Page 1

62-0255-07

T775U Series 2000 Electronic

Stand-Alone Controller

INSTALLATION INSTRUCTIONS

PRODUCT DESCRIPTION

The T775 electronic stand-alone controllers are the next

generation of universal controls capable of remote

sensing of temperature, humidity, pressure, etc. and

providing switched and proportional outputs to various

types of loads. A built-in time clock is standard.

The T775U controller allows a wide range of sensors to

be configured. Humidity, pressure, temperature, or any

0-5 Vdc, 0-10 Vdc, or 4-20 mA input is supported.

A Reset function is available where the Sensor B

temperature (e.g. outside temperature) is used to provide

reset control for Sensor A (e.g. humidity). For example,

as the outside temperature gets colder, the setpoint can

automatically be adjusted to prevent condensation.

IMPORTANT

The T775U is an operating control, not a limit or

safety control. If used in applications requiring

safety or limit controls, a separate safety or limit

Table 1. T775U Controller Configurations.

Controller

a

Model

T775U2006

T775U2016 N/A Yes 2 2

a

The T775U includes a digital input for use with the disable or setback option.

b

The modulating (analog) outputs may be 4-20 mA, 0-10 Vdc, 2-10 Vdc, or Series 90 selectable.

c

For the H775C1004, H775D1003, and H775E1002 model replacement, the T775U only partially replaces the function

of these devices. Check application for suitability.

d

For the sensor inputs, Sensor A can be 0-10Vdc, 4-20mA, or a standard temperature input. Sensor B is a standard

temperature sensor input only. Sensor B is used only for reset on the T775U2001.

e

The T775U2016 can control Sensor A (universal) and Sensor B (temperature) independently, like other standard

T775 controllers.

Description Replaces

H775A1006

H775A1022

Universal:

Humidity,

Pressure,

Temperature,

etc.

H775A1048

H775A1063

H775B1005

H775C1004

H775D1003

H775E1002

Output

Reset

Yes 2 2

c

c

c

control device is required.

SPDT

Relay

Outputs

Analog

(Mod)

Outputs

b

Sensor

Sensors

Inputs

Included Enclosure

d

2

e

2

Nbr of

None NEMA 1

None NEMA 1

E4436

Page 2

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

Temperature Sensorsa (Sensor A or B)

The controller accepts 1,097 Ohms PTC at 77°F (25°C):

• 50021579-001 – Standard sensor (included with all

models except NEMA 4X models)

• T775-SENS-WR – Water resistant with 5 foot leads

(included with NEMA 4X models)

• T775-SENS-WT – Watertight with 6 foot lead

• T775-SENS-OAT – Outdoor air temperature sensor

• C7031D2003 – 5 inch immersion sensor with wiring

box (use immersion well; P/N 50001774-001)

• C7031J2009 – 12 foot duct averaging sensor with

wiring box

• C7046D1008 – 8 inch duct probe with mounting flange

• C7100D1001 – 12 inch fast response, duct averaging

sensor with flange

• C7130B1009 – Room mount sensor

Differential Pressure Sensors

(Sensor A only)

P7640A and PWT pressure transducer models with

selectable pressure ranges can be used.

The controller accepts pressure sensors with a signal

output of 0-10 Vdc or 4-20 mA for any output range within

the following ranges (the minimum and maximum for the

sensor output range can be adjusted within the following

limits):

• -500 to 500 PSI

• -30.0 to 30.0 inches w.c.

• -3,000 to 3,000 Pa

• -3,000 to 3,000 kPa

Humidity Sensors (Sensor A only)

The controller accepts 0-10 Vdc or 4-20 mA input with a

range of 0-100%.

H7625, H7635, and H7655 models (available in 2, 3, and

5% RH accuracy) can be used.

CO2 Sensors

The controller accepts a 0-10 Vdc or 4-20 mA input from

C7232 and C7632 CO

units.

sensors and is settable in PPM

2

Universal Sensors (Sensor A only)

The controller accepts 0-5 Vdc, 0-10 Vdc or 4-20 mA input

for temperature, pressure, humidity CO

be programmed in units of °F, °C, %, Pa, kPa, PSI, In

W.C., PPM, or may be unitless (none).

The PPM range is 0 to 9990.

Choosing none for units, results in no units being

displayed on the home screen. If no unit is specified the

range is -9999 to +9999.

Actuators

For more information on compatible actuators or other

Honeywell products, such as dampers and valves, go to

www.customer.honeywell.com

select Product Selection Tool under Products.

• Spring return models: ML6425, ML7425, MS4105,

MS4110, MS4120, MS7505, MS7510, MS7520,

MS8105, MS8110, MS8120

• Non-spring return models: ML4161, ML6174, ML7161,

MN6105, MN1010, MN7505, ML7164, MN8810

, etc. They may

2

. From the home page

Accessories

• 107324A – Bulb Holder, duct insertion

• 107408 – Heat Conductive Compound, 4 ounce

• 50001774-001 – Immersion Well, stainless steel 304,

1/2 in. threading

Product Changes

Below are the changes to T775U models starting with

Series 3 (March 2009). Series 3 can be identified by the

sideways 3 after the part number on the device label.

1. Setpoint and Enable options added to the DI

options.

2. 0-5 Vdc sensor inputs are now available (for both

models).

3. MIN ON time added.

4. HIDE option added to MOD1 and MOD2 (to hide

them on the home screen).

5. PPM and None added to sensors’ unit of measure.

6. With the new T775U2016 model, all outputs can be

controlled to Sensor A or Sensor B. The

T775U2006 model controls only to Sensor A.

a

See form 62-0265 – Temperature Sensors for the T775

Series 2000 Stand-alone Controller

62-0255—07 2

Page 3

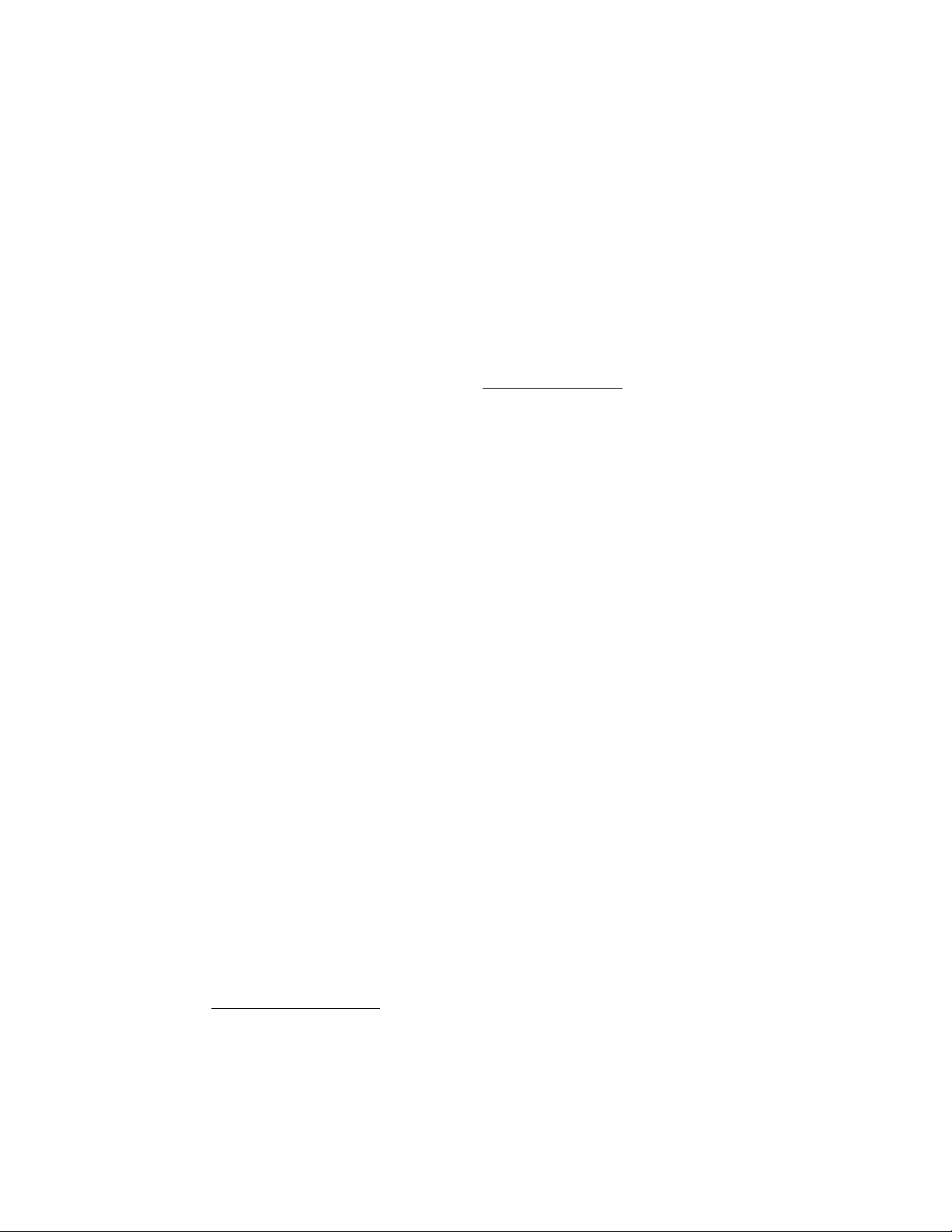

Controller Dimensions

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

1 (25.5)

7/8 (22.5)

2 15/16 (74)

LEFT RIGHT

4 1/16 (103.4)

1/64 (3.8)

8 5/32

(207.1)

4 1/16 (103.4)

2 11/16 (68.1)

7/8 (22.5)

7 23/32

(196)

7/8 (22.5)

Fig. 1. T775U Dimensions in inches (mm).

BEFORE INSTALLATION

Review the “Specifications” on page 37 before

installing the controller.

When Installing This Product

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the product to ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

INSTALLATION AND SETUP

The following installation procedures are typically

performed in the order listed:

1. Mounting — see “Mounting” below.

2. Wiring — see “Wiring” on this page.

3. Checkout — see page 10.

Interface and Programming overview – see page 11.

4.

5. Setup – see page 13.

TOP

4 13/32 (112.1)

3 31/32 (101)

FRONT VIEW

1 (25.5)

BOTTOM

Programming the Controller with no Reset – see page 25

6.

or

Programming the Controller with Reset – page 28.

7. Scheduling (optional)— see page 33.

Additional topics are:

• Sensor calibration begins on page 10.

• Interface overview begins on page 11.

• Summary menu begins on page 37.

• Troubleshooting begins on page 37.

1/2 (12.4)

MOUNTING

This section describes the mounting procedures for the

controller and temperature sensor(s).

Controller Mounting

IMPORTANT

Avoid mounting in areas where acid fumes or

other deteriorating vapors can attack the metal

parts of the controller circuit board, or in areas

where escaping gas or other explosive vapors

are present.

IMPORTANT

The controller must be mounted in a position that

allows clearance for wiring, servicing, and

removal.

2 13/16 (71.8)

7/8 (22.5)

M24546

3 62-0255—07

Page 4

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

CAUTION

Use a screwdriver to pry out only the knockouts that you

will use.

If mounting on DIN rail, be sure to remove the knockouts

before mounting. See “Controller Wiring” on page 7 and

Fig. 12 on page 9 for recommended knockout usage and

locations. If you do not use an opened knockout be sure

to cover it.

Mount the controller on any convenient interior location

using the four mounting holes provided on the back of the

enclosure using #6 or #8 screws (screws are not provided

and must be obtained separately). Use controller

dimensions in Fig. 1 on page 3 as a guide.

The controller may be mounted in any orientation.

However, mounting in the orientation shown in Fig. 1 on

page 3 permits proper viewing of the LCD display and use

of the keypad.

Humidity, Pressure, and Universal

Sensor(s) Mounting and Location

These sensors may be mounted on a wall or panel.

Follow the installation instructions specific to the sensor

you are installing.

