Page 1

T7200, T7300 and Q7300

63-4038-7

Programmable Commer cial

Thermostats and Subbases

The T7200, T7300 Thermostats and Q7300 Subbases control commerical single zone heating, ventilating and air conditioning (HVAC) equipment.

■ One model can be used for single-stage and multi-

stage applications.

■ 7-day programming—two occupied/unoccupied

periods per day.

■ Individual temperature setpoints for:

—Occupied heat and cool.

—Unoccupied heat and cool.

■ Proportional plus integral control—eliminates temp-

erature fluctuations and thermostat tampering.

■ Intelligent Recovery™—automatically optimizes

start time depending on building load.

■ Intelligent Fan™—energizes fan on call for heating

or cooling only. Fan can be configured to run cont-

inuously in occupied mode.

■ Automatic heat/cool changeover.

■ Universal Versaguard™ Thermostat Guard avail-

able for T7200 and T7300/Q7300.

■ Locking setpoints and schedules eliminate tamp-

ering (use keyboard security).

■ One thermostat can be used for heat pump or con-

ventional control.

■ Optional remote sensors.

■ Configurable to vary fan and reversing valve operation.

■ Use with Q7300 to interface with C7400/W7459

Economizer System for total integration of rooftop

control.

■ Convenient overrides allow temporary changes.

■ Battery backup saves program and maintains clock

time during power failure.

■ Auxiliary contacts available for use with economizer.

CONTENTS

Specifications ................................................ 2

Ordering Information.................................... 2

Recycling Notice............................................ 4

Installation .................................................... 4

Temperature Averaging Networks

(See Fig. 5-9) ........................................ 5

Set Q7300 Subbase DIP Switches............. 6

Set Thermostat DIP Switches.................... 9

Set Thermostat Mini-Jumper .................. 11

Program the Thermostat ............................. 12

Checkout...................................................... 13

Test Mode................................................ 13

Operation .................................................... 15

Cross Reference .......................................... 18

Wiring Diagrams......................................... 22

Troubleshooting .......................................... 45

J. A. • Rev. 12-95 • • ©Honeywell Inc. 1995

M3375

1 63-4038—7

Page 2

T7200/T7300/Q7300

SPECIFICATIONS • ORDERING INFORMATION

Specifications

IMPORTANT: The specifications given in this publication

do not include normal manufacturing tolerances.

Therefore, this unit may not exactly match the listed

specifications. This product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

• T7300A is a fully configurable programmable commercial thermostat to be used with a Q7300 Subbase.

• T7300B is a fully configurable programmable commercial thermostat with the 3-HOUR OVERRIDE key in the

cover, to be used with a Q7300 Subbase. (See Fig. 2).

• T7300C is a fully configurable programmable commercial thermostat with limited access cover for easy programming. Cover includes Set Heat, Set Cool, Warmer,

T7200 AND T7300 THERMOSTATS

• T7200A is an autochangeover programmable commer-

Cooler and Occupied/Unoccupied keys. Use with Q7300

Subbase. (See Fig. 3).

cial thermostat to be used with a single stage conventional

heat/cool system.

•T7200B is an autochangeov er programmable commercial

Q7300 SUBBASE

Q7300 Subbases provide features listed in Table 1.

thermostat to be used w ith a sing le stage heat pump system .

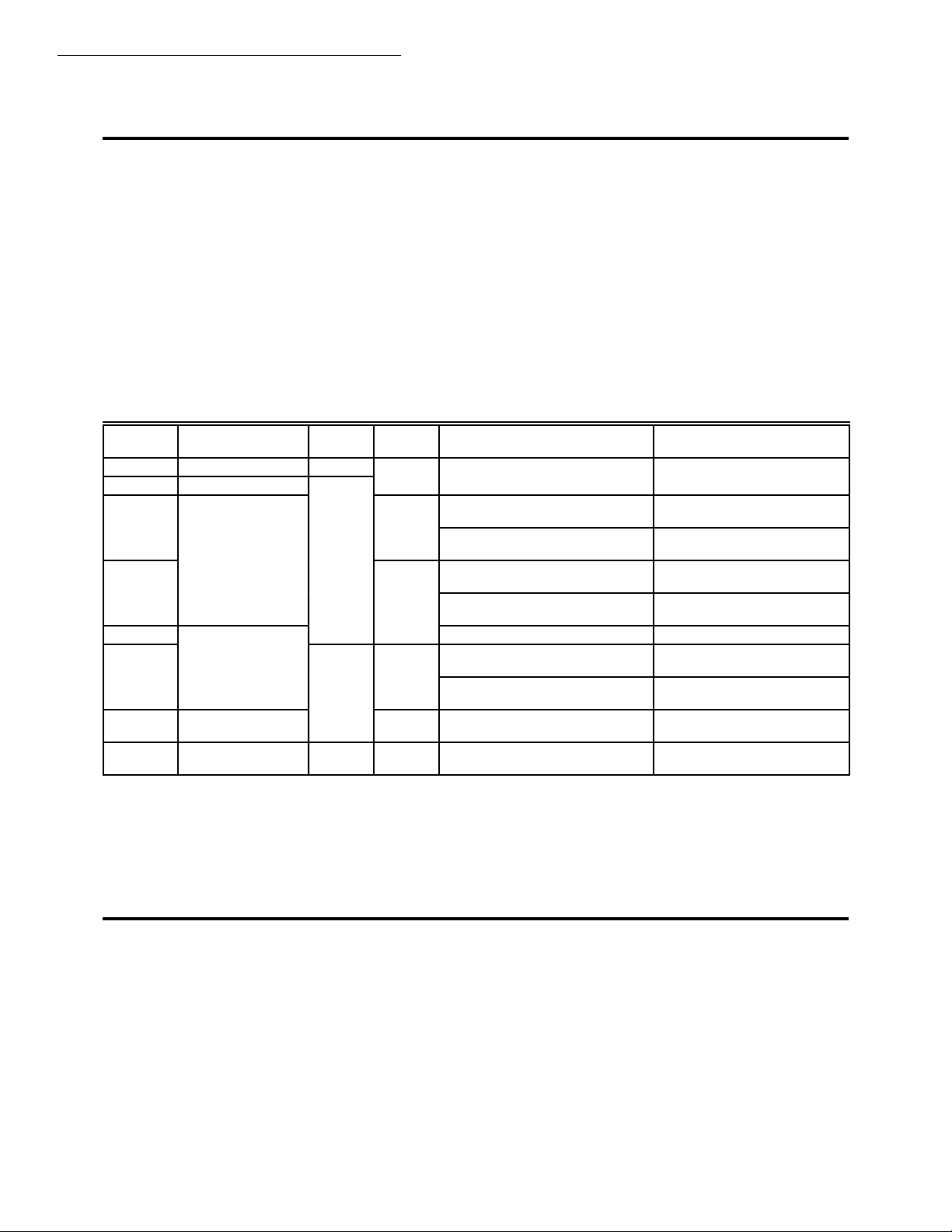

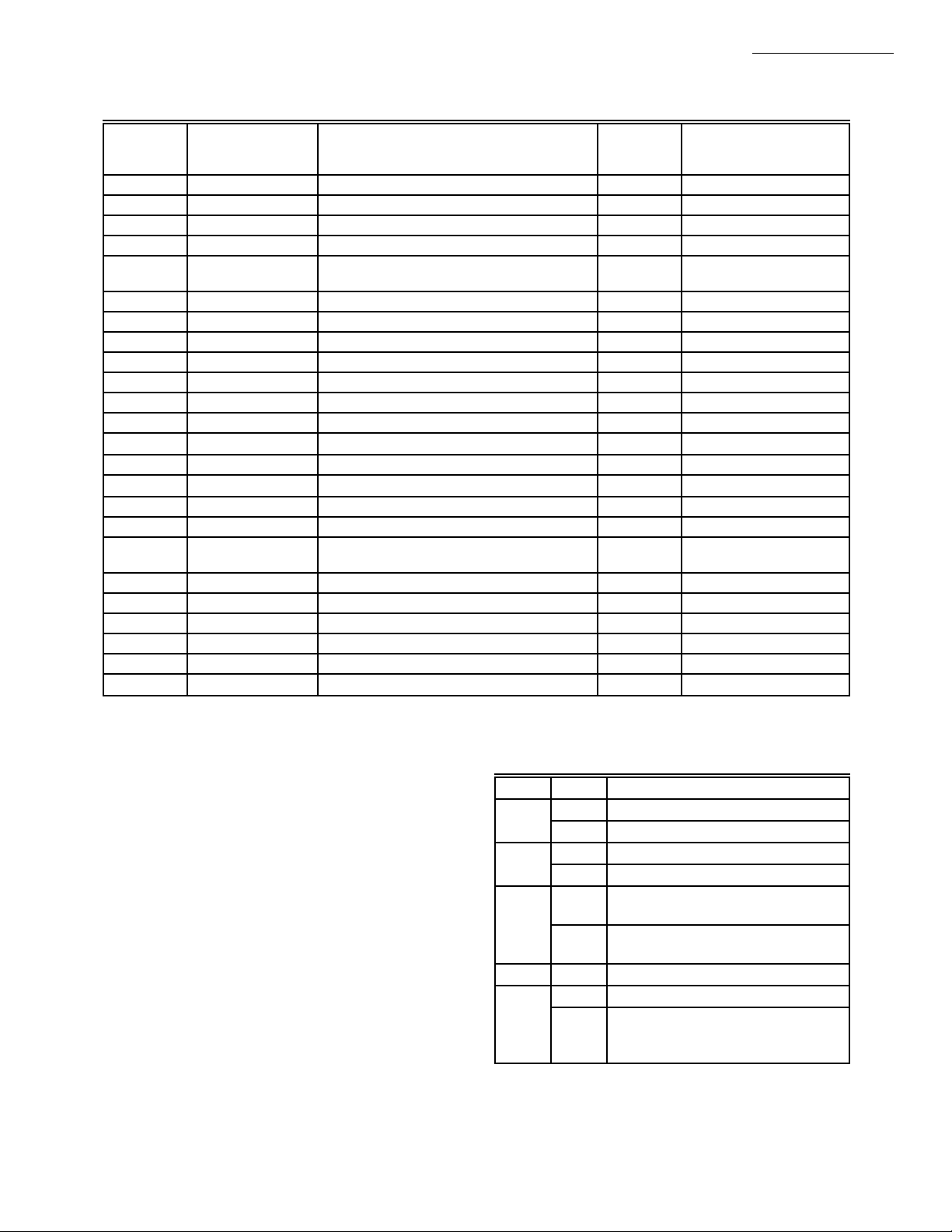

TABLE 1—Q7300 SUBBASE FEATURES.

Model System Switch

Q7300A

Q7300B Heat-Off-Cool-Auto Auto-On 2 heat-1 cool; 2 heat-2 cool

Q7300C Em. Ht.-Heat-Off-

Q7300D None 1 stage heat pump compressor with

Q7300E None Conventional 1 heat-1 cool; 2 heat-2 cool

Q7300F None Aux. Ht. 1 stage heat pump compressor with

Q7300G Heat-Off-Cool-Auto None Conventional 1 stage heat with

Q7300L None Auto-On Heat Cool 2 stage heat (ML984 actuator/

a

a,b

None None None Conventional 1 heat-1 cool; 1 heat-2 cool

Cool-Auto

Select models do not have auxiliary relay output. The auxiliary relay output is used with an ecomonomizer for minimum

Fan

Switch LEDs Application Selectable Output

Em. Ht.,

Aux. Ht.

1 stage heat pump compressor with

auxiliary heat

2 stage heat pump compressor with

auxiliary heat

auxiliary heat

2 stage heat pump compressor with

auxiliary heat

auxiliary heat

2 stage heat pump compressor with

auxiliary heat

3-stage cool

V5013 Valve) 1 stage cool

c

1 heat-1 cool; 2 heat-1 cool

1 heat-1 cool; 2 heat-1 cool;

3 heat-1 cool

1 heat-1 cool; 2 heat-1 cool

1 heat-1 cool; 2 heat-1 cool;

3 heat-1 cool

1 heat-1 cool; 2 heat-1 cool

1 heat-1 cool; 2 heat-1 cool;

3 heat-1 cool

1 heat-3 cool (fixed)

1 heat-1 cool; 2 heat-1 cool

position control based on programmed time schedule. Can also be used for switching other external equipment.

b

Q7300A1000 model configures for 1 heat-1 cool only (fixed).

c

Uses conventional terminal designations. Compressor changeover is controlled by the heat pump equipment.

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the Tradeline

Catalog or price sheets for complete ordering number, or specify—

1. Order number. 3. Order additional system components and system accessories

2. Accessories, if desired. separately.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Home and Building Control Sales Office (please check the white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International Sales and

Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico,

Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-4038—7 2

Page 3

THERMOSTAT

ELECTRICAL RATING: 24 to 30 Vac, 50/60 Hz.

SYSTEM CURRENT DRAW: 6 VA maximum at 30 Vac,

50 or 60 Hz.

OUTPUT RELAY DRAW: See Table 2.

TABLE 2—MAXIMUM AMPS AT 30 VAC.

Relay Running (A) Inrush (A)

Fan 1.6 3.5

Heat 1.6 3.5

Cool 1.6 7.5

Auxillary (Economizer) 1.6 3.5

TEMPERATURE:

Ratings:

Ambient: 40°F to 110°F (4°C to 43°C).

Shipping: -30°F to +150°F (-34°C to +65°C).

Display Accuracy: ±1°F (±1°C).

Setpoint:

Range: 45°F to 95°F (7°C to 35°C).

Differential: 2°F (1°C).

Default Settings: See Table 3.

TABLE 3—DEFAULT SETPOINTS.

