Page 1

T7770A,B,C,D,E,F,G

Wall Modules

INSTALLATION INSTRUCTIONS

BEFORE INSTALLATION

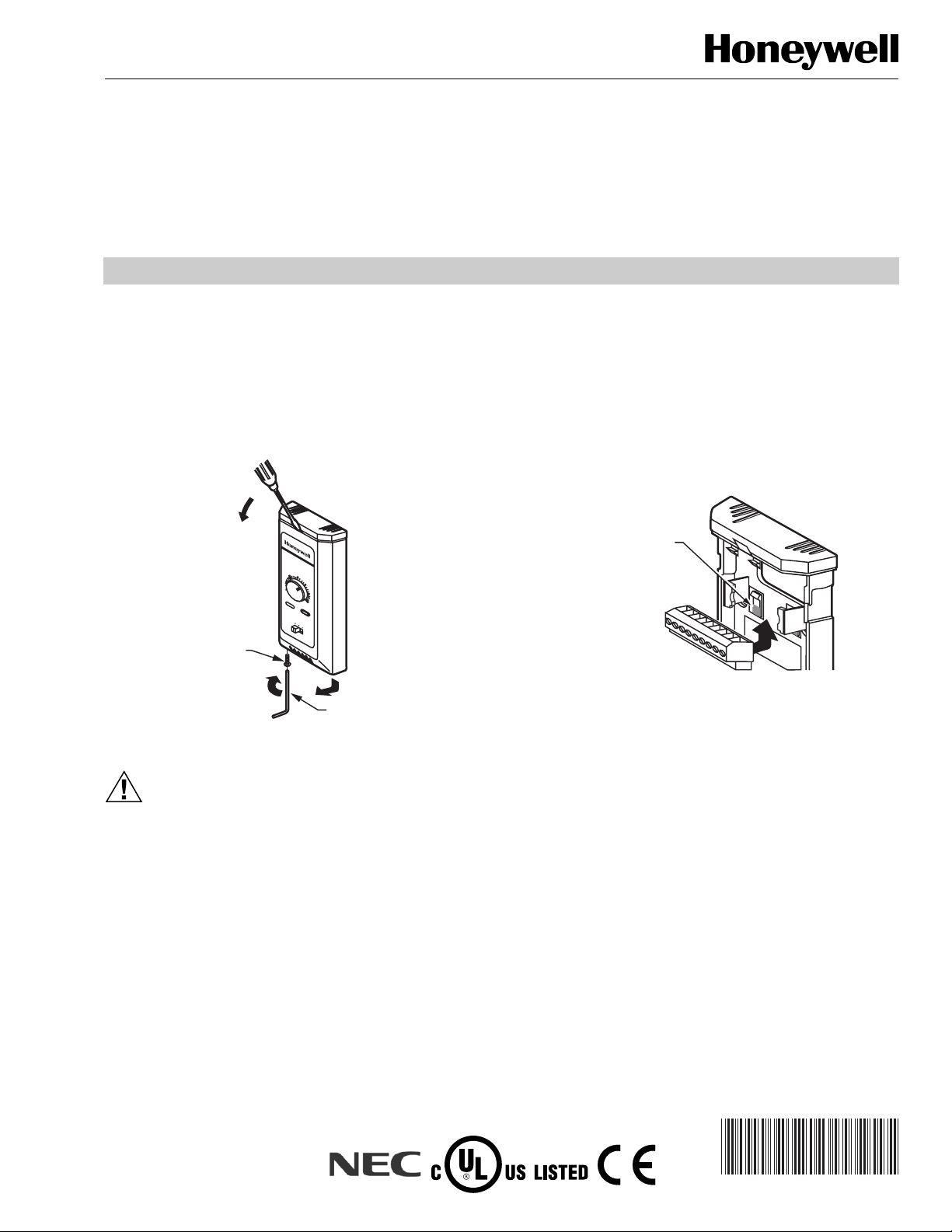

Cover Disassembly

Two locking mechanisms are used on the cover of the wall

module. After installation, to disassemble the cover and the

subbase see Fig. 1.

