Page 1

Smart Field

Communicator Model

STS103

Operating Guide

34-ST-11-14F

4/99

Page 2

Copyright, Notices, and Trademarks

© Copyright 1995 by Honeywell Inc.

Revision F – 4/99

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in its

written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special, or consequential

damages. The information and specifications in this document are subject to

change without notice.

This document was prepared using Information Mapping® methodologies and

formatting principles.

Information Mapping® is a registered trademark of Information Mapping, Inc.

ST 3000 and SFC are U.S. registered trademarks of Honeywell Inc.

Honeywell

Industrial Automation and Control

Automation College

2820 West Kelton Lane

Phoenix, Arizona 85023

ii STS103 Operating Guide 4/99

Page 3

About This Publication

This manual provides operating instructions for the STS103. The operating instructions cover the

use of the SFC with the Smart Pressure Transmitter ST 3000, the Smart Temperature Transmitter

STT 3000 Models STT350, STT25D, STT25M, STT302 and STT300, the Magnetic Flowmeter

MagneW 3000, and the Smart Multivariable Transmitter SMV 3000.

The operating instructions for using the SFC with the SCM 3000 Smart Coriolis Mass Flowmeter,

the SGC 3000 Smart Gas Chromatograph, and the Model STT350, STT 3000 Smart Temperature

Transmitter are presented in the User’s Manual for that specific instrument.

Chapters 1, 2, and 3, in this manual, contain information relating to the common information for

the SFC. The specific operating information for using the SFC with ST 3000, STT 3000,

MagneW 3000, and SMV 3000 is contained in separate chapters in this manual.

The format of this manual is completely different than the STS102 Operating Guide. The key

sequences are graphically laid out to aid you in learning how to use the SFC for the first time, as

well as reminding experienced users how to perform operations you have not done in a while. The

format of this manual is designed to make finding, reading, and understanding the information

presented easier than ever before.

4/99 STS103 Operating Guide iii

Page 4

iv STS103 Operating Guide 4/99

Page 5

Table of Contents

SECTION 1 – SMART FIELD COMMUNICATOR STS103 OVERVIEW........................... 1

1.1 Introduction .................................................................................................. 1

1.2 STS103 Physical and Functional Description .............................................. 3

1.3 Connections ................................................................................................. 9

1.4 STS103/SFI Communication...................................................................... 10

SECTION 2– STS103 INSTALLATION............................................................................ 13

2.1 STS103 Overview......................................................................................13

2.2 Keypad Functions....................................................................................... 14

2.3 Display Functions....................................................................................... 15

2.4 Prompt Character Definitions..................................................................... 16

2.5 Function Keys Data Entry........................................................................... 17

2.6 Configuration Key Data Entry..................................................................... 19

2.7 Other Key Sequences................................................................................ 21

SECTION 3 – STS103 OPERATION................................................................................ 23

3.1 Overview .................................................................................................... 23

3.2 Power Up ................................................................................................... 24

3.3 Diagnostics and SFC Messages................................................................ 25

3.4 Common Key Sequences and Displays..................................................... 28

3.5 Using the Transmitter as a Current Source................................................ 43

3.6 Disconnecting the SFI................................................................................ 45

SECTION 4 – ST 3000 PRESSURE TRANSMITTER...................................................... 47

4.1 Overview .................................................................................................... 47

4.2 Wiring......................................................................................................... 48

4.3 Set-up......................................................................................................... 50

4.4 Configuration.............................................................................................. 62

4.5 Output Calibration......................................................................................64

4.6 Operation ................................................................................................... 67

4.7 Diagnostics and SFC Messages................................................................ 71

4.8 Troubleshooting ......................................................................................... 75

SECTION 5 – STT 3000 TEMPERATURE TRANSMITTER............................................ 77

5.1 Overview .................................................................................................... 77

5.2 Wiring......................................................................................................... 78

5.3 Set-up......................................................................................................... 80

5.4 Configuration.............................................................................................. 93

5.5 Output Calibration....................................................................................102

5.6 Operation ................................................................................................. 105

5.7 Diagnostics and SFC Messages.............................................................. 109

5.8 Troubleshooting ....................................................................................... 114

SECTION 6 –MAGNEW 3000 ELECTROMAGNETIC FLOWMETER .......................... 115

6.1 Overview .................................................................................................. 115

6.2 Wiring....................................................................................................... 116

6.3 Set-up....................................................................................................... 118

6.4 Configuration............................................................................................ 129

6.5 Calibration................................................................................................ 154

6.6 Operation ................................................................................................. 167

6.7 Diagnostics and SFC Messages.............................................................. 171

6.8 Troubleshooting ....................................................................................... 175

4/99 STS103 Operating Guide v

Page 6

Table of Contents

SECTION 7 –SMV 3000 MULTIVARIABLE TRANSMITTER ........................................177

7.1 Overview...................................................................................................177

7.2 Wiring........................................................................................................178

7.3 Configuration ............................................................................................180

7.4 Output Calibration.....................................................................................235

7.5 Operation..................................................................................................239

7.6 Diagnostics and SFC Messages...............................................................244

7.7 Troubleshooting........................................................................................253

vi STS103 Operating Guide 4/99

Page 7

Figures

Figure 1-1 Smart Field Communicator STS103.........................................................3

Figure 1-2 STS103 Keypad and LCD Display............................................................ 4

Figure 1-3 STS103 Switch and Terminals.................................................................. 7

Figure 1-4 STS103 Battery Pack................................................................................ 8

Figure 1-5 STS103 –Junction Box ............................................................................. 9

Figure 1-6 Typical Analog Data Exchange............................................................... 11

Figure 1-7 Typical Digital Data Exchange................................................................ 12

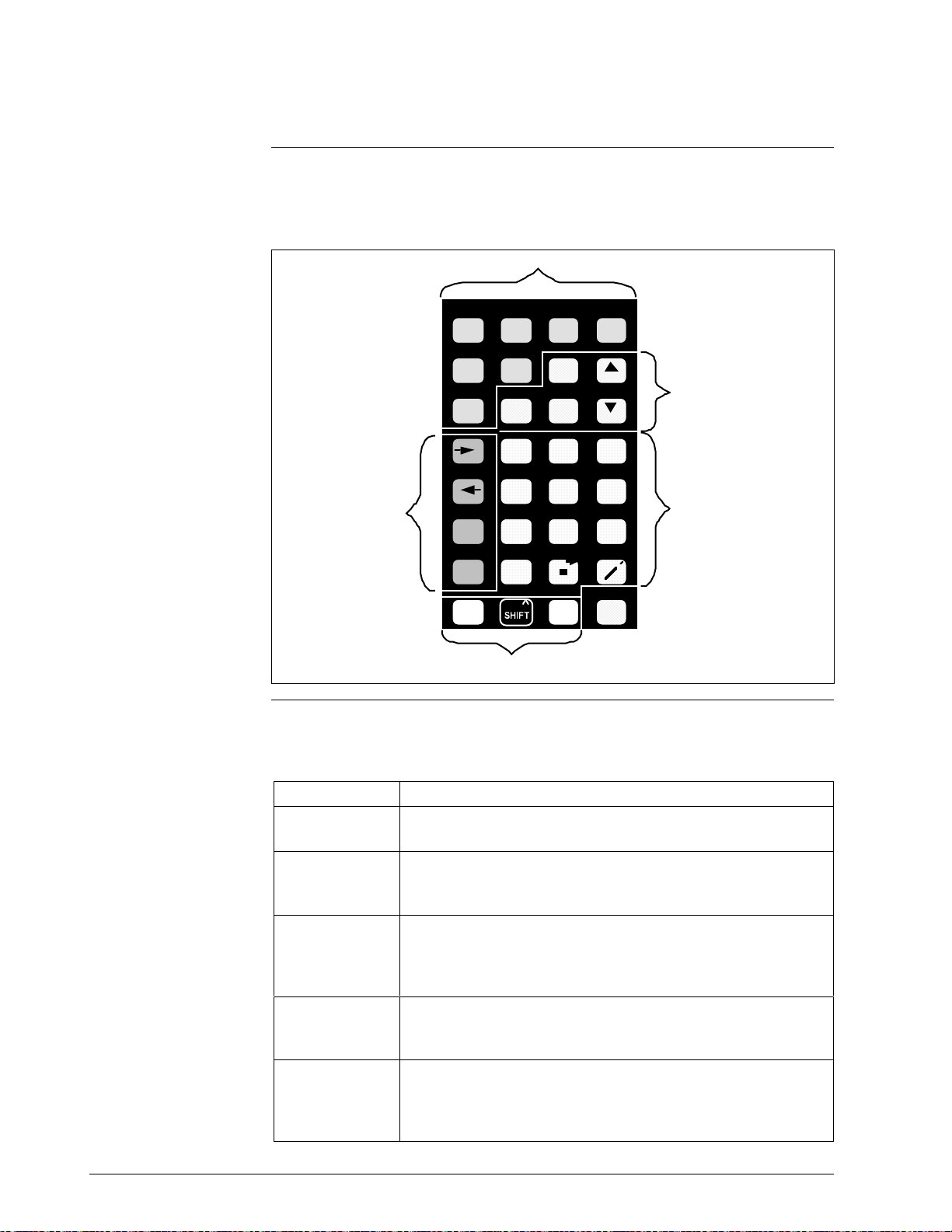

Figure 2-1 STS103 Keypad Color Groups ............................................................... 14

Figure 3-1 Power Up Sequence............................................................................... 24

Figure 3-2 Read Digital Database............................................................................ 24

Figure 3-3 Changing Communications Mode........................................................... 28

Figure 3-4 Configuring the Elements of the DE Communications Mode

(Single PV Transmitter)........................................................................... 30

Figure 3-5 Configuring the Elements of the DE Communications Mode

(Multiple PV Transmitter)........................................................................31

Figure 3-6 Adjusting the Damping Time Value......................................................... 33

Figure 3-7 Displaying, Setting, and Calibrating the Lower Range Value.................. 34

Figure 3-8 Displaying, Setting, and Calibrating the Upper Range Value.................. 35

Figure 3-9 Displaying and Changing the Span......................................................... 36

Figure 3-10 Displaying and Changing the Upper Range Limit................................... 37

Figure 3-11 Corrects Reset........................................................................................ 38

Figure 3-12 Displaying, Setting, and Clearing the Current Output............................. 39

Figure 3-13 Displaying and calibrating the Current Input Value................................. 40

Figure 3-14 Displaying the SFI Diagnostic Status...................................................... 41

Figure 3-15 Software Version..................................................................................... 41

Figure 3-16 Writing Data in Scratch Pad Area...........................................................42

Figure 4-1 STS103 – Junction Box and IS Connection............................................ 48

Figure 4-2 STS103–ST 3000 Connections .............................................................. 49

Figure 4-3 Adjusting the ST 3000 Damping Time Value.......................................... 53

Figure 4-4 Changing the ST 3000 Communications Mode...................................... 55

Figure 4-5 Configuring the ST 3000 DE Communications Mode ............................. 57

Figure 4-6 Changing the ST 3000 Lower Range Value (LRV)................................. 58

Figure 4-7 Changing the ST 3000 Upper Range Value (URV) ................................ 59

Figure 4-8 Configuring the ST 3000 Transmitter...................................................... 63

Figure 4-9 ST 3000 Troubleshooting Procedure...................................................... 75

Figure 5-1 STS103 – Junction Box and IS Connection............................................ 78

Figure 5-2 STS103 Connections to Model STT350 Transmitter..............................79

Figure 5-3 STS103 Connections to Model STT25D and STT25M Transmitters...... 79

Figure 5-4 STS103 Connections to Model STT300 and STT302 Transmitters........ 80

Figure 5-5 Adjusting the STT 3000 Damping Time Value........................................ 84

Figure 5-6 Changing the STT 3000 Communications Mode.................................... 86

Figure 5-7 Configuring the STT 3000 DE Communications Mode........................... 88

Figure 5-8 Changing the STT 3000 Lower Range Value (LRV)...............................89

Figure 5-9 Changing the STT 3000 Upper Range Value (URV).............................. 90

Figure 5-10 STT 3000 Temperature Transmitter Configuration................................. 94

Figure 5-11 STT 3000 Probe Configuration............................................................... 98

Figure 5-12 Save/Restore Data.................................................................................. 99

Figure 5-13 Alarm Latching/Open Input Failsafe...................................................... 100

Figure 5-14 Write Protect and Password ................................................................. 101

Figure 5-15 STT 3000 Troubleshooting Procedure.................................................. 114

Figure 6-1 STS103 – Junction Box and IS Connection.......................................... 116

Figure 6-2 STS103–MagneW Connections............................................................ 117

Figure 6-3 Adjusting the MagneW 3000 Damping Time Value .............................. 122

4/99 STS103 Operating Guide vii

Page 8

Figures

Figure 6-4 Selecting the MagneW 3000 Units in which to Display Values..............124

Figure 6-5 Changing Communications Mode .........................................................125

Figure 6-6 Configuring the MagneW 3000 DE Communications Mode..................127

Figure 6-7 Changing the MagneW 3000 Upper Range Value (Span) ....................128

Figure 6-8 MagneW 3000 Prompt hierarchy...........................................................130

