Page 1

T775 Series 2000 Electronic Stand-Alone

Controllers

APPLICATION GUIDE AND CROSS REFERENCE

63-7147—3

Page 2

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

IMPORTANT

The T775R is an operating control, not a limit or

safety control. If used in applications requiring safety

or limit controls, a separate safety or limit control

device is required.

TABLE OF CONTENTS

T775 Application Tips .....................................................3

Compatible Components ...............................................3

Temperature Sensors....................................................3

Humidity Sensors (T775U only) ...................................3

Low Differential Pressure Sensors (T775U only) .........3

Universal Sensors (T775U only) ..................................3

Accessories .................................................................. 3

Features ...........................................................................4

T775 Operations ..............................................................6

Integral Action .............................................................. 6

Derivative Action ..........................................................6

Differential vs. Throttling Range ...................................6

Setpoint High Limit ....................................................... 6

Reset Programming (T775L, T775P, T775R, and

T775U models only) .....................................................7

T775 Applications ........................................................... 8

Water Source Heat Pump Loop Water Controller –

T775B .......................................................................... 8

Chiller – T775B ............................................................ 9

Chiller, Rotary Compressor – T775B ......................... 10

Cooling Tower Control – T775B2040 ..........................11

Time-based Control of Fan, Pump, etc. – T775

(all models) ................................................................. 12

Damper or Valve Modulation – T775M or T775R ...... 13

Hot Water Reset – T775R ......................................... 14

Chilled Water Reset – T775R .................................... 16

Multi-Stage Boiler Control (No Reset) – T775P ......... 18

Multi-Stage Boiler Control (Reset) – T775P .............. 19

Multi-Stage Chiller Control (No Reset) – T775P ........ 21

4 Stage with Pump Output and Reset – T775P using

a T775S Expansion Module ...................................... 22

3 Stage Reciprocating Chiller – T775L ...................... 24

4 Stage Heat and 6 Stage Cool – T775L ................... 25

Pressure with a Variable Frequency Drive (VFD) –

T775U ........................................................................ 27

Carbon Dioxide (CO2) Sensing – T775U .................. 28

T775 Application Replacement Examples ................. 29

T775M2030 Replacement for W973A Logic Panel ... 29

T775R Replacement for W964F Aquatrol Panel with

Floating Actuator ....................................................... 32

T775L Replacement for S984 Step Controller ........... 35

T775L Replacement for W7100C Discharge Air

Controller ................................................................... 37

T775 Cross Reference .................................................. 40

Notes ............................................................................. 51

63-7147—3 2

Page 3

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

T775 APPLICATION TIPS

Q Does the T775 save programmed values if the power is

lost?

A Yes. The T775 has an EEPROM that saves all values

entered and restores them once power is reapplied. The

date and time settings are retained for 24 hours after a

power outage. After a power loss of more than 24 hours,

the date and time settings may need to be reentered. All

other settings are stored permanently.

Q What is the time constant for the T775?

A The T775 standard sensor (50021579-001) has a time

constant of approximately 8 seconds. The T775 samples

sensor input every 100 milliseconds and updates the

control and display every 1 second.

Q Can sensors be shared by several T775s to simplify

installation or provide more stages?

A Each T775 must be wired to its own sensor(s), However, a

benefit of the T775 controller's high accuracy is that there

is no more than a 2° differential between any two T775

controllers.

COMPATIBLE COMPONENTS

Temperature Sensors

The controller accepts 1,097 Ohms PTC at 77° F (25° C):

• 50021579-001 – Standard sensor (included with all models

except T775U2006 and NEMA 4X models)

• T775-SENS-STRAP – Strap on sensor with wiring box

• T775-SENS-WR – Water resistant with 5 foot leads

(included with NEMA 4X models)

• T775-SENS-WT – Watertight with 6 foot lead

• T775-SENS-OAT – Outdoor air temperature sensor

• C7031B2005 – 6 inch duct mount with wiring box.

• C7031D2003 – 5 inch immersion sensor with wiring box

(use immersion well; P/N 50001774-001)

• C7031J2009 – 12 foot duct averaging sensor with wiring

box

• C7046D1008 – 8 inch duct probe with mounting flange

• C7100D1001 – 12 inch fast response, duct averaging

sensor with flange

• C7130B1009 – Room mount sensor

Humidity Sensors (T775U only)

The controller accepts 0-10 Vdc or 4-20 mA input with a range

of 0-100%

H7625, H7635, and H7655 models (available in 2, 3, and 5%

RH accuracy) can be used.

1

Q Can a T775 be powered with dc voltage?

A No. The T775 controllers may be powered with 24 Vac,

120 Vac, or 240 Vac only, and a separate earth ground is

required.

Q Is a separate earth ground required?

A Yes. Each T775 controller must have its own earth ground,

regardless of the power source (24, 120, or 240 Vac). The

earth ground must be connected to the earth ground

terminal on the 24 Vac terminal block.

Q Can sensors be series-parallel wired to the T775 to provide

an average temperature?

A Yes. Sensors can be series-parallel wired to the T775. In

order to maintain control accuracy, the number of sensors

wired must be of the n

Q How do I know that my selection or value has been

entered?

A Once you have selected an item from a list or entered a

value using the ! and " buttons, pressing the # or $ or

HOME button accepts your selection or value and stores it

in the controller’s memory.

Q What are the T775 Series 2000 Controller specifications?

A Refer to the T775 Series 2000 Electronic Stand-Alone

Controllers - Specification Data (form 63-1318-01).

2

power (i.e. 4, 9, 16, etc.).

Low Differential Pressure Sensors (T775U only)

P7640A pressure transducer models with selectable pressure

ranges can be used.

The controller accepts pressure sensors with a signal output

of 0-10 Vdc or 4-20 mA for any output range within the

following ranges (the minimum and maximum for the sensor

output range can be adjusted within the following limits):

-500 to 500 PSI

-30.0 to 30.0 inches w.c.

-3,000 to 3,000 Pa

-3,000 to 3,000 kPa

Universal Sensors (T775U only)

The controller accepts 0-10 Vdc or 4-20 mA input for

temperature, pressure, humidity, etc. C7232 and C7632 CO

sensors are also compatible but output is displayed in %

instead of ppm. (Refer to Table 2 on page 29 and the T775U

installation Instructions, form 62-0255-01.)

Actuators

For more information on compatible actuators or other

Honeywell products, such as dampers and valves, go to

www.customer.honeywell.com

Product Selection Tool under Products.

• Spring return models: ML6425, ML7425, MS4105,

MS4110, MS4120, MS7505, MS7510, MS7520, MS8105,

MS8110, MS8120

• Non-spring return models: ML4161, ML6174, ML7161,

ML7164, MN1010, MN6105, MN7505, MN8810

. From the home page select

2

3 63-7147—3

Page 4

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

1

See form 62-0265 - Temperature Sensor for the T775 Series

2000 Stand-alone Controller

Accessories

• 107324A – Bulb Holder, duct insertion

• 107408 – Heat Conductive Compound, 4 ounce

• 50001774-001 – Immersion Well, stainless steel 304,

1/2 in. threading

FEATURES

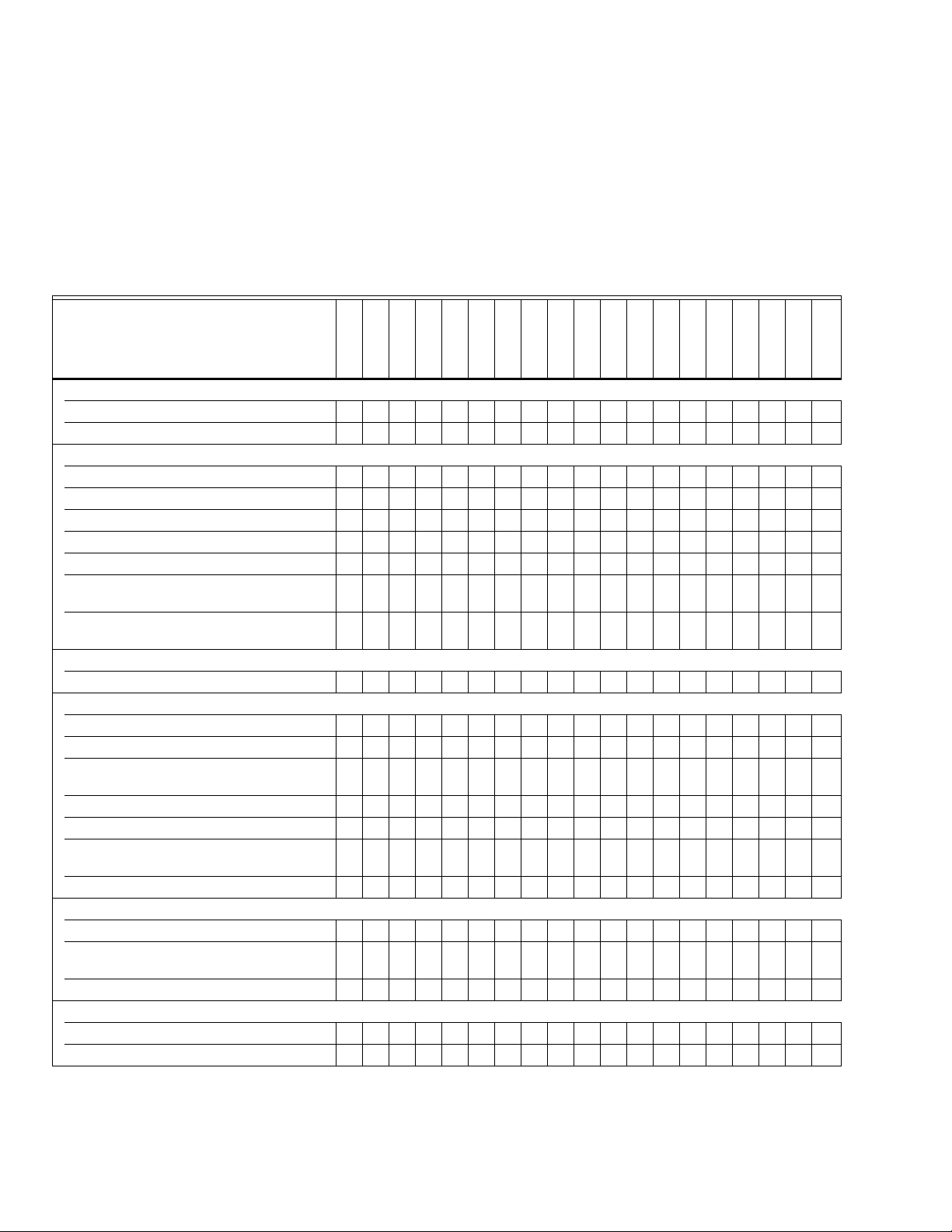

In Table 1, a check mark (!) indicates that the controller

model has this feature. A number indicates the quantity (e.g.,

the T775M2030 has 4 standard SPDT relay outputs), and

“n/a” indicates the feature is not applicable to that controller

model.

Table 1. T775 Controller Features by Model Number.

Feature

User Interface

2x4 inch LCD display with English language display !!!! !!!!!!!!!!!!!!n/a

Keypad lockout !!!!!!!!!!!!!!!!!!n/a

Applications

Standard heating/cooling !!!!!!!!!!!!!!!!!!!

Modulating !!!!! !! !!

Boiler/Chiller !!!!!!!!!!!!!!!!!!!

Reset ! !!!!!!!!

Stage (Loop) control of up to 12 relays !! !

Temperature, humidity, pressure, or other

application requiring 0-10 Vdc or 4-20 mA input

Expansion module (4-relays per module; 2 modules

max.)

Power

24 or 120/240 Vac with separate earth ground !!!!!!!!!!!!!!!!!!!

Relay Outputs

SPDT !!!!!!!!!!!!!!!!!!!

Number of standard 1242440424244422024

Number of floating

(each floating output eliminates 2 relays)

Runtime displayed on relays 1-4 (optional) !!!!!!!!!!!!!!!!!!n/a

Configurable minimum off time !!!!!!!!!!!!!!!!!!!

Expandable to 12 relays using T775S expansion

modules (4 relays per expansion module)

Warm weather shutdown ! n/a

Modulating Outputs

Number of outputs 0000002222200220220

Independently selectable for 0-10 Vdc, 2-10 Vdc,

4-20 mA, or Series 90

Modulating high/low limit control !!!! ! n/a

Digital Output

Number of outputs 0000000000010000000

High, low, and differential alarm !

T775A2009

T775B2016

T775B2024

T775B2032

T775B2040

0121200000002001000

T775M2006

T775M2014

T775M2022

T775M2030

T775L2007

!! !

!!!!! !! !!

T775M2048

T775R2001

T775P2003

T775R2019

T775R2027

T775R2035

T775R2043

T775U2006

T775S2008

!

!

