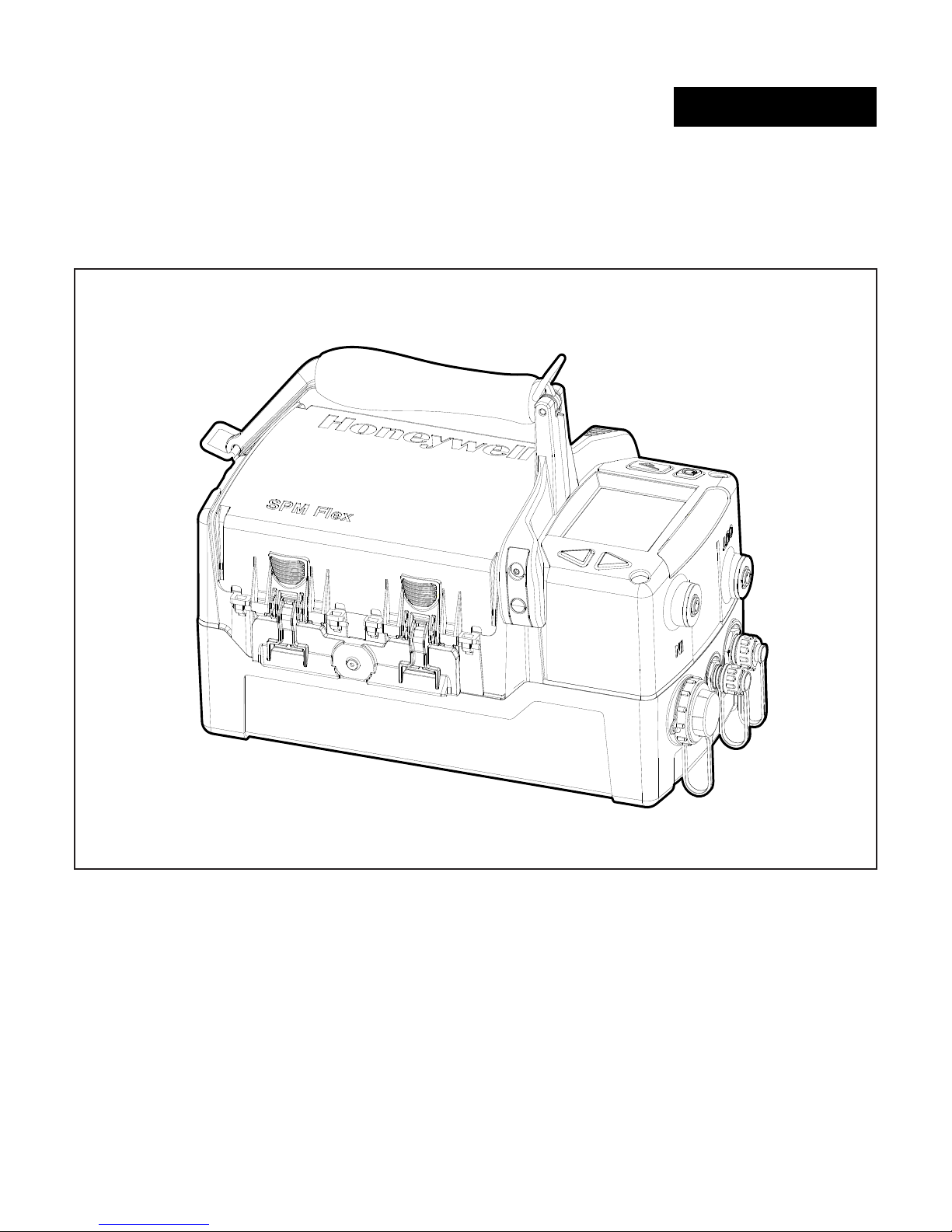

Honeywell SPM Flex User Manual

SPM Flex

Single Point Monitor Gas Detector

User’s Manual

SPM Flex Gas Detector

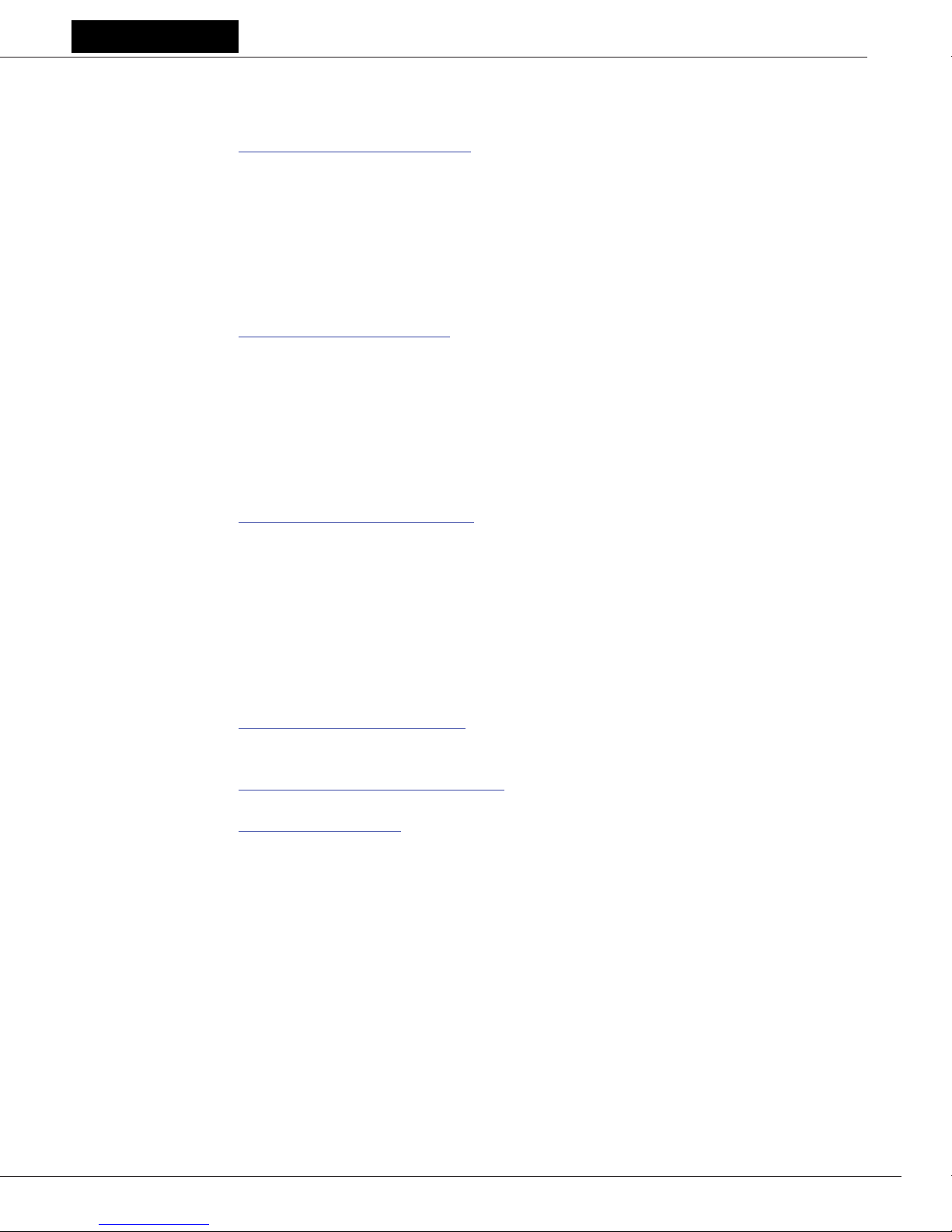

Introduction ����������������������������������������������������������������������������������������������������������������5

Safety Information

Contact Information

Glossary

���������������������������������������������������������������������������������������������������������������������� 8

Product Overview

Battery operation

The handle (portable model)

Opening the cover

Main power rocker switch

Turning the detector on and off

Navigation

Menu Map

�������������������������������������������������������������������������������������������������������������14

�������������������������������������������������������������������������������������������������������������15

Loading a Chemcassette cartridge

Wiring and tubing

Typical fixed installation topologies

Wiring diagrams

4-20 mA wiring

Modbus register definitions

Setup

������������������������������������������������������������������������������������������������������������������������� 26

Installation drawing

Mounting options

Dimensions

������������������������������������������������������������������������������������������������������������27

Standard mounting bracket

Backward-compatible mounting bracket

In-line filters

�����������������������������������������������������������������������������������������������������������30

Optional sampling wand

Attaching the shoulder strap

Operation

Controls

Setup menu

����������������������������������������������������������������������������������������������������������������� 32

����������������������������������������������������������������������������������������������������������������� 32

����������������������������������������������������������������������������������������������������������� 38

Troubleshooting

Maintenance

������������������������������������������������������������������������������������������������������������� 46

Storing the detector

Recycling

���������������������������������������������������������������������������������������������������������������49

Storing Chemcassette

Labels

������������������������������������������������������������������������������������������������������������������������50

Detectable Gases

Specifications

Accessories and Parts

Certifications

Warranties

������������������������������������������������������������������������������������������������������������56

����������������������������������������������������������������������������������������������������������������� 57

SPM Flex warranty

Chemcassette

Index

�������������������������������������������������������������������������������������������������������������������������60

��������������������������������������������������������������������������������������������������6

������������������������������������������������������������������������������������������������ 7

������������������������������������������������������������������������������������������������������� 9

�������������������������������������������������������������������������������������������������� 10

��������������������������������������������������������������������������������11

������������������������������������������������������������������������������������������������11

������������������������������������������������������������������������������������12

����������������������������������������������������������������������������13

����������������������������������������������������������������������17

�����������������������������������������������������������������������������������������������������19

��������������������������������������������������������������������� 19

���������������������������������������������������������������������������������������������������� 21

