Page 1

T8400C1099, T8401C1031

Electronic Thermostats

The T8400 and T8401 Thermostats provide single-stage,

non-programmable temperature control for 24V heatingcooling systems with manual changeover from heat to

cool. Heating cycle rate is selectable at 1, 3, 4, 5, 6, 9, or

12 cph. Cooling cycle rate is fixed at 3 cph. Temperature

indication can be set for °F or °C.

The T8400 Thermostat is powered through the heating/

cooling system controls. The T8401 requires a common

wire for operation. Batteries are not required because

setpoints are held permanently by non-volatile memory.

The T8400 and T8401 models include a thermostat,

wallplate (for wiring and mounting thermostat) and

owner’s guide.

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash.

Contact your local waste management authority

for instructions regarding recycling and the

proper disposal of an old control containing

mercury in a sealed tube.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

INSTALLATION INSTRUCTIONS

CAUTION

Electrical Shock or Equipment Damage

Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

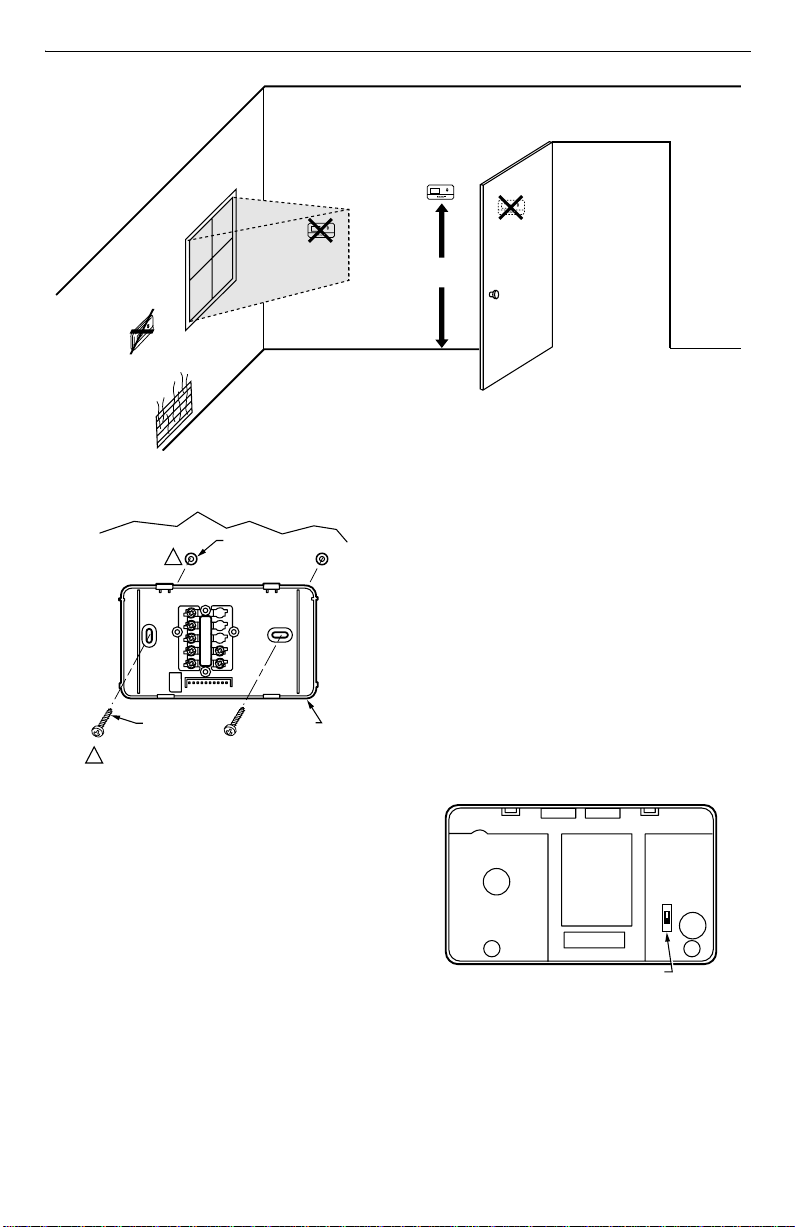

Location

Install the thermostat about 5 ft (1.5m) above the floor in

an area with good air circulation at average temperature.

