T7560A,B,C Digital Wall Module

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION INSTRUCTIONS

BEFORE INSTALLATION

All wiring must comply with local electrical codes and

ordinances or as specified on installation wiring diagrams.

Digital Wall Module (DWM) wiring can be sized from 16 to 22

AWG (1.5 to 0.34 mm

max. length of wire from a device to a DWM is 164 ft (50 m).

Twisted pair wire is recommended for wire runs longer than

100 ft (30.5 m).

2

), depending on the application. The

CAUTION

EMI Noise Introduction.

Risk of erratic system operation.

Keep wiring at least one ft (305 mm) away from large

inductive loads such as motors, line starters, lighting

ballasts and large power distribution panels. During

installations, try to avoid areas of high EMI noise.

Run DWM wiring separately from 50 Vac or greater

power wiring.

WARNING / CAUTION

Risk of electric shock or equipment damage!

► Do not touch any live parts inside the DWM housing.

► Disconnect the power supply before making connections

to or removing connections from the DWM's terminals.

► Do not reconnect the power supply until you have com-

pleted the installation.

► If the DWM is powered via terminal 8 and connected to

earth ground, then the cable must be shielded.

► Observe precautions for handling electrostatic sensitive

devices.

Table 1. Types of DWM

T7560A

T7560B

T7560C

1

Tmp = Temperature sensor; Hum = Humidity sensor

Table 2. Controller SW requirements for powering via

VAV

W7751H

1.02.15 1.00.04 1.00.02 1.00.03 1.00.03

NOTE: A software module (ModAL module GNRSC02A) is

sensor1 setpoint bypass fan override

Tmp wheel button button

Tmp/Hum wheel button button

Tmp/Hum - - -

terminal 5 and new LCD signaling

Fan Coil Unit

W7752 W7754

available to adapt the DWM to the respective Excel

20, 50, 100, 500, 600, or 800 controller, making any

further configuring obsolete. Contact your local

Honeywell distributor for further details.