Figure 6-9 MagneW 3000 Units Key Configuration ................................................132

Figure 6-10 MagneW 3000 Range Configuration Graphic........................................137

Figure 6-11 MagneW 3000 Detector Data Configuration..........................................139

Figure 6-12 MagneW 3000 Alarm Setting Configuration..........................................141

Figure 6-13 MagneW 3000 Failsafe Condition Configuration...................................143

Figure 6-14 MagneW 3000 Digital Input/Output Configuration.................................145

Figure 6-15 MagneW 3000 Totalizer Menu Hierarchy..............................................147

Figure 6-16 MagneW 3000 Pulse Output Configuration...........................................148

Figure 6-17 MagneW 3000 Pulse Config?................................................................150

Figure 6-18 MagneW 3000 Set Trip Value ...............................................................151

Figure 6-19 Save/Restore Data................................................................................152

Figure 6-20 MagneW 3000 Calibration Set-up .........................................................155

Figure 6-21 MagneW 3000 Calibration Menu Hierarchy...........................................161

Figure 6-22 MagneW 3000 Excitation Current Check ..............................................162

Figure 6-23 MagneW 3000 Excitation Current Calibration .......................................164

Figure 6-24 MagneW 3000 Gain Calibration ............................................................165

Figure 6-25 MagneW 3000 DI/DO Check.................................................................166

Figure 6-26 MagneW 3000 Troubleshooting Procedure...........................................175

Figure 7-1 STS103 – Junction Box and IS Connection...........................................178

Figure 7-2 STS103–SMV 3000 Connections ..........................................................179

viii STS103 Operating Guide 4/99

Page 9

Tables

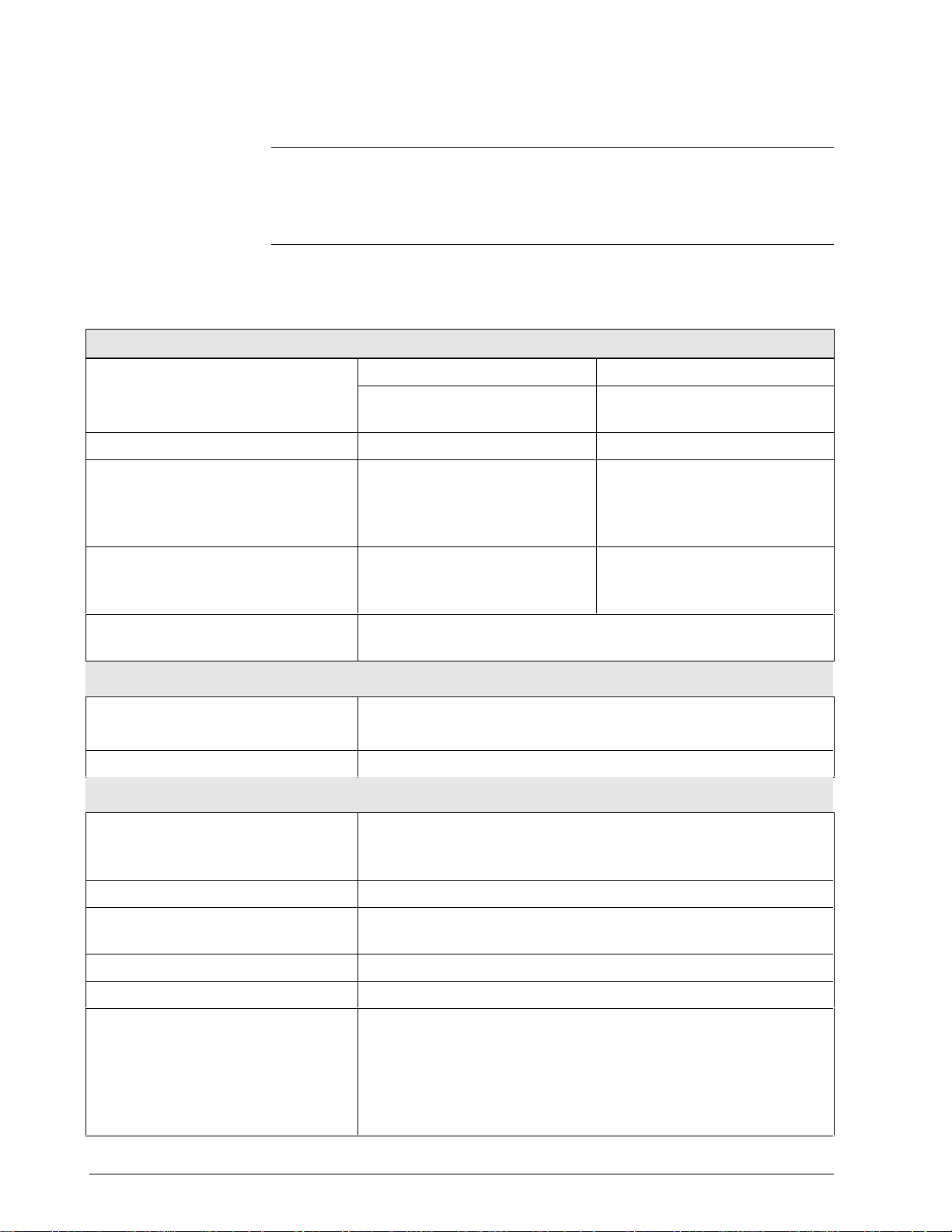

Table 1-1 Model STS103 Specifications................................................................... 2

Table 1-2 STS103 Key Functions.............................................................................5

Table 1-3 Communication Format Description........................................................ 10

Table 1-4 Typical Digital Data Exchange Sequence of Events............................... 12

Table 2-1 STS103 Key Color Group Description .................................................... 14

Table 2-2 LCD Display Functions ........................................................................... 15

Table 2-3 STS103 LCD Character Definitions and General Rules ......................... 16

Table 2-4 Function Key Sequence.......................................................................... 18

Table 2-5 Configuration Key Sequence .................................................................. 19

Table 2-6 Other Key Sequences............................................................................. 21

Table 3-1 Diagnostic Messages for SFC ................................................................ 26

Table 3-2 DE Configuration Elements..................................................................... 29

Table 3-3 Storing Data in Non-volatile memory......................................................32

Table 3-4 Using the SFI as a Constant Current-source.......................................... 44

Table 3-5 Disconnect Check List............................................................................. 45

Table 4-1 Keying–in the ST 3000 ID and Uploading the Database ........................ 50

Table 4-2 Selecting the ST 3000 Units ................................................................... 54

Table 4-3 The ST 3000 DE Configuration Elements............................................... 56

Table 4-4 Setting the ST 3000 Lower Range Value Using Applied Pressure......... 60

Table 4-5 Setting the ST 3000 Upper Range Value Using Applied Pressure......... 61

Table 4-6 Scrolling through the ST 3000 Parameters............................................. 62

Table 4-7 ST 3000 Digital to Analog Current Output Signal Calibration ................. 64

Table 4-8 ST 3000 Operating Data......................................................................... 68

Table 4-9 Diagnostic Messages for SFC and ST 3000........................................... 72

Table 5-1 Keying–in the STT 3000 ID and Database ............................................. 81

Table 5-2 Selecting the STT 3000 Units.................................................................85

Table 5-3 STT 3000 DE Configuration Elements....................................................87

Table 5-4 Setting the STT 3000 Lower Range Value Using Applied Temperature. 91

Table 5-5 Setting the STT 3000 Upper Range Value Using Applied Temperature. 92

Table 5-6 Scrolling through the STT 3000 Parameters........................................... 93

Table 5-7 STT 3000 Probe Configuration Elements...............................................95

Table 5-8 STT 3000 Probe Types and Ranges ...................................................... 97

Table 5-9 STT 3000 Digital to Analog Current Output Signal Calibration............. 102

Table 5-10 STT 3000 Operating Data.....................................................................106

Table 5-11 Diagnostic Messages for SFC and STT 3000....................................... 110

Table 6-1 Keying–in the MagneW 3000 ID and Upload Database Procedure...... 118

Table 6-2 List of the MagneW 3000 Units by Application...................................... 123

Table 6-3 MagneW 3000 DE Configuration Elements..........................................126

Table 6-4 Scrolling through the MagneW 3000 Parameters................................. 131

Table 6-5 MagneW 3000 Range Config? Elements.............................................. 133

Table 6-6 Ranging Function Definitions................................................................ 134

Table 6-7 Function Selection Combinations.......................................................... 136

Table 6-8 MagneW 3000 Detector Config? Elements........................................... 138

Table 6-9 MagneW 3000 Alarm Config? Elements............................................... 140

Table 6-10 MagneW 3000 Failsafe Config? Elements............................................ 142

Table 6-11 MagneW 3000 Digital I/O? Elements.................................................... 144

Table 6-12 MagneW 3000 Totalizer Menu Elements.............................................. 146

Table 6-13 MagneW 3000 Pulse Configure? Elements.......................................... 149

Table 6-14 MagneW 3000 Calibration Set-up Procedure ....................................... 156

Table 6-15 Set the MagneW 3000 Units to m/sec .................................................. 157

Table 6-16 Set the MagneW 3000 Span to 10.001 m/sec......................................158

Table 6-17 MagneW 3000 Digital to Analog Current Output Signal Calibration ..... 159

Table 6-18 MagneW 3000 Operating Data.............................................................168

Table 6-19 Diagnostic Messages for SFC and MagneW 3000............................... 172

4/99 STS103 Operating Guide ix

Page 10

Tables

Table 7-1 Keying-in Tag Number...........................................................................182

Table 7-2 Selecting Output Conformity..................................................................184

Table 7-3 Adjusting Damping Time .......................................................................185

Table 7-4 Selecting Engineering Units for PV1 and PV2.......................................188

Table 7-5 Selecting Engineering Units for PV3, etc...............................................189

Table 7-6 Selecting Engineering Units for PV4 .....................................................191

Table 7-7 Selecting Engineering Units for Design Density for PV4.......................192

Table 7-8 Identifying PV3 Probe Type...................................................................193

Table 7-9 Selecting Source of CJ Compensation..................................................195

Table 7-10 Selecting Input Filter Frequency............................................................196

Table 7-11 Activating Sensor Fault Detection .........................................................198

Table 7-12 Selecting Output Characterization.........................................................199

Table 7-13 Setting selections for PV4 Equation Definition ......................................205

Table 7-14 Setting Parameters for PV4 Equation....................................................211

Table 7-15 Setting Low and High Limits for Low Flow Cutoff..................................214

Table 7-16 Selecting PV to Represent Analog Output ............................................215

Table 7-17 Keying in LRV and URV for PV1...........................................................217

Table 7-18 Setting LRV and URV for PV1 to Applied Pressures.............................218

Table 7-19 Keying in LRV and URV for PV2...........................................................220

Table 7-20 Setting LRV and URV for PV2 to Applied Pressures.............................222

Table 7-21 Keying in LRV and URV for PV3...........................................................224

Table 7-22 Setting LRV and URV for PV3 to Applied Input Signals........................225

Table 7-23 Setting URL for PV4..............................................................................228

Table 7-24 Keying in LRV and URV for PV4...........................................................229

Table 7-25 Selecting PVs for Broadcast..................................................................232

Table 7-26 Selecting Message Format....................................................................234

Table 7-27 Calibrating Output Signal for Transmitter in Analog Mode ....................235

Table 7-28 ST 3000 Operating Data .......................................................................240

Table 7-29

Table 7-30 Non-Critical Status Diagnostic Message Table .....................................247

Table 7-31 Communication Status Message Table.................................................250

Table 7-32 Informational Status Message Table.....................................................251

Table 7-33 SFC Diagnostic Message Table............................................................252

Table 7-34 Accessing SMV 3000 Diagnostic Information using the SFC................253

Critical Status Diagnostic Messa ge Table

...................................................245

x STS103 Operating Guide 4/99

Page 11

Acronyms

AP ............................................................................................................Absolute Pressure

DAC ............................................................................................................ Digital to Analog

DE....................................................................................................Digital Communications

DI/DO...........................................................................................Digital Input/Digital Output

DP.........................................................................................................Differential Pressure

DR...................................................................................................................... Dual Range

DVM............................................................................................................Digital Voltmeter

GND.......................................................................................................................... Ground

GP...............................................................................................................Gauge Pressure

I/O......................................................................................................................Input/Output

LCD.....................................................................................................Liquid Crystal Display

PV ..............................................................................................................Process Variable

SFC.............................................................................................Smart Field Communicator

SFI ....................................................................................................Smart Field Instrument

SR....................................................................................................................Single Range

Parameters

BRL/P......................................................................................................... Barrels per pulse

CC/P .........................................................................................Cubic centimeters per pulse

DAMP............................................................................................................ Damping value

EU..............................................................................................................Engineering units

F/S DIR......................................................................................................Failsafe Direction

G/cm .......................................................................................Grams per square centimeter

Gal/P......................................................................................................... Gallons per pulse

I/P..................................................................................................................Liters per pulse

ID ..................................................................................................................Transmitter I.D.

inHg...........................................................................................................Inches of mercury

Kg/cm................................................................................ Kilograms per square centimeter

Kgal/P................................................................................................... Kilogallons per pulse

KPa .....................................................................................................................Kilopascals

