31-00109EF-01

SmartVFD HVAC2

GENERAL

SmartVFD HVAC2 variable frequency drives provide step

less speed control for various applications:

•Pumps

•Fans

•Compressors

PRODUCT DATA

• Fire Mode feature

• Integrated RFI-filters

• Models available with or without Class C2 EMC filter

• Wide input and output connection possibilities

• Configurable inputs and outputs

• 30 second Start-Up Wizard

• Easy “keypad to remote” change with 1 button

• Parameter upload/download even without main

power to the drive with HVFDCABLE accessory

• Quiet motor operation with 4 kHz switching

frequency

• Overtemperature ride-through

• Motor pre-heat

• Power ride-through

• Automatic restart

• Integrated PID controller

• Optional NEMA 1 enclosure

• Built in RS485 Modbus communication

SPECIFICATIONS

FEATURES

• Compact size - saves space in your equipment

cabinet

• Models available up to 25HP

• Permanent Magnet motor support

• Energy optimization feature

• Programmable FB (Fieldbus) process data

• Settable Limit supervisions

• Temperature measurement with temperature sensor

option board HVFDOPTTMP

• Flexible side-by-side mounting with screws or DINrail as standard for MI1-MI3 frame sizes

• Single rating suitable for both pump and fan or

machine applications

• Maximum ambient temperature: + 122 °F for most

drives

Mains Connection

Input voltage U

115 V, -15%...+10% 1~

208…240 V, -15%...+10% 1~

208…240 V, -15%...+10% 3~

380 - 480 V, -15%...+10% 3~

600 V, -15%...+10% 3~

Input frequency: 45…66 Hz

Connection to mains: Once per minute or less (normal

case)

in:

Supply Network

Networks:

SmartVFD HVAC2 (400 V) cannot be used with corner

grounded networks

Short circuit current:

Maximum short circuit current has to be < 50 kA

SMARTVFD HVAC2

Motor Connection

Output voltage: 0 - U

Output current:

Continuous rated current I

+50 ºC (dependson the unit size), overload:

1.5 x I

1 min / 10 min

Starting current/torque: Current 2 x I

Output frequency: 0…320 Hz

Frequency resolution: 0.01 Hz

max

N

20 sec period. Torque depends on motor.

Control connections

Digital input:

Positive, Logic1: 18…+30V, Logic0: 0…5V; Negative,

Logic1: 0…10V, Logic0: 18…30V; Ri = 10KΩ (floating)

Analogue input voltage: 0….+10V,Ri = 250KΩ

Analogue input current 0(4)…20mA, Ri ≤ 250Ω

Analogue output:

0…10V, RL ≥ 1KΩ; 0(4)…20mA,RL ≤ 500Ω, Selectable

through microswitch

Digital output:

Open collector, max. load 35V/50mA (floating)

Relay output: Switching load: 250Vac/3A, 24V DC 3A

Auxiliary voltage: ±20%,max.load 50mA

in

at ambient temperature max.

N

for 2 sec in every

N

Control Characteristics

Control method:

Frequency Control U / f

Open Loop Sensorless Vector Control

Switching frequency: 1...16 kHz; Factory default 4 kHz

Frequency reference: Resolution 0.01 Hz

Field weakening point: 30…320 Hz

Acceleration time: 0.1…3000 sec

Deceleration time: 0.1…3000 sec

Braking torque:

100%*T

with brake option (only in 3~ drives sizes MI2-5)

N

30%*T

without brake option

N

Ambient Conditions

Operating temperature:

14 °F (-10 °C) (no frost)…+104/122 °F (+40/50 °C)

(depends on the unit size): rated loadability IN

Side by side installation for MI1-3 it is always 104 °F

(40 °C); For IP21/Nema1 option in MI1-3 the maximum temperature is also 104 °F (40 °C)I

Storage temperature: -40 °F (-40 °C)…+158 °F (70 °C)

Air quality:

Chemical vapors:

IEC 721-3-3, unit in operation, class 3C2

Mechanical particles:

IEC 721-3-3, unit in operation, class 3S2

Altitude:

100% load capacity (no derating) up to 3281 ft. (1000 m).

1% derating for each 328 ft. (100 m) above 3281 ft.

(1000 m); max. 6562 ft. (2000 m)

Relative humidity:

0…95% RH, non-condensing, non-corrosive, no dripping

water

Vibration: 3...150 Hz

EN60068-2-6:

Displacement amplitude 1 (peak) mm at 3...15.8 Hz Max

acceleration amplitude 1 G at 15.8...150 Hz

Shock

IEC 68-2-27:

UPS Drop Test (for applicable UPS weights)

Storage and shipping: max 15 g, 11 ms (in package)

Enclosure class: IP20 for MI1-3, IP21 for MI4-5.

With HVFDCDNEMA1xxx kit, IP21/NEMA1 for MI1-5.

Pollution degree: PD2

Electro Magnetic Compatibility (EMC)

Immunity:

Complies with EN50082-1, -2, EN61800-3

Emissions:

230V: Complies with EMC category C2; With an internal

RFI filter

400V: Complies with EMC category C2; With an internal

RFI filter

Safety:

For safety: UL508C, EN61800-5, CE, UL, cUL, KC

For EMC: EN61800-3, CE, KC

Protections

Overvoltage protection:

875VDC in HVFD2DXCXXXXXXX

437VDC in HVFD2DXBXXXXXXX

Undervoltage protection:

333VDC in HVFD2DXCXXXXXXX

160VDC in HVFD2DXBXXXXXXX

Earth-fault protection:

In case of earth fault in motor or motor cable, only the fre-

quency converter is protected

Unit overtemperature protection: YES

Motor overload protection: YES

Motor stall protection (fan/pump blocked): YES

Motor underload protection

(pump dry / belt broken detection): YES

Short-circuit protection of +24V and +10V

reference voltages: YES

Overcurrent protection: Trip limit 4,0*I

instantaneously

N

31-00109EF—01 2

SMARTVFD HVAC2

MODELS

Mains voltage 208-240 V

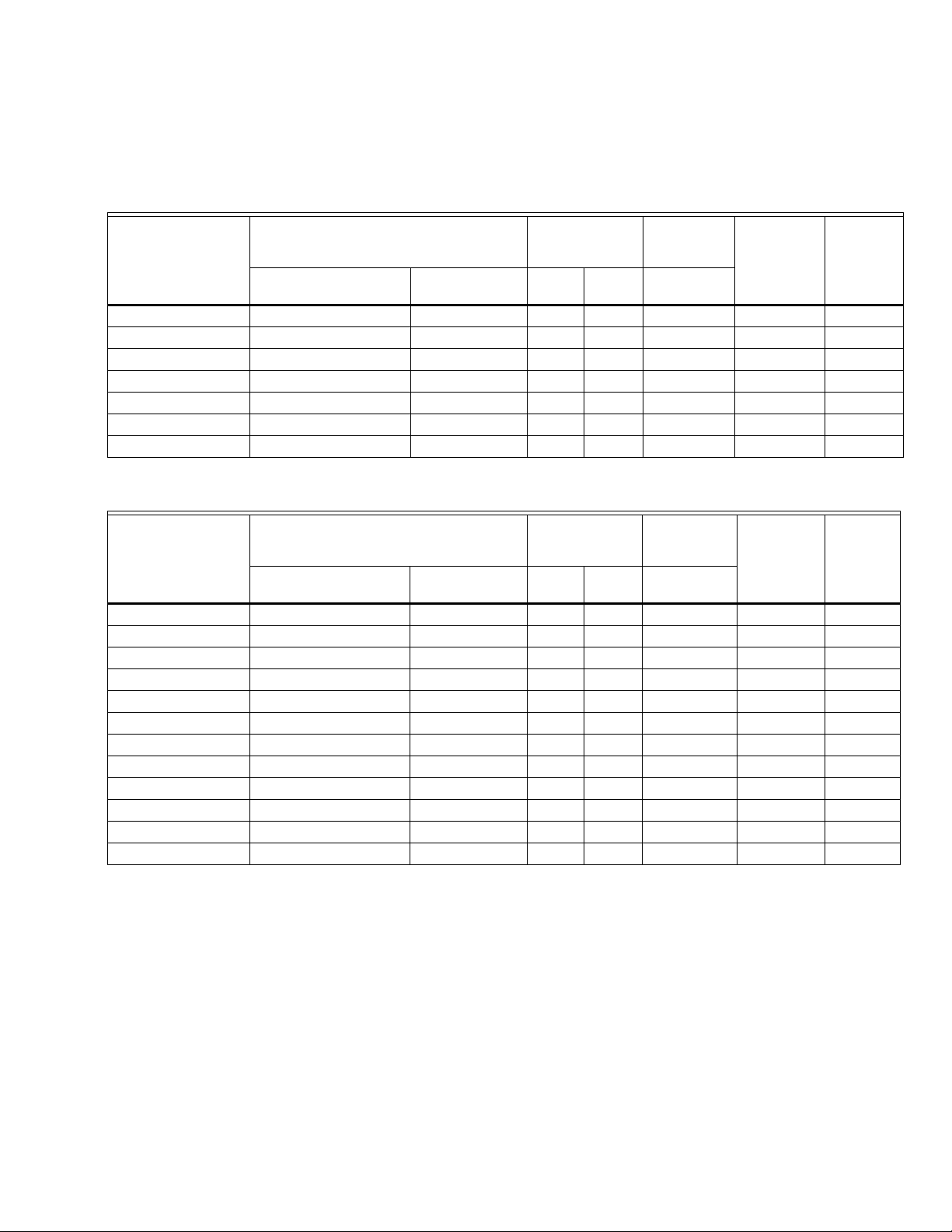

Table 1. Mains voltage 208-240 V, 50/60 Hz, 1~ series.

Nominal

Motor shaft

Part number

Rated loadability

100% contin.

current I

[A]

N

150% overload

current [A]

power

P

[HP]P[KW] [A]

HVFD2D1B0003E2 1.7 2.6 0.33 0.25 4.2 MI1 1.21

HVFD2D1B0005E2 2.4 3.6 0.5 0.37 5.7 MI1 1.21

HVFD2D1B0007E2 2.8 4.2 0.75 0.55 6.6 MI1 1.21

HVFD2D1B0010E2 3.7 5.6 1 0.75 8.3 MI2 1.54

HVFD2D1B0015E2 4.8 7.2 1.5 1.1 11.2 MI2 1.54

HVFD2D1B0020E2 7 10.5 2 1.5 14.1 MI2 1.54

HVFD2D1B0030E2* 9.6 14.4 3 2.2 22.1 MI3 2.18

* The maximum ambient operating temperature of this drive is 104 °F (40 °C)

Table 2. Mains voltage 208 - 240 V, 50/60 Hz, 3~ series.

