Page 1

SMV 3000

Smart Multivariable Transmitter

User’s Manual

34-SM-25-02

3/04

Page 2

Copyright, Notices, and Trademarks

© Copyright 1999 by Honeywell Inc.

Revision 0 – January 18, 1999

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in its

written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

This document was prepared using Information Mapping® methodologies and

formatting principles.

TotalPlant, TDC 3000 and SFC are U.S. registered trademarks of Honeywell Inc.

SmartLine is a U.S. trademark of Honeywell Inc.

Information Mapping is a trademark of Information Mapping Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell

Industrial Automation and Control

Automation College

2820 West Kelton Lane

Phoenix, AZ 85023

ii SMV 3000 Transmitter User’s Manual 1/99

Page 3

About This Publication

This manual is intended as a detailed “how to” reference for installing, piping, wiring, configuring,

starting up, operating, maintaining, calibrating, and servicing Honeywell’s SMV 3000 Smart

Multivariable Transmitter. It is based on using the SCT 3000 Smartline

software version 2.0 or greater as the operator interface.

While this manual provides detailed procedures to assist first time users, it also includes

summaries for most procedures as a quick reference for experienced users.

Configuration Toolkit

If you will be digitally integrating the SMV 3000 transmitter with our TPS/TDC 3000

control

system, we recommend that you use the PM/APM Smartline Transmitter Integration Manual

supplied with the TDC 3000X bookset as the main reference manual and supplement it with

detailed transmitter information in Appendix A of this manual.

Note that this manual does not include detailed transmitter specifications. A detailed Specification

Sheet is available separately or as part of the Specifier’s Guide which covers all Smartline

transmitter models.

Conventions and Symbol Definitions

The following naming conventions and symbols are used throughout this manual to alert users of

potential hazards and unusual operating conditions:

ATTENTION

ATTENTION indicates important information, actions or procedures that

may indirectly affect operation or lead to an unexpected transmitter

response.

CAUTION

CAUTION indicates actions or procedures which, if not performed

correctly, may lead to faulty operation or damage to the transmitter.

WARNING

WARNING indicates actions or procedures which, if not performed

correctly, may lead to personal injury or present a safety hazard.

ElectroStatic Discharge (ESD) hazard. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth terminal. Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

1/99 SMV 3000 Transmitter User’s Manual iii

Page 4

iv SMV 3000 Transmitter User’s Manual 1/99

Page 5

Table of Contents

References ....................................................................................................................................xii

Technical Assistance...................................................................................................................xii

SECTION 1

1.1 Introduction.................................................................................................................... 1

1.2 CE Conformity (Europe) ................................................................................................ 3

1.3 SMV 3000 Smart Multivariable Transmitters ................................................................. 4

1.4 Smartline Configuration Toolkit (SCT 3000).................................................................. 7

1.5 Smart Field Communicator (SFC) ................................................................................. 8

1.6 Transmitter Order ........................................................................................................ 11

SECTION 2

2.1 Introduction.................................................................................................................. 13

2.2 Getting SMV 3000 Transmitter On-Line Quickly.......................................................... 14

SECTION 3

3.1 Introduction.................................................................................................................. 16

3.2 Considerations for SMV 3000 Transmitter................................................................... 17

3.3 Considerations for SCT 3000 ...................................................................................... 21

SECTION 4

4.1 Introduction.................................................................................................................. 23

4.2 Mounting SMV 3000 Transmitter................................................................................. 24

4.3 Piping SMV 3000 Transmitter...................................................................................... 29

4.4 Installing RTD or Thermocouple.................................................................................. 35

4.5 Wiring SMV 3000 Transmitter...................................................................................... 36

OVERVIEW - FIRST TIME USERS ONLY ................................................................ 1

QUICK START REFERENCE .................................................................................. 13

PREINSTALLATION CONSIDERATIONS............................................................... 16

INSTALLATION........................................................................................................ 23

SECTION 5

5.1 Introduction.................................................................................................................. 45

5.2 Establishing Communications...................................................................................... 46

5.3 Making Initial Checks................................................................................................... 50

5.4 Write Protect Option .................................................................................................... 51

SECTION 6

6.1 Introduction.................................................................................................................. 45

6.2 Overview...................................................................................................................... 47

6.3 Configuring the SMV 3000 with The SCT.................................................................... 50

6.4 Device Configuration.................................................................................................... 51

6.5 General Configuration.................................................................................................. 52

6.6 DPConf Configuration - PV1....................................................................................... 56

6.7 AP/GPConf Configuration - PV2................................................................................. 61

6.8 TempConf Configuration - PV3................................................................................... 64

6.9 FlowConf Configuration - PV4 ....................................................................................71

6.10 Using Custom Engineering Units................................................................................. 77

6.11 Flow Compensation Wizard......................................................................................... 78

6.12 Saving, Downloading and Printing a Configuration File............................................... 81

6.13 Verifying Flow Configuration........................................................................................ 82

GETTING STARTED ................................................................................................ 45

CONFIGURATION.................................................................................................... 45

1/99 SMV 3000 Transmitter User’s Manual v

Page 6

SECTION 7 STARTUP ................................................................................................................. 79

7.1 Introduction.................................................................................................................. 79

7.2 Startup Tasks............................................................................................................... 80

7.3 Running Output Check ................................................................................................ 81

7.4 Using Transmitter to Simulate PV Input....................................................................... 85

7.5 Starting Up Transmitter................................................................................................ 89

SECTION 8

8.1 Introduction.................................................................................................................. 93

8.2 Accessing Operation Data........................................................................................... 94

8.3 Changing Default Failsafe Direction ............................................................................ 98

8.4 Saving and Restoring a Database............................................................................. 102

SECTION 9

9.1 Introduction................................................................................................................ 103

9.2 Preventive Maintenance ............................................................................................ 104

9.3 Inspecting and Cleaning Barrier Diaphragms............................................................ 105

9.4 Replacing Electronics Module or PROM.................................................................... 108

9.5 Replacing Meter Body Center Section....................................................................... 113

SECTION 10

10.1 Introduction................................................................................................................ 111

10.2 Overview.................................................................................................................... 112

10.3 Calibrating Analog Output Signal............................................................................... 114

10.4 Calibrating PV1 and PV2 Range Values.................................................................... 115

10.5 Resetting Calibration.................................................................................................. 117

SECTION 11

11.1 Introduction................................................................................................................ 119

11.2 Overview.................................................................................................................... 120

11.3 Troubleshooting Using the SCT................................................................................. 121

11.4 Diagnostic Messages................................................................................................. 122

OPERATION............................................................................................................. 93

MAINTENANCE...................................................................................................... 103

CALIBRATION ..................................................................................................... 111

TROUBLESHOOTING.......................................................................................... 119

SECTION 12

12.1 Replacement Parts .................................................................................................... 137

SECTION 13

13.1 Wiring Diagrams and Installation Drawings............................................................... 147

APPENDIX A – PM/APM/HPM SMV 3000 INTEGRATION........................................................... 149

A.1 Overview.................................................................................................................... 149

A.2 Description................................................................................................................. 150

A.3 Data Exchange Functions.......................................................................................... 153

A.4 Installation.................................................................................................................. 160

A.5 Configuration ............................................................................................................. 162

A.6 Operation Notes......................................................................................................... 169

APPENDIX B

APPENDIX C —PV4 FLOW VARIABLE EQUATIONS................................................................. 175

C.1 Overview.................................................................................................................... 175

C.2 Standard Flow Equation............................................................................................ 176

C.3 Dynamic Compensation Flow Equation..................................................................... 181

vi SMV 3000 Transmitter User’s Manual 1/99

PARTS LIST ......................................................................................................... 137

REFERENCE DRAWINGS................................................................................... 147

SMV 3000 CONFIGURATION RECORD SHEET ............................................... 179

Page 7

Figures and Tables

Figure 1 SMV 3000 Transmitter Handles Multiple Process Variable

Measurements and Calculates Flow Rate................................................................ 4

Figure 2 Functional Block Diagram for Transmitter in Analog Mode of Operation.................. 5

Figure 3 Functional Block Diagram for Transmitter in Digital DE Mode of

Operation.................................................................................................................. 6

Figure 4 Smartline Configuration Toolkit................................................................................. 7

Figure 5 Typical SFC Communication Interface ..................................................................... 8

Figure 6 Typical SMV 3000 Transmitter Order Components................................................ 11

Figure 7 Typical Mounting Area Considerations Prior to Installation..................................... 17

Figure 8 Typical Bracket Mounted Installations..................................................................... 24

Figure 9 Leveling a Transmitter with a Small Absolute Pressure Span. ............................... 28

Figure 10 Typical 3-Valve Manifold and Blow-Down Piping Arrangement.............................. 29

Figure 11 Transmitter Location Above Tap for Gas Flow Measurement ................................ 31

Figure 12 Transmitter Location Below the Tap for Liquid or Steam Flow

Measurement.......................................................................................................... 32

Figure 13 Operating Range for SMV 3000 Transmitters......................................................... 36

Figure 14 SMV 3000 Transmitter Terminal Block ...................................................................37

Figure 15 RTD Input Wiring Connections. .............................................................................. 42

Figure 16 Thermocouple Input Wiring Connections................................................................ 42

Figure 17 Ground Connection for Lightning Protection........................................................... 43

Figure 18 SCT Hardware Components................................................................................... 46

Figure 19 Write Protect Jumper Location and Selections with Daughter PCB

Removed................................................................................................................. 51

Figure 20 SMV On-line Configuration Process .......................................................................47

Figure 21 Square Root Dropout Points for PV1...................................................................... 59

Figure 22 Typical Range Setting Values for PV3.................................................................... 68

Figure 23 Example of LRV and URV Interaction..................................................................... 69

Figure 24 Typical Volumetric Flow Range Setting Values ...................................................... 74

Figure 25 Graphic Representation of Sample Low Flow Cutoff Action................................... 76

Figure 26 Typical SCT or SFC and Meter Connections for SMV Start up

Procedure. .............................................................................................................. 92

Figure 27 Location of Failsafe Jumper on main PWA of Electronics Module........................ 101

Figure 28 Typical PV1 or PV2 Range Calibration Hookup.................................................... 116

Figure 29 Major SMV 3000 Smart Multivariable Transmitter Parts Reference. .................... 138

Figure 30 SMV 3000 Electronics Housing............................................................................. 139

Figure 31 SMV 3000 Terminal Block Assembly.................................................................... 142

Figure 32 SMV 3000 Meter Body.......................................................................................... 143

Figure A-1 Typical PM/APM/HPM SMV 3000 Integration Hierarchy. ..................................... 151

Figure A-2 Mapped Parameters are Basis for Data Exchange............................................... 153

Figure A-3 Sixteen AI Points per STIMV IOP ......................................................................... 155

Figure A-4 AI Point for Each Transmitter Input....................................................................... 156

Figure A-5 Connection Rule Example. ................................................................................... 161

Figure A-6 Detail Display with PV Number and Number of PVs Field.................................... 169

Figure A-7 Example of DECONF Download Error Message.................................................. 171

1/99 SMV 3000 Transmitter User’s Manual vii

Page 8

Figures and Tables, Continued

Table 1 Start-up Tasks Reference....................................................................................... 14

Table 2 Operating Temperature Limits................................................................................ 19

Table 3 Transmitter Overpressure Ratings.......................................................................... 19

Table 4 Thermocouple Types for Process Temperature Sensor......................................... 20

Table 5 Mounting SMV 3000 Transmitter to a Bracket........................................................ 26

Table 6 Installing 1/2 inch NPT Flange Adapter .................................................................. 34

Table 7 Wiring the Transmitter............................................................................................. 38

Table 8 Making SCT 3000 Hardware Connections.............................................................. 47