63-7147—3 4

Page 5

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

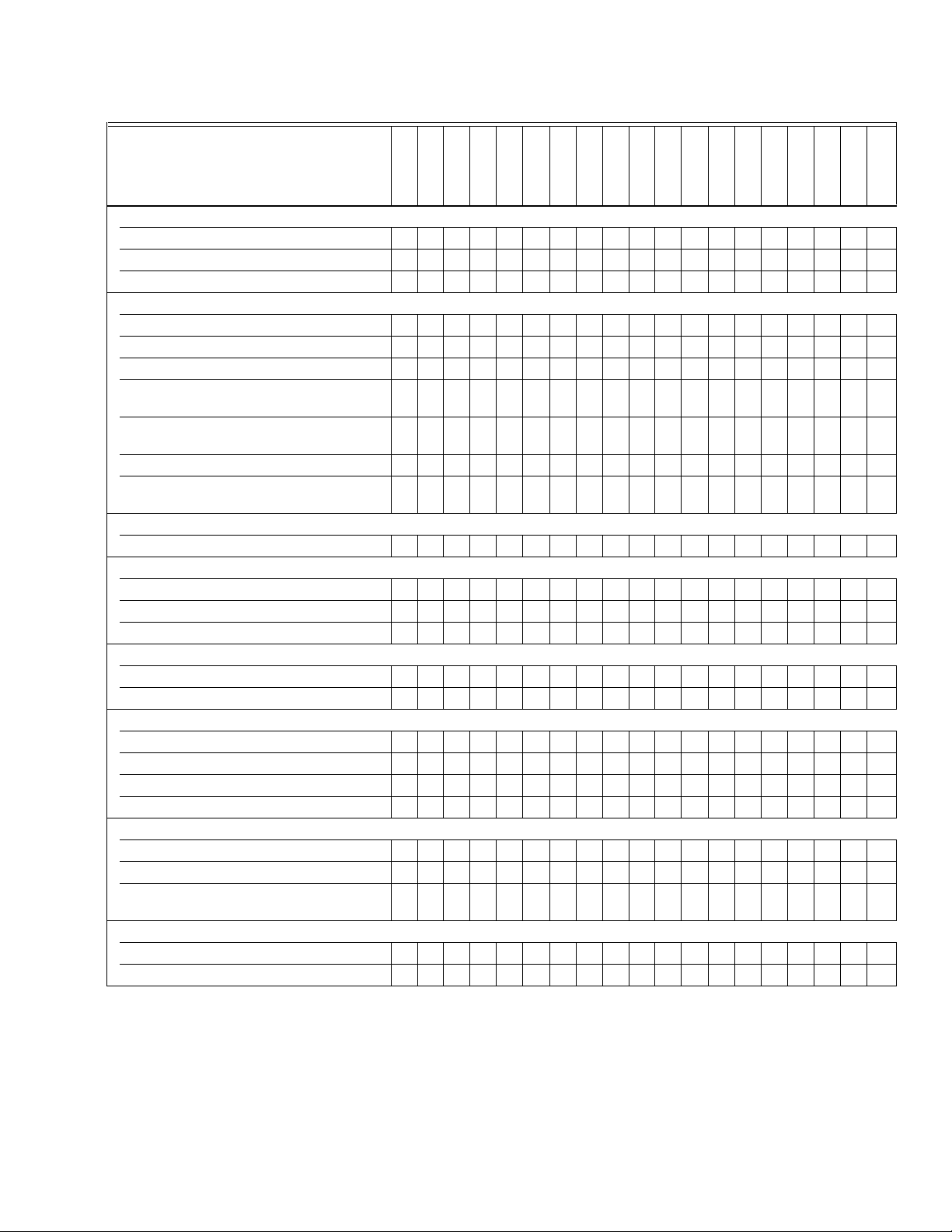

Table 1. T775 Controller Features by Model Number. (Continued)

T775M2006

T775M2014

T775M2022

T775M2030

T775A2009

T775B2016

T775B2024

T775B2032

T775B2040

T775L2007

T775M2048

T775R2001

T775R2019

T775R2027

T775R2035

T775R2043

T775P2003

T775U2006

T775S2008

Feature

Pump Output (configurable for last relay)

Number of outputs 0000000000010000001

Prepurge/Postpurge !!

Pump Exercise !!

Sensor Inputs

Number of sensor inputs 1222222222232222220

Number of sensors included 111111111113222220n/a

1097 Ohms PTC at 77° F (25° C) !!!!!!!!!!!!!!!!!!n/a

0-10 Vdc or 4-20 mA input for temperature, humidity,

! n/a

pressure, etc.

Calibration capability ±10° F (±6° C) or

!!!!!!!!!!!!!!!!!!n/a

for T775U, ±10% of sensor range

1° sensed temperature accuracy !!!!!!!!!!!!!!!!!!n/a

Sensed temperature range from -60° to 270° F

!!!!!!!!!!!!!!!!!!n/a

(-51° to 132° C)

Digital Input

Number of inputs 1111111111111111111

Setpoints

Maximum number of setpoints 124244264641464224n/a

Range -40° to 248° F (-40° to 120° C) !!!!!!!!!!!!!!!!!!!

Maximum high setpoint option (irreversible) !!!!!!!!!!!!!!!!!!n/a

Integral and Derivative Options

Integral time selectable from 0 to 3,600 seconds ! !!!!!!!!!!!!!!!!!n/a

Derivative time selectable from 0 to 3,600 seconds !!!!!!!!!!!!!!!!!!n/a

Stag ing

Standard staging !! !

First on, first off !!

Equalized runtime !!

On delay and Off delay between stages !! !

Time Clock Scheduler

DST option !!!!!!!!!!!!!!!!!!n/a

2 events per day !!!!!!!!!!!!!!!!!!n/a

Selectable for setback, disable, or ignore to control

!!!!!!!!!!!!!!!!!!n/a

all outputs

Enclosures

NEMA 1 ! !!!! !!!!!!!!! !

NEMA 4X !! !!

5 63-7147—3

Page 6

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

T775 OPERATIONS

Integral Action

“Droop” and equipment hunting can be minimized by

summing (integrating) the offset errors over time and adding

this correction to the output voltage.

A non-zero value for the integral time will allow the controlled

temperature to try and reach the setpoint value.

The integral time is factory set for 400 seconds and is similar

to the response time to the T775 Series 1000 models. This is

a good middle range and should satisfy many applications.

The integral time can be increased for applications where

sensed response is slow, and can be decreased for

applications where sensed response is fast (e.g. discharge air

control).

As a starting point, an optimal integral time for discharge air

typically ranges from 12 to 200 seconds. An optimal integral

time for room control typically ranges from 60 to 2,500

seconds. The purpose of integral action is to reduce or

eliminate the offset from setpoint during steady state control

that is often seen in proportional-only control.

Keep in mind that the controller is most sensitive to throttling

range. Adjust the throttling range first before making any

adjustment to integral time. Adjust throttling range to be as

wide as possible to start, because this will provide the most

stable control. Remember that the integral will eliminate the

steady state error so you do not need to have a small throttling

range to have accurate control. (Integral action allows for

controlling to setpoint even with a wide throttling range.)

Derivative Action

Proportional-integral-derivative (PID) control adds the

derivative function to PI control. The derivative function

opposes any change and is proportional to the rate of change.

The more quickly the control point (actual sensed

temperature) changes, the more corrective action the PID

system provides.

Differential vs. Throttling Range

Differential is used for relay outputs, and throttling range is

used for modulating outputs.

Setpoint and Differential

The following describes the relationship between setpoint and

differential for heating and cooling. These settings are

programmed for each output relay.

HEATING MODE SETPOINT AND DIFFERENTIAL

In heating mode, the differential is below the setpoint. The

relay de-energizes when the temperature rises to the setpoint.

As the temperature drops to the setpoint minus the

differential, the relay energizes.

COOLING MODE SETPOINT AND DIFFERENTIAL

In cooling mode, the differential is above the setpoint. The

relay de-energizes when the temperature falls to the setpoint.

As the temperature rises to the setpoint plus the differential,

the relay energizes.

Throttling Range

The throttling range brackets the setpoint setting, e.g., if the

setpoint is 72° F (22° C) and the throttling range is 10° F

(-12° C), then the effective throttling temperature range is

67° to 77° F (19° to 25° C) . This applies to both modulating

outputs and floating outputs.

Throttling Range for Modulating High or Low Limit

On models that support this feature, the throttling range for

the modulating high or low limit positions the setpoint at the

end of the throttling range. For example, with a high (Heat)

limit at sensor B of 200° F (93° C) and a throttling range of

10° F (-12° C), the modulating output controlling sensor A

begins to throttle back at 190° F (88° C), and fully closes at

200° F (93° C). Conversely, the throttling range for the low

limit begins above the Cooling setpoint in the same manner.

If the control point moves away from the setpoint, the

derivative function outputs a corrective action to bring the

control point back more quickly than through integral action

alone. If the control point moves toward the setpoint, the

derivative function reduces the corrective action to slow down

the approach to the setpoint, which reduces the possibility of

overshoot. The rate time setting determines the effect of the

derivative action. The rate time is the time interval by which

the derivative function advances the effect of the proportional

action. In T775 controllers, the derivative rate time can range

from 0 to 3,600 seconds. The higher the derivative setting, the

greater the effect.

For all T775 Series 2000 controllers, the derivative default

value is factory set to zero (no derivative control). It is strongly

recommended that the derivative remain at zero (0) unless

you have a very good reason to adjust it. Derivative control is

not needed in the vast majority of HVAC applications.

63-7147—3 6

Setpoint High Limit

You can set an irreversible setpoint high limit maximum value

for any single setpoint temperature value. This prevents the

user from setting any setpoint above the chosen high setpoint

limit, which is useful for meeting some local codes.

Adjust the setpoint (at any output) to the desired maximum

setpoint. Then, simultaneously press the HOME, #, and $

buttons, and continue to press all three buttons for five

seconds to set the setpoint high limit maximum to this value.

NOTE: You must press all three buttons at exactly the same

time for this action to occur.

IMPORTANT

1. This action sets the maximum setpoint value of all

outputs to the setpoint high limit maximum.

2. Setting the high limit setpoint maximum is

irreversible. If you perform the action inadvertently

and this setpoint adversely affects the control of your

system, you must replace the controller.

Page 7

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Reset Programming (T775L, T775P, T775R, and T775U models only)

To program an output for reset, refer to the values as shown in

the example below and in Fig. 1. Choose your own

appropriate values for Sensor A maximum and minimum and

Sensor B maximum and minimum.

Reset Example:

• Sensor A is the boiler sensor and sensor B is the outdoor

sensor.

• Maximum boiler temperature desired is 210° F (99° C)

when the outdoor temperature is 20° F (-7° C).

• Minimum boiler temperature desired is 160° F (71° C)

when the outdoor temperature is 70° F (21° C).

With the above settings example, when the outdoor

temperature is 50° F (10° C), the effective setpoint is 180° F

(82° C).

Setpoint Offset

NOTE: The Setpoint Offset is used for subsequent outputs

only.

This value is the number of degrees plus (+) or minus (-) that

you want the temperature to be offset from the first output’s

setpoint. See Fig. 1. For example, If you want the second

output setpoint to be 10° F (-12° C) less than the first output

setpoint, enter -10° F (-23° C).

°F

SP MAX A1

(BOILER MAX)

SP MIN A2

(BOILER MIN)

Fig. 1. Reset Curve with Offset for Subsequent Outputs.

The reset curve established when programming the first

output (Fig. 1) is then used for all subsequent outputs that are

configured for Reset = YES, and each of those outputs will be

offset from this curve.

220

210

S

200

E

N

190

S

O

180

R

170

A

160

150

140

RELAY 2

SETPOINT

OFFSET

-10°F

10

20

RESET B1

(OUTSD MIN)

30 40 50 60

SENSOR B

RELAY 1

SETPOINT

70

RESET B2

(OUTSD MAX)

°F80

M24862

Choose Reset = NO for any outputs you do not wish to reset,

then press the HOME button to record your selection.

NOTES:

1. A single reset curve is programmed for the first

output and is used by all outputs setup for Reset.

2. For subsequent outputs, a setpoint offset is used

if that output is also being Reset.

When Reset is programmed, the home screen conveniently

displays the calculated Heat/Cool setpoint(s) for the outputs

based on the reset curve.

Setback (Optional) Description

The Setback temperature option is available only if scheduling

is enabled or the Digital Input Option is set to Setback.

This value is the number of degrees plus (+) or minus (-) that

you want the temperature to be setback (offset) from the

setpoint at a predetermined time.

For example, if you want the temperature to be 10° F (-12° C)

less than the setpoint during setback mode, enter -10° F

(-23° C). See Fig. 2

In normal operations for heating, the offset will be a negative

value; for cooling, the offset will be a positive value.

