Honeywell CUL6438SR-CV1, STRYKER CVAHU ZIO CUL6438SR-CV1 Configuration Manual

STRYKER CVAHU ZIO

CUL6438SR-CV1

CONFIGURATION GUIDE

Nov-2013

31-00023-01

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Table of Contents

Introduction ........................................................................................................................................................... 9

Description of Devices .............................................................................................................................. 9

Stryker™ Lon Configurable CVAHU Controller .............................................................................. 9

General ................................................................................................................................. 9

Features ................................................................................................................................ 9

Zio®/Zio Plus LCD Wall Modules ................................................................................................. 10

General ............................................................................................................................... 10

Features .............................................................................................................................. 10

Control Application ....................................................................................................................... 10

Control Provided .......................................................................................................................... 11

Products Covered ........................................................................................................................ 12

Organization of Manual ................................................................................................................ 12

Applicable Literature .................................................................................................................... 12

Product Names ............................................................................................................................ 12

Agency Listings ............................................................................................................................ 13

Abbreviations ............................................................................................................................... 14

Constructions of Controller and Wall Module ............................................................................... 14

Stryker CVAHU configuration by Zio wall module ........................................................................................... 15

Contractor Mode: Introduction ................................................................................................................ 15

Initial Power-Up ............................................................................................................................ 16

Contractor Mode: Configuration Steps ......................................................................................... 17

Set Home Screen ................................................................................................................ 17

Set View More ..................................................................................................................... 18

Parameters.......................................................................................................................... 20

Sensors ...................................................................................................................... 21

Status ......................................................................................................................... 22

Temp Sp ..................................................................................................................... 25

Override ..................................................................................................................... 28

Alarms ........................................................................................................................ 28

Snsr Calibration .......................................................................................................... 31

Wm Config ................................................................................................................. 31

Cnfg Ctl ................................ ...................................................................................... 35

Cnfg Ui ....................................................................................................................... 39

Cnfg Di ....................................................................................................................... 39

Cnfg In........................................................................................................................ 40

AO1 ............................................................................................................................ 44

2

STRYKER CVAHU ZIO CONFIGURATION GUIDE

AO2 ........................................................................................................................... 44

AO3 ........................................................................................................................... 45

Cnfg Out .................................................................................................................... 46

Time .......................................................................................................................... 50

Set Time .................................................................................................................... 51

Set Date..................................................................................................................... 51

Schedule.................................................................................................................... 53

Tenant Mode: Introduction ..................................................................................................................... 54

Tenant Mode: View Steps ........................................................................................................... 54

Fan ..................................................................................................................................... 55

Override.............................................................................................................................. 56

System & View More .......................................................................................................... 57

3

STRYKER CVAHU ZIO CONFIGURATION GUIDE

List of Figures

Figure 1: Stryker™ Lon Configurable CVAHU Controller ......................................................................................... 9

Figure 2: Zio/Zio Plus LCD Wall Modules............................................................................................................... 10

Figure 3: Typical Stryker CVAHU control application ............................................................................................. 11

Figure 4: Stryker CVAHU configuration by Zio wall module ................................................................................... 15

Figure 5: Key position of wall module ..................................................................................................................... 15

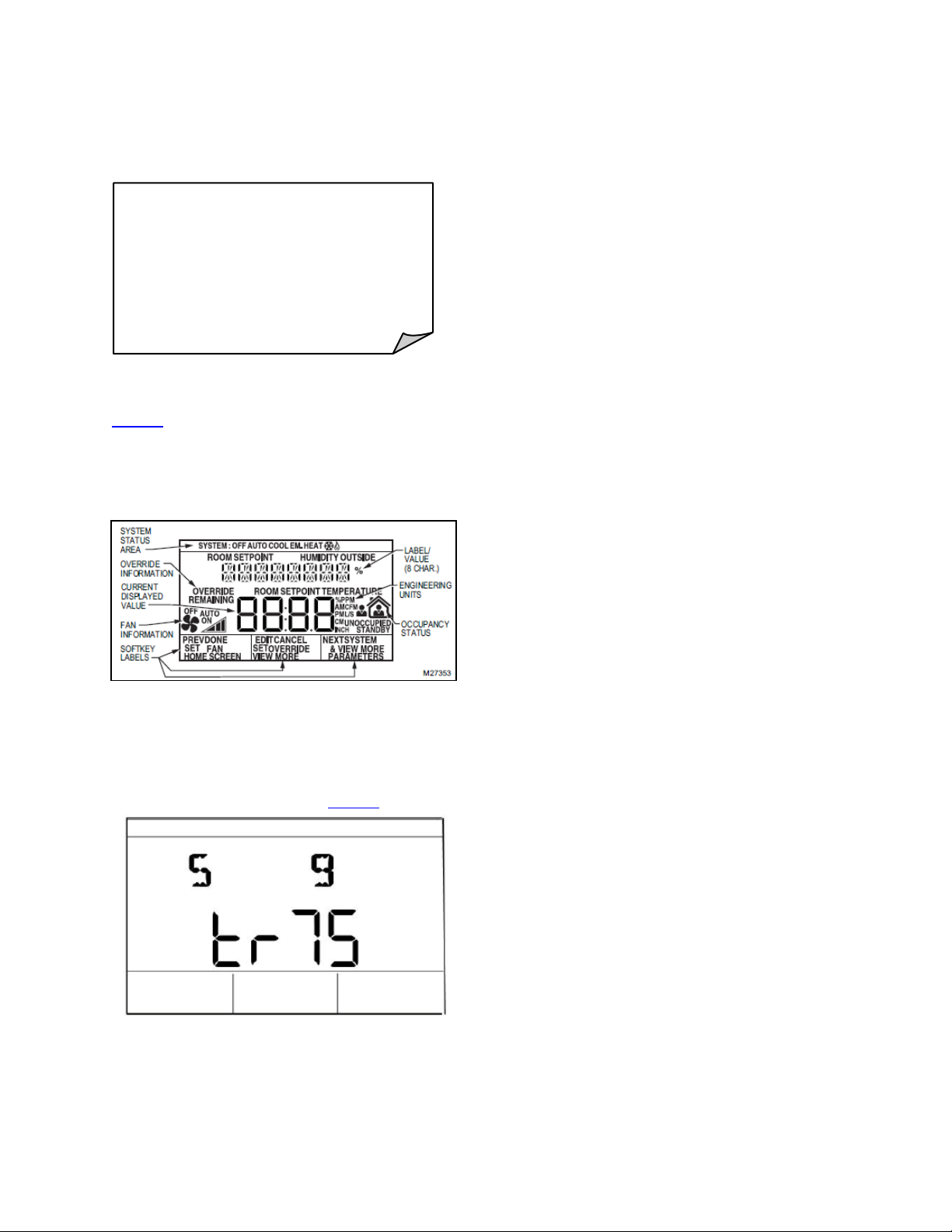

Figure 6: TR70 Series Wall Module - LCD screen ................................................................................................. 16

