40 to 90°F (4 to 32°C) Only shown if system has heat stages.

Range Stops

a

Setting available for modification in both the Installer and User setup modes.

63-2635—2 14

Page 15

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Table 6. Installer Setup Menu. (Continued)

Installer

Setup

Number

0610 Cool Temperature

Installer Setup

Name

Default

Setting All Settings Notes

50 50 to 99°F (10 to 37°C) Only shown if system has cool stages.

Range Stops

a

0640

0650 Extended Fan

0660 Extended Fan

0670 Keypad Lockout 0 0—Unlocked

0680 Temperature Control

Clock Format 12 12—12 Hour

24—24 Hour

00—Off

On time Heat

90—90 seconds

00—Off

On time Cool

40—40 seconds

1—Partial Lockout 1

2—Partial Lockout 2

3—Fully Locked

2 1—Less Aggressive

Heat

2—Standard

3—More Aggressive

Not displayed with fan set to fossil or with cool-only

systems

Only shown if system has cool stages.

Unlocked: All functions accessible.

Partial 1: Locks all but Holiday, Override, and Up/Down.

Partial 2: Locks all but Holiday and Override.

Full: Entire interface locked/non-functional.

Only shown if system has heat stages.

Only integral gains affected. Affects control operation in all

control regimes (not just recovery or setpoint change).

More Aggressive stops signal prior to reaching the setpoint.

(For use with oversized equipment.)

0685 Recovery Heat

Ramp Rate

5 0-20°F/hour Only shown if system has heat stages.

0 disables ramped recovery (step setpoint change at period

start time)

0690 Temperature Control

Cool

2 1—Less Aggressive

2—Standard

3—More Aggressive

Only shown if system has cool stages.

Only integral gains affected. Affects control operation in all

control regimes (not just recovery or setpoint change).

More Aggressive stops signal prior to reaching the setpoint.

(For use with oversized equipment.)

0695 Recovery Cool

Ramp Rate

3 0-20°F/hour Only shown if system has cool stages.

0 disables ramped recovery (step setpoint change at period

start time)

0700 Temperature Display

Offset

0 -3 (-1.5)— -3°F (-1.5°C)

-2 (-1.0)— -2°F (-1.0°C)

-1 (-0.5)— -1°F (-0.5°C)

This offset applies to both the control temperature and to

the display temperature for indoor sensor (and remote

indoor sensor)

0 (0.0)—0°F (0.0°C)

1 (0.5)—1°F (0.5°C)

2 (1.0)— 2°F (1.0°C)

3 (1.5)—3°F (1.5°C)

0710 Restore Factory

Defaults

0 0—No

1—Yes

Resets all Installer Setup parameters to default values and

resets the schedule to default Energy Star. Retains only

calendar settings and time.

INSTALLER SYSTEM TEST ITEMS

Test 1 Installer Test

Cool

00—Off

1—Cool Stage 1

2—Cool Stage 2

Test 2 Installer Test

Fan

Test 3 Installer Test

Heat

00—Off

1—Fan On

00—Off

1—Heat Stage 1

2—Heat Stage 1 and 2

3—Heat Stage 1,2 and 3

Test 4 Installer Test

Auxiliary Heat

Test 8 Installer Test

TOD/Economizer

a

Setting available for modification in both the Installer and User setup modes.

0 0—Auxiliary Heat Off

1—Auxiliary Heat On

0 0—TOD/Economizer Off

1—TOD/Economizer On

NOTE: Press the Done button to exit the Installer System Test.

15 63-2635—2

Page 16

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

MAIN SCREEN

LOWERS TEMPERATURE SETTING OR

MAKES SELECTIONS IN OTHER SCREENS

RAISES TEMPERATURE SETTING OR

MAKES SELECTIONS IN OTHER SCREENS

SYSTEM & FAN BUTTON

SELECTS FAN AUTO OR ON

SELECTS HEAT, OFF, COOL

AND EM HEAT

Fig. 34. Main screen selections.

