Page 1

T7300F/Q7300H Series 2000 Commercial

Thermostats and Communicating

Subbases

Contents

INTRODUCTION

CONSTRUCTION

APPLICATION STEPS

........................................................................................................................... 3

Description of Devices ....................................................................................... 3

Control Application............................................................................................. 3

Control Provided................................................................................................. 4

Product Names .................................................................................................. 4

Products Covered............................................................................................... 5

Organization of Manual...................................................................................... 5

Applicable Literature .......................................................................................... 6

Agency Listings.................................................................................................. 6

Abbreviations and Definitions............................................................................. 6

........................................................................................................................... 7

Performance Specifications ............................................................................... 8

Input/Output Summary .................................................................................. 8

Communications............................................................................................ 9

LonMark® Functional Profile.............................................................................. 10

Configurations.................................................................................................... 10

General.......................................................................................................... 10

........................................................................................................................... 11

Overview ............................................................................................................ 11

Step 1. Plan The System.................................................................................... 11

Step 2. Determine Required Network Devices................................................... 12

Step 3. Lay Out Communications and Power Wiring......................................... 12

LonWorks Bus Layout ................................................................................ 12

Cable Termination......................................................................................... 14

Singly Terminated Network Segment ....................................................... 14

Doubly Terminated Daisy-chain Network Segment.................................. 15

Wiring Details................................................................................................ 15

Step 4. Prepare Wiring Diagrams ...................................................................... 15

General Considerations................................................................................. 18

Step 5. Order Equipment.................................................................................... 19

Step 6. Configure T7300F/Q7300H.................................................................... 20

Step 7. Troubleshooting..................................................................................... 20

APPENDIX A

USER ADDRESS

NETWORK VARIABLES

........................................................................................................................... 20

Sequence of Operations.................................................................................... 20

See form number 63-4366, Q7300 Communicating Subbase System Integration

User Address Manual.

LonWorks®, LonTalk®, LonMark® and Excel LonSpec™ are

U.S. registered trademarks of Echelon® Corporation.

®U.S. Registered Trademark

Copyright © 1998 Honeywell Inc. • All Rights Reserved

63-4365

Page 2

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

LIST OF FIGURES

LIST OF TABLES

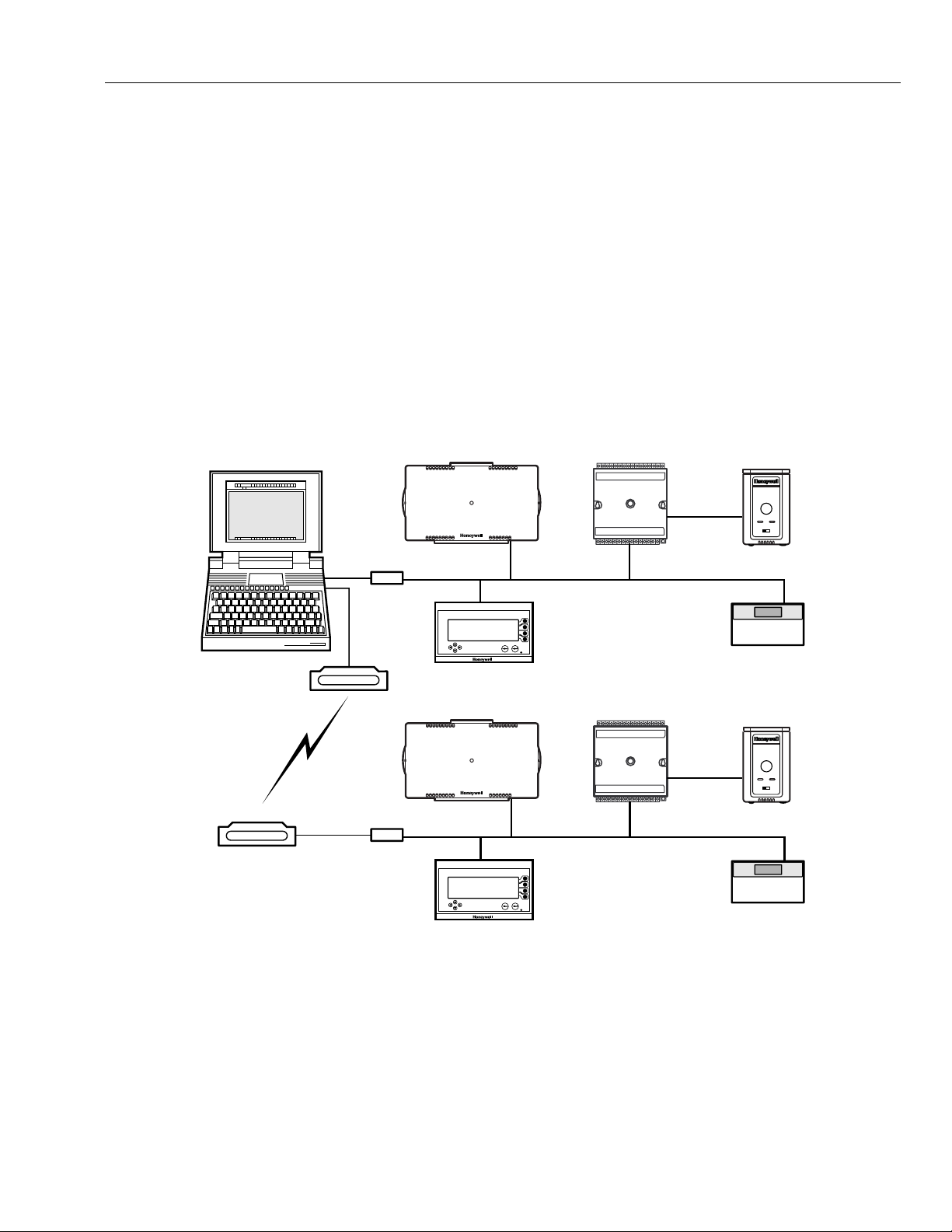

Fig. 1. Typical T7300F/Q7300H LonWorks® network diagram.......................... 3

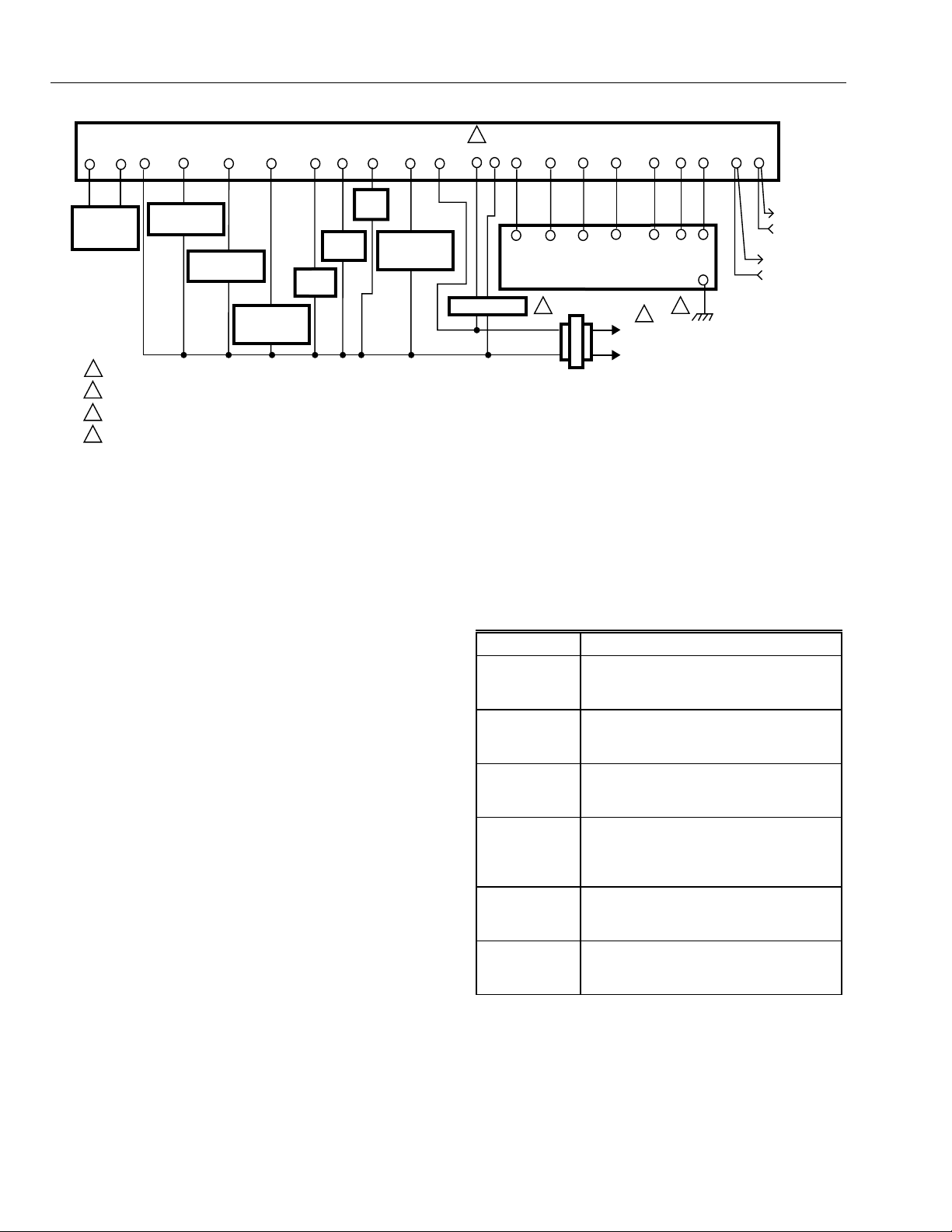

Fig. 2. Typical T7300F/Q7300H application....................................................... 4

Fig. 3. T7300F/Q7300H dimensions in in. (mm)................................................ 8

