Page 1

Heat Pump

Thermostat

&

Cross Reference Selection Guide

Page 2

Select a Honeywell Heat Pump Thermostat

for Peak Performance that Meets Every Heat Pump Demand

Rapid advances in heat pump technology, resulting in high efficiency units and lower operating costs, have made the heat pump a popular choice

with consumers. Honeywell heat pump thermostats are ideal for all your heat pump applications and provide the highest level of comfort

available. Our thermostats offer consistent control. They optimize desired comfort level and energy savings. Because your customers’ needs vary,

we’ve developed the most complete line of heat pump thermostats.

NON-PROGRAMMABLE HEAT PUMP THERMOSTATS

T841 Standard Non-Programmable Thermostat

• Good performance without any

“frills”.

• Electromechanical.

• Two heat/one cool; manual

changeover.

• Single-piece construction–no

subbase required.

• Front test probe access for easy

checkout.

Y594 Deluxe Non-Programmable Thermostat

• Proven reliability with excellent

temperature control.

• Electromechanical.

• Classic styling.

• Two heat/one cool; automatic or

manual changeover.

• Two-piece, front-wired construction for easy installation.

T8411 Standard Electronic Non-Programmable

Thermostat

• Microelectronic technology

provides precise zero-droop

performance.

• Attractive styling complements

any décor.

• Two heat/one cool; manual

changeover eliminates

unexpected system operation.

• Large digital display for quick,

easy readability.

• Fan and system switches are located on the lower edge of the

thermostat to eliminate accidental setting changes.

T8511 Deluxe Electronic Non-Programmable

Thermostat

• Microelectronic technology

provides precise zero-droop

performance.

• Attractive styling complements

any décor.

• Two heat/one cool; automatic or

manual changeover.

• Easy-to-read backlit display.

• Most frequently used keys are

located by LCD for quick and easy access to information.

• Outdoor temperature display available with optional outdoor

temperature sensor.

PROGRAMMABLE HEAT PUMP THERMOSTATS

T8011 Standard Programmable Thermostat

• Microelectronic technology

provides precise zero-droop

performance.

• Attractive styling complements

any décor.

• Two heat/one cool; manual

changeover.

• Program up to four time periods

and temperature setpoints.

• Large temperature display for

quick, easy readability.

• Conveniently sized thermostat with two-piece installation make it easy

to install and troubleshoot.

PC8900/W8900B1002 Perfect Climate Comfort Center™ Control System

• Automated, all-in-one comfort control.

• PC8900 Control Panel mounts in living space and accurately measures and

controls room temperature and humidity. W8900 Remote Panel mounts near

the heating and cooling equipment.

• Optional remote sensors can be used for optimum temperature control.

• Up to three heat/two cool.

• Seven-day (auto copy) programming.

• Large, continuously lit display.

• Simultaneous display of heat and cool setpoints with push of a button.

• Circulation fan setting improves indoor air quality.

T8611 Chronotherm® IV Deluxe Programmable

Thermostat

• Microelectronic technology

provides precise zero-droop

performance.

• Attractive styling complements

any décor.

• Two heat/one cool; automatic

or manual changeover.

• Seven-day programming.

• COPY key makes programming easier for the installer and the homeowner.

• Easy-to-read backlit display.

• Adaptive Intelligent Recovery™ optimizes heat pump energy savings.

• Outdoor temperature display available with optional outdoor

temperature sensor.

Page 3

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Table of Contents

About This Cross Reference/Selection Guide

Heat Pump Thermostat Model Specifications

Thermostat Descriptions and General Information

Understanding Circuits

Typical System Hookup Diagrams

Electronic Thermostat (T8011, T8411, T8511, T8611) Sequences of Operation

Thermostat Manufacturer Cross Reference

Tips for Using This Heat Pump Cross Reference

Wiring Connections for Honeywell Heat Pump Thermostats

Manufacturer Cross Reference

Index

.......................................................................................................................................................................................

Index to Figure Diagrams

............................................................................................................................................................

..........................................................................................................................................

...............................................................................................................................................

........................................................................................................................................................

........................................................................................................................

.........................................................................................................................

.................................................................................................................

...................................................................

............................................................................................................................

...................................................................................................................

..................................................................................................

About This Cross Reference/Selection Guide

1

2-4

5-12

13-14

15-25

26-28

29-32

33

34-35

36-116

117-118

119

Heat pumps require thermostats with special features. This Cross Reference/Selection Guide contains information about

all aspects of selecting a Honeywell replacement thermostat for any heat pump application. Table 1 shows a list of the

Honeywell TRADELINE® and SUPER TRADELINE® OS numbers and their specifications. Immediately following the

table are more detailed descriptions and related application information. In this section you will find additional

information explaining features and requirements that are unique to heat pump thermostat applications. Following the

general information section are the internal schematics, wiring diagrams, and sequence of operation information for the

electronic thermostats. The Thermostat Manufacturer Cross Reference is listed next. Finally, there is the heat pump

manufacturer cross reference, including tips on how to use it. This cross reference, which is organized alphabetically by

equipment or thermostat manufacturer, provides the needed information to select and wire any Honeywell heat pump

thermostat in new installations and replacement applications.

70-6627 • 1

Page 4

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Heat Pump Thermostat Model Specifications

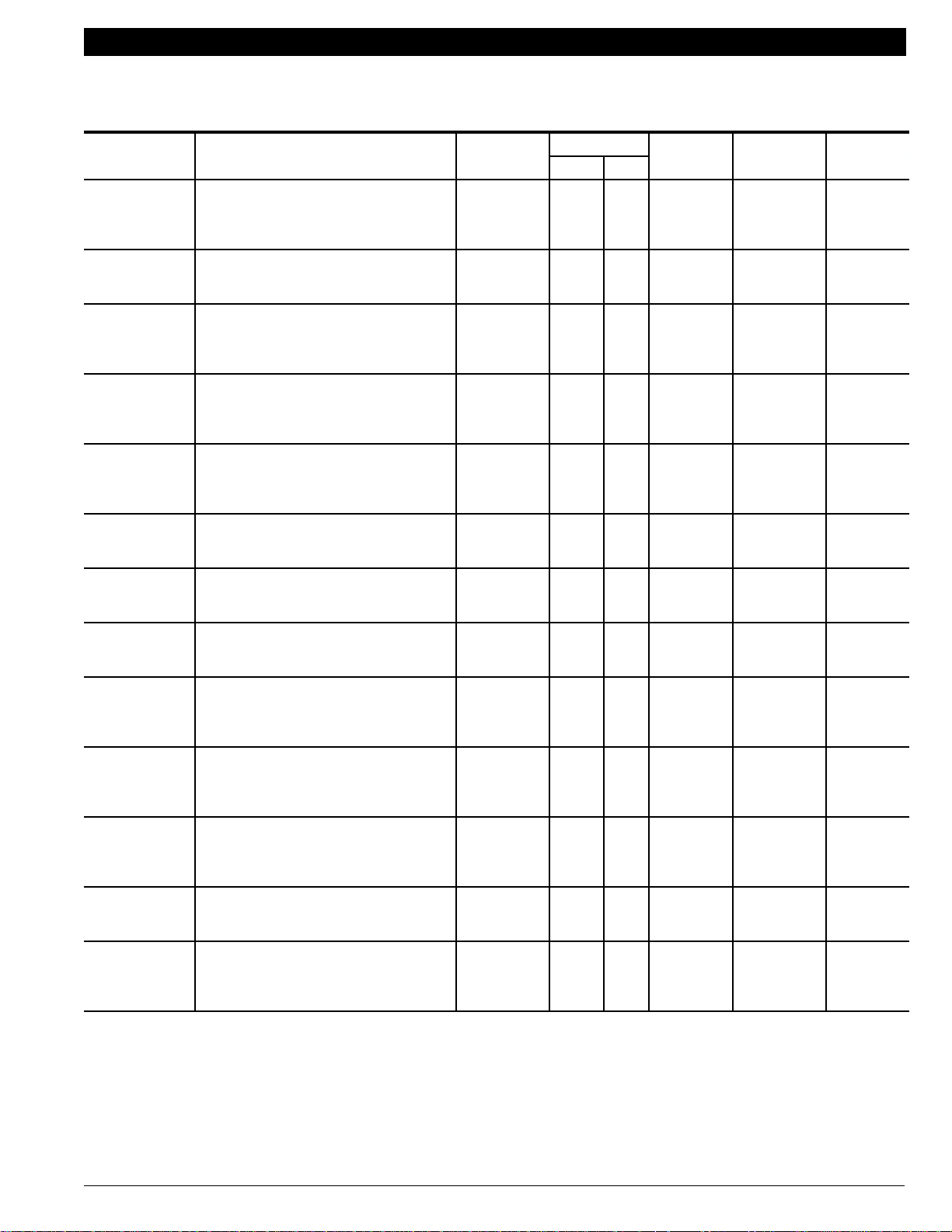

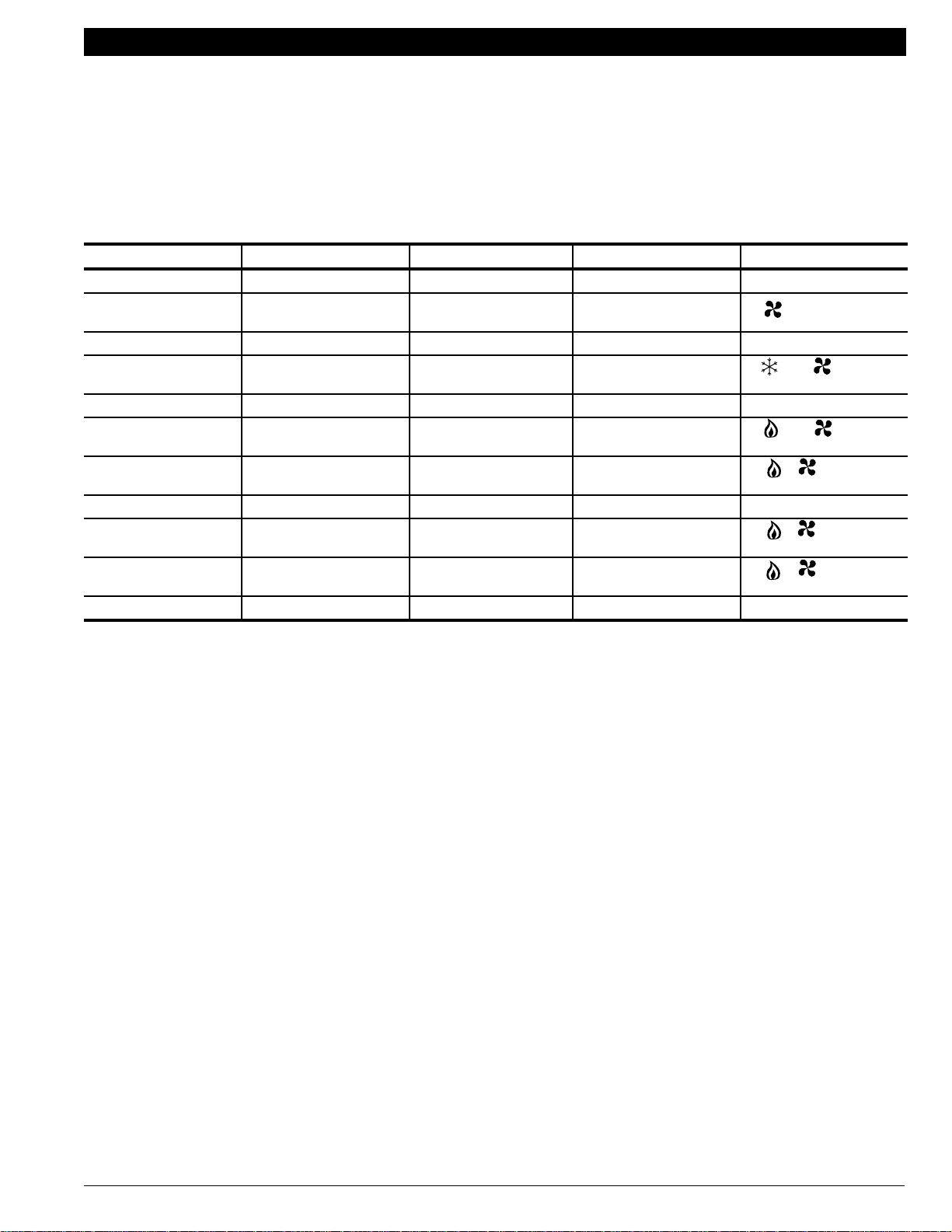

Table 1. Model Number Specifications.

Order

Number

T841A1308 TRADELINE®; fixed anticipation. For

use where E and W2 may be jumpered.

No auto fan in EM.HT. (Fig. 16).

T841A1555 Replaces T841A1068 and T841A1407,

T841A1530, GE AY28Y078 and

AY28Y139. Includes outdoor reset and

fixed anticipation on stage 2 heat. Auto

fan in EM. HT. (Fig. 17).

T841A1712 SUPER TRADELINE®; for two-stage

heating and one-stage cooling. Fixed

anticipation except Stage 2, which is

adjustable. Auto fan in EM. HT. (Fig. 18).

T841A1738 Same as T841A1712, except Premier

White™. SUPER TRADELINE®; for

two-stage heating and one-stage

cooling. Fixed anticipation except

Stage 2, which is adjustable. Auto fan

in EM. HT. (Fig. 18).

T841B1000 For “No Emergency Heat” applications.

Fixed anticipation except stage 2, which

is adjustable. (Fig. 19).

Y594G1161 Includes T874G1204/Q674J1043. With

outdoor reset; replaces GE AY28X077

and AY28X138; no stage 2 heat

anticipation. No auto fan in EM. HT.

(Fig. 20).

Y594G1419 SUPER TRADELINE®; includes

T874G1642/Q674F1444. Auto fan in

EM. HT. (Fig. 22).

Y594G1476 Same as Y594G1419, except Premier

White™; SUPER TRADELINE®.

Includes T874G1741/Q674F1477. Auto

fan in EM. HT. (Fig. 22).

Y594G1633 TRADELINE®; includes T874G1972/

Q674F1584. No auto fan in EM.HT.

Replaces Coleman/Evcon Y594G1377

(Fig. 21).

Y594R1425 SUPER TRADELINE®; includes

T874R1616/Q674L1587. Fixed

anticipation. Auto fan in EM. HT.

(Fig. 25).

Description Terminals Heat Cool

W2,Y,G,R,

O,B,L,E,X

W,Y,G,R,O,

B,X2,T,F,U

W2,W3,Y,G,

B,O,R,X,E

W2,W3,Y,G,

B,O,R,X,E

W1,W2,Y1,

G,R,O,B,X

W,Y,G,R,O,

X2,T,F,B

W1,W2,W3,

Y1,G,R,O,B,

E,X,X1,X2

W1,W2,W3,

Y1,G,R,O,B,

E,X,X1,X2

W2,Y,G,R,

O,B,E,X,L

W1,W2,W3,

G,Y,R,O,B,

E,X,X2,L

Stages

2 1 EM.HT.-

2 1 EM.HT.-

2 1 EM.HT.-

2 1 EM.HT.-

2 1 HEAT-OFF-

2 1 EM.HT.-

2 1 OFF-

2 1 OFF-

2 1 OFF-

2 1 EM. HT.-

Systems Led

Switch

HEAT-OFF-

COOL

HEAT-OFF-

COOL

HEAT-OFF-

COOL

HEAT-OFF-

COOL

COOL

AUTO-OFF

EM.HT.

HEAT-

AUTO-

COOL

EM.HT.

HEAT-

AUTO-

COOL

EM.HT.

HEAT-

AUTO-

COOL

HEAT-OFF-

COOL

Changeover

Manual heat

or cool

Manual cool EM.HT.,

Manual heat

or cool

Manual heat

or cool

Manual heat

or cool

Auto cool AUX.HT.,

Auto heat

or cool

Auto heat

or cool

Auto heat

or cool

Manual heat

or cool

Indication

EM.HT.d,

AUX.HT.

AUX. HT.

EM.HT.,

AUX. HT.

EM.HT.,

AUX. HT.

None

EM.HT.

EM.HT.,

AUX.HT.

CHECK

EM.HT.,

AUX.HT.

CHECK

EM.HT.,

AUX.HT.

AUX. HT.,

EM. HT.,

CHECK

(continued)

