Solid State Economizer System

W7212/13/14

C7400

M7215

C7150

C7046

C7232B

C7632A

C7660

(CONSISTING OF: C7046C DISCHARGE AIR SENSOR OR C7150B MIXED AIR SENSOR, C7232 OR C7632 CARBON DIOXIDE SENSOR, C7400 SOLID STATE ENTHALPY SENSOR OR C7660 SOLID STATE TEMPERATURE SENSOR, M7215

DAMPER ACTUATOR AND W7212, W7213 OR W7214 SOLID STATE ECONOMIZER LOGIC MODULE)

SYSTEM ENGINEERING GUIDE

FEATURES

C7046C Discharge Air Sensors have probe lengths of 8 in.

(203 mm) and nominal sensor resistance of 3000 ohms at

77°F (25°C).

• No setting or calibration required.

• Solid state components not affected by dust or dirt.

• Fast reacting.

• Rugged aluminum insertion probe.

C7150B Mixed Air Sensor is used with the M7215 Damper

Actuator to sense mixed or discharged air in rooftop packaged

air conditioning equipment.

• No setting or calibration required.

APPLICATION

The Solid State Economizer System provides an economical

method of providing cooling air by incorporating outdoor air in

the first stage of cooling in heating, ventilating and air

conditioning (HVAC) systems. The Solid State Economizer

System consists of the C7046 Discharge Air Sensor, C7150

Mixed Air Sensor, C7232 or C7632 Demand Control

Ventilation (DCV) Sensor, C7400 Enthalpy Sensor or C7660

Dry Bulb Temperature Sensor, M7215 Damper Actuator, and

W7212 Solid State Economizer Logic Module.

C7232 and C7632 DCV Sensors are stand-alone carbon dioxide (CO

with heating ventilation and air conditioning (HVAC) controllers. They measure the CO

space or duct. They are used in HVAC systems to control the

amount of fresh outdoor air supplied to maintain acceptable

levels of CO

• C7232 models available with LCD that provides sensor

• Non-Dispersion-Infrared (NDIR) technology used to

• Gold-plated sensor provides long-term calibration

• Device provides voltage output based on CO

• C7232 models available with SPST relay output.

• Used for CO

• Automatic Background Calibration (ABC) algorithm

• C7632 has fixed 0 to 10 Vdc from 0 to 2000 ppm. No

) sensors for use in determining ventilation necessity

2

concentration in the ventilated

2

in the space.

2

readings and status information.

measure carbon dioxide gas.

stability.

levels.

2

based ventilation control.

2

based on long-term evaluation reduces required

typical zero-drift check maintenance.

adjustments are necessary.

(Continued)

63-2576—02

SOLID STATE ECONOMIZER SYSTEM

CAUTION

C7400 Solid State Enthalpy Sensor and C7660 Solid State

Temperature Sensors are used with the W7212 Solid State

Economizer Logic Module to allow using outdoor air as the

first stage of cooling in HVAC systems.

• C7400 senses and combines temperature and

humidity of outdoor air (heat index).

• C7660 senses dry bulb temperature only.

• Long-lasting, solid state sensing element is accurate

and stable over time.

• When enthalpy/temperature of outdoor air increases,

the outdoor air damper closes to a preset minimum

position.

• When enthalpy/temperature of outdoor air is low, the

outdoor air damper opens to reduce the building

cooling load.

• Provides 4 to 20 mA output signal to the Economizer

Logic Modules; setpoint is located on economizer

control.

• Maximum economizer savings is achieved with two

C7400 Enthalpy Sensors connected to one

Economizer Logic Modules for differential enthalpy

changeover control.

M7215 Damper Motors are 25 lb-in. spring return damper

actuators that provide modulating control of economizer systems, ventilation dampers and combustion air dampers used

in residential or commercial HVAC equipment.

• M7215 Damper Motors provide modulating control of

economizer dampers from a 2-10 Vdc controller.

• Quiet, high efficiency drive motor.

• High impact, glass-fiber reinforced plastic case is

rugged, lightweight and corrosion resistant.

• Provides 2-10 Vdc output signal proportional to the

shaft position.

W7212 Economizer Logic Modules are used with C7232

Demand Control Ventilation (DCV) Sensors, and solid state

C7400 Enthalpy Sensors or C7660 Dry Bulb Temperature

Sensors to proportion outdoor and return air dampers for control of free cooling in commercial HVAC equipment.

• Operates from thermostat and DCV sensor to provide a

totally integrated control system.

• Solid state control package provides accurate, reliable

and stable control.

• Mounts on M7215 Motor or duct work.

• Control can be tempered by DCV and fan cycling.

• Used with Honeywell actuators.

• Combines minimum and DCV maximum damper

position potentiometers with compressor staging.

• Relay functions with solid state enthalpy or dry bulb

changeover control.

• Terminals included for switching between Occupied

and Unoccupied operation.

• Terminals included for connecting optional S963B1128

Remote Potentiometer for remote minimum damper

position control.

• LED indicates when free cooling is available.

• LED indicates when module is in DCV mode.

• LED indicates when exhaust fan contact is closed.

• W7213 is used with heat pump B terminal.

• W7214 is used with heat pump O terminal.

IMPORTANT

Specifications given in this publication do not include

normal manufacturing tolerances. Therefore, this unit

may not exactly match the listed specifications. Also,

this product is tested and calibrated under closely

controlled conditions and some minor differences in

performance can be expected if those conditions are

changed.

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

63-2576—02 2

C7046C DISCHARGE AIR SENSORS

)

D

)

02

(25)

)

)

)

)

)

)8 (

)

GASKET

R

)

USH

)

C

BUS

G

SENSO

OBE

GE

)

S

(

)

O

E

SYSTEM

COMPO

S

CO

W

O

W

S

(

)

3

SENSO

E

SYS

UM

GE

S

Y

CONDU

OX

CO

OR

CONDUIT

E

(

)

SYS

COMPO

S

CO

S

(

)

P

)

SOLID STATE ECONOMIZER SYSTEM

Specifications

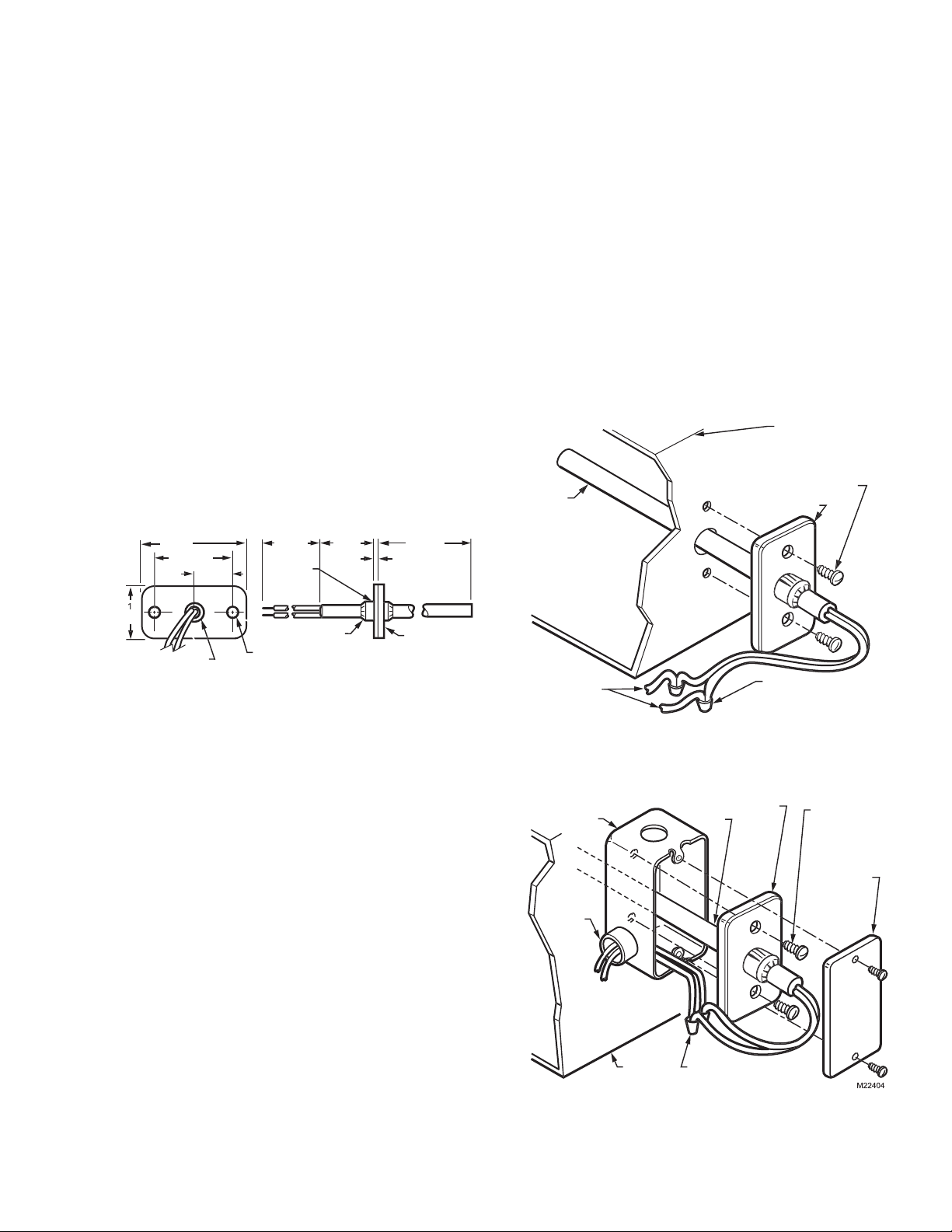

Intended for use as a discharge sensor in rooftop applications.

Dimensions: See Fig. 1.

Mounting: Mounting flange requiring two No. 8 screws.

Sensing Element: Carbon type, thermistor-resistor element.

Maximum Ambient Temperature: 250°F (121°C).

Operating Temperature Range: 40 to 150°F (4 to 66°C).

Wiring Connections: 6 in. (152 mm) leadwires.

Performance Characteristics:

Reaction Time Constant with Air Approach Velocity of

500 ft/min (2 m/sec): 60 seconds.

Resistance/Temperature (NTC):

Nominal Resistance: 3000 ohms at 77°F (25°C).

Nominal Sensitivity: 70 ohms per degree F (124 ohms per

degree C) at midrange.

2 (51

1-1/2 (38

3/4 (19

203

PLASTI

HIN

1 (25

6 (152

1/16 (2

4. Fasten the sensor to the duct or plenum surface

with two No. 8 sheet metal screws (not provided).

Mounting in a Junction Box (Fig. 3)

1. Cut a 3/8 in. (9.5 mm) hole in the duct or plenum

surface at the desired location.

2. Remove the center rear knockout from the junction box

and insert the sensing probe through the knockout with

the flange flat against the outlet box.

3. Using the flange as a template, mark and drill two holes

in the junction box and the duct or plenum surface for

No. 8 mounting screws.

4. Insert sensor probe through both the junction box

knockout and the 3/8 in. (9.5 mm) hole drilled in the duct

or plenum and fasten the junction box and sensor to the

duct or plenum surface.

SYSTEM DUCT

OR PLENUM

NO. 8 (4mm

MOUNTING SCREW

PR

R

NOT PROVIDED

FLAN

5/16 (9) DIAMETE

(BUSHING

LOCKING P

1/4 (6

NUTS (2

IAMETER (2 HOLES

NEOPRENE

M224

Fig. 1. C7046C Air Temperature Sensor dimensions

in in. (mm).

NOTE: Sensor probe diameter is 1/4 in. (6 mm).

Installation

The sensor assembly (see Fig. 1) consists of an aluminum

sensor probe (element housed internally) with attached flange

that can be mounted on a flat duct or plenum surface, or in

a 2 in. by 4 in. (51 by 102 mm) junction box using two No. 8

screws. Connections to the sensor are made through two 6 in.

(152 mm) leadwires.

LOCATION

The sensor should be located in the air duct or plenum where

it will sample an average air temperature. Avoid locations

where air stratification can cause sensing errors.

MOUNTING

Mounting on a Flat Duct or Plenum Surface (Fig. 2)

1. Cut a 3/8 in. (9.5 mm) hole in the duct or plenum

surface at the desired location.