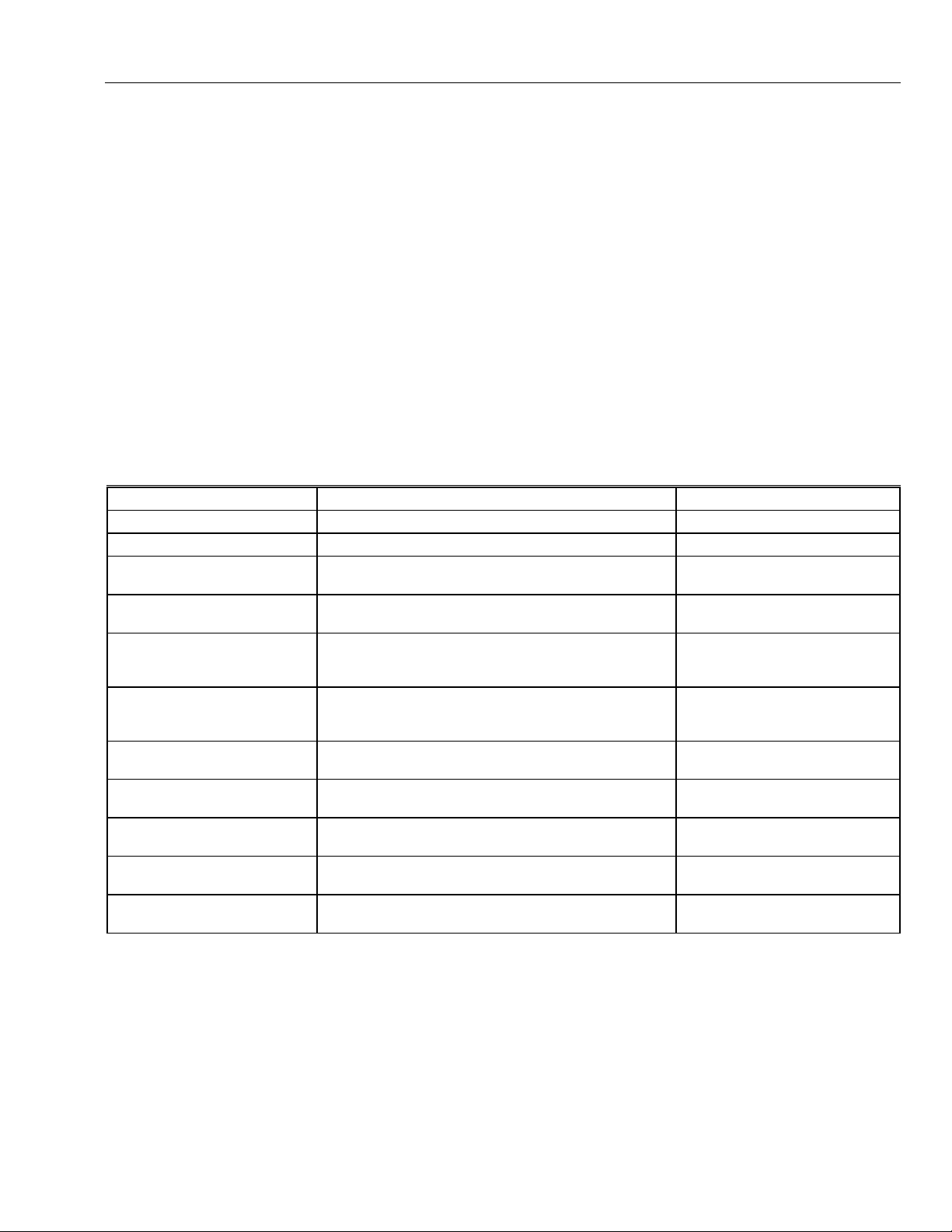

Fig. 4. Functional Profile Number 8060LonMark® Thermostat Object

(Type 09) (Thermostat profile variables not used are grayed). ..................... 10

Fig. 5. Connecting personal computer to LonWorks® Bus................................ 11

Fig. 6. Typical topology for T7300F/Q7300H devices in

LonWorks® network..................................................................................... 13

Fig. 7. Wiring layout for two doubly terminated LonWorks® Bus segments...... 13

Fig. 8. Wiring layout for one doubly terminated daisy-chain

LonWorks® Bus segment. ............................................................................ 14

Fig. 9. Singly terminated LonWorks Bus termination module. ........................ 14

Fig. 10. Doubly terminated LonWorks® Bus termination modules. ................... 15

Fig. 11. Proper wiring technique. ....................................................................... 15

Fig. 12. Ferrite core wires from Q7300H to digital inputs and outputs............... 15

Fig. 13. Typical hookup of T7300F/Q7300H in three-stage heat,

two-stage cool heat pump system................................................................. 16

Fig. 14. Typical hookup of T7300F/Q7300H in three-stage heat,

two-stage cool heat pump system................................................................. 16

Fig. 15. Typical hookup of T7300F/Q7300H in three-stage heat,

three-stage cool conventional system........................................................... 17

Fig. 16. Typical hookup of T7300F/Q7300H in two-stage heat,

one-stage cool conventional system............................................................. 17

Table 1. Additional Products.............................................................................. 5

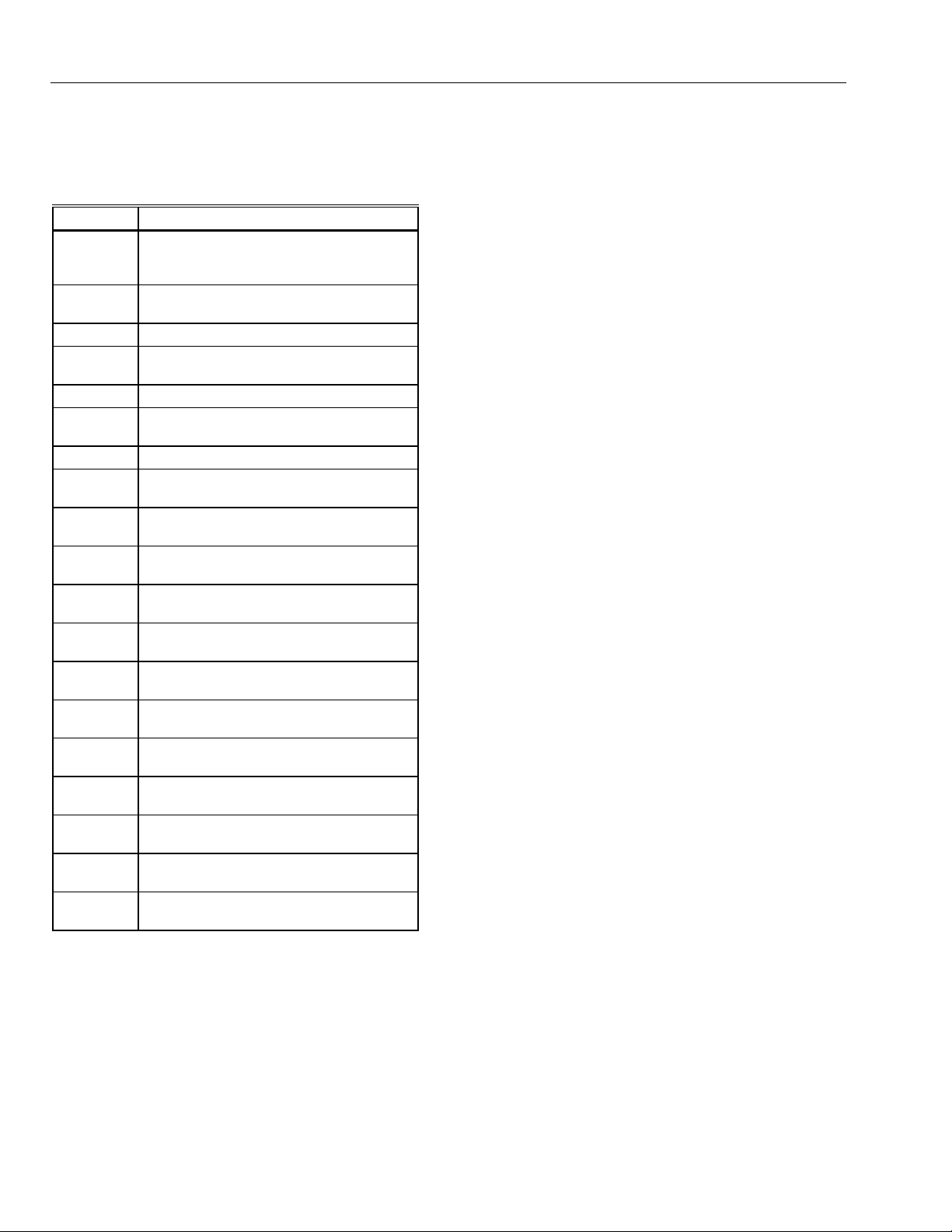

Table 2. Terminal descriptions and conditions................................................... 9

Table 3. Application Steps. ................................................................................ 11

Table 4. LonWorks® Configuration Rules and Device Node Numbers.............. 12

Table 5. Field Wiring Reference Table ............................................................... 18

Table 6. Ordering Information............................................................................ 19