Table 9 Making SCT 3000 On-line Connections.................................................................. 48

Table 10 PV Type Selection for SMV Output......................................................................... 52

Table 11 SMV Analog Output Selection ................................................................................ 54

Table 12 Pre-programmed Engineering Units for PV1 .......................................................... 56

Table 13 Pre-programmed Engineering Units for PV2*......................................................... 61

Table 14 Pre-programmed Engineering Units for PV3 .......................................................... 64

Table 15 Sensor Types for PV3 Process Temperature Input................................................ 66

Table 16 Pre-programmed Volumetric Flow Engineering Units for PV4................................ 71

Table 17 Pre-programmed Mass Flow Engineering Units for PV4 ........................................ 72

Table 18 Primary Flow Elements........................................................................................... 78

Table 19 Analog Output Check Procedure............................................................................ 81

Table 20 Output Check for SMV Transmitters in DE Mode ................................................... 84

Table 21 Using SMV Transmitter in the Input Mode.............................................................. 85

Table 22 Start up Procedure for SMV Transmitter Model SMA125....................................... 87

Table 23 Start up Procedure for SMV Transmitter Model SMG170....................................... 89

Table 24 Start up Procedure for SMV Transmitter Model SMA110....................................... 90

Table 25 Accessing Transmitter Operation Data Using SCT................................................. 94

Table 26 Cutting Failsafe Jumper........................................................................................ 100

Table 27 Inspecting and Cleaning Barrier Diaphragms....................................................... 105

Table 28 Replacing Electronics Module or PROM............................................................... 108

Table 29 Replacing Meter Body Center Section.................................................................. 113

Table 30 Accessing SMV 3000 Diagnostic Information using the SCT ............................... 121

Table 31 Critical Status Diagnostic Message Table............................................................. 123

Table 32 Non-Critical Status Diagnostic Message Table..................................................... 126

Table 33 Communication Status Message Table ................................................................ 132

Table 34 Informational Status Message Table .................................................................... 134

Table 35 SFC Diagnostic Message Table ........................................................................... 135

Table 36 Parts Identification for Callouts in Figure 30 .........................................................140

Table 37 Parts Identification for Callouts in Figure 31 .........................................................142

Table 38 Parts Identification for Callouts in Figure 32 .........................................................143

Table 39 Summary of Recommended Spare Parts............................................................. 146

Table A-1 Summary of SMV 3000 Transmitter PVs Configuration........................................ 158

Table A-2 Typical SMV 3000 Database Size and Broadcast Time ....................................... 159

Table A-3 Base Engineering Units for SMV 3000 Transmitter PVs....................................... 164

Table A-4 Sensor Type Selections for SMV 3000 PVs.......................................................... 165

Table A-5 PV Characterization Selections for SMV 3000 PVs.............................................. 165

Table A-6 DECONF and PV Type Parameter Entry Comparison ......................................... 166

Table A-7 Example URLs for a SMV Transmitter Model SMA125. .......................................166

Table A-8 Damping Range Values for SMV 3000 Transmitter PVs ......................................168

viii SMV 3000 Transmitter User’s Manual 1/99

Page 9

Figures and Tables, Continued

Table A-9 Conversion Values for PV1 and PV2 Pressures................................................... 172

Table A-10 Conversion Values for PV3 Temperature............................................................. 172

Table A-11 Conversion Values for PV4 as Volumetric Flow Rate........................................... 174

Table A-12 Conversion Values for PV4 as Mass Flow Rate................................................... 176

Table A-13 Additional IOP Status Messages........................................................................... 177

Table C-1 Air Through a Venturi Meter Configuration Example ............................................177

Table C-2 Superheated Steam using an Averaging Pitot Tube Configuration

Example................................................................................................................ 179

Table C-3 Liquid Propane Configuration Example ............................................................... 182

Table C-4 Air Configuration Example.................................................................................... 185

Table C-5 Superheated Steam Configuration Example......................................................... 189

1/99 SMV 3000 Transmitter User’s Manual ix

Page 10

Acronyms

A.G.A. ......................................................................................................... American Gas Association

AP ............................................................................................................................Absolute Pressure

APM .........................................................................................................Advanced Process Manager

AWG ..................................................................................................................American Wire Gauge

CJ.....................................................................................................................................Cold Junction

CJT ............................................................................................................Cold Junction Temperature

DE.........................................................................................Digital Enhanced Communications Mode

DP.........................................................................................................................Differential Pressure

ECJT............................................................................................External Cold Junction Temperature

EMI.......................................................................................................... Electromagnetic Interference

FTA...........................................................................................................Field Termination Assembly

GP............................................................................................................................... Gauge Pressure

HP...................................................................................................................................High Pressure

HP...............................................................................................High Pressure Side (DP Transmitter)

Hz..................................................................................................................................................Hertz

inH

O...........................................................................................................................Inches of Water

2

KCM............................................................................................................................Kilo Circular Mils

LCN....................................................................................................................Local Control Network

LGP.................................................................................................................In-Line Gauge Pressure

LP.................................................................................................................................... Low Pressure

LP.................................................................................................Low Pressure Side (DP Transmitter)

LRL ......................................................................................................................... Lower Range Limit

LRV........................................................................................................................Lower Range Value

mAdc..........................................................................................................Milliamperes Direct Current

mmHg ................................................................................................................ Millimeters of Mercury

mV............................................................................................................................................Millivolts

n.m................................................................................................................................Newton.Meters

NPT......................................................................................................................National Pipe Thread

NVM.....................................................................................................................Non-Volatile Memory

PM............................................................................................................................... Process Manger

PROM............................................................................................Programmable Read Only Memory

PSI ..................................................................................................................Pounds per Square Inch

PSIA.................................................................................................Pounds per Square Inch Absolute

PV .............................................................................................................................. Process Variable

PWA............................................................................................................... Printed Wiring Assembly

RFI.........................................................................................................Radio Frequency Interference

RTD................................................................................................. Resistance Temperature Detector

SFC.............................................................................................................Smart Field Communicator

STIM .............................................................................................Smart Transmitter Interface Module

STIMV IOP..................................... Smart Transmitter Interface Multivariable Input/Output Processor

T/C................................................................................................................................. Thermocouple

URL......................................................................................................................... Upper Range Limit

URV .......................................................................................................................Upper Range Value

US.............................................................................................................................. Universal Station

Vac................................................................................................................. Volts Alternating Current

Vdc.........................................................................................................................Volts Direct Current

XMTR..................................................................................................................................Transmitter

x SMV 3000 Transmitter User’s Manual 1/99

Page 11

Parameters

A’d...................................................................................................................................Area of orifice

A’u......................................................................................................................................Area of pipe

C ..................................................................................Flow coefficient or orifice discharge coefficient

d1......................................................................................................................Inside diameter of pipe

d2........................................................................... Orifice plate bore diameter at flowing temperature

do...................................................................................................................Inside diameter of orifice

Ev................................................................................................................Velocity of approach factor

Fpv............................................................................................................ Super compressibility factor

g.........................................................................................................................Acceleration of gravity

Kq........................................................................... Scaling factor for volumetric flow in PV4 algorithm

Kw..................................................................................Scaling factor for mass flow in PV4 algorithm

Nc......................................................................................................................Units conversion factor

P..............................................................................................................................................Pressure

Pa.......................................................................................Measured static pressure in PV4 algorithm

Pc..................................................................................................Absolute critical pressure of the gas

Pd.................................................................................................Static pressure at downstream point

Pdp...........................................................Measured differential pressure in Pascals in PV4 algorithm

Pf....................................................................................................... Absolute pressure of flowing gas

Pr.............................................................................................................................Reduced pressure

Pu......................................................................................................Static pressure at upstream point

Qh.......................................................................................... Volumetric rate of flow in PV4 algorithm

Qs ...................................................................................................................................... Rate of flow

R ......................................................................................................................................Gas constant

T..........................................................................................................................Absolute temperature

Ta...............................................................................Measure process temperature in PV4 algorithm

Tc............................................................................................Absolute critical temperature of the gas

Tf..................................................................................................Absolute temperature of flowing gas

Tr.........................................................................................................................Reduced temperature

T

...............................................................Absolute temperature of reference flow in PV4 algorithm

ref

v ................................................................................................................................... Specific volume

Vd.................................................................................................... Fluid velocity at downstream point

Vu.........................................................................................................Fluid velocity at upstream point

Wh...................................................................................................Mass rate of flow in PV4 algorithm

Y..................................................................................................................................Expansion factor

Z..........................................................................................................................Compressibility factor

γ (gamma)........................................................................................................................... Fluid density

ρ ..............................................................................................................................................................Density

ρ

..................................................................................................................Actual density in PV4 algorithm

act

ρ

...............................................................................................................Design density in PV4 algorithm

des

ρ

........................................................................................ Density of fluid under reference conditions

r

1/99 SMV 3000 Transmitter User’s Manual xi

Page 12

References

Publication

Title

SCT 3000 Smartline Configuration

Toolkit Start-up and Installation Manual

ST 3000 Smart Field Communicator

Model STS103 Operating Guide

For R400 and later:

PM/APM Smartline Transmitter

Integration Manual

Publication

Number

34-ST-10-08

34-ST-11-14

PM12-410 Implementation/

PM/APM Optional Devices

Binder

Title

Binder

Number

TDC 2045

Technical Assistance

If you encounter a problem with your SMV 3000 Smart Multivariable Transmitter, check to see

how your transmitter is currently configured to verify that all selections are consistent with your

application.

If the problem persists, you can call our Solutions Support Center between the hours of 8:00 am

and 4:00 pm EST Monday through Friday for direct factory technical assistance.

1-800-423-9883 (U. S. only)

OR

1-215-641-3410

FAX: 1-215-641-3400

An engineer will discuss your problem with you. Please have your complete model number, serial

number, and software revision number on hand for reference. You can find the model and serial

numbers on the transmitter nameplates. You can also view the software version number using the

SCT or SFC.

If it is determined that a hardware problem exists, a replacement transmitter or part will be shipped

with instructions for returning the defective unit. Please do not return your transmitter without

authorization from Honeywell’s Solutions Support Center or until the replacement has been

received.

xii SMV 3000 Transmitter User’s Manual 1/99

Page 13

Section 1 Overview - First Time Users Only

1.1 Introduction

Section Contents

About This Section

ATTENTION

This section includes these topics.

Topic See Page

1.1 Introduction..............................................................................1

1.2 CE Conformity (Europe)...........................................................3

1.3 SMV 3000 Smart Multivariable Transmitters............................4

1.4 Smartline Configuration Toolkit (SCT 3000).............................7

1.5 Smart Field Communicator (SFC)............................................8

1.6 Transmitter Order...................................................................11

This section is intended for users who have never worked with our

SMV 3000 Smart Multivariable Transmitter and the SCT 3000 Smartline

Configuration Toolkit before. It provides some general information to

acquaint you with the SMV 3000 transmitter and the SCT 3000.

To be sure that you have the SCT software version that is compatible with

your SMV 3000, please note the following table.

STIMV IOP Module

Revision Level

If your SMV 3000 contains

software

version . . .

1.1 through 1.5 3.06.00

2.1 3.11.2 5.3

2.5 or 3.1 3.12.3

2.5, 3.1 or 4.0 4.02.013a

Then use this compatible

SCT software version . . .

* If the SMV 3000 will be integrated with our TPS/TDC control systems,

you must have an STIMV IOP module in your Process Manager,

* Compatible TDC

STIMV IOP module

Advanced Process Manager, or High Performance Process Manager.

The STIMV IOP module must be at least revision level 5.3 or greater to

be compatible with the SMV 3000. Contact your Honeywell

representative for information on upgrading an STIMV IOP.