Figure 7: Model number and Sylk bus address ...................................................................................................... 16

Figure 8: Contractor mode default home screen .................................................................................................... 17

Figure 9: Home screen Roomtemp ........................................................................................................................ 17

Figure 10: Home screen Room Setpoint, Roomtemp............................................................................................. 17

Figure 11: Home screen Outside Room Temperature ........................................................................................... 18

Figure 12: Home screen Room, Room Setpoint Temperature ............................................................................... 18

Figure 13: Set View More First screen ................................................................................................................... 18

Figure 14: Parameter group Sensors ..................................................................................................................... 20

Figure 15: Parameters Sensors Zio Temp ............................................................................................................. 20

Figure 16: Parameters Sensors Zio Temp ............................................................................................................. 21

Figure 17: Parameter Status Htg Out ..................................................................................................................... 22

Figure 18: Parameter Status Clg Out ..................................................................................................................... 22

Figure 19: Parameter Status Damper .................................................................................................................... 22

Figure 20: Parameter Status Dmd Limit ................................................................................................................. 22

Figure 21: Parameter Status Trmnl Ld ................................................................................................................... 23

Figure 22: Parameter Status Aux Econ .................................................................................................................. 23

Figure 23: Parameter Status Free Mod .................................................................................................................. 23

Figure 24: Parameter Status Free Dtg ................................................................................................................... 23

Figure 25: Parameter Status Fan ........................................................................................................................... 24

Figure 26: Parameter Temp Sp Occ Clg ................................................................................................................ 25

Figure 27: Parameter Temp Sp Occ Htg ................................................................................................ ................ 25

Figure 28: Parameter Temp Sp Unoc Clg .............................................................................................................. 25

Figure 29: Parameter Temp Sp Unoc Htg .............................................................................................................. 25

Figure 30: Parameter Temp Sp Stby Clg ............................................................................................................... 26

Figure 31: Parameter Temp Sp Stby Htg ............................................................................................................... 26

Figure 32: Parameter Temp Sp Setpoint ................................................................................................................ 26

Figure 33: Parameter Temp Sp Frz Prtc ................................................................................................................ 26

Figure 34: Parameter Temp Sp Eff Sp ................................................................................................................... 27

Figure 35: Parameter Override Fan Ovrd ............................................................................................................... 28

Figure 36: Parameter Alarms Emrg Ovrd ............................................................................................................... 28

4

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Figure 37: Parameter Alarms Clg Ovrd .................................................................................................................. 28

Figure 38: Parameter Alarms Htg Ovrd .................................................................................................................. 29

Figure 39: Parameter Alarms Fan Ovrd.................................................................................................................. 29

Figure 40: Parameter Alarms Frost ........................................................................................................................ 29

Figure 41: Parameter Alarms Iaq Alm .................................................................................................................... 29

Figure 42: Parameter Alarms Invld Sp.................................................................................................................... 30

Figure 43: Parameter Alarms Spc Temp ................................................................................................................ 30

Figure 44: Parameter Snsr Cal Zio T Of ................................................................................................................. 31

Figure 45: Parameter Snsr Cal Zio H Of................................................................................................................. 31

Figure 46: Parameter Wm Config Units .................................................................................................................. 31

Figure 47: Parameter Wm Config Type .................................................................................................................. 31

Figure 48: Parameter Wm Config Cntr Sp .............................................................................................................. 32

Figure 49: Parameter Wm Config Cntsp Hi ................................ ............................................................................ 32

Figure 50: Parameter Wm Config Cntsp Lo............................................................................................................ 32

Figure 51: Parameter Wm Config Byps Min ........................................................................................................... 32

Figure 52: Parameter Wm Config Htgsp Hi ................................ ............................................................................ 33

Figure 53: Parameter Wm Config Htgsp Lo............................................................................................................ 33

Figure 54: Parameter Wm Config Clgsp Hi ............................................................................................................ 33

Figure 55: Parameter Wm Config Clgsp Lo ............................................................................................................ 33

Figure 56: Parameter Wm Config Efhtg HI ............................................................................................................. 34

Figure 57: Parameter Wm Config Efhtg Lo............................................................................................................. 34

Figure 58: Parameter Wm Config Efclg HI ............................................................................................................. 34

Figure 59: Parameter Wm Config Efclg Lo ............................................................................................................. 34

Figure 60: Parameter Cnfg Ctl Hp Type ................................................................................................................. 35

Figure 61: Parameter Cnfg Ctl Clg Type ................................................................................................................ 35

Figure 62: Parameter Cnfg Ctl Clg Tr ..................................................................................................................... 35

Figure 63: Parameter Cnfg Ctl Clg It ...................................................................................................................... 36

Figure 64: Parameter Cnfg Ctl Htg Type ................................................................................................ ................ 36

Figure 65: Parameter Cnfg Ctl Htg Tr ..................................................................................................................... 37

Figure 66: Parameter Cnfg Ctl Htg It ...................................................................................................................... 37

Figure 67: Parameter Cnfg Ctl Fan Mode............................................................................................................... 38

Figure 68: Parameter Cnfg Ctl Oc Snorp................................................................................................................ 38

Figure 69: Parameter Cnfg Ui Ui 1 ......................................................................................................................... 39

Figure 70: Parameter Cnfg Di Di 1 ......................................................................................................................... 39

Figure 71: Parameter Cnfg In Spe Temp................................................................................................................ 40

Figure 72: Parameter Cnfg In Spe Rh .................................................................................................................... 40

Figure 73: Parameter Cnfg In Spe CO2 .................................................................................................................. 41

Figure 74: Parameter Cnfg In Dischair ................................................................................................................... 41

Figure 75: Parameter Cnfg In Mixedair................................................................................................................... 42

5

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Figure 76: Parameter Cnfg In Od Temp ................................................................................................................. 42