63-4365 2

Page 3

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

INTRODUCTION

Description of Devices

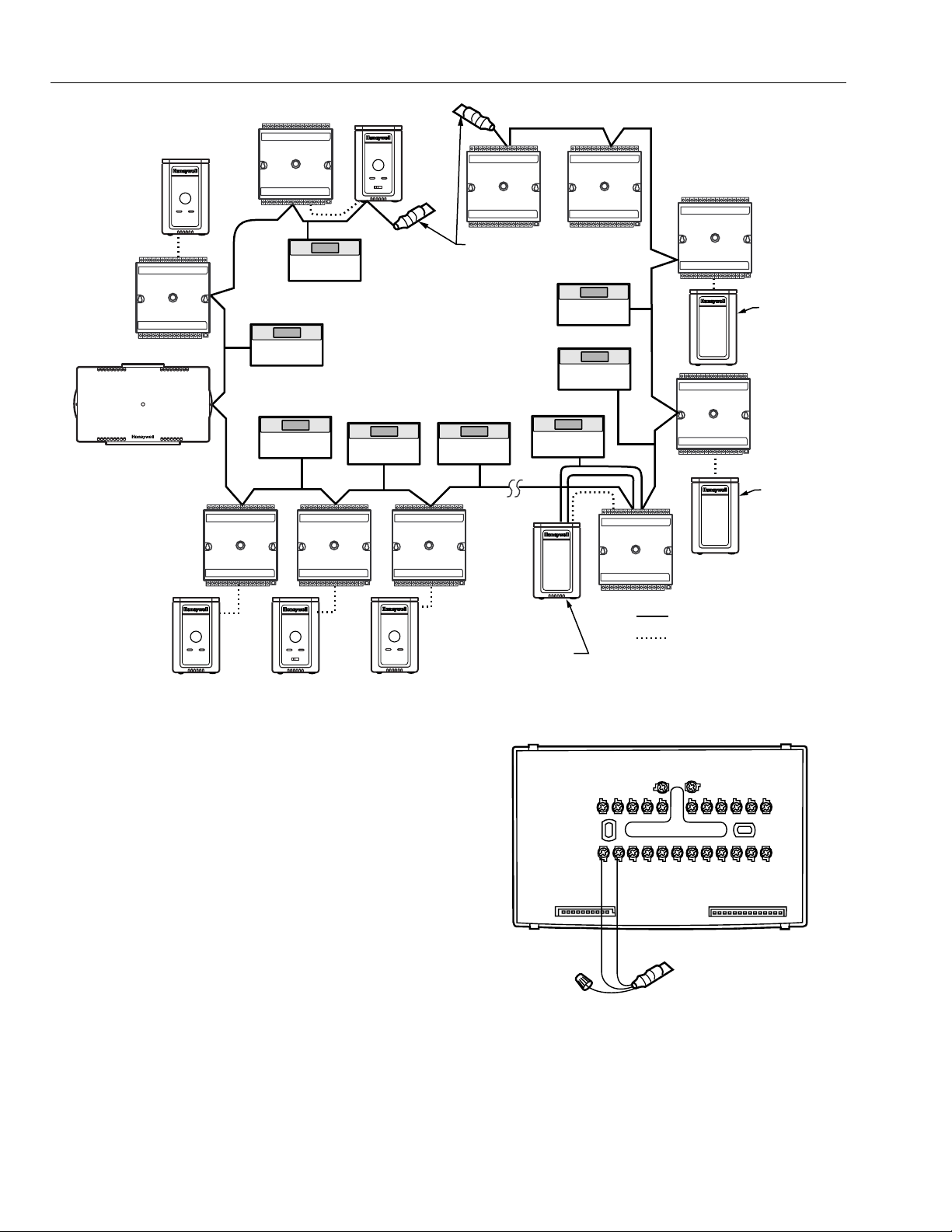

The Q7300H Subbase is a LonMark® certified device that

provides networking capability for the T7300F Thermostat

in a LonWorks® system using a transformer-coupled Free

Topology Transceiver (FTT). See Fig. 1.

The T7300F/Q7300H communicates with all LonMark®

devices including the following:

Other T7300F/Q7300H Commercial

Thermostat/Communicating Subbases.

— Excel 15 S7760A Command Display.

— Excel 10 W7750A,B Constant Volume Air Handler

Unit (CVAHU) Controller.

— Excel 15 W7760A Building Manager.

— Excel 10 W7761A Remote Input/Output (RIO)

Controller.

BUILDING MANAGER

NOTEBOOK PC

RS-232

SERIAL

PORT

SLTA

1 4 8 12 16

EXCEL 15

W7760

17 23

Control Application

The T7300F/Q7300H Series 2000 Commercial

Thermostats and Communicating Subbases control 24

Vac commercial single zone heating, ventilating and air

conditioning (HVAC) equipment. In addition, the Q7300H

can communicate schedule information and system

instructions to other devices in a LonWorks® network.

Fig. 2 shows a typical T7300F/Q7300H application in a

three-stage heat and two-stage cool heat pump system.

For additional T7300F/Q7300H hookups, see Fig. 13, 15,

16.

WALL MODULE

EXCEL 10

CVAHU

30 31

44

37

S7760

LonWorks® BUS

T7300

MODEM

Select

Back

MODEM

BUILDING MANAGER

1 4 8 12 16

RS-232

SERIAL

PORT

SLTA

EXCEL 15

W7760

17 23

30 31

44

37

S7760

Select

Back

EXCEL 10

CVAHU

LonWorks® BUS

Fig. 1. Typical T7300F/Q7300H LonWorks® network diagram.

WALL MODULE

T7300

M16083B

3 63-4365

Page 4

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

g

g

g

g

SUBBASE

3

Y2

AS AS

DISCHARGE

AIR

SENSOR

1

2

3

4

X

COMPRESSOR

CONTACTOR 2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION INSTRUCTIONS.

USE A1 AND A2 WHEN CONTACTS ARE NORMALLY CLOSED IN OCCUPIED MODE.

CONNECT GND TO EARTH GROUND.

Y1 O G

COMPRESSOR

CONTACTOR 1

COOL

CHANGEOVER

VALVE

E

EM. HT.

RELAY

FAN

RELAY

W1

AUX.

HEAT

HEAT

CHANGEOVER

VALVE

R

B

ECONOMIZER

Fig. 2. Typical T7300F/Q7300H application.

A2A1

C4 C3C5

CA4 CA3CA5

T7147 REMOTE COMFORT ADJUST MODULE

2

TRANSFORMER

C2

CA2

L1

(HOT)

L2

C1 T

CA1

1

T

GND

4

TEBEB

T

M16056

LonWorks®

BUS

LonWorks®

BUS

Communicating subbases for T7300F Thermostats add

value by allowing remote-site access—via telephone

lines—for diagnostics, maintenance and monitoring. In

addition, the T7300F can act as the user interface for onsite Excel 10 Controllers (after initial installation with Excel

LonSpec™) without the need for a personal computer

workstation. Through the T7300F/Q7300H

Thermostat/Communicating Subbase, a building operator

can control Excel 10 devices by setting occupancy

schedules, setpoints and additional features.

Control Provided

The Q7300H communicates with other network devices, or

nodes, for the purpose of sharing data. Through the

network, the T7300F/Q7300H sets and deletes schedules.

Schedules can be bypassed by selecting Continuous

Unoccupied or Temporary Override. By using network

messaging, the Q7300H sets fan operation (ON, AUTO)

and system mode (HEAT, COOL, AUTO, OFF, EM HEAT)

designated by a remote T7300F. Schedules can be

programmed for seven days with four designated periods

per day; Occupied 1, Occupied 2, Unoccupied 1 and

Unoccupied 2. In external schedule mode, the T7300F

changes occupancy through a network-based scheduler.

In local schedule mode, the T7300F changes occupancy

through an internal scheduler. If the external schedule is

not periodically updated, the T7300F defaults to the local

schedule.

The T7300F/Q7300H is also able to provide time of day,

temporary setpoint, bypass status and additional

information to multiple Excel 10 devices by sending

instructions from one T7300F/Q7300H to the Excel 10

devices. When the T7300F is configured to schedule

temporary setpoint and effective bypass information for

other devices, certain restrictions apply such as:

— When the T7300F is scheduling temporary setpoints

for Excel 10 devices, the Excel 10 cannot adjust

setpoints using the T7770 wall module.

— When the T7300F is providing effective bypass

information to Excel 10 devices, the Excel 10 cannot

change the bypass status using the T7770 wall

module.

63-4365 4

Product Names

When combined with the T7300F Series 2000 Commercial

Thermostat, the Q7300H Communicating Subbase

communicates with other devices in a LonWorks®

network. The thermostat and subbase are available in the

following models:

Part Number Product Description

Q7300H2003 Communicating subbase with O and B

terminals for three-sta

cool heat pump system.

Q7300H2011 Communicating subbase without O and

B terminals for three-sta

stage cool heat pump system.

Q7300H2029 Communicating subbase for three-stage

heat, three-sta

e cool conventional

system.

Q7300H2037 Communicating subbase for two-stage

heat, one-sta

e cool conventional

system with valve two-position heat

output.

T7300F2002 Series 2000 Commercial Electronic

Thermostat without system and fan

switching.

T7300F2010 Series 2000 Commercial Electronic

Thermostat with system and fan

switching.

e heat, two-stage

e heat, two-

Page 5

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Products Covered

This System Engineering manual describes how to apply

the T7300F Thermostat and Q7300H Communicating

Subbase and related accessories to typical applications.

Devices include:

T7300F Series 2000 Commercial Thermostat.

Q7300H Series 2000 Communicating Subbase.

Excel 15 W7760A Building Manager.

Excel 10 Controllers, as follows:

W7750A,B Constant Volume Air Handler Unit (CVAHU)

Controller.

W7761 Remote Input/Output (RIO) Controller.

Other products:

Q7751A,B Bus Router.

Q7760A Serial LonTalk Adapter.

Q7740A,B FTT Repeaters.

209541B FTT Termination Module.

See Table 1 for additional products.

Table 1. Additional Products.

Part Number Product Description Comments

R8242A Contactor, 24 Vac coil, DPDT. —

AT72D, AT88A, etc. Transformers. —

4074EYD Wallplate for T7770 Wall Modules. For covering an existing hole in a

— Serial Interface Cable, male DB-9 to female DB-9 or

Honeywell (US only)

AK3791 (one twisted pair)

AK3792 (two twisted pairs).

Honeywell (US only)

AK3781 (one twisted pair)

AK3782 (two twisted pairs).

Honeywell AK3725 (US only),

typical or equivalent.

Honeywell AK3752 (US only),

typical or equivalent.

Honeywell AK3702 (US only),

typical or equivalent.

Honeywell AK3712 (US only),

typical or equivalent.

Honeywell AK3754 (US only),

typical or equivalent.

female DB-25.

LonWorks® Bus (plenum): 22 AWG (0.325 sq mm)

twisted pair solid conductor, nonshielded or Echelon

approved shielded cable.

LonWorks® Bus (nonplenum): 22 AWG (0.325 sq mm)

twisted pair solid conductor, nonshielded or Echelon

approved shielded cable.

Inputs: 18 AWG (1.0 sq mm) five wire cable bundle. Standard thermostat wire.

Outputs/Power: 14 to 18 AWG (2.0 to 1.0 sq mm). NEC Class 2, 140°F (60°C) rating.

18 AWG (1.0 sq mm) twisted pair. Non-plenum.

16 AWG (1.3 sq mm) twisted pair. Non-plenum.

14 AWG (2.0 sq mm) two conductor. Non-plenum.

Organization of Manual

This manual is divided into four basic sections:

Introduction

1.