c

c

c

70-6627 • 2

Page 5

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

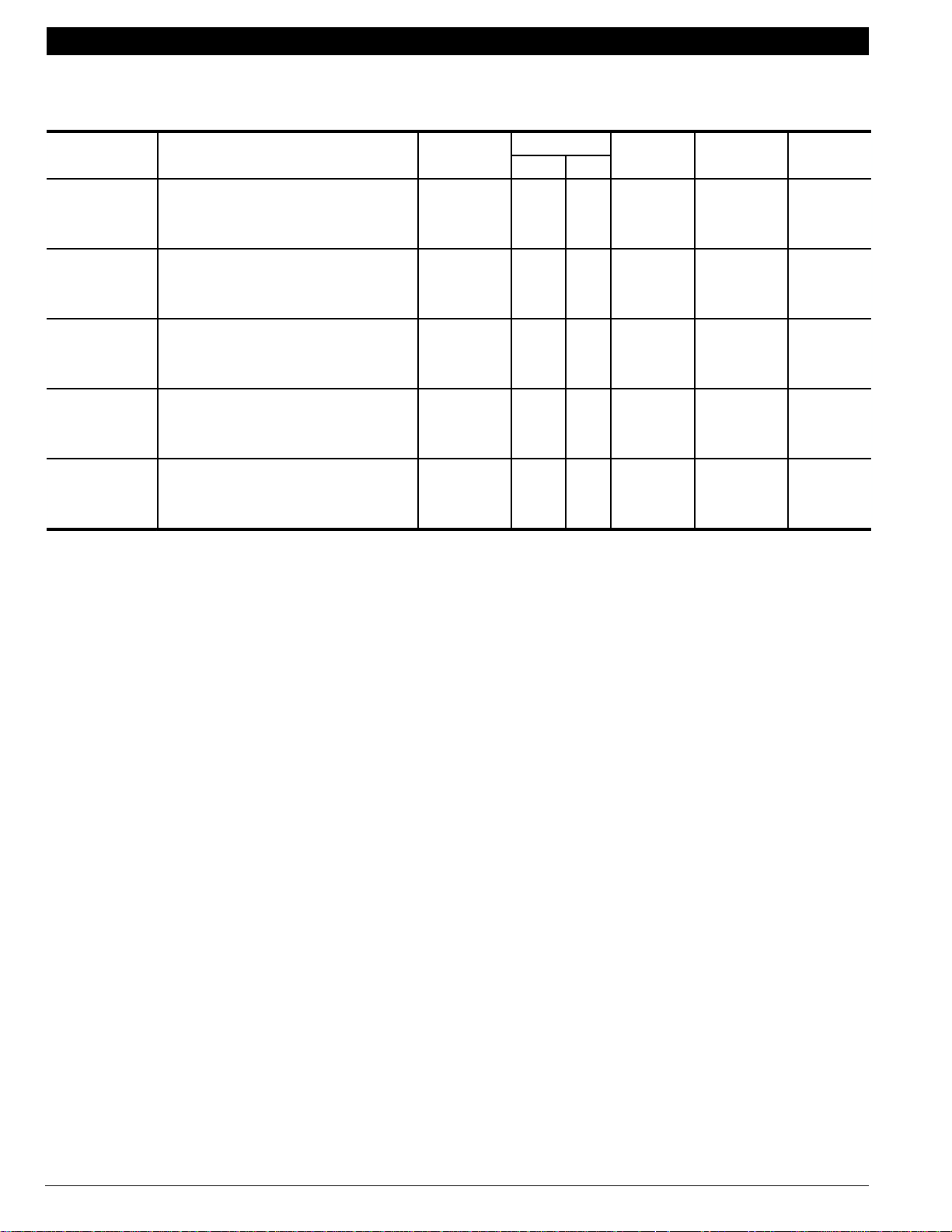

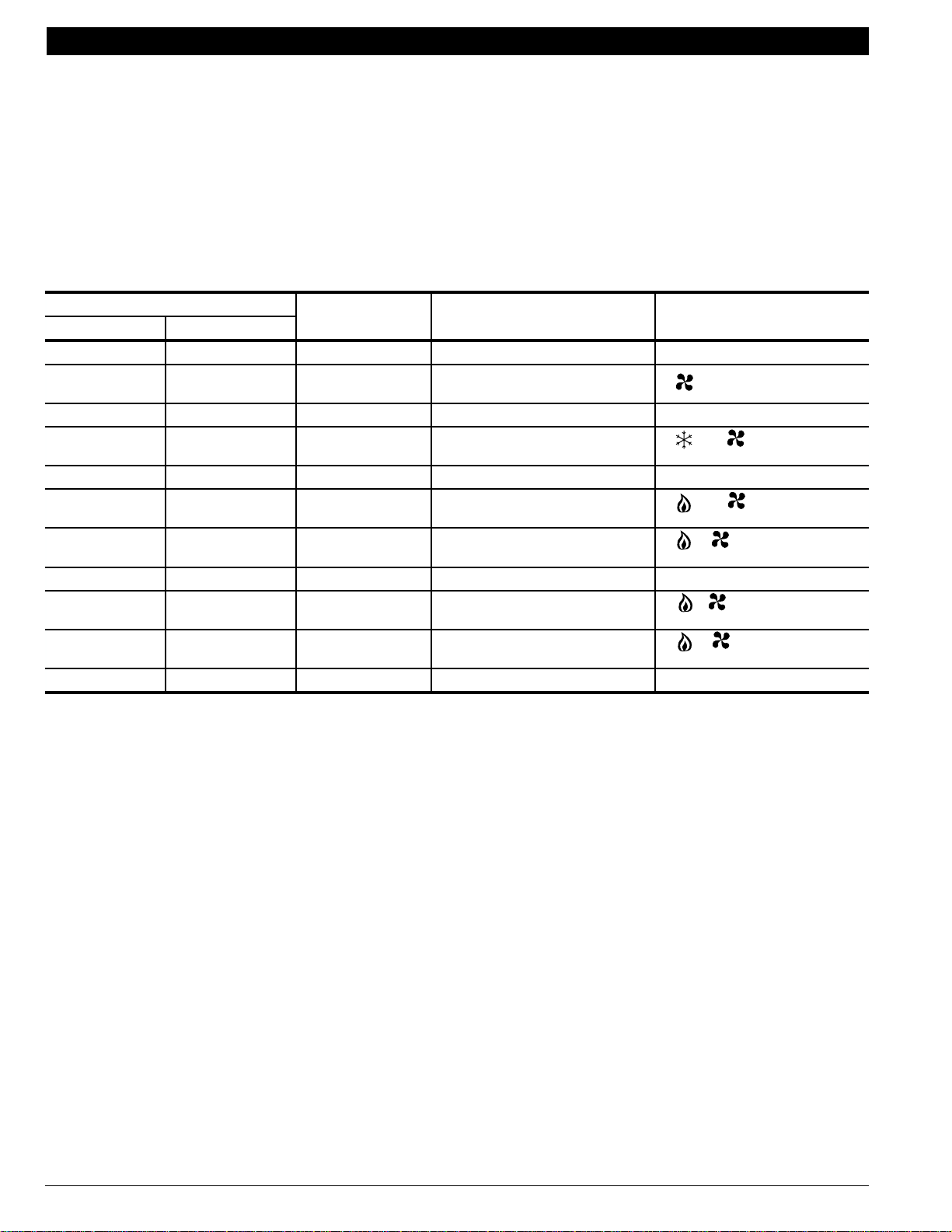

Table 1. Model Number Specifications (continued).

Order

Number

Y594R1763 TRADELINE®; includes

T874R1954/Q674L1827. Replaces

Y594R1136. Auto fan in EM.HT.

(Fig. 23).

Y594R1797 Includes T874R1988/Q674L1868.

Replaces Coleman/Evcon Y594R1235.

No auto fan in EM.HT. (Fig. 24).

T8611G1004 TRADELINE®; 5-1-1 programming.

Auto fan in EM.HT. (Fig. 26).

T8611G1103 Same as T8611G1004, except Premier

White™; TRADELINE®. 5-1-1

programming. Auto fan in EM.HT.

(Fig. 26).

T8611M7008 TRADELINE®; 7 day programming.

Auto fan in EM.HT. (Fig. 27).

T8611R1000 TRADELINE®; 5-1-1 programming.

Auto fan in EM.HT. (Fig. 28).

T8411R1002 TRADELINE®; non-programmable

electronic thermostat. Auto fan in

EM.HT. (Fig. 29).

T8411R1028 Same as T8411R1002 except Premier

White™. Auto fan in EM.HT. (Fig. 29).

T8511G1021 TRADELINE®; Deluxe Electronic

Thermostat. Outdoor sensor capability.

Auto fan in EM.HT. (Fig. 30).

T8511G1047 Same as T8511G1021 except Premier

White™. Outdoor sensor capability.

Auto fan in EM.HT. (Fig. 30).

T8511M1002 TRADELINE®; Deluxe Electronic

Thermostat. Outdoor sensor capability.

Auto fan in EM.HT.

T8011R1006 Same as T8011R1014 except Premier

White™. Fixed anticipation except stage

2, which is selectable. (Fig. 29).

T8011R1014 TRADELINE®; program up to four time

periods and temperatures. Fixed

anticipation except stage 2, which is

selectable. (Fig. 29).

Description Terminals Heat Cool

W,Y,G,R,O,

B,X2,T,F,U

W2,Y,G,R,

O,B,X,E,L

W2,Y,G,R,

C,O,B,E,X1,

X2,L

W2,Y,G,R,

C,O,B,E,X1,

X2,L

W2,W3,Y,Y2,

G,R,C,O,B,

E,X1,X2,L

W1,W2,Y1,

G,R,C,O,B,

E,L,P

W1,W2,Y,

G,R,C,L,

E,O,B

W1,W2,Y,

G,R,C,L,

E,O,B

R,C,Y1,W1,

W2,O/B,G,

E,L,OT,OT

R,C,Y1,W1,

W2,O/B,G,

E,L,OT,OT

R,C,Y1,Y2,

W2,W3,O/B,

G,E,L,OT,OT

R,C,G,W1,

W2,Y,O,

B,E,L

R,C,G,W1,

W2,Y,O,

B,E,L

Stages

Systems Led

Switch

2 1 EM.HT.-

HEAT-OFF-

COOL

AUX.HT.

2 1 EM.HT.-

HEAT-OFF-

COOL

2 1 EM.HT.-

HEAT-OFF-

AUTO-

COOL

2 1 EM.HT.-

HEAT-OFF-

AUTO-

COOL

3 2 EM.HT.-

HEAT-OFF-

AUTO-

COOL

2 1 EM.HT.-

HEAT-OFF-

COOL

2 1 EM.-HT.-

HEAT-OFF-

COOL

2 1 EM.-HT.-

HEAT-OFF-

COOL

2 1 EM.-HT.-

HEAT-OFF-

AUTO-

COOL

2 1 EM.-HT.-

HEAT-OFF-

AUTO-

COOL

3 2 EM.-HT.-

HEAT-OFF-

AUTO-

COOL

2 1 EM.-HT.-

HEAT-OFF-

COOL

2 1 EM.-HT.-

HEAT-OFF-

COOL

Changeover

Indication

Manual cool EM.HT.,

AUX.HT.

Manual cool EM.HT.,

AUX.HT.

Automatic

a

EM.HT.,

AUX. HT.,

CHECK

SYSTEM

Automatic

a

EM.HT.,

AUX.HT.,

CHECK

SYSTEM

Automatic

a

EM.HT.,

AUX.HT.,

CHECK

SYSTEM

Manual EM.HT.d,

AUX.HT.

SYSTEM

Manual None

Manual None

Automatic

Automatic

Automatic

a

a

a

CHECKc

CHECKc

CHECKc

Manual None

Manual None

(continued)

c

b

c

b

c

b

b

70-6627 • 3

Page 6

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Table 1. Model Number Specifications (continued).

Order

Number

T8611G2002 TRADELINE®; Full seven-day program

capability. Programmable fan and back

lighting features. (Fig. 31).

Description Terminals Heat Cool

Y1,W1,W2,

G,E,L,R,C,

O/B,X1,X2,

OT,OT

T8611G2028 Same as T8611G2002 except Premier

White™, 7-day program capability.

Programmable fan and back lighting

features. (Fig. 31).

T8611M2017 TRADELINE®; full 7-day program

capability. Programmable fan and back

lighting features.

Y1,W1,W2,

G,E,L,R,C,

O/B,X1,X2,

OT,OT

Y1,Y2/W2,

W3,G,E,L,

R,O/B,C,X1,

X2,OT,OT

T8611M2025 Same as T8611M2017 except Premier

White™, 7-day program capability.

Programmable fan and back lighting

features.

PC8900A1007/

W8900B1002

TRADELINE®; Perfect Climate Comfort

Center™ Control System. 7-day (auto

copy) programming.

Y1,Y2,W2,

W3,G,E,L,R,

O/B,C,X1,

X2,OT,OT

R,C,RH,Y1/

W1,G,O/B,

AUX,E,Y2,

W2,L

a

I

n freezing climates, be sure the cooling compressor has adequate cold start protection.

b

SYSTEM LED lights when heating or cooling equipment is running.

c

CHECK LED indicates compressor malfunction.

d

EM. HT. LED indicates compressor malfunction.

e

CHECK LED comes on when 24 Vac is applies to the L terminal.

f

FAIL LED come on when a complete cirucuit is made on the X1 and X2 terminals.

g

CHECK LED lights to alert homeowner to HVAC maintenance or service needs.

Stages

Systems Led

Switch

2 1 EM.HT.-

HEAT-OFF-

AUTO-

COOL

2 1 EM.HT.-

HEAT-OFF-

AUTO-

COOL

3 2 EM.HT.-

HEAT-OFF-

AUTO-

COOL

3 2 EM.HT.-

HEAT-OFF-

AUTO-

COOL

3 2 EM.HT.-

HEAT-OFF-

AUTO-

COOL

Changeover

Automatic

Automatic

Automatic

Automatic

Automatic

a

a

a

a

a

Indication

CHECK

f

FAIL

CHECK

f

FAIL

CHECK

f

FAIL

CHECK

f

FAIL

CHECK

SYSTEM

e

e

e

e

g

b

70-6627 • 4

Page 7

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Thermostat Descriptions and General Information

This section describes some of the heat pump thermostats that Honeywell manufactures. Since heat pumps require

thermostats with special features such as control of changeover valves, this section also explains some of the features

and requirements unique to heat pump thermostat applications.

Electromechanical Heat Pump Thermostats

T841 Heat Pump Thermostats

The T841 models control two-stage heat and one-stage cool in heat pump systems, using manual changeover. Heat

anticipators are either adjustable or fixed; cooling anticipator is fixed. T841A models include up to three LED indicator

lights; T841B models include up to two LED indicator lights. Provision for an outdoor reset to improve thermal

performance is also available on select models.

Y594 Combination Packs for Heat Pump Applications

The Y594 Packs combine the appropriate T874 Multistage Thermostat and the Q674 Subbase for specific heat pump

applications. Y594G models have automatic changeover; Y594R model has manual changeover. Heat anticipators are

either adjustable or fixed; cooling anticipator is fixed. Accessories include tamper-resistant cover and locking lever

assembly with thermometer, locking lever stops, outdoor thermistor, TG504 Key Lock® Cover, and the TG511

Versaguard™ Universal Thermostat Guard.

Outdoor Reset

Some heat pump thermostats apply outdoor reset to minimize the effect of the interstage differential. It takes more than a

one-degree change in temperature to initiate the second stage of heating. Added to a certain amount of droop under

high loads, there can be a fairly large offset between the setpoint temperature and the room temperature. To correct this

difference, an outdoor thermistor is used.

In warm weather, the outdoor thermistor has a very low resistance, permitting a large amount of current to flow in the

heater. This reduces the call for second stage heating.

In cool weather, the outdoor thermistor has a very high resistance, permitting a small amount of current to flow in the

heater. When this happens, calls for second stage heating are more frequent. This helps reduce the difference between

the setpoint temperature and the room temperature.

Select one of the following T841 or Y594 models if a thermostat with outdoor reset capability is required:

T841A1555

Y594G1161

Y594R1763

If an outdoor thermistor is not provided, use the Honeywell C815A Outdoor Thermistor, ordered separately.

NOTE: All Honeywell

electronic

heat pump thermostats are droopless controls and do not require the use of outdoor reset.

Electronic Non-programmable Heat Pump Thermostats

T8411 Electronic Heat Pump Thermostats

The T8411 models control two-stage heat and one-stage cool in heat pump systems, using manual changeover only.

First stage heat anticipation is fixed; second stage heat anticipation is selectable at 3, 6, or 9 cph. Setpoints are

permanently held in memory (no batteries required) and retained during power failures. Electronic thermostats provide

droopless temperature control.

70-6627 • 5

Page 8

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

T8511 Deluxe Electronic Heat Pump Thermostats

The T8511 models control two-stage heat and one-stage cool in heat pump systems, using manual or automatic

changeover. First stage heat anticipation is fixed; second stage heat anticipation is selectable at 3, 6, or 9 cph. Setpoints

are permanently held in memory (no batteries required) and retained during power failures. Electronic thermostats provide

droopless temperature control. The T8511 models also include a backlit display and outdoor sensing capability.

Electronic Programmable Heat Pump Thermostats

T8011 Standard Electronic Heat Pump Thermostats

The T8011 models provide two-stage heat and one-stage cool control for heat pump systems, using manual

changeover. First stage heat anticipation is fixed; second stage heat anticipation is selectable at 1, 3, 6, or 9 cph. The

user can program up to four time periods and temperature setpoints. All programs and setpoints are permanently held in

memory in the event of a power outage. Electronic thermostats provide droopless temperature control.

Chronotherm® III Electronic Heat Pump Thermostats

The T8611 Chronotherm III models provide up to three-stage heat and two-stage cool control for heat pump systems,

using manual or automatic changeover. Models are available with selectable daily schedules for weekdays, Saturday,

and Sunday; or full 7-day programming. Models include LED indication for system operation and status. Battery backup,

with low battery indication, maintains clock and memory during power outages. Adjustable second stage cycling allows

for use of the thermostat with electric heat or fossil fuel while providing optimum comfort.

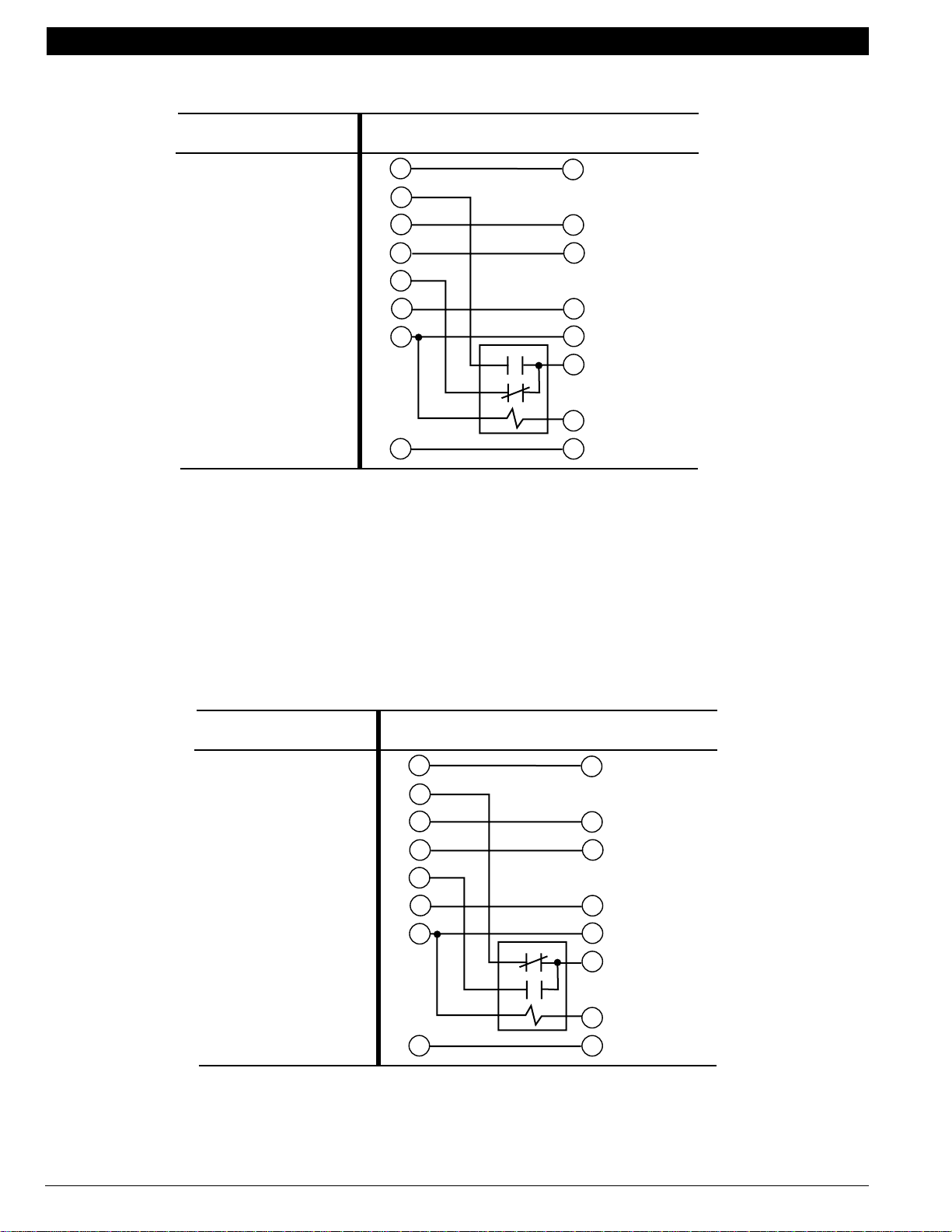

Using the Chronotherm III or Chronotherm IV T8611M on Two-Speed Heat Pump Compressor Equipment

The T8611M is a three-stage heat/two-stage cool thermostat used to control multistage heat pump equipment. However,

there is no difference in controlling multistage equipment and in controlling two-speed multistage equipment. The

differential required between stage 1 and stage 2 in multistage equipment is the same as the differential required

between low-speed and high-speed in two-speed equipment.