Control Occupied Unoccupied

Heating 68°F (20°C) 55°F (13°C)

Cooling 78°F (26°C) 90°F (32°C)

T7200/T7300/Q7300

SPECIFICATIONS

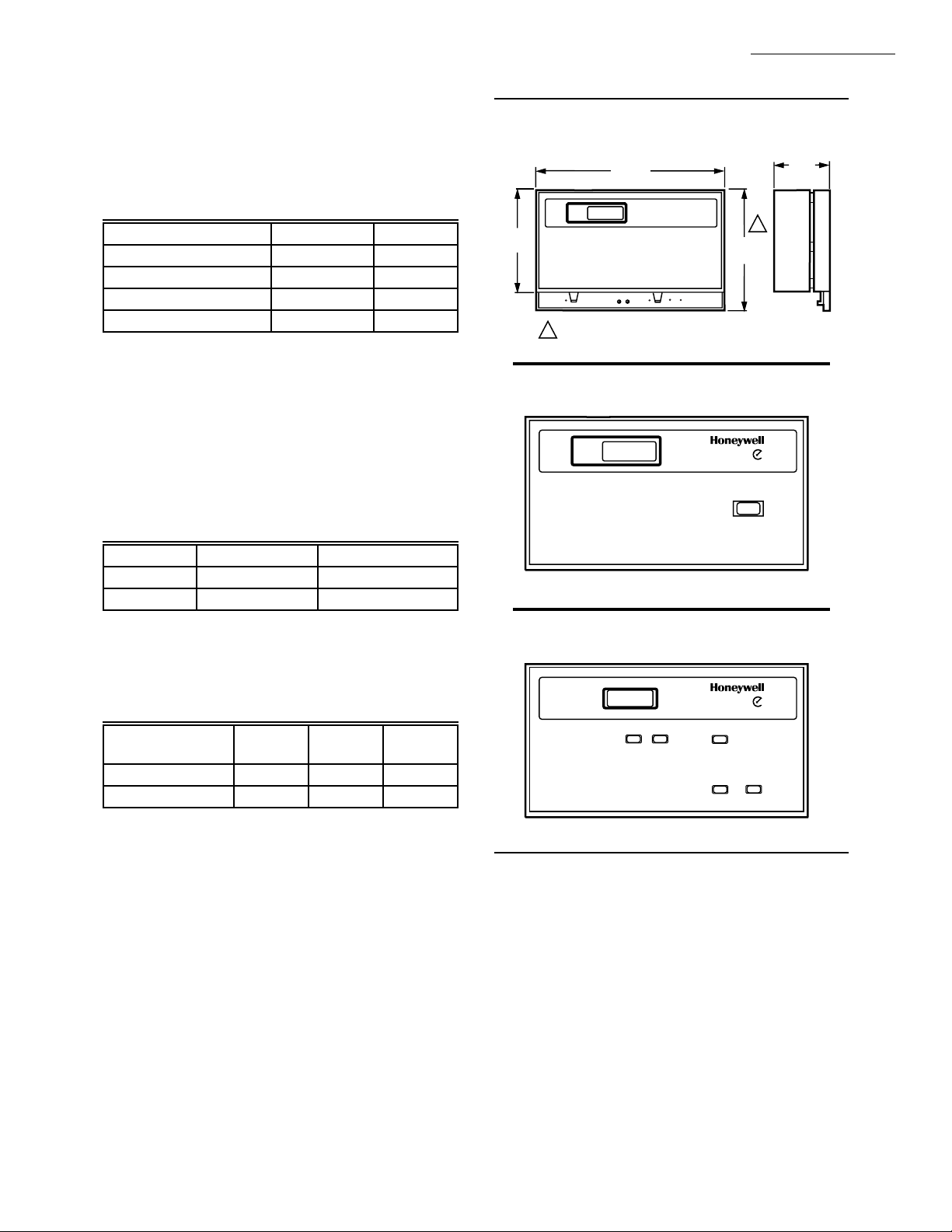

Fig. 1—Thermostat and subbase dimensions in

in. (mm).

8 (204)

4

(102)

FAN

1

EM. HEAT AUX. HEAT

ONAUTO COOLOFFHEATEM. HEAT

T7300/Q7300 ONLY.

Fig. 2—T7300B door.

OCCUPIED •

UNOCCUPIED •

CONT UNOC •

3 HR OCCUPIED •

ENVIRONMENTAL

CONTROL

4-5/8

(118)

3 HOUR

OCCUPIED

1-3/4

1

(41)

M4404

M4421

REMOTE SENSOR WIRING TEMPERATURE OFFSET:

Temperature offset occurs with 500 ft (157m) to 1000 ft

(305m) of 2-wire cable. See Table 4.

TABLE 4—TEMPERATURE OFFSET.

Temperature

Range 18 AWG 20 AWG 22 AWG

50-90°F -0.4°F -0.7°F -1.0°F

10-32°C -0.3°C -0.4°C -0.6°C

MINIMUM STAGE OPERATION TIME:

Conventional Heat: Two minutes On or Off.

Compressor: Two minutes On and four minutes Off.

HUMIDITY RATINGS: 5% to 90% RH, noncondensing.

CLOCK ACCURACY: ±1 minute per month.

BATTERY BACKUP: Up to 60 hours with fresh 9-volt

alkaline battery. Mallory MN11604™ or equivalent.

FINISH: Beige thermostats with brown subbases or Premier

White™ thermostats with light gray subbases.

DIMENSIONS: See Fig. 1.

T7300 Doors: See Fig. 2.

MOUNTING MEANS: T7200 Thermostat mounts on a

wallplate. The T7300 mounts on the Q7300 Subbase. The

Q7300 and wallplate mount horizontally on a wall or

outlet box with two no. 6 x 32 screws (included).

Fig. 3—T7300C door.

OCCUPIED •

UNOCCUPIED •

TO ADJUST HEAT

PRESS SET HEAT THEN

PRESS WARMER OR COOLER

TO ADJUST COOLING

PRESS SET COOL THEN

PRESS WARMER OR COOLER

FOR AFTER HOURS

PRESS OCCUPIED UNOCCUPIED

FOR BUSINESS HOURS

PRESS OCCUPIED UNOCCUPIED AGAIN

SET SET

HEAT COOL

TO ACCESS FULLY PROGRAMMABLE TIME AND TEMPERATURE FEATURES LIFT COVER

ENVIRONMENTAL

CONTROL

WARMER

COOLER

OCCUPIED

UNOCCUPIED

M4422

ACCESSORIES:

— 229997BU T7300B Conversion Kit. (See Fig. 2).

— 229997BY T7300A Conversion Kit. (See cover photo).

— 229997CE T7300C Conversion Kit. (See Fig. 3).

— 231054AA White Door Assembly for T7300C. (See

Fig. 3.

— 231055AA White Door Assembly for T7300B. (See

Fig. 2).

— 231056AA White Door Assembly for T7300A. (See

cover photo).

— 4074EEP Hardware for door and hinge pin assembly.

3 63-4038—7

Page 4

T7200/T7300/Q7300

SPECIFICATIONS • RECYCLING • INSTALLATION

— 4074EFS Bag Assembly (two sheet metal screws and

two machine screws).

— 4074EKA Bag Assembly (Allen wrench and four

Allen head screws).

— 4074ENE Hinge Pin Assembly.

— C7400 Enthalpy Sensor.

—M7415 Damper Actuator.

— T675A Temperature Control.

— T7022A1010 Remote Temperature Sensor.

— T7047C1025 Remote Temperature Sensor.

— T7047G1000 Remote Temperature Sensor.

If this control is replacing a control that contains mer-

cury in a sealed tube, do not place your old control in the

trash.

Contact your local waste management authority for

instructions regarding recycling and the proper disposal of

— T7147A1002 Remote Temperature Sensor and Over-

ride Module.

— T7147A1010 Remote Temperature Sensor and Over-

ride Module.

— T7147A1028 Remote Temperature Sensor and Over-

ride Module.

— R8222 Switching Relay.

—W950A System Supervisor.

—W859D Packaged Economizer.

—W7459 Economizer Logic Module.

Recycling Notice

M3375

this control, or of an old control containing mercury in a

sealed tube.

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given on the product to make sure

the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. Allow thermostat to warm to room temperature before

operating.

5. After installation is complete, check out product operation as provided in these instructions.

CA UTION

Disconnect power supply before beginning installation to prevent electrical shock or equipment

damage.

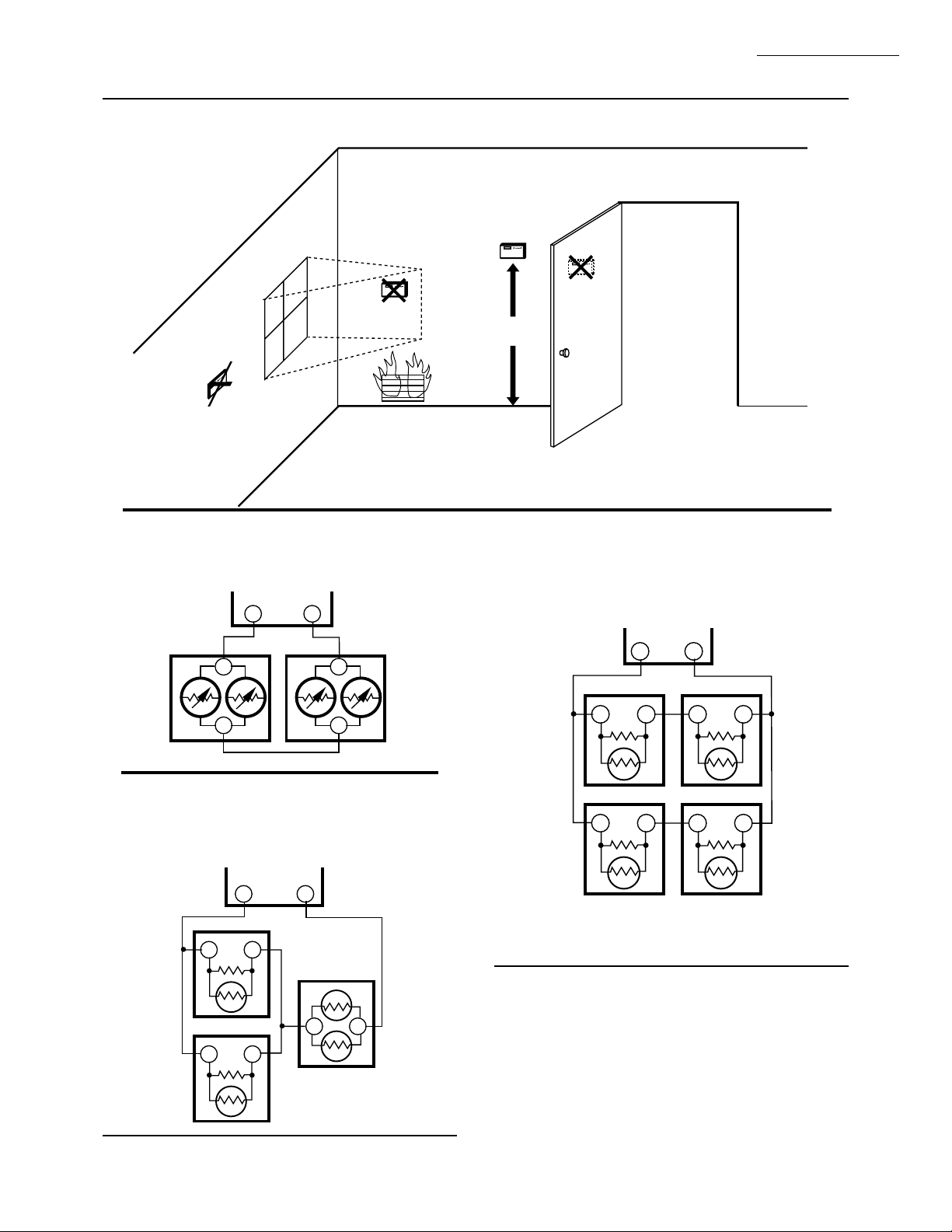

LOCATION

Thermostat Without Remote-Mounted

Temperature Sensor

Install the thermostat about 5 ft (1.5m) above the floor in

an area with good air circulation at average temperature.

See Fig. 4.

Do not mount the thermostat where it can be affected by:

— drafts or dead spots behind doors, in corners or under

cabinets.

— hot or cold air from ducts.

— radiant heat from the sun, fireplace, or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

Thermostat With Remote-Mounted

Temperature Sensor(s)

Install the thermostat in an area that is accessible for

setting and adjusting the temperature and settings.

Install the remote-mounted sensor(s) about 5 ft (1.5m)

above the floor in an area with good air circulation at

average temperature. See Fig. 4.

Do not mount the sensor(s) where it can be affected by:

— drafts or dead spots behind doors, in corners or under

cabinets.

— hot or cold air from ducts.

