ST 700 SmartLine Series HART/DE

Option

User’s Manual

34-ST-25-47

Revision 5.0

June 2020

Honeywell Process Solutions

Copyrights, No tices and Trademarks

© Copyright 2020 by Honeywell, Inc.

June 2020, Revision 5.0

While the information in this document is presented in good faith and believed to be

accurate, Honeywell disclaims any implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in the written

agreement with and for its customers. In no event is Honeywell liable to anyone for any

indirect, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Honeywell, TDC 3000, SFC, SmartLine, PlantScape, Experion PKS, and TotalPlant are

registered trademarks of Honeywell International Inc. Other brand or product names and

service marks are the property of their respective owners.

Honeywell Process Solutions

1860 Rose Garden Lane

Phoenix, AZ 85027

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page ii

About This Manual

This manual provides the details of programming Honeywell ST 700 SmartLine Pressure

Transmitter for applications involving HART versions 5, 6, and 7 and Honeywell’s Digitally

Enhanced (DE) communication protocols. For installation, wirin g , and maintenance information

refer to the ST 700 SmartLine Pressure Transmitter User Manual, Document # 34-ST-25-44.

The configuration of your Transmitter depends on the mode of operation and the options selected

for it with respect to operating controls, displays and mechanical installation. Details for

operations involving the Honeywell Multi-Communication (MC) Tookit (MCT404/202) are

provided only to the extent necessary to accomplish the tasks-at-hand. Refer to the associated

MCT404/202 User Manual for complete details. The “Reference” section in the fr on t m atter of

this manual lists document titles and numbers.

• The ST 700 SmartLine Pressure transmitter can be digitally integrated with one of two

systems:Experion PKS: you will need to supplement the information in this document

with the data and procedures in the Experion Knowledge Builder.

• Honeywell’s TotalPlant Solutions (TPS): you will need to supplement the information in

this document with the data in the PM/APM SmartLine Transmitter Integration Manual,

which is supplied with the TDC 3000 book set. (TPS is the evolution of the TDC 3000).

References

The following list identifies publications that may contain information relevant to the information

in this document.

• SmartLine Pressure Transmitter ST 800/ST 700 Quick Start Installation Guide,

# 34-ST-25-36

• ST 800 & ST 700 SmartLine Pressure Transmitter Safety Manual, # 34-ST-25-37

• ST 700 SmartLine Pressure Transmitter User Manual, # 34-ST-25-44

• ST 700 SmartLine FF Transmitter w/ FOUNDATION Fieldbus Option , # 34-ST-25-48

• MC Tookit (MCT404) User Manual, # 34-ST-25-50

• MC Tookit (MCT202) User Manual, # 34-ST-25-20

• PM/APM SmartLine Transmitter Integration Manual, # PM 12-410

• ST 800 & ST 700 Series Pressure, Analog, HART and DE Communications form,

Honeywell Drawing # 50049892.

• Smart Field Communicator Model STS 103 Operating Guide, # 34-ST-11-14

• Technical Bulletin, Communicating with Honeywell™ ST3000/STT3000 Smart

Transmitters, # TB-960704B

• MC Toolkit Modem Code Download Instruction Manual, # 34-ST-25-33

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page iii

United States and

Canada

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

Global Email

Support

Honeywell Process

Solutions

Release Information This Document # 34-ST-25-4

• Rev. 1.0, February 2013- 1st Release

• Rev. 2.0, January 2014 – Calibration updates

• Rev. 3.0, March 2016 – Simple Display added

• Rev. 4.0, December 2016 – Basic Models added

• Rev. 5.0, June 2020 – Std display updates - Russian language, Eng and PV units

Patent Notice

The Honeywell ST 700 SmartLine Pressure Transmitter family is covered by one or more of the

following U. S. Patents: 5,485,753; 5,811,690; 6,041,659; 6,055,633; 7,786,878; 8,073,098 ; and other

patents pending.

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, refer to the appropriate

Honeywell Solution Support web site:

Honeywell Corporate www.honeywellprocess.com

Honeywell Process Solutions www.honeywellprocess.com/pressue-transmitters/

Training Classes http://www.automationccollege.com

Telephone and Email Contacts

Area Organization Phone Number

Honeywell Inc.

Page iv ST 700 Series HART/DE Option User’s Manual Revision 5.0

ask-ssc@honeywell.com

Contents

Copyrights, Notices and Trademarks ..................................................................................................... ii

1 ST 700 Transmitter Series .............................................................................................................. 1

1.1 Overview ................................................................................................................................ 1

2 Introduction to the ST 700 Standard Transmitter ........................................................................... 1

2.1 Features and Options .............................................................................................................. 1

2.1.1 Physical Characteristics .................................................................................................. 2

2.1.2 Functional Characteristics .............................................................................................. 3

2.2 ST 700 Standard Transmitter Nameplate ............................................................................... 3

2.3 Safety Certification Information ............................................................................................. 3

2.4 Transmitter Adjustments ........................................................................................................ 4

2.5 Display Options –Standard Display ....................................................................................... 5

2.6 Optional 3-Button Assembly (Basic Display) ........................................................................ 5

2.7 Optional Integrated Two-Button Assembly (Standard Display) ............................................ 6

3 Communication Model for ST 700 Standard Transmitter .............................................................. 7

3.1 Overview ................................................................................................................................ 7

3.2 Digitally Enhanced (DE) Mode Communication ................................................................... 7

3.3 HART Mode Communication ................................................................................................ 8

4 Configuration Tools and Interfaces for ST 700 Standard Transmitter .......................................... 9

4.1 Overview ................................................................................................................................ 9

4.2 Pre-requisites .......................................................................................................................... 9

4.3 Application Design, Installation, Startup, and Operation ....................................................... 9

4.3.1 Organization ................................................................................................

4.4 MC Toolkit Participation ...................................................................................................... 10

4.4.1 MC Toolkit Software Applications .............................................................................. 10

4.4.2 Configuration Databases .............................................................................................. 10

4.4.3 Configuration ................................................................................................................ 10

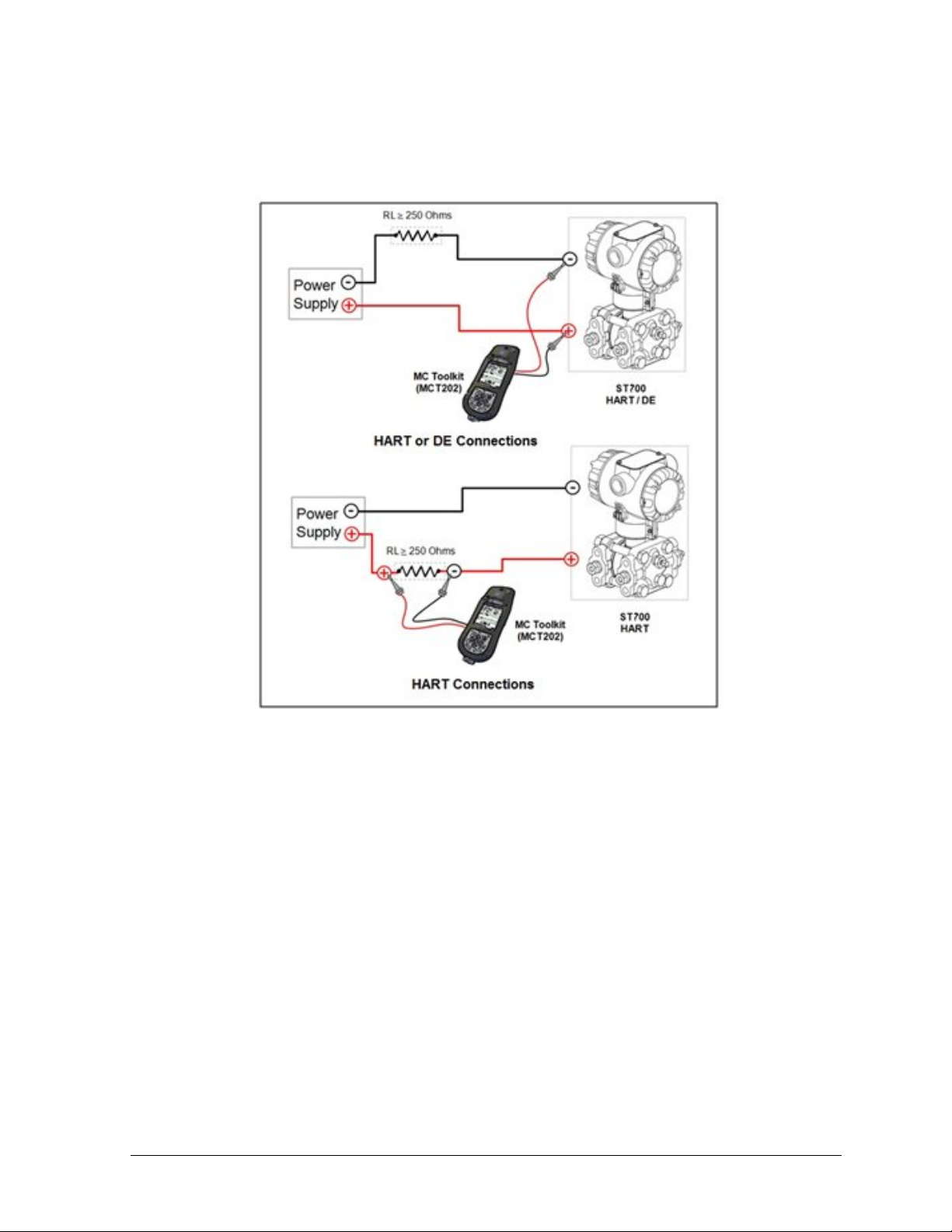

4.4.4 MC Toolkit–Transmitter Electrical/Signal Connections .............................................. 11

5 DE Transmitter Configuration for ST 700 Standard Transmitter ................................................ 12

5.1 Configuration Personnel Requirements ................................................................................ 12