To connect the T8611M to two-speed heat pump equipment:

1. Connect the Y terminal to the low-speed compressor terminal.

2. Jumper the Y2 and W2 terminals.

3. Connect the Y2 terminal to the high-speed compressor terminal.

4. Connect all other terminals as shown in the wiring diagram below.

5. Configure the O/B terminal for changeover in either heating or cooling.

Equipment Function

Transformer Common

Power

Cooling Changeover

Heating Changeover

1st Stage Compressor

2nd Stage Compressor

Fan

a

a

Equipment

Terminals

C C

RR

GG

OO or

BB or

YY

Y2 Y2

T8611M

Terminals

O/B

O/B

a

W2

70-6627 • 6

Third Stage Heat

Emergency Heating

Fig. 1. Using the T8611M on two-speed heat pump compressor equipment.

a

On selected T8611M models, the high speed compressor is wired to the Y2 terminal. In these cases, no jumper is required.

W3 W3

EE

M13229

Page 9

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Chronotherm IV Electronic Deluxe Heat Pump Thermostats

The T8611 Chronotherm IV thermostat models provide up to three-stage heat and two-stage cool control for heat pump

systems, using manual or automatic changeover. These models provide full 7-day programming capability. Models with

programmable fan operation are available for homeowner comfort. Backlighting on the large display makes the LCD very

easy to read. Adaptive Intelligent Recovery™ control brings the room temperature to the desired temperature setpoint at the

programmed time, maximizing comfort and energy savings. First stage heat anticipation is fixed; second stage heat

anticipation is selectable.

Adaptive Intelligent Recovery™ Control (Night Setback and Heat Pumps)

Heat pump applications are ideal for night setback and energy savings. However, in order to maximize the energy saved

in a night setback mode, use the T8611 Chronotherm® III or T8611 Chronotherm® IV Thermostats with Adaptive

Intelligent Recovery™ control.

Adaptive Intelligent Recovery™ control assures that the comfort setting is achieved at the programmed time regardless

of weather conditions. Conventional recovery starts recovery at the beginning of the programmed time period and uses

the equipment to achieve the comfort settings as soon as possible.

Unlike the Chronotherm

mode in the Chronotherm IV thermostat. Honeywell does not recommend this because the auxiliary heat comes on

when the program time begins, and runs continuously until the setpoint is reached.

III models, the Adaptive Intelligent Recovery control can be turned off in the Installer Set-up

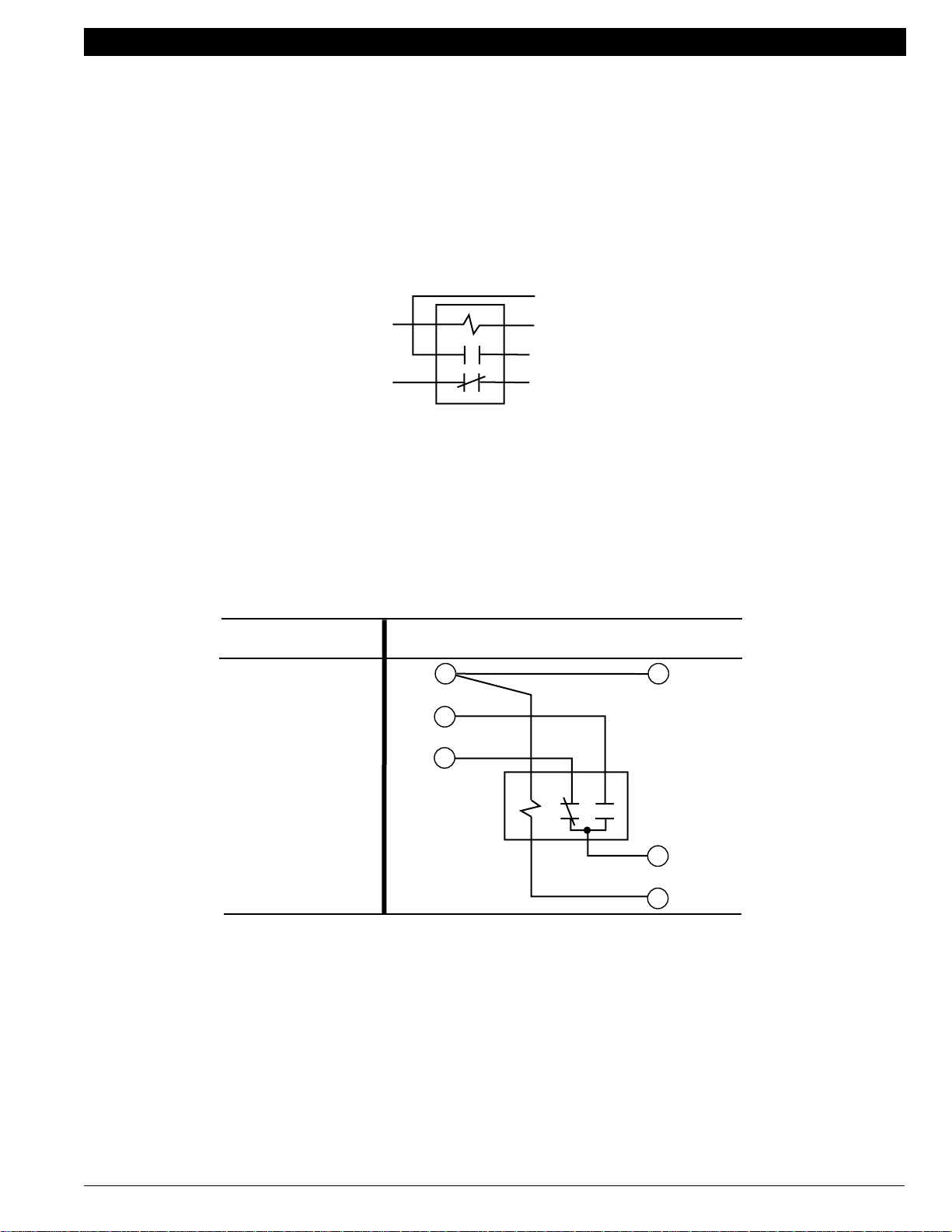

Applications Requiring Special System Hookups

Using a Chronotherm III T8611G or T8611M on Systems Requiring Separate W1 and Y

Terminals

The Chronotherm III T8611G and T8611M are designed with only one common compressor terminal. The Y terminal is

energized on a call for stage 1 heat and stage 1 cool. However, some multistage heat pump equipment requires one

terminal to be energized on a call for stage 1 heat (W

In order for the T8611G or T8611M to accommodate this requirement, a separate switching relay must be added to the

installation. See the following wiring diagrams for heat pumps that provide changeover in the heating mode and for heat

pumps that provide changeover in the cooling model.

Heat Pumps with Heating Mode Changeover

Here is how the switching relay allows the system to work properly:

* The Y terminal is connected to the equipment terminal W1 through the normally closed contacts on the R8222B

Switching Relay. When the thermostat calls for heat, the thermostat Y terminal activates the first stage of heating.

* The O terminal is connected to the coil terminals on the R8222B Switching Relay. When the system switch is in the

COOL position, the O terminal is energized, reversing the logic of the Chronotherm III T8611G and T8611M Y

terminal. Now when the thermostat calls for cooling, the Y terminal activates the first stage of cooling.

) and one terminal to be energized on a call for stage 1 cool (Y1).

1

1

70-6627 • 7

Page 10

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Fan

Equipment

Terminals

RR

Y1

Y2 Y2

GG

W1

W2 W2

CC

BB

Equipment Function

Power

1st Stage Cool

2nd Stage Cool

1st Stage Heat

2nd Stage Heat

Transformer Common

Heating Changeover

Fig. 2. Installing an R8222B Switching Relay on heat pumps requiring heating mode changeover.

Heat Pumps with Cooling Mode Changeover

Here is how the switching relay allows the system to work properly:

* The Y terminal is connected to the equipment terminal Y1 through the normally closed contacts on the R8222B

Switching Relay. When the thermostat calls for cooling, the thermostat Y terminal activates the first stage of cooling.

T8611M

Terminals

Y

O

R8222B Relay

M13231

* The B terminal is connected to the coil terminals of the R8222B Switching Relay. When the system switch is in the

HEAT position, the B terminal is energized, reversing the logic of the Chronotherm® III T8611G and T8611M Y

terminal. Now when the thermostat calls for heating, the Y terminal activates the first stage of heating.

Equipment Function

Power

1st Stage Cool

2nd Stage Cool

Fan

1st Stage Heat

2nd Stage Heat

Transformer Common

Cooling Changeover

Equipment

Terminals

RR

Y1

Y2 Y2

GG

W1

W2 W2

CC

OO

R8222B Relay

T8611M

Terminals

Y

B

M13230

70-6627 • 8

Fig. 3. Installing an R8222B Switching Relay on heat pumps requiring cooling mode changeover.

Page 11

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Changing Fan Operation in Emergency Heat Mode for Electronic Thermostats

In the emergency heat mode (system switch in EM. HT. position), the thermostat controls the fan operation with a call for

first stage heat. This means that when the thermostat calls for heat, the thermostat also calls for fan operation. However,

this fan operation is not desirable on some types of systems.

To change the fan operation on the TRADELINE and SUPER TRADELINE models, follow the wiring diagram shown

below. Connecting the thermostat and relay to the equipment in this manner disables the fan switch in the emergency

heat mode. During normal operation, the fan switch is enabled and the fan operation is as described in the installation

instructions.

R (Power)

E C (Common)

E (EM. Heat)

G G (Fan)

Thermostat

Fig. 4 Changing fan operation in emergency heat mode for electronic thermostats.

R8222B Relay

Equipment

M13232

Heat Pump Manufacturer Relay Wiring Connections

The wiring connections for some thermostats to specific types of heat pump equipment require a separate relay for

proper operation. Refer to Fig. 5 through 13 for the wiring connections of these types of equipment.

Equipment Function

Transformer Common

1st Stage Cooling

1st Stage Heating

Existing Control

Terminal Designation

CC

Y1

W1

New T erminal

Designation

Y

O

M13235

Fig. 5. Relay wiring connections for Carrier equipment (typical 38BQ), and T8511M, T8611M,

PC8900/W8900B1002. Require relay (R8222B1067 typically) for proper operation.

70-6627 • 9

Page 12

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Equipment Function

Common

Power

Existing Control

Terminal Designation

Black

Red

New T erminal

Designation

C

R

Emergency Heat

AL

E

M13241

Fig. 6. Relay wiring connections for Evcon/Coleman equipment (3200, 3300). Requires R8222B1067

Relay to operate system. Equipment requires normally energized emergency heat.

Equipment Function

Common

Existing Control

Terminal Designation

Black

New T erminal

Designation

C or X

Power

Emergency Heat

Red

A

R

E

M13236

Fig. 7. Relay wiring connections for Evcon/Coleman equipment (3200, 3300, 3360, 3400, 6000, and 6500).

Requires R8222B1067 Relay to operate system. Equipment requires normally energized emergency heat.

Equipment Function

Indoor Power

System Monitor

Existing Control

Terminal Designation

VR

L

New T erminal

Designation

R

or

X1

L

M13237

Fig. 8. Relay wiring connections for Lennox equipment (HP9, HP10). Requires R8222B1067 Relay to operate the

system monitor light (emergency heat LED) on TRADELINE replacement thermostats. Tape off if light is not desired.

70-6627 • 10

Page 13

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Equipment Function

Power

System Monitor

Existing Control

Terminal Designation

VR

L

New T erminal

Designation

R

or

or

X1

L

F

M13238

Fig. 9. Relay wiring connections for Lennox equipment (HP16, HP19, HP21, HP22 Direct Replacements).

Requires R8222B1067 Relay to operate the system monitor light (emergency heat LED) on

TRADELINE replacement thermostats. Tape off if light is not desired.

Equipment Function

Power

System Monitor

Existing Control

Terminal Designation

RR

X1

New T erminal

Designation

or

L

X1

M13239

Fig. 10. Relay wiring connections for Magic Chef equipment (PE Series). Requires R8222B1067 Relay

if outdoor section has reset shunt relay and malfunction light indicator is desired on thermostat.

Equipment Function

Power

System Monitor

Existing Control

Terminal Designation

R1

or R R

L or X

New T erminal

Designation

or

X1

L

M13240

Fig. 11. Relay wiring connections for Mammoth. Requires R8222B1067 Relay if outdoor

section has reset shunt relay and malfunction light indicator is desired on thermostat.

70-6627 • 11

Page 14

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Equipment Function

Transformer Common

Power

Fan

Equipment

Terminals

CC

RR

GG

PC8900

Terminals

O/B

1st Stage Heating

1st Stage Cooling

Changeover V alv e

2nd Stage Heating

Emergency Heat

2nd Stage Cooling

W1 Y1/W1

Y1

B

W2 Aux.

EE

Y2 Y2

M13233

Fig. 12. Relay wiring connections for PC8900 in heat pump applications

requiring separate Y

Equipment Function

Transformer Common

and W1 terminals with a heating changeover.

1

Equipment

Terminals

PC8900

Terminals

CC

Power

Fan

RR

GG

O/B

1st Stage Cooling

1st Stage Heating

Changeover V alv e

2nd Stage Heating

Emergency Heat

2nd Stage Cooling

Y1 Y1/W1

W1

O

W2 Aux.

EE

Y2 Y2

Fig. 13. Relay wiring connections for PC8900 in heat pump applications

requiring separate Y1 and W1 terminals with a cooling changeover.

M13234

70-6627 • 12

Page 15

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Understanding Circuits

To understand wiring diagrams, it is important to know what all the symbols mean and how to trace the path of the

circuits from the transformer. Circuit descriptions and terminology are defined as follows:

Auto changeover—refers to the presence of an AUTO position in the system switching (EX: Q674F with OFF-COOL

AUTO-HEAT-EM. HEAT switching). The thermostat automatically changes between heat and cool modes as

indoor temperature changes.

Manual changeover—requires a system switch movement to change mode (EX: Q674L with EM. HT.-HEAT-OFF-

COOL switching).

Cool changeover valve—operates on cooling. The reversing valve or relay is activated either by moving the system

switch to COOL (manual changeover) or by a mercury switch that makes on a temperature rise (auto changeover).

Heat changeover valve—operates on heating. The reversing valve or relay is activated either by moving the system

switch to HEAT (manual changeover) or by a mercury switch that makes on a temperature fall (auto changeover).

System monitor relay—optional equipment on some heat pumps. This system monitor relay detects a malfunction in

the compressor and indicates the malfunction by activating the EMERGENCY HEAT LED on the switching

subbase. The system monitor relay may be wired to the L terminal on some thermostats

Each mercury switch is identified by function:

H1—Stage 1 Heating.

H2—Stage 2 Heating.

H3—Stage 3 Heating.

C1—Stage 1 Cooling.

C2—Stage 2 Cooling.

C3—Stage 3 Cooling.

C/O—Changeover (heat pumps).

Each anticipator is identified and each switch affected is named (EX: H1 anticipator, C1 anticipator).

All T874 Multistage Thermostats use mercury switches. Each schematic indicates switch operation by being drawn

in the open position with an arrow indicating operation with a temperature RISE or FALL.

KEY TO HOOKUP SYMBOLS

TRANSFORMER

(24 VAC SECONDARY)

RELAY OR CONTACTOR COIL

MERCURY SWITCH

FIXED ANTICIPATOR

HIGH RESISTANCE

(TYPICALLY 5 KILOHMS)

ADJUSTABLE ANTICIPATOR

LOW RESISTANCE

(TYPICALLY 0 TO 5 OHMS)

RELAY/CONTACTOR CONTACTS

B

TERMINAL

LED

ODT

OUTDOOR THERMOSTAT

EHR

EMERGENCY HEAT RELAY

RTD

TIME DELAY RELAY

RD

DEFROST RELAY

CHP

PRESSURE SWITCH

LACO

LOW AMBIENT CUTOFF

M5848

Fig. 14. Key to hookup symbols.

70-6627 • 13

Page 16

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

NEMA Standard Transformers Give You Better Control

UL sets the safety standards all transformers must meet. But these are minimum standards. The Honeywell AT20A,

AT40A, AT72D and AT87A Transformers do even more; they meet tough voluntary standards of the National Electrical

Manufacturer’s Association (NEMA).

Why is this so important? Because today’s sophisticated control systems require reliable, accurate voltage output for

optimal system performance. It’s especially important for electrical controls (OEM boards in high efficiency furnaces, for

example) or resistive heaters, such as thermostat heat anticipators.

For better performance, some heat pumps require a NEMA standard transformer. Conformance to NEMA standards

assures the voltage output of a transformer will remain within acceptable limits, regardless of load conditions. No

excessively high open-circuit voltage under light load conditions. No low, “brown-out” voltage levels under heavy load

conditions. At 100% load, the transformer secondary must supply between 23 and 25 volts to meet the NEMA standard.

How can you tell that the transformers you buy meet this tough, high standard? Look for the transformer to be marked:

NEMA Type B (20VA), NEMA Type D (40VA), NEMA Type E (48-50 VA). Only transformers conforming to the NEMA

standard can be marked in this way. The following are recommended Honeywell NEMA standard transformers:

AT72D1691, AT72D1683, AT87A1106

27

26

25

24

23

22

21

20

19

18

SECONDARY VOLTAGE

17

16

15

14

0 50 100 150

% OF LOAD

200

M993

Fig. 15. NEMA Class 2 transformer band.

70-6627 • 14

Page 17

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

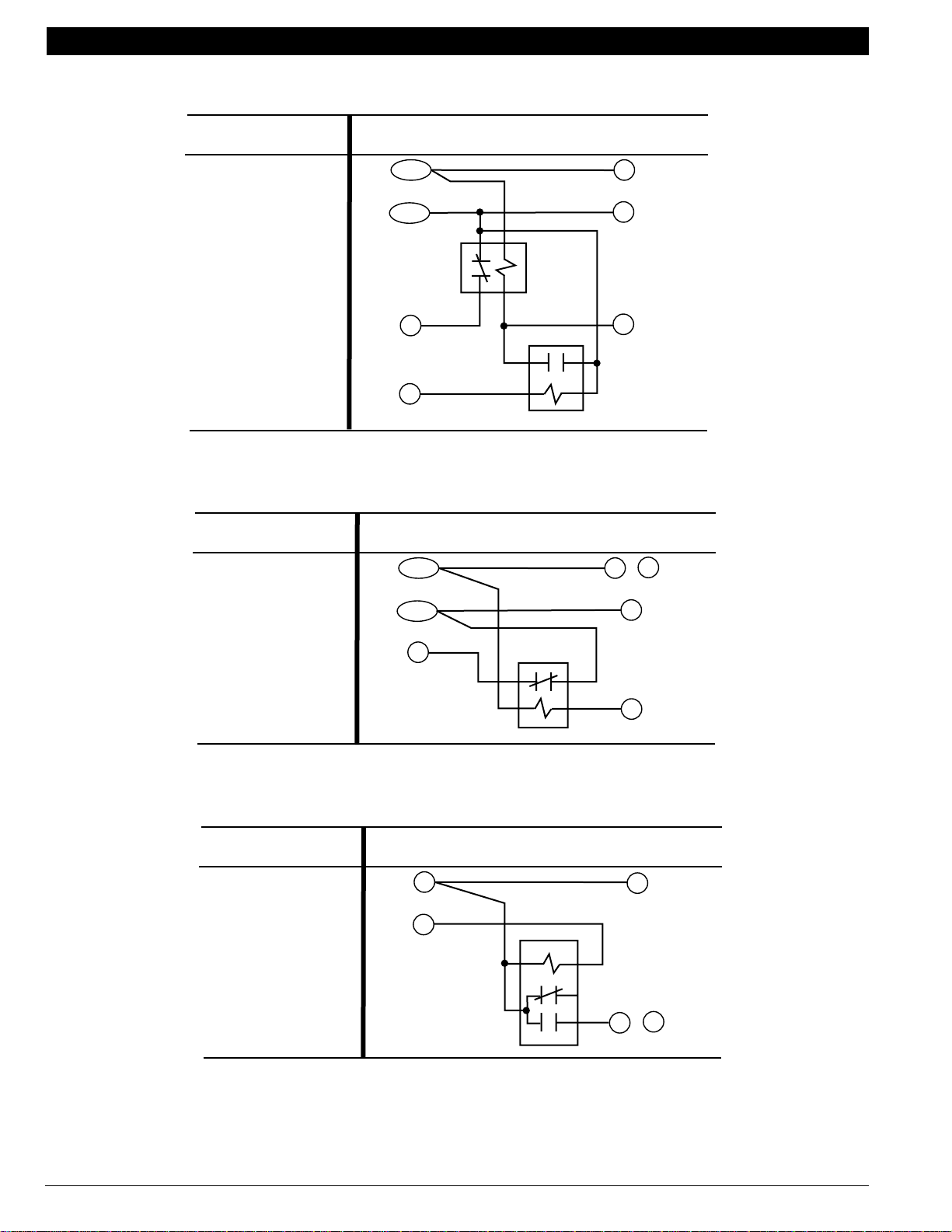

Typical System Hookup Diagrams

L1

(HOT)

L2

2

EM. HT.