— radiant heat from the sun, fireplace, or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

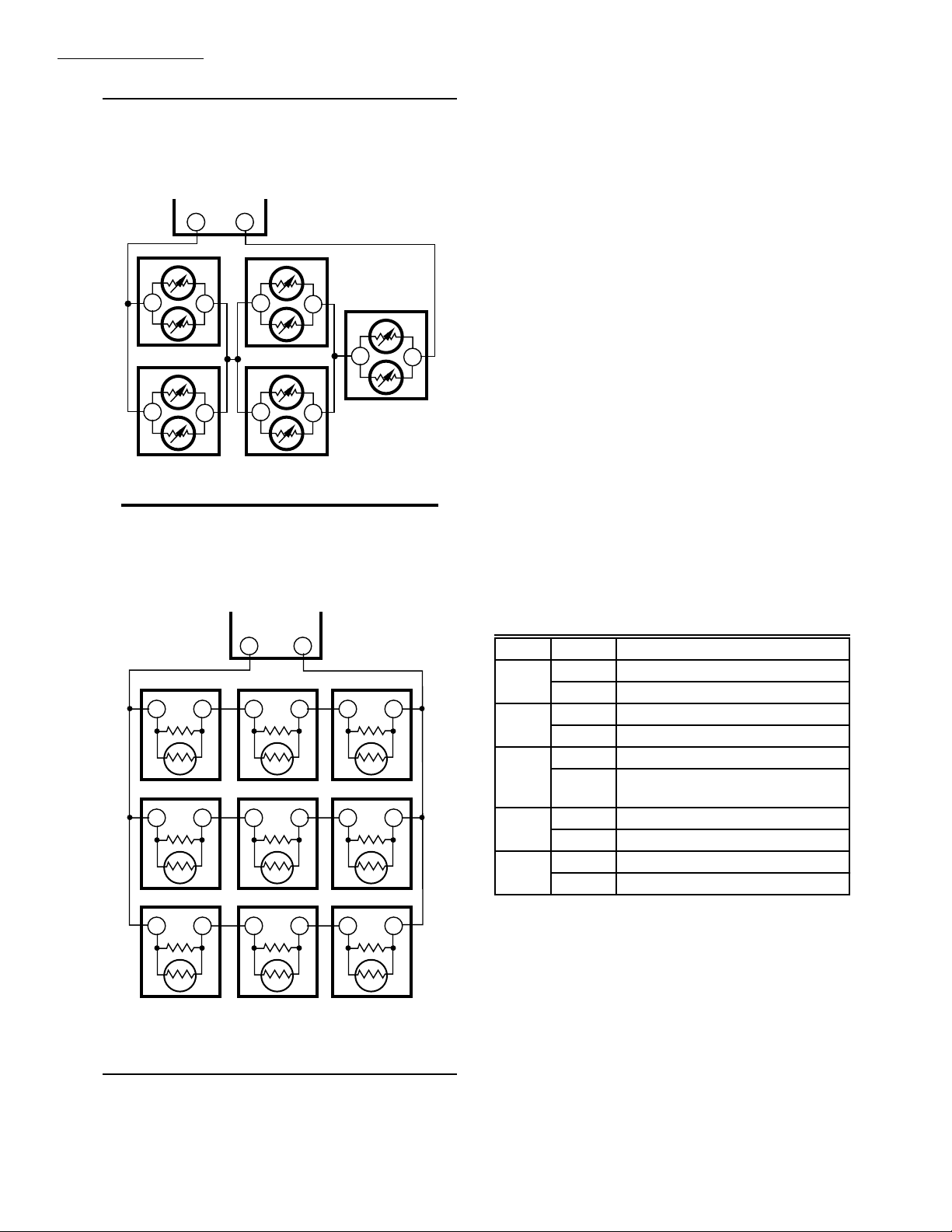

If more than one remote sensor is required, they must be

arranged in a temperature averaging network consisting of

two, three, four, five, or nine sensors. Instal as shown in

Fig. 5-9.

REPLACE AN EXISTING THERMOSTAT OR

NEW INSTALLATION

Replace An Existing Thermostat

Turn off all sources of power for the thermostat. Re-

move any existing wallplate or subbase from the wall. To

avoid miswiring later, label or write down each wire color

with the letter or number on the wiring terminal as the wire

is removed.

63-4038—7 4

Page 5

Fig. 4—Location for installing thermostat or remote-mounted sensor.

YES

NO

5 FEET

[1.5 METERS]

NO

T7200/T7300/Q7300

INSTALLATION

NO

M4385

Fig. 5—Two T7047G1000 Sensors providing a

temperature averaging network for a T7300/

Q7300 Thermostat/Subbase.

Q7300

TT

T7047G1000T7047G1000

T

T

T

T

M3421

Fig. 6—Two T7047C1025 and one T7047G1000

Sensors providing a temperature averaging

network for a T7300/Q7300 Thermostat/Subbase.

Q7300

TT

T7047C

TT

T7047G1000

Fig. 7—Four T7047C1025 Sensors providing a

temperature averaging network for a T7300/

Q7300 Thermostat /Subbase.

Q7300

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

M3420

T7047C

TT

TT

M3418

5 63-4038—7

Page 6

T7200/T7300/Q7300

INSTALLATION

Fig. 8—Five T7047G1000 Sensors providing a

temperature averaging network for a T7300/

Q7300 Thermostat/Subbase.

Q7300

TT

T7047G

T

T7047G

T

T7047G

T

T

T

T7047G

T

T

T7047G

T

T

M3422

Fig. 9—Nine T7047C1025 Sensors providing a

temperature averaging network for a T7300/

Q7300 Thermostat/Subbase.

New Installation

Run cable to a hole at the selected wall location for the

thermostat and pull about 3 in. (76 mm) of wire through the

opening. Color-coded, 18-gauge thermostat cable with at

least one conductor for each wiring terminal is recommended. Good service practice recommends selecting a

cable with one or two extra conductors than the immediate

application requires.

If using remote temperature sensor(s) or LAN override

switch module, refer to the mounting instructions included

with the device for wiring cable requirements. Route cable

away from sources of electrical noise.

IMPORTANT: The remote sensor(s) or override switch

T

wires must be in a shielded cable if bundled or placed

in the same conduit with the cooling control wires.

Earth ground the shield at the thermostat.

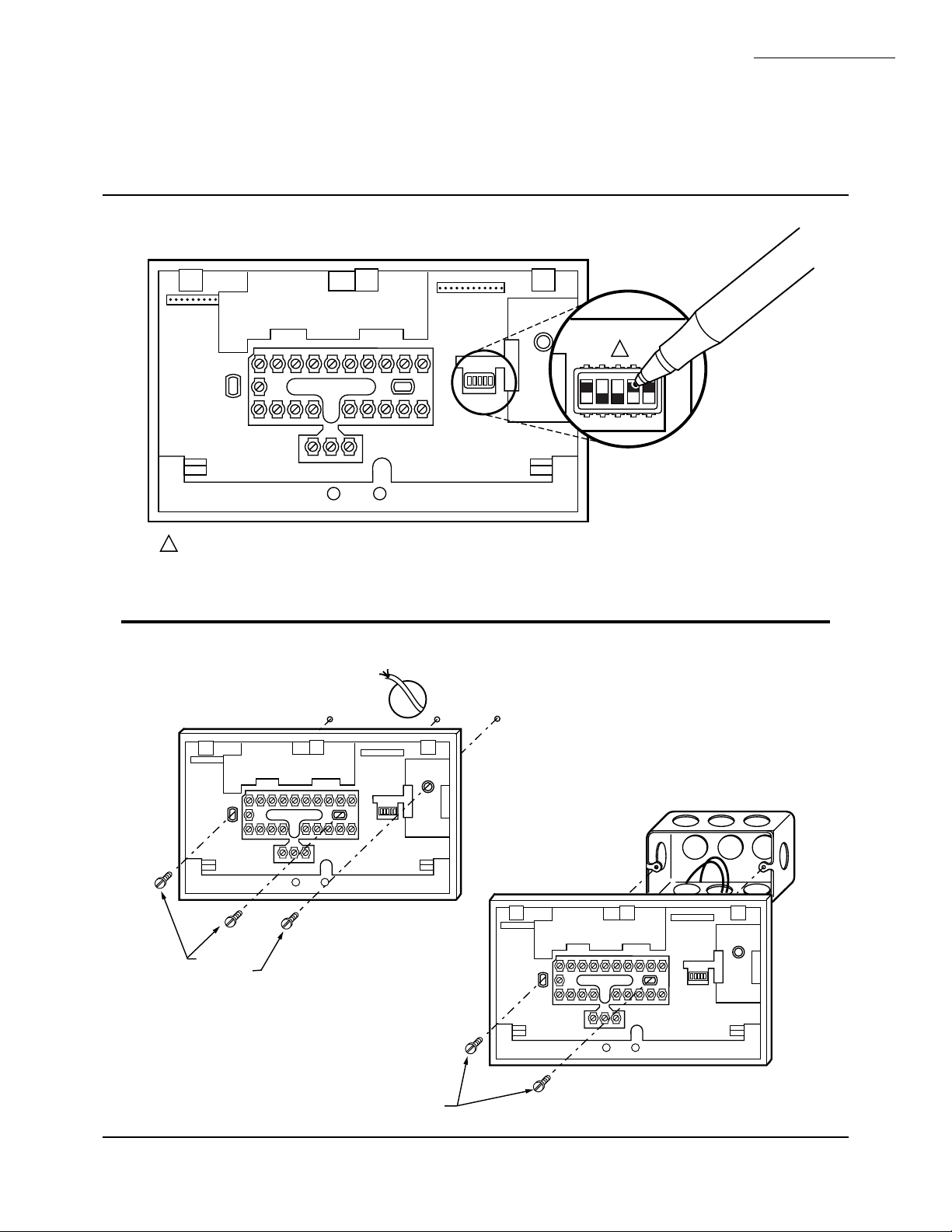

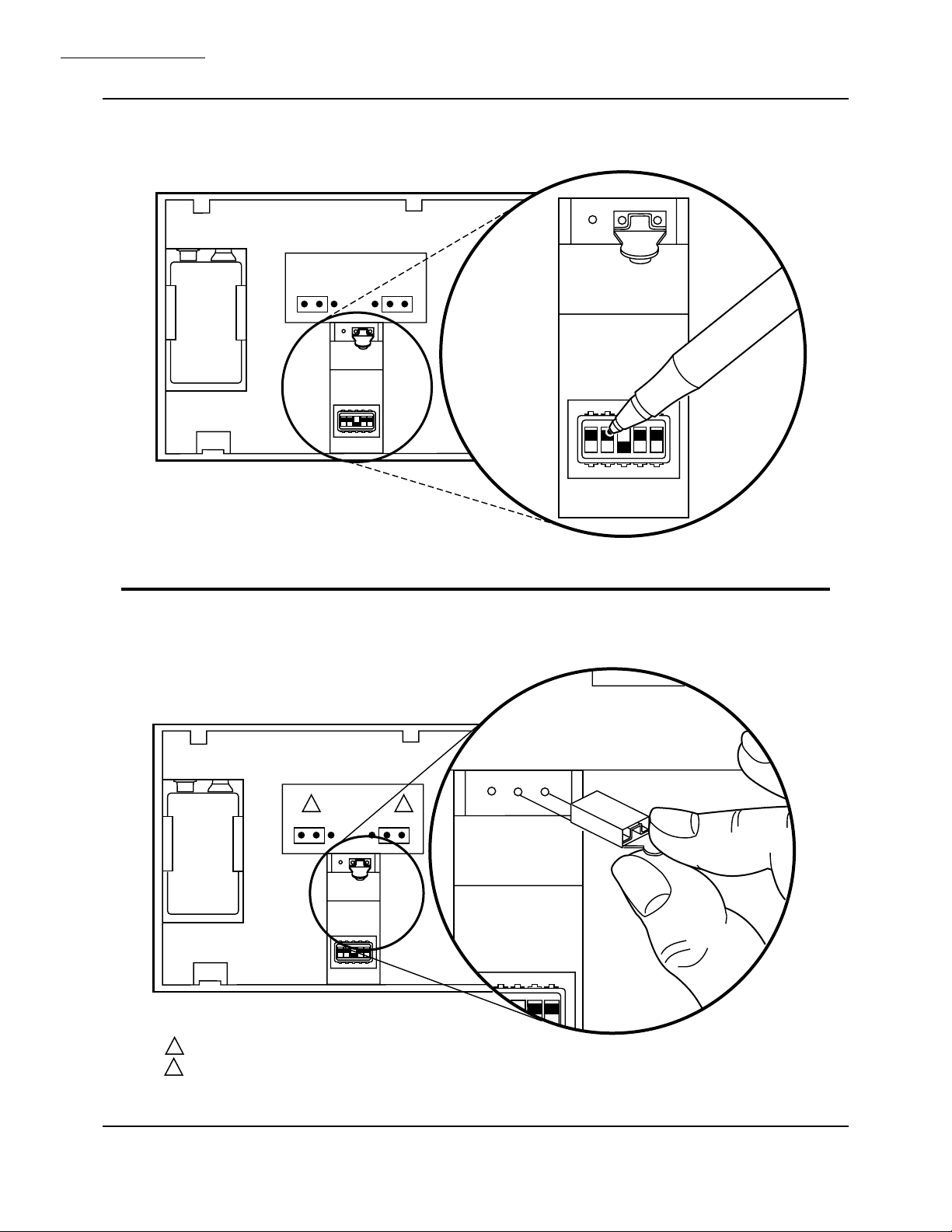

SET Q7300 SUBBASE DIP SWITCHES

NOTE: Subbase dip switches are not available on the T7200

Wallplate.

The Q7300 Subbase provides the T7300 Thermostat

with an interface to the single zone HVAC system. See

Table 5 for DIP switch settings. The subbase DIP switches

are located on the front and to the right of the wiring

terminals. See Fig. 10. Set the DIP switches for the system

being controlled.

T7047C

TT

T7047C

TT

T7047C

TT

Q7300

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

M3419

TABLE 5—SUBBASE DIP SWITCH SETTINGS.

Switch Setting Function

a

1

OFF 1 stage heat

ONb2 stage heat

a

2

OFF 1 stage cool

ONb2 stage cool

3 OFF Proportional control (allows droop)

ONbProportional plus integral (P+I)

control (droopless)

c

4

ONbEnergizes fan on cool only

OFF Energizes fan on heat and cool

5ONbUse internal sensor

OFF Use remote sensor

a

No effect on 1 heat/1 cool (Q7300A) or 1 heat/3 cool

(Q7300G) models.

b

Factory setting.

c

No effect on heat pump systems.

MOUNT SUBBASE OR WALLPLATE

The subbase or wallplate can be mounted on a horizon-

tal outlet box or directly on the wall. For an outlet box

installation, go to step 3.

63-4038—7 6

Page 7

T7200/T7300/Q7300

INSTALLATION

1. For a wall installation, hold subbase or wallplate in

position and mark holes for the anchors. See Fig. 4. Wall

anchors must be obtained locally. Be careful that the wires do

not fall back into the wall opening. Set aside subbase or

wallplate.

Fig. 10—Setting subbase DIP switches.