1/99 SMV 3000 Transmitter User’s Manual 1

Page 14

1.2 CE Conformity (Europe)

About Conformity

ATTENTION

This product is in conformity with the protection requirements of

89/336/EEC, the EMC Directive. Conformity of this product with any

other “CE Mark” Directive(s) shall not be assumed.

Deviation from the installation conditions specified in this manual may

invalidate this product’s conformity with the EMC Directive.

ATTENTION

The emission limits of EN 50081-2 are designed to provide reasonable

protection against harmful interference when this equipment is operated in

an industrial environment. Operation of this equipment in a residential area

may cause harmful interference. This equipment generates, uses, and can

radiate radio frequency energy and may cause interference to radio and

television reception when the equipment is used closer than 30 meters (98

feet) to the antenna(e). In special cases, when highly susceptible apparatus

is used in close proximity, the user may have to employ additional mitigating

measures to further reduce the electromagnetic emissions of this equipment.

2 SMV 3000 Transmitter User’s Manual 1/99

Page 15

1.3 SMV 3000 Smart Multivariable Transmitters

About the Transmitter

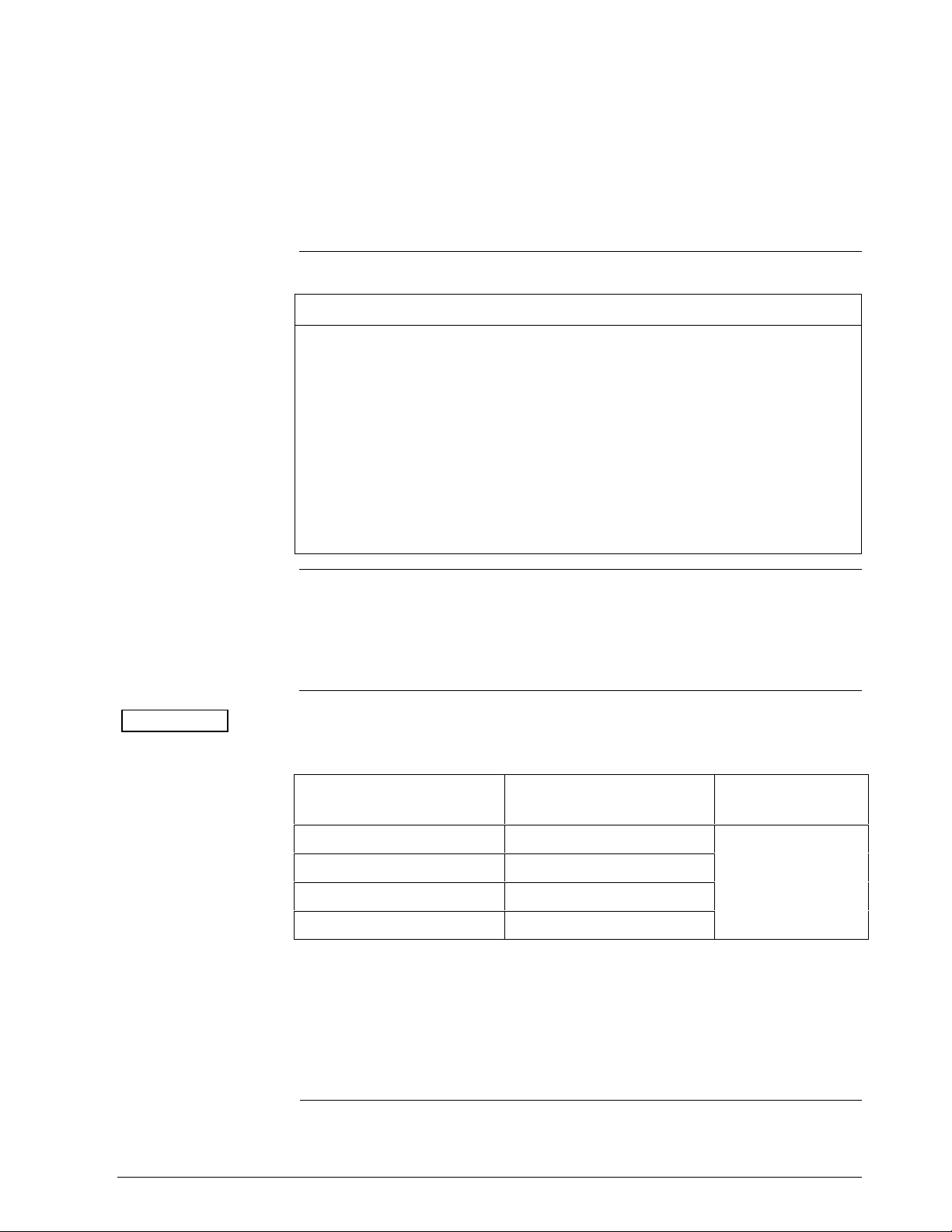

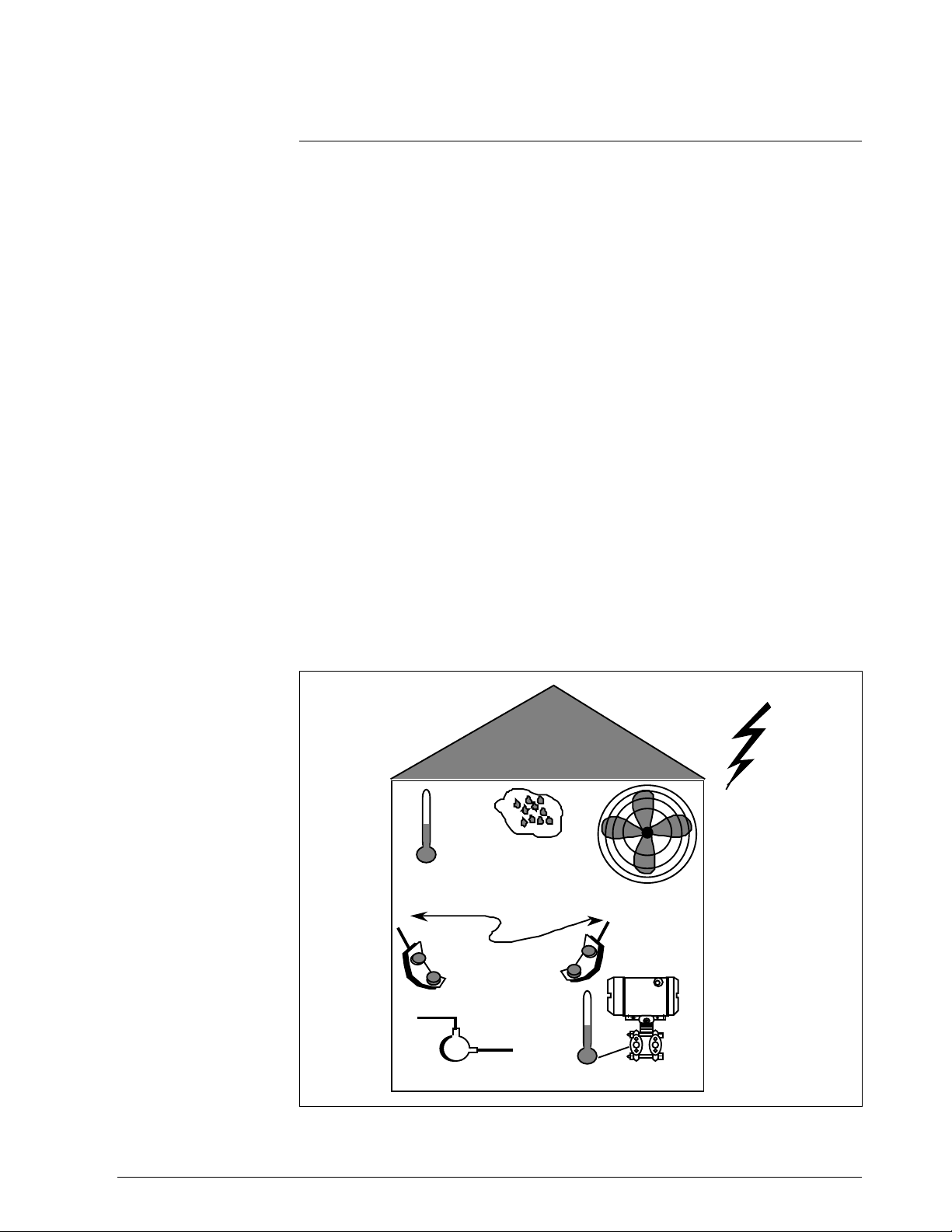

The SMV 3000 Smart Multivariable Transmitter shown in Figure 1

measures three separate process variables and calculates volumetric or

mass flow rate for gases, steam or liquids for output over a 4 to 20

milliampere, two-wire loop. Its general design is based on the field proven

technology of our ST 3000 Smart Pressure Transmitter and meets the

same high performance standards.

Figure 1 SMV 3000 Transmitter Handles Multiple Process Variable

Measurements and Calculates Flow Rate

Electronics

Housing

Meter body

The SMV 3000 transmitter accepts process temperature signals from an

external Resistance Temperature Detector (RTD) or any one of several

common thermocouple types. Its unique measurement sensor

simultaneously handles differential pressure, static pressure, and meter

body temperature signals while a separate circuit processes the process

temperature input. Note that the static pressure (absolute or gauge) is read

from the high pressure side of the meter body.

Using stored equations in conjunction with the multiple process variable

inputs, the SMV 3000 calculates a compensated volumetric or mass flow

rate output for gases, liquids and steam. Its output signal is proportional to

the calculated differential flow rate.

Continued on next page

1/99 SMV 3000 Transmitter User’s Manual 3

Page 16

1.3 SMV 3000 Smart Multivariable Transmitters, Continued

SMV Operating Modes

The SMV 3000 can transmit its output in either an analog 4 to 20

milliampere format or a Digitally Enhanced (DE) protocol format for

direct digital communications with our TPS/TDC 3000 control system. In

the analog format, only a selected variable is available as an output which

can be any one of the following:

• Differential Pressure PV1,

• Static Pressure PV2,

• Process Temperature PV3, or

• Calculated Flow Rate PV4

Note that the secondary variable is only available as a read only parameter

through the SCT or SFC. See Figure 2.