Setback (optional) Example:

• Setback of -10° F (-23° C) is used to drop the temperature

at night by 10° F (-12° C).

With the above settings example, when the outdoor

temperature is 50° F (10° C), the effective setback setpoint is

170° F (77° C) 180° F (82° C) setpoint minus the 10° F

(-12° C) setback).

°F

220

SP MAX A1

(BOILER MAX)

SP MIN A2

(BOILER MIN)

Fig. 2. Reset Curve for First Output with Setback Offset.

210

S

200

E

N

190

S

O

180

R

A

170

160

150

140

10

(OUTSD MIN)

20

RESET B1

SETBACK

OFFSET

-10°F

30 40 50 60

SENSOR B

(OUTSD MAX)

70

RESET B2

°F80

M24861

7 63-7147—3

Page 8

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

T775 APPLICATIONS

Water Source Heat Pump Loop Water

Controller – T775B

Application Description

Water is circulated in a loop to remove waste heat and to

provide cooling from a multiple heat pump system. In this

example, the T775B controls heating and cooling systems to

maintain the loop water temperature between preset upper

and lower limits. Alarms are sounded to annunciate

abnormally high or low water temperatures.

NOTE: T775R reset models can also be used in this

application.

Sensor Designation

This device application only requires one sensor. Sensor A is

mounted in a well, located in the main loop water line before

the water source heat pump take-offs.

Operation

In this example, if the loop water temperature drops to 55° F

(13° C), heat is added to the system by the boiler (Relay 1)

until it reaches the setpoint. If the temperature drops further,

Relay 2 sounds the low temperature alarm at 54° F (12° C).

If the loop water temperature rises to 95° F (35° C), Relay 3

brings on cooling. If the temperature rises to 96° F (36° C),

Relay 4 powers the high temperature alarm.

NOTE: If no alarms are present, Relay 2 and 4 may be used

as additional heating and cooling relays.

Programming Example

Relay 1: Enables boiler circuit

Program for:

—Heat

— Setpoint = 65° F (18° C)

— Differential = 10° F (-12° C)

Relay 2: Low temperature alarm circuit

Program for:

—Heat

— Setpoint = 55° F (13° C)

— Differential = 1° F (-17° C)

Relay 3: Enables cooling circuit (heat extraction)

Program for:

—Cool

— Setpoint = 85° F (29° C)

— Differential = 10° F (-12° C)

Relay 4: High temperature alarm circuit

Program for:

—Cool

— Setpoint = 95° F (35° C)

— Differential = 1° F (-17° C)

Setpoints may differ according to equipment manufacturers.

See their recommendations.

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

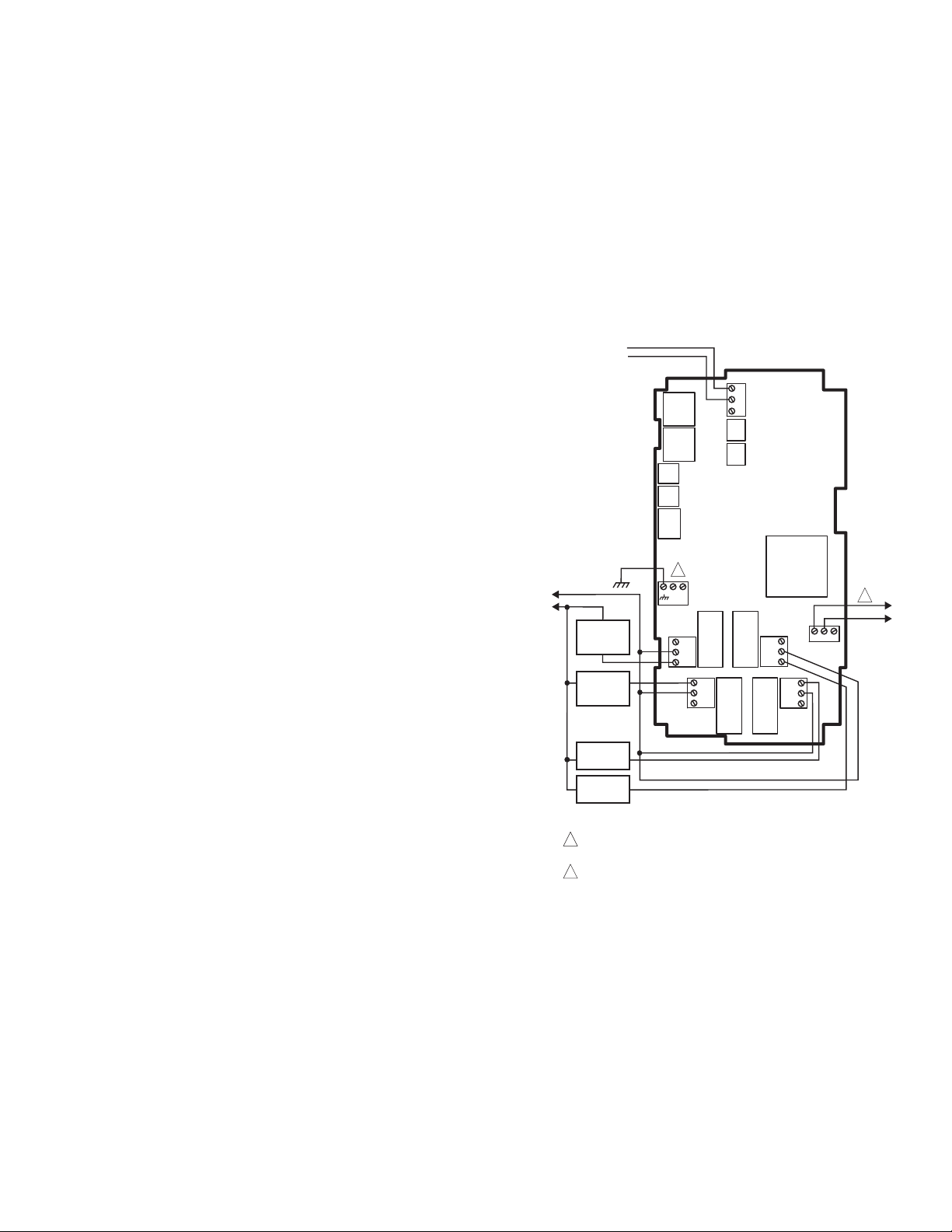

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

SENSOR A

(LOOP WATER)

T

T

T775B

2

L1

(HOT)

L2

HI TEMP

ALARM

ADD

HEAT

LO TEMP

ALARM

SUBTRACT

HEAT

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE TERMINAL BLOCK.

1

2

24 VAC POWER TERMINAL BLOCK.

C

+

RELAY

4

NC

NO

RELAY

RELAY

3

NC

C

NO

C

NC

1

NO

C

NO

C

NC

RELAY

2

120

COM

1

120 VAC

240

M24863

63-7147—3 8

Fig. 3. T775B Wiring - Loop Water Controller.

Page 9

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Chiller – T775B

Application Description

As the water temperature in the sump rises, the T775B

sequentially cycles on the spray pump valve and two relays of

fans. If the water temperature in the sump drops below 40° F

(4° C), the T775B energizes a sump dump drain valve to

prevent system freeze up.

NOTE: T775R reset models can also be used in this

application.

Sensor Designation

This device application only requires one sensor. Sensor A is

sensing sump water temperature.

Operation

In this example, the sump water temperature rises above the

Cooling relay 1 setpoint plus differential 65° F (18° C) to bring

on the spray pump valve. If the temperature continues to rise,

Cooling relays 2; 70° F (21° C) and 3; 75° F (24° C) energize

the evaporation fans as needed.

If the sump water temperature drops below 40° F (4° C)

(setpoint minus differential), the sump water freeze up

protection is provided by energizing Heating relay 4.

Relay 4: Controlling dumping of sump at freeze condition

Program for:

— Heat

— Setpoint = 50° F (10° C)

— Differential = 10° F (-12° C)

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

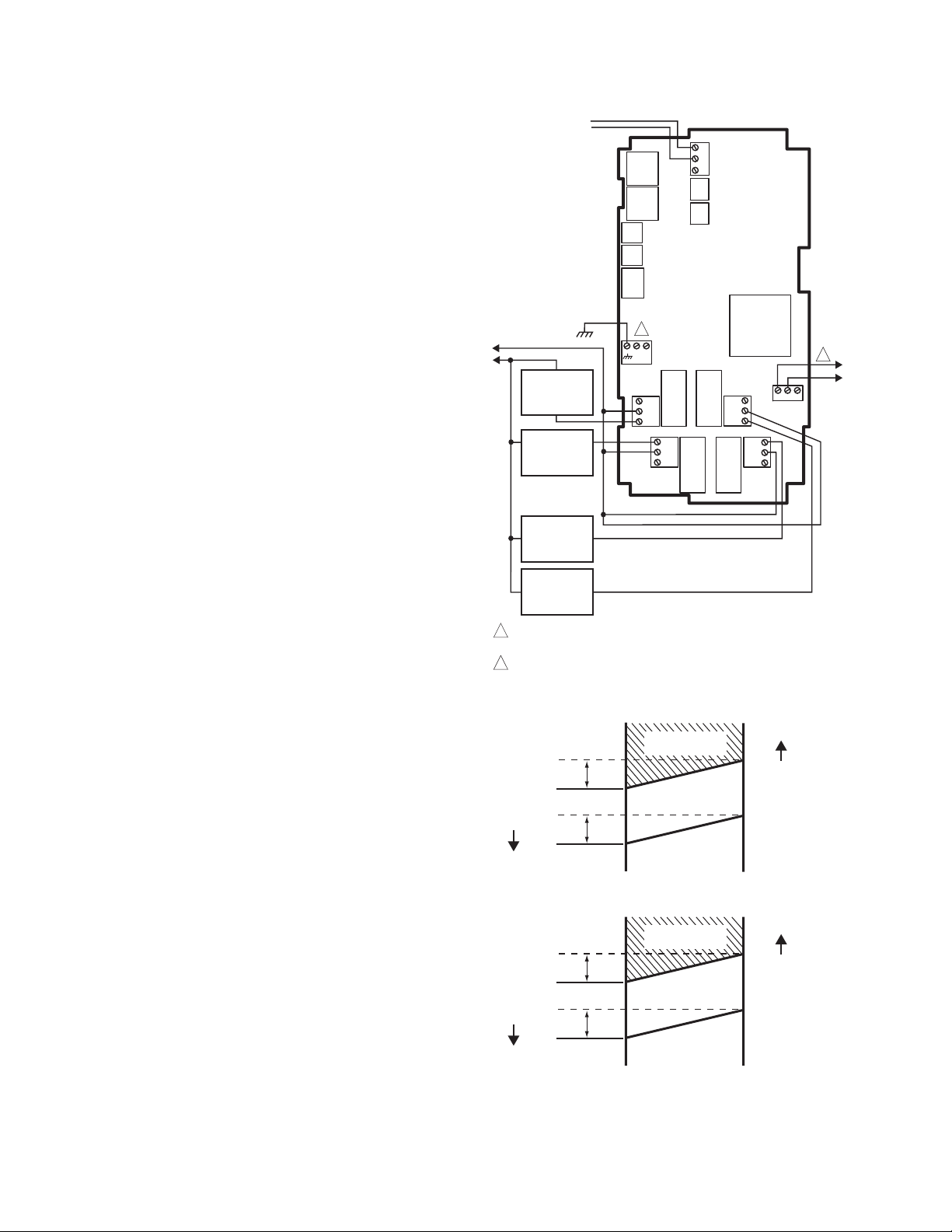

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

SENSOR A

(SUMP WATER)

T

T

T775B

Programming Example

Relay 1: Controlling spray water pump and/or valve

Program for:

— Cool

— Setpoint = 60° F (16° C)

— Differential = 5° F (12° C)

Relay 2: Controlling fan # 1

Program for:

— Cool

— Setpoint = 65° F (18° C)

— Differential = 5° F (12° C)

Relay 3: Controlling fan # 2

Program for:

— Cool

— Setpoint = 70° F (21° C)

— Differential = 5° F (12° C)

L1

(HOT)

L2

2

C

+

SUMP

DUMP

VALV E

SPRAY

PUMP

VALV E

FAN

#1

FAN

#2

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

1

TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

RELAY

4

NC

NO

C

NO

NC

RELAY

1

C

RELAY

3

NC

C

NO

NO

C

NC

RELAY

2

Fig. 4. T775B Wiring - Chiller.

120

COM

1

120 VAC

240

M24864

9 63-7147—3

Page 10

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Chiller, Rotary Compressor – T775B

Application Description

The T775B is controlling the discharge water temperature of a

rotary compressor. The T775B provides an optional low

temperature or low pressure cut-out circuit.

NOTE: T775R reset models can also be used in this

application.

Sensor Designation

This device application only requires one sensor. Sensor A is

sensing discharge water and controls 1 or 2 compressors.

