Honeywell SmartVFD Data Sheet

Put Bar Code Here

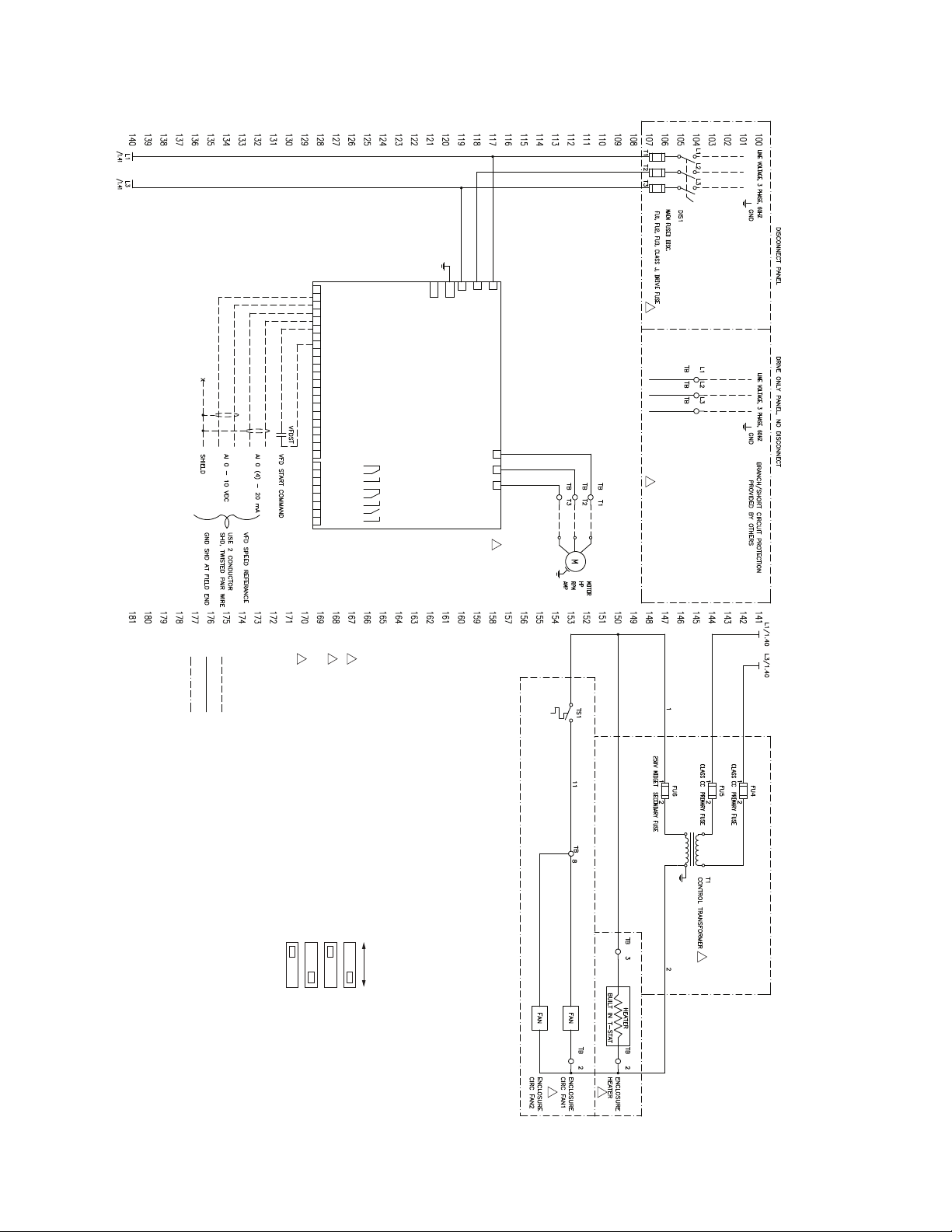

SmartVFD Frame 7 Wiring Diagrams

and Dimensional Drawings

SPECIFICATION DATA

SmartVFD Frame Size 7

460 Vac: 50-75 HP

208/230 Vac: 25-40 HP

CONTENTS

SmartVFD Frame 7 Wiring Diagrams .............................................................................................2

Frame 7, Fused Disconnect Wiring Diagrams ......................................................................... 2