BA3A2W2Y2TA1 T

Y1

GRCRH

LED1

1

CONFIGURATION OF ILLUSTRATED SWITCH IS:

1 – ON

2 – OFF

3 – OFF

4 – ON

5 – ON

CA1

LED2 COM

CA2 CA3 CA4 CA5

2. Drill four 3/16 in. (4.8 mm) holes and gently tap

anchors into the holes until flush with the wall.

3. Pull wires through the cable opening. See Fig. 11.

1

O

N

1

234

5

M4401

Fig. 11—Installing subbase on outlet box or on wall.

BA3A2W2Y2TA1 T

Y1

GRCRH

SHEET METAL

SCREWS

MOUNTING TO WALL BOARD

CA2 CA3 CA4 CA5

CA1

LED2 COM

LED1

MACHINE

SCREWS

OR

BA3A2W2Y2TA1 T

Y1

GRCRH

MOUNTING TO HORIZONTAL 2 X 4 JUNCTION BOX

CA2 CA3 CA4 CA5

CA1

LED2 COM

LED1

M4410

7 63-4038—7

Page 8

T7200/T7300/Q7300

INSTALLATION

4. Secure the subbase or wallplate with the screws provided. Do not fully tighten the screws.

5. Level the subbase or wallplate for appearance only.

Leveling is not required for operation. Securely tighten the

screws.

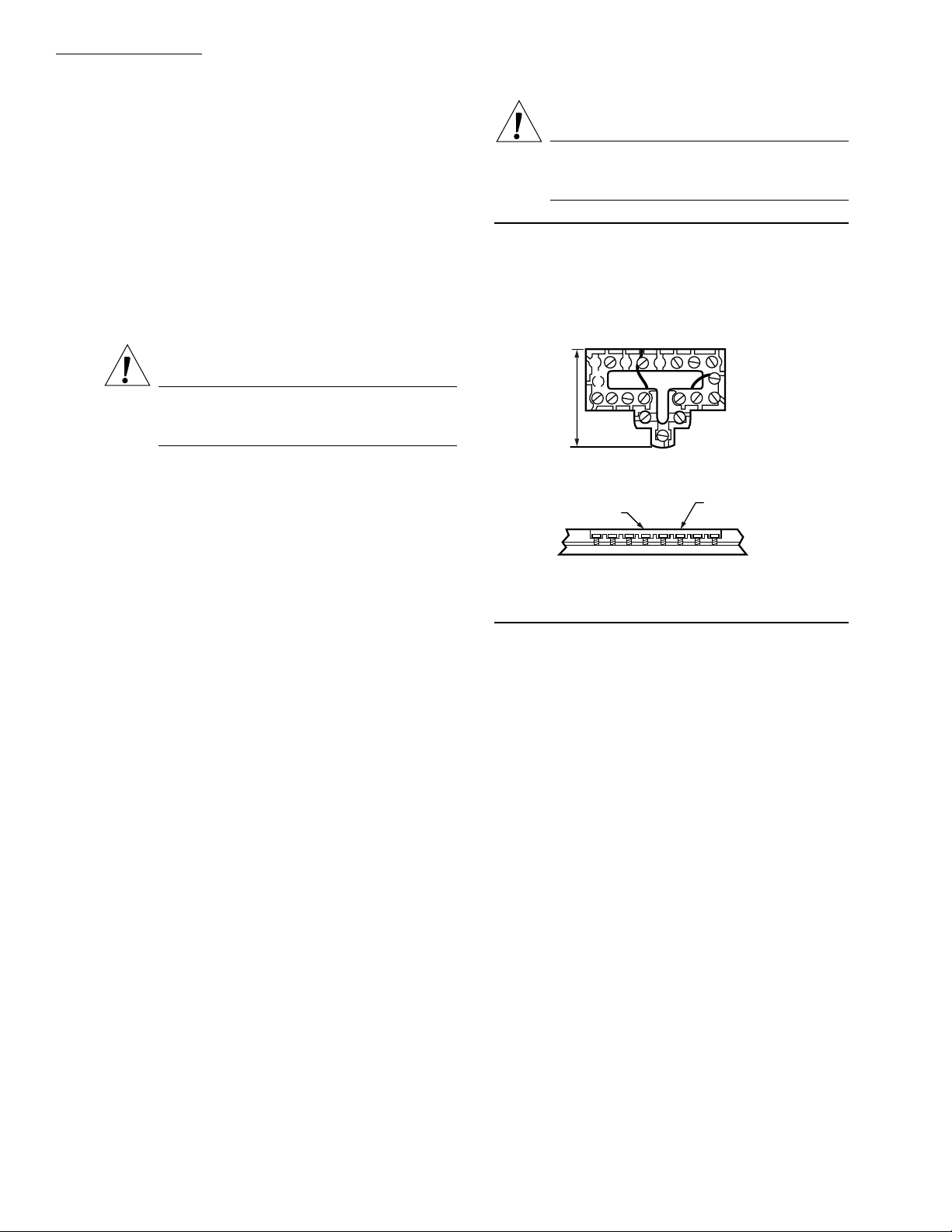

WIRE SUBBASE OR WALLPLATE

CA UTION

Never install more than one wire per terminal

unless using factory-supplied jumper with spade

terminal.

IMPORTANT: Most equipment manufacturers size system

transformers for the equipment installed at the factory. Before connection, be sure that the system transformer can supply the T7200 OR T7300 and Q7300

with adequate power (6 VA). If less than 6 VA is

available, install a separate 24 Vac transformer.

CA UTION

Disconnect power supply before beginning installation to prevent electrical shock or equipment

damage.

All wiring must comply with local electrical codes and

ordinances.

IMPORTANT: Use 18 gauge, solid-conductor wire when-

ever possible. If using 18 gauge stranded wire, no

more than 10 wires can be used. Do not use larger

than 18 gauge wire.

Follow equipment manufacturer’s wiring instructions

when available. See Fig. 23-46 for wiring diagrams. To

wire subbase, proceed as follows:

1. Connect the correct wires to the terminals as shown in

applicable diagram; the terminal barrier allows straight or

wraparound wiring connection. See Fig. 12. A letter code is

located near each terminal for identification. Typical terminal designation and wiring connections are listed in Table

6. Connect remote temperature sensor or override switch

module.

NOTE: If a remote sensor is used, be sure that the Q7300 DIP

switch 5 is placed in the OFF position.

Fig. 12—Barrier configuration. Keep wiring

restricted to recessed area surrounding terminals.

FOR STRAIGHT

INSERTION –

STRIP 5/16 in. [8 mm]

FOR WRAPAROUND –

RESTRICT

WIRING TO

THIS AREA

FRONT VIEW OF

TERMINAL AREA

WIRING TO BE BELOW

THIS SURFACE

CROSS-SECTIONAL VIEW OF

TERMINAL AREA

STRIP 7/16 in. [11 mm]

TOP SURFACE

OF SUBBASE

M3062

2. Firmly tighten each terminal screw. Loose or intermittent wire connections can cause inconsistent system operation.

3. Fit wires as close as possible to the subbase. Push

excess wire back into the hole.

4. Plug hole with nonflammable insulation to prevent

drafts from affecting the thermostat.

Refer to Fig. 23-46 for typical hookups. When system

installation is complete, perform the initial power up procedure in the Checkout section.

63-4038—7 8

Page 9

T7200/T7300/Q7300

TABLE 6—TERMINAL DESIGNATIONS.

Standard

Terminal

Designation

BHeating damper motor; changeover valve/relay Output 24 Vac powered contact

EKEmergency heat relay Output 24 Vac powered contact

GFFan relay coil Output 24 Vac powered contact

ORCooling damper motor; changeover valve/relay Output 24 Vac powered contact

RVPower connection to transformer (internally

RC Power connection to cooling transformer Input

RH Power connection to heating transformer Input

W1 H1, R3 Stage 1 heating control Output 24 Vac powered contact

W2 H2, Y, R4 Stage 2 heating control Output 24 Vac powered contact

W3 Stage 3 heating control Output 24 Vac powered contact

Y1 C1, M Stage 1 cooling control Output 24 Vac powered contact

Y2 C2 Stage 2 cooling control Output 24 Vac powered contact

a

Y3

XX1,X2,C Common connection Input

T

LED1,

LED2, COM

YMCompressor contactor

A1, A2, A3 Auxiliary relay Output Dry contact

CA1-CA5

a

Q7300G only.

b

Shielded cable can be required in some installations where electrical interference (noise) can cause control problems.

Alternate

Designations Or

Customer Specials Typical Connection Function Terminal Type

Input

connected for heating and cooling)

Stage 3 cooling control

Remote sensor

L, C, H HSII control panel

OMomentary circuit, changeover

A,A1,A2,Z,C,L LEDs Annunciation

TExternal temperature readout, T relay

R1, R2 LO and HI speed fan relays

RS Cooling contactor

Remote override

b

a

b

Output 24 Vac powered contact

Input

Input Low power

INSTALLATION

SET THERMOSTAT DIP SWITCHES

The thermostat DIP switches provide the thermostat

with an interface to the single zone HVAC system. See

Table 7 for DIP switch settings. The thermostat DIP switches

are located on the back of the thermostat. See Fig. 13. Set

the DIP switches for the desired thermostat features and the

system being controlled.

IMPORTANT: The thermostat configuration must match

the application, or the control logic will not function

properly.

TABLE 7—THERMOSTAT DIP SWITCH SETTINGS

Switch Setting Function

1ONa°F display

OFF °C display

2ONa12 hour clock display

OFF 24 hour clock display

3ON

a,b

Intermittent fan operation in occupied

period

OFF Continuous fan operation in occupied

period

4 Nonfunctional switch

5ONaKeyboard is used for programming

OFF Keyboard disabled, but can be used to

review program, perform overrides

and make clock changes.

a

Factory setting.

b

Q7300B,C,D,E,L: fan switch will override this switch

setting.

Q7300A,F,G: no override is available.

9 63-4038—7

Page 10

T7200/T7300/Q7300

INSTALLATION

Fig. 13—Setting thermostat DIP switches.

T7300 ONLY

HEAT PUMP CONV

12 HR. TIME

°F - TEMP

ON

1

°C

12 HR. TIME

INT - FAN

90

45

234

24

CON

ON - KEYBD

5

OFF

°F - TEMP

ON

45

1

234

24

°C

M4085A

Fig. 14—Setting thermostat mini-jumper for conventional or heat pump system.

T7300 ONLY

1 2

HEAT PUMP CONV

- KEYBD

INT - FAN

5

OFF

CON

ON - KEYBD

12 HR. TIME

INT - FAN

°F - TEMP

ON

90

45

1

234

5

24

°C

OFF

CON

ONLY PUT MINI-JUMPER IN THIS POSITION WHEN USING Q7300C,D, OR F SUBBASES.

1

2

ONLY PUT MINI-JUMPER IN THIS POSITION WHEN USING Q7300A,B,E, OR G SUBBASES.

63-4038—7 10

12 HR. TIME

INT - FAN

°F - TEMP

90

ON - KEYBD

M4086A

Page 11

BATTERY

SNAPS

STEP 1:

STEP 2:

STEP 3:

CONNECT THERMOSTAT

CABLES TO THE SUBBASE.

FIRST CONNECT THE 12 PIN

THEN THE 9 PIN.

SNAP BATTERY INTO PLACE.

SLIDE BATTERY UP TO THE

BATTERY CONNECTOR

UNTIL CONNECTED.

M4408

T7200/T7300/Q7300

INSTALLATION

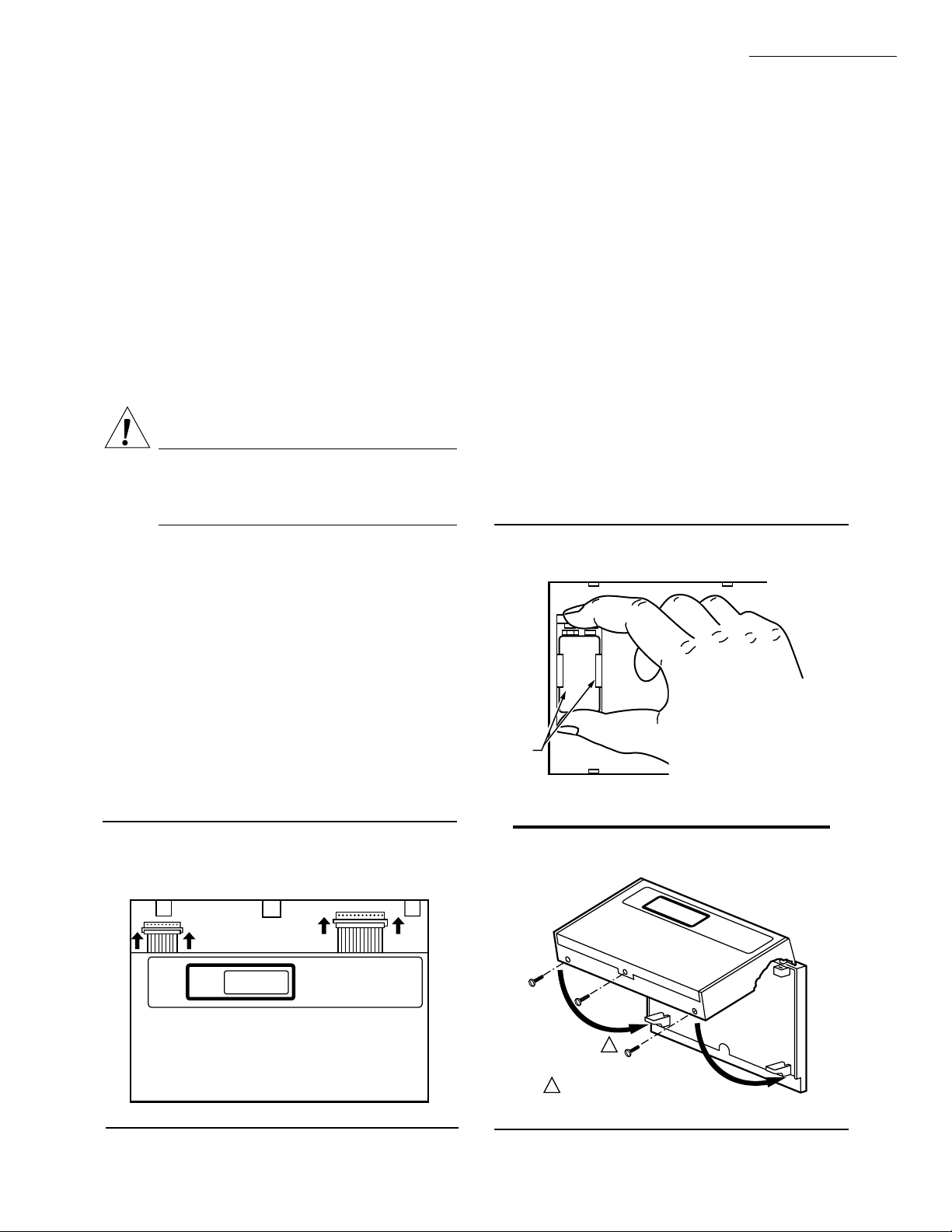

SET THERMOSTAT MINI-JUMPER

NOTE: This operation must be done prior to installing the

batteries. If batteries are installed prior to this operation,

remove battery for 15 minutes and begin.