Operation

In this example, the cooling capacity of a Rotary Compressor

is controlled by a slide valve, which when moved towards

open or closed, allows more or less refrigerant into the

compressor. Open and Closed solenoid valves position this

slide valve. The T775B is configured such that two relays are

used to position a single slide valve in a floating mode by

controlling the respective solenoid valves. Capacity of rotary

compressors may also be controlled by variable speed drives,

not covered here.

Programming Example

Relay 1: Compressor #1 controlling the Close solenoid valve

Program for:

—Cool

— Setpoint = 52° F (11° C)

— Differential = 2° F (-17° C)

Relay 2: Compressor #1 controlling the Open solenoid valve

Program for:

—Cool

— Setpoint = 56° F (13° C)

— Differential = 2° F (-17° C)

Relay 3: Compressor #2 controlling the Close solenoid valve

Program for:

—Cool

— Setpoint = 56° F (13° C)

— Differential = 2° F (-17° C)

Relay 4: Compressor #2 controlling the Open solenoid valve

Program for:

—Cool

— Setpoint = 60° F (16° C)

— Differential = 2° F (-17° C)

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

(DISCHARGE WATER)

SENSOR A

T

T

T775B

2

C

+

RELAY

4

NC

C

NO

NO

C

NC

RELAY

1

COOL MODE COMPRESSOR #1

OPEN SOLENOID

ENERGIZED

NULL

CLOSE SOLENOID

ENERGIZED

COOL MODE COMPRESSOR #2

OPEN SOLENOID

ENERGIZED

NULL

CLOSE SOLENOID

ENERGIZED

RELAY

3

NC

C

NO

RELAY

NO

C

NC

2

(HOT)

L1

L2

COMPRESSOR

#2

OPEN

SOLENOID

COMPRESSOR

#1

CLOSE

SOLENOID

COMPRESSOR

#1

OPEN

SOLENOID

COMPRESSOR

#2

CLOSE

SOLENOID

1

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

T

E

M

P

E

R

A

F

T

A

U

L

R

L

E

T

E

M

P

E

R

A

F

T

A

U

L

R

L

E

2°

56°

2°

52°

2°

60°

2°

56°

Fig. 5. T775B Wiring - Chiller, Rotary Compressor.

120

T

E

M

P

E

R

A

T

U

R

E

T

E

M

P

E

R

A

T

U

R

E

120 VAC

COM

R

I

S

E

R

I

S

E

1

240

M24865

63-7147—3 10

Page 11

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

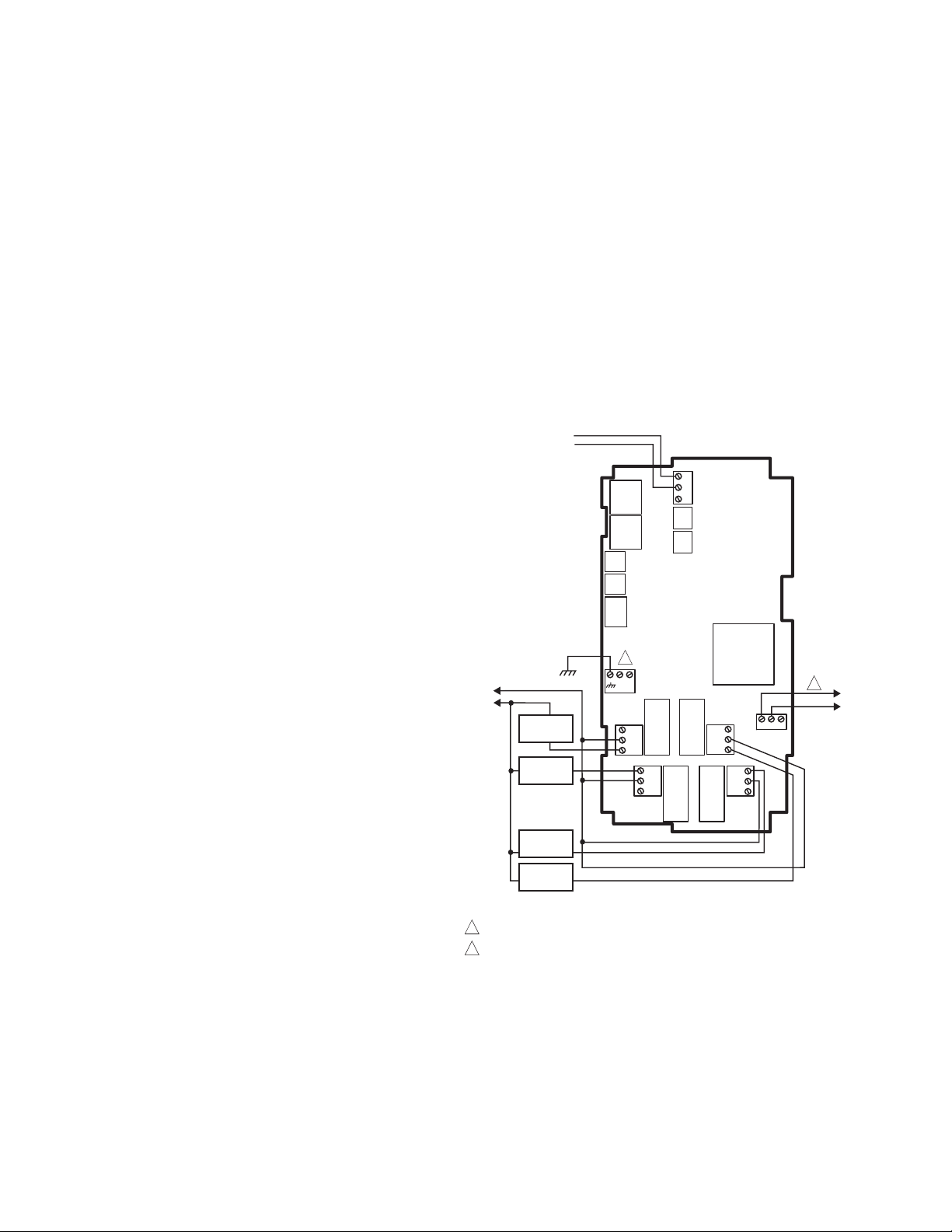

Cooling Tower Control – T775B2040

Application Description

The T775B2040 is controlling a cooling tower fan, based on

two sensor inputs, to control the low and high fan speeds and

provide cold weather shutdown.

NOTE: T775R2001 reset model can also be used in this

application.

Sensor Designation

This device application requires two sensors:

• Sensor A is sensing the sump temperature.

• Sensor B is sensing the outside air temperature.

Operation

As the sump temperature increases, the low fan speed is

energized by relay 1. On further increase in temperature, relay

2 closes, which energizes the high fan speed and shuts off the

low fan speed. Relay 3 provides cold weather shutdown of the

fan. Relay 3 is wired in series with the common wire of relays

1 and 2, so when relay 3 breaks at 55° F (13° C), power to the

fan is interrupted.

Programming Example

Optional: In Setup, label sensors A and B as desired.

Relay 1: Control to the fan low speed based on the sump

temperature.

Program for:

— Setpoint = 65° F (18° C)

— Differential =5° F (12° C)

— Cool

— Sensor A

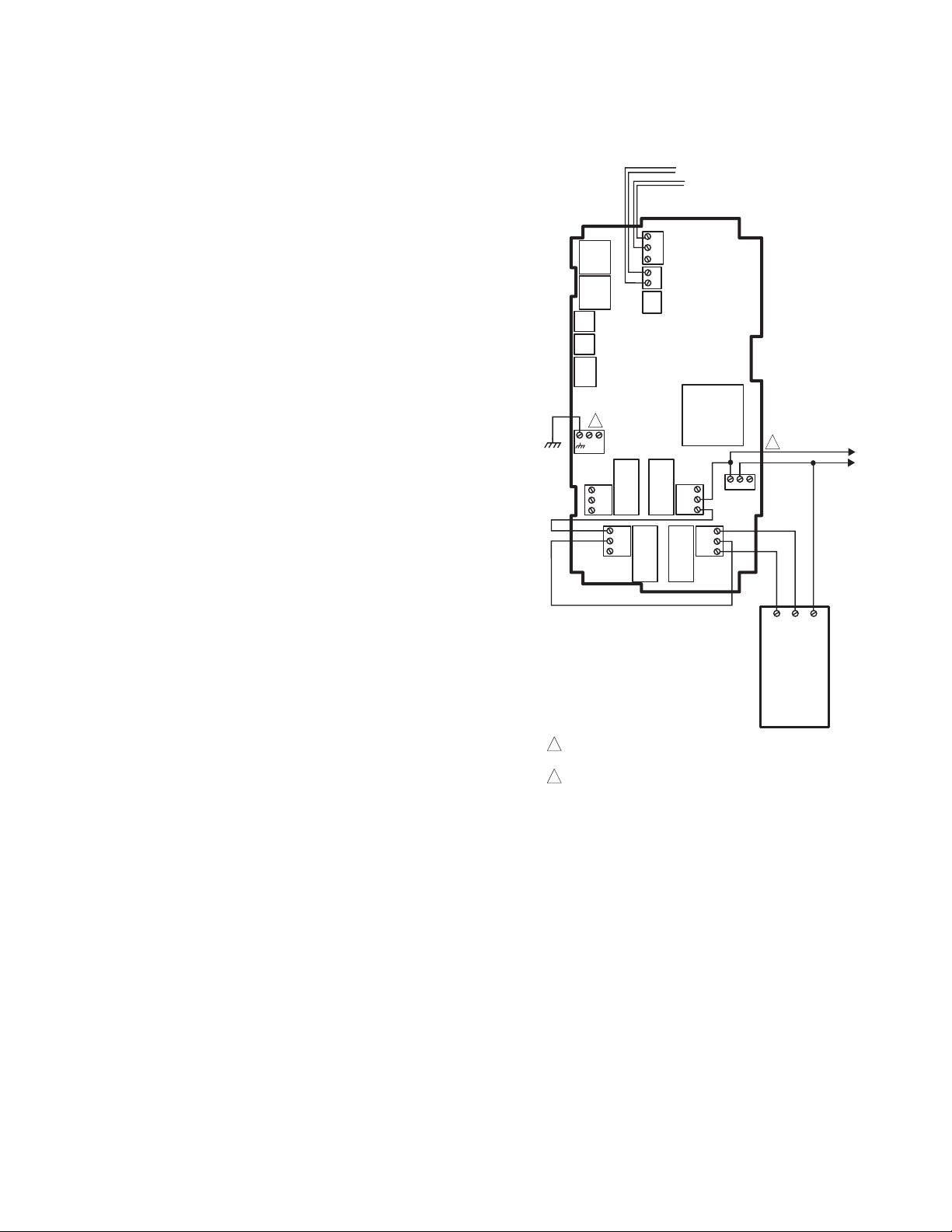

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring

SENSO R B - OUTSID E AIR TEM PERATUR E

SENSO R A - SUMP TE MPERATURE

T

T

T

T775B2040

T

2

120

COM

240

NO

NC

1

120 VAC

COM

FAN

NO

COM

C

+

RELAY

4

NC

NO

C

NO

NC

RELAY

1

RELAY

3

NC

C

NO

C

NO

C

NC

RELAY

2

Relay 2: Control to the fan high speed based on the sump

temperature

Program for:

— Setpoint = 70° F (21° C)

— Differential = 5° F (12° C)

— Cool

— Sensor A

Relay 3: Control to the fan cutoff based on the outside air

temperature

Program for:

— Setpoint = 55° F (13° C)

— Differential = 1° F (12° C)

— Cool

— Sensor B

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

IMPORTANT

By programming the relay 3 setpoint at 55° F (13° C),

the T775 is wired to cutoff power to the cooling fan.

Once the outside air temperature rises above 55° F

(13° C), relays 1 and 2 control the fan speed based

on their setpoints for Sensor A Sump.

MOTOR COMMON

LOW SPEED WINDING

HIGH SPEED WINDING

1

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

M25513

Fig. 6. T775B2040 Wiring for Cooling Tower Control.

Device Checkout

The T775B performance can be checked out to determine if

proper operation exists.

For example, when the outside air temperature is at 55° F

(13° C) or less, the fan should be off. Use the alternate Home

screens to verify that the fan is on or off, based on the outside

air temperature (sensor B).

NOTE: The alternate Home screens do not show live

updates of the sensor temperature. They show the

temperature only at the moment the button is

pressed.

1. From the Home screen, use the $ button to verify

the setpoint temperature for relay 3.

2. Then, press the HOME button to view the actual

outside air temperature (sensor B).

11 63-7147—3

Page 12

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Time-based Control of Fan, Pump, etc. –

T775 (all models)

Application Description

In this example, the T775B is able to energize a fan, pump,

lights, economizer, or other device based on a daily time

schedule rather than based on temperature.