See Fig. 1. Do not install the thermostat where it can be

affected by:

— drafts or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from the sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

This thermostat is a precision instrument and was

carefully adjusted at the factory. Handle it carefully.

Mounting Wallplate to Wall

IMPORTANT

Level only for appearance. The thermostat functions normally even when not level.

Mount the T8400 and T8401 with the screws provided

(see Fig. 2) as follows:

1. Place the wallplate at the desired location on the

wall.

2. Pull the thermostat wire through the entrance hole

on the wallplate.

3. Fasten the wallplate to the wall using the anchors

and screws provided.

4. After wiring the wallplate, plug the hole to prevent

drafts from affecting the thermostat; see Wiring

section.

® U.S. Registered Trademark

Copyright © 2002 Honeywell • • All Rights Reserved

69-1484-2

Page 2

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

M12202A

M12580

FAN OPERATION (FUEL) SWITCH

NO

WALL

MOUNTING

SCREWS (2)

1

WHEN USING WALL ANCHORS, DRILL 3/16 INCH

HOLES FOR DRYWALL, 7/32 INCH HOLES FOR

PLASTER OR WOOD.

WALL

ANCHORS (2)

1

WALLPLATE

Fig. 2. Mounting wallplate to wall.

YES

NO

5 FEET

[1.5 METERS]

Fig. 1. Typical location of thermostat.

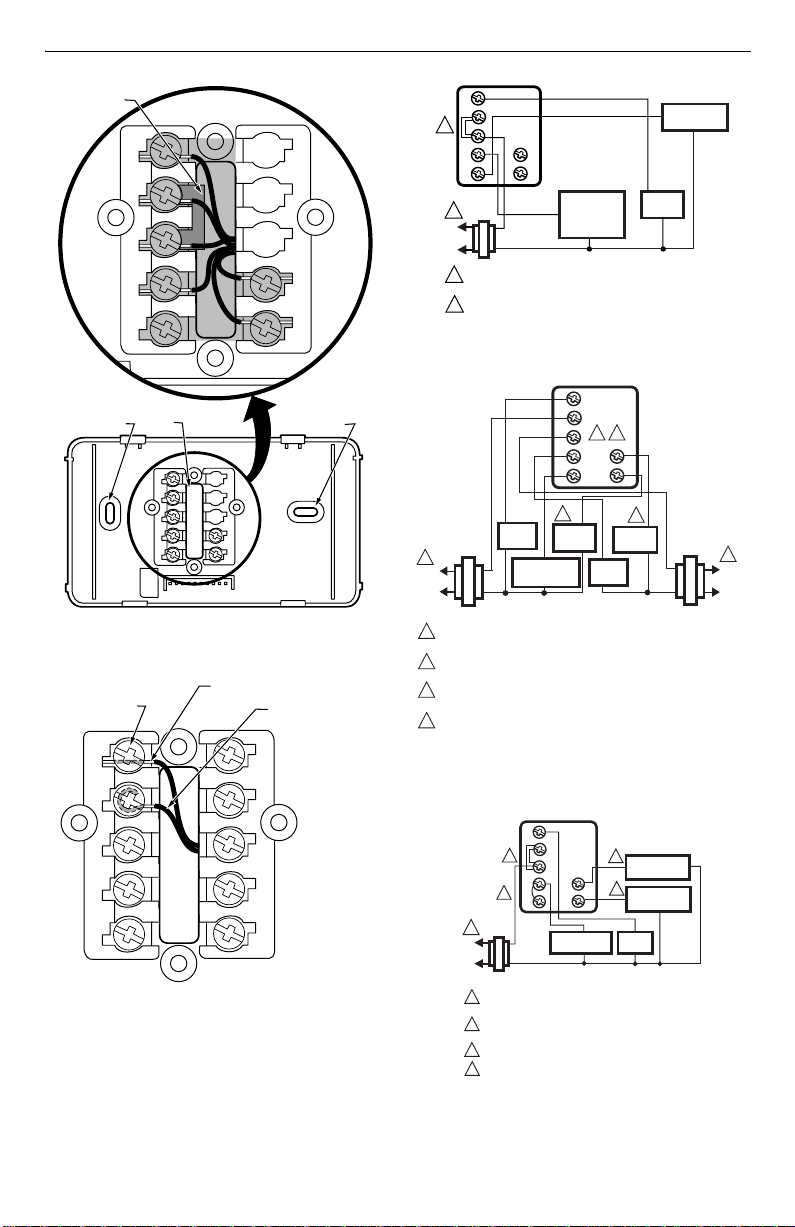

Wiring

IMPORTANT

Use an 18-gauge maximum wire to wire the

T8400 and T8401 Thermostats.

