Page 1

Thermostatic Control

The T104F Thermostatic Control is used with a V110

Valve Body to control radiators, convectors, baseboard

heating units, or other heating units with standard capacity

requirements. The control is self-powered and requires no

electrical connection. The T100A includes a setpoint dial

and valve actuator, connected by a capillary tube to a sensor.

The T104F Control attaches to the valve body by threaded

connections and may be mounted at any angle. Install the

remote sensor beneath the heating coils in the cold air return, or on a nearby wall where the air flow is not restricted.

The setpoint dial has reference marks (1-6). The control

has a low limit of 43°F (6°C) when the dial is turned fully

clockwise to the frost protection mark*. The red button

indicates the 68°F (20°C) setpoint limit. Higher settings may

be made by holding in the button while turning. The thermostatic sensor is protected by a safety spring against temperatures to 125°F (52°C).

T104F

3

2

M9730

Specifications

MATERIALS OF CONSTRUCTION:

Body: Industrial grade plastics with low thermal

conductivity.

Fastening Ring: Plated brass.

Internal Parts: Brass thermostat capsule, other metals.

TEMPERATURE RANGE: 43° to 79°F (6° to 26 °C).

MAX. SENSOR TEMPERATURE: 125°F (52°C).

MAX. OVERALL DIMENSIONS: 2-1/8 in. (54 mm) wide,

3-5/16 in. (84 mm) long. See Fig. 1.

CAPILLARY LENGTH: 6 ft. 8 in. (2 m).

TEMPERATURE SETTINGS:

These are the setpoint temperatures, which correspond

to the setpoint dial reference marks, under ideal conditions.

Factors affecting the temperature at the sensor vary for each

installation. It may be necessary to adjust the setpoint

higher or lower to obtain the desired space temperature.

Temperature 0 *123456

°F Off 43 46 54 61 68 73 79

°C Off 6 8 12 16 20 23 26

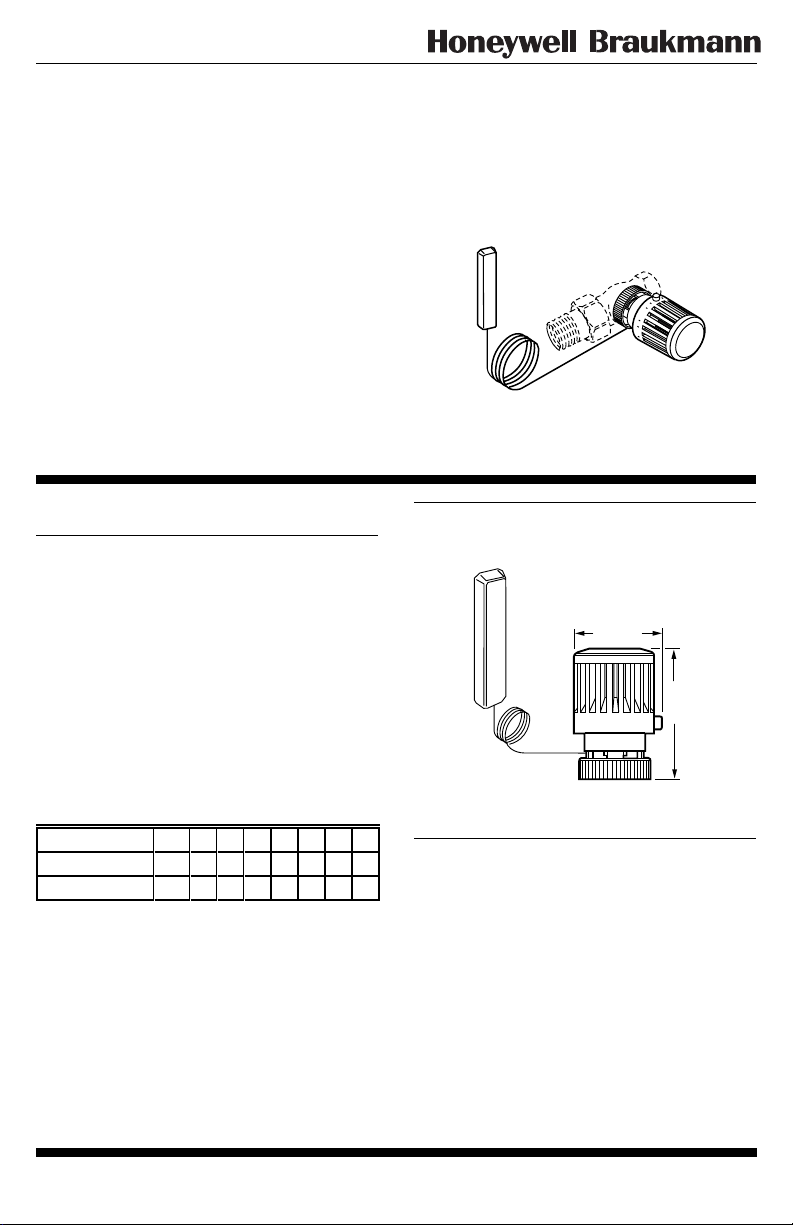

Fig. 1—T104F dimensions in in. (mm).