Hydronic

W7762

Chilled Ceiling

W7763

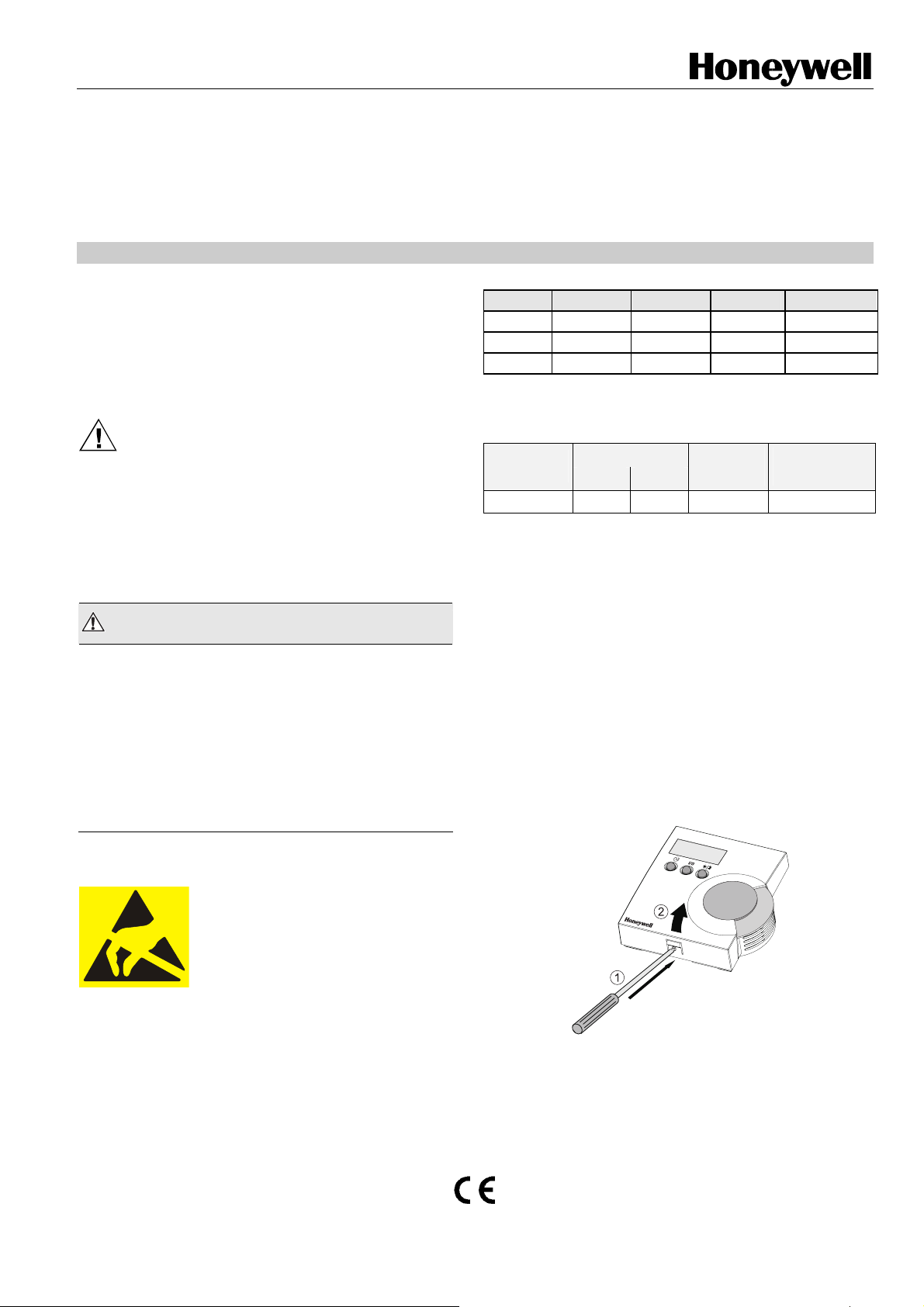

DWM DISASSEMBLY

The T7560A,B,C comes packed with a sub-base that mounts

separately for ease of installation. The cover is fixed by a

latch on the underside of the unit. Remove the cover as

shown in Fig. 1 (T7560A,B) or Fig. 2 (T7560C):

1. Insert the tip of an awl or a similar narrow, pointed object

into the small hole in the latch (T7560A,B) or simply

depress the latch by hand (T7560C).

2. Pry off the cover.

® U.S. Registered Trademark

Copyright © 2009 Honeywell Inc. • All Rights Reserved EN1B-0146GE51 R0309B

Fig. 1. DWM disassembly (T7560A,B)

T7560A,B,C DIGITAL WALL MODULES

Fig. 2. DWM disassembly (T7560C)

INSTALLATION

Mount the DWM on an inside wall approximately 54 in.

(1.3 m) from the floor (or as specified on the installation

drawings) to allow exposure to the average zone temperature.

Do not mount the DWM on an outside wall, on a wall

containing water pipes or near air ducts. Avoid locations that

are exposed to discharge air from registers or radiation from

lights, appliances, or the sun.