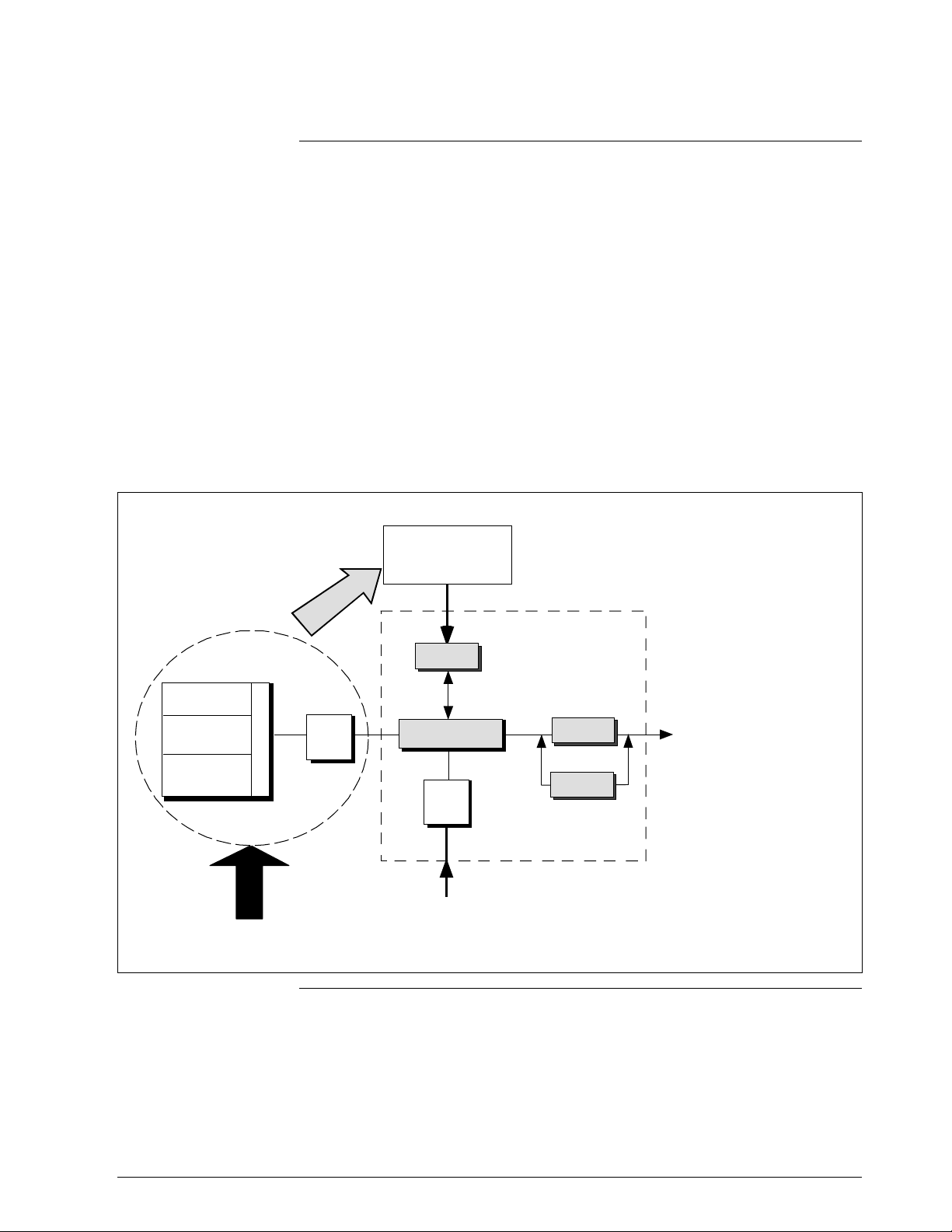

Figure 2 Functional Block Diagram for Transmitter in Analog Mode of Operation.

Factory

Characterization

Data

s

c

i

g

t

n

s

i

i

t

Meter Body

r

a

e

r

t

e

c

p

a

r

O

a

h

C

Electronics Housing

∆P Senso r

PV1

Temperature

Sensor

SV1

Static Pre ssure

Sensor

PV2

Pressure

PROM

r

e

x

e

l

p

i

t

l

u

M

A/D

Microprocessor

A/D

PV3

RTD or

PV4

D/A

Digital I/O

Proportional 4 to 20mA

output for selected PV

(Digital signal imposed

during SFC

communications).

PV1 = Differential Pressure

PV2 = Static Pressure

PV3 = Process Tem peratur e

PV4 = Calculated Volumetric

or Mass Flow

SV1 = Meter Body Temperature

(Read only)

Thermocouple

Input

Continued on next page

4 SMV 3000 Transmitter User’s Manual 1/99

Page 17

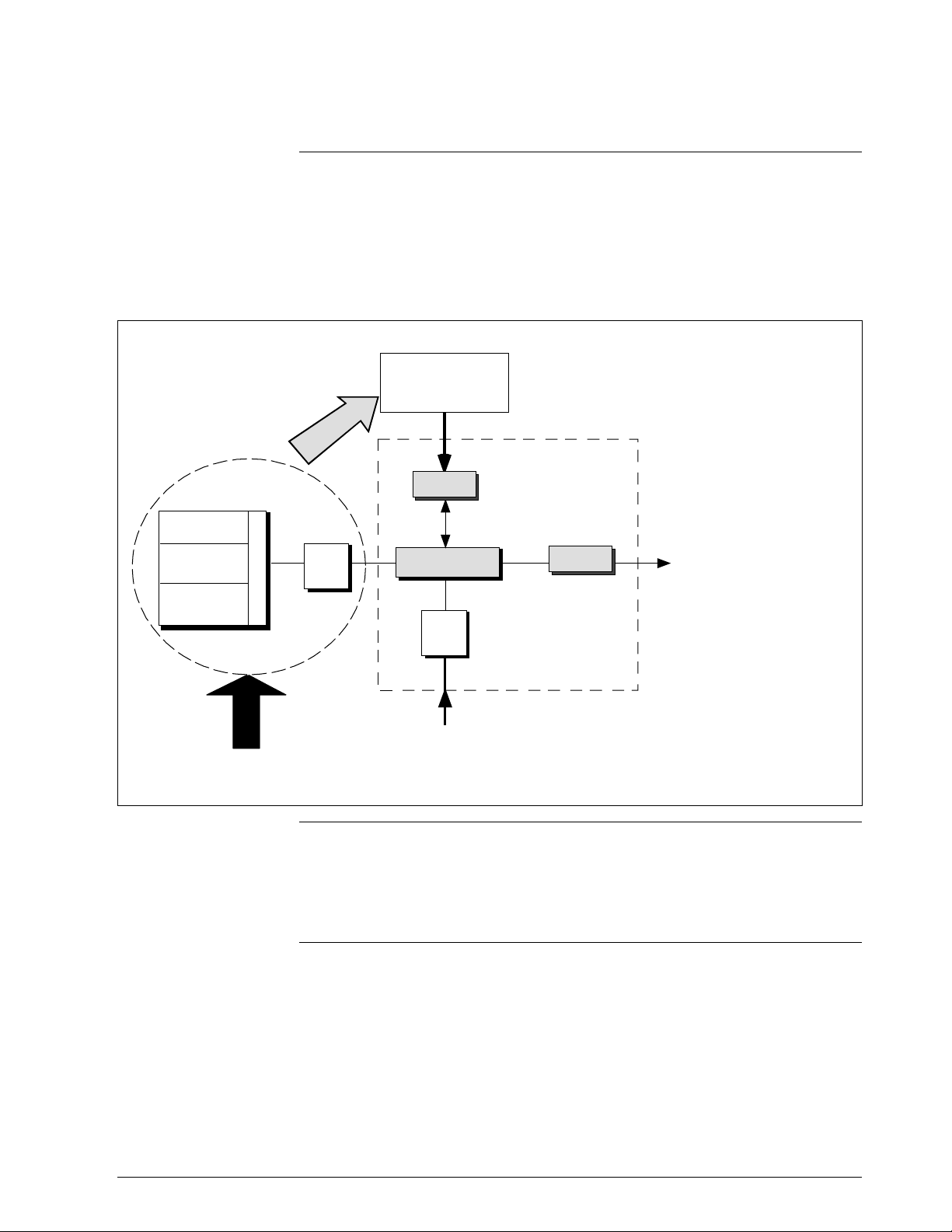

1.3 SMV 3000 Smart Multivariable Transmitters, Continued

SMV Operating

Modes, continued

In the digital DE protocol format, all four process variables are available

for monitoring and control purposes; and the meter body temperature is

also available as a secondary variable for monitoring purposes only - See

Figure 3.

Figure 3 Functional Block Diagram for Transmitter in Digital DE Mode of Operation.

Factory

Characterization

Data

s

c

i

g

t

n

s

i

i

t

Meter Body

∆P Sensor

PV1

Temperature

Sensor

SV1

Static Pressure

Sensor

PV2

Pressure

r

a

e

r

t

e

c

p

a

r

O

a

h

C

PROM

r

e

x

e

l

p

i

t

l

u

M

A/D

Microprocessor

A/D

RTD or

Thermocouple

Input

Electr onics Housing

PV4

PV3

Digital I/O

Digital signal broa dcast s

up to 4 PVs plus

secondary variable i n

floating point format over

20mA loop.

PV1 = Differential Pr essure

PV2 = Static Pressure

PV3 = Process Temperature

PV4 = Calculated Volumetric

or Mass Flow

SV1 = Meter Body Temperature

(Monitoring purposes only)

Transmitter

adjustments

The SMV 3000 transmitter has no physical adjustments. You need an SCT

to make any adjustments in an SMV 3000 transmitter. Alternately, certain

adjustments can be made through the Universal Station if the transmitter is

digitally integrated with our TPS/TDC 3000 control system.

1/99 SMV 3000 Transmitter User’s Manual 5

Page 18

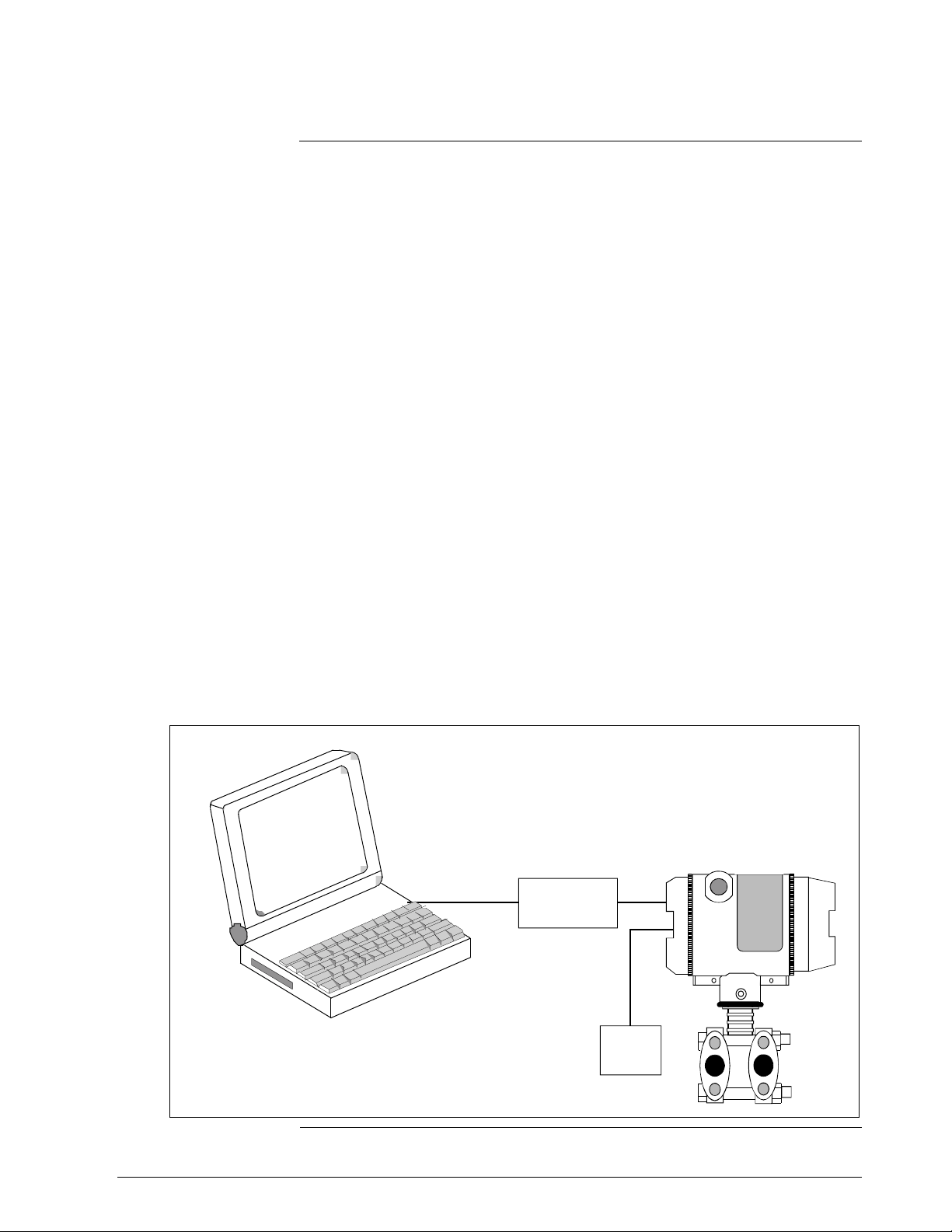

1.4 Smartline Configuration Toolkit (SCT 3000)

Smartline

Configuration Toolkit

Honeywell’s SCT 3000 Smartline Configuration Toolkit is a cost-effective

means to configure, calibrate, diagnose, and monitor the SMV 3000 and

other smart field devices. The SCT 3000 runs on a variety of Personal

Computer (PC) platforms using Windows 95

. It is a bundled Microsoft Windows software and PC-interface

NT

Window 98 and Windows

hardware solution that allows quick, error-free configuration of SMV

transmitters. Figure 4 shows the major components of the SCT 3000.