2 1/8 (54)

M9731

AVAILABLE VALVE BODIES:

See Fig. 2.

3 5/16

(84)

MAX.

1 62-3047

C. H. • 12-94 • ©Honeywell Inc. 1994 • Form Number 62-3047

Page 2

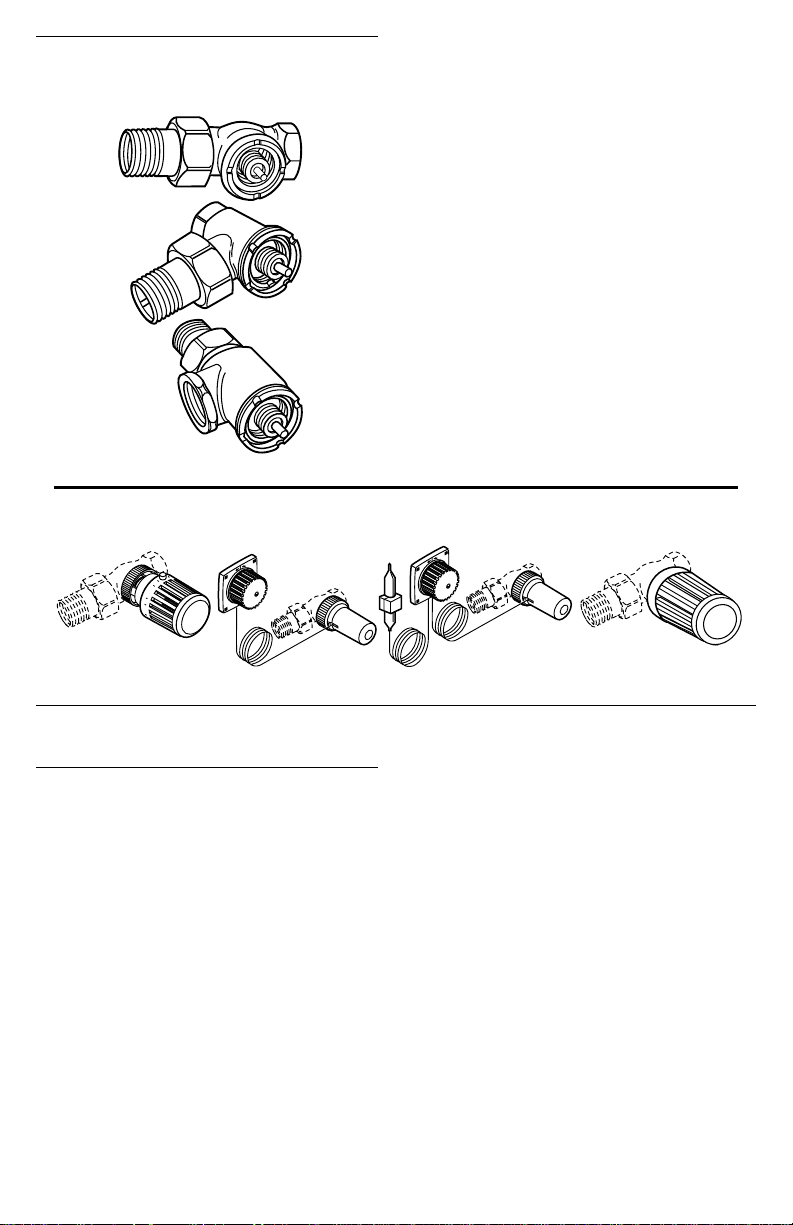

Fig. 2—V110 Valve Bodies.

VALVE BODIES

V110D

V110E

V110F

M9735

Fig. 3—T104A,B,C,V Thermostatic Controls.

4

5

3

3

2

2

1

OTHER AVAILABLE T100 THERMOSTATIC

CONTROLS (See Fig. 3):

T104A Control with internal sensor.

T104B Control with remote sensor/setpoint.

T104C Control with remote sensor and remote setpoint.

