Page 1

SMV800 SmartLine Multivariable Transmitter

Quick Start Installation Guide

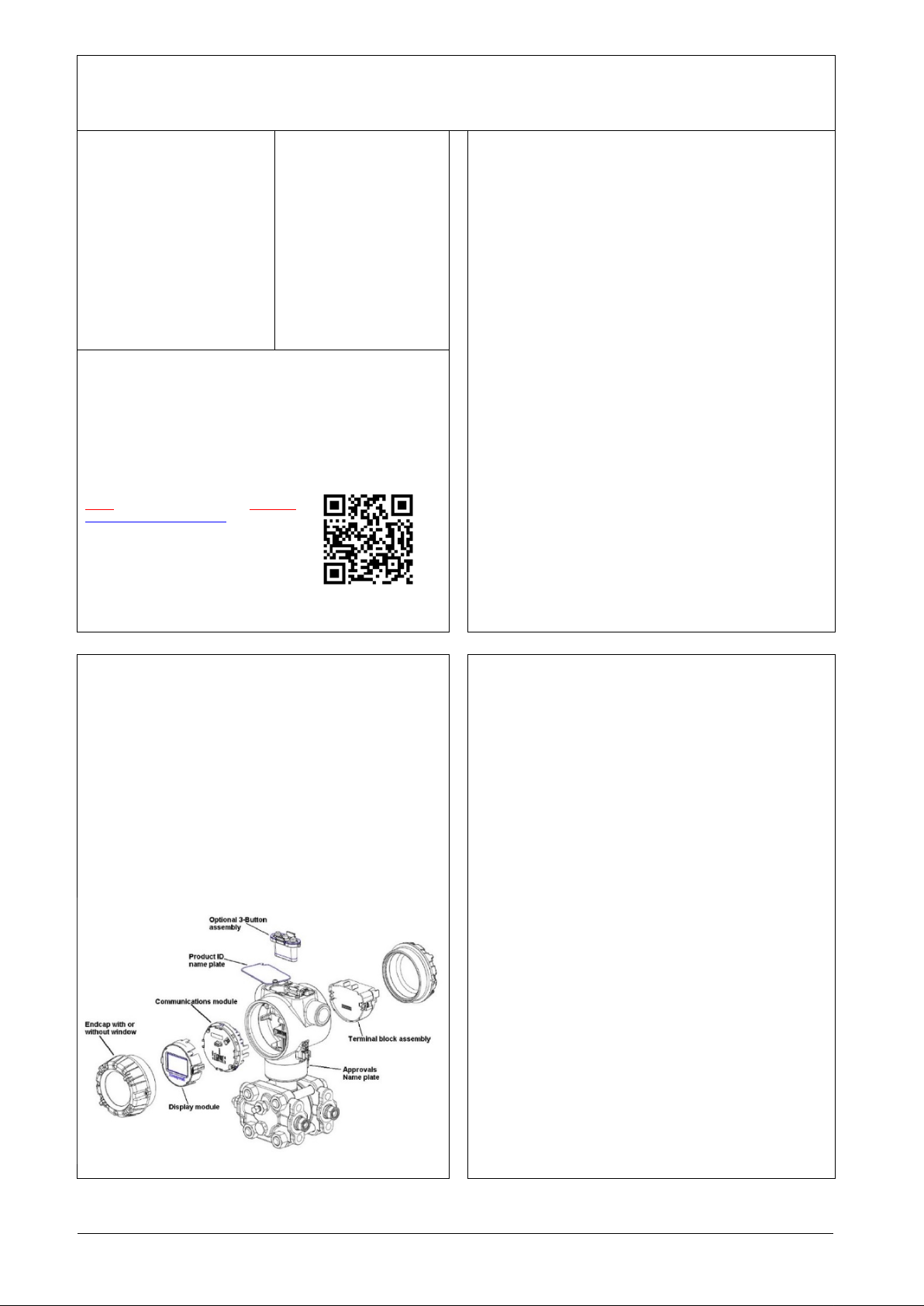

Figure 1: Electronic housing components

34-SM-25-04, Revision 8, November 2020

This document provides descriptions

and procedures for the quick

installation of Honeywell’s family of

SmartLine transmitters.

The SmartLine Multivariable

transmitter is available in a variety of

models for measuring differential

pressure, static press ur e, pro ces s

temperature, volume and mass flow

and Totalizer.

For full details refer to the man ual s

listed below for protocols , us er

Interface (HMI) operation, Install atio n,

configuration, calib ra ti on ,

maintenance, parts, and safety and

approvals etc. including options

Copyrights, Notices and

Trademarks.

Copyright 2020 by Honeywell

Revision 8, November 2020

Trademarks

SmartLine, SMV800 are U.S.

registered trademarks of

Honeywell Inc.

HART® is Trademarks of

FieldComm Group™

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

Installation ................................................................................................................... 1

Features and Options ................................................................................................. 1

Mounting the Transmitter ............................................................................................ 2

Bracket mounting ................................................................................................. 2

Mounting bracket ................................................................................................. 2

Rotating Transmitter Housing .............................................................................. 2

Leveling Transmitters with Small Absolute or Differential Pressure Spans .......... 2

Conduit Entry Connectors, Plugs and Adapters .......................................................... 3

Wiring Connections and Power Up ............................................................................. 3

Wiring Variations .................................................................................................. 4

Explosion-Proof Conduit Seal ..................................................................................... 5

Tri m the Transmitter .................................................................................................... 5

Set of Jumpers for Modbus ......................................................................................... 6

Configuration Guide .................................................................................................... 6

Appendix A. PRODUCT CERTIFICATIONS ............................................................... 7

A3. Hazardous Locations Certifications (MSG Code from Table V) .................... 8

MODBUS Communications ........................................................................................ 9

WARNING: FOR CONNECTION IN AMBIENTS ABOVE 60oC USE WIRE

RATED 105oC ...................................................................................................... 9

Control Drawing ........................................................................................................ 10

Table 1: Conduit entry connectors and plugs .............................................................. 3

Table 2 - Conduit Adapters ......................................................................................... 3

Table 3: Wiring details for SMV Modbus Terminal block ............................................. 4

Table 4: AC Termination and Write Protect Jumpers for Modbus ............................... 6

Figure 1: Electronic housing components ................................................................... 1