5.2 MC Toolkit Software Application Overview ....................................................................... 12

5.3 DE Transmitter Online Configuration .................................................................................. 13

5.3.1 Uploading a Transmitter Configuration ....................................................................... 13

5.3.2 Device Information Configuration ............................................................................... 15

5.3.3 General Configuration Parameters ............................................................................... 16

5.3.4 DE-Specific Configuration Parameters ........................................................................ 17

5.3.5 Transmitter Display Configuration ............................................................................... 19

5.3.6 Monitor Status Configuration ....................................................................................... 21

5.3.7 Saving the Configuration to File .................................................................................. 22

5.3.8 DE Online Configuration Summary ............................................................................. 23

5.4 DE Transmitter Offline Configuration ................................................................................. 23

5.4.1 Overview ...................................................................................................................... 23

5.4.2 DE Offline File Management ....................................................................................... 23

5.4.3 Save to a File ................................................................................................................ 24

5.4.4 Downloading in DE Offline Mode ............................................................................... 24

5.4.5 DE Offline Parameterization. ....................................................................................... 24

6 HART Transmitter Configuration for ST 700 Standard Transmitter .......................................... 25

6.1 Overview .............................................................................................................................. 25

6.1.1 Personnel Requirements ............................................................................................... 25

................... 9

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page v

6.2 Overview of FDC Homepage .............................................................................................. 26

6.2.1 Settings ......................................................................................................................... 27

6.2.2 Manage DDs ................................................................................................................ 28

6.2.3 Online configuration .................................................................................................... 29

6.2.4 Offline configuration.................................................................................................... 30

6.2.5 Online Configuration Overview ................................................................................... 30

6.2.6 Overview of Device Homepage ................................................................................... 31

6.2.7 Tabs on the Device Homepage .................................................................................... 32

6.2.8 Using FDC for various device operations .................................................................... 34

6.2.9 Device Configuration and Param eter Desc ripti ons ...................................................... 35

6.2.10 Procedure to Enter the Transm itter Tag ....................................................................... 46

6.2.11 Selecting the Process Variable (PV) Unit of Pressure Measurement ........................... 46

6.2.12 Setting PV URV, and LRV Range Values ................................................................... 47

6.2.13 Setting Range Values for Applied Pressure ................................................................. 48

6.2.14 Saving device history ................................................................................................... 48

6.2.15 Exporting device history records to FDM .................................................................... 49

6.2.16 Exporting device history records to Documint ............................................................ 50

6.2.17 Custom Views .............................................................................................................. 50

6.2.18 Offline Configuration ................................................................................................... 52

7 DE Calibration for ST 700 Standard Transmitter ........................................................................ 55

7.1 Overview .............................................................................................................................. 55

7.2 Calibration Recommendations ............................................................................................. 55

7.3 Test Equipment Required for Calibration ............................................................................ 55

7.4 Analog Output Signal Calibration ........................................................................................ 55

7.5 Calibrating Range Using the MC Toolkit ............................................................................ 57

7.5.1 Conditions for Input Calibration .................................................................................. 57

7.5.2 Input Calibration Procedures Description .................................................................... 58

7.5.3 Input Calibration Procedure ......................................................................................... 59

7.6 DE Output Calibration ......................................................................................................... 63

7.6.1 Output Calibration Preparation .................................................................................... 63

7.7 Manually Setting the Process Variable Range ..................................................................... 65

7.8 Procedure to Reset Calibration ............................................................................................ 68

8 HART Calibration for ST 700 Standard Transmitter ................................................................... 69

8.1 About This Section .............................................................................................................. 69

8.1.1 About Calibration ......................................................................................................... 69

8.1.2 Equipment Required .................................................................................................... 69

8.2 Analog Output Signal Calibration ........................................................................................ 70

8.3 Calibrating Range ................................................................................................................ 71

8.3.1 Correcting the Lower Range Value (LRV) .................................................................. 71

8.3.2 Correcting the Upper Range Value (URV) .................................................................. 71

8.3.3 Resetting Calibration.................................................................................................... 72

8.3.4 Calibration Records...................................................................................................... 72

9 HART Advanced Diagnostics for ST 700 Standard Transmitter ................................................ 74

9.1 About This Section .............................................................................................................. 74

9.2 Advanced Diagnostics.......................................................................................................... 74

9.2.1 Install Date ................................................................................................................... 74

9.2.2 PV Tracking Diagnostics ............................................................................................. 75

9.2.3 SV Tracking ................................................................................................................. 77

9.2.4 TV Tracking Diagnostics ............................................................................................. 78

9.2.5 ET Tracking Diagnostics ............................................................................................. 78

9.2.6 % Stress Life ................................................................................................................ 80

Page vi ST 700 Series HART/DE Option User’s Manual Revision 5.0

9.2.7 % Service Life .............................................................................................................. 80

9.2.8 Operating Voltage Diagnostics ..................................................................................... 80

9.2.9 AVDD Tracking Diagnostics ....................................................................................... 81

9.2.10 Sensor CPU Temperature Tracking Diagnostics .......................................................... 81

9.2.11 Power Up Diagnostics .................................................................................................. 82

10 Troubleshooting and Maintenance for ST 700 Standard Transmitter ..................................... 84

10.1 HART Diagnostic Message s ................................................................................................ 84

10.2 HART Diagnostic Details ..................................................................................................... 85

10.3 DE Diagnostic Messages ...................................................................................................... 89

11 Using DTMs ............................................................................................................................. 92

11.1 Introduction .......................................................................................................................... 92

11.2 Components .......................................................................................................................... 92

11.3 Downloads ............................................................................................................................ 92

11.4 Procedure to Install and Run the DTM ................................................................................. 92

11.5 ST 700 Online Parameterization........................................................................................... 93

11.5.1 Device Health: .............................................................................................................. 94

11.5.2 Device Icon / Honeywell Logo:.................................................................................... 94

11.5.3 Process Variables: ........................................................................................................ 94

11.5.4 Shortcuts: ...................................................................................................................... 94

11.6 Basic Setup Page .................................................................................................................. 95

11.6.1 Pressure Transfer Fn: .................................................................................................... 95

11.6.2 Low Flow Cutoff Mode: ............................................................................................... 95

11.6.3 Device Information ....................................................................................................... 95

11.6.4 Model Number: ............................................................................................................ 96

11.6.5 Device Assembly: ......................................................................................................... 96

11.6.6 System Setup: ............................................................................................................... 96

11.7 Calibration Page ................................................................................................................... 97

11.7.1 Calibration Methods ..................................................................................................... 97

11.7.2 Calibration Records ...................................................................................................... 98

11.8 Process Variables.................................................................................................................. 99

11.9 Trend Charts ....................................................................................................................... 100

11.10 Device Status .................................................................................................................. 101

11.11 Critical and Non-Critical Help Display .......................................................................... 102

11.12 Diagnostics ..................................................................................................................... 103

11.13 Services .......................................................................................................................... 104

11.14 Detailed Setup ................................................................................................................ 105

11.15 Meterbody Selection ....................................................................................................... 106

11.16 Display Setup.................................................................................................................. 106

11.17 Read Screen Info: ........................................................................................................... 106

11.18 Screen Configuration: ..................................................................................................... 106

11.19 Common setup: ............................................................................................................... 106

11.20 Review ............................................................................................................................ 107

11.21 ST 700 Offline Parameterization .................................................................................... 108

12 . HART DD binary file format compatibility matrix for ST 700 Standard Transmitter ......... 109

13 Introduction for ST 700 Basic Transmitter ............................................................................. 110

13.1 Features and Options .......................................................................................................... 110

13.1.1 Physical Characteristics .............................................................................................. 111

13.1.2 Functional Characteristics .......................................................................................... 113

13.2 Series, Model and Number ................................................................................................. 113

13.3 Safety Certification Information ......................................................................................... 114

13.4 Transmitter Adjustments .................................................................................................... 114

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page vii

13.5 Local Display Options ....................................................................................................... 115

13.6 Integrated 2-Push Button Assembly (Standard Display) ................................................... 115

14 Communication Modes for ST 700 Basic Transmitter ......................................................... 116

14.1 Overview ............................................................................................................................ 116

14.2 HART Mode Communication ............................................................................................ 116

15 Configuration Tools and Interfaces for ST 700 Basic Transmitter ....................................... 118

15.1 Overview ............................................................................................................................ 118

15.2 Pre-requisites ...................................................................................................................... 118

15.3 Application Design, Installation, Startup and Operation ................................................... 118

15.3.1 Organization ............................................................................................................... 118

15.4 MC Toolkit Participation ................................................................................................... 119

15.4.1 MC Toolkit Software Applications ............................................................................ 119

15.4.2 Configuration Databases ............................................................................................ 119

15.4.3 Configuration ............................................................................................................. 119

15.4.4 MC Toolkit–Transmitter Electrical/Signal Connections............................................ 120

16 HART Transmitter Configuration for ST 700 Basic Transmitter ......................................... 121

16.1 Overview ............................................................................................................................ 121

16.2 Overview of FDC Homepage ............................................................................................ 122

16.2.1 Settings ....................................................................................................................... 123

16.2.2 Manage DDs .............................................................................................................. 124

16.2.3 Online configuration .................................................................................................. 125

16.2.4 Offline configuration.................................................................................................. 126

16.2.5 Online Configuration Overview ................................................................................. 126

16.2.6 Overview of Device Homepage ................................................................................. 127

16.2.7 Tabs on the Device Homepage .................................................................................. 128

16.2.8 Using FDC for various device operations .................................................................. 130

16.2.9 Device Configuration and Param eter Desc ripti ons .................................................... 131

16.2.10 Procedure to Enter the Transm itter Tag ................................................................. 141

16.2.11 Selecting the Process Variable (PV) Unit of Pressure Measurement ..................... 141

16.2.12 Setting PV URV, and LRV Range Values ............................................................. 142

16.2.13 Setting Range Values for Applied Pressure ........................................................... 143

16.2.14 Saving device history ............................................................................................. 143