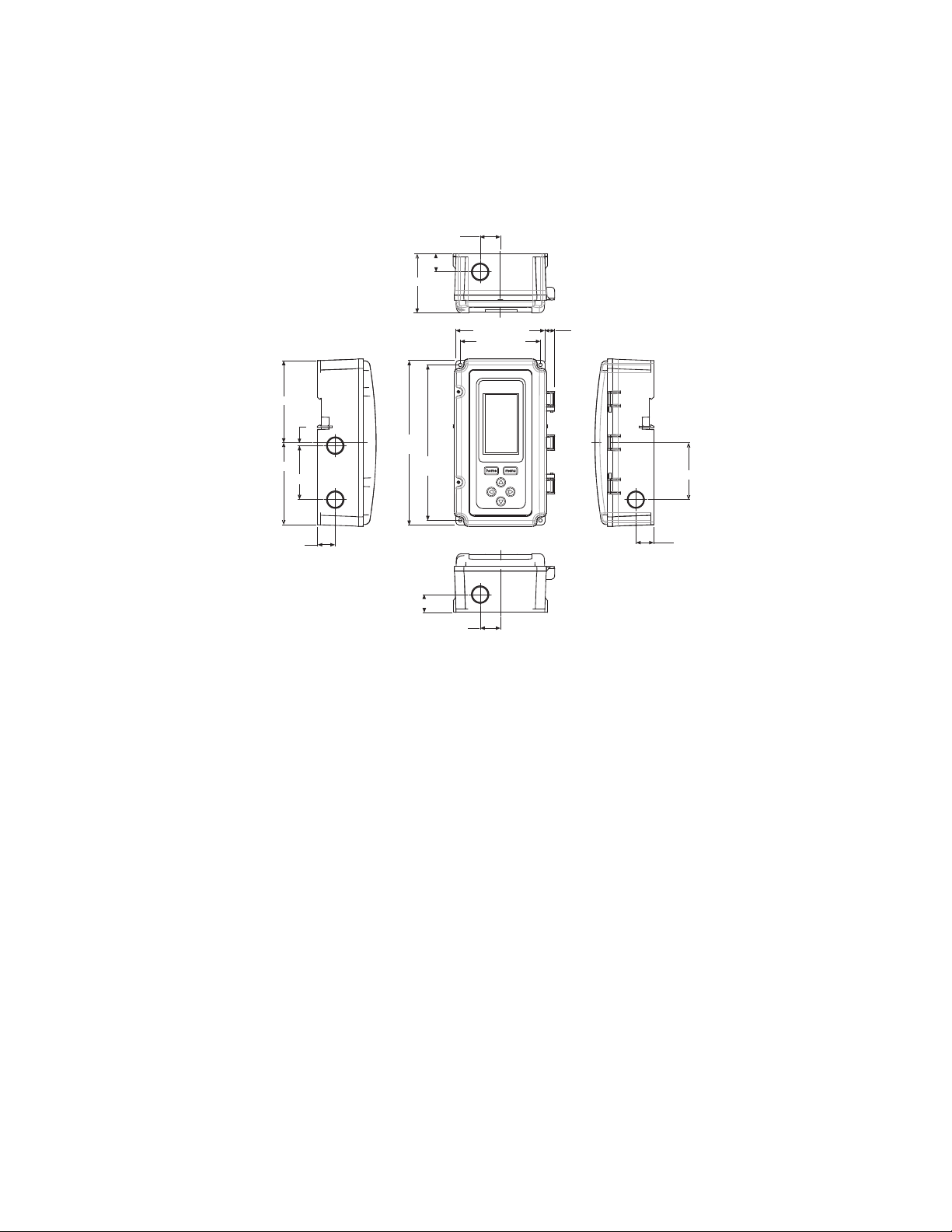

Temperature Sensor(s) Mounting

and Location

Temperature sensors may be located up to 1,000 feet

(304 m) from the T775U controller. See Table 4 on

page 11 for calibration guidelines.

The sensors may be mounted on a wall or panel for

sensing space temperature, strapped to a pipe or inserted

in an immersion well (see Fig. 2) for hot or cold water

sensing, or taped to a standard cap or bulb holder for duct

air sensing. To prevent moisture or condensation entering

the sensor through the lead wire holes, mount the sensor

with the lead wires exiting the bottom of the sensor.

NOTES:

1. The included sensor is not designed for very

wet applications. For immersion applications,

an immersion well is used.

2. Heat conductive compound must be used in

immersion wells.

3. See “Temperature Sensors (Sensor A or B)”

on page 2 for this type of installation.

SENSOR

PLACED

IN WELL

USE HEAT

CONDUCTIVE

COMPOUND

WIRING

All wiring must comply with applicable electrical codes

and ordinances, or as specified on installation wiring

diagrams. Controller wiring is terminated to the screw

terminal blocks located inside the device.

The remainder of this section describes the sensor wiring

and the T775U controller wiring.

Wiring Connections Access

To access the wiring connections, remove the two screws

on the left side of the enclosure and gently swing open the

top. Be careful to not stress the ribbon cables that

connect the keypad and LCD display to the controller

circuit board.

Temperature Sensor Wiring

Electrical Shock Hazard.

Can short equipment circuitry.

Make sure that metal tube of sensor does not

short against T terminals in wall-mounted case.

IMPORTANT

Poor wiring practices can cause erratic readings

from the sensor. Avoid the following to ensure

proper operation:

• Do not route the temperature sensor wiring with

building power wiring.

• Do not locate the temperature sensor wiring next

to control contactors.

• Do not locate the temperature sensor wiring near

electrical motors.

• Do not locate the temperature sensor wiring near

welding equipment.

• Make sure good mechanical connections are

made to both the sensor and the controller.

• Do not mount the sensor with the lead wire end

pointing up in an area where condensation can

occur.

If any of the above conditions cannot be

avoided, use shielded cable.

NOTE: Each T775 controller must be wired to its own

sensor(s). However, a benefit of the T775

controller’s accuracy is that there is no more

than a 2°F differential between any two T775

controllers.

1/2 NPT

Fig. 2. Sensor inserted in immersion well.

NOTE: Multiple sensors may be parallel-series wired to

sense average temperatures in large spaces.

See Fig. 3 on page 5.

62-0255—07 4

IMMERSION

WELL

M24379

Reset Temperature Control

If you are implementing two-sensor reset control, Sensor

A must always be the controlled temperature and Sensor

B must always be the controlling temperature.

For example, in a reset control based on outside

temperature, Sensor A must be the inside sensor and

Sensor B must be the outside sensor.

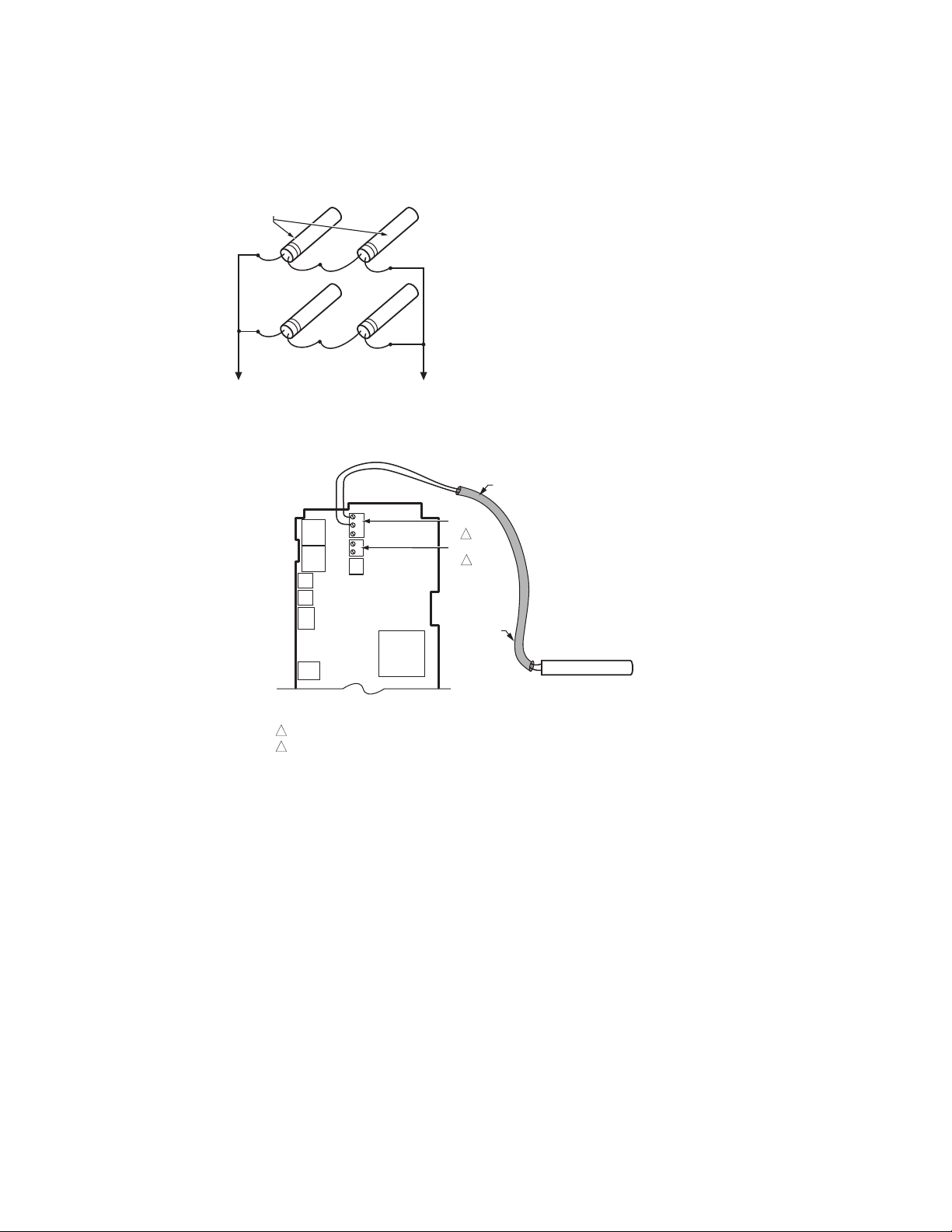

Multiple Parallel Temperature Sensors

Multiple sensors can be parallel-series wired to sense

average temperatures in large spaces. To maintain

control accuracy, the number of sensors to be parallelseries wired must be of the n

16, etc.). See Fig. 3.

2

power (for example, 4, 9,

Page 5

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

SENSORS

TO T775 CONNECTIONS (SENSOR A) OR (SENSOR B).

M24548

Fig. 3. Parallel-series wiring of sensors.

T

T

T

T

Temperature Sensor Wire Type and Size

Temperature sensors use standard AWG 18/2 unshielded

wire. For cable runs greater than 25 feet or where

electrical interference may be a problem, shielded cable

is recommended. See Fig. 4.

Refer to “Temperature Sensor Calibration” on page 10 for

wire size selection where cable runs are longer than

25 feet.

SHIELDED

CABLE

SENSOR A

1

SENSOR B

2

NOTE: SHIELDED CABLE MUST BE

CONNECTED TO A SEPARATE EARTH

GROUND.

HOWEVER, DO NOT GROUND

SHIELDED CABLE AT SENSOR END.

SHIELDED

CABLE

SENSOR

NOTE: TO MINIMIZE NOISE PICKUP,

MAKE SENSOR CONNECTION FROM

SHIELDED CABLE AS CLOSE AS

POSSIBLE TO SENSOR BODY.

SENSORS A AND B ARE POLARITY INSENSITIVE WHEN USING A 1097 OHM PTC TEMPERATURE SENSOR.

1

SENSOR B IS USED ONLY IN RESET APPLICATIONS ON THE T775U20006.

2

Fig. 4. Sensor Wiring — 2-wire shielded cable connection from Sensor A to temperature sensor.

Humidity, Pressure, and Universal

Sensor Wiring

Sensors with a 0-5 Vdc, 0-10Vdc or 4-20mA input to the

T775U must be wired to the Sensor A terminal. Sensor B

is used only as a temperature input.

Sensors use standard AWG 18 unshielded wire. For cable

runs greater than 25 feet, shielded cable is

recommended.

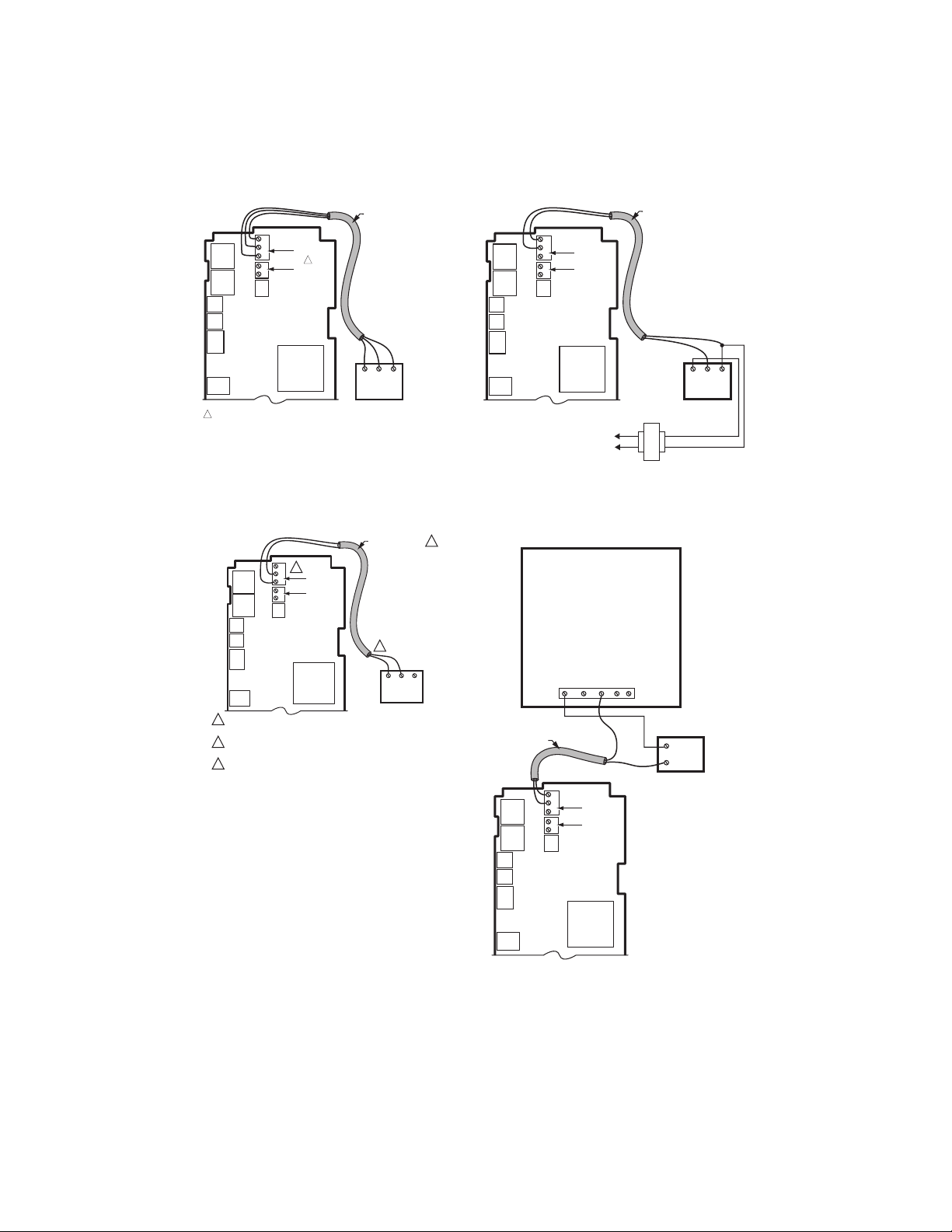

The sensors in Fig. 5 – 8 beginning on page 6 are

examples and illustrate voltage and current wiring for 3wire and 2-wire sensors to the Sensor A terminal. For

terminal wiring details, see Fig. 11 and Table 2 on page 8.