All wiring must comply with local electrical codes and

ordinances. Disconnect the power supply to prevent

electrical shock or equipment damage.

NOTE: To ensure proper mounting of thermostat,

restrict all wiring to the shaded area. See Fig. 4.

The shape of the terminals permits insertion of straight or

wraparound wiring connections; either method is

acceptable. See Fig. 5.

Refer to Fig. 6 through 10 for typical wiring hookups.

NO

M11338

Setting Fan Operation (Fuel) Switch

The fan operation (fuel) switch is preset at the factory in

the F position. See Fig. 3. This is the correct setting for

most systems. If this system is an electric heat system,

set the switch to the E position. The E setting allows the

fan to turn on immediately with the heating or cooling

equipment in a system where the G terminal is

connected.

69-1484-2 2

E

F

Fig. 3. Fan operation (fuel) switch.

Page 3

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

)

A

T)

L

(

L

L

(

L

0

KEEP WIRING IN

SHADED AREA

G

Rc

R

W

Y

MOUNTING

SCREW HOLE

WIRING ENTRANCE

HOLE

Fig. 4. Restrict wiring to shaded area

(T8400C1099 shown).

FOR STRAIGHT INSERTION

TERMINAL

SCREW

STRIP 5/16 IN. (8 MM)

G

Rc

B

O

MOUNTING

SCREW HOLE

M16432

FOR WRAPAROUND

STRIP 7/16 IN. (11 MM

G

Rc

2

R

W

Y

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

2

Fig. 6. Typical hookup of T8400C1099 in heat-cool

1

1

HOT)

2

COOLING

TRANSFORMER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

REMOVE RC TO R JUMPER WHEN INSTALLED ON A TWO TRANSFORMER

SYSTEM.

3

CAN BE USED FOR CHANGEOVER VALVE ON SINGLE-STAGE HEAT

PUMP SYSTEMS.

4

POWER TO R TERMINAL IS REQUIRED WHEN THE SYSTEM SWITCH IS IN

THE OFF POSITION.

Fig. 7. Typical hookup of T8400C1099 in heat-cool

B

O

HEATING

PRIMARY

24V

CONTROL

system with single transformer.

G

Rc

R

2

W

Y

3

FAN

COOL

RELAY

DAMPER

COMPRESSOR

CONTACTOR

HEAT

RELAY

system with two transformers.

4

B

O

HEAT

DAMPER

3

FAN

RELAY

COOLING

CONTACTOR

M13275

HEATING

TRANSFORMER

M12562

1

L1

(HO

L2

R

W

B

Y

Fig. 5. Wiring connections

(T8400C1099 shown).

O

M13274

HOT)

TRANSFORMER

Fig. 8. Typical hookup of T8400C1099 in single-stage

G

Rc

3

R

W

4

Y

1

1

2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CAN BE USED FOR CHANGEOVER VALVE ON

2

SINGLE-STAGE HEAT PUMP SYSTEMS.

3

FACTORY INSTALLED JUMPER.

4

FIELD INSTALLED JUMPER.

COMPRESSOR

24V

2

B

2

O

heat pump systems.

HEAT

CHANGEOVER

COOL

CHANGEOVER

FAN

RELAY

M2088

3 69-1484-2

Page 4

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

L

(

L

1

L

(

L

2

CASE TO LATCH.

G

C

R

W

Y

1

1

HOT)

TRANSFORMER

24V

2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 9. Typical hookup of T8401C1031 in heat-cool

G

C

R

W

Y

1

1

HOT)

2

TRANSFORMER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CAN BE USED FOR CHANGEOVER VALVE ON

2

SINGLE-STAGE HEAT PUMP SYSTEMS.

3

FIELD INSTALLED JUMPER.