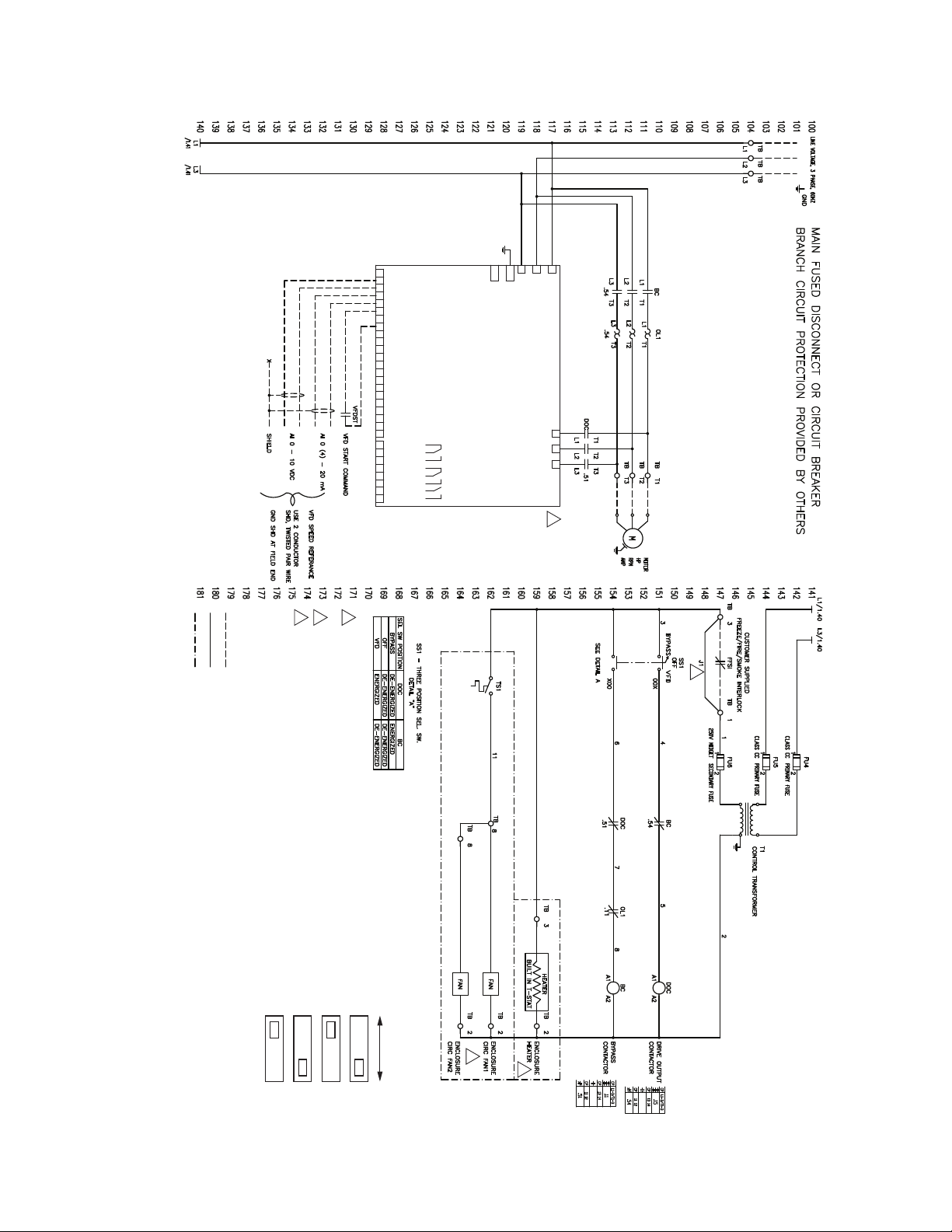

Frame 7, 2 Contactor Wiring Diagrams .................................................................................... 3