Some SCT 3000 features include:

• Preconfigured templates that simplify configuration and allow rapid

development of configuration databases.

• Context-sensitive help and a comprehensive on-line user manual.

• Extensive menus and prompts that minimize the need for prior training

or experience.

• The ability to load previously configured databases at time of

installation.

• Automatic verification of device identification and database

configuration menus and prompts for bench set up and calibration.

• The ability to save unlimited transmitter databases on the PC.

Please refer to the table on Page 1 for SCT software versions that are

compatible with your SMV 3000 transmitter. Contact your Honeywell

representative for more information.

Figure 4 Smartline Configuration Toolkit

PC or Laptop running

SCT 3000 Software Program

SMV 3000

Smartline

Option Module

Power

Supply

6 SMV 3000 Transmitter User’s Manual 1/99

Page 19

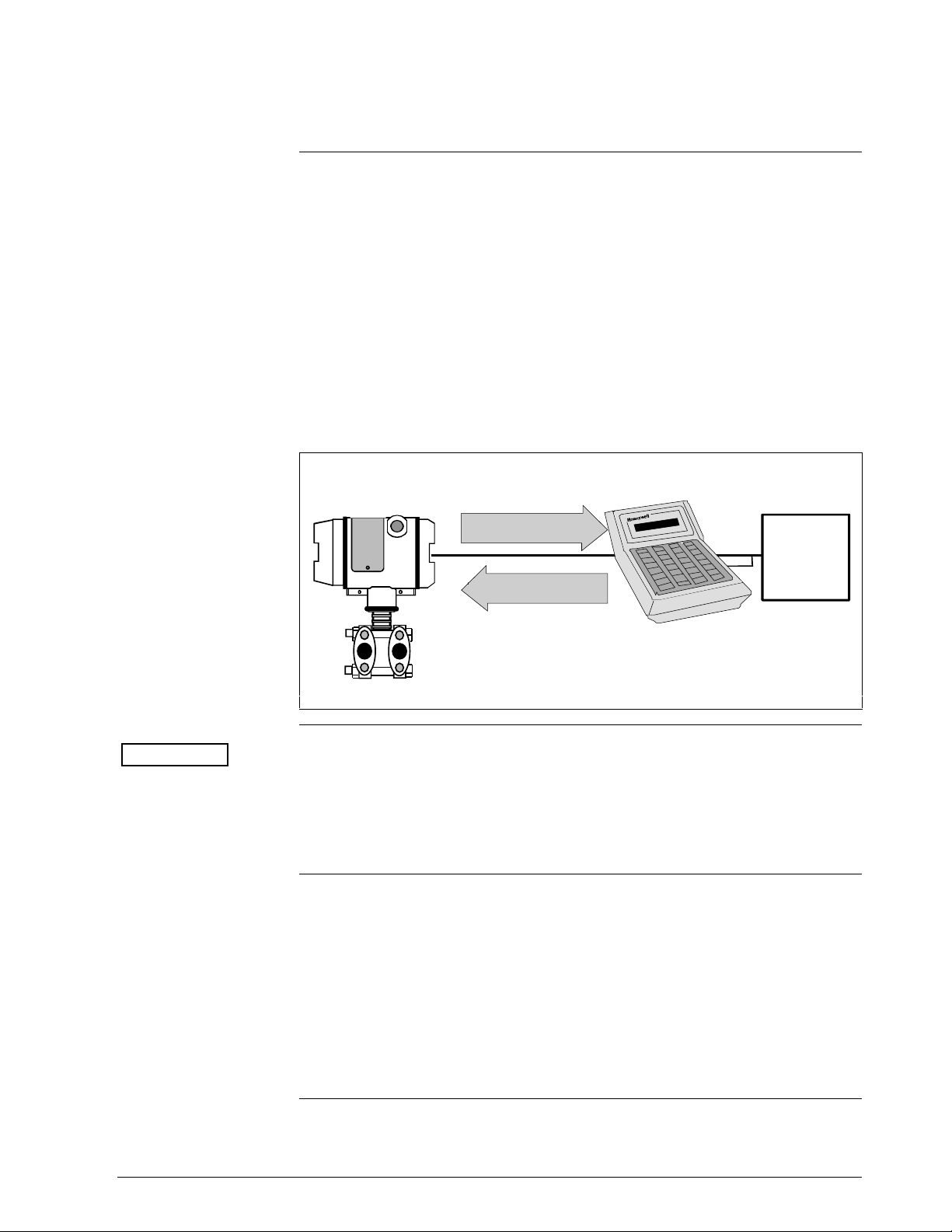

1.5 Smart Field Communicator (SFC)

About SFC

Communications

The portable, battery-powered SFC serves as the common communication

interface device for Honeywell’s family of Smartline Transmitters. It

communicates with a transmitter through serial digital signals over the 4 to

20 milliampere line used to power the transmitter. A request/response

format is the basis for the communication operation. The transmitter’s

microprocessor receives a communication signal from the SFC, identifies

the request, and sends a response message.

Figure 5 shows a simplified view of the communication interface provided

by an SFC.

Figure 5 Typical SFC Communication Interface

SMV 3000

Response

4 to 20 mA line

Request

SFC

Power

Supply and

Receiver

ATTENTION

Because of the advanced capabilities built-in to the SMV 3000, we do not

recommend that you use the SFC to configure the SMV transmitter. Some

of the SMV’s advance functions are not supported by the SFC. Although

you can use the SFC to perform certain operations, such as calibrate or rerange the transmitter, read transmitter status and diagnose faults.

Using the SFC with

the SMV 3000

If you use the SFC to communicate with the SMV, you can adjust

transmitter values, or diagnose potential problems from a remote location

such as the control room. You can use the SFC to:

• Monitor: Read the input pressure, process temperature, or

secondary variable to the transmitter in engineering

units.

• Display: Retrieve and display data from the transmitter or SFC

memory.

Continued on next page

1/99 SMV 3000 Transmitter User’s Manual 7

Page 20

1.5 Smart Field Communicator (SFC), Continued

Using the SFC with

the SMV 3000,

continued

ATTENTION

• Change Mode

of Operation: Tell transmitter to operate in either its analog (4-20

mA) mode or its digital enhanced (DE) mode.

• Check Current

Output: Use the transmitter to supply the output current desired

for verifying analog loop operation, troubleshooting, or

calibrating other components in the analog loop.

• Simulate

Input: Use the transmitter to simulate a desired input value for

the selected PV for verifying transmitter operation.

• Troubleshoot: Check status of transmitter operation and display

diagnostic messages to identify transmitter,

communication, or operator error problems.

For more information about using the SFC with the SMV 3000, see the

Smart Field Communicator Model STS103 Operating Guide,

34-ST-11-14. The document provides complete keystroke actions and

prompt displays.

Continued on next page

8 SMV 3000 Transmitter User’s Manual 1/99

Page 21

1.6 Transmitter Order

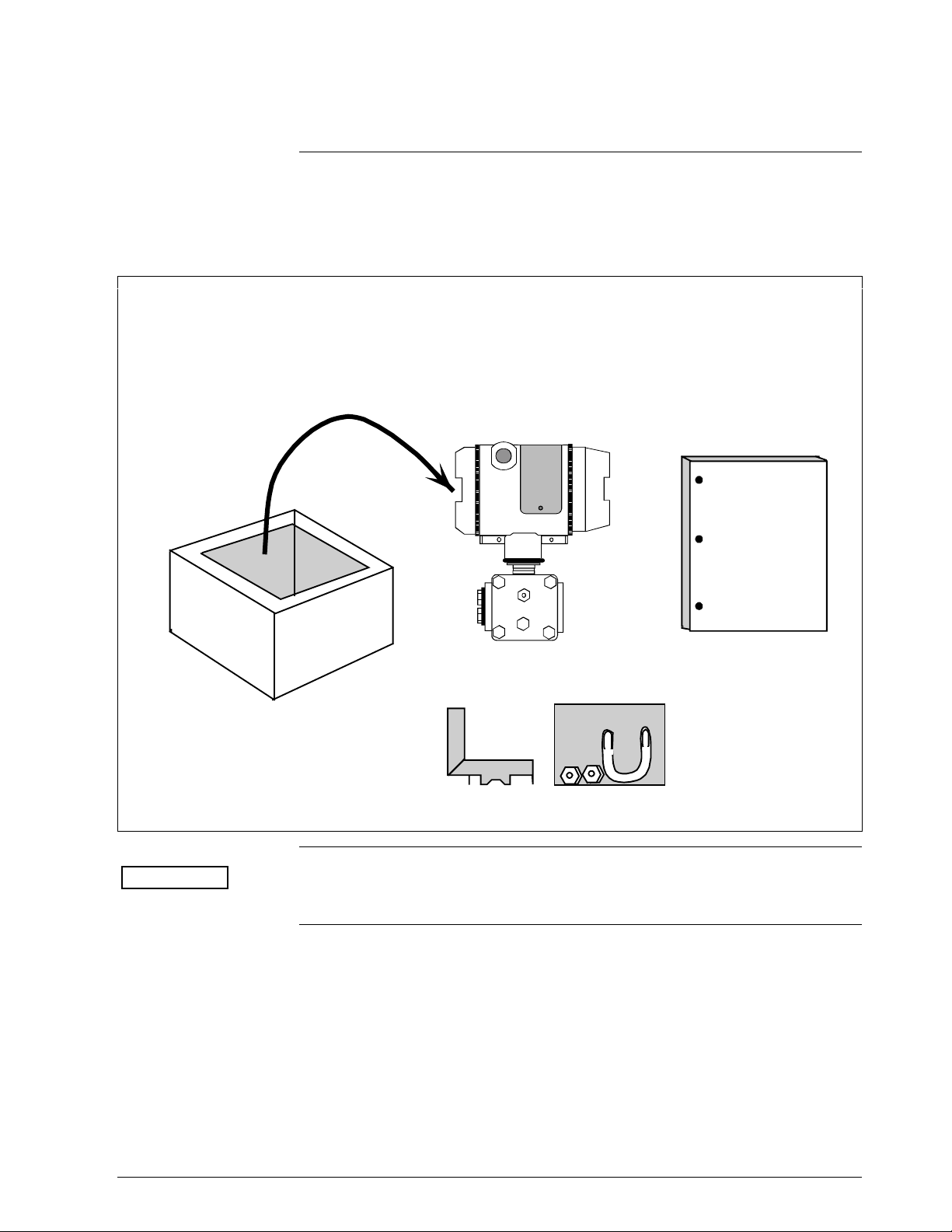

Order Components

Figure 6 shows the components that would be shipped and received for a

typical SMV 3000 transmitter order.

Figure 6 Typical SMV 3000 Transmitter Order Components

Ordered

w SMV 3000 T ransmitter wi th optional mounting br acket

Shipped

Received

SMV 3000

User’s

Manual

ATTENTION

Mounting Bracket (Optional)

Honeywell can also supply the RTD or Thermocouple for use with an

SMV 3000. See “About Documentation,” next.