HEAT

COOL

SYSTEM

SWITCH

FAN

SWITCH

AUTO

OFF

H1

H2

C1

FALL

H1/C1

ANTICIPATOR

H2 ANTICIPATOR

FALL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

NO AUTO FAN IN EMERGENCY HEAT.

2

ON

G

R

W2

AUX. HT.

LED (GREEN)

E

L

EM. HT.

LED (RED)

B

X

Y

O

RTD 1

LACO CHP

COOL CHANGEOVER VALVE

ODT 1

EHR 1

ODT 2

EHR 2

RD

SYSTEM MONITOR

HEAT CHANGEOVER VALVE

COMPRESSOR

CONTACTOR

1

RTD 2

RTD 3

FAN RELAY

RTD 1

EM. HT. RELAY

M6060A

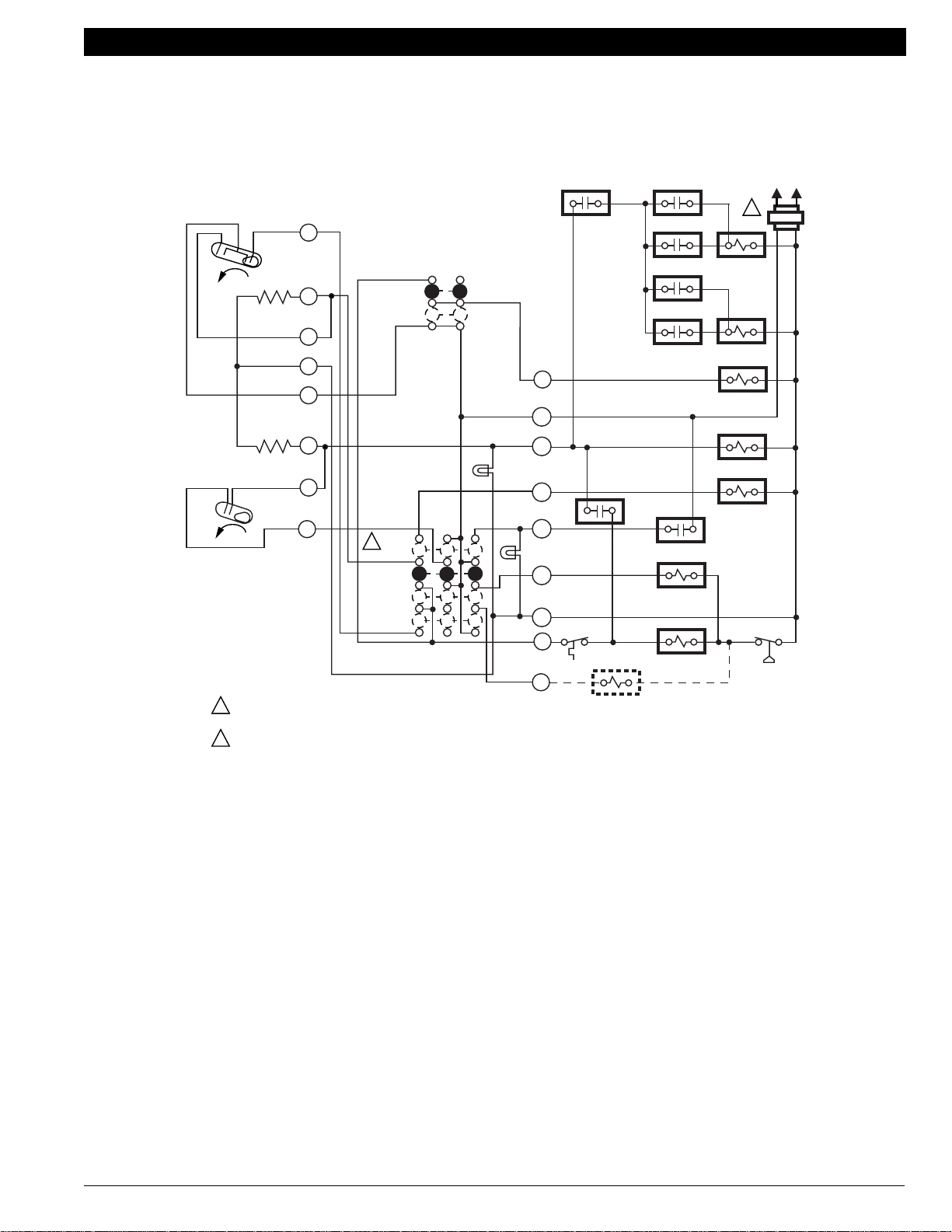

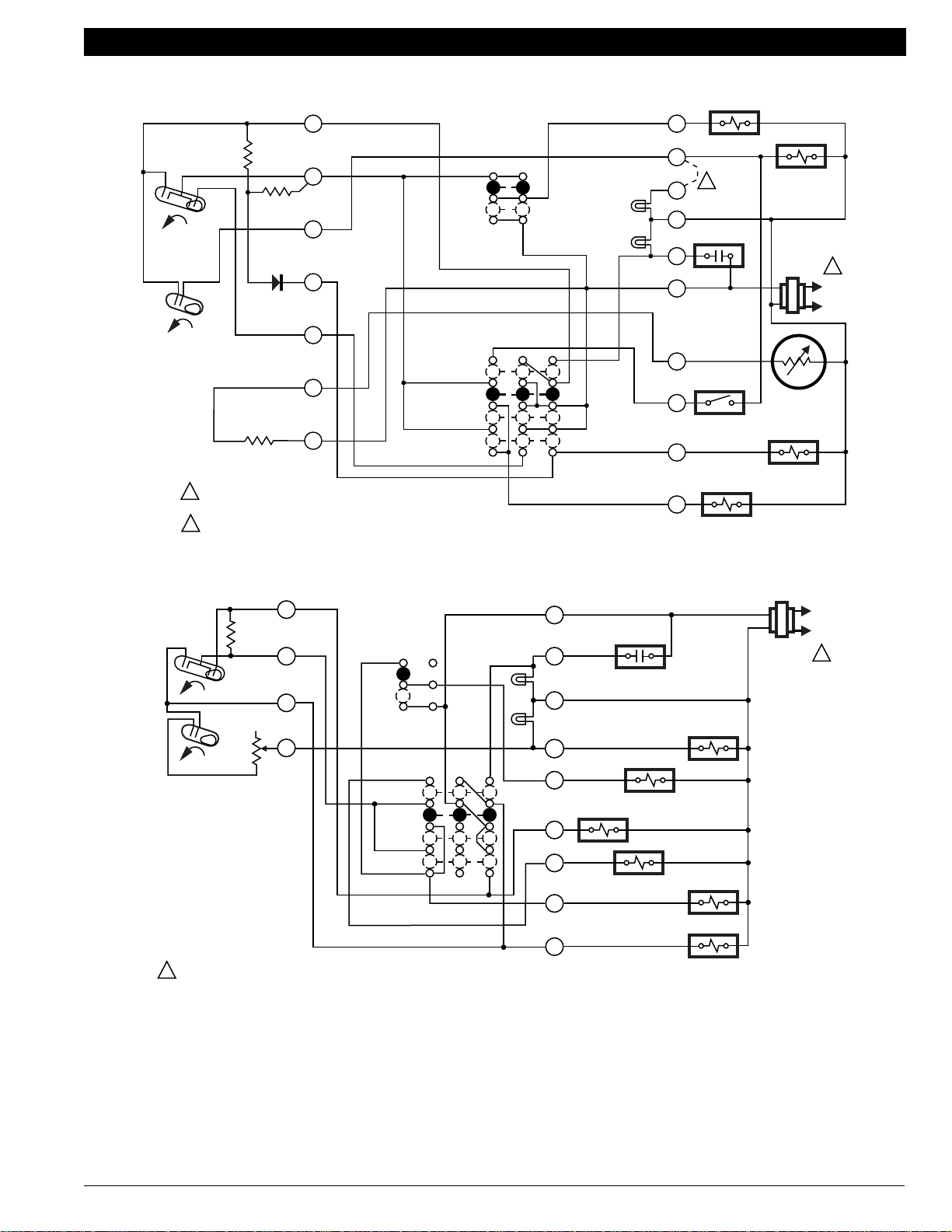

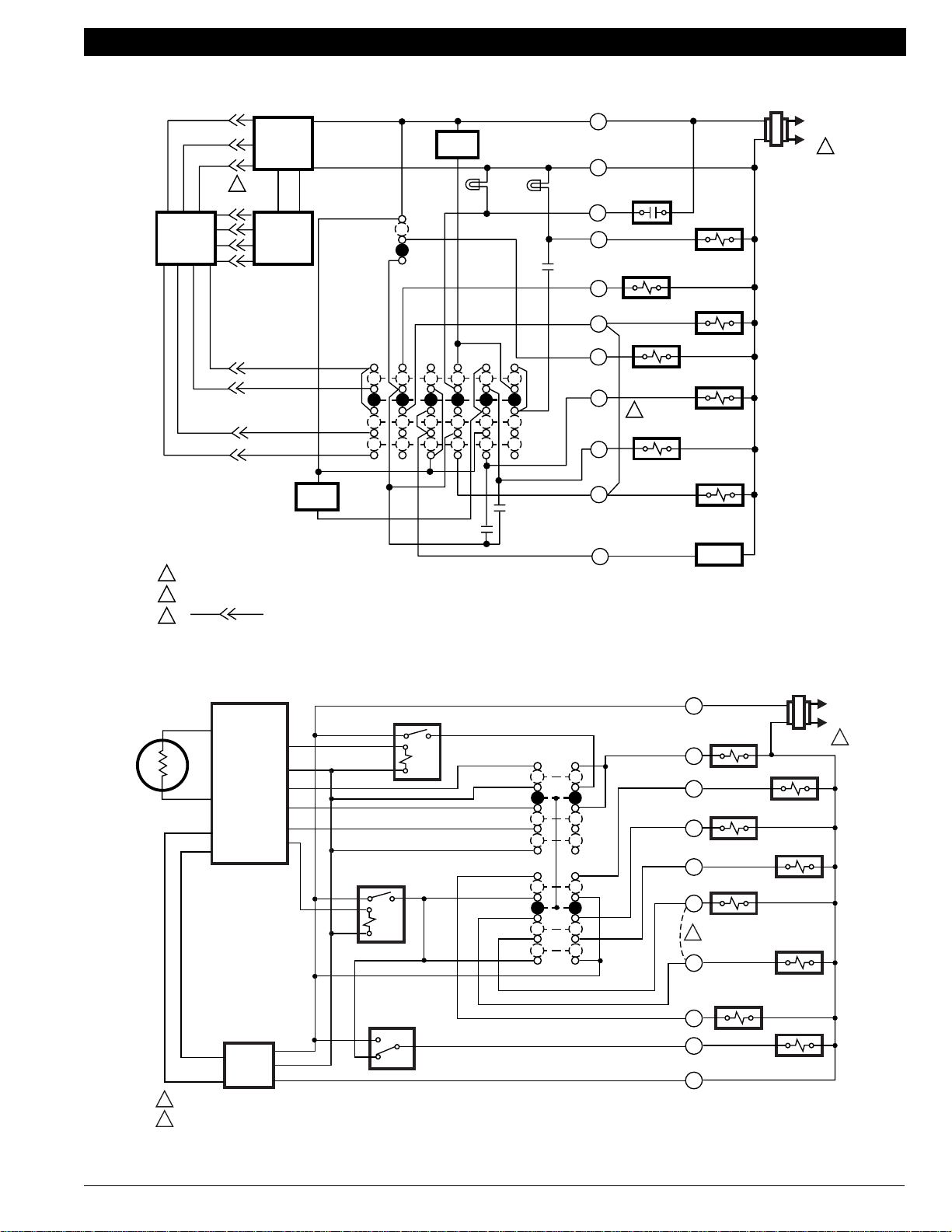

Fig. 16. Internal schematic and typical wiring diagram for T841A1308.

70-6627 • 15

Page 18

HEAT PUMP TH ERMOSTAT CROSS REFERENCE/SELECTION GUIDE

9

H1

C1

FALL

C

ANTICIPATOR

H1/C

ANTICIPATOR

H2

FALL

RESET

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

FIELD REMOVABLE JUMPER.

AUTO FAN IN EMERGENCY HEAT.

3

2

3

5

8

11

12

10

1

4

Fig. 17. Internal schematic and typical wiring diagram for T841A1555.

FAN

SWITCH

AUTO

ON

SYSTEM SWITCH

3

EM. HT.

HEAT

OFF

COOL

AUX. HEAT

LED (GREEN)

EM. HEAT

LED (RED)

G

FAN RELAY

W

2

U

B

F

COMPRESSOR

MONITOR

R

OUTDOOR

THERMOSTAT

X2

T

O

COOL CHANGEOVER

RELAY

Y

AUX. HEAT

RELAY

OUTDOOR

THERMISTOR

COMPRESSOR

CONTACTOR

M8728

L1

(HOT)

L2

1

FALL

H1

C1

10

5

H1

ANTICIPATOR

C1

ANTICIPATOR

7

8

2

3

9

6

12

H2

ANTICIPATOR

H2

FALL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

11

FAN

SWITCH

AUTO

ON

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

EM. HEAT

LED (RED)

AUX. HEAT

LED (GRN)

W3

O

G

R

E

X

W2

B

Y

COOL

CHANGEOVER

RELAY

FAN RELAY

EM. HEAT RELAY

HEAT

CHANGEOVER

RELAY

W3 RELAY

AUX. HEAT RELAY

COMPRESSOR

CONTACTOR

M13249

L2

L1

(HOT)

1

70-6627 • 16

Fig. 18. Internal schematic and typical wiring diagram for T841A1712 and T841A1738.