Motor shaft

Part number

Rated loadability

100% contin.

current I

[A]

N

150% overload

current [A]

power

P

[HP]P[KW] [A]

HVFD2D3B0003 1.7 2.6 0.33 0.25 2.7 MI1 1.21

HVFD2D3B0005 2.4 3.6 0.5 0.37 3.5 MI1 1.21

HVFD2D3B0007 2.8 4.2 0.75 0.55 3.8 MI1 1.21

HVFD2D3B0010 3.7 5.6 1 0.75 4.3 MI2 1.54

HVFD2D3B0015 4.8 7.2 1.5 1.1 6.8 MI2 1.54

HVFD2D3B0020* 7 10.5 2 1.5 8.4 MI2 1.54

HVFD2D3B0030* 11 16.5 3 2.2 13.4 MI3 2.18

HVFD2D3B0040 12.5 18.8 4 3 14.2 MI4 19.13

HVFD2D3B0050 17.5 26.3 5 4 20.6 MI4 19.13

HVFD2D3B0075 25 37.5 7.5 5.5 30.3 MI4 19.13

HVFD2D3B0100 31 46.5 10 7.5 36.6 MI5 24.4

HVFD2D3B0150 38 57 15 11 44.6 MI5 24.4

* The maximum ambient operating temperature of these drives is 104 °F (40 °C).

input

current

Nominal

input

current

Mechanical

size

Mechanical

size

Weight

Weight

(lbs)

(lbs)

3 31-00109EF—01

SMARTVFD HVAC2

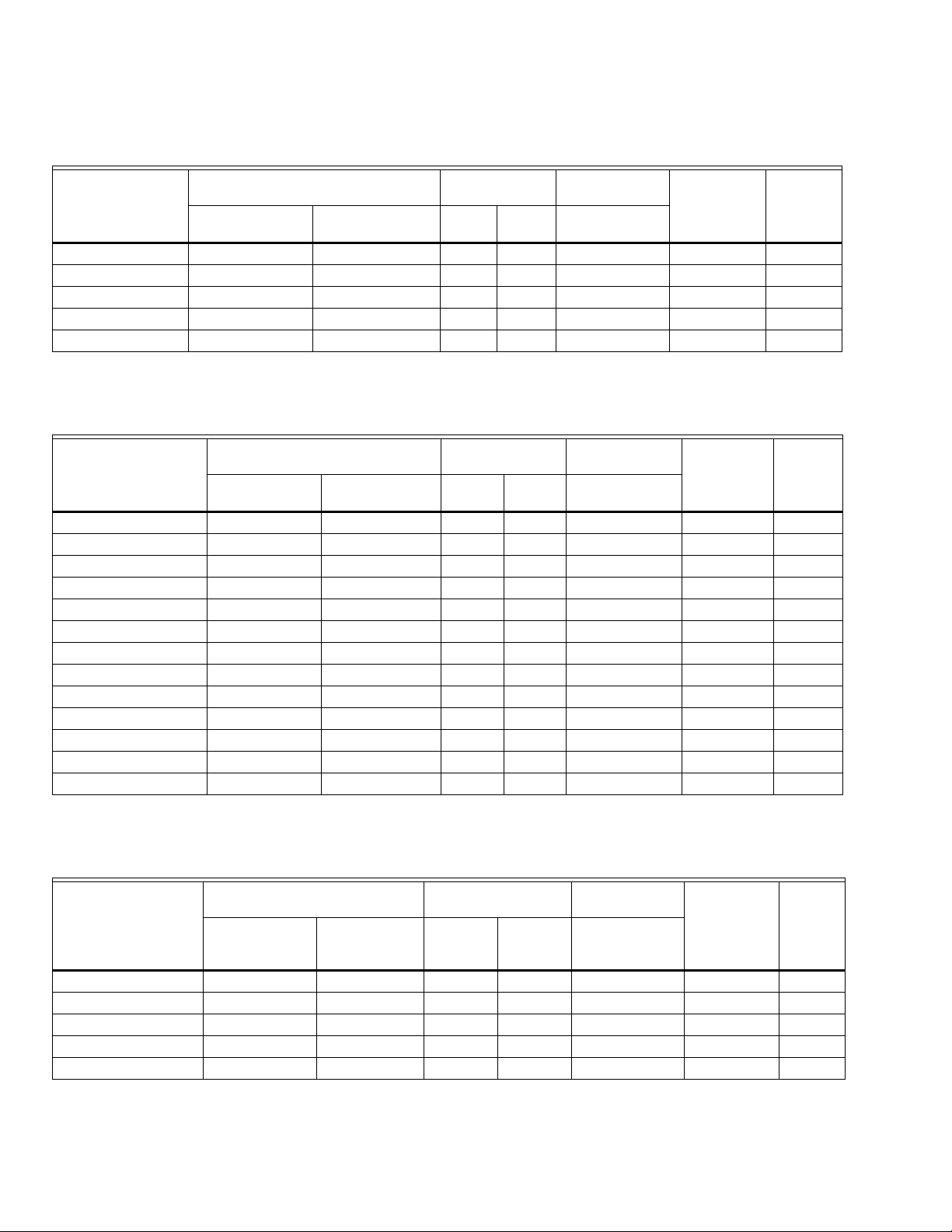

Mains voltage 115 V

Table 3. Mains voltage 115 V, 50/60 Hz, 1~ series.

Part number

Rated loadability

100% contin.

current I

[A]

N

150% overload

current [A]

Motor shaft

power

P

[HP]P[KW] [A]

Nominal input

current

Mechanical

size

Weight

(lbs)

HVFD2D1A0003 1.7 2.6 0.33 0.25 9.2 MI2 1.54

HVFD2D1A0005 2.4 3.6 0.5 0.37 11.6 MI2 1.54

HVFD2D1A0007 2.8 4.2 0.75 0.55 12.4 MI2 1.54

HVFD2D1A0010 3.7 5.6 1 0.75 15 MI2 1.54

HVFD2D1A0015 4.8 7.2 1.5 1.1 16.5 MI3 2.18

Mains voltage 380-480 V

Table 4. Mains voltage 380-480 V, 50/60 Hz, 3~ series.

Motor shaft

Part number

Rated loadability

100% contin.

current I

[A]

N

150% overload

current [A]

power

P

[HP]P[KW] [A]

HVFD2D3C0005xx 1.3 2 0.5 0.37 2.2 MI1 1.21

HVFD2D3C0007xx 1.9 2.9 0.75 0.55 2.8 MI1 1.21

HVFD2D3C0010xx 2.4 3.6 1 0.75 3.2 MI1 1.21

HVFD2D3C0015xx 3.3 5 1.5 1.1 4 MI2 1.54

HVFD2D3C0020xx 4.3 6.5 2 1.5 5.6 MI2 1.54

HVFD2D3C0030xx 5.6 8.4 3 2.2 7.3 MI2 1.54

HVFD2D3C0040xx 7.6 11.4 4 3 9.6 MI3 2.18

HVFD2D3C0050xx 9 13.5 5 4 11.5 MI3 2.18

HVFD2D3C0075xx 12 18 7.5 5.5 14.9 MI3 2.18

HVFD2D3C0100xx 16 24 10 7.5 17.1 MI4 19.13

HVFD2D3C0150xx 23 34.5 15 11 25.5 MI4 19.13

HVFD2D3C0200xx 31 46.5 20 15 33 MI5 24.4

HVFD2D3C0250xx 38 57 25 18.5 41.7 MI5 24.4

Nominal input

current

Mechanical

size

Weight

(lbs)

Mains voltage 600 V

Table 5. Mains voltage 600 V, 50/60 Hz, 3~ series.

Rated loadability Motor shaft power

150%

Part number

100% contin.

current I

[A]

N

overload

current [A]

P

[HP]

P

[KW] [A]

HVFD2D3F0010 1.7 2.6 1 0.75 2 MI3 2.18

HVFD2D3F0020 2.7 4.2 2 1.5 3.6 MI3 2.18

HVFD2D3F0030 3.9 5.9 3 2.2 5 MI3 2.18

HVFD2D3F0050 6.1 9.2 5 4 7.6 MI3 2.18

HVFD2D3F0075 9 13.5 7.5 5.5 10.4 MI3 2.18

31-00109EF—01 4

Nominal input

current

Mechanical

size

Weight

(lbs)

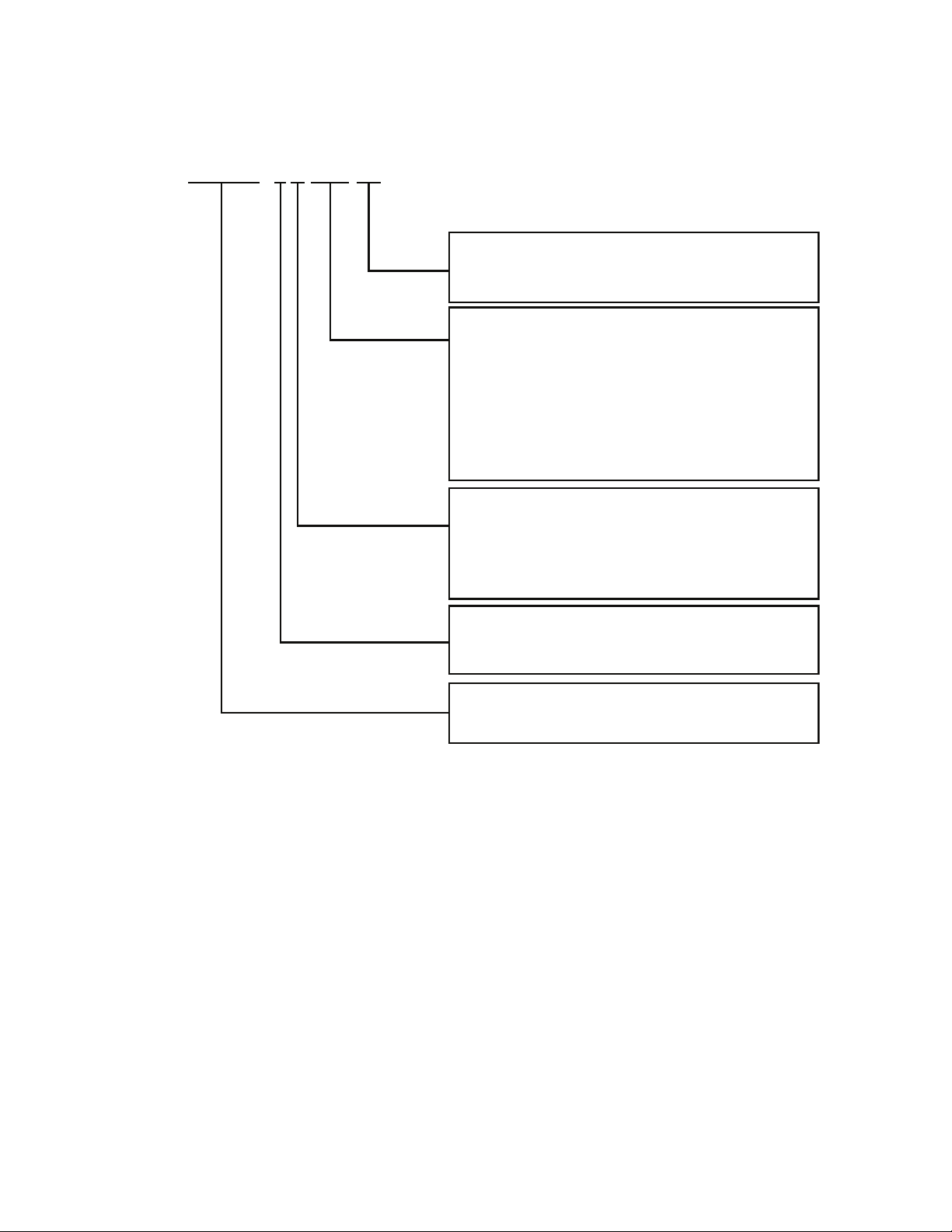

PRODUCT IDENTIFICATION CODE

3E2C0000HVFD2D

EMC Filter

E2 = EMC Filter

(Blank) = No EMC Filter

Phases

1 = Single Phase

3 = 3-Phase

Product Family

HVFD2D = Honeywell SmartVFD HVAC2

Nominal Horsepower

Nominal Voltage

A = 105 V - 120 V

B = 208 V - 240 V

C = 380 V - 480 V

F = 520 V - 600 V

0003 = .33 HP

0005 = .5 HP

0007 = .75 HP

0010 = 1 HP

0015 = 1.5 HP

0020 = 2 HP

0030 = 3 HP

0040 = 4 HP

0050 = 5 HP

0075 = 7.5 HP

0100 = 10 HP

0150 = 15 HP

0200 = 20 HP

0250 = 25 HP

MCR36499A

SMARTVFD HVAC2

Fig. 1. SmartVFD HVAC2 type designation code.