T104V Control with internal sensor and tamper-resistant

setpoint and mounting.

ACCESSORY

A104F1007 Limit Pins.

G111B1053 Bulb guard for protection of sensor when

mounted on the wall.

4

5

3

2

1

T104B T104CT104A T104V

Installation

IMPORTANT: The T104F can be mounted inside an enclo-

sure if the sensor is located a minimum of 3 in. (76 mm)

beneath the heating coils in the cold air return. Coil

excess capillary tubing beneath and away from the

62-3047 2

M9736

heating coils. Take care not to break, kink or sharply

bend the capillary tubing.

When mounting the T104F, make sure the bosses on

the T104F base fit securely into the valve body grooves.

Firmly hand tighten the knurled ring. Improper mounting can cause overheating. Refer to Fig. 4 for typical

installations.

Page 3

Fig. 4—Typical installations.

18 INCH

MINIMUM

M9734

Settings and Calibration

The T104F Control includes an adjustable range limit-

ing pin (order additional pins separately). The pin is factory-set to limit the low range of the control to the frost

protection (*) setting (see Fig. 5). The pin can be moved to

a different low or high limit setting and lock point, or it can

be removed. Use a second pin if both low and high limit

settings are desired.

Fig. 5—Temperature settings.

ADJUSTMENT RANGE SETTING

°C

OFF

OFF

°F

01

6

4384612541661206823732679

SCALE MARKING

*

23

Setting the Limit

To set a limit different from the factory setting, proceed

as follows:

1. Determine the desired temperature range limit or locking temperature. Select the appropriate number on the adjustment knob to match the desired temperature setting. See

Fig. 5.

1PIN REQUIRED.

2

FACTORY SETTING.

TEMP.

4

56

2

1

1

PIN

POS.

3

NONE

4a

4b

4b

4b + *

5

5 + *

*

RANGE

°F

43 - 79

61 - 79

OFF - 79

68

72

0 - 68

43 - 68

0 - 73

43 - 73

TEMP.

RANGE

°C

6 - 26

16 - 26

OFF - 26

20

22

0 - 20

6 - 20

0 - 23

6 - 23

M9729

3 62-3047

Page 4

2. Lift the end cap off the adjustment knob. See Fig. 6.

Fig. 6—Lift the end cap off the adjustment knob.

3. Remove the adjustment knob from the actuator as

2

ACTUATOR

ADJUSTMENT

KNOB

END

3

CAP

M9715

follows:

a. Turn the adjustment knob so the desired knob setting

is aligned with the white line on the actuator base.

b. Pull the knob off the head or use a screwdriver inserted

into one of the slots to pry off the knob. See Fig. 7.

Fig. 7—Remove the knob from the actuator.

4. Push the limit pin up and slide it into the slot that

BASE

ACTUATOR HEAD

ARM CLIP (3)

M9714

SCREWDRIVER SLOT (2)

WHITE LINE

CALIBRATION

INDENT

RED

BUTTON

corresponds with the desired temperature limit. If the lower

limit remains at the frost protection mark (*), insert an

additional pin in the slot that corresponds with the second

limit.

Example 1:

If the desired temperature range is 43° to 73°F (6° to

23°C), leave the pin in the slot marked * and add one pin in

slot 5.

Example 2:

If the desired temperature range is OFF to 68°F (23 °C),

move the pin to slot 5. No additional pin is required.

5. To replace the adjustment knob, realign the knob

setting in step 3a with the white line on the base and push the

knob toward the base. Make sure the three arm clips snap into

place at the top of the adjustment knob. If the actuator was

turned with the adjustment knob off, recalibrate the control

according to the instructions in Recalibrate T104F Control

section.

6. Replace the end cap.

Locking the Control at a Single Temperature

1. Determine the desired locking temperature. Select the

appropriate number on the adjustment knob to match the

desired temperature setting. See Fig. 5.

2. Lift the end cap off the adjustment knob. See Fig. 6.

3. Remove the adjustment knob from the actuator as

follows:

a. Turn the adjustment knob so the desired knob setting

is aligned with the white line on the actuator base.

b. Pull the knob off the head or use a screwdriver inserted

in one of the slots to pry off the knob. See Fig. 7.

4. Insert the pin in slot 4a for 68°F (20°C) or slot 4b for

72 °F (22°C).

Fig. 8—Insert the pin in the slot to set the limit

range.