Page 19

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

H1/C1

ANTICIPATOR

H1

1

C1

FALL

FAN SWITCH

AUTO

ON

SYSTEM

SWITCH

H2 ANTICIPATOR

H2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

FALL

HEAT

OFF

COOL

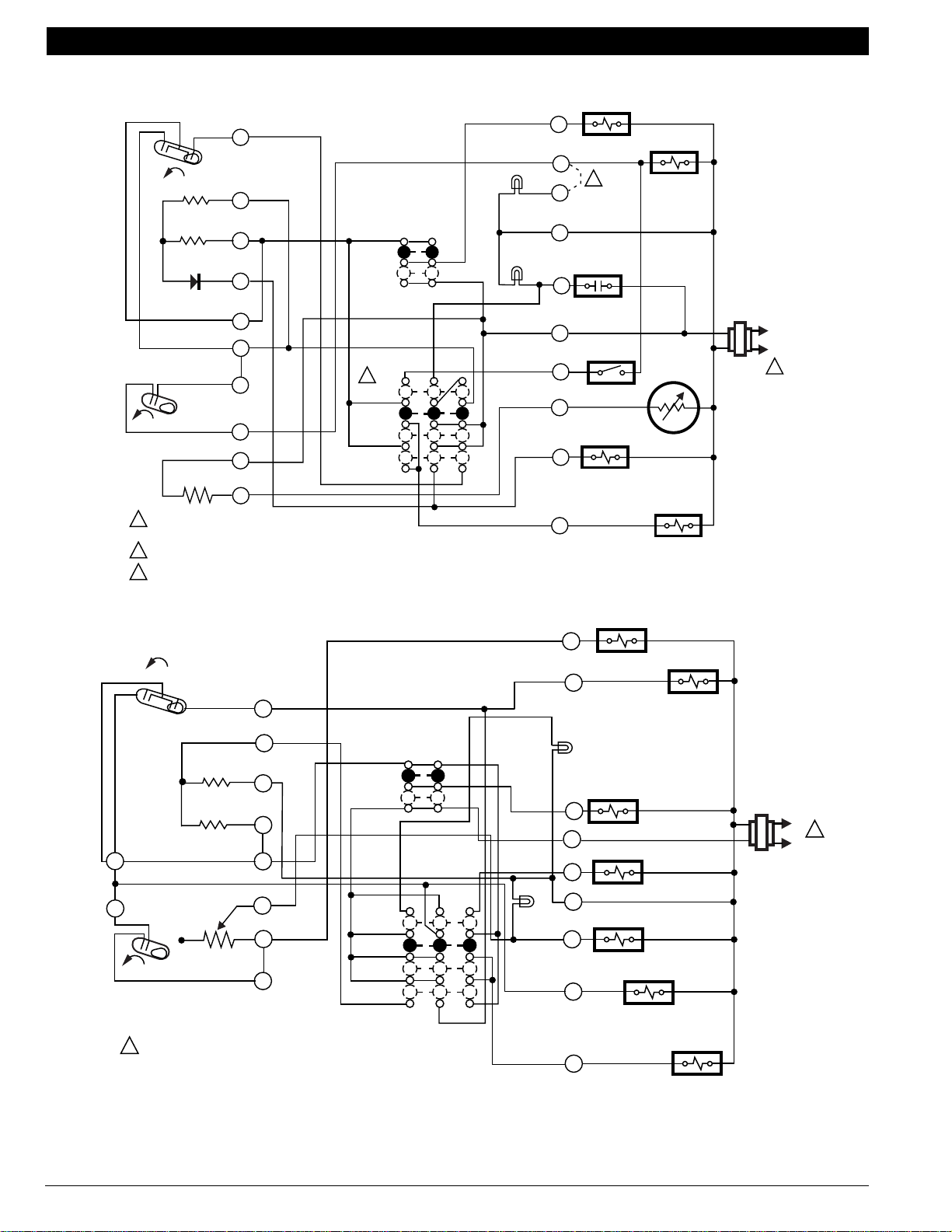

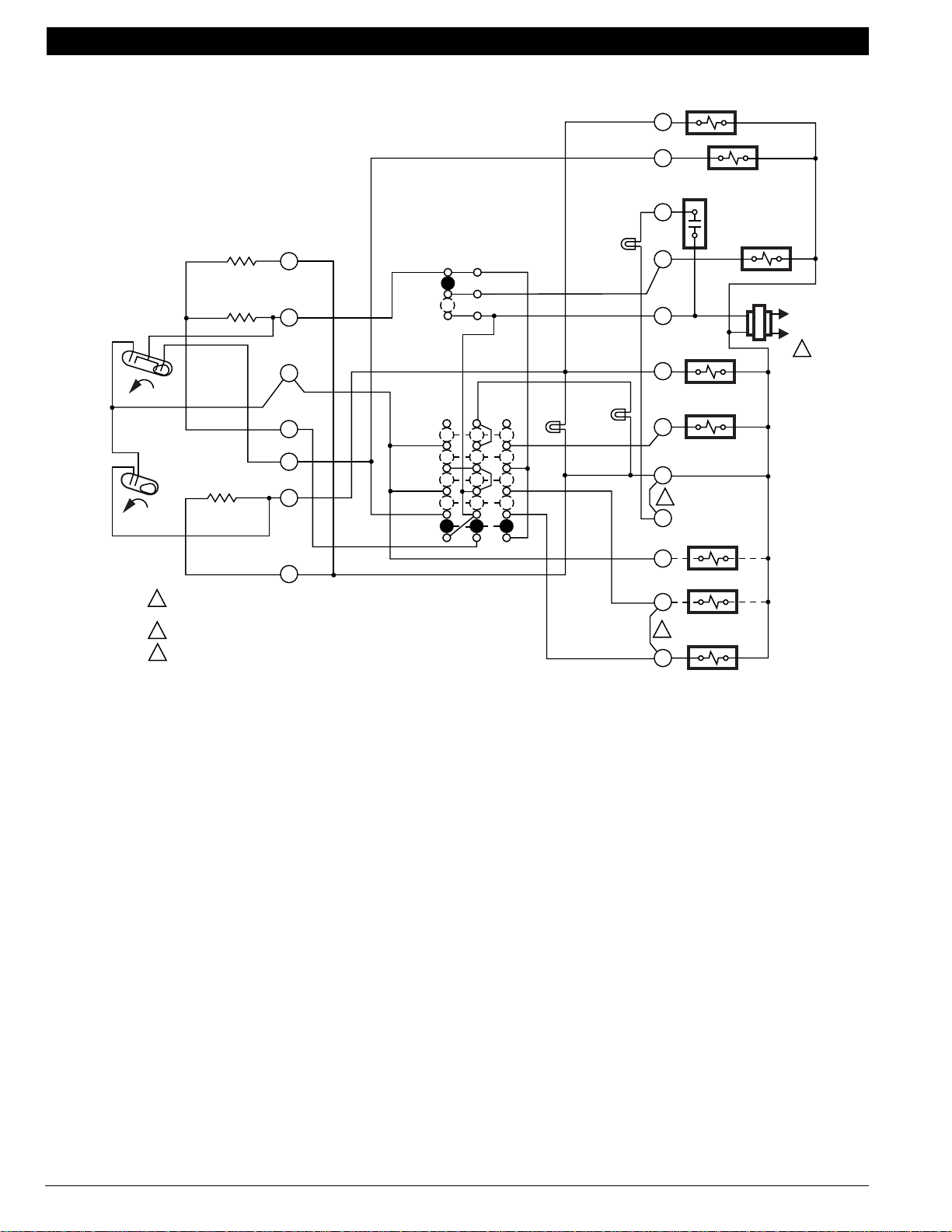

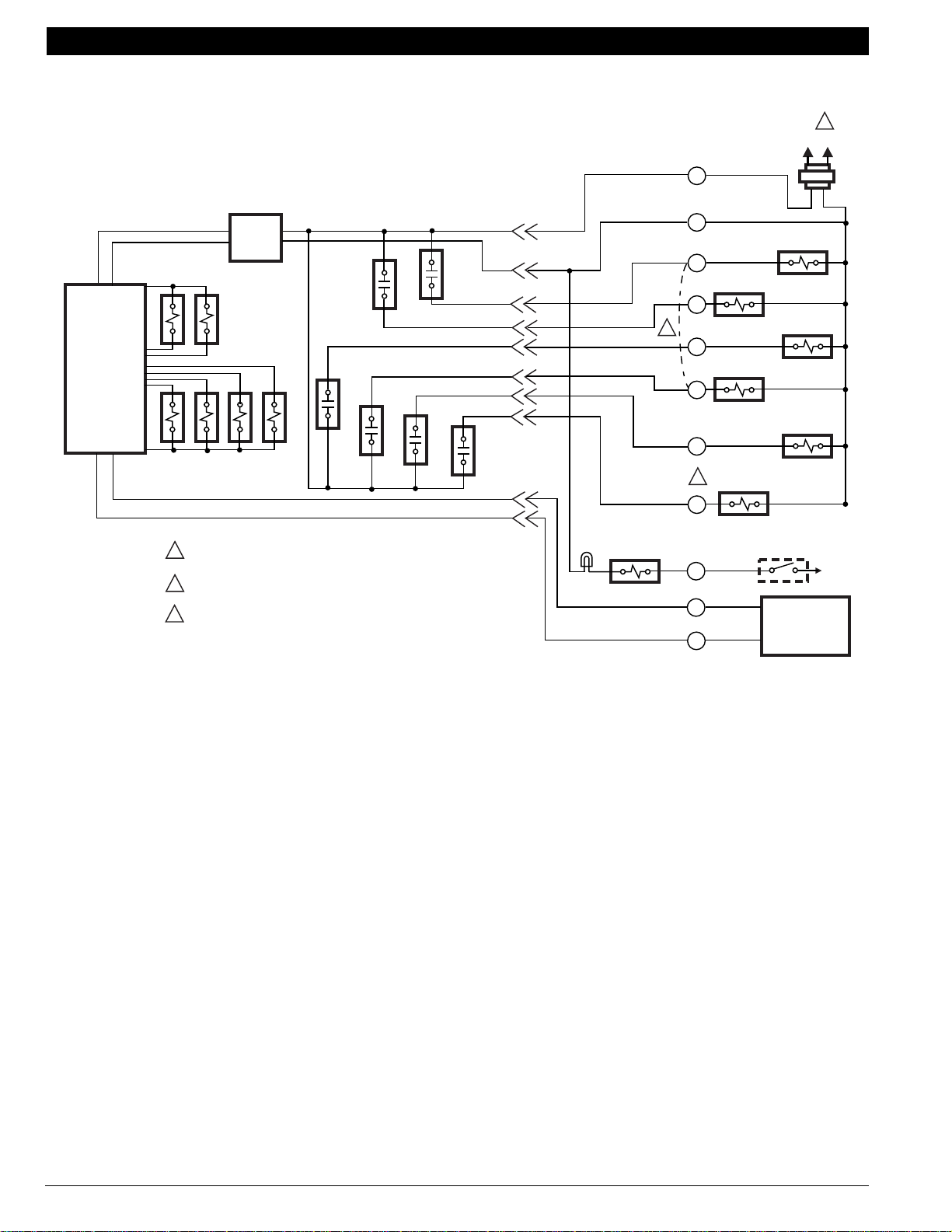

Fig. 19. Internal schematic and typical wiring diagram for T841B1000.

W1

HEAT RELAY 1

W2

HEAT RELAY 2

B

HEAT CHANGEOVER

VALVE

G

FAN RELAY

R

X

Y1

COMPRESSOR

CONTACTOR

O

COOL CHANGEOVER VALVE

M6068A

L1

(HOT)

L2

1

H2

FALL

CHANGEOVER

FALL

H1

H1 ANTICIPATOR

RISE

C1

RESET

HEATER

C1

ANTICIPATOR

RISE

FAN

SWITCH

AUTO

ON

SYSTEM

SWITCH

EM .HT.

AUTO

OFF

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

T

G

O

R

X2

W

AUX. HT.

LED (GREEN)

B

EM. HT.

LED (RED)

F

Y

OUTDOOR

THERMOSTAT

CHANGEOVER

VALVE

C815A OUTDOOR

THERMISTOR

FAN RELAY

AUX. HT.

RELAY

L1

(HOT)

L2

M1593

1

Fig. 20. Internal schematic and typical wiring diagram for Y594G1161.

70-6627 • 17

Page 20

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

FALL

H1

CO

H1

RISE

H1 ANTICIPATOR

H2

ANTICIPATOR

FALL

H2

RISE

C1

C1 ANTICIPATOR

RISE

1

2

4

6

8

9

10

11

12

FAN SWITCH

AUTO

ON

SYSTEM

SWITCH

OFF

EM. HT.

HEAT

AUTO

COOL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

Fig. 21. Internal schematic and typical wiring diagram for Y594G1633.

1

CHANGEOVER

(HEAT)

FALL

FALL

FALL

CHANGEOVER

(COOL)

C1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

W1 - Y1 JUMPER IS Y TERMINAL; REMOVE JUMPER WHEN W1 RELAY IS USED.

H2

H2 ANTICIPATOR

RISE

C1

ANTICIPATOR

H1

ANTICIPATOR

2

3

4

5

6

8

9

10

11

FAN

SWITCH

AUTO

ON

SYSTEM

SWITCH

OFF

EM. HT.

HEAT

AUTO

COOL

O

G

B

R

E

L

EM. HT.

LED (RED)

X

AUX. HEAT

LED (GREEN)

W2

Y

AUX.

HT. LED

(GREEN)

EM. HT.

LED (RED)

COOL CHANGEOVER

VALVE

B RELAY

EM. HT. RELAY

AUX. HEAT RELAY

W3

G

FAN RELAY

R

W2

EM. HT.

RELAY

E

X1

CHECK

LED (RED)

X2

X

O

B

W1

2

Y1

COMPRESSOR

FAULT

COOL CHANGEOVER

VALVE

W1 RELAY

COMPRESSOR

CONTACTOR

FAN RELAY

COMPRESSOR

CONTACTOR

M8702

W3 RELAY

AUX. HEAT

RELAY

HEAT CHANGEOVER

VALVE

1

L2

L1

(HOT)

1

L1

(HOT)

L2

M8703

70-6627 • 18

Fig. 22. Internal schematic and typical wiring diagram for Y594G1419 and Y594G1476.

Page 21

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

1

2

H1

C1

FALL

H2

FALL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

FIELD REMOVABLE JUMPER.

2

3

4

5

6

11

AUTO

ON

SYSTEM

SWITCH

EM. HEAT

HEAT

OFF

COOL

FAN

SWITCH

AUX. HEAT

LED (GREEN)

EM. HEAT

LED (RED)

G

FAN RELAY

W

2

U

B

COMPRESSOR

MONITOR

F

R

T

X2

OUTDOOR

THERMOSTAT

O

COMPRESSOR

CONTACTOR

Y

AUX. HEATER

RELAY

OUTDOOR

SENSOR

COOL

CHANGEOVER

VALVE

M8701

1

L1

(HOT)