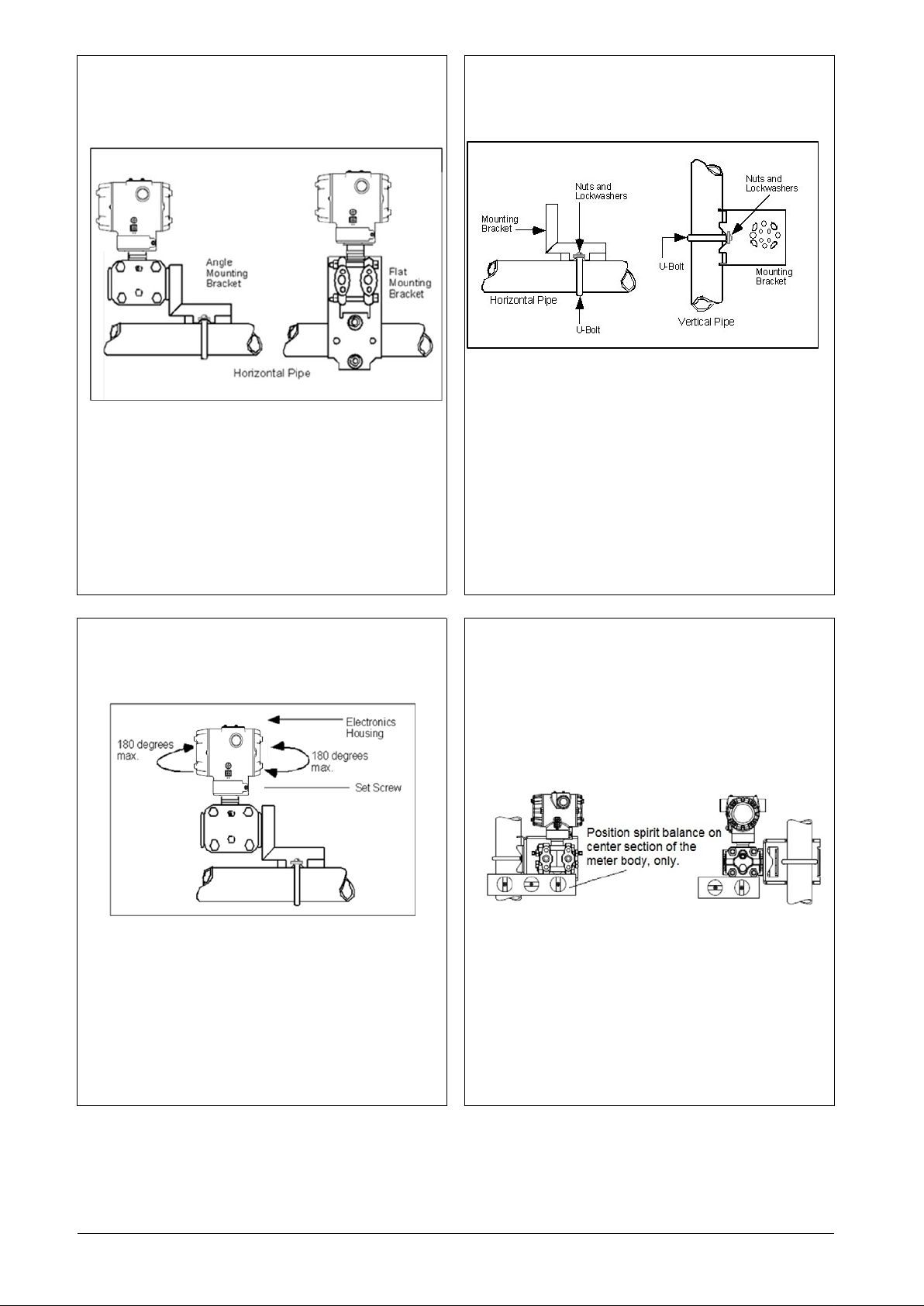

Figure 2: Mounting brackets ....................................................................................... 2

Figure 3: Angle mounting bracket ............................................................................... 2

Figure 4: Rotating Transmitter Housing ...................................................................... 2

Figure 5: Using level to mount transmitter .................................................................. 2

Figure 6: Electronic Housing Conduit Entries ............................................................. 3

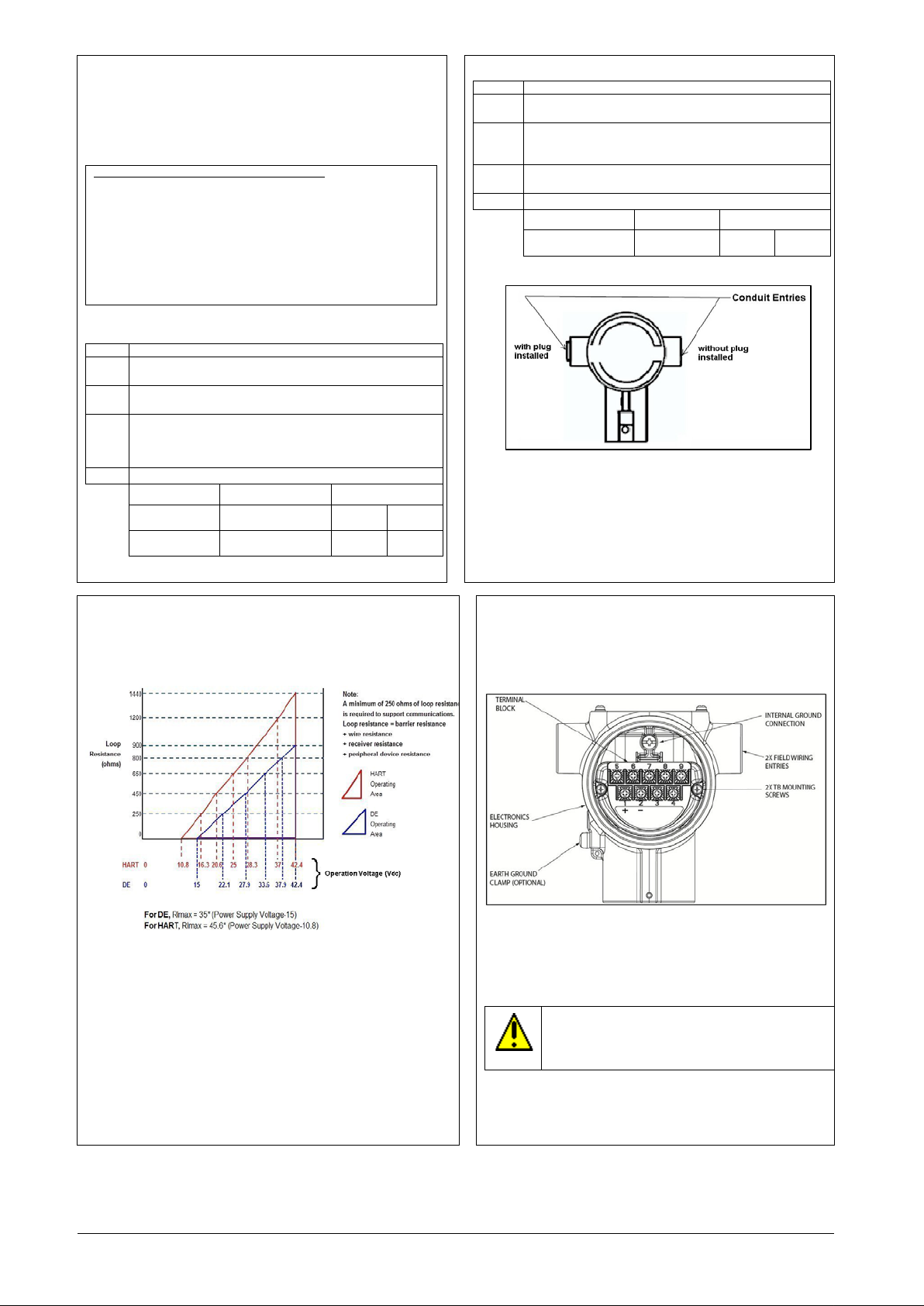

Figure 7: Two-wire power/current loop ........................................................................ 3

Figure 8: Terminal Block and Grounding Screw location ............................................ 3