SHOWS CURRENT

DAY OF WEEK

UP ARROW BUTTON

System

Cool

System & Fan Schedule Clock & More

SCHEDULE BUTTON

SELECTS PROGRAMMING

MODE

Fan Auto

CURRENT

TIME

DOWN BUTTON

Set To

CLOCK &

MORE BUTTON

SELECTS TIME AND

FURNACE FILTER

INFORMATION

TEMPERATURE

SETTING

M22316

PROGRAMMING

Table 7 shows default program settings.

Table 7. Energy Star Default Program Settings.

Schedule

Period Time

Occ1 8:00am 70°F (21°C) 75°F (24°C)

Unocc1 10:00pm 55°F (10°C) 85°F (29.5°C)

Occ2 — — —

Unocc2 — — —

Fan Settings

Auto: Fan runs only when heating/cooling system is on.

See the Fan Schedule section for more information.

On: Fan runs continuously.

System Settings

Heat: Thermostat controls the heating system.

Off: Both heating and cooling systems are off.

Cool: Thermostat controls the cooling system.

Auto: Thermostat automatically changes between heat and

cool operation, depending on indoor temperature.

Programming Heating and Cooling Schedule

The thermostat can control up to four different schedule

periods per day:

OCC 1: Work arrival time. Period to keep space at a

comfortable temperature.

UNOCC1: Work exit time. Period to keep space at an

energy-saving temperature.

OCC 2: Second occupied period.

UNOCC2: Second unoccupied period.

NOTE: Available schedule times are at 15-minute intervals.

Setpoints

Heat Cool

Mon

Aux Heat On

Fan Auto

System Auto

System & Fan

CURRENT

SYSTEM SETTING

CURRENT

FAN SETTING

Schedule Clock & More

INDICATES

THERMOSTAT IS

"CALLING FOR

COOL OR HEAT"

M22317

Fig. 35. Main screen display.

63-2635—2 16

Editing Schedule

1. Press MORE

2. Press SCHEDULE.

3. Press EDIT.

4. Press SELECT DAY to select the days you wish to

schedule.

5. Press NEXT when finished selecting days

NOTES:

— Multiple days can be selected.

— To skip over a day, press the Up or Down arrow

keys.

— Checkmarks appear next to selected days. These

are scheduled with identical times and temperatures.

Page 17

Mon

Tue

Wed

Thu

Fri

Sat

Sun

Select Day

Next Step

Cancel

M22332

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

OPERATION

Setting Temperature Overrides

There are three temperature override options:

— Hold Temperature Until

— Override, and

—Holiday.

HOLD TEMPERATURE UNTIL

Holds the temperature temporarily until the time set by the

user, or the next scheduled period time.

1. Press the Up or Down arrow next to the temperature to

adjust. The Hold Until time appears on the screen. The

time defaults to the next scheduled period start time

2. Press NEXT to adjust the time for the thermostat to

resume schedule.

Fig. 36. Initial schedule edit screen.

6. OCCUPIED 1 flashes, denoting the period that is about

to be edited.

7. Press NEXT, and the start time for that period flashes.

8. Change the start time by pressing the Up and Down

arrow keys.

9. Press NEXT to edit the heating and cooling setpoints.

10. Continue to cycle through the remaining periods and

make changes by pressing the NEXT key.

DAYS

SELECTED

Mon

Tue

Wed

Thu

Fri

GO BACK BUTTON

GOES BACK TO THE

LAST SCHEDULE STEP

NEXT STEP BUTTON

ADVANCES PERIOD,TIME,

HEAT AND COOL TEMPERATURES

SCHEDULE

PERIOD

Period

Wake Leave

AM

Heat

Go Back Next Step Done

HEAT OR COOL

TEMPERATURES

UP ARROW

CHANGES TIME

AND

TEMPERATURES

DOWN ARROW

CHANGES TIME

AND

TEMPERATURES

DONE BUTTON

EXITS AND SAVES

CHANGES MADE

TO SCHEDULE

M22333

NOTE: The installer setup can limit the length of time

for an override to 1, 2, 3, or 4 hours beyond the

current time.

3. Press DONE or wait 5 seconds.

4. Press CANCEL or SCHEDULE to cancel “Hold Tempera-

ture Until” and resume the schedule.

OVERRIDE

Changes temperature setting until the next period takes effect.

For use during Unoccupied periods.

1. Press OVERRIDE. The settings change by default to the

next Occupied period.

