Page 1

APPLICATION:

This standalone micro-controller based LCD temperature

controller provides proportional plus integral (P+I) and on/off

temperature control for commercial Heating, Ventilating & Air

Conditioning System such as Hydronic Heating, Air Handling

Unit, Heat Exchanger or Condensing Tower.

This controller has a modulating analog 2 to 10Vdc or 4 to

20mA output and a 2A on/off output to realize various optional

control functions including cool/heat changeover, heat/cool

sequence control, emergency interlocking and auto-alarming

control.

Table of Contents

Application………………………………………….1

Features…………………………………………….1

Specification………………………………………..2

Dimensions, Installation & Wiring Terminals..….3

Control Operation………………………………….4

Installer SetUp……………………………………..12

FEATURES:

• PI (proportional plus integral) control action

provides accurate, stable and comfortable

temperature control.

• Compatible with series 70 direct-coupled

damper / valve actuator like ML7161,

ML7174, ML7420 / ML7421series ML7425,

ML7984 series, N20010, S10010, M7410E

series, CN7505, CN7510 / CN72 series

CN7220 & CN7234 also VC79 series etc.

• Backlit LCD to display both setting and

measured value.

• Adjustable Zero Energy Band, On/Off

Differential, Proportional Band and

Temperature Offset.

• Analog output can be forced manually to be

convenient for installation & commissioning.

• Optional 2 to 10Vdc or 4 to 20mA direct

acting and reverse acting analog output.

• Selectable internal and external temperature

sensor.

• Wide temperature control range (-20 to 110

°C by using external temperature sensor) is

suitable for extreme temperature control such

as steam and ice water.

• Watch Dog Timer: to resume the controller

from hanging condition.

• Brownout effect to avoid malfunctioning and

care on power ON and power OFF.

• Pluggable terminal block allows pre-wiring

outside of the controller.

• Compact size and slim design provide

elegant and attractive modern style

appearance.

Page 1 of 18 APHITEMPCON001-11-04

Page 2

SPECIFICATIONS:

IMPORTANT: The specifications given in this publication

do not include normal manufacturing tolerances.

Therefore, this unit may not exactly match the listed

specifications. Also, this product is tested and calibrated

under closely controlled conditions and some minor

difference in performance can be expected if those

conditions are changed.

MODEL: T2798I2000

Control Performance: This controller provides 4 to 20mA

or 2 to 10Vdc Proportional plus Integral modulating control

and 4(2) A On/Off control.

INPUTS:

1) Analog - 1 No. (Only PT1000)

2) Digital - 1 No. (Dry Contact)

OUTPUTS:

1) Analog - 1 No.

2) Digital - 1 No.

SETPOINT RANGE:

5-50°C (internal temperature sensor)

-20-110°C (external temperature sensor)

POWER SUPPLY: AC24V ±20%, 50/60Hz,

2 VA.

ANALOG OUTPUT:

2 to 10Vdc OR

4 to 20mA.

DIGITAL OUTPUT:

2A, 24Vac

MOUNTING: Direct wall mounting

with standard electrical mounting box [type-3 module].

TERMINALS: Plug-in screw terminals

are suitable for 1.5 square mm wire.

OPERATING AMBIENT:

0-50°C, 5-80%RH.

Shipping & Storage:

-20 - 45°C, 5-95%RH

ACCURACY:

< / = +/- 0.30°C

REMOTE SENSOR: RTD

PT1000.

Maximum 15m cable length

(line resistance < 4.5Ω)

Enclosure: ABS Plastic, 2-piece. (IP30)

OPERATING PARAMETER:

See TABLE 2 for installer selections.