Continued on next page

1/99 SMV 3000 Transmitter User’s Manual 9

Page 22

1.6 Transmitter Order, Continued

About Documentation

• SCT 3000 Smartline Configuration Toolkit Start-up and Installation

Manual 34-ST-10-08: One copy supplied with the SCT 3000

Smartline Configuration Toolkit. This document provides basic

information on installation, setup and operation of the SCT 3000. It is

a companion document to the SCT on-line user manual.

• SMV 3000 Smart Multivariable Transmitter User’s Manual 34-SM-25-

02: One copy is shipped with every transmitter order up to five units.

Orders for more than five units will ship with one SMV user manual

for every five transmitters. This document provides detailed

information for installing, wiring, configuring, starting up, operating,

maintaining, and servicing the SMV 3000 transmitter. This is the main

reference manual for the SMV 3000 transmitter.

• Smart Field Communicator Model STS103 Operating Guide

34-ST-11-14: One copy is shipped with every SFC. This document

provides generic SFC information and detailed keystroke actions for

interfacing with these Honeywell Smartline Transmitters.

– SMV 3000 Smart Multivariable Transmitter

– ST 3000 Smart Pressure Transmitter

– STT 3000 Smart Temperature Transmitter

– MagneW 3000 Smart Electromagnetic Flowmeter

• Guide to Temperature Sensors and Thermowells, 34-44-29-01: This

document tells you how to properly specify thermal probes and

thermowell assemblies for your application. Model selection guides

also are included for various temperature probes.

10 SMV 3000 Transmitter User’s Manual 1/99

Page 23

Section 2 Quick Start Reference

2.1 Introduction

Section Contents

About this section

This section includes these topics

Topic See Page

2.1 Introduction............................................................................13

2.2 Getting SMV 3000 Transmitter On-Line Quickly.....................14

This section provides a list of typical start-up tasks and tells you where

you can find detailed information about performing the task.

This section assumes that the SMV 3000 transmitter has been installed

and wired correctly, and is ready to be put into operation. It also assumes

that you are somewhat familiar with using the SCT and that the transmitter

has been configured correctly for your application. If the transmitter has

not been installed and wired, you are not familiar with SCT operation,

and/or you do not know if the transmitter is configured correctly, please

read the other sections of this manual or refer to the SCT 3000 Smartline

Configuration Toolkit Start-up and Installation Manual (34-ST-10-08)

before starting up your transmitter.

1/99 SMV 3000 Transmitter User’s Manual 11

Page 24

2.2 Getting SMV 3000 Transmitter On-Line Quickly

Quick Start-up Tasks

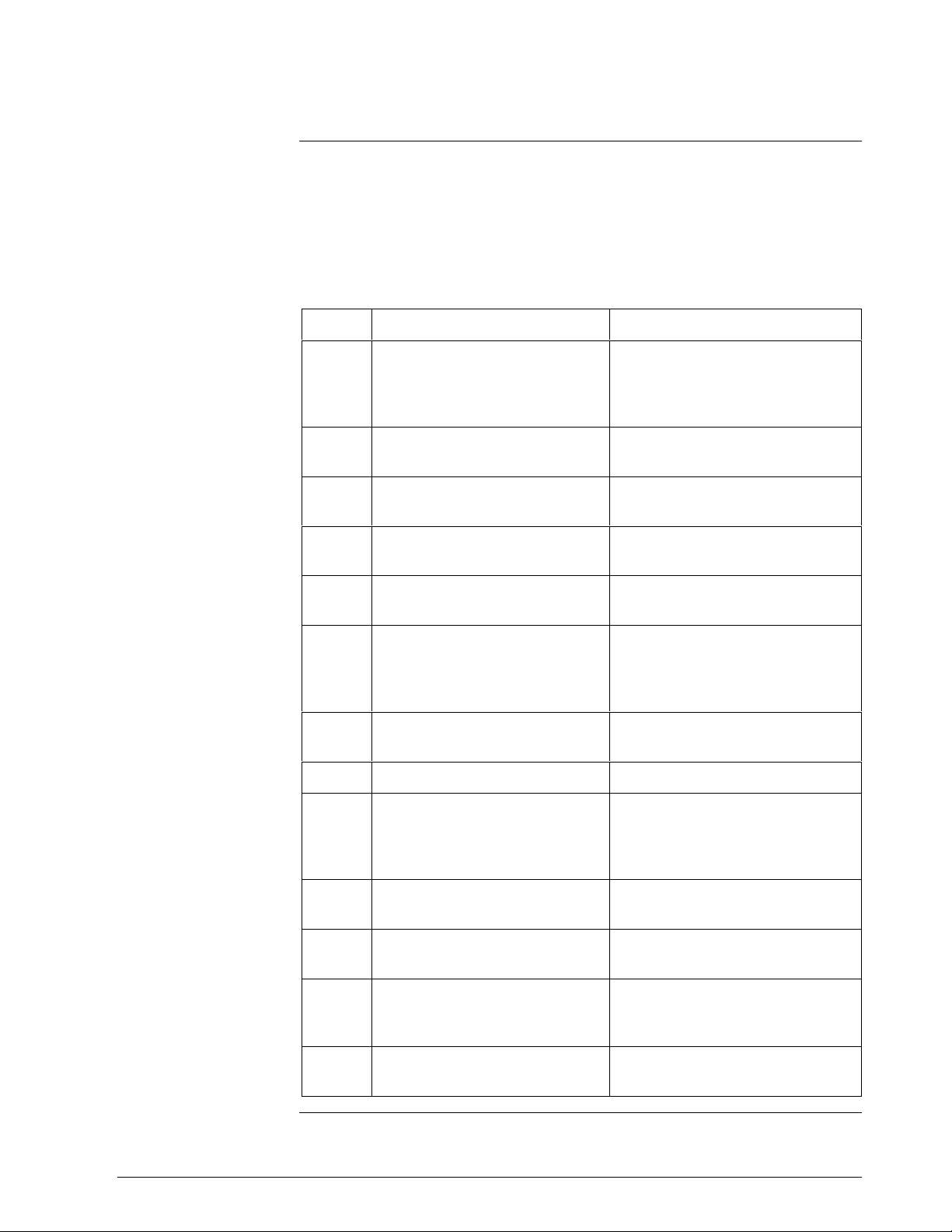

Table 1 lists common start-up tasks for an SMV 3000 transmitter using the

SCT and gives an appropriate section in this manual to reference for more

information about how to do the task. The start-up tasks are listed in the

order they are commonly completed.

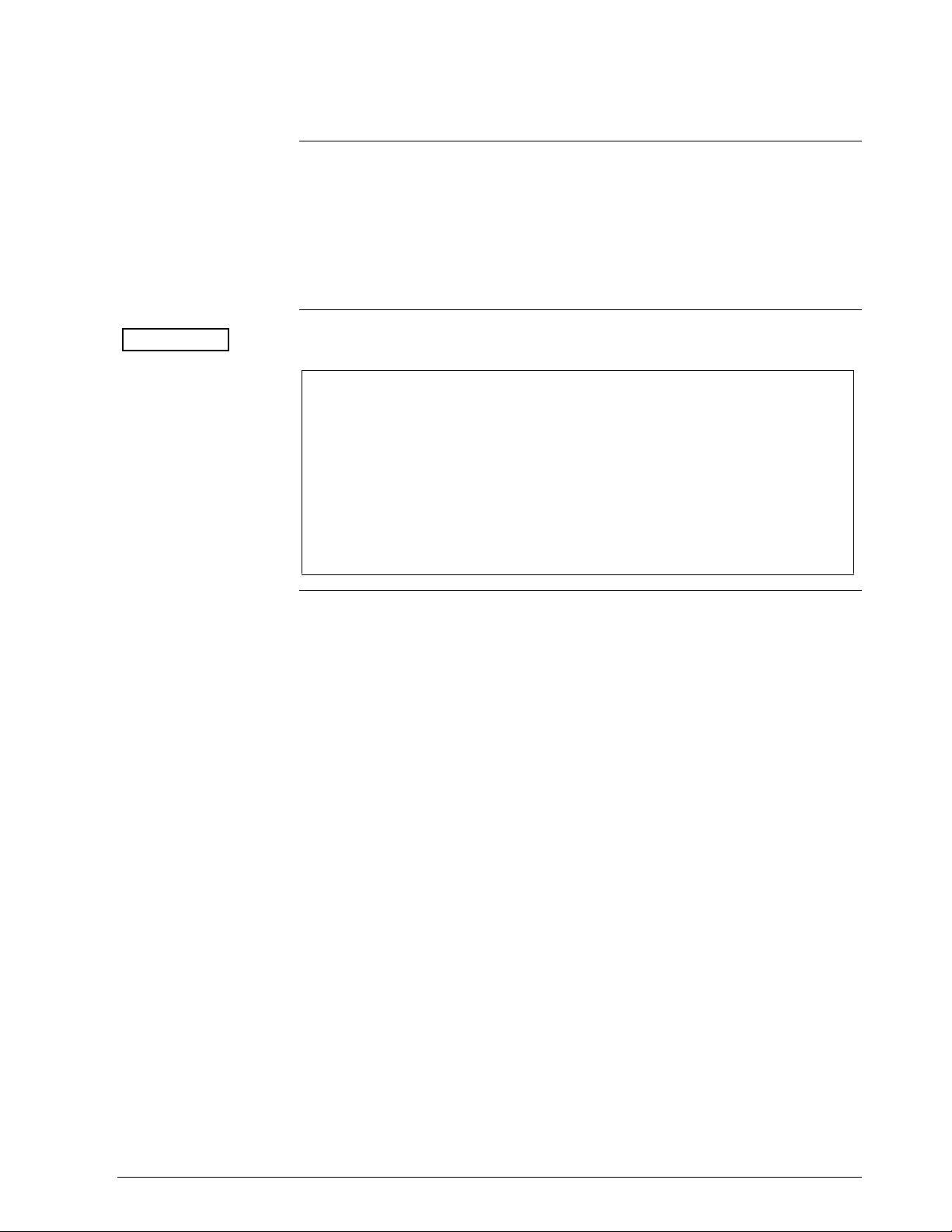

Table 1 Start-up Tasks Reference

Task Description Reference Section

Put analog loop into manual

1

mode.

Connect SCT to transmitter and

2

establish communications

Identify transmitter’s mode of

3

operation.

Change mode of operation, if

4

required.

Check/set output conformity

5

(Linear/Square Root) for PV1.

Appropriate vendor documentation

for controller or recorder used as a

receiver in analog loop with

SMV 3000 transmitter.

5.2

5.3

5.3

6.6

10

11

12

13

Check/set damping times for all

6

PVs.

Check/set Probe Configuration

7

for PV3

Check/set PV4 Algorithm 6.9, 6.10, 6.11

8

Check/set Lower Range Values

9

and Upper Range Values for all

PVs.

Select PV to represent output for

transmitter in analog mode only.

Run optional output check for

analog loop.

Perform start-up procedures Check zero input and set, if

required.

Check transmitter status, access

operating data.

6.6 (for PV1)

6.7 (for PV2)

6.8 (for PV3)

6.9 (for PV4)

6.8

6.6 (for PV1)

6.7 (for PV2)

6.8 (for PV3)

6.9 (for PV4)

6.5

7.3

7.5

8.2

12 SMV 3000 Transmitter User’s Manual 1/99

Page 25

Section 3 Preinstallation Considerations

3.1 Introduction

Section Contents

About this section

This section includes these topics

Topic See Page

3.1 Introduction............................................................................16

3.2 Considerations for SMV 3000 Transmitter..............................17

3.3 Considerations for SCT 3000.................................................21

This section reviews things you should take into consideration before you

install the transmitter and start using the SCT. Of course, if you are

replacing an existing SMV 3000 transmitter, you can skip this section.

