Page 1

T7350

Commercial Programmable Thermostat

SYSTEM ENGINEERING

Contents

Introduction .................................................................................................................................. 2

Device Description .............................................................................................. 2

Control Application .............................................................................................. 2

Network Control Provided ................................................................................... 3

Models .................................................................................................................................. 3

Abbreviations and Definitions .................................................................................................................................. 4

Network Configurations .................................................................................................................................. 9

Application Steps .................................................................................................................................. 10

Appendix A - Network Tools & Workstations ......................................................................................................................... 20

Appendix B - Network Alarm Reporting .................................................................................................................................. 21

Appendix C - Network Error Reporting ................................................................................................................................... 23

Products Covered ................................................................................................ 3

Applicable Literature ............................................................................................ 4

Performance Specifications ................................................................................. 5

Communications .................................................................................................. 7

L

ONMARK

Overview ............................................................................................................. 10

Step 1. Plan the System ...................................................................................... 11

Step 2. Determine Required Network Devices .................................................... 11

Step 3. Layout Communications and Power Wiring: .......................................... 11

L

ONWORKS

Cable Termination ............................................................................................... 12

Wiring Details ...................................................................................................... 12

Step 4. Prepare Wiring Diagrams ........................................................................ 12

General Considerations ....................................................................................... 15

Step 5. Order Equipment ..................................................................................... 17

Step 6. Configure T7350 ..................................................................................... 17

Step 7. Troubleshooting ....................................................................................... 18

®

Functional Profile .............................................................................. 8

®

Bus Layout ...................................................................................... 11

Appendix D - Network Access to Local Sensor Data ............................................................................................................. 25

Appendix E - Scheduling Network Devices ............................................................................................................................ 25

Appendix F - Network Master Clock ........................................................................................................................................ 25

Appendix G - Network Connections to Other LCBS Devices ................................................................................................ 26

Appendix H - T7350H Network Variable Summary ................................................................................................................. 34

® U.S. Registered Trademark

© 2004 Honeywell International Inc.

All Rights Reserved

63-4368

Page 2

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

INTRODUCTION

Device Description

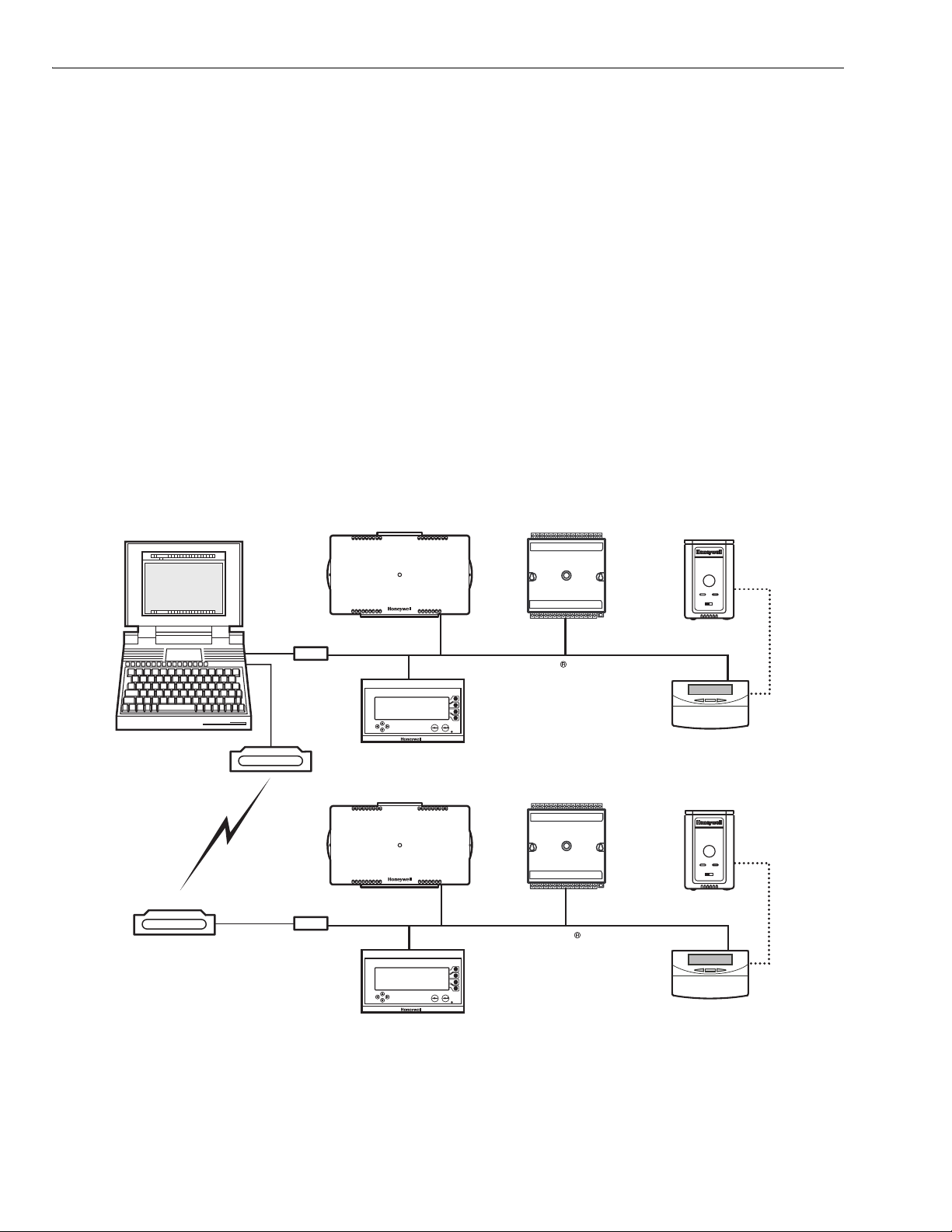

The T7350H is a LONMARK® certified thermostat that provides

networking capability in a L

ONWORKS

transformer-coupled Free Topology Transceiver (FTT). See

Fig. 1.

The T7350H communicates with many L

including the following:

— Other T7350H Communicating Commercial Thermostat

devices.

— T7300F/Q7300H Commercial Thermostat/Communicating

Subbase.

— Excel 15 S7760A Command Display.

— Excel 10 W7750A,B,C Constant Volume Air Handler Unit

(CVAHU) Controller.

— Excel 15 W7760A, B, C Building & Plant Managers.

— Excel 10 W7751B, D, F, H, J Variable Air Volume Terminal

Unit Controllers.

— Excel 10 W7752D, E, F, G Fan Coil Unitcontrollers.

— Excel 10 W7753A Unit Ventilator Controller.

— Excel 10 W7762A,B Hydronic Controllers.

— Excel 10 W7763C, D, E Chilled Ceiling Controllers.

NOTEBOOK PC

®

system using a

ONMARK

RS-232

SERIAL

PORT

SLTA

®

devices

BUILDING MANAGER

1481216

EXCEL 15

W7760

30 31

17 23

37

Control Application

The T7350H programmable communicating Thermostat

controls commercial single zone heating, ventilating and air

conditioning (HVAC) equipment through staged and

modulating outputs. The T7350H consists of a two piece

assembly with a thermostat cover and subbase. The

thermostat cover includes the keypad and display for 7-day

programming. Calendar programming is available through a

direct connect PDA (Configuration Tool) or network

(L

ONSPEC™ with model T7350H) tool configuration. The

subbase includes equipment control, inputs and network

connections. The subbase mounts on the wall and the

thermostat cover mounts to the subbase. In addition, the

T7350H model can communicate local sensor data, schedule

information, master clock operations and accept configuration

and override instructions to or from other devices/tools in a

L

ONWORKS

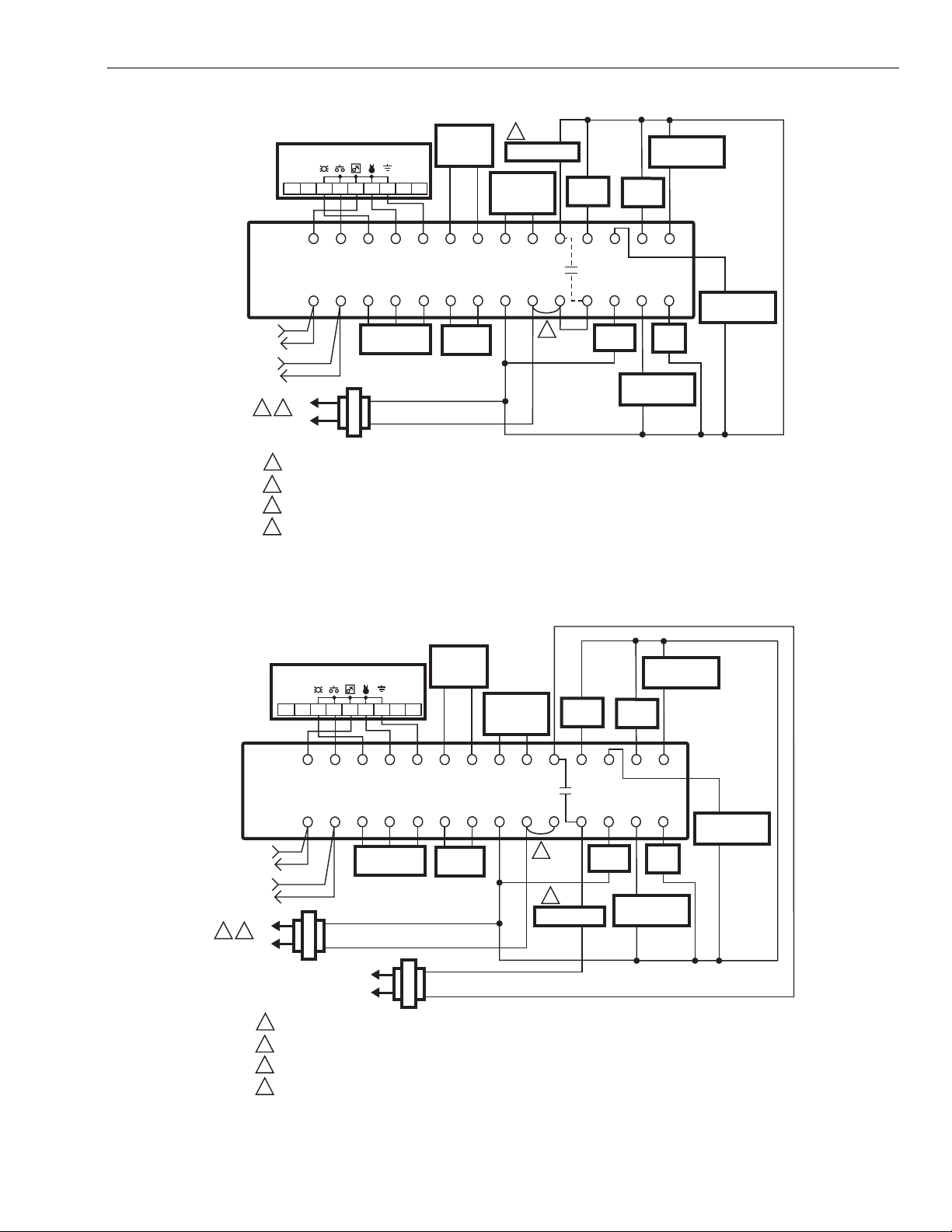

application in a three-stage heat and two-stage cool heat

pump system. For additional hookups, see Fig. 10 through 12.

44

S7760

®

network. Fig. 9 shows a typical T7350H

WALL MODULE

EXCEL 10

CVAHU

LonWorks BUS

T7350H

MODEM

Select

Back

MODEM

BUILDING MANAGER

1481216

RS-232

SERIAL

PORT

SLTA

EXCEL 15

W7760

17 23

30 31

44

37

S7760

Select

Back

EXCEL 10

CVAHU

LonWorks BUS

Fig. 1. Typical T7350H LONWORKS® network diagram.

WALL MODULE

T7350H

M22490

63-4368 2

Page 3

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Network Control Provided

The T7350H communicates with other network devices, or

nodes, for sharing data such as local inputs. Through the

network, a Command Display (S7760) is used to view or

modify T7350H operational modes including:

• Weekly Schedule.

• Holiday Schedule.

• Room Temperature SetPoints (Occupied, Unoccupied,

Standby).

• Manual Occupancy Override.

• Temperature Setpoints.

• Update Time Clock.

Network connected Workstations and Configuration Tools are

used to view and modify additional T7350 operational modes:

• Command Fan operating mode (On, Auto)

• Command Application mode (Auto, Off, Heating, Cooling)

By using network messaging, the T7350H may share the

following local inputs with other T7350, T7300/Q7300, XL15

or XL10 network connected devices:

• Room Humidity and Temperature.

• Outdoor Air Temperature.

• Occupancy Sensor.

• Unoccupied Bypass User Input.