NOTE: Changes are limited to those allowed by the

lockout level.

2. Press Up or Down arrow to change the override temperature, and NEXT to adjust override time.

HOLIDAY

Changes temperature setting for a designated number of days.

Press MORE and then HOLIDAY. The screen shows “Hold

Until 1 DAYS”.

1. Press Up or Down arrow to change the temperature

desired for the thermostat to override the schedule.

2. Press NEXT to change the desired days for the duration

of the holiday.

3. To cancel the Holiday Override early, press CANCEL.

Fig. 37. Screen to edit existing settings.

11. When complete, press DONE. SAVING CHANGES

appears on the screen to indicate changes are being

saved to the day(s) modified.

12. To exit schedule without saving changes, press CANCEL

any time.

Setting Time

1. Press CLOCK.

2. Use arrows to set current time.

3. Press DONE.

IMPORTANT

The current day of the week should already be set

correctly. If not, see the Advanced Settings section to

set the day.

Fan Status Displayed on Main Screen

. When the thermostat is running the fan, the fan blade symbol

appears next to FAN to indicate the thermostat has the fan

on.

NOTE: If the thermostat is not controlling the fan—typical for

many gas, forced-air heating systems—the fan blade

symbol will not appear even though the fan may

be running.

Replacing Batteries

Not all thermostat models require batteries. If the thermostat

has batteries, a low battery warning (see Fig. 38) flashes on

the main screen for approximately 30 days.

17 63-2635—2

Page 18

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

NOTES:

— If batteries are not replaced when the Low Battery

warning is flashing, the LO batt screen displays

continuously and the thermostat stops operating

until batteries are replaced.

— The thermostat has a low battery indicator.

However, it is recommended that the batteries be

replaced once each year. Do this to prevent

leakage and prevent the thermostat and HVAC

system from shutting down due to lack of

thermostat battery power.

M22322

Fig. 38. Low battery signal.

Replace the batteries as follows:

1. Remove the thermostat from the base by pulling it

straight out. (See Fig. 39.)

2. Install two new AA alkaline batteries with proper polarization.

NOTES:

— Always use AA alkaline batteries.

— All programming (Schedule, Date and Time)

information is retained during battery replacement.

3. Place thermostat back on subbase by aligning terminal

screw blocks with the pins on the back of the thermostat.

(See Fig. 40.)

4. Push the thermostat straight onto the base.

WALLPLATE

TERMINAL SCREW BLOCK

PINS ON

BACK OF

THERMOSTAT

M22299

Fig. 40. Placing thermostat back onto subbase.

Reading Remote Indoor Temperature

If connected to an installed remote indoor temperature sensor,

the thermostat displays the indoor temperature from the

remote sensor(s).

NOTE: If connected to an installed remote indoor temperature

sensor, the thermostat internal sensor is not used.

ONE REMOTE INDOOR SENSOR INSTALLED

If one remote indoor temperature sensor is used, the screen

showing the Inside temperature reading displays the

temperature at the indoor remote sensor location.

MULTIPLE REMOTE INDOOR SENSORS INSTALLED

If more than one remote indoor sensor is used, the screen

showing the Inside temperature reading displays the average

of all the remote indoor sensors.

WALL

M23024

Fig. 39. Removing thermostat from subbase.

63-2635—2 18

Reading Outdoor Temperature

If connected to an outdoor sensor, the thermostat can display

the Outside temperature.

VIEW OUTSIDE TEMPERATURE

View the outdoor temperature by pressing MORE until the

outside temperature shows where the Indoor temperature was

displayed. The word Outdoor will be displayed on the LCD.

Screen Locked

Portions of the touch screen interface can be fully or partially

locked. See the Advanced Settings section for information to

use these features. When the thermostat displays LOCKED,

the buttons are either fully or partially locked.

Fully Locked Screen

In this mode, the entire interface is locked and not functional.

To unlock screen, see the Advanced Settings section. The

screen continuously displays SCREEN LOCKED.

Page 19

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Partially Locked Screen

When partially locked:

— Pressing a locked key prompts the screen to indicate

SCREEN LOCKED for five to seven seconds.

— Pressing an unlocked key with SCREEN LOCKED active

removes SCREEN LOCKED from the display.