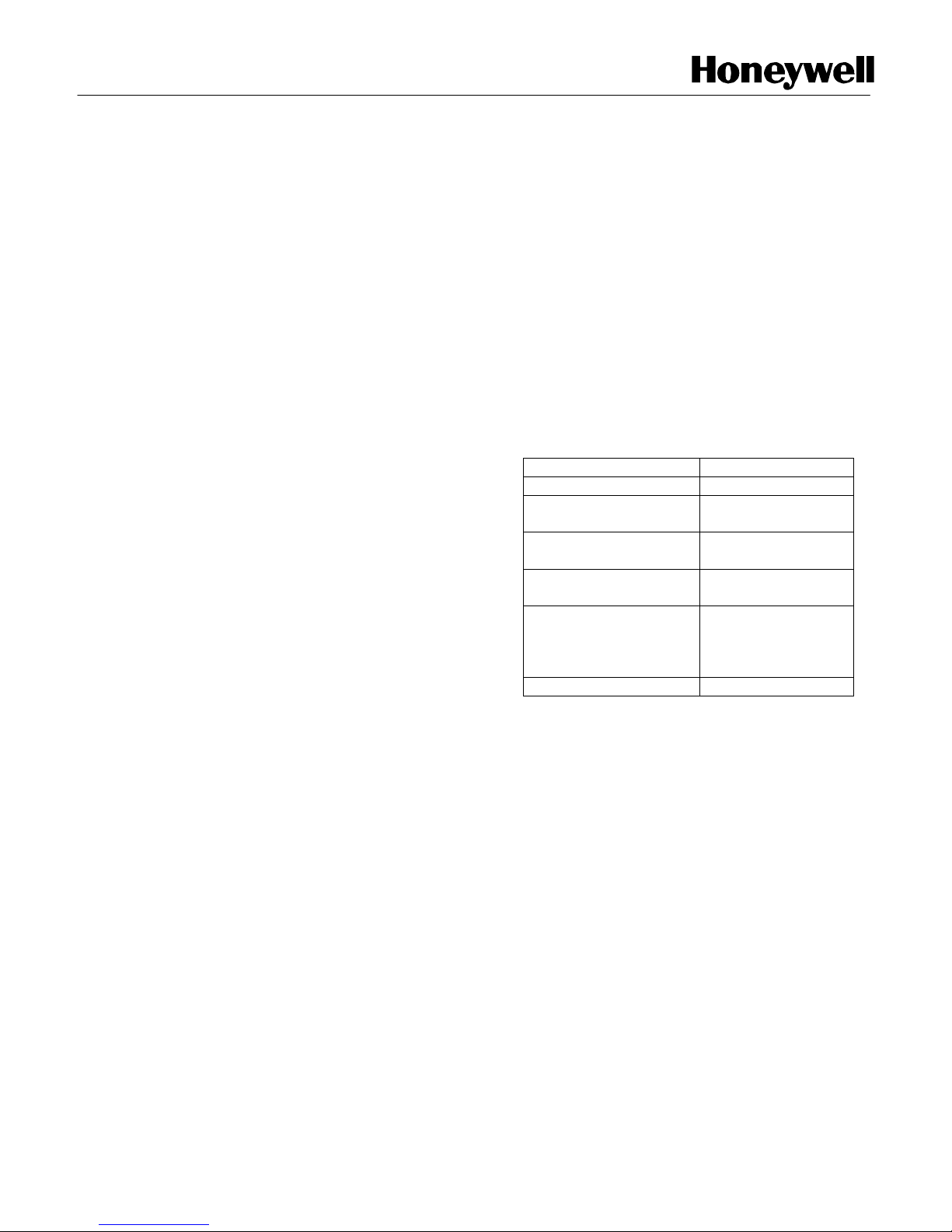

Parameter Selection

Zero Energy Band 1.5 or 3.0°C

On/Off Differential 0.5 to 3.0°C (0.5°C

step change)

Proportional Band 2.0 to 19.0°C (0.1°C

step change)

Offset -3.0 to 3.0°C (0.5°C

step change)

Set Point Definition Heating, Cooling,

H/C midpoint,

Heating/Alarming or

Cooling/Alarming.

Main Sensor Remote or Internal

ACCESSORIES:

Duct Mount Remote Sensor PT1000.

DIN Class B.

Model # RSPT1000

Probe Length: 300mm

(to be ordered separately)