Network messaging also supports distribution of local user

commands and operational states from a single T7350H. That

is, network connected T7350H and XL10 devices can be

configured to follow the local user commands and states from

a single (master) T7350H. These local T7350 commands

include the following:

• Application mode (Auto, Off, Heating, Cooling).

• Occupancy (Occupied, Unoccupied, Bypass, Standby).

• Bypass (unoccupied override).

• Setpoint.

• Time synchronization from a T7350H designated as

network master clock.

• Master Time Scheduling of Occupied, Unoccupied and

Standby states.

MODELS

Table 1. T7350 Communicating Thermostat Models.

Maximum

a

Stages

Model Applications

T7350H1009 Conventional

or

Heat Pump

T7350H1017 Modulating

a

All models are down-selectable and can be configured to

control fewer stages than the maximum allowed.

b

Heat pump applications for these models have a maximum

of two heat stages and two cool stages.

c

One extra stage (of either heat or cool) can be configured

using the auxiliary relay.

3 (2)b3 (4)

2 modulating, 2

relay

b

c

FeaturesHeat Cool

Humidity, Occupancy,

Outdoor, Discharge Air

Capability

Humidity, Occupancy,

Outdoor, Discharge Air

Capability, 4-20 mA

output (2-10 Vdc with

500 ohm resistor)

Products Covered

This System Engineering manual describes how to apply the

T7350H Communicating Thermostat and related accessories

to typical applications. Devices include:

• T7350H Commercial Communicating Thermostat.

• Excel 15 W7760A or B Building Manager.

• Excel 15 W7760C Plant Manager.

• Excel 10 Controllers including: W7750, W7751, W7752,

W7753, W7762.

Other products:

• Q7760A Serial LonTalk

• Q7740A,B FTT Repeaters.

• 209541B FTT Termination Module.

See Table 2 for additional products.

Table 2. Additional Products.

Part Number

R8242A Contactor, 24 Vac

AT72D, AT88A … 24vac

T7770A-D Wall Modules

T7771 Wall Module with

4074EYD Wallplate for

AK3798 Single pair network

AK3797 Single pair network

AK3799 Double pair

®

Adapter.

Product

Description Comments

coil, DPDT.

Transformers.

active display.

For covering an

T7770 Wall

Modules.

cable, U.L. Type

CMR

cable plenum

rated, U.L. Type

CMP

network cable

plenum rated, U.L.

Typ e CMP

existing hole in

a wall

3 63-4368

Page 4

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Applicable Literature

The following list of documents contains general information

related to the T7350H Communicating Commercial

Thermostats.

Table 3. Applicable Literature

Form No. Title

63-1299 T7350 Commercial Programmable

Thermostat Spec Data

62-0195 T7350 Commercial Programmable

Thermostat Installation Instructions

63-2605 T7350 Commercial Programmable

Thermostat Product Data

74-2976 Excel L

ONSPEC™ ZL7760A Specification

Data

74-2937 Excel LONSPEC™ ZL7760A User’s Guide

74-3123 Light Commercial Building Solution System

Communication Guide

74-2697 T7770A, B, C, D, E, F, G Wall Module

Specification Data

95-7538 T7770A, B, C, D, E, F, G Wall Module

Installation Instructions

63-2617 T7771 Wall Module Product Data

74-2972 S7760A Command Display Specification

Data.

74-2858 Q7740A,B FTT Repeater Specification

Data.

95-7555 Q7740A,B FTT Repeater Installation

Instructions.

®

74-2954 Q7760A SLTA-10 Serial LonTalk

Adapter

Specification Data.

®

95-7511 Q7760A SLTA-10 Serial LonTalk

Adapter

Installation Instructions.

95-7554 209541B Termination Module Installation

Instructions

ABBREVIATIONS AND DEFINITIONS

Application—A special use Building Control function.

Binding—The process of logically connecting network

variables in one node to network variable(s) in other node(s).

Binding is performed by a network management Tool (such as

L

ONSPEC™) that writes the binding information into the

EEPROM memory of all the neuron’s involved. The binding

information is saved in the network image of each neuron.

Building Manager—A LONMARK® certified device that can be

used to monitor and control HVAC equipment and other

miscellaneous loads in a distributed network.

Command Display—A device that can be used to monitor

data and change parameters of network connected devices.

CVAHU—Excel 10 Constant Volume Air Handler Unit

Controller.

Excel 10s—A family of application - specific HVAC controllers

such as the Excel 10 CVAHU and Excel 10 VAV.

HVAC—Heating, Ventilating and Air Conditioning.

I/O—Input/Output.

LCBS—Light Commercial Building Solution. These systems

are configured with the L

monitored with a Workstation such as LonStation

ONSPEC™ network tool and

®. Many

LCBS networks include the W7760B & C plant managers.

Routers (including Q7751A) are not supported by the LCBS

network configuration L

ONSPEC™-ZL7760A—A network connected tool which

L

ONSPEC™ tool.

configures, commissions, calibrates and monitors the

Honeywell Light Commercial Building Solution Q7300,

T7350H, Excel 10 and Excel 15 family of controllers.

L

ONSTATIO N™—A low-cost, easy-to-use Light Commercial

Building Solution workstation that provides advanced building

control capabilities for small to medium-size buildings.

ONWORKS

L

communicating with each other using the LonTalk

®

Network—A data network based on neurons

®

protocol.

Mandatory Mechanisms/Objects/Network Variables—

Mandatory mechanisms and network variables that are

implemented in all the Excel 10 devices.

NamedObjects—These objects are visible on the network as

functional independent entities and are accessed by name.

Typical examples of NamedObjects are Controllers,

ControlLoops and LogicFunction blocks contained in devices

such as the XL5a or XL15b.

Network Management Node—A L

ONWORKS

®

node that is

responsible for configuring the network, installing the nodes,

binding the network variables between nodes, and general

network diagnostics.

63-4368 4

Page 5

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Network Variables—A class of variables defined in Neuron C

that allows communication over the L

ONWORKS

®

network to

other nodes on the network. An output network variable in one

node can be bound to a corresponding input network

variable(s) in other node(s). Changing the value of the output

network variable in one node causes the new value to be

automatically communicated to the bound input network

variable(s) in other node(s). When an input network variable is

updated, a nv_update_occurs and the event is posted at the

receiving node(s) so that the application program can take

action based on the change. A network management node

(for example XL15A or XL15C) that explicitly reads and/or

writes the network variable can also poll network variables.

Network variables can contain one data field (one or two

bytes) or multiple data fields (a structure).

Neuron—Refers to the Echelon

implements the L

ONWORKS

®

semiconductor device which

®

protocol on a network connected

device such as the T7350H Honeywell controller.

Node—A device implementing layers one through six of the

LonTalk

®

protocol including a Neuron® Chip, transceiver,

memory, and support hardware.

Notebook PC—Portable personal computer.

PDA—Personal Digital Assistant. In the case of the T7350

product this is a hand held electronic device operating with the

Palm OS. A Honeywell provided PDA application program is

used to configure the T7350 thermostat using a direct RS232

connection. Before purchasing a PDA, check the latest

Configuration software release note for a list of qualified PDA

models. Network connected T7350H models can be

configured without a PDA using L

ONSPEC™.

Programmable Controller—A controller that has a variable

number of control loops of different types and is user

programmed to execute an application. The user can select

the number and type of control loops. The user also has the

capability of generating new types of control loops. Some

examples of Honeywell programmable controllers include the

XL15A and XL15B.

Recovery Mode or Recovery Period—The time in

unoccupied periods when the temperature control is adjusting

the control setpoint so that the space temperature reaches the

occupied setpoint when the schedule change occurs.

RIO—Excel 10 Remote Input/Output device.

RTC—Real Time Clock.

Schedule—The structure that defines the occupancy states

and the time of the changes between these states. In the case

of the T7350, schedules are organized around a eight day

weekly structure including an extra day for designated

holidays. Holidays are scheduled by yearly calendar events.

SGPU—Significant Event Notification and Guaranteed

Periodic Update.

SGPUC—Significant Event Notification and Guaranteed

Periodic Update with Change Field.

SLTA—Serial LonTalk

coupled LonTalk

®

Adapter. Adapts the transformer

®

messages to the RS-232 Serial Port.

SNVT—Standard Network Variable Type.

SCPT—Standard Configuration Parameter Type.

XL15A—W7760A Honeywell building level controller.

XL15B—W7760B Honeywell building level controller.

XL15C—W7760C Honeywell plant level controller.

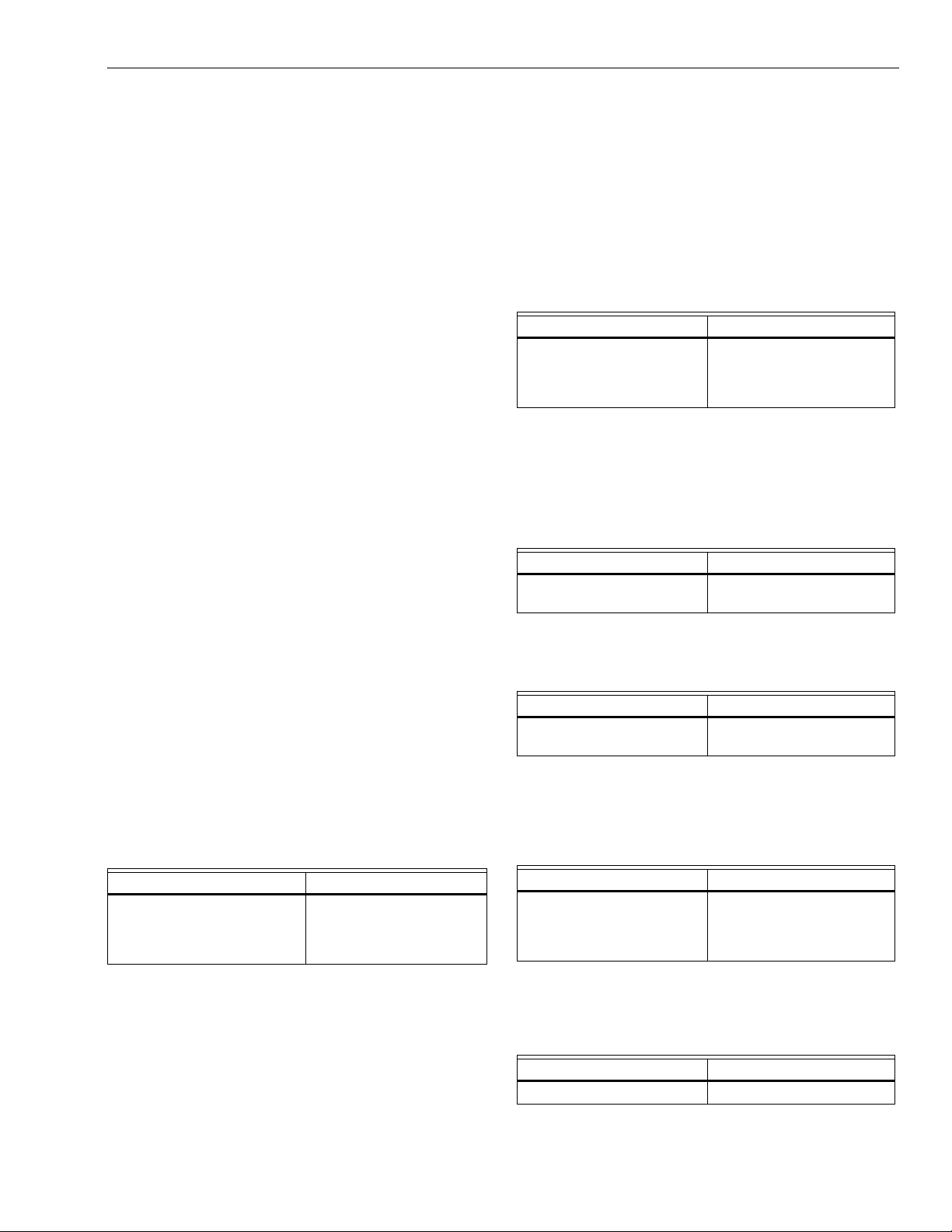

Performance Specifications

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit might not exactly match listed specifications.

This product is tested and calibrated under closely

controlled conditions; minor performance differences

can be expected if those conditions are changed.

Models: See Table 4.