T7300F/Q7300H, discusses related devices, lists

additional literature, and provides a glossary of

abbreviation and terms.

Construction

2.

network connections and dimensions.

Application Steps

3.

provides the information necessary to plan and lay

out the T7300F/Q7300H application and accurately

order materials.

Appendix

4.

operations for configuring network controllers.

The organization of the manual assumes a project is being

engineered from start to finish. If you are changing an

existing system, refer to the Table of Contents for relevant

sections.

. Provides an overview of the

. Describes T7300F/Q7300H features,

. A step-by-step procedure that

. Appendix A provides a sequence of

wall.

Obtain locally from any computer

hardware vendor.

Level IV, 140°F (60°C) rating.

Level IV, 140°F (60°C) rating.

5 63-4365

Page 6

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Applicable Literature

The following list of documents contains general

information related to the T7300F/Q7300H Series 2000

Commercial Thermostats and Communicating Subbases.

Form No. Title

62-0125 T7300F Series 2000 Commercial

Microelectronic Conventional or Heat

Pump Thermostat Installation Instructions

62-0155 Q7300H Series 2000 Commercial

Thermostat Installation Instructions

74-2976 Excel LonSpec™ Specification Data

74-2977 Excel LonSpec™ Software Release

Bulletin

74-2937 Excel LonSpec™ User’s Guide

74-2982 Light Commercial Building Solutions

System Specification Data

74-2865 E-Bus Wiring Guidelines User’s Guide

74-2967 Excel 15 W7760A Building Manager

Specification Data

95-7565 Excel 15 W7760A Building Manager

Installation Instructions

74-2969 Excel 15 W7760A Building Manager

System Engineering

74-2956 Excel 10 W7750A,B CVAHU Controller

Specification Data

95-7521 Excel 10 W7750A,B CVAHU Controller

Installation Instructions

74-2958 Excel 10 W7750A,B CVAHU Controller

System Engineering

74-2698 Excel 10 W7761A RIO Controller

Specification Data

95-7539 Excel 10 W7761A RIO Controller

Installation Instructions

74-2699 Excel 10 W7761A RIO Controller System

Engineering

74-2697 T7770A, B, C, D, E, F, G Wall Module

Specification Data

95-7538 T7770A, B, C, D, E, F, G Wall Module

Installation Instructions

95-7554 209541B Termination Module Installation

Instructions

ABBREVIATIONS AND DEFINITIONS

Application

Binding

variables in one node to network variable(s) in other

node(s). Binding is performed by a network management

node that writes the binding information into the EEPROM

memory of all the neuron's involved. The binding

information is saved in the network image of each neuron.

Building Manager

be used to monitor and control HVAC equipment and other

miscellaneous loads in a distributed network.

Command Display

and change parameters.

Control Loop

function in a node that includes processes, loops and

programs. A node can contain one or more control loops.

(In Excel 10 class devices, the control loop occupies the

entire node.)

CVAHU

Controller.

Excel 10s

controllers such as the Excel 10 CVAHU and Excel 10

RIO.

HVAC

I/O

—Input/Output.

LonWorks® Network

communicating with each other using the LonTalk®

protocol.

Mandatory Mechanisms/Objects/Network Variables

Mandatory mechanisms and network variables that are

implemented in all the Excel 10 devices.

NamedObject

NamedObjects. These objects are visible on the network

as functional independent entities and are accessed by

name. Typical examples of NamedObjects are Controllers,

ControlLoops and LogicFunction blocks.

Network Management Node

responsible for configuring the network, installing the

nodes, binding the network variables between nodes, and

general network diagnostics.

—A specific Building Control function.

—The process of logically connecting network

—A LonMark® certified device that can

—A device that can be used to monitor

—A primitive control function. A type of

—Excel 10 Constant Volume Air Handler Unit

—A family of application - specific HVAC

—Heating, Ventilating and Air Conditioning.

—A data network based on neurons

—

—Objects that have names are called

—A LonWorks® node that is

Agency Listings

European Community Mark (CE): Conforms to

requirements of European Consortium Standards.

63-4365 6

Page 7

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Network Variables

Neuron C that allows communication over the LonWorks®

network to other nodes on the network. An output network

variable in one node can be bound to corresponding input

network variable(s) in other node(s). Changing the value of

the output network variable in one node causes the new

value to be automatically communicated to the bound input

network variable(s) in other node(s). When an input

network variable is updated, an nv_update_occurs event is

posted at the receiving node(s) so that the application

program can take action based on the change. A network

management node that explicitly reads and/or writes the

network variable can also poll network variables. Network

variables can contain one data field (one or two bytes) or

multiple data fields (a structure).

Node

—A device implementing layers one through six of

the LonTalk® protocol including a Neuron® Chip,

transceiver, memory, and support hardware.

Notebook PC

Optional Mechanism/Object/Network Variables

Optional mechanisms and variables that shall be

implemented on an as-needed basis. However, a different

mechanism or network variable cannot be implemented if

an existing optional mechanism or network variable can

perform the same function.

Programmable Controller

variable number of control loops of different types and is

user-programmed to execute an application. The user can

select the number and type of control loops. The user also

has the capability of generating new types of control loops.

Recovery Mode or Recovery Period

unoccupied periods when the temperature control is

adjusting the control setpoint so that the space

temperature reaches the occupied setpoint when the

schedule change occurs.

—A class of variables defined in

—Portable personal computer.

—

—A controller that has a

—The time in

RIO

—Excel 10 Remote Input/Output device.

RTC

—Real Time Clock.

Schedule

states, setpoints and the time of the changes between

these states.

SGPU

Periodic Update.

SGPUC

Periodic Update with Change Field.

SLTA

coupled LonTalk® messages to the RS-232 Serial Port.

SNVT

SCPT

—The structure that defines the occupancy

—Significant Event Notification and Guaranteed

—Significant Event Notification and Guaranteed

—Serial LonTalk® Adapter. Adapts the transformer

—Standard Network Variable Type.

—Standard Configuration Parameter Type.

CONSTRUCTION

The T7300F Thermostat has a keypad for setting system

parameters, a corresponding LCD display and a flip-down

keypad cover. The T7300F Thermostat mounts on the

Q7300H Subbase.

The Q7300H Communicating Subbase includes

LonWorks® Bus terminals and a jack for temporary

network connections to a personal computer. A service pin

push button provides service messaging to physically

locate the device on the LonWorks® network. The

subbase mounts horizontally on the wall or on a

2 in. x 4 in. junction box.

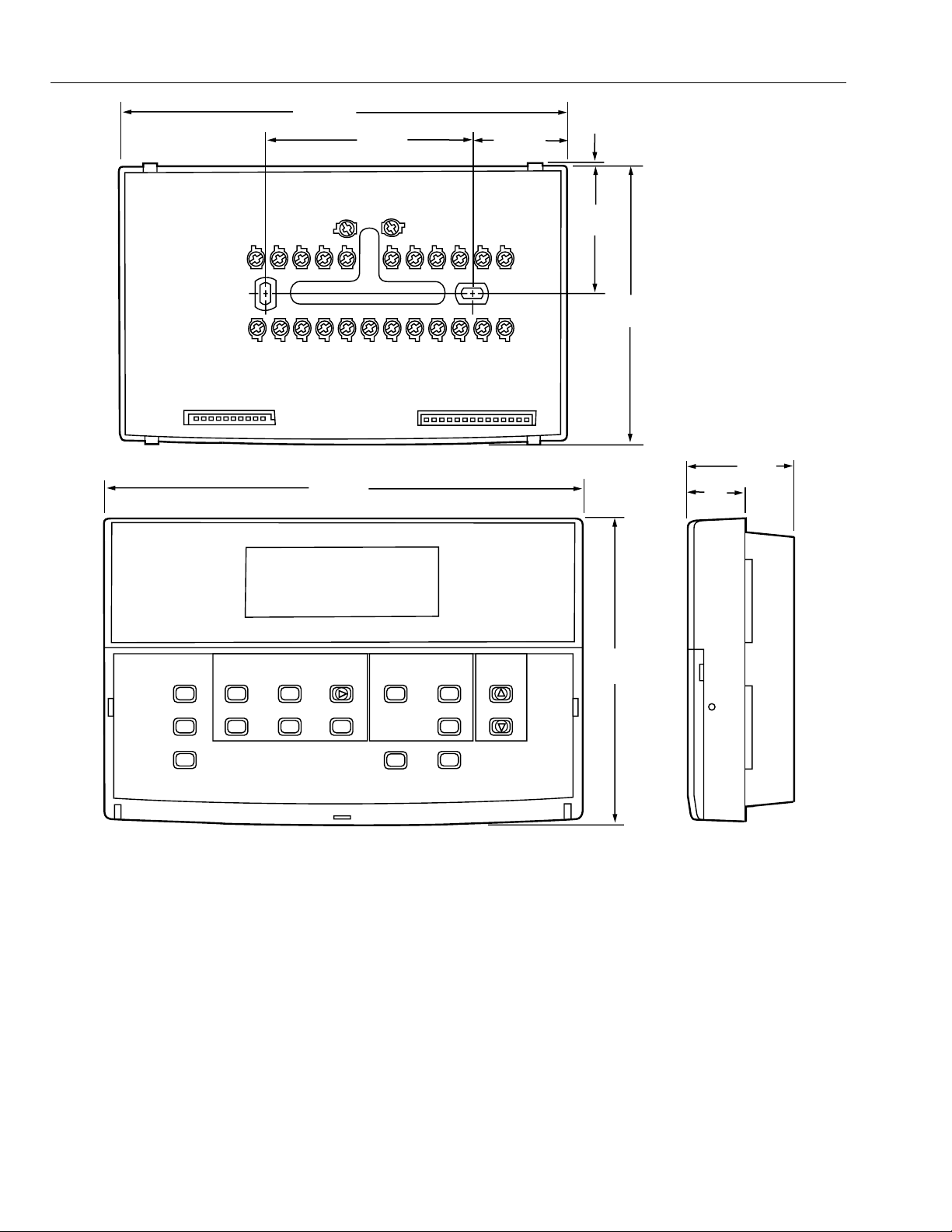

Fig. 3 shows T7300F/Q7300H dimensions.