2. Insert sensor probe into the duct or plenum until the

flange rests against the duct or plenum wall.

3. If necessary, use the flange as a template to mark

and drill two holes for No. 8 mounting screws.

T

APPROPRIAT

NENT

M2240

Fig. 2. Mounting C7046 Air Temperature

Sensor on a flat duct or plenum surface.

FLAN

TANDARD UTILIT

IT B

NNECT

LOCKNUT

TO APPROPRIATE

TEM

NENT

TEM

DUCT OR

PLEN

R

PROB

NNECT SENSOR WIRE

WITH TWO WIRENUT

CONNECTORS

Fig. 3. Mounting C7046 Air Temperature

Sensor in a junction box.

NNECT SENSOR

IRES WITH TW

IRENUT CONNECTOR

NOT PROVIDED

NO. 8 (4mm)

MOUNTING

SCREWS (NOT

ROVIDED

FACEPLAT

OPTIONAL

NOT PROVIDED

3 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

CAUTION

CAUTION

Wiring

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Erratic System Operation Hazard.

Failure to follow proper wiring practices can

introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive

loads such as motors line starters, lighting ballasts,

and large power distribution panels.

Shielded cable is required in installations where these

guidelines cannot be met.

Ground shield only to grounded controller case.

IMPORTANT

1. All wiring must agree with applicable codes,

ordinances and regulations.

2. Do not mount sensor in incorrect environment.

3. Wire according to the applicable controller

instructions.

4. Erratic temperature readings from a sensor can be

caused by improper wiring practices. These must

be avoided to assure proper operation:

•Avoid poor wiring connections.

•Avoid intermittent or missing building earth ground.

•Do not mount sensor in incorrect environment.

Connect low voltage wiring from the sensor to the appropriate

system component terminals using solderless connectors.

See Fig. 3.

Operation

The C7046C Air Temperature Sensors consist of a thermistor

sensing element mounted in a tubular probe. They are applied

at various locations throughout single zone and multizone

duct systems. The negative temperature coefficient (NTC)

characteristic of the thermistor element causes its resistance

to decrease as the sampled air temperature increases. This

resistance shift is balanced with other system sensor signals

by appropriate system logic panels to stabilize system control.

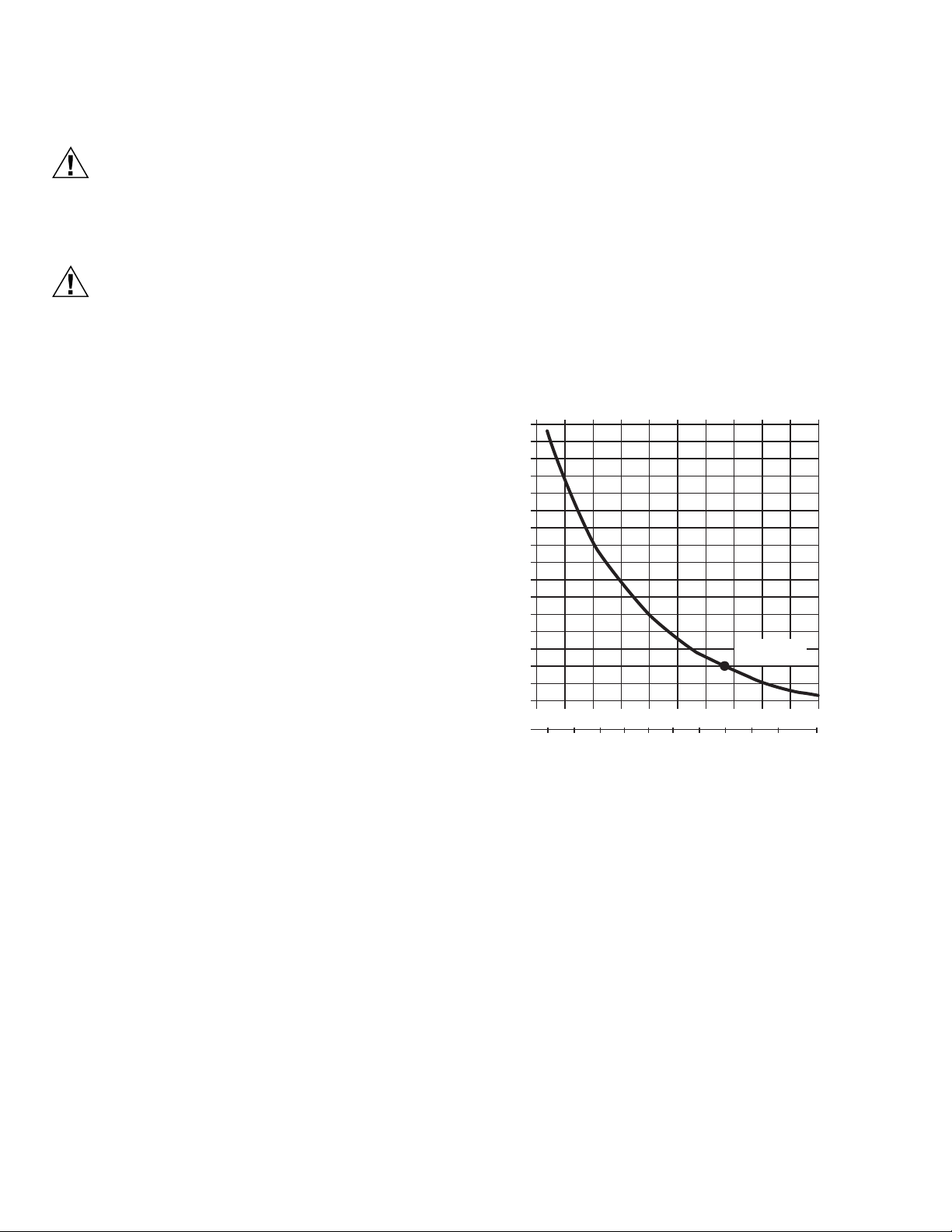

Checkout

Allow the C7046 Air Temperature Sensor to soak in the air

moving through the duct or plenum for a minimum of five

minutes before taking a resistance measurement.

1. Disconnect the sensor leadwires from the associated

system components.

2. Connect an ohmmeter across the leadwires.

3. Assure nominal resistance measurements are in

accordance with the resistance/temperature curves

shown in Fig. 4.

4. Reconnect sensor leadwires to associated system

components.

5. Check operation of the complete control system.

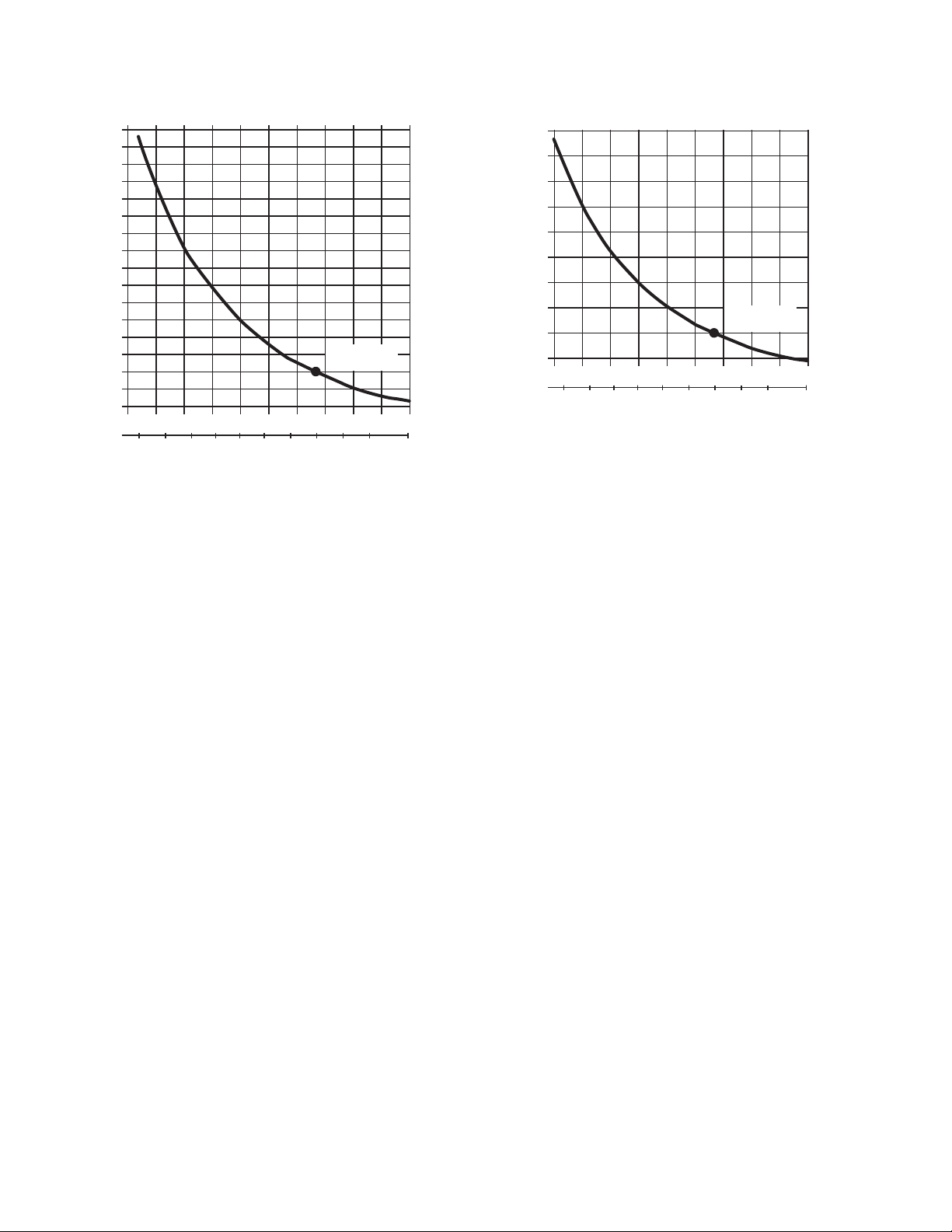

17000

16000

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

RESISTANCE (OHMS)

5000

4000

3000

2000

1000

605040 70

0-10

5

TEMPERATURE (DEGREES)

2010

15

Fig. 4. C7046C Sensor resistance vs. temperature.

3,000 OHMS

AT 77 F (25 C)

8010 20 30 90 100

30 35

25-5

F

C

M17969

63-2576—02 4

C7150B MIXED AIR SENSOR

3

R

)

1-1/2

(38)

(51)

3/4

(19)

3/4

(19)

2-3/8

(60)

2-1/4 (57)