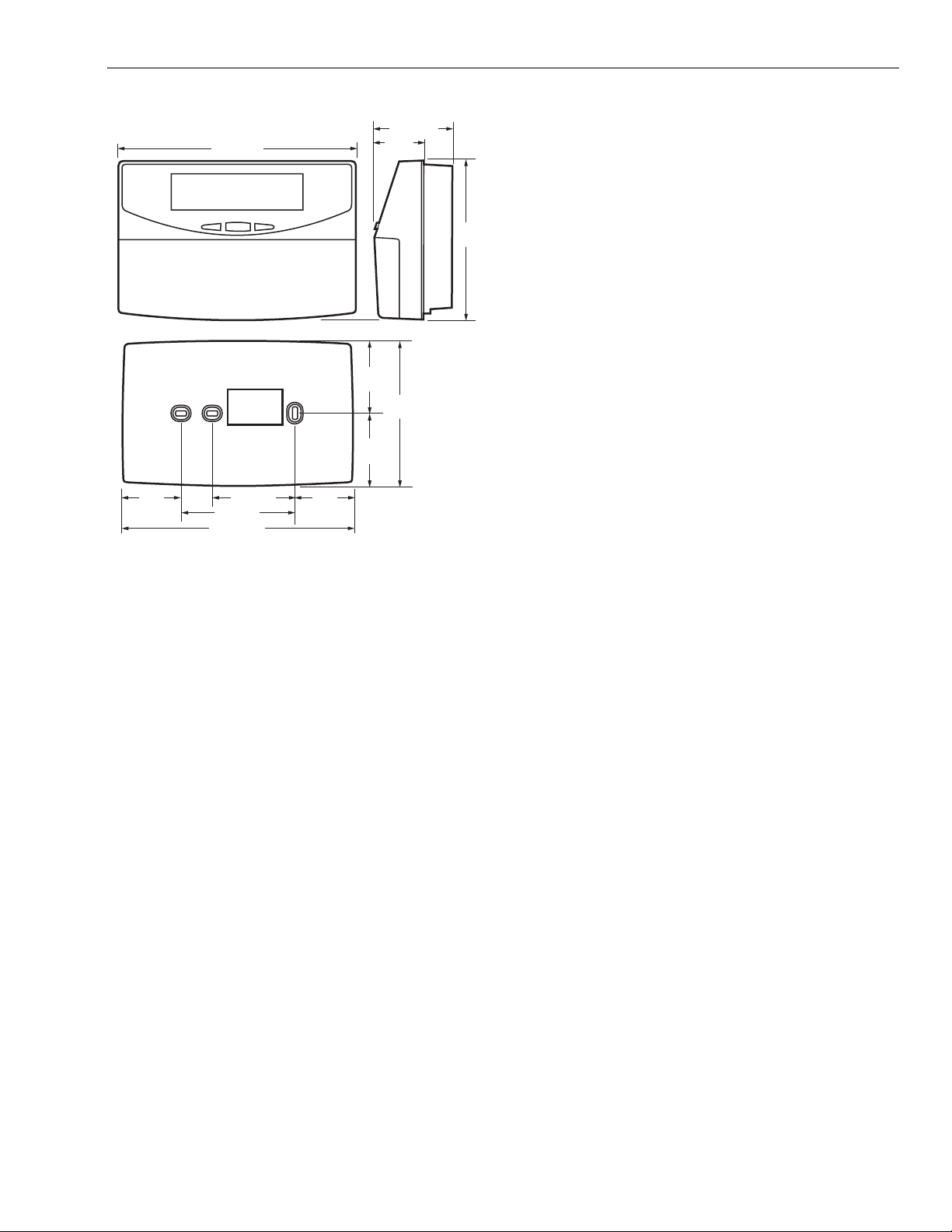

Dimensions: See Fig. 2.

Finish (color): Trident White.

Batteries: No batteries required.

Table 4. T7350 Thermostat Features.

a

b

Humidity, Occupancy,

Outdoor, Discharge Air Capability

Features

Model Applications

T7350H1009 Conventional

or

Maximum Stages

b

3 (2)

3 (4)

Heat Pump

T7350H1017 Modulating

2 modulating, 2

c

Humidity, Occupancy,

relay

Outdoor, Discharge Air Capability,

4-20 mA output (2-10 Vdc with 500 ohm resistor)

a

All models are down-selectable and can be configured to control fewer stages than the maximum allowed.

b

Heat pump applications for these models have a maximum of two heat stages and two cool stages.

c

One extra stage (of either heat or cool) can be configured using the auxiliary relay.

5 63-4368

Auxiliary

Relay

Isolated

Normally

Open

ONWORKS®

L

Capability?Heat Cool

Yes

Yes

Page 6

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Mounting Means:

Mounts on subbase.

Subbase Mounts On:

Wall: Using two 5/8 in. long #6-32 screws (included).

Outlet Box: Using sheet metal screws.

Throttling Range for Modulating Outputs:

Automatically adjusts based on heat/cool stages. Manually

adjustable with PDA.

Clock Accuracy (at 77°F [25°C]): ±1 min./month (30 days).

Minimum Stage Operation Time (fixed):

Minimum On

Heat: 1 minutes.

Cool: 3 minutes.

Minimum Off (Cool and Heat Pump): 1 minute.

Electrical Ratings:

Power: 24 Vac, 50/60 Hz.; 20 to 30 Vac, 50/60 Hz.

Input:

Temperature: 20K ohms.

Humidity: 0-10 Vdc.

Outdoor: 3000 PTC.

Discharge Air: 20K ohms.

Occupancy Sensor: Dry contact switching 30 Vdc at 1 mA.

All Relay Outputs (at 30 Vac):

Running: 1.5A maximum.

Inrush: 7.5A maximum.

Modulating Output: 4 to 20 mA with 510 ohm maximum

terminating resistance.

System Current Draw (without load):

5 VA maximum at 30 Vac, 50/60 Hz.

NOTE: Relays are N.O. Single-Pole, Single-Throw (SPST).

Outdoor Sensor Wiring: Requires 18 gauge wire.

Humidity Ratings: 5% to 90% RH, noncondensing.

Emergency Heat Indication:

Display indicates when Emergency Heat is activated (Em).

Temperature:

Ratings:

Operating Ambient: 30°F to 110°F (-1°C to 43°C).

Shipping: -30°F to +150°F (-34°C to +66°C).

Display Accuracy: ±1°F (±1°C).

Setpoint:

Range:

Heating: 40°F to 90°F (4°C to 32°C).

Cooling: 45°F to 99°F (7°C to 37°C).

Deadband: 2°F (1°C).

Default Settings: See Table 5.

Loss of Power: The thermostat maintains programmed times

and temperatures for the life of the product. Clock and day

information is retained for a minimum of 48 hours.

NOTE: To achieve the 48-hour power-loss clock retention,

the T7350 must be powered for at least 5 minutes.

Communicating Model T7350H:

Connection Terminals for the L

ONWORKS

®

Bus.

Network jack for quick access by personal computer based

tools.

Communications service-pin pushbutton to simplify startup.

L

ONMARK

ONMARK

L

L

ONMARK

ONMARK

L

Honeywell L

®

Controller.

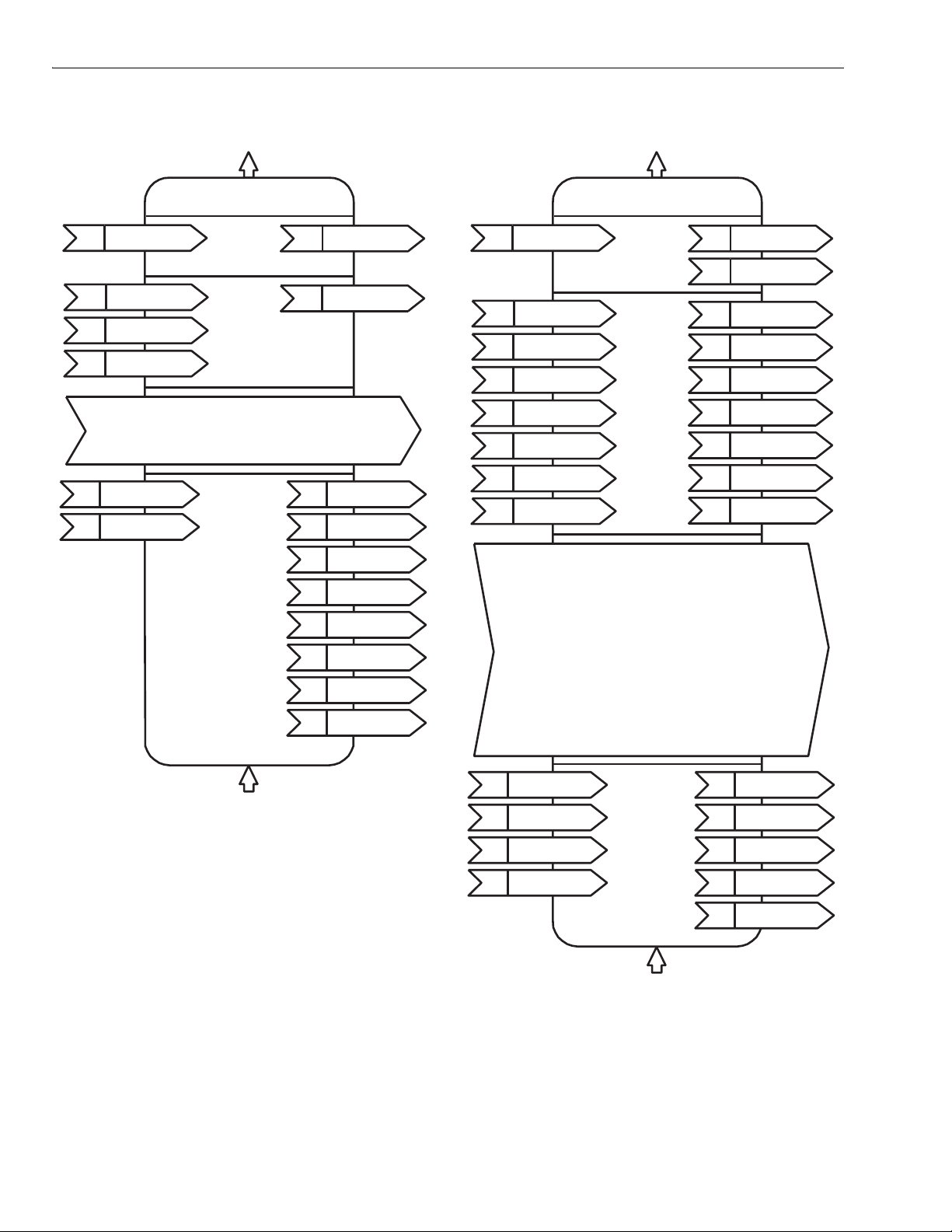

Functional Profile: 8500_20 Space Comfort

®

SCC Object Type: 8504 Rooftop See Fig. 3.

®

Program Identifier: 80:00:0C:55:04:03:04:2E.

®

Application Interoperability: version 3.3

ONMARK

®

Plug-In file downloads:

http://plugin.ge51.honeywell.de/index.htm#

PDA System Requirements:

Palm OS: 3.5.x to 5.2.1

Dynamic Heap: 256K bytes.

Free RAM Space: 1000K bytes.

Serial Communications: RS232.

Approvals:

European Community Mark (CE) Listed.

UL 873 Recognized, NEC Class 2.

FCC Part 15 subpart J Class A.

cUL.

Table 5. Default Setpoints.

Not

Control Occupied

Occupied Standby

Heating 70°F (21°C) 55°F (13°C) 67°F (19°C)

Cooling 75°F (24°C) 85°F (29°C) 78°F (26°C)

Accessories:

Duct Discharge Air Sensors: C7041B (6 or 12 in.),

C7041C (18 in.), C7041J (12 ft averaging),

C7770A (8 in. probe).

Outdoor Air Sensors: C7089A, C7170A,

C7031G2014 (weatherproof).

Temperature Sensors (Remote): C7772A, T7770A1006,

T7770B1046, T7770C1044, T7770D1000, T7771.

Economizer Logic Modules: W6210, W6215, W7210, W7212,

W7215, W7459.

Humidity Sensors: H7625A,B; H7635A,B,C, H7655B.

PDA Units: Palm™ V, M125, and i705 handhelds;

TRGPro™ handheld; ZIRE™ 71 handheld;

TUNGSTEN™ T handheld.

Others:

209541B FTT network termination module.

209651A Vertical Mounting Hardware Wallplate Adapter

(Trident white).

50000083-001 Thermostat Interface Module (TIM).

50000452-001 Troubleshooting Cable.

AK3797 Single pair network cable plenum rated,

U.L. Type CMP.

AK3798 Single pair network cable, U.L. Type CMR.

AK3799 Double pair network cable plenum rated,

U.L. Type CMP.

Q7740A FTT network 2-way repeater.

Q7740B FTT network 4-way repeater.

TG511, TG512 Universal Versaguard™ Thermostat

guards.

63-4368 6

Page 7

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

2-3/16 (56)

2-1/32

(52)

2-1/32

(52)

1-9/16

(40)

4-1/16

(104)

M22432

4-1/2

(114)

SUBBASE

1-5/8

(42)

6-3/4 (171)

2-3/8 (60)

3-1/4 (83)

6-9/16 (166)

1-5/8

(42)

Fig. 2. Dimensions of thermostat and subbase in in. (mm).