Fig. 10. Typical hookup of T8401C1031 in single-

COMPRESSOR

24V

stage heat pump system.

HEAT

RELAY

system.

3

B

O

COOL

RELAY

B

O

FAN

RELAY

2

HEAT

CHANGEOVER

2

COOL

CHANGEOVER

FAN

RELAY

M2088

M2088

Mounting Thermostat to Wallplate

1. Engage the tabs at the top of the thermostat and

wallplate.

2. Swing down the thermostat and press the lower

edge of the thermostat onto the wallplate to latch.

See Fig. 11.

DASHED LINES INDICATE TABS

ON BACK OF THERMOSTAT

FAN

Auto On

SYSTEM

Cool Off Heat

A

ENGAGE T ABS AT TOP OF THERMOSTA T

WITH SLOTS ON MOUNTING PLATE.

FAN

Auto On

SYSTEM

Cool Off Heat

PRESS LOWER EDGE OF

B

M14677

Fig. 11. Mounting thermostat wallplate.

OPERATION

Setting FAN and SYSTEM Switches

Fan and system settings are controlled manually by

using the switches located at the bottom of the

thermostat case. See Fig. 12.

69-1484-2 4

FAN Switch

Fan switch settings are:

On: The fan runs continuously. Use for improved air

circulation and air quality.

Auto: Normal setting for most homes. In cooling, the

fan starts and stops with the cooling equipment. In

heating, the fan is controlled directly by the heating

equipment and may start a few minutes after the

heating equipment turns on (on most systems).

When using an electric heat thermostat, the fan

starts and stops with the heating equipment.

Slide the FAN switch in the bottom left corner of the

thermostat to select the desired fan setting.

Page 5

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

S

9

0

1

2

3

4

5

6

SYSTEM Switch

System switch settings control thermostat operation as

follows:

Cool: The thermostat controls the cooling system.

Off: Both heating and cooling are off.

Heat: The thermostat controls the heating system.

Slide the SYSTEM switch in the bottom right corner of

the thermostat to select the desired system setting.

TEMPERATURE DISPLAY

INCREASE SETTING

DECREASE SETTING

FAN

Auto On

SYSTEM

FAN SWITCH

Fig. 12. Digital display and system

switches (FAN and SYSTEM).

Cool Off Heat

SYSTEM SWITCH

M14678

Set Temperature Setpoint

NOTE: Temperature setpoint range is 40° to 99°F (5° to

37°C).

The temperature setpoint and the room temperature are

shown separately on the digital display. The ▼ indicator

points to Set when the temperature setpoint is displayed

and to Room when the room temperature is displayed.

.

INDICATOR

ROOM TEMPERATURE

Room

et

SETPOINT TEMPERATURE

To set temperature setpoint:

1. Select Heat or Cool by sliding the SYSTEM switch

in the lower right corner of the thermostat to the

desired mode. See Fig. 12.

2. To display the temperature setpoint on the digital

display, press either the ▲ or ▼ key once. The tem-

perature setpoint is displayed for approximately

five seconds as the indicator points to Set and

flashes.

M1468

M1467

3. To increase the temperature setpoint press the ▲

key. Each press changes the setpoint one degree;

press and hold to change the setpoint several

degrees.

M1468

4. To decrease the temperature setpoint press the ▼

key. Each press changes the setpoint one degree;

press and hold to change the setpoint several

degrees.

M1468

Setting °F/°C Indication and Heat Cycle Rate

NOTE: To save changes to the °F/°C indication, the

heat cycle rate and the C3/C1 temperature

control, tap the ▲ key until exiting the installer

setup.

To set the °F/°C indication, the heat cycle rate and the

C3/C1 temperature control:

1. If the temperature is displayed in °F, set the temperature setpoint to 52°F. If the room temperature

is displayed in °C, set the temperature setpoint to

11° C.

M1468

OPTIONAL SYSTEM CHECKOUT

When in steps 2 and 3 only, the

turn heat or cool outputs on and off. Change the

SYSTEM switch setting to test heat or cool outputs. No

action takes place If the system switch is in the Off

position.

Examples: System setting at HEAT: If heat is on, the ▼

key turns it off; if heat is off, ▼ turns it on.