5 31-00109EF—01

SMARTVFD HVAC2

=

M5

MI3

MI1

=M4

MI2

=M5

LOC

REM

BACK

RESET

OK

M36500

LOC

REM

BACK

RESET

OK

LOC

REM

BACK

RESET

OK

MI4

MI5

LOC

REM

BACK

RESET

OK

M36501

=M 6

=M 6

LOC

REM

BACK

RESET

OK

12

M36502

M36503

LOC

REM

BACK

RESET

OK

13/64 (6)

M36504

TOP

6

(153)

Ø 1/4 (7)

14-1/2 (370)

DRIVE OUTLINE

OPENING OUTLINE

14-19/64 (362)

14 (356)

15-7/64 (384)

6-1/2

(166)

6-51/64

(173)

7-13/32

(189)

OPENING OUTLINE

16 (407)

DRIVE OUTLINE

Ø 1/4 (7)

TOP

6

(153)

14 (356)

15-45/64 (400)

17 (431)

13/64 (6)

6-1/2

(166)

6-51/64

(173)

7-13/32

(189)

M36505

MI4

M36507

MI5

1-3/32

(29)

51/64

(20)

13

(332)

15/32

(12)

29/32

(23)

3-1/2

(89)

6-1/2 (165)

3

(77)

5/8

(16)

1-3/32

(29)

15

(379)

19/32

(15)

29/32

(23)

8 (202)

3-45/64

(95)

4-7/32

(107)

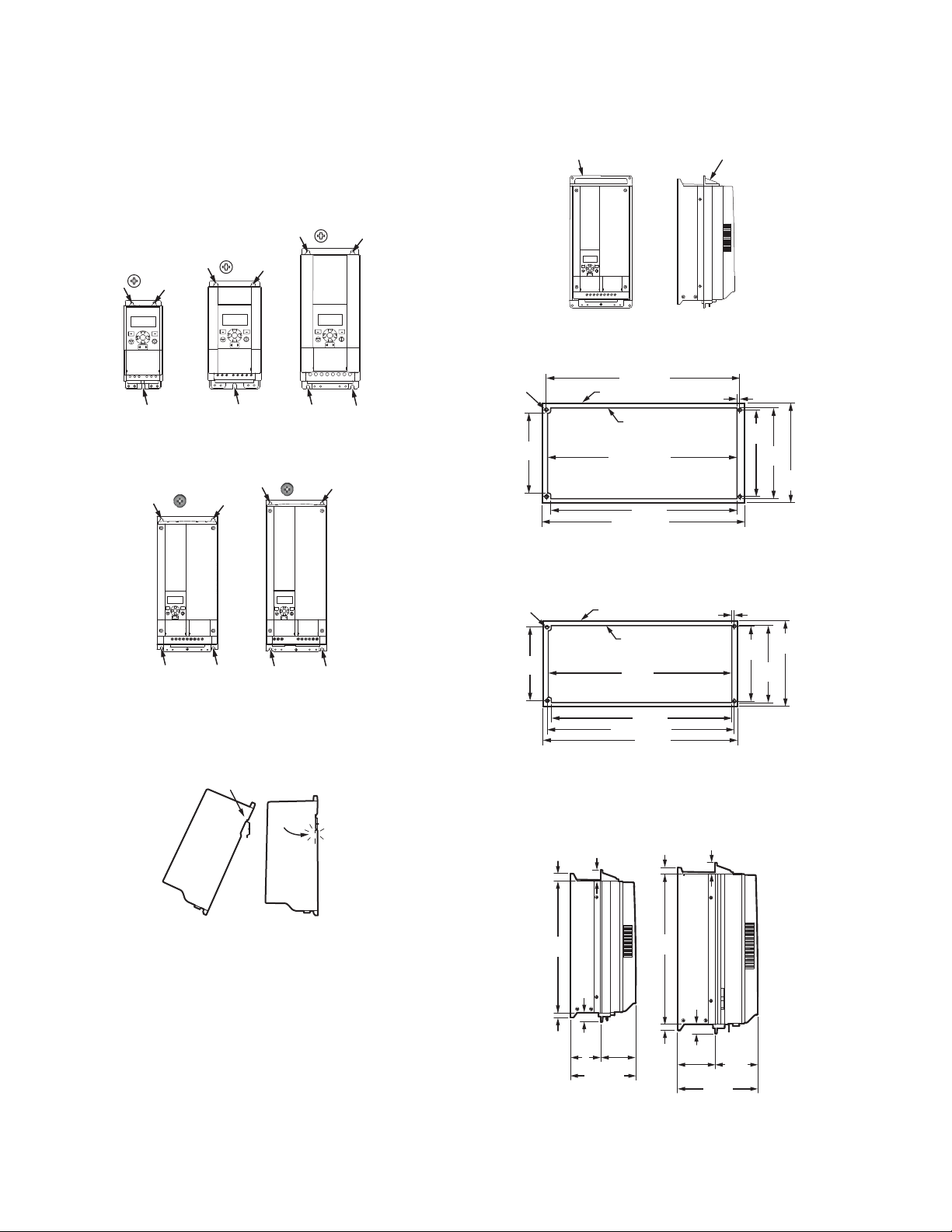

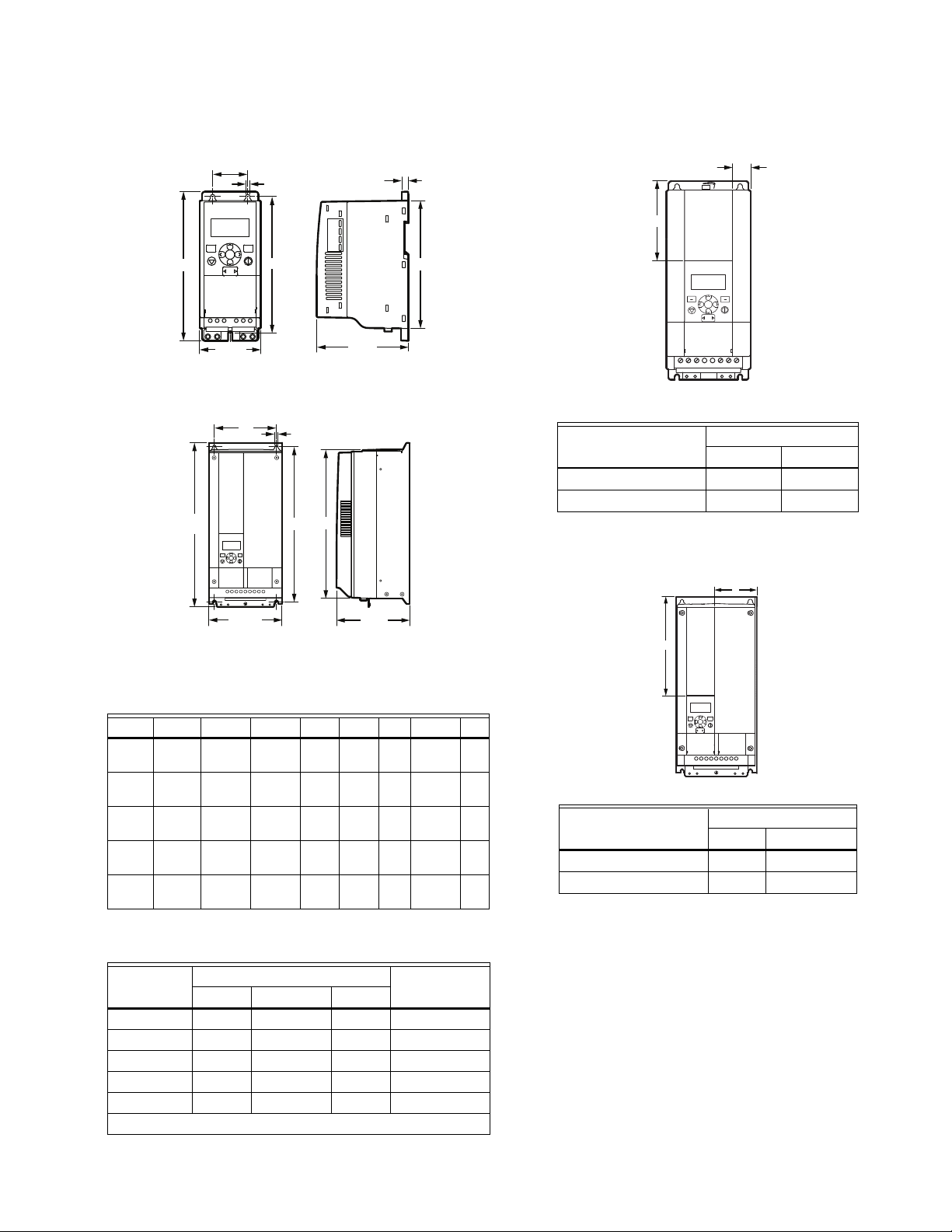

MECHANICAL MOUNTING

There are two possible ways to mount SmartVFD HVAC2 in

the wall. For MI1-MI3, either screw or DIN-rail mounting;

For MI4-MI5, screw or flange mounting.

Fig. 2. Screw mounting, MI1 - MI3

Fig. 5. Flange mounting, MI4 - MI5

Fig. 3. Screw mounting, MI4 - MI5

NOTE: See the mounting dimensions on the back of the

drive.

Fig. 4. DIN-rail mounting, MI1 - MI3

Fig. 6. Flange mounting cutout dimensions for MI4

[Unit: inches (mm)]

Fig. 7. Flange mounting cutout dimensions for MI5

[Unit: inches (mm)]

31-00109EF—01 6

Fig. 8. Flange mounting depth dimensions for MI4 and

MI5 [Unit: inches (mm)]

DIMENSIONS

W2

W3

H

(H1)

H2

H3

L1 L2 L3

DC+R+ R-

DC- U/T1

V/T2

W/T3

D (D1)

W (W1)

M36509

LOC

REM

BACK

RESET

OK

A

B

M36527

SMARTVFD HVAC2

H (H1)

W2

W (W1)

W3

H2

D (D1)

D2

H3

M36508

Fig. 9. SmartVFD HVAC2 dimensions, MI1 - MI3.

D

A

LOC

BACK

REM

RESET

OK

M36510

Dimensions in

inches (mm)

Frame

MI2 MI3

A .7 (17) .9 (22.3)

B 1.7 (44) 4 (102)

Fig. 11. SmartVFD HVAC2 dimensions, MI2 - 3 Display

Location.

Fig. 10. SmartVFD HVAC2 dimensions, MI4 - MI5.

Table 6. SmartVFD HVAC2 dimensions in inches (mm).

Type H1 H2 H3 W1 W2 W3 D1 D2

MI1 6.3

(160.1)

MI2 7.7

(195)

MI3 10

(254.3)

MI4 14.6

(370)

MI5 16.3

(414)

5.8

(147)

7.2

(183)

5.4

(137.3)

6.7

(170)

9.6

(244)90(229.3)

13.8

(350.5)

13.2

(336.5)

15.7

(398)15(383)

2.6

1.5

(65.5)

(37.8)

3.5

2.5

(90)

(62.5).2(5.5)4(101.5)

3.9

2.95

(100)

(75).2(5.5)

6.5

5.5

(165)

(140)

6.5

5.5

(165)

(140)

.18

(4.5)

.28

(7)

.28

(7)

Table 7. SmartVFD HVAC2 frame dimensions (mm) and

weights in lbs (kg).

Dimensions in inches (mm)

Frame

MI1 2.6 (66) 6.3 (160) 3.9 (98) 1.2 (0.5)

MI2 3.5 (90) 7.7 (195) 4 (102) 1.5 (0.7)

MI3 3.9 (100) 10 (254.3) 4.3 (109) 2.2 (1)

MI4 6.5 (165) 14.3 (370) 6.5 (165) 18 (8)

MI5 6.5 (165) 16.3 (414) 8 (202) 22 (10)

*without shipping package

3.9

(98.5)

.28

(7)

.28

(7)

4.3

(108.5)

6.5

.28

(7)

-

(165)

7.9

-

(202)

Weight in

lbs (kg.)*WHD

Dimensions in

inches (mm)

Frame

MI4 MI5

A 8 (205) 9.8 (248.5)

B 3.4 (87) 3.4 (87)

Fig. 12. SmartVFD HVAC2 dimensions, MI4 - 5 Display

Location.