LIN .............................................................................................................................. Linear

LRV........................................................................................................Lower Range Value

mBAR.........................................................................................................................Millibar

mGAL/P .............................................................................................10-3 gallons per pulse

mH2O............................................................................................................Inches of water

mH2O............................................................................................................Meters of water

mmH2O.................................................................................................. Millimeters of water

mmHg ................................................................................................ Millimeters of mercury

MPa.................................................................................................................. Megapascals

NVM..................................................................................................... Non-volatile memory

PSI .................................................................................................. Pounds per square inch

SQRT................................................................................................................ Square Root

SWVER........................................................................................Software Version Number

URL......................................................................................................... Upper Range Limit

URV .......................................................................................................Upper Range Value

4/99 STS103 Operating Guide xi

Page 12

References

Publication

Title

SFC Information Card

ST 3000 User’s Manual

(for Series 100e and Series 900 Transmitters)

ST 3000 User’s Manual (for Release 300 Transmitters)

ST 3000 Operating Card

STT 3000 User’s Manual

(Model STT350)

STT 3000 Series STT250 Operator Manual

STT 3000 Operating Card

MagneW 3000 User’s Manual

MagneW 3000 Operating Card

SCM 3000 Smart Coriolis Mass Flowmeter User’s Manual

SGC 3000 Smart Gas Chromatograph User’s Manual

Publication

Number

34-ST-10-01

34-ST-25-11

34-ST-25-14

34-ST-11-15

34-ST-25-12

EN1I-6190

34-ST-11-16

36-KI-25-01

34-ST-11-17

34-CM-25-01

34-GC-25-01

SMV 3000 Smart Multivariable Transmitter User’s Manual

34-SM-25-02

xii STS103 Operating Guide 4/99

Page 13

Section 1 —Smart Field Communicator STS103 Overview

1.1 Introduction

Function

Smart Field

Instruments (SFIs)

ATTENTION

The hand-held Smart Field Communicator(SFC), Model STS103 is a

battery-powered device which establishes two-way communications

between Honeywell’s Smart Field Instruments (SFIs) and an operator over

the existing SFI signal lines. The operator can send data to and receive

data from the SFI’s microprocessor, through the STS103, when connected

to the SFI’s signal lines at any accessible location from the control room

to the Smart Field Instrument.

There are many current SFIs with which the STS103 communicates. The

STS103 is designed for expansion and will be used with other new SFIs as

they become available. The current Honeywell smart field instruments

with which the STS103 may be used are listed below.

• Smart Pressure Transmitter ST 3000,

• Smart Temperature Transmitter STT 3000,

• Magnetic Mass Flowmeter MagneW 3000,

• Smart Coriolis Mass Flowmeter SCM 3000,

• Smart Gas Chromatograph SGC 3000, and

• Smart Multivariable Transmitter SMV 3000.

The specific instructions for using the SFC with SCM 3000, and SGC

3000 are contained in User’s Manual for that specific instrument.

Operation

You can use the STS103 to

• Select the Communications Mode – Command the SFI to transmit its

output signal in either an Analog (4-20 mA) mode or in the Digital

Communications (DE) mode.

• Configure – Enter the desired operating parameters (For example:

LRV, URV, Damping, Failsafe Mode, Configuration Parameters) into

the Smart Field Instrument.

• Diagnose – Access the SFI self-diagnostic capabilities to troubleshoot

suspected operation or communication problems.

• Calibrate – The SFC provides a simplified procedure for calibrating

Smart Field Instruments, thus maintaining excellent accuracy with

significantly reduced maintenance requirements.

• Display – Readout all the configured operating parameters from the

SFI as well as other data such as PROM Serial Number, Device ID,

Scratch pad memory, Sensor Temperature, Input values in selected

Engineering Units, and others.

Continued on next page

4/99 STS103 Operating Guide 1

Page 14

1.1 Introduction, Continued

Operation, continued

• Checkout – Put the SFI in the Output mode and command the SFI to

transmit a precise signal, selectable from 0% to 100% full scale, to assist

you in verifying loop operation, loop calibration, or troubleshooting.

Specifications

The STS103’s specifications are listed in Table 1-1.

Table 1-1 Model STS103 Specifications

Operating Conditions

Operating Limits Transportation and Storage

Ambient Temperature °C

°F

Humidity % 10% to 90% RH 5% to 95% RH

Vibration

Maximum Acceleration (G)

Frequency (Hz)

Amplitude (mm peak to peak)

Shock

Maximum Acceleration (G)

Duration (ms)

–10° to 50°

14° to 122°

0.2

0 to 100

0.75

5

50

–20° to 60°

–4° to 140°

0.5

0 to 100

- - - - -

15

11

Minimum load resistance

@ 24 Vdc Supply Voltage

250 Ohms

Performance

Safety Approvals FM Intrinsic Safe, Class I, II, III, Div 1, GP A-G Outdoor

Nonincendive, Class I, Div 2, GP A-G Outdoor

CE Conformity, Europe 89/336/EEC, the EMC Directive

Physical

Dimensions

Overall

Keypad

Weight 470 g (1 lb.)

LCD Display

Display Character

Keyboard Type Tactile feedback embossed membrane, 4 by 8 matrix, 32 keys

Lead Connectors Easy hook and alligator clips

Battery Charger

Input Power

Output Power

Time to charge

Time between charges

102 mm x 42 mm x 206 mm (4 In. x 1.7 in. x 8 in.)

86 mm x 136 mm (3.4 x 5.4 in.)

2 lines x 16 characters

5 x 7 dots with line for cursor

108 – 120 Vac, 200 – 240 Vac, 50/60 Hz

7 Vdc, 180 mA

16 hours minimum

24 hours minimum, a colon”:” in the eighth character position indicates low

battery power.

2 STS103 Operating Guide 4/99

Page 15

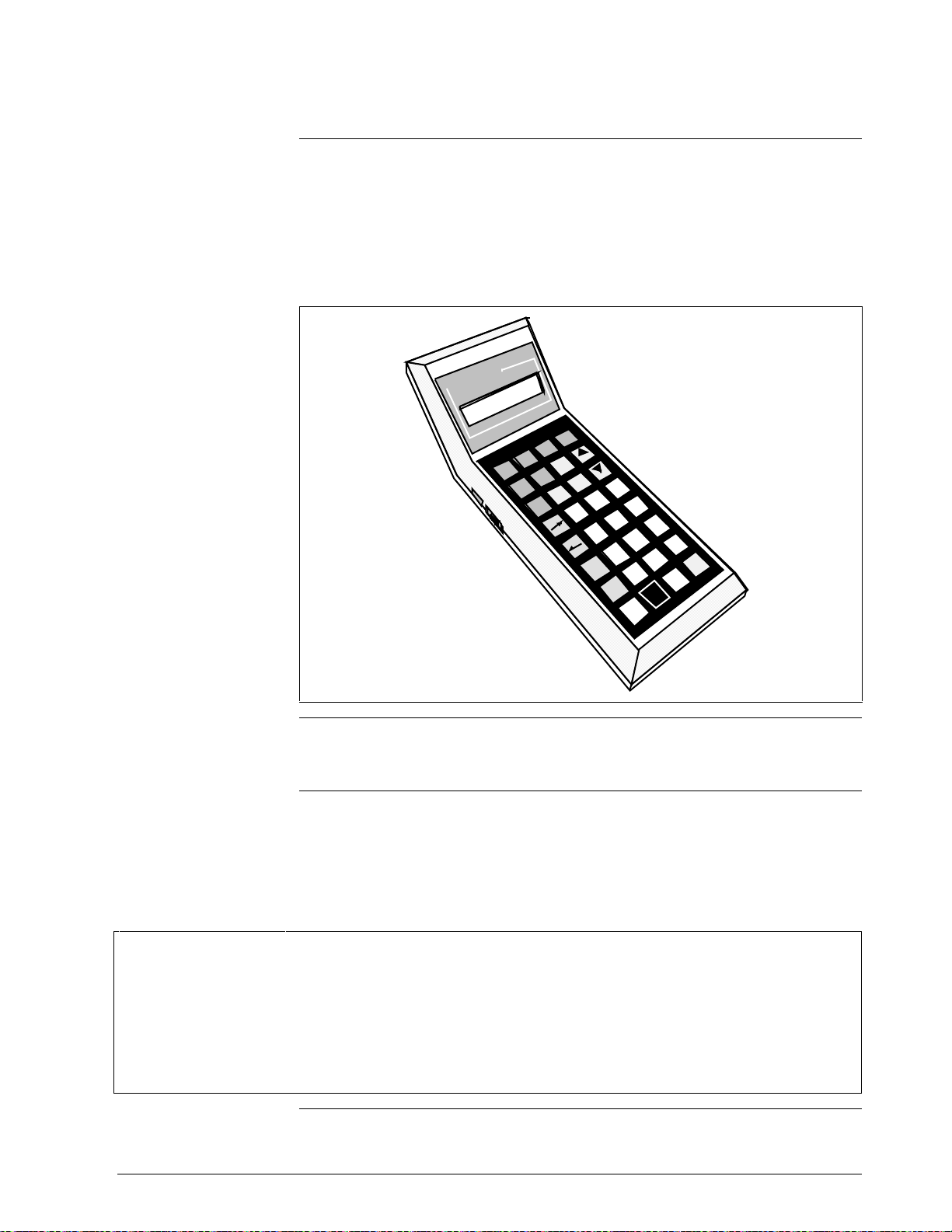

1.2 STS103 Physical and Functional Description

STS103 physical

description

The STS103 is a hand-held unit that has a 2-line by 16-character digital

liquid crystal display (LCD) and a keypad. The STS103 connects to the

SFI by way of a cable connected to the SFI junction box terminals. A

NiCd battery pack allows the STS103 to be used in the field without the

need for input power. The STS103 is shown in Figure 1-1.

Figure 1-1 Smart Field Communicator STS103

l

l

e

w

y

e

n

o

H

N

AG

T

FC

S

.

.

.

G

N

.

I

o

K

R

O

W

S

T

I

N

U

P

M

DA

F

N

O

C

D

I

RV

U

0

1

RV

L

%

0

NU

E

M

M

E

T

I

T

X

NE

T

E

S

%

0

T

U

O

U

P

V

RE

P

R-

O

C

RECT

T

9

8

7

6

5

4

T

A

T

S

3

2

/-

+

1

0

N

A

P

S

H

S

/

M

U

N

A

H

P

L

A

R

E

T

.

F

I

)

N

S

E

E

Y

(

R

L

C

)

O

N

(

T

20330

EMC classification

Industrial Control Equipment, Group 1, Class A, ISM Equipment (ref.

EN 55011).

CE Conformity

(Europe)

This product is in conformity with the protection requirements of

European Council Directive 89/336/EEC, the EMC Directive. Conformity

of this product with any other “CE Mark” Directive(s) shall not be

assumed. Deviation from the operating conditions specified may

invalidate this product’s conformity with the EMC Directive.

ATTENTION

The emission limits of EN 50081-2 are designed to provide reasonable protection against harmful interference

when this equipment is operated in an industrial environment. Operation of this equipment in a residential area

may cause harmful interference. This equipment generates, uses, and can radiate radio frequency energy and

may cause interference to radio and television reception when the equipment is used closer than 30 meters (98

feet) to the antenna(e). In special cases, when highly susceptible apparatus is used in close proximity, the user

may have to employ additional mitigating measures to further reduce the electromagnetic emissions of this

equipment.