Other sensors are supported. See sensor descriptions on

page 2.

NOTES:

1. Other transmitters can be wired in the same

manner. For example, the 0-10Vdc wiring

shown in Fig. 5 on page 6 with the H76XX

sensor can also be done with the P7640 or

any other transmitter.

2. The T775U V terminal outputs 18 Vdc.

5 62-0255—07

M24549A

Page 6

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

SHIELDED CABLE

C

S

SENSOR A

V

1

T

SENSOR B

T

1

THE T775U WILL ONLY ACCEPT 0-10 VDC AND 4-20 MA SENSORS.

IF REPLACING AN H775 CONTROLLER THAT USES A C7600B OR OTHER

2-10 VDC SENSOR, THE SENSOR MUST BE REPLACED. REPLACE THE

C7600B2008 SENSOR (2-10VDC OUTPUT) WITH THE H7655A1001

(0-10 VDC OUTPUT) SENSOR. THE H7655A1001 SENSOR USES THE SAME

ENCLOSURE STYLING AND WIRING AS THE C7600B.

Fig. 5. Sensor Wiring — 3-wire shielded cable

connection from Sensor A to 0-10 Vdc sensor

(H76xx humidity sensor shown).

C

3

S

SENSOR A

V

T

SENSOR B

T

NOTES:

1. SHIELDED CABLE MUST BE

CONNECTED TO A SEPARATE

EARTH GROUND. HOWEVER,

DO NOT GROUND SHIELDED

CABLE AT SENSOR END.

2. TO MINIMIZE NOISE PICKUP,

MAKE SENSOR CONNECTION

FROM SHIELDED CABLE AS

CLOSE AS POSSIBLE TO

SENSOR BODY.

CSV

EXAMPLE OF

VO

GND

VIN

H76XX HUMIDITY

SENSOR;

0-10 VDC

CONNECTION

SHIELDED CABLE

2

V

PWR

OUT

1

S

COM

M24550

SHIELDED CABLE

C

S

SENSOR A

V

T

SENSOR B

T

Fig. 7. Sensor Wiring — 2-wire shielded cable

connection from Sensor A to a 0-10 Vdc sensor

using separate transformer.

EXAMPLE OF P7640A 4-20 MA SENSOR CONNECTION

PWR ZEROCOMOUT

NOTES:

1. SHIELDED CABLE MUST BE

CONNECTED TO A SEPARATE

EARTH GROUND. HOWEVER,

DO NOT GROUND SHIELDED

CABLE AT SENSOR END.

2. TO MINIMIZE NOISE PICKUP,

MAKE SENSOR CONNECTION

FROM SHIELDED CABLE AS

CLOSE AS POSSIBLE TO

SENSOR BODY.

EXAMPLE OF

P7640A

PRESSURE

SENSOR;

0-10 VDC

CONNECTION

L1

(HOT)

L2

24 VAC

PWR

S

OUT

C

COM

M24551

1

SHIELDED CABLE MUST BE CONNECTED TO A SEPARATE EARTH GROUND.

DO NOT GROUND SHIELDED CABLE AT SENSOR END.

TO MINIMIZE NOISE PICKUP, MAKE SENSOR CONNECTION FROM SHIELDED

2

CABLE AS CLOSE AS POSSIBLE TO SENSOR BODY.

THE T775 HAS AN INTEGRAL LOAD OF 500 OHMS WHICH RESULTS IN A

3

10V DROP AT 20MA. TO USE 4-20MA LOOP POWERED WIRING, THE SENSOR

MUST BE CAPABLE OF OPERATION WITH 8V OR LESS ACROSS ITS TERMINAL.

Fig. 6. Sensor Wiring — 2-wire shielded cable

connection from 4-20 mA sensor to

T775 controller (loop powered wiring).

M24890C

62-0255—07 6

12-30 VDC

SHIELDED CABLE

C

S

V

T

T

Fig. 8. Sensor Wiring — 2-wire 4-20mA sensor input

to T775 controller using a separate (Vdc only)

S

SENSOR A

SENSOR B

transformer.

POWER SUPPLY

+

–

C

NOTES:

1. SHIELDED CABLE MUST BE

CONNECTED TO A SEPARATE

EARTH GROUND. HOWEVER,

DO NOT GROUND SHIELDED

CABLE AT SENSOR END.

2. TO MINIMIZE NOISE PICKUP,

MAKE SENSOR CONNECTION

FROM SHIELDED CABLE AS

CLOSE AS POSSIBLE TO

SENSOR BODY.

M24889A

Page 7

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

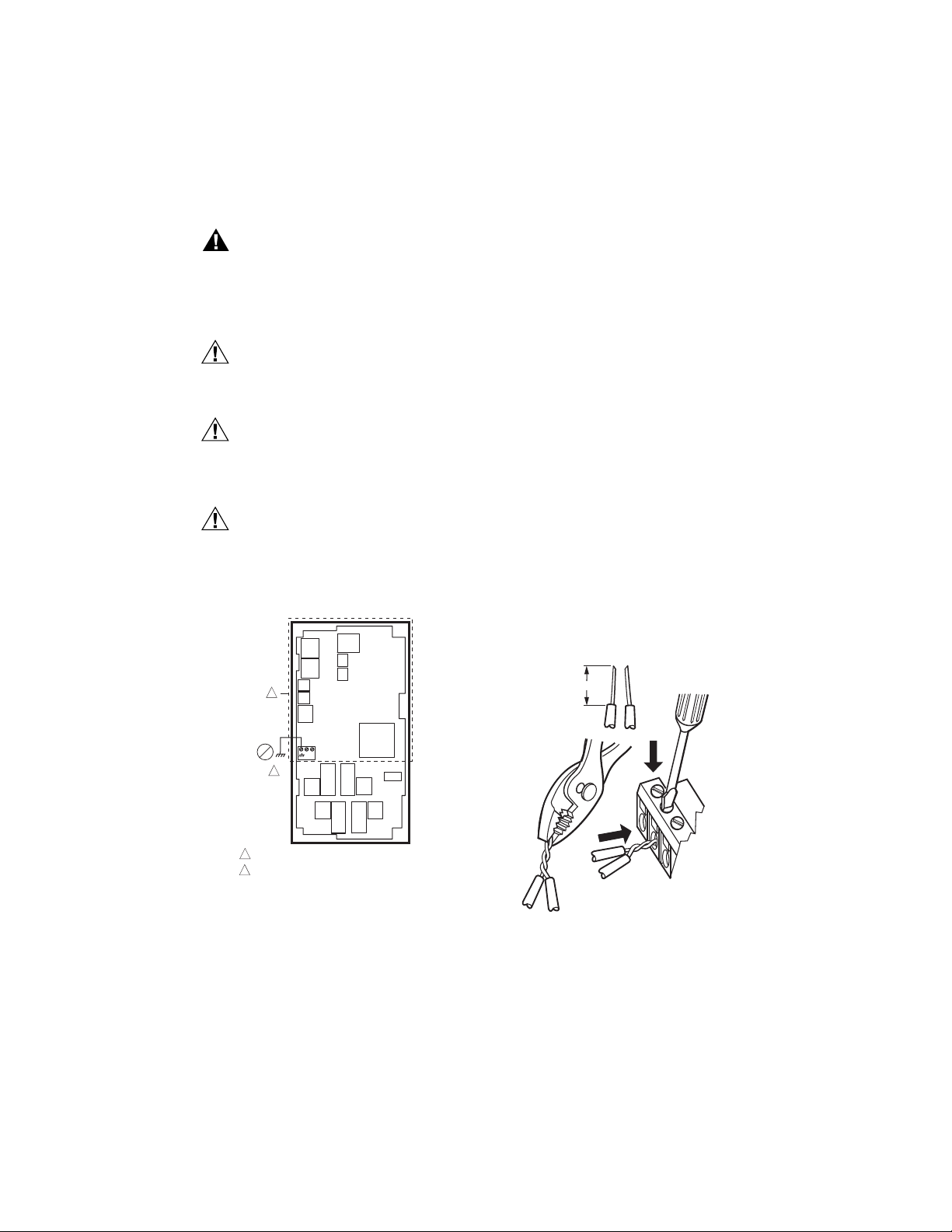

WARNING

CAUTION

CAUTION

CAUTION

Controller Wiring

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring,

or making wiring connections, to prevent electrical

shock or equipment damage.

Do not use 24 Vac power to power any external

loads if 120 Vac or 240 Vac is used to power

the T775U.

A separate earth ground is required.

Equipment damage can result if the earth ground

is not connected. See Fig. 9 and Table 2 on

page 8.

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the unit.

1

See Fig. 11 on page 8 for locating the appropriate power

input, remote sensors input, low voltage, contact closure,

and load output terminals.

Access to the terminals can be gained through standard

conduit knockouts (A through E in Fig. 11 on page 8)

located around the perimeter of the enclosure:

• Knockouts A and B should be used only for sensor and

low-voltage wiring.

• Knockouts C, D, and E can be used to gain access to

the load relay output terminals and 120/240 Vac power

wiring.

Controller Wiring Method

Wire the sensors and outputs, then wire the power

connection.

Each terminal can accommodate the following gauges of

wire:

• Single wire – from 14 AWG to 22 AWG solid or

stranded

• Multiple wires – up to two 22 AWG stranded

For 24, 120, or 240 Vac power connections:

Single wire – from 14 to 18 AWG solid or stranded

Using Fig. 10 on page 7 as a guide, prepare wiring for the

terminal blocks, as follows:

1. Strip 1/2 in. (13 mm) insulation from the conductor.

2. Cut a single wire to 3/16 in. (5 mm). Insert the wire

in the required terminal location and tighten the

screw.

3. If two or more wires are being inserted into one terminal location, twist the wires together a minimum

of three turns before inserting them to ensure

proper electrical contact.

4. Cut the twisted end of the wires to 3/16 in. (5 mm)

before inserting them into the terminal and tightening the screw.

5. Pull on each wire in all terminals to check for good

mechanical connection.

1. STRIP 1/2 IN. (13 MM)

FROM WIRES TO

BE ATTACHED AT

ONE TERMINAL.

1/2 (13)

C

W

NO HIGH VOLTAGE. CLASS 2 WIRING ONLY.

1

EARTH GROUND TERMINAL MUST BE CONNECTED

2

TO CONDUIT CLAMP LOCALLY.

+

2

Fig. 9. Earth Ground.

IMPORTANT

Poor wiring practices can cause erratic readings

from the sensor. To ensure proper operation,

ensure that good mechanical connections are

made to both the sensor and the controller.

IMPORTANT

When wiring the input power, only one source of

power can be applied to the T775U (24 Vac or

120 Vac or 240 Vac).

M24296

2. TWIST WIRES

TOGETHER WITH

PLIERS (A MINIMUM

OF THREE TURNS).

3. CUT TWISTED END OF WIRES

TO 3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING SCREW.

THEN PULL ON EACH WIRE IN ALL

TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M24552

Fig. 10. Attaching two or more wires at terminal

7 62-0255—07

blocks.