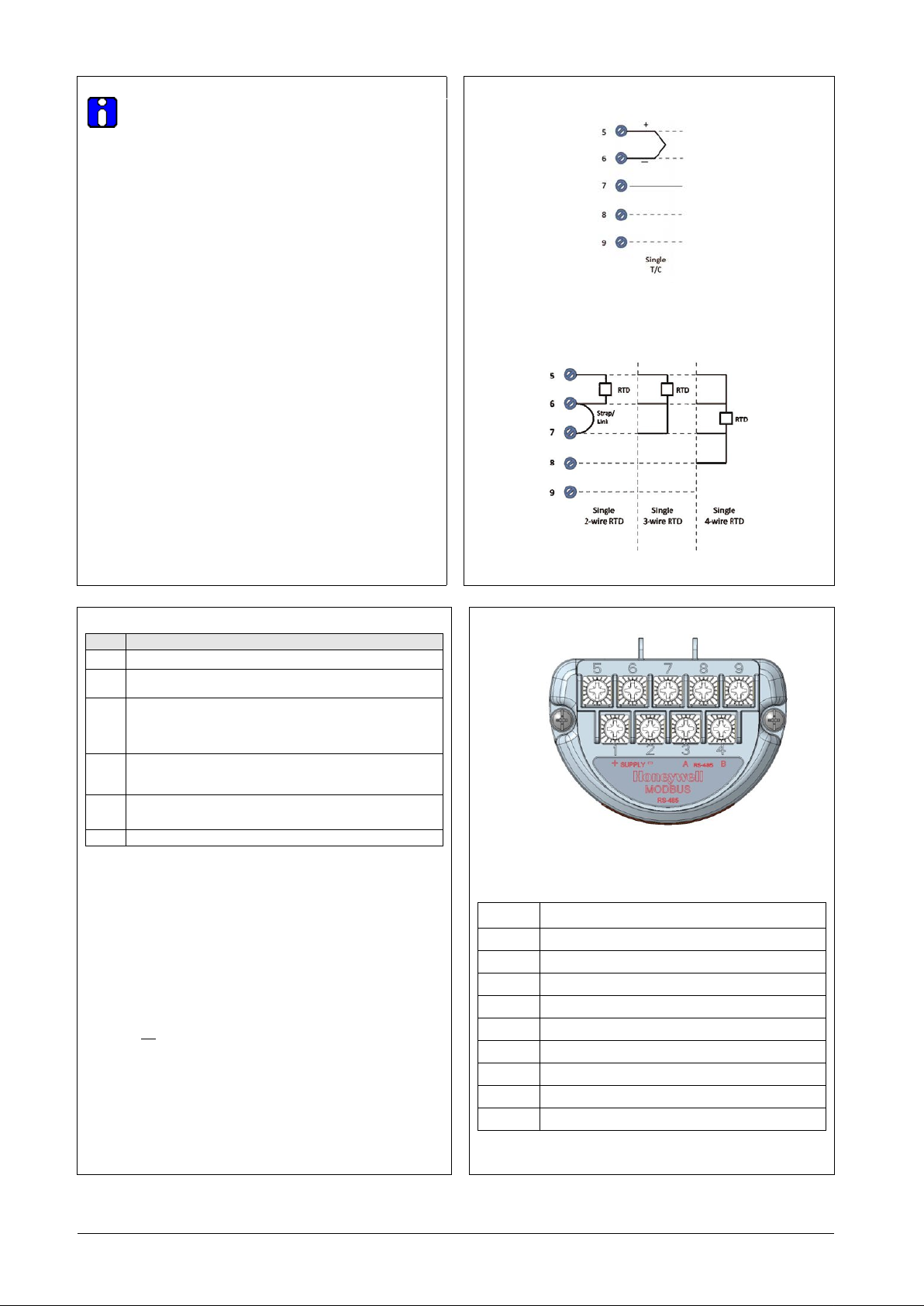

Figure 9: Thermocouple connections .......................................................................... 4

Figure 10: RTD connections ....................................................................................... 4

Figure 11: Wiring details for SMV Modbus Terminal block ......................................... 4

Figure 12: Transmitter configuration via Modbus (RS-485) network port .................... 5

Figure 13: Jumper location HART ............................................................................... 6

Figure 14: Jumper settings HART ............................................................................... 6

Figure 15: Loading AC termination enable and write protect jumper for Modbus (RS-

485) ............................................................................................................................. 6

Table of Contents

Tables

Figures

Installation

Evaluate the site selected for the transmitter installation with respect to

the process system design specifications and Honeywell’s published

performance characteristics for your model.

Temperature extremes can affect display quality. The display can become

unreadable at temperature extremes; however, this is only a temporary

condition. The display will again be readable when temperatures return to

within operable limits.

Features and Options

The SMV800 is packaged in two major assemblies: the electronics

housing and the meter body. The elements in the electronic housing

respond to setup commands and execute the software and protocol for

the different pressure m eas urem e nt t ypes. Figure 1 shows the

assemblies in the electronics housing with available options.

The meter body provides connection to a process system. Several

physical interface configurations are available, as determined by the

mounting and mechanical connections.

The SMV800 SmartLine multivariable transmitter measures differential

pressure, static pressure (absolute or gauge), and process temperature.

These measurements are used to calculate volumetric or mass flow

rates. The measured values and calculated flow can be read by a

connected Host.

Available communication protocols are Honeywell Digitally Enhanced

(DE), HART and Modbus RTU. Digi tal or analog (4-20ma) output modes

are available. The SMV800 measures process temperature from an

external RTD or thermocouple.

Universal temperature input is available as a selectable feature with the

device or as license enabled, field upgradable option.

With Modbus protocol, Flow calculation capability also is available as

selectable feature with the device or as license enabled, field upgradable

option while this is a standard feature with HART and DE protocols

Device Variables

SMV800 supports 6 device variables:

1. Differential Pressure

2. Static Pressure

3. Process Temperature

4. Calculated Flow Rate

5. Totalizer

6. Meter Body Temperature.

For DE transmitters, Differential Pressure, Static Pressure, Process

Temperature or Flow ma y be assig ne d to analog output. In HART

transmitters, Differential Pressure, Static Pressure, Process

Temperature, Flow and Totalizer may be mapped to device variables PV

(analog output), SV, TV or QV and Meter Body temperature may be

mapped to SV, TV or QV. All six variables are Modbus process

variables.

SMV800 Quick Start Installation Guide 1

Page 2

Mounting the Transmitter

Mounting bracket

Transmitter models can be attached to a two-inch (50 millimeter) vertical

or horizontal pipe using Honeywell’s optional angle or flat mounting

bracket; alternately you can use your own bracket.

Typical bracket mount ed in st alla tions

Figure 2: Mounting brackets

Bracket mounting

Mounting bracket, see Figure 3

Rotate the transmitter housing, see Figure 4

Level a transmitter with small abs ol ut e or diff e re ntial pr ess ure sp ans , se e

Figure 5

Position bracket on 2-inch (50.8 mm) and install “U” bolt around pipe and

through holes in bracket. Secure with nuts and lock washers provided.

Figure 3 Example - Angle mounting bracket secured to horizontal or

vertical pipe.

Figure 3: Angle mounting bracket

Rotating Transmitter Housing

Use a 2mm hex wrench to loosen the set screw on outside neck of

transmitter one full turn. Rotate the transmitter housing to a maximum of

180 degree increment in left or right direction from center to position you

require and tighten set scre w (1. 46 to 1 .68 Nm / 13 to 15 lb-in).

Leveling Transmitters with Small Absolute or Differential Pressure Spans

Mounting position of these transmitters is critical due to the smaller

transmitter spans.

To minimize these positional effects on calibration (zero shift), take the

appropriate mounting precautions that follow for the given transmitter

model.

See figure below for suggestions on how to level the transmitter using a

spirit balance.

To perform a Zero Trim after leveling, refer to Trim the Transmitter.

Figure 4: Rotating Transmitter Housing

For a model SMA810 or SMA845 transmitters, you must ensure that the

transmitter is vertical when mounting it. You do this by leveling the

transmitter side-to-side and front-to-back.

Mount transmitter vertically to assure best accuracy. Position a spirit

balance on pressure connection surface of AP body.

Figure 5: Using level to mount transmitter

SMV800 Quick Start Installation Guide 2

Page 3

Conduit Entry Connectors, Plugs and Adapters

CONDUIT ENTRY PRECAUTIONARY NOTICE

AUTHORITIES AS APPLICABLE.