7 31-00109EF—01

SMARTVFD HVAC2

B

C

B

A

D

A

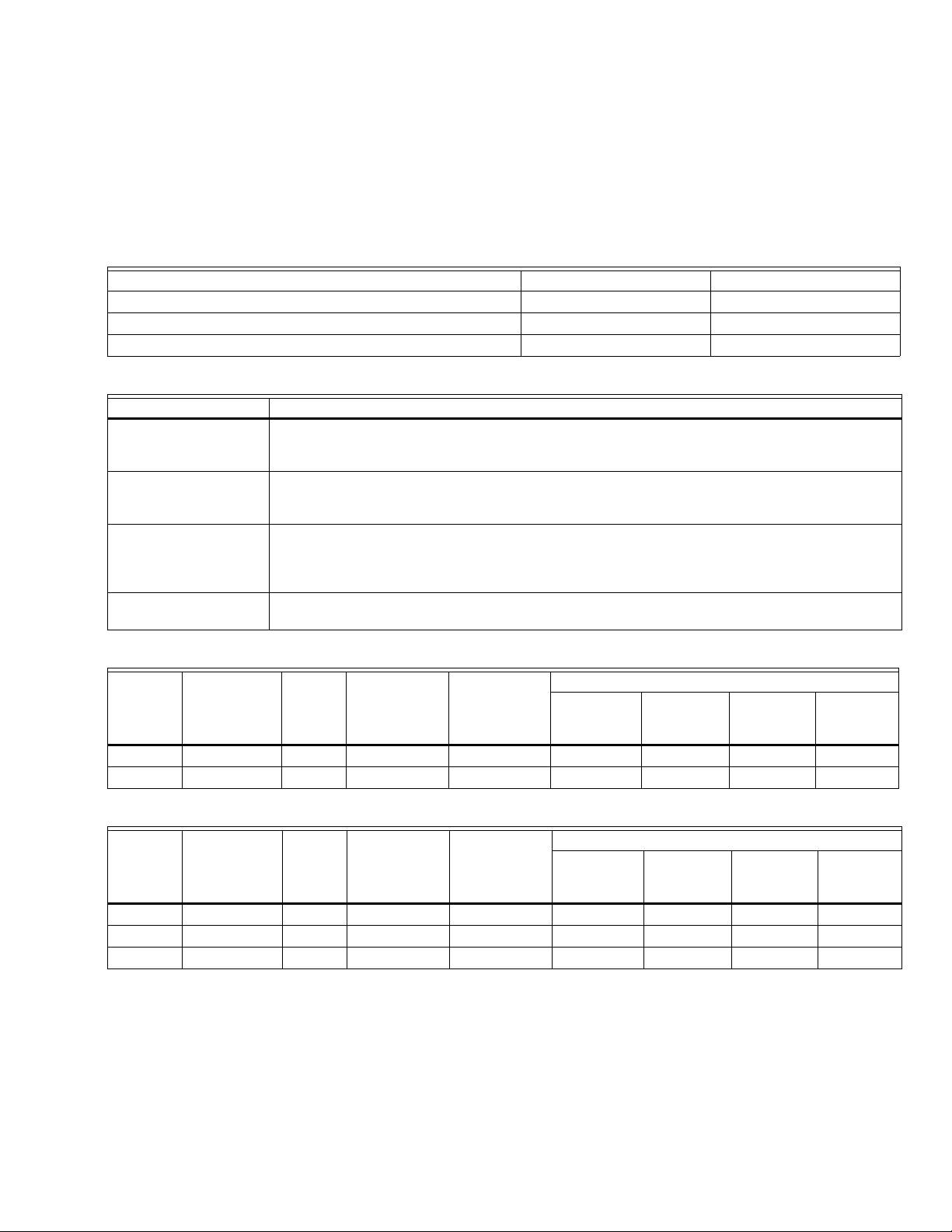

COOLING

Enough free space shall be left above and below the frequency converter to ensure sufficient air circulation and cooling.

You will find the required dimensions for free space in the table below.

If several units are mounted above each other the required free space equals C + D. Moreover, the outlet air used for

cooling by the lower unit must be directed away from the air intake of the upper unit.

The amount of cooling air required is indicated below. Also make sure that the temperature of the cooling air does not

exceed the maximum ambient temperature of the converter.

Table 8. Min. clearances around AC drive

Min clearance in inches (mm)

Type A B C D

MI1 .8 (20) .8 (20) 3.9 (100) 2 (50)

MI2 .8 (20) .8 (20) 3.9 (100) 2 (50)

MI3 .8 (20) .8 (20) 3.9 (100) 2 (50)

MI4 .8 (20) .8 (20) 3.9 (100) 3.9 (100)

MI5 .8 (20) .8 (20) 4.7 (120) 3.9 (100)

Fig. 13. Installation space.

31-00109EF—01 8

SMARTVFD HVAC2

CABLING AND FUSES

Use cables with heat resistance of at least 158 °F (70 °C). The cables and the fuses must be dimensioned according to the

tables below.

The fuses function also as cable overload protection.

These instructions apply only to cases with one motor and one cable connection from the frequency converter to the

motor. In any other case, ask the factory for more information.

Table 9. Cable types required to meet standards.

EMC category cat. C2 cat. C4

Mains cable types 1 1

Motor cable types 3 1

Control cable types 4 4

Table 10. Cable type descriptions.

Cable type Description

1 Power cable intended for fixed installation and the specific mains voltage. Shielded cable not

2 Power cable equipped with concentric protection wire and intended for the specific mains

3 Power cable equipped with compact low-impedance shield and intended for the specific mains

4 Screened cable equipped with compact low-impedance shield (NKCABLES /Jamak, SAB /

required.

(NKCABLES / MCMK or similar recommended)

voltage.

(NKCABLES / MCMK or similar recommended).

voltage.

(NKCABLES / MCCMK, SAB / ÖZCUY-J or similar recommended).

*360º earthing of both motor and FC connection required to meet the standard

ÖZCuY-O or similar).

Table 11. Cable and fuse sizes for SmartVFD HVAC2, 115 V, 1~.

Terminal cable size (min/max)

Main

Frame Horsepower

MI2 .33-1HP 20 2*14+14 3*16+16 16-12 16-12 20-16 20-16

MI3 1.5HP 32 2*10+10 3*16+16 16-12 16-12 20-16 20-16

Frame Horsepower

MI1 .33-.75HP 10 2*16+16 3*16+16 16-12 16-12 20-16 20-16

MI2 1-2HP 20 2*14+14 3*16+16 16-12 16-12 20-16 20-16

MI3 3HP 32 2*10+10 3*16+16 16-10 16-10 20-16 20-16

Fuse

[A]

Table 12. Cable and fuse sizes for SmartVFD HVAC2, 208 - 240 V, 1~.

Fuse

[A]

Mains cable

Cu [AWG]

Mains cable

Cu [AWG]

Motor cable

Cu [AWG]

Motor cable

Cu [AWG]

terminal

[AWG]

Main

terminal

[AWG]

Earth

terminal

[AWG]

Terminal cable size (min/max)

Earth

terminal

[AWG]

Control

terminal

[AWG]

Control

terminal

[AWG]

Relay

terminal

[AWG]

Relay

terminal

[AWG]

9 31-00109EF—01

SMARTVFD HVAC2

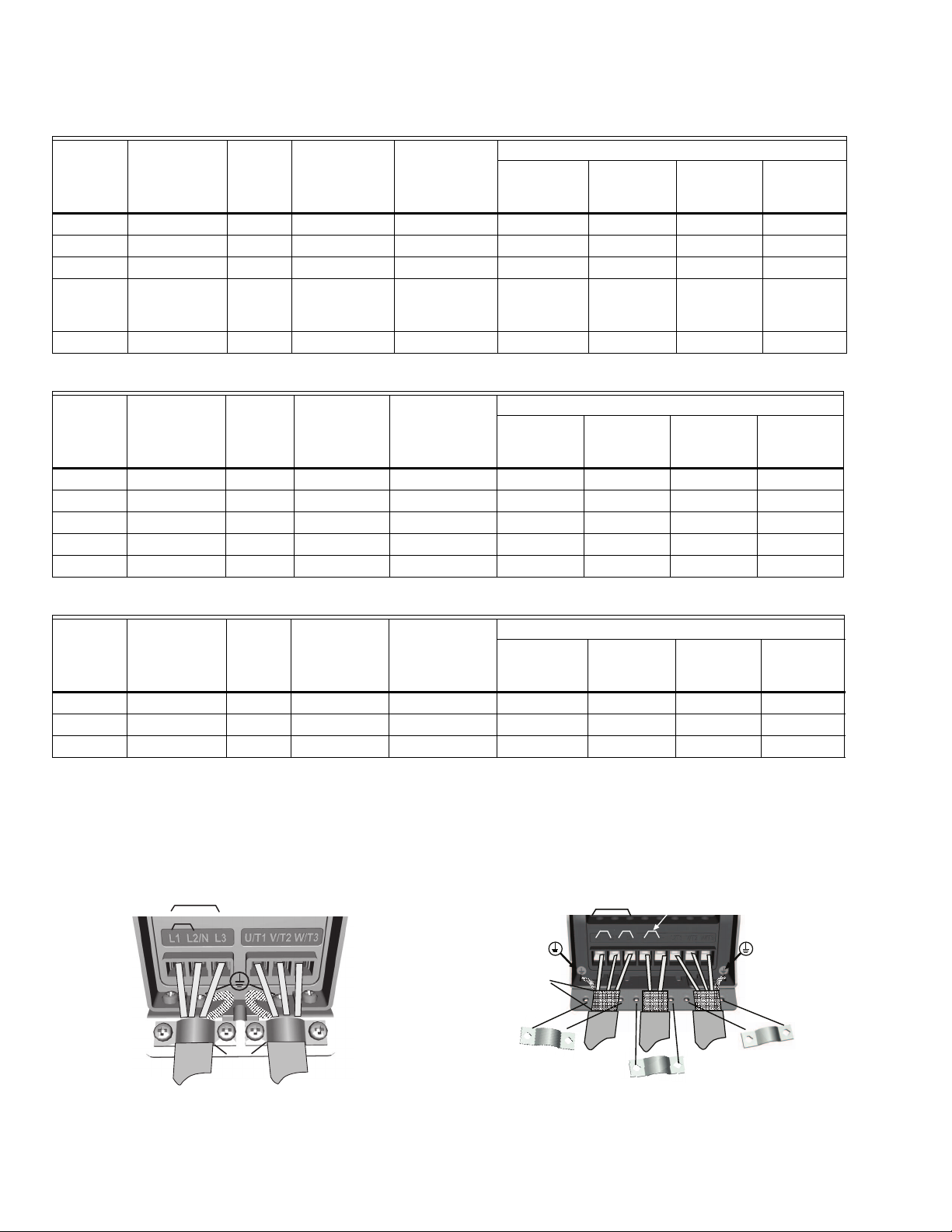

L1 L2/N L3 U/T1V/T2 W/T3

R+ R-

1~ (230V)

3~(230V,400V,600V)

1~ (115V)

MAINS

MOTOR

EXTERNAL BRAKERESI STOR

3~(230V, 400V,600V)

MOTO R OUT

STRIP T HE

PLASTIC

CABLE

COATING

FOR 360°

EARTHING

BRAKE RESISTOR

(NOT USED)

M36555

Table 13. Cable and fuse sizes for SmartVFD HVAC2, 208 - 240 V, 3~.

Terminal cable size (min/max)

Frame Horsepower

Fuse

[A]

Mains cable

Cu [AWG]

Motor cable

Cu [AWG]

Main

terminal

[AWG]

Earth

terminal

[AWG]

Control

terminal

[AWG]

Relay

terminal

[AWG]

MI1 .33-.75HP 6 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI2 1-2HP 10 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI3 3HP 20 3*14+14 3*14+14 16-10 16-10 20-16 20-16

MI4 4-7.5HP 20

3*10+10 3*10+10 17-6 Cu 17-6 20-16 20-16

25

40

MI5 10-15HP 40 3*6+6 3*6+6 14-1 Cu / Al 14-2 20-16 20-16

Table 14. Cable and fuse sizes for SmartVFD HVAC2, 380 - 480 V, 3~.

Terminal cable size (min/max)

Relay

terminal

[AWG]

Frame Horsepower

Fuse

[A]

Mains cable

Cu [AWG]

Motor cable

Cu [AWG]

Main

terminal

[AWG]

Earth

terminal

[AWG]

Control

terminal

[AWG]

MI1 .5-1HP 6 3*16+16 3*16+16 1.5-4 16-12 20-16 20-16

MI2 1.5-3HP 10 3*16+16 3*16+16 1.5-4 16-12 20-16 20-16

MI3 4-7.5HP 20 3*14+14 3*14+14 16-10 16-10 20-16 20-16

MI4 10-15HP 25 3*10+10 3*10+10 17-6 Cu 17-6 20-16 20-16

MI5 20-25HP 40 3*6+6 3*6+6 14-1 Cu / Al 14-2 20-16 20-16

Table 15. Cable and fuse sizes for SmartVFD HVAC2, 600 V,3~.

Terminal cable size (min/max)

Relay

terminal

[AWG]

Frame Horsepower

Fuse

[A]

Mains cable

Cu [AWG]

Motor cable

Cu [AWG]

Main

terminal

[AWG]

Earth

terminal

[AWG]

Control

terminal

[AWG]

MI3 1-3HP 6 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI3 5HP 10 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI3 7.5HP 20 3*14+14 3*14+14 16-10 16-10 20-16 20-16

NOTE: To fulfill standard EN61800-5-1, the protective conductor should be at least 8 AWG Cu or 6 AWG Al. Another pos-

sibility is to use an additional protective conductor of at least the same size as the original one.