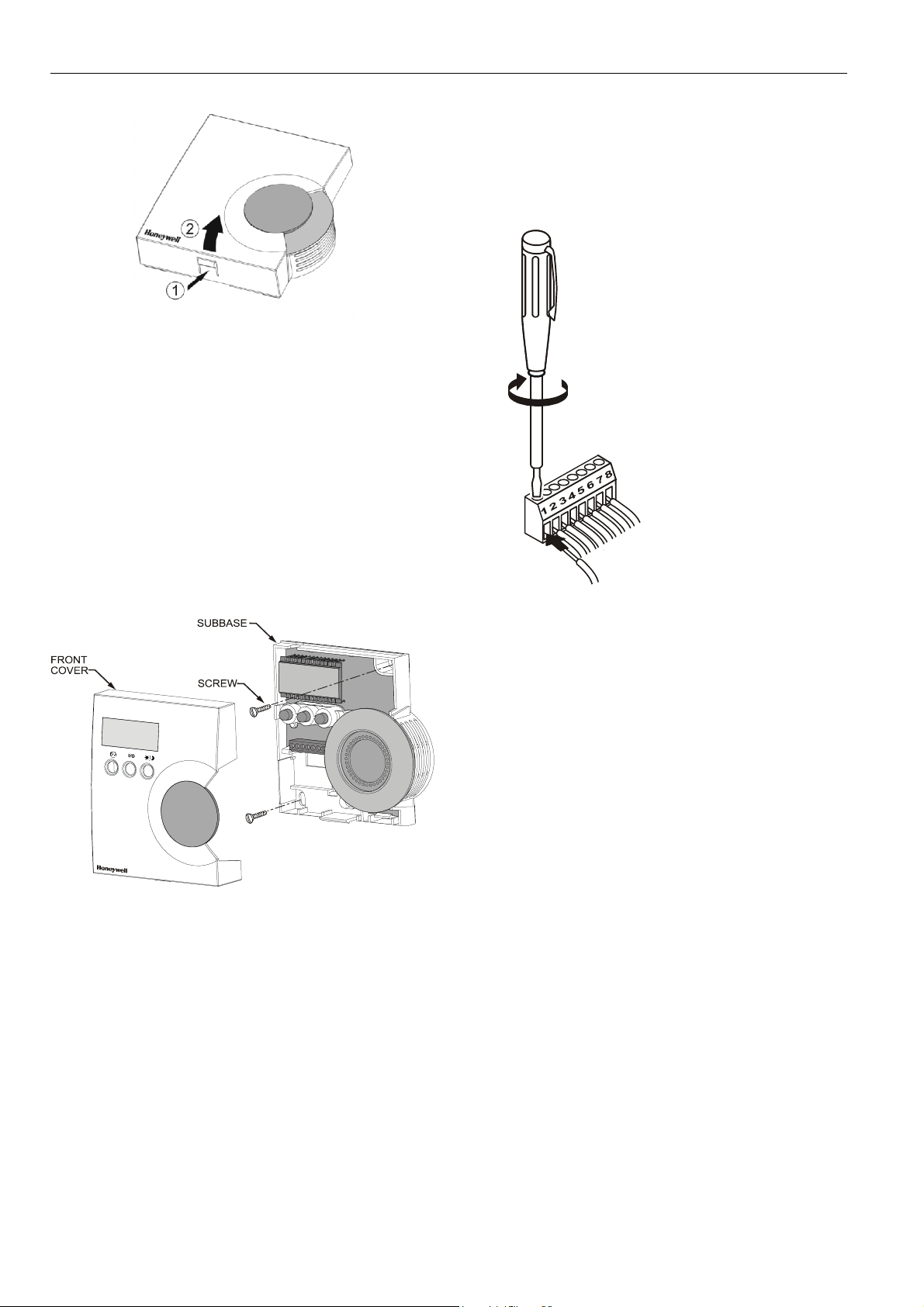

The DWM is furnished with a terminal block; all field wiring

connections are made to these eight terminals.

The DWM has to be mounted in vertical position with the LCD

display to the top.

Mount the subbase directly on a wall (see Fig. 3) using the

type of screws appropriate for the wall material.

Fig. 3. Mounting of DWM (T7560A,B shown)

See Fig. 6 for T7560A,B,C mounting dimensions.

Wiring

Wire the terminal blocks as follows:

1. Strip 3/16 in. (5 mm) of insulation from the conductor.

2. Insert the wire in the required terminal location and tighten

the screw to complete the termination.

IMPORTANT

Deviation from this rule can result in improper

electrical contact. See Fig. 4.

3. Verify DWM is wired according to Fig. 4.

NOTE: For specific wiring requirements, see the following

Power section.

Terminals

1 = Common

2 = Temperature sensor

3 = Setpoint (T7560C: Do not connect!)

4 = Bypass/fan* (T7560C: Do not connect!)

5 = LED input (T7560C: Do not connect!)

6 = Bypass** (T7560C: Do not connect!)

7 = Humidity output

8 = 24 Vac / 22 Vdc input

* With Excel 10 Controllers:

W7750 (CVAHU), W7752 (FCU),

and XL12

2

** With Excel 10 Controllers:

W7751H (VAV), W7762 (HYD), and

W7763 (CHC)

For W7753 (UV) and W7761 (RIO),

see below.

NOTE

1

Fig. 4. Wiring of DWM

NOTE: If connected to W7753 (UV) Controller, both

terminals 4 and 6 must be connected.

W7761 Remote I/O Controller supports only

terminals 2 (temperature), 7 (humidity), and

1 (common), as well as terminal 8 as voltage supply.