������������������������������������������������������������������������������������������������������ 22

����������������������������������������������������������������������������������24

�����������������������������������������������������������������������������������������������26

�������������������������������������������������������������������������������������������������� 26

����������������������������������������������������������������������������������28

������������������������������������������������������������ 29

��������������������������������������������������������������������������������������� 30

�������������������������������������������������������������������������������� 31

�������������������������������������������������������������������������������������������������������� 42

���������������������������������������������������������������������������������������������� 49

®

cartridges �����������������������������������������������������������������������49

����������������������������������������������������������������������������������������������������� 51

���������������������������������������������������������������������������������������������������������� 52

���������������������������������������������������������������������������������������������53

������������������������������������������������������������������������������������������������57

®

cartridge warranty ���������������������������������������������������������������������� 57

3

SPM Flex Gas Detector

4

SPM Flex Gas Detector

Introduction

The SPM Flex gas detector is an extractive gas monitoring system that draws gas

®

samples locally or from a remote point to a Chemcassette

detection system� A wide range of toxic gas Chemcassette cartridges are available

that enable detection of gases used or generated in semiconductor manufacturing

and industrial environments�

The SPM Flex gas detector, available in wall mounted and portable versions,

locally displays gas concentration, alarm, fault and status information via its backlit

color LCD and LEDs� A simple to use 4-button keypad adjacent to the display

provides the ability to set-up, review, operate and make changes to the detector’s

configuration� The intuitive display and menu structure are designed to require

minimal training� The SPM Flex has a local audio alarm with user-configurable

output levels� The detector can be used both indoors and outdoors in a wide range

of weather conditions�

The detector has flexible power and communications capabilities� These include

3 on-board relays, 4-20 mA analog output and Modbus/TCP outputs for signal

and service connectivity� The gas detector is equipped with a USB port for

configuration-sharing firmware updates and data downloads� For web-enabled

devices, web pages are available via the Ethernet port�

tape-based optical gas

Standard operation conditions

The SPM Flex gas detector is designed for use in temperatures between 32ºF

and 104ºF (0ºC and 40ºC) and relative humidities between 0 and 100% (the

relative humidities are limited by tape and calibration)� The sample line will require

additional hardware to remove moisture in high relative humidity conditions where

condensing may occur (the sample must be non-condensing)� Dry conditions may

require humidification�

High-altitude applications

The SPM Flex pump is optimized for operation at altitudes between –1000 feet

(–305 meters) and 3000 ft� (945 m) above sea level� At altitudes above 3,000 ft�

(915 m), up to a maximum of 6,000 ft� (1,830 m), contact Honeywell Analytics for

calibration� (At 6,000 feet, pump capacity is reduced 18% and a flow-system

adjustment to the bypass valve is required� This must be performed by a Honeywell

Analytics certified technician� Contact Customer Service�)

5

SPM Flex Gas Detector

DANGER

!

Safety Information

Danger notices contain information that could prevent death or serious injury�

!