Page 2 of 18 APHITEMPCON001-11-04

Page 3

1234567

8

14

135

17

135

107.5

83.5

86.5

20

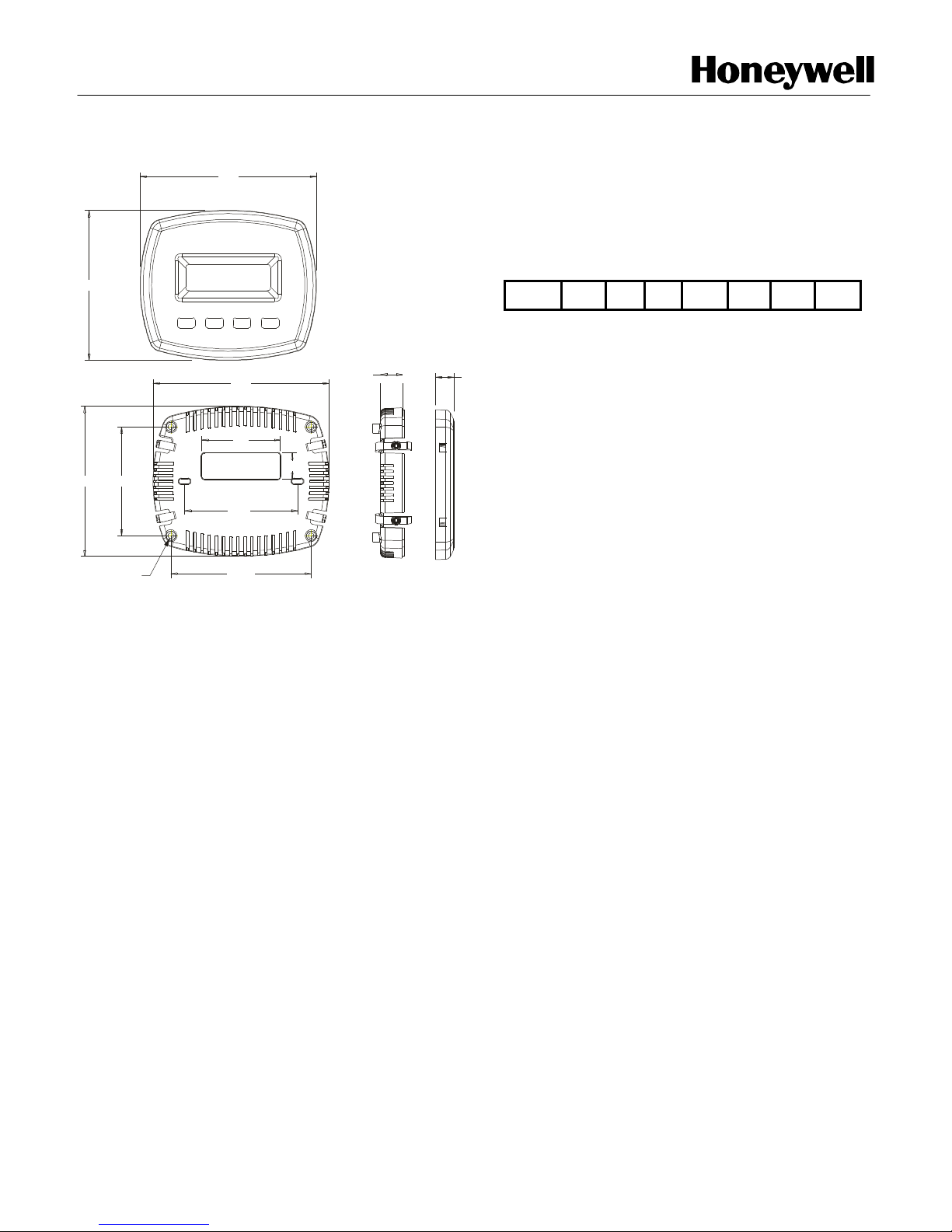

DIMENSIONS:

115

60

115

M3 Self Tapping screw

INSTALLATION:

The controller can be installed in any position on a

flat surface using electrical box [Type-3 Module].

To measure room temperature by internal sensor

and choosing wall mounting method, it is

recommended to be installed 1.5m (about 5 ft.)

above the floor in the area at average temperature

conditions.

For all kinds of mounting method, the product must

be installed in an area with good air circulation.

Do not install the controller where it may be

affected by:

Draughts or dead air spots behind doors

and in corners.

Hot or cold air from ducts.

Radiant heat from sun or appliances.

Concealed pipes and chimneys

WIRING TERMINAL:

1 & 2 – Relay Output

3 – 0Vac

4 – 24Vac

5 – Digital Input

6 – 2…10Vdc OR 4…20mA analog output

7 & 8 – PT1000 Remote Sensor

Page 3 of 18 APHITEMPCON001-11-04

Page 4

CONTROL OPERATION:

Input1 –Remote Temperature Sensor

The controller has an integral sensing device mounted internally. It is also possible to install a

remote room or duct return sensor at different locations. See wiring diagram.

Note#1: The remote sensor should be PT1000 (Refer Accessories)

Input2- Emergency Input

Input2 is to connect with an On/Off dry contact for system error or emergency interlock control. If

the contact is close, the controller will automatically close all output (or open to the maximum

position in reverse mode) and cut off the power. The controller can only be restarted manually.

Note#2: If you don’t want to use the interlock function/emergency input please use a jumper wire

to connect input2 (terminal no.5) and neutral port (Terminal no.3), see wiring diagram.

Output1-Modulating Analog Output (2 to 10Vdc or 4 to 20mA)

Output1 is modulating P+I analog 2 to 10Vdc or 4 to 20mA. It can be selected by Selector

switch. The output signal is normal mode (2 to 10Vdc or 4 to 20mA) or reverse mode (10 to

2Vdc or 20 to 4mA) selectable.

Output2- On/Off digital Output (2A, 24Vac)

Output2 is digital output with 24VAC 2A Contact rating, nominal capacity. It provides On/Off

control for electric heater, on/off valve actuator or fan etc.

Output2 can provide limitation control through pre-setting a separate temperature limitation.