T7770E

STEP 2

65

70

60

75

55

80

85

auto

0

BUTTON HEAD

SOCKET CAP

SCREW

STEP 1

M11394

Fig. 1. Cover disassembly.

1

STEP 3

ALLEN TOOL

— Wall module wiring can be sized from 14 to 22 AWG

(2.0 to 0.34 sq mm) depending on the application.

— The maximum length of wire from a device to a wall

module is 1000 ft (305m).

— Twisted pair wire is recommended for wire runs longer than

100 ft (30.5m).

— The cover for the wall module is packed separately from

the subbase for ease of installation.

See Fig. 2 to release/replace the subbase terminal block.

PRESS SHADED AREA

OF TAB WITH THUMB TO

RELEASE TERMINAL BLOCK

FOR EASIER WIRING

M17988

Fig. 2. Releasing/replacing terminal block.

INSTALLATION

CAUTION

Erratic System Operation Hazard.

Failure to follow proper wiring practices can

introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive

loads such as motors line starters, lighting ballasts,

and large power distribution panels.

Shielded cable is required in installations where these

guidelines cannot be met.

Ground shield only to grounded controller case.

IMPORTANT

All wiring must comply with local electrical codes

and ordinances or as specified on installation

wiring diagrams.

® U.S. Registered Trademark

© 2004 Honeywell International Inc.

All Rights Reserved

Mount the T7770A,B,C,D,E,F,G Wall Modules on an inside

wall approximately 54 in. (1372 mm) from the floor (or in the

specified location) to allow exposure to the average zone

temperature. Do not mount the wall modules on an outside

wall, on a wall containing waterpipes or near air ducts. Avoid

locations that are exposed to discharge air from registers or

radiation from lights, appliances, or the sun.