PARTIAL LOCKOUT 1

This mode locks all keys except HOLIDAY, OVERRIDE, and

temperature Up/Down arrows:

— User can change the temperature setpoint, but cannot

change schedule settings.

— The temporary temperature change lasts until next

scheduled period. The screen displays that time.

— User can change the temperature setpoint, but cannot

change schedule settings.

— Pressing HOLIDAY sets the temperature to the Unoccupied

setting for the selected period of time. The next Occupied

period switches back to the program settings.

— Pressing OVERRIDE sets the temperature to the Occupied

setting for the selected period of time. The next Unoccupied

period switches back to the program settings.

— To cancel the temperature override and follow the

programmed schedule, press CANCEL.

— To unlock the screen, see Advanced Settings section.

PARTIAL LOCKOUT 2

This mode locks all keys except HOLIDAY and OVERRIDE:

— Pressing HOLIDAY sets the temperature to the Unoccupied

setting for the selected period of time. The next Occupied

period switches back to the program settings.

— Pressing OVERRIDE sets the temperature to the Occupied

setting for the selected period of time. The next Unoccupied

period switches back to the program settings.

— To cancel the temperature override and follow the

programmed schedule, press CANCEL.

— To unlock the screen, see Advanced Settings section.

Temperature Recovery

The thermostat is equipped with a feature to eliminate

guesswork when setting a schedule. That is, the user need not

know the amount of time for the HVAC system to bring the

space to temperature (without overshoot) prior to the

scheduled time.The thermostat manages that automatically.

Simply set the program schedule to the desired time to have

the space at comfort temperature. In addition, program the

temperature to this comfort temperature. The thermostat

activates the heating or cooling at the proper time to reach the

scheduled temperature at the scheduled time.

NOTE: The setpoint changes gradually to use economical

stages and avoid overshoot.

For example—the space will be occupied at 8:00 AM and the

desired temperature is 70°F. Set the OCC 1 period for 8:00 AM

and 70°F. The thermostat turns on the heat prior to 8:00 AM to

raise the temperature to 70°F by 8:00 AM.

Minimum-Off Timer Compressor Protection

The thermostat has an adjustable Minimum-Off Timer that can

be set from zero to five minutes (Factory Setting—five

minutes). The Minimum-Off Timer can be bypassed through

the Installer System Test or it can be bypassed permanently by

setting the Minimum-Off Timer to 0 minutes in the Installer

Setup. The Minimum-Off Timer is activated after the

compressor turns off:

— If the thermostat is system powered (common wire), the

Minimum-Off Timer is also activated upon initial startup and

after power interruptions.

— If there is a call for cooling or heating during the Minimum-

Off Time, the thermostat displays “Wait.”

— When the Minimum Off Timer expires, “Cool On” or “Heat

On” (heat pumps only)” appears solidly in the display and

the compressor and fan turn on.

Economizer/TOD Logic (Table 8)

Table 8. Operation of Terminal A.

Effective

Occupancy

Occupied — Energized Energized

Unoccupied Yes Energized De-energized

Override — Energized Energized

Call for

Cool

No De-energized De-energized

Economizer TOD

Terminal A

Heat Pump Temperature Lockouts

Dual Fuel Heat Pump and Outdoor Temperature

Sensor

In this operation, there is no external fossil fuel kit (dual fuel kit)

installed; the thermostat controls this function:

1. Choose correct heat pump application in ISU 0170.

2. Choose Outdoor Temperature Sensor for Heat Pump

Temperature Lockouts Option in ISU 0340.

3. Choose appropriate Balance Point Temperature in

ISU 0350.

OPERATION IN HEAT MODE ABOVE BALANCE POINT (OUTDOOR

TEMPERATURE)

When the outdoor temperature is above the selected Balance

Point Temperature (ISU 0350), only the compressor operates

and the fan (G terminal) energizes when the thermostat calls

for heat.

OPERATION IN HEAT MODE BELOW BALANCE POINT (OUTDOOR

TEMPERATURE)

When the outdoor temperature is below the selected Balance

Point Temperature (ISU 0350), only the Fossil Fuel (auxiliary

heat) operates and the fan (G terminal) does not energize

when the thermostat calls for heat.