Page 4 of 18 APHITEMPCON001-11-04

Page 5

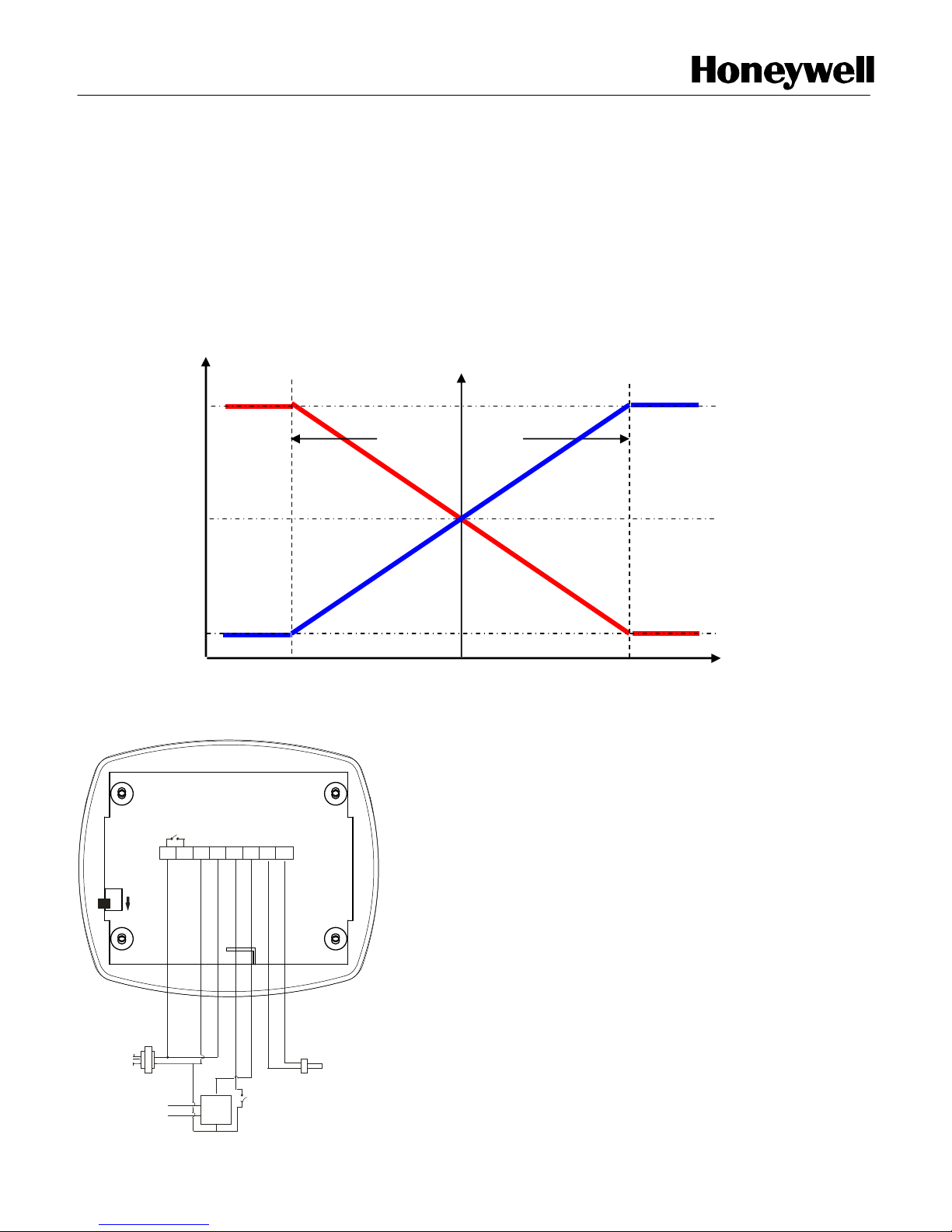

Heat / Cool Changeover of Output1

Valve Open

Temperature Increase

Valve Close

Output1 is suitable for Heat/Cool changeover (manually) control in 2pipe AHU, Zoning control or

Hydronic Heating application. Wiring connection is shown in fig.

With cooling or heating selected, the user set point (SP) will be positioned at the middle of

proportional band. The output percentage is proportional to the temperature measured and

decided by proportional band. The proportional band can be set from 2.0°C to 19.0°C. The

control logic is seen in Diagram 1.

Diagram 1:

100%

50%

0%

Wiring Diagram

Heating

sp

Cooling

Proportional band

Pt1000

sensor

24VAC

A/OD/I

8

PT1000

REMOTE SENSOR

4 - 20 mA

2 - 10 VDC

110VAC /

230VAC

1 2 3 4 5 6 7

L

24VAC

N

0VAC

E

POWER

SUPPLY

0VAC

2-10VDC /

4-20mA

Actuator

Unit

Add link between terminal No 5 & 3.