The T7300 is factory-set for conventional system control using the Q7300A,B,E,G. If using with a heat pump

and Q7300C,D,F, locate the mini-jumper on the back of the

T7300. See Fig. 14. Pull the mini-jumper off the two

CONV pins and move to the two HEAT PUMP pins. This

changes the thermostat to the heat pump algorithm.

If you wish to change the control of the thermostat

because a new subbase has been purchased, remove battery

for 15 minutes, change mini-jumper position, and re-install

battery.

MOUNT THERMOSTAT

CA UTION

Always disconnect power supply and remove battery from the T7300 before connecting the ribbon

cables to prevent electrical shock and equipment

damage.

Use the following procedure to connect the T7300 ribbon cables to the Q7300.

1. Check that the 24 Vac power supply is disconnected

from the Q7300.

2. Check that the 9 Vdc battery is not installed in the

T7300.

INSTALL BATTERY (OPTIONAL)

The 9 volt battery is not necessary for the operation of

the thermostat, but holds the program during power outages. When the power is restored, the system will resume

normal operation. Without the battery, the system will

follow the default setpoints. See Table 3. Use the following

steps to install a battery:

1. Locate the battery holder on the back of the thermo-

stat.

2. Slide the battery up to the connector until it is firmly

seated. See Fig. 16.

NOTE: Observe the polarity when snapping a 9 volt alkaline

battery into the holder.

NOTE: The plugs must be firmly seated on the connectors

for the thermostat to work properly.

6. Hang the top edge of the thermostat on the subbase

hooks. See Fig. 17.

7. Swing down and press on the lower edge until the

thermostat snaps in place.

8. Insert and tighten three Allen head screws on the

bottom of the thermostat. See Fig. 17.

Fig. 16—Installing optional 9 volt battery.

IMPORTANT: First be sure to connect the 12 pin ribbon

cable to the Q7300.

3. Connect the 12 pin (larger) ribbon cable to the Q7300.

See Fig. 15.

4. Connect the 9 pin (smaller) ribbon cable to the Q7300.

5. If using a 9 Vdc battery, go to the Install Battery

Backup section for installation instructions.

Fig. 15—Connecting the pin ribbon cables to the

subbase connectors.

9-PIN SUBBASE

CONNECTOR

12-PIN SUBBASE

CONNECTOR

M4403

Fig. 17—Mounting thermostat on subbase.

1

1

DO NOT OVERTIGHTEN SCREWS

M4391

11 63-4038—7

Page 12

T7200/T7300/Q7300

PROGRAM THE THERMOSTAT

Program the Thermostat

OVERVIEW

The keyboard is located behind the thermostat flip-up

cover. See Fig. 18. There are 16 keys to set, review and

modify programmed times and temperatures. The liquid

crystal display (LCD) shows day, time or temperature and

which programming period is operating.

The thermostat can be set for two occupied and two

unoccupied time and temperatures for each day of the week

(28 independent settings). The two override keys provide

quick temporary programming changes for increased occupant comfort.

IMPORTANT: To program the thermostat, 24 Vac is re-

quired (turn on system power) and the keyboard lockout switch (see Fig. 27) must be in the ON-KEYBD

position.

Fig. 18—Thermostat programming keys and

LCD display.

OCCUPIED •

UNOCCUPIED •

3 HR OCCUPIED •

SET SET START TIME

CLOCK

DAY

CONT UNOC •

SELECT

DAY

COPY

11:32

OCCUPIED

START TIME

START TIME

HEAT

AM

SET TEMPERATURE DATA CHANGE

OCCUPIED

OCCUPIED

COOL

HEAT

UNOC

UNOC

UNOC

HEAT

COOL

DISPLAY

CLEAR

START TIME

OVERRIDE

3 HOUR

+

OCCUPIED

CONT

–

UNOC

NOTE: The programming times are in intervals of ten

minutes; i.e., 8:00, 8:10, 8:20.

1. Press the SELECT DAY key. The display shows the

abbreviation for a day.

2. Press and hold the + or - key until the desired day

appears.

3. Press the OCCUPIED START TIME key. The pro-

gram indicator will point to OCCUPIED.

4. Press and hold the + or - key until the desired start time

appears.

NOTE: Anytime a start time is not required, press the

CLEAR START TIME key.

5. Press the UNOC START TIME key. The program

indicator will point to UNOCCUPIED.

6. Press and hold the + or - key until the desired start time

appears.

7. To program a second occupied start time for the

selected day, repeat Step 3 until four dashes (----) are displayed or the second start time (if previously programmed) is

displayed. Then repeat Step 4.

8. To program a second unoccupied start time for the

selected day, repeat Step 5 until four dashes (----) are displayed or the second start time (if previously programmed) is

displayed. Then repeat Step 6.

9. Repeat Steps 1 through 8 for each remaining day of the

week or refer to the following section, COPY A DAY.

M4384

SET CURRENT TIME/DAY

1. Set the current time by pressing and releasing the

CLOCK key once.

2. Press the + or - key until the current time appears on the

LCD.

3. Set the current day by pressing and releasing the DAY

key once.

4. Press the + or - key until the current day appears on the

LCD.

NOTE: Su=Sunday; Mo=Monday; Tu=Tuesday; We=

Wednesday; Th=Thursday; Fr=Friday; Sa=Saturday.

SET PROGRAM TIMES

IMPORTANT: The thermostat will remain in occupied

mode from the point of initial programming until it

encounters the first unoccupied start time. To avoid

the unnecessary occupied period following initial programming, set a 12:00 AM unoccupied start time on

the thermostat when programmed.

COPY A DAY

1. Press the SELECT DAY key. The display shows the

abbreviation for a day.

2. Press and hold the + or - key until the day to be copied

from appears.

3. Press the COPY key.

4. Press and hold the + or - key until the day to be copied

to appears.

NOTE: The day to be copied from will remain on the display.

5. Press the COPY key a second time to perform the

copy.

6. Repeat Steps 3 to 5 to copy to another day.

SET PROGRAM TEMPERATURE SETPOINTS

NOTE: The setpoint temperature range is 45°F (unoccupied

heat) to 95°F (unoccupied cool). The occupied heat setpoint

must be at least 2°F less than the occupied cool setpoint.

1. Press the SET TEMPERATURE key (OCCUPIED

HEAT, OCCUPIED COOL, UNOC HEAT, or UNOC

COOL). The program indicator will point to OCCUPIED or

UNOCCUPIED and the LCD will indicate HEAT or COOL.

63-4038—7 12

Page 13

T7200/T7300/Q7300

PROGRAM THE THERMOSTAT • CHECKOUT

2. Press and hold the + or - key until the desired tempera-

ture appears.

3. Repeat Steps 1 and 2 until all four temperatures are set.

SET OPERATING DISPLAY

The LCD can show time or temperature. To change the

current display, press the DISPLAY key until the desired

operating display appears.

CLEAR START TIME

1. Press the SELECT DAY key.

2. Press and hold the + or - key until the desired day

appears.

3. Press and hold the OCCUPIED START TIME or

the UNOC START TIME key until the time to clear

appears.

4. Press and hold the CLEAR START TIME key until

the display shows four dashes (----).

NOTE: If there is a second OCCUPIED setting, the start for

time this setting will appear instead of four dashes (----).

TEMPORARILY OVERRIDE PROGRAM

There are three overrides available. The 3 hour occupied

overrides can be initiated from a remote location or the

thermostat. The 3 hour occupied override without + or -

keys can also be initiated from the T7300B cover.

NOTE: Pressing the DISPLAY key at anytime will return

the thermostat to the program.

3 Hour Occupied

The 3 HOUR OCCUPIED key is used to override the

unoccupied program when people need to use the area

temporarily (working late, weekends or holidays).

1. Press the 3 HOUR OCCUPIED key to change the

unoccupied temperature setting to the occupied setpoint for

three hours.

NOTE: The program indicator will point to 3 HR OCCU-

PIED while the override is in effect.

3 Hour Occupied with + or - Key

SET + OR - KEY VALUE

When using the + or - key with the 3 HOUR OCCU-

PIED key, the + or - key has a preassigned value of 0 to 5°F

(default is 0). Use the following steps to check or change

the value:

1. Press the 3 HOUR OCCUPIED key. The program

indicator will point to 3 HR OCCUPIED.

2. Press the DISPLAY key. The LCD will show a

number from 0 to 5.

3. Press the + or - key to change the value.

4. Press the DISPLAY key to return to the program.

Set 3 Hour Occupied Override With + or - Key

The 3 HOUR OCCUPIED key with the + or - key will

override the unoccupied program for three hours with the

occupied temperature setpoint + the preassigned key value

(see Set + or - Key Value section).

1. Press the 3 HOUR OCCUPIED key to change the

unoccupied temperature setting to the occupied setpoint for

three hours.

2. Press the + key to increase or press the - key to

decrease the occupied setpoint by the key value.

EXAMPLE: Unoccupied setpoint is 62°F, occupied

setpoint is 70°F and key value is 3°F. Pressing the

3 HOUR OCCUPIED key and the + key will change

the setpoint from 62°F to 70°F plus 3°F or 73°F.

Pressing the - key would change the setpoint to 70°F

minus 3°F or 67°F.

NOTE: The program indicator will point to 3 HR OCCU-

PIED while the override is in effect. The LCD will not

reflect the key value.

Cont Unoc

The continuous unoccupied override feature holds the

setpoint at the unoccupied temperature setpoint until the

DISPLAY or CONT UNOC key is pressed. This override

is used when the area will be closed for a temporary closing

such as a long holiday.

1. Press the CONT UNOC key to hold the temperature

at the unoccupied setpoint.

2. Press the CONT UNOC key again to return to the

program.

OVERVIEW

Check that all wiring is correctly completed and all

sensors are installed. The thermostat should be mounted on

the wallplate or subbase. If the thermostat has not been

programmed, when the power is first turned on, the LCD

will show four dashes (----). Without programming, the

thermostat will operate from default temperature setpoints

(see OPERATION section).

NOTE: It is helpful to program the thermostat before using

the Checkout procedure. Refer to the Programming sec-

tion to set a program.

Checkout

If the display has two dashes and a degree sign (--°), wait

sixty seconds and press the DISPLAY key twice. If the

display does not change or is blank, refer to the Troubleshooting section.

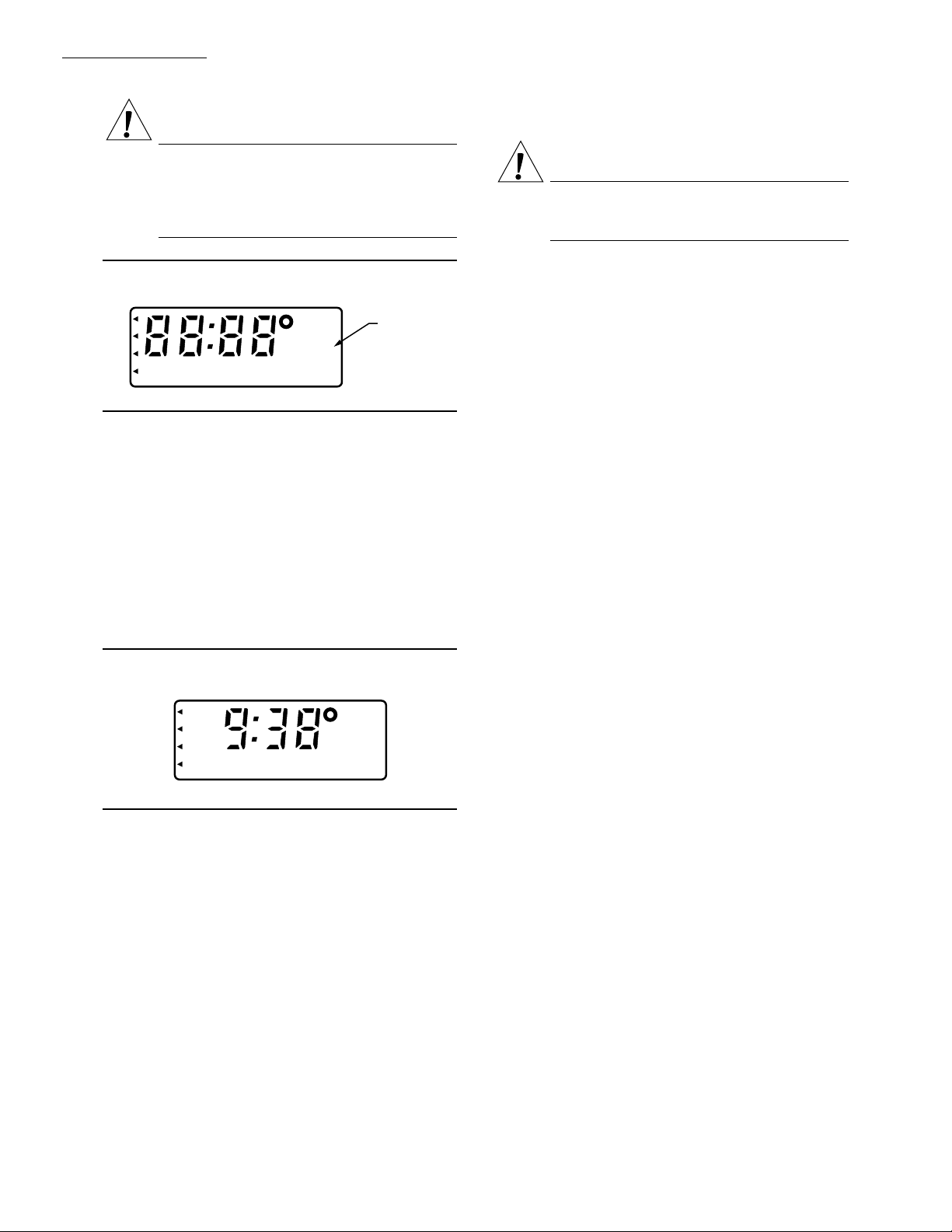

TEST MODE

The thermostat has a test mode that aids the installer in

performing the checkout. The test mode overrides the

minimum on and off times so the checkout can be quickly

performed. Press the CLOCK and DAY keys at the same

time to start the test mode. All the display segments will

appear. See Fig. 19

13 63-4038—7

Page 14

T7200/T7300/Q7300

CHECKOUT

CA UTION

Do not use the test mode for longer than 10 minutes. The test mode overrides the minimum on and

off times that protect the system. Equipment damage can result if the thermostat remains in the test

mode.