M17992

C7150B1004 C7150B1046

SOLID STATE ECONOMIZER SYSTEM

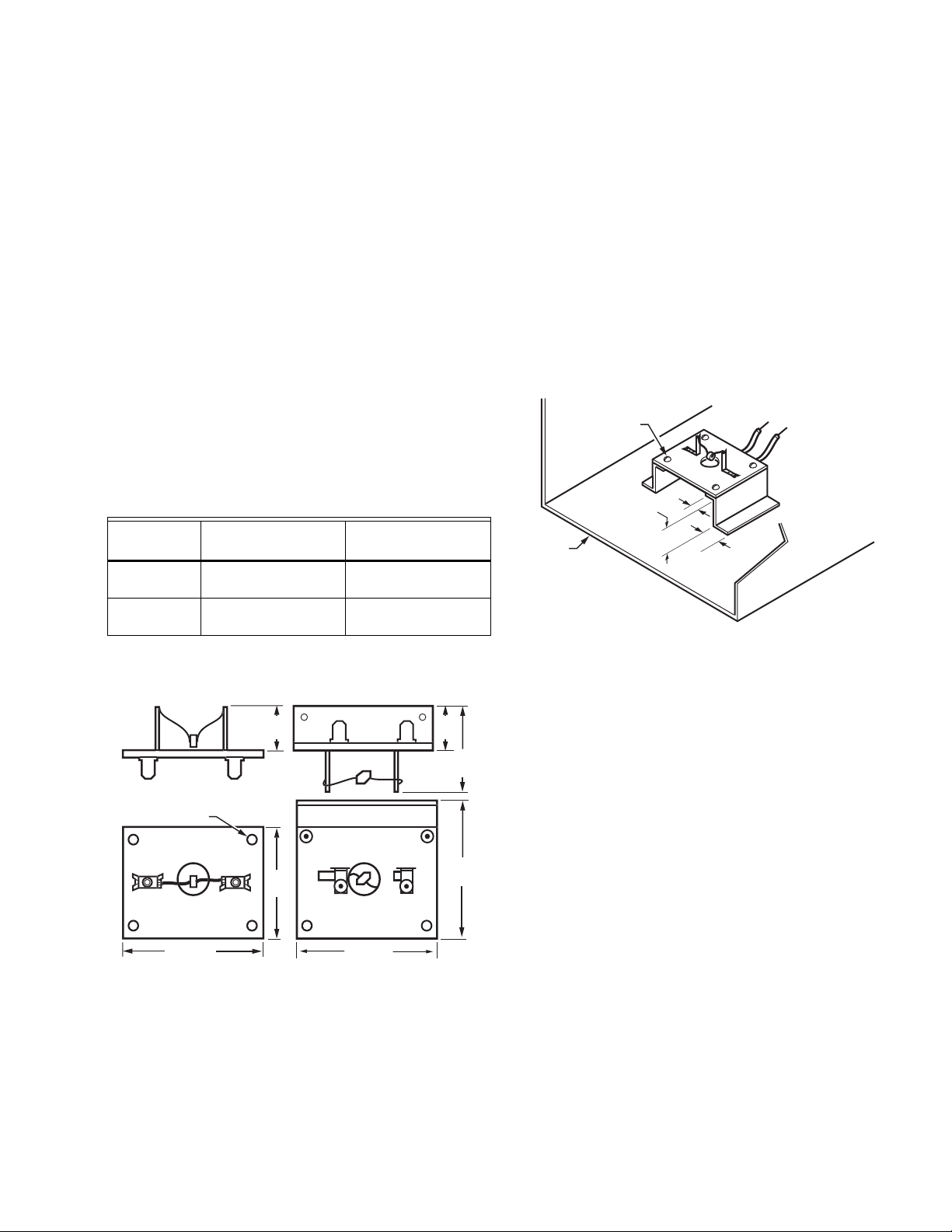

Specifications

Models: See Table 1.

Dimensions: See Fig. 5.

Mounting Arrangement:

Integral mounting flange that requires No. 8 screws.

NOTE: The C7150B1004 requires four No. 8 screws;

the C7150B1046 requires two No. 8 screws.

Ambient Temperature Ratings:

Maximum: 250°F (121°C).

Operating Range: -40 to 110°F (-40 to 43°C).

Shipping Range: -30 to 150°F (-34 to 66°C).

Wiring Connection: 1/4 in. (6 mm) quick-connects.

NOTE: The C7150B1046 includes 4 in. lead wires with

connector for W7340 compatibility.

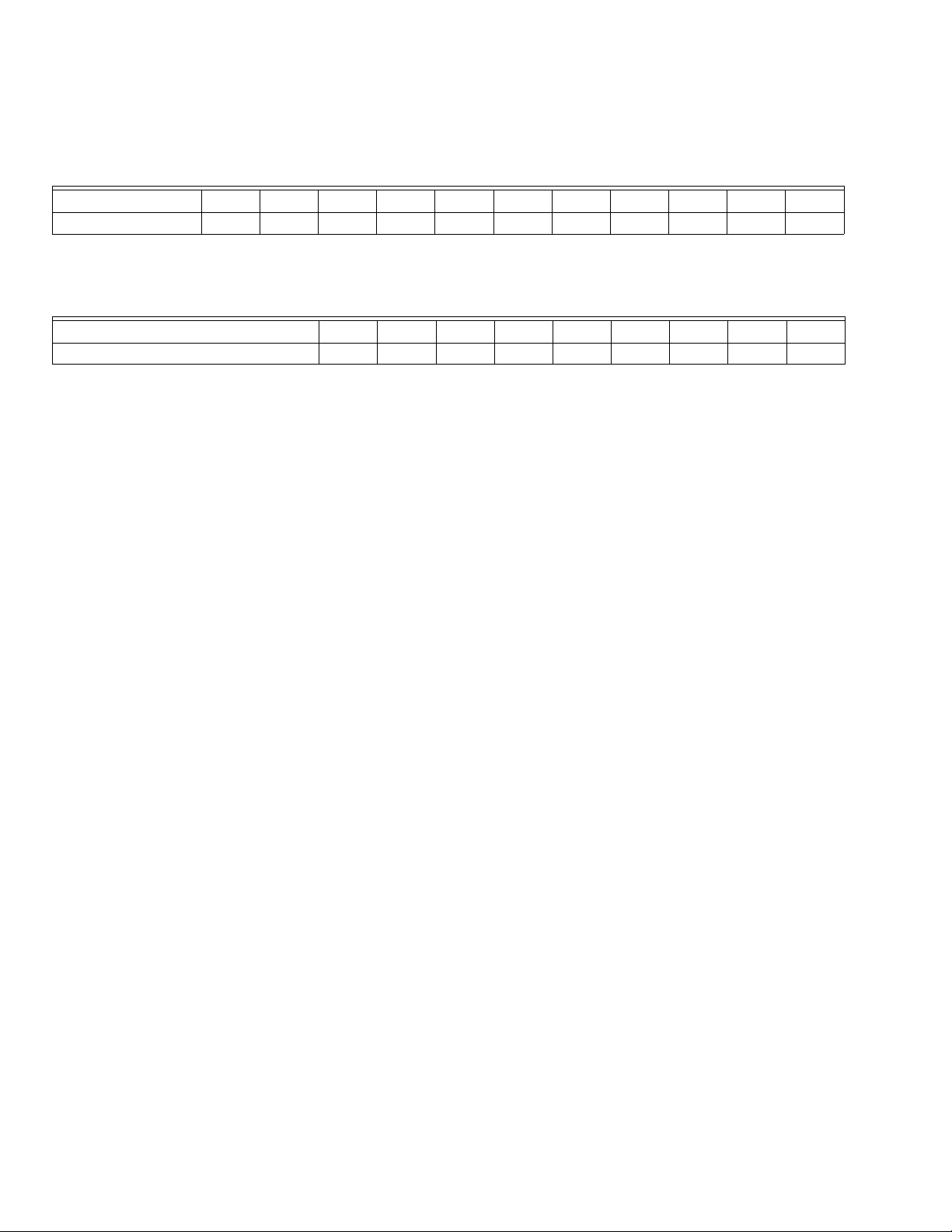

Table 1. C7150B Models.

Nominal Resistance

Model

at 77°F (25°C)

C7150B1004 3000 ohms 70 ohms per °F

C7150B1046 10K ohms 234 ohms per °F

a

Negative Temperature Coefficient (NTC).

Nominal Sensitivity

at midrange

(124 ohms per °C)

(415 ohms per °C)

Installation

1. Install on a mounting bracket (not included) inside the

2. Wire using 1/4 in. (6 mm) female quick-connect

a

DUCT

mixed air or discharge air duct using No. 8 mounting

screws and nuts. (See Fig. 6).

NOTE: When mounting, ensure that terminals do not

touch metallic conductive surfaces.

terminated wires from C7150B to control inputs.

NOTE: For C7150B1046, splice additional wiring as

needed between sensor and connector.

NO. 8

MOUNTING

SCREW

2 (51)

3/8

(9)

TO APPROPRIATE

SYSTEM SENSOR

1/2 (13)

INPUT

M17938A

Fig. 6. Mounting C7150B [C7150B1004 shown].

/16 (5) DIAMETE

2-1/2 (64

Fig. 5. C7150B approximate dimensions in in. (mm).

NOTE: Fig. 6 displays bracket (not included) and suggested

bracket dimensions in in. (mm).

Operation

The C7150B Air Temperature Sensor consists of a thermistor

sensing element mounted on a phenolic board. It is applied in

ventilation duct systems. The thermistor element negative

temperature coefficient (NTC) characteristic causes its

resistance to decrease as the sampled air temperature

increases. This resistance change is used as a control system

sensor to regulate discharge air temperature in a W973 Single

Zone System or damper position of the M7215A Motor (either

directly, or through the Economizer Logic Module).

Checkout

Allow the C7150B Sensor to soak in the air moving through

the duct for a minimum of 5 minutes before taking a resistance

measurement:

1. Disconnect sensor leadwires from associated system

components.

2. Connect an ohmmeter across the leadwires.

3. Nominal resistance measurements should be in

accordance with the resistance/temperature curves

shown in Fig. 7 and Fig. 8.

4. Reconnect sensor leadwires to associated system

components.

5. Check operation of the M7215A Motor, W973 System,

or the Economizer Logic Module.

5 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

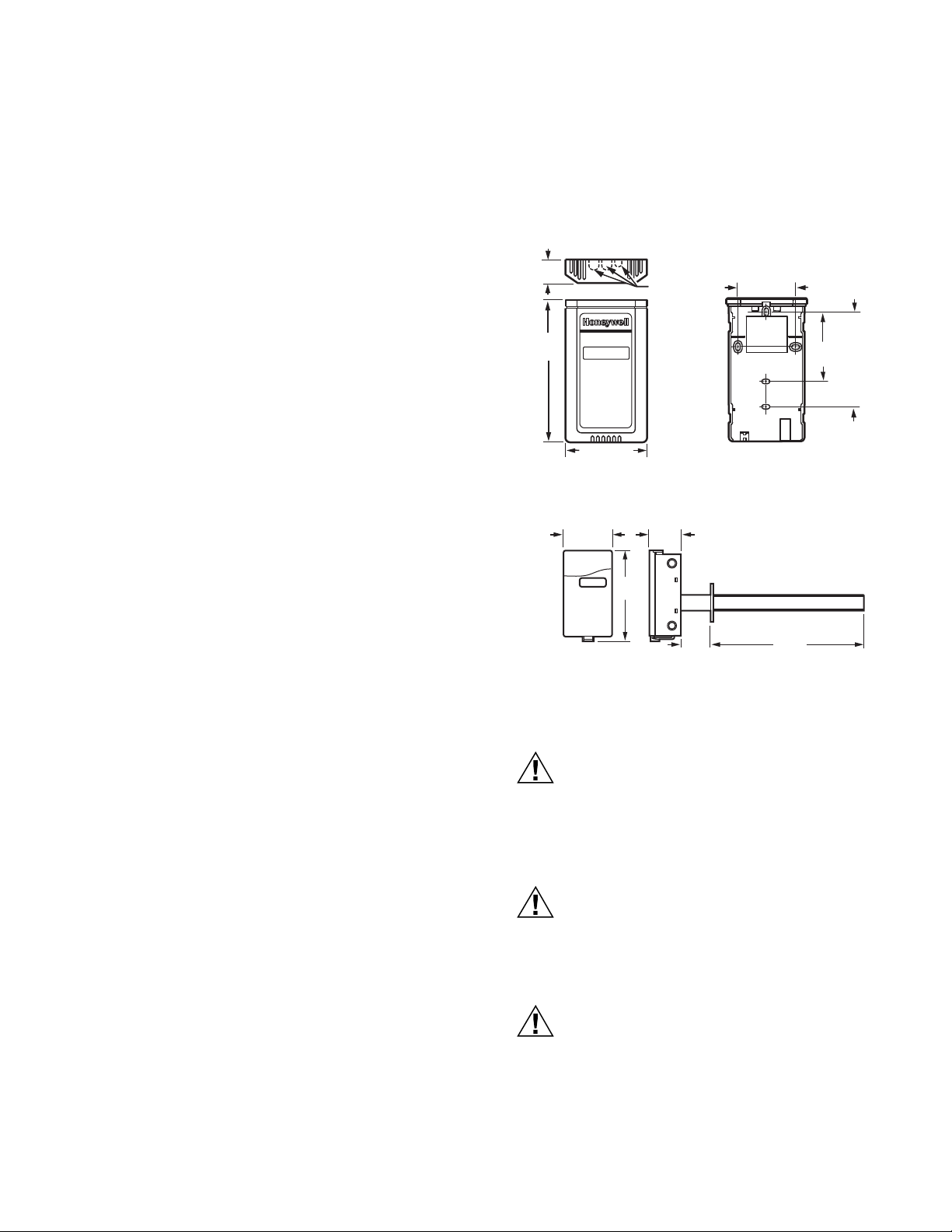

17000

16000

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

RESISTANCE (OHMS)

5000

4000

3000

2000

1000

605040 70

0-10

5

TEMPERATURE (DEGREES)

15

2010

3,000 OHMS

AT 77 F (25 C)

8010 20 30 90 100

30 35

25-5

F

C

M17969

Fig. 7. C7150B1004 Sensor resistance temperature.