Page 5 of 18 APHITEMPCON001-11-04

Note: If Emergency IP [D/I] not used then

Page 6

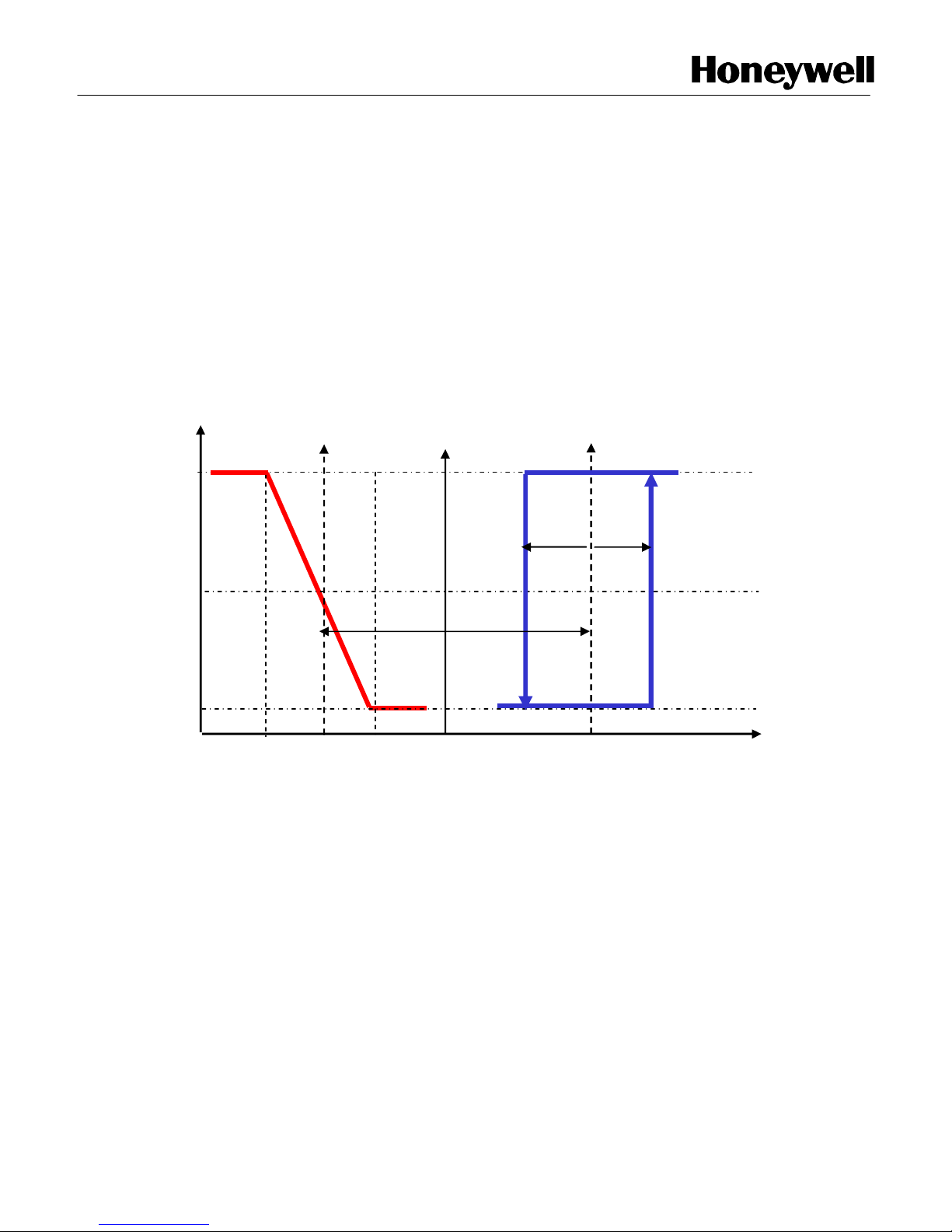

Heating + Cooling Sequence control with Zero Energy Band

Z-Band

Output 2

Valve Open

Temperature Increase

Valve Close

Output 1

This kind of control requires Zero Energy Band (Z-Band). Z-Band is pre-set. For control purpose,

the zero energy band is centered on the user set point (SP), so its value defines the effective

heating (H SP) & cooling (C SP) set points. The cooling set point (C SP) will be positioned on

the right side of Z-Band & the heating set point (H SP) on the left side of Z-Band. Z-Band can be

set as 1.5°C or 3.0°C. Any change of set point will cause both heating and cooling set points to

change in parallel. Either output1 or output2 can be used for cooling or heating control. The

control logic is seen in Diagram 2 and 3.

Diagram 2: Heating + Cooling Sequence Control.

100%

0%

50%

Heating

H SP

SP

C SP

Cooling

Diff

Page 6 of 18 APHITEMPCON001-11-04

Page 7

Diagram 3: Cooling + Heating Sequence Control.