Step

Action

1

Remove the protective plastic cap from the threaded conduit

entry.

3

Thread the appropriate size conduit connector or plug (M20

adapters or reducers will be used .

4

Tighten plugs per the following table.

M20 Conduit

Entry

½” NPT

Conduit Entry

Step

Action

1

Remove the protective plastic cap from the threaded conduit

entry.

2

To ensure the environmental ingress rating on taper ed

used.

3

Thread the appropriate size adapter (M20 or ½ NPT) into

the conduit entry opening

½ to ¾ NPT

Adapter

power supply end.

Procedures

It is the user/installer’s responsibility to install the transmitters in

accordance with national and local code requirements. Conduit entry

plugs and adapters shall be suitable for the environment, shall be

certified for the hazardous location when required and acceptable to the

authority having jurisdiction for the plant.

THE CONDUIT/CABLE GLAND ENTRIES OF THIS PRODUCT ARE

SUPPLIED WITH PLASTIC DUST CAPS WHICH ARE NOT TO BE

USED IN SERVICE.

IT IS THE USER’S RESPONSIBILITY TO REPLACE THE DUST

CAPS WITH CABLE GLANDS, ADAPTORS AND/OR BLANKING

PLUGS WHICH ARE SUITABLE FOR THE ENVIRONMENT INTO

WHICH THIS PRODUCT WILL BE INSTALLED. THIS INCLUDES

ENSURING COMPLIANCE WITH HAZARDOUS LOCATION

REQUIREMENTS AND REQUIREMENTS OF OTHER GOVERNING

Use the following procedures for installation.

Wiring Connections and Power Up

Summary

The transmitter (HART/DE) is designed to operate in a two-wire

power/current loop with loop resistance and power supply voltage within the

HART/DE operating range shown below.

Table 1: Conduit entry connectors and plugs

2 To ensure the environmental ingress protection rating on

tapered (NPT), a non-hardening thread sealant may be used.

or ½” NPT) into the conduit entry opening. Do not install

conduit entry connectors or plugs in conduit entry openings if

Description Tool Torque

10mm Hex Wrench 32 Nm 24 Lb-ft

10mm Hex Wrench 32 Nm 24 Lb-ft

Table 2 - Conduit Adapters

threads (NPT), a non-hardening thread sealant may be

4 Tighten adapters as per the following table.

Description Tool Torque

1 ¼” Wrench 32Nm 24Lb-ft

Figure 6: Electronic Housing Conduit Entries

Note. No conduit connectors or plugs come installed in the housings. All

housings come with temporary plastic dust protectors (red) installed and

are not certified for use in any installation.

After wiring the Transmitter as outline in the next sections, torque the screws to

1.1 Nm (10 lb-in)

Supply Voltage for SMV Modbus

Modbus (RS-485) Mod els : 9.5 V to 30 Vdc at terminals.

Power Consumption: Average power consumption is 70 mW at 9.5 V

Supply. This includes RS-485 communication at 9600 baud rate at a

rate of once per second without termination at room temperature.

Figure 7: Two-wire power/current loop

A minimum of 250 ohms of loop resistance is required to support

communications. Loop resistance = barrier resistance., + wire resistance,

=receiver resistance, +peripheral device

resistance

Loop wiring is connected to the tr ans m i tt er b y attaching the positive (+) and

negative (–) loop wires to the positive (+) and negative (–) terminals on th e

transmitter terminal block in the electronics housing shown in Figure 8.

Connect the loop power wirin g s hield to earth ground only at the power

supply end.

Figure 8: Terminal Block and Grounding Screw location

As shown above, each transmitter has an internal terminal to connect it

to earth ground. Optionally, a ground terminal can be added to the

outside of the Electronics Housing.

Screw terminals 1, 2, 3, 5, 6, 7 & 8 only required for single input,

terminals 4 and 9 are only used for a Modbus dev ic e

CAUTION: For proper operation of the transmitter,

grounding of the transmitter is mandatory. This minimizes

the possible effects of noise on the output signal and

affords protection against lighting and static discharge

An optional lightning terminal block can be installed in place of the nonlightning terminal block for transmitters that will be installed in areas

that are highly susceptible to lightning strikes. As noted above, the loop

power wiring shield shoul d onl y be co n nect ed to earth ground at the

SMV800 Quick Start Installation Guide 3

Page 4

Input Sensor Wiring

Loop Wiring (H ART/DE)

Step

Action

1

Remove the end cap cover from the terminal block end of the

3

Feed loop power leads through one end of the conduit

4

Connect the positive loop power lead to the positive (+)

5

6

Replace the end cap, and secure it in place.

Terminal

Number

Description

Wiring must comply with local co des, regulations and

ordinances. Grounding may be required to meet various

approval body certification, for example CE conformity. Refer

to Appendix A of this document for details.

The HART/DE transmitter is designed to operate in a 2-wire

power/current loop with loop resistance and power supply voltage within

the operating range; see Figure 7.

With an optional remote meter (for HART/DE), the voltage drop for this

must be added to the basic power supply voltage requirements to

determine the required transmitter voltage and maximum loop resistance.

Additional consideration is required when selecting intrinsic safety

barriers to ensure that they will supply at least minimum transmitter

voltage, including the re qui r ed 250 ohms of resistance (typically within

the barriers) needed for digital communications.

Wiring Variations

The above procedures are used to connect power to a transmitter. For

loop wiring and external wi rin g, det ai le d drawings are provided for

transmitter installation in

non-intrinsically safe areas and for intrinsically safe loops in hazardous

area locations.

The screw terminals suitable for wirings up to (16AWG)

- Shielded, twisted-pair cable such as Belden 9318 or equivalent must

be used for all signal/power wi rin g.

Note: If solid core wire is used strip insulation 1/4 in (6 mm). Once

inserted under the square washer the stripped portion should be

contained under the squa re was he r. If m ult i-str an de d wir e is use d, a

ferrule is to be used and the stripped wire should be in the insulated

portion of the ferrule. The ferrule can be also used on the solid core

wire.

- The cable shield must be connected at only one end of the cable.

Connect it to the power supply side and leave the shield insulated at the

transmitter side.

After wiring the Transmitter as outline in the next sections, torque the

screws to 1.1 Nm (10 lb-in).

Connect the input sensors as shown in Figure 9 below:

RTD Connections

o Resistance temperature detector (RTD) measurements use the 3 or

4 wire approach. The transmitter determines by itself if a 3 or 4 wire

RTD is connected when powered up.

Figure 9: Thermocouple connections

Figure 10: RTD connections

2

Power Supply Wiring (Modbus) Procedure

1. See Figure 8, for parts locations. Loosen the end cap lock

2. Remove the end cap cover from the terminal block end of the

3. Feed twisted pair shielded power supply leads through one

4. Connect the positive power supply lead to the positive (+)

5. Modbus communication wires can be fed through the sam e

6. Feed input sensor wires through the 2nd conduit entrance and

7. Replace the end cap, and secure it in place.

See Figure 8, for parts locations.

electronics housing.

entrances on either side of the electronics housing. The

transmitter accepts up to 16 AWG wire. Shield of the cable to

be grounded on the supply/host side.

terminal and the negative loop power lead to the negative (-)

terminal. Note that the transmitter is not polarity-sensitive.

Feed input sensor wires through the 2nd conduit entrance and

connect wire.

using a 1.5 mm Allen wrench.

electronics housing.

end of the conduit entrances on either side of the electronics

housing. The transmitter accepts up to 16 AWG wire. Shield of

the cable to be grounded on the Supply/Host side.

terminal (Terminal #1) and negative power supply lead to the

negative (-) terminal (Terminal #2). Note that the transmitter is

not polarity-sensitive.

conduit that is being used for feeding power supply inputs. For

details related to Modbus connection refer to Table 3 and the

section on SMV Modbus Half-Duple x Modb us (R S-485) Wiring

Procedure.

connect wire.