Continued on next page

4/99 STS103 Operating Guide 3

Page 16

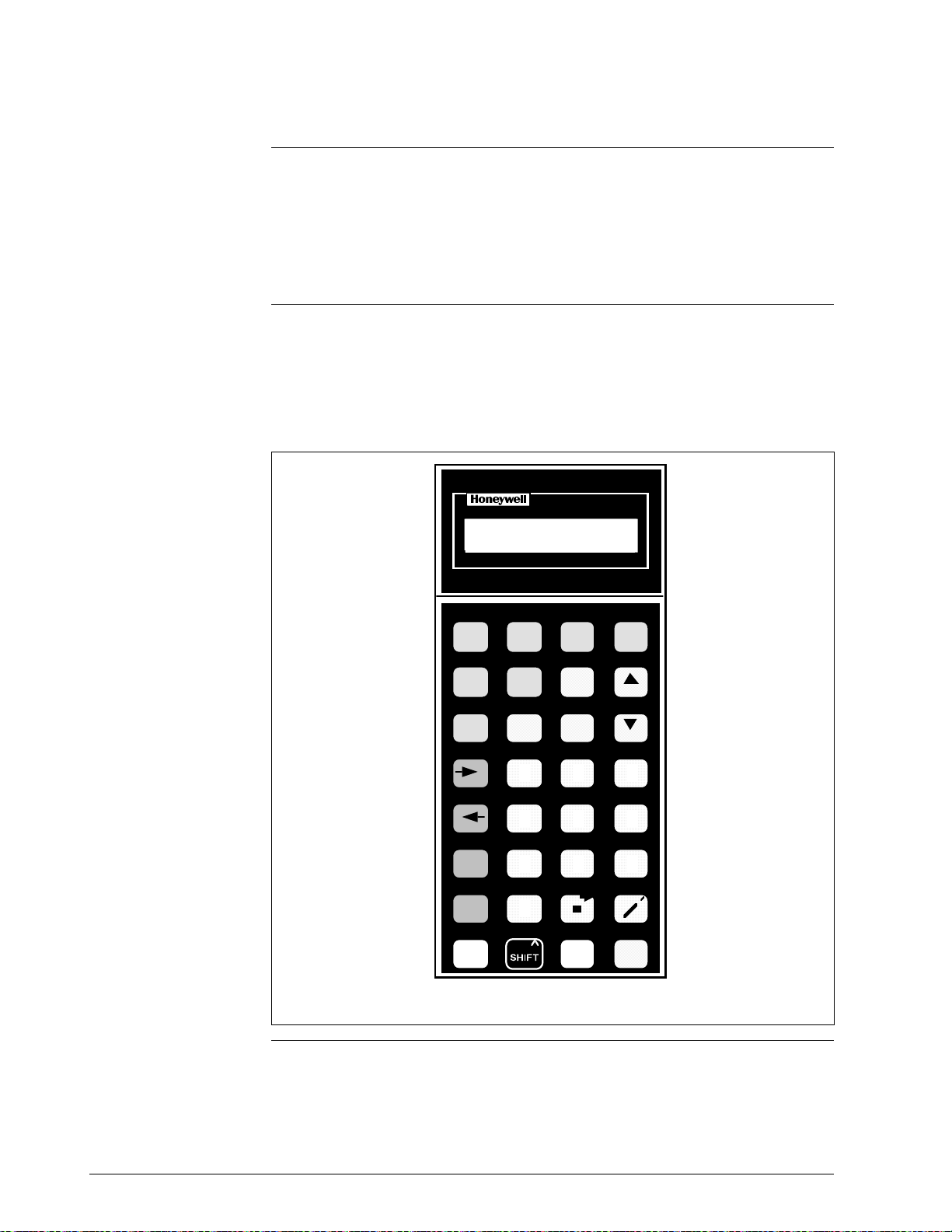

1.2 STS103 Physical and Functional Description, Continued

2-line by 16-character

LCD display

STS103 keypad

The LCD display provides prompts and displays values, keypad input,

statuses, and alarms. Each character on the display is in a 5 X 7 dot matrix

with a line below the character for the cursor. The STS103 is multi-lingual

and can display parameters and statuses in engineering or metric units.

The desired language is selected through menus, as is the desired

parameter format.

Through the STS103’s keypad, the parameters and characteristics of each

SFI may be viewed and changed. In several instances, several keys are

used together to perform certain functions. Figure 1-2 shows the STS103

keypad and LCD display.

Figure 1-2 STS103 Keypad and LCD Display

L

ABCDEFGHIJKLMNOPQR

ABCDEFGHIJKLMNOP

QRSTUVWXYZ012345

STUVWXYZ1234567890

DE READ

ABCD

CONF

ID DAMP UNITS

EFGH

LRV URV

0% 100%

DE CONF RESET

MENU

A <–> DE

F/S DIR

STAT

SPAN

NUM /

ALPHA

INPUT

IJKL

OUT-

PUT RECTITEM

MNOP

QR ST

UVWX

URL

YZ

SHIFT

SET

COR-

7 8 9

5 64

SW VER

1 2 3

SCR PAD

0

CLR

(NO)

+

NON-VOL

ENTER

20720

NEXT

PREV

–

(YES)

Continued on next page

4 STS103 Operating Guide 4/99

Page 17

1.2 STS103 Physical and Functional Description, Continued

STS103 key functions

Table 1-2 STS103 Key Functions

Key Function

NUM /

ALPHA

^

^^

^

^

S

H

I

F

T

SS

SHH

HII

IFF

FTT

T

S

H

I

F

T

CLR

(NO)

NON-VOL

ENTER

(YES)

DE READ

A

ID

Table 1-2 describes the use and function of the STS103 keypad keys.

The white NUM/ALPHA key toggles between the alpha mode or numeric mode

for the STS103. In the alpha mode, the capital letter or character in the upper

right-hand corner of the keys is input when that key is pressed. In the numeric

mode, the number is input or the indicated first function is performed.

The black SHIFT key enables the second function above certain keys to be

performed. When shifted functions are enabled, the word “SHIFT–” is displayed

on line two of the display. The second function desired must be selected

immediately after the Shift key is pressed. The Shift key upper right-hand

character, the caret character, is input when in the alpha mode.

The white CLR (NO) key cancels the current function or task when pressed and

backs out to its previous operating state. The NO, or negative response, function

is used in response to questions in the LCD display or decisions.

The orange ENTER (YES) (NON-VOL) key is used to send a write/set command

to the RAM memory in an SFI or to answer “Yes” to prompts. The NON-VOL

second function writes data into the non-volatile memory of an SFI.

The Alpha keys A – Z input the alpha character in the upper righthand corner when the alpha mode is activated. The alpha mode is

Z

0

available to enter an ID name or to use the Scratch Pad. The cursor

is replaced by a “

*” character when the alpha mode is activated.

Z

0

SCR PAD

+

–

DE READ

A

ID

P

9

The yellow decimal point (SCR PAD) key inputs a decimal point when in the

number mode and a space in the alpha mode. The SCR PAD second function

displays data in the SFI’s scratch pad memory.

The yellow positive/negative key functions as follows:

•

When entering an ID name or using the Scratch Pad function, the

ALPHA/NUM key toggles to allow a (–) hyphen (NUM mode) or a (/) slash

(ALPHA mode) to be entered using the +/– key.

• In the configuration mode, use the +/– key to enter a positive or negative

symbol when entering a value. The NUM/ALPHA key toggles between “+”

and “–”.

The green ID (DE READ) key reads and displays the device’s tag name (ID)

when pressed. In analog devices, the database is also read. The DE READ

second function reads the digital enhanced SFI’s database along with the tag

name.

The yellow Numeric keys 0 – 9 input the number character when the

number mode is activated. When in the numeric mode, the cursor is

shown as a blinking

.

Continued on next page

4/99 STS103 Operating Guide 5

Page 18

1.2 STS103 Physical and Functional Description, Continued

Key functions,

continued

Table 1-2 STS103 Key Functions (Continued)

Key Description

The green CONF key starts each SFI’s configuration mode. The unique settings

B

CONF

DAMP

UNITS

LRV

0%

are the parameters and characteristics that are configured into the SFI.

The green DAMP key displays the damping constant of the SFI. (See Note 1.)

C

The green UNITS key displays the SFI’s currently selected engineering units.

D

The units may be changed by repeatedly pressing the key until the desired units

appear. (See Note 1.)

The green LRV 0% key displays the SFI lower range value (LRV) in the

E

engineering unit selected by the UNITS Key.

(See Note 1.)

F

URV

100%

DE CONF

I

MENU

ITEM

G

SET

H

NEXT

INPUT

J

OUT-

PUT

RESET

K

CORRECT

The green URV 100% key displays the SFI upper range value (URV) in the

engineering unit selected by the UNITS key.

(See Note 1.)

The green MENU ITEM (DE CONF) key selects the current PV from multi-PV

devices. The DE CONF second function displays the current Digital (DE)

configuration. Allows the selection of one data item from a series of grouped

functions in the configuration mode.

The orange SET key sets the function of the key pressed immediately before this

key in the SFI. For example, setting the URV or LRV to the applied PV.

L

The orange NEXT and PREV keys set the damping constant, change

the engineering units, increase and decrease numeric values during

PREV

output D/A calibrations, and displays the next/previous units in the

unit selection. These keys also select the next or previous

configuration element in an SFI’s unique setting mode.

The orange OUTPUT (INPUT) key displays the currently selected transmitted

output in percent. The second function displays the SFI’s currently selected input

in the active engineering units.

The orange CORRECT (RESET) key is used to make on-line zero corrections

and to calibrate output signal and range values. The RESET second function

returns the ST and STT transmitters to their original factory calibration states.

Resetting the MagneW transmitter is done through the calibration menus.

Note 1. For Multi-PV SFI’s, the STS103 displays the value for the currently selected PV.

Continued on next page

6 STS103 Operating Guide 4/99

Page 19

1.2 STS103 Physical and Functional Description, Continued

Key functions,

continued

Table 1-2 STS103 Key Functions (Continued)

Key Description

F/S DIR

STAT

URL

SPAN

SW VER

3

STS103 switch and

terminals

A <–> DE

M Q

The olive STAT (F/S DIR) key sequentially displays the result of an SFI’s

diagnostics. The second function displays the failsafe direction, Hi or Lo, for

U

analog SFIs. The failsafe direction is hard-wired in the analog SFI and

determines the direction the SFI output goes in burnout (SFI failure).

The olive SPAN (URL) key displays the span in Engineering units selected by the

UNITS key. The second function displays the upper range limit (URL) value of

Y

the SFI.

The yellow 3 (SW VER) key second function displays the software version of the

X

STS103 when not communicating with an SFI, or the software versions of the

STS103 and SFI when connected to an SFI.

Figure 1-3 shows the STS103 ON/OFF switch and the terminals on the

sides of the unit.

Figure 1-3 STS103 Switch and Terminals

The olive cursor keys move the cursor forward or backward one

position while the cursor is displayed. In the number mode, the cursor

back key performs a backspace function. The A <–> DE second

function of the cursor back key toggles the SFI output mode between

analog and digital enhanced communication.

Charging

Terminal

Left Side

4/99 STS103 Operating Guide 7

ON/OFF

Switch

Communications

Terminal

Right Side

20721

Continued on next page

Page 20

1.2 STS103 Physical and Functional Description, Continued

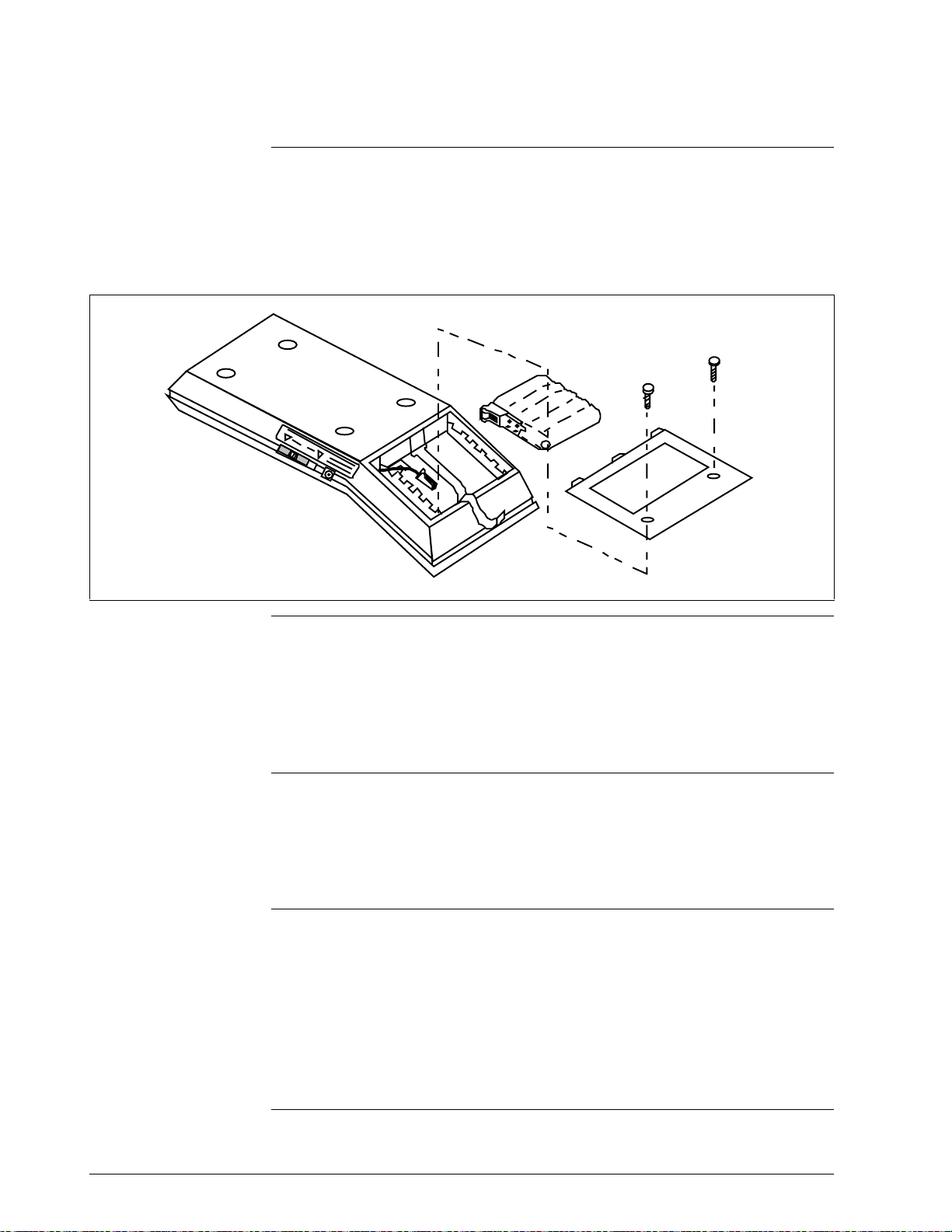

Battery pack location

The battery pack is located behind the LCD display and is accessed

through a back panel. Two hex screws need to be removed to access the

battery pack. Figure 1-4 shows the location of the battery pack and how it

fits into the STS103.