Communications

The T7350H provides networking capability in a LONWORKS®

system using a Free Topology Transceiver (FTT) transformercoupled communications port running at 78 kilobits per

second (kbs). The transformer-coupled communications

interface offers a much higher degree of common-mode noise

rejection while ensuring dc isolation. L

ONWORKS

networks are very flexible and convenient to install and

maintain, but it is imperative that the network layout be

carefully planned and accurate documentation created and

maintained. This aids in compliance verification and future

expansion of the network. It also minimizes unknown or

inaccurate wire run lengths, node-to-node (device-to-device)

distances, node counts, total wire length, inaccurate repeater/

router locations, and misplaced or missing terminations.

L

ONWORKS

®

networks can be configured in a variety of ways;

refer to the E-Bus FTT Network Wiring Guidelines, form 742865, for a complete description of network topology rules and

maximum network wire length. If longer runs are required, add

a Q7740A 2-way or Q7740B 4-way repeater to extend the

L

ONWORKS

on LCBS L

types for L

®

Bus length. Q7751A routers are not supported

ONSPEC™ configured systems. Approved cable

ONWORKS

®

Bus communications wiring are Level

IV, 22 AWG (0.34 sq mm) plenum or non-plenum rated

unshielded, twisted pair, solid or stranded conductor wire.

Refer to Table 2 for a list of Honeywell network cable part

numbers. Other Echelon® approved cable may also be used.

Run communications wiring in a conduit, if needed, with nonswitched 24 Vac or sensor wiring. The Free Topology

Transceiver (FTT) communications L

ONWORKS

a polarity insensitive, free topology wiring scheme that, in turn,

supports star, loop, and/or bus wiring.

®

FTT

®

Bus supports

7 63-4368

Page 8

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

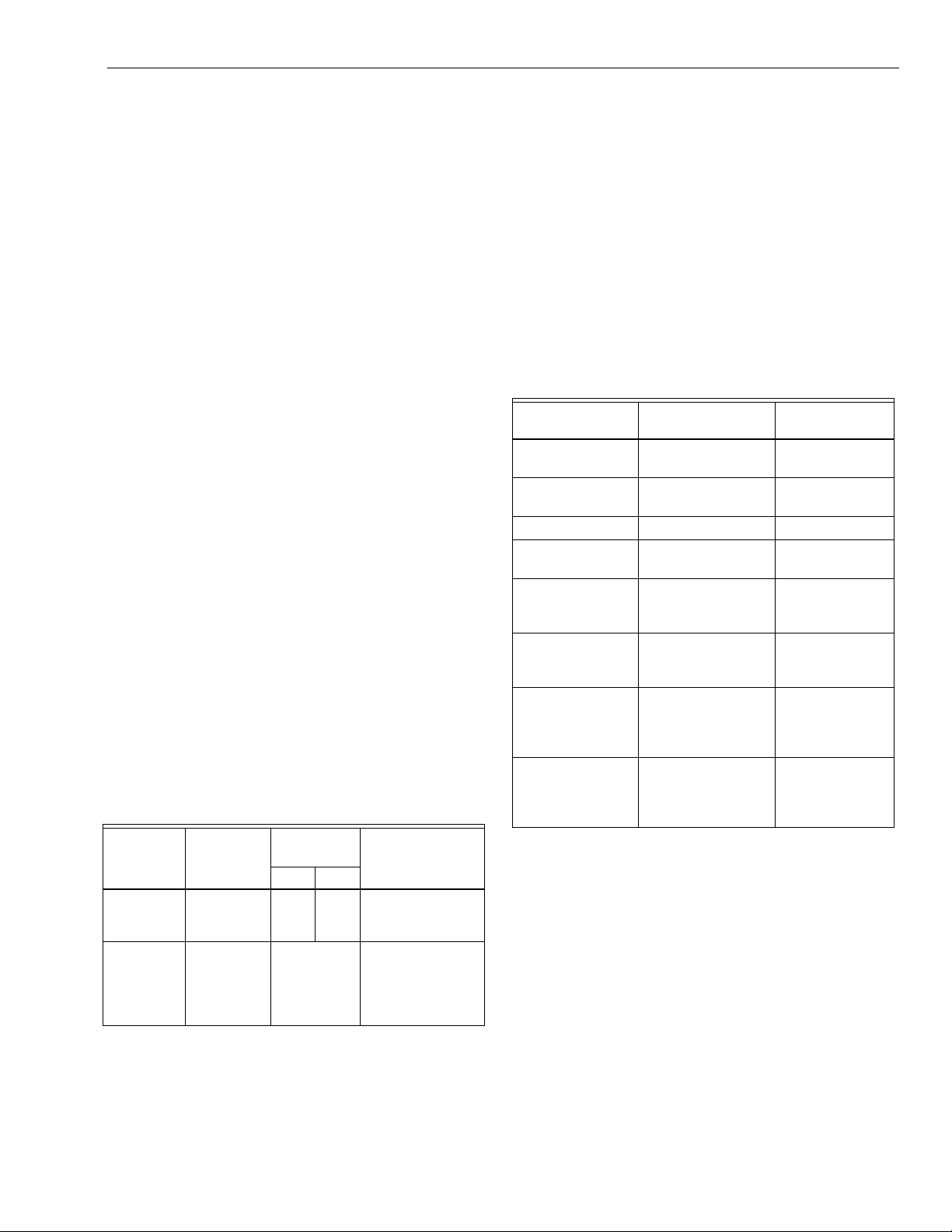

LONMARK® Functional Profile

Hardware OutputHardware Output

nviRequest

nv1

SNVT_obj_request

nviTimeSet

nv3

SNVT_ time_stamp

nviFileReq

nv5

SNVT_file_req

nviFilePos

nv7

SNVT_file_pos

nc1 - nciDeviceName

nc2 - nciApplVer

nviInUse

nv9

UNVT_inUse

nviPgm

nv10

UNVT_pgmIn

Node

Object

Mandatory

Network

nvoStatus

nv2

SNVT_ obj_status

Variables

nvoFileStat

nv6

SNVT_file_status

Optional

Network

Variables

Configuration Properties

UCPTdevName

UCPTapplVer

Manufacturer

(manf specific)

(manf specific)

nv11

nv12

nv13

Defined

Section

nv14

nv15

nv16

nv17

nv18

nroT7350Ver

UNVT_version

nroPgmVer

UNVT_pgmId

nvoPgm

UNVT_pgmOut

nvoTime

SNVT_time_stamp

nvoAlarmH

UNVT_alarm

nvoAlarmStatus

UNVT_alarmStatus

nvoAlarmLog

UNVT_alarmLog

nvoError

UNVT_error

nviSpaceTemp

nv1

SNVT_temp_p

nviSetpoint

nv2

SNVT_ temp_p

nviOccSchedule

nv5

SNVT_tod_event

nviOccManCmd

nv6

SNVT_occupancy

nviOccSensor

nv7

SNVT_occupancy

nviApplicMode

nv8

SNVT_hvacMode

nviOutdoorTemp

nv19

SNVT_Temp_p

nviSpaceRH

nv20

SNVT_lev_percent

nc1 - nciSndHrtBt

nc4 - nciRevHrtBt

nc2 - nciSetpoints

nc6 - nciBypassTime

nciConfig

nciConfigPts

nciDayLghtSav

nciDaySchedule0

nciDaySchedule1

nciDaySchedule2

nciDaySchedule3

nciDaySchedule4

nciDaySchedule5

nciDaySchedule6

nciDaySchedule7

nciHolSched

SCC-Rooftop

Object Number 8504.

nvoSpaceTemp

Mandatory

Network

Variables

Optional

Network

Variables

nv26

SNVT_ temp_p

nvoUnitStatus

nv27

SNVT_hvac_status

nvoEffectSetpt

nv28

SNVT_temp_p

nvoEffectOccup

nv29

SNVT_occupancy

nvoHeatCool

nv30

SNVT_hvac_mode

nvoDischAirTemp

nv34

SNVT_temp_p

nvoTerminalLoad

nv37

SNVT_lev_percent

nvoSpaceRH

nv43

SNVT_lev_percent

nvoOutdoorTemp

nv45

SNVT_temp_p

Configuration Properties

SNVT_time_sec

SNVT_time_sec

SNVT_temp_setpt

SNVT_time_min

UCPTconfig

UCPTconfigPts

UCPTdaylightSav

UCPTschedule0

UCPTschedule1

UCPTschedule2

UCPTschedule3

UCPTschedule4

UCPTschedule5

UCPTschedule6

UCPTschedule7

UCPTholSched

(mandatory)

(mandatory)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(manf specific)

(optional)

(optional)

Hardware Input

Fig. 3. T7350H LONMARK® Space Comfort Controller Rooftop Object (8504) with Node Object.

63-4368 8

nviBypass

nv30

SNVT_switch

nviFanAuto

nv31

SNVT_switch

nviManValue

nv32

UNVT_manValue

nviDlcShed

nv34

UNVT_dlcShed

Manufacturer

Defined

Section

Hardware Input

nvoBypass

nv43

SNVT_switch

nvoOccSchedule

nv44

SNVT_tod_event

nvoOccSensor

nv45

SNVT_occupancy

nvoData1

nv46

UNVT_data1

nvoData2

nv47

UNVT_data2

M22431

Page 9

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

NETWORK CONFIGURATIONS

The T7350H can be configured to perform a variety of

activities in which data is sent to and/or received from other

nodes on the L

ONWORKS

shared with other network devices includes:

— Current year, month, day, hour, minute, second.

— System mode (HEAT, COOL, AUTO, OFF, EM HEAT).

— Current fan setting (ON, AUTO).

— Space temperature.

— Space relative humidity.

— Discharge air temperature.

— Outdoor air temperature.

— Occupancy sensor status.

— Terminal load.

— Current setpoint.

— Occupied/Unoccupied schedule commands.

— Current occupancy status.

— Occupancy schedule including current occupancy state,

next state and time in minutes until next scheduled

change of occupancy state.

— Relay status (heat/cool stages and fan).

— Alarm status.

— Alarm log including the last five alarms.

— Device Error status.

— Bypass state (multiple XL10 devices follow the bypass

operation of a master device).

A network configuration tool is used to configure the T7350H

Thermostats and other nodes with which the T7350H

interacts. The following is a brief description of the

configurable features that can be commanded over the

network:

•Time Master:

When a T7350H is designated as the network time master,

the current time of day and date is synchronized across the

network every minute. The L

Screen can be used to configure a T7350H as the Network

Time Master. Whenever the time of day or date of the time

master is changed, it automatically adjusts all the other

network devices (T7350H, Q7300 & XL15A) bound to the

time master. When a T7350H is controlled by a time

master, the local day light saving schedule is disabled. The

Day Light Saving option on all time master recipients

should be disabled. This prevents erroneous time changes

(local daylight savings switchover) during temporary

network outages.

Source Destination

T7350H.nvoTime

or

XL15a.nvoTimeOut

Q7300.nvoTime

®

network. Information that can be

ONSPEC™ T7350H General

T7350H.nviTimeSet

or

XL15a.nviTimeIn

Q7300.nviTime

the user is not prevented from making local schedule

changes at the recipient thermostat. Local schedule

changes (at a recipient device) have no effect on the

scheduling commands received from the master device.

When a T7350H is designated as a master schedule

device, it sends its schedule information (current state,

next state, time until next change of state) to the

appropriate T7350H(s) which, in turn, overrides any

existing internal time schedule. The T7350H Thermostat

can provide master scheduling information to multiple

Excel 10 devices. One T7350H shares the schedule

information (current state, next state, time until next

change of state) with the designated Excel 10 devices.

Source Destination

T7350H.nvoOccSchedule

or

XL15a.nvoTodEventCmd[i]

Q7300.nvoOccSchedulei

T7350H.nviOccSchedule

or

XL10.nviTodEvent

XL15c.nviTodEventIn[i]

• System Mode Settings:

System mode settings (HEAT, COOL, AUTO, OFF, EM

HEAT) can be commanded by a remote T7350H or other

compatible XL10 device. A one to many network binding

can be used to command multiple devices from a single

unit. In addition, a network connected Workstation can be

used to change the System Mode.

Command Source Command Destination

T7350H.nvoHeatCool

T7350H.nviApplicMode

or Workstation

• Fan Settings:

Fan settings (ON, AUTO) can be changed from a network

connected Workstation.

Source Destination

Workstation

T7350H.nviFanAuto

or Network Tool

• Outdoor Air Temperature Sharing:

If a valid outdoor air temperature value is received at the

T7350H OAT network variable input, that value will be used

in the T7350H. The local OAT sensor of the T7350H is

ignored until the network sensor fails.

Source Destination

T7350H.nviOutdoorTemp

or

XL10.nvoOdTemp

XL15c.nvoOdTemp

T7350H.nvoOutdoorTemp

or

XL10.nviOdTemp

XL15c.nviOdTemp

• Time Schedule:

The occupancy schedule used by a T7350H may reside

locally in that device or remotely in another schedule

device (T7350H, XL15a, XL15b or T7300/Q7300). Local

schedules can be created and modified using the T7350H

keypad, a direct connected PDA, a network connected

configuration tool (L

ONSPEC™) or Command Display.