50000

45000

40000

35000

30000

25000

RESISTANCE (OHMS)

20000

15000

10000

5000

605040 70

0

15

5

TEMPERATURE (DEGREES)

2010

10,000 OHMS

AT 77 F (25 C)

8020 30 90 100

30 35

25-5

F

C

M20071

Fig. 8. C7150B1046 Sensor resistance temperature.

63-2576—02 6

C7232 DCV SENSORS

CAUTION

CAUTION

CAUTION

SOLID STATE ECONOMIZER SYSTEM

Specifications

Models: C7232 Sensor and Controller. A stand-alone carbon

dioxide (CO

(one analog and one spst relay).

C7232A: Wall mount model.

C7232B: Duct mount model.

NOTE: Models are available with or without a 4-digit LCD

Dimensions:

C7232A: See Fig. 9.

C7232B: See Fig. 10.

Sensor Performance Ratings:

Response Time: 2 min.

Carbon Dioxide Sensor:

Operation: Non-dispersive infrared (NDIR).

Sampling: Diffusion.

Range: 0 to 2000 ppm ±5% and ±50 ppm.

Annual Drift: 20 ppm (nominal).

Electrical Ratings:

Power Supply: 24 Vac ±20%, 50/60 Hz (Class 2).

Maximum Power Consumption: 3W.

Peak Current (at 20 ms): 600 mA.

Relay:

Configuration: Shipped N.O. (reconfigure with software.)

Contact Rating: 1A at 50 Vac/24 Vdc.

Minimum Permissible Load: 1 mA at 5 Vdc.

Linear Analog Output:

Voltage: 0/2-10 Vdc (resistive load greater than

5000 ohms).

Current: 0/4-20 mA (resistive load less than 500 ohms).

Outputs (Jumper Adjustable, see Table 3):

Analog: 0-10 Vdc (Default: 2-10 Vdc, 500 to 1500 ppm).

Relay: Normally Open Spst (Default: Close at 800 ppm).

) sensor with two jumper-adjustable outputs

2

that indicates the current CO

concentration.

2

Underwriters Laboratories Inc. Listed, File No. E4436.

cUL.

C7232B: Flammability Rating, UL94-5V.

C7232A: NEMA1.

C7232B: NEMA3.

1

(25)

5-1/16

(128)

3-5/32 (80)

KNOCKOUTS

FOR

EUROPEAN

APPLICATIONS

2-3/8 (60)

STANDARD

2-3/8

(60)

MOUNTING

CONDUIT

Fig. 9. C7232A dimensions in in. (mm).

3-5/16 (84)

M17592

5-5/8

(142)

1-13/16

(46)

1-5/8

(41)

8 (203)

Fig. 10. C7232B dimensions in in. (mm).

Installation

UTILITY

BOX

(2X4)

HOLES

M17540

Ambient Ratings:

Temperature:

Operating: +32°F to +122°F (0°C to +50°C).

Storage: -4°F to +158°F (-20°C to +70°C).

Relative Humidity (non-condensing): 0 to 95 percent.

CO

Pressure Dependence: 1.4% change in reading per

2

1 kPa deviation from 100 kPa.

Connections:

Wiring:

C7232A: 20-gauge cable with six 8 in. leadwires.

C7232B: 20-gauge cable with six 6 in. leadwires.

Mounting:

C7232A: Vertical surface with standard single-gang junction

box.

C7232B: Sheet metal duct with a sampling tube.

Automatic Background Calibration (ABC) default: On.

Approvals:

CE.

Health Hazard.

Improper use can create dangerous situations.

Use in application for sensing carbon dioxide only.

For life-safety applications, this device can function

only as a secondary or lesser device.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the unit.

7 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

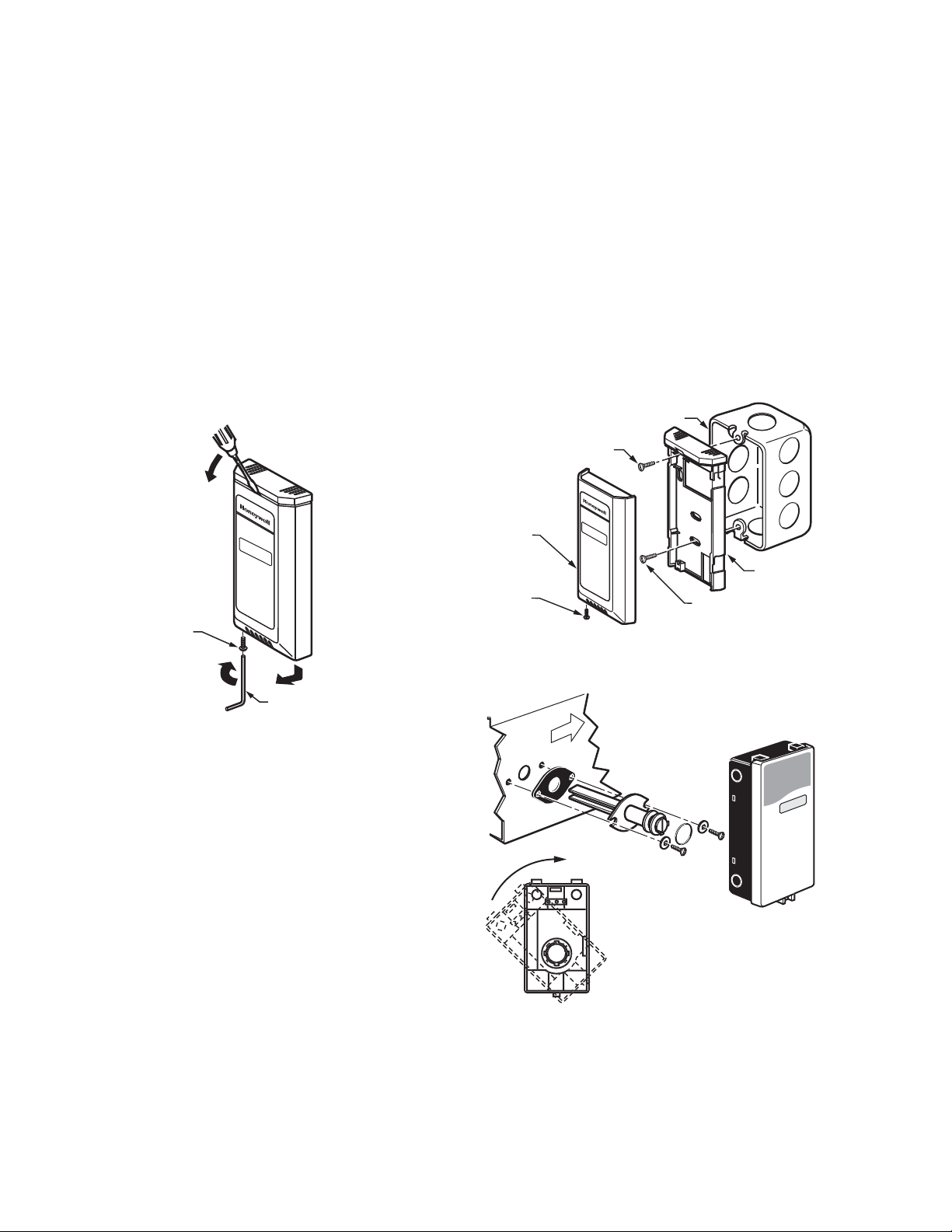

C7232A Cover Removal/Replacement

C7232A COVER REMOVAL (SEE FIG. 11)

1. Remove button head socket cap screw and set it aside.

2. Insert the head of a small screwdriver into the slot at the

center and near the top of the cover.

3. Gently pull the handle down toward the bottom of the

device until a small gap between the subbase and the

cover appears.

4. Remove the screwdriver and pull the cover straight

down until it meets a stop.

5. Pull the cover straight off the subbase.

C7232A COVER REPLACEMENT

1. Feed the wires through the opening in the subbase.

2. Place the cover, with a small gap at the top, flat on top

of the subbase.

3. When the cover rests flat on the subbase, slide it

straight up until it latches in place.

B

NOTE: When mounting on a junction box, see Fig. 12.

3. Replace the cover.

DUCT MOUNTING (SEE FIG. 13)

1. Place gasket on aspiration tube.

IMPORTANT

Ensure largest tab at tube control end is at the top.

2. Insert tube into duct; attach using screws and washers.

IMPORTANT

Leakage into the duct or the C7232 box cover from

the room will skew the sensor readings. Ensure the

box cover and duct seal completely.

3. Place o-ring on tube end; mount the control to the tube.

STANDARD UTILITY CONDUIT BOX

NO. 6 SCREW

FRONT

COVER

BUTTON HEAD

SOCKET CAP

SCREW

A

M17541

C

ALLEN TOOL

Fig. 11. C7232A cover removal.

Location and Mounting

C7232 Sensors mount directly on the wall, sheet metal duct,

or a panel. When planning the installation, allow enough

clearance for maintenance and service. Mount the sensor in a

well-ventilated area.

NOTES: Do not install the sensor where it can be affected by:

WALL MOUNTING

The C7232 Wall Mount models can be mounted using two or

four screws:

— drafts or dead spots behind doors and in corners.

— air from ducts.

1. Remove C7232 cover.

2. Mount the subbase to the wall using washers and two or

four screws (not supplied) appropriate for the wall

material.

BUTTON HEAD

SOCKET CAP

SCREW

NO. 6 SCREW

Fig. 12. Junction box mounting (C7232A).

FLOW

Fig. 13. Duct mounting (C7232B).

SUBBASE

M17542

M17591

63-2576—02 8

SOLID STATE ECONOMIZER SYSTEM

CAUTION

CAUTION

L1

(HOT)

L2

M17543

1

1 POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

C7232

24V

YELLOW

BLACK

RED

BROWN

ORANGE

GREEN

ANALOG

OUT

+

–

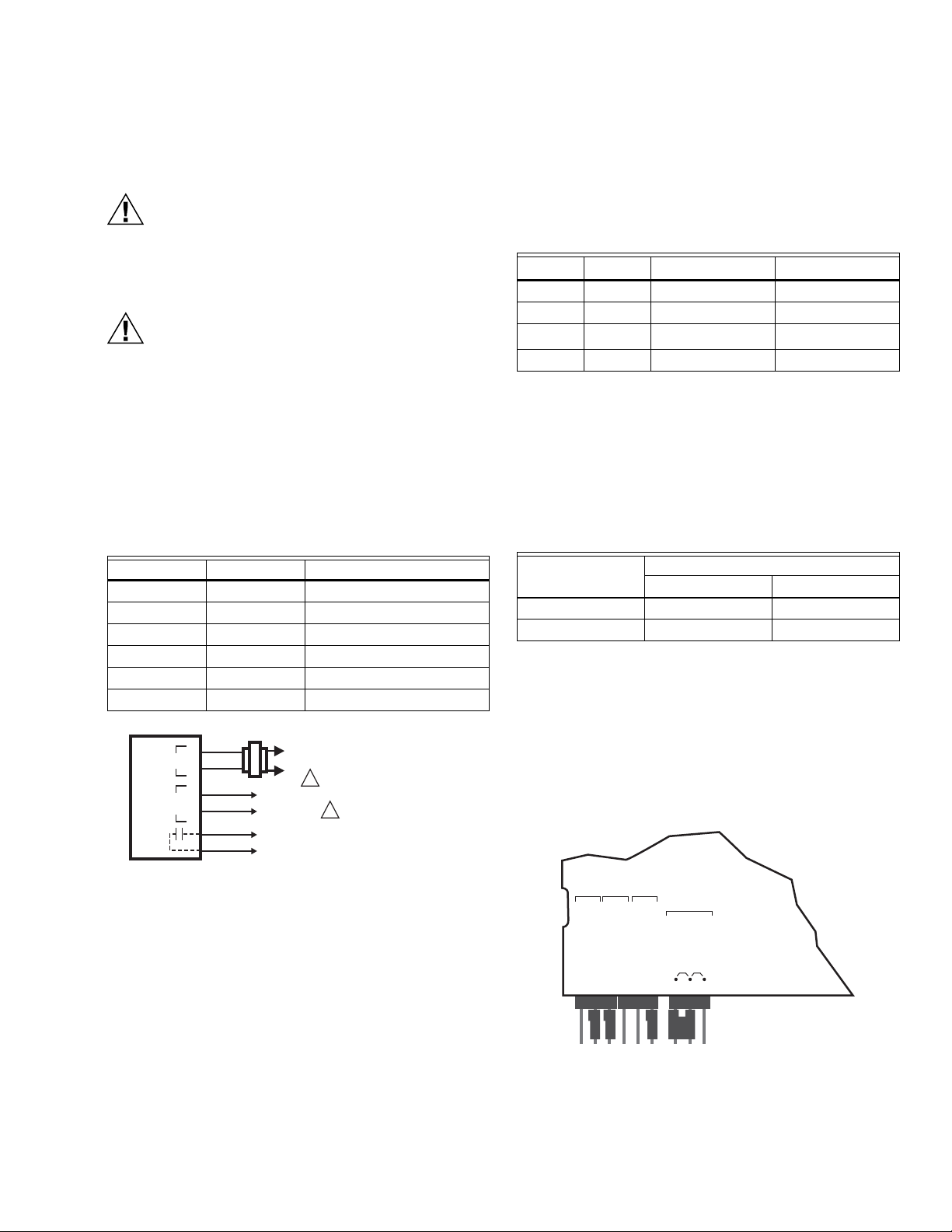

Wiring

The factory ships the device with the output default settings

shown in Table 3 and Table 4. Set the jumpers and wire the

device (see Table 2 and Fig. 14).