16.2.15 Exporting device history records to FDM .............................................................. 145

16.2.16 Exporting device history records to Documint. ..................................................... 145

16.2.17 Custom Views ........................................................................................................ 146

16.2.18 Offline Configuration ............................................................................................. 147

17 HART Calibration for ST 700 Basic Transmitter .................................................................. 148

17.1 About This Section ............................................................................................................ 148

17.1.1 About Calibration ....................................................................................................... 148

17.1.2 Equipment Required .................................................................................................. 148

17.2 Analog Output Signal Calibration ...................................................................................... 149

17.3 Calibrating Range .............................................................................................................. 150

17.3.1 Correcting the Lower Range Value (LRV) ................................................................ 150

17.3.2 Correcting the Upper Range Value (URV) ................................................................ 150

17.3.3 Resetting Calibration.................................................................................................. 151

17.3.4 Calibration Records.................................................................................................... 151

18 HART Advanced Diagnostics for ST 700 Basic Transmitter ............................................... 153

18.1 About This Section ............................................................................................................ 153

18.2 Advanced Diagnostics........................................................................................................ 153

18.2.1 Install Date ................................................................................................................. 153

18.2.2 PV Tracking Diagnostics ........................................................................................... 154

Page viii ST 700 Series HART/DE Option User’s Manual Revision 5.0

18.2.3 SV Tracking................................................................................................................ 156

18.2.4 TV Tracking Diagnostics ........................................................................................... 157

18.2.5 ET Tracking Diagnostics ............................................................................................ 157

18.2.6 % Stress Life............................................................................................................... 159

18.2.7 % Service Life ............................................................................................................ 159

18.2.8 Operating Voltage Diagnostics ................................................................................... 159

18.2.9 AVDD Tracking Diagnostics ..................................................................................... 160

18.2.10 Sensor CPU Temperature Tracking Diagnostics .................................................... 160

18.2.11 Power Up Diagnostics ............................................................................................ 161

19 Troubleshooting and Maintenance for ST 700 Basic Transmitter ......................................... 162

19.1 HART Diagnostic Message s .............................................................................................. 162

19.2 HART Diagnostic Details ................................................................................................... 163

20 Using DTMs for ST 700 Basic Transmitter .......................................................................... 167

20.1 Introduction ........................................................................................................................ 167

20.2 Components ........................................................................................................................ 167

20.3 Downloads .......................................................................................................................... 167

20.4 Procedure to Install and Run the DTM ............................................................................... 167

20.5 ST 700 Online Parameterization......................................................................................... 168

20.5.1 Device Health: ............................................................................................................ 169

20.5.2 Device Icon / Honeywell Logo:.................................................................................. 169

20.5.3 Process Variables: ...................................................................................................... 169

20.5.4 Shortcuts: .................................................................................................................... 169

20.6 Basic Setup Page ................................................................................................................ 170

20.6.1 Pressure Transfer Fn: .................................................................................................. 170

20.6.2 Low Flow Cutoff Mode: ............................................................................................. 170

20.6.3 Device Information ..................................................................................................... 170

20.6.4 Model Number: .......................................................................................................... 170

20.6.5 Device Assembly: ....................................................................................................... 170

20.6.6 System Setup: ............................................................................................................. 170

20.7 Calibration Page ................................................................................................................. 171

20.7.1 Calibration Methods ................................................................................................... 171

20.7.2 Calibration Records .................................................................................................... 172

20.8 Process Variables................................................................................................................ 173

20.9 Trend Charts ....................................................................................................................... 174

20.10 Device Status .................................................................................................................. 175

20.11 Critical and Non-Critical Help Display .......................................................................... 176

20.12 Diagnostics ..................................................................................................................... 177

20.13 Services .......................................................................................................................... 178

20.14 Detailed Setup ................................................................................................................ 179

20.15 Meterbody Selection ....................................................................................................... 180

20.16 Display Setup.................................................................................................................. 180

20.17 Read Screen Info: ........................................................................................................... 180

20.18 Screen Configuration ...................................................................................................... 180

20.19 Common setup: ............................................................................................................... 180

20.20 Review ............................................................................................................................ 181

20.21 ST 700 Offline Parameterization .................................................................................... 182

21 . HART DD binary file format compatibility matrix for ST 700 Standard Transmitter ......... 183

Glossary .............................................................................................................................................. 184

INDEX................................................................................................................................................ 186

Sales and Ser ...................................................................................................................................... 188

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page ix

List of Figures

Figure 1 – ST 700 Standard Major Assemblies ..................................................................................... 2

Figure 2 – Electronics Housing Components ........................................................................................ 2

Figure 3 –Typical Standard Transmitter Name Plate Information ......................................................... 3

Figure 4 – DE Mode Value Scaling ....................................................................................................... 7

Figure 5 – HART Point-to-Point and Multi-drop Value Scaling ........................................................... 8

Figure 6 – MC Toolkit-Transmitter Electrical/Signal Connections ..................................................... 11

Figure 7 – Differential Pressure Square Root Conformity Curve ........................................................ 19

Figure 8 – FDC Homepage .................................................................................................................. 26

Figure 9 – Device Homepage .............................................................................................................. 31

Figure 10 – Analog Outp u t C alibration Test Se tu p ............................................................................. 56

Figure 11 – Input Calibration Connections .......................................................................................... 58

Figure 12 – Output Calibration Test Connections ............................................................................... 63

Figure 13 – DE Analog Mode Scaling and Test Connections ............................................................. 63

Figure 14 – Setup to Manually Set the PV LRV and URV ................................................................. 65

Figure 15 – ST 700 Basic Major Assemblies .................................................................................... 111

Figure 16 - Electronics Housing Components ................................................................................... 112

Figure 17 –Typical BasicTransmitter Name Plate Information ......................................................... 113

Figure 18 – HART Point-to-Point and Multi-drop Value Scaling ..................................................... 116

Figure 19 – MC Toolkit-Transmitte r El ec trical/Sign al C on ne ct ions ................................................. 120

Figure 20 – FDC Homepage .............................................................................................................. 122

Figure 21 – Device Homepage........................................................................................................... 127

Page x ST 700 Series HART/DE Option User’s Manual Revision 5.0

List of Tables

Table 1 - ST 700 Standard and Basic Transmitter Model Types ........................................................... 2

Table 2 – Features and Options .............................................................................................................. 1

Table 3 – Available Display Characteristics .......................................................................................... 5

Table 4 – User Manual Related Topics .................................................................................................. 9

Table 5 – Device Information Parameters ............................................................................................ 15

Table 6 – General Configuration Parameters ....................................................................................... 16

Table 7 – DE Configuration Parameters .............................................................................................. 17

Table 8 – Local Display Configuration Parameters ............................................................................. 20

Table 9 – Monitor Parameters .............................................................................................................. 21

Table 10 - FDC homepage elements .................................................................................................... 26

Table 11 - Device health status ............................................................................................................ 31

Table 12 – HART Transmitter Param eters ........................................................................................... 35

Table 13 – Tamper Reporting Logic Implementation with Write Protect ............................................ 45

Table 14 – Calibration Records ............................................................................................................ 73

Table 15 – Viewing Advanced Diagnostics ......................................................................................... 74

Table 16 – Maximum PV Tracking ...................................................................................................... 75

Table 17 – Minimum PV Tracking ...................................................................................................... 76

Table 18 – Maximum SV Tracking ...................................................................................................... 77

Table 19 – Minimum SV Tracking ...................................................................................................... 77

Table 20 – TV Tracking Diagnostics ................................................................................................... 78

Table 21 – Maximum ET Diagnostics .................................................................................................. 78

Table 22 – Minimum ET Diagnostics .................................................................................................. 79

Table 23 – Operating Voltage Diagnostics........................................................................................... 80

Table 24 – Maximum and Minimum AVDD Tracking ........................................................................ 81

Table 25 – Maximum Sensor CPU Temperature Tracking .................................................................. 81

Table 26 – Minimum Sensor CPU Temperature Tracking ................................................................... 81

Table 27 – Power Up Diagnostics ........................................................................................................ 82

Table 28 – HART Diagnostic Messages .............................................................................................. 84

Table 29 – HART Critical and Non-Critical Diagnostic Details .......................................................... 85

Table 30 – DE Diagnostics ................................................................................................................... 89

Table 31 - Features and Options ......................................................................................................... 110

Table 32 – Available Display Characteristics .................................................................................... 115

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page xi

Table 33 – User Manual Related Topics ............................................................................................ 118

Table 34 - FDC homepage elements .................................................................................................. 122

Table 35 - Device health status .......................................................................................................... 127

Table 36 – HART Transmitter Param eters ........................................................................................ 131

Table 37 – Calibration Records ......................................................................................................... 152

Table 38 – Viewing Advanced Diagnostics ....................................................................................... 153

Table 39 – Maximum PV Tracking ................................................................................................... 154

Table 40 – Minimum PV Tracking .................................................................................................... 155

Table 41 – Maximum SV Tracking ................................................................................................... 156

Table 42 – Minimum SV Tracking .................................................................................................... 156

Table 43 – TV Tracking Diagnostics ................................................................................................. 157

Table 44 – Maximum ET Diagnostics ............................................................................................... 157

Table 45 – Minimum ET Diagnostics ................................................................................................ 158

Table 46 – Operating Voltage Diagnostics ........................................................................................ 159

Table 47 – Maximum and Minimum AVDD Tracking ..................................................................... 160

Table 48 – Maximum Sensor CPU Temperature Tracking ............................................................... 160

Table 49 – Minimum Sensor CPU Temperature Tracking ................................................................ 160

Table 50 – Power Up Diagnostics...................................................................................................... 161

Table 51 – HART Diagnostic Messages ............................................................................................ 162

Table 52 – HART Critical and Non-Critical Diagnostic Details ....................................................... 163

Page xii ST 700 Series HART/DE Option User’s Manual Revision 5.0

1 ST 700 Transmitter Series

1.1 Overview

SmartLine Pressure Transmitter ST 700 family conists of a series of ST 700 Standard Transmitter

models and a series of ST 700 Basic Transmitter models.