Power cabling

NOTE: Tightening torque for power cables is 0.5 - 0.6 Nm (4-5 in.lbs).

3~ (230V, 400V)

1~ (230V)

STRIP THE

MAINS

PLASTIC CABLE

COATING FOR

360˚ EARTHING

Fig. 14. SmartVFD HVAC2 power connections, MI1.

MOTOR OU T

MOTOR

M36554

Fig. 15. SmartVFD HVAC2 power connections, MI2 -

MI3.

31-00109EF—01 10

SMARTVFD HVAC2

MAINS

MOTOR

MOTOR OUT

3~ (380, 480V)

BRAKE

RESISTOR

(NOT USED)

M36556

ATTACH THIS PLATE

BEFORE INSTALLING

THE POWER CABLES

ATTACH THE SUPPORT

AFTER INSTALLING

THE POWER CABLES

M36558

Fig. 16. SmartVFD HVAC2 power connections, MI4.

Control cabling

3~ (380, 480V)

MAINS

MOTOR OUT

BRAKE

RESISTOR

(NOT USED)

MOTOR

M36557

Fig. 17. SmartVFD HVAC2 power connections, MI5.

ATTACH THE SUPPORT

AFTER INSTALLING

ATTACH THIS PLATE

BEFORE INSTALLING

THE POWER CABLES

Fig. 18. Mount the PE-plate and API cable support,

MI1 - MI3.

M36559

Fig. 19. Mount the PE-plate and API cable support,

MI4 - MI5.

11 31-00109EF—01

SMARTVFD HVAC2

M36560

M36561

STRIP THE PLASTIC

CABLE COATING

FOR 360° EARTHING

CONTROL CABLE

TIGHTENING

TORQUE: 0.4 NM

M36562

M36563

Fig. 20. Open the lid, MI1 - MI3.

Fig. 22. Install the control cables. MI1 - MI3.

Fig. 21. Open the lid, MI4 - MI5.

AI2 G ND DO- DI 4 DI 5 DI6 AO DO +

4513141516 2018

123 6 7 8 910

+10V AI 1 GND 2 4V DI- C DI1 DI 2 DI3 A B RO2 CMRO2

Fig. 24. SmartVFD Compact control connection terminals.

Fig. 23. Install the control cables. MI4 - MI5.

RO1 NORO1

CM *

22 23 26

RO2

NO

2425

NC

31-00109EF—01 12

The table below shows the SmartVFD HVAC2 control connections with the terminal numbers.

mA

SMARTVFD HVAC2

Table 16. SmartVFD HVAC2 General purpose application default I / O configuration and connections for control board

P = Programmable function.

1–10 kΩ Terminal Signal Factory preset Description

1 +10 Vref Ref. voltage out Maximum load 10 mA

2 AI1 Analog signal in 1 Freq. reference

P)

0 - 10 V, Ri = 250 kΩ

3 GND I / O signal ground

6 24 Vout 24 V output for DI's ±20%, max. load 50 mA

7 DI_C Digital Input

Digital Input Common for DI1- DI6.

Common

8 DI1 Digital input 1 Start forward

9 DI2 Digital input 2 Start reverse

10 DI3 Digital input 3 Fault reset

P)

Positive,

P)

P)

Logic1: 18…30V,

Logic0: 0…5V;

Negative,

Logic1: 0…10V,

Logic0: 18…30V;

Ri = 10KΩ (floating)

A A RS485 signal A FB Communication Negative

B B RS485 signal B FB Communication Positive

4 AI2 Analog signal in 2 PID actual value

and Freq. reference

P)

Default:

0(4) - 20 mA, Ri ≤ 250 Ω

Other:

0 - + 10 V, Ri = 250 kΩ

Selectable through microswitch

5 GND I / O signal ground

13 DO- Digital Output

Digital Output Common

Common

14 DI4 Digital input 4 As DI1

15 DI5 Digital input 5 As DI1,

Selectable through microswitch

16 DI6 Digital input 6 As DI1

18 AO Analog Output Output frequency

P)

0(4) - 20 mA, RL ≤ 500Ω

0 - 10 V, RL ≥ 1 KΩ

Selectable through microswitch

20 DO Digital signal out Active = READY

22 RO1 NO

23 RO1 CM

24 RO2 NC

25 RO2 CM

Relay out 1

Relay out 2

Active = RUN

Active = FAULT

P)

Open collector, max. load 35 V / 50 mA

P)

Switching load:

250 Vac / 3 A, 24V DC 3A

P)

Switching load:

250 Vac / 3 A, 24V DC 3A

26 RO2 NO

Fig. 25. Control inputs and outputs – API Full.

13 31-00109EF—01

SMARTVFD HVAC2

FEATURES / FUNCTIONS

Easy to set-up features

Table 17.

Feature Functions Benefit

30 second Start-up wizard Quick wizard allows you to set up basic parameters upon first

power up of drive.

“Keypad – Remote”

Operation

Quick Setup Menu Only the most commonly used parameters are visible in basic

SmartVFD Commissioning

Too l

Push the Local/Remote button. Single button operation to

view to provide easier navigation. The full view can be seen after

P16.2 in HVAC2 Parameter conceal is deactivated by changing

the value to 0.

1. Parameter sets can be uploaded and downloaded with

this tool.

2. Easy to use PC-tool for commissioning the SmartVFD

Inverters. Connection with HVFDCABLE and MCA adapter,

(HVFDCDMCAKIT/U), to the USB port of the PC. PC-tools

available for download free of charge from

https:// en-US/support/commercial/software/vfds/Pages/default.aspx

Speeds up drive set-up for

basic parameters. Includes

fire mode set-up if needed.

change the control to

manual (keypad) and back.

Useful function when

commissioning and

testing applications

Easy navigation through

the most common

parameters

Parameter copying easily

from 1 inverter to another.

Easy download of

parameter sets created

with PC-tool

Parametering with PC

Saving settings to PC

Comparing parameter

settings

Compact and robust design with easy installation

Table 18.

Feature Functions Benefit

Compact size Minimum free space above and below the drive is required for

cooling airflow.

Integrated RFI-filters Units with E2 suffix in the part number comply with EN61800-

3 category C2 as standard. This level is the required level for

public electricity networks such as buildings.

Max. ambient temperature

+ 122 °F (some exceptions)

Side by side mounting with

screws or DIN-rail as

standard

High maximum ambient operating temperature Uninterruptible operation

SmartVFD HVAC2 MI1-MI3 can be mounted side by side with

no space between the units either with screws or on DIN-rail

as standard. (For MI4-MI5, side to side installation is not

allowed and there is no DIN rail option.)

Dimensions for screw mounting can be found also on the back

of the inverter.

Uninterruptible operation functions

Table 19.

Feature Functions Benefit

Overtemperature

ride-through

Power ride-through Automatically lowers motor speed to adapt to sudden voltage

Auto restart function Auto restart function can be configured to make VFD restart

Automatically adjusts switching frequency to adapt to

unusual increase in ambient

drop such as power loss

automatically once fault is addressed

Minimum space

requirements

Easy selection and

installation of products.

Space savings

Cost savings

Easy installation

Space savings

Uninterruptible operation

Uninterruptible operation

Uninterruptible operation

31-00109EF—01 14

SMARTVFD HVAC2

VFD and motor control features

Table 20.

Feature Functions Benefit

Flying start Ability to get an already spinning fan under speed control Improved performance

Inbuilt PID controller Capability to make a standalone system with sensor

connected directly to the inverter for complete PI- control.

Ease of application

Cost saving

OPTIONAL ACCESSORIES

Table 21.

Part Number Description

HVFDCDNEMA1FR1/U Nema 1 Kit MI1

HVFDCDNEMA1FR2/U Nema 1 Kit MI2

HVFDCDNEMA1FR3/U Nema 1 Kit MI3

HVFDCDNEMA1FR4 Nema 1 Kit MI4

HVFDCDNEMA1FR5 Nema 1 Kit MI5

HVFD2DMOUNTKIT/U SmartVFD HVAC2 door mounting kit

HVFDCABLE/U SmartVFD Commissioning Cable and USB Adapter

HVFDCDMCA/U Compact Commissioning Device

HVFDCDMCAKIT/U Compact Commissioning Kit (Cable, USB Adapter, and Device combined)

Table 22. Table 23.

Option boards (all boards are varnished)

HVFDSDOPT6DI/U 6 x DI/DO, each I/O can be

individually

HVFDSDOPT2RO1T/U 2 x Relay output + Thermistor

HVFDSDOPT1AI2AO/U 1 x AI, 2 x AO (isolated)

HVFDSDOPT3RO/U 3 x Relay output

HVFDSDOPT1RO5DI/U 1 x RO, 5 x DI (42-240 VAC)

HVFDOPTTMP 3 x Temperature measurement

(support for PT100, PT1000,

NI1000, KTY84-130, KTY84-

150, KTY84-131 sensors)

Option board assembly structure

HVFD2DOPTFR123 Option board mounting kit

HVAC2 MI1-MI3

HVFD2DOPTFR45 Option board mounting kit

HVAC2 MI4-MI5

15 31-00109EF—01

SMARTVFD HVAC2

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any

liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Home and Building Technologies

In the U.S.:

Honeywell

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

31-00109EF—01 M.S. 12-16

Printed in United States

31-00109EF-01

SmartVFD HVAC2

INFORMATIONS D'ORDRE GÉNÉRAL

Les variateurs de fréquence SmartVFD HVAC2 permettent

un contrôle de vitesse continu pour diverses applications :

DONNÉES DU PRODUIT

• Fonction de mode de déclenchement

• Filtres RFI intégrés

• Modèles disponibles avec ou sans filtre CEM de la

classe C2

• Vastes possibilités de connexion d'entrée et de sortie

• Entrées et sorties configurables

• Assistant de démarrage en 30 secondes

• Passage facile du « clavier au mode à distance » avec

1 bouton

• Paramétrage des transmissions/réceptions même

sans alimentation principale du variateur grâce à

l'accessoire HVFDCABLE

• Fonctionnement silencieux du moteur avec une

fréquence de commutation de 4 kHz

• Système anti-panne de surchauffe

• Préchauffage du moteur

• Système anti-panne d'alimentation

• Redémarrage automatique

•Régulateur PID intégré

• Boîtier NEMA 1 en option

• Communication Modbus RS485 intégrée

•Pompes

• Ventilateurs

• Compresseurs

CARACTÉRISTIQUES

• Format compact : fait gagner de la place dans

l'armoire de votre équipement

• Modèles disponibles jusqu'à 25 HP

• Support de moteur à aimants permanents

• Fonctionnalité d'optimisation énergétique

• Données de processus FB (Fieldbus) programmable

• Supervisions des limites réglables

• Mesure de la température avec la carte en option

HVFDOPTTMP du capteur de température

• Montage côte à côte flexible avec vis ou rails DIN

standard pour les dimensions de cadre MI1-MI3

• Régime nominal unique adapté aux applications de

pompes et de ventilateurs ou de machines

• Température ambiante maximale : +122 °F pour la

plupart des variateurs

SPÉCIFICATIONS

Raccordement au secteur

Tension d'entrée Uin:

115 V, -15 %...+10 % monophasé

208...240 V, -15 %...+10% monophasé

208...240 V, -15 %...+10 % triphasé

380 - 480 V, -15 %...+10 % triphasé

600 V, -15 %...+10 % triphasé

Fréquence d'entrée : 45...66 Hz

Raccordement au secteur : Une fois par minute ou moins

(cas normal)

Réseau d'alimentation

Réseaux :

Le SmartVFD HVAC2 (400 V) ne peut pas être utilisé avec

des réseaux à une phase connectée à la terre

Courant de court-circuit :

Le courant de court-circuit maximal doit être < 50 kA

SMARTVFD HVAC2

Raccordement du moteur

Tension de sortie : 0 - U

Courant de sortie :

Courant nominal continu IN à une température ambiante

maximale de +50 °C (selon la taille de l'unité),

surcharge :

1,5 x IN max

1 min / 10 min

Courant/couple de démarrage : Courant 2 x I

s toutes les 20 s. Le couple dépend du moteur.