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Equipment Damage Hazard.

Electrostatic Discharge Can Short Equipment

Circuitry.

Ensure that you are properly grounded before

handling the unit.

IMPORTANT

1. All low voltage connections to this device must be

24 Vac Class 2.

2. All wiring must comply with applicable local codes,

ordinances and regulations.

Table 2. C7232 Wiring Connections (see Fig. 14).

Wire Color Designation Function

Red G+ 24 Vac Hot

Black G0 24 Vac Common

Yellow OUT1 Analog Output Signal

Brown M Analog Output Common

Orange NO Relay Output Normally Open

Green COM Relay Output Common

Operation

Input Signal

The C7232 Sensors have an adjustable range. These ranges

are determined by the SW1 and SW2 jumper settings

(see Table 3).

Tab l e 3 . C O

SW1 SW2 AN (ppm) Relaya (ppm)

On On 0 to 1000 1000

On Off 0 to 2000 1200

Off

b

On

b

Off Off 500 to 2000 1200

a

When the level reaches this value, the contacts close;

when the level drops 100 ppm below this value, the contacts open.

b

Setting when shipped from the factory.

Output Signal

The output signal can be adjusted for 0/2-10Vdc or 0/4-20mA

(see Table 4).

Table 4. Output Signal Jumper Settings

AN

Voltage 0-10Vdc 2-10Vdc

Current 0-20 mA 4-20 mA

NOTES:

— On duct models, remove the screw holding the

board in place to view jumper settings on reverse.

(See Fig. 15.)

— The CO

are independent of each other. 0-100% and

20-100% are simply markings for the OUT jumper

settings on the sensor (to differentiate between

the two voltage and the two current ranges) and

do not refer to or alter the ppm range chosen.

Range Jumper Settings

2

500 to 1500 800

OUT

0-100% 20-100%

settings and the output signal settings

2

Fig. 14. Wiring the C7232.

SW2SW1 OUT

ON

OFF

ON

OFF

AN

20 – 100%

0 – 100%

Current

Voltage

M19424

Fig. 15. C7232 default jumper settings.

9 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

Example

For a CO2 setting of 0-2000 ppm and a voltage output of 0-10 Vdc, the output would be as shown in Table 5 (arbitrary points

along the analog curve).

Table 5. 0-10 Vdc Output Example.

CO

Level (ppm)

2

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Voltage Output (Vdc)012345678910

For a CO

along the analog curve).

setting of 0-2000 ppm and a voltage output of 2-10 Vdc, the output would be as shown in Table 6 (arbitrary points

2

Table 6. 2-10 Vdc Output Example.

CO

Level (ppm)

2

0 250 500 750 1000 1250 1500 1750 2000

Voltage Output (Vdc) 2 3 4 5 6 7 8 9 10

Calibration

Typically, calibration is unnecessary. No calibration kits are

available. However, if CO

chamber using a general gas purge device, the sensor can be

rezeroed:

gas can be purged from the sensor

2

Checkout

Perform a quick test of the unit with the unit powered:

1. Stand close to the unit and breathe air into the sensor.

2. Check the CO2 level registered by the controller to

ensure a strong rise.

3. When connected to a damper in a ventilation system,

IMPORTANT

Any CO

zero level resulting in incorrect CO

present during calibration skews the sensor

2

level reports.

2

the controller typically signals an increase in air flow.

1. Once the sensor stabilizes, use a screwdriver to

connect the two MENU soldering pads.

2. The display should indicate CAL.

3. Execute the zero calibration by connecting the two

ENTER soldering pads.

4. The display should return to providing the measured

CO

level.

2

63-2576—02 10

SOLID STATE ECONOMIZER SYSTEM

9096

S

9/16

(14)

)

5/16

(8)

3-5/3

(80)

(70)

)

/32

(6)

C7400A AND C7400C SOLID STATE ENTHALPY SENSORS

Specifications

Dimensions: See Fig. 16.

Output Signal: 4 to 20 mA current signal increases from

4 mA to 20 mA as enthalpy decreases.

Ambient Temperature Ranges:

Operating: 32°F to +125°F (0°C to +52°C).

Shipping: -40°F to +150°F (-40°C to +66°C).

Maximum Power Consumption: 0.50 VA at 24 Vdc.

Supply Voltage: 12 to 40 Vdc.

Electrical Connections:

Two 1/4 in. (6 mm) quick connect terminals.

Approvals:

Underwriters Laboratories Inc. Flammability Rating: UL94-5V.

2

2-3/4

— Use the C7400A sensor with economizer logic

modules with A, B, C, and D set points and use

the C7400C sensor with economizer logic modules with A, B, C, D, and E set points.

Operation

The C7400 Solid State Enthalpy Sensor is used with a solid

state economizer logic module and damper actuator to

proportion an outdoor air damper in a ventilation system.

Each enthalpy control setpoint (A, B, C, and D for C7400A

and A, B, C, D, and E for C7400C) combines temperature and

humidity conditions, resulting in the control curve shown in

Fig. 35. When the enthalpy of the outdoor air is below (left of)

the appropriate curve, the outdoor air damper can proportion

open on a call for cooling. If the outdoor enthalpy rises above

(right of) the control curve, the outdoor air damper closes to

the minimum position.

NOTE: Curves illustrate reset in temperature control point

due to changes in relative humidity.

For differential enthalpy, turn the control setpoint to D for

C7400A and to E for C7400C (fully clockwise ):

— If outdoor air enthalpy is lower than return air enthalpy, the

outdoor air damper proportions open on a call for cooling.

— If outdoor air enthalpy is higher than return air enthalpy, the

outdoor air damper closes to minimum position. Differential

enthalpy control provides energy savings and increased

comfort by using the air with the lowest enthalpy.

— If outdoor air enthalpy and return air enthalpy are equal, the

outdoor air damper proportions open on a call for cooling.

7

1 (25

3-7/8 (96

M

Fig. 16. Approximate dimensions of C7400 Solid State

Enthalpy Sensor in in. (mm).

Installation

Location

IMPORTANT

When selecting the location, make sure the C7400

Solid State Enthalpy Sensor is not exposed to rain,

snow or direct sunlight.

NOTES:

— The C7400 Sensor can be mounted in any

position. However, the sensor must be installed

where it is exposed to freely circulating air, but

protected from rain, snow and direct sunlight.

— Differential enthalpy control requires two C7400

Sensors. Mount one sensor in the outdoor intake

duct, the other in the return air duct.

— The C7400 Sensor is designed to operate in

500 ft/min. minimum airflow.

NOTE: The relationship between the C7400A Sensor output

current and relative humidity is shown in Fig. 17.

100

90

80

70

60

50

PERCENT RF

40

30

20

10

40

(4)

C7400A OUTPUT CURRENT

20 mA

1

18 mA

50

(10)

60

(16)

TEMPERATURE F ( C)

12 mA

6 mA

14 mA

70

(21)80(27)

10 mA

8

mA

6

mA

4 mA

90

(32)

100

(38)

M22117

Fig. 17. C7400A Sensor output current vs. RH.

11 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

10

20

30

40

50

60

70

80

90

100

40

(4)

50

(10)

TEMPERATURE ºF ( ºC)

M27816

C7400C SENSOR OUTPUT CURRENT

PERCENT RF

60

(16)70(21)80(27)90(32)

100

(38)

20 mA

18 mA

16 mA

14 mA

12 mA

10 mA

8 mA

6 mA

4 mA

NOTE: The relationship between the C7400C Sensor output

current and relative humidity is shown in Fig. 18.

Fig. 18. C7400C Sensor output vs. RH.

63-2576—02 12

C7632A DCV SENSORS

CAUTION

CAUTION

CAUTION

Specifications

Models: C7632 Sensor and Controller. A stand-alone carbon

dioxide (CO

C7632A: Wall mount model.

C7632B: Duct mount model.

Dimensions:

C7632A: See Fig. 9.

C7632B: See Fig. 10.

) sensor with one 0-10 Vdc analog output.

2

4-1/8

(104)

3-3/8

(86)

SOLID STATE ECONOMIZER SYSTEM

Ambient Ratings:

Temperature:

Operating: +32°F to +122°F (0°C to +50°C).

Storage: -4°F to +158°F (-20°C to +70°C).

Relative Humidity (non-condensing): 0 to 95 percent.

Automatic Background Calibration (ABC) default: On.

Electrical Ratings:

Power Supply: 24 Vac ±20%, 50/60 Hz (Class 2).

Maximum Power Consumption:

Average: 1W.

Peak: 2W.

Peak Current (at 20 ms): 300 mA.

Linear Analog Output: 0-10 Vdc.

Mounting:

C7632A: Vertical surface with standard single-gang junction

box.

C7632B: Sheet metal duct with a sampling tube.

CO

Pressure Dependence: 1.6% change in reading per

2

1 kPa deviation from 100 kPa.

Output: Analog: 0-10 Vdc, 0-2000 ppm (fixed).

Sensor Performance Ratings:

Response Time: 2 min.

Carbon Dioxide Sensor:

Operation: Non-dispersive infrared (NDIR).

Sampling: Diffusion.

Range: 0 to 2000 ppm (fixed).

Annual Drift: ±10 ppm (nominal).

Accuracy: ±(30 ppm+2%) at normal temperature/pressure.

Wiring Connections:

C7632A: Terminal block.

C7632B: 20-gauge cable with three 6 in. leadwires.

2-11/16 (68)

Fig. 19. C7632A dimensions in in. (mm).

3-5/16 (84)

5-5/8

(142)

1-13/16

(46)

1-5/8

(41)

8 (203)

Fig. 20. C7632B dimensions in in. (mm).

Installation

Health Hazard.

Improper use can create dangerous situations.

Use in application for sensing carbon dioxide only.

For life-safety applications, this device can function

only as a secondary or lesser device.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

1-1/16

(27)3-7/8 (99)

M19794

M19795

Approvals:

CE.

Underwriters Laboratories Inc. Listed, File No. E4436.

cUL.

C7632B: Flammability Rating, UL94-5V.

C7632A: NEMA1.

C7632B: NEMA3.

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the unit.

13 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

M19796

C7632A Cover Removal/Replacement

The cover of the C7632A is fixed by a latch on the underside

of the unit.

C7632A COVER REMOVAL (SEE FIG. 11)

1. Unless the device is mounted, hold the base using the

wiring hole and/or the perforated vent.

2. Depress the tab on the underside of the device.

3. Swing the cover away from the base.

4. Lift cover from base.

C7632A COVER REPLACEMENT

1. Place top cover tab over the ridge along the base top.

2. Swing the cover down.

3. Press the lower edge of the case to latch.

Location and Mounting

C7632 Sensors mount directly on the wall, sheet metal duct,

or a panel. When planning the installation, allow enough

clearance for maintenance and service. Mount the sensor in a

well-ventilated area.