Figure 77: Parameter Cnfg In Occ Snsr ................................................................................................................. 43

Figure 78: Parameter Cnfg In Window ................................................................................................................... 43

Figure 79: Parameter AO1 Range.......................................................................................................................... 44

Figure 80: Parameter AO2 Range.......................................................................................................................... 44

Figure 81: Parameter AO3 Range.......................................................................................................................... 45

Figure 82: Parameter Cnfg Out Clg Stg1 ............................................................................................................... 46

Figure 83: Parameter Cnfg Out Clg Stg2 ............................................................................................................... 46

Figure 84: Parameter Cnfg Out Clg Stg3 ............................................................................................................... 47

Figure 85: Parameter Cnfg Out Hp Chang ................................................................ ............................................. 47

Figure 86: Parameter Cnfg Out Htg Stg1 ............................................................................................................... 48

Figure 87: Parameter Cnfg Out Htg Stg2 ............................................................................................................... 48

Figure 88: Parameter Cnfg Out HtgStg3 ................................................................................................................ 49

Figure 89: Parameter Cnfg Out Fan Out ................................................................................................................ 49

Figure 90: Parameter Cnfg Out Damper ................................................................................................................ 50

Figure 91: Parameter Time Time ........................................................................................................................... 50

Figure 92: Parameter Set Time Hours ................................................................................................................... 51

Figure 93: Parameter Set Time Min ....................................................................................................................... 51

Figure 94: Parameter Set Date Year ...................................................................................................................... 51

Figure 95: Parameter Set Date Month ................................................................................................................... 51

Figure 96: Parameter Set Date Day ....................................................................................................................... 52

Figure 97: Parameter Schedule ............................................................................................................................. 53

Figure 98: Parameter Schedule Monday ................................................................................................................ 53

Figure 99: Parameter Schedule Monday Mon E1 .................................................................................................. 53

Figure 100: Tenant mode home screen ................................................................................................................. 54

Figure 101: Tenant mode Fan Auto ....................................................................................................................... 55

Figure 102: Tenant mode Fan On .......................................................................................................................... 55

Figure 103: Tenant mode Fan Off .......................................................................................................................... 55

Figure 104: Tenant Override .................................................................................................................................. 56

Figure 105: Tenant System and View More Sys mode .......................................................................................... 57

Figure 106: Tenant mode Room Temp .................................................................................................................. 57

Figure 107: Tenant mode Rh ................................................................................................................................. 57

Figure 108: Tenant mode Oat ................................................................................................................................ 58

Figure 109: Tenant mode Eff Sp ................................................................................................ ............................ 58

Figure 110: Tenant mode Cntr Sp .......................................................................................................................... 58

Figure 111: Tenant mode Time .............................................................................................................................. 58

Figure 112: Tenant Mode Hours ............................................................................................................................ 59

Figure 113: Tenant Mode Min ................................................................................................................................ 59

Figure 114: Tenant Mode Year .............................................................................................................................. 59

6

STRYKER CVAHU ZIO CONFIGURATION GUIDE

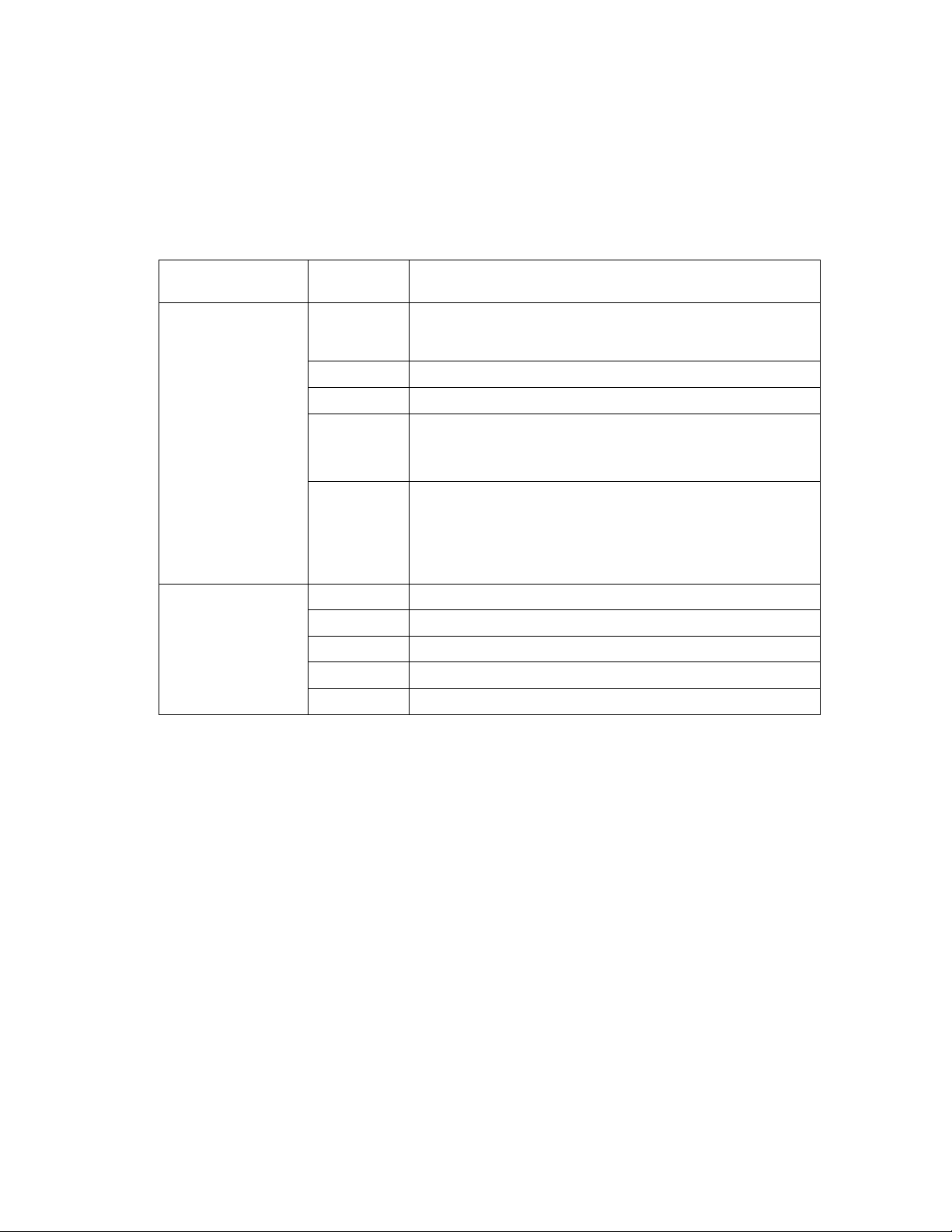

List of Tables

Table 1: Stryker reference documents...................................................................................................................... 9