Z-Band

Output 1

Valve Open

Valve Close

SP

Output 2

H SP

Heating

100%

Diff

50%

0%

C SP

Cooling

Page 7 of 18 APHITEMPCON001-11-04

Page 8

Output 1

Valve Open

Temperature Increase

Valve Close

Output 2

Heating/Cooling + Temperature Limitation Control

Output2 can be used for temperature limitation control. To select this function, 2 temperature set

points must be pre-set. One is in the mid of proportional band of output1 (C SP / H SP) as main

setting temperature. The second one is the temperature limitation of heating or cooling (A SP).

In this mode if the measured temperature is higher (in heating mode) or lower (in cooling mode)

than temperature limitation, output2 will close and output an alarming signal. The control logic is

seen in Diagram 4 and 5.

Diagram 4: Cooling + Temperature Limit Control.

A SP

Alarm

100%

50%

0%

C SP

Cooling

Page 8 of 18 APHITEMPCON001-11-04

Page 9

Output 2

Valve O

pen

Temperature Increase

Valve Close

Output 1

Diagram 5: Heating + Temperature Limit Control.

H SP

Heating

100%

50%

0%

Wiring Diagram

I] STANDARD WIRING DIAGRAM:

A SP

Alarm

Pt1000

A/OD/I

sensor

ON / OFF

Valve /

Actuator

8

PT1000

REMOTE SENSOR

4 - 20 mA

2 - 10 VDC

110VAC /

230VAC

L

N

E

POWER

SUPPLY

0VAC

24VAC

1 2 3 4 5 6 7

24VAC

0VAC

2-10VDC /

4-20mA

Actuator

Unit

Note : If Emergency IP [D/I] not used then add link between terminal No 5 & 3.

Page 9 of 18 APHITEMPCON001-11-04

Page 10

A]

WIRING DIAGRAM T2798I2000 WITH ML-7984

A

/

O

D

/

I

DIP SWITCH CONFIGURATION

B]

WIRING DIAGRAM T2798I2000 WITH ML-7421

230VAC, 50Hz

0-10V / 0- 20mA

2-10V / 4- 20mA

II] T2798I2000 wiring with frequently used Actuators

4 - 20 mA

2 - 10 VDC

50 / 60 Hz

OVAC

110VAC

230VAC

NOTE:

DIRECT ACTING FUN CTION (A CTUATOR STEM MOVES

UPWARD WITH S IGNAL INCREASES) OR REVE RSAL ACTING

FUNCTION (ACTUATOR STEM MOVES DOWN WARDS WITH

SIGNAL INCREAS ES)

50 / 60 Hz

OVAC

110VAC

230VAC

TRANSFORMER

4 - 20 mA

2 - 10 VDC

TRANSFORMER

24VAC

0VAC

24VAC

0VAC

0VAC

A/O

D/I

24VAC

1 2 3 4 5 6 7 8

Pt1000

sensor

Pt1000

0VAC

24VAC

sensor

NTC20K

Ml7984

R

T6

W

C

PT1000

REMOTE

SENSOR

24VAC

T5

FUNCTION

2-10V DC DIRECT ACTING

10-2V DC REVERSE ACTING

%

100 50 0

0 0 0

REMOTE

SENSOR

TRANSFORM ER

230V AC, 50Hz

DIP SWITCH OF ML 7984A

ML-7421

M

W1

W2

V

mA

ML-7421

TRANSFORMER

24VAC

ON

OFF

ON

OFF

W2

10V / 20mA

W3

10V / 20mA

Page 10 of 18 APHITEMPCON001-11-04

Page 11

1 2 3 4 5

CN-7510

To IMS

optional

D]

WIRING DIAGRAM T2798I2000 WITH

OD/I

C]

WIRING DIAGRAM T2798I2000 WITH M7410E

A

/

O

D

/

I

SELECT 2-1 0V OPTION FO R

USING M7 410E with T2798I 2000

50 / 60 Hz

OVAC

110VAC

230VAC

4 - 20 mA

2 - 10 V DC

TRANSFORMER

50 / 60 Hz

OVAC

110VAC

230VAC

Pt1000

0VAC

24VAC

sensor

24VAC

0VAC

N10010/N20010/N34010/CN7510

4 - 20 mA

2 - 10 VDC

TRANSFORMER

24VAC

0VAC

0VAC

24VAC

PT1000

REMOTE

SENSOR

Pt1000

A/

sensor

0 - 100%

100 - 0%

GREEN

BROWN

WHITE

PT1000

REMOTE

SENSOR

M7410E

0 - 100%

100 - 0%

0 - 10V

2 - 10V

HOT

0 - 10V

2 - 10V

INPUT

FEEDBACK

COM

Page 11 of 18 APHITEMPCON001-11-04

Page 12

4 - 20 mA

E]

WIRING DIAGRAM T2798I2000 WITH VC-7934

Pt1000

A/O

0VAC

D/I

24VAC

sensor

VC-7934

50 / 60 Hz

OVAC

110VAC

230VAC

2 - 10 VDC

PT1000

REMOTE

SENSOR

TRANSFORMER

24VAC

0VAC

BLACK

BROWN

BLUE

HOT

COM

1 2 3

INPUT

Installer Set-Up:

1. Power ON/OFF :

- Connect the main power. Display will show “Honeywell”, as shown in fig.1, for 5 Sec.