Fréquence de sortie : 0...320 Hz

Résolution en fréquence : 0,01 Hz

in

pendant 2

N

Raccordements des commandes

Entrée numérique :

Positive, Logique 1 : 18…+30 V, Logique 0 : 0…5V;

Négative, Logique 1 : 0…10 V, Logique 0 : 18…30 V; Ri = 10

KΩ (variable)

Tension d'entrée analogique : 0….+10 V,Ri = 250 KΩ

Analogue input current 0(4)…20 mA, Ri ≤ 250 Ω

Sortie analogique :

0…10 V, RL ≥ 1 KΩ; 0(4)…20 mA, RL ≤ 500Ω, sélectionnable

à l'aide du microcommutateur

Sortie numérique :

Collecteur ouvert, charge max. 35 V/50 mA (variable)

Sortie de relais : Pouvoir de coupure :

250 Vca/3 A, 24 V c. c 3 A

Tension auxiliaire : ±20 %, charge max. 50 mA

Caractéristiques de contrôle

Méthode de contrôle :

Régulation de fréquence U/f

Commande vectorielle sans capteur en boucle ouverte

Fréquence de commutation : 1...16 kHz; réglage par

défaut 4 kHz

Référence de fréquence : Résolution 0,01 Hz

Point de shuntage : 30...320 Hz

Temps d'accélération : 0,1…3 000 s

Temps de décélération : 0,1…3 000 s

Couple de freinage :

100 %*T

variateurs triphasés de tailles MI2-5) 30 %*T

option de frein

avec option de frein (uniquement sur les

N

sans

N

Conditions ambiantes

Températures de fonctionnement :

14 °F (-10 °C) (sans gel)…+104/122 °F (+40/50 °C) (selon

la taille de l'unité) : capacité de charge nominale IN

En cas d'installation côte à côte pour MI1-3, la

température est toujours de 104 °F (40 °C); Pour

l'option IP21/Nema1 dans l'unité MI1-3, la

température maximale est aussi de 104 °F (40 °C)I

Température de stockage :

-40 °F (-40 °C)…+158 °F (70 °C)

Qualité de l'air :

Vapeurs chimiques :

IEC 721-3-3, unité en service, classe 3C2

Particules mécaniques :

IEC 721-3-3, unité en service, classe 3S2

Altitude :

Capacité de charge de 100 % (sans réduction de charge)

jusqu'à 3 281 pi (1 000 m).

Réduction de charge de 1 % tous les 328 pi (100 m) au-

dessus de 3 281 pi (1 000 m); 6 562 pi (2 000 m) max.

Humidité relative :

0…95 % HR, sans condensation, sans corrosion, sans

ruissellement d'eau

Vibration : 3...150 Hz

EN60068-2-6 :

Amplitude de déplacement 1 mm (pic) à 3...15,8 Hz

Amplitude d'accélération max. 1 G à 15,8...150 Hz

Choc

IEC 68-2-27:

Essai de chute UPS (pour les poids UPS applicables)

Entreposage et transport : 15 g max., 11 ms (emballé)

Classe de protection : IP20 pour MI1-3, IP21 pour MI4-5.

Avec le kit HVFDCDNEMA1xxx; IP21/NEMA1 pour MI1-5.

Degré de pollution : PD2

Compatibilité électromagnétique (CEM)

Immunité :

Conforme aux normes EN50082-1, -2, EN61800-3

Émissions :

230 V : Conforme à la catégorie C2 de CEM; avec filtre RFI

interne

400 V : Conforme à la catégorie C2 de CEM; avec filtre RFI

interne

Sécurité :

Pour la sécurité : UL508C, EN61800-5, CE, UL, cUL, KC

Pour la CEM : EN61800-3, CE, KC

Protections

Protection contre les surtensions :

875 VDC dans HVFD2DXCXXXXXXX

437 VDC dans HVFD2DXBXXXXXXX

Protection contre les soustensions :

333 VDC dans HVFD2DXCXXXXXXX

160 VDC dans HVFD2DXBXXXXXXX

Protection contre les défauts à la terre :

En cas de défauts à la terre dans le moteur ou dans le

câble du moteur, seul le variateur de fréquence est

protégé

Protection contre la surchauffe de l'appareil : OUI

Protection contre la surcharge du moteur : OUI

Protection contre le calage du moteur

(ventilateur/pompe bloqués) : OUI

Protection contre la sous-charge du moteur (détection

de pompe sèche/courroie brisée) : OUI

Protection contre les courts-circuits de tensions de

référence de +24 V et +10 V : OUI

Protection contre les surintensités : Limite de

déclenchement 4,0*I

instantanément

N

31-00109EF—01 2

SMARTVFD HVAC2

MODÈLES

Tension secteur 208-240 V

Tableau 1. Tension secteur 208-240 V, 50/60 Hz, série monophasée.

Puissance de

l'arbre du

Capacité de charge nominale

moteur

Courant de

Numéro de pièce

Courant continu à

100 % I

[A]

N

surintensité à

150 % [A]

P

[HP]P[KW] [A]

HVFD2D1B0003E2 1.7 2.6 0.33 0.25 4.2 MI1 1.21

HVFD2D1B0005E2 2.4 3.6 0.5 0.37 5.7 MI1 1.21

HVFD2D1B0007E2 2.8 4.2 0.75 0.55 6.6 MI1 1.21

HVFD2D1B0010E2 3.7 5.6 1 0.75 8.3 MI2 1.54

HVFD2D1B0015E2 4.8 7.2 1.5 1.1 11.2 MI2 1.54

HVFD2D1B0020E2 7 10.5 2 1.5 14.1 MI2 1.54

HVFD2D1B0030E2* 9.6 14.4 3 2.2 22.1 MI3 2.18

* La température ambiante de fonctionnement maximale de ce variateur est de 104 °F (40 °C).

Courant

d'entrée

nominal

Dimensions

mécaniques Poids (lb)

Tableau 2. Tension secteur 208-240 V, 50/60 Hz, série triphasée.

Capacité de charge nominale

Puissance de

l'arbre du

moteur

Courant

d'entrée

nominal

Courant de

Dimensions

mécaniques Poids (lb)

Numéro de pièce

Courant continu à

100 % I

[A]

N

surintensité à

150 % [A]

P

[HP]P[KW] [A]

HVFD2D3B0003 1.7 2.6 0.33 0.25 2.7 MI1 1.21

HVFD2D3B0005 2.4 3.6 0.5 0.37 3.5 MI1 1.21

HVFD2D3B0007 2.8 4.2 0.75 0.55 3.8 MI1 1.21

HVFD2D3B0010 3.7 5.6 1 0.75 4.3 MI2 1.54

HVFD2D3B0015 4.8 7.2 1.5 1.1 6.8 MI2 1.54

HVFD2D3B0020* 7 10.5 2 1.5 8.4 MI2 1.54

HVFD2D3B0030* 11 16.5 3 2.2 13.4 MI3 2.18

HVFD2D3B0040 12.5 18.8 4 3 14.2 MI4 19.13

HVFD2D3B0050 17.5 26.3 5 4 20.6 MI4 19.13

HVFD2D3B0075 25 37.5 7.5 5.5 30.3 MI4 19.13

HVFD2D3B0100 31 46.5 10 7.5 36.6 MI5 24.4

HVFD2D3B0150 38 57 15 11 44.6 MI5 24.4

* La température ambiante de fonctionnement maximale de ces variateurs est de 104 °F (40 °C).

3 31-00109EF—01

SMARTVFD HVAC2

Tension secteur 115 V

Tableau 3. Tension secteur 115 V, 50/60 Hz, série monophasée.

Capacité de charge nominale

Puissance de

l'arbre du moteur

Courant d'entrée

nominal

Courant de

Numéro de pièce

Courant continu

à 100 % I

[A]

N

surintensité à

150 % [A]

P

[HP]

P

[KW] [A]

Dimensions

mécaniques

Poids

(lb)

HVFD2D1A0003 1.7 2.6 0.33 0.25 9.2 MI2 1.54

HVFD2D1A0005 2.4 3.6 0.5 0.37 11.6 MI2 1.54

HVFD2D1A0007 2.8 4.2 0.75 0.55 12.4 MI2 1.54

HVFD2D1A0010 3.7 5.6 1 0.75 15 MI2 1.54

HVFD2D1A0015 4.8 7.2 1.5 1.1 16.5 MI3 2.18

Tension secteur 380-480 V

Tableau 4. Tension secteur 380-480 V, 50/60 Hz, série triphasée.

Puissance de

Numéro de pièce

Capacité de charge nominale

Courant

continu à

100 % I

[A]

N

Courant de

surintensité à

150 % [A]

l'arbre du moteur

P

[HP]

[KW] [A]

HVFD2D3C0005xx 1.3 2 0.5 0.37 2.2 MI1 1.21

HVFD2D3C0007xx 1.9 2.9 0.75 0.55 2.8 MI1 1.21

HVFD2D3C0010xx 2.4 3.6 1 0.75 3.2 MI1 1.21

HVFD2D3C0015xx 3.3 5 1.5 1.1 4 MI2 1.54

HVFD2D3C0020xx 4.3 6.5 2 1.5 5.6 MI2 1.54

HVFD2D3C0030xx 5.6 8.4 3 2.2 7.3 MI2 1.54

HVFD2D3C0040xx 7.6 11.4 4 3 9.6 MI3 2.18

HVFD2D3C0050xx 9 13.5 5 4 11.5 MI3 2.18

HVFD2D3C0075xx 12 18 7.5 5.5 14.9 MI3 2.18

HVFD2D3C0100xx 16 24 10 7.5 17.1 MI4 19.13

HVFD2D3C0150xx 23 34.5 15 11 25.5 MI4 19.13

HVFD2D3C0200xx 31 46.5 20 15 33 MI5 24.4

HVFD2D3C0250xx 38 57 25 18.5 41.7 MI5 24.4

Courant d'entrée

P

nominal

Dimensions

mécaniques

Poids

(lb)

Tension secteur 600 V

Tableau 5. Tension secteur 600 V, 50/60 Hz, série triphasée.

Puissance de l'arbre

Numéro de pièce

Capacité de charge nominale

Courant

continu à

100 % I

N

[A]

Courant de

surintensité à

150 % [A]

du moteur

P

[HP]

[KW] [A]

HVFD2D3F0010 1.7 2.6 1 0.75 2 MI3 2.18

HVFD2D3F0020 2.7 4.2 2 1.5 3.6 MI3 2.18

HVFD2D3F0030 3.9 5.9 3 2.2 5 MI3 2.18

HVFD2D3F0050 6.1 9.2 5 4 7.6 MI3 2.18

HVFD2D3F0075 9 13.5 7.5 5.5 10.4 MI3 2.18

31-00109EF—01 4

Courant d'entrée

P

nominal

Dimensions

mécaniques

Poids

(lb)

CODE D'IDENTIFICATION DES PRODUITS

3E2C0000HVFD2D

Filtre CEM

E2 = Filtre CEM

(Vide) = Pas de filtre CEM

Phases

1 = monophasé

3 = triphasé

Gamme de produits

HVFD2D = Honeywell SmartVFD HVAC2

Puissance nominale

Tension nominale

A = 105 V - 120 V

B = 208 V - 240 V

C = 380 V - 480 V

F = 520 V - 600 V

0003 = 0,33 HP

0005 = 0,5 HP

0007 = 0,75 HP

0010 = 1 HP

0015 = 1,5 HP

0020 = 2 HP

0030 = 3 HP

0040 = 4 HP

0050 = 5 HP

0075 = 7,5 HP

0100 = 10 HP

0150 = 15 HP

0200 = 20 HP

0250 = 25 HP

MFCR36499

SMARTVFD HVAC2

Fig. 1. Code de désignation du type SmartVFD HVAC2.