WARNING

Warnings contain information that could prevent injury or equipment damage�

!

CAUTION

Caution notices contain information that could prevent equipment damage�

NOTE

Notes contain helpful information�

6

Contact Information

Find out more:

www�honeywellanalytics�com

Americas

Honeywell Analytics

405 Barclay Boulevard

Lincolnshire, IL 60069

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

detectgas@honeywell�com

Europe, Middle East, and Africa

Life Safety Distribution AG

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell�com

SPM Flex Gas Detector

Asia Pacic

Honeywell Analytics Asia Pacic Co., Ltd.

#701 Kolon Science Valley (1)

43 Digital-Ro 34-Gil, Guro-Gu

Seoul, 152-729

Korea

Tel: +82 2 6909 0321

VOIP: +8 5401 0321

analytics�ap@honeywell�com

Technical Services

ha�global�service@honeywell�com

www�honeywell�com

7

SPM Flex Gas Detector

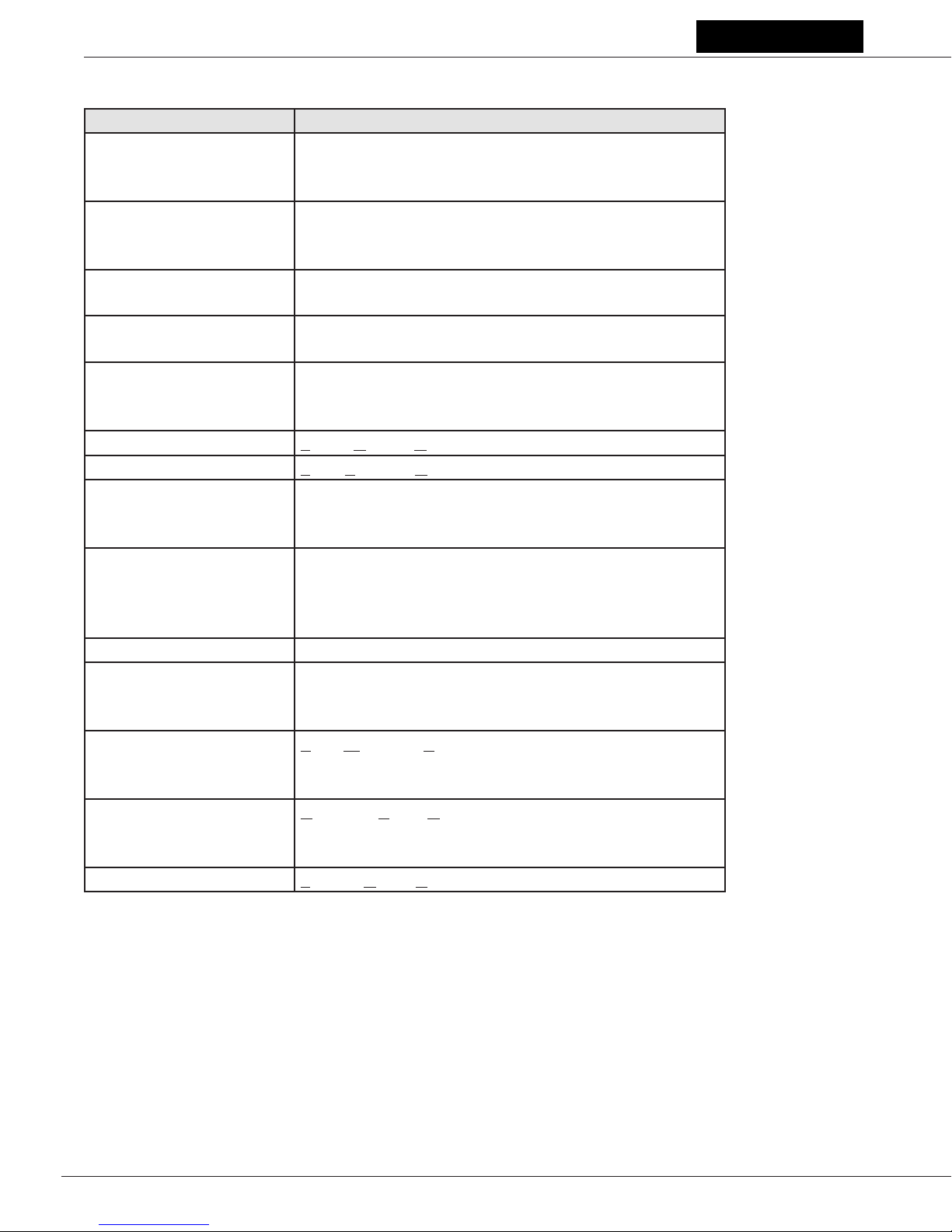

Glossary

Term Description

An analog communication method using a current

4-20 mA loop

®

Chemcassette

Ethernet

In monitor

Latching alarm or fault

LCD

LED

Modbus TCP

Non-latching alarm or

fault

Out of monitor The detector is on but idle

Relay

TWA

USB

VDC

cartridge

loop to indicate concentration readings and fault

status�

An easy-to-install case that carries Honeywell’s

Chemcassette tape� Cartridges are specific to

different gas types/families�

Commonly used network technology for wired Local

Area Networks�

The unit is actively monitoring the specified gas or

family of gases

When configured, the SPM Flex will hold the alarm or

fault status active until the user performs an alarm/

fault reset�

Liquid Crystal Display

Light Emitting Diode

Communications protocol running over Ethernet that

is commonly used for communicating with industrial

devices�

An alert in which the SPM Flex will reset

automatically when the condition is no longer

present (i�e�, the detector does not have to be reset

by the user)�

An electrical-operation output switch that can be

used to indicate the presence of alarm and fault

conditions�

Time Weighted Average, the average exposure to a

harmful gas, usually calculated over a period of eight

hours (a the typical workday)�

Universal Serial Bus is an industry standard

communications protocol and bus that is commonly

available on personal computers�

Volts of Direct Current

8

SPM Flex Gas Detector

WARNING

!