Figure 1-4 STS103 Battery Pack

20722

Charging the batteries

STS103 charging

terminal

Self-diagnostics

The battery pack is charged by plugging the battery charger into an outlet

and inserting the lead into the charging terminal of the STS103. The

battery pack takes a minimum of 10 hours to charge and the STS103 may

be used continuously for up to 24 hours before the battery pack needs

recharging. A colon (:) will be appear in the middle of the top line on the

LCD display when the battery pack needs charging.

The battery pack is charged through a battery charger that plugs into the

charging terminal. The charger inputs 110 or 220 Vac 50/60 Hz and

outputs 7 Vdc 180 mA to the NiCd battery pack. The connector of the

battery charger is inserted into the charging terminal on left side of the

STS103 by the ON/OFF switch.

When the STS103 is turned on, it automatically runs diagnostics on its

functions. Upon successful completion of the diagnostics, the message,

“PUT LOOP IN MAN” (analog communications) or

“DE-XMTR PRESS ID” (digital communications)

appears. If an error occurs, the message,

“CRITICAL STATUS” appears.

Refer to Section 3 for a description of the STS103 errors or the individual

device sections for device specific error messages.

8 STS103 Operating Guide 4/99

Page 21

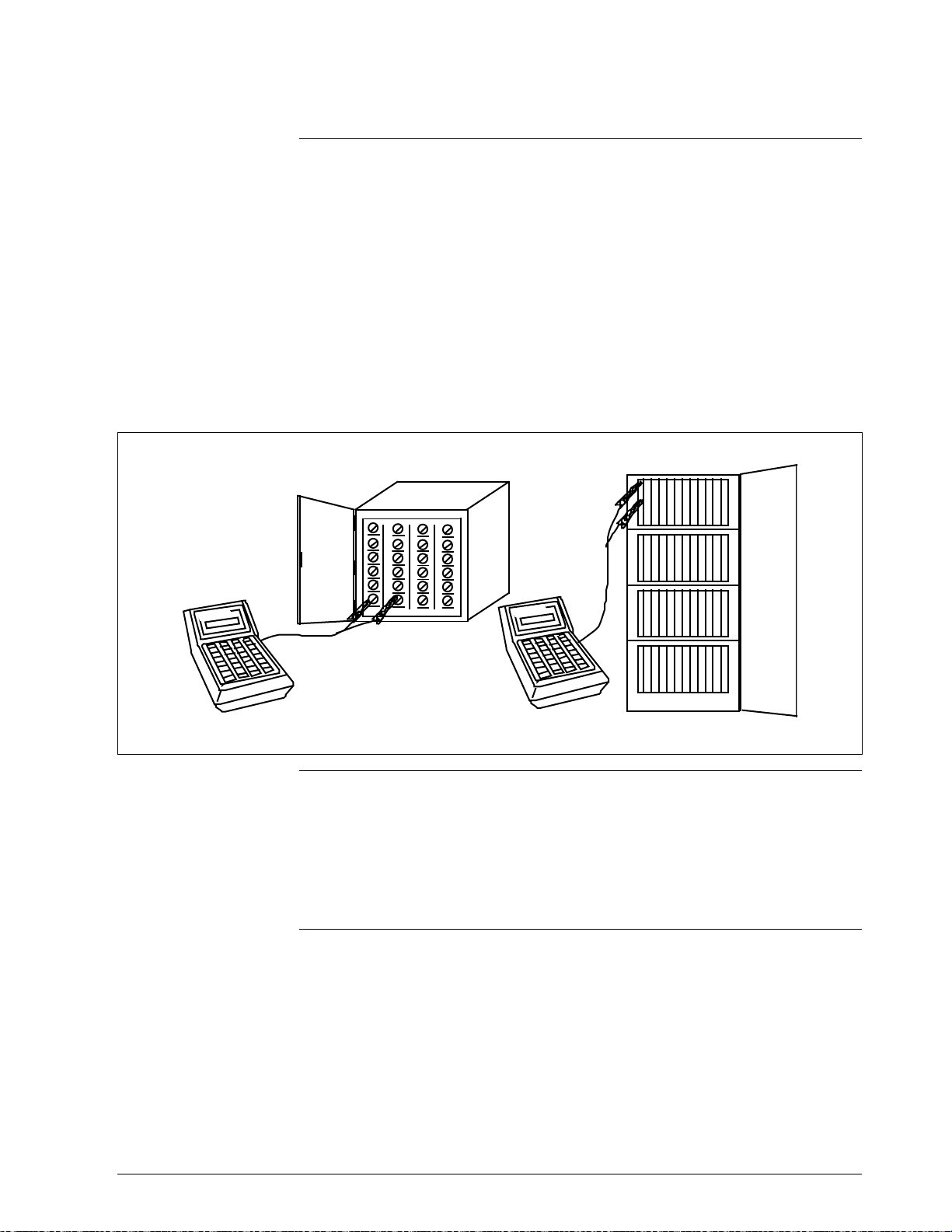

1.3 Connections

Connecting the

STS103 to junction

boxes and IS panels

The STS103 connects to SFIs, IS panels, and junction boxes through a

pair of wires with alligator clips on the ends. The STS103

communications terminal end of the wires has a stereo phone jack

connection that is inserted into the communications terminal. The other

end of the wires are clipped onto terminals in the junction box or IS

barrier panel, or directly to the transmitter. The red SFC lead connects to

the junction box or SFI positive terminal, the black lead to the negative

terminal.

Figure 1-5 shows the STS103 connected to a junction box and an IS

barrier panel.

Figure 1-5 STS103 –Junction Box and IS Connection

Transmitter Junction Box IS Panel

w

l

l

e

w

ey

n

o

H

ney

o

H

l

l

e

Connecting the

STS103 to a smart

field instrument (SFI)

20723

The STS103 connects directly to the positive and negative terminals on

the SFI. The STS103 can connect to only one SFI at a time.

REFER TO THE INDIVIDUAL DEVICE SECTIONS IN THIS

MANUAL for instructions on how to wire the STS103 to your particular

device (SFI).

4/99 STS103 Operating Guide 9

Page 22

1.4 STS103/SFI Communication

How data is

transferred

Types of

communication

Sending and receiving data to and from an SFI is done over the

transmitter’s 4-20 mA wires. When the STS103 is connected to a

transmitter and turned on, it automatically determines what type of

transmitter it is communicating with. When data is sent to a transmitter, a

request is sent to the transmitter and a response is sent back to the

STS103. When the STS103 and SFI are communicating, the message

“SFC Working...” is displayed on the STS103.

The message handling routines are transparent to you. The way the request

and response messages are handled depend on whether the transmitter is

an analog only model or an analog/digital model, and the mode

configuration.

Analog communications uses half duplex communication (data can be

sent in one direction at a time, to the transmitter or to the STS103) while

the digital communication uses half duplex with or without broadcast (4 or

6 bytes). Table 1-3 describes the communication formats used.

Table 1-3 Communication Format Description

Format Description

Analog

Communication

Mode

DE READ

A

ID

Digital (DE)

Communication

Mode

DE READ

^

^^

^

S

SS

SHH

S

^

H

I

F

T

HII

IFF

FTT

T

H

I

F

T

ID

Analog communication uses a half-duplex , variable-length

message with a wake-up pulse for on-demand requests and

responses. While the messages travel back and forth, the

transmitter’s output varies between 4-20 mA, therefore, the

control loop must be in manual so the data exchange does

not interfere with the control loop.

Digital communication also uses a half-duplex , variablelength message with no wake-up pulse for on-demand

requests and responses (not including data uploads). The

data is piggybacked on the process variable data being sent

on the control loop.

The broadcast 4-byte format is rarely used because no

A

database protection can be performed when used in the

TDC 3000 system. This mode is only used when faster PV

update rates are required. One byte is for transmitter status

and configuration data; the other three are for process data.

The broadcast 6-byte format is used for uploading the

transmitter’s database to the STS103’s hold memory. The

bytes are similar to the 4-byte format, but it includes two

additional bytes of transmitter database information.

Continued on next page

10 STS103 Operating Guide 4/99

Page 23

1.4 STS103/SFI Communication, Continued

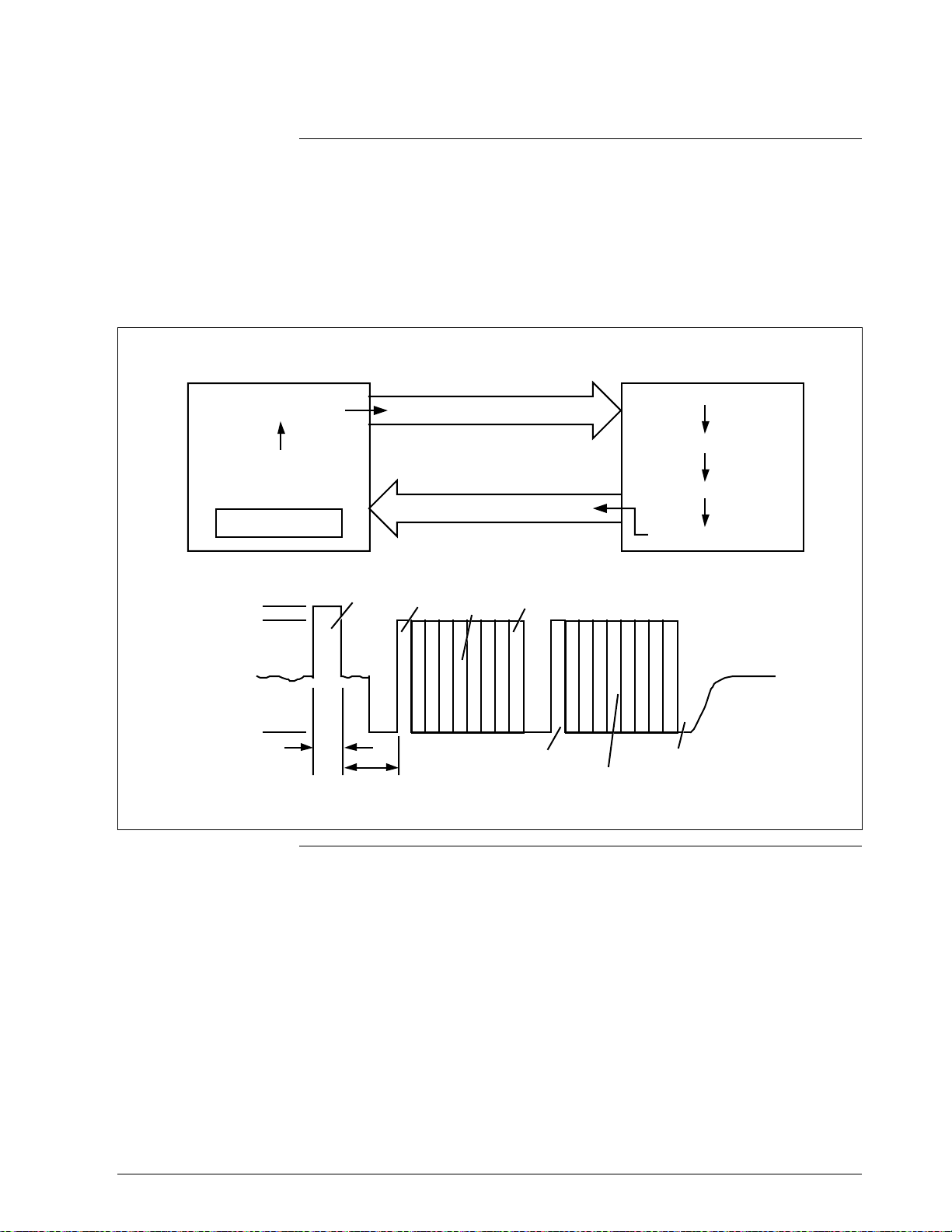

Analog data exchange

When the STS103 communicates with an analog transmitter, a 26 mA

wake-up pulse is sent to the transmitter to put the device into the

communication mode. The pulse also causes the current drawn by the

device to drop to 4 mA. Data is then exchanged in an analog fashion

(4-20 mA) between the STS103 and SFI. Figure 1-6 shows a typical

analog data exchange using the STS103.

Figure 1-6 Typical Analog Data Exchange

SFC103 Smart Transmitter

Send Request

Keypad Action

Display Message

26 mA

20 mA

Wake-up

Pulse

Wake-up Signal and Message

Data and

Start

Request

Response

Message

Parity

Receive Data

Identify Request

Process Information

Send Response

Stop

Analog PV

10 mA

4 mA

Turn-On

Turn-Off

Request

Start

Response

Data and

Parity

Analog PV

Stop

20724

Continued on next page

4/99 STS103 Operating Guide 11

Page 24

1.4 STS103/SFI Communication, Continued

Digital data exchange

Data exchanges between the STS103 and digital devices are in ASCII.

The exchange starts off with the STS103 requesting the transfer and the

SFI then responds. Figure 1-7 shows a typical digital data exchange using

the STS103 and Table 1-4 Describes the sequence of events.