Table 2: Zio reference documents .......................................................................................................................... 10

Table 3: List of applicable literature ................................................................ ........................................................ 12

Table 4: Agency listing ........................................................................................................................................... 13

Table 5: TR values used by the space cooling pid control...................................................................................... 35

Table 6: IT values used by the space cooling pid control. ...................................................................................... 36

Table 7: TR values used by the space heating pid control. ................................................................ .................... 37

Table 8: IT values used by the space heating pid control. ...................................................................................... 37

7

STRYKER CVAHU ZIO CONFIGURATION GUIDE

8

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Form No.

Title

63-4529—03

Stryker™ Lon Configurable

VAV/CVAHU Controller

Specification Data

62-2029—02

Stryker™ Lon Configurable

VAV/CVAHU Controller

Installation Instructions

INTRODUCTION

Description of

Devices

Stryker™ Lon

Configurable CVAHU

Controller

Figure 1: Stryker™ Lon Configurable CVAHU

Controller

Features

Uses the Echelon® LONWORKS® network

protocol.

Free Topology Transceiver (FTT) high-speed

78 kilobits communications network.

Capable of stand-alone operation, but may

also use LONWORKS® bus network

communications.

Sylk™ bus for use with Sylk-enabled sensors.

120 controllers per Q7751A, B router when

configured as a repeater.

Field configurable for control, input, and output

functions using the NIAGARA FRAMEWORK®

software.

Built-in zone control functions include a remote

wMarkall module interface and a scheduler.

All wiring connections are made to removable

terminal blocks to simplify controller installation

and replacement.

For more information, refer below mentioned

documents as shown in Table 1:

Table 1: Stryker reference documents

General

The CUL6438SR-CV1 is part of the Stryker family.

The controllers are Free Topology Transceiver

(FTT) LONMARK®-certified devices designed to

control HVAC equipment. This is advanced system

feature that allows state-of-the-art, commercial

building control. Each controller is configurable

using the NIAGARA FRAMEWORK® software.

The Stryker controllers require the Stryker feature

to be licensed in the WEBpro workbench tool and

the WEBs AX JACE Controller for programming. It

can download to any brand of the Niagara

Workbench or JACE controller.

Controllers are used in VAV (Variable Air Volume)

and CVAHU (Constant Volume Air Handling Unit)

control applications. Each controller contains a host

microcontroller to run the main HVAC application

and a second microcontroller for LONWORKS®

network communications. Each controller provides

flexible, universal inputs for external sensors, digital

inputs, and a combination of analog outputs and

digital outputs.

9

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Form No.

Title

63-1322—02

Zio®/Zio Plus LCD Wall

Modules Wall Module

Specification Data

62-0271-07

Zio®/Zio Plus LCD Wall

Modules Wall Module

Installation Instructions

63-2719

LCD Wall Modules Wall

operating guide

Note:

Refer to the Zio/Zio plus LCD Wall

Modules Operating Guide (form 63-

2719) for information about customizing

the wall module configuration in the

WEBs-AX Workbench, such as

modifying the default Home screens or

creating your own application.

Zio®/Zio Plus LCD Wall

Modules

Figure 2: Zio/Zio Plus LCD Wall Modules

General

The TR70 Series Zio (TR70/TR70-H, TR71/TR71H) and Zio Plus (TR75/TR75-H) are 2-wire, nonpolarity sensitive, and Sylk bus communicating wall

modules for use with Spyder® and Comfort Point™

programmable controllers.

All models have a space-temperature sensor,

network bus jack, and an LCD panel with three soft

keys and two Up/Down adjustment keys. The TR7H, TR71-H and TR75-H models include an onboard humidity sensor.

Features

The TR70 Series wall modules include:

Ability to control tenant access to controller

parameters via password protection.

Ability to assign labels for enumerated values.

Customized parameter access, by using the

Honeywell WEBs-AX Workbench tool.

Ability to link setpoint limits to a network

variable.

Programmable for: home screen options,

tenant access, contractor access, optional

password protection to contractor mode,

access to controller parameters, Setpoint,

override, fan, and other parameters.

Ability to access and adjust most parameters in

the programmable controller.

TR75 can access and adjust the controller

schedule.

Ability to balance the VAV system from the wall

module.

Home screen can display one out of three

following parameters: temperature setpoint,

room temperature, room humidity, outdoor

humidity, outdoor temperature, and time, or

virtually any one of parameters in the

controller.

Network bus jack.

Simple 2-wire terminal connection to the

programmable controller (includes power) and

an optional 2-wire terminal connection for the

network. All connections are polarity

insensitive.

Permanent retention of user configuration,

including Setpoints after a power outage.