Figure 11: Wiring details for SMV Modbus Terminal block

Table 3: Wiring de ta i ls for SM V Modbus Termina l bl ock

1 Power Supply input +ve

2 Power Supply input -ve (Return)

3 Modbus (RS-485) A

4 Modbus (RS-485) B

5 Temperature Sensor Input

6 Temperature Sensor Input

7 Temperature Sensor Input

8 Temperature Sensor Input

9 Modbus (RS-485) Common

SMV800 Quick Start Installation Guide 4

Page 5

SMV Modbus Transmitter Connection to a PC based Modbus

the integrated circuits in the Transmitter PWAs are vulnerable to damage by

Step

Action

1

Attach the transmitter to the mounting bracket but do not

completely tighten the mounting bolts

2

3

Connect 24 Vdc power to the transmitter. For HART/DE,

connect a digital voltmeter to monitor the PV output.

4

Use applicable communicator to establish communications with

PC application

5

While reading the transmitter’s output on a communication

mounting bolts.

6

The local display or applicable communicator can be used to

tightened.

7

If a SMV Modbus transmitter is directly hooked up to DC

distributed lines, it is mandatory to use transmitters with lightening

protection option.

A wire from the earth ground clamp (ref. Figure 8) of transmitter must

be connected to earth ground to make the lightening protection

effective. Use a size 8 AWG or (8.37mm

for this connection.

SMV Modbus Half-Duplex Modbus (RS-485) Wiring Procedure

The Modbus A, Modbus B & Modbus Common inputs are applied to

terminals Terminal #3, Terminal #4 & Terminal #9 respectively.

A 3-wire approach for Modbus communication is recommended to

avoid potential difference related issues and to ensure error-free

communication bet we en driv ers and receivers. For Modbus

communication, minimum 24 AWG shielded twisted pair cable with

nominal characteristic impedance of 120 ohms is recommended. Shield

of the communication cable must be connected to chassis ground on

host side.

Modbus RS-485 network recommends to use Termination on either

side of the network. Typically, 120ohm DC termination on eit h er en ds

(Host side & at last device) are provi ded.

Alternately “AC Termination” feature can be enabled internal to the

device (refer Figure 12, Table 3), when transmitter is the last device in

the network. In this case, external termination (if any) at the transmitter

end needs to be removed.

Multiple termination (apart from both ends of the network), can cause

communication failure. For improved performance, DC termination is

recommended.

Ensure Power lines & Modbus Communication lines are not

swapped during installation/maintenance

2

) bare or green covered wire

.

After wiring the Transmit ter as o utli n e in the next sect io ns, tor q ue

the screws to 1.1 Nm (10 lb-in)

(RS-485) Host

For configuration of the Transmitter using Laptop/PC bas e d application

following wiring recommendation are to be followed:

• Supply voltage (9.5V to 30V DC) is to be fed between

Terminal #1 & Terminal #2.

• Sensor inputs can be connected on Terminal #5 to Terminal

#8 as per the Sensor type

• Isolated USB to RS-485 adaptor is recommended for

connecting between PC based Host and Transmitter

• Default configuration of Modbus communication parameters

unless otherwise changed is: Baud rate – 9600 bps, Parity –

None and Device address - 247.

Before connectin g t o the PC bas ed H os t the device needs to be

disconnected from external host (if any).

Isolated RS-485 USB adaptor is recommended when connecting

the transmitter to PC.

Figure 12: Transm it ter co nfi g urat io n via M od bus (RS-485) network

port

(Refer to Table 3: Wiring details for SMV Modbus Terminal block)

ATTENTION: Please take appropriate steps to avoid ESD damage;

stray static discharges.

Explosion-Proof Conduit Seal

When installed as explosion proof in a Division 1 Hazardous

Location, keep covers tight while the transmitter is energized.

Disconnect power to the transmitter in the non-ha zard ous area prior to

removing end caps for service.

When installed as non-incendive equipment in a Division 2 hazardous

location, disconnect power to the transmitter in the non-hazardous ar ea,

or determine that the location is non-hazardous befo re disconnecting or

connecting the transmit t er wi re s.

Transmitters installed as explosionproof in Class I, Division 1, Group A

Hazardous (classified) locations in accordance with ANSI/NFPA 70, the

US National Electrical Code, with ½ inch conduit do not require an

explosionproof seal for installation.

If ¾ inch conduit is used, a LISTED explosionproof seal to be installed in

the conduit, within 18 inches (457.2 mm) of the transmitter.

Trim the Transmitter

Procedure to trim the transmitter

For a transmitte r wit h a small differential pressure spa n, you must ensure

that the transmitter is vertical when mounting it. You do this by leveling the

transmitter side-to-side and front-to-back. See Figure 5 for suggestions on

how to level the transmitter using a spirit balance. You must also zero the

transmitter by following the steps in this table.

Connect a tube between the input connections in the high

pressure (HP) and low pressure (LP) heads to eliminate the

effects of any surrounding air currents.

the transmitter. For DE transmitter use the SmartLine

Configuration Toolkit (SCT3000).

For HART, use MCT404-FDC applic a tion or oth er HA R T

Communicator with ap plic a ble H on e yw ell DD's.

For MODBUS, use Honeywell’s SmartLine Modbus manager

tool or a voltmeter, position the transmitter so the output

reading is at or near zero, and then completely tighten the

perform the zero corrects. This corrects the transmitter for

any minor error that may occur after the mounting bolts are

Remove the tube from between the input connections, the

power, and the digital voltmeter or communication tool.

SMV800 Quick Start Installation Guide 5

Page 6

SET JUMPERS FOR HART/DE

Step

Action

1

Turn OFF transmitter power.

2

Loosen the end-cap lock, and unscrew the end cap from the

electronics side of the transmitter housing.

3

If applicable, carefully depress the tabs on the sides of the

preferred orientation of the display module in the window.

4

5

Screw on the end cap and tighten the end-cap lock.

6

Turn ON transmitter power.

Jumper Settings

Description

Write Protect = ON (Protected)

Figure 14: Jumper settings HART

Step

Action

1

Turn OFF transmitter power.

2

Loosen the end-cap lock, and unscrew the end cap from the

electronics side of the transmitter housing.

3

If applicable, carefully depress the tabs on the sides of the

preferred orientation of the display module in the window.

4

Set the AC Termination jumper to the desired action and the

jumper positioning.

5

Screw on the end cap and tighten the end-cap lock.

6

Turn ON transmitter power.

AC termination = OFF

Protected)

AC termination = ON

Protected)

AC termination = ON

(Protected)

AC termination = OFF

(Protected)

Setting failsafe direction and write protect jumpers

The SmartLine Multivariable transmitter (DE or HART) provides two

jumpers to set the desired failsafe action and write protect option. See

Figure 13.

The top jumper on the electronics module sets the failsafe direction. The

default setting is up-scale failsafe.

Upscale drives the loop to a value greater than 21mA while down scale

drives the loop to a value less than 3.8mA.

You can change the failsafe direction by moving the failsafe jumper (top

jumper) to the desired position (UP or DOWN).

The bottom jumper sets the write protect.

The default setting is OFF (Un-protected).

When set to the ON (Protected) position, changed configuration

parameters cannot be written to the transmitter.

When set to the OFF (Un-protected) position, changed configuration

parameters can be written to the transmitter.