Page 8

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

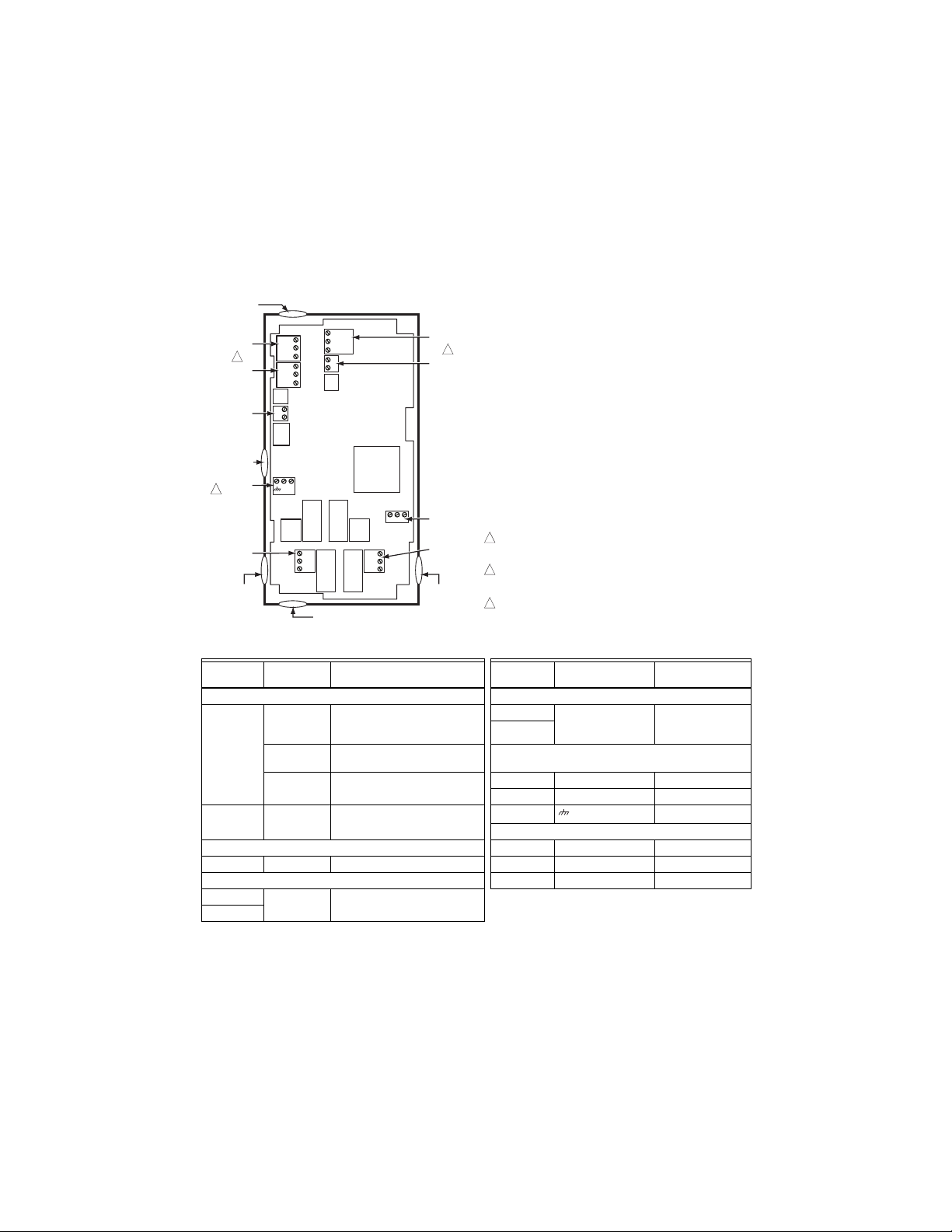

Controller Wiring Details

The wiring connection terminals are shown in Fig. 11 and

are described in Table 2. See Fig. 12 – Fig. 18 beginning

on page 9 for typical T775U wiring applications.

Fig. 11. T775U Terminal and Feature Locations.

KNOCKOUT A

–

C

MOD 1

2

MOD 2

DIGITAL

INPUT

KNOCKOUT B

POWER

3

24 VAC

OUTPUT

RELAY 1

KNOCKOUT C

NO

C

NC

KNOCKOUT E

T

S

+

T

V

T

T

NO

C

NC

B

–

R

+

W

B

–

R

+

W

–

+

C

+

120

COM

240

SENSOR A

1

SENSOR B

POWER

120/240 VAC

OUTPUT

RELAY 2

KNOCKOUT D

1

WHEN USED FOR TEMPERATURE OR 4-20mA SENSING, SENSORS A

AND B USE THE TWO TT CONNECTIONS AND ARE POLARITY

INSENSITIVE.

2

FOR MOD 1 AND MOD 2 CURRENT (mA) OR VOLTAGE (VDC) OUTPUT,

USE SIGNAL (+) & COMMON (-).

FOR MOD 1 AND MOD 2 SERIES 90 OUTPUT, USE W, R, & B.

3

A SEPARATE EARTH GROUND IS REQUIRED FOR ANY POWER

SOURCE (24, 120, OR 240 VAC)

M24553A

Table 2. Description of Wiring Terminal Connections.

Connection

Ter mi nal

Label Description Connection Terminal Label Description

Sensors Outputs

C – common

S – signal

V – voltage

a

Sensor A

S and V 4-20mA input; see Fig. 7 on

T T

Sensor B T T Temperature Sensor; polarity

0-10 Vdc input: Universal

sensor for humidity, pressure,

temperature, etc.

Mod 1

Mod 2

+ - (Vdc or mA)

W R B (Series 90)

page 6 24 Vac Power

Temperature Sensor; polarity

insensitive

insensitive

24V + + 24 Vac Hot

Common - 24 Vac Common

Ground

120 or 240 Vac Power

Modulating Output

b

Earth Ground

Input 120 Vac 120 120 Vac Power

DI + - Digital Input (dry contact) Common COM Common

Outputs 240 Vac 240 240 Vac Power

Relay 1 NO / COM /

Relay 2

a

For applications that do not use Reset, only Sensor A is available for use.

b

For Series 90 connections, you must insert a 340 Ohm resistor across terminals R and W. See Fig. 17 on page 10.

The resistor is included with the controller.

c

A separate earth ground is required for all installations regardless of the power source (24, 120, or 240 Vac).

62-0255—07 8

NC 120-240 Vac Relay Output

c

Page 9

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

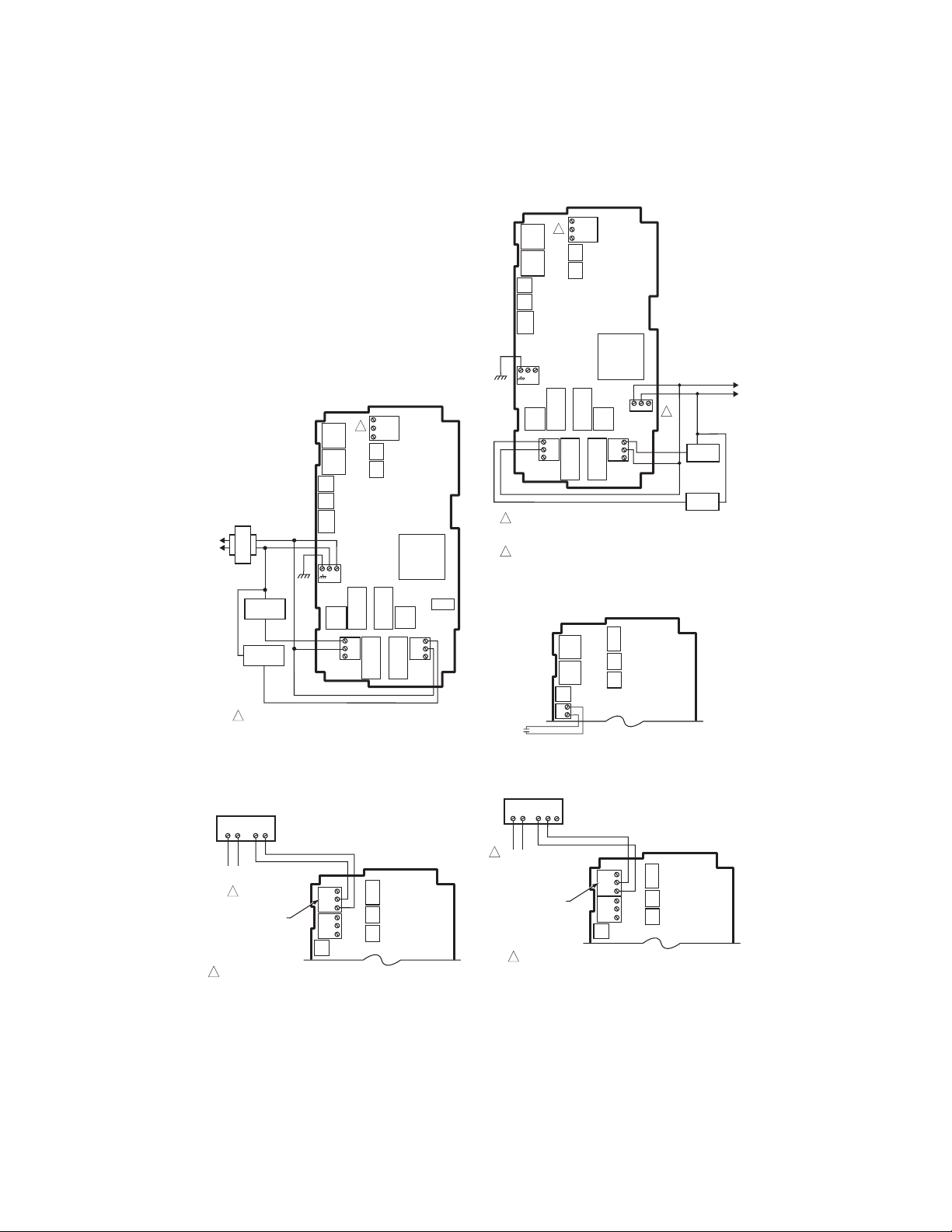

WIRING APPLICATION

EXAMPLES

Fig. 12 – 18 illustrate typical controller wiring for various

applications.

NOTE: The electronic Series 90 output provided with

modulating T775 models can not drive electromechanical slidewire devices like older Series 3

modulating meters (prior to Series 6), V9055s,

and S984s.

NOTE: For a wiring example of three Series 90 Modutrol

Motors, refer to the T775A/B/M Series 2000

Electronic Stand-alone Controllers Installation

Instructions (form 62-0254).

–

C

T

1

S

+

T

V

L1

(HOT)

L2

LOAD 1

LOAD 2

24 VAC

NO

COM

C

+

NO

C

NC

NO

C

NC

–

C

T

S

+

T

1

V

C

+

NO

COM

Fig. 14. Wiring for Two-stage Control with 120 or 240

NO

C

NC

FOR SPECIFIC SENSOR WIRING (TEMPERATURE, HUMIDITY,

1

PRESSURE, ETC), REFER TO THE SENSOR WIRING SECTIONS

BEGINNING ON PAGE 4.

FOR 240 VAC LOAD, CON NECT TO 240 TERMINAL .

2

NO

C

NC

Vac (120 Vac Input and 120 Vac Load).

120V

COM

2

120

240

COM

NO

LOAD 2

COM

LOAD 1

M24555A

COM

NO

FOR SPECIFIC SENSOR WIRING (TEMPERATURE, HUMIDITY,

1

PRESSURE, ETC), REFER TO THE SENSOR WIRING SECTIONS

BEGINNING ON PAGE 4.

Fig. 12. Wiring for Two-stage Control – 24 Vac Input

HONEYWELL MODUTROL MOTOR WITH

4-20 mA MODULATING INPUT

T1 T2

POWER

OUTPUT

1

MODULATING OUTPUT

TERMINAL (MOD 1)

USE SEPARATE TRANSFORMER FOR T775 WHEN USING 24 VAC.

1

Fig. 13. Wiring for mod motor or direct coupled

actuator with 4 to 20 mA control input.

–

+

and 24 Vac Load.

B

–

R

+

W

B

–

R

+

W

M24554A

M24557A

INPUT

–

+

M24559

DIGITAL

Fig. 15. Wiring for Digital Input (dry contact).

HONEYWELL MODUTROL MOTOR WITH

VOLTAGE CONTROL INPUT

–

+

T1 T2 C R

1

POWER

OUTPUT

MODULATING OUTPUT

TERMINAL (MOD 1)

Fig. 16. Wiring for mod motor or direct coupled

9 62-0255—07

F

B

–

R

+

W

B

–

R

+

W

1

USE SEPARATE TRANSFORMER FOR T775 WHEN USING 24 VAC.

actuator with 0-10 Vdc control input.