The entire manual is broadly classified in two two sections.

The first half of this manual, Sections 2 through 12, are for ST 700 Standard Transmitter model series

and the second half, Section 13 through 21 are applicable only to ST 700 Basic Transmitter model

series.

Which type of transmitte r do I have?

To determine which version you have:

1. Look at the nameplate ont top of the unit shown in Figure 3. Refer to the Mo del n um bers in

the table below to identify which type of Transmitter you have; Standard or Basic.

2. The standard transmitter will have a three button assembly, the basic transmitter will have

two button assembly.

3-button Standard ST 700 Transmitter 2-button Basic ST 700 Transmitter

If you have a ST 700 Standard Transmitter use Sections 2 through 12.

If you have a ST 700 Basic Transmitter go straight to Section 13 through 21

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 1

Smart Line Pressure ST 700

Standard Models

Basic Models

Dual head DP

STD720/730/770

STD725/735/775

Dual head GP

STG730/740/770

STG735/745/775

Inline GP

STG73L/74L/77L/78L/79L

STG73S/74S/77S/78S/79S

Inline flush GP

STG73P

STG73SP

Dual head AP

STA722/740

STA725/745

Inline AP

STA72L/74L/77L

STA72S/74S/77S

Flush flanged level

STF724/732

STF725/735

Pseudo flanged level

STF72F/73F

STF72P/73P

Remote seal DP/GP

STR73D/74G

STR735D/745G

Transmitter

Configuration

Table 1 - ST 700 Standard and Basic Transmitter Model Types

Page 2 ST 700 Series HART/DE Option User’s Manual Revision 5.0

Communication Protoco ls

HART* version 7, Digitally Enhanced (DE), Fieldbus*

Human-Machine Interface (HMI)

Basic Digital Display:

• Basic display language: English only

Standard Display:

• Two-mode operations: PV display and Menu

Calibration

Manual, 34-ST-25-44 for details.

Single

Approvals

Manual, 34-ST-25-44 for details.

FM, CSA, ATEX, IECEx, SAEx, INMETRO, NEPSI,

Mounting Brackets

Angle/flat carbon steel/304 and 316 stainless steel,

Marine 304 stainless steel, 316 Stainless Steel

2 Introduction to the ST 700 Standard Transmitter

This section is an introduction to the physical and functional characteristics of Honeywell’s ST 700

Standard SmartLine Pressure Transmitter.

2.1 Features and Options

The ST 700 Standard SmartLine Pressure Transmitter is available in a variety of models for

measuring Differential Pressure (DP), Gauge Pressure (GP), and Absolute Pressure (AP). Table 2 lists

the protocols, human interface (HMI), materials, approvals, and mounting bracket options for the ST

700.

Table 2 – Features and Options

Feature/Option Standard/Available Options

Options (Basic Display)

Refer to the Calibration sections of the

ST 700 SmartLine Transmitters User’s

Refer to the Approvals sections of the

ST 700 SmartLine Transmitters User’s

• Three-button programming (optional)

• Two-button programming (optional)

• Standard display language: English only

GOST and MARINE

The 3-button option is available for the Basic Display.

The 2-button option is available for the Standard Display.

Also, for the Standard Display, the three button reed switch is used only for span &

zero correction and not for the Display navigation.

* The DE and Fieldbus protocols are not supported with the Standard display.

Revision 4.0 ST 700 Series HART/DE Option User’s Manual Page 1

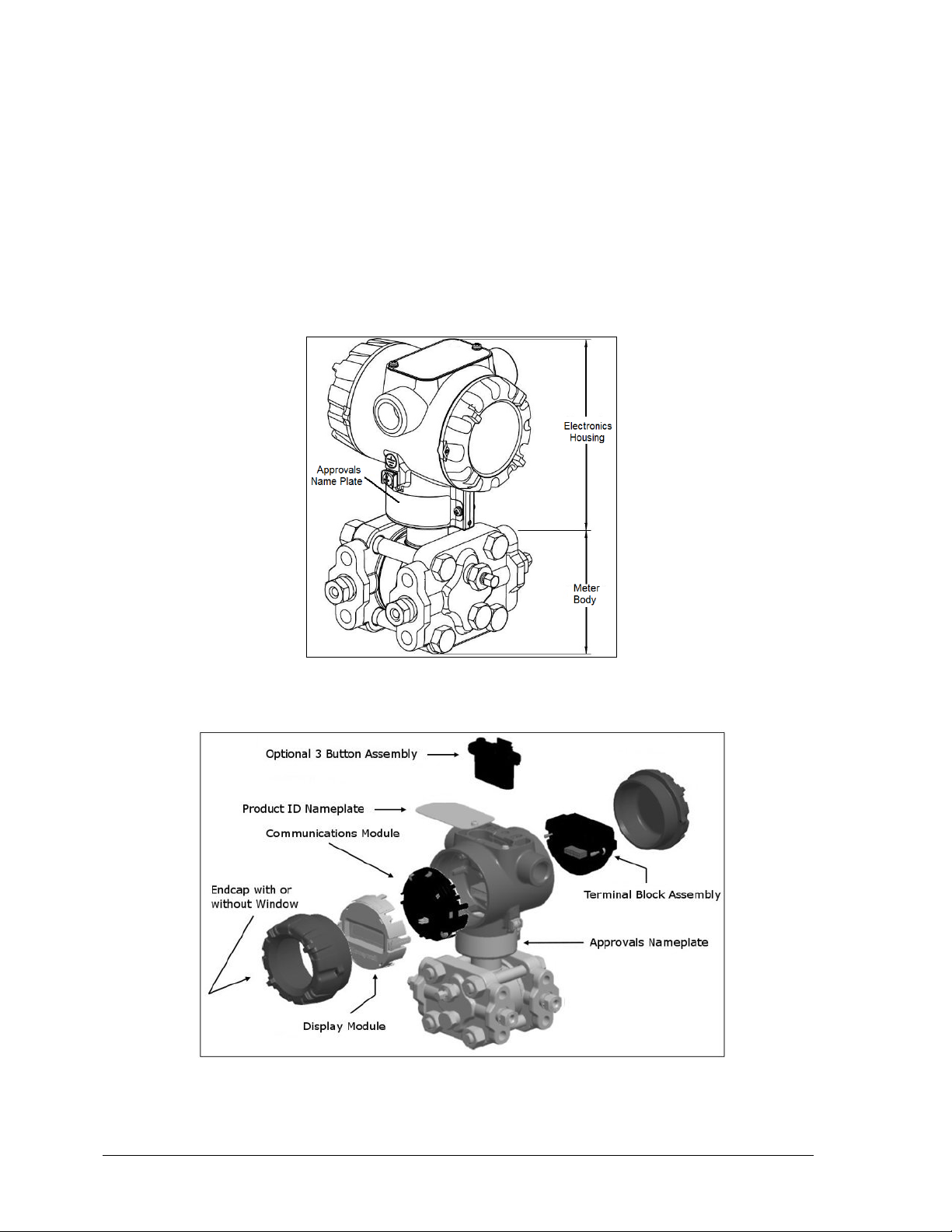

2.1.1 Physical Characteristics

As shown in Figure 1, the ST 700 is packaged in two major assemblies: the Electronics Housing and

the Meter Body. The elements in the Electronic Housing respond to setup commands and execute the

software and protocol for the different pressure measurement types. Figure 2 shows the assemblies in

the Electronics Housing with available options.

The Meter Body provides connection to a process system. Several physical interface configurations

are available, as determined by the mounting and mechanical connections. Refer to the ST 700

SmartLine User’s Manual, Document# 34-ST-25-44 for installation and wiring details.

Figure 1 – ST 700 Standard Major Assemblies

Figure 2 – Electronics Housing Components

Page 2 ST 700 Series HART/DE Option User’s Manual Revision 5.0

• A = Absolute Pressure

• D = Differential Pressure

• F = Flange Mounted

• G = Gauge Pressure

• R = Remote Seals

2.1.2 Functional Characteristics

Functionally, the Transmitter measures process pressure and outputs a signal proportional to the

measured process variable (PV). Available output communication protocols include analog 4 to

20mA, Honeywell Digitally Enhanced (DE) protocol, HART, and FOUNDATION Fieldbus.

An optional 3-button assembly is available to set up and m ak e adjustm ents to the Tr ansm itter. I n

addition, a Honeywell Multi-Communication (MC) Toolkit (not supplied with the Transmitter) can

facilitate setup and adjustment procedures. Certain adjustments can be made through an Experion

Station or a Universal Station if the Transmitter is digitally integrated with Honeywell’s Experion or

TPS/TDC 3000 control system.

An optional 2-button display is also available for configuring / adjusting the Transmitter.

2.2 ST 700 Standard Transmitter Nameplate

The Transmitter nameplate mounted on the top of the Electronics Housing (see Figure 2) lists the

model number, physical configuration, electronics options, accessories, certifications, and

manufacturing specialties. Figure 3 is an example of a typical Differential Pressure (DP) or Gauge

Pressure (GP) or Absolute Pressure (AP) Transmitter name plate. The model number format consists

of a Key Number with several table selections. The Differen tia l Pressu re (DP), Absolute Pressure

(AP), and Gauge Pressure (GP) name plates are essentially the same. However, the DP provides one

additional entry (7 vs. 6 characters) in the Meter Body Selections (Table I) to accommodate the static

pressure rating.

Figure 3 –Typical Standard Transmitter Name Plate Information

You can readily identify the series and basic Transmitter type from the third and fourth digits in the

key number. The letter in the third digit represents one of these basic transm itter ty pes:

For a complete selection breakdown, refer to the appropriate Specification and Model Selection

Guide provided as a separate document.