Operation

In this example, one relay will energize at 6:00 a.m. and deenergize at 6:00 p.m. daily to operate a fan, pump, or anything

at all.

Configuration Example

Place a 1,000 Ohm resistor at Sensor B (to simulate a

constant 32° F (0° C) temperature reading).

Wire the device to the normally open contacts on a relay.

Relay 1 is used in this example. See Fig. 7

Programming Example

Program in Setup for:

— Outputs

Options

Use Scheduler = YES

NOTE: Keep in mind that if the scheduler is energized, all

relays will follow the time schedule. If you do not

want some outputs to go into a setback mode,

choose Scheduler = NO for those outputs, or

program the setpoint and setback to the same

temperature.

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

1

T

T775B

T

T

SENSOR B

T

Program in Schedule for:

— Options

Set Date = current date

1

Set Time = current time

Set Daylight = YES or NO

— Mon-Fri

E1 Setpoint = Setpoint

E1 Time = 06:00 AM

E2 Setpoint = Setback

E2 Time = 6:00 PM

Relay 1: Control the device (fan, pump, etc.)

Program for:

— Setpoint = 0° F (-17° C)

— Differential = 1° F (-17° C)

— Sensor = Sensor B

— Setback =100° F (38° C)

— Action = Cool

Now the relay will close at 6:00 a.m. and open at 6:00 p.m.,

daily.

1

The Date must be set before the Time is set.

2

COM

3

120 VAC

240

M28021

L2

L1

(HOT)

C

+

RELAY

4

NC

C

FAN,

PUMP,

LIGHTS,

ECONOMIZER,

OR

OTHER DEVICE

INSERT 1000 OHM RESISTOR.

1

24 VAC POWER TERMINAL BLOCK.

2

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

3

TERMINAL BLOCK.

NO

RELAY

NO

C

NC

1

RELAY

3

NC

C

NO

RELAY

NO

NC

120

C

2

Fig. 7. T775B Wiring for time-based fan, pump or other

device.

63-7147—3 12

Page 13

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Damper or Valve Modulation – T775M or

T775R

Application Description

In this example, a T775M is controlling an actuator, based on

temperature input, to modulate a damper or valve.

Sensor Designation

This device application requires one sensor.

• Sensor A is sensing outside temperature

NOTE: Sensor A or Sensor B can be used in this

application.

Programming Example

Program in Setup for:

— Modulating Output (MOD) 1:

Type = 2-10V (or whatever output signal is preferred)

Minimum Output % = 0% (range is 0-100%)

Modulating Output 1:Enable actuator circuit

Program for:

— Setpoint = 120° F (49° C)

— Throttling Range = 10° F (-12° C)

— Sensor = Sensor A

— Heat or Cool

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

Wiring

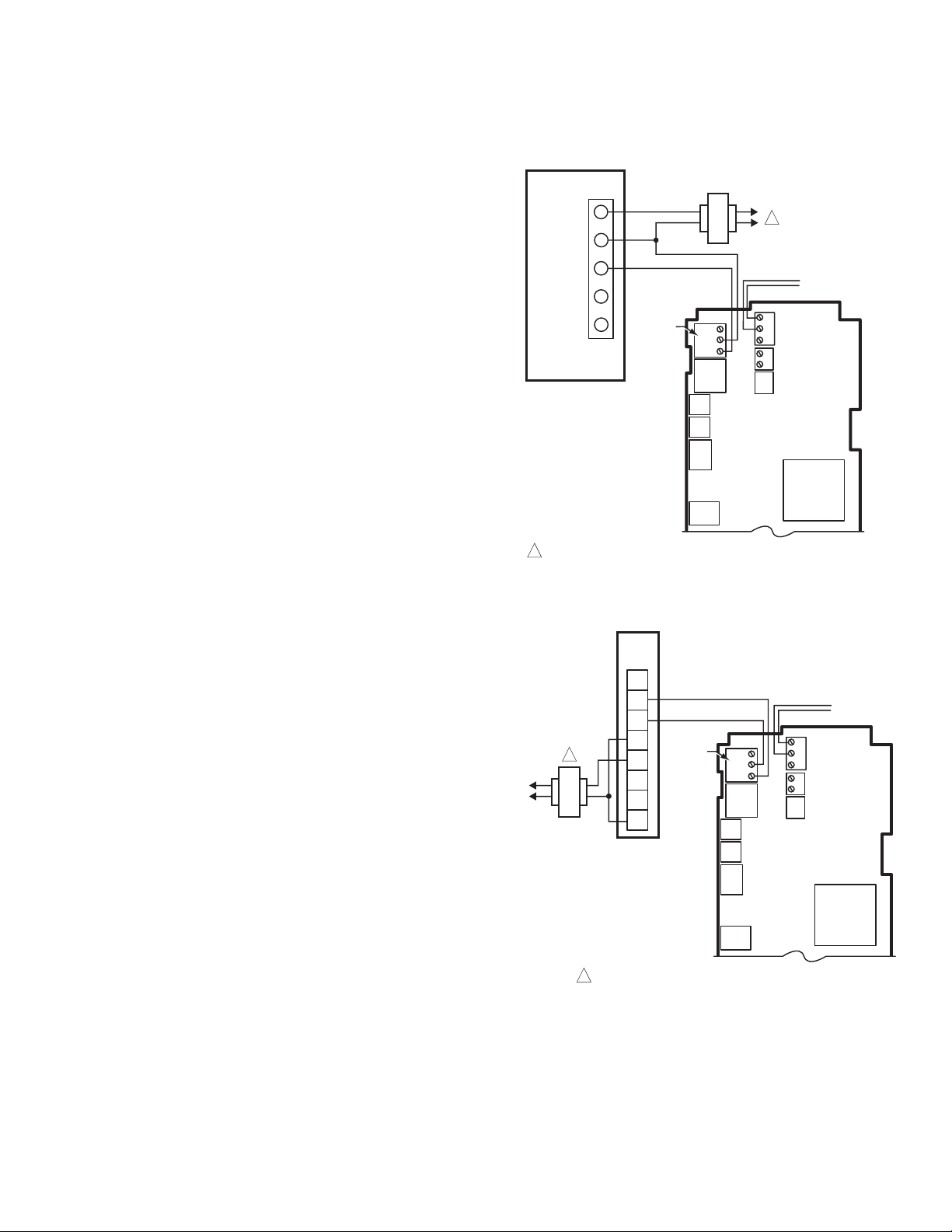

See Figures 8-9 for wiring connections for the T775M with

examples of an MS75xx actuator and an ML7425 valve

actuator.

MS75xx

SPRING RETURN

DIRECT COUPLED ACTUATOR (DCA)

WIRING

STRIP

1

2

3

4

5

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

MOD 1

B

R

W

L1

(HOT)

1

L2

C

–

+

S

V

T

T

Fig. 8. T775M Wiring - Damper Modulation

(2-10 Vdc shown).

ML7425

SPRING RETURN

ACTUATOR

1

L1

(HOT)

L2

VALV E

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

MOD 1

B

–

R

+

W

SENSOR A

T775M

C

S

V

T

T

M24881A

SENSOR A

T775M

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

M28042

Fig. 9. T775M Wiring - Valve Modulation (2-10 Vdc shown).

13 63-7147—3

Page 14

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Hot Water Reset – T775R

Application Description

The T775R is controlling the boiler water temperature with two

stages (relays), based on outside temperature using a reset

curve and an offset for relay 2.

Sensor Designation

This device application requires two sensors.

• Sensor A is sensing hot water discharge temperature of

the boiler.

• Sensor B is sensing outside air temperature

Operation

In this example, when the outside temperature reaches

70° F (21° C), the desired water temperature of the boiler is

160° F (71° C). Likewise, when the outside temperature drops

to 20° F (-7° C), the hot water temperature needs to be

210° F (99° C). See Fig. 10.

°F

SP MAX A1

(BOILER MAX)

SP MIN A2

(BOILER MIN)

220

210

S

200

E

N

190

S

O

180

R

170

A

160

150

140

10

(OUTSD MIN)

OFFSET -10°F

20

RESET B1

RELAY 2

SETPOINT

30 40 50 60

SENSOR B

Fig. 10. Hot Water Reset Curve.

RELAY 1

SETPOINT

70

RESET B2

(OUTSD MAX)

°F80

M24871

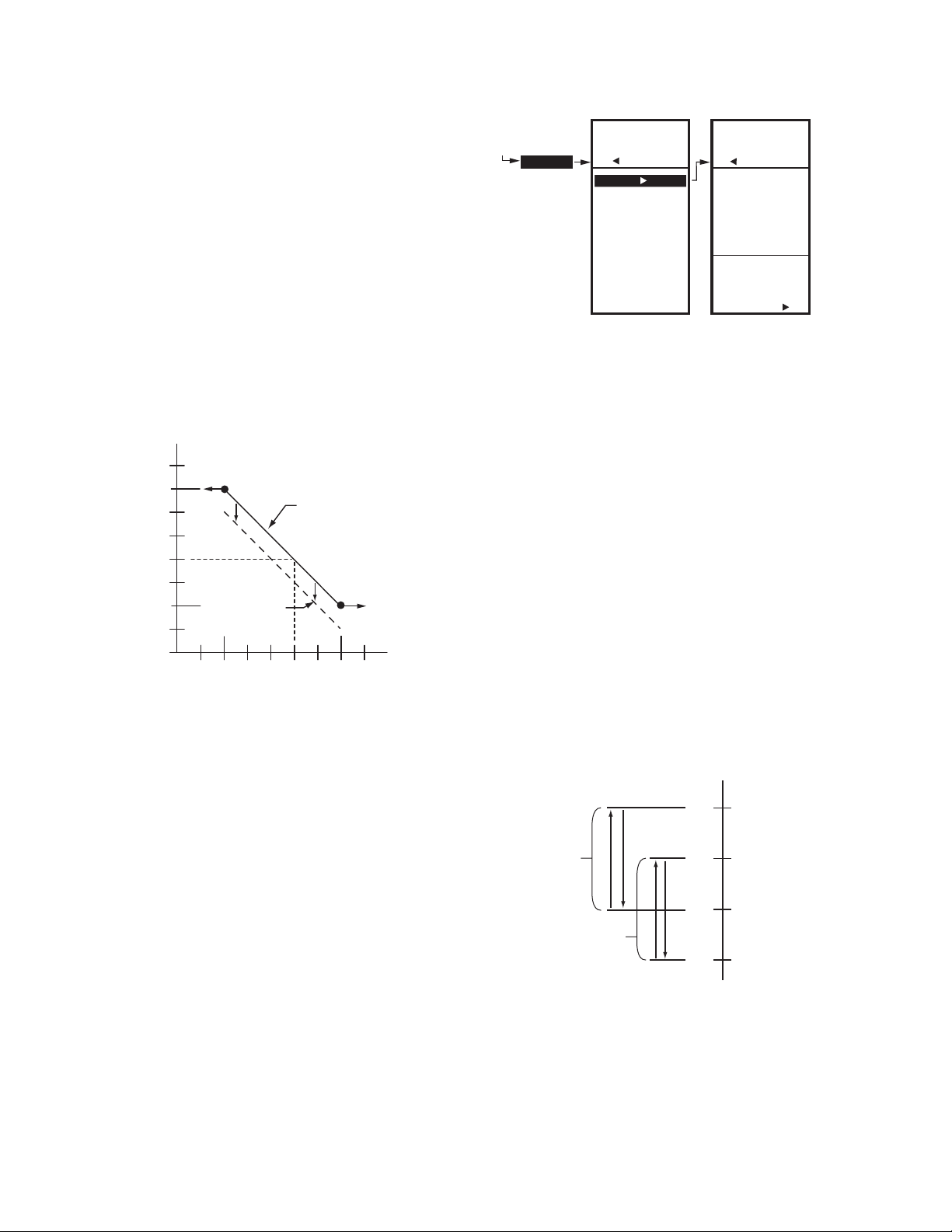

MENU

PROGRAM

RELAY 2

OFFSET

-10

ENTER

SETPOINT

OFFSET

FOR

RELAY 2

o

F

M24321

PROGRAM

RELAY 2

MENU

PROGRAM

RELAY 2

OFFSET

DIFFRNTL

HEAT/COOL

SETBACK

EXIT

Fig. 11. Program Mode - Relay 2 Offset.

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

IMPORTANT

By programming the boiler setpoint at 210° F (99° C)

the T775 has established 210° F (99° C) as the

highest operating point that will be allowed when the

outside temperature falls below 20° F (-7° C). As the

outside temperature increases above 20° F (-7° C),

the boiler will be reset downward per the reset ratio

until it reaches the minimum setpoint, 160° F.