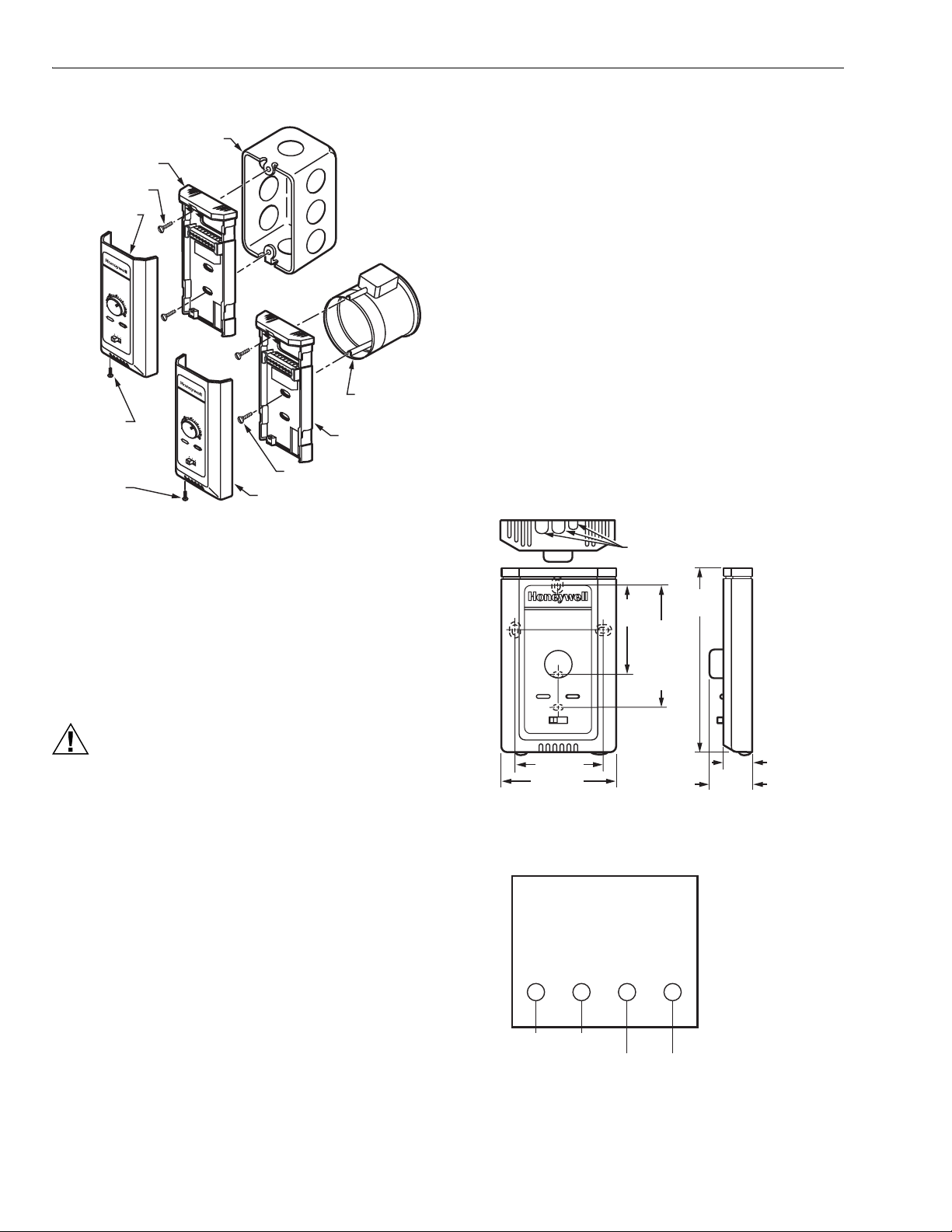

The wall modules can be mounted on a wall, on a standard

utility conduit box using No. 6 (3.5 mm) screws or on a 60 mm

wall outlet box (see Fig. 3). When mounting directly on a wall,

use the type of screws appropriate for the wall material.

95-7538—4

Page 2

T7770A,B,C,D,E,F,G WALL MODULES

STANDARD UTILITY

CONDUIT BOX

SUBBASE

NO. 6 SCREW

FRONT COVER

6

5

7

0

6

0

7

5

5

5

8

0

8

5

auto

0

1

BUTTON

HEAD

SOCKET

CAP SCREW

BUTTON

HEAD

SOCKET

CAP SCREW

6

5

7

0

6

0

7

5

5

5

8

0

8

5

auto

0

1

3.5 mm SCREW

FRONT COVER

60 mm WALL

OUTLET BOX

SUBBASE

M17989

Fig. 3. Mounting wall modules on standard utility

conduit box or 60 mm wall outlet box.

See Fig. 4 for subbase mounting dimensions.

Wiring

Attach the wires from the device sensor terminals to the

appropriate wall module terminals. See Fig. 5 through 16.

NOTE: None of these wall modules are compatible with

W7751A,C,E,G Controllers.

NOTE: Unless otherwise noted, sensor and E-Bus

terminals are not polarized; reversing the two sensor

leads does not affect the signal.

Wiring Modules With a Removable Terminal Block

Wire the terminal blocks as follows:

1. For single wires, strip 3/16 in. (5 mm); for multiple wires

going into one terminal, strip 1/2 in. (13 mm) insulation

from the conductor.

2. If two or more wires are being inserted into one

terminal, twist the wires together before inserting.

NOTE: When two or more wires are being inserted

into one terminal, be sure to twist them

together. Deviation from this rule can result

in improper electrical contact. See Fig. 17.

3. Insert the wire in the required terminal location and

tighten the screw to complete the termination.

4. Verify wall module wiring with Fig. 5 through 16.

NOTE: Wire the E-Bus using Level IV 22 AWG (0.34 sq mm)

plenum or non-plenum rated, unshielded, twisted

pair, solid conductor wire.

KNOCKOUTS FOR

EUROPEAN APPLICATIONS

UTILITY

CONDUIT

HOLES

5-1/16

(128)

2-3/8

(60)

STANDARD

BOX (2 X 4)

MOUNTING

CAUTION

Improper Electrical Contact Hazard.

Screw type terminal blocks are designed to accept

no more than one 14 AWG (2.5 sq mm) conductor.

Connect multiple wires that are 14 AWG (2.5 sq mm)

with a wire nut. Include a pigtail with this wire group

and attach the pigtail to the individual terminal block.

Wiring Modules Without a Removable Terminal Block

Attach the wires as follows:

1. Connect controller sensor leads to the sensor screw

terminals.