Product Overview

The SPM Flex gas detector is available in two configurations, portable and fixed�

The portable model is equipped with a handle assembly and a shoulder strap�

The fixed unit is supplied with a mounting bracket� If replacing an old SPM

detector, a retrofit bracket is available (these are shown on pages 28 and 29)�

All units are supplied with a power adaptor1 and cable, a CD containing the user

manual, and a printed quick start guide�

Operate and service the SPM Flex gas detector only as specified in this manual

and the accompanying quick start guide� Failure to do so may impair the

protection provided by the detector and may also void the warranty�

Initial setup

Prior to use, the detector requires some minimal setup:

• Unpack the unit (save the packaging to re-use for service requests)�

• Read the quick start guide and this manual�

• Install a filter at the unit or at the end of a sample line

Portable detectors

• Connect the power adaptor (in a dry, indoor location)

• Charge for at least 4 hours (the detector can be used while being charged)

• Open the detector’s cover

• Remove the rocker switch cover

• Turn the rocker switch to the on position

• Replace the rocker switch cover

• Remove the paper optics card from the gate (save the card for later use)

• Load a chemcassette

• Configure the detector and begin to monitor (see pages 15-16 for basic

display usage)

• See detailed Operation (pages 32-41) and Optional accessories (pages 53-55)

Fixed detectors

• Install the wall-mount bracket and mount the detector to it (see pages 28-29)

• Wire in accordance with local electrical codes utilizing a trained electrician

(see pages 19-25)

• Input

• Honeywell-supplied power adaptor (indoor, dry location use only) or

• 24 VDC power supply

• Signal (as desired)

• 4-20 mA

• Relays

• Ethernet

• Open the detector’s cover

• Remove the rocker switch cover

• Turn the rocker switch to the on position

• Replace the rocker switch cover

• Remove the paper optics card from the gate (save the card for later use)

1 FSP Group Model FSP135-AAAN rated 1 5.62A / 24V (UL Listed QQGQ (E190414))

9

SPM Flex Gas Detector

• Load a Chemcassette cartridge

• Configure the detector and begin to monitor (see pages 15-16 for basic display

usage)

• See detailed Operation (pages 32-41) and Optional accessories (pages 53-55)

Additional accessories

• External dust filters (required on inlet)

• Tubing

• Sampling wand

• Mating signal connectors for fixed installations

ports of a typical installation is shown in the figure below�

The

Sample in port

Ethernet

connector

Figure 1. terminals and ports

Exhaust out port

Power connector

Relays or 4-20 mA connector

Battery operation

The SPM Flex gas detector is supplied with a power supply/charger than can

connect the detector’s power connection and a standard

the correct power cable has been ordered for local operation�) The power supply/

charger is designed for indoor, dry-location use only� The lithium-ion battery pack

provides continuous operation of 6+ hours, depending on sampling conditions

and unit configuration� The battery’s charge time is typically 4 hours� The

detector can be operated while its battery is being charged (this may increase

the charge time)� Because batteries discharge slowly when not in use, Honeywell

Analytics recommends keeping the detector connected to the power supply/

charger when not in use�

wall outlet� (Ensure that

!

WARNING

• The battery is not field-replaceable� Return the unit to Honeywell Analytics if

a battery replacement is necessary�

• Risk of fire and burns� Do not open, crush, heat above 140ºF (60ºC), or

incinerate the battery� Follow manufacturer’s instructions�

10

SPM Flex Gas Detector

How to extend battery life

Power consumption is optimized to extend battery life when not in monitor mode�

In addition, the unit should not be exposed to extreme temperatures which

shortens battery life� The time before recharging is required can be extended by

taking the detector out of monitor mode when it is not in use�

The handle (portable model)

The detector can be conveniently carried with the optional handle, which is

mounted onto the cover at three locations� If necessary, the handle can be

removed by the user by removing two bolts� All of the detector’s functions can be