1/99 SMV 3000 Transmitter User’s Manual 13

Page 26

3.2 Considerations for SMV 3000 Transmitter

Evaluate conditions

The SMV 3000 transmitter is designed to operate in common indoor

industrial environments as well as outdoors. To assure optimum

performance, evaluate these conditions at the mounting area relative to

published transmitter specifications and accepted installation practices for

electronic pressure transmitters.

• Environmental Conditions

– Ambient Temperature

– Relative Humidity

• Potential Noise Sources

– Radio Frequency Interference (RFI)

– Electromagnetic Interference (EMI)

• Vibration Sources

– Pumps

– Motorized Valves

– Valve Cavitation

• Process Characteristics

– Temperature

– Maximum Pressure Rating

Figure 7 illustrates typical mounting area considerations to make before

installing a transmitter.

Figure 7 Typical Mounting Area Considerations Prior to Installation

Lightning

(EMI)

Relative

Ambient

Temperature

Pump

(vibration)

Humidity

Transceivers

(RFI)

Large Fan Motors

(EMI)

Meter Body

Temperature

21003

Continued on next page

14 SMV 3000 Transmitter User’s Manual 1/99

Page 27

3.2 Considerations for SMV 3000 Transmitter, Continued

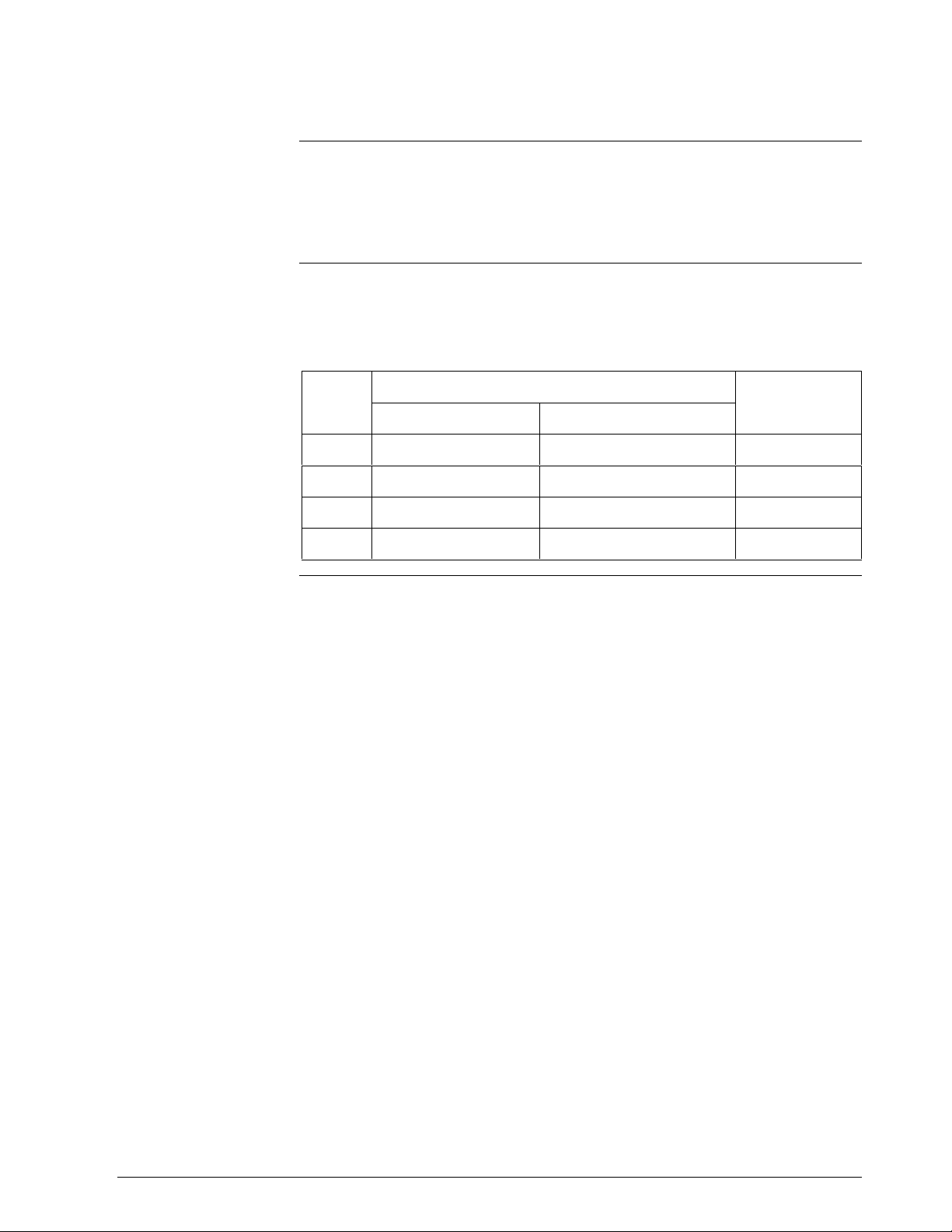

Temperature limits

Table 2 lists the operating temperature limits for reference.

Table 2 Operating Temperature Limits

Overpressure ratings

Transmitter Type Ambient

Temperature

Multivariable °C

°F

* For CTFE fill fluid, the rating is –15 to 110 °C (5 to 230 °F)

–40 to 93

–40 to 200

Table 3 lists overpressure rating for a given Upper Range Limit (URL) for

Meter Body

–40 to 125 *

–40 to 257 *

reference.

Table 3 Transmitter Overpressure Ratings

SMV 3000

Transmitter Model Upper Range Limit (URL) Overpressure Rating

SMA110

25 inches H2O @ 39.2

°F (differential pressure)

100 psi

100 psia (absolute pressure) * 100 psi

SMA125

SMG170

* Static pressure is referenced at high pressure port.

400 inches H2O @ 39.2

750 psia (absolute pressure) * 3000 psi

400 inches H2O @ 39.2

3000 psig (gauge pressure) 3000 psi

°F (differential pressure)

°F (differential pressure)

3000 psi

3000 psi

1/99 SMV 3000 Transmitter User’s Manual 15

Page 28

3.2 Considerations for SMV 3000 Transmitter, Continued

RTD requirements

Thermocouple

requirements

Use a two-, three-, or four-wire platinum 100 ohm (Pt100) Resistance

Temperature Detector with rated measurement range limits of –200 to

450 °C (–328 to 842 °F) per DIN 43760 standard (α = 0.00385 Ω/Ω/°C)

as the input source for the process temperature PV.

Use one of the thermocouple types listed in Table 4 as the input source for

the process temperature.

Table 4 Thermocouple Types for Process Temperature Sensor

Type Rated Range Limits Standard

°C °F

E

J

K

T

0 to 1000 32 to 1832 IEC584.1

0 to 1200 32 to 2192 IEC584.1

–100 to 1250 –148 to 2282 IEC584.1

–100 to 400 –148 to 752 IEC584.1

16 SMV 3000 Transmitter User’s Manual 1/99

Page 29

3.3 Considerations for SCT 3000

SCT 3000

Requirements

The SCT 3000 consists of the software program which is contained on

diskettes and a Smartline Option Module which is the hardware interface

used for connecting the host computer to the SMV transmitter.

Be certain that the host computer is loaded with the proper operating

system necessary to run the SCT program. See the SCT 3000 Smartline

Configuration Toolkit Start-up and Installation Manual 34-ST-10-08 for

complete details on the host computer specifications and requirements for

using the SCT 3000.

1/99 SMV 3000 Transmitter User’s Manual 17

Page 30

18 SMV 3000 Transmitter User’s Manual 1/99

Page 31

4.1 Introduction

Section 4 Installation

Section Contents

About this section

This section includes these topics

Topic See Page

4.1 Introduction............................................................................19

4.2 Mounting SMV 3000 Transmitter............................................20

4.3 Piping SMV 3000 Transmitter.................................................29

4.4 Installing RTD or Thermocouple.............................................35

4.5 Wiring SMV 3000 Transmitter................................................36

This section provides information about installing the SMV 3000

transmitter. It includes procedures for mounting, piping and wiring the

transmitter for operation.

1/99 SMV 3000 Transmitter User’s Manual 19

Page 32

4.2 Mounting SMV 3000 Transmitter

Summary

You can mount the transmitter to a 2-inch (50 millimeter) vertical or

horizontal pipe using our optional angle or flat mounting bracket or a

bracket of your own.

Figure 8 shows typical bracket mounted installations for comparison.

Figure 8 Typical Bracket Mounted Installations

Angle

Mounting

Bracket

Flat

Mounting

Bracket

Dimensions

Horizontal Pipe

Angle

Mounting

Bracket

Vertical Pipe

Flat

Mounting

Bracket

Detailed dimension drawings for given mounting bracket type are listed in

the back of this manual for reference. This section assumes that the

mounting dimensions have already been taken into account and the

mounting area can accommodate the transmitter.

Continued on next page

20 SMV 3000 Transmitter User’s Manual 1/99

Page 33

4.2 Mounting SMV 3000 Transmitter, Continued

Bracket mounting

Table 5 summarizes typical steps for mounting a transmitter to a bracket.

Table 5 Mounting SMV 3000 Transmitter to a Bracket

Step Action

1

If you are using an… Then…

optional mounting bracket go to Step 2.

existing mounting bracket go to Step 3.

Position bracket on 2-inch (50.8 mm) horizontal or vertical pipe, and

2

install “U” bolt around pipe and through holes in bracket. Secure with

nuts and lockwashers provided.

Example - Angle mounting bracket secured to horizontal or vertical

pipe.

Nut s and

Lockwashers

Mounting

Bracket

Nuts and

Lockwashers

Horizontal Pipe

U-Bolt

U-Bolt

Vertical Pipe

Mounting

Bracket

Continued on next page

1/99 SMV 3000 Transmitter User’s Manual 21

Page 34

4.2 Mounting SMV 3000 Transmitter, Continued

Bracket mounting,

continued

Table 5 Mounting SMV 3000 Transmitter to a Bracket, continued

Step Action

Align alternate mounting holes in end of meter body heads with holes

3

in bracket and secure with bolts and washers provided.

Loosen the 4 mm set screw on outside neck of transmitter. Rotate

4

electronics housing in maximum of 90 degree increments in left or

right direction from center to position you require and tighten set

screw.

Example - Rotating electronics housing.

90 degrees

max.

Electronics

Housing

90 degrees

max.

Set Screw

Continued on next page

22 SMV 3000 Transmitter User’s Manual 1/99

Page 35

4.2 Mounting SMV 3000 Transmitter, Continued

ATTENTION

Precautions for

Mounting

Transmitters with

Small Differential

Pressure Spans

The mounting position of an SMV 3000 Transmitter is critical as the

transmitter spans become smaller for the absolute and/or differential

pressure range. A maximum zero shift of 0.048 psi for an absolute

pressure range or 1.5 in H

O for a differential pressure range can result

2

from a mounting position which is rotated 90 degrees from vertical. A

typical zero shift of 0.002 psi or 0.20 in H

O can occur for a 5 degree

2

rotation from vertical.

To minimize these positional effects on calibration (zero shift), take the

appropriate mounting precautions that follow for the given pressure range.

• For a transmitter with a small differential pressure span, you must

ensure that the transmitter is vertical when mounting it. You do this by

leveling the transmitter side-to-side and front-to-back. See Figure 9 for

suggestions on how to level the transmitter using a spirit balance.

• You must also zero the transmitter by adjusting the mounting position

of the transmitter. Refer to start-up procedure in Section 7 for SMV

3000 transmitter model SMA110 and transmitters with small

differential pressure spans.