For more information, refer below mentioned

documents as shown in Table 2

Table 2: Zio reference documents

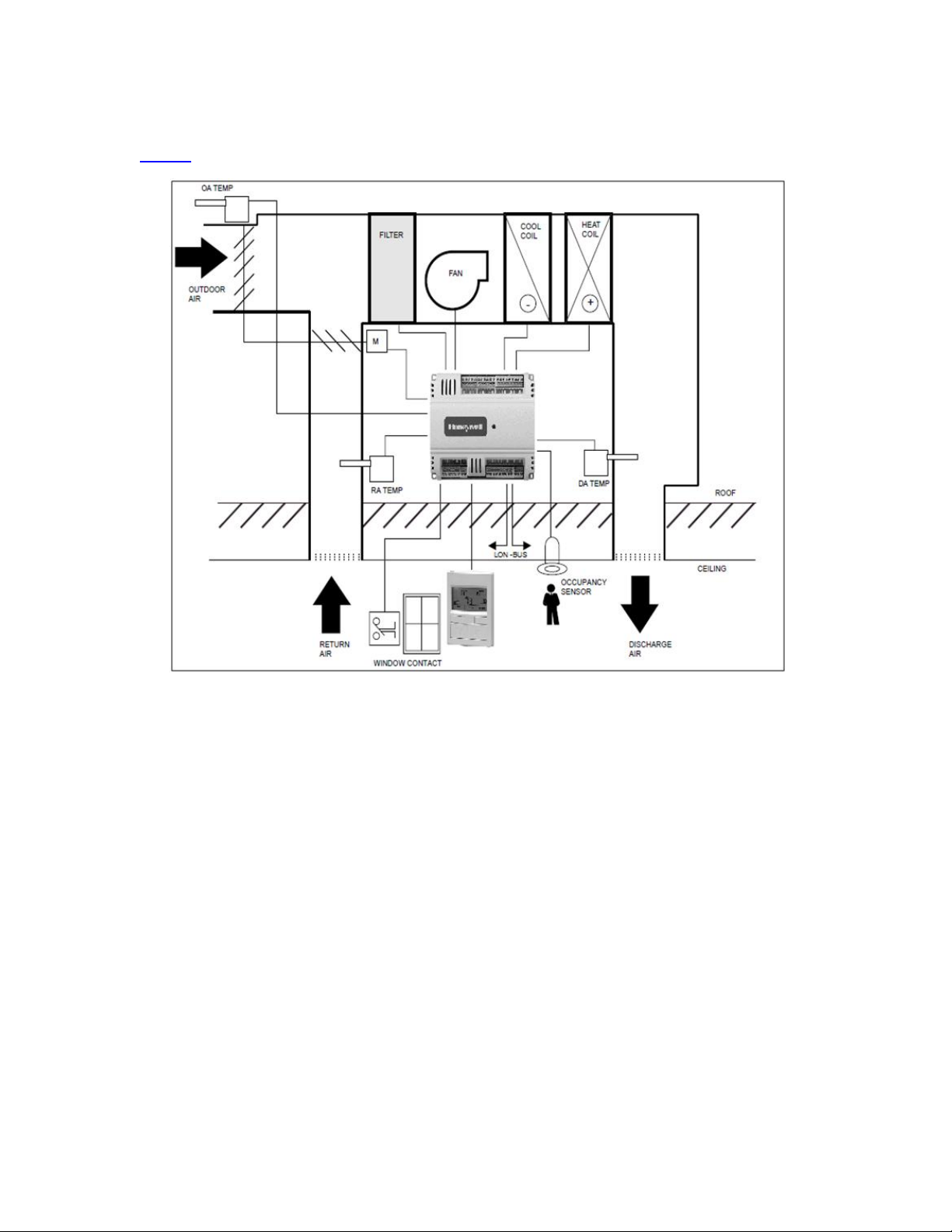

Control Application

Stryker CVAHU systems in commercial buildings

typically incorporate a packaged air handler system

that delivers a constant volume of air at

preconditioned temperatures to the zone being

served. Each zone is usually serviced by a

separate AHU; however, sometimes two or more

AHUs service the same zone. The Stryker CVAHU

can control staged or modulating heating and

cooling coils, mixed air economizer dampers, and

the system fan. Control of heat pump units, where

the compressor(s) is used for both cooling and

heating, is also provided. The zone the Stryker

CVAHU services can use a TR71/75 for space

temperature sensing and an S-bus and LON bus

network access for users via Zio and front end

graphics respectively.

10

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Figure 3 shown below is typical Stryker CVAHU control application.

Figure 3: Typical Stryker CVAHU control application

Control Provided

The Stryker CVAHU Controller is designed to

control a single air handler to maintain the unit’s

space temperature at the current Setpoint. Heating

and cooling control are provided for either staged or

modulating equipment. Up to three stages of

mechanical cooling and up to three stages of

heating are allowed. Modulating outputs can be

either floating type such as a series 60 control, or

pulse width modulated (PWM) control. The

economizer dampers can be controlled directly with

floating or PWM outputs, or indirectly using a digital

output as an enable/disable signal to a packaged

economizer controller. The economizer enable

function, determines when to allow outdoor air for

free, cooling, can be configured, to one of the

strategies based on the inputs. When the

economizer position is controlled from the Stryker

CVAHU, the minimum position setting (for

ventilation requirements) is adjusted based on

indoor air quality (IAQ) needs in the space. IAQ

monitoring is provided through either a CO2 sensor

or a digital input from a space-mounted IAQ limit

switch.

For heat pump configurations, up to three

compressors can be controlled, along with up to

three stages of auxiliary heat, and a heat/cool

change over valve. Including the supply fan, a

combination of these items may not exceed eight

outputs in a Stryker CVAHU. The Stryker CVAHU

Controller can monitor a space-mounted occupancy

sensor, and a door/window contact. These inputs

affect the operational mode of the controller.

The Stryker CVAHU Controller allows other

controllers in the system to use the physical inputs

and outputs. A digital input and an analog input can

be configured to read switch states and voltage

sensor values, respectively, and send them out

over the S and LON-bus network.

11

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Form No.

Title

63-4529—03

Stryker™ Lon Configurable

VAV/CVAHU Controller

Specification Data

62-2029—02

Stryker™ Lon Configurable

VAV/CVAHU Controller

Installation Instructions

63-1322—02

Zio®/Zio Plus LCD Wall Modules

Wall Module Specification Data

62-0271-07

Zio®/Zio Plus LCD Wall Modules

Wall Module Installation

Instructions

63-2719

LCD Wall Modules Wall

operating guide

209541B

LONWORKS® Bus Wiring

Guidelines/ Termination Module

Installation Instructions

Note:

All models have a space-temperature

sensor, network bus jack, and an LCD

panel with three soft keys and two up/down

adjustment keys. The TR70-H, TR71-H

and TR75-H models include an onboard

humidity sensor.

Products Covered

This System Engineering Guide describes how to

configure Stryker CVAHU controller via TR71/75

Zio wall module.

Stryker CVAHU Controllers and related accessories

to typical applications are as follows:

Stryker CVAHU controller.

TR71/75 wall modules.

209541B FTT termination module.

Organization of Manual

This manual is divided into two basic parts:

introduction and configuration.

The Introduction provides information for Stryker

LON configurable CVAHU controller and TR70

series Zio/Zio Plus LCD wall modules, control

application, control provided, product covered, and

abbreviations.

Configuration steps provide information for the

engineering of Stryker LON configurable CVAHU

controller by TR70 series Zio/Zio Plus LCD wall

modules using its various function keys.

The organization of the manual assumes a project

is being engineered from installation to finish.