L2

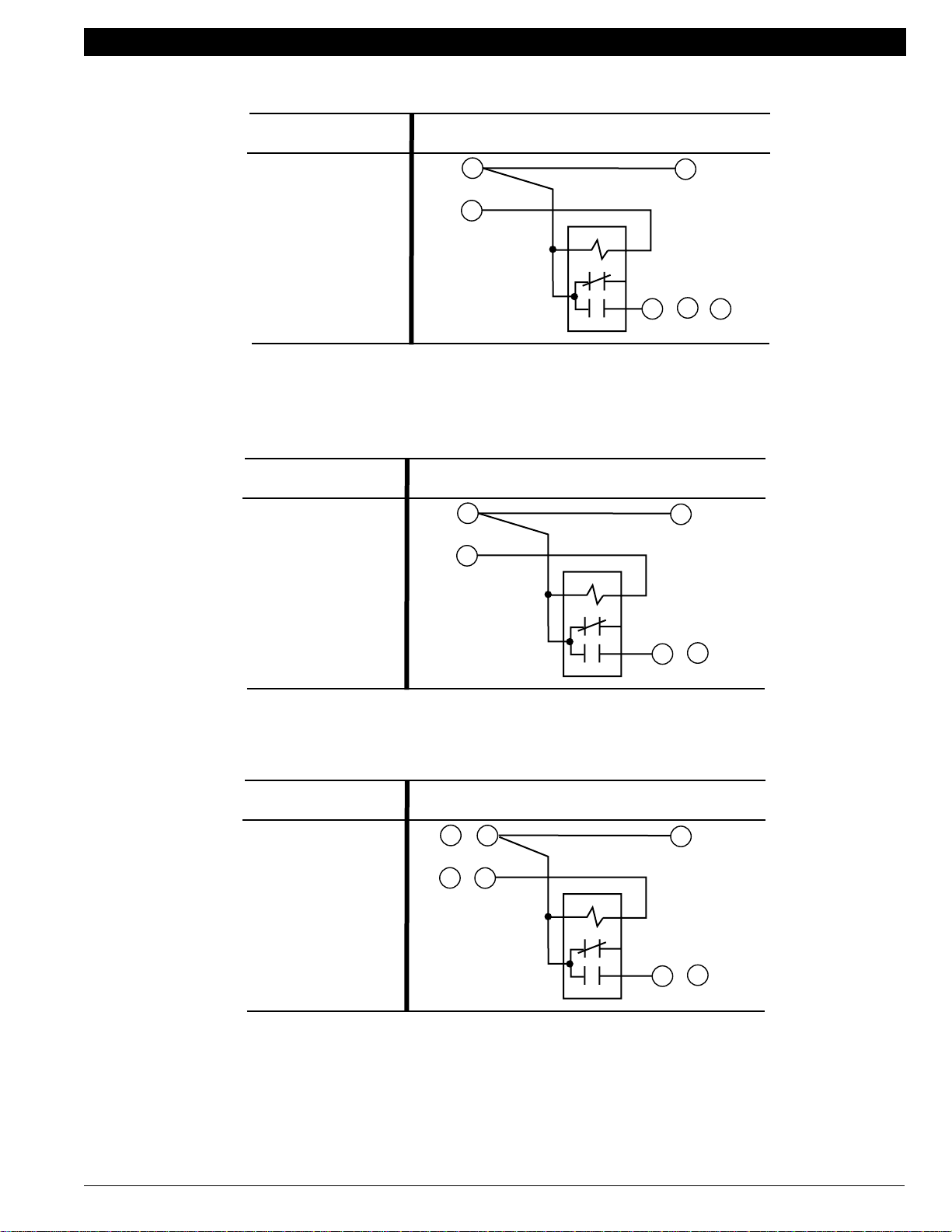

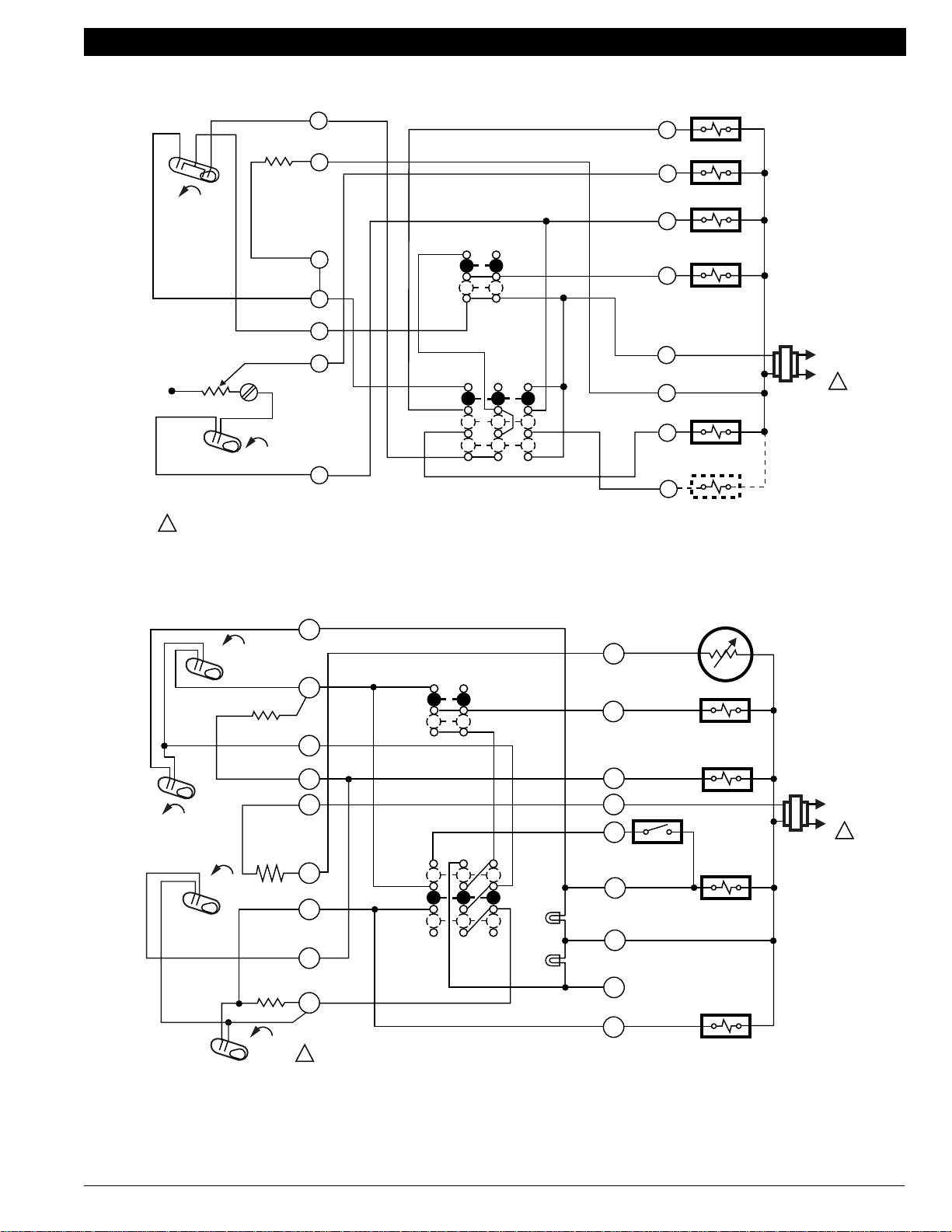

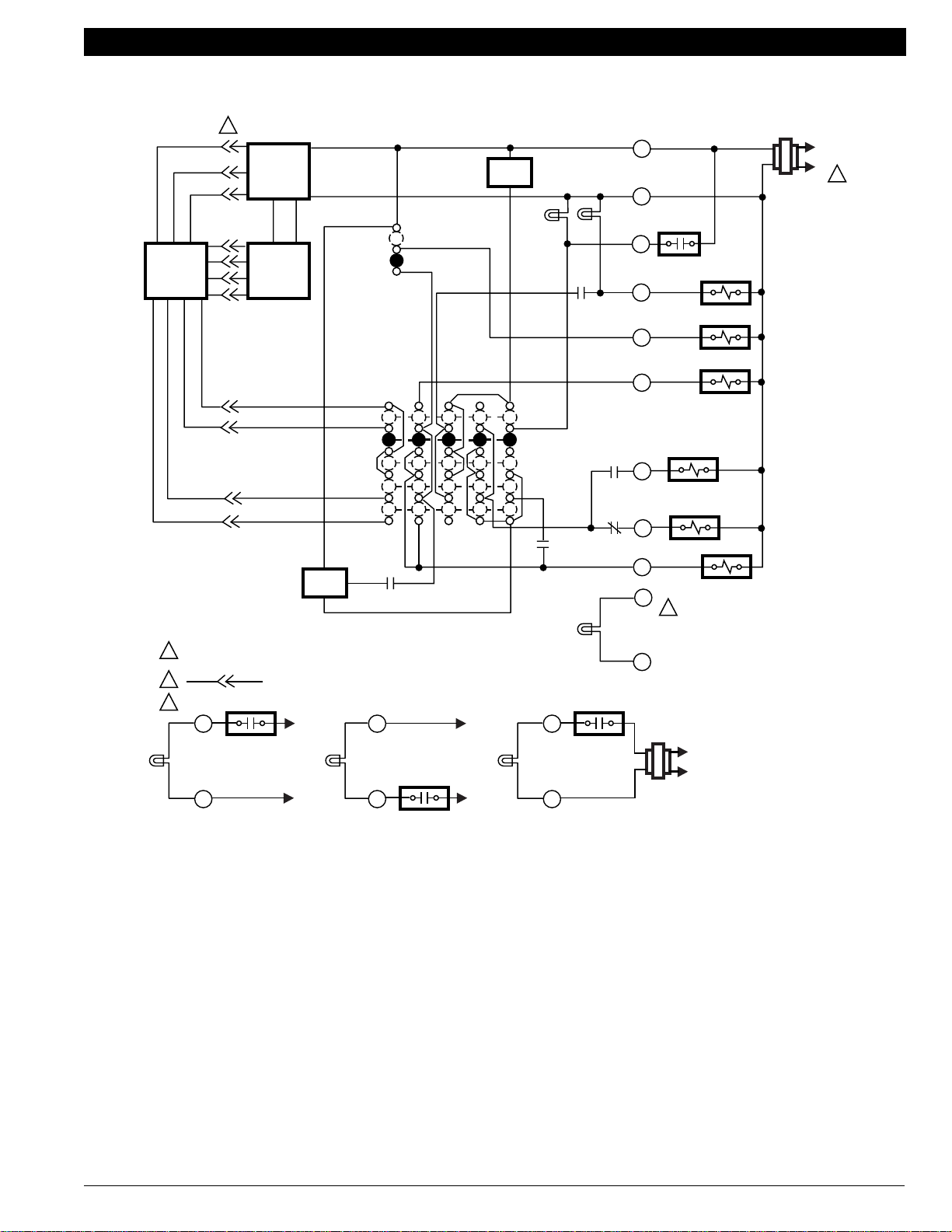

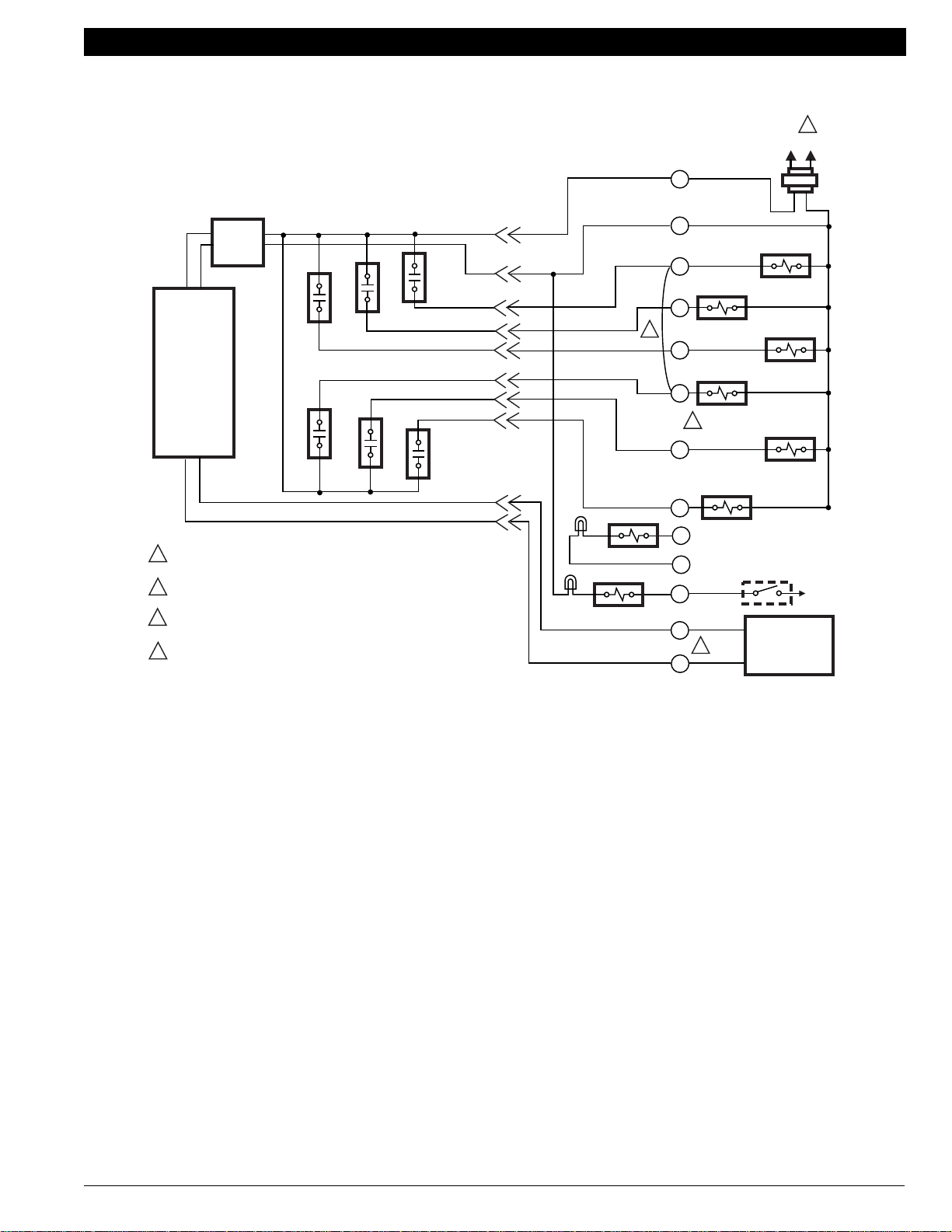

Fig. 23. Internal schematic and typical wiring diagram for Y594R1763.

2

H1 AND C1

ANTICIPATOR

3

H1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

FALL

FALL

C1

H2

ANTICIPATOR

H2

4

6

FAN

SWITCH

AUTO

ON

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

R

L

EM. HEAT

LED (RED)

X

AUX. HEAT

LED (GRN)

W2

G

O

E

Y

B

Fig. 24. Internal schematic and typical wiring diagram for Y594R1797.

FAN RELAY

COOL

CHANGEOVER

VALVE

EM. HEAT

RELAY

AUX. HEAT

RELAY

COMPRESSOR

CONTACTOR

"B" RELAY

M8700

L1

(HOT)

L2

1

70-6627 • 19

Page 22

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

H1

H1

ANTICIPATOR

C ANTICIPATOR

C

FALL

H2

ANTICIPATOR

H2

FALL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

REMOVE JUMPER WHEN W1 RELAY IS USED.

3

FACTORY-INSTALLED JUMPER.

1

2

3

4

5

6

11

FAN

SWITCH

AUTO

ON

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

EM. HT.

LED (RED)

AUX. HT.

LED (GRN)

W3

O

L

G

R

W2

AUX. HT. RELAY

E

EM. HT. RELAY

X

3

HEAT

X2

CHANGEOVER

VALVE

B

W1 RELAY

W1

COMPRESSOR

2

CONTACTOR

Y

W3 RELAY

COOL CHANGEOVER

VALVE

COMPRESSOR

MONITOR

FAN RELAY

M8713

L1

(HOT)

L2

1

Fig. 25. Internal schematic and typical wiring diagram for Y594R1425.

70-6627 • 20

Page 23

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

2

L1

(HOT)

L2

POWER

SUPPLY

FAN

SWITCH

ON

THERMOSTAT

LOGIC

CIRCUIT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

3

POSSIBLE CHECK LED CIRCUITS:

X1

CHECK

LED

(YELLOW)

X2

SWITCH TO R (POWER) SIDE

OF SYSTEM TRANSFORMER

SUBBASE

LOGIC/

CONTROL

CIRCUIT

FAULT DETECTION

SWITCH

HIGH

LIMIT

TO R

TO C/X

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

AUTO

COOL

HEAT 1

X1

CHECK

LED

(YELLOW)

SWITCH TO C (COMMON) SIDE

OF SYSTEM TRANSFORMER

FAULT DETECTION

SWITCH

X2

HIGH

LIMIT

EM. HT.

LED

(RED)

TO R

CHECK

LED

(YELLOW)

TO C/X

SWITCH IN SECONDARY OF

SEPARATE TRANSFORMER

COOL

X1

X2

AUX. HT.

LED (GREEN)

HEAT 2

C. O.

C. O.

CHECK

LED

(YELLOW)

SWITCHING

DEVICE

24 VAC

R

C/X

L

MONITOR

W2

G

EM. HT. RELAY

E

COOL CHANGEOVER

VALVE

O

HEAT CHANGEOVER

VALVE

B

Y

X1

3

X2

M6020A

AUX. HT.

RELAY

FAN RELAY

COMPRESSOR

CONTACTOR

L1

(HOT)

L2

1

Fig. 26. Typical wiring diagram for T8611G1004 and T8611G1103.

70-6627 • 21

Page 24

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

THERMOSTAT

LOGIC

CIRCUIT

S1 S1

S2 S2

S3 S3

200905 REMOTE

6

SENSOR

POWER

SUPPLY

SUBBASE

LOGIC/

CONTROL

CIRCUIT

R

HIGH

LIMIT

FAN

SWITCH

ON

AUTO

HEAT 1

HIGH

LIMIT

5

EM. HT.

LED

(RED)

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

AUTO

COOL

COOL 1

HEAT 3

4

C

AUX. HT.

LED (GREEN)

L

MONITOR

W3

W2

HEAT 2

E

G

C. O.

O

C. O.

B

STAGE 1 COMPRESSOR

CONTACTOR

Y

STAGE 2 COMPRESSOR

CONTACTOR

Y2

COOL 2

X1

CHECK

LED

(YELLOW)

X2

3

AUX. HT.

RELAY

STAGE 2

RELAY

EM. HT. RELAY

FAN RELAY

COOL CHANGEOVER

VALVE

HEAT CHANGEOVER

VALVE

2

L1

(HOT)

L2

1

70-6627 • 22

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

POSSIBLE CHECK LED CIRCUITS:

2

X1

CHECK

LED

(YELLOW)

3

4

5

6

FAULT DETECTION

SWITCH

X2

SWITCH TO R (POWER) SIDE

OF SYSTEM TRANSFORMER

SOME OLDER HEAT PUMP THERMOSTATS USE X FOR COMMON TERMINAL.

NOMINAL 24 VAC POWER MUST BE PRESENT BETWEEN R AND C TERMINALS FOR THERMOSTAT OPERATIONS.

AVAILABLE ONLY ON MODLES WITH SEPARATE SENSOR FOR REMOTE TEMPERATURE SENSING.

RECOMMENDED INTERCONNECT CABLE: 18-GAUGE THERMOSTAT CABLE, 200 FT. (61 M) MAXIMUM LENGTH.

ROUTE INTERCONNECT CABLE AWAY FROM SOURCES OF ELECTRICAL NOISE.

TO R

TO C

X1

CHECK

LED

(YELLOW)

SWITCH TO C (COMMON) SIDE

OF SYSTEM TRANSFORMER

FAULT DETECTION

SWITCH

X2

TO R

CHECK

LED

(YELLOW)

TO C

SWITCH IN SECONDARY OF

SEPARATE TRANSFORMER

X1

X2

SWITCHING

DEVICE

24 VAC

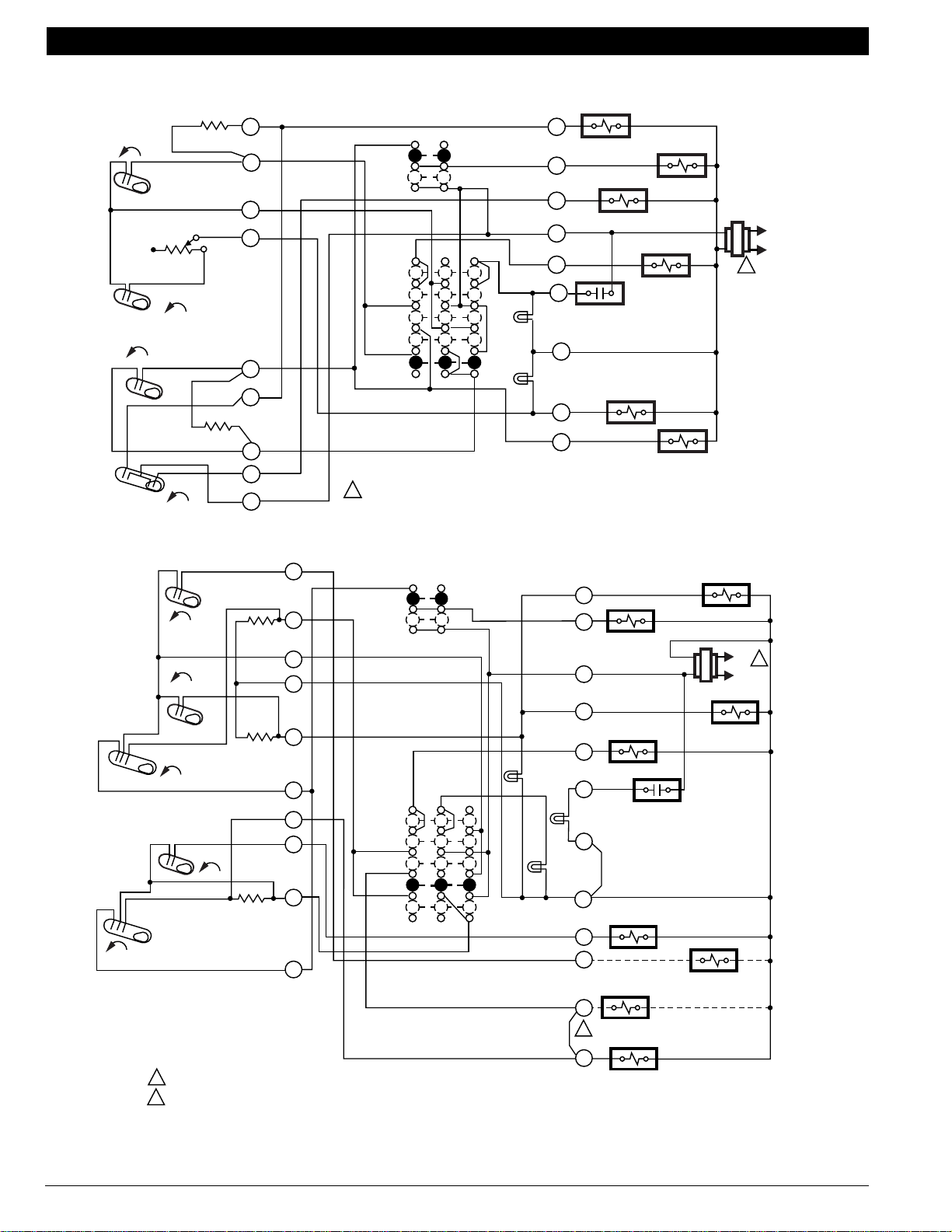

Fig. 27. Typical wiring diagram for T8611M7008.

L1

(HOT)

L2

M2656

Page 25

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

POWER

SUPPLY

3

FAN

HIGH

LIMIT

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

SWITCH

ON

AUTO

THERMOSTAT

LOGIC

CIRCUIT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

REMOVE JUMPER FOR SYSTEM WITH ISOLATED STAGE 1 HEATING AND COOLING CONNECTIONS.

2

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

3

SUBBASE

LOGIC/

CONTROL

CIRCUIT

HIGH

LIMIT

COOL 1

EM. HT.

LED

(RED)

HEAT 1

R

C

AUX. HT.

LED (GREEN)

L

W2

HEAT 2

E

W1

G

O

B

Y1

P

MONITOR

EM. HT. RELAY

FAN RELAY

COOL

2

CHANGEOVER VALVE

HEAT CHANGEOVER

VALVE

AUX. HT.

RELAY

STAGE 1

HEAT RELAY

COMPRESSOR

CONTACTOR

DEFROST

CONTROL

M6019A

L1

(HOT)

L2

1

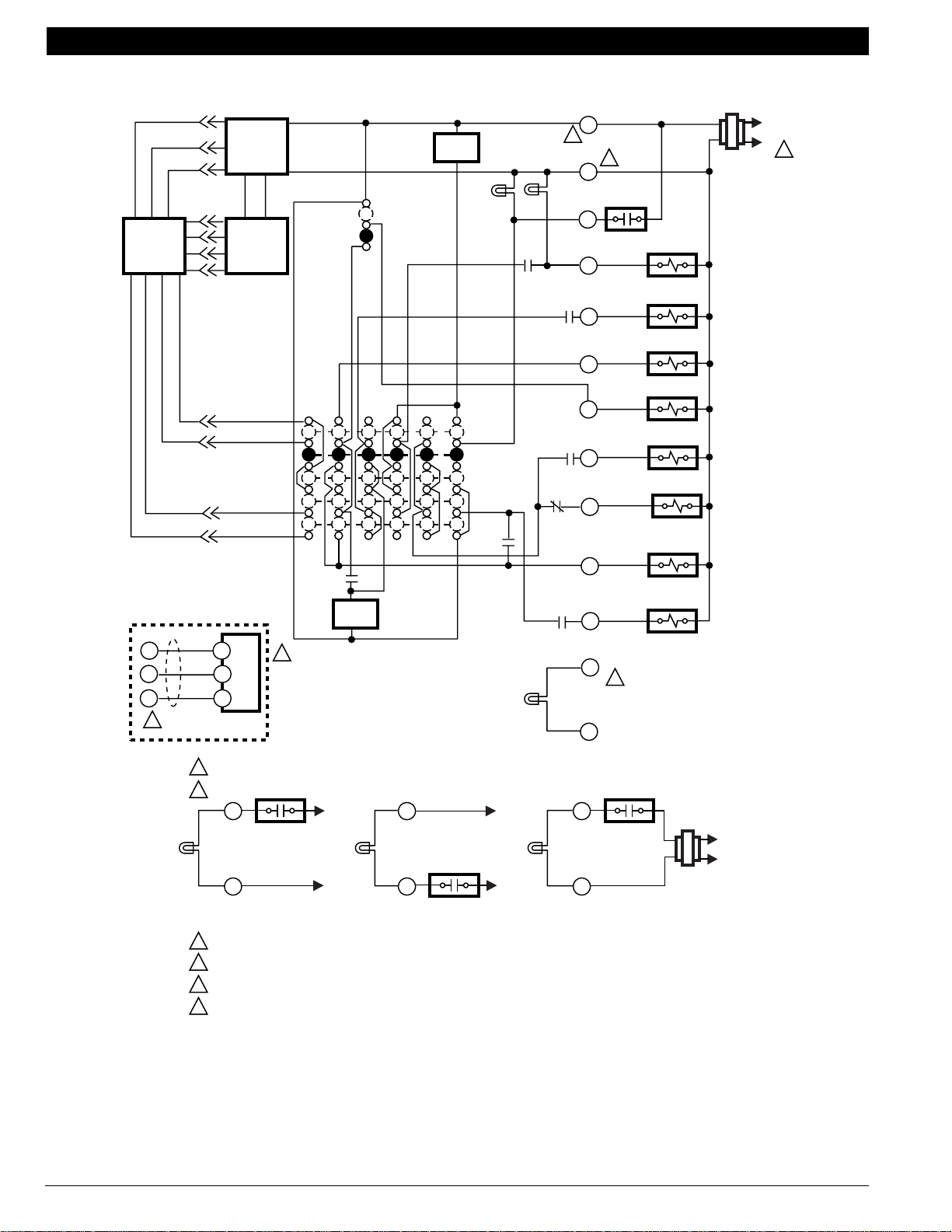

Fig. 28. Typical wiring diagram for T8611R1000.