Assuming an outside temperature of 20° F (-7° C), Fig. 12

describes the actions of relays 1 and 2 to control the boiler

temperature. As the boiler temperature falls below 210° F

(99° C), relay 1 activates (relay 1 Differential is 20° F (-7° C),

so relay closes at 190° F (88° C). If relay 1 cannot raise the

boiler temperature and the boiler temperature continues to fall

to 180° F °, relay 2 activates (relay 2 Differential is 20° F

(-7° C) 180° to 200° F (82° to 93° C) When the boiler is able to

reach 200° F (93° C), then relay 2 deactivates and relay 1

remains active until the temperature reaches 210° F (99° C).

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

—MOD 1

—# Relays = 2

— Relay 1

— Relay 2

Relay 1: Control to the discharge water temperature

Program for: (Refer to the reset curve in Fig. 10.)

— Boiler Max = 210° F (99° C)

— Outside Min = 20° F (-7° C)

— Boiler Min = 160° F (71° C)

— Outside Max = 70° F (21° C)

— Differential = 20° F (-7° C)

—Sensor A

—Heat

Relay 2: Control to the discharge water temperature

Program for:

— Setpoint Offset = -10° F (-12° C) (See Fig. 11)

—Sensor A

—Heat

63-7147—3 14

→ Reset = YES-BOILER

→ Reset = YES-BOILER

→ Reset = YES-BOILER

BOILER DISCHARGE

TEMPERATURE

RELAY 1 OFF

210°

RELAY 1

DIFFERENTIAL

RANGE

DIFFERENTIAL

RELAY 2

RANGE

200°

190°

180°

RELAY 2 OFF

RELAY 1 ON

RELAY 2 ON

M24877

Fig. 12. Relay Actions.

NOTE: The Hot Water Reset application continues on the

next page.

Page 15

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Hot Water Reset (continued)

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

(HOT WATER DISCHARGE)

L1

(HOT)

L2

SENSOR A

SENSOR B

(OUTSIDE AI R)

HOT

WATER

BOILER #1

HOT

WATER

BOILER #2

2

C

+

RELAY

4

NC

NO

C

NO

NC

RELAY

1

T

T

T

T775R

T

1

120

COM

120 VAC

240

RELAY

3

NC

C

NO

C

NO

C

NC

RELAY

2

Device Checkout

The T775 performance can be checked out to determine if

proper operation exists.

For example, when the outside air temperature is at 50° F

(10° C), the boiler setpoint temperature should be 180° F

(82° C). See Fig. 14. Use the alternate Home screens to

check that the effective setpoint is adjusting correctly based

on the outside air temperature (sensor B).

NOTE: The alternate Home screens do not show live

updates of the sensor temperature. They show the

temperature only at the moment the button is

pressed.

1. From the Home screen, use the $ button to verify

the setpoint temperature for each output.

2. Then, press the HOME button to view the actual

outside air temperature (sensor B).

BOILER SETPOINT

TEMPERATURE

210°

190°

180°

170°

160

Fig. 14. Boiler Discharge Temperature Setpoint vs.

Outside Temperature.

OUTSIDE AIR

TEMPERATURE

20°

30°200°

40°

50°

60°

70°

M24873

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

1

TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

Fig. 13. T775R WirIng - Hot Water Reset.

M24872

15 63-7147—3

Page 16

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Chilled Water Reset – T775R

Application Description

The T775R is controlling the chiller water temperature, based

on outside temperature using a reset curve.

Multiple stages can also be controlled by using an offset from

the main setpoint for the subsequent relay outputs. When

enabling multiple stages for reset, each stage can have its

own programmable offset from relay 1 (stage 1).

Sensor Designation

This device application requires two sensors.

• Sensor A is sensing the water temperature of the chiller.

• Sensor B is sensing outside air temperature.

Operation

In this example, when the outside temperature reaches 90° F

(32° C), the desired water temperature of the chiller is

45° F (7° C). Likewise, when the outside temperature drops to

70° F (21° C), the chilled water temperature needs to be 60° F

(16° C).

°F

65

SP MAX A1

SENSOR A

(CHILLER)

60

55

50

Relay 1: Control to the chilled water temperature

Program for: (Refer to the reset curve in Fig. 15.)

— Setpoint Max A1 (Chiller) = 60° F (16° C)

— Reset B1 (Outside Min) = 70° F (21° C)

— Setpoint Min A2 (Chiller) = 45° F (7° C)

— Reset B2 (Outside Max) = 90° F (32° C)

— Differential = 10° F (-12° C)

—Cool

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

IMPORTANT

By programming the Chiller setpoint at 45° F (7° C)

the T775 has established 45° F (7° C) as the lowest

operating control point that will be allowed during

reset with the above conditions satisfied.

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

SENSOR B

(OUTSIDE AI R)

SENSOR A (CHILLED WATER)

T

T

T

T775R

T

SP MIN A2

45

40

65 95

RESET B1

(OUTSD MIN)

70

75 80 85

90

RESET B2

(OUTSD MAX)

SENSOR B (OUTSIDE AIR)

Fig. 15. Chiller Reset Curve.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

—MOD 1

—# Relays = 1

— Relay 1

→ Reset = YES-OTHER

→ Reset = YES-OTHER

°F

M24874

2

COM

1

120 VAC

240

M24875

L2

L1

(HOT)

C

+

RELAY

4

NC

C

NO

CHILLER

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

1

TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

NO

NC

RELAY

1

C

RELAY

3

NC

C

NO

NO

C

NC

RELAY

2

120

Fig. 16. T775R Wiring - Chilled Water Reset.

NOTE: The Chilled Water Reset application continues on

the next page.

63-7147—3 16

Page 17

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Chilled Water Reset (continued)

Device Checkout

The T775 performance can be checked out to determine if

proper operation exists.

For example, when the outside air temperature is at 80° F

(27° C), the chiller water temperature should be 52.5° F

(11° C). See Fig. 17. Use the alternate Home screens to

check that the effective setpoint is adjusting correctly based

on the outside air temperature (sensor B).

NOTE: The alternate Home screens do not show live

updates of the sensor temperature. They show the

temperature only at the moment the button is

pressed.

1. From the Home screen, use the $ button to verify

the setpoint temperature for each output.

2. Then, press the HOME button to view the actual

outside air temperature (sensor B).

CHILLED WATER

SETPOINT TEMPERATURE

60°

56.25°

52.5°

48.75°

45°

OUTSIDE AIR

TEMPERATURE

70°

75°

80°

85°

90°

M24876

Fig. 17. Chiller Setpoint vs. Outside Temperature.

17 63-7147—3

Page 18

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Multi-Stage Boiler Control (No Reset) –

T775P

Application Description

The T775P is providing multistage boiler control based on the

boiler's discharge water temperature. The T775P uses the

fourth output relay to energize the primary pump.

Sensor Designation

This device application requires two sensors.

• Sensor A is sensing discharge water and is used to control

3 boiler stages.

• Sensor C is sensing the return water.

NOTE: Control can be to either sensor A or C.

Operation

In this example, as the heating load increases, additional

stages of heat will cycle ON as the boiler water temperature

decreases. The T775P will stage three boilers to provide

sufficient heating. (See Fig. 18.) The primary circulating pump

energizes whenever any stage is energized.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

— # Stages = 3 (T775 assigns pump to Relay 4)

— Options

Seconds = 0 to 3,600 (default is 0)

— Options

Temperature = 30 to 100° F (-1 to 38° C)

— STG4/Pump: (Relay 4 controls the pump output)

Enable = YES

Exercise = YES or NO

Prepurge = -300 to 300 seconds (default is 0)

Postpurge = 0 to 300 seconds (default is 0)

NOTES:

1. A positive Prepurge time causes the pump to

2. The Postpurge time causes the pump to run for

Return to the Setup menu, and select Alarms:

— High Alarm = YES

— High Limit = 220° F (93° C)

NOTE: This model has Equal Runtime options, which can be

Stages 1-3: Control to the discharge water temperature

Program for:

— Setpoint = 200° F (93° C)

— Throttling Range = 18° F (-8° C)

—Sensor A

—Heat

IMPORTANT

→ On Delay and Off Delay:

→ WWSD = YES or NO

energize before the first stage energizes.

A negative time causes the pump to energize

after the first stage energizes.

the set number of seconds after the last stage

de-energizes.

configured with the Lead Lag output option in Setup.

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

Refer to the staging diagram in Fig. 18 for individual stage

behavior.

STAGES

STAGE 3 ON

HYST.

STAGE 2 ON

STAGE 1 ON

STAGE 1

-33%

206°F 200°F 194°F 188°F

1

STAGE ENERGIZES STAGE DE-ENERGIZES

DISCHARGE WATER TEMPERATURE

1

STAGE 2

0% 33% 67%

THROTTLING RANGE (18°F)

STAGE 3

M24867

Fig. 18. Boiler Control Staging Behavior (when the

effective setpoint = 200° F).