performed with the handle attached� The handle swings out of the way for access

to the Chemcassette cartridge area�

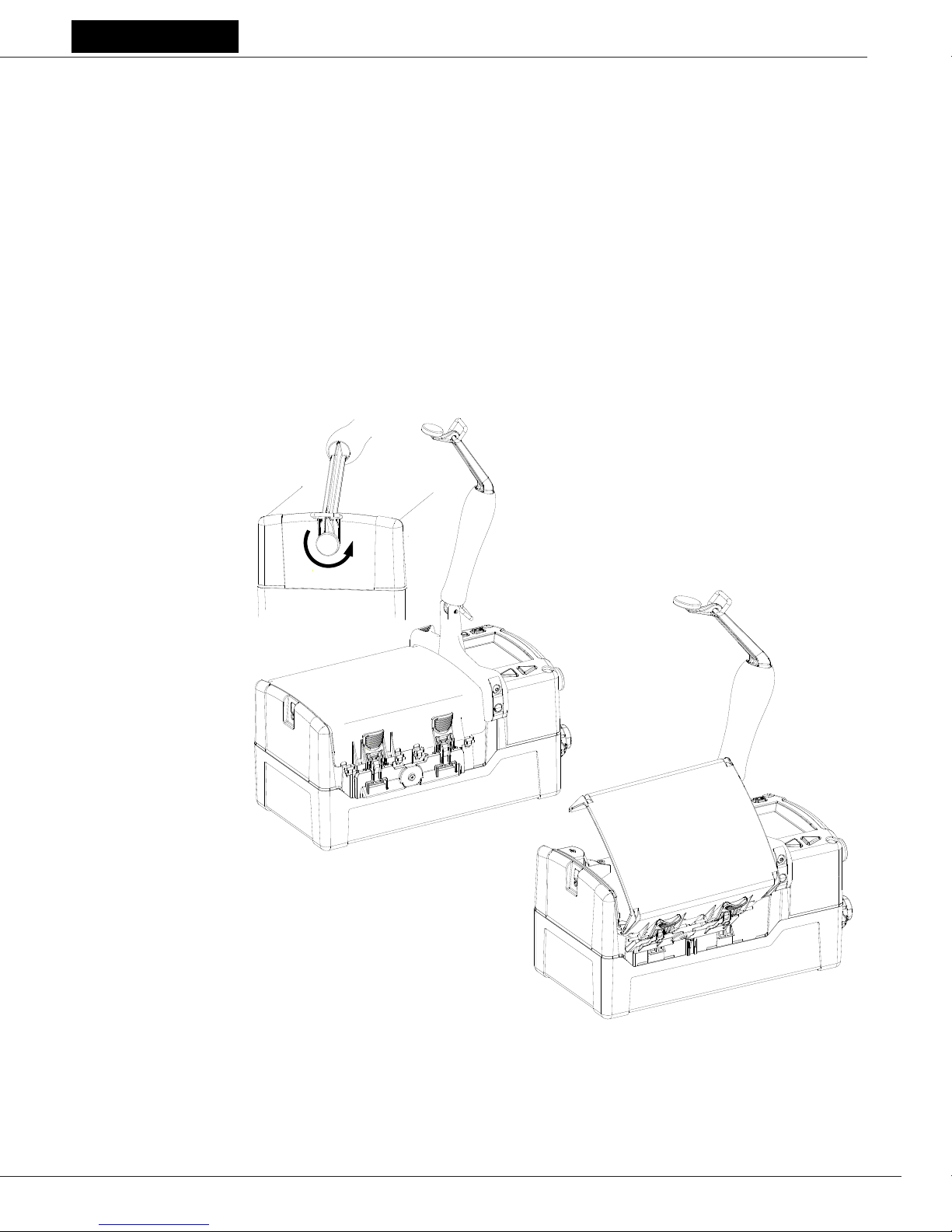

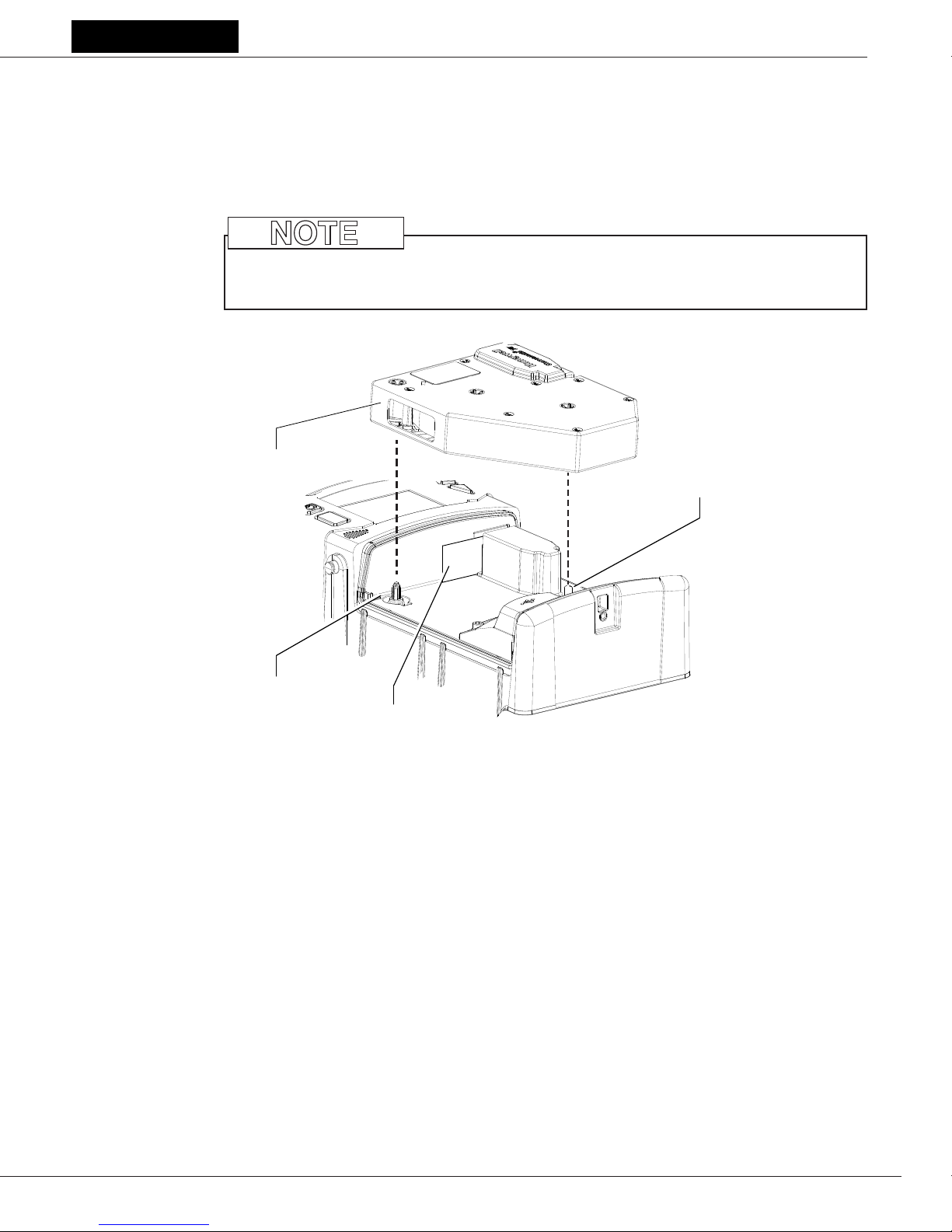

Opening the cover

Figure 2. Opening the detector cover

11

SPM Flex Gas Detector

Release the cover by first unscrewing the handle pin� Pivot the handle up as

shown in the illustration and push down the four latches (two on each side)�

The detector cover will then be free to swing open, allowing a Chemcassette

cartridge to be inserted or replaced, the power switch to be turned on or off, or