M24558A

Page 10

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

WARNING

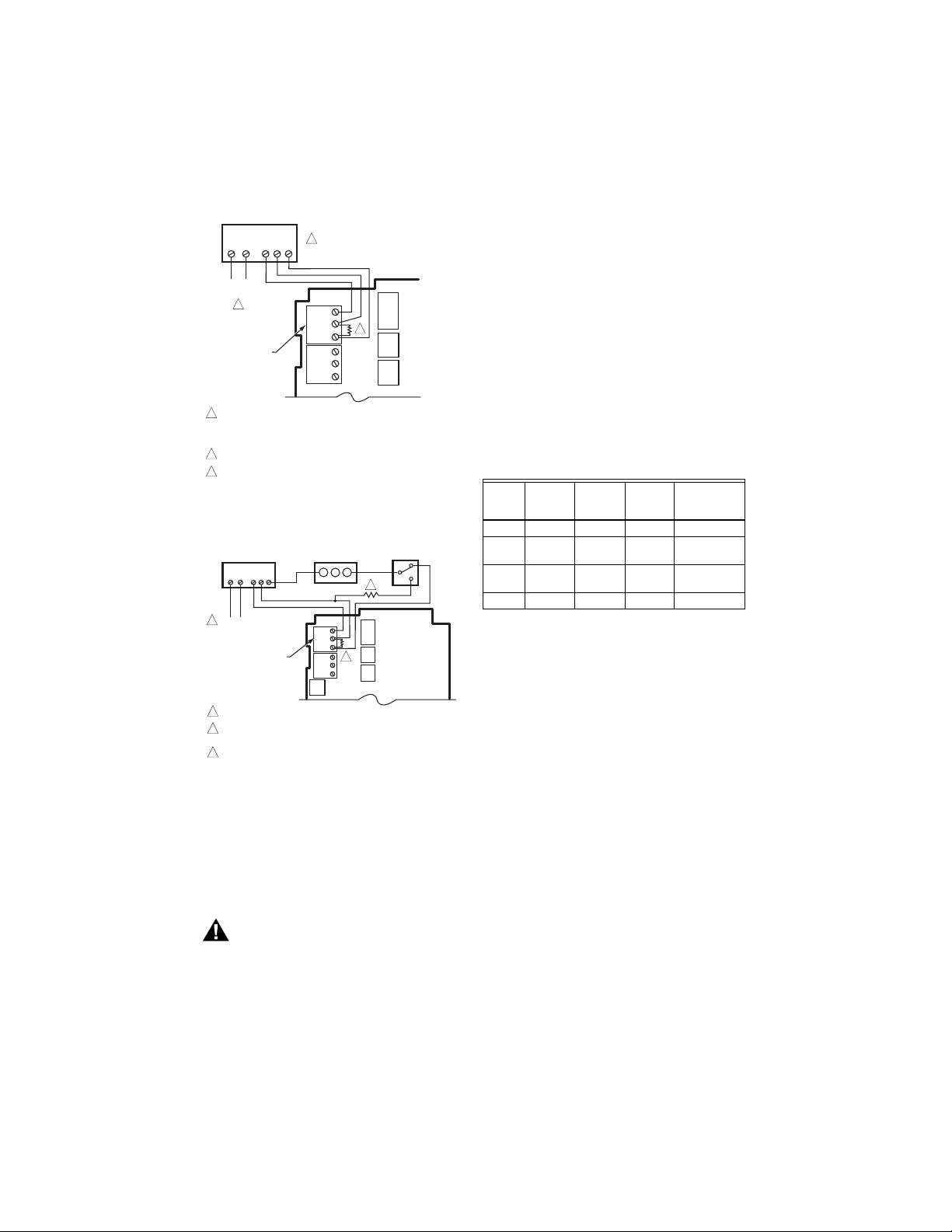

HONEYWELL ELECTRONIC

SERIES 90 MODUTROL MOTOR

T1 T2 B WR

POWER

OUTPUT

2

MODULATING

OUTPUT

TERMINAL

(MOD 1)

1

TO VERIFY OUTPUT, TEST OPEN CIRCUIT VOLTAGE BETWEEN

THE MOD 1 TERMINALS W AND R.

- MINIMUM (DRIVE CLOSED) SIGNAL LESS THAN 0.17 VDC

- MAXIMUM (DRIVE OPEN) SIGNAL IS GREATER THAN 1.7 VDC

2

USE SEPARATE TRANSFORMER FOR T775 WHEN USING 24 VAC.

INSERT 340 OHM RESISTOR (INCLUDED) ACROSS TERMINALS R AND W.

3

1

B

R

–

W

W

3

+

B

R

–

+

M24560A

Fig. 17. Wiring for Series 90 Modutrol Motor Control.

HONEYWELL

ELECTRONIC SERIES 90

MODUTROL MOTOR

T1 T2 B WR

1

POWER

OUTPUT

MODULATING OUTPUT

TERMINAL (MOD 1)

1

USE SEPAR AT E TRANSFORM ER FOR T775 WHEN USIN G 24 VAC.

A 250 OHM RES ISTOR PROVIDES 40% AUTH ORITY WHEN

2

USING A 150 OH M MINIMUM POSIT ION POTENTIOME TER.

3

INSERT 340 OHM RESISTOR (INCLUDED) ACROSS TERMINALS R AND W.

Fig. 18. Wiring for Changeover Relay and

Minimum Position Potentiometer used with

MINIMUM POSITION

POTENTIOMETER

(Q209)

W R B

B

–

R

+

W

B

–

R

+

W

SPDT CHAN GEOVER

2

3

Series 90 Modutrol Motors.

(H205 OR H705)

M24561A

CHECKOUT

Inspect all wiring connections at the controller terminals,

and verify compliance with the installation wiring

diagrams.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

or making wiring connections, to prevent electrical

shock or equipment damage.

If any wiring changes are required, first be sure to remove

power from the controller before starting work. Pay

particular attention to verifying the power connection

(24, 120, or 240 Vac).

After the controller is mounted and wired, apply power.

Power Loss

The date and time settings are retained for 24 hours after

a power outage. After a power loss of more than 24 hours,

the date and time settings may need to be reentered. All

other settings are stored permanently.

Humidity, Pressure, and Universal

Sensor Calibration

A calibration parameter is available using Setup mode.

The calibration range is +/- 10% of the Min Value to Max

Value range setup for the sensor. See examples in

Table 3.

Table 3. Calibration Range Examples.

Units

Min.

Value

Example

Max.

Valu e

Example

Min-Max

Range

Result

Calibration

Range

PSI 100 400 300 ± 30 PSI

Inches

W.C.

Pa or

kPa

-20.0 20.0 40 ± 4 in. W.C.

-2,000 3000 5000 ± 500 Pa/kPa

% 10 100 90 ± 9%

The calibration value is set in section “1.2.2.3.

CALIBRATE (Sensor A or B)” on page 16.

Temperature Sensor Calibration

As wire length increases, resistance increases and thus

the temperature reading increases. If necessary, calibrate

the sensor input by reducing the value by the amount

shown in the Table 4 on page 11. For example, a wire run

with 18 gauge wire of 1,000 feet, requires a calibration

offset of -6.0°F.

IMPORTANT

If the calibration value in the table exceeds the

controller’s calibration limits of +/-10°F (+/-6°C),

you must use a heavier gauge wire.

For example, with a wire run of 1,000 feet you

must use 20 AWG wire or heavier in order to calibrate for wire loss within the limits of the controller.

See “1.2.2.3. CALIBRATE (Sensor A or B)” on page 16 for

the instructions to enter the calibration value.

NOTE: The resistance output on the temperature

sensors change at the rate of 2.2 Ohms per °F

(3.85 Ohms per °C).

62-0255—07 10

Page 11

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

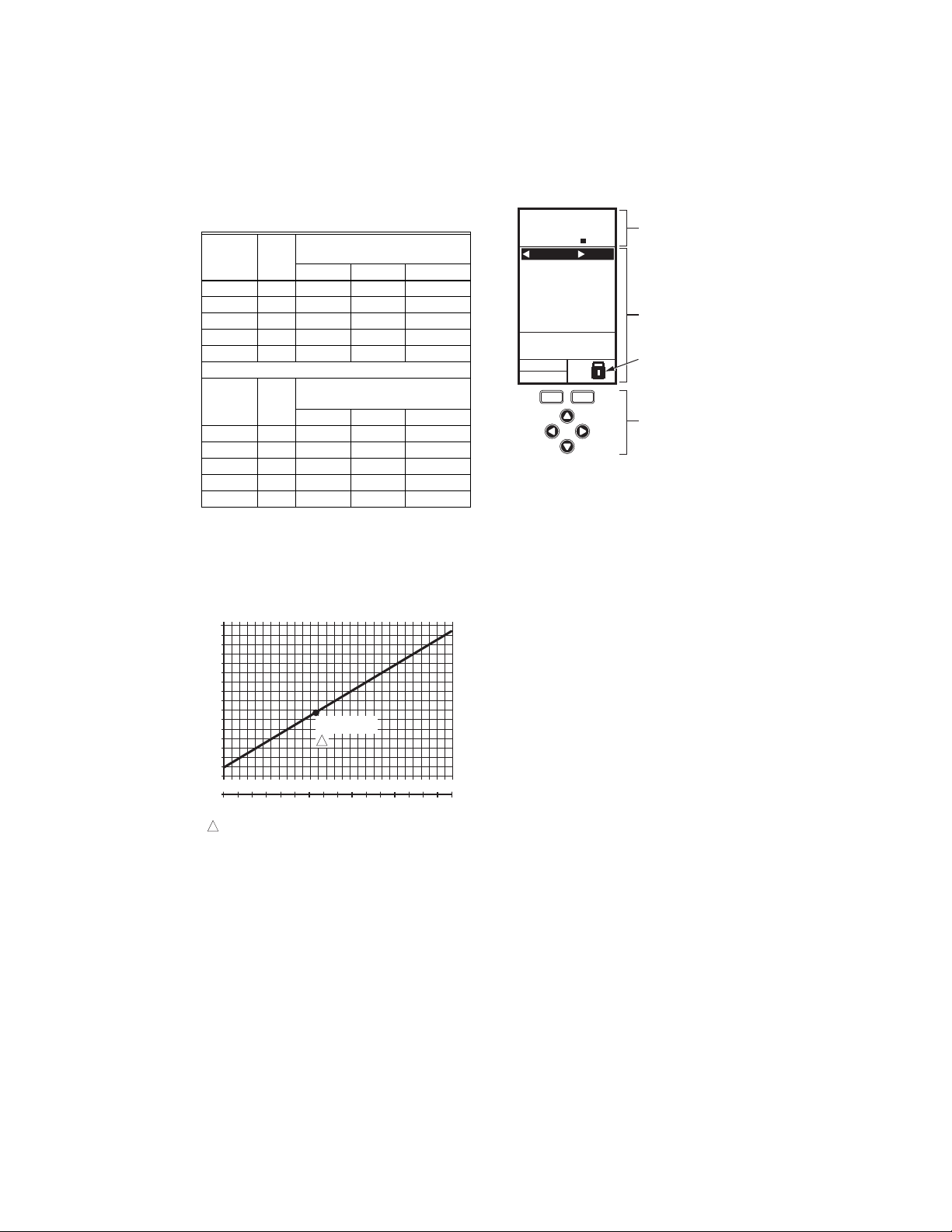

Table 4. Temperature Sensor Calibration for

Resistance Loss due to Wire Length.

AWG

Rating mΩ/ft

Temperature Offset in

200 ft 500 ft 1,000 ft

°F (Feet)

a

14 2.5 0.46 1.14 2.28

16 4.0 0.72 1.82 3.64

18 6.4 1.16 2.90 5.82

20 10.2 1.86 4.64 9.28

22 16.1 2.92 7.32 14.64

AWG

Rating mΩ/m

Temperature Offset in

°C (Meter)

100 m 200 m 300 m

a

14 8.3 0.44 0.86 1.30

16 13.2 0.68 1.38 2.06

18 21.0 1.10 2.18 3.28

20 33.5 1.74 3.48 5.22

22 52.8 2.74 5.48 8.22

a

This is the distance from the controller to the sensor

(already accounts for round trip distance).

Fig. 19 shows how sensor resistance varies with

temperature for a sensor having a positive temperature

coefficient (PTC) of 2.1 Ohms per degree F (3.85 Ohms

per degree C).

RESISTANCE (OHMS)

1489

1403

1317

1231

1145

1059

973

887

801

-40 -20 -10-30

1

20 40 60 80 100 120 140 160 180 200 220

0-20-40

POSITIVE TEMPERATURE COEFFICIENT (PTC) OF 2.1 OHMS PER °F

1097 ± 0.08 OHMS

AT 77°F (25°C)

1

0 10 20 30 40 50 60 70 80 90 100

TEMPERATURE (DEGREES)

250

110

120

M24304

Fig. 19. Sensor Resistance vs. Temperature.

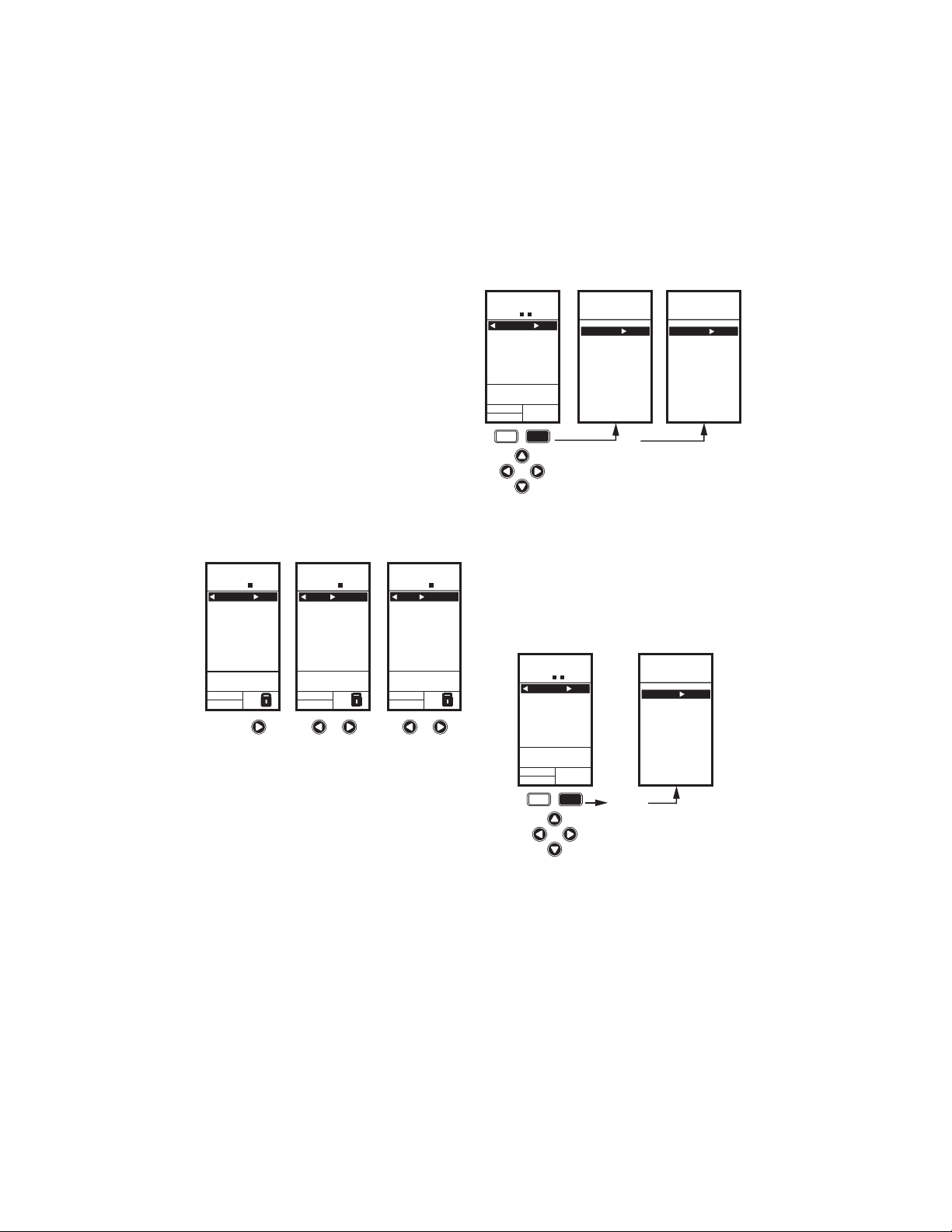

INTERFACE OVERVIEW

The T775U controller uses an LCD panel and 6-button

keypad to provide status information and permit user input

of the programming, setup, and scheduling parameters.