7 63-4365

Page 8

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

6-11/16 (170)

7-5/16 (186)

3-3/16 (77)

1-3/8 (35)

1/16 (2)

1-7/8

(47)

4-1/8

(105)

7/8

(22)

1-11/16

(43)

Occupied

Start Time

Day/Time

Set Program

Unoccupied

Start Time

Clear

Start Time

Day

Copy

Run

Program

Temporary

Occupied

Continous

Unoccupied

Set Current

Fig. 3. T7300F/Q7300H dimensions in in. (mm).

Performance Specifications

Electrical Ratings:

Power: 20 to 30 Vac, 50/60 Hz.

System Current: 6 VA maximum at 30 Vac, 50 or 60 Hz.

Temperature Ratings:

Setpoint Range: Heating: 40°F to 90°F (4°C to 32°C;

Cooling: 45°F to 90°F (7°C to 32°C).

Operating: 40°F to 110°F (4°C to 43°C).

Shipping: -20°F to +130°F (-29°C to +54°C).

Display Accuracy: ±1°F (+0.5°C).

Set Temperature

Occupied

Temp

System

Unoccupied

Temp

Heat/Cool

Settings

Fan

Change

Time/Temp

4-5/8

(117)

Differential:

2°F (1°C).

Humidity Ratings:

5% to 90% RH, noncondensing.

Input/Output Summary:

Table 2 summarizes the T7300F/Q7300H

Thermostat/Subbase inputs and outputs.

M16086A

63-4365 8

Page 9

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

g

Table 2. Terminal descriptions and conditions.

Standard Terminal

Designations Typical Connection Function Terminal Type

A1, A3 Damper control relay. See T7300F Installation Instructions, form

A2 Dry auxiliary contact. (A2 is common to A1, A3.) Input —

AS,AS C7150B Discharge Air Sensor connection. Input —

B Heating changeover valve. Output 24V powered

BM ML7984 Actuator connection. No call for heat; valve closed

C1, C2, C3, C4, C5 Communication input for T7147. Input/Output Low power

E Emergency heat relay. Output 24V powered

EB, EB LonWorks® Bus connection to LonWorks® network. Input/output Communications

FC Fan control transformer. Input —

G Fan relay. Output —

GH High speed fan output. Activated during call for cooling. Output —

GL Low speed fan output. Activated on call for heat and fan On

O Cooling changeover valve. Output —

P1, P2 Pump interlock relay. Operates circulator pump in hydronic heat

R 24V system transformer. Input —

RC 24V cooling transformer. Input —

RH 24V heating transformer. Input —

RM ML7984 Actuator connection. No call for heat; valve closed. Call

T, T Remote sensor input for T7047 or T7147. Input —

W1 Stage 1 heating relay or auxiliary heat relay. Output —

W2 Stage 2 heating relay Output —

W3 Stage 3 heating relay Output —

X Heating transformer common. Input —

Y Cool call. 24V output on Y —

Y1 Stage 1 compressor contactor. Output —

Y2 Stage 2 cooling compressor (conventional). Stage 2

Y3 Stage 3 cooling compressor. Output —

69-1025-3, installer setup 18, for control parameters.

during occupied periods and open during unoccupied periods.

selection.

or energizes conventional heat system.

for sta

stage 2 heat; valve fully open.

compressor contactor (heat pump).

e 1 heat; valve approximately one-half open. Call for

Output Dry contract

contact

Output —

contact

Output —

Input, output —

Output —

Output —

Communications

The Q7300H provides networking capability in a

LonWorks® system when using a Free Topology

Transceiver (FTT) transformer-coupled communications

port running at 78 kilobits per second (kbs). The

transformer-coupled communications interface offers a

much higher degree of common-mode noise rejection

while ensuring dc isolation.

LonWorks® FTT networks are very flexible and convenient

to install and maintain, but it is imperative that the network

layout be carefully planned and accurate documentation

created and maintained. This aids in compliance

verification and future expansion of the network. It also

minimizes unknown or inaccurate wire run lengths, nodeto-node (device-to-device) distances, node counts, total

wire length, inaccurate repeater/router locations, and

misplaced or missing terminations. LonWorks® networks

can be configured in a variety of ways; refer to the E-Bus

FTT Network Wiring Guidelines, form 74-2865-1, for a

complete description of network topology rules and

maximum wire length. If longer runs are required, add a

Q7740A 2-way or Q7740B 4-way repeater to extend the

LonWorks® Bus length. Add a Q7751A to partition the

system into two segments to double the length of

LonWorks® Bus.

9 63-4365

Page 10

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Approved cable types for LonWorks® Bus

communications wiring are Level IV, 22 AWG (0.34 sq

mm) plenum or non-plenum rated unshielded, twisted pair,

solid conductor wire. For nonplenum areas, use US part

AK3781 (one pair) or US part AK3782 (two pair). In

plenum areas, use US part AK3791 (one pair) or US part

AK3792 (two pair). Other Echelon approved cable may

also be used. Run communications wiring in a conduit, if

needed, with

non-switched

24 Vac or sensor wiring. The

Free Topology Transceiver (FTT) communications

LonWorks® Bus supports a polarity insensitive, free

topology wiring scheme that, in turn, supports star, loop,

and/or bus wiring.

LonMark® Functional Profile

The Q7300H supports the LonMark® Functional Profile

Number 8060,Thermostat Object (Type 09). See Fig. 4.

Hardware

Output

Thermostat Object

Type Number 09.

nv1

nviSetpoint

SNVT_temp_p

Mandatory

Network

Variables

nvoHeatOutput

nv2

SNVT_ lev_percent

nvoCoolOutput

nv3

SNVT_ lev_percent

nvoSpaceTemp

nv4

SNVT_ temp_p

nvoUnitStatus

nv5

SNVT_hvac_status

NOTE: For additional information on the LonMark®

Functional Profile, see the LonMark® Application

Layer Interoperability Guidelines and the

LonMark® Functional Profile: Thermostat. Both

documents are available from LonMark® at

internet address: www.lonmark.org.

CONFIGURATIONS

General

The T7300F/Q7300H can be configured to perform a

variety of activities in which data is sent to and/or received

from other nodes on the LonWorks network.

Information that can be shared with other network devices

includes:

— Day-of-week and time-of-day

— System mode (HEAT, COOL, AUTO, OFF, EM HEAT)

— Current fan setting (ON, AUTO)

— Space temperature

— Current setpoint

— Occupied/Unoccupied schedule commands

— Current occupancy status

— Relay status (heat/cool stages and fan)

— Alarm status

— Alarm log

A network configuration tool is used to configure Q7300Hs

and other nodes with which the Q7300H interacts.

nviSpaceTemp

nv6

SNVT_ temp_p

nviOccCmd

nv7

SNVT_occupancy

nviApplicMode

nv8

SNVT_hvac_mode

nviSetptOffset

nv9

SNVT_ temp_p

nviEnergyHoldOff

nv10

SNVT_switch

Optional

Network

Variables

nvoTerminalLoad

nv11

SNVT_ lev_percent

nvoEffectSetpt

nv12

SNVT_ temp_p

nvoTerminalfan

nv13

SNVT_switch

nvoEnergyHoldOff

nv14

SNVT_switch

Configuration Properties

nc49 - nciSndHrtBt

nc48 - nciRcvHrtBt

nc64 - nciMin Delta

nc17 - neiLocation

nc60 - nciSetPnts

nc79 - nciUpSPHeat

nc80 - nciLrSPHeat

nc76 - nciUpSPCool

nc77 - nciLrSPCool

SNVT_time_sec

SNVT_time_sec

SNVT_temp_p

SNVT_str_asc

SNVT_temp_setpt

SNVT_temp_p

SNVT_temp_p

SNVT_temp_p

SNVT_temp_p

(mandatory)

(optional)

(optional)

(optional)

(mandatory)

(optional)

(optional)

(optional)

(optional)

Manufacturer

Defined

Section

Hardware

Input

M16087A

Fig. 4. Functional Profile Number 8060LonMark®

Thermostat Object (Type 09).

(Thermostat profile variables not used are grayed).

The following is a brief description of the configurable

features that can be commanded over the network:

•

Day-of-Week/Time-of-Day:

When a T7300F Thermostat is designated as the

network time master, the current time of day and day of

week is synchronized across the network every minute.

Whenever the time of day or day of week of the time

master is changed, it automatically adjusts all the other

T7300Fs on the network. When a T7300F is controlled

by a time master, its time cannot be changed using its

keypad. If an attempt is made to change its time, the

LOC

controlled T7300F LED displays

•

System Switch Settings:

.

System switch settings (HEAT, COOL, AUTO, OFF, EM

HEAT) can be designated by a remote T7300F, or if

configured to allow it, from the T7300F keypad.

•

Fan Settings:

Fan settings (ON, AUTO) are selected as designated by

a remote T7300F, or from the T7300F keypad.

•

Space Temperature:

If a valid space temperature value is received at the

Q7300H DestRmTemp network variable input, that

value will be used in the T7300F as the primary

controlled variable. In this case, the internal space

sensor of the T7300F is ignored.

•

Current Setpoint:

If a valid setpoint value is received at Q7300H

DestSetPoint, that value will be used by the Q7300H as

center

the

setpoint. The heat and cool setpoints are

then calculated from this value and are used in the

T7300F as the occupied setpoints. During unoccupied

periods, DestSetPoint is ignored.

63-4365 10

Page 11

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

•

Schedule:

The occupancy schedule used by a T7300F may reside

locally in that device or remotely in another schedule

device (T7300F or Excel 15). Local schedules can be

created and modified using the T7300F keypad, or with

a configuration tool. External schedules can also be

modified using the keypad of the schedule device, or

with a configuration tool. When a T7300F receives

scheduling information over the network, the user is

locked out from making schedule changes at the

LOC

keypad, and the LCD displays

if attempted. When

a T7300F Thermostat is designated as a schedule

device, it sends its schedule file to the appropriate

Q7300H(s) which, in turn, overwrites any existing

internal schedule in their T7300F Thermostat. The

T7300F/Q7300H Thermostat/Subbase can provide

scheduling information to multiple Excel 10 devices by

taking instruction from one T7300F/Q7300H and

sharing the information with the desired Excel 10

devices.

•

Occupancy Bypass:

Any internal schedule in the T7300F is overridden if a

valid occupancy command is received by its Q7300H

(resulting from an existing external schedule on the

LonWorks network).