the USB data port to be accessed�

Main power rocker switch

Rocker switch cover

Main power rocker switch

Figure 3. SPM Flex main power rocker switch

After the detector’s cover is open, use a Phillips screwdriver to remove the

rocker switch cover� Turn the main power rocker switch to the on position and

replace the rocker switch cover�

The detector can now be turned on�

12

SPM Flex Gas Detector

Turning the detector on and off

Press and hold the Power/Cancel button until the green LED begins blinking� The

detector will begin a startup sequence that lasts about 30 seconds�

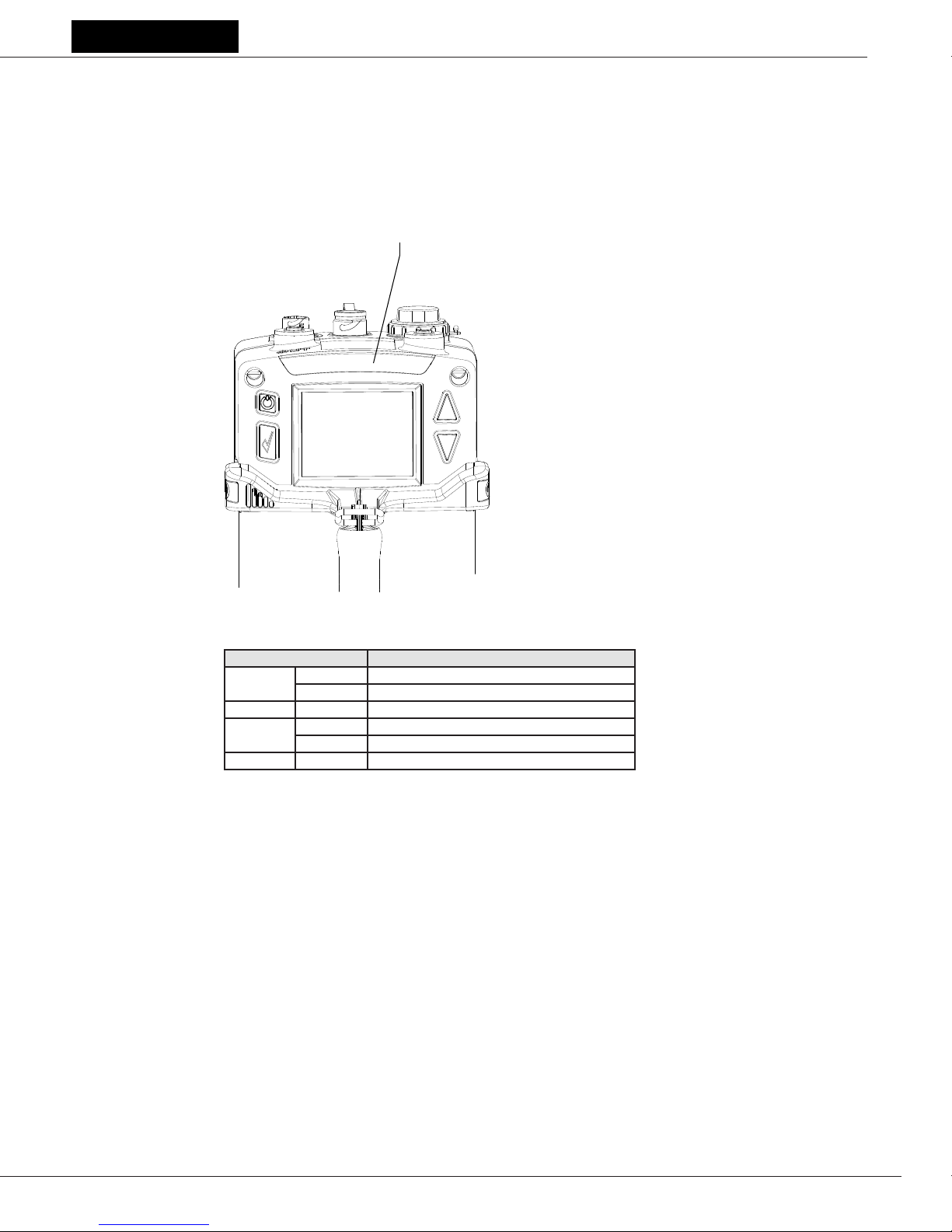

The four LEDs provide at-a-glance information about the current state of the

detector:

LEDs (red, green, yellow, blue)

Figure 4. SPM Flex LEDs

LED Description

Red

Green blinking The detector is active

Yellow

Blue solid Connected to external power

solid Alarm 1

blinking Alarm 2

solid Maintenance fault

blinking Instrument fault

To turn the detector off, press and hold the Power/Cancel button for 5 seconds or

select “Power Off” from the menu�

13

SPM Flex Gas Detector

Navigation

Display

Power/Cancel

Accept/Select

Figure 5. SPM Flex controls

Up arrow

Down arrow

All SPM Flex menus are navigated by the four buttons shown in Figure 5�

Pressing either of the arrows or the Accept/Select button will access the menu

from the main display screen� The arrows also are used to scroll up and down

through lists of options� The Accept/Select button is used to initiate a highlighted