External schedules can also be modified using the keypad

of the master schedule device, or with a network

connected configuration tool or Workstation. When a

T7350H receives scheduling information over the network,

• Discharge Air Temperature Sharing:

The discharge air temperature value can be shared with

other devices on the network. Note that the T7350H does

not accept a network discharge air temperature input.

Source Destination

T7350H.nvoDischAirTemp XL15c.nviDATemp

• Space Temperature Sharing:

If a valid space temperature value is received at the

T7350H Space Temperature network variable input, that

9 63-4368

Page 10

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

value will be used in the T7350H as the primary controlled

variable. The local space temperature sensor of the

T7350H is ignored until the network sensor fails.

Source Destination

T7350H.nvoSpaceTemp

or XL10.nvoSpaceTemp

• Space Humidity Sharing:

If a valid humidity value is received at the T7350H Space

Humidity network variable input, that value will be used in

the T7350H as the humidity control variable. The local

space humidity sensor of the T7350H is ignored until the

network sensor fails.

Source Destination

T7350H.nvoSpaceRH T7350H.nviSpaceRH

• Current Setpoint Sharing:

If a valid setpoint value is received at T7350H nviSetpoint,

that value will be used by the T7350H as the center

setpoint. The heat and cool setpoints are then calculated

from this value and are used in the T7350H as the

occupied setpoints. During unoccupied periods,

nviSetpoint is ignored.

Source Destination

T7350H.nvoEffectSetpt

or XL10.nvoEffectSetpt

T7350H.nviSpaceTemp

or XL15c.nviRARH

T7350H.nviSetpoint

• Occupancy Bypass:

Any internal or external scheduled unoccupied state in the

T7350H is overridden by a network occupancy bypass

command. Bypass is a method to command unoccupied

override over the network from another controller (typically

a T7350H or XL10). The source controller manages the

bypass timing.

Source Destination

T7350H.nvoBypass

or

XL10.nvoBypass

XL15a.nvoBypass[i]

XL15c.nvoBypass[i]

• Manual occupancy:

Provides a method to command the occupancy state from

a network workstation. Effective occupancy override works

on a “last in wins” basis. That is, the last occupancy

override command received from any source determines

the override state. The workstation can command

occupied, unoccupied, standby, bypass, or not active (null).

There are several ways to return the device to normal

schedule operation.

1. Power failure reset at the T7350H.

2. Workstation issues a “not active” (null) network com-

mand to T7350H.nviOccManCmd.

3. User activates “Temporary Occupied” button on the

local keyboard. This can be followed by a “Run Schedule” local command.

4. If manual occupancy is commanded to bypass and the

bypass timer times out.

T7350H.nviBypass

• Occupancy Sensor Sharing:

If a valid value is received at the T7350H occupancy

sensor network variable input, that value will be used in the

T7350H as the occupancy sensor. The local T7350H

occupancy sensor is ignored until the network sensor fails.

Source Destination

T7350H.nvoOccSensor

or XL10.nvoSensorOcc

NetworkSensor

NOTE: The occupancy or motion sensor is active whenever

The T7350H effective occupancy is determined in Table 6.

Occupied Open Standby

Occupied Closed Occupied

Standby NA Standby

Unoccupied NA Unoccupied

the device is scheduled “Occupied” and a remote or

network occupancy sensor is configured.

Table 6. T7350H Effective Occupancy.

Schedule

Occupancy

Occupancy/Motion

Sensor Contact

T7350H.nviOccSensor

Effective

Occupancy

Source Destination

Workstation

Command Display

XL15b

T7350H.nviOccManCmd

APPLICATION STEPS

Overview

The application steps shown in Table 7 are guidelines for

configuring the T7350H in a L

explain the network role of the T7350H.

Table 7. Application Steps.

Step Description

1 Plan the system.

2 Determine required network devices.

3 Lay out communications and power wiring.

4 Prepare wiring diagrams.

5 Order equipment.

6 Configure T7350.

7 Troubleshooting.

ONWORKS

®

Bus network and

63-4368 10

Page 11

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Refer to the Light Commercial Building Solution System

Communication Guide form 71-3123 and the E-Bus Wiring

Guidelines, form 74-2865 for a complete description of

network topology rules. Prepare Wiring Diagrams, for wiring

details. Plan to configure each controller. Refer to the Excel

L

ONSPEC™ User Guide, form 74-2937, to configure the

T7350H, XL15 and XL10 Controllers.

Step 1. Plan the System

Plan the use of the T7350H Thermostat according to the job

requirements. Determine the location and functionality of each

device. Verify the sales estimate for the number of other

controllers and devices required. Check the number and type

of other required accessories. When planning the system

layout, consider potential expansion possibilities for future

growth. Planning is very important if HVAC systems and

controllers are to be added in future projects.

NOTEBOOK PC

SHIELDED

RS-232

SERIAL

PORT

INTERFACE

CABLE

Q7760

SLTA

CABLE

PART

NO. 205979

LonWorks

BUS PORT

T7350H

Step 2. Determine Required Network Devices

A maximum of 60 nodes can communicate on a single

L

ONWORKS

comprises one node. If more than 60 nodes are needed, a

Q7751A Router or Q7740 Repeater is necessary. A router or

repeater allows up to 120 controller nodes per network,

divided between two L

that routers are not supported by the LCBS L

system configuration tool. Refer to the Light Commercial

Building Solution System Communication Guide form 71-3123

for LCBS details. Refer to the E-Bus Wiring Guidelines, form

74-2865, for a complete description of network topology rules

and maximum wire lengths. A 209541B Termination Module

may be required. Refer to the Excel 10 FTT Termination

Module Installation Instructions form, 95-7554.

®

Bus segment. Each LONWORKS® Bus device

ONWORKS

®

Bus segments. Please note

ONSPEC™

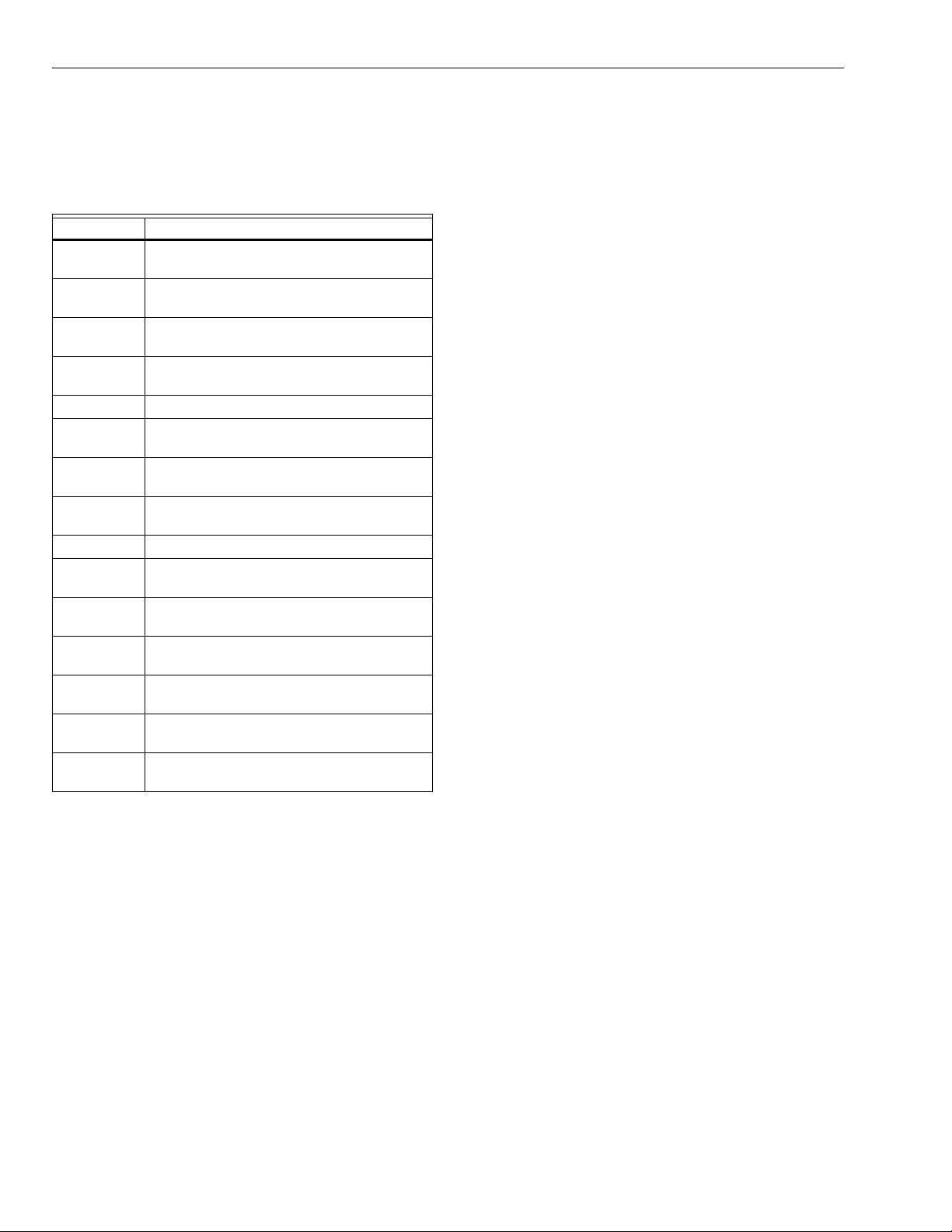

Step 3. Layout Communications and Power Wiring:

L

ONWORKS

The communications LONWORKS® Bus, is a 78-kilobit network

that uses transformer isolation and differential Manchester

encoding. The Free Topology Transceiver (FTT) LONWORKS®

communications Bus supports a polarity insensitive, free

topology wiring scheme, refer to the E-Bus Wiring Guidelines

form, 74-2865, for a complete description of L

network topology rules. Fig. 5 shows T7350H devices

connected in a typical free topology L

®

Bus Layout

ONWORKS

ONWORKS

®

network.

®

M22492

Fig. 4. Connecting personal computer to LonWorks® bus.

NOTEBOOK PC

T7350H

RS-232

SLTA

MODEM

T7350H

MODEM

RS-232

SLTA

T7350H T7350H

LonWorks BUS

MODEM

T7350H T7350H

LonWorks BUS

RS-232

SLTA

T7350H

T7350H

LonWorks BUS

T7350H

T7770

WITH NO

LonWorks

BUS ACCESS

T7770

LonWorks BUS

I/O CONNECTIONS

JACK FOR OPERATOR TERMINAL

Fig. 5. Typical topology for T7350 devices in LONWORKS® network.

11 63-4368

M22493

Page 12

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Cable Termination

The FTT network segment requires termination for proper

data transmission performance. Use a 209541B Termination

Module to connect two of the three termination module wires

to the L

ONWORKS

Wiring Guidelines form 74-2865 for details.

®

Bus terminals. Refer to LONWORKS® Bus

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Singly Terminated Network Segment

In a singly terminated topology segment, only one termination

is required and can be placed anywhere on the segment.

Singly terminated segments use the yellow and brown wires.

If the network topology requires a singly terminated

termination module at a T7350H, connect the singly

terminated module wiring on the appropriate terminals as

shown in Fig. 6.

SUBBASE

BROWN

ORANGE

T5 T6 T7 T4

EB

YELLOW

T3

OSOS ASAS

M

MHC HPHSEB

X

PART NO. 209541B

TERMINATION MODULE

W3/Y4 Y3 W2

AUX

RC

AUXRH

Y2

W1 GY1

M22494

Fig. 6. Singly terminated LonWorks® bus termination

module.

Doubly Terminated Daisy-Chain Network Segment

In a doubly terminated daisy-chained topology segment, two

terminations are required, one at each end of the topology

segment. Doubly terminated segments use the orange and

brown wires. If the network topology requires a doubly

terminated module at a T7350H (T7350H is the first or last

device on the network cable) connect the termination module

wiring on the appropriate terminals as shown in Fig. 7. For

additional wiring information, refer to the E-Bus Wiring

Guidelines, form 74-2865, and the Excel 10 FTT Termination

Module Installation Instructions, form 95-7554.

SUBBASE

T5 T6 T7 T4

T3

OSOS ASAS

W3/Y4 Y3 W2

AUX

Y2

IMPORTANT

All wiring must agree with applicable codes, ordinances and regulations.

1. Loosen subbase terminal screws and connect system

wires.

NOTE: Maximum (and recommended) wire size is 18-

gauge. Do not use wire smaller than 22-gauge. Follow equipment manufacturer wiring instructions

when available. Refer to the Wiring Diagram section

for typical hookups. A letter code is located near

each terminal for identification. Refer to the Specifications section, Tables 8 and 9 for terminal designations.