The following figure describes the display areas of the

LCD and the keypad.

RELA

HOME

YS 1 2

MENU AREA

ON

SENSORS

SENSOR A

78

SENSOR B

84

o

F

o

F

DATA AREA

MOD1 40%

MOD2 60%

DI ON

home menu

LOCK ICON

6 BUTTON KEYPAD

M24563

Fig. 20. LCD Display - Home Screen And Keypad.

Menu Area – On the home screen, the LCD displays the

configured relays and whether they are active. In

Program, Setup or Schedule mode, the LCD displays the

current menu selection and its order within the menu

hierarchy.

Data Area – On the home screen, the LCD displays the

sensors and outputs status. In Setup or Program mode,

the LCD displays menu choices, parameter selections,

and data values.

Lock Icon – The icon indicates the MENU button is

locked and prevents access to the Setup and Program

menus.

NOTE: Pressing and holding the HOME and MENU but-

tons simultaneously for five seconds locks/

unlocks the MENU button.

6-Button Keypad – The keypad is used to access the

menus and enter values (see “Using the LCD Panel

Interface”).

Using the LCD Panel Interface

The 6-button keypad is used to move through the menus

and enter or change parameter values.

°F

Home Button

°C

Pressing the HOME button at any time exits the current

Programming or Setup display screen and returns to the

home screen as shown in Fig. 20 and Fig. 21.

Menu Button

• Pressing the MENU button always displays the

Program menu. If you are in Setup mode, you exit

setup and return to the Program menu.

• Pressing and holding the MENU button for five

seconds leaves the current screen and displays

the Setup menu.

Left and Right Arrow Buttons (W and X)

Use these buttons to move backward (W) and forward (X)

through the Program and Setup menus.

11 62-0255—07

Page 12

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

Up and Down Arrow Buttons (S and T)

Use these buttons to move your selection up and down

through a menu or list.

• When the desired item is highlighted, you press the X

arrow button to display that item’s content.

• When a value is displayed (e.g. 70°F), the up and

down arrows increase and decrease the value.

NOTE: Once you select an item from a list or enter a

value, pressing the W or X or HOME button

accepts your selection or value and stores it in

the controller’s memory.

Program, Schedule, and Summary

Menus

To access these menus from the home screen, press the

MENU button. See Fig. 22.

Home Screen

In the normal run state, the LCD home screen displays

the current sensed temperatures, the modulating outputs

status, the active status of the output relays, and error and

status codes.

When using Reset, the Heat/Cool setpoint(s) display on

the home screen for the Mod and Relay outputs; see

Fig. 21.

Active relays are indicated by the small black square ()

just below the relay number. Fig. 21 shows the home

screen with relay 2 energized.

Pressing the W and X buttons from the home screen

cycles through each modulating output that is paired with

the sensor it controls and the active output relays.

HOME

RELAYS 1 2

ON

SENSORS

SENSOR A

78

SENSOR B

84

MOD1 40%

MOD2 60%

DI ON

Fig. 21. LCD Display - Home Screen Displaying

Sensors, Mod Outputs, and Active Relays.

NOTES:

1. The modulating output home screen and the

2. In Reset mode, the home screen displays the

IMPORTANT

After four minutes of inactivity (no buttons

pressed), the LCD display reverts to the home

screen display.

HOME

RELAYS 1 2

ON

MOD 1 40%

COOL

o

F

SETPOINT

74

o

F

SENSOR A

62

MOD1 40%

MOD2 60%

DI ON

relay home screen do not dynamically update

the active relay status, sensor values, and

modulating output percentages. The information is a snapshot taken when you press the

W or X button to display the screen.

effective setpoint.

o

F

o

F

HOME

RELAYS 1 2

ON

REL 2 ON

HEAT

SETPOINT

60

SENSOR A

62

RT 12345 HRS

MOD1 40%

MOD2 60%

DI ON

Accessing the Menus

Menus are used for programming, scheduling, viewing the

summary settings, and setup of advanced options.

62-0255—07 12

Depending on whether scheduling is enabled or not, the

LCD displays one of two menus as shown in Fig. 22.

Scheduling is enabled from the Setup menu’s Output

settings (see “1.3.3.1. USE SCHED” on page 21).

Setup Menu

To access the Setup menu, press and hold the MENU

o

F

button for five seconds. See Fig. 23.

o

F

M24564

Using the Menus

When you are working with the menus, use the:

• Left arrow button (W) to scroll backward through the

• Right arrow button (X) to select the highlighted menu

• Up and Down arrow buttons (S and T) to scroll up

OR

MENU DISPLAY WHEN

SCHEDULING IS NOT SET

MENU

PROGRAM

EXIT

HOME

RELAYS 1 2

ON

SENSORS

SENSOR A

78

SENSOR B

84

MOD1 40%

MOD2 60%

DI ON

menu

home

MENU DISPLAY WHEN

SCHEDULING IS SET

PROGRAM

SCHEDULE

o

F

SUMMARY

EXIT

o

F

MENU

Fig. 22. Menus.

HOME

RELAYS 1 2

ON

SENSORS

SENSOR A

78

SENSOR B

84

MOD1 40%

MOD2 60%

DI ON

menu

home

o

F

o

F

SECONDS

FIVE

SETUP

SENSORS

OUTPUTS

EXIT

M24566

Fig. 23. Setup Menu.

menus

item and display its content

and down through a list of items or to increase or

decrease the value of a displayed parameter

M24565

Page 13

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

NOTES:

1. If you press the HOME button or there is no

keypad activity for four minutes, you exit

Program mode and return to the home

screen.

2. If you press the MENU button, you exit and

return to the menu.

PROGRAMMING OVERVIEW

The controller must be programmed before being placed

into service.

IMPORTANT

During programming, the controller is live at all

times. For example, the contacts may open and

close when adjusting the setpoint.

The Programming process uses a hierarchical menu

structure that is easy to use. You press the W and X

arrow buttons to move forward and backward through the

menus.

NOTES:

1. The T775U controller interface is intuitive.

You may find that you do not need the following procedure instructions to program the

controller. You may want to use this procedure simply as a reference to locate the particular option or parameter of interest.

2. The menus can display only those relays that

are defined in Setup (see “1.3.2. NBR OF

RELAYS” on page 21). For example, if you

configure only one relay, then only one relay

displays on the appropriate menus.

3. If you press the HOME button or there is no

keypad activity for four minutes, you exit Program mode and return to the home screen.

4. If you press the MENU button, you exit

Program mode and return to the menu.

Setpoint and Differential

The following describes the relationship between setpoint

and differential for heating and cooling. These settings are

programmed for each output relay.

In heating mode, reverse acting mode, and humidify

mode, the differential falls below the setpoint. The relay

de-energizes when the temperature rises to the setpoint.

As the temperature drops to the setpoint minus the

differential, the relay energizes.

In cooling mode, direct acting mode, and dehumidify

mode, the differential falls above the setpoint. The relay

de-energizes when the temperature falls to the setpoint.

As the temperature rises to the setpoint plus the

differential, the relay energizes.

IMPORTANT

1. This action sets the maximum setpoint value of

all outputs to the setpoint high limit maximum.

2. Setting the high limit setpoint maximum is irre-

versible. If you perform the action inadvertently

and this setpoint adversely affects the control of

your system, you must replace the controller.

Programming the T775U

Controller

To program the controller, perform the setup configuration

(see “1. Setup”) and then select one of the following

procedures depending on whether the Reset function is to

be used:

• Program the Outputs for No Reset — see

“2. Programming Outputs (MOD and Relay) with No

Reset” on page 25.

• Program the Outputs for Reset — see

“3. Programming Outputs (MOD and Relay) with

Reset” on page 28.

When programming is complete, you may continue with

“4. Scheduling” on page 33.

1. SETUP

Setup provides the ability to change the factory default

settings for the temperature sensors and outputs, to

enable/disable reset control, and to enable/disable

scheduling.

NOTE:

1. The T775U controller interface is intuitive.

You may find that you do not need the following setup instructions for the sensors and outputs. You may want to use this procedure

simply as a reference to locate the particular

option or parameter of interest.

2. If you press the HOME button or there is no

keypad activity for four minutes, you exit

Setup mode and return to the home screen.

3. If you press the MENU button, you exit Setup

mode and return to the menu.

Once in Setup mode, you use the —

• Left arrow button (W) to scroll backward through the

Setup menus

• Right arrow button (X) to select the highlighted menu

item and display its content

• Up and Down arrow buttons (S and T) to scroll up

and down through a list of items or to increase or

decrease the value of a displayed setup parameter

Setpoint High Limit

You can set an irreversible setpoint high limit maximum

value for any single displayed setpoint value.

Adjust the setpoint (at any output) to the desired

maximum setpoint. Then, simultaneously press the

HOME, W, and X buttons and continue to press all three

buttons for five seconds to set the setpoint high limit

maximum to this value.

NOTE: You must press all three buttons at exactly the

same time for this action to occur.

13 62-0255—07

Page 14

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

Setup Procedure

The Setup process uses a hierarchical menu structure

that is easy to use. You press the W and X arrow buttons

to move forward and backward through the menus.

NOTE: The menus can display only those relays that

are defined in Setup (see “1.3.2. NBR OF

RELAYS” on page 21). For example, if you configure only two relays, then only two relays display on the appropriate menus.

SETUP

SENSORS

Fig. 24. Setup - Sensors Menu.

SETUP

SENSORS

# SENSORS

Fig. 25. Setup - Sensors - Number of Sensors.

SETUP

SENSORS

# SENSORS

SENSOR A

SENSOR B

EXIT

SETUP

SENSORS

# SENSORS

ENTER

NUMBER OF

SENSORS

M24586

2

M24587

To change the controller’s sensors and output setup

parameters, perform the following procedures in the order

listed:

1. Enter Setup mode — see “1.1. Entering Setup

Mode”

2. Setup Sensors — see “1.2. Setting up the Sensors”

3. Setup Outputs — see “1.3. Setting up the Outputs”

on page 17

4. Exit Setup Mode — see “1.4. Exiting Setup” on

page 24

1.1. Entering Setup Mode

To enter Setup mode, press and hold the MENU button

for five seconds to display the Setup menu. See Fig. 23

on page 12.

1.2. Setting up the Sensors

1. From the Setup menu, use the S and T buttons to

highlight SENSORS.

2. Press the X button to display the Sensors menu.

1.2.1. Number of SENSORS

The value entered here determines the number of

sensors displayed on the home screen.

NOTE: For applications that do not use Reset, only one

sensor (Sensor A) is available for use.

1.

From the Sensors menu, highlight # SENSORS then

X

press the

2. Use the S and T buttons to enter the number of

sensors (1 or 2).

3. Press the X button to accept the value and display

the SENSOR A selection.

button to display the number of sensors.

Default: 2

SENSOR A

TYPE = 0-5V, 0-10V,

OR 4-20MA

SETUP

SENSORS

SENSOR A

TYPE

UNITS

MIN VAL

MAX VAL

CALIBRATE

LABEL

EXIT

M24588A

1.2.2. SENSOR A

If you are implementing two-sensor reset control, Sensor A

must always be the controlled temperature and Sensor B must

always be the controlling temperature. For example, in a reset

control based on outside temperature, Sensor A must be the

inside sensor and Sensor B must be the outside sensor.

The menu selections change depending on whether the

sensor type is 1097Ω PTC (temperature) or 0-10V / 420MA.

SETUP

SENSORS

SENSOR A

SENSOR A

TYPE = PT1000

SETUP

SENSORS

SENSOR A

TYPE

UNITS

CALIBRATE

LABEL

EXIT

Fig. 26. Setup - Sensors - Sensor A Menu.

62-0255—07 14

1. From the Sensors menu, highlight SENSOR A.

2. Press the X button to display the Sensor A selec-

tions.

Page 15

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

A

SETUP

SENSORS

SENSOR A

TYPE

SENSORS

SENSOR A

PT 1000

0-5V

0-10V

4-20MA

TYPE FOR

SENSOR A

SETUP

TYPE

SELECT

Fig. 27. Setup - Sensors - Sensor A - Type.