option� During navigation, the Power/Cancel button will cancel a command or,

when pressed for more than 3 seconds, it will exit to the main display�

14

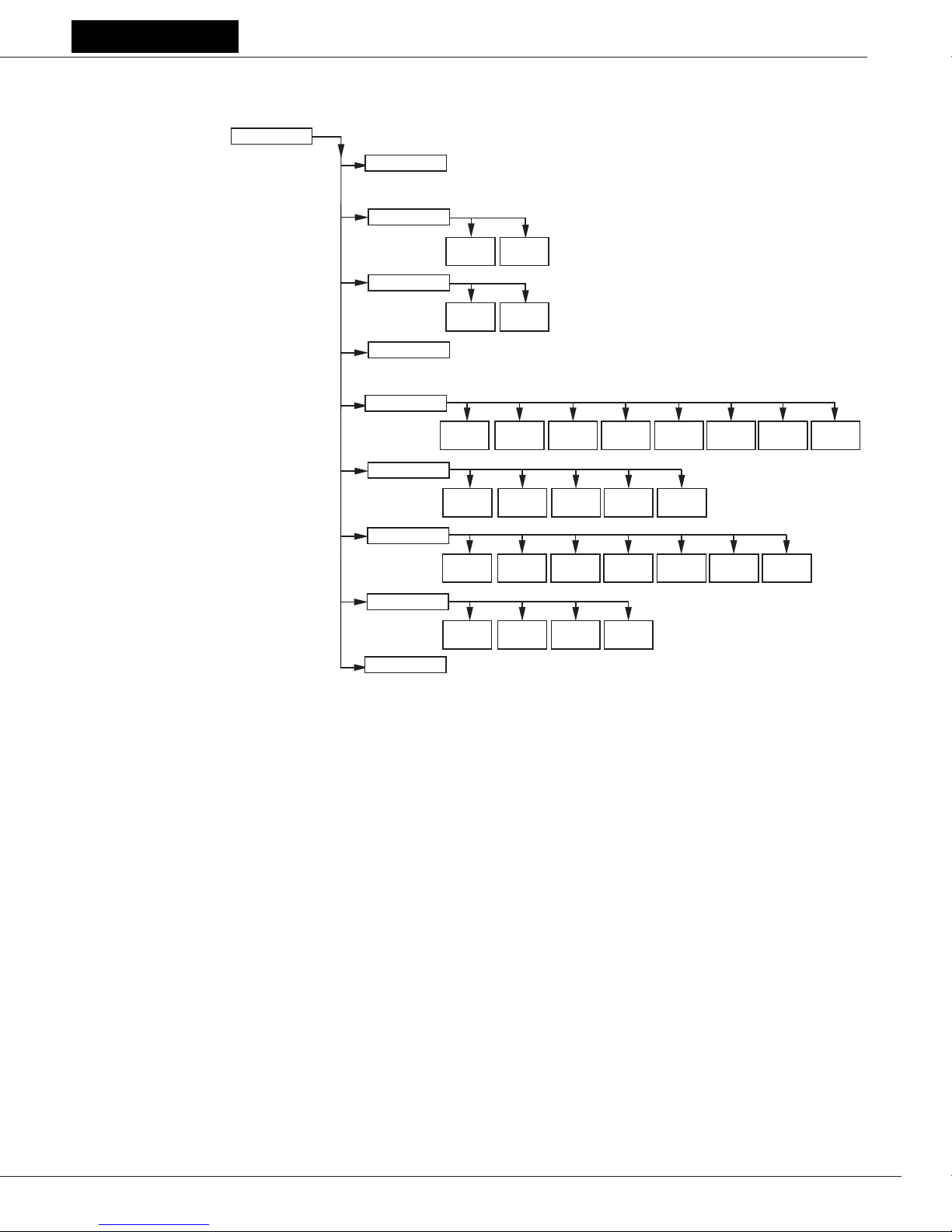

Menu Map

Main Menu

SPM Flex Gas Detector

Login/Logout

Reset Alarms & Faults

Monitor Mode

Change Chemcassette

Review Mode

Maintenance

Setup

Test

Power Off

Reset all

Enter

monitor mode

Event

History

Inhibit

Summary

General

Optics

Verification

Silence

audio alarm

Out of

monitor mode

Chem-

cassette

4-20 mA

Current Loop

Monitoring Latching

Simulate

Gas

Settings

Flow Characterization

Force

Relay

Gate

Force

4-20 mA

Additional

Status

Update

Program

Network

Open/Close

Outputs Network

Output

State

Security

Configuration

Manager

SoftwareTrend/Plot

The SPM Flex detector’s menus are easily navigated� As an example, this is how

a user could review the detector’s gas settings when starting from the In Monitor

screen:

1� Press the Up Arrow > to return to the Main Menu�

2� Press the Down Arrow 4 times to highlight the Review Mode option�

3� Press the Accept/Select button to enter Review Mode�

4� Press the Up Arrow or Down Arrow until the Gas settings option is

highlighted�

5� Press the Accept/Select button to display the Gas Summary�

To return to the detector to the In Monitor display, press the Power/Cancel button

three times to back out of the Main Menu options�

15

SPM Flex Gas Detector

The display

Figure 6 shows the elements of the display that will be seen in various situations�

Status bar

Mute

Alarm 1/

Alarm 2/

Inhibit

indicator

Instrument

Maintenance

Fault

Fault

Concentration

trend

indicator

Menu

Clock

Monitor

mode

Indicator

Battery

indicator

title

15:

42:

01

0

123

.

-

H2S

Hydrogen Sulfide

In monitor

Gas name

Gas concentration

2

Menu

ppm

Units

5.678

1.234

options

Bar graph

w/upper, lower

alarm limits

42:

01

15:

Login / Logout

Reset alarms/faults

Monitor mode

Change Chemcassette

Main menu

Highlighted

Scroll bar

option

Monitor mode indicator

Figure 6. Elements of typical SPM Flex detector displays

The bar graph on the right shows the current concentration relative to the Alarm

1 and Alarm 2 setpoints� (The bar’s range is relative to the alarm levels, not to the

full scale of the selected gas)�

The color of the status bar changes according to the system status (green = OK/

in monitor, yellow = fault, red = alarm, blue = Out of Monitor mode)�

Display and navigation

Under normal operation the LCD and LED display system status, gas

concentrations, and alarms� In set-up, review, calibration, and test modes, the

LCD shows the relevant menu options and system status bar� The interface is

navigated using the four buttons:

Control Function

Up arrow Scroll up through lists of options

Down arrow Scroll down through lists of options

Accept/Select Accept or select a highlighted option

Power/Cancel

Power/Cancel will turn the unit on if it’s in the off state, will exit back to the previous menu level, and will

enter Reset mode (quick press), or Power Off mode (long press and hold) from the main display.

In the main display mode, the display shows the current gas name and

concentration, the monitoring states and faults and/or alarm status, if applicable�

16

SPM Flex Gas Detector

Loading a Chemcassette cartridge

Close the Chemcassette cartridge door before putting the detector into Monitor

mode (this holds the Chemcassette cartridge in place)� Take the detector out of

Monitor mode before opening the door�

NOTE

Chemcassette cartridges must be stored according to the manufacturer’s

guidelines when not in use�

Chemcassette

cartridge

Take-up spindle

Encoder

Optics gate card

Figure 7. The optics gate card and Chemcassette cartridge

1� If the detector’s handle is installed, release it by unscrewing the thumbscrew�

For fixed installations, skip to Step 3�

2� Tilt the handle up as far as possible�

3� Unfasten the latches on the sides of the detector (two on each side) that

secure the Chemcassette cartridge access cover�

4� The detector has slotted hinges� Lift up the cover slightly and then open it all

the way to the right�

5� Select the Change Chemcassette menu option and follow the on screen

instructions�

6� If required, remove the old Chemcassette cartridge� When prompted, snap

the new Chemcassette cartridge into place. It will t in only one orientation.

The takeup spindle will “utter” back and forth to allow easy installation.

7� To close the cover, position it over the base and press so that it contacts the

gasket uniformly�

8� Close the latches on the sides of the detector to secure the cover�

17

SPM Flex Gas Detector

If there is an error (i�e�, the same cartridge was reinserted, the new cartridge has

expired, or an unqualified user is attempting to insert a cartridge that detects

a different gas than the last one), an error message will be displayed and the

installation will be canceled� If the installation is successful, a summary of the

current configuration will be displayed and the user can then choose whether to

enter Monitor Mode or exit the Change Chemcassette Mode out of monitor�

Removing a Chemcassette cartridge

1� Navigate to Maintenance > Open/Close gate�

2� Select “Open Gate�”

3� Remove the cartridge�

4� Select “Close Gate�”

Changing the selected gas

1� While out of monitor mode, navigate to Set-up > Monitoring > Gas�

2� Select “Current gas” and pick the desired gas from the selection box

3� Select “Save�”

Entering monitor mode

From the main menu, navigate to the “Monitor Mode” option and select “Enter

monitor mode�”

1� If a Chemcassette cartridge has been installed, the detector will enter Monitor

�

Mode

2� If a Chemcassette cartridge has not been installed, a user with the necessary

passcode can inititate the Chemcassette wizard� Otherwise, the detector will

not enter monitor mode�

18

SPM Flex Gas Detector

Wiring and tubing

Typical fixed installation topologies

The SPM Flex gas detector has flexible installation options that allow the user to

select the one most suitable for a specific application� The detector is supplied

with weather-sealed connectors for power, Ethernet, and communications

(for relays or

connections in accordance with local codes (allowing the user to wire directly to

terminal block)� Install each detector near a dedicated circuit breaker�

the

!