COOL

Move switch to auto.

CA UTION

Do not operate cooling if outdoor temperature is

below 50°F (10°C). Refer to the manufacturer

recommendations.

Fig. 19—All segments on display.

TEST MODE

INDICATOR

M4415

S

U

M

O

TUWETHFRS

AM

PM

A

COMM

HEAT

● ● ●

COOL

BATT

To discontinue the test mode at any time, press the

CLOCK and DAY keys at the same time. The Test Mode

Indicators will no longer show on the screen.

HEAT

NOTE: When the thermostat is used with a subbase with

subbase and fan switches, set the switches to AUTO.

1. Press the CLOCK and DAY keys at the same time.

This starts the test mode.

2. Press the DISPLAY key. See Fig. 20.

Fig. 20—Display when starting test sequence.

COMM

HEAT

AM

● ● ●

COOL

S

U

BATT

M4418

NOTE: When cooling setting changes, thermostat will wait

up to five minutes before turning on the cooling equip-

ment. This delay is to protect the compressor.

1. Press the OCCUPIED COOL key.

2. Press the - key to lower the setpoint 5°F (3°C) below

the room temperature. The cooling should start (both stages

if multistage), and the fan should run.

NOTE: It can be necessary to change the OCCUPIED

HEAT setpoint. However, be aware that the OCCUPIED

HEAT and OCCUPIED COOL setpoints must have a

2°F difference.

3. Press the OCCUPIED COOL key.

4. Press the + key to raise the setpoint 5°F (3°C) above

the room temperature. The cooling and fan should shut off.

When the thermostat has a system switch, move the

switch to the COOL position and repeat Steps 1 through 4.

Move the system switch to the OFF position. All heating

or cooling should stop.

FAN

Thermostat

Fan Switch (located on the back of the thermostat):

— CON: Fan operates continuously in the occupied

mode.

— INT-FAN: Fan operates directly with the thermo-

stat call for heating or cooling in the occupied

mode.

Subbase

3. Press the OCCUPIED HEAT key.

4. Press the + key to raise the setpoint 5°F (3°C) above

the room temperature. The heating should start (both stages

if multistage), and the fan should run (may be a short delay on

forced air systems).

NOTE: It can be necessary to change the OCCUPIED

COOL setpoint. However, be aware that OCCUPIED

HEAT and OCCUPIED COOL setpoints must have a

2°F difference.

5. Press the OCCUPIED HEAT key.

6. Press the - key to lower the setpoint 5°F (3°C) below

the room temperature. The heating should shut off, followed

by the fan shutoff.

When the thermostat has a system switch, move the

switch to the HEAT position and repeat steps 3 through 6.

63-4038—7 14

NOTE: Subbase fan switch overrides the thermostat fan

switch.

Subbase Dip Switch No. 4:

— ON: Fan operates only with cool.

— OFF: Fan operates with heat and cool.

Q7300E Fan Switch:

— ON: Fan operates continuously.

— AUTO: Fan operates directly with the thermostat

call for heating or cooling.

IMPORTANT: Press the CLOCK and DAY keys at the same

time to discontinue the test mode. The Test Mode Indicators will no longer show on the screen. See Fig. 19.

Page 15

T7200/T7300/Q7300

OPERATION

Operation

T7200/T7300 RELAY LOGIC

The T7300 contains three switching relays. When the

mini-jumper is set for conventional applications, the relays

control first stage cooling, first stage heating, and fan.

When the mini-jumper is set for heat pump applications,

the relays control the heat pump compressor, auxiliary heat,

and fan. Because of this change in switching logic, it is

important to use Q7300C,D, or F subbases when the T7300

is set for heat pump applications and use Q7300A,B,E,G

subbases when the T7300 is set for conventional applications.

The T7200A Relay Logic is for conventional applications. The T7300B Relay Logic is for heat pump applications.

T7200/T7300 AND CONVENTIONAL

THERMOSTATS

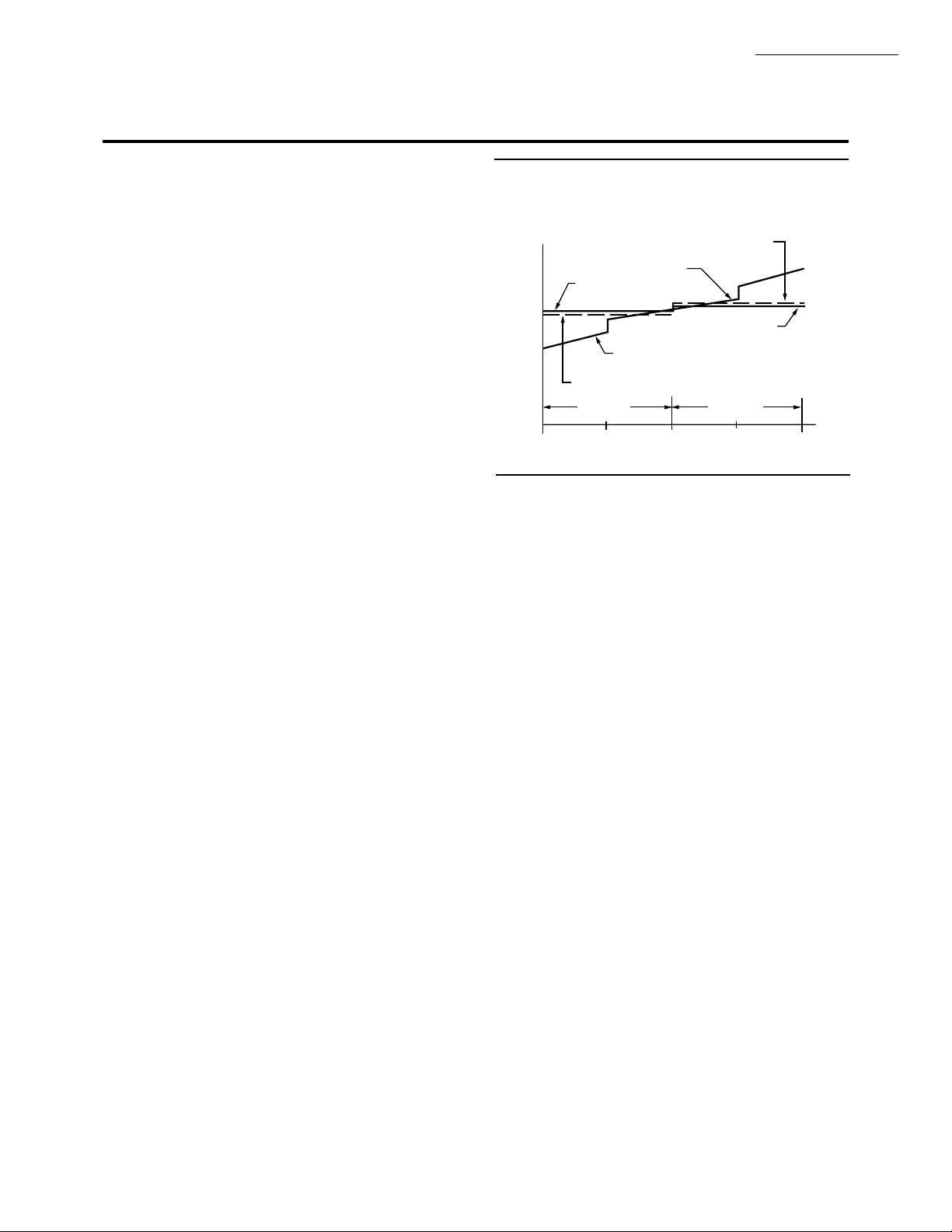

P+I Control

The T7200/T7300 microprocessor based control requires

that the user understands temperature control and thermostat performance. A conventional electromechanical or electronic thermostat does not control temperature precisely at

setpoint. Typically, there is an offset (droop) in the control

point as the system load changes. This is a phenomenon

that most people in the industry know and accept. Many

factors contribute to offset including switch differential,

thermal lag, overshoot, cycle rates and system load.

The thermostat microprocessor simultaneously gathers,

compares and computes data. Using this data, it controls a

wide variety of functions. The special proprietary algorithm (program) in the thermostat eliminates the factors

causing offset. This makes temperature control more accurate than the conventional electromechanical or electronic

thermostats. The temperature control algorithm is called

proportional plus integral (P+I) control.

The thermostat sensor, located on the thermostat or

remote, senses the current space temperature. The proportional error is calculated by comparing the sensed temperature to the programmed setpoint. The deviation from the

setpoint is the proportional error.

The thermostat also determines integral error, which is a

deviation based on the length of error time. The sum of the

two errors is the (P+I) error. The cycle rate used to reach

and maintain the setpoint temperature is computed using

the P+I. The addition of the integral error is what differentiates the thermostat from many other electronic and electromechanical thermostats. See Fig. 21.

Fig. 21—Proportional temperature control

versus P+I temperature control.

THERMOSTAT

COOL SETPOINT

PROPORTIONAL COOL

CONTROL POINT

P+I CONTROL

POINT

P+I CONTROL POINT

TEMPERATURE

100 50 0 50 100

PROPORTIONAL HEAT

CONTROL POINT

THERMOSTAT

HEAT SETPOINT

HEATING

PERCENT LOAD

COOLING

M4414

While the thermostat is designed to eliminate droop,

allowing droop can be desirable in applications where

building visitors are dressed for the weather and their stays

are brief. Examples of these applications include fast food

restaurants and convenience stores. The droopless feature

of the thermostat can be overridden by placing the droop/

droopless select switch located on the subbase in the OFF

position. This removes the integral calculation from the

thermostat control scheme, allowing only the proportional

control to occur.

EQUIPMENT PROTECTION

As part of the operational sequence, the T7200/T7300

microprocessor also incorporates minimum On and Off

times for all heating and cooling stages. Minimum On and

Off times assure that rapid cycling of equipment will not

occur, extending equipment life. Minimum On/Off times

for compressor stages are two minutes On and four minutes

Off. Minimum On/Off times for heat (electric resistive or

gas) are two minutes.

T7200/T7300 THERMOSTAT OPERATION

Startup

When power to the thermostat is turned on, a startup and

initialization program begins. The startup takes place after

total loss of power (24 Vac and battery backup). At this

time, the system default values are put into memory (replacing the user program that was lost). Default values are

heating 68°F (20°C) and cooling 78°F (26°C) for the occupied modes. Unoccupied default values are heating 55°F

(13°C) and cooling 90°F (32°C).

15 63-4038—7

Page 16

T7200/T7300/Q7300

OPERATION

NOTE: These unoccupied defaults are only used if an unoc-

cupied start time is entered or the CONT UNOC key is

pressed. Immediately following initialization, the user

can enter new setpoints to be used in place of the default

values.

If the battery backup was operating during a power

failure, and 24 Vac power comes back on, the user-entered

time and temperature program saved in memory is used. If

24 Vac is lost, and no battery backup exists, the default

temperatures is placed into memory when the power comes

back on. These default values are then used for temperature

control.

Occupied

When the thermostat is operating in the occupied mode,

the temperature is controlled to the occupied heat or cool

setpoint. The normally open (A1) auxiliary relay contacts

are closed and the normally open contacts (A3) auxiliary

relay contacts are opened during the occupied modes (if the

subbase being used has this option). The fan operates as

follows:

• No switching subbase used: Operation of the fan is

continuous (fan always energized) unless the fan option switch on the back of the T7300 (#3) is set to

intermittent (cycles with Y1 or W1).

• Switching subbase used: Q7300 fan switch can be set

to ON (always energized) or AUTO (cycles with Y1

or W1).

NOTE: If subbase configuration switch no. 4 (on any Q7300

conventional subbase) is set to the ON position, the fan

cycles on a call for cooling only; switch no. 4 has no effect

on heat pump subbases (Q7300C, D, F).

Unoccupied

When the thermostat is operating in the unoccupied

mode, the temperature is controlled to the unoccupied heat

or cool setpoint. The auxiliary relay contacts is open and the

fan operates as follows:

• Switching or non-switching subbase used: Fan is always be intermittent (cycles with Y1 or W1). See

NOTE for OCCUPIED.