2. Securely tighten each terminal screw.

3. Push excess wire back into the hole in the wall.

4. Plug the hole with nonflammable insulation to prevent

drafts from affecting the thermostat.

Wiring Details

LONWORKS® network cable should be wired separately from

the power and I/O wires when installing T7350H models. If

this is not possible, use a minimum of 4 in. (102 mm)

separation between split ferrite cores (Fair-Rite 0443164151,

www.fair-rite.com) to ensure compliance with Class B limits

(does not apply to Class A limits). See Fig. 8 to apply ferrite

cores to L

ONWORKS

®

Bus input and output.

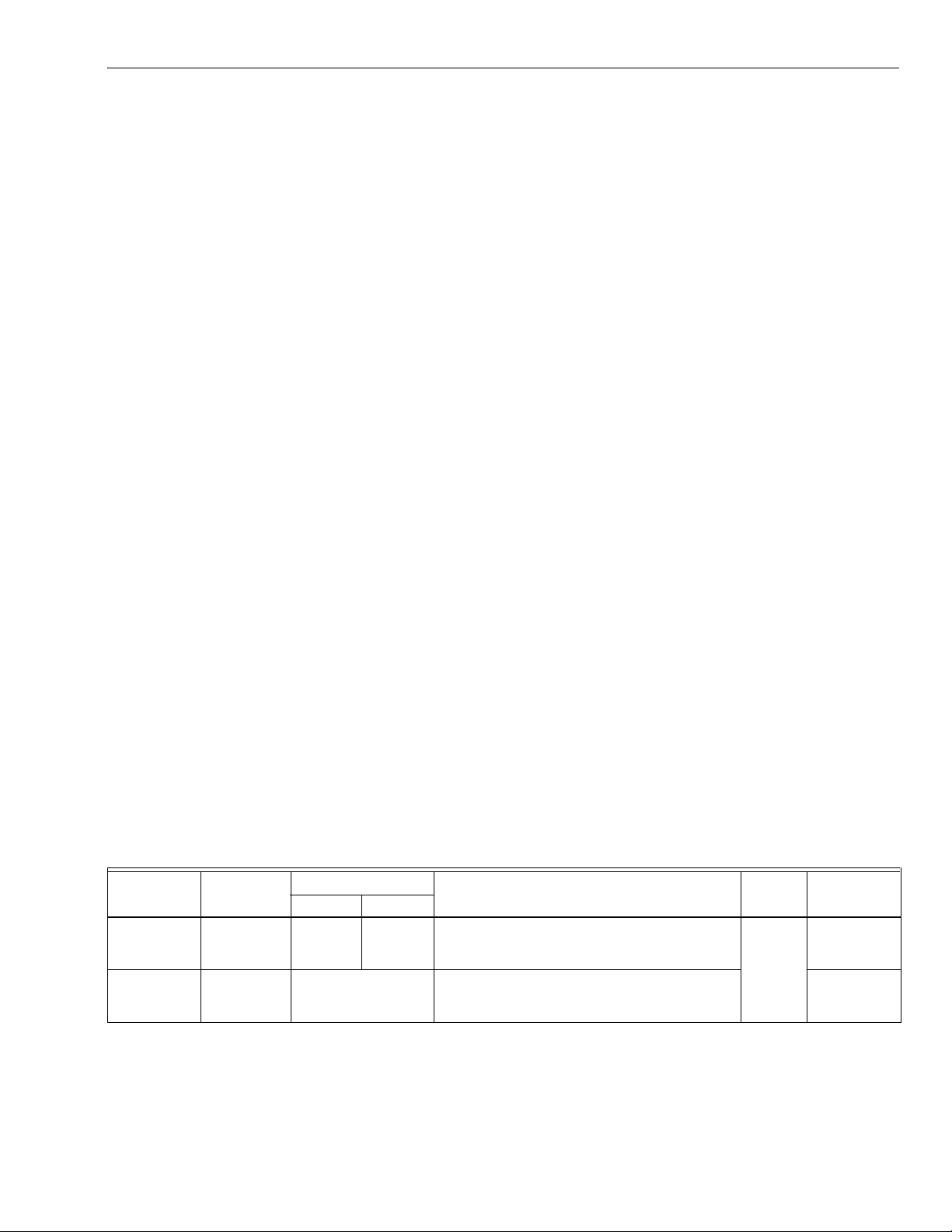

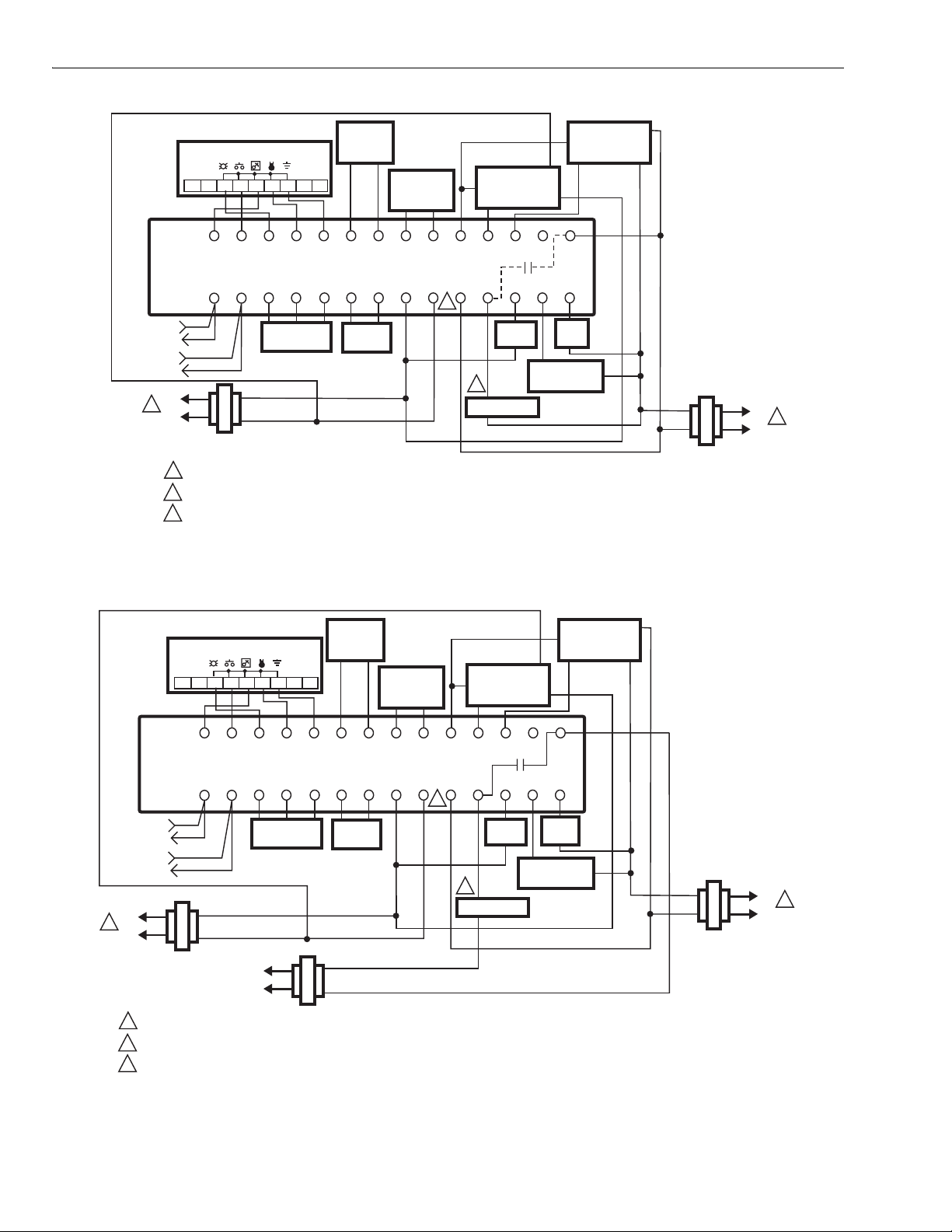

Step 4. Prepare Wiring Diagrams

Fig. 9 through 12 show T7350 terminal arrangements and

provide detailed wiring diagrams. Reference these diagrams

to prepare the site-specific job drawings.

1.

WIRES TO T7300H

COMMUNICATING SUBBASE

RC

W1 GY1

AUXRH

M22495

®

bus termination

BROWN

YELLOW

EB

ORANGE

M

PART NO. 209541B

TERMINATION MODULE

Fig. 7. Doubly terminated L

MHC HPHSEB

X

ONWORKS

modules.

63-4368 12

M22496

WIRES TO ALL

INPUTS AND

OUTPUTS

2.

WIRES TO T7300H

COMMUNICATING SUBBASE

Fig. 8. Ferrite core wires from T7350H to L

inputs and outputs.

WIRES TO ALL

INPUTS AND

OUTPUTS

ONWORKS

®

Page 13

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

DISCHARGE

AIR

SENSOR

OSOS ASAS

MHC HPHSEB

4

ECONOMIZER

X

3

HEAT

RELAY 3

AUX

W3/Y4 Y3 W2

AUXRH

RC

HEAT

RELAY 2

W1 G

Y1

HEAT

RELAY 1

COMPRESSOR

CONTACTOR 1

COMPRESSOR

CONTACTOR 2

Y2

COMPRESSOR

CONTACTOR 3

FAN

RELAY

M22499

LONWORKS

BUS

LONWORKS

BUS

OUTDOOR

123456789

T3

AIR

SENSOR

M

MOTION

SENSOR

T7770 REMOTE SENSOR

SUBBASE

T5 T6 T7 T4

EB

®

®

L2

2

1

L1

(HOT)

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

ENSURE TRANSFORMER IS SIZED TO HANDLE THE LOAD.

2

3

HEAT/COOL SYSTEMS WITH ONE TRANSFORMER REQUIRE THE FACTORY-INSTALLED JUMPER.

4

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

HUMIDITY

SENSOR

Fig. 9. Typical hookup of T7350H1009 in three-stage heat and three-stage cool conventional system with one

transformer.

LONWORKS

BUS

LONWORKS

BUS

2

1

OUTDOOR

T7770 REMOTE SENSOR

SUBBASE

T5 T6 T7 T4

EB

®

®

L2

L1

(HOT)

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

ENSURE TRANSFORMER IS SIZED TO HANDLE THE LOAD.

2

3

HEAT/COOL SYSTEMS WITH ONE TRANSFORMER REQUIRE THE FACTORY-INSTALLED JUMPER.

4

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

L2

L1

(HOT)

HUMIDITY

SENSOR

AIR

SENSOR

123456789

T3

M

MOTION

SENSOR

AUXILIARY

TRANSFORMER

DISCHARGE

AIR

SENSOR

OSOS ASAS

MHC HPHSEB

X

HEAT

RELAY 3

AUX

W3/Y4 Y3 W2

AUXRH

RC

3

4

ECONOMIZER

HEAT

RELAY 2

W1 G

Y1

HEAT

RELAY 1

COMPRESSOR

CONTACTOR 1

COMPRESSOR

CONTACTOR 2

Y2

COMPRESSOR

CONTACTOR 3

FAN

RELAY

M22497

Fig. 10. Typical hookup of T7350H1009 with auxiliary transformer.

13 63-4368

Page 14

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

LONWORKS

BUS

LONWORKS

BUS

1

OUTDOOR

123456789

T3

AIR

SENSOR

M

MOTION

SENSOR

DISCHARGE

AIR

SENSOR

OSOS AS AXAS

MHC HPHSEB

RCX

2

MODULATING

HEAT

–

(4-20 mA)

+

AC

AH

W1 G

AUXRH

HEAT

RELAY 1

3

ECONOMIZER

T7770 REMOTE SENSOR

SUBBASE

T5 T6 T7 T4

EB

®

®

L2

L1

(HOT)

HEATING

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

WHEN INSTALLED ON A SYSTEM WITH TWO TRANSFORMERS, REMOVE THE FACTORY-INSTALLED JUMPER.

2

3

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

HUMIDITY

SENSOR

MODULATING

–

+

R

X

AUX

Y1

FAN

RELAY

COMPRESSOR

CONTACTOR 1

(4-20 mA)

COOL

R

X

COOLING

TRANSFORMER

L2

L1

(HOT)

M22498

1

Fig. 11. Typical hookup of T7350H1017 for system with two independent heat stages (one modulating), two independent

cool stages (one modulating), and two transformers.

OUTDOOR

T7770 REMOTE SENSOR

SUBBASE

T5 T6 T7 T4

HS

®

LONWORKS

BUS

®

ONWORKS

L

BUS

L2

1

L1

(HOT)

HEATING

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

WHEN INSTALLED ON A SYSTEM WITH TWO TRANSFORMERS, REMOVE THE FACTORY-INSTALLED JUMPER.