CAUTION

• The safety of any system incorporating the SPM Flex gas detector is the

responsibility of the assembler of the system�

• Position a permanently-installed SPM Flex gas detector so that it does not

interfere with access to the dedicated circuit breaker�

4-20 mA)� Any of the ports can be replaced with appropriate

Electrical connection is made via conduit directly to ports or via the connector

(see Figure 1 on page 10)� The terminals used are suitable for conductors of 24

to 14 AWG (0�5 to 1�8mm Dia�)� The use of 16 AWG (1�5 mm dia�) conductors is

recommended�

!

CAUTION

Use the supplied power adaptor/connector only� (The adaptor is rated for

indoor use only�)

19

SPM Flex Gas Detector

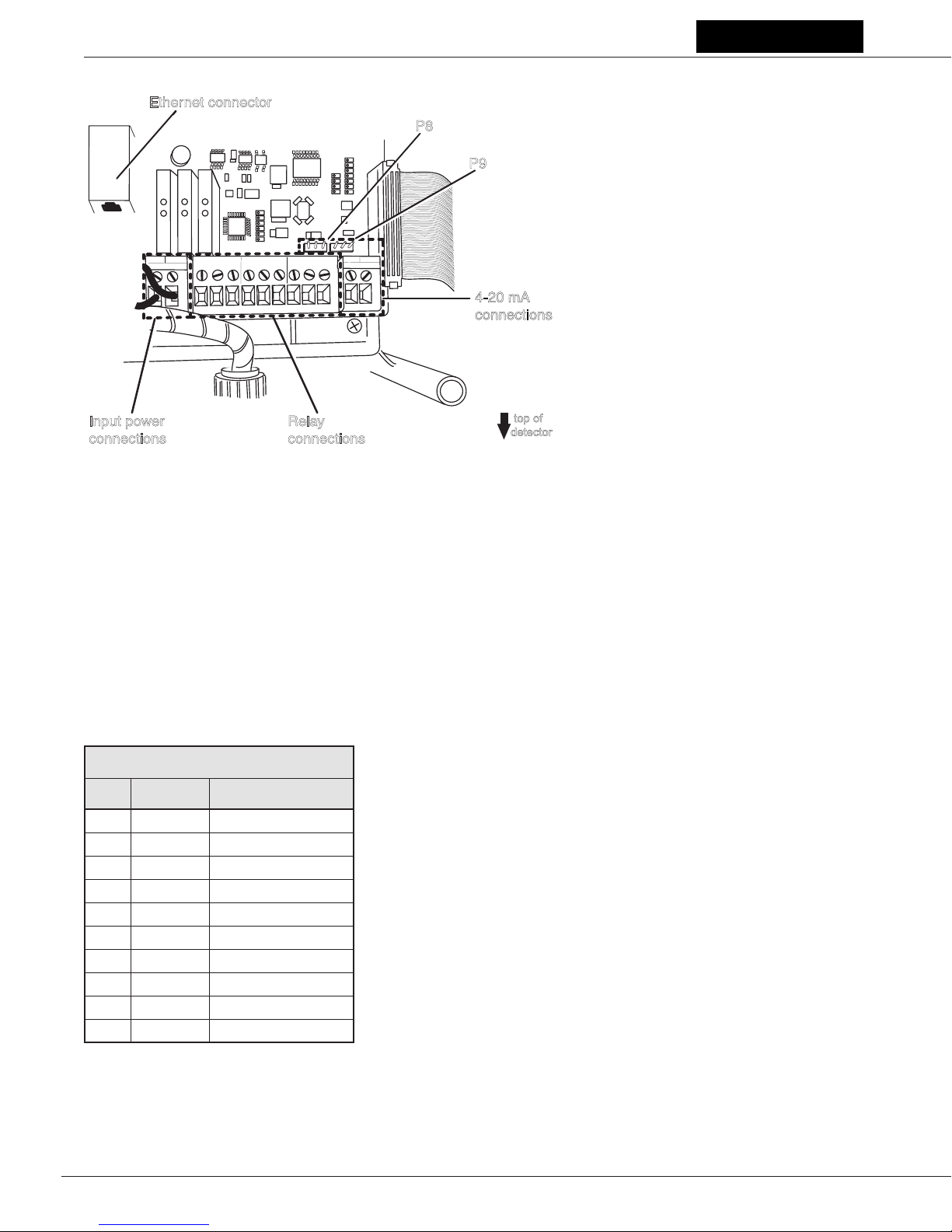

Ethernet connector

P8

P9

+

24 VDC

-

Fault

Relay 2

NO

NC

COM

COM

Relay 1

NO

NC

NC

COM

+

-

4-20 mA

NO

4-20 mA

connections

Input power

connections

Relay

connections

top of

detector

Figure 8. SPM Flex connections

Terminal Module

The terminal module is located on the main PCB inside the gas detector� All

power, relay, and 4-20 mA connections to SPM Flex are made via this module�

Wire entry to the terminal module area is via the cable entry/conduit entry located

at the top of the detector�

This table shows the default wiring configuration for the communication

connector when installed by Honeywell Analytics� The relays are labeled for the

factory default but the configuration can be modified to have a single alarm and

separate faults�

Relay Terminal Connections

No. Color Assign to Relay

1 Brown

2 Red

3 Orange

4 Yellow

5 Green

6 Blue

7 Purple

8 Gray

9 White

10 Black

Alarm2 COM

Alarm2 NO

NC

Alarm1 COM

Alarm1 NO

NC

Fault COM

Fault NO

NC

NC

For 4-20 mA wiring, wires 1 through 8 would be disconnected and wires 9 and 10

would be used� Do not run 4-20 mA signals and relay signals in the same cable

bundle�

20