NOTE: T7770A1006 have a 20K ohm sensor,

T7770A3002 have a 10K ohm sensor. They

are for use in averaging for the T7350. They do

not have E-bus network terminals.

2. If the module has E-bus terminals, connect the

controller E-bus leads to these screw terminals.

NOTE: Wire the E-Bus using Level IV 22 AWG

(0.34 sq mm) plenum or non-plenum rated,

unshielded, twisted pair, solid conductor wire.

95-7538—4 2

2-3/8 (60)

3-3/16 (80)

15/16

(23)

1-1/4 (32)

M17990

Fig. 4. T7770A,B,C,D,E,F,G Subbase

dimensions in in. (mm).

SENSOR SENSOR E-BUS E-BUS

SENSOR

SENSOR

NETWORK

BUS

E-BUS TERMINALS

ARE NOT USED FOR

C-BUS DEVICES.

NETWORK

BUS

M20359

Fig. 5. Wiring diagram for T7770A20XX Wall Modules.

Page 3

T7770A,B,C,D,E,F,G WALL MODULES

E-BUS TERMINALS

ARE NOT USED FOR

C-BUS DEVICES.

M11400

SETPT

AI COM

(OR) GND

SENSOR

E-BUS

123456789

E-BUS

Fig. 6. Wiring diagram for T7770B10XX Wall Modules.

PRINTED WIRING BOARD

DIP SWITCH POSITIONS

LED

BYPASS

SETPT

SENSOR

E-BUS

AI COM

(OR) GND

(S4-1,2,3,4=ON; 5=OFF)

E-BUS

123456789

S4

1

2345

ON

M11401

Fig. 7. Wiring diagram for T7770C10XX Wall Modules

wired to Excel 10 W7750, W7751, W7752.

2

1

BYPASS

LED

1

2

LED

RETURN

BYPASS

RETURN

USING AN EXCEL 20 WITH THIS WALLMODULE REQUIRES WIRING (AT

CONTROLLER) THE 1500 OHM BAG ASSEMBLY RESISTOR IN SERIES

WITH TERMINAL 7.

TERMINAL 5 IS USED ONLY WITH T7770C MODEL SENSORS.

SETPT

AI COM

SENSOR

NOTE: CHANGE AND VERIFY

DIP SWITCH POSITIONS FOR

THESE EXCEL CONTROLLERS

(S4-1,4=ON; 2,3,5=OFF)

S4

1

123456789

2345

ON

M11402

Fig. 8. Wiring diagram for T7770C10XX, D10XX

Wall Modules wired to Excel 600/500/100/80/20.

NOTE: VERIFY DIP

SWITCH POSITIONS

LED

BYPASS

1

1

TERMINAL 5 IS USED ONLY WITH T7770C MODEL SENSORS.

SETPT

SENSOR

GND

E-BUS

(S4-1,3,5=ON; 2,4=OFF)

E-BUS

123456789

S4

1

2345

ON

M11403

NOTES:

—T7770E HAS A SINGLE-SPEED FAN

LED

FAN

SPEED

SWITCH

BYPASS/FAN

SETPT

GND

SENSOR

—T7770F HAS A THREE-SPEED FAN

E-BUS

E-BUS

—VERIFY DIP SWITCH POSITIONS

(S4-1,2,3,4=ON; 5=OFF)

123456789

2345

S4

1

ON

Fig. 11. Wiring diagram for T7770E10XX, F10XX

Wall Modules wired to Excel 10 W7752.

NOTES:

1

BYPASS/FAN

LED

LED

RETURN

1

USING AN EXCEL 20 WITH THIS WALL MODULE REQUIRES WIRING (AT

CONTROLLER) THE 1500 OHMBAG ASSEMBLY RESISTOR IN SERIES

WITH TERMINAL 7.

SETPT

FAN

SPEED

SWITCH

AI COM

SENSOR

—T7770E HAS A SINGLE-SPEED FAN

—T7770F HAS A THREE-SPEED FAN

—CHANGE AND VERIFY DIP SWITCH

POSITIONS FOR THESE EXCEL

CONTROLLERS (S4-2,4=ON;

1,3,5=OFF)

123456789

S4

1

2345

ON

Fig. 12. Wiring diagram for T7770E10XX, F10XX

Wall Modules wired to Excel 600/500/100/80/20.