2.3 Safety Certification Information

An “approvals” name plate is located on the bottom of the Electronics Assembly; see Figure 1 for the

exact location. The approvals name plate contains information and service marks that disclose the

Transmitter compliance information. Refer to Appendix A of the ST 700 SmartLine Transmitters

User’s Manual, Document # 34-ST-25-44 for details.

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 3

2.4 Transmitter Adjustments

Zero and Span adjustments are possible in new generation ST 700 Standard SmartLine Pressure

Transmitter by using the optio n a l thr ee -button assembly located at the top of the Electronic Housing

(see Figure 2). However, certain capabilities are limited in the following configurations:

• Without a display: Zero and Span setting only for HART and DE devices.

• With a display: Complete Tra nsmitter configuration is possible for HART & DE devices.

You can also use the Honeywell MCT404/202 Configuration Tool to make any adjustments to an ST

700 Transmitter. The MCT404/202 tool has two applications; MC Toolkit and FDC. Using the MC

Toolkit application you can adjust the ST 700 DE model configuration. Using the Field Device

Configurator (FDC) application, you can adjust the ST 700 HART model configuration. Alternately,

you can use the Honeywell SmartLine Configuration Tool, SCT 3000, for configuring DE models.

Certain adjustm ents can also be made through the Experion or Universal Station if the Transmitter is

digitally integrated with a H oneywell Experion or TPS system.

ST 700 HART models can be configured using Honeywell tools such as Experion in conjunction with

FDM, using DTMs running in FDM or Pactware, or Emerson 375 or 475.

The Standard Display has limited configuration functionality is supported for entering LRV and

URV values.

Page 4 ST 700 Series HART/DE Option User’s Manual Revision 5.0

• Supports optional 3-B utt on c onf iguration and calibration

• Has a limitedl character display

2.5 Display Options –Standard Display

Table 3 – Available Display Characteristics

• Suitable for basic process needs

o

rotation in 90o Increments

bar, mbar, inHg, FTH

o atm, bar, ftH

kgf/cm

Torr, mH

O68F, gf/cm2, inH2O39F, inH2O60F, inH2O68F, inHg0C,

2

2

, kPa, mbar, mmH2O4C, m, mH2O68F, mmHg0C , MPa, Pa, psi,

O4C, cmH2O4C

2

O, mmH2O, MMHG, & PSI

2

Basic Display

Standard Display

• 360

• 2 lines, 16 characters

• Standard units of measurement: Pa, KPa, MPa, KGcm

• Diagnostic messaging

• Square root output indications

• 360o rotation in 90o Increments

• 2 lines, 6 characters

• Standard units of measurement:

• Diagnostic messaging

2

, TORR, ATM, inH2O,

2.6 Optional 3-Button Assembly (Basic Display)

The optional 3-Button Assembly for the Basic Display provides the following features and

capabilities:

• Increment, decrement, and enter key functions.

• With the menu-driven display:

o Comprehensive on-screen menu for navigation.

o Transmitter c on f ig ur a tio n .

o Transmitter c a lib ration

o Display configuration.

o Set zero and span parameters.

The optional 3-button assembly provides the following benefits:

• Opportunity for immediate reaction with minimal disruptions

• Improved maintenance time

• Potential savings on hand-held units

• Suitable for all environments: hermetically sealed for long life in harsh environments

• Suitable for use in all electrical classifications (flameproof, dustproof, and intrinsically safe)

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 5

If you are using the optional external two-butt o n asse mbly with the

2.7 Optional Integrated Two-Button Assembly (Standard Display)

The Standard Display does not support all the transmitter configurations and has limited features. The

optional 2-Button Assembly for the Standard Display provides the following features and capabilities:

• Menu and enter key functionality.

• With the menu-driven display:

o Comprehensive on-screen menu for navigation.

o Transmitter configuration: enter LRV, enter URV and Loop Test.

o Transmitter c a lib ration

o Display configuration

o Set zero and span parameters.

Standard Display then you can perform all the above operations without

removing external glass cap using the external buttons

Lower range value (LRV): A display parameter (Standard display), which

allows users to enter the measuring value for which the analog output will

be scaled to 4mA.

Upper range value (URV): A display parameter (Standard display), which

allows users to enter the measuring value for which the analog output will

be scaled to 20mA.

Page 6 ST 700 Series HART/DE Option User’s Manual Revision 5.0

3 Communication Model for ST 700 Standard

Transmitter

3.1 Overview

The ST 700 Standard SmartLine Pressure Transmitter can be configured for operation with

Honeywell’s Digitally Enhanced (DE) communication protocol, HART version 7, and Fieldbus

communication. This manual addresses the processes to configure and calibrate a Transmitter for DE

and HART communication. Refer to the ST 700 SmartLine FF Transmitter with FOUNDATION

Fieldbus Option Installation & Device Reference Guide, Document # 34-ST-25-48 for Fieldbus

details.

3.2 Digitally Enhanced (DE ) Mode Communication

Although it is unnecessary to put a control loop in manual mode before communicating

with a Transmitter operating in DE mode, caution is required if there is potential for error in

identifying the operating mode.

In DE mode, the PV is available for monitoring and control purposes; and the meter body temperature

(secondary variable) is availab le for monitoring purposes only.

Much of the operation in the Digitally Enhanced (DE) mode is similar to that of analog operation.

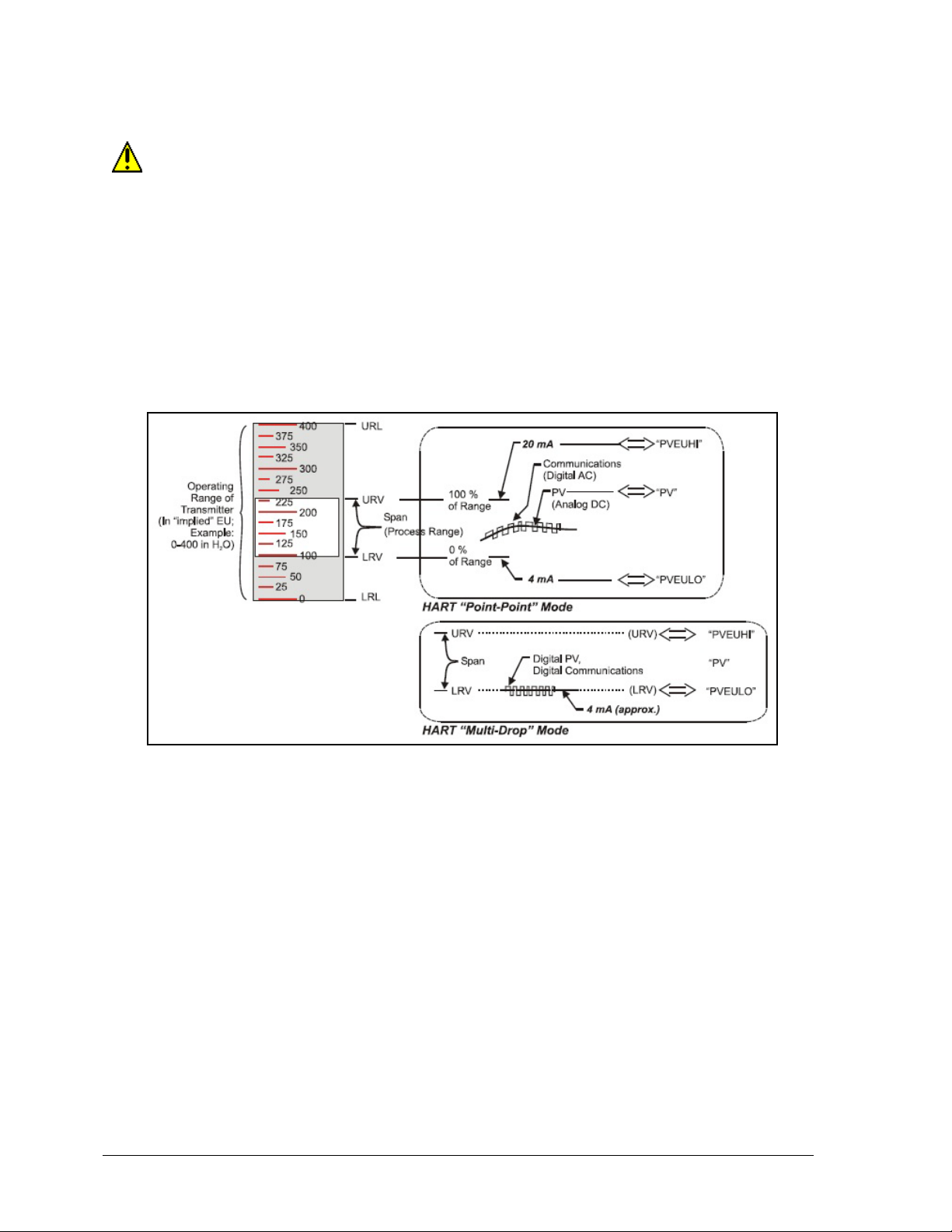

The essential characteristics of DE mode operation are shown in Figure 4.

Figure 4 – DE Mode Value Scaling

As indicated at the r ig ht o f Figure 4, output values of process variables, as well as com m u nications

are transferred to a receiving device digitally. The digital coding is Honeywell proprietary, which

requires the use of DE-capable Honeywell control equipment.

The use of DE mode offers several advantages:

• Process Safety: Unlike analog mode, communications devices do not bump the PV value.

• Accuracy: requires less maintenance.

• Digital communication: Relatively immune to small variations in circuit resistance or supply

voltage.

• Facilitates Maintenance Tasks: Honeywell control systems include operating displays that

enable direct communication with transmitters operating in DE mode.