Figure 1-7 Typical Digital Data Exchange

No. of Bytes 4 4 4 4 14 4 4 4

Xmtr

SFC

Digital data exchange

sequence of events

PV PV PV PV

12 3

4

Table 1-4 describes the sequence of events in a typical digital data

exchange. The steps correspond to the numbers in Figure 1-7.

5

Request and

Message

6

7

PV and

Response

8

PV PV PV

20725

Table 1-4 Typical Digital Data Exchange Sequence of Events

Step Occurrence

1 The STS103 waits at least 100 msec for any digital communications.

2 The STS103 detects the transmitter message length and gap

location.

3 The STS103 synchronizes its operation with the next transmitter

message.

4 The STS103 transmits a request and message during the next inter-

message gap.

5 The transmitter halts broadcasting process variable (PV) data when

the request is detected.

6 After receipt of a complete message, the transmitter returns to its

configured broadcast mode and processes a response message.

7 After completion of processing, the transmitter sends the response

message in half duplex protocol after the next PV data broadcast.

8 Upon completion of the data transfer, the transmitter returns to its

configured broadcast mode within 100 msec.

12 STS103 Operating Guide 4/99

Page 25

Section 2 —STS103 User Interface Guidelines

1.2 STS103 Overview

Introduction

What’s in this section?

This section describes the User Interface functions and guidelines for the

STS103 Smart Field Communicator (SFC).

There are several features of the STS103 that will make communicating

with a Smart Field Instrument (SFI) easier to accomplish. They are:

• Common operation for all Smart Field Instruments

• A two-line LCD display

• A new keypad with improved key responsiveness

• Direct key access for the “most used” functions

• Configuration key access for SFI-specific configuration and “lesser

used” functions

This section contains the following topics:

Topic See Page

2.1 Overview 13

2.2 Keypad Functions 14

2.3 Display Functions 15

2.4 Prompt Character Definitions 16

2.5 Function Key Data Entry 17

2.6 Configuration Key Data Entry 19

2.7 Other Key Sequences 21

4/99 STS103 Operating Guide 13

Page 26

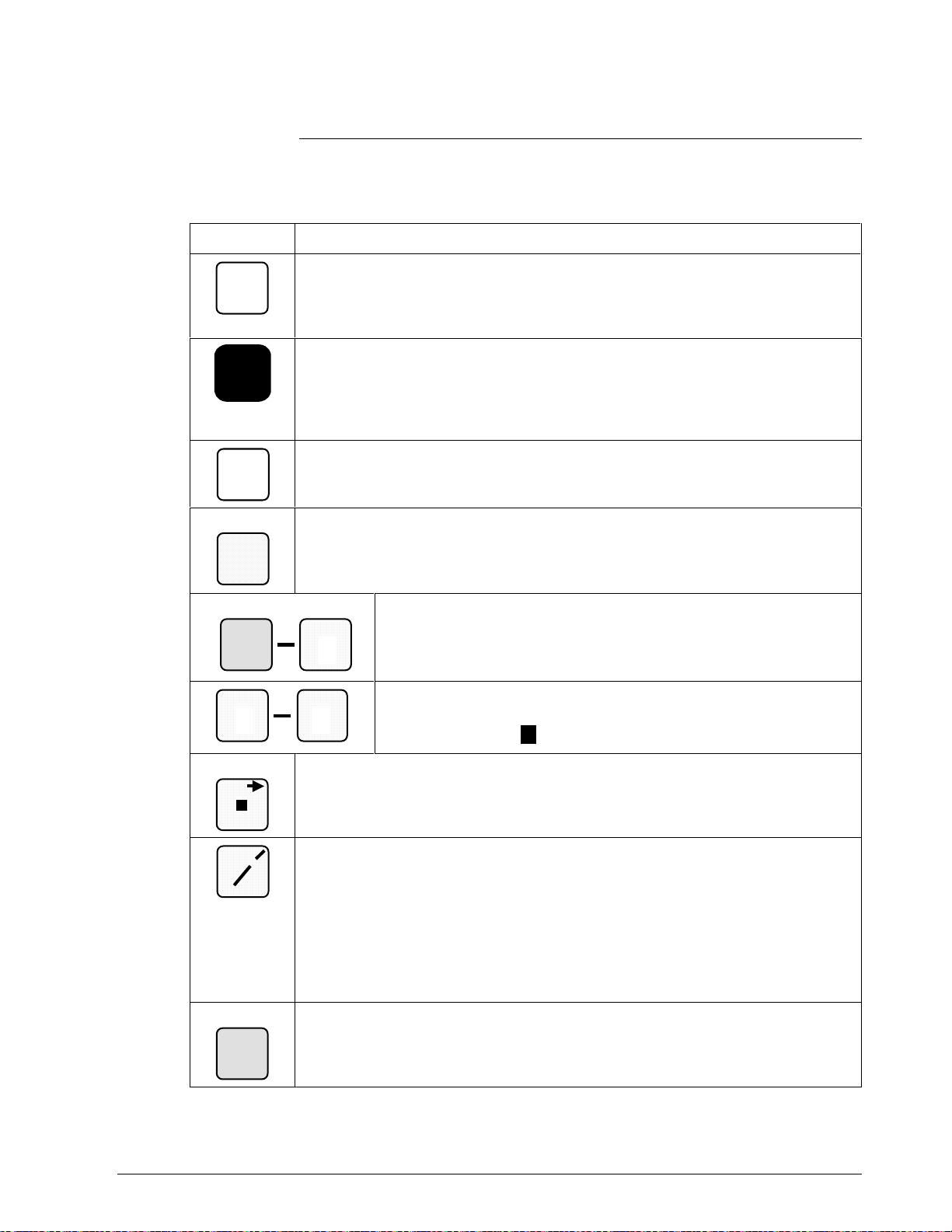

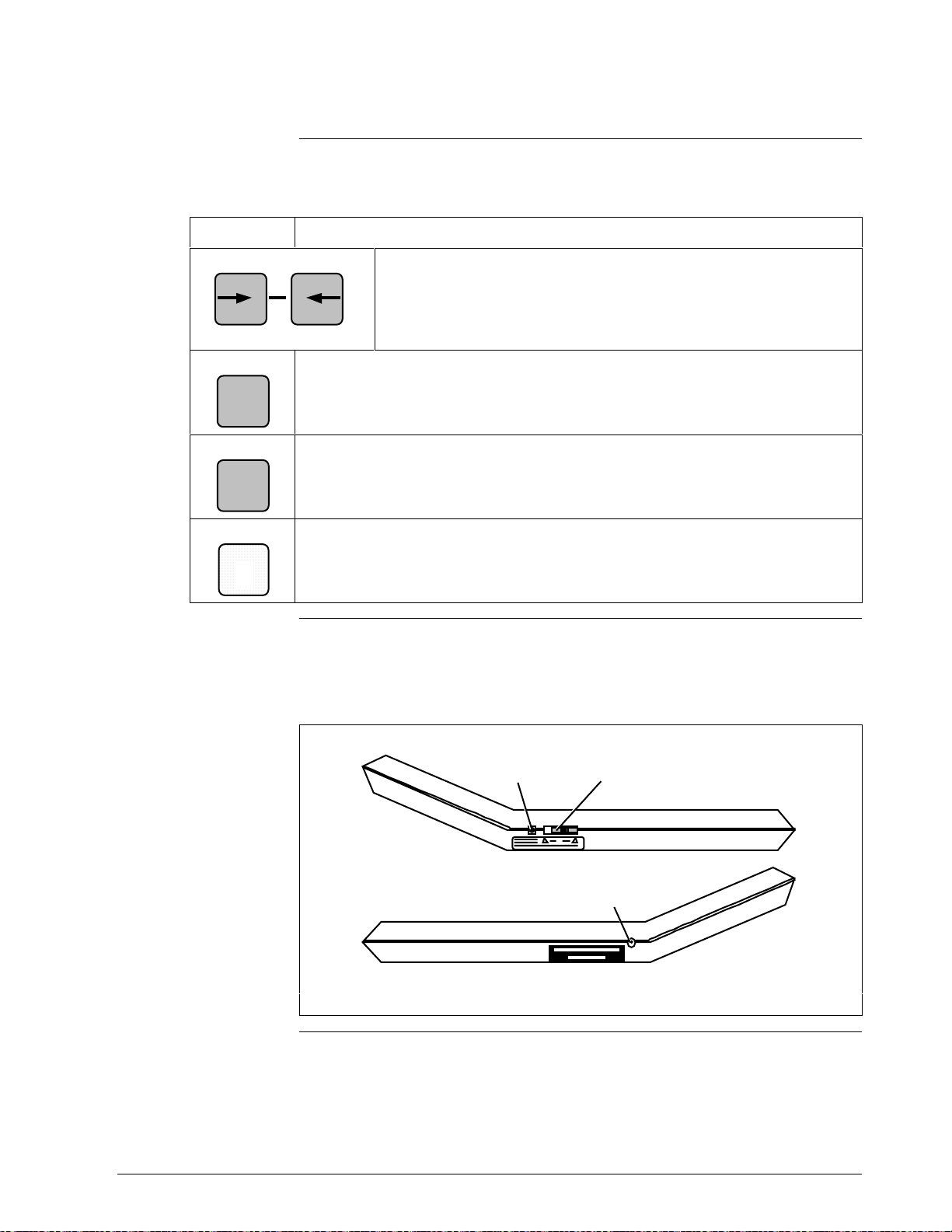

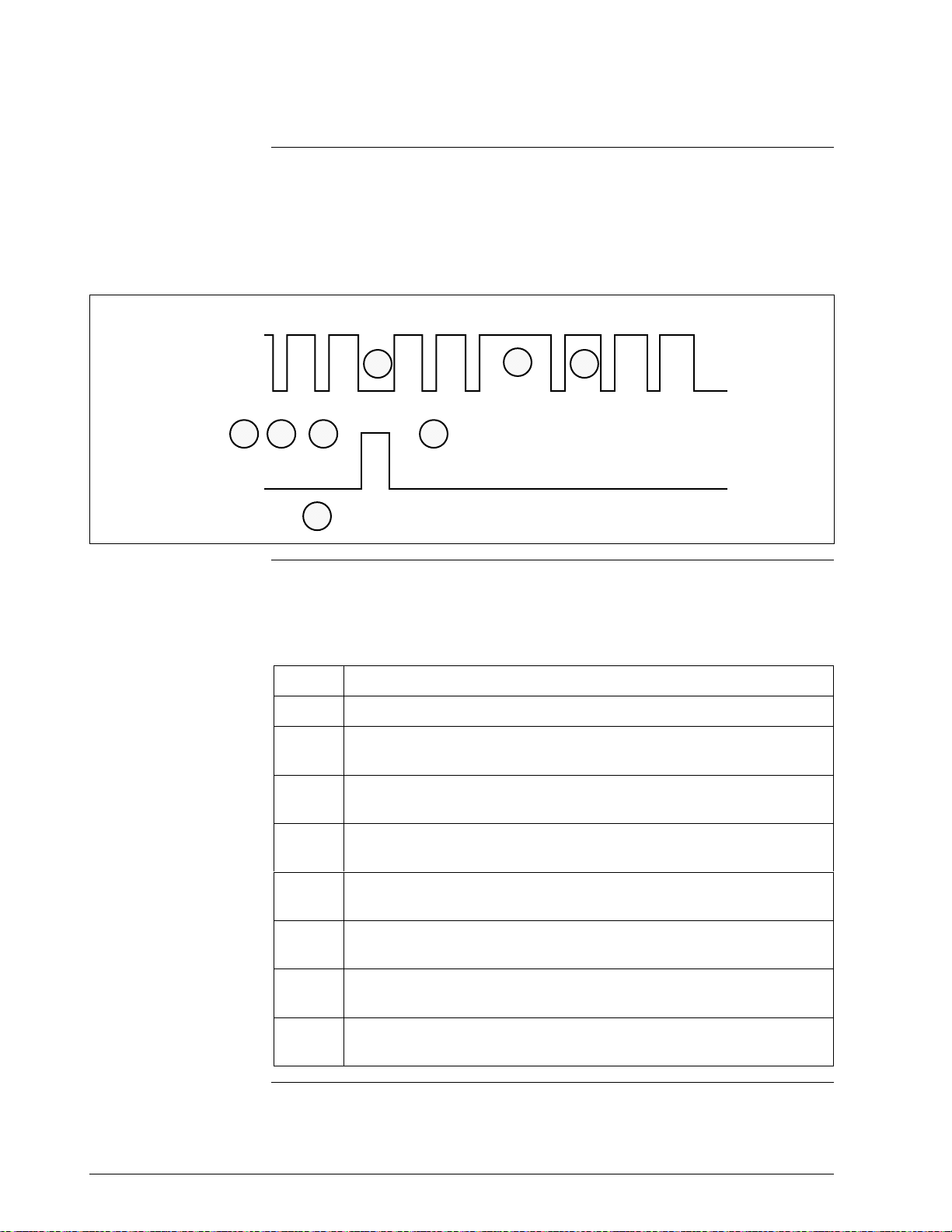

2.2 Keypad Functions

Keypad color groups

The keypad keys are grouped in several different colors that correspond to

specific functions. Figure 2-1 shows the grouping of the STS103 keys.