1

FAN

BYPASS

LED

1 TERMINAL 5 IS USED ONLY WITH T7770E,F MODEL SENSORS.

SETPT

FAN

SPEED

SWITCH

GND

SENSOR

NOTE:

—T7770E HAS A SINGLE-SPEED FAN

—T7770F HAS A THREE-SPEED FAN

—VERIFY DIP SWITCH POSITIONS

E-BUS

E-BUS

(S4-1,3,5=ON; 2,4=OFF)

123456789

S4

1

2345

ON

Fig. 13. Wiring diagram for T7770E10XX, F10XX,

G10XX Wall Modules wired to Excel 10 W7753.

M11407

M11408

M11409

Fig. 9. Wiring diagram for T7770C10XX, D10XX

Wall Modules wired to Excel 10 W7753.

NOTE: VERIFY DIP

SWITCH POSITIONS

LED

BYPASS

GND

SENSOR

E-BUS

(S4-1,2,3,4=ON; 5=OFF)

E-BUS

123456789

S4

1

2345

ON

M11404

Fig. 10. Wiring diagram for T7770D10XX Wall Modules

wired to Excel 10 W7750, W7751, W7752.

NOTES:

LED

BYPASS/FAN

FAN

SPEED

SWITCH

GND

SENSOR

—T7770G HAS A THREE-SPEED FAN

E-BUS

E-BUS

—VERIFY DIP SWITCH POSITIONS

(S4-1,2,3,4=ON; 5=OFF)

123456789

S4

1

2345

ON

M11410

Fig. 14. Wiring diagram for T7770G10XX Wall

Modules wired to Excel 10 W7752.

3 95-7538—4

Page 4

T7770A,B,C,D,E,F,G WALL MODULES

1

BYPASS/

FAN

LED

LED

RETURN

1

USING AN EXCEL 20 WITH THIS WALL MODULE REQUIRES WIRING

(AT CONTROLLER) THE 1500 OHM BAG ASSEMBLY RESISTOR IN SERIES

WITH TERMINAL 7.

FAN

SPEED

SWITCH

AI COM

SENSOR

NOTES:

—T7770G HAS A THREE-SPEED FAN

—CHANGE AND VERIFY DIP SWITCH

POSITIONS FOR THESE EXCEL

CONTROLLERS (S4-2,4=ON;

1,3,5=OFF)

123456789

S4

1

2345

ON

Fig. 15. Wiring diagram for T7770G10XX Wall

Modules wired to Excel 600/500/100/80/20.

T7350 SUBBASE

T4 T3

T3

T4

T7770A3002

THE T7771A3002 IS A 10K OHM SENSOR.

1

T4

11

T7770A3002

T3

M22408

M11411

1.

1/2

(13)

STRIP 1/2 IN.

(13 MM) FROM

WIRES TO BE

ATTACHED AT

ONE TERMINAL.

2.

TWIST WIRES

TOGETHER

WITH PLIERS

(A MINIMUM OF

THREE TURNS).

CONTROLLER OR

WALL MODULE

E-BUS CONNECTOR

TERMINALS

3.

CUT TWISTED END OF WIRES TO

3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE

IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M11413

Fig. 17. Attaching two wires at wall module terminals.

When all wiring is complete, attach the cover of the

T7770A,B,C,D,E,F,G Wall Module by reversing step 3

of Fig. 1. Insert and tighten locking screw by reversing

step 1 on Fig. 1.

NOTE: The locking screw must be installed and tight for

a secure T7770 installation.

Fig. 16. Two T7770A3002 Wall Modules wired to a T7350

for temperature averaging.

Automation and Control Solutions ACS Control Products

Honeywell International Inc. Honeywell Limited-Honeywell Limitée Honeywell AG

1985 Douglas Drive North 35 Dynamic Drive Böblinger Straße 17

Golden Valley, MN 55422 Scarborough, Ontario D-71101 Schönaich

M1V 4Z9 Phone (49-7041) 637-01

Fax (49-7041) 637-493

95-7538—4 B.B. Rev. 7-04 www.honeywell.com

Loading...

Loading...