The thermostat provides an alert that the heating or cooling

system is coming on before a scheduled time by displaying

“Recovery” on the screen.

Heat Pump with Auxiliary (Backup) Heat and Outdoor

Temperature Sensor

1. Choose correct heat pump application in ISU 0170.

2. Choose Outdoor Temperature Sensor for Control

Option in ISU 0340.

3. Choose Compressor Lockout Temperature in

ISU 0350.

4. Choose Auxiliary Lockout Temperature in ISU 0360.

19 63-2635—2

Page 20

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

NOTE: There is a 5°F deadband between Compressor and

Auxiliary Heat lockout temperatures

Operation in Heat Mode

When the outdoor temperature is:

— Below Compressor Lockout Temperature: only Auxiliary

Heat operates.

— Above Auxiliary Lockout Temperature: only the Compressor

operates.

— Between the two temperatures: both the Compressor and

Auxiliary Heat operate.

COMPRESSOR ONLY

50

BOTH COMPRESSOR AND

AUXILIARY HEAT

35

AUXILIARY ONLY

OUTDOOR TEMPERATURE

AUXILIARY

LOCKOUT

TEMPERATURE

COMPRESSOR

LOCKOUT

TEMPERATURE

M19950

Fig. 41. Heat Pump Operation with Lockout Temperatures

Set.

Operating Sequence

The thermostat energizes specific terminal(s), depending on

the demand for heating, cooling or fan. The thermostat screen

shows the time, inside temperature, system and fan selections.

Additional indicators are shown when the heating, cooling or

fan is energized. See Tables 9 and 10 for specification

information.

Table 9. Sequence of Operation for Conventional Systems.

System

Setting

Off Auto — — —

Cool Auto — — —

Cool

or Auto

Cool

or Auto

Heat Auto — — —

Heat

or Auto

Heat

or Auto

a

If Installer Setup System type is set to two stages of cooling.

b

G energizes only if Installer Setup 0180 is set to Electric.

c

If Installer Setup System type is set to two stages of heating.

Fan

Setting Call for Action

Auto Stage 1

Cooling

Auto Stages 1 and 2

Cooling

Auto Stage 1

Heating

Auto Stages 1 and 2

Heating

Energize

Terminals

Screen

Message

Y, G Cool On

Y, Y 2

W, G

W, W2

a

, G

b

Cool On

Heat On

c

b

Heat On

, G

Table 10. Sequence of Operation for Heat Pump Systems.

System

Setting

Off Auto —

Fan

Setting Call for Action

Energize

Terminals

a

O/B

Screen

Message

—

Cool

a

a

a

d

, G,

a

b

, G,

c

b

,

, G,

a

a

Cool On

—

Heat On

Auxiliary

Heat On

Cool

or Auto

Heat Auto None

Heat

or Auto

Auto Stage 1 Cooling

Stages 1 and 2

Cooling

Auto Stage 1 Heating

Stages 1 and 2

Heating

Stages 1, 2 and 3

Heating

Y, G, O/B

Y, Y 2

O/B

O/B

Y, G, O/B

Y, W 1

O/B

Y, Y 2

W1

O/B

a

Configure O/B in Installer Setup. Based on last piece of

equipment called (cooling = O; heating = B).

b

If Installer Setup System Type is set to 3Heat/2Cool Heat

Pump with Auxiliary Heat.

c

If Installer Setup System Type is set to 2Heat/1Cool Heat

Pump with Auxiliary Heat.

d

This terminal does not energize if Installer Setup System type

is set to 2 Heat/2 Cool Heat Pump with no Auxiliary Heat.

Second Stage Heat and Cool Control

While maintaining setpoint, several factors affect when 2nd

stage energizes such as load conditions, environmental

conditions, P+I control, and home insulation. The second stage

energizes when the thermostat senses 1st stage is running at

90% capacity. This operation is droopless control.

Temperature Sensor Operation and Checkout

Allow outdoor or indoor temperature sensor to absorb the air

for a minimum of five minutes before taking a reading. See the

Sensor instructions for more information.

NOTE: The C7089U, C7189U, and T7770A Temperature

Sensors are calibrated at the factory and cannot

be recalibrated in the field.