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 7

3.3 HART Mode Communication

When using MCT404/202,before connecting to a HART transmitter, verify that the FDC

application is used and not the MC Toolkit application. When you use the MC Toolkit

application, the MCT404/202 is set for DE communications, where the current amplitude can

bump process variables in either point-to-point or in the multi-drop mode in HART.

Transmitters with HART capability have features that vary among manufacturers and with the

characteristics of specific devices. The FDC software application executing on the MCT404/202

supports the HART Universal, Common Practice and Device Specific Commands which are

implemented in the Honeywell Transmitters.

As indicated in Figure 5, the output of a Transmitter configured for HART protocol includes two

primary modes:

Figure 5 – HART Point-to-Point and Multi-drop Value Scaling

• Point-to-Point Mode: Where one Transmitter is connected via a two-conductor, 4-20mA

current loop to one receiver.

• Multi-Drop Mode: Where several Transmitters are connected through a two-conductor

network to a multiplexed receiver device.

In point-to-point mode, the value of the primary Process Variable (PV) is represented by a 4-20mA

current loop, almost identical to that of a Transmitter operating in analog mode. In this case, however,

the analog signal is modulated by Frequency Shift Keying (FSK), using frequencies and current

amplitude that do not affect analog sensing at the receiver. The accuracy of the analog level must be

precisely controlled for accurate sensing. HART communication will not bump process variables.

In multi-drop mode, up to 16 transmitters in HART 5 (addresses 0-15) and up to 64 transmitters in

HART6/7 (addresses 0-63) can exist on the two-conductor network.

Page 8 ST 700 Series HART/DE Option User’s Manual Revision 5.0

correction

4 Configuration Tools and Interfaces for

ST 700 Standard T ransmitter

4.1 Overview

This section describes the tools and interfaces involved in configuring a new ST 700 Standard

SmartLine Pressure Transmitter for HART or DE communication operation. The information in this

section also applies to adjusting the configuration of a Transmitter that has been in operation and

updating one that is currently in operation.

4.2 Pre-requisites

The information and procedures in this manual are based on the assumption that personnel

performing configuration and calibration tasks are fully qualified and knowledgeable in the use of the

Honeywell MC To olkit or MCT404/202. The name MC Toolkit or Toolkit and MCT404/202 are used

interchangeably as MCT404/202 is the model name for the Honeywell MC Toolkit product.

Furthermore, we assume that the reader is intimately familiar with the ST 700 family of SmartLine

Pressure Transmitters and thoroughly experienced in the type of process application targeted for

Transmitter deployment. Therefore, detailed procedures are supplied only in so far as necessary to

ensure satisfactory completion of configuration tasks.

4.3 Application Design, I ns tallation, Startup, and Operation

The ST 700 SmartLine Pressure Transmitters User’s Manual, Document # 34-ST-25-44, provides the

details for application design, installation, and startup; see Table 4 for topics.

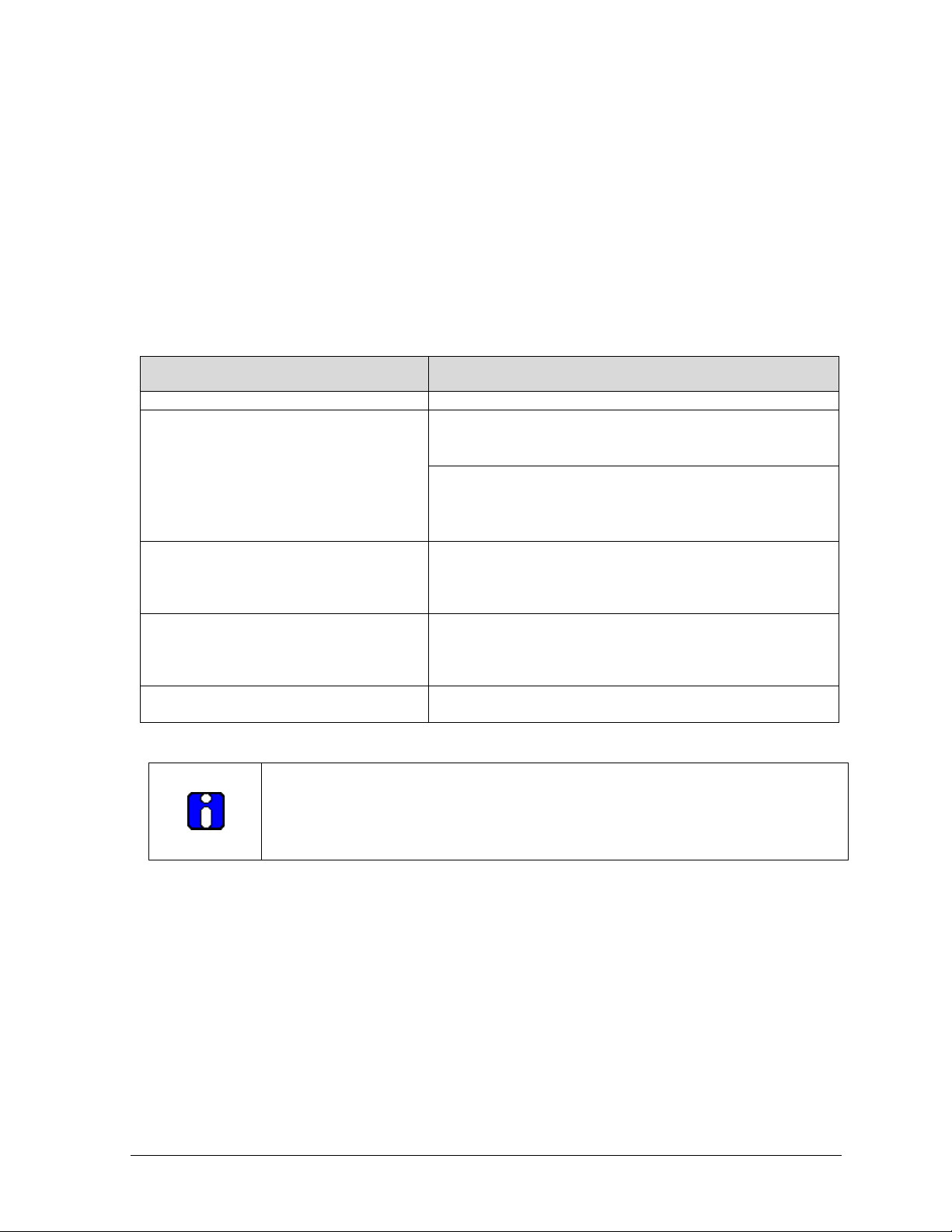

Table 4 – User Manual Related Topics

ST 700 SmartLine Pressure Transmitters User’s Manual

Section 2.

Application Design

Safety and accuracy

Diagnostics messages

Design consideration

Section 3. Installation and Star tup Section 4. Operation

Site evaluation

Toolkit issues

Display installation concerns

Transmitter mounting & zeroPiping & wiring

Startup tasks and procedures

Three-button option (Basic

Display)

Two-button option (Standard

Display)

Failsafe direction setup

Monitoring displays

4.3.1 Organization

This information in this section is arranged in the following sequence:

• MC Toolkit participation in ST 700 Transmitter Setup and Configuration:

o Physical circuit connection s

o Application components

o Configuration for Analog, DE, and HART operation

• ST 700 Transmitter:

o Basic displays (3-buttons)

o Standard Displays (2-buttons)

o Health indications

o Ability to be configured and operate in a process system

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 9

4.4 MC Toolkit Participation

Before using the MC Toolkit, ensure that you are aware of the potential consequences of

each procedure, and that you use appropriate safeguards to avoid possible problems. For

example, if the Transmitter is an element in a control loop, the loop needs to be put in manual

mode, and alarms and interlocks (i.e., trips) need to be disabled, as appropriate, before

starting a procedure.

4.4.1 MC Toolkit Software Applications

The MC Toolkit has two software applications to work with ST 700 Standard SmartLine Pressure

Transmitters:

• Field Device Configurator (FDC): This application is used for configuring, calibrating,

monitoring, and diagnosing HART devices. FDC conforms to the IEC 61804-3 EDDL

(Electronic Data De scription Lang uage) standard specification. The FDC applica tion is an open

solution that supports devices with a registered device description (DD) file compatible with

HART Communication Foundation (HCF) requirements.

• MC Toolkit: This application is used for configuring, calibrating, monitoring, and diagnosing

Honeywell Digitally Enhanced (DE) devices.

Details for work in g with the MC Toolkit are provided in the MC Tookit User Manual, Document #

34-ST-25-20 (MCT202) or #34-ST 25-50 (MCT404). In subsequent sections of this manual, explicit

operating instructions are provided only in so far as necessary to complete required tasks and

procedures.

4.4.2 Configuration Databases

The MC Toolkit is used to establish and/or change selected operating pa ram eters in a Transm itte r

database.

4.4.3 Configuration

Configuration can be accomplished both online and offline with the Transmitter powered up and

connected to the MC Toolkit. Online configuration immediately changes the Transm itter operat ing

parameters. For offline configuration, Transmitter operating characteristics are entered into Too lkit

memory for subsequent downloading to a Transmitter.

When you set up or configure a Transmitter, it can take up to 30 seconds for the value

to be permanently stored. If you change the Sensor Type or ID and the Transmitter power is

interrupted before the change is copied to nonvolatile memory, the changed value will not be

moved to nonvolatile memory.

When Sensor Type or ID is changed, the associated parameters (Field calibration data,

Sensor bias value, disable CVD option, default CVD data and disable match PV if it is dual

input model) which are specific to that sensor input, are written to default values.

Page 10 ST 700 Series HART/DE Option User’s Manual Revision 5.0

4.4.4 MC Toolkit–Transmitter Electrical/Signal Connections

Figure 6 displays how to connect the MC Toolkit directly to the terminals of a HART or DE

Transmitter (top), and a HART-only Transmitter (bottom).