Conventional System

RECOVERY FROM UNOCCUPIED

Intelligent Recovery™ is a Honeywell trademark for

the way the thermostat controls the heating and cooling

equipment during recovery from unoccupied to occupied

setting. During recovery, the control point ramps up at the

rate of 5°F (3°C) per hour rather than jumping from the

energy savings setting to the comfort setting all at once.

This provides additional energy savings.

When the Intelligent Recovery™ is used in the heating

mode, the control point raises 5°F (3°C) per hour, maximizing the use of the more economical first stage heat to bring

the sensed temperature to the desired comfort setpoint. This

minimizes using the typically more expensive second stage

heat.

The advantages are:

• Comfort setting is achieved at the programmed time

and maintained regardless of weather conditions; occupants are comfortable.

• Drafts from low temperature discharge air are minimized during occupied periods.

• The thermostat automatically uses the more economical first stage of heat as the primary heat source during

heat mode recovery, avoiding the use of the expensive

second stage heating.

• Comfort and energy savings can be achieved in both

heating and cooling.

• The thermostat reduces heat cycling, extending equipment life.

Heat Pump Operation

The T7200 is fixed for either heat pump or conventional

control applications. The T7300 is configurable for either

heat pump or conventional applications, depending on the

subbase used. Additional information is required when

configured for heat pump.

The heat pump mini-jumper (located on the back of the

thermostat) places the thermostat into the heat pump mode.

Refer to the Installation section.

O AND B TERMINALS FOR HEATING

OR COOLING CHANGEOVER

The Q7300C and F controls heat pump changeover. The

Q7300D is only used in a heat pump application when the

heat pump controls the reversing valve changeover. See

Table 8 for the operation of the O and B terminals on the

Q7300C and F.

TABLE 8—OPERATION OF THE Q7300

O AND B TERMINALS.

System Switch O B

Heat Open Closed

Cool Closed Open

Auto (Heat)

Auto (Cool)

a

b

Open Closed

Closed Open

Emergency Heat Open Closed

Off

a

When the system is calling for heat or is de-energized, but

cc

the last function was heat.

b

When the system is calling for cool or is de-energized, but

the last function was cool.

c

When the last function was heating, the operation is the

same as Auto (Heat). If the last function was cooling, the

operation is the same as Auto (Cool).

RECOVERY FROM UNOCCUPIED

The heating recovery ramp is 3°F per hour, which

differs from the 5°F per hour for conventional systems. The

3°F degree difference helps the system use the economical

heat pump more and the expensive auxiliary heat less. The

cooling ramp is 5°F, the same as conventional systems.

63-4038—7 16

Page 17

T7200/T7300/Q7300

OPERATION

FAN OPERATION

When the subbase fan switch is in the ON position, the

fan is energized continuously in the occupied mode. The

AUTO position energizes the fan with the heating or cooling system. If the subbase is Q7300D, during unoccupied

mode, the fan cycles with Y1 and W1.

NOTE: The Q7300 switch no. 4 has no effect when the

thermostat is configured for heat pump.

EMERGENCY HEAT

When the system switch is in the EM. HEAT position

(on select Q7300 subbases), the auxiliary heat is stage 1 and

the compressor stages are locked off. The fan cycles with

the auxiliary heat.

GENERAL OPERATION INFORMATION

Cycle Rates

The thermostat control algorithm maintains the temperature by cycling stages of heating or cooling to meet

setpoint. See Table 9 for the nominal cycle rates provided.

TABLE 9—NOMINAL CYCLE RATES

FOR HEATING AND COOLING.

System Type H1 H2 C1 C2 C3

Conventional 8 8444

Heat Pump 4 8 4 4 —

Subbase Auxiliary Relay

The Q7300 auxiliary relay output acts as a time-of-day

switch to be used with an economizer minimum position

control. The normally open (A1) auxiliary relay contacts

are closed during the occupied period and open during the

unoccupied period. The normally closed (A3) auxiliary

relay contacts are open during the occupied period and

closed during the unoccupied period. The contacts are in

the normal state during recovery.

Interfacing with Electromechanical Economizers

(Subbases with Auxiliary Relay)

Mechanical cooling is often used when outside temperatures are in the 50° to 60°F range and humidity is below 50

percent. In central and northern climates, hundreds of hours

fall into this temperature category. By permitting 80 to 100

percent outside air into the system, mechanical cooling

may not be needed at all, particularly during spring and fall.

An economizer is used to take advantage of the outside

air. The typical economizer consists of an outside air damper,

motor, outdoor air changeover control and a minimum

position potentiometer. The motor controls the dampers.

Suitability of the outside air for cooling is determined by

the outdoor air changeover control. The potentiometer is

used for adjusting the minimum position of the economizer

dampers, which provide a minimum amount of fresh air for

ventilation.

The economizer reduces compressor run time, thereby

saving energy and extending the compressor life. The

drawback to the economizer is that during the unoccupied

period, if there is no call for cooling or outdoor air is not

suitable for free cooling, the economizer is controlled to

minimum position. This position allows some percentage

of outdoor air to enter the building, regardless of air suitability. The situation can cause the heating or cooling to run

more often than if suitable outdoor air is permitted to enter

the building.

The thermostat can take advantage of an economizer by

connecting the auxiliary relay contacts (A1 and A2) of the

subbase to control the economizer minimum position potentiometer. The contacts close during the occupied period,

allowing the economizer to operate normally. The contacts

are open duirng the unoccupied period, disabling the minimum position feature of the economizer. The open contacts

cause the economizer to drive dampers fully closed instead

of staying at minimum open position. This reduces the

possibility of unsuitable outdoor air from entering the

building, which lowers the internal load on the HVAC

system are saves additional energy.

Other Uses for the Auxiliary Relay

Examples of other uses of the auxiliary relay are hot

water heaters, lighting or baseboard heat. The additional

loads are connected to the auxiliary relay contacts on the

subbase. The contacts are rated for 1.6A at 30 Vac, but can

be adapted to higher current applications with the use of an

external relay and transformer. See Fig. 22.

Duty Cycle Interface

Duty cycling HVAC equipment controlled with a T7200

or T7300 is recommended because the thermostat is already maintaining an optimum control cycle rate. Adding

another external duty cyle increases the P+I error being

sensed and results in degradation of temperature control

and equipment efficiency.

Fig. 22—Use of external relay and transformer

for auxiliary loads greater than 1.6A.

L1

L2

(HOT)

Q7300 SUBBASE

A1

A2

A3

AUXILIARY

RELAY

CONTACTS

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

RELAY REQUIRED (R8222 OR SIMILAR).

2

TERMINAL A3 AVAILABLE ON Q7300A,B,D,E AND G MODELS ONLY

3

3

1

TO

LOAD

2

M4383

17 63-4038—7

Page 18

T7200/T7300/Q7300

CROSS REFERENCE

Refer to Table 10 for thermostat and subbase cross referencing information.

Model

Number

Fig.

No. Description

T7200A 7-day programmable thermostat for commercial conventional systems.

A1006 23,24,25 Tradeline®. T7200A1006 Beige color

A1022 23,24,25 International faceplate. T7200A1006 Beige color

T7200B 7-day programmable thermostat for commercial water source heat pump systems.

B1004 9,26 Tradeline. T7200B1004 Beige color

B1012 9,26 Mammoth part number 71116701. T7200B1004 Beige color

B1020 9,26 Carrier part number HH07AX010A. T7200B1004 Beige color

T7300A 7-day programmable thermostat for commercial conventional systems.

A1005 Tradeline®. T7300A1005 Beige color

A1013 York part no. 025-27506. Used in Y7300B1008, T7300A1005 Beige color

A1021 Lennox part no. 81G5901. T7300A1005 Beige color

A1039 Trane part no. THT-0608. T7300A1005 Beige color

A1047 Micrometl part no. 901-114. Used in Y7300A1000 T7300A1005 Beige color

A1054 International face plate. T7300A1005 Beige color

A1062 Carrier part no. HH07AX005. Used in Y7300A1018. T7300A1005 Beige color

A1070 International face plate. T7300A1005 Beige color

A1088 Spanish face plate. T7300A1005 Beige color

A1104 Tradeline. T7300A1104 Premier White™ color

1

1

1

1

1

1

1

1

1

1

T7300B Fully configurable programmable thermostat with 3-HOUR OVERRIDE key on cover. See figure 2

for view of door.

B1003 Tradeline. T7300B1003 Beige color

B1011 Climate Control part no. 490249B-05. T7300B1003 Beige color

B1029 McQuay part no. 490249B-06. T7300B1003 Beige color

B1037 Arcoaire part no. 1506746. Used in Y7300B1024. T7300B1003 Beige color

B1045 Comfort Maker part no. 1505746. Used in T7300B1003 Beige color

B1052 Tradeline. T7300B1052 Premier White™ color

1

See subbase for figure number.

1

1

1

1

1

1

Cross Refer ence

TABLE 10—THERMOSTAT AND SUBBASE CROSS REFERENCE.

Trade

Replacement Remarks

Y7300C1006 and Y7300D1004. T7300A1104 Premier White™ color

T7300A1104 Premier White™ color

T7300A1104 Premier White™ color

and Y7300C11014. T7300A1104 Premier White™ color

T7300A1104 Premier White™ color

T7300A1104 Premier White™ color

T7300A1104 Premier White™ color

T7300A1104 Premier White™ color

T7300B1052 Premier White™ color

T7300B1052 Premier White™ color

T7300B1052 Premier White™ color

Y7300B1016. T7300B1052 Premier White™ color

(Continued)

63-4038—7 18

Page 19

T7200/T7300/Q7300

CROSS REFERENCE

TABLE 10—THERMOSTAT AND SUBBASE CROSS REFERENCE (Continued).

Model

Number

Fig.

No. Description

Trade

Replacement Remarks

T7300C Fully configurable programmable thermostat with limited access cover. See Figure 3 for view of

door.

C1001 Tradeline. T7300C1001 Beige color

C1019 Tradeline. Premier White™ T7300. T7300C1019 Premier White™ color

1

1

Subbase

Q7300A Conventional equipment. System: none. Fan: none.

A1000 27 Tradeline. 1 heat and 2 cool. Q7300A1000 Brown color

A1018 28,29,

Tradeline. 2 heat and 2 cool. Q7300A1018 Brown color

30,32,

35,36

A1034 27,32 Trane part no. BAS-0444. Q7300A1000 Brown color

Q7300A1075 Light gray color

A1042 28,29, Trane part no. BAS-0445. Q7300A1018 Brown color

30,32,

Q7300A1083 Light gray color

35,36

A1059 28,29 Micrometl part no. 901-3. Used in Y7300A1000. Q7300A1018 Brown color

30,32,

Q7300A1083 Light gray color

35,36

A1067 28,29, Carrier part no. HH93AX005. Q7300A1018 Brown color

30,32,

Q7300A1083 Light gray color

35,36

A1075 27,32 Tradeline. Used with Premier White™ T7300.

Q7300A1075 Light gray color

1 heat and 1 cool.

A1083 28,29,

30,32,

Tradeline. Used with Premier White™ T7300.

2 heat and 2 cool.

Q7300A1083 Light gray color

35,36

Q7300B Conventional equipment. System: Heat-Off-Cool-Auto. Fan: Auto-On.

B1008 28,29,

Tradeline. 2 heat and 2 cool. Q7300B1008 Brown color

30,32,

35,36

B1016 28,29, Lennox part no. 81G6001. Q7300B1008 Brown color

30,32, Q7300B1073 Brown color

35,36 Q7300B1081 Light gray color

B1024 28,29, York part no. 025-227507. Used in Y7300B1008. Q7300B1008 Brown color

30,32, Q7300B1073 Brown color

35,36 Q7300B1081 Light gray color

B1032 28,29, Trane part no. BAS-0446. Q7300B1008 Brown color

30,32, Q7300B1073 Brown color

35,36 Q7300B1081 Light gray color

B1040 28,29, Carrier part no. HH93AAX004. Q7300B1008 Brown color

30,32, Q7300B1073 Brown color

35,36 Q7300B1081 Light gray color

B1057 28,29, Snyder General part no. 1520510. Used in Q7300B1008 Brown color

30,32, Y7300B1016 and Y7300B10224. Q7300B1073 Brown color

35,36 Q7300B1081 Light gray color

B1065 28,29 Snyder General part no. 490249B-04. Q7300B1008 Brown color

30,32, Q7300B1073 Brown color

35,36 Q7300B1081 Light gray color

1

See subbase for figure number.

(Continued)

19 63-4038—7

Page 20

T7200/T7300/Q7300

CROSS REFERENCE

Model

Number

B1073 28,29,

30,32,

35,36

B1081 28,29,

30,32,

35,36

Q7300C Heat pump systems. System: Em. Ht.-Heat-Off-Cool-Auto. Fan: Auto-On.

C1006 38,42 Tradeline. 1 stage heat pump. Q7300C1006 Brown color

C1014 40 Tradeline. 2 stage heat pump. Q7300C1014 Brown color

C1022 40 Lennox part no.81G6901. Q7300C1014 Brown color

C1030 40 York part no. 025-27508. Used in Y7300C1006. Q7300C1014 Brown color

C1048 38,42 Trane part no.BAS-0447. Q7300C1014 Brown color

C1055 40 Trane part no.BAS-0448. Q7300C1014 Brown color

C1063 38,42 Micrometl part no. 901-24. Used in Y7300C1014. Q7300C1006 Brown color

C1071 40 Obsolete Brown color

C1089 40 Tradeline. 2 stage heat pump. Q7300C1089 Brown color

C1097 38,42 Tradeline. Used with Premier White T7300.

C1105 40 Tradeline. Used with Premier White T7300.

Q7300D Heat pump system. System: Em.Ht.-Heat-Off-Cool-Auto. Fan: Auto-On.

D1004 41 Carrier part no. HH93AX002. Q7300D1038 Brown color

D1012 39,42 Carrier part no. HH93AX003. Q7300D1053 Brown color

D1020 41 York part no. 025-27724-000. Used in Y7300D1004. Q7300D1038 Brown color

D1038 41 Tradeline. 2 stage heat pump. Q7300D1038 Brown color

D1046 41 Lennox part no. 13H7601. Q7300D1038 Brown color

TABLE 10—THERMOSTAT AND SUBBASE CROSS REFERENCE (Continued).