NOTES: Do not install the sensor where it can be affected by:

— drafts or dead spots behind doors and in corners.

— air from ducts.

4. Mount the subbase and wallplate to the junction box

using the lower screw.

5. Replace the cover.

DUCT MOUNTING (SEE FIG. 13)

1. Place gasket on aspiration tube.

IMPORTANT

Ensure largest tab at tube control end is at the top.

2. Insert tube into duct; attach using screws and washers.

IMPORTANT

Leakage into the duct or the C7632 box cover from

the room will skew the sensor readings. Ensure the

box cover and duct seal completely.

3. Place o-ring on tube end; mount the control to the tube.

Fig. 21. C7632A cover removal.

WALL MOUNTING (C7632A)

Mount the C7632A to the wall as follows:

1. Remove the C7632 cover.

2. Mount the device in a vertical position.

3. Mount the subbase directly on a wall using the type of

screws (not supplied) appropriate for the wall material.

4. Replace the cover.

JUNCTION BOX MOUNTING (FIG. 12)

Mount the C7632A to a junction box as follows:

1. Attach the wallplate using only the top screw.

2. Remove the C7632 cover.

3. Place the subbase on the wallplate hook.

M19797

Fig. 22. Junction box mounting (C7632A).

FLOW

M19798

Fig. 23. Duct mounting (C7632B).

63-2576—02 14

SOLID STATE ECONOMIZER SYSTEM

CAUTION

CAUTION

Wiring (Fig. 14)

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Equipment Damage Hazard.

Electrostatic Discharge Can Short Equipment

Circuitry.

Ensure that you are properly grounded before

handling the unit.

IMPORTANT

1. All low voltage connections to this device must be

24 Vac Class 2.

2. All wiring must comply with applicable local codes,

ordinances and regulations.

Table 7. C7632 Wiring Connections (see Fig. 14).

Designation C7632B Wire Color Function

G+ Red 24 Vac

G0 Black Common

CO

2

C7632

G0 CO

Brown Analog Output Signal

L1

(HOT)

L2

G+

2

1

Calibration

Typically, calibration is unnecessary. No calibration kits are

available. However, if CO

desirable level, the sensor can be reset using either zero or

background calibration:

IMPORTANT

• With zero calibration, all CO

calibration skews the sensor zero level.

• Using background calibration, practical operation

(with a higher than zero level set) can be obtained.

Zero Calibration

1. Remove the sensor cover and set it aside.

2. Apply a steady flow of CO

minute into the gas inlet tube located on the gold sensor.

3. Execute calibration by shorting the proper two soldering

pads (see Fig. 25).

NOTE: The device should now provide accurate out-

put.

4. Check the output signal. (See “Checkout” on page 16.)

5. Reinstall the device.

Background Calibration

1. Remove the sensor cover and set it aside.

2. Ventilate the area and reduce occupancy to lower the

CO

levels.

2

3. Maintain a reasonable proximity from the sensor to

avoid breathing on it, thus skewing calibration accuracy.

4. Keep the sensor in this environment for three to four

minutes.

5. Execute calibration by shorting the proper two soldering

pads (see Fig. 25).

levels can be brought to a

2

present during

2

-free gas at 0.1 to 0.5 liter per

2

0-10 Vdc

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

Fig. 24. Wiring the C7632.

Output (Table 5)

Table 8. 0-10 Vdc Output Signal.

CO

2

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Level

(ppm)

Voltage

Output

012345678910

(Vdc)

M19799

NOTE: The device should now provide accurate out-

put.

6. Check the output signal. (See “Checkout” on page 16.)

7. Reinstall the device.

ZERO

CALIBRATION

BACKGROUND

CALIBRATION

M19856

Fig. 25. C7632 calibration pads.

15 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

Checkout

Perform a quick test of the unit with the unit powered:

1. After calibration:

a. Check output signal immediately following proper

calibration (with minimum environmental change):

(1) Proper zero calibration: 0 Vdc.

(2) Typical background calibration: 2 Vdc. Depending

on ambient CO

level, range: 1.75 to 2.5 Vdc.

2

b. If the output is incorrect, repeat calibration

procedure.

c. Otherwise, continue with checkout.

2. Stand close to the unit and breathe air into the sensor.

NOTE: When connected to a damper in a ventilation

system, breathing on the sensor typically

signals an increase in air flow.

3. Check the output to ensure a strong rise in CO2 level.

63-2576—02 16

C7660 SOLID STATE TEMPERATURE SENSOR

9096

S

9/16

(14)

)

5/16

(8)

3-5/3

(80)

(70)

)

/32

(6)

Specifications

Dimensions: See Fig. 26.

Case: Duct mount.

Temperature Sensing Element: Thermistor.

Output Signal:

4 mA not OK to economize or 20 mA OK to economize.

Operating Ambient Temperature Range:

+40°F to +100°F (+4°C to +38°C).

Shipping Temperature Range:

-40°F to +150°F (-40°C to +66°C).

Maximum Power Consumption: 0.45 VA.

Supply Voltage: 15 to 23 Vdc.

Electrical Connections:

Two 1/4 in. (6.5 mm) quick connect terminals.

Approval:

Underwriters Laboratories Inc. Flammability Rating: UL94-5V.

Installation

Location

The C7660 Temperature Sensor can be mounted in any

position as long as the air flow through the device is linear and

is in the air intake of the unit. However, the sensor must be

installed where it is exposed to freely circulating air, but

protected from rain and direct sunlight.

SOLID STATE ECONOMIZER SYSTEM

2

2-3/4

7

1 (25

3-7/8 (96

M

Fig. 26. C7660 Thermistor Temperature Sensor

Dimensions in in. (mm).

The C7660 is designed to operate in 500 ft/min minimum

airflow.

Control Dial Setting

Control setpoint scale is located on the cover of the logic

module. Control point is selected by selecting one of the 8

change over temperatures. Adjust the dip switch on the device

to match the temperature setting required for change over.

The economizer will economize 1°F below the setpoint and

will not economize 1°F above the setpoint providing a 2

degree total hysteresis.

17 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

M7215 DAMPER MOTORS

Specifications

25 lb-in. (2.8 N•m) torque, foot-mounted spring-return damper

motor with 2-10 Vdc feedback signal. Accepts 2-10 Vdc

control signal.

Dimensions: See Fig. 27.

Electrical Ratings:

Supply Voltage: 24 ±6 Vac 50/60 Hz.

Power Consumption:

24 Vac, 60 Hz: 8.7 VA.

24 Vac, 50 Hz: 8.4 VA.

Torque:

Lift and Hold: 25 lb-in. (2.8 N•m).

Spring Return: 25 lb-in. (2.8 N•m).

Breakaway: 40 lb-in (4.5 N•m).

IMPORTANT

Never use motor continuously at the breakaway

torque rating.

NOTE: NOTE:Breakaway torque available to overcome

occasional large loads such as a seized damper.

Stroke:

Travel: 90°.

Timing:

Driving: 86 ±5 seconds.

Spring Return: 13 ±5 seconds.

Motor Rotation (Viewed From Shaft End):

Closed Position: Limit of clockwise rotation.

Open Position: Limit of counterclockwise rotation.

Crank Arm Rotation Limits: See Fig. 28.

Shipped with shaft in closed position.

Ambient Ratings:

Temperature:

Operating: -25°F to +125°F (-32°C to +52°C).

Storage: -30°F to +150°F (-34°C to +66°C).

Humidity: 5 to 95 percent relative humidity, noncondensing.

Terminal Connections: 1/4 in. (6 mm) quick-connect

terminals mounted on motor.

Shaft: Single-ended drive shaft with crank arm supplied.

Reliability:

Full-Stroke Cycles: 60,000.

Repositions: 1,500,000.

Approvals:

Underwriters Laboratory Inc.:

Flammability Rating: UL94-5V.

Component Recognized: File No. E4436, Guide No.

XAPX2, Vol. 9, Section 1, 7-25-83.

7/16

(11)

4-1/2 (114)

4-1/32

(102)

4-1/2

(114)

2-1/4 (57)

3-1/2 (89)

5-3/16 (132)

TOP VIEW SIDE VIEW POWER END VIEW

1-1/4

(32)

5

(127)

4-1/2

(114)

Fig. 27. M7215 Damper Motor dimensions in in. (mm).

1/4 (6)

1-3/8 (35)

3-1/8 (79)

M3851

63-2576—02 18

Fig. 28. Limits of crank arm rotation.

CAUTION

CAUTION

CAUTION

1

1

CRANK ARM FIELD ADJUSTABLE IN 7.5 DEGREE INCREMENTS.

MOTOR MOUNTING SURFACE

M3850

MAXIMUM

OPEN

POSITION

MAXIMUM

CLOSED

POSITION

Installation

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Personal Injury Hazard.

Spring-return assembly can release.

Leave end covers attached to the motor.

Location and Mounting

Locate motor as close as possible to the equipment to be

controlled. Refer to Fig. 27 for mounting dimensions.

1. Mount motor with the shaft horizontal to ensure

maximum life.

NOTE: Operation in other positions is possible when

required by the application.

2. Remove crank arm (secured with two screws) from the

motor hub.

IMPORTANT

Position crank arm on hub so it does not strike motor

mounting surface during any portion of full stroke.

See Fig. 28.

3. Reposition the crank arm to accommodate specific

damper requirements.

NOTE: Crank arm position is adjustable in eight

degree increments.

SOLID STATE ECONOMIZER SYSTEM

4. Reconnect crank arm to the motor hub.

5. If there is an excess length of linkage rod, cut it to size.

Make necessary minor adjustments until desired

operation is obtained.

6. Tighten all nuts and set screws.

Wiring

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

The M7215 Damper Motor accepts input from a 2-10 Vdc

controller. The motor can be checked out either directly or by

using a controller.

IMPORTANT

1. If necessary, release one of the previously tightened

linkage connections to prevent damage.

2. Check for proper operation, making sure that the linkage does not bind and that the motor travels smoothly

throughout its cycle from fully open to fully closed.

NOTES: This motor checkout assures that:

1. The motor operates the load.

2. The motor responds properly to the controller.

3. There is no linkage binding or motor stalling at

any point of travel.

4. If questions arise regarding this product, contact

your distributor or local Honeywell representative.

Direct Checkout

1. Mount the motor for the required application.

2. Check the damper position and make sure 24 Vac is

present across TR and TR1.

3. Apply 10 Vdc to IN+ and IN- to move damper to the

opposite position. The motor should drive the damper.

4. If the motor does not run, verify that the motor and crank

arm are properly installed for either clockwise or

counterclockwise rotation.

5. If installation is correct, but the motor does not run,

replace the motor.

Controller Checkout

1. Adjust controller setpoint to call for cooling. Observe the

motor.

2. If the damper is closed, it should begin to open.

3. If the damper remains closed, move controller setpoint

farther below room temperature.

4. If the damper still does not move, check for the

presence of 24 Vac in the input.

5. If 24 Vac is present and motor does not operate, reverse

controller leadwires to determine if device was miswired.

6. If the wiring is correct and 24 Vac is present on the input

terminals but the motor does not run, replace the motor.

19 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

CAUTION

W7212, W7213, W7214 LOGIC MODULES

Specifications

For use with any Honeywell 2-10 Vdc actuator; includes DCV

input; adjustable exhaust fan setpoint.

4-3/8 (112)

NOTES:

— All models include a minimum damper position

potentiometer, and setpoints for: enthalpy or

dry-bulb, occupied/unoccupied control, DCV

operation, and DCV maximum.

— Occupied/Unoccupied overrides minimum

damper position setting when building is

unoccupied.

Dimensions: See Fig. 29.

Electrical Ratings:

Input Voltage: 24 Vac ±20%; 50/60 Hz (Class 2).

Nominal Power Consumption (at 24 Vac, 60 Hz): 11.5 VA.

Relay Contact Rating at 30 Vac (maximum power from class 2

input only): 1.5A run, 3.5A inrush.

IMPORTANT

All inputs and outputs must be 24 Vac Class 2.

Ambient Ratings:

Temperature: -40°F to +149°F (-40°C to +65°C).

Humidity: 5 to 95 percent rh (noncondensing).

Inputs:

Enthalpy (C7400): 2-wire (18,20,22 AWG) connection.