SETUP

SENSORS

SENSOR A

UNITS

SENSORS

SENSOR A

DEG F

DEG C

UNITS FOR

SENSOR A

SETUP

UNITS

SELECT

Fig. 28. Setup - Sensors - Sensor A - Units.

1.2.2.1. TYPE (Sensor A only)

1. From the Sensor A selections, use the S and T

buttons to highlight TYPE.

2. Press the X button to display the type values.

3. Use the S and T buttons to highlight the desired

value PT1000 (1097Ω PTC), 0-5V, 0-10V, or 420MA.

Default: PT1000

NOTE: The default label PT1000 refers to a 1097Ω PTC

temperature sensor.

M24589

4. Press the X button to accept the units and return to

the Sensor A selections.

5. For PT1000 (1097Ω PTC) temperature sensors, go

to “1.2.2.2.1. UNITS (Sensor A or B; PT1000

[1097W PTC)]”.

For 0-5V, 0-10V, and 4-20MA sensors, go to

“1.2.2.2.2. UNITS (Sensor A only; 0-5V, 0-10V, or 420mA)”

1.2.2.2.1. UNITS (Sensor A or B; PT1000

[1097Ω PTC)]

If Sensor A is configured for °F or °C units, then the units

selection does not appear for Sensor B, since Sensor B

uses the units specified for Sensor A.

1. From the Sensor A selections, use the S and T

buttons to highlight UNITS.

2. Press the X button to display the temperature units.

3. Use the S and T buttons to highlight F or C.

Default: F (Fahrenheit)

M24590

4. Press the X button to accept the units and return to

the Sensor A selections.

Continue with “1.2.2.3. CALIBRATE (Sensor A or B)”.

SETUP

SENSORS

SENSOR A

UNITS

SENSORS

SENSOR A

DEG F

DEG C

PSI

IN WC

% RH

PA

KPA

PPM

NONE

UNITS FOR

SENSOR A

SETUP

UNITS

SELECT

Fig. 29. Setup - Sensors - Sensor A - Units.

1.2.2.2.2. UNITS (Sensor A only; 0-5V, 0-10V, or

4-20mA)

1. From the Sensor A selections, use the S and T

buttons to highlight UNITS.

2. Press the X button to display the units list.

3. Use the S and T buttons to scroll through the list

and highlight the desired unit of measure.

You may need to scroll up or down to view all units.

Default: F (Fahrenheit)

M24591A

4. Press the X button to accept the units and return to

the Sensor A selections.

15 62-0255—07

Page 16

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

ENTER

MINIMUM

VALUE FOR

SENSOR A

SETUP

SENSORS

SENSOR A

MIN VAL

0.0

F

o

M24592A

ENTER

MAXIMUM

VALUE FOR

SENSOR A

SETUP

SENSORS

SENSOR A

MAX VAL

0.0

F

o

SETUP

SENSORS

SENSOR A

MIN VAL

OR

MAX VAL

Fig. 30. Setup - Sensors - Sensor A - 0-5V, 0-10V, OR

4-20MA - MIN and MAX Value (showing °F).

SETUP

SENSORS

SENSOR A

CALIBRATE

SETUP

SENSORS

SENSOR A

CALIBRATE

0.0

ENTER

VALUE TO

CALIBRATE

SENSOR A

o

F

M24594

Fig. 31. Setup - Sensors - Sensor A - Calibrate.

1.2.2.2.3. MIN or MAX VALUE

0-5V, 0-10V or 4-20mA)

The minimum and maximum values display only for

Sensor A when its type is

1. From the Sensor A selections, use the S and T

buttons to highlight MIN VAL or MAX VAL.

2. Press the X button to display the units.

3. Use the S and T buttons to increase/decrease the

desired value.

Sensor Ranges:

°F -60.0 to 270.0

°C -51.0 to 132.0

PSI -500 to 500

IN WC -30.0 to 30.0

% 0.0 to 100.0

PA -3000 to 3000

KPA -3000 to 3000

PPM 0 to 9990

NONE -9999 to 9999

4. Press the X button to accept the units and return to

the Sensor A selections.

0-5V,

(Sensor A only;

0-10V or 4-20MA.

1.2.2.3. CALIBRATE (Sensor A or B)

Ensure that the wire size calibration value is within the

limits for the sensor.

• For temperature sensors, see “Temperature Sensor

Calibration” on page 10.

• For other sensors, see “Humidity, Pressure, and

Universal Sensor Calibration” on page 10.

1. From the Sensor A selections, use the S and T

buttons to highlight CALIBRATE.

2. Press the X button to display the calibration value.

3. Use the S and T buttons to increase/decrease the

desired calibration value.

Default: 0.0

Sensor Range Temperature: +/-10°F (+/-6°C)

Other Sensor Range: +/-10% of the Min to Max

values specified previously. See Table 3 on

page 10 for examples.

4. Press the X button to accept the value and return to

the Sensor A selections.

SETUP

SENSORS

SENSOR A

LABEL

SETUP

SENSORS

SENSOR A

LABEL

SENSOR A

BOILER A

OUTDOOR A

DUCT A

DISCHRG A

CHILLER A

ROOM A

SELECT

LABEL FOR

SENSOR A

Fig. 32. Setup - Sensors - Sensor A - Label.

62-0255—07 16

1.2.2.4. LABEL (Sensor A or B input)

For a sensor already labeled, the display positions to and

highlights that label.

1. From the Sensor A selections, use the S and T

buttons to highlight LABEL.

2. Press the X button to display the label list.

3. Use the S and T buttons to scroll through the list

and highlight the desired label.

You may need to scroll up or down to view all possible labels.

M24595

4. Use the X button to accept the highlighted label

and exit the list.

NOTE: The label names in list order are: Sensor, Boiler,

Outdoor, Duct, Dischrg, Chiller, Room, Supply,

Return, and Animals.

Page 17

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

A

SETUP

SENSORS

SENSOR A

UNITS

CALIBRATE

LABEL

EXIT

Fig. 33. Setup - Sensors - Sensor A - Exit.

SETUP

SENSORS

SETUP

SENSORS

# SENSORS

SENSOR A

SENSOR B

EXIT

Fig. 34. Setup - Sensors - Sensor B Menu.

1.2.2.5. Exit Sensor A Setup

Press the W button to exit Sensor A selections and return

to the Sensors menu.

or

Use the S and T buttons to highlight EXIT and press the

X button.

Continue with “1.2.3. SENSOR B (Temperature only)”

M24596

1.2.3. SENSOR B (Temperature only)

For two-sensor reset control, Sensor B must always be

the controlling temperature. For example, in a reset

control based on outside temperature, Sensor B must be

the outside sensor.

NOTE: Sensor B is available only for reset on the

T775U2006, but can be controlled just like Sensor A on the T775U2016.

1. From the Sensors menu, use the T button to high-

M24597

light SENSOR B.

2. Press the X button to display the Sensor B menu.

3. Repeat the selections described in “1.2.2. SENSOR

A” through “1.2.2.4. LABEL (Sensor A or B input)”

beginning on page 14, but perform only those steps

applicable to Sensor B.

4. Press the W button to exit SENSOR B and return to

the Sensors menu.

or

Use the S and T buttons to highlight EXIT and

press the X button.

5. Press the W button to exit the Sensors menu and

return to the Setup menu.

Continue with “1.3. Setting up the Outputs”.

SETUP

OUTPUTS

MOD 1

Fig. 35. Setup - Outputs Menu.

SETUP

OUTPUTS

MOD 1

TYPE

MIN OUT %

INTEGRAL

DERIVATIV

SCHEDULE

RESET

HIDE

EXIT

1.3. Setting up the Outputs

1. From the Setup menu, use the Sand T buttons to

highlight OUTPUTS.

2. Press the X button to display the Outputs menu.

NOTE: The menus (e.g. the Outputs menu shown here)

can display only those relays that are defined in

Setup (see page 21). For example, if you configure only two relays, then only two relays display

on the appropriate menus.

M24599

The following procedures set up each modulating output

and relay output.

17 62-0255—07

Page 18

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

SETUP

OUTPUTS

MOD 1

SETUP

OUTPUTS

MOD 1

TYPE

MIN OUT %

INTEGRAL

DERIVATIV

SCHEDULE

RESET

EXIT

M24599

Fig. 36. Setup - Outputs - Modulating Output Menu.

SETUP

OUTPUTS

MOD 1

TYPE

SETUP

OUTPUTS

MOD 1

TYPE

4 - 20 mA

0-10 V

2-10 V

SERIES 90

SELECT

TYPE FOR

MOD 1

M24600

Fig. 37. Setup - Outputs - Mod Out - Type.

SETUP

OUTPUTS

MOD 1

MIN OUT %

Fig. 38. Setup - Outputs - Mod Out - Minimum Output

Percentage.

SETUP

OUTPUTS

MOD 1

MIN OUT %

0

ENTER

MINIMUM

PERCENT FOR

MOD 1

%

M24601

1.3.1. Setting up the Modulating Outputs

1. From the Output menu, use the S and T buttons to

highlight the desired modulating output (MOD 1 or

MOD 2).

2. Press the X button to display the selected MOD

menu.

Use the remaining procedures, beginning with “1.3.1.1.

TYPE (of output signal)”, to set up each modulating

output. If you have two modulating outputs, repeat these

procedures for each modulating output.

1.3.1.1. TYPE (of output signal)

1. From the Mod menu, use the S and T buttons to

highlight TYPE.

2. Press the X button to display the Type selections.

3. Use the Sand T buttons to highlight the desired

output type.

Default: 4-20 mA

4. Press the X button to accept the selected type and

return to the Mod menu.

1.3.1.2. MIN OUT %

The minimum output % prevents the output from dropping

below the value entered. This value can be useful to

maintain minimum damper position.

Using the time clock or digital input to disable the output

forces the output to 0%.

1. From the Mod menu, use the S and T buttons to

highlight MIN OUT %.

2. Press the X button to display the Min Out %.

3. Use the S and T buttons to increase/decrease the

desired value from 0% to 100% in 1% increments.

Default: 0%

Range: 0 to 100%

4. Press the X button to accept the percentage and

return to the Mod menu.

SETUP

OUTPUTS

MOD 1

INTEGRAL

Fig. 39. Setup - Outputs - Mod Out - Integral.

62-0255—07 18

SETUP

OUTPUTS

MOD 1

INTEGRAL

400

ENTER

INTEGRAL

TIME FOR

MOD 1

SEC

1.3.1.3. INTEGRAL

1. From the Mod menu, use the S and T buttons to

highlight INTEGRAL.

2. Press the X button to display the Integral seconds.

3. Use the S and T buttons to increase/decrease the

value from 0 to 3,600 in 10 second increments.

Default: 400 seconds

Range: 0 to 3,600 seconds

4. Press the X button to accept the seconds and

return to the Mod menu.

M24602

See the Notes on page 19 for Integral timing information.

Page 19

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

NOTES: (Integral Timing)

1. The Integral time is factory set for 400 seconds. This

is a good middle range and should satisfy many

applications. The integral time can be increased for

applications where sensed response is slow, and can

be decreased for applications where sensed

response is fast (e.g. discharge air control).

2. As a starting point, an optimal integral time for

discharge air typically ranges from 12 to 200

seconds. An optimal integral time for room control

typically ranges from 60 to 2,500 seconds. The

purpose of integral action is to reduce or eliminate

the offset from setpoint during steady state control

that is often seen in proportional only control.

3. Keep in mind that control is most sensitive to

throttling range. Adjust the throttling range first

before any adjustment to integral time. Adjust

throttling range to be as wide as possible to start

since this will provide the most stable control.

Remember that the integral will eliminate the steady

state error so you do not need to have a small

throttling range to have accurate control. (Integral

action allows for controlling to a setpoint even with a

wide throttling range).

SETUP

OUTPUTS

MOD 1

DERIVATIV

SETUP

OUTPUTS

MOD 1

DERIVATIV

0

ENTER

DERIVATIVE

TIME FOR

MOD 1

SEC

Fig. 40. Setup - Outputs - Mod Out - Derivative.

SETUP

OUTPUTS

MOD 1

SCHEDULE

OUTPUTS

SCHEDULE

YES

NO

SCHEDULE

OUTPUTS

SETUP

MOD 1

USE

FOR

Fig. 41. Setup - Outputs - Mod Out - Schedule.

1.3.1.4. DERIVATIVE

The Derivative default value is factory set to zero (no

derivative control). It is strongly recommended that the

derivative remain at zero (0) unless you have a very good

reason to adjust it. Derivative control is not needed in the

vast majority of HVAC applications.

1. From the Mod menu, use the S and T buttons to

highlight DERIVATIV.

2. Press the X button to display the Derivative sec-

onds.

M24603

3. Use the S and T buttons to increase/decrease the

value.

Default: 0 (zero)

Range: 0 to 3,600 seconds

4. Press the X button to accept the seconds and

return to the Mod menu.

1.3.1.5. SCHEDULE

The Schedule option displays only if the USE SCHED

parameter is set to Yes (see page 21).

1. From the Mod menu, use the S and T buttons to

highlight SCHEDULE.

2. Use the S and T buttons to highlight YES or NO.

Default: YES

3. Press the X button to accept the selection and

return to the Mod menu.

Each output can be set up to follow or ignore the built in

M24604

scheduler. To disable the scheduler for all outputs, see

“1.3.3.1. USE SCHED” on page 21.