•

Continuous Unoccupied:

In this mode, the T7300F Thermostat sets the operating

setpoints to the unoccupied setpoints. The T7300F

remains in this mode until the Run Program key is

pressed.

•

Setpoint Changes:

Selecting a temporary setpoint modifies that setpoint for

the present schedule period. Pressing Run Program

terminates temporary setpoints. Temperature setpoint

range is 40°F to 90°F (4°C to 32°C).

•

Temporary Override:

Modifies the schedule to operate the thermostat in

occupied mode for a designated number of hours.

Temporary occupied time can be selected for 1, 3, 8 or

12 hours. If a change from occupied to unoccupied is

scheduled and the Temporary Override key is pressed,

the thermostat remains in occupied mode until the

designated override time expires. If the thermostat is in

the unoccupied mode when the Temporary Occupied

key is pressed, the thermostat operates at the occupied

setpoint until the override time expires.

APPLICATION STEPS

Overview

The application steps shown in Table 3 are guidelines for

configuring the T7300F/Q7300H Thermostat/Subbase in a

LonWorks® Bus network and explain the network role of

the T7300F/Q7300H.

Table 3. Application Steps.

Step Description

1 Plan the system.

2 Determine required network devices.

3 Lay out communications and power wiring.

4 Prepare wiring diagrams.

5 Order equipment.

6 Configure T7300F/Q7300H.

7 Troubleshooting.

Step 1. Plan the System

Plan the use of the T7300F/Q7300H Thermostat/Subbase

according to the job requirements. Determine the location

and functionality. Verify the sales estimate for the number

of other controllers and devices required. Check the

number and type of other required accessories.

When planning the system layout, consider potential

expansion possibilities for future growth. Planning is very

important if HVAC systems and controllers are to be added

in future projects.

NOTEBOOK PC

SHIELDED

INTERFACE

RS-232

SERIAL

PORT

CABLE

Q7760

SLTA

CABLE

PART

NO. 205979

Fig. 5. Connecting personal computer to LonWorks

Bus.

Refer to the E-Bus Wiring Guidelines, form 74-2865 for a

complete description of network topology rules. See

Application Step 3. Lay Out Communications and Power

Wiring, for more information on bus wiring layout and Fig.

6 through 10 in Application Step 4. Prepare Wiring

Diagrams, for wiring details.

Refer to the Excel LonSpec™ User Guide, form 74-2937,

to configure the W7760A Building Manager, W7750A,B

and W7761 Controllers and the Q7300H Subbase.

T7300

LonWorks

BUS PORT

®

M10102B

11 63-4365

Page 12

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Step 2. Determine Required Network

Devices

A maximum of 60 nodes can communicate on a single

LonWorks Bus segment. Each LonWorks Bus device

comprises one node. If more than 60 nodes are needed, a

Q7751A Router or Q7740 Repeater is necessary. In a

network with Excel 15 devices, a router allows up to 120

controller nodes per network, divided between two

LonWorks Bus segments. A router or repeater allows up

to 120 controller nodes per network, divided between two

LonWorks Bus segments. The router comprises two

nodes (one node on each side of the router). Router and

operator access nodes are not counted in the maximum

controller node totals. All devices are able to talk to each

other through the router.

Multiple operator terminals can be connected to the

LonWorks Bus at the same time. Table 4 summarizes

the LonWorks Bus segment configuration rules.

Refer to the E-Bus Wiring Guidelines, form 74-2865, for a

complete description of network topology rules and

maximum wire lengths. If longer runs are required, use a

Q7740A 2-way or Q7740B 4-way repeater to extend the

length of the LonWorks Bus. Each network segment can

only have one repeater. If more nodes or longer distances

are required, add a router or repeater to limit bus traffic or

boost distance.

In addition, a 209541B Termination Module may be

required. Refer to the E-Bus Wiring Guidelines, form 742865, and the Excel 10 FTT Termination Module

Installation Instructions form, 95-7554, or if Excel 15s are

present, see Application Step 3. Lay Out Communications

and Power Wiring in the W7760A System Engineering

Guide, form 74-2969.

Step 3. Lay Out Communications and

Power Wiring

LonWorks® Bus Layout

The communications LonWorks Bus, is a 78-kilobit

network that uses transformer isolation and differential

Manchester encoding.

The Free Topology Transceiver (FTT) LonWorks

communications Bus supports a polarity insensitive, free

topology wiring scheme, refer to the E-Bus Wiring

Guidelines form, 74-2865, for a complete description of

LonWorks network topology rules.

Fig. 6 shows a typical wiring diagram for the

T7300F/Q7300H in a LonWorks® network. Fig. 7 and 8

show wiring layouts for two doubly daisy-chained

LonWorks Bus segments.

Table 4. LonWorks Bus Configuration Rules and Device Node Numbers.

One LonWorks Bus Segment Maximum Number of Controller Nodes 60

Maximum number of Excel 10s 60 nodes (minus number of Excel 15s)

Maximum number of Excel 15s 4 nodes

Total 60 nodes maximum

Two LonWorks Bus Segments;

Controllers, more than 60 devices

One Q7751A,B Router 2 nodes

Maximum number of Excel 15s 8 nodes

Maximum number of Excel 10 RIO devices 24 nodes

Maximum number of Excel 10s (20 per each Excel 15) 112 nodes (minus number of RIOs)

Two LonWorks Bus Segments;

Controllers, more than 60 devices

One Q7751A,B Router 2 nodes

Maximum number of Excel 10s (60 per segment) 120 nodes

with

without

Excel 15

Excel 15

Maximum Number of Controller Nodes 112, plus two

nodes for router access.

Total 122 nodes maximum

Maximum Number of Controller Nodes 120, plus two

nodes for router access.

Total 122 nodes maximum

63-4365 12

Page 13

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

NOTEBOOK PC

MODEM

209541B

TERMINATION

MODULE

T7300

T7300 T7300 T7300

RS-232

SLTA

LonWorks® BUS

T7300

MODEM

MODEM

RS-232

SLTA

LonWorks® BUS

T7300 T7300 T7300 T7300

RS-232

SLTA

LonWorks® BUS

Fig. 6. Typical topology for T7300F/Q7300H devices in LonWorks network.

LonWorks® BUS SEGMENT NUMBER 1

EXCEL 10

EXCEL 10

CVAHU

T7770

CVAHU

T7300

M16063A

EXCEL 10

CVAHU

209541B

TERMINATION

MODULE

®

LonWorks

LonWorks® BUS

SEGMENT NUMBER 2

BUILDING MANAGER

1 4 8 12 16

EXCEL 15

W7760

30 31

17 23

44

37

T7300 T7300

BUS ACCESS

LonWorks® BUS SEGMENT NUMBER 2

EXCEL 10

CVAHU

EXCEL 10

CVAHU

Fig. 7. Wiring layout for two doubly terminated LonWorks Bus segments.

Q7751A

FTT

E-BUS

ROUTER

209541B

TERMINATION

MODULE

209541B

TERMINATION

MODULE

EXCEL 10

CVAHU

M16084C

13 63-4365

Page 14

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

LonWorks® BUS

EXCEL 10

CVAHU

T7770

EXCEL 10

RI0

EXCEL 10

RI0

EXCEL 10

CVAHU

BUILDING MANAGER

1 4 8 12 16

EXCEL 15

W7760

30 31

17 23

37

EXCEL 10

RI0

EXCEL 10

RI0

LonWorks® BUS

I/O CONNECTIONS

T7770

WITH NO

LonWorks®

BUS ACCESS

T7770

WITH NO

LonWorks®

BUS ACCESS

M16085B

T7300

T7300

T7300

EXCEL 10

CVAHU

T7770

209541B TERMINATION

MODULES (AT ENDS OF

LonWorks® BUS

DAISY-CHAIN)

T7300 T7300

EXCEL 10

RI0

T7770

T7770

JACK FOR

OPERATOR

TERMINAL

T7300

T7300

T7300

EXCEL 10

RI0

BUS

®

LonWorks

44

LonWorks®

BUS

EXCEL 10

RI0

T7770

Fig. 8. Wiring layout for one doubly terminated daisy-chain LonWorks segment.

Cable Termination

The FTT network segment requires termination for proper

data transmission performance. Use a 209541B

Termination Module to connect two of the three termination

module wires to the LonWorks Bus terminals.

Singly Terminated Network Segment

In a singly terminated topology segment, only one

termination is required and can be placed anywhere on the

segment. Singly terminated segments use the yellow and

brown wires. Mount the termination modules on the

appropriate terminals as shown in Fig. 9.

C1 C2 C3 C4 C5

BROWN

ORANGE

EB EB

YELLOW

XTTASAS

PART NO. 209541B

TERMINATION MODULE

M16202

Fig. 9. Singly terminated LonWorks Bus termination

module.

63-4365 14

Page 15

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Doubly Terminated Daisy-Chain Network Segment

In a doubly terminated daisy-chained topology segment,

two terminations are required, one at each end of the

topology segment. Doubly terminated segments use the

orange and brown wires. Mount the termination modules

on the appropriate terminals as shown in Fig. 10. For

additional wiring information, refer to the E-Bus Wiring

Guidelines, form 74-2865, and the Excel 10 FTT

Termination Module Installation Instructions, form 95-7554.

2.

Securely tighten each terminal screw.

3.

Push excess wire back into the hole.

4.

Plug the hole with nonflammable insulation to

prevent drafts from affecting the thermostat.

NOTE: After wiring, check that all connections are tight

and secure. See Fig. 11. Loose or intermittent

wire connections can cause inconsistent system

operation.

C1 C2 C3 C4 C5

EB EB

ORANGEBROWN

YELLOW

EB EB

ORANGEBROWN

YELLOW

XTTASAS

PART NO. 209541B

TERMINATION MODULE

C1 C2 C3 C4 C5

XTTASAS

PART NO. 209541B

TERMINATION MODULE

Fig. 10. Doubly terminated LonWorks Bus

termination modules.

M16122

FOR STRAIGHT

FOR WRAPAROUND

INSERTION STRIP

7/16 IN. (11 MM).

INSERTION STRIP

5/16 IN. (8 MM).

M4826

Fig. 11. Proper wiring technique.