System setting at COOL: If cool is on, ▼ key

turns it off; if cool is off, ▼ turns it on.

2. Press the ▲▼ keys simultaneously for more than

one second to light all segments on display and to

enter installer setup mode. When the keys are

released, a two-digit software revision code is displayed.

▼

key can be used to

M1468

M1468

M1468

5 69-1484-2

Page 6

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

7

8

9

0

A

0

NOTE: In installer setup mode only, each press of the

▲ key momentarily displays 01. Each press of

the ▼ key momentarily displays 02. When the

keys are released, these two-digit codes are no

longer displayed.

3. Press the ▲ key. Factory information is displayed.

A typical example is shown, but information displayed varies by model. This information is for factory use only.

M1468

4. Press the ▲ key again to display °C or °F.

M1468

5. Press the ▼ key to change the °C or °F indication.

M1468

6. Press the ▲ key to display the heat cycle rate of 1,

3, 4, 5, 6, 9, or 12. To change the heat cycle rate,

press the ▼ key to scroll between 1, 3, 4, 5, 6, 9, or

12. Stop scrolling when the desired rate is displayed. See Table 1 for the cycle rate options and

the corresponding system equipment.

M1469

7. Press the ▲ key to display heating/cooling temper-

ature control default..

M18419

8. Press the ▼ key again to change heating/cooling

temperature control to C1 or C3.

C1 = Standard heating/cooling temperature

control.

C3 = Aggressive heating/cooling temperature

control (can cause room temperature to

9. Press the ▲ key again. Factory information (varies

overshoot the setpoint).

by model) is shown.

M1842

Table 1. Heating Cycle Rates.

System Cycles Per Hour

Steam, gravity 1

Hydronic heat, condensing gas

a

furnace

3

Gas or oil forced air 6

Electric heat 9

Special applications

a

High efficiency furnace.

b

Refer to equipment manufacturer’s instructions.

10. Press the ▲ key to save all changes, exit installer

setup mode and return to normal operation.

NOTE: After exiting installer setup mode, slide the

System switch to the desired position and

change the setpoint to the desired room

temperature.

b

4, 5, 12

CHECKOUT

Heating

1. Slide the SYSTEM switch to Heat and the FAN

switch to Auto.

2. Press and hold the ▲ key to raise the temperature

setting several degrees above the room temperature. After approximately ten seconds, the heating

equipment should start. In conventional systems,

the system turns on the fan through the use of a

time delay relay or through a limit control. When

using an electric heat thermostat, the fan starts

immediately.

3. Press the ▼ key to lower the temperature setting

below the room temperature. Heating equipment

should stop.

Cooling

CAUTION

Low Temperature Hazard.

Operating at too low of an outdoor

temperature may cause compressor damage.

Do not operate cooling if outdoor temperature is

below 50°F (10°C). Refer to manufacturer’s

recommendations.

• For compressor protection, during power

interruption and on initial startup, the T8400

and T8401 Thermostats go into a five-minute

delay. During this delay, the cooling icon (a

snowflake ❄) flashes.

1. Slide the SYSTEM switch to Cool and the FAN

switch to Auto.

2. Press the ▼ key to lower the temperature setting

several degrees below the room temperature. After

approximately five minutes, the cooling equipment

should start. The fan starts and stops with the cooling equipment.

69-1484-2 6

Page 7

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

3. Press the ▲ key to raise the temperature setting

above the room temperature. Cooling system

should shut down.

NOTE: To bypass the five-minute delay, see the

Optional System Checkout section.

Fan

1. Slide the SYSTEM switch to Off and the FAN

switch to On. The fan should run continuously.

2. Slide the FAN switch to Auto. In heating, the fan is

controlled directly by the heating equipment and

may start a few minutes after the heating equipment turns on (on most systems). When using an

electric heat thermostat, the fan starts and stops

with the heating equipment. In cooling, the fan

starts and stops with the cooling equipment.

Be sure all equipment responds correctly to the

thermostat.

7 69-1484-2

Page 8

T8400C1099, T8401C1031 ELECTRONIC THERMOSTATS

Automation and Control Solutions

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

M1V 4Z9

69-1484-2 G.H. Rev. 11-02 Printed in Mexico www.honeywell.com/yourhome

Loading...

Loading...