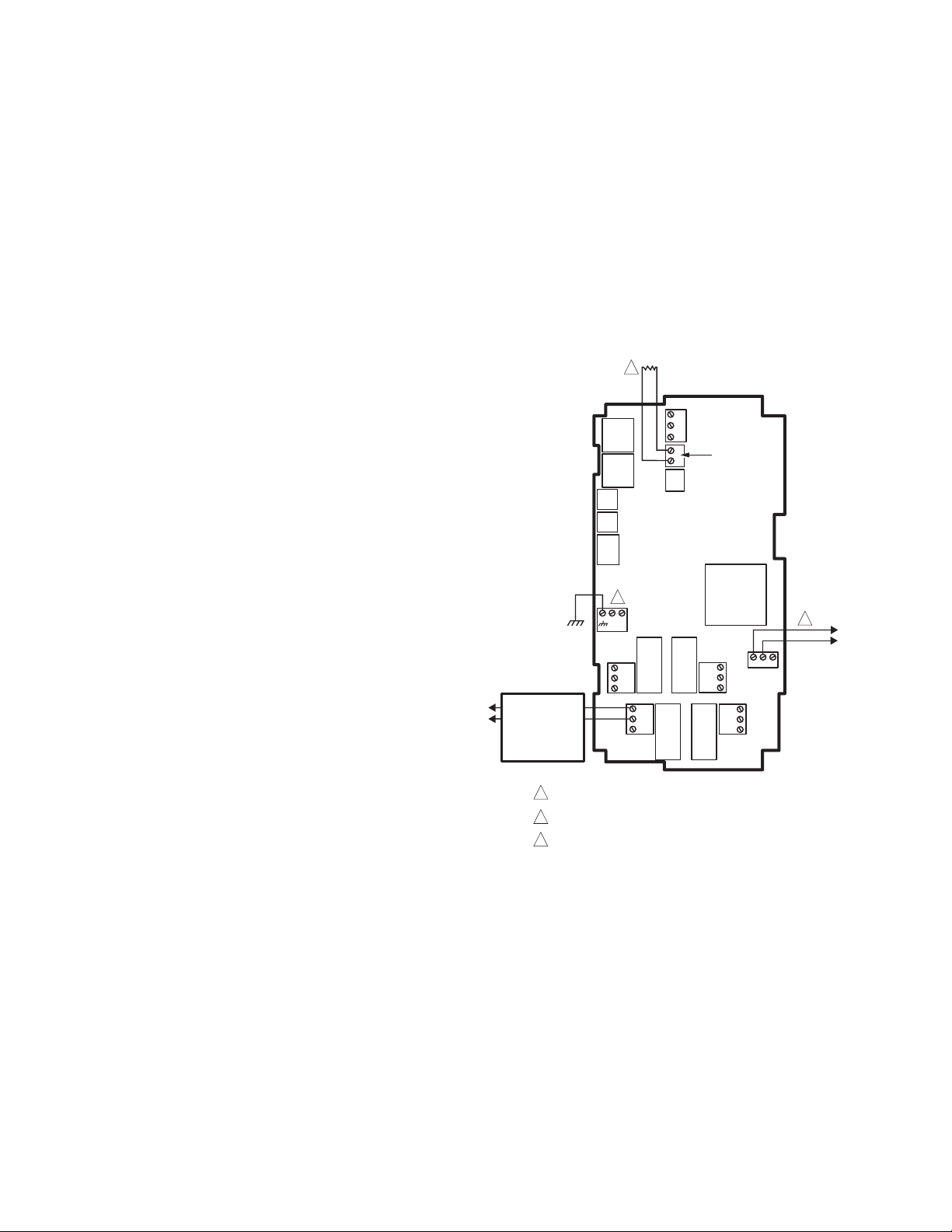

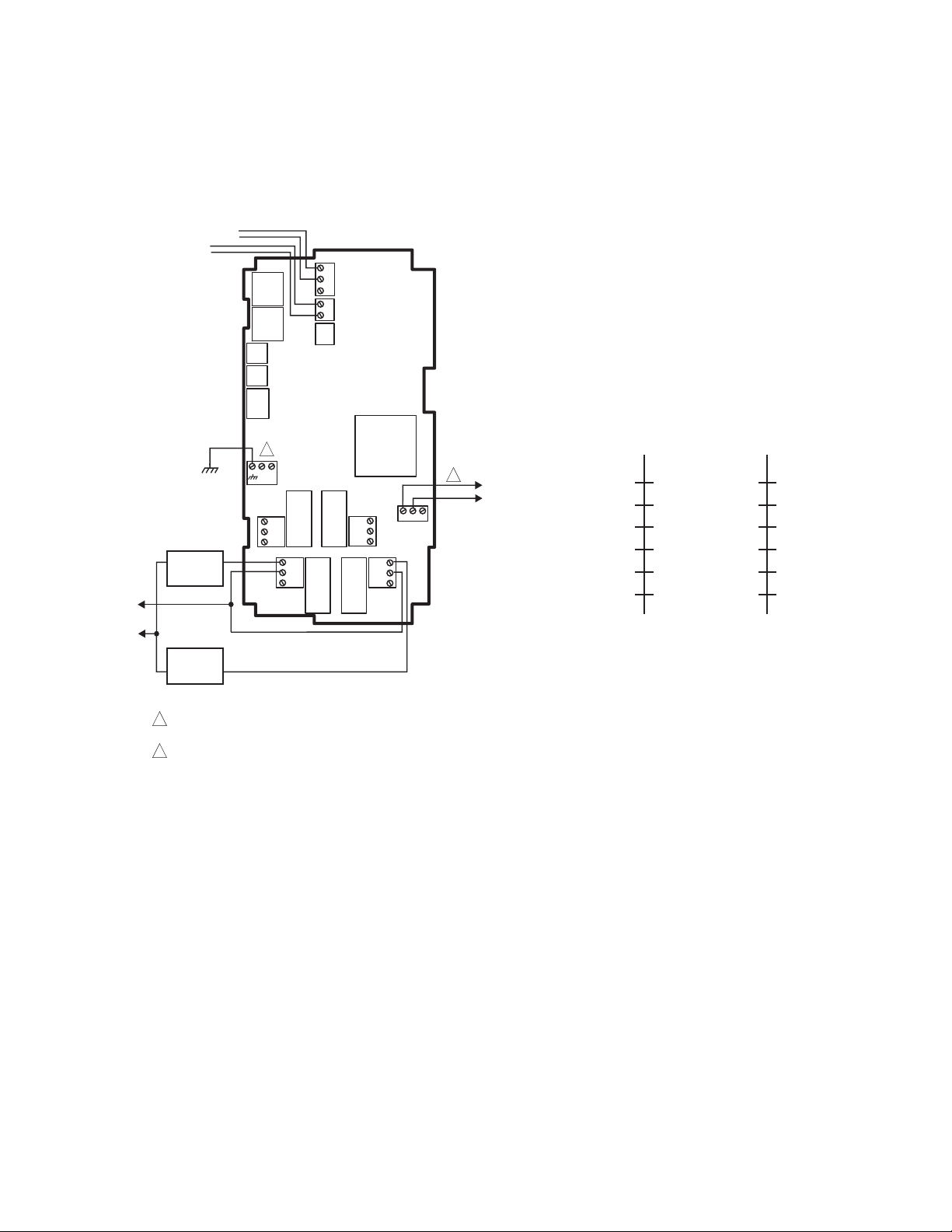

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

SENSOR A (DISCHARGE WATER)

T

SENSOR C

(RETURN WATER)

ALARM

NC

NO

C

NC

C

RELAY

2

+

4

NC

NO

C

RELAY

(HOT)

L1

(HOT)

L2

L2

DIGITAL OUTPUT

C

NO

L1

PUMP

BOILER #1

BOILER #2

BOILER #3

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE

1

TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

Fig. 19. T775P Wiring - Multi-Stage Boiler Control

(No Reset).

T

T775P

T

T

1

120

COM

120 VAC

240

M24866

RELAY

3

NC

C

NO

NO

C

NC

1

NO

C

NC

RELAY

2

63-7147—3 18

Page 19

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Multi-Stage Boiler Control (Reset) – T775P

Application Description

The T775P is providing multistage boiler control based on the

boiler's discharge water temperature. The T775P uses the

fourth output relay to energize the primary pump.

Any number of stages from 1 to 12 can be configured (T775P

and T775L models). The throttling range is divided equally

among the stages.

Sensor Designation

This device application requires three sensors.

• Sensor A is sensing discharge water and is used to control

3 boiler stages.

• Sensor B is sensing outside temperature and is used for

reset.

• Sensor C is sensing the return water temperature.

NOTE: Control can be to either sensor A or C.

Operation

In this 3-stage example, as the heating load increases,

additional stages of heat will cycle ON as the boiler water

temperature decreases. The T775P will stage three boilers to

provide sufficient heating. See Fig. 20 for staging behavior.

The primary circulating pump energizes whenever any stage

is energized.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

— # Stages = 3 (T775 assigns pump to Relay 4)

— Options

— Options

Seconds = 0 to 3,600 (default is 0)

— Options

Temperature = 30 to 100° F (-1 to 38° C)

— STG4/Pump: (Relay 4 controls the pump output)

Enable = YES

Exercise = YES or NO

Prepurge = -300 to 300 seconds (default is 0)

Postpurge = 0 to 300 seconds (default is 0)

Return to the Setup menu, and select Alarms:

— High Alarm = YES

— High Limit = 220° F (104° C)

Stages 1-3: Control to the discharge water temperature

Program for: (Refer to the reset curve in Fig. 21.)

— Boiler Max = 210° F (99° C)

— Outside Min = 20° F (-7° C)

— Boiler Min = 160° F (71° C)

— Outside Max = 70° F (21° C)

— Throttling Range = 18° F (-8° C)

— Sensor A

— Heat

— Setback = -10° F (-12° C) (Optional)

→ Reset = YES-BOILER

→ On Delay and Off Delay:

→ WWSD = YES or NO

1

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

STAGES

STAGE 3 ON

HYST.

STAGE 2 ON

STAGE 1 ON

STAGE 1

-33% 0% 33% 67%

206°F 200°F 194°F 188°F

1

STAGE ENERGIZES STAGE DE-ENERGIZES

DISCHARGE WATER TEMPERATURE

1

STAGE 2

THROTTLING RANGE (18°F)

STAGE 3

M28043

Fig. 20. Boiler Control Staging Behavior (when effective

setpoint = 200° F).

°F

220

SP MAX A1

(BOILER MAX)

SP MIN A2

(BOILER MIN)

210

S

200

E

N

190

S

O

180

R

A

170

160

150

140

10

(OUTSD MIN)

20

RESET B1

SETBACK

OFFSET

-10°F

(OPTIONAL)

30 40 50 60

SENSOR B

70

RESET B2

(OUTSD MAX)

°F80

M24869

Fig. 21. Reset Curve with Optional Setback Offset.

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

See Fig. 22 on page 20.

NOTE: The Multi-Stage Boiler Control (Reset) application

continues on the next page.

1

See Notes in “Programming Example” on page 18 for an

explanation of Prepurge and Postpurge times

19 63-7147—3

Page 20

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

Multi-Stage Boiler Control (Reset) (continued)

SENSOR B (OUTSIDE AIR)

SENSOR C

(RETURN WATER)

2

C

+

RELAY

L1

(HOT)

L2

L1

(HOT)

L2

1

2

PUMP

BOILER #1

BOILER #2

BOILER #3

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE TERMINAL BLOCK.

24 VAC POWER TERMINAL BLOCK.

4

NC

C

NO

RELAY

NO

C

NC

1

Fig. 22. T775P Wiring - Multi-Stage Boiler Control

with Reset.

SENSOR A

(DISCHARGE WATER)

T

T

T

T775P

T

T

T

RELAY

3

NC

C

NO

NO

C

NC

RELAY

2

120

COM

1

120 VAC

240

M24868

Multi-Stage Chiller Control (No Reset) –

T775P

Application Description

The T775P is providing multistage cooling control based on

the chiller’s discharge water temperature. The T775P uses

the fourth output relay to energize the primary pump.

Any number of stages from 1 to 12 can be configured (T775P

and T775L models). The throttling range is divided equally

among the stages.

Sensor Designation

This device application requires three sensors.

• Sensor A is sensing chiller discharge water and is used to

control 3 chiller stages.

• Sensor B is sensing outside temperature and is used to

control relay 4, the pump output.

• Sensor C is sensing the chiller return water temperature.

NOTE: Control can be to either sensor A or C.

Operation

In this 3-stage example, as the cooling load increases,

additional stages of cooling will cycle ON as the chiller water

temperature increases. The T775P will stage three chillers to

provide sufficient cooling. See Fig. 23 for staging behavior.

The primary circulating pump energizes whenever any stage

is energized.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

— # Stages = 3 (T775 assigns pump to Relay 4)

— Options

Seconds = 0 to 3,600 (default is 0)

— STG4/Pump: (Relay 4 controls the pump output)

Enable = YES

Exercise = YES or NO

Prepurge = -300 to 300 seconds (default is 0)

Postpurge = 0 to 300 seconds (default is 0)

Return to the Setup menu, and select Alarms:

— Low Alarm = YES

— Low Limit = 54° F (12° C)

Stages 1-3: Control to the discharge water temperature

Program for:

— Setpoint = 72° F (22° C)

— Throttling Range = 12° F (-11° C)

—Sensor A

—Cool

IMPORTANT

1

See Notes in “Programming Example” on page 18 for an

explanation of Prepurge and Postpurge times.

STAGE 1 ON

Fig. 23. Chiller Control Staging Behavior (when the

→ On Delay and Off Delay:

1

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

STAGES

STAGE 3 ON

HYST.

STAGE 2 ON

STAGE 2

STAGE 1

-33%

68°F 72°F 76°F 80°F

1

STAGE ENERGIZES STAGE DE-ENERGIZES

CHILLER DISCHARGE WATER TEMPERATURE

1

0% 33% 67%

THROTTLING RANGE (12°F)

effective setpoint = 72° F).

STAGE 3

M28009

63-7147—3 20

Page 21

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

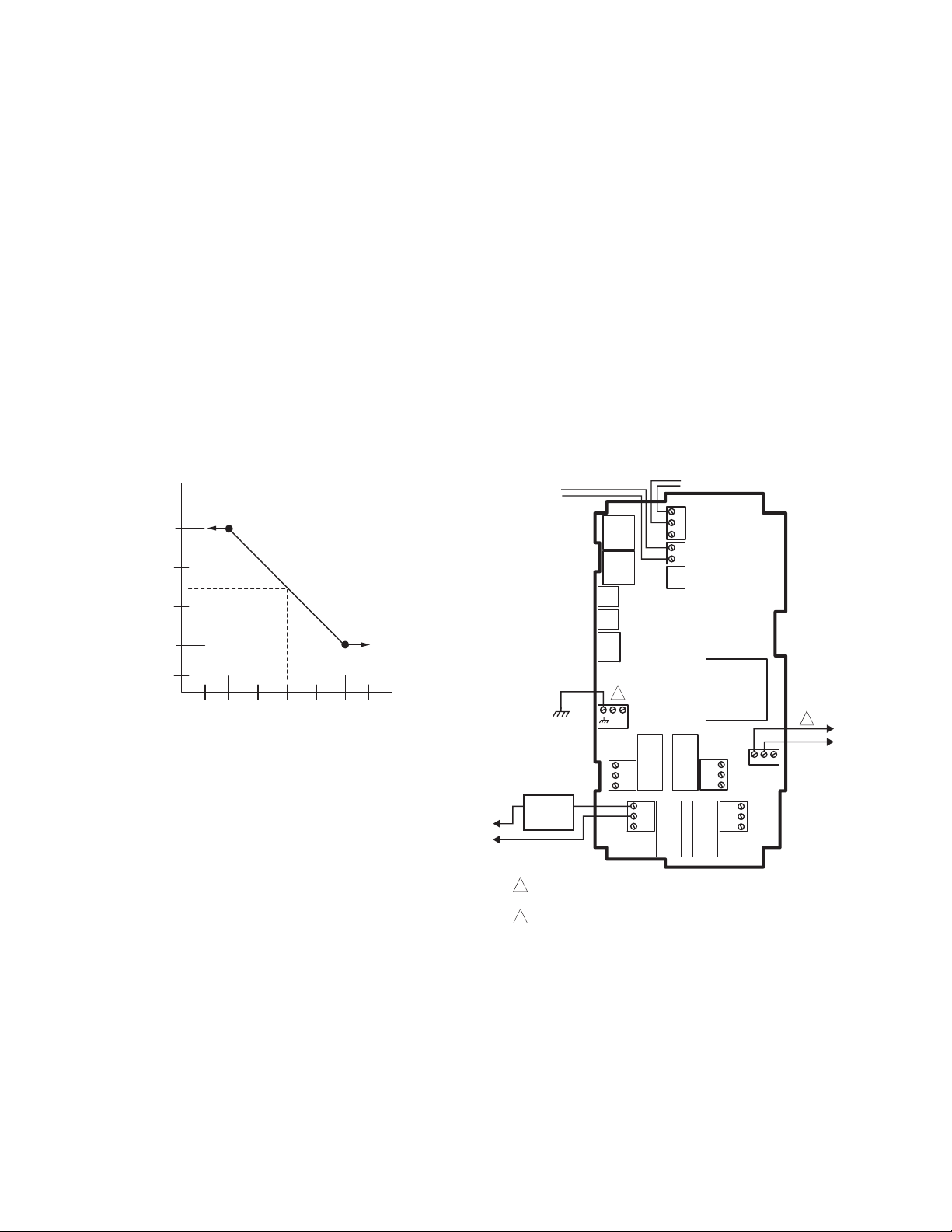

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

SENSOR B (OUTSIDE AIR)

SENSOR C

(CHILLER

RETURN WATER)

2

C

+

RELAY

L1

(HOT)

L2

L1

(HOT)

L2

1

2

PUMP

CHILLER 1

CHILLER 2

CHILLER 3

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE TERMINAL BLOCK.