5 31-00109EF—01

SMARTVFD HVAC2

=

M5

MI3

MI1

=M4

MI2

=M5

LOC

REM

BACK

RESET

OK

M36500

LOC

REM

BACK

RESET

OK

LOC

REM

BACK

RESET

OK

MI4

MI5

LOC

REM

BACK

RESET

OK

M36501

=M 6

=M 6

LOC

REM

BACK

RESET

OK

12

M36502

M36503

LOC

REM

BACK

RESET

OK

13/64 (6)

MF36504

HAUT

6

(153)

Ø 1/4 (7)

14-1/2 (370)

SCHÉMA DU VARIATEUR

SCHÉMA D'OUVERTURE

14-19/64 (362)

14 (356)

15-7/64 (384)

6-1/2

(166)

6-51/64

(173)

7-13/32

(189)

MI4

M36507

MI5

1-3/32

(29)

51/64

(20)

13

(332)

15/32

(12)

29/32

(23)

3-1/2

(89)

6-1/2 (165)

3

(77)

5/8

(16)

1-3/32

(29)

15

(379)

19/32

(15)

29/32

(23)

8 (202)

3-45/64

(95)

4-7/32

(107)

MONTAGE MÉCANIQUE

Il existe deux possibilités d'installation du SmartVFD

HVAC2 au mur. Pour MI1-MI3, montage à vis ou sur rail

DIN; pour MI4-MI5, montage à vis ou sur bride.

Fig. 2. Montage à vis, MI1 - MI3

Fig. 5. Montage sur bride, MI4 - MI5

Fig. 3. Montage à vis, MI4 - MI5

REMARQUE : Reportez-vous aux dimensions de montage,

au dos du variateur.

Fig. 4. Montage sur rail DIN, MI1 - MI3

Fig. 6. Montage sur bride, dimensions de découpe pour

MI4 [Unité : pouces (mm)]

Ø 1/4 (7)

HAUT

6

(153)

SCHÉMA DU VARIATEUR

SCHÉMA D'OUVERTURE

16 (407)

14 (356)

15-45/64 (400)

17 (431)

13/64 (6)

6-1/2

(166)

6-51/64

(173)

MF36505

7-13/32

(189)

Fig. 7. Montage sur bride, dimensions de découpe pour

MI5 [Unité : pouces (mm)]

31-00109EF—01 6

Fig. 8. Montage sur bride, dimensions en profondeur

pour MI4 et MI5 [Unité : pouces (mm)]

DIMENSIONS

W2

W3

H

(H1)

H2

H3

L1 L2 L3

DC+R+ R-

DC- U/T1

V/T2

W/T3

D (D1)

W (W1)

M36509

LOC

REM

BACK

RESET

OK

A

B

M36527

SMARTVFD HVAC2

H (H1)

W2

W (W1)

W3

H2

D (D1)

D2

H3

M36508

Fig. 9. Dimensions du SmartVFD HVAC2, MI1 - MI3.

D

A

LOC

BACK

REM

RESET

OK

M36510

Dimensions en

pouces (mm)

Châssis

MI2 MI3

A .7 (17) .9 (22.3)

B 1.7 (44) 4 (102)

Fig. 11. Dimensions du SmartVFD HVAC2, MI2 - 3

Emplacement de l'affichage.

Fig. 10. Dimensions du SmartVFD HVAC2, MI4 - MI5.

Tableau 6. Dimensions du SmartVFD HVAC2 en

pouces (mm).

Type H1 H2 H3 W1 W2 W3 D1 D2

MI1 6.3

MI2 7.7

MI3 10

MI4 14.6

MI5 16.3

(160.1)

(195)

(254.3)

(370)

(414)

5.8

5.4

(147)

(137.3)

7.2

6.7

(183)

(170)

9.6

(244)90(229.3)

13.8

13.2

(350.5)

(336.5)

15.7

(398)15(383)

2.6

1.5

(65.5)

(37.8)

3.5

2.5

(90)

(62.5).2(5.5)4(101.5)

3.9

2.95

(100)

(75).2(5.5)

6.5

5.5

(165)

(140)

6.5

5.5

(165)

(140)

.18

(4.5)

.28

(7)

.28

(7)

3.9

(98.5)

4.3

(108.5)

6.5

(165)

7.9

(202)

.28

(7)

.28

(7)

.28

(7)

-

-

Dimensions en

pouces (mm)

Châssis

MI4 MI5

A 8 (205) 9.8 (248.5)

B 3.4 (87) 3.4 (87)

Fig. 12. Dimensions du SmartVFD HVAC2, MI4 -5

Emplacement de l'affichage.

Tableau 7. Dimensions (mm) et poids en lb (kg) du

châssis du SmartVFD HVAC2.

Dimensions en pouces (mm)

Châssis

MI1 2.6 (66) 6.3 (160) 3.9 (98) 1.2 (0.5)

Poids en lb

(en kg).*WHD

MI2 3.5 (90) 7.7 (195) 4 (102) 1.5 (0.7)

MI3 3.9 (100) 10 (254.3) 4.3 (109) 2.2 (1)

MI4 6.5 (165) 14.3 (370) 6.5 (165) 18 (8)

MI5 6.5 (165) 16.3 (414) 8 (202) 22 (10)

*sans l'emballage d'expédition

7 31-00109EF—01

SMARTVFD HVAC2

B

B

A

LOC

REM

BACK

RESET

OK

C

M36528

A

D

REFROIDISSEMENT

Il convient de laisser suffisamment d'espace libre au-dessus et en dessous du variateur de fréquence pour garantir une

circulation de l'air et un refroidissement suffisants. Vous trouverez les dimensions requises pour l'espace libre dans le

tableau ci-dessous.

Si plusieurs appareils sont installés l'un au-dessus de l'autre, l'espace libre requis équivaut à C + D. Par ailleurs, l'air de

sortie utilisé par l'appareil inférieur pour le refroidissement doit être orienté en direction opposée à l'entrée d'air de

l'appareil supérieur.

La quantité d'air de refroidissement requise est indiquée ci-dessous. Veillez également à ce que la température de l'air de

refroidissement ne dépasse pas la température ambiante maximale du variateur.

Tableau 8. Dégagement min. autour du variateur CA.

Dégagement min. en pouces (mm)

Type A B C D

MI1 .8 (20) .8 (20) 3.9 (100) 2 (50)

MI2 .8 (20) .8 (20) 3.9 (100) 2 (50)

MI3 .8 (20) .8 (20) 3.9 (100) 2 (50)

MI4 .8 (20) .8 (20) 3.9 (100) 3.9 (100)

MI5 .8 (20) .8 (20) 4.7 (120) 3.9 (100)

Fig. 13. Espace d'installation.

31-00109EF—01 8

SMARTVFD HVAC2

CÂBLAGE ET FUSIBLES

Utilisez des câbles dotés d'une résistance à la chaleur d'au moins 158 °F (70 °C). Les câbles et les fusibles doivent

posséder les dimensions indiquées dans les tableaux ci-dessous.

Les fusibles jouent également le rôle de protection contre la surcharge des câbles.

Les présentes instructions s'appliquent uniquement aux cas possédant un moteur et un raccordement de câble reliant le

variateur de fréquence au moteur. Dans tout autre cas, demandez davantage d'informations à l'usine.

Tableau 9. Types de câbles requis pour respecter les normes.

Catégorie CEM cat. C2 cat. C4

Types de câbles secteur 1 1

Types de câbles du moteur 3 1

Types de câbles de commande 4 4

Tableau 10. Description des types de câbles.

Type de câble Description

1 Câble d'alimentation destiné à une installation fixe et à une tension secteur spécifique. Câble

blindé non requis.

(NKCABLES/MCMK ou similaires recommandés)

2 Câble d'alimentation équipé d'un fil de protection concentrique et destiné à une tension secteur

spécifique.

(NKCABLES/MCMK ou similaires recommandés).

3 Câble d'alimentation équipé d'un blindage de faible impédance compact et destiné à une tension

4 Câble blindé doté d'un blindage de faible impédance compact (NKCABLES/Jamak, SAB/ÖZCuY-O

secteur spécifique.

(NKCABLES/MCCMK, SAB/ÖZCUY-J ou similaires recommandés).

*Mise à la masse à 360º à la fois du moteur et de la connexion FC requise pour respecter la norme

ou similaire).

Tableau 11. Tailles de câbles et de fusibles pour le SmartVFD HVAC2, 115 V, monophasé.

Taille du câble de la borne (min./max.)

Fusible

Châssis Puissance

MI2 0,33-1 HP 20 2*14+14 3*16+16 16-12 16-12 20-16 20-16

MI3 1,5 HP 32 2*10+10 3*16+16 16-12 16-12 20-16 20-16

Tableau 12. Tailles de câbles et de fusibles pour le SmartVFD HVAC2, 208 - 240 V, monophasé.

Châssis Puissance

MI1 0,33-0,75 HP 10 2*16+16 3*16+16 16-12 16-12 20-16 20-16

MI2 1-2 HP 20 2*14+14 3*16+16 16-12 16-12 20-16 20-16

MI3 3 HP 32 2*10+10 3*16+16 16-10 16-10 20-16 20-16

[A]

Fusible

[A]

Câbles

secteur Cu

[AWG]

Câbles

secteur Cu

[AWG]

Câble de

moteur Cu

[AWG]

Câble de

moteur Cu

[AWG]

Borne

principale

[AWG]

Taille du câble de la borne (min./max.)

Borne

principale

[AWG]

Borne de

terre [AWG]

Borne de

terre [AWG]

Borne de

commande

[AWG]

Borne de

commande

[AWG]

Borne

relais

[AWG]

Borne

relais

[AWG]

9 31-00109EF—01

SMARTVFD HVAC2

Monophasé (230 V)

Triphasé (230 V, 400 V)

SORTIE MOTEUR

SECTEUR

MOTEUR

ENLEVEZ LE

REVÊTEMENT EN

PLASTIQUE DU

CÂBLE POUR UNE

MISE À LA MASSE

À 360°

MF36554

É

Tableau 13. Tailles de câbles et de fusibles pour le SmartVFD HVAC2, 208 - 240 V, triphasé.

Taille du câble de la borne (min./max.)

Châssis Puissance

Fusible

[A]

Câbles

secteur Cu

[AWG]

Câble de

moteur Cu

[AWG]

Borne

principale

[AWG]

Borne de

terre [AWG]

Borne de

commande

[AWG]

Borne

relais

[AWG]

MI1 0,33-0,75 HP 6 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI2 1-2 HP 10 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI3 3 HP 20 3*14+14 3*14+14 16-10 16-10 20-16 20-16

MI4 4-7,5 HP 20

3*10+10 3*10+10 17-6 Cu 17-6 20-16 20-16

25

40

MI5 10-15 HP 40 3*6+6 3*6+6 14-1 Cu / Al 14-2 20-16 20-16

Tableau 14. Tailles de câbles et de fusibles pour le SmartVFD HVAC2, 380 - 480 V, triphasé.

Taille du câble de la borne (min./max.)

Borne

relais

[AWG]

Châssis Puissance

Fusible

[A]

Câbles

secteur Cu

[AWG]

Câble de

moteur Cu

[AWG]

Borne

principale

[AWG]

Borne de

terre

[AWG]

Borne de

commande

[AWG]

MI1 0,5-1 HP 6 3*16+16 3*16+16 1.5-4 16-12 20-16 20-16

MI2 1,5-3 HP 10 3*16+16 3*16+16 1.5-4 16-12 20-16 20-16

MI3 4-7,5 HP 20 3*14+14 3*14+14 16-10 16-10 20-16 20-16

MI4 10-15 HP 25 3*10+10 3*10+10 17-6 Cu 17-6 20-16 20-16

MI5 20-25 HP 40 3*6+6 3*6+6 14-1 Cu / Al 14-2 20-16 20-16

Tableau 15. Tailles de câbles et de fusibles pour le SmartVFD HVAC2, 600 V, triphasé.

Taille du câble de la borne (min./max.)

Borne de

commande

[AWG]

Châssis Puissance

Fusible

[A]

Câbles

secteur Cu

[AWG]

Câble de

moteur Cu

[AWG]

Borne

principale

[AWG]

Borne de

terre

[AWG]

MI3 1-3 HP 6 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI3 5 HP 10 3*16+16 3*16+16 16-12 16-12 20-16 20-16

MI3 7,5 HP 20 3*14+14 3*14+14 16-10 16-10 20-16 20-16

REMARQUE : Pour satisfaire à la norme EN61800-5-1, le conducteur de protection doit être au moins un câble Cu 8 AWG

ou un câble Al 6 AWG. Une autre possibilité consiste à utiliser un conducteur de protection supplémentaire

ayant au moins la même taille que l'original.

Câblage d'alimentation

REMARQUE : Le couple de serrage pour les câbles d'alimentation est de 0,5 - 0,6 Nm (4-5 po.lb).