ATTENTION: Electrostatic Discharge (ESD) hazards. Observe

precautions for handling electrostatic sensitive devices.

display module and pull it off.

If necessary, move the interface connector from the

communication module to the display module to provide the

Set the failsafe jumper (top jumper) to the desired action (UP or

DOWN). And the write protect jumper (Bottom jumper) to the

desired behavior (Protected or Unprotected) See Figure 14 for

jumper positioning.

Figure 13: Jumper location HART

Failsafe = UP (High)

Write Protect = OFF (Not Protected)

Failsafe = DOWN (Low)

Write Protect = OFF (Not Protected)

Failsafe = UP (High)

Write Protect = ON (Protected)

Failsafe = DOWN (Low)

Set of Jumpers for Modbus

The SmartLine Multivariable Modbus transmitter provides two jumpers to

set the desired AC Termination setting and write protect option. See

Figure 15.

ATTENTION: Electrostatic Discharge (ESD) hazards. Observe

precautions for handling electrostatic sensitive devices

display module and pull it off.

If necessary, move the interface connector from the

communication module to the display module to provide the

write protect jumper to the des ir ed be h av ior (Se e Figure 15 for

Table 4: AC Termination and Write Protect Jumpers for Modbus

Jumper Arrang em ents Description

(Disabled)

Write Protect = OFF (Not

(Enabled)

Write Protect = OFF (Not

(Enabled)

Write Protect = ON

(Disabled)

Write Protect = ON

Configuration Guide

This transmitter comes with a standard factory configuration. Consult the

nameplate for basic information.

Reconfiguration for your particular application can be accomplished by

following instructions in the Transmitter User’s manual.

This can be found by following the website URL or QR code on page 1 of

this document.

Figure 15: Load i n g AC ter m i nation enable a nd wr it e protect jumper

for Modbus (RS-485)

SMV800 Quick Start Installation Guide 6

Page 7

Appendix A. PRODUCT CERTIFICATIONS

SIL 2/3

IEC 61508 SIL 2 for non-redundant use and SIL 3 for redundant

use according to EXIDA and TÜV Nord Sys Tec GmbH & Co. KG

2010; IEC61508-3: 2010.

A1. Safety Instrumented Systems (SIS) Installations

For Safety Certified Installations, please refer to SMV800 SmartLine

Multivariable Safety Manual 34-SM-25-05 for installation procedure and

system requirements.

Certification

A2. European Directive Information (CE Mark)

under the following standards: IEC61508-1: 2010; IEC 61508-2:

SMV800 Quick Start Installation Guide 7

Page 8

MSG CODE/

AGENCY

TYPE OF PROTECT ION

Electrical

Parameters

Ambient

Temperature

Explosion proof:

IIIC T 95oC..T 115oC Db

Intrinsically Safe:

T4 Ga

Non-Incendive and

T4 Gc

Enclosure: Type 4X/ IP66/ IP67

Standards: FM 3600:2018; ANSI/ ISA 60079-0: 2013; FM

2003 ; ANSI/ IEC 60529 : 2004

Explosion proof:

T 95oC..T 115oC Db

Intrinsically Safe:

Ex ia IIC T4 Ga

Non-Incendive and

Class I Zone 2 AEx nA IIC T4 Gc

Enclosure: Type 4X/ IP66/ IP67

Standards:

CSA C22.2 No 25:2017; CSA

No 61010

CSA C22.2 No 213: 2017; CSA C22.2 No 60529:2016; CSA C22.2 No

60079

11:2014; CSA C22.2

12.12.01:2017; ANSI/UL 61010

0:2013(R2017); ANSI/ UL 60079

ANSI/ UL 60079

60079

2017; UL 913:2015; UL 916: 2015; FM3615: 2006; FM 3616: 2011; FM

3600: 2011; ANSI/UL 50E: 2015

Flameproof:

T 115oC Db

Intrinsically Safe:

II 1 G Ex ia IIC T4 Ga

Non Sparking and

II 3 G Ex ic IIC T4 Gc

Note 2

Standards: EN 60079-0: 2018; EN 60079-1 :2014; EN 60079-11:

2015/A1: 2018

Enclosure: IP66/ IP67

Intrinsically Safe:

Ex ia IIC T4 Ga

Non Sparking:

Ex ic IIC T4 Gc

Flameproof:

Ex tb IIIC T 95oC.. T 115 oC Db

Enclosure: IP66/ IP67

Standards: IEC 60079-0: 2017; IEC 60079-1:2014; IEC 60079-11:

2011; IEC 60079-7: 2018; IEC 60079-31: 2013; IEC 60079-26: 2014

Intrinsically Safe:

Ex ia IIC T4 Ga

Non Sparking:

Ex ic IIC T4 Gc

Flameproof:

Ex tb IIIC T 95oC..T 115 oC Db

Enclosure: IP66/ IP67

Intrinsically Safe:

Ex ia IIC Ga

Non Sparking:

Ex ic IIC T4 Gc

Flameproof:

Ex tb IIIC T 95oC..T 115 oC Db

Enclosure: IP66/ IP67

Standards: ABNT NBR IEC 60079-0:2013 (IEC 60079-0:2011); ABNT

26:2006);

ABNT NBR IEC 60079-31:2014 (IEC 60079-31:2013).

Intrinsically Safe:

Ex ia IIC T4 Ga

T4: -50oC to 70oC

Non Sparking:

Ex nA IIC T4 Gc

Flameproof:

Db

Enclosure: IP66/ IP67

Flameproof:

Ex tD A21 T 95oC..T 115oC

Intrinsically Safe:

Ex ia IIC Ga

Ex d IIC T6..T5 Ga/Gb

Ex tb IIIC T 95oC..T 115oC Db

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

Intrinsically Safe:

Ex ia IIC T4 Ga

Non Sparking:

2 Ex nA IIC T4 Gc

Enclosure : IP 66/67

II 1/ 2 G Ex db IIC T6..T5

Ga/Gb

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

T4: -50 ºC to 70ºC

FISCO

Enclosure : IP 66/67

1/ ATEX and

IECEx

Combined ATEX and IECEX

See codes C and D

HART and DE

Voltage= 11 to 42 V

Current = 4-20 mA Normal (3.8 – 23 mA Faults)

A3. Hazardous Locations Certifications

(MSG Code from Table V)

Class I, Division 1, Groups

A, B, C, D

Class I, Zone 0/1, AEx db

IIC T6..T5 Ga/Gb

A/

FM

ApprovalsTM

Dust Ignition Proof:

Class II, Division 1, Groups

E, F, G;

Suitable for Division 1,

Class III;

Class II, Zone 21, AEx tb

Class I, II, III, Division 1,

Groups A, B, C,

D, E, F, G

Class I Zone 0 AEx ia IIC

Intrinsically Safe:

Class I, Division 2, Groups

A, B, C, D

Class I Zone 2 AEx nA IIC

T4 Gc

Class I Zone 2 AEx ic IIC

3615:2018; ANSI/ ISA 60079-1 :2015; FM 3616: 2011 ; ANSI/ ISA

60079-31 :2015; FM 3610:2018; ANSI/ ISA 60079-11 :2014; FM

3810 : 2018; ANSI/ ISA 60079-26 :2017; FM 3611:2018; ANSI/

ISA 60079-15 : 2013; ANSI/ ISA 61010-1: 2004;NEMA 250 :

Note 1

Note 2 T4: -50oC to 70oC

Note 1 T4: -50oC to 85oC

T95 oC /T5: -50 ºC

to 85ºC

T6: -50 ºC to 65ºC

B/

CSACanada

Class I, Division 1, Groups A, B,

C, D

Dust Ignition Proof:

Class II, III, Division 1, Groups E,

F, G

Suitable for Division 1, Class III;