Figure 6 – MC Toolkit-Transmitter Electrical/Signal Connections

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 11

5 DE Transmitter Configuration for

ST 700 Standard Transmitter

5.1 Configuration Personnel Re quirements

The configuration processes in this section reflect the assumption that you will use the Honeywell

MC Toolkit Configuration Tool to configure an ST 700 Standard SmartLine Pre ss ure T ransm it ter.

The MC Toolkit application is used to configure the Honeywell ST 3000 Pressure Transmitter, the

STT 3000 Smart Temperature Transmitters, as well as the ST 700 Standard SmartLine Pressure

Transmitter. Throughout, the term Transmitter means the ST 700 Standard SmartLine Pressure

Transmitter.

The other tools that support the DE Transmitter configuration are the SmartLine Configuration

Toolkit (SC T 3000), Experion PKS, and Smart Field Communicator (SFC).

5.2 MC Toolkit Software Application Overview

Each new ST 700 Standard SmartLine Pressure Transmitter is shi pped from the factory with a basic

configuration installed. This basic configuration must be edited or revised to meet the requirements of

your process system.

The MC Toolkit application supports both online and offline configuration.

• Online operation allows you to establish communication with a DE Transmitter for the

following tasks:

o Upload a Transmitter database.

o Configure Transmitter para meters.

o Calibrate a Transmitter.

o Execute diagnostics.

o Save a configuration to a file.

• Offline operation allows you to click a basic template, edit the parameters and download to a

Transmitter after establishing communication with it. Parameter updates can also be saved in

a file without actually downloading them to a Transm i tte r.

Specific operating details for the MC Toolkit displays are prov ided in Section 3.5, “MC Toolkit

Application Software Display Conventions,” of the MC Toolkit User Manual, Document # 34-ST-2520 (MCT202) or #34-ST-25-50 (MCT404), for the following:

• Navigation

• The MC Toolkit Menu Bar

• File Menu

• Modem Menu

• Help Menu

• Data Entry and Display

Page 12 ST 700 Series HART/DE Option User’s Manual Revision 5.0

5.3 DE Transmitter Online Conf iguration

Online configuration consists of establishing communication between the MC Toolkit and a

Transmitter configured fo r DE communication. Each Transmitter has a configured database, whether

new from the factory, a spare, or one to be reconfigured. In any case, the MC Toolkit application is

used to upload the existing configuration from the Transmitter for review and editing.

5.3.1 Uploading a Transmitter Configuration

1. Connect a DE Transmitter to the MC Toolkit. Ensure that both devices have power applied.

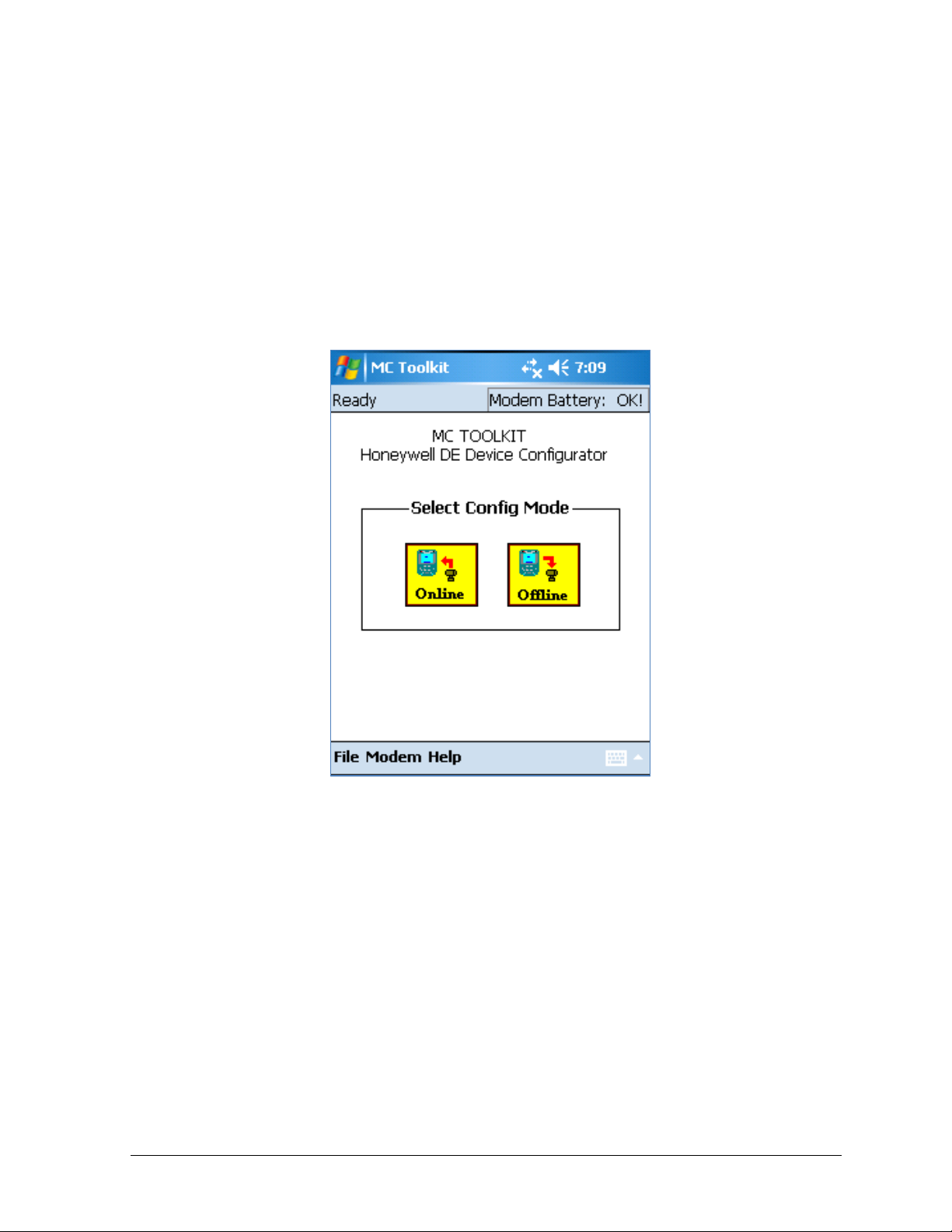

2. To start the MC Toolkit application, click Start / MC Toolkit on the MC Toolk it /

MCT404/202. The MC TOOLKIT homepage will be displayed.

3. Click the Online button, and establish communication between the Toolkit and the

Transmitter.

4. When the warning message for connecting to a DE device appears, click OK.

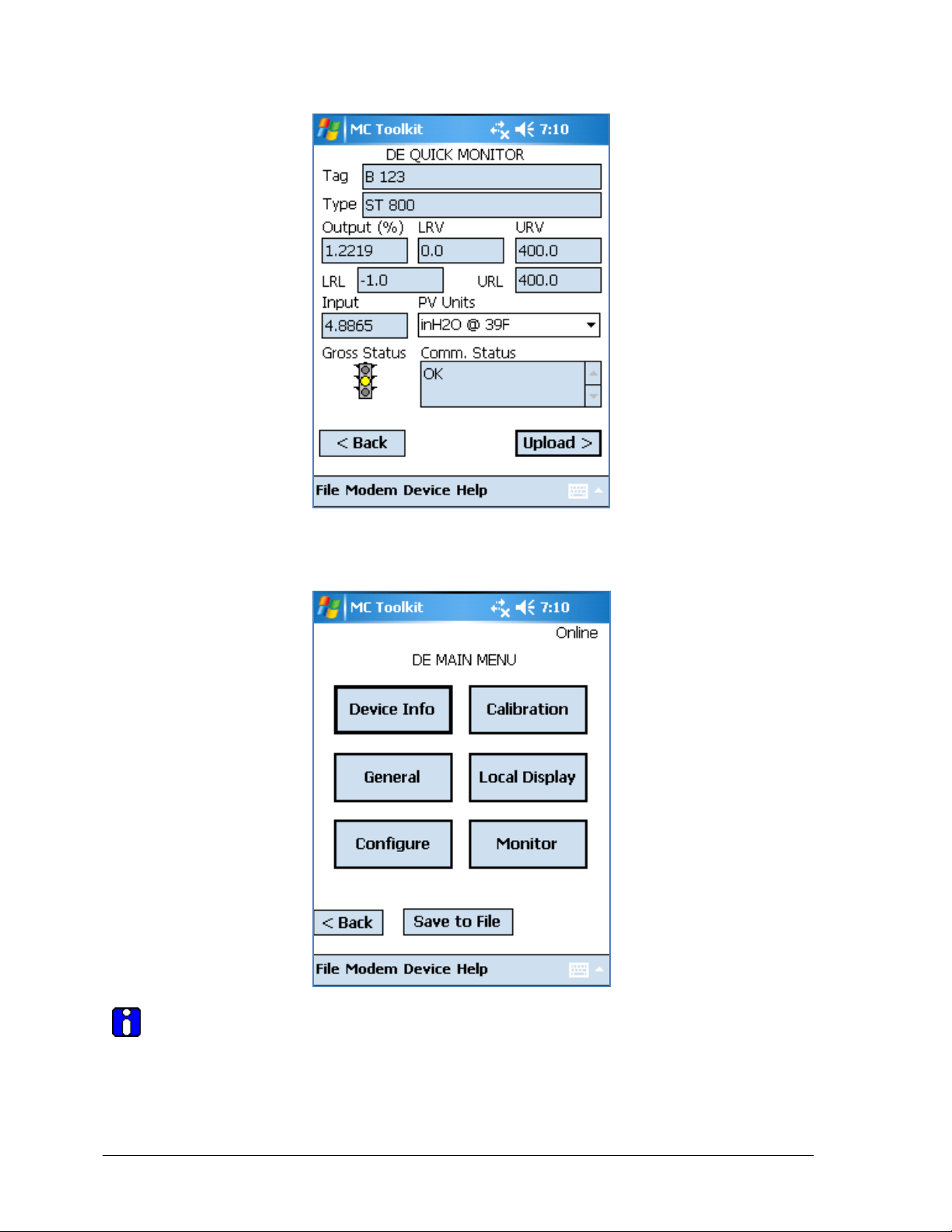

5. Process the three warning pop-ups as appropriate, and then click OK in the Put loop in

Manual… pop-up. The DE QUICK MONITOR bo x w ill be displayed.