THERMISTOR

SENSOR

1

2

THERMOSTAT

LOGIC

POWER

SUPPLY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

REMOVE JUMPER, WHEN SUPPLIED, FOR SYSTEMS WITH SEPARATE HEATING COMPRESSOR CONTACTOR (W1 SEPARATE FROM Y).

STAGE 2 RELAY

STAGE 1 RELAY

FAN SWITCH

ON

AUTO

SYSTEM

SWITCH

EM. HT.

HEAT

OFF

COOL

R

AUXILARY

HEAT RELAY

W2

L

CHANGEOVER

VALVE HEAT

B

O

COMPRESSOR

CONTACTOR

Y

2

W1

EMERGENCY

HEAT RELAY

E

G

C

RELAY

CHANGEOVER

VALVE COOL

COMPRESSOR

CONTACTOR

HEAT

FAN RELAY

M11333

L1

(HOT)

L2

1

Fig. 29. Typical wiring diagram for T8011R and T8411R.

70-6627 • 23

Page 26

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

R

L1

(HOT)

1

L2

THERMOSTAT

LOGIC

POWER

SUPPLY

W2

W1

O/B

G

Y1

E

E

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

O/B IS FIELD CONFIGURABLE TO SELECT ENERGIZED IN HEATING OR

2

COOLING. (DEFAULT IS ENERGIZED IN HEATING).

3

REMOVE JUMPER, WHEN SUPPLIED, FOR SYSTEMS WITH SEPARATE

HEATING COMPRESSOR CONTACTOR (W1 SEPARATE FROM Y1).

W2

Y1

W1

G

O/B

3

CHECK LED (RED)

C

W1

AUXILIARY

HEAT RELAY

W2

E

COMPRESSOR

CONTACTOR

Y1

G

CHANGEOVER

2

VALVE

O/B

L

OT

OT

COMPRESSOR

CONTACTOR HEAT

EMERGENCY

HEAT RELAY

FAN RELAY

COMPRESSOR

MONITOR

TO R

OUTDOOR

SENSOR C7089B

M13281

Fig. 30. Typical wiring diagram for T8511G.

70-6627 • 24

Page 27

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

1

L1

L2

(HOT)

R

POWER

SUPPLY

THERMOSTAT

LOGIC

Y

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

WIRES TO OT TERMINALS SHOULD NOT SHARE CABLE WITH OTHER

2

CONNECTIONS.

3

INSTALLER CONFIGURABLE. FACTORY DEFAULT IS O-ENERGIZED IN

COOL MODE.

4

FACTORY-INSTALLED JUMPER; REMOVE IF A HEAT RELAY IS CONNECTED

TO W1.

W2

E

O/B

W1

G

4

FAIL LED (RED)

CHECK LED (RED)

C

W1

AUXILIARY

HEAT RELAY

W2

E

COMPRESSOR

CONTACTOR

Y1

3

O/B

G

X1

X2

L

OT

2

OT

COMPRESSOR

CONTACTOR HEAT

EMERGENCY

HEAT RELAY

CHANGEOVER

VALVE

FAN RELAY

COMPRESSOR

MONITOR

OUTDOOR

SENSOR C7089B

TO R

M13250

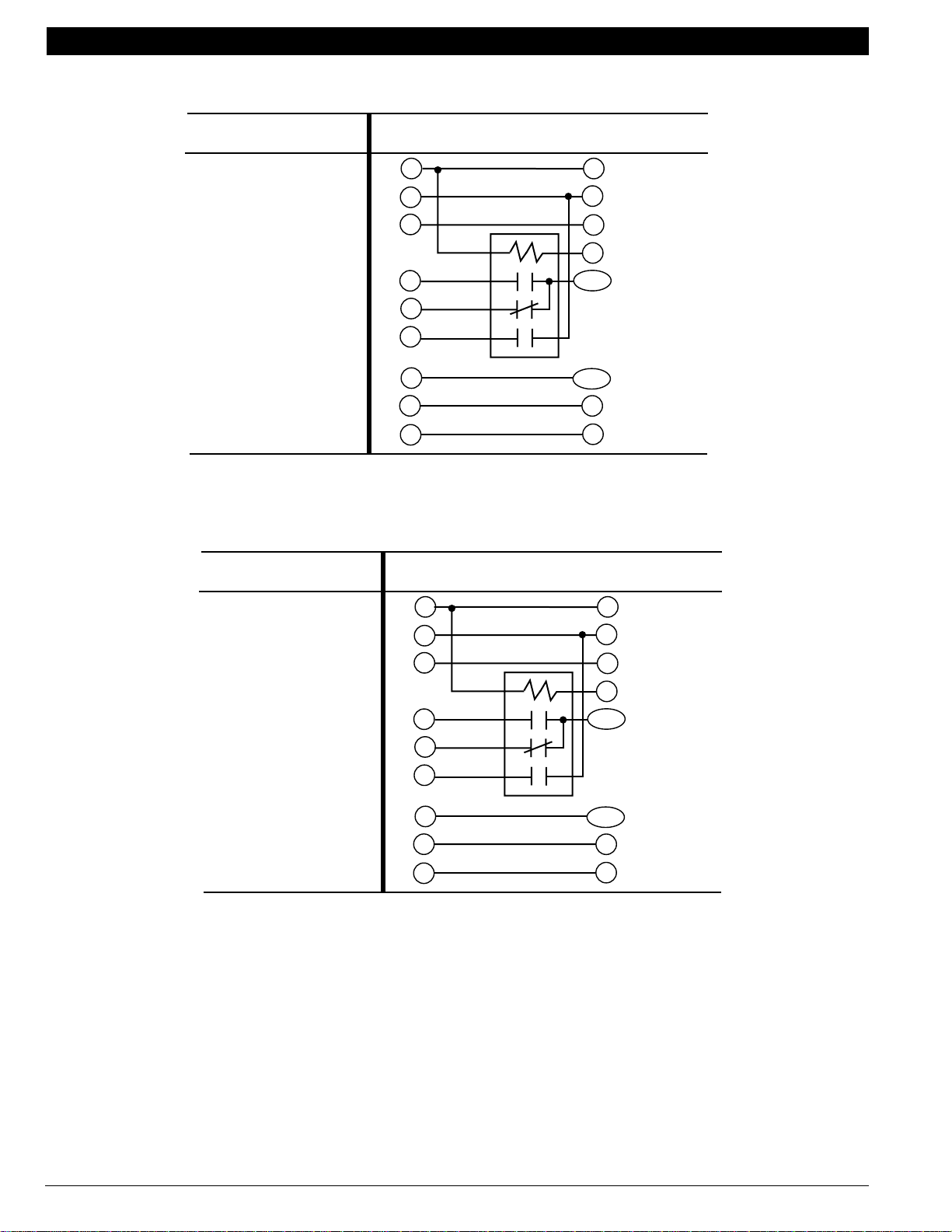

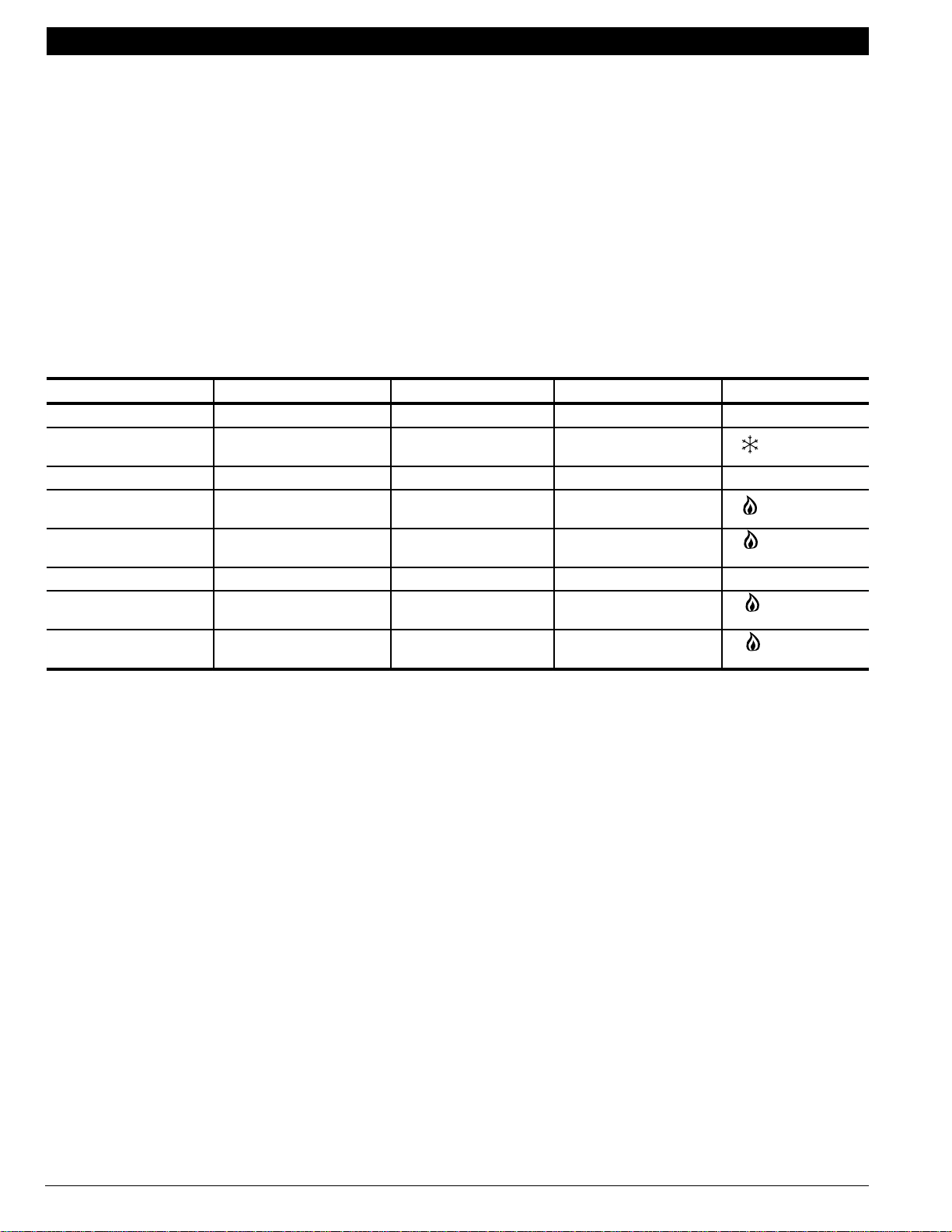

Fig. 31. Typical wiring diagram for T8611G2002 and T8611G2028.

70-6627 • 25

Page 28

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Electronic Thermostat (T8011, T8411, T8511, T8611)

Sequences of Operation

T8011 Programmable Heat Pump Thermostat and

T8411 Electronic Heat Pump Thermostat

Sequence of Operation

The Fan, Heat and Cool outputs are relay controlled. A loss of ac power, or a change in the SYSTEM switch setting can cause the

outputs to turn off. Table 2 shows the sequence of operations for the Fan settings and System modes.

Table 2. T8011 and T8411 Sequence of Operation.

FAN Switch Settings SYSTEM Switch Settings Call for Action Energize Terminals Display Icons

Auto Cool None O None

Auto Cool Cooling O, Y, G

Auto Heat None B

Auto Heat Stage 1 Heat B, W1, G

Auto Heat Stage 2 Heat B, W1, W2, G , Aux Ht

Auto Em. Ht. None L Em Ht indicator

Auto Em. Ht. Stage 1 Heat L, E, G , Em Ht indicator

Auto Em. Ht. Stage 2 Heat L, E, W2, G , Em Ht and Aux

None

indicator

Ht indicators

70-6627 • 26

Page 29

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

T8511 Deluxe Electronic Heat Pump Thermostat

Sequence of Operation

The thermostat energizes specific terminals depending on the Fan and System Settings. The LCD will display symbols and words to

report the condition of system. See Table 3 for specific information.

Table 3. T8511G Sequence of Operation for Separate Compressor Terminal (Y and W1) Models.

Fan Selection System Selection Call Energize Display Icons

Auto Off None None None

On Off Fan G

Auto Cool None O/B

Auto Cool or Auto Cooling O/Ba, G, Y1 and

Auto Heat None O/B

Auto Heat or Auto Stage 1 heating O/Ba, W1, G and

Auto Heat or Auto Stage 2 heating O/Ba, W1, W2, G , , and Aux Ht

Auto Em Heat None O/B

Auto Em Heat Stage 1 heating O/Ba, E, G , and Em Ht

Auto Em Heat Stage 2 heating O/Ba, E, W2, G , , Em Ht and

Auto Auto None O/B

a

Configure O/B (Select Models) in Installer Setup.

a

a

a

a

None

None

Em Ht

Aux Ht

None

70-6627 • 27

Page 30

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

T8611 Chronotherm IV Deluxe Programmable Heat Pump Thermostat

Sequence of Operation

The thermostat energizes specific terminals depending on the Fan and System Settings. The LCD will display the time, room

temperature, system and fan selection. Symbols will be displayed when the heating, cooling or fan is energized. See Table 4 for

specific information.

NOTE: Terminals listed in the Energize column vary depending on model.

Table 4. Heat Pump System Sequence of Operation.

Selection

Fan System Call Energize Display Icons

Auto Off None None None

On Off None G

Auto Cool None O or O/B

Auto Cool or Auto Stage 1 Cooling O or O/B

G and Y1

Auto Heat None B or O/B

Auto Heat or Auto Stage 1 heating B or O/Ba with W1 and G and

Auto Heat or Auto Stage 2 heating B or O/Ba with W2, W1 and G , , and Aux Ht

Auto Em Heat None B or O/B

Auto Em Heat Stage 1 heating B or O/Ba, E and G

(select models)

Auto Em Heat Stage 2 heating B or O/Ba, E and W2 and G

(select models)

Auto Auto None O/Ba, O or B

a

Configure O/B (select models) in Installer Setup.

b

Based on last piece of equipment called (cooling = O or heating = B) and Installer Setup selection.

a

a

a

a

with

None

and

None

Em Ht

, and Em Ht

, , Em Ht and Aux Ht

b

None

70-6627 • 28

Page 31

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Thermostat Manufacturer Cross Reference

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

American Stabilisa HP-1 T841A1712, Y594R1425, Y594G1419, T8411, T8511, T8011,

HP-1EF T841A1712, Y594R1425, Y594G1419, T8411, T8511, T8011,

HP-10EF

b

HP-15 Y594G1252, T8411, T8511, T8011, T8611R, T8611G,

a

See page 37 for hookup details.

b

Compressor protection is generally provided by the equipment manufacturer.

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

Carrier Totaline

b,c

Multistage Heat Pump MP10/11 T8611G

MP30 T8611M

MS10/11 Y594R1425

MS12/13 T841A1316

MS20/21 Y594G1419

a

Use with ST82 Time Delay Relay for extended fan operation.

b

See pages 42-45 for hookup details.

c

Carrier thermostats manufactured by American Stabilis.

T8611R, T8611G

T8611R, T8611G

T841A1712, Y594R1425, Y594G1419, T8411, T8511, T8011,

T8611R, T8611G

a

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

a

Climate Technology Corporation CTC400 T841A1316, Y594G1419, T8411, T8511, T8011, T8611

CTC403 T841A1316, Y594G1419, T8411, T8511, T8011, T8611,

a

Use T8611M or W8900B for 3 heat, 2 cool applications.

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

Enerstat

b

DSP400 T841A1001a

DSP410 T841A1001a

DSP600 T874W1031/Q674L1546, Y594W1014

a

Provision for optional remote sensor, not provided.

b

See page 49 for hookup details.

70-6627 • 29

Page 32

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

General Electric

a

See pages 57-58 for hookup details.

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

a

Lennox

a

See pages 75-81 for hookup details.

a

3AAT86B21A1 Y594G1161, T8411, T8511, T8011, T8611

3AAT86B14A1 T841A1316, Y594R1425, T8411, T8511, T8011, T8611

3AAT86B16D1 T841A1316, Y594R1425, T8411, T8511, T8011, T8611

3AAT80A1A1 T841A1712, Y594R1425, T8411, T8511, T8011, T8611

3AAT80A2A1 T841A1712, Y594R1425, T8411, T8511, T8011, T8611

3AAT80B1A1 Y594G1161, T8411, T8511, T8011, T8611

3AAT86B1A1 Y594G1161, T8411, T8511, T8011, T8611

51H3901

T841A1316, Y594R1425, T8411, T8511, T8011, T8611G

(3AAB83C38)

51H4001

T841A1712, Y594G1419, T8411, T8511, T8011, T8611G

(3AAT88D38B2)

51H4301

T8611M, PC8900A1007/W8900B1002

(3AAT88D38C2)

21J7101

(3AAT89B38D1)

21J7201

T841A1555, Y594R1763, Y594G1161, T8411, T8511, T8011,

T8611G

T841A1712, Y594R1425, T8411, T8511, T8011, T8611G

(3AAT89B38E1)

21J7301

T841A1712, Y594G1419, T8411, T8511, T8011, T8611G

(3AAT89B38F1)

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

Maple Chase 09520 T841A1316, Y594R1425, Y594G1419, T8411, T8511, T8011,

T8611G

09620 T8611M, PC8900A1007/W8900B1002

09720 T8611M, PC8900A1007/W8900B1002

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

a

Seco

TA2000 T841A1001, Y594R1425, Y594G1419, T8411 T8511, T8011,

T8611

TA2010 T841A1001, Y594R1425, Y594G1419, T8411 T8511, T8011,

T8611

TA2040 T841A1001, Y594R1425, Y594G1419, T8411 T8511, T8011,

T8611

TA2050 T841A1001, Y594R1425, Y594G1419, T8411

TA2060 T841A1555 plus C815A1005

a

See pages 92-93 for hookup details.

70-6627 • 30

Page 33

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

a,b

Trane

Single-Stage Heat Pump

Multistage Heat Pump ASYSTAT651 Y594G1161, T8411, T8511, T8011, T8611

a

See pages 97-100 for hookup details.

b

Trane thermostats manufactured by General Electric or Honeywell.

BAY28X182/BAY28X185

(T874A1184/Q674B1141)

BAY28X182/BAY28X187

(T874A1184/Q674E1033)

BAYSTAT009

(T874A1085/Q674B1018)

AY28X138 Y594G1161, T8411, T8511, T8011, T8611

AY28X139 T841A1068, Y594R1763, T8411, T8511, T8011, T8611

AY28X164 T874D1165/Q674E1049

BAY28X138

(3AAT80B1A1),

BAY28X140,

BAYSTAT138

BAYSTAT239

(3AAT86B1A1),

BAY28X139,

BAY28X141,

BAY28X153A,

(3AAT83F1B2)

BAYSTAT240 (3AAT80A1A1)

BAYSTAT339

(Y594R1284)

BAYSTAT024B T8611M, PC8900A1007/W8900B1002

TAYSTAT500 T8611R, T8611G

T874A1036/Q674B1075

T874A1036/Q674C1058

T874A1036/Q674B1018

Y594G1161, T8411, T8511, T8011, T8611

T841A1068, Y594R1763, T8411, T8511, T8011, T8611

T841A1068, Y594R1763, T8411, T8511, T8011, T8611

70-6627 • 31

Page 34

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

MANUFACTURER MODEL NUMBER HONEYWELL REPLACEMENT

White Rodgersa

Single-Stage Heat Pump

Multistage Heat Pump IC70-18 T841A1001, Y594G1252

a

See page 108 for hookup details.