Dry Bulb Temperature (C7660): 2-wire (18,20,22 AWG)

connection.

Discharge Air (C7046): 2-wire (18,20,22 AWG) connection.

Mixed Air (C7150): 2-wire (18,20,22 AWG) connection.

DCV Sensor (C7232): 0/2-10 Vdc control signal;

100K ohm input impedance.

Outputs:

Actuator Signal: 2-10 Vdc.

Minimum Actuator Impedance: 1K ohm.

Exhaust Fan: Contact closure.

24 Vac Out: 25 VA maximum.

1-5/8

(41)

2-1/16

(53)

1-15/16

(49)

4-1/8

(104)

1/8 (4)

2-5/8 (66)

M20578A

Fig. 29. Logic module dimensions in in. (mm).

Installation

Location and Mounting

The logic modules mount on a sheet metal duct or panel.

When planning the installation, allow enough clearance for

maintenance and service (see Fig. 29 for dimensions). Mount

device in a location protected from rain, snow, and direct

sunlight. Secure device to sheet metal using the two supplied

mounting screws, see Fig. 31.

Approvals:

Underwriters Laboratories Inc.: UL873 listed.

Flammability Rating: UL94-5VB.

Plenum Rated.

CE.

C-tick.

63-2576—02 20

Equipment Damage Hazard.

Mounting screws longer than 5/8 in. can damage

internal motor components.

When mounting the module to an M7215 use only the

included #6 5/8 in. thread-forming screw.

NOTE: See Fig. 32 for representative locations of connected

system devices.

CAUTION

M7215 DAMPER MOTOR

5/8

.

M20601

W7212

ECONOMIZER

LOGIC MODULE

Fig. 30. Direct mounting of module.

INCH SCREW INCLUDED WITH LOGIC MODULE

M20717A

SOLID STATE ECONOMIZER SYSTEM

Wiring

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

1. All wiring must comply with applicable local codes,

ordinances and regulations.

2. All device inputs and outputs must be 24 Vac Class 2.

3. Ensure proper polarity of sensor connections.

Incorrect polarity negates the sensor signal.

C7400 Enthalpy Sensor and C7660 Dry

Bulb Temperature Sensor

W7212, W7213, W7214 Logic Modules accept signals from

either the C7400 Enthalpy Sensor or the C7660 Dry Bulb

Temperature Sensor. The wiring is the same for either sensor.

IMPORTANT

When using differential sensing, both sensors must

be of the same type (enthalpy or dry bulb).

Fig. 31. Mounting the module on sheet metal.

Only use enthalpy with differential enthalpy, the

C7660 is not designed for differential dry bulb and

the system will not work.

Outdoor Air Sensing

1. Mount sensor in any orientation exposing it to freely

circulating air while protecting it from rain, snow, and

direct sunlight.

2. Connect it to the SO and SO+ terminals of the device.

Return Air Sensing

1. Ensure differential enthalpy control has a second

sensor in the return air duct. Differential dry bulb cannot

be used with the C7660 sensor.

2. Connect this sensor to the SR and SR+ terminals.

Demand Control Ventilation

The DCV can be any sensor that provides a 0/2-10 Vdc

output. The DCV modulates the outdoor damper to provide

ventilation based on occupancy. The designer determines

contaminants to monitor, selects appropriate sensor,

determines the sensor threshold, and adjusts the DCV

potentiometer accordingly. The DCV LED lights when the

DCV signal is above setpoint. Mount the sensor according to

the manufacturer specifications. If not available, use the

following guidelines:

1. Mount sensor in an area with unobstructed air

circulation.

2. Connect it to the AQ

(see “Wiring” on page 21 for details).

3. Adjust the DCV potentiometer setpoint to correspond to

DCV voltage output at the threshold.

and AQ1 terminals of the W7212

21 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

DISCHARGE

AIR SENSOR

C7046A

DIRECT

EXPANSION

COIL

C7400

ENTHALPY

SENSOR

C7400

C7232

ENTHALPY

SENSOR

RETURN AIR

OUTDOOR

AIR

C7150B

MIXED AIR

SENSOR

SPACE

THERMOSTAT

FOR DIFFERENTIAL ENTHALPY, THE TWO C7400

ENTHALPY SENSORS ARE CONNECTED TO THE

ECONOMIZER LOGIC MODULE —ONE

IS MOUNTED IN RETURN AIR, AND THE OTHER IS

MOUNTED IN OUTDOOR AIR.

USE EITHER MIXED AIR SENSOR OR DISCHARGE

AIR SENSOR, NOT BOTH.

M19547A

1

1

1

2

2

2

HONEYWELL

ACTUATOR

W7212,

W7213,

W7214

DCV

SENSOR

EXHAUST AIR

DISCHARGE

AIR

INDOOR

FAN

EXHAUST

FAN

Fig. 32. Representative locations of connected economizer system devices.

Optional Applications

HEAT PUMP CHANGEOVER (W7213, W7214 ONLY)

In heat pump applications, the controller must have control of

the changeover valve. To provide the logic module with the

information necessary for proper information, there must be a

connection to the logic module O/B terminal. This terminal

alerts the logic module as to when the system operates in

cooling (the only time the economizer is used).

W7213 (Changeover Terminal B)

Connect the B terminal according to the following details:

— 24V power to B: System is in heating mode, free cool

disabled.

— No power to B: System is in cooling mode, free cool

available. Actuator operates according to W7213

Economizer logic. (See Table 9 for logic details.)

W7214 (Changeover Terminal O)

Connect the O terminal according to the following details:

— No power to O: System is in heating mode, free cool

disabled.

— 24V power to O: System is in cooling mode, free cool

available. Actuator operates according to W7214

Economizer logic. (See Table 9 for logic details.)

REMOTE MINIMUM POSITION CONTROL

Remote control of outdoor air dampers is desirable when

requiring temporary additional ventilation. The addition of a

S963B1128 Remote Potentiometer allows occupants to open

or close the dampers beyond minimum position for modified

ventilation. Connect the potentiometer as shown in Fig. 33.

63-2576—02 22

IMPORTANT

— The minimum position signal takes priority over the

DCV maximum position signal. With DCV maximum

set below the minimum, the logic module signals the

actuator to maintain the minimum position.

— Freeze protection logic takes priority over all signals.

For details, see the notes in the “Adjusting Minimum

and Maximum Positions” on page 24.

NOTE: For additional wiring applications, refer to the Design

and Application Guide for Honeywell Economizers

(form 63-8594).

The purpose of the economizer is to use outdoor air for

cooling, whenever possible, to reduce compressor operation.

When wired as shown in Fig. 37, the logic module responds to

the cooling thermostat signal. This system uses C7400 Solid

State Enthalpy Changeover Sensor(s) or C7660 Dry Bulb

Temperature Sensor. The C7400 responds to both dry bulb

temperature and humidity, allowing use of outdoor air at

higher temperatures for free cooling when humidity is low. The

C7660 responds only to dry bulb temperature; use only in dry,

arid climates for single dry bulb changeover only.

The logic module functions as a true first stage of cooling

providing maximum energy economy during the cooling cycle.

It automatically locks out free cooling during heating; holding

the outdoor air damper at the minimum position setting.

NOTE: When module is operating in Occupied mode, the

minimum position is defined by the potentiometer.

When the module is operating in Unoccupied mode,

the minimum position is fully closed.

The logic module can operate as either a basic free cooling

controller, or it can incorporate additional functions. Table 9

details the input/output (I/O) logic of the module.

S963B1128 REMOTE

POTENTIOMETER

R

CW

CLOSE

W

SOLID STATE ECONOMIZER SYSTEM

MINIMUM

P

POSITION

ADJUSTMENT

CW

P1

B

ECONOMIZER

Fig. 33. S963B1128 Remote Potentiometer used with

logic module for remote damper control.

Table 9. W7212 Economizer I/O Logic.

INPUTS OUTPUTS

DCV

Below set

(DCV LED Off)

Enthalpy

Outdoor Return 1 2 Occupied

High

(Free Cooling LED Off)

Low

(Free Cooling LED On)

a

Y1bY2

Low On On On On Minimum position Closed

On Off On Off

High On On On Off

On Off Off Off

Compressor Damper

b

c

Modulatingd

(between min. position

and full-open)

Above set

(DCV LED On)

High

(Free Cooling LED Off)

Low On On On On

On Off On Off

Modulating

(between min. position

e

and DCV maximum)

Low

(Free Cooling LED On)

a

For single enthalpy control, the module compares outdoor enthalpy to the ABCD setpoint.

b

If both stages of cooling are off, the system is off and the damper is at:

High On On On Off

On Off Off Off

Modulating

f

• Minimum position if DCV is below setpoint and system is Occupied.

• Closed if DCV is below setpoint and system is Unoccupied.

• Modulating if DCV is above setpoint.

c

Power at N terminal (relative to TR1) determines Occupied/Unoccupied setting:

• W7212: 24 Vac (Occupied), no power (Unoccupied).

• W7213,W7214: No power (Occupied), 24 Vac (Unoccupied).

d

Modulation is based on the mixed air sensor signal.

e

Modulation is based on the DCV signal.

f

Modulation, based on the greater of DCV and mixed air sensor signals, between minimum position and either

maximum position (DCV) or fully open (mixed air signal).

g

Modulation, based on the greater of DCV and mixed air sensor signals, between closed and either

maximum position (DCV) or fully open (mixed air signal).

M20603A

Unoccupied

c

Modulatingd

(between closed and

full-open)

Modulatinge

(between closed and

DCV maximum)

Modulating

g

NOTES:

— DCV and Free Cooling have setpoints and LED indications.

— For models with a B terminal (W7213):

No power to B: cooling mode, free cool enabled. Module follows logic detailed above.

24V power to B: heating mode, free cool disabled. Actuator drives to minimum position (closed when Unoccupied).

— For models with an O terminal (W7214):

24V power to O: cooling mode, free cool available. Module follows logic detailed above.

No power to O: heating mode, free cool disabled. Actuator drives to minimum position (closed when Unoccupied).

23 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

TOOA×()TRRA×()+ TM=

0.1 60°F×()0.9 75°F×()+ 6.0°F 67.5°F+ 73.5°F==

Settings and Adjustments

Potentiometers with screwdriver adjustment slots, located on

device face, provide adjustments for several parameters

(see Fig. 34 for locations on device):

— DCV setpoint.

— Minimum damper position.

— Maximum damper position.

— Enthalpy changeover.

— Exhaust setpoint.

Demand Control Ventilation Setpoint

The logic module modulates the outdoor damper to provide

ventilation based on the 0/2-10 Vdc DCV. With no cooling

signal, the DCV overrides the outdoor air damper when

ventilation requires outdoor air.

EXHAUST

FAN SETPOINT

LED LIGHTS

WHEN EXHAUST

CONTACT IS MADE

MINIMUM DAMPER

POSITION SETTING

MAXIMUM DAMPER

DEMAND CONTROL

VENTILATION SETPOINT

LED LIGHTS WHEN

DEMAND CONTROL

VENTILAION INPUT

IS ABOVE SETPOINT

DEMAND CONTROL

VENTILAION SETPOINT

LED LIGHTS WHEN

OUTDOOR AIR IS

SUITABLE FOR

FREE COOLING

CHANGEOVER SETPOINT

ENTHALPY

AQ1

SO+

SR+

N1

N

P1

P

T1

T

AQ

SO

SR

Fig. 34. Potentiometer and LED locations.

Adjusting Minimum and Maximum

Positions

The minimum position potentiometer maintains the minimum

outdoor air flow into the building during occupied period. The

DCV maximum position potentiometer allows the installer to

limit the amount of outdoor air flow into the building when the

DCV overrides the mixed air sensor. Setting the DCV

maximum position of the damper prevents the introduction of

large amounts of hot or cold air into the space.

EXH

DCV

Free

Cool

EXH

Set

10V

2V

Min

Pos

Open

DCV

Max

10V

2V

DCV

Set

2V

10V

C

B

D

A

M20604

MINIMUM POSITION ADJUSTMENT

For detailed assistance in minimum position selection

reference the Economizer Application Guide (form 63-8594)

Ventilation section. The following provides basic guidelines for

minimum position selection and adjustment:

IMPORTANT

Adjust the minimum position potentiometer to allow

the minimum amount of outdoor air, as required by

local codes, to enter the building.