2

3

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

L2

L1

(HOT)

HUMIDITY

SENSOR

AIR

SENSOR

123456789

T3

M

MOTION

SENSOR

AUXILIARY

TRANSFORMER

DISCHARGE

AIR

SENSOR

OSOS AS MXAS

MHC HP

RCX

2

ECONOMIZER

MODULATING

–

(4-20 mA)

+

MC

MH

W1 G

AUXRH

HEAT

RELAY 1

3

R

HEAT

X

Y1

COMPRESSOR

CONTACTOR 1

FAN

RELAY

MODULATING

–

(4-20 mA)

+

AUX

COOL

R

X

L2

1

L1

COOLING

TRANSFORMER

(HOT)

M22491

Fig. 12. Typical hookup of T7350H1017 for system with two independent heat stages (one modulating), two independent

cool stages (one modulating), and three transformers.

63-4368 14

Page 15

General Considerations

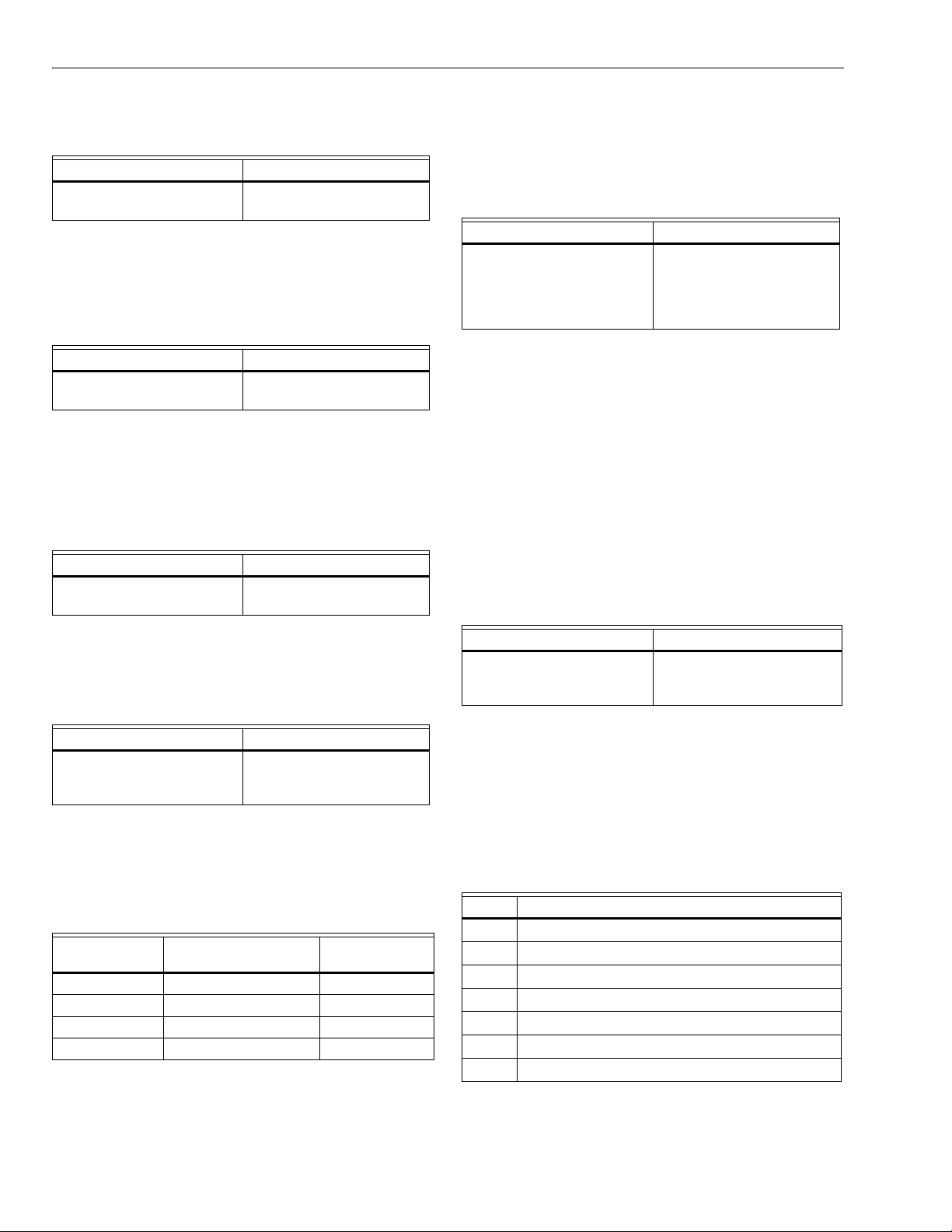

Table 8 lists wiring types, sizes and distances for the T7350

and Excel 10 products. The T7350 terminal strip accepts 18

through 22 AWG (0.82 to 0.34 sq. mm) wire.

Table 8. Field Wiring Reference.

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Wire Function

Digital Outputs:

W Y G AUX X

Modulating Outputs:

MX MH MC

Remote Humidity

Sensor:

HS HC HP

Discharge Air

Temperature Sensor:

AS

Outdoor Air

Temperature Sensor:

OS

Motion Sensor:

M

Wall Module

connections:

T3-T7

Power Wiring to:

X RH RC

ONWORKS

L

®

Bus

(Non-Plenum).

LONWORKS® Bus

(Plenum Rated).

Recommended Wire

Size (Minimum)

18 AWG (0.82 sq mm)

five wire cable bundle.

Specification or

Requirement

Standard thermostat

wire.

Honeywell Part

Number Distance (Maximum)

AK3726 1000 feet.

18 AWG (0.82 sq mm) 1 pair per output. AK3757C, AK3744C,

AK3741A, AK3702x

18 to 22 AWG

(0.82 to 0.34 sq mm)

18 to 22 AWG

(0.82 to 0.34 sq mm)

3 wires. AK3746C, AK3724,

AK3703x

1 pair. AK4606ABE,

AK4628AWH,

AK3702x, AK3741A,

AK3744C, AK3757C

18 AWG (0.82 sq mm) 1 pair. AK3757C, AK3744C,

AK3741A, AK3702x

18 to 22 AWG

(0.82 to 0.34 sq mm)

1 pair. AK4606ABE,

AK4628AWH,

AK3702x, AK3741A,

AK3744C, AK3757C

18 to 22 AWG

(0.82 to 0.34 sq mm)

Twisted pair wire is

recommended for wire

runs longer than 100

ft. The number of pairs

depends on the model

AK4606ABE,

AK4628AWH,

AK3702x, AK3741A,

AK3744C, AK3757C,

AK3726

and functions

selected.

18 to 14

(0.82 to 2.0 sq mm)

use heavier wire for

1

AWG

NEC Class II,

140°F (60°C) rating.

AK3702x, AK3741A,

AK3744C, AK3757C,

AK3712x, AK3754

longer runs.

22 AWG

(0.34 sq mm)

Nema Level IV

U.L. Type CMR

AK3798 (1 pair) Refer to E-bus Wiring

Twisted pair stranded

conductor,

nonshielded.

22 AWG

(0.34 sq mm)

Nema Level IV

U.L. Type CMP

AK3797 (1 pair)

AK3799 (2 pair)

Twisted pair stranded

conductor,

nonshielded.

1000 feet.

500 feet.

1000 feet.

500 feet.

1000 feet.

1000 feet.

Limited by line-loss

effects on power

consumption.

Guidelines Users

Guide 74-2865 for

maximum length and

generic cable

specifications.

—

NOTE: 1. The X, RH and RC terminals will accept 14 to 22 AWG. 14 and 16 AWG should be avoided since the stiff cable

interferes with the cover to subbase installation.

15 63-4368

Page 16

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Table 9. Honeywell Cable Details.

Honeywell Part

Number Size (AWG) Number of wires Jacket Plenum Rated Description

AK3798 22 2 Yes No E-bus cable.

AK3797 22 2 Yes Yes E-bus cable.

AK3799 22 4 Yes Yes E-bus cable.

AK4606ABE 22 2 Yes No Beige jacket.

AK4628AWH 22 2 Yes Yes White jacket.

AK3702x 18 2 No No —

AK3741A 18 2 Yes No —

AK3744C 18 2 Yes Yes Red jacket.

AK3757C 18 2 Yes Yes White jacket.

AK3703x 18 3 No No —

AK3724 18 3 Yes No Tan jacket.

AK3746C 18 3 Yes Yes Tan jacket.

AK3726 18 5 Yes No Tan jacket.

AK3712x 16 2 No No TFN

AK3754 14 2 No No TFN

63-4368 16

Page 17

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Step 5. Order Equipment

After compiling a bill of materials through completion of the

previous application steps, refer to Table 10, Ordering

Information.

Table 10. Ordering Information.

Part Number Product Description Comments

T7350H1009 Communicating Thermostat with three heating and

three cooling digital outputs.

T7350H1017 Communicating Thermostat with two modulating

outputs, one heating and one cooling digital output.

T7771A Remote Temperature Sensor. • Pushbutton setpoint adjustment with LED indicators.

T7770A1006 Remote Wall Module. • Basic model with room temperature sensor.

T7770B1046 Remote Wall Module. • ± setpoint change.

T7770C1044 Remote Wall Module. • ± setpoint change.

T7770D1000 Remote Wall Module. • OCC button and LED.

AK3798 L

AK3797 L

AK3799 L

ONWORKS

ONWORKS

ONWORKS

®

Bus (Non-Plenum), 1 pair. —

®

Bus (Plenum rated), 1 pair. —

®

Bus (Plenum rated), 2 pair. —

209541B FTT Network Termination Module. —

H7625

Remote Humidity Sensors —

H7635

C7089A

Outdoor Air Sensors. —

C7170A,

C7031G2014

Duct Discharge Air Sensors:

C7041B

C7041C

C7041J

C7770A

50000452-

6 inch probe.

18 inch probe.

150 inch averaging.

6 inch probe.

Troubleshooting Cable. One Troubleshooting Cable required for each

001

50000083-

Thermostat Interface Module (TIM). One TIM required for each installation technician. Note

001

PDA Qualified Palm OS PDA. One PDA required for each installation technician.

50000314-

PDA Configuration Software. One Configuration software package can be used to

001

• Optional heat pump control.

• Isolated auxiliary digital output.

• Isolated auxiliary digital output.

• Occupied/unoccupied override (bypass) with LED.

•L

ONWORKS

®

Bus jack.

• OCC button and LED.

—

installation technician.

that a network tool such as L

ONSPEC™ eliminates the

need for a TIM.

Refer to the PDA Configuration Software for an up-todate list of qualified PDA hardware. Note that a network

tool such as L

ONSPEC™ eliminates the need for a PDA.

program multiple PDAs. Note that a network tool such

ONSPEC™ eliminates the need for a PDA.

as L

Step 6. Configure T7350

Use Excel LONSPEC™ Software to configure the T7350H

Thermostat for specific applications. The Excel L

User’s Guide, form 74-2937, provides software operation

instructions for this personal computer based application.

ONSPEC™

17 63-4368

Page 18

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Step 7. Troubleshooting

Table 11. Troubleshooting Information.

Symptom Possible Cause Action

Display will not

come on.

Temperature

display is

incorrect.

Temperature

settings will not

change.

(Example: Cannot

set heating higher

or cooling lower.)

Room

temperature is out

of control.

Heat will not come

on.

Thermostat is not being powered. Check that X terminal is connected to the system transformer.

Check for 24 Vac between X and RH terminals.

If missing 24 Vac:

• Check if circuit breaker is tripped; if so, reset circuit breaker.

• Check if system fuse is blown; if so, replace fuse.

• Check if the HVAC equipment power switch is in the Off position; if

so, set to the On position.

• Check wiring between thermostat and HVAC equipment. Replace

broken wires and tighten loose connections.

If 24 Vac is present, proceed with troubleshooting.

Room temperature display has been

recalibrated.

Thermostat is configured for °F or °C

Use PDA or L

ONSPEC™ configuration software to recalibrate as

desired.

Press both Run Schedule and Copy, then reconfigure the display.

display.

Bad thermostat location. Relocate the thermostat.

Display shows three dashes and a

degree sign (all systems shut down).

Upper or lower temperature limits

were reached.

T7350 is set for remote sensing and sensor is missing or circuit is

either open or shorted.

Check the temperature setpoints:

• Heating limits are 40 to 90°F (7 to 31°C)

• Cooling limits are 45 to 99°F (9 to 37°C)

Occupied setpoint temperature

range stops were configured.

Keypad is locked. When a locked

key is pressed, LOCKED appears

momentarily on the LCD.

Remote temperature sensing is not

Using a PDA or L

ONSPEC™, check setpoint stops. If necessary,

reconfigure the stop(s).

• Use PDA or L

ONSPEC™ (Set, Display) to unlock keypad.

• Press both Run Schedule and Copy, then change keypad lock

level.

Check all remote sensors.

working.

No power to the thermostat. Check that X terminal is connected to the system transformer.