Figure 9 Leveling a Transmitter with a Small Absolute Pressure Span.

Spirit

Balance

1/99 SMV 3000 Transmitter User’s Manual 23

Process

Head

Center

Section

Page 36

4.3 Piping SMV 3000 Transmitter

Summary

The actual piping arrangement will vary depending upon the process

measurement requirements. Process connections can be made to standard

1/4-inch NPT female connections on 2-1/8 inch centers in the doubleended process heads of the transmitter’s meter body. Or, the connections

in the process heads can be modified to accept 1/2 inch NPT adapter

flange for manifolds on 2, 2-1/8, or 2-1/4 inch centers

The most common type of pipe used is 1/2 inch schedule 40 steel pipe.

Many piping arrangements use a three-valve manifold to connect the

process piping to the transmitter. A manifold makes it easy to install and

remove a transmitter without interrupting the process. It also

accommodates the installation of blow-down valves to clear debris from

pressure lines to the transmitter.

Figure 10 shows a diagram of a typical piping arrangement using a threevalve manifold and blow-down lines for a flow measurement application.

Figure 10 Typical 3-Valve Manifold and Blow-Down Piping

Arrangement.

To Upstream TapTo Downstream Tap

Blow-Down

Valve

Blow-Down

Piping

To Low Pressure

Side of Transmitter

24 SMV 3000 Transmitter User’s Manual 1/99

3-Valve

Manifold

To High Pressure

Side of Transmitter

Blow-Down

Valve

Blow-Down

Piping

To WasteTo Waste

21010

Continued on next page

Page 37

4.3 Piping SMV 3000 Transmitter, Continued

Transmitter location

The suggested mounting location for the transmitter depends on the

process to be measured. Figure 11 shows the transmitter located above the

tap for gas flow measurement. This arrangement allows for condensate to

drain away from the transmitter.

Figure 12 shows the transmitter located below the tap for liquid or steam

flow measurement. This arrangement minimizes the static head effect of

the condensate. Although the transmitter can be located level with or

above the tap, this arrangement requires a siphon to protect the transmitter

from process steam. (The siphon retains water as a “fill fluid.”)

Figure 11 Transmitter Location Above Tap for Gas Flow Measurement

High

Pressure

Connection

Low

Pressure

Connection

3-Valve

Manifold

Pressure

Connection

To High

To Low

Pressure

Connection

Continued on next page

1/99 SMV 3000 Transmitter User’s Manual 25

Page 38

4.3 Piping SMV 3000 Transmitter, Continued

Figure 12 Transmitter Location Below the Tap for Liquid or Steam

Flow Measurement

High

Pressure

Connection

3-Valve

Manifold

To High

Pressure

Connection

Low

Pressure

Connection

To Low

Pressure

Connection

ATTENTION

For liquid or steam, the piping should slope a minimum of 25.4 mm (1

inch) per 305 mm (1 foot). Slope the piping down towards the transmitter

if the transmitter is below the process connection so the bubbles may rise

back into the piping through the liquid. If the transmitter is located above

the process connection, the piping should rise vertically above the

transmitter; then slope down towards the flow line with a vent valve at the

high point. For gas measurement, use a condensate leg and drain at the

low point (freeze protection may be required here).

Continued on next page

26 SMV 3000 Transmitter User’s Manual 1/99

Page 39

4.3 Piping SMV 3000 Transmitter, Continued

General piping

guidelines

Installing flange

adapter

ATTENTION

• When measuring fluids containing suspended solids, install permanent

valves at regular intervals to blow-down piping.

• Blow-down all lines on new installations with compressed air or steam

and flush them with process fluids (where possible) before connecting

these lines to the transmitter’s meter body.

• Be sure all the valves in the blow-down lines are closed tight after the

initial blow-down procedure and each maintenance procedure after that.

Table 6 gives the steps for installing an optional 1/2 inch NPT flange

adapter on the process head.

Slightly deforming the gasket supplied with the adapter before you insert it

into the adapter may aid in retaining the gasket in the groove while you

align the adapter to the process head. To deform the gasket, submerse it in

hot water for a few minutes then firmly press it into its recessed mounting

groove in the adapter.

Continued on next page

1/99 SMV 3000 Transmitter User’s Manual 27

Page 40

4.3 Piping SMV 3000 Transmitter, Continued

Installing flange

adapter, continued

Table 6 Installing 1/2 inch NPT Flange Adapter

Step Action

Insert filter screen (if supplied) into inlet cavity of process head.

1

Carefully seat Teflon (white) gasket into adapter groove.

2

Thread adapter onto 1/2-inch process pipe and align mounting holes

3

in adapter with holes in end of process head as required.

Secure adapter to process head by hand tightening 7/16-20 hex-head

4

bolts.

Example - Installing adapter on process head.

Filter Screen

Teflon Gasket

Flange Adapter

7/16 x 20 Bolts

ATTENTION

Apply an anti-seize compound on the stainless steel

bolts prior to threading them into the process head.

5

Evenly tighten adapter bolts to a torque of 47.5 to 54 N.m

(35 to 40 ft-lb).

Process

Hea d

21011

28 SMV 3000 Transmitter User’s Manual 1/99

Page 41

4.4 Installing RTD or Thermocouple

Considerations

CE Conformity

Special Conditions

(Europe)

You are responsible for installing the thermowell to house the RTD or

thermocouple sensor. Be sure to use a spring-load accessory to hold the

RTD sensor against the end of the thermowell.

To reduce the effects of “noise,” use shielded cable or run sensor leads in

a conduit.

See the Guide to Temperature Sensors and Thermowells, 34-44-29-01

which tells you how to properly specify thermal probes and thermowell

assemblies for your application. Model selection guides also are included

for various temperature probes.

You must use shielded cable to connect sensor to transmitter’s

temperature circuit.

1/99 SMV 3000 Transmitter User’s Manual 29

Page 42

4.5 Wiring SMV 3000 Transmitter

CE Conformity Special

Conditions (Europe)

Summary

You must use shielded, twisted-pair cable such as Belden 9318 for all

signal/power wiring.

The transmitter is designed to operate in a two-wire power/current loop

with loop resistance and power supply voltage within the operating range

shown in Figure 13.

Figure 13 Operating Range for SMV 3000 Transmitters

1440

Loop

Resistance

(ohms)

1200

800

650

450

250

= Operating

Area

NOTE: A minimum of 250

0hms of loop resistance is

necessary to support

communications. Loop

resistance equals barrier

resistance plus wire

resistance plus receiver

resistance. Also 45 volt

operation is permitted if

not an intrinsically safe

installation.

0 10.8 16.28 20.63 25 28.3 37.0 42.4

Operating Voltage (Vdc)

21012

You simply connect the positive (+) and negative (–) loop wires to the

positive (+) and negative (–) SIGNAL terminals on the terminal block in

the transmitter’s electronics housing shown in Figure 14.

Continued on next page

30 SMV 3000 Transmitter User’s Manual 1/99

Page 43

4.5 Wiring SMV 3000 Transmitter, Continued

Figure 14 SMV 3000 Transmitter Terminal Block

TC

34

++

+

–

+

–

Terminal

Block

Electronics

Housing

12

METER L SIGNAL

–––

TEST SIG

Summary, continued

You connect RTD leads to the TC terminals 1, 2, 3, and 4 as appropriate

for the given probe type.

You connect thermocouple leads to terminals 1 (–) and 3 (+), observing

polarity.

Each transmitter includes an internal ground terminal to connect the

transmitter to earth ground or a ground terminal can be optionally added to

the outside of the electronics housing. While it is not necessary to ground

the transmitter for proper operation, we suggest that you do so to minimize

the possible effects of “noise” on the output signal and provide additional

protection against lightning and static discharge damage. Note that

grounding may be required to meet optional approval body certification.

Refer to section 1.2 CE Conformity (Europe) Notice for special

conditions.

Transmitters are available with optional lightning protection if they will be

used in areas highly susceptible to lightning strikes.

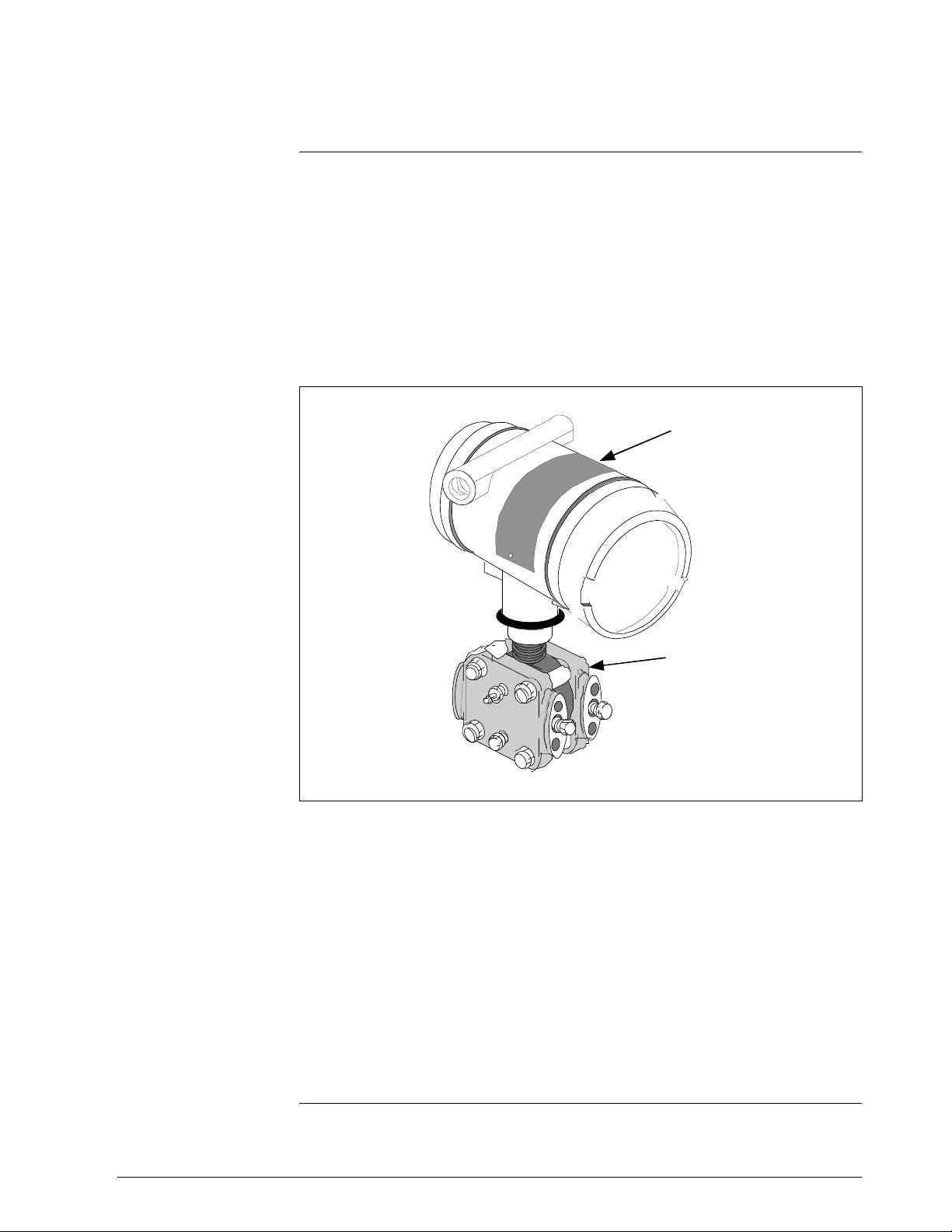

Barriers must be installed per manufacturer’s instructions for transmitters