Then display will show the Process value

(PV) and Set point (SP) as shown in fig.2

H o n e y w e l l

Fig. 1

2. Set Point configuration (SP):

- Press key one time to step up the set point value by 0.1°C. If pressed

continuously for more than ten steps then the value will increment by the step of 1.0°C

up to 60.0°C (for internal sensor) or 110.0°C (for external sensor). Release key to

stop the increment of temp set value.

- Press key one time to step down set point value by 0.1°C. If pressed

continuously for more than ten steps then the value will decrement by the step of 1.0°C

up to 10.0°C (for internal sensor) or –20.0°C (for external sensor). Release

key to stop decrement of temp set value.

- Press “ENTER” key to save the set value.

P V : 3 0 . 2 ° C

S P : 1 9 . 0 ° C

Fig. 2

Page 12 of 18 APHITEMPCON001-11-04

Page 13

3. Zero Energy Band setting:

- Press “SELECT” to choose “Zero Energy Band Setting”, the display will show as in

fig.3

- Press key one time to switches from 1.5°C to 3.0°C.

- Press key one time to switches from 3.0°C to 1.5°C.

- Press “ENTER” key to save the set value.

P V : 3 0 . 2 ° C

Z - B A N D 3 . 0 ° C

Fig. 3

4. Differential setting:

- Press “SELECT” to choose “Differential Setting”, the display will show as in fig.4

- Press key one time to step up the differential setting by 0.5°C, it will stop

incrementing at 3.0°C. The range is 0.5 to 3.0 °C.

- Press key one time to step down the differential setting by 0.5°C. It will stop

decrementing at 0.5°C. The range is 3.0 to 0.5 °C.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

D I F F 1 . 0 ° C

Fig. 4

5. Proportional Band Setting:

- Press “SELECT” to choose “Proportion Band

Setting”, the display will show as in fig.5

- Press key one time to step up the Proportional band by 0.1°C. If pressed

continuously for more than ten steps then the value will increment by the step of 1.0°C

up to 19.0°C. Release

key to stop the increment of the value.

- Press key one time to step down Proportional Band by 0.1°C If pressed

continuously for more than ten steps then the value will decrement by the step of 1.0°C

up to 2.0°C. Release key to stop the decrement of the value.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

P - B A N D 1 0 . 0 ° C

Fig. 5

6. Offset Setting:

- Press “SELECT” to choose “Offset Setting”, the display will show as in fig.6

- Press key one time to step up Offset by 0.1°C. If pressed continuously for

more than ten steps then the value will increment by the step of 1.0°C up to 3.0°C.

Release key to stop increment of the value. The range is –3.0 to 3.0 °C.

- Press key one time to step down Offset by 0.1°C. If

pressed continuously for more than ten steps then

the value will decrement by the step of 1.0°C up to -3.0°C. Release

key to stop increment of the value.

Page 13 of 18 APHITEMPCON001-11-04

Page 14

The range is 3.0 to –3.0 °C.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

O F F S E T - 1 . 0 ° C

Fig. 6

7. Mode Setting:

- Press “SELECT” to choose “MODE Setting”, the display will show as in fig.7

- Press key one time to step up. The total number of modes is 6. It will stop

incrementing at last mode i.e. H/AL mode.

-

MODES: Output 1 function: Output 2 function:

COOL Cooling No Function

HEAT Heating No Function

C/H Cooling Heating

H/C Heating Cooling

C/AL Cooling Low Temp. limit Alarm

H/AL Heating High Temp. limit Alarm

- Press key one time to step down. The total number of modes is 6. It will stop

decrementing at first mode i.e. COOL mode.

- Press “ENTER” key to save the setting value.

-

P V : 3 0 . 2 ° C

M O D E C O O L

Fig. 7

8. Sensor setting :

- Press “SELECT” to choose “Sensor Setting”, the display will show as in fig. 3

- Press key one time to switches from INT to EXT.

INT : Internal sensor

EXT : External sensor

- Press key one time to switches from EXT to INT.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

S E N S O R I N T

Fig. 8

Page 14 of 18 APHITEMPCON001-11-04

Page 15

9. Reverse Action Setting :

- Press “SELECT” to choose “Reverse Setting”, the display will show as in fig. 9

- Press key one time to switches from OFF to ON.