Fig.

No. Description

Tradeline. 2 heat and 2 cool. Q7300B1073 Brown color

Tradeline. Used with Premier White T7300.

2 heat and 2 cool.

1 stage heat pump.

2 stage heat pump.

Trade

Replacement Remarks

Q7300B1081 Light gray color

Q7300C1089 Brown color

Q7300C1105 Light gray color

Q7300C1089 Brown color

Q7300C1105 Light gray color

Q7300C1089 Brown color

Q7300C1105 Light gray color

Q7300C1089 Brown color

Q7300C1105 Light gray color

Q7300C1097 Light gray color

Q7300C1097 Light gray color

Q7300C1105 Light gray color

Q7300D1061 Brown color

Q7300D1079 Light gray color

Q7300D1087 Light gray color

Q7300D1061 Brown color

Q7300D1079 Light gray color

Q7300D1061 Brown color

Q7300D1079 Light gray color

63-4038—7 20

(Continued)

Page 21

TABLE 10—THERMOSTAT AND SUBBASE CROSS REFERENCE (Continued).

Model

Number

D1053 Tradeline. 1 stage heat pump. Q7300D1053 Brown color

D1061 41 Tradeline. 2 stage heat pump. Q7300D1061 Brown color

D1079 41 Tradeline. Used with Premier White T7300.

D1087 39,42 Tradeline. Used with Premier White T7300.

Q7300E Conventional equipment. System: none. Fan: none.

E1001 28,29,30Tradeline. 2 heat and 2 cool. Q7300E1001 Brown color

Fig.

No. Description

2 stage heat pump.

1 stage heat pump.

Trade

Replacement Remarks

Q7300D1079 Light gray color

Q7300D1087 Light gray color

T7200/T7300/Q7300

CROSS REFERENCE

E1019 28,29,30Tradeline. Used with Premier White T7300.

2 heat and 2 cool.

Q7300F Heat pump systems. System: none. Fan: none.

F1009 44 Tradeline. 1 stage heat pump. Q7300F1009 Brown color

F1017 44 Tradeline. 2 stage heat pump. Q7300F1017 Brown color

F1025 44 Tradeline. Used with Premier White T7300.

1 stage heat pump.

F1033 44 Tradeline. Used with Premier White T7300.

2 stage heat pump.

F1041 43 Carrier part no. HH93AX006. Used in Y7300A1018. Q7300F1009 Brown color

Q7300G Conventional equipment. System: Heat-Off-Cool-Auto. Fan: none.

G1007 31,32,

33,34

G1015 31,32,

33,34

Q7300L Conventional equipment. System: none. Fan: Auto-On.

L1006 45 LDS Church. Q7300L1014 Brown color

L1014 46 Tradeline. 2 heat and 1 cool. Q7300L1014 Brown color

Tradeline. 1 heat and 3 cool. Q7300G1007 Brown color

Tradeline. Used with Premier White T7300.

1 heat and 3 cool.

Q7300E1019 Light gray color

Q7300F1025 Light gray color

Q7300F1033 Light gray color

Q7300F1025 Light gray color

Q7300G1015 Light gray color

21 63-4038—7

Page 22

T7200/T7300/Q7300

WIRING DIAGRAMS

Fig. 23—T7200A with wallplate.

Wiring Diagrams

T7200

THERMOSTAT

C1

H1

FAN

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

FIELD INSTALLED JUMPER.

2

WALLPLATE

RH

2

RC

X

Y1

W1

G

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

TERMINAL STRIP

Y1

W1

SYSTEM

TRANSFORMER

R

C

(IF NO "C" TERMINAL)

COOL 1

HEAT 1

G

FAN

M4405

L1

(HOT)

L2

1

63-4038—7 22

Page 23

T7200/T7300/Q7300

WIRING DIAGRAMS

Fig. 24—T7200A with 1-stage cooling system with differential enthalpy changeover using W7459A/C7400 with

M7415 Actuator.

AIR ENTHALPY

X

Y1

W1

G

RH

RC

T7200A

WALLPLATE

OUTDOOR

SENSOR

C7400

RETURN AIR

ENTHALPY

SENSOR

C7400

6

C7150B MIXED

OR DISCHARGE

AIR SENSOR

+

S

+

5

S

W

R

TR1

TR

+

SO

+

SR

5

2

1

3

4

TT1

P

P1

T6301 AMBIENT

LOCKOUT CONTROL

o

F SETPOINT

50

W7459A ECONOMIZER PACKAGE

1K

4

18

2K

MINIMUM POSITION

ADJUSTMENT

C

Y1

Y2

W1

G

R

HVAC EQUIPMENT

TERMINAL STRIP

COOL 1

HEAT 1

FAN

1S1

M7415 ACTUATOR

TR

TR1

24 VAC

3

L1

(HOT)

L2

T

T1

MIXED AIR

SENSOR

P1

P

MINIMUM

POSITION

1

2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED. 24 VAC SECONDARY.

2

ASSURE THAT EQUIPMENT TRANSFORMER IS SIZED TO HANDLE THE EXTRA LOAD OF THE ECONOMIZER, ACTUATOR,

T7200 AND WALLPLATE

3

AN ELECTRONIC SWITCH THAT CLOSES WHEN POWERED BY A 24 VAC INPUT.

4

RELAYS 1K AND 2K ACTUATE WHEN THE ENTHALPY SENSED BY THE C7400 IS HIGHER THAN THE ENTHALPY SETPOINT A-D.

5

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD BE REMOVED ONLY IF A C7400 ENTHALPY SENSOR IS

ADDED TO SR AND + FOR DIFFERENTIAL ENTHALPY.

6

FIELD INSTALLED JUMPER.

23 63-4038—7

M4407

Page 24

T7200/T7300/Q7300

WIRING DIAGRAMS

Fig. 25—T7200A with electric heat system.

T7200

THERMOSTAT

C1

H1

FAN

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

2

FIELD INSTALLED JUMPER.

3

RELAY REQUIRED (R8222 OR SIMILAR).

WALLPLATE

RH

2

RC

Y1

W1

G

EXISTING HVAC EQUIPMENT

Y1

W1

SYSTEM

TRANSFORMER

R

CX

(IF NO "C" TERMINAL)

COOL 1

3

ELECTRIC

HEAT FAN

RELAY 1K

1K1

G

HEAT 1

FAN

M4406

L1

(HOT)

L2

1

Fig. 26—T7200B with 1-stage heat pump system.

T7200

THERMOSTAT

C/O

H1/C1

FAN

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

WALLPLATE

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

TERMINAL STRIP

R

X

O

Y

G

R

C

O

Y

G

SYSTEM

TRANSFORMER

(IF NO "C" TERMINAL)

REV.

VALVE

COMP.

FAN

M4396

1

L1

(HOT)

L2

63-4038—7 24

Page 25

Fig. 27—T7300/Q7300A with single transformer 1-stage heat/1-stage cool system.

T7200/T7300/Q7300

WIRING DIAGRAMS

T7300

THERMOSTAT

C1

H1

FAN

T7147

REMOTE

COMFORT

ADJUST

MODULE

Q7300 SUBBASE

CA1

CA2

CA3

CA4

CA5

T

T

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

RH

2

RC

X

Y1

W1

G

COM

3

LED1

LED2

1

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

FIELD INSTALLED JUMPER.

2

24 VAC ONLY.

3

TERMINAL STRIP

R

C

(IF NO "C" TERMINAL)

Y1

W1

G

SYSTEM

TRANSFORMER

COOL 1

HEAT 1

FAN

L1

(HOT)

L2

1

M4386

L1

(HOT)

L2

1

25 63-4038—7

Page 26

T7200/T7300/Q7300

WIRING DIAGRAMS

Fig. 28—T7300/Q7300A,B,E used with single transformer 1-stage heat/2-stage cool system.

T7300

THERMOSTAT

C1

H1

FAN

T7147

REMOTE

COMFORT

ADJUST

MODULE

1

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

FIELD INSTALLED JUMPER.

2

24 VAC ONLY.

3

4

MODEL

NUMBER

Q7300A

Q7300B

Q7300E

Q7300 SUBBASE

CA1

CA2

CA3

CA4

CA5

T

T

FAN

SWITCH

NO

YES

YES

AUXILIARY

RELAY

CONTACTS

SYSTEM

SWITCH

NO

YES

NO

RH

2

RC

X

C2

H2

Y2

Y1

W2

W1

COM

LED1

LED2

A1

A2

A3

G

3

3

ECONOMIZER

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

TERMINAL STRIP

Y1

W1

SYSTEM

TRANSFORMER

R

C

(IF NO "C" TERMINAL)

COOL 1

Y2

G

L1

(HOT)

L2

1

COOL 2

HEAT 1

FAN

SYSTEM SWITCH

HEAT

OFF

COOL

AUTO

FAN SWITCH

ON

AUTO

M4387

L1

(HOT)

L2

1

4

4

63-4038—7 26

Page 27

Fig. 29—T7300/Q7300A,B used with single transformer 2-stage heat/1-stage cool system.

T7200/T7300/Q7300

WIRING DIAGRAMS

T7300

THERMOSTAT

C1

H1

FAN

T7147

REMOTE

COMFORT

ADJUST

MODULE

1

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

FIELD INSTALLED JUMPER.

2

24 VAC ONLY.

3

4

MODEL

NUMBER

Q7300A

Q7300B

Q7300E

Q7300 SUBBASE

CA1

CA2

CA3

CA4

CA5

T

T

FAN

SWITCH

NO

YES

YES

AUXILIARY

RELAY

CONTACTS

SYSTEM

SWITCH

NO

YES

NO

RH

2

RC

X

C2

H2

Y2

Y1

W2

W1

G

COM

3

LED1

LED2

A1

3

A2

A3

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

TERMINAL STRIP

ECONOMIZER

Y1

W1

W2

SYSTEM

TRANSFORMER

R

C

(IF NO "C" TERMINAL)

COOL 1

HEAT 1

HEAT 2

G

L1

(HOT)

L2

1

FAN

SYSTEM SWITCH

HEAT

OFF

COOL

AUTO

FAN SWITCH

ON

AUTO

M4388

L1

(HOT)

L2

1

4

4

27 63-4038—7

Page 28

T7200/T7300/Q7300

WIRING DIAGRAMS

Fig. 30—T7300/Q7300A,B,E used with single transformer 2-stage heat/2-stage cool system without economizer.

T7300

THERMOSTAT

REMOTE

COMFORT

ADJUST

MODULE

1

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

FIELD INSTALLED JUMPER.

2

24 VAC ONLY.

3

4

MODEL

NUMBER

Q7300A

Q7300B

Q7300E

C1

H1

FAN

T7147

Q7300 SUBBASE

CA1

CA2

CA3

CA4

CA5

T

T

FAN

SWITCH

NO

YES

YES

AUXILIARY

RELAY

CONTACTS

SYSTEM

SWITCH

NO

YES

NO

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

RH

2

RC

X

C2

H2

Y2

Y1

W2

W1

G

COM

LED1

LED2

A1

A2

A3

3

3

ECONOMIZER

TERMINAL STRIP

R

C

Y1

Y2

W1

W2

G

1

(IF NO "C" TERMINAL)

L1

(HOT)

L2

SYSTEM

TRANSFORMER

COOL 1

COOL 2

HEAT 1

HEAT 2

FAN

SYSTEM SWITCH

FAN SWITCH

HEAT

OFF

AUTO

COOL

ON

AUTO

M4389

L1

(HOT)

L2

1

4

4

63-4038—7 28

Page 29

Fig. 31—T7300/Q7300G with single transformer 1-stage heat/3-stage cool system.

T7200/T7300/Q7300

WIRING DIAGRAMS

T7300

THERMOSTAT

C1

H1

FAN

T7147

REMOTE

COMFORT

ADJUST

MODULE

1

24 VAC SECONDARY; MUST BE ABLE TO CARRY ADDITIONAL 6 VA LOAD OF THERMOSTAT AND SUBBASE.

FIELD INSTALLED JUMPER.

2

24 VAC ONLY.

3

Q7300 SUBBASE

CA1

CA2

CA3

CA4

CA5

T

T

AUXILIARY

RELAY

CONTACTS

RH

2

RC

X

C2

C3

Y2

Y1

Y3

W1

G

COM

3

LED1

LED2

A1

3

A2

A3

EXISTING HVAC EQUIPMENT

HVAC EQUIPMENT

TERMINAL STRIP

ECONOMIZER

Y1

Y2

W1

SYSTEM

TRANSFORMER

R

C

(IF NO "C" TERMINAL)

COOL 1

COOL 2

Y3

G

L1

(HOT)

L2

1

COOL 3

HEAT 1

FAN

SYSTEM SWITCH

HEAT

OFF

AUTO

COOL

M4390

L1

(HOT)

L2

1

29 63-4038—7

Page 30

T7200/T7300/Q7300

WIRING DIAGRAMS

Fig. 32—T7300/Q7300A,B,G defeating economizer minimum position during unoccupied period in a

2-stage cool system with single enthalpy changeover using W7459A/C7400 with an M7415 actuator.

A1

A2

X

ENTHALPY

SENSOR

C7400

620 OHM

5

RESISTOR

C7150B MIXED

OR DISCHARGE

AIR SENSOR

W7459A ECONOMIZER PACKAGE

TR1

TR

+

S

SO

SR

1

3

TT1

P

P1

+

+

5

1K

2

4

4

18

2K

MINIMUM POSITION

ADJUSTMENT

C

3

1S1

M7415 ACTUATOR

24 VAC

SENSOR

MIN

POS

TR

TR1

T1

T

P1

P

TR

TR1

T

T1

P1

P

24 VAC

MIXED AIR

SENSOR

MINIMUM