Wiring with terminal 8 is not necessary if:

a) an FCU or CHC controller with software is

connected (see table 2); or

b) an Excel 500 with 6V/8V/10V signaling from the

controller is used.

The T7560A must then be powered by terminal 5.

Power

The DWM can be powered as follows:

• T7560A: preferably via the 5 V LED input (terminal 5); via

terminal 8 is also possible

• T7560B,C: via the 24 Vac/dc input (terminal 8).

IMPORTANT

The DWM can be powered only via terminal 5 with

those controllers listed in Table 2, and if a

SW version listed in Table 2 or higher is installed.

If the DWM is powered via terminal 5, the Excel 10

controller must be configured for LCD_DISPLAY

(LED output continuously ON).

NOTE: The 24 Vac power supply is needed only with the

T7560B,C DWM (for the humidity sensor).

EN1B-0146GE51 R0309B

2

Alternatively, a DC voltage source with 5...15 V can

be connected to terminal 5 (see IMPORTANT note

above).

Alternatively, a DC voltage source with 18...30 V

(e.g. 22 Vdc from W7750 CVAHU) can be connected

to terminal 8.

Input ratings

Terminal 5:

min. 5 Vdc I

max. 15 Vdc I

max

max

3 mA

4 mA

or LED output of any Excel 10 controller

Terminal 8:

24 Vac from controller; I < 6 mA

or

18 Vdc (I < 2.4 mA) ... 30 Vdc (I < 10 mA)

Controllers with the following output ratings can be connected

to terminal 5

(ratings are met by all Excel 10 controllers):

• 5 V with 389 Ω

• 4.3 V with 100 Ω

• 14.3 V with 1.5kΩ

Use up to 16 AWG (1.5 mm

(1.0 mm

2

) wire for connecting 24 Vac power to terminal 8.