OFF : Output1 in normal mode, i.e. 2 - 10Vdc or 4 - 20mA

ON : Output in reversing mode, i.e. 10 - 2Vdc or 20 - 4mA.

- Press key one time to switches from ON to OFF.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

R E V E R S E O F F

Fig. 9

10. Display Setting :

- Press “SELECT” to choose “Display Setting”, the display will show as in fig.10

- Press key one time to switches from OFF to ON.

OFF : Normal mode, as shown in fig. 2.

ON : Percentage mode, output1 is percent value (2Vdc or 4mA – 0% & 10Vdc

or 20mA – 100%) as shown fig.11.

- Press key one time to switches from ON to OFF.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

D I S P L A Y O F F

Fig. 10

P V : 3 0 . 2 ° C

A 0 : 9 1 %

Fig. 11

11. Manual Setting:

- Press “SELECT” to choose “Manual Setting”, the display will show as in fig.12

- Press key one time to switches from OFF to ON.

OFF: Manual OFF

ON : Manual ON

- Press key one time to switches from ON to OFF.

- Press “ENTER” key to save the setting value.

- If manual on, the display will show as in fig.13

P V : 3 0 . 2 ° C

M A N U A L O N

Fig. 12

P V : 3 0 . 2 ° C

A 0 : 9 1 %

Fig. 13

Page 15 of 18 APHITEMPCON001-11-04

Page 16

- If manual ON, press key one time to step up the display value by 1%. If

pressed continuously for more than ten steps then the value will increment by the step

of 1.0% up to 100%. Release key to stop the increment of value.

- If manual ON, press key one time to step down the display value by 1%.

- If press continuously more than ten steps then the value will decrement by the

step of 1.0% up to 0%. Release key to stop the decrement of value.

- After 90 minutes of manual ON operation the controller will return to manual OFF

mode automatically.

12. F1 Setting :

- Press “SELECT” to choose “F1 setting”, the display will show as in fig.14

- Press key one time to step up the Integral time by 0.1Sec. If pressed

continuously for more than ten steps then the value will increment by the step of

1.0Sec. up to 60.Sec. Release

key to stop the increment of value.

The range is 0.1 to 60-Sec.

- Press key one time to step down the Integral time by 0.1Sec. If pressed

continuously for more than ten steps then the value will decrement by the step of

1.0Sec. up to 0.1Sec. Release key to stop the decrement of value. The range is 60

to 0.1Sec.

- Press “ENTER” key to save the setting value.

- This value setting shows how long the output1 will update the output value

P V : 3 0 . 2 ° C

F 1 ( I ) 1 . 0 S E C

Fig. 14

13. F2 Setting :

- Press “SELECT” to choose “F2 setting”, the display will show as in fig.15

- Press key one time to step up the Alarm Set point by 0.1°C. If is pressed

continuously for more than ten steps then the value will increment by the step of 1.0°C

up to 60.0°C (for internal sensor) or 110.0°C (for external sensor). Release key to

stop the increment of value.

- Press key one time to step down the Alarm set point by 0.1°C. If pressed

continuously for more than ten steps then the value will decrement by the step of 1.0°C

up to 10.0°C (for internal sensor) or -20.0°C (for external sensor).

Release key to stop decrement of value.

- Press “ENTER” key to save the setting value.

P V : 3 0 . 2 ° C

F 2 3 0 . 0 ° C

Fig. 15

Page 16 of 18 APHITEMPCON001-11-04

Page 17

Default Setting:

S e t t i n g P a ra m e t e rs D e fa u lt V a lu e

Z - B A N D 1 .5 °C

D IF F 0 .5 °C

P - B A N D 2 .0 °C

O F F S E T 0 °C

C / A L

M O D E

R E V E R S E O F F

D IS P L A Y O F F

M A N U A L O F F

S P 2 1 °C

F 1 ( I) 1 5 S E C

A L A R M (F 2 ) 1 0 °C

( C O O L + A L A R M )

IMPORTANT: Before setting, please check the following points.

1. Inspect the controller visually & check the push button before connecting the main power.

2. There should not be any abnormal phenomena or obvious shipping damage.

3. Check the Selector Switch & make sure that the switch is set at the right position.

Page 17 of 18 APHITEMPCON001-11-04

Page 18

Environmental & Combustion Controls

Honeywell Automation India Limited

56 & 57, Hadapsar Industrial Estate,

Pune – 411 013, India.

Phone: (91) 20 6603 9400

Fax: (91) 20 6603 9979

Subject to change without notice. Printed in India.

Page 18 of 18 APHITEMPCON001-11-04

Loading...

Loading...