Wiring Details

LonWorks® network cable should be wired separately

from the power and I/O wires when installing Q7300s. If

this is not possible, use a minimum of 4 in. (102 mm)

separation between split ferrite cores (Fair-Rite

0443164151, or equivalent Honeywell part no. 229997CB,

containing five split ferrite cores) to ensure compliance

with Class B limits (does not apply to Class A limits). See

Fig. 12. to apply ferrite cores to LonWorks® Bus input and

output.

1.

WIRES TO ALL

INPUTS AND

OUTPUTS

WIRES TO Q7300H

COMMUNICATING SUBBASE

2.

WIRES TO ALL

INPUTS AND

OUTPUTS

CAUTION

Electrical Shock Hazard.

Power supply can cause electrical shock.

Disconnect power supply before beginning

installation.

1.

Loosen the terminal screws on the subbase and

connect the system wires. See Fig. 11.

IMPORTANT

Use 18-gauge, solid-conductor color-coded

thermostat cable for proper wiring. If using 18gauge stranded wire, do not use more than two

wires. Do not use larger than 18-gauge wire.

M10886A

WIRES TO Q7300H

COMMUNICATING SUBBASE

Fig. 12. Ferrite core wires from Q7300H to LonWorks®

inputs and outputs.

Step 4. Prepare Wiring Diagrams

Fig. 13 through 16 show T7300F/Q7300H terminal

arrangements and provide detailed wiring diagrams.

Reference these diagrams to prepare the site-specific job

drawings.

15 63-4365

Page 16

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

SUBBASE

AS AS

DISCHARGE

AIR

SENSOR

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

USE A1 AND A2 WHEN CONTACTS ARE NORMALLY CLOSED IN OCCUPIED MODE.

USE A2 AND A3 WHEN CONTACTS ARE NORMALLY OPEN IN OCCUPIED MODE.

3

CONNECT GND TO EARTH GROUND.

4

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

Y1 G

X R

COMPRESSOR

CONTACTOR 1

Y2

FAN

RELAY

COMPRESSOR

CONTACTOR 2

EM. HT.

RELAY

W3E

HEAT

RELAY 3

W2

HEAT

RELAY 2

W1

HEAT

RELAY 1

ECONOMIZER

2

A2 A3A1

4

C4 C3C5

CA4 CA3CA5

T7147 REMOTE COMFORT ADJUST MODULE

TRANSFORMER

C2

CA2

C1 T

CA1

1

L1

(HOT)

L2

T

T

T

GND

3

Fig. 13. Typical hookup of T7300F/Q7300H in three-stage heat, two-stage cool heat pump system

(without O/B terminals).

SUBBASE

3

AS AS

Y2

X

Y1 O G

E

W1

R

B

A2A1

C4 C3C5

C1 T

C2

EB EB

LonWorks® BUS

LonWorks® BUS

M16057

TEBEB

AUX.

FAN

RELAY

HEAT

HEAT

CHANGEOVER

VALVE

ECONOMIZER

CA1

CA4 CA3CA5

T7147 REMOTE COMFORT ADJUST MODULE

2

TRANSFORMER

CA2

L1

(HOT)

L2

T

GND

4

1

T

M16056

LonWorks®

BUS

LonWorks®

BUS

DISCHARGE

AIR

SENSOR

1

2

3

4

COMPRESSOR

CONTACTOR 2

COMPRESSOR

CONTACTOR 1

COOL

CHANGEOVER

VALVE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION INSTRUCTIONS.

USE A1 AND A2 WHEN CONTACTS ARE NORMALLY CLOSED IN OCCUPIED MODE.

CONNECT GND TO EARTH GROUND.

EM. HT.

RELAY

Fig. 14. Typical hookup of T7300F/Q7300H in three-stage heat, two-stage cool heat pump system (with O/B terminals).

63-4365 16

Page 17

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

SUBBASE

Y1 G X

AS AS

DISCHARGE

AIR

SENSOR

RC RH

2

COMPRESSOR

CONTACTOR 1

FAN

RELAY

L1

(HOT)

L2

1

COOLING

TRANSFORMER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

JUMPER RC TERMINAL TO RH TERMINAL WHEN INSTALLED ON A

SYSTEM WITH ONE TRANSFORMER.

3

USE A1 AND A2 WHEN CONTACTS ARE NORMALLY CLOSED

IN OCCUPIED MODE. USE A2 AND A3 WHEN CONTACTS

ARE NORMALLY OPEN IN OCCUPIED MODE.

Y2

COMPRESSOR

CONTACTOR 2

COMPRESSOR

CONTACTOR 3

HEAT

RELAY 3

W3Y3

W2

HEAT

RELAY 2

W1

HEAT

RELAY 1

3

A2 A3A1

ECONOMIZER

5

4

5

CONNECT GND TO EARTH GROUND.

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

C4 C3C5

CA4 CA3CA5

T7147 REMOTE COMFORT ADJUST MODULE

1

L1

(HOT)

L2

HEATING

TRANSFORMER

C2

CA2

C1 T

CA1

T

4

GND

Fig. 15. Typical hookup of T7300F/Q7300H in three-stage heat, three-stage cool conventional system.

SUBBASE

EB EB

T

LonWorks®

BUS

T

LonWorks®

BUS

M16058

GND

EB EB

T

LonWorks® BUS

T

LonWorks® BUS

2

M16059

GL GH R

AS AS

DISCHARGE

AIR

SENSOR

FC Y

LOW

SPEED

FAN

RELAY

1

L1

(HOT)

L2

FAN TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

CONNECT GND TO EARTH GROUND.

2

SEE TABLE 2 FOR VALVE AND VALVE ACTUATOR MODELS.

3

HIGH

SPEED

FAN

RELAY

X

RM

ML7984

VALVE

ACTUATOR

COOLING

RELAY

3

PUMP

INTERLOCK

RELAY

A2A1P1 P2BM

DAMPER

CONTROL

RELAY

C4 C3C5

CA4 CA3CA5

T7147 REMOTE COMFORT

ADJUST MODULE

TRANSFORMER

C2

L1

(HOT)

L2

C1 T

CA1 TCA2

1

Fig. 16. Typical hookup of T7300F/Q7300H in two-stage heat, one-stage cool conventional system.

17 63-4365

Page 18

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

g g

g

General Considerations

Table 5 lists wiring types, sizes and distances for the T7300F/Q7300H and Excel 10 products. The Q73000H accepts 14

through 22 AWG (2.0 to 0.34 sq. mm wire).

Table 5. Field Wiring Reference Table.

Wire

Function

Thermostat

wire.

Thermostat

wire.

LonWorks

Bus (NonPlenum).

Power

Wiring.

Recommended

Wire Size

(Minimum) Construction

Inputs: 18 AWG

(1.0 sq mm) five

wire cable bundle.

Outputs/Power:

14 to 18 AWG

(2.0 to

1.0 sq mm).

22 AWG

(0.34 sq mm)

14 AWG

(2.0 sq mm)

Standard thermostat

wire.

NEC Class 2, 140°F

(60°C) rating.

Twisted pair solid

conductor,

nonshielded or

Echelon® approved

cable.

Any pair nonshielded

(use heavier wire for

longer runs).

Specification

or Requirement Vendor Wire Type

Level IV, 140°F

(60°C) rating.

Level IV, 140°F

(60°C) rating.

NEC Class II,

140°F (60°C)

rating.

Honeywell AK3725

(US only), typical or

equivalent.

Honeywell AK3752

(US only), typical or

equivalent.

Honeywell AK3781

(one twisted pair),

AK3782 (two twisted

pair).

Honeywell AK3754

(14 AWG) twisted

pair), AK3909

(14 AWG) sin

conductor or

equivalent.

le

Distance

(Maximum)

Refer to E-bus

Wirin

Users Guide

74-2865-1 for

maximum length.

Limited by line-loss

effects on power

consumption.

uidelines

63-4365 18

Page 19

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

g

g

g

g

g

g

g

g

g

g

g

Step 5. Order Equipment

After compiling a bill of materials through completion of the previous application steps, refer to Table 6, Ordering Information.

Table 6. Ordering Information.

Part Number Product Description Comments

Q7300H2003 Communicating subbase with O and B

Q7300H2011 Communicating subbase without O and B

Q7300H2029 Communicating subbase for three-stage

Q7300H2037 Communicating subbase for two-stage heat,

T7300F2002 Series 2000 Commercial Electronic

T7300F2010 Series 2000 Commercial Electronic

W7750A,B Excel 10 Constant Volume Air Handler Unit. Single-speed fan provides continuous supply air

W7761A Excel 10 Remote Input/Output Device. Service messaging feature identifies physical

— Serial Interface Cable, male DB-9 to female

Honeywell (US only)

AK3791 (one twisted pair)

AK3792 (two twisted pairs).

Honeywell (US only)

AK3781 (one twisted pair)

AK3782 (two twisted pairs).

Honeywell AK3725 (US only),

typical or equivalent.

Honeywell AK3752 (US only),

typical or equivalent.

Honeywell AK3702 (US only),

typical or equivalent.

Honeywell AK3712 (US only),

typical or equivalent.

Honeywell AK3754 (US only),

typical or equivalent.

terminals for three-sta

heat pump system.

terminals for three-sta

heat pump system.

heat, three-stage cool conventional system.

one-sta

valve two-position heat output.

Thermostat without system and fan

switching.

Thermostat with system and fan switching.

DB-9 or female DB-25.

LonWorks Bus (plenum): 22 AWG

(0.325 sq mm) twisted pair solid conductor,

nonshielded or Echelon approved shielded

cable.

LonWorks Bus (nonplenum): 22 AWG

(0.325 sq mm) twisted pair solid conductor,

nonshielded or Echelon approved shielded

cable.

Inputs: 18 AWG (1.0 sq mm) five wire cable

bundle.

Outputs/Power: 14 to 18 AWG

(2.0 to 1.0 sq mm).

18 AWG (1.0 sq mm) twisted pair. Non-plenum.

16 AWG (1.3 sq mm) twisted pair. Non-plenum.

14 AWG (2.0 sq mm) two conductor. Non-plenum.

e cool conventional system with

e heat, two-stage cool

e heat, two-stage cool

Includes AS terminals for optional dischar

sensin

economizer.