Zone 0/1, Ex db IIC T6..T5

Ga/Gb

Class I, Zone 0/1, AEx db IIC

T6..T5 Ga/Gb

Ex tb IIIC T 95oC.. T 115oC Db

Class II, Zone 21, AEx tb IIIC

Class I, II, III, Division 1, Groups

A, B, C,

D, E, F, G;

Intrinsically Safe:

Class I, Division 2, Groups A, B,

C, D

Ex nA IIC T4 Gc

CSA C22.2 No 0: 2010 (R2015); CSA C22.2 No. 0-M91;

-1: 2012 (R2017); CAN/ CSA-C22.2 N o.157: 1992(R20 16);

-0:2015; CSA C22.2 No 60079-1: 2016; CS A C22.2 60079-

-31 :2015; ANSI/ IEC 60529-2004(R2011); ANSI/UL 122701:

60079-15:2016; CSA C22.2 60079-31:2015; ISA

-15:2013(R2017); ANSI/ UL 60079-26 :2017; ANSI/ UL

Note 1

Note 2 T4: -50oC to 70oC

Note 1 T4: -50oC to 85oC

C22.2 No 30M; 1986(R2016);CSA C22.2

-1: 2016; ANSI/ UL 60079-

-1:2015; ANSI/ UL 60079-11:2014;

T5: -50 oC to 85oC

T6: -50 oC to 65 oC

Sira 15ATEX2039X

II 1/2 G Ex db IIC T6..T5

Ga/Gb

II 2 D Ex tb IIIC T 95oC..

Sira 15ATEX2039X

C/

ATEX

IECEx

Intrinsically Safe:

Sira15ATEX4040X

II 3 G Ex ec IIC T4 Gc

2012; EN 60079-31: 2014; EN 60079-26 :2015; ; EN 60079-7:

IECEx SIR 15.0022X

IECEx SIR 15.0022X

Ex ec IIC T4 Gc

D/

Ex db IIC T6..T5 Ga/Gb

E/

SAEx

(South

Africa)

Ex ec IIC Gc

Ex db IIC T6..T5 Ga/Gb

Note 1

Note 2 T4: -50oC to 70oC

Note 1

Note 2

Note 1

Note 2 (ic)

Note 1

Note 2

Note 1

Note 2 (ic)

Note 1

T5/ T95oC: -50 ºC to

85ºC

T6: -50 ºC to 65ºC

T4: -50oC to 85oC

T4: -50oC to 70oC

T4: -50oC to 85oC

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

T4: -50oC to 70oC

T4: -50oC to 85oC

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

G/

NEPSI

(CHINA)

H/

KOSHA

(Korea)

I/

EAC Ex

(Russia,

Belarus and

Kazakhstan)

K/

UATR

(Ukraine)

Notes

1. Operating Parameters:

2. See Control Drawing 50128060, on Page 10. Intrinsically Safe Entity

Parameters

Ex d IIC T6..T5 Ga/Gb

Ex tb IIIC Db T 95oC..T 115 oC

Ex d IIC T6..T5

Intrinsically Safe:

Ex ia IIC T4 Ga

Note 2

Note 1 T4: -50oC to 85oC

Note 1

Note 1

Note 2 T4: -50oC to 70oC

Note 1

Note 2 T4: -50 ºC to 70ºC

Note 1 T4: -50oC to 85oC

Note 1

Note 2

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

T4: -50oC to 45oC

Ex ec IIC T4 Gc

F/

INMETRO

(Brazil)

SMV800 Quick Start Installation Guide 8

Ex db IIC T6..T5 Ga/Gb

NBR IEC 60079-1:2009 (IEC 60079-1:2007); ABNT NBR IEC 6007911:2013 (IEC 60079-11:2011); ABNT NBR IEC 60079-15:2012 (IEC

60079-15:2010); ABNT NBR IEC 60079-26:2008 (IEC 60079-

Note 2

Note 1

Note 2 (ic)

Note 1

T4: -50oC to 70oC

T4: -50oC to 85oC

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

Page 9

MODBUS Communications

MSG

AGENCY

TYPE OF PROTECT ION

Ambient Temperature

Explosion proof:

T 95o.. T 115oC Db

C

Non-Incendive

Class I Zone 2 AEx nA IIC T4 Gc

Enclosure: Type 4X/ IP66/ IP67

Standards: FM 3600:2018; FM 3610: 2018; ANSI/ ISA 60079-0:

1: 2004;NEMA 250 : 2003 ; ANSI/ IEC 60529 :

2004

Explosion proof:

T 115oC Db

Non-Incendive

Class I Zone 2 AEx nA IIC T4 Gc

Enclosure: Type 4X/ IP66/ IP67

Standards: CSA C22.2 No 0: 2010(R2015); CSA C22.2 No. 94-M91;

26: 2016;

-

2006; FM 3600: 2011; ANSI/UL 50E: 2015

Flameproof:

Non Sparking

Standards: EN 60079-0: 2018; EN 60079-1 :2014; EN 60079-31:

Enclosure: IP66/ IP67

Non Sparking:

T4: -50oC to 85oC

Flameproof:

Ex tb IIIC T 95oC.. T 115 oC Db

Enclosure: IP66/ IP67

Standards: IEC 60079-0: 2017; IEC 60079-1 :2014;

W/ ATEX

Combined ATEX and IECEX

Voltage= 9 to 32 V

Current= 30 mA

A4. Marking ATEX Directive

Protection type

Temperature Class

T4

Ex ia

Ta = -50°C to 70°C or -50°C to 45°C

Tp = -40 to 125°C

Ex ic

Ta = -50°C to 85°C or -50°C to 45°C

Tp = -40 to 125°C

Protectio

n type

Temperature Class

T4

T5

T6

Ex db

Ta = -50 to 85°C

Tp = -40 to 125°C

Ta = -50 to 85°C

Tp = -40 to 100°C

Ta = -50°C to 65°C

Tp = -40 to 85°C

A.5 continued …

Protection type

Temperature Class

T95°C…115°C/T4

Ex tb and Ex ec

Ta = -50 to 85°C

Tp = -40 to 115°C

CODE/

Class I, Division 1, Groups A, B, C, D

Class I, Zone 0/1, AEx db IIC T6..T5

Ga/Gb

Dust Ignition Proof:

Class II, Division 1, Groups E, F, G;

Suitable for Division 1, Class III;

Class II, Zone 21, AEx tb IIIC

6/

FM

ApprovalsTM

Class I, Division 2, Groups A, B, C, D

2013; FM 3615:2018; ANSI/ ISA 60079-1 :2015; FM 3616 : 2011 ;

ANSI/ ISA 60079-31 :2015; FM 3810 : 2018; ANSI/ ISA 6007926 :2017; FM 3611:2018; ANSI/ ISA 60079-15 : 2013; FM 3810 :

2005; ANSI/ ISA 61010-

T95 oC /T5: -50 ºC to 85º

T6: -50 ºC to 65ºC

T4: -50oC to 85oC

810/

ATEX

9/

IECEx

Sira 15ATEX2039X

II 1/2 G Ex db IIC T6..T5 Ga/Gb

II 2 D Ex tb IIIC T 95oC..T 115oC Db

Sira 15ATEX4040X

II 3 G Ex ec IIC T4 Gc

2014; EN 60079-26 :2015; ; EN 60079-7: 2015/A1: 2018

IECEx SIR 15.0022X

Ex ec IIC T4 Gc

Ex db IIC T6..T5 Ga/Gb

IEC 60079-7: 2018; IEC 60079-31: 2013; IEC 60079-26: 2014

T5/ T95oC: -50 ºC to

85ºC

T6: -50 ºC to 65ºC

T4: -50oC to 85oC

T5: -50 ºC to 85ºC

T6: -50 ºC to 65ºC

Class I, Division 1, Groups A, B, C, D

Dust Ignition Proof:

Class II, III, Division 1, Groups E, F, G

Suitable for Division 1, Class III;

Zone 0/1, Ex db IIC T6..T5 Ga/Gb

Class I, Zone 0/1, AEx db IIC T6..T5

Ga/Gb

Ex tb IIIC T 95oC..T 115oC Db

Class II, Zone 21, AEx tb IIIC T 95oC..