24 VAC POWER TERMINAL BLOCK.

4

NC

NO

RELAY

Fig. 24. T775P Wiring - Multi-Stage Chiller Control

(No Reset).

SENSOR A

(CHILL ER DISC HARGE WATER)

T

T

T

T

T

T

RELAY

NC

C

NO

C

NC

1

C

NO

T775P

3

NO

C

NC

RELAY

2

120

COM

1

120 VAC

240

M28008

4 Stage with Pump Output and Reset – T775P using a T775S Expansion Module

Application Description

The T775P is providing multistage boiler control based on the

boiler's discharge water temperature. Four stages and a

dedicated pump output are used in this example. The T775P

uses the eighth output relay to energize the primary pump.

NOTE: The pump output is always the last relay output. In

this application example, four relays are used for

staged boiler control. A T775S expansion module is

added to provide the additional relay for the pump.

However, the pump must be the last relay, so it is

configured as relay 8 on the T775S module.

Any number of stages from 1 to 12 can be configured (T775P

and T775L models). The throttling range is divided equally

among the stages.

Sensor Designation

This device application requires three sensors.

• Sensor A is sensing discharge water and controls 4 stages.

• Sensor B is sensing outside temperature and is used for

reset.

• Sensor C is sensing the return water temperature.

NOTE: Control can be to either sensor A or C.

Operation

As the heating load increases additional stages of heat will

cycle ON as the boiler water temperature decreases. In this

example, the T775P provides four stage control when the

effective setpoint is 200° F (93° C). (See Fig. 25.) The primary

circulating pump energizes whenever any stage is energized.

NOTE: The pump output must always be the last relay on

the controller or expansion module (relay 4, 8, or 12).

NOTE: For applications with 3 stages or less with a pump

output, an additional expansion module is not

needed.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

— # Stages = 4 (T775 assigns pump to Relay 8)

—Options

21 63-7147—3

→ Reset = YES-BOILER

Page 22

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

— STG8/Pump: (Relay 8 controls the pump output)

Enable = YES

Exercise = YES or NO

Prepurge = -300 to 300 seconds (default is 0)

Postpurge = 0 to 300 seconds (default is 0)

Stages 1-4: Control to the discharge water temperature

Program for: (Refer to the reset curve in Fig. 26.)

— Boiler Max = 210° F (99° C)

— Outside Min = 20° F (-7° C)

— Boiler Min = 160° F (71° C)

— Outside Max = 70° F (21° C)

— Throttling Range= 20° F (-7° C)

—Sensor A

—Heat

1

See Notes in “Programming Example” on page 18 for an

explanation of Prepurge and Postpurge times.

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

1

IMPORTANT

By programming the boiler setpoint at 210° F

(-99° C) the T775 has established 210° F (-99° C) as

the highest operating point that will be allowed when

the temperature falls below 20° F (-7° C). As

temperature increases above 20° F (-7° C), the boiler

will be reset downward per the reset ratio until it

reaches the minimum setpoint of 160° F (-99° C), at

70° F (21° C) and above outdoor temperature.

STAGES

STAGE 4 ON

50%

STAGE 4

75%0% 25%

M28010

STAGE 3 ON

STAGE 2 ON

STAGE 1 ON

HYST.

STAGE 2

STAGE 1

-25%

205°F 185°F200°F 195°F 190°F

1

THROTTLING RANGE (20°F)

STAGE ENERGIZES STAGE DE-ENERGIZES

DISCHARGE WATER TEMPERATURE

1

STAGE 3

Fig. 25. Staging Behavior (when the effective setpoint =

200° F (93° C))

°F

220

SP MAX A1

(BOILER MAX)

SP MIN A2

(BOILER MIN)

210

S

200

E

N

190

S

O

180

R

A

170

160

150

140

10

(OUTSD MIN)

20

RESET B1

30 40 50 60

SENSOR B

(OUTSD MAX)

70

RESET B2

°F80

M24878

Fig. 26. Reset Curve.

NOTE: The 4 Stage with Pump Output and Reset application

continues on the next page.

63-7147—3 22

Page 23

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

4 Stage with Pump Output and Reset (continued)

T

T

T

T

T

T

NO

C

NC

1

(HOT)

L2

–

1

+

L1

STAGE

4

COM

NO

STAGE

STAGE

STAGE

NO

COM

1

2

3

3

C

+

RELAY

4

NC

C

NO

RELAY

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

SENSOR B

SENSOR A

SENSOR C

T

T

T775P T775S

–

1

+

3

C

NO

+

RELAY

8

NC

NO

PUMP

C

NO

RELAY

5

C

NC

L2

L1

(HOT)

RELAY

3

NC

C

NO

NO

C

NC

RELAY

2

COM

NO

120

COM

COM

NO

240

2

120 VAC

COM

RELAY

7

NC

C

NO

NO

C

NC

RELAY

6

120

COM

2

120 VAC

240

T775 BUS TERMINALS PROVIDE WIRING CONNECTIONS TO/FROM T775P/L AND T775S.

1

POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE TERMINAL BLOCK.

2

24 VAC POWER TERMINAL BLOCK.

3

Fig. 27. T775P Wiring - 4 Stage with Pump Output and Reset.

Device Checkout

The T775 performance can be checked out to determine if

proper operation exists.

For example, when the outside air temperature is at 50° F

(10° C), the boiler temperature should be 180° F (22° C). See

Fig. 28. Use the alternate Home screen to check that the

effective setpoint is adjusting correctly based on the outside

air temperature (sensor B).

NOTE: The alternate Home screen does not show live

updates of the sensor temperature. They show the

temperature only at the moment the button is

pressed.

1. From the Home screen, use the $ button to verify

the setpoint temperature for each output.

2. Then, press the HOME button to view the actual

outside air temperature (sensor B).

M24556

BOILER DISCHARGE

SETPOINT TEMPERATURE

210°

OUTSIDE AIR

TEMPERATURE

20°

30°200°

190°

180°

170°

160

40°

50°

60°

70°

M24880

Fig. 28. Boiler Discharge Temperature vs. Outside

Temperature.

23 63-7147—3

Page 24

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

3 Stage Reciprocating Chiller – T775L

Application Description

The T775L is controlling the return water in a reciprocating

chiller with fast-dump freeze protection, low temperature

cutoff, and optional low pressure cutoff.

Sensor Designation

This device application requires two sensors.

• Sensor A is sensing return water and controlling three

stages of cooling.

• Sensor B is sensing discharge water and is controlling

relay 4 for freeze protection.

Operation

Return water is one indication of the cooling load in the water

loop. For example, the higher the return water temperature

the higher the apparent load and more stages of refrigeration

or cooling would be required. If a large load is quickly dropped

from the loop, or for some reason water flow through the

chiller is reduced, discharge water temperature may drop

rapidly to freezing conditions. In this example, Sensor B in the

discharge water will prevent damage to the system by fast-

dumping all cooling stages upon close-to-freezing conditions.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

—# Relays = 3

— # Loops = 1

— Options

— Loop 1

— Loop 1

Loop 1: Chiller cooling

Program for:

— Setpoint = 62° F (17° C)

— Throttling Range = 12° F (-11° C)

—Sensor A

—Cool

Relay 4: Low temperature cutoff for freeze protection

Program for:

— Setpoint = 40° F (4° C)

— Differential = 4° F (-16° C)

—Sensor B

—Heat

→ DI Options = Disable

(acts as low pressure cutoff)

→ # Relays = 3

→ Reset = NO

SENSOR A

(RETURN WATER)

SENSOR B

(DISCHARGE

WATER)

DIGITAL INPUT

(LOW PRESSURE

CUTOFF)

L1 (HOT)

L2

COOL #1

COOL #2

COOL #3

12POWER WITH 24 VAC OR 120/240 VAC AT THE APPROPRIATE TERMINAL BLOCK.

24 VAC POWER TERMINAL BLOCK.

2

C

RELAY

4

NC

NO

C

RELAY

T

T

T

T775L

T

RELAY

3

NC

C

120

NO

NO

C

NC

1

NO

C

NC

RELAY

240

COM

2

Fig. 29. T775L Wiring - Reciprocating Chiller.

STAGES

STAGE 3 ON

STAGE 2 ON

STAGE 1 ON

HYST.

STAGE 2

STAGE 1

-33%

58°F 62°F 66°F 70°F

1

STAGE ENERGIZES STAGE DE-ENERGIZES

0% 33% 67%

THROTTLING RANGE (12°F)

STAGE 3

1

120 VAC

COM

M25514

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

63-7147—3 24

CHILLER DISCHARGE WATER TEMPERATURE

1

M13895

Fig. 30. Chiller Control Staging Behavior (when the

effective setpoint = 62° F (17° C)).

Page 25

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

4 Stage Heat and 6 Stage Cool – T775L

Application Description

The T775L is providing control for four boilers based on the

boiler's discharge water temperature and providing multistage

cooling control.

NOTE: The T775L (with up to two expansion modules) can

control any number of heating and cooling stages up

to a maximum of 12 stages.

Sensor Designation

This device application requires two sensors.

• Sensor A is sensing boiler discharge water temperature for

staged heating control.

• Sensor B is used for cooling control.

Operation

In this example, as the heating load increases, additional

stages of heat will cycle ON as the temperature decreases at

sensor A. The T775L will use four stages to provide sufficient

heating. The six cooling stages are controlled by sensor B.

NOTES:

1. The Interstage ON and OFF delay is an option for

both the heating and the cooling loops.

2. Because only 10 of the 12 relays are being used,

the remaining two relays can be used as

independent controls, each with its own setpoint

and throttling range.

Loop 2: Control to sensor B

Program for:

— Setpoint = 72° F (22° C)

— Throttling Range = 12° F (-11° C)

— Sensor B

— Cool

— Relays = 5-10

IMPORTANT

After the desired value is selected, be sure to press

the # or $ or HOME button in order to save that

value in the controller’s memory.

Wiring

All output relays should have a common power wiring source,

which may or may not be the same as the T775 power wiring.

See Fig. 31 on page 26.

NOTE: The 4 Stage Heat and 6 Stage Cool application

continues on the next page.

Programming Example

Program in Setup:

Press and hold the MENU button for 5 seconds to enter

Setup mode. Select the Outputs menu, and then select:

— # Relays = 10 (4 heat and 6 cool)

— # Loops = 2

— Loop 1

— Loop 1

— Loop 2 → # Relays = 6

— Loop 2

NOTES:

1. The Integral setup parameter can be left at the

2. The On Delay and Off Delay setup parameters

Loop 1: Control to sensor A

Program for:

— Setpoint = 200° F (93° C)

— Throttling Range = 20° F (-7° C)

— Sensor A

— Heat

— Relays = 1-4

1

Reset can be used for the T775L. However, keep in mind

that only one reset curve can be programmed. This means

that you can offset from the curve, but you cannot create a

second reset curve. Normally reset curves can be used for

Heat or Cool, not both.

→ # Relays = 4

→ Reset = NO

1

→ Reset = NO

factory default setting or adjusted as needed for

each loop.

can be adjusted according to the application.

25 63-7147—3

Page 26

63-7147—3 26

4 Stage Heat and 6 Stage Cool (continued)

SENSOR B

SENSOR A

T775 SERIES 2000 ELECTRONIC STAND-ALONE CONTROLLERS

L1

(HOT)

L2

L1

(HOT)

L2

24 VAC

HEAT

4

HEAT

1

HEAT

2

HEAT

3

COM

NO

NO

COM

T

T

T

T775L FIRST

T

–

1

+

–

1

+

5

C

C

+

RELAY

4

NC

NO

C

NO

NC

RELAY

1

NO

C

NC

RELAY

2

COM

NO

120

4

COM

COM

240

COM

NO

NO

COM

RELAY