Applicable Literature

List of documents containing information related to

the configurable lighting controllers as shown in

Table 3.

Table 3: List of applicable literature

For additional CVAHU Stryker and Zio wall module

latest documents and updates visit

http//www.customer.honeywell.com

And search for CVAHU Stryker and Zio wall module

respectively.

Product Names

Stryker LON CVAHU controller is available as one

model.

CUL6438SR-CV1: Constant volume air handling

unit controller from Stryker LON family.

The TR70 series Zio wall module is available in four

models:

TR70

TR70H

TR71

TR71H

The TR70 series Zio Plus wall module is available

in two models.

TR75

TR75H

Other products:

Q7751A, B: Router (configured as a repeater)

Q7752A, B: Serial interface adapter

209541B: Termination module.

12

Device

Agency

Comments

CUL6438SR-CV1

controller

UL

Tested and listed under UL916 (Standard for open energy

management equipment) with plenum rating. File number E87741

cUL

Listed (E87741).

CSA

LR95329-3 listed.

FCC

Meets FCC Part 15, Subpart B, Class B (radiated emissions)

requirements.

Meets Canadian standard C108.8 (radiated emissions).

CE

Conforms to the following requirements per European

Consortium standards:

EN 61000-6-1; 2001 (EU immunity)

EN 61000-6-3; 2001 (EU emissions)

Zio®/Zio Plus LCD

wall modules

TR70, TR71, TR75

with Sylk® bus

UL

(Not applicable.)

cUL

(Not applicable.)

CSA

(Not applicable.)

FCC

(Not applicable.)

CE

(Not applicable.)

Agency Listings

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Table 4: Agency listing

13

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Abbreviations

AHU: Air Handling Unit. The central fan system

includes the blower, heating equipment, cooling

equipment, ventilation air equipment, and other

related equipment.

CO: Carbon Monoxide. Occasionally used as a

measure of indoor air quality.

CO2: Carbon Dioxide. Often used as a measure of

indoor air quality.

CPU: Central Processing Unit

cUL: Underwriters Laboratories Canada

CVAHU: Constant Volume Air Handling Unit; refers to

a type of air handler with a single-speed fan that

provides a constant amount of supply air to the space

it serves.

Echelon: The Company that developed the LON®

bus and the Neuron® chips used to communicate on

the E-bus.

Economizer: Mixed-air dampers that regulate the

quantity of outdoor air that enters the building. In cool

outdoor conditions, fresh air is used to supplement

the mechanical cooling equipment. Since this action

saves energy, the dampers are often referred to as

economizer dampers.

EMI: Electromagnetic Interference. Electrical noise

that can cause problems with communications

signals.

EMS: Energy Management System; refers to the

controllers and algorithms responsible for calculating

optimum operational parameters for maximum energy

savings in the building.

Enthalpy: The energy content of air measured in

BTUs per pound (Kilojoules per Kilogram).

Firmware: Software stored in a nonvolatile memory

medium such as an EPROM.

Floating Control: Floating Control utilizes one digital

output to pulse the actuator open, and another digital

output to pulse it closed.

FTT: Free Topology Transceiver.

IAQ: Indoor Air Quality. It refers to the quality of the

air in the conditioned space, as it relates to occupant

health and comfort.

I/O: Input/Output; the physical sensors and actuators

connected to a controller.

I * R: I times R or current times resistance; refers to

Ohm’s Law: V = I x R.

K: Degrees Kelvin.

NV: Network Variable; a Stryker CVAHU parameter

that can be viewed or modified over the Lon/S-bus

network.

PWM: Pulse Width Modulated output; allows analog

modulating control of equipment using a digital output

on the controller.

RTD: Resistance Temperature Detector; refers to a

type of temperature sensor whose resistance output

changes according to the temperature change of the

sensing element.

TPT: Twisted Pair Transceiver.

VA: Volt Amperes; a measure of electrical power

output or consumption as applied to an AC device.

Vac: Voltage alternating current; AC voltage rather

than DC voltage.

VAV: Variable Air Volume; refers to either a type of

air distribution system, or VAV Box Controller that

controls a single zone in a variable air volume delivery

system.

Constructions of

Controller and Wall

Module

For more details, refer to the following literature:

63-4529–03: Stryker™ Lon Configurable

VAV/CVAHU Controller Specification Data

62-2029–02: Stryker™ Lon Configurable

VAV/CVAHU Controller Installation Instructions

63-1322–02: Zio®/Zio Plus LCD Wall Modules Wall

Module Specification Data

62-0271–07: Zio®/Zio Plus LCD Wall Modules Wall

Module Installation Instructions

63-2719: LCD Wall Modules Wall operating guide.

209541B: LONWORKS® Bus Wiring Guidelines/

Termination Module Installation Instructions

14

STRYKER CVAHU ZIO CONFIGURATION GUIDE

STRYKER CVAHU

CONFIGURATION

BY ZIO WALL

MODULE

Figure 4: Stryker CVAHU configuration by Zio wall

module

Strykers are configured by the new TR71/75 wall

modules. Nearly every configuration parameter is

available at the Zio wall module, so configuration and

even balancing is done by simply powering up the

controller, connecting a Zio and then configuring the

parameters available. After configuration is done via

the Zio, an Integrator perform an upload and the

configuration is added to the WEBs-AX station

database.

Since Stryker has the capability to utilize Zio, an

installer uses a conventional sensor on all installed

Stryker units, and then uses a single Zio to configure

as many Stryker’s as desired. Since the Zio’s program

and configuration are stored in the Stryker, each time

the Zio is connected to a new Stryker, it gets its

program from that device.

This document serves as a configuration guide for an

installer who is configuring a Stryker CVAHU

controller via a TR71 or TR75 wall module.

Parameters are grouped into logical categories rather

than on a large list. To access the “contractor” mode

for configuration, press the up, down and middle keys

simultaneously. During this time the model number

and firmware revision of the TR71/75 are displayed.

You are then prompted to enter a password (default

0000).

Compatibility

The TR70 Series LCD Wall Modules operate with the

Sylk Enhanced Stryker controller. The TR71/TR75

can replace a TR70 in an installation where an

upgrade to WEBs- AX or Stryker or reprogramming is

not desired. Features like scheduling, additional

memory, etc. are not available. Likewise, a TR71 is

replaced by another TR71 or TR75 without

reprogramming required. A TR75 can only be

replaced with a TR75 where no reprogramming is

desired.