2

) with a minimum of 18 AWG

T7560A,B,C DIGITAL WALL MODULES

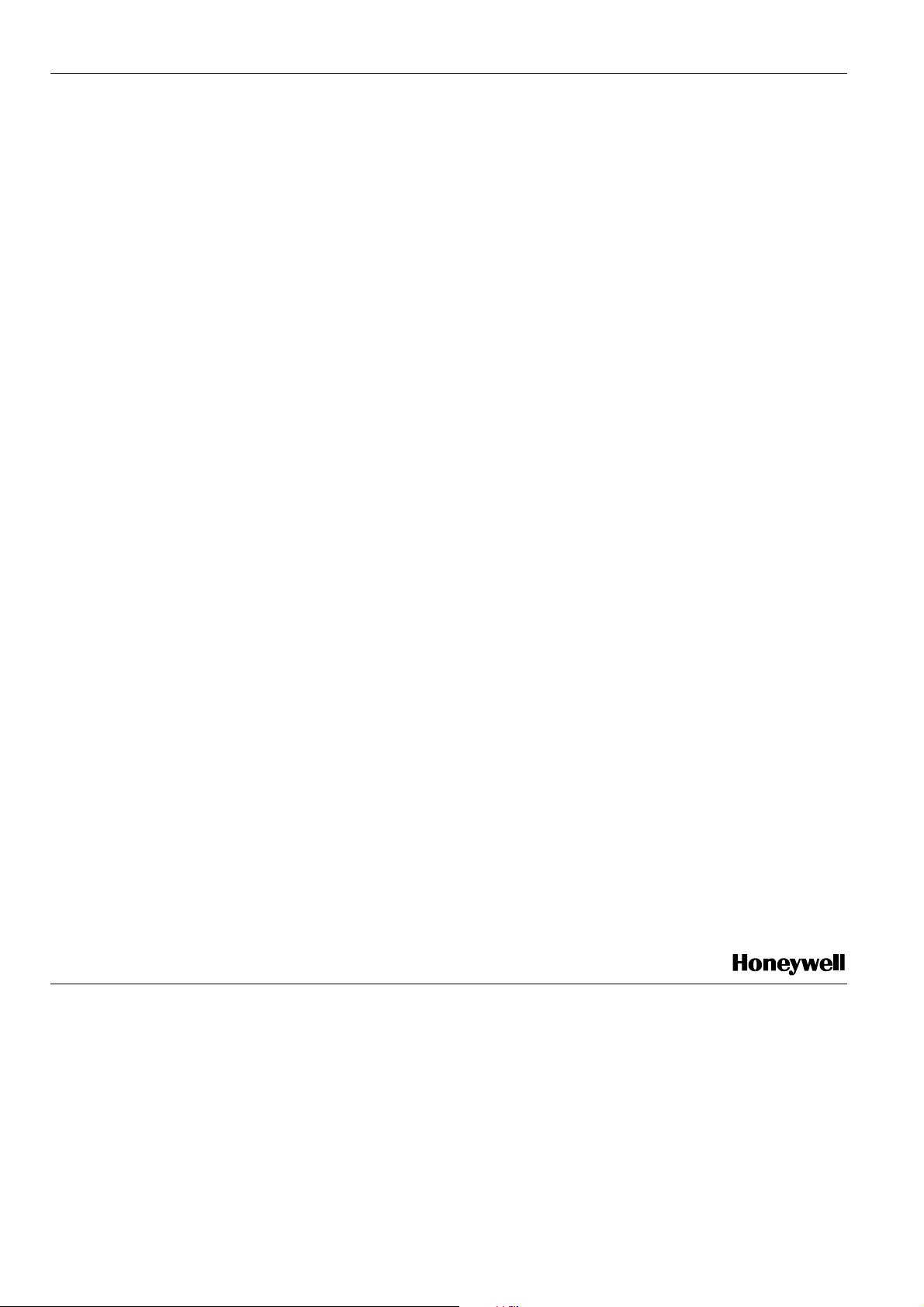

Fig. 5. Mounting cover of T7560A,B DWM

CAUTION

Low Voltage Equipment.

Risk of equipment damage.

The 24 Vac power source for the DWM must be a

Class II Power Source. To conform to Class II

restrictions, transformers must not be larger than

100 VA. A transformer that is CE certified and meets

the Low Voltage Device (LVD) requirements must be

used in Europe for all installations of this product.

The DWM power usage is < 0.2 VA at 24 Vac. The DWM

does not require a dedicated transformer. The DWM can get

power from any convenient location in the 24 Vac power

circuit.

The 24 Vac power can come from the 24 Vac power terminals

on the nearest controller or directly from a 24 Vac

transformer, whichever is closer.

When all wiring is complete, attach the cover of the DWM as

is shown in Fig. 5.

NOTE: Make sure that the latch on the underside of the

DWM engages properly.

Fig. 6. DWM dimensions in inches (mm)

EN1B-0146GE51 R0309B

3

T7560A,B,C DIGITAL WALL MODULES

CONFIGURATION (T7560A,B)

After installation, the T7560A,B DWM must be configured in

order to perform as desired. This is done by using the buttons

and the setpoint wheel (see Fig. 7).

Fig. 7. Control elements of T7560A,B DWM

Normal Operating Mode

After the DWM is powered up by the controller, it will display

the room temperature and will operate as configured by

default; the respective default setting is marked with an

asterisk in the following.

After power-up, all display segments are switched on for

approx. one second (see Fig. 8).

AUTO

MANU

PROG

Fig. 8. Display of all segments after power-up

Entering Configuration Mode

1. Press FAN OVERRIDE for at least 5 seconds.

2. Press UNIT ENABLE, then release FAN OVERRIDE,

hold UNIT ENABLE for at least 5 seconds.

3. Release UNIT ENABLE.

RESULT: The display shows

ready for configuration (see below).

4. Press and hold FAN OVERRIDE while turning the

setpoint wheel to select the parameter number.

RESULT: The parameters with their currently set

values are displayed; the

value indicates the currently set value (see

below for values).

5. Release FAN OVERRIDE and turn the setpoint wheel to

select the parameter value.

6. Confirm selection by pressing UNIT ENABLE.

7. Repeat steps 4 to 6 to configure next parameter, or

press BYPASS to leave the configuration mode.

NOTE: After approx. 10 seconds without further action, the

DWM automatically falls back to normal mode.

and the DWM is

≡ behind the

In the following, default settings are marked with an asterisk

(*).

P1 Setpoint Type Setting / Scale Type Setting

•

•

*

• Celsius absolute

P2 Room Temperature Setting

• Do not display room temperature

* Display room temperature

•

P3 Bargraph Use Setting

•

•

•

*

P4 Controller Type Setting

*

•

•

•

•

•

P5 Pin 4 (Bypass/Fan) Grounding

•

*

P6 Device type

This item configures different devices.