NOTE: Make minimum position adjustments with at least a

10°F [6°C] temperature difference between outdoor

and return air.

1. Calculate the appropriate mixed air temperature, see

Equation 1. Formula to aid minimum position adjustment.

2. Disconnect mixed air sensor from terminals T and T1.

3. Ensure that either the factory-installed jumper is in place

across terminals P and P1 or, of remote damper position is required, that it is wired according to Fig. 33 and

turned fully clockwise.

4. Connect 24 Vac across terminals TR and TR1.

5. Carefully adjust the potentiometer on the face of the

device with a small screwdriver until the mixed air

temperature reaches the calculated value.

NOTE: Ensure that the sensed air is well mixed.

Equation 1. Formula to aid minimum position adjustment.

Where:

T

= Outdoor air temperature

O

OA = Percent of outdoor air

T

= Return air temperature

R

RA = Percent of return air

TM = Resulting mixed air temperature

IMPORTANT

This procedure requires use of a quality thermometer

capable of reading to 0.5°F [0.25°C].

NOTE: The following sample calculation uses only

Fahrenheit temperature.

EXAMPLE: Assume local codes require 10% outdoor air

during occupied conditions, outdoor air is 60°F

and return air is 75°F. Under these conditions,

what is the temperature of the mixed air?

IMPORTANT

With the DCV maximum position set below the

minimum position, the minimum position overrides

the maximum position (negating most DCV functions

of the logic module, as the damper cannot move).

NOTES:

— When the mixed air sensor takes control, it

overrides the DCV maximum position

potentiometer.

— If the mixed air temperature drops to 45°F, the

mixed air sensor overrides the DCV and fully

closes the damper to protect from freezing the hot

or chilled water coils. Control returns to normal

once the mixed air temperature rises to 48°F.

63-2576—02 24

Mixed air will be 73.5°F when OA is 60°F and RA is 75°F with

10 percent outdoor air entering the building.

DCV MAXIMUM POSITION ADJUSTMENT

1. Disconnect mixed air sensor from terminals T and T1

and short terminals T and T1.

2. Connect a jumper between terminals AQ and SO+.

3. Connect 24 Vac across terminals TR and TR1.

4. Adjust the potentiometer on the face of the device with a

screwdriver for desired maximum position.

SOLID STATE ECONOMIZER SYSTEM

Enthalpy Changeover

OUTDOOR ENTHALPY CHANGEOVER SETPOINT

(SINGLE ENTHALPY)

The outdoor enthalpy changeover setpoint returns the outdoor

air damper to minimum position when enthalpy rises above its

setpoint. Enthalpy setpoint scale markings, located in the

device, are A, B, C, and D. See Fig. 35 for the corresponding

control point. The factory-installed 620-ohm jumper must be in

place across terminals SR and SR+.

DIFFERENTIAL ENTHALPY CHANGEOVER SETTING

Differential enthalpy control uses two C7400 Enthalpy

Sensors connected to one logic module. The logic module

compares outdoor air to return air instead of to a setpoint as it

does for single enthalpy.

NOTE: Turn the setpoint potentiometer fully clockwise to the

D or E setting.

CONTROL

CURVE

A

B

C

D

CONTROL POINT

APPROX. °F (°C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

The logic module selects the lower enthalpy air (return or

outdoor) for cooling. For example, when outdoor air has lower

enthalpy than return air, the outdoor air damper opens to bring

in outdoor air for free cooling.

Exhaust Setpoint

The exhaust setpoint determines when the exhaust fan runs

based on damper position. When the exhaust fan call is

made, the module provides a 60 ±30 second delay before

exhaust fan activation. This delay allows the damper to reach

the appropriate position to avoid unnecessary fan overload.

NOTE: EF and EF1 are dry contacts only. An external line

voltage contactor is required to operate the exhaust

fan.

Adjustable Exhaust Setpoint

These logic modules have an adjustable setpoint. This

potentiometer allows the installer to set the exhaust setpoint

at an actual damper position percentage open from fully

closed.

75

(24)

80

(27)

85

(29)90(32)95(35)

100

(38)

105

(41)

110

(43)

70

(21)

100

90

65

55

C

55

(13)

60

(16)

B

60

(16)

(18)

A

(18)

ENTHALPY—BTU PER POUND DRY AIR

(13)

50

(10)

45

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46

40

(4)

35

(2)

35

40

(2)

(4)

D

(7)

45

50

(7)

(10)

80

70

60

50

A

B

C

D

65

70

75

(24)

80

(27)

(21)

APPROXIMATE DRY BULB TEMPERATURE— °F (°C)

1

HIGH LIMIT CURVE FOR W6210D, W7210D, W7212, W7213, W7214.

RELATIVE HUMIDITY (%)

40

30

1

85

(29)90(32)95(35)

20

100

(38)

105

(41)

M11160B

10

110

(43)

Fig. 35. Partial psychrometric chart with single C7400A Solid State Enthalpy Sensor and

W7212 Solid State Economizer Logic Module performance curves.

25 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

85

(29)

90

(32)

95

(35)

100

(38)

105

(41)

110

(43)

CONTROL

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

CURVE

A

B

C

D

E

CONTROL POINT

APPROX. °F (°C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

55 (13)

ENTHALPY—BTU PER POUND DRY AIR

45

(7)

40

E

(4)

40

(4)

45

(7)

35

(2)

35

(2)

50

(10)

50

(10)

44 46

75

(24)

70

(21)

100

90

55

(13)

60

(16)

B

A

65

(18)

80

C

D

D

E

55

60

65

(13)

(16)

(18)

70

(21)

APPROXIMATE DRY BULB TEMPERATURE— °F (°C)

1

HIGH LIMIT CURVE FOR W7210D, W7212, W7213, W7214, W7340C.

75

(24)

70

C

80

(27)

60

B

(27)

80

50

A

85

(29)

40

1

RELATIVE HUMIDITY (%)

30

90

95

(32)

(35)

20

100

(38)

105

(41)

M23879A

10

110

(43)

Fig. 36. Partial psychrometric chart with single C7400C Solid State Enthalpy Sensor and W7212 Solid State Economizer

Logic Module performance curves.

63-2576—02 26

C7400

OUTDOOR

AIR

ENTHALPY

SENSOR

+

S

C7150B MIXED

AIR OR C7046A

DISCHARGE

AIR SENSOR

0/2-10 VDC

INDOOR AIR

SENSOR

SOLID STATE ECONOMIZER SYSTEM

TR1

HOT

TR

24

24 Vac

Vac

COM

ñ+

24 VAC HOT

24 VAC COM

2-10 VDC CONTROL

SIGNAL INPUT

21

5

4

3

EF

EF1

M7215

5

L1

(HOT)

L2

EXHAUST

FAN

N1

N

P1

P

T1

T

ñ

+

AQ1

SO+

SR+

AQ

SO

SR

3

620 OHM

RESISTOR

MINIMUM POSITION

ADJUSTMENT

W7212

W2

W1

RH

Y1

Y2

A3

A2

4

G

Y1

Y2

W2

W1

A3

A2

C

COOL 1

COOL 2

HEAT 2

HEAT 1

G

FAN

RC

X

T7300/Q7300

THERMOSTAT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

ENSURE THAT TRANSFORMER IS SIZED TO HANDLE THE EXTRA LOAD OF THE ECONOMIZER AND ACTUATOR.

3

FACTORY INSTALLED 620 OHM, 1 WATT, 5% RESISTOR SHOULD NOT BE REMOVED. DIFFERENTIAL ENTHALPY NOT RECOMMENDED FOR USE

WITH SINGLE-STAGE COOLING SYSTEMS OR SINGLE-STAGE COOLING THERMOSTATS.

T7300 TERMINALS A1 AND A3 ARE CONNECTED WHEN THERMOSTAT IS IN THE UNOCCUPIED MODE.

4

EF AND EF1 ARE DRY CONTACTS IN THE LOGIC MODULE.

5

R

HVAC EQUIPMENT

TERMINAL STRIP

Fig. 37. W7212 used with M7215 Damper Motor.

2

L2

L1

(HOT)

M20716B

1

27 63-2576—02

SOLID STATE ECONOMIZER SYSTEM

CAUTION

Checkout and Troubleshooting

Checkout requires a 9V battery, 620 ohm, 1.2K ohm,

5.6K ohm, and 6.8K ohm resistors. Use Table 10 and Fig. 38

for checkout.

Equipment Damage Hazard.

Excessive force can damage potentiometer

controls.

Use a small screwdriver when adjusting enthalpy

changeover and minimum damper position controls.

1

DC VOLTMETER

+

–

S

C7400

+

1

INSERT DC VOLTMETER BETWEEN AQ AND AQ1 FOR

CHECKOUT AND TROUBLESHOOTING.

2

JUMPER USED FOR SINGLE ENTHALPY CONTROL.

W7212

N1

N

P1

P

T1

T

AQ1

AQ

SO+

SO

SR+

SR

2

620 OHM RESISTOR

Free

Cool

2V

EXH

2V

DCV

2V

B

A

Fig. 38. Meter location for checkout and troubleshooting.

Table 10. Checkout for W7212 Economizers Connected to Honeywell Actuator.

Step Checkout Procedure Proper Response

1. CHECKOUT PREPARATION

Disconnect power at TR and TR1. All LED are off; Exhaust Fan contacts are open.

Disconnect devices at P and P1.

Jumper P to P1.

Place 5.6K ohm resistor across T and T1.

Jumper TR to 1.

W7212 only: Jumper TR to N.

If connected, remove C7400 Enthalpy Sensor from terminals S

Connect 1.2K ohm 4074EJM Checkout Resistor across terminals S

Put 620 ohm resistor across S

and +.

R

and +.

O

and +.

O

Set minimum position, DCV, and Exhaust potentiometers fully CCW.

Turn DCV maximum position potentiometer fully CW.

Set enthalpy potentiometer to D.

W7214 only: Jumper TR to O.

Apply power (24 Vac) to terminals TR and TR1.

2. DIFFERENTIAL ENTHALPY

Execute step one, Checkout Preparation. —

Place 620 ohm resistor across S

and +. —

O

Place 1.2K ohm resistor across SR and +. Free cool LED turns on.

Remove 620 ohm resistor from S

and +. Free cool LED turns off.

O

3. SINGLE ENTHALPY

Execute step one, Checkout Preparation. —

Set enthalpy potentiometer to A (fully CCW). Free cool LED turns on.

Set enthalpy potentiometer to D (fully CW). Free cool LED turns off.

Open

EXH

10V

DCV

10V

DCV

10V

Set

Min

Pos

Max

Set

C

D

M20612

63-2576—02 28

SOLID STATE ECONOMIZER SYSTEM

Table 10. Checkout for W7212 Economizers Connected to Honeywell Actuator. (Continued)

Step Checkout Procedure Proper Response

4. DCV AND EXHAUST

Execute step one, Checkout Preparation. —

Ensure terminals AQ and AQ1 are open. LED for both DCV and Exhaust should be off.

Actuator drives fully closed.

Connect 9V battery positive to AQ and negative to AQ1. LED for both DCV and Exhaust turn on.

Actuator drives 90 to 95 percent open.

Turn Exhaust potentiometer CW until Exhaust LED turns off. Exhaust LED turns off with potentiometer at approximately 90 percent.

Actuator remains in position.

Turn DCV potentiometer CW. DCV LED turns off with potentiometer at approximately 9V.

Actuator drives fully closed.

Turn DCV and Exhaust potentiometers CCW until Exhaust LED turns on. Exhaust contacts close 30-120 seconds after Exhaust LED turns on.

5. MINIMUM AND MAXIMUM POSITION

Execute step one, Checkout Preparation. —

Connect 9V battery positive to AQ and negative to AQ1. DCV LED turns on. Actuator drives 90 to 95 percent open.

Turn DCV maximum position potentiometer to midpoint. Actuator drives to between 20 and 80 percent open.

Turn DCV maximum position potentiometer to fully CCW. Actuator drives fully closed.

Turn minimum position potentiometer to midpoint. Actuator drives to between 20 and 80 percent open.

Turn minimum position potentiometer fully CW. Actuator drives fully open.

W7212: Remove jumper from TR and N. Actuator drives fully closed.

W7213, W7214: Jumper TR to N.

6. MIXED AIR INPUT

Execute step one, Checkout Preparation. —