Check for 24 Vac between X and RH terminals.

If missing 24 Vac:

• Check if circuit breaker is tripped; if so, reset circuit breaker.

• Check if system fuse is blown; if so, replace fuse.

• Check if the HVAC equipment power switch is in the Off position; if

so, set to the On position.

• Check wiring between thermostat and HVAC equipment. Replace

broken wires and tighten loose connections.

If 24 Vac is present, proceed with troubleshooting.

Thermostat minimum off time is

activated.

System selection is set to Off or

• Wait up to five minutes for the system to respond.

• Use PDA or L

ONSPEC™ to configure heating response.

Set system selection to Heat or Auto.

Cool.

63-4368 18

Page 19

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Table 11. Troubleshooting Information. (Continued)

Symptom Possible Cause Action

Cooling will not

come on.

No power to the thermostat. Check that X terminal is connected to the system transformer.

Check for 24 Vac between X and RH terminals.

If missing 24 Vac:

• Check if circuit breaker is tripped; if so, reset circuit breaker.

• Check if system fuse is blown; if so, replace fuse.

• Check if the HVAC equipment power switch is in the Off position; if

so, set to the On position.

• Check wiring between thermostat and HVAC equipment. Replace

broken wires and tighten loose connections.

If 24 Vac is present, proceed with troubleshooting.

Thermostat minimum off time is

activated.

System selection is set to Off or

• Wait up to five minutes for the system to respond.

• Use PDA or L

ONSPEC™ to configure cooling response.

Set system selection to Cool or Auto.

Heat.

System indicator

(flame: heat,

snowflake: cool) is

displayed, but no

warm or cool air is

coming from the

registers.

The call for heat or cool is not yet

given.

Conventional heating equipment

turns the fan on only after the

Check if any stage indicators (dots next to the system indicator) are

displayed. With no display of stage indicators, no call for cool/heat is

yet given.

For the modulating T7350H1017 only: Check the information

screens. MODHEAT or MODCOOL percentages of zero and 100

indicate an extreme signal from the given terminal.

Wait one minute after seeing the on indicator and then check the

registers.

furnace has warmed to a setpoint.

Heating or cooling equipment is not

Verify operation of heating or cooling equipment in self-test.

operating.

19 63-4368

Page 20

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

APPENDIX A - NETWORK TOOLS & WORKSTATIONS

Table 12. T7350H Operational Support.

Network Tools & Workstations

T7350H Operational Support

Device Configuration X X X

View & Modify Weekly Schedule X X X X X

View & Modify Holiday Schedule X X X X X

Data Monitoring XXXXXX

Command Outputs to Manual Value X X X X

Override System Delays X X X X

Room Temperature Calibration X X X

Command Occupancy Override XXXXXX

Command Fan Operation (On Auto) X X X X

Command System Mode (off, auto, heat, cool) X X X X

View & Modify Temperature Setpoints XXXXXX

Report T7350 alarm data XXXX

Network Time Scheduler for T7350 Devices X

Generate Trend & Log files with T7350 data X

User defined T7350 analog & digital alarms X

Update T7350 Time Clock XXXXXX

Set T7350 as network Time Master X

View T7350 Cover Firmware Version X X X

Update T7350 Cover Firmware X

View T7350H SubBase Firmware Version X X X

Update T7350H SubBase Firmware X

Summary of

LONSPEC™

LONSTATION™

XL15B

W7760B -

Cmd Display -

CARE

S7760

LNS Plugin

DataMon

63-4368 20

Page 21

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

APPENDIX B - NETWORK ALARM REPORTING

Table 13. T7350H Alarm Change of State Event.

A T7350H alarm change of state event is reported by the manufacturer defined output network variable nvoAlarmH.

nvoAlarmH Field Description

subnet

The L

ONWORKS

bound, it reports domain index 0.

0: Invalid subnet (power up value)

1-255: Subnet number

node

The L

ONWORKS

bound, it reports domain index 0.

0: Invalid entry (power up value)

1-127: Node number

type The alarm type being issued.

0: AT_NO_ALARM (power up value)

1: AT_INVALID_SUBBASE_TYPE

2: AT_NETWORK_COMM_FAIL

3: AT_SENSOR_FAIL

4: AT_INVALID_IO_CONFIG

5: AT_COVER_COMM_FAIL

6: AT_COVER_SUBBASE_MISMATCH

Return to Normal Codes

-127: AT_rtnINVALID_SUBBASE_TYPE

-126: AT_rtnNETWORK_COMM_FAIL

-125: AT_rtnSENSOR_FAIL

-124: AT_rtnINVALID_IO_CONFIG

-123: AT_rtnCOVER_COMM_FAIL

-122: AT_rtnCOVER_SUBBASE_MISMATCH

-1: AT_ALARM_NOTIFY_DISABLED

®

subnet number in the domain entry to which nvoAlarmH is bound. If nvoAlarmH is not

®

node number in the domain entry to which nvoAlarmH is bound. If nvoAlarmH is not

Table 14. T7350 Current Alarm Status.

The T7350 current alarm status is reported by the manufacturer defined output network variable nvoAlarmStatus.

nvoAlarmStatus

Field

Description

coverCommFail Communications between the cover and sub-base.

0: No alarm (power up value).

1: The communications between the thermostat cover assembly and the sub-base has failed in one or

both directions. The data from the cover to the sub-base has not been received for at least 90

seconds, or data from the sub-base is not updating the cover assembly.

invalidIOConfig Output configuration error.

0: No alarm (power up value).

1: The number of outputs configured exceeds the capability of the sub-base to support them.

Considers sub-base type, heat pump/conventional application, maxCoolStgs, maxHeatStgs.

sensorFail Sensor failure.

0: No alarm (power up value).

1: One of the analog sensors on the cover assembly has failed or is out of range (high or low).

networkCommFail Network Communications Failure.

0: No alarm (power up value).

1: One of the bound network input network variables is not being updated periodically. This alarm may

be caused by a failed node or a damaged L

ONWORKS NETWORK cable.

invidSubBaseTyp Sub-base type error.

0: No alarm (power up value).

1: The detected sub-base type is not supported by the firmware version of the cover assembly.

21 63-4368

Page 22

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Table 15. Identifying Five Most Recent T7350 Alarms.

The five most recent T7350 alarms are identified in the manufacturer defined output network variable nvoAlarmLog.

nvoAlarmLog Field Description

alarm1 Alarm log: Most recent alarm.

Alarm Codes

0: AT_NO_ALARM (power up value)

1: AT_INVALID_SUBBASE_TYPE

2: AT_NETWORK_COMM_FAIL

3: AT_SENSOR_FAIL

4: AT_INVALID_IO_CONFIG

5: AT_COVER_COMM_FAIL

6: AT_COVER_SUBBASE_MISMATCH

Return to Normal Codes

-127: AT_rtnINVALID_SUBBASE_TYPE

-126: AT_rtnNETWORK_COMM_FAIL

-125: AT_rtnSENSOR_FAIL

-124: AT_rtnINVALID_IO_CONFIG

-123: AT_rtnCOVER_COMM_FAIL

-122: AT_rtnCOVER_SUBBASE_MISMATCH

-1: AT_ALARM_NOTIFY_DISABLED

alarm2

Alarm log: 2

nd

most recent alarm.

0: No alarm (power up value).

alarm3

Alarm log: 3

rd

most recent alarm.

0: No alarm (power up value).

alarm4

Alarm log: 4

th

most recent alarm.

0: No alarm (power up value).

alarm5 Alarm log: Oldest alarm.

0: No alarm (power up value).

63-4368 22

Page 23

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

APPENDIX C - NETWORK ERROR REPORTING

Table 16. Reporting T7350H Errors.

T7350H errors are reported through the manufacturer defined output network variable, nvoError.

nvoError Field Description

errLoclSpaceSensr Local space temperature sensor not working.

0: Sensor value is OK. (power up value)

1: Sensor is configured to function and is out of range or disconnected.

errRemtSpaceSensr Remote space temperature sensor not working.

0: Sensor value is OK. (power up value)

1: Sensor is configured to function and is out of range or disconnected.

errNetSpaceSensr Network space temperature sensor not working.

0: Sensor value is OK. (power up value)

1: Sensor is configured by the thermostat to function but is not being updated by either the bound

network sensor or by the subbase (faulty subbase).

errLoclHumSensr Local Humidity sensor not working.

0: Sensor value is OK. (power up value)

1: Sensor is configured to function and is out of range or disconnected.

errRemtHumSensr Remote Humidity sensor not working.

0: Sensor value is OK. (power up value)

1: Sensor is configured to function and is out of range or disconnected.

errNetHumSensr Network Humidity sensor not working.

errRemtOdSensr Remote Outdoor air sensor not working.

errNetOdSensr Network Outdoor air sensor not working.

errRemtSetPt Remote wall module set point is out of range or disconnected.

errDischSensr Discharge sensor out of range or disconnected.

errIOConfig Output configuration error. Considers sub-base type, heat pump / conventional application.

errSubBaseType Sub-base type error.

errUnused1 Not currently used

errSelfTest Self test failure. Upon factory test power up, a self test of memory is performed. If external RAM,

errCoverCommFail Communications between the cover and sub-base

0: Sensor value is OK. (power up value)

1: Sensor is configured by the thermostat to function but is not being updated by either the bound

network sensor or by the subbase (faulty subbase).

0: Sensor value is OK. (power up value)

1: Sensor is configured to function and is out of range or disconnected.

0: Sensor value is OK. (power up value)

1: Sensor is configured by the thermostat to function but is not being updated by either the bound

network sensor or by the subbase (faulty subbase).

0: Value is OK. (power up value)

1: Remote wall module set point is configured to function and is out of range or disconnected.

0: Sensor value is OK. (power up value)

1: Sensor is configured to function and is out of range or disconnected.

maxCoolStgs, maxHeatStgs.

0: The outputs configuration is consistent with the sub-base type selected (power up value)

1: The number of outputs configured exceeds the capability of the sub-base to support them.

0: The sub-base is a valid sub-base type (power up value)

1: The detected sub-base type is not supported by the firmware version of the cover assembly.

EEPROM, or application FLASH memory fails the test, nvoError.errSelfTest is set. This bit is intended

for use in production testing. Field devices should ignore this bit.

0: Passed the test

1: Failed the test

0: No error (power up value)

1: The communications between the thermostat cover assembly and the sub-base has failed in

one or both directions. The data from the cover to the sub-base has not been received for at least

90 seconds, or data from the sub-base is not updating the cover assembly.

23 63-4368

Page 24

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

Table 16.

Reporting T7350H Errors. (Continued)

T7350H errors are reported through the manufacturer defined output network variable, nvoError.

nvoError Field Description

errSubBaseVerMisMatch Sub-base/cover firmware mismatch.

0: Sub-base and cover firmware are compatible. (power up value)

1: The firmware version in the sub-base is unable to communicate correctly with the firmware

version of the cover assembly. The cover assembly Public Interface number of the sub-base is not

compatible with the Public Interface number of the sub-base. That is nroT7350Ver.commVer does

not match the version supported by the sub-base. Communications with the sub-base is turned

off.

errNviSpaceTemp nviSpaceTemp network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

errNviOccSchedule nviOccSchedule network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure).

errNviOccSensor nviOccSensor network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

errNviApplicMode nviApplicMode network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

errNviOutdoorTemp nviOutdoorTemp network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

errNviSpaceRH nviSpaceRH network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

errNviBypass nviBypass network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

errNviDlcShed nviDlcShed (Demand Limit Control Shed signal) network variable is:

0: either not bound or is bound and being updated periodically (power up value)

1: bound and not being updated periodically (communications or source node failure)

63-4368 24

Page 25

T7350 COMMERCIAL PROGRAMMABLE THERMOSTAT

APPENDIX D - NETWORK ACCESS TO LOCAL SENSOR DATA

Table 17. T7350H Reports Local Sensor Data.

The T7350H reports local sensor data using the following output network variables.

Nv Name

nvoDischAirTemp Discharge Temperature

nvoOccSensor Occupancy Sensor Out Status of occupancy sensor

nvoOutdoorTemp Outdoor Temperature Out The current outdoor temperature. The sensor value source is specified by

nvoSpaceRH Space Humidity Out The current space humidity. The sensor value source is specified by

nvoSpaceTemp Space Temperature Out The current space temperature. The sensor value source is specified by

LonSpec Reference

Name Description

Out

The current discharge air temperature. The sensor value source is configured

by nciConfig.dischAirSensor. A value of 327.67 means the sensor is not

functioning correctly or is out of range.

327.67: Power up value

0: OC_OCCUPIED

1: OC_UNOCCUPIED

-1: OC_NUL (not configured and power up value)

nciConfig.oDAirSensor. A value of 327.67 means the sensor is not functioning

correctly or is out of range.

327.67: Power up value

nciConfig.humiditySensor. A value of 163.84 means the sensor is not