C7089U Outdoor Temperature Sensor

Operation

When installed with Thermostat ISU 0340 set to 1 or 2, the

thermostat can display outside temperature.

63-2635—2 20

Checkout

Allow C7089U Outdoor Sensor to absorb outdoor air for a

minimum of twenty minutes before taking a reading.

With an accurate thermometer (±1°F [0.5°C]) measure the

temperature at the sensor location, allowing time for the

thermometer to stabilize before reading.

Page 21

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

To verify sensor resistance, remove one wire from one of the

C7089U 60-in. leadwires. Use an ohmmeter to measure the

resistance across the sensor. Then compare sensor accuracy

with the temperature/resistance curve in Fig. 42.

C7189U Remote Indoor Temperature Sensor

Operation

When installed with Thermostat ISU 0340 set to 3, the remote

inside temperature is displayed on the Thermostat Home

Screen as Inside Temperature. The thermostat internal

temperature sensor is not used.

The C7189U can be used to provide one remote sensor input

or as a temperature averaging network with multiple C7189U

Sensors connected, as shown in Fig. 29.

Checkout

For best results, allow C7189U Wall Mount Temperature

Sensor to absorb the air moving through the room for a

minimum of twenty minutes before taking a resistance

measurement.

With an accurate thermometer (±1°F [0.5°C]) measure the

temperature at the sensor location, allowing time for the

thermometer to stabilize before reading.

T7770A Remote Temperature Sensor

Operation

When installed with Thermostat ISU 0340 set to 3 or 4, the

remote inside temperature is displayed on the Thermostat

Home Screen as Inside Temperature. The thermostat internal

temperature sensor is not used.

The T7770A can be used to provide one remote sensor input

or as a temperature averaging network with multiple T7770A

Sensors connected, as shown in Fig. 26 through 28.

Checkout

For best results, allow T7770A Wall Mount Temperature

Sensor to absorb the air moving through the room for a

minimum of twenty minutes before taking a resistance

measurement.

With an accurate thermometer (±1°F [0.5°C]) measure the

temperature at the sensor location, allowing time for the

thermometer to stabilize before reading.

To verify sensor resistance, remove one wire from one of the

wiring terminals. Use an ohmmeter to measure the resistance

across the sensor. Then verify the sensor accuracy with the

temperature/resistance in Fig. 43.

To verify sensor resistance, remove one wire from one of

C7189U wiring terminals. Use an ohmmeter to measure the

resistance across the sensor. Then compare sensor accuracy

with the temperature/resistance curve in Fig. 42.

220K

190K

160K

130K

100K

90K

60K

RESISTANCE (OHMS)

60

10 20

10K OHM AT

o

F (25oC)

77

100

80

30

o

120

F

o

50

40

C

M22823

30K

0K

-40

-40

-20 0 20 40

-30

-10

-20

TEMPERATURE (DEGREES)

0

Fig. 42. 10K ohm sensor resistance versus temperature.

80K

70K

60K

50K

40K

30K

RESISTANCE (OHMS)

20K

10K

30

0

40 50 60 70

10

20

TEMPERATURE (DEGREES)

20K OHM AT

77

80

30

o

F (25oC)

90

100

110

40

M5874A

o

F

o

C

Fig. 43. 20K ohm sensor resistance versus temperature.

21 63-2635—2

Page 22

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

TROUBLESHOOTING (TABLE 11)

Table 11. Troubleshooting.

Symptom Possible Cause Action

Display does not come on. Thermostat is not being powered. Check for 24 Vac between C and Rc.

Check that AAA batteries are installed correctly

and are good.

Temperature settings do not

change.

Heating or cooling does not come

on.

Thermostat is calling for Heat

(Heat on) or Cool (Cool on) but

no heating or cooling is running.

Heat does not turn on (Heat On is

solid in the display).

The upper or lower temperature limits were

reached.

The keypad is fully locked. Check ISU 0670 to change keypad locked

Thermostat minimum off-time is activated. Wait up to five minutes for the system to respond.

System selection is not set to Heat or Cool. Set system Selection to correct position.

System type Selection is incorrect. Check ISU 0170 and make sure correct System

Heating or cooling equipment is not

operating.