LIMIT PIN

*

FIXED STOP

LIMIT PIN REMOVED

WHITE LINE

34a4b5

POSITION

(SEE FIG. 5)

PIN

M9723

5. To replace the adjustment knob, align the knob setting

from step 3a with the white line on the base and push the

knob toward the base. Make sure the three arm clips snap in

place at the top of the adjustment knob.

6. Replace the end cap.

Recalibrate T104F Control

1. Lift the end cap off the adjustment knob. See Fig. 6.

2. Pull the knob off the head or use a screwdriver inserted

in one of the slots to pry off the knob. See Fig. 7.

3. Turn the actuator head clockwise until the head stops

(Fig. 7). The calibration indent should be aligned approximately with the white line on the base when the head stops.

If the indent is 180 degrees from the white mark, unscrew the

head completely from the base and rethread the head to the

base so that it is aligned with the white mark. Turn the actuator head clockwise until the head stops. Complete removal

of the head from the base is required only if the actuator was

previously dismantled.

NOTE: The distance between the actuator head and the static

portion of the control should be approximately 3/8 in.

(9 mm).

4. Turn the actuator head counterclockwise approximately one turn until the calibration indent on the head aligns

with the white line on the base. For the 72 °F (22°C) single

temperature setting, align the indent with the center of the

adjustable limiting pin.

5. Replace the adjustment knob by aligning the red

button with the white line on the base and pushing the knob

toward the base. For the 72°F (22°C) single temperature

setting, align the red button with the center of the adjustable

limiting pin. Make sure the three arm clips snap in place at

the top of the adjustment knob.

6. Replace the end cap.

62-3047 4

Page 5

Troubleshooting

Sympton Possible Cause Solution

All sections of

the radiator are

not heating.

Underheating. 1. Sensor is in the wrong location. 1. Change the sensor location or change the control

Overheating. 1. Sensor is in the wrong location. 1. Change the sensor location or change the control

Chattering or

knocking.

1. Many radiators are over-sized and all

sections are not required to heat up to

maintain the set room temperature.

2. Excess capillary tube is coiled above or

too near the heat source.

3. Flow through the valve is in the wrong

direction.

4. Inadequate system temperature or

pressure.

5. Steam traps are defective. 5. Repair or replace the traps.

6. Air lock in the hot water system. 6. Open the valve fully to allow air to pass. Install

7. Scale or debris is blocking flow. 7. Flush the system. Do not use oil base additives.

8. Heating cabinet dampers are closed. 8. Open or remove the dampers.

2. Control is not properly installed. 2. Set the bosses in the grooves and tighten the

3. Capillary tube is broken, kinked, or

bent sharply.

4. Dirt or scale is under the seat,

preventing tight shutoff.

5. Flow through the valve is in the wrong

direction, damaging the valve seat.

6. Steam traps are defective. 6. Repair or replace the traps.

7. Excessive differential pressure is

forcing the valve open (hot water

systems).

1. Flow through the valve is in the wrong

direction.

2. Vacuum in the system. 2. For steam—check traps and vents. For hot water—

3. Excessive differential pressure. 3. Install a differential pressure regulator (D146A) to

4. Binding of piping. 4. Make sure there is adequate space for piping.

1. System is operating properly.

type. See installation instructions.

2. Coil excess capillary tube below or away from the

heat source.

3. Check the arrow on the valve body. It should be in

the direction of the flow. Change the valve direction

or flow direction.

4. Check the operating and limiting controls on the

boiler. Check the circulating pump and isolating

valves.

vents.

Clean strainer insert in steam applications.

type.

knurled ring to the valve body.

3. Replace the control.

4. Remove the control from the valve body, allowing

the valve to open fully and flush away scale and

debris. Reinstall the control and turn fully clockwise. If the valve does not fully close, remove control and cartridge using a cartridge changer tool or

service socket (isolate valve from system if not

using changer tool). Inspect and clean valve seat

area and disc. Always use a strainer insert in steam

applications.

5. Check the arrow on the valve body. It should be in

the direction of the flow. Change the valve direction

or flow direction. Remove the valve cartridge and

inspect for damage to the seat disk.

7. Install a differential pressure regulator (D146A) to

maintain less than 117 kPa (17 psi) differential

between supply and return pipes.

1. Check the arrow on the valve body. It should be in

the direction of the flow. Change the valve direction

or flow direction.

check expansion tank operation and location.

maintain less than 117 kPa (17 psi) differential

between supply and return pipes.

5 62-3047

Page 6

Honeywell Braukmann Honeywell Braukmann Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

62-3047 6

Printed in Germany www.honeywell.ca/braukmann

QUALITY IS KEY

Loading...

Loading...