Contractor Mode:

Introduction

Contractor mode: You can navigate to the desired

category of parameters. You can then begin

configuring and viewing information from the device.

Each screen below has a brief explanation of the

data; values within the contractor mode are only

visiable in English (U.S.) units of measure.

Temperatures however can be shown on the home

screen as C or F.

Contractor mode allows access to the Setup function

of the wall module. To enter and exit the setup

function – press the up and down arrow keys and the

middle soft key all at the same time (see key positions

of wall module as shown in Figure 5).

Figure 5: Key position of wall module

Contractor mode allows advanced options (such as

modifying configured parameters) using the soft keys.

Contractor mode also allows for customizing the

tenant’s view including setting the tenant’s Home

screen and controlling the tenant’s “view more”

access, which can provide the tenant with a view of

the configured parameters.

15

STRYKER CVAHU ZIO CONFIGURATION GUIDE

IMPORTANT:

1. Make sure the TR70 Series wall module is

properly mounted and properly wired and

connected to the programmable controller.

2. Refer to the Zio™ LCD wall modules TR70

Series with Sylk™ bus – installation

instructions, form no. 62 – 0271, for

specific installation requirements.

Initial Power-Up

Upon initial power-up before configuring the wall

module, the LCD screen of the wall module will

display status as “PLEASE LOAD”. As shown in

Figure 6, the startup screen of the wall module where

the status is displayed.

And also illustrates all the possible LCD Wall Module

display elements. Only those elements pertinent to

the current configuration and status actually display.

Controller features not supported by Zio

configuration

Network functionality

Accessory loops

Custom sensors

Local sensor (UI 1-4) calibration

CVAHU controller default configuration

Wall module: Zio

Center setpoint source: Zio

Center setpoint: disabled (controller ignores

center setpoint value

Center setpoint high limit: 100

Center setpoint low limit: –10

Room temperature source: Zio (TR71/75)

Figure 6: TR70 Series Wall Module - LCD screen

This phrase alternates with any onboard sensor

display such as temperature. The TR71/TR75 also

display the firmware revision number, model number

and Sylk bus address as shown in Figure 7.

Figure 7: Model number and Sylk bus address

On power-up, screen displays revision and Zio model

number.

16

STRYKER CVAHU ZIO CONFIGURATION GUIDE

Contractor Mode:

Configuration Steps

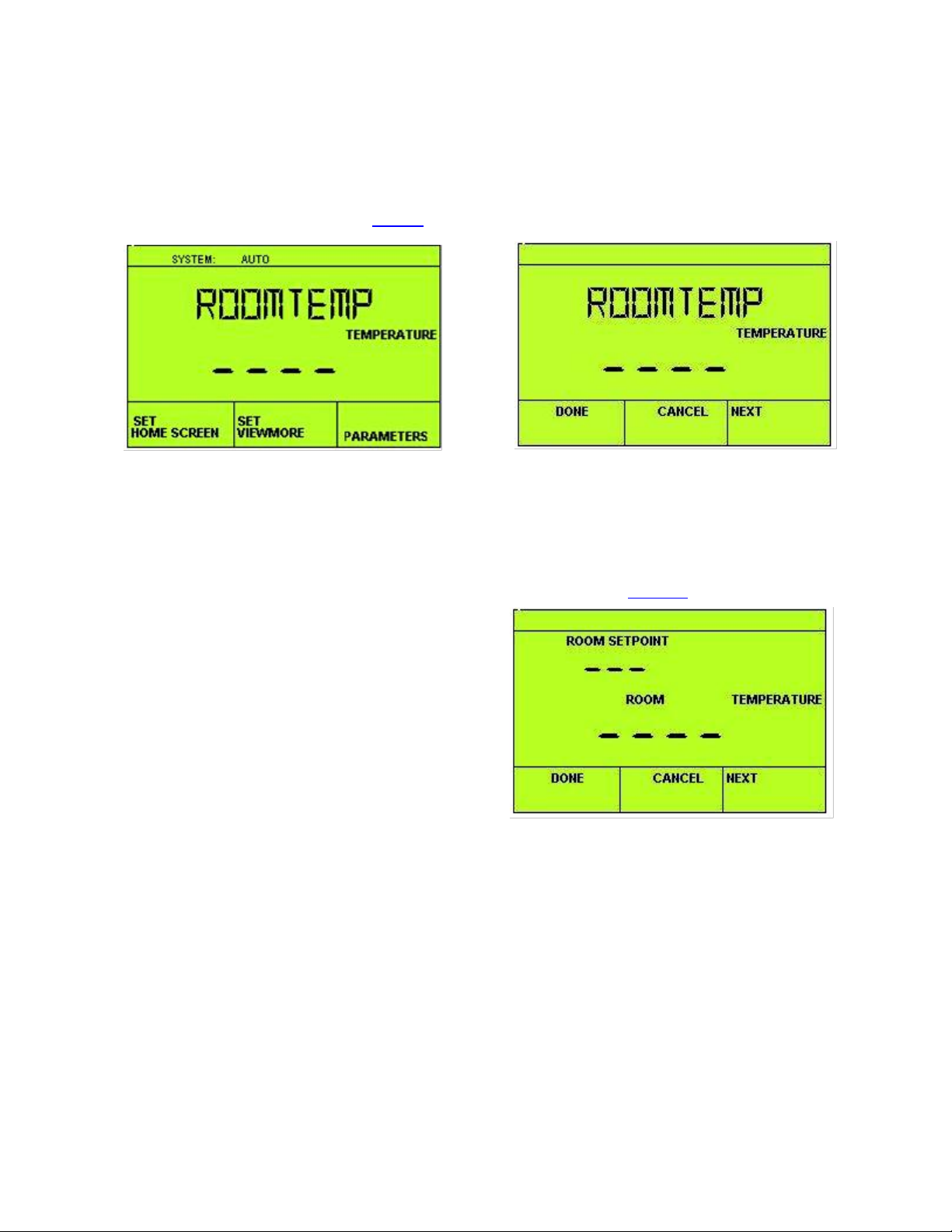

The Contractor Mode screen as shown in Figure 8

Figure 8: Contractor mode default home screen

The three soft keys on the contractor home screen

provide the following three options

1. Set home screen

2. Set view more

Figure 9: Home screen Roomtemp

Home screen: ROOMTEMP

Description: Default home screen displays room

temperature (setpoint is not adjusted from this home

screen as shown in Figure 10)

3. Parameters

Set Home Screen

SET HOME SCREEN allows the contractor to choose

among multiple home screen options for the tenant.