Includes AS terminals for optional dischar

sensin

economizer.

Includes AS terminals for optional discharge air

sensin

economizer.

Includes AS terminals for optional dischar

sensin

economizer.

Use with Q7300H Communicatin

network communications.

Use with Q7300H Communicating Subbase for

network communications.

to designated area.

location of specific Excel 10s on network.

Obtain locally from any computer hardware

vendor.

Level IV, 140°F (60°C) rating.

Level IV, 140°F (60°C) rating.

Standard thermostat wire.

NEC Class 2, 140°F (60°C) rating.

; A1, A2, A3 terminals for optional

; A1, A2, A3 terminals for optional

; A1, A2, A3 terminals for optional

; A1, A2, A3 terminals for optional

Subbase for

e air

e air

e air

19 63-4365

Page 20

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Step 6. Configure T7300F/Q7300H

Use Excel LonSpec™ Software to configure the

T7300F/Q7300H Thermostat/Subbase for specific

applications. The Excel LonSpec™ User’s Guide, form 742937, provides software operation instructions for the

personal computer.

Step 7. Troubleshooting

1.

Check for 24 Vac power.

a. Turn on power.

b. Use a meter to check for 24 Vac power at the

subbase.

c. If 24 Vac is not present, check the transformer

for secure connections and proper operation.

d. If 24 Vac is present at the subbase, turn off the

power.

2.

Check wiring.

a. Inspect all wiring connections at the Q7300H

terminals and verify compliance with the job

site engineering drawings.

b. If any wiring changes are required,

sure to remove power from the device

starting work.

c. Pay particular attention to:

Terminal connections. Connect GND to

earth ground.

Device Wiring. In hookups with A1 and A2

terminals, use A1 and A2 when contacts

are normally closed in Occupied mode. In

hookups with A2, A3 terminals, use A2

and A3 when contacts are normally open

in Occupied mode.

O/B Terminals. The Q7300H2003

provides O/B terminals for cool/heat

changeover.

NOTE: All wiring must comply with applicable electrical

codes and ordinances or as specified in

installation wiring diagrams.

first

be

before

APPENDIX A: SEQUENCE OF

OPERATIONS

This appendix provides the network related control

sequences of operation for the T7300F/Q7300H. For

temperature control related sequences, refer to the

T7200D,E, T7300D,E,F and Q7300 Series 2000

Programmable Commercial Thermostat and Subbase

Product Data, form no. 63-4355.

Network Operations

Room Temperature Sensor (DestRmTemp)

This is the room space temperature sensor. This sensor

can be local (contained internally within the T7300F),

remote (external but hard-wired back to the Q7300H

subbase), or network (physical sensor is located

elsewhere on the LonWorks Bus, and its value is

communicated to the Q7300H). The Room Temperature

sensor provides the temperature input for the temperature

control loop of the T7300F. If both local and remote

sensors are available, the two values can be

the resulting value supplied to the temperature control

routine.

NOTE: A physical sensor (either local or remote)

be averaged with a network sensor. A valid value

for the network sensor input gives the network

sensor priority over any locally-wired sensors.

If a valid room temperature value is not available to the

T7300F/Q7300H, the temperature control algorithm in the

T7300F is disabled, causing the heating and cooling

control outputs to be turned off.

averaged

cannot

and

Network Setpoint (DestSetPoint)

This is a center-setpoint signal sent from another

LonWorks Bus device. When received, it is used to

calculate the actual cooling or heating occupied setpoint.

The DestSetPoint value becomes the center of the Zero

Energy Band (ZEB) between the cooling and heating

occupied setpoints. The size of the ZEB is found by taking

the difference between the programmed heating and

cooling occupied setpoints (CoolOccSpt and HeatOccSpt);

therefore, the actual setpoints are found as follows:

ActualCoolSpt = DestSetPoint + (CoolOccSpt -

HeatOccSpt) / 2

ActualHeatSpt = DestSetPoint - (CoolOccSpt -

HeatOccSpt) / 2

During unoccupied times, the network setpoint value is not

referenced, and the programmed setpoints are used

instead (CoolUnoccSpt and HeatUnoccSpt). During

occupied times, if DestSetPoint is valid, it will be used to

override any internal setpoints.

Network Setpoint Offset (DestSptOffset)

This is a setpoint adjustment signal sent from another

LonWorks device. When received, it is used to

current setpoint value up or down. The amount of the

bump is the value of DestSptOffset itself. The actual

setpoints are found as follows:

ActualSetpoint = CurrentSetPoint + DestSptOffset

During unoccupied times, the network setpoint offset value

is not referenced, and the programmed setpoints are used

instead (CoolUnoccSpt and HeatUnoccSpt).

bump

the

Setpoint Limits (MinCoolSetPt and MaxHeatSetPt)

User-entered setpoint limits are provided by MinCoolSetPt

and MaxHeatSetPt. The occupied setpoints used in the

control algorithms are limited by these parameters. The

lowest actual setpoint allowed in cool mode is equal to

MinCoolSetPt, and the highest actual setpoint allowed in

heat mode is equal to MaxHeatSetPt.

63-4365 20

Page 21

T7300F/Q7300H SERIES 2000 COMMERCIAL THERMOSTATS AND COMMUNICATING SUBBASES

Bypass Operation (StatusOcc, DestManOcc and

DestBypass)

During unoccupied periods, the facility occupant can

request that the occupied temperature control setpoints be

observed by doing any one of the following:

— Depressing the Temporary Occupied button on the

T7300F, or

— Setting the DestManOcc network point to Bypass, or

— Setting the DestBypass network point to ON.

When activated, the thermostat remains in Bypass mode

until:

— Bypass duration setting has timed out (BypTime), or

— User presses the Run button on the T7300F to switch

off the Bypass mode, or

— Occupancy schedule switches the mode to occupied,

or

— User sets the DestManOcc network point to occupied,

or unoccupied.

BypassTime

BypassTime is the time between the pressing of the

override button at the wall module (or initiating bypass

mode via DestManOcc) and the return to the original

occupancy state. When the bypass state has been

activated, the bypass timer is set to BypTime (default of

180 min.).

NOTE: A Bypass mode initiated via DestBypass does

cause the bypass timer to run. The DestBypass

signal source is assumed to be tracking the

duration peiod using its internal bypass timer.

not

Override Priority

A network bypass signal always has priority over local

pushbutton induced overrides. When DestManOcc is not

OC_NUL, then the effective occupancy is DestManOcc,

regardless of the T7300F keypad-initiated override state.

Continuous Unoccupied Mode

This mode is entered when the Continuous Unoccupied

button on the T7300F is pressed. This mode can also be

entered via a network command (DestManOcc set to

Unoccupied). If the controller is in this mode, it reverts to

the unoccupied setpoints for temperature control. The

thermostat remains in this mode indefinitely until the Run

button is pressed to exit the mode, or a network command

is sent to clear the mode.

Occupancy Mode Arbitration (StatusOcc)

The T7300F/Q7300H has multiple sources for occupancy

schedule information and, therefore, it employs an

arbitration scheme to determine the current actual mode.

Time-of-day (TOD) schedule status comes from either one

of two sources:

— Internal schedule contained in the T7300F, or

— DestOccSchedule network input received from

another LonWorks device.

If DestOccSchedule is valid, it has highest priority and

determines the occupancy mode; otherwise, the status is

determined by the internal schedule of the T7300F.

StatusOcc has two possible states: occupied, or

unoccupied.

not

NOTE: The T7300F/Q7300H does

mode.

Manual Override of occupancy mode can occur from three

sources and is governed by two selectable arbitration

schemes. The two schemes are: Network Wins or Last-in

Wins, (as set in OvrdPriority).

The three sources of manual override status are:

— DestManOccPossible states: Occupied,

Unoccupied, Bypass, Standby and Null (not active). If

Standby is received, it is ignored. This input source

has the highest priority in determining manual override

status for a Network Wins arbitration scheme, or in the

event there is more than one source change at a time

in the Last-in Wins arbitration scheme. Bypass

initiates a self-timed bypass of the control unit and

expires upon completion of the defined timed period.

The controller then treats the bypass status of this

input as Null until the next change in status.

— DestBypassPossible states: Bypass On, Bypass Off

or Not Assigned (not active). This input places the

controller in an untimed bypass state or turns off the

bypass mode. This source is second in priority to

DestManOcc under the same arbitration schemes

mentioned above.

— The T7300F keypad (Temporary Occupied and

Continuous Unoccupied keys).

support Standby

Demand Limit Control (DestDlcShed)

When the Q7300H receives a high-electrical-demand

signal, the controller applies a DlcBumpTemp amount to

the current actual space temperature setpoint value. The

setpoint is always adjusted in the energy-saving direction.

This means that if the T7300F is in cooling mode, the DLC

offset bumps the control point up and when in heating

mode, bumps the control point down.

When returning from a DLC Shed event, the setpoint is

gradually ramped back to its original (unbumped) value

over a 30-minute period.

Start-Up

START_UP_WAIT is the first mode after application restart

or power-up. During START_UP_WAIT, no control

algorithms are active.

NOTES:

After a controller commission via Excel LonSpec™,

the Q7300 is reset and an application restart occurs.

Not all network inputs can be received during the

START_UP_WAIT period because many network

variables are updated at a slower rate; therefore some

control decisions can be considered temporarily

inappropriate during START_UP_WAIT.

21 63-4365

Page 22

63-4365 22

Page 23

23 63-4365

Page 24

Home and Building Control Home and Building Control Honeywell Asia Pacific Inc.

Honeywell Inc. Honeywell Limited-Honeywell Limitee Room 3213-3225

Honeywell Plaza 155 Gordon Baker Road Sun Hung Kai Centre

P.O. Box 524 North York, Ontario No. 30 Harbour Road

Minneapolis, MN 55408-0524 M2H 3N7 Wanchai

Hong Kong

Honeywell Latin American Region Honeywell Europe S.A.

480 Sawgrass Corporate Parkway 3 Avenue du Bourget

Suite 200 1140 Brussels

Sunrise, FL 33325 Belgium

Printed in U.S.A. on recycled

paper containing at least 10%

63-4365 J.S. 12-98

post-consumer paper fibers.

www.honeywell.com

Loading...

Loading...