7/

CSACanada

And USA

Class I, Division 2, Groups A, B, C, D

Ex nA IIC T4 Gc

CSA C22.2 No 25:2017; CSA C22.2 No 30M; 1986(R2016);CSA No

61010-1: 2012(R2017); CSA C22.2 No 213: 2017; CSA C22.2 No

60529:2016; CSA C22.2 No 60079-0:2015; CSA C22.2 No 600791:2016;; CSA C22.2 60079-15:2016; CSA C22.2 No 60079CSA C22.2 60079-31:2015; ANSI/UL 12.12.01:2017; ANSI/UL 61010

1: 2016; ANSI/ UL 60079-0:2013(R2017); ANSI/ ISA 60079-1:2015;

ANSI/ UL 60079-15:2013(R2017); ANSI/ UL 60079-26 :2017; ANSI/

UL 60079-31 :2015; ANSI/IEC 60529: 2004(R2011); ANSI/ UL

913:2015; ANSI/ UL 916: 2015; ANSI/ UL 122701: 2017; FM 3615:

General:

The following information is provided as part of the labeling of the transmitter:

A.5 Conditions of Use” for Ex Equipment”, Hazardous Location

Equipment or “Schedule of Limitations”:

Apparatus Marked with Multiple Types of Protection

The user must determine the type of protection required for installation the equipment.

The user shall then check the box [] adjacent to the type of protection used on the

equipment certification nameplate. Once a type of protection has been checked on the

nameplate, the equipment shall not then be reinstalled using any of the other

certification types.

Intrinsically Safe: Must be installed per drawing 50128060

The enclosure is manufactured from low copper, aluminum alloy. In rare cases,

ignition sources due to impact and friction sparks could occur. This shall be considered

during installation, particularly if the equipment is installed in a Zone 0/ Division 1

location.

The applicable temperature class, ambient temperature (Ta) range and process

temperature (Tp) range of the equipment when installed with type protection “Ex ia”

and “Ex ic” are as follows:

Flameproof “db” and Explosionproof - The applicable temperature class, ambient

temperature (Ta) range and process temperature (Tp) range of the equipment when

installed with type protection “Ex db” are as follows:

The Transmitter can be installed in the boundary wall between an area of EPL Ga/

Class I Zone 0/ Category 1 and the less hazardous area, EPL Gb/ Class I Zone 1/

Category 2. In this configuration, the process connection is installed in EPL Ga/ Class I

Zone 0/ Category 1, while the transmitter housing is located in EPL Gb/ Class I Zone

1/ Category 2.

SMV800 Quick Start Installation Guide 9

• Name and Address of the manufacturer

• Notified Body identification: DEKRA Quality B.V., Arnhem, the

Netherlands

and IECEx

T5: -50 oC to 85oC

T6: -50 oC to 65 oC

T4: -50oC to 85oC

Notes

Operating Parameters:

FM Approval: Carbon disulphide is excluded for Ex d installations as the enclosure has

a volume greater than 100 cm3.

• FM Approval: For information on flameproof joint dimensions and repair,

• The installer shall provide transient over-voltage protection external to the

WARNING: DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE MAY BE

PRESENT

Dust ignition “tb” enclosure and non-sparking “ec” - The applicable temperature class,

ambient temperature (Ta) range and process temperature (Tp) range of the equipment when

installed with type prot ection “Ex tb” and “Ex ec” are as follows :

Non-Incendive Equipment:

Division 2: This equipment is suitable for use in a Class I, Division 2, Groups A, B, C,

D; T4 or Non-Hazardous Locations Only

WARNING: DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE MAY BE

PRESENT

WARNING: SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

USE IN HAZARDOUS LOCATIONS

ALL PROTECTIVE MEASURES:

WARNING: FOR CONNECTION I N AMBIENTS ABOVE 60oC USE WIRE RA TED 105oC

Maximum permissible working pressure is 207 bar (3,000 psig).

If a charge-generating mechanism is present, the exposed painted metallic part on the

enclosure is capable of storing a level of electrostatic charge that could become

incendive for IIC/ Groups A, B, C or D gases. Therefore, the user/installer shall

implement precautions to prevent the build-up of electrostatic charge, e.g. earthing the

metallic part.

This is particularly important if the equipment is installed in a zone 0/ Division 1

location. Cleaning of the painted surface shall only be done with a damp cloth.

See codes 8 and 9

contact the manufacturer using instructions given in the user’s manual.

equipment such that the voltage at the supply terminal of the equipment

does not exceed 140 % of the voltage rating of the equipment.

Page 10

Control Drawing

SMV800 Quick Start Installation Guide 10

Page 11

For more information

Process Solutions

Honeywell

2101 City West Blvd,

Honeywell Control Systems Ltd

Shanghai City Centre, 100 Jungi Road

www.honeywellprocess.com

ASIA PACIFIC (TAC) hfs-tac-support@honeywell.com

9015

EMEA, Phone: + 80012026455 or +44 (0)1202645583. FAX: +44 (0) 1344 655554

Sales and Service

For application assistance, current specifications, pricing, or name of the nearest

Authorized Distributor, contact one of the offices below.

Australia Honeywell Limited, Phone: +(61) 7-3846 1255, FAX: +(61) 7-3840 6481

Toll Free 1300-36-39-36, Toll Free Fax: 1300-36-04-70

China – PRC – Shanghai, Honeywell China Inc. Phone: (86-21) 5257-4568,

Fax: (86-21) 6237-2826

Singapore, Honeywell Pte Ltd. Phone: +(65) 6580 3278. Fax: +(65) 6445-3033

South Korea, Honeywell Korea Co Ltd. Phone:+(822)799 6114. Fax:+(822) 792

Email: (Sales) sc-cp-apps-salespa62@honeywell.com

or (TAC) hfs-tac-support@honeywell.com

Web: Knowledge Base search engine http://bit.ly/2N5Vldi

AMERICAS, Honeywell Process Solutions, Phone: 1-800-423-9883,

or 1-215/641-3610. (TAC) hfs-tac-support@honeywell.com.

Sales 1-800-343-0228. Email: (Sales) ask-ssc@honeywell.com

Web: Knowledge Base search engine http://bit.ly/2N5Vldi

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and

faulty workmanship. Contact your local sales office for warranty information.

If warranted goods are returned to Honeywell during the period of coverage,

Honeywell will repair or replace without charge those items it finds defective.

The foregoing is Buyer's sole remedy and is in lieu of all other warranties,

expressed or implied, including those of merchantability and fitness for a

particular purpose. Specifications may change without notice.

The information we supply is believed to be accurate and reliable as of this printing.

However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the

Honeywell web site, it is up to the customer to determine the suitability of the product

in the application.

To learn more about SmartLine Transmitters,

visit www.honeywellprocess.com

Or contact your Honeywell Account Manager

Houston, USA, TX 77042

Honeywell House, Skimped Hill Lane

Bracknell, England, RG12 1EB

Shanghai, China 20061

34-SM-25-04, Rev.8

November 2020

2020 Honeywell International Inc.

Loading...

Loading...