The tenant’s home screen choices are created by the

configuration wizard and downloaded to the wall

module. Each wall module may have different home

screen choices. The contractor, using the soft keys,

may choose which home screen is to be used. He

may configure the Tenant view to show a subset (or

none) of the configured parameters.

When the contractor clicks the SET HOME SCREEN

soft key, the display changes as shown in the Figure

9 to Figure 12. The soft keys change to DONE,

CANCEL, and NEXT as per configuration

requirement.

Click NEXT soft key to cycle through the

configured home screens.

Click DONE soft key when the desired home

screen to be set as default home screen for

Tenant view.

The CANCEL soft key exits the home screen

display without saving any changes.

Figure 10: Home screen Room Setpoint,

Roomtemp

Home screen: ROOM SETPOINT, ROOMTEMP

Description: Displays room temperature and

effective room temperature setpoint (setpoint is not

adjusted from this home screen)

17

STRYKER CVAHU ZIO CONFIGURATION GUIDE

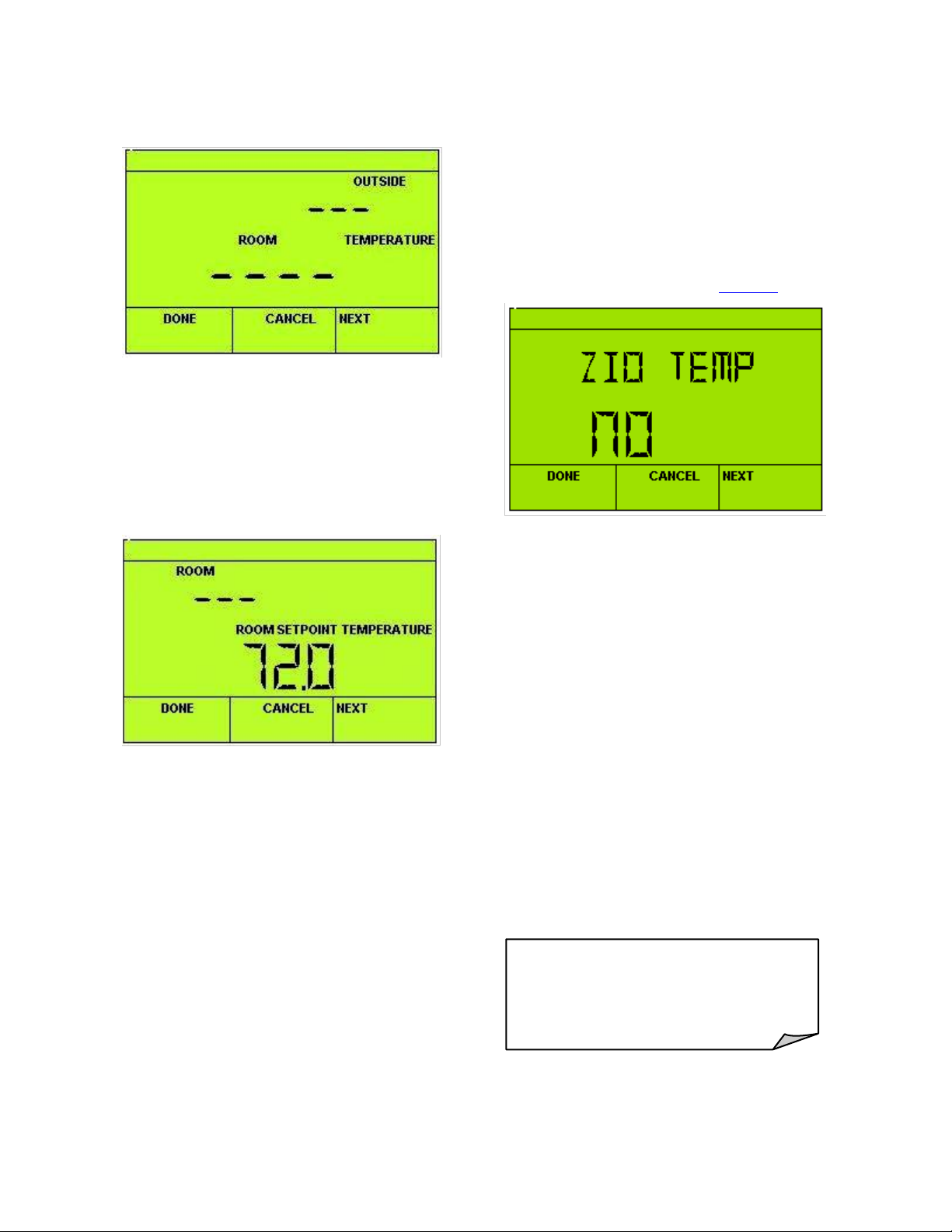

Note:

Click NEXT, DONE, and CANCEL to do

YES or NO configuration for below

mentioned parameters.

Figure 11: Home screen Outside Room

Temperature

Home screen: OUTSIDE ROOMTEMPERATURE

Description: Displays outside air temperature and

room temperature (setpoint is not adjusted from this

home screen)

Figure 12: Home screen Room, Room Setpoint

Temperature

Home Screen: ROOM, ROOM SETPOINT

TEMPERATURE

Description: Displays room temperature and room

setpoint temperature (setpoint is adjusted from this

home screen)

Set View More

SET VIEW MORE allows the contractor to provide

parameter access (view only or adjustable) to the

tenant’s VIEW MORE soft key.

Click SET VIEW MORE soft key to display the first

configured parameter as shown in Figure 13.

Figure 13: Set View More First screen

The soft keys changes to DONE, CANCEL, and

NEXT as per configuration requirement.

The Up and Down arrow keys switch the

parameter between YES and NO (view or no

view in tenant mode).

o YES means that the tenant has access to

the parameter on the VIEW MORE screen.

o NO means that the tenant does not have

access to the parameter.

o If NO is selected for all parameters, then the

VIEW MORE soft key does not display in

tenant mode.

Click NEXT soft key to cycle through the

configured VIEW MORE screen’s next parameter

or category

Click DONE soft key to save configuration

changes.

Click CANCEL soft key to exit VIEW MORE

without saving any changes.

18

Loading...

Loading...