Figure 2-1 STS103 Keypad Color Groups

Green

DE READ

ABCD

ID DAMP UNITS

CONF

EFGH

Olive

LRV URV

0% 100%

DE CONF RESET

A <–> DE

F/S DIR

ALPHA

INPUT

IJKL

MENU

STAT

NUM /

OUT- COR-

PUT

MNO P

QRST

UVWX

URL

YZ

SHIFT

SET

NEXT

564

PREV

SW VER

+

–

NON-VOL

ENTER

(YES)(NO)

RECTITEM

789

123

SCR PAD

0SPAN

CLR

Orange

Yellow

Orange

Key color group

description

White/Black

20726

Table 2-1 describes the key color grouping on the STS103.

Table 2-1 STS103 Key Color Group Description

Key Color Description

Green

Orange

Yellow

White/Black

Olive

The green keys are used to enter and verify SFI configuration

data.

The orange keys are keys the operator uses to control the

actions of the STS103 and SFIs. These keys also select and

set parameters for the SFIs.

The primary function of the yellow keys is to enter numeric

data into the STS103. Data may be entered into the scratch

pad memory of certain SFIs and the software version may be

displayed through these keys.

The white and black keys enter the alpha or numeric modes

and enable the STS103’s second functions to be activated.

CLR (no) key takes you to a previous function level.

The olive keys allow backspacing or advancing in certain

modes, switching from analog to digital modes for

communicating with different SFIs, and viewing the status of

SFIs. Allows viewing of Span and Upper Range Limit.

14 STS103 Operating Guide 4/99

Page 27

2.3 Display Functions

LCD display

The STS103 uses a two-line display.

Table 2-2 lists the data that may appear on each line of the display and

some examples of each.

Table 2-2 LCD Display Functions

Line Display Data Examples

Upper Type of transmitter MAG SR, LIN DP, STT, etc..

Tag Name (User defined ID name)

A label that identifies the value,

message, or sub-level title on

the lower line.

Configuration sub-level title for

which the menu selections or

settings are shown on the lower

line.

The non critical status indicator ( # )

The low battery indicator ( : )

Lower Alpha-numeric string for ID

name or Scratch Pad entries.

LRV1, OUTPT2, SPT CONFIG,

etc.

RANGE CONFIG?,

PROBE CONFIG?

CONFORMITY?, etc.

(user defined name or message)

The numerical value and units

for the parameter defined on the

upper line.

Configuration sub-level title with

a “?” indicating that the next

configuration level may (“YES”)

or may not (“NO”) be selected

for viewing.

Pre-set or menu selectable

configuration values

(Configuration level 2 or 3).

STS103 processor status

messages.

STS103 communication status

messages.

53.99%, 23.121°C, 28.763 Gal/hr,

etc.

CONFORMITY?,

RANGE CONFIG?,

TOTALIZER MENU?, etc.

CURRENT PV: 1,

F/SAFE UPSCALE,

VELOCITY,

(for MagneW UNITS KEY), etc.

SFC WORKING...,

READY...,

ENTERED IN SFC, etc.

NO TRANSMITTER RESPONSE,

IN OUTPUT MODE, etc.

4/99 STS103 Operating Guide 15

Page 28

2.4 Prompt Character Definitions

Definitions and general

rules

Certain characters on the LCD display indicate to you which type of

response is permitted.

Table 2-3 shows these characters and the rules and what the STS103 is

looking for in the way of input.

Table 2-3 STS103 LCD Character Definitions and General Rules

Character Display Example Requested Action

“ _ ” When the display

contains a cursor,

for example,

LRV = 1.22

“ = “ When the display

shows an item after

an equal (=) sign,

for example,

F/S = B/O Lo

“ ? ” When the display

shows an item with

a question mark (?)

after the item, for

example,

Range Config?

The STS103 is asking you to enter a

numerical value at the cursor point.

Type in a new value and press the ENTER

key to store the value.

Numeric entries are also allowed in the ID

name and Scratch Pad messages.

The STS103 is asking for a selection after

the equal sign.

Your selection can be made using the

MENU

from a pre-defined list of values or

selections.

The STS103 is asking if you want to enter a

particular group of configuration parameters.

If the parameters are what you desire, press

the YES

Press the CLR

current configuration level and return the

SFC display to the next highest configuration

level.

key or the or

key.

key to cancel from the

keys

Press NEXT

next or previous group of parameters.

“ * “

16 STS103 Operating Guide 4/99

When the display

shows an item with

* “, for example:

a “

ABC

*

The STS103 is asking you to enter an alpha

character.

This prompt is used only when entering an

ID name or Scratch Pad messages.

or PREV to go on to the

Continued on next page

Page 29

2.5 Function Keys Data Entry

Function keys

Multiple process

variables

To access the basic functions or parameters which are common to all

SFIs, press any one of the labeled function keys. These common items

are:

•ID

• SPAN/LRV/URV/URL

• INPUT/OUTPUT

• INPUT and OUTPUT CORRECTS

• LRV and URV CORRECTS and SETS

• RESET CORRECTS

• STATUS

• UNITS

• DAMPING

• FAILSAFE DIRECTION

• DE OPERATIONS

•SW VERSION

• SCRATCH PAD

In some cases, more than one Process Variable is available. Press the

MENU key to select which PV will be referenced when the following

operating parameters are displayed:

• SPAN/LRV/URV/URL/LRL

• INPUT/OUTPUT

• DAMP

• UNITS

For example, consider an SFI that may analyze up to four components.

Each time the MENU key is pressed, the display will step through the

available Process Variables (PVs)-(CURRENT PV:1, CURRENT PV:2,

CURRENT PV:3, CURRENT PV:4).

If PV:2 were selected and the SPAN key pressed, “SPAN 2” (the span

for input 2) would be displayed.

Continued on next page

4/99 STS103 Operating Guide 17

Page 30

2.5 Function Keys Data Entry, Continued

Function key sequence

Most of the common operating parameters are numerical values which

may be altered by the operator. To display and/or change these values,

follow the key sequence procedure in Table 2-4.

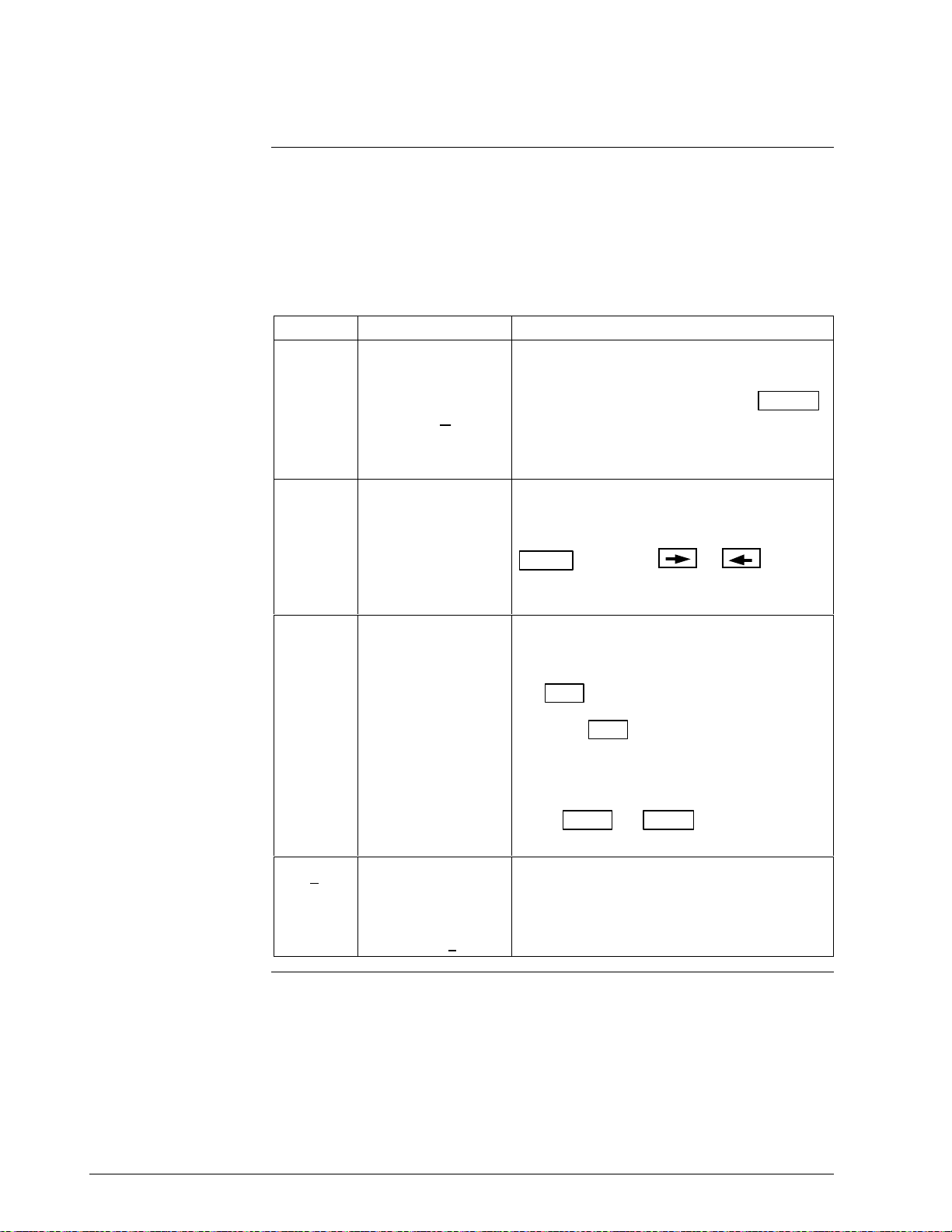

Table 2-4 Function Key Sequence

Step Action

1 Press the desired Function key. The display will show the current

setting or value of the selected parameter.

A numerical value may be changed only if the first digit of the

currently displayed value is underlined.

2Enter a new value by pressing the appropriate number keys.

For some values, such as Damping, the

used to step through a menu of permitted selections.

3

Press the ENTER

ATTENTION

the data will not be downloaded to the SFI.

4

The CLR

operating display without making any changes.

key may be used at any time to return to the normal

(yes) key to store the new data in the STS103.

If the operator exits the display using any other key,

and keys may be

18 STS103 Operating Guide 4/99

Page 31

2.6 Configuration Key Data Entry

Configuration key

Configuration key

sequence

Press the CONF key to access SFI-specific configuration menus. SFI

configuration is divided into two or three levels.

• Level 1 – contains a list of configuration categories which is unique

to each SFI.

• Level 2 – contains a list of configuration parameters for each of the

level 1 categories (two level configuration), or

a sub-level of categories which pertains to the level 1

categories (three level configuration).

• Level 3 – contains a list of configuration parameters for each of the

level 2 categories.

To display and/or change configuration, follow the key sequence

procedure in Table 2-5.

Table 2-5 Configuration Key Sequence

Step Action

1

Press the CONF

key.

Configuration level 1 is accessed.

2

Press the NEXT

desired category. The “ ? “ prompt at the end of each selection

indicates:

• the YES

• the NO

the STS103 display to the next higher level.

3

Press the ENTER

displayed. Configuration level 2 (or 3*) is accessed.

* for 3-level configuration, repeat steps 2 and 3 to access level 3.

key will exit the current configuration level and will return

or PREV keys, if necessary, to reach the

key will access configuration level 2 (or 3*).

(yes) key when the desired category is

Table continued on next page

4/99 STS103 Operating Guide 19

Page 32

2.6 Configuration Key Data Entry, Continued

Configuration key

sequence, continued

Table 2-5 Configuration Key Sequence, continued

Step Action

4 At this point you may:

• press the MENU

settings for the displayed parameter, or

• press the

the menu settings, or

• enter a numerical value. (Numbered entries allowed when the first

digit of the current numerical value is underlined.

• press the ENTER (YES) key to enter a new value or setting. The

new data is stored in the SFC and “ENTERED IN SFC” is

displayed.

ATTENTION

setting display, the data will not be changed.

• press the NEXT

parameters within the selected category.

• press the CLR

and return to the next higher level.

5 When any configuration values or settings in a given category have

been updated, the SFC will display the prompt “DOWNLOAD

CHANGES?” before returning to level 1. You may :

key to step through the menu of allowable

or

If you use any other key to exit the new value or

or PREV keys to reach other configuration

(NO) key to exit the current configuration level

keys to step forward or backward through

• press the ENTER

SFI, or

• press the CLR

downloading the new settings to the SFI. Configuration values in

the SFC will also revert to their original setting.