SISTANCE DE FREINAGE EXTERNE

R

Triphasé (230 V, 400 V, 600 V)

MOTO R OUT

R+ R-

MOTEUR

Triphasé (230 V, 400 V, 600 V)

1~ (230V)

1~ (115V)

L1 L2/N L3 U/T1V/T2 W/T3

ENLEVEZ LE

REVÊTEMENT EN

PLASTIQUE DU

CÂBLE POUR UNE

MISE À LA MASSE

À 360°

SECTEUR

Borne

relais

[AWG]

Fig. 14. Raccordements électriques du SmartVFD

HVAC2, MI1.

31-00109EF—01 10

RÉSISTANCE DE FREINAGE

(NON UTILISÉE)

MF36555

Fig. 15. Raccordements électriques du SmartVFD

HVAC2, MI2 - MI3.

SMARTVFD HVAC2

SECTEUR

MOTEUR

SORTIE MOTEUR

Triphasé (380 V, 480 V)

RÉSISTANCE

DE FREINAGE

(NON UTILISÉE)

MF36556

Fig. 16. Raccordements électriques du SmartVFD

HVAC2, MI4.

Câblage de commande

FIXEZ LE SUPPORT

APRÈS AVOIR INSTALLÉ

LES CÂBLES

D'ALIMENTATION

Triphasé (380 V, 480 V)

SECTEUR

SORTIE MOTEUR

RÉSISTANCE

DE FREINAGE

(NON UTILISÉE)

MOTEUR

MF36557

Fig. 17. Raccordements électriques du SmartVFD

HVAC2, MI5.

FIXEZ LE SUPPORT

APRÈS L'INSTALLATION

FIXEZ CETTE PLAQUE

AVANT D'INSTALLER

LES CÂBLES

D'ALIMENTATION

Fig. 18. Installation de la plaque en PE et du support de

FIXEZ CETTE PLAQUE

AVANT D'INSTALLER

LES CÂBLES

D'ALIMENTATION

câble API, MI1 - MI3.

MF36559

Fig. 19. Installation de la plaque en PE et du support de

câble API, MI4 - MI5.

MF36558

11 31-00109EF—01

SMARTVFD HVAC2

M36560

M36561

M36563

COUPLE DE SERRAGE

DU CÂBLE DE

COMMANDE : 0,4 NM

ENLEVEZ LE

REVÊTEMENT EN

PLASTIQUE DU

CÂBLE POUR UNE

MISE À LA MASSE

À 360°

Fig. 20. Ouverture du couvercle, MI1 - MI3.

Fig. 21. Ouverture du couvercle, MI4 - MI5.

AI2 G ND DO- DI 4 DI 5 DI6 AO DO +

4513141516 2018

123 6 7 8 910

+10V AI 1 GND 2 4V DI- C DI1 DI 2 DI3 A B RO2 CMRO2

MF36562

Fig. 22. Installation des câbles de commande. MI1 -

MI3.

Fig. 23. Installation des câbles de commande. MI4 -

MI5.

RO1 NORO1

CM *

22 23 26

RO2

NO

2425

NC

Fig. 24. Bornes de raccordement de commande du SmartVFD Compact.

31-00109EF—01 12

SMARTVFD HVAC2

mA

Le tableau ci-dessous indique les raccordements de commande du SmartVFD HVAC2 avec les numéros de bornes.

Tableau 16. Configuration et raccordements par défaut des E/S pour la carte de commande avec l'application

généraliste du SmartVFD HVAC2 P = Fonction programmable.

1–10 kΩ Borne Signal Préréglage usine Description

1 +10 Vref Tension réf. en sortie Charge maximale 10 mA

2 AI1 Signal analogique en 1 Réf. de fréquence

P)

0 - 10 V, Ri = 250 kΩ

3 GND Terre du signal d'E/S

6 Sortie 24 V Sortie 24 V pour les entrées

±20%, max. load 50 mA

numériques (DI)

7 DI_C Commun d'entrée numérique Commun d'entrée numérique pour DI1-DI6.

8 DI1 Entrée numérique 1 Marche avant

9 DI2 Entrée numérique 2 Marche arrière

10 DI3 Entrée numérique 3 Réarmement défaut

P)

Positif,

P)

Logique 1: 18…30 V,

Logique 0: 0…5 V;

P)

Negative,

Logic1: 0…10 V,

Logic0: 18…30 V;

Ri = 10KΩ (variable)

A A Signal RS485 A Communication FB Négatif

B B Signal RS485 B Communication FB Positif

4 AI2 Signal analogique en 2 Valeur réelle PID et réf. de

fréquence

P)

Préréglage :

0(4) - 20 mA, Ri ≤ 250 Ω

Autre :

0 - + 10 V, Ri = 250 kΩ

Sélectionnable par microcommutateur

5 GND Terre du signal d'E/S

13 DO- Commun de sortie

Commun de sortie numérique

numérique

14 DI4 Entrée numérique 4 Comme DI1

15 DI5 Entrée numérique 5 Comme DI1,

Sélectionnable par microcommutateur

16 DI6 Entrée numérique 6 Comme DI1

18 AO Sortie analogique Fréquence de sortie

P)

0(4) - 20 mA, RL ≤ 500Ω

0 - 10 V, RL ≥ 1 KΩ

Sélectionnable par microcommutateur

20 DO Sortie signal numérique Active = READY

22 RO1 NO

23 RO1 CM

24 RO2 NC

25 RO2 CM

Sortie relais 1

Sortie relais 2

Active = RUN

Active = FAULT

P)

Collecteur ouvert, charge max. 35 V/50 mA

P)

Charge de coupure :

250 V CA/3 A, 24 V CC 3 A

P)

Charge de coupure :

250 V CA/3 A, 24 V CC 3 A

26 RO2 NO

Fig. 25. Entrées et sorties de commande - API complète.

13 31-00109EF—01

SMARTVFD HVAC2

CARACTÉRISTIQUES/FONCTIONS

Fonctionnalités de configuration facile

Tableau 17.

Caractéristique Fonctions Avantage

Assistant de démarrage

en 30 secondes

Fonctionnement "

Clavier - À distance "

Menu de configuration

rapide

Outil de mise en service

du SmartVFD

L'assistant de démarrage rapide vous permet de configurer les

paramètres de base dès la première mise sous tension du

variateur.

Appuyez sur le bouton Local/Remote (Local/À distance). Fonctionnement à touche

Seuls les paramètres les plus fréquemment utilisés sont visibles

dans la vue de base pour faciliter la navigation. La vue complète

peut être affichée après la désactivation de P16.2 dans HVAC2

Masquer les paramètres en basculant la valeur sur 0.

1. Les paramètres peuvent être transférés et téléchargés

grâce à cet outil.

2. Outil PC facile à utiliser pour mettre en service les conver-

tisseurs SmartVFD. Raccordement à l'aide du HVFDCABLE

et de l'adaptateur MCA, (HVFDCDMCAKIT/U), au port USB

du PC. Outils PC disponibles en téléchargement gratuit à

partir de https:// en-US/support/commercial/software/vfds/Pages/default.aspx

Accélère la configuration des

paramètres de base. Comporte

une configuration du mode de

déclenchement si besoin.

unique pour basculer la

commande en manuel (clavier)

et inversement. Fonction utile

pendant les applications de

tests et de mise en service

Navigation facile dans

l'ensemble des paramètres les

plus fréquents

Copie facile de paramètres d'un

convertisseur à un autre.

Téléchargement facile

d'ensembles de paramètres

créés avec l'outil PC

Paramétrage avec le PC

Enregistrement des paramètres

sur le PC Comparaison des

réglages des paramètres

Conception compacte et solide avec installation facile

Tableau 18.

Caractéristique Fonctions Avantage

Format compact Un espace libre minimum au-dessus et en dessous du variateur

Filtres RFI intégrés Les appareils dont le numéro de pièce comporte le suffixe E2 sont

Température ambiante

maximale de + 122 °F

(quelques exceptions)

Montage côte à côte

avec vis ou rails DIN

standard

est nécessaire pour la circulation d'air de refroidissement.

conformes à la catégorie C2 de la norme EN618003 en standard.

Il s'agit du niveau requis pour les réseaux électriques publics tels

que les immeubles.

Température ambiante de fonctionnement maximale élevée Fonctionnement sans coupure

Les appareils SmartVFD HVAC2 MI1-MI3 peuvent être installés

côte à côte sans espace entre eux, soit avec des vis, soit sur rail

DIN standard. (Pour MI4-MI5, l'installation côte à côte n'est pas

autorisée et il n'y a pas d'option de rail DIN.)

Les dimensions pour le montage avec les vis sont indiquées au

dos du variateur.

Exigences d'espace minimales

Facilité de choix et

d'installation des produits.

Installation facile

Gains de place

31-00109EF—01 14

Fonctions du fonctionnement sans coupure

Tableau 19.

Caractéristique Fonctions Avantage

Système anti-panne de

surchauffe

Système anti-panne

d'alimentation

Fonction de redémarrage

automatique

Ajuste automatiquement la fréquence de commutation pour

s'adapter à une augmentation inhabituelle de la température

ambiante

Réduit automatiquement la vitesse du moteur pour s'adapter

à une chute de tension brutale comme une perte de puissance

La fonction de redémarrage automatique peut être configurée

pour faire redémarrer le VFD automatiquement dès qu'une

défaillance est détectée

Fonctionnement sans

coupure

Fonctionnement sans

coupure

Fonctionnement sans

coupure

Fonctions de commande du VFD et du moteur

Tableau 20.

Caractéristique Fonctions Avantage

Démarrage à la volée Capacité à maîtriser la vitesse d'un ventilateur déjà en train de

tourner

Régulateur PID intégré Capacité à connecter directement un système autonome avec

capteur au variateur pour une régulation PI complète.

Rendement amélioré

Facilité d'application

Économie

SMARTVFD HVAC2

ACCESSOIRES EN OPTION

Tableau 21.

Numéro de pièce Description

HVFDCDNEMA1FR1/U Kit MI1 Nema 1

HVFDCDNEMA1FR2/U Kit MI2 Nema 1

HVFDCDNEMA1FR3/U Kit MI3 Nema 1

HVFDCDNEMA1FR4 Kit MI4 Nema 1

HVFDCDNEMA1FR5 Kit MI5 Nema 1

HVFD2DMOUNTKIT/U Kit de montage de la porte du SmartVFD HVAC2

HVFDCABLE/U Câble de mise en service du SmartVFD et adaptateur USB

HVFDCDMCA/U Dispositif de mise en service du Compact

HVFDCDMCAKIT/U Kit de mise en service du Compact (câble, adaptateur USB et dispositif combinés)

Tableau 22. Tableau 23.

Cartes en option (toutes les cartes sont vernies)

HVFDSDOPT6DI/U 6 x DI/DO, chaque E/S peut

être individuelle

HVFDSDOPT2RO1T/U 2 x sorties de relais +

Thermistance

HVFDSDOPT1AI2AO/U 1 x AI, 2 x AO (isolées)

HVFDSDOPT3RO/U 3 x sorties de relais

HVFDSDOPT1RO5DI/U 1 x RO, 5 x DI (42-240 VCA)

HVFDOPTTMP 3 x mesures de température

(prise en charge pour capteurs

PT100, PT1000, NI1000,

KTY84-130, KTY84-150,

KTY84-131)

Structure d'assemblage de la carte en option

HVFD2DOPTFR123 Kit de montage de la carte en option

HVAC2 MI1-MI3

HVFD2DOPTFR45 Kit de montage de la carte en option

HVAC2 MI4-MI5

15 31-00109EF—01

SMARTVFD HVAC2

Par l'utilisation de la présente documentation Honeywell, vous consentez à ce qu'Honeywell ne possède aucune responsabilité

pour tous dommages résultant de votre utilisation ou modification de la dite documentation. Vous défendrez et indemniserez

Honeywell, ses sociétés affiliées, filiales pour et contre toute responsabilité, frais ou dommages, y compris les honoraires

d'avocats, résultant de quelque manière, ou survenant en connexion avec toute modification à la documentation de votre part.

Home and Building Technologies

Aux États-Unis :

Honeywell

® Marque de commerce déposée aux États-Unis

© 2016 Honeywell International Inc.

31-00109EF—01 M.S. 12-16

Imprimé aux États-Unis

Loading...

Loading...