IMPORTANT:

Fahrenheit relative

Fahrenheit absolute

Celsius relative

(setpoint, only)

Display room temperature and humidity,

alternating every 5 seconds (T7560B, only)

No Fan

Auto, Off, On

Auto, Off, 2 Speeds

Auto, Off, 3 Speeds

New LCD signaling from controller (only for

controllers and SW versions as listed in

Table 2 or higher, in which case this setting

must be selected; set Excel 10 controller

to LCD_DISPLAY)

LED override mode from controller,

US signaling (100 ms pulses);

with contr. W7750, W7751, W7753, W7761,

and XL12

LED override mode from controller,

European signaling (500 ms pulses);

with contr. W7752, W7762, W7763, and XL12

(in the case of SW versions as listed in

Table 2 or higher, select

LED occupancy mode from controller,

European signaling (500 ms pulses);

with contr. W7752, W7762, W7763, and XL12

Same as

Excel 500 signaling from controller

(10 V, 8 V, 6 V)

Pin 4 not shorted to GND if override is

pressed (UV-controller, W7753)

Pin 4 shorted to GND if override is pressed

Stay on P6:1 and do not change to other

configurations.

).

EN1B-0146GE51 R0309B

4

T7560A,B,C DIGITAL WALL MODULES

j

P7 Temperature offset

*

P8 Switch back fan / temperature offset if unoccupied

*

• enable FAN Key / disable Setpoint Key

•

•

To "disable" means to switch back to FAN= auto / Setpoint

offset = zero and disable operation.

To "enable" means to make normal operation possible (no

action if unoccupied).

"Unoccupied" means:

• Effective Unoccupied (moon on continuously)

or

• Override Unoccupied (moon flashing).

"Occupied" means:

• Effective Occupied (sun on continuously)

or

• Override Occupied (sun flashing).

P8 works only with configuration P4:1: LCD signalling.

The setpoint will be set to zero only if set to relative: P1:1 and

P1:3.

P9 Limit setpoint

•

PA Limit for humidity low limit output value

•

Temperature offset; values of 0 through 99

are valid. 50 = no change (default),

49 = -0.1 °C, 51 = +0.1 °C, etc.

This offset varies the LCD display value, only.

It must be set separately in the XL10 controller.

enable FAN Key / enable Setpoint Key

disable FAN Key / enable Setpoint Key

disable FAN Key / disable Setpoint Key

-

Limit setpoint to ±0 … 5 °C (if set to Celsius) or to

0 … 9 °F (if set to Fahrenheit).

Default (if set to Celsius):

Default (if set to Fahrenheit):

Example (units set to Celsius): A setting of

means that the set point offset is limited to -3 to +3 °C.

Example (units set to Fahrenheit): A setting of

means that the set point offset is limited to -8 to +8 °F.

-

Limit the output value to 10 … 20% relative humidity in

steps of 5%.

This affects the output voltage on pin 7, only, and has

no effect upon values appearing in the display.

= 10%, = 15%, = 20% (default).

How to Check the Software Version

Press the left and right button for approx. 5 seconds: After a

LCD display test, you will see the current SW version of the

device.

ACCESSORIES

T7460LONJACK

The T7460-LONJACK is a small board and allows easy

access to L

already connected, in compliance with the max. cable lengths

set forth by the L

network via a L

3.5 mm jack plug on the board, a PC connection can be

established.

Order quantity: set with 5 pieces

Mounting

Remove the setpoint wheel and put in the LonJack as shown

in the following:

T7560 Blinds

Same material and color as housing; for covering nonoperational buttons.

Order quantity: set of 50 pieces.

ONWORKS via the DWM (the DWM must be

ONWORKS Guidelines, to the LONWORKS

ONWORKS bus cable). Via an additional

LonWorks

connection

terminals

PC con-

nection

(3.5 mm

ack plug)

Fig 9. T7460LONJACK

Fig 10. Mounting T7460-LONJACK

EN1B-0146GE51 R0309B

5

T7560A,B,C DIGITAL WALL MODULES

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN1B-0146GE51 R0309B

Loading...

Loading...