Heating equipment failure. Check for 24 Vac at the equipment on the

Check temperature setpoints.

Check ISU 0600 and 0610; modify as needed.

options.

type is chosen.

Check wiring.

Check ISU 0170 and make sure correct system

type is chosen.

Verify operation of equipment in System Test

mode.

secondary side of the transformer between power

and common. If voltage is not present, check the

heating equipment to find the cause of the

problem.

Cooling does not turn on (Cool

On is solid in the display).

Fan does not turn on in a call for

heat (electric furnace).

Heat pump puts out cool air in the

heat mode and warm air in the

cool mode.

Both the heating and cooling

equipment are running at the

same time.

Check for 24 Vac between the heat terminal (W)

and transformer common. If 24 Vac is present, the

thermostat is functional. Check the heating

equipment to find the cause of the problem.

Loose or broken wire connection between

thermostat and heating equipment.

Cooling equipment failure. Check for 24 Vac at the equipment on the

Loose or broken wire connection between

thermostat and cooling equipment.

Fan Control in Heating is set to Gas or Oil

Furnace (Setting 0180).

Changeover Valve (ISU 0190) is not

configured to match the changeover

required by the installed heat pump.

The heating equipment is not a heat pump

but the System Type (ISU 0170) is set to

Heat Pump.

Heating and cooling wires are shorted

together.

Check for 24 Vac between the heat terminal (W)

and transformer common. If voltage is not

present, check wire connection (loose or broken)

between the thermostat and the heating

equipment.

secondary side of the transformer between power

and common. If voltage is not present, check the

cooling equipment to find the cause of the

problem.

Check for 24 Vac between the cool terminal (Y)

and transformer common. If 24 Vac is present, the

thermostat is functional. Check the cooling

equipment to find the cause of the problem.

Check for 24 Vac between the cool terminal (Y)

and transformer common. If voltage is not

present, check the wire connection (loose or

broken) between the thermostat and the cooling

equipment.

Set Fan Control in Heating to Electric Furnace

(Setting 0180).

Set Changeover Valve (ISU 0190) to match the

changeover required by the installed heat pump.

Set System Type (ISU 0170) to match the

installed heating and/or cooling equipment.

Separate the shorted heating and cooling wires.

63-2635—2 22

Page 23

Symptom Possible Cause Action

Heating equipment is running in

the cool mode.

Heating equipment does not turn

off and heat temperature setting

is set below room temperature

(Heat On is not in the display).

Cannot set the system setting to

Heat.

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Table 11. Troubleshooting. (Continued)

Heating equipment is not a heat pump but

System Type (ISU 0170) is set to Heat

Pump.

Heating equipment is not a heat pump but

System Type (ISU 0170) is set to Heat

Pump.

System Type (ISU 0170) is set to Cool

Only.

Set System Type (ISU 0170) to match the

installed heating and/or cooling equipment.

Set System Type (ISU 0170) to match the

installed heating and/or cooling equipment.

Set System Type (ISU 0170) to match the

installed heating and/or cooling equipment.

Cannot set the system setting to

Cool.

Heat On is not in the display. System setting is not set to Heat and/or

Cool On is not in the display. System setting is not set to Cool and/or the

Wait is in the display. Compressor minimum off timer is active. Wait up to five minutes for the cooling or heating

“Screen Locked” appears on the

screen and all or some of the

keys do not respond.

System Type (ISU 0170) is set to Heat

Only or Heat Only with Fan.

temperature setting is not set above room

temperature.

temperature setting is not set below room

temperature.

The keypad is fully or partially locked. Check ISU 0670 to change keypad locked

Set System Type (ISU 0170) to match the

installed heating and/or cooling equipment.

Set the system setting to Heat and set the

temperature setting above the room temperature.

Set the system setting to Cool and set the

temperature setting below the room temperature.

(heat pump) equipment to turn on.

options.

Perchlorate Material

This thermostat contains a Lithium battery which may contain

Perchlorate material.

The following statement is required:

Perchlorate Material—special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

23 63-2635—2

Page 24

TB7220 COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the

literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including

attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

63-2635—2 C.H. Rev. 12-06

Loading...

Loading...