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 13

6. Click Upload. A progress bar will be displayed on the DE QUIC K M ON ITOR box, and

when the upload is complete, the DE MAIN MENU will be displayed.

A confirmation request message will be displayed if you click <Back for a Transmitter

that was previously set to Output Mode during calibration, and was not subsequently

cleared. If you confirm the message (Yes answer), the display will exit the DE MAIN MENU.

Page 14 ST 700 Series HART/DE Option User’s Manual Revision 5.0

Tag ID

R/W

User ID up to 8 alphanumeric characters.

Type

R

Manufacturer’s device t ype identif ier

Firmware Version

R

Manufacturer’s firmware version identifier

PROM ID Number

R

PROM ID Number

Scratch Pad

R/W

Up to 32 alphanumeric characters

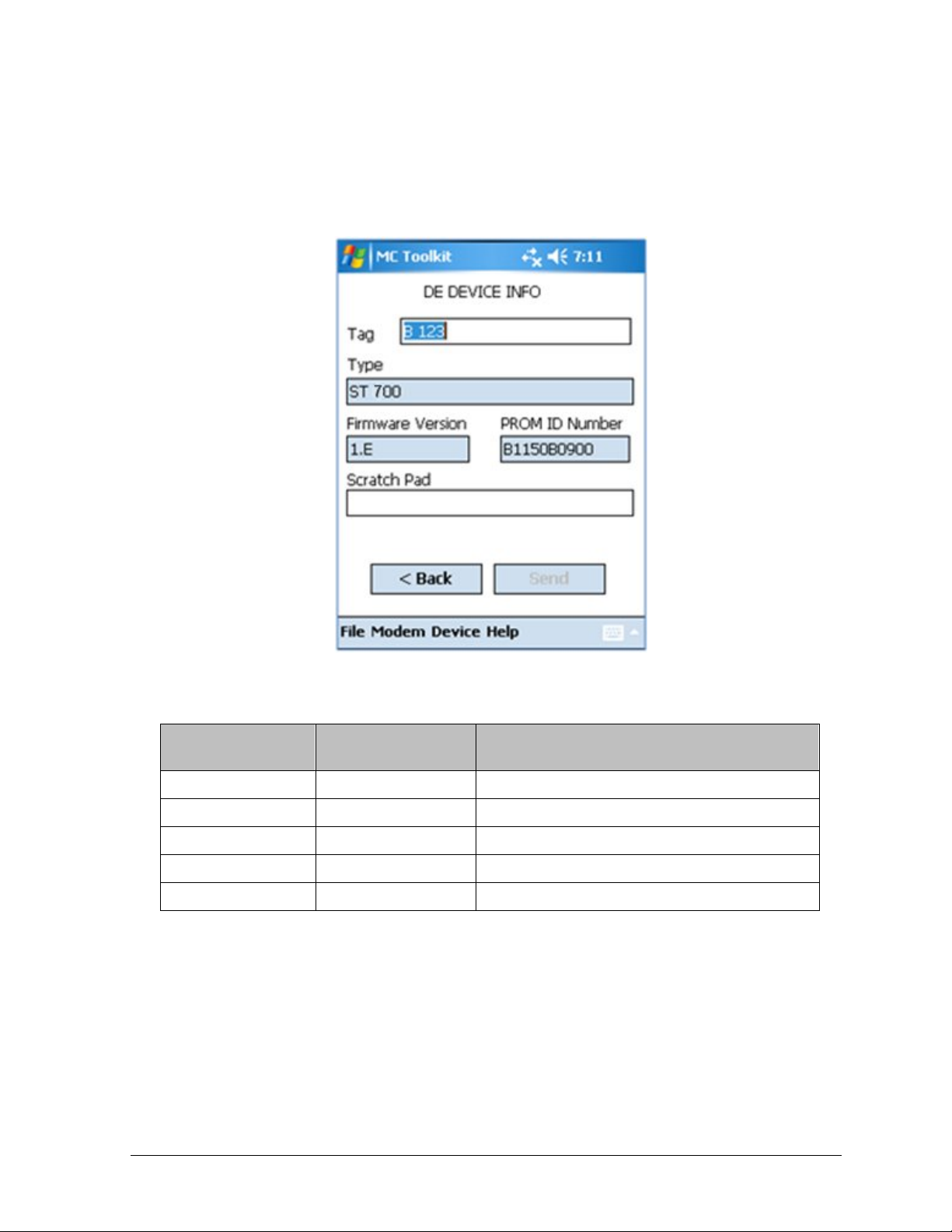

5.3.2 Device Information Configuration

In this and subsequent procedures, the notations R for read only and R/W for read/write are used to

indicate if a parameter can be edited.

1. On the DE MAIN MENU, click Device Info. The DEVICE INFO box will be displayed.

2. Configure device information according to Table 5.

Table 5 – Device Information Parameters

Parameter

Read (R) or

Read/Write (R/W)

Configuration Details

3. Click the Back button to return to the DE MAIN MENU.

Revision 5.0 ST 700 Series HART/DE Option User’s Manual Page 15

Read (R) or

Read/Write (R/W)

Failsafe (FS) direction: upscale or downscale, switch

details.

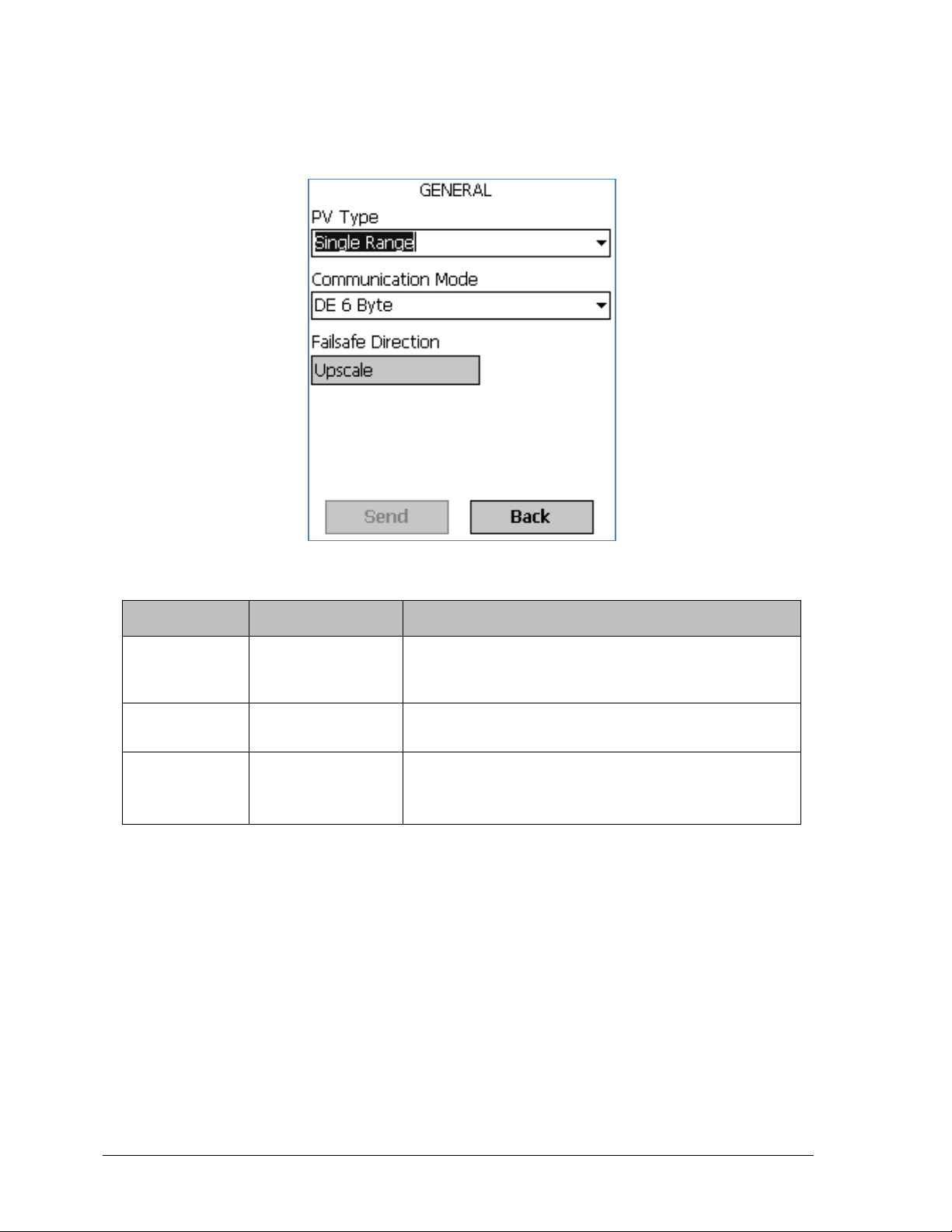

5.3.3 General Configuration Par ameters

Click the General button on the DEVICE MAIN MENU page, and configure parameters according

to Table 6.

Table 6 – General Configuration Parameters

Parameter

PV Type

Communication

Mode

FS Direction

R/W

R/W

R

Configuration Details

Dual Range Smart Transmitter Digital Communications

(STDC) or Single Range or Single Range with

secondary variable (SV).

Analog, DE 4-byte, or DE 6-byte

selectable on the electronics module. Se e the ST 700

SmartLine Transmitter User Manual, 34-ST-25-44 for

Click the Back button to return to the DE MAIN MENU.

Page 16 ST 700 Series HART/DE Option User’s Manual Revision 5.0

Loading...

Loading...