20 STS103 Operating Guide 4/99

(YES) key to download the new settings to the

(NO) key to exit configuration level 1 without

Page 33

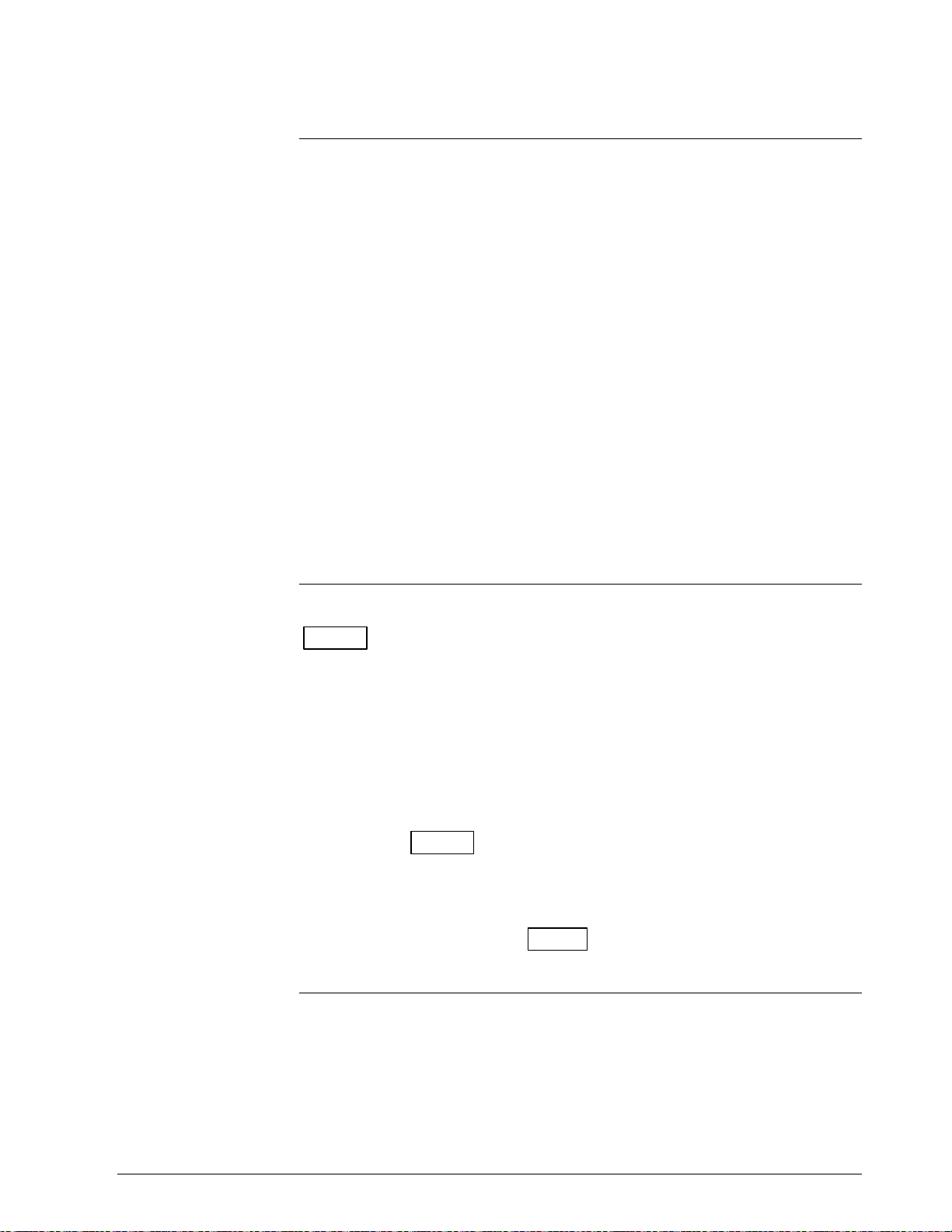

2.7 Other Key Sequences

Other keys

Table 2-6 lists several other keys that are available on the keyboard and

how they are used for data entry.

Table 2-6 Other Key Sequences

Key(s) Usage

M

• When entering an ID name or using the Scratch Pad, the right

and left arrow keys move the cursor within any alphanumeric

or

A <–> DE

NUM /

ALPHA

S

H

I

F

SS

SHH

HII

IFF

FTT

S

H

I

F

Q

^

^^

^

^

T

T

T

string.

• These keys are also used to step forward or backward through

the parameter menus in configuration levels 2 and 3 (see

“Configuration Key Method”).

This key toggles the keys of the SFC keyboard between the

function/number printed on the key and the alpha characters

which are printed in the upper right hand corner of each key.

Use this key to enter letters, numbers, “+”, “—”, space, “

^

”, “,”,

“.”, “/” when entering an ID name and when using the Scratch

Pad.

Pressing the SHIFT key, followed by a second key, selects the

function printed above the second key.

CLR

(NO)

The CLR(NO) key:

• clears the current display and returns it to the main “READY”

display (See Function Key Method), or

• clears the current display to the next highest configuration level

(see “Configuration Key Method”), or

• clears a typed-in numerical value before it has been entered

(ENTER

key)

4/99 STS103 Operating Guide 21

Page 34

22 STS103 Operating Guide 4/99

Page 35

3.1 Overview

This section contains all the information you will need to know in order to

operate the STS103 Smart Field Communicator with a Smart Field

Instrument.

Refer to the individual device User’s Manual for transmitter operating and

installation information.

The STS103 operations given here are more or less the same for every

SFI. See the individual device sections in this manual for operations

specific to your particular SFI.

This section gives you the keystrokes and displays that are specific for

SFC communications with the Smart Field Instruments.

Section 3 —STS103 Operation

What’s in this section?

This section contains the following topics:

Topic See Page

3.1 Overview 23

3.2 Power up 24

3.3 Diagnostics and SFC Messages 25

3.4 Common Key Sequences and Displays 28

3.5 Using the Transmitter as a Current Source 43

3.6 Disconnecting the SFC 45

4/99 STS103 Operating Guide 23

Page 36

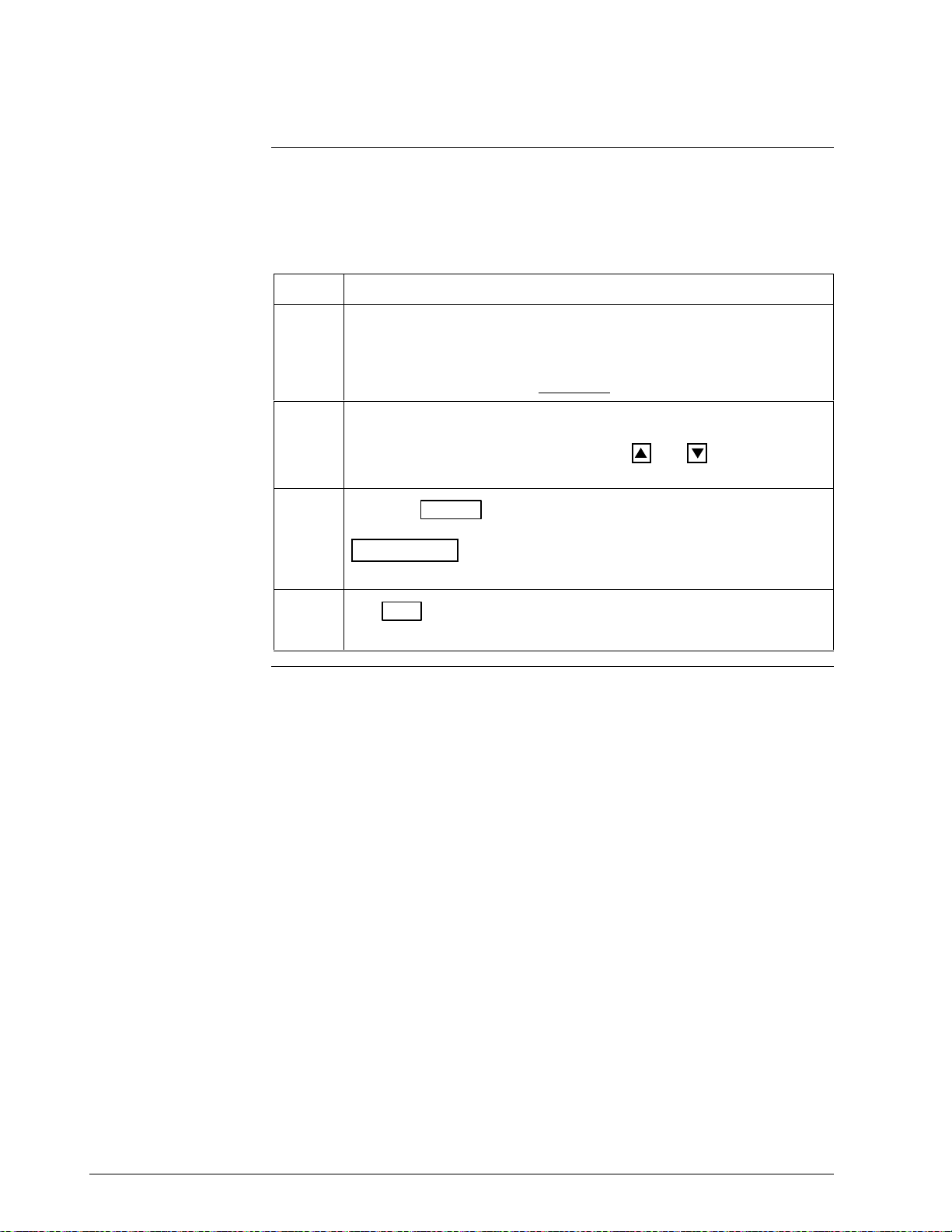

3.2 Power Up

Power-up key and

display sequences

After connecting the leads directly to the transmitter or through the

junction box or IS panel, and the STS103 is turned on, the key and display

sequences depend on whether your SFI is an Analog or Digital mode

instrument. Figure 3-1 shows the displays and key presses for both modes.

Figure 3-1 Power Up Sequence

Analog Mode Digital Mode

PUT LOOP IN MAN

ID

TAG No.

TRIPS SECURED ?

ENTER

TAG NO.

SFC WORKING...

SFI Type (TAG NO.)

XXXXXXXX

DE-XMTR PRESS ID

ID

TAG NO.

SFC WORKING...

DE XMITTER TAG NO.

XXXXXXXX

20727

When the ID key is pressed, the ID of the device is read in.

For Analog devices, the database is also read in along with the ID.

For digital devices, the second function of the ID key reads in the

database of the digital transmitter. Figure 3-2 shows an example of the

key presses and display that may appear.

Figure 3-2 Read Digital Database

DE READ

A

ID

TAG No

WORKING . . .

(SFI Type) TAG NO .

XXXXXXXX

20728

24 STS103 Operating Guide 4/99

Page 37

3.3 Diagnostics and SFC Messages

Introduction

OK Status

Critical status

The STS103 and the SFIs both run continuous self-diagnostics.

This means that they are constantly testing the communications, the loop,

and themselves.

Any time you want results of these diagnostics, press the STAT key.

The SFC displays its report, in the form of messages, which identify

diagnostic conditions.

Diagnostic conditions are broken down into three categories:

• an OK condition

• a critical condition

• a non-critical condition

An OK condition means no problem exists, and the display looks like this:

STATUS XXXX

STATUS CHECK=OK

A critical condition means that the SFI is not functioning properly. When

this occurs, the SFI goes into upscale burnout and maintains an output of

21.8 mA, or into downscale burnout and maintains an output of less than

3.9 mA. This message CRITICAL STATUS interrupts your operation and

is followed by the message PRESS STATUS.

Non-critical status

Low battery voltage

After the PRESS STATUS message, you press the STAT key to find

out what problem exists. You will receive one or more messages. Take

whatever corrective action necessary to solve the problem. Remember that

the SFI will stay in upscale or down scale burnout until the condition is

corrected.

If the SFI sends more than one message, each message will be displayed

in the order of importance for about 5 seconds. If you need to see them

again, press the STAT key again.

A non-critical condition means that although a problem exists, the SFI is

still operating. When a non-critical condition occurs a “#” character

appears on the right side of the display, along with whatever you’re

displaying at the time.

This character means press the STAT key because some type of a

problem exists. Again, one or more messages will appear on the display

for about five seconds each.

When the battery voltage becomes low, a colon “:” will appear in the

middle of the display. It stays on the display until you either charge or

replace the batteries.

Continued on next page

4/99 STS103 Operating Guide 25

Page 38

3.3 Diagnostics and SFC Messages, Continued

Diagnostic Messages

Table 3-1 is a list of all the diagnostic messages that are common to the

STS103 when used with a Smart Field Instrument (SFI).They are listed in

alphabetical order along with the problem associated with the message and

the corrective action to take when the message appears.

ATTENTION

Refer to the individual device sections for a comprehensive list of error

messages and troubleshooting procedures specific to that particular device.

Table 3-1 Diagnostic Messages for SFC

Message Problem Corrective Action

SFC FAULT

or

SFC FAILURE

COMM ABORTED

ENTRY>SENS RNG

EXCESS ZERO CORR

EXCESS SPAN CORR

FAILED COMM CHK

HI RES/LOW VOLT

H.W. MISMATCH

ILLEGAL RESPONSE

INVALID DATABASE

INVALID REQUEST

SFC communication is not

possible due to a detected SFC

problem.

Communication aborted by user.

The number entered is beyond 1.5

times the upper range limit of the

sensor.

The ZERO correction factor is

outside the acceptable limits for

accurate operation.

The SPAN correction factor is

outside the acceptable limits for

accurate operation.

The SFC failed a communication

diagnostic check. This could be a

SFC electronics problem or a

faulty or dead communication loop.

Either there is too much resistance