IF56-444 T8034C1234

IF93-36 T8600C1162

IC70-24 T874D1165/Q674F1022

IC71-2 Y594G1419

IF58-910/S28-1 T841A1217, Y594R1300

IF58-910/S28-2 T841A1423, Y594R1615

IF58-910/S28-16 T841A1316, Y594R1425

IF58-911/S28-5 T841A1316, Y594G1419

IF58-911/S28-17 T841A1001, Y594G1252

IF58-911/S28-18 T841A1068, Y594R1136

IF58-56 T841A1050, Y594R1425

IF58-57 T841A1068, Y594R1136

IF58-58 T841A1217, Y594R1425

IF58-72 T841A1233, Y594R1615

IF58-77 T841A1316, Y594R1425

IF58-78 T841A1217, Y594R1425

IF58-83 T841A1217, Y594R1243

IF59-79 T841A1316, Y594R1425

IF60-25 T8600C1162

IF62-21 T8411, T8511, T8011, T8611R, T8611G

IF82-79 T8411, T8511, T8011, T8611R, T8611G

IF91-71 T8611M, PC8900A1007/W8900B1002

IF92-71 T8611M, PC8900A1007/W8900B1002

IF94-71 T8611M, PC8900A1007/W8900B1002

IF95-71 T8611M, PC8900A1007/W8900B1002

70-6627 • 32

Page 35

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

Tips for Using This Heat Pump Cross Reference

This cross reference, alphabetized by equipment or thermostat manufacturer, provides the information needed to

choose and wire the Honeywell electromechanical, Chronotherm III, or electronic heat pump thermostats in new

installations and replacement applications. It also gives you the opportunity to upgrade the system from a standard to a

deluxe thermostat for improved performance and from manual changeover to the convenience of automatic heat/cool

changeover and to a Chronotherm® IV thermostat that puts the heat pump to work to save money. Best of all, you can

upgrade to the PC8900/W8900B1002 Perfect Climate Comfort Center™ Control System. This

controls temperature, indoor air quality, ventilation, humidity, and zoning.

To use this Cross Reference:

1. Identify heat pump equipment manufacturer and refer to those diagrams in this reference.

2. Identify existing

logo, and try to match up for verification. Some typical thermostats and subbases are listed in each section to make

identification easier. The Honeywell model number is listed, followed by the equipment manufacturer model number,

if available.

3. Make a listing of wiring terminals used and wire colors. You may want to write on the appropriate diagram in this

cross reference.

4. Note the unique control requirements your heat pump may have.

— Determine reversing valve (changeover) mode. O terminal cool or B terminal heat is typical.

— Identify first stage heat terminal. Connect to Y if a common terminal is used for first stage heat and cool, or to

W1 if a separate terminal is used for first stage heat.

— Identify if device has manual or automatic changeover from heat to cool.

— Identify what action, if any, is required for LED selection; e.g., auxiliary heat, emergency heat, check, or fail.

5. Select a replacement based both on the technical requirements and your customer’s needs; e.g., a working family

may find a Chronotherm® IV upgrade desirable.

6. After selecting the proper thermostat, use the corresponding control hookup diagram. See example below.

subbase

model number if made by Honeywell, even if thermostat has equipment manufacturer’s

one

comfort center

Existing

Control

Terminal

Designation

CXC C C C

RRR R R R

7. Connect only those terminals shown with lines to them on the diagram. Some terminals on the new thermostat may

not be used.

8. Refer to the following two pages for an example of a typical cross reference diagram and the associated footnotes.

Electromechanical

Thermostat

Hook wire

previously

on C to X

Hook wire

previously

on R to R

Chronotherm III

Thermostat

or to

or to

or to

or to

Electronic

Replacement

or Upgrade

Chronotherm IV

Thermostat

or to

or to

Perfect Climate

Comfort Center

Control System

or to

or to

M13251

70-6627 • 33

Page 36

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

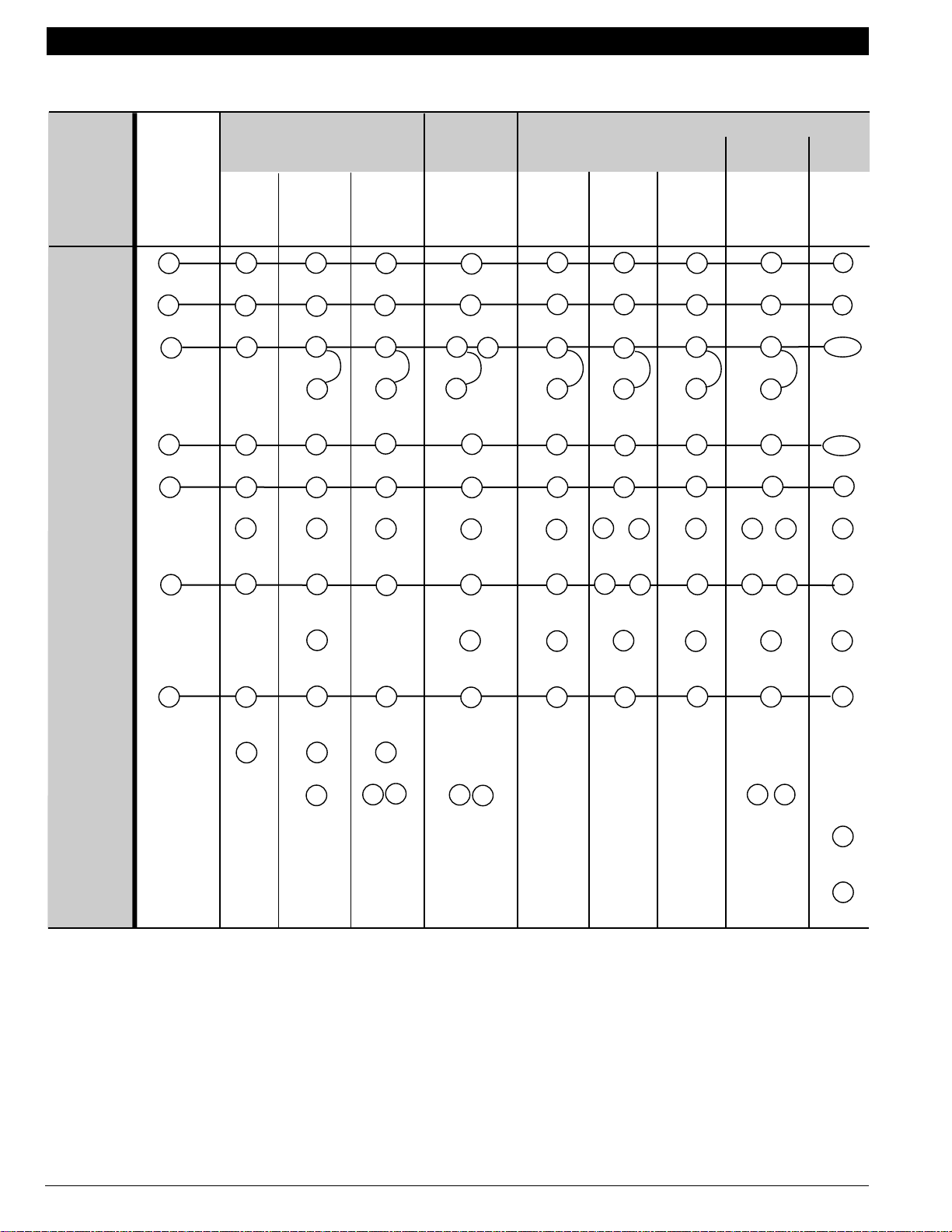

Electronic Replacement or Upgrade

Chronotherm

IV

Electronmechanical

Chronotherm®

III

Function

Common

Compressor

System Monitor/

Sytem Defrost

A

Power

1st Stage

Heat

M

Auxiliary

Heat

Fan

C/O V alve

Heat

C/O V alve

Cool

KL

PC8900/

W8900B1002

L

T841A1712

Y594R1425

Y594G1419

Y594G1476

XX X C CCCC C C

T8611R1000

T8611G1004

T8411R1002

T8411G1028

T8511G1021

T8511G1047

T8011R1006

T8011R1014

T8611G2002

T8611G2028

T8611M1002

T8611M2017

T8611M2025

RR R R RRRR R R

Y Y Y1 Y1 or Y Y Y1 Y Y1 Y1

I

I

I

– W1 W1 W1 W1 W1 W1 W1

I

II

I

––

W2 W2 W2 W2 W2 W2 W2 W2 Y2 Aux.

GG G G GGGG G G

P

BB B B BB or

OO O O OO or

–L LLLLLLL

G

H

P

P

C

O/B

C

O/B

H

G

P

BB or

OO or

H

P

O/B

O/B

G

P

C

C

B or

O/B O/B

O or

O/B O/B

GH

C

C

E

Y1/W1

F

P

C

C

G

Em. Heat

Multiple

Heat

Loads

B

LED Indication

Defrost

2nd Stage

Compressor

2nd Stage

Cool in two

Stage System

EE E E EEEE E E

W3 W3 W3 W3

–X2

D

X1 X2 X1 X2

–– – P –––– – –

J

D

N

J

–––

J

–– – – ––––

–– – – –––– –

J

J

D

D

X1 X2 X1 X2

Y2 W2

J

–

F

Y2

M13245

O

70-6627 • 34

Page 37

HEAT PUMP THERMOSTAT CROSS REFERENCE/SELECTION GUIDE

A Terminal must be connected to the transformer common.

B Terminal is for multiple auxiliary heat loads such as contactors, sequencers, or relays.

C Configure O/B (Select Models) in Installer Setup.

D Optional LED indication activated with completed circuit on X1 and X2 terminals.

E If separate Y1 and W1 terminals are required, install R8222D1014; (See page 12.)

F When W2 is not used, configure W2 cycle rate to NC.

G LED is energized when terminal is powered.

H L terminal is powered continuously when thermostat is in Em. Ht. position.

I Do not remove factory-installed jumper.

J If multiple auxiliary heat loads are used, connect to W2 (Aux W8900B) terminal.

K Used on two-speed compressor heat pump applications.

L Used on heat pumps that energize the compressor on both first stage cooling and first stage heating through a common Y

terminal.

M Q674F1022 switching subbase available when separate first stage heat and cool terminals are required. See specific heat pump

manufacturer’s listing for hookup information.

N P terminal on T8611R1000 only. Energized in heating and cooling modes; shown only when used.

O Jumper W2 and Y2 if stage 2 heating and cooling are common.

P To change fan operation in Emergency Heat mode, see page 9.

X1

CHECK

LED

(YELLOW)

FAULT DETECTION

SWITCH

X2

SWITCH TO R (POWER) SIDE

OF SYSTEM TRANSFORMER

TO R

TO C/X

X1

CHECK

LED

(YELLOW)

SWITCH TO C (COMMON) SIDE

OF SYSTEM TRANSFORMER

FAULT DETECTION

SWITCH

X2

TO C/X

TO R

CHECK

LED

(YELLOW)

SWITCH IN SECONDARY OF

SEPARATE TRANSFORMER

X1

X2

SWITCHING

DEVICE

24 VAC

L1

(HOT)

L2

M13246

70-6627 • 35

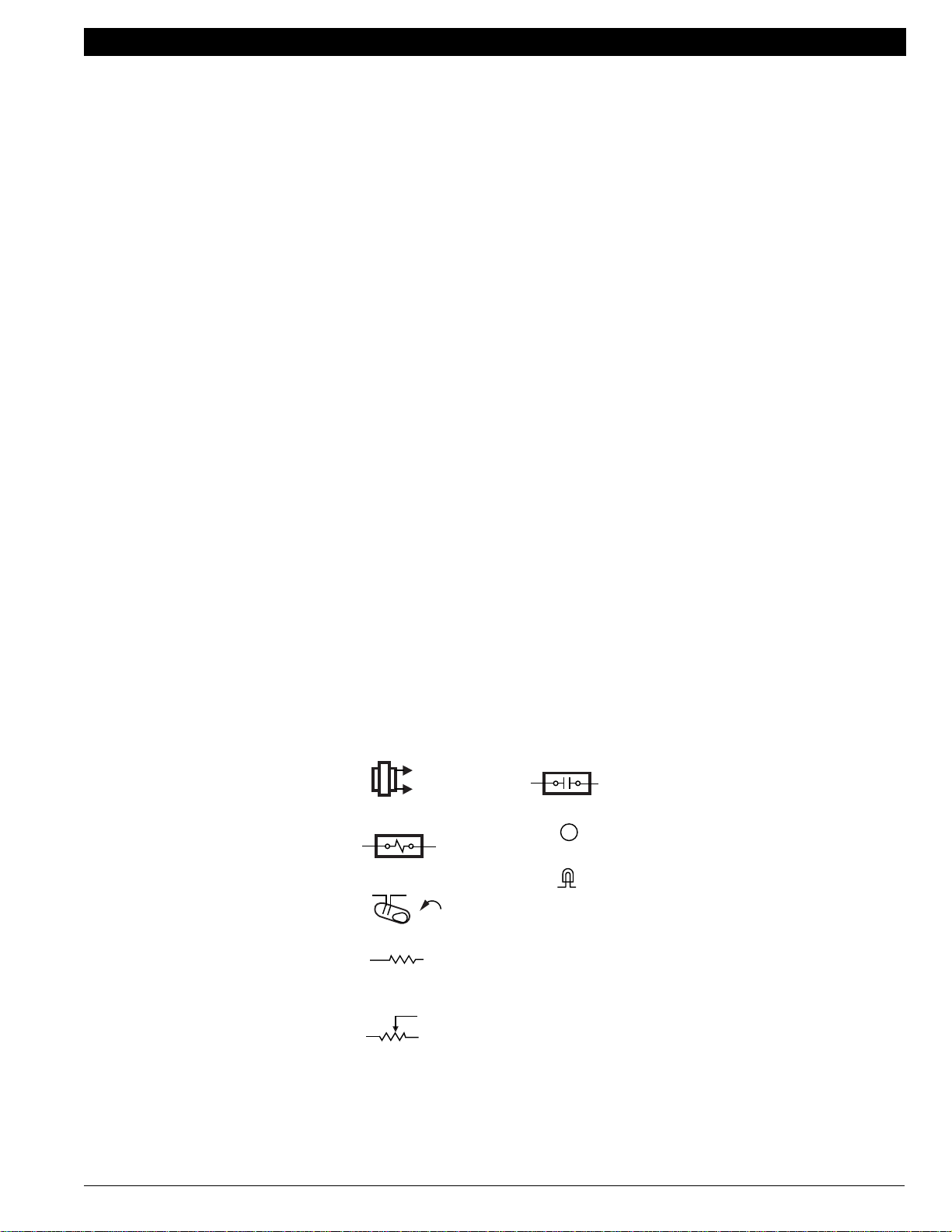

Page 38

AMANA

Models: RHA1842A, RHA (24-42)A2A, RHA (48-60)A2A, RHA (36, 48, 60)A3A & A4A, RHD (18-24)A2A, RHD (30-60)A2A,

RHE (18-24)A2A, RHE (30-60)A2A, RHA (36, 48, 60)A3B & A4B.

Electronic Replacement or Upgrade

Electromechanical

Chronotherm

III

®

Chronotherm

IV

Function

Common

Compressor

1st Stg. Heat

System Monitor/

System Defrost

C

Power

Aux. Heat

Fan

C/O V alve

Cool

C/O V alve

Heat

Em. Heat

Existing

Terminals

or

X

X1 or C

T841A1712

Y594R1425

Y594G1419

Y594G1476

T8611G1004

T8611R1000

T8411R1002

T8411R1028

T8511G1021

T8511G1047

T8011R1006

T8011R1014

T8611G2002

T8611G2028

XXX C CCCCC

PC8900/

W8900B1002

RRRR R RRR RR

YYYY1Y1

B

B

B

Y Y Y1 Y Y1

B

B

B B

B

W1 – W1 W1 W1 W1 W1 W1 W1

W2 W2 W2 W2 W2 W2 W2 W2 W2 Aux.

or

Y1/W1

–

D

I

GGGG G GGG GG

H

OOOO O O O

or

O/B

OO

H

or

O/B O/B

H

H

BBBB B BB

or

O/B

BB

H

or

O/B O/B

H

EEEE E EEE EE

A

L L L LLL LL

J

F

F

J

F

J

J

Multiple Aux.

A

W3 W3 W3 W3

Heat Loads

LED

Indication

Defrost

2nd Stage

––

A

P––– – ––– ––

–––– – ––– –

E

X2 X1 X2 X1 X2

Compressor

2nd Stage

–––– – ––– –

Cool

A Not available on all models.

B Do not remove factory-installed jumper.

C Terminal must be connected to the transformer common.

D If separate Y1 and W1 terminals are required, install R8222D1014.

See page 12.

E Field-installed X2 to X jumper.

TYPICAL THERMOSTATS AND SUBBASES — HONEYWELL MODEL NUMBER (CUSTOMER PART NUMBER)

T841A1241 (D99458003) T8611R1083 (D9807605) T874R1194/Q674L1249

G

G

G

G

–– –

G

X1 X2

G

–

W2

Y2

F L terminal is powered continuously when thermostat is in Em. Ht. position.

G If multiple auxiliary heat loads are used, connect to W2 (Aux W8900B)

terminal.

H Configure O/B (select models) in Installer Setup.

I When W2 is not used, configure W2 cycle rate to NC.

J LED is energized when terminal is powered.

M13172

I

70-6627 • 36

Page 39

AMERICAN STABILIS

TYPICAL THERMOSTATS AND SUBBASES: HP1, HP1EF, HP10EF, HP15

Function

Common

Compressor

1st Stg. Heat

System Monitor/

System Defrost

E

Power

Aux. Heat

Fan

C/O V alve

Heat

C/O V alve

Cool

Electromechanical

Chronotherm

Existing

Terminals

T841A1712

Y594R1425

Y594G1419

Y594G1476

C XXX C CCC CC

T8611R1000

T8611G1004

T8611M7008

®

III

T8411R1002

Electronic Replacement or Upgrade

T8411R1028

T8511G1021

T8511G1047

T8011R1006

T8011R1014

Chronotherm

IV

T8611G2002

T8611G2028

PC8900/

W8900B1002

R RRR R RRR RR

Y1 Y Y1 Y1 Y1

––

W1 W1 W1 W1 W1 W1 W1

G

G

or

Y Y Y1 Y Y1

G

G

G

G

G

Y1/W1

–

B

W2 W2 W2 W2 W2 W2 W2 W2 W2 Aux.

G GGG G GGG GG

A

or

or

O/B

O/B

C

A

BBBB B BB

OOOO O OO

X LX1 L LLL LL

CC

D

D

B B

OO

D

A

or

O/B O/B

A

or

O/B O/B