19 62-0255—07

Page 20

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

SETUP

OUTPUTS

MOD 1

RESET

SETUP

OUTPUTS

MOD 1

RESET

YES-BOILER

YES-OTHER

NO

USE

RESET

FOR

MOD1

Fig. 42. Setup - Outputs - Mod Out - Reset.

SETUP

OUTPUTS

MOD 1

HIDE

SETUP

OUTPUTS

MOD 1

HIDE

YES

NO

HIDE MOD 1 ON

HOME SCREEN

Fig. 43. Setup - Outputs - Mod 1/2- Hide.

1.3.1.6. RESET

This selection enables the controller’s Reset function, and

allows each output to be individually programmed for

Reset or No Reset.

IMPORTANT

To use the Reset function of the controller, the

first modulating output (MOD1) must be set for

Reset here.

The RESET choice is offered for all outputs in setup

M24605

mode, and you can set any or all of them for Reset=YES

or Reset=NO. The default is Reset=NO.

For the remaining outputs, if Reset=YES, then these

outputs use the reset curve programmed for the first

output.

1. From the Mod menu, use the S and T buttons to

highlight RESET.

2. Use the S and T buttons to highlight the desired

value.

Default: NO

3. Press the X button to accept the selection and

return to the Mod menu.

1.3.1.7. Hide

The Hide option is used to prevent the MOD 1 and MOD 2

outputs from displaying on the Home screen.

1. From the Mod menu, use the S and T buttons to

highlight HIDE.

2. Use the S and T buttons to highlight YES or NO.

Default: YES

3. Press the X button to accept the selection and

return to the MOD menu.

NOTE: The MOD1 and MOD2 outputs are still active

M28656

even when hidden from the Home screen.

SETUP

OUTPUTS

MOD 1

TYPE

MIN OUT %

INTEGRAL

DERIVATIV

SCHEDULE

EXIT

1.3.1.7. Exit Modulating Outputs Setup

Press the W button (or highlight EXIT and press the X

button) to exit the Mod menu and return to the Outputs

menu.

To configure the second modulating output, go to “1.3.1.

Setting up the Modulating Outputs” on page 18.

When you finish setting up the two modulating outputs,

continue with “1.3.2. NBR OF RELAYS”.

M24606

Fig. 44. Setup - Outputs - Mod Out - Exit.

62-0255—07 20

Page 21

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

A

SETUP

OUTPUTS

OPTIONS

USE SCHED

SETUP

OUTPUTS

OPTIONS

USE SCHED

USE

SCHEDULE

FOR

OUTPUTS

YES

NO

M24609

SETUP

OUTPUTS

# RELAYS

SETUP

OUTPUTS

# RELAYS

2

ENTER

NUMBER OF

RELAYS

Fig. 45. Setup - Outputs - Number of Relays.

SETUP

OUTPUTS

OPTIONS

Fig. 46. Setup - Outputs - Options Menu.

Fig. 47. Setup - Outputs - Options - Schedule.

SETUP

OUTPUTS

OPTIONS

USE SCHED

MIN OFF

MIN ON

DI OPTS

SHOW RT

EXIT

1.3.2. NBR OF RELAYS

1. From the Outputs menu, use the Sand T buttons

to highlight # RELAYS.

2. Press the X button to display the number of relays.

3. Use the S and T buttons to display the number

from 1 to 2.

4. Press the X button to accept the value and display

the Outputs menu.

The number of relay outputs entered here determines

how many relays display on the home screen.

M24607

1.3.3. OPTIONS

1. From the Outputs menu, use the Sand T buttons

to highlight OPTIONS.

2. Press the X button to display the Options menu.

M24608

1.3.3.1. USE SCHED

1.

Press the X button to display the schedule selections.

2. Use the Sand T buttons to highlight YES or NO.

Default: NO

3. Press the X button to accept the value and display

the MIN OFF option.

Selecting NO disables scheduling for all outputs.

Selecting YES enables scheduling for all outputs. When

YES is selected, all individual outputs default to follow the

schedule. However, each individual output can be

removed from scheduling as desired.

With Scheduling enabled, when you return to Program

mode, the new option for Scheduling displays. You can

press the HOME button and then the MENU button to

view the Schedule options in the menu.

See “1.3.1.5. SCHEDULE” on page 19.

21 62-0255—07

Page 22

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

M24610A

SETUP

OUTPUTS

OPTIONS

ENTER

MINIMUM

OFF TIME

FOR RELAYS

SETUP

OUTPUTS

OPTIONS

MIN OFF

0

SEC

OR

MIN ON

SETUP

OUTPUTS

OPTIONS

MIN ON

0

SEC

MIN OFF

ENTER

MINIMUM

ON TIME

FOR RELAYS

1.3.3.2. MIN OFF or MIN ON

This is the minimum number of seconds of “off time” or

“on time” for all relays.

1. Press the X button to display the Min Off/On value.

2. Use the S and T buttons to increase/decrease the

3. Press the X button to accept the seconds and

Fig. 48. Setup - Outputs - Options - Min Off/On Time.

NOTES:

desired number of seconds from 0 to 990 seconds

in 10 second increments.

Default: 0 (zero)

Range: 0 to 990 seconds

display the DI OPTIONS.

1. The minimum off time applies to all relay

outputs.

2. When minimum off time is active, relays

waiting to be energized display a flashing

square underneath the relay number on the

home screen.

3. If the minimum off time is not equal to zero

(0), the minimum off time activates at powerup. To manually override, press the W button

at any time.

SETUP

OUTPUTS

OPTIONS

DI OPTS

SETUP

OUTPUTS

OPTIONS

DI OPTS

DISABLE

SETPOINT

SETBACK

ENABLE

IGNORE

SELECT DI

OPTIONS

FOR

OUTPUTS

M24611A

Fig. 49. Setup - Outputs - Options - DI Options.

1.3.3.3. DI OPTIONS (digital input options)

The DI Option you select applies to all outputs. This

option overrides any Setpoint/Setback values entered in

the Schedule.

1. Press the X button to display the DI Option selec-

tions.

2. Use the S and T buttons to highlight DISABLE,

SETBACK, or IGNORE.

Default: DISABLE

3. Press the X button to accept the value and display

the SHOW RT option.

When the digital input (DI) closes, all outputs follow the DI

option value (Disable, Setback, or Ignore):

• DISABLE disables the outputs; relays return to deenergized state and Mod outputs return to 0% output.

• SETPOINT forces the control to the setpoint

temperature.

• SETBACK enables a setback temperature value to be

programmed for each output.

— To program the Setback temperature with Reset,

see Fig. 73 on page 31.

— To program the Setback temperature without

Reset, see Fig. 60 on page 26.

• ENABLE energizes all relays to 100%. Use this option

carefully.

• IGNORE causes the digital input to have no effect on

the Relay or Mod outputs.

62-0255—07 22

Page 23

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

SETUP

OUTPUTS

OPTIONS

SHOW RT

YES

NO

SETUP

OUTPUTS

OPTIONS

SHOW RT

USE

RUNTIME

FOR

RELAYS

M24612

Fig. 50. Setup - Outputs - Options - Show Runtime.

SETUP

OUTPUTS

OPTIONS

USE SCHED

MIN OFF

DI OPTION

SHOW RT

EXIT

M24613

Fig. 51. Setup - Outputs - Options - Exit.

SETUP

OUTPUTS

RELAY 1

SETUP

OUTPUTS

RELAY 1

SCHEDULE

RESET

RESET RT

EXIT

1.3.3.4. SHOW RT (show run time hours)

1. Press the X button to display the Show RT values.

2. Use the S and T buttons to select YES or NO.

Default: YES

3. Press the X button to accept the value and return to

the Options menu.

Selecting YES shows the RT (run time) hours for each

relay on the home screen displays.

NOTE: Run times can be reset to zero for each individ-

ual relay. You must do this for each relay that

you want to reset to zero. See “1.3.4.3. RESET

RT (run time)” on page 24.

1.3.3.5. Exit Options Setup

Press the W button to exit the Options set up and return to

the Outputs menu.

or

Use the S and T buttons to highlight EXIT and press the

X button.

Continue with “1.3.4. Setting up the Relays”.

1.3.4. Setting up the Relays

1. From the Outputs menu, use the S and T buttons

to highlight the desired relay (1 or 2).

2. Press the X button to display the selected Relay

menu.

Continue with the remainder of this section to setup the

relay outputs.

M24614

Fig. 52. Setup - Outputs - Relay Menu.

SETUP

OUTPUTS

RELAY 1

SCHEDULE

Fig. 53. Setup - Outputs - Relay - Schedule.

OUTPUTS

RELAY 1

SCHEDULE

YES

NO

SCHEDULE

OUTPUTS

SETUP

USE

FOR

1.3.4.1. SCHEDULE

This selection displays only if “Use Sched = YES” is

selected during the Output Options setup (see page 21).

When selected, individual outputs default to follow the

schedule.

1. Press the X button to display the Schedule values.

2. Use the S and T buttons to select YES or NO.

Default: YES

3. Press the X button to accept the value and return to

the Relay menu.

An individual output can be selected to be controlled or

M24615

not controlled by the schedule.

If NO is selected, the Setback selection does not appear

in the Program menu for this output.

23 62-0255—07

Page 24

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

SETUP

OUTPUTS

RELAY 1

RESET

YES

NO

SETUP

OUTPUTS

RELAY 1

RESET

USE

RESET

FOR

RELAY 1

Fig. 54. Setup - Outputs - Relay - Reset.

SETUP

OUTPUTS

RELAY 1

RESET RT

YES

NO

SETUP

OUTPUTS

RELAY 1

RESET RT

RESET

RUN TIME

FOR

RELAY 1

M24617

Fig. 55. Setup - Outputs - Relay - Reset Runtime.

1.3.4.2. RESET

IMPORTANT

For relays to use the Reset function of the controller, both modulating outputs (MOD 1 and

MOD 2) must be set for Reset.

Relays that have Reset set to YES use the reset curve

configured for MOD 1.

1. Press the X button to display the Reset values.

M24616

2. Use the S and T buttons to select YES or NO.

Default: NO

3. Press the X button to accept the value and return to

the Relay menu.

• If you select YES, then all other outputs display this

Setup option and will use the reset curve programmed

for the first output.

• If you select NO, then No Reset is configured for that

output and all other subsequent outputs.

1.3.4.3. RESET RT (run time)

This selection displays only if “Show RT = YES” is

selected during Output Options setup (see page 23).

1. Press the X button to display the Reset RT values.

2. Use the S and T buttons to select YES or NO.

Default: NO

3. Press the X button to accept the value and return to

the Relay menu.

Selecting YES immediately resets the output run time

hours to zero for this output. When you subsequently

return to this screen, the RESET RT defaults to NO.

NOTE: Run times can be reset to zero for each individ-

ual relay. You must do this for each relay that

you want to reset to zero.

SETUP

OUTPUTS

RELAY 1

RESET

SCHEDULE

RESET RT

EXIT

1.3.4.4. EXIT Relay Setup

Press the W button to exit the selected relay set up and

return to the Outputs menu.

To setup the next relay output go to “1.3.4. Setting up the

Relays” on page 23.

When you finish setting up the relay outputs, continue

with “1.4. Exiting Setup”.

M24618

Fig. 56. Setup - Outputs - Relay - Exit.

1.4. Exiting Setup

Press the HOME button to exit Setup mode and return to

the home screen display.

or

Use the S and T buttons to highlight EXIT from the menu

and press the X button.

This completes the Setup procedure.

62-0255—07 24

Page 25

T775U SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLER

2. PROGRAMMING OUTPUTS

(MOD AND RELAY) WITH NO

RESET

The T775U can be programmed for Reset or No Reset.

From the factory, the T775U is programmed for No Reset.

This section describes the steps necessary to program

the controller for No Reset.

MENU

MENU

PROGRAM

Fig. 57. Program Menu.

PROGRAM

MOD 1

Fig. 58. Program Menu - No Reset.

PROGRAM

MOD 1

MOD 2

RELAY 1

RELAY 2

EXIT

MENU

PROGRAM

MOD 1

SETPOINT

SETBACK

SENSOR

THROT RNG

ACTION

EXIT

M24567

M24580A

NOTE: For applications where Reset is not used, only

one sensor (Sensor A) is available for use.

2.1. Entering Program Mode

Press the MENU button, then select PROGRAM and

press the X button to view the Program menu.

2.1.1. Program Menu for Outputs with

No Reset

From the Program menu, select MOD 1, MOD 2,

RELAY 1, or RELAY 2 to view the parameters. This

section illustrates the screens for selecting MOD 1, but

other than as noted below, the programming is the same

for each output.

NOTE: For Relays, DIFFRNTL replaces THROT RNG.

NOTE: The Setback parameter displays only if schedul-

ing is enabled (see Fig. 47 on page 21) or the DI

Option is set to Setback. (see Fig. 49 on

page 22).

Continue with “2.1.2. SETPOINT”.

PROGRAM

MOD 1

SETPOINT

Fig. 59. Program - Setpoint.

MENU

PROGRAM

MOD 1

SETPOINT

70

ENTER

SETPOINT

FOR

MOD 1

2.1.2. SETPOINT

1. From the menu, use the S and T buttons to high-

light SETPOINT.

2. Press the X button to display the setpoint value.

3. Use the S and T buttons to increase/decrease the

o

F

M24581

desired setpoint temperature.