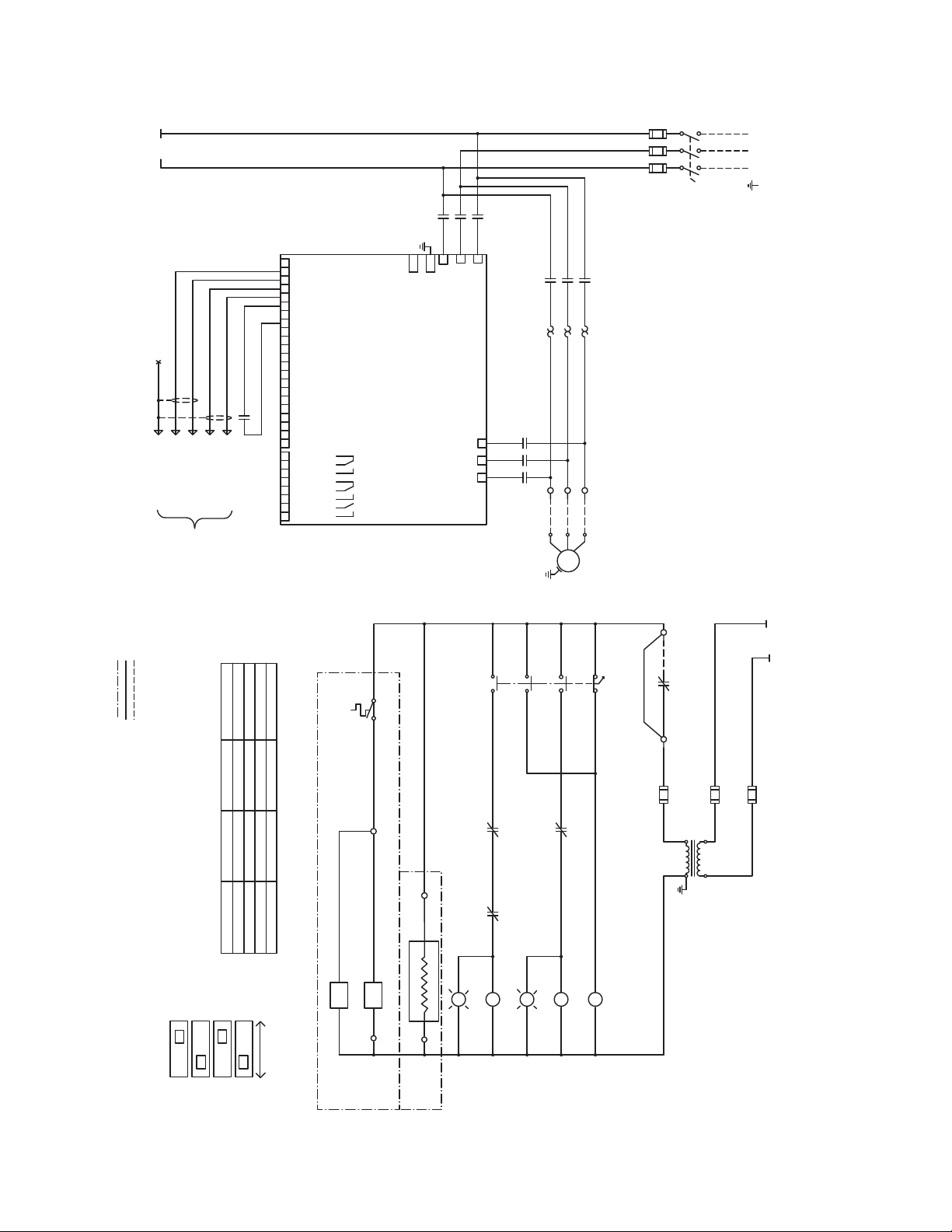

Frame 7, 3 Contactor Wiring Diagrams .................................................................................... 4

Frame 7, 3 Contactor Auto-bypass Wiring Diagrams ............................................................. 5

SmartVFD Frame 7 Dimensional Diagrams .................................................................................. 6

Frame 7 NEMA 1: Disconnect Only and 2 Contactor Dimensional Drawings ...................... 6

Frame 7 NEMA 1: 3 Contactor & 3 Contactor with Auto-bypass Dimensional Drawings.... 7

Frame 7 NEMA 12: 2 Contactor and 3 Contactor .................................................................... 8

Frame 7 NEMA 3R: 2 Contactor, 3 Contactor, 3 Contactor with Auto-Bypass ..................... 9

63-1374-01

SMARTVFD FRAME 7 WIRING DIAGRAMS AND DIMENSIONAL DRAWINGS

ALL PANELS SHIPPED WITH VFD DEFAULT PROGRAMMING

PARAMETERS. SET DIP SWITCHES AS NEEDED.

TS1, ENCLOSURE FAN1 STANDARD ON ALL NEMA 3R PANELS.

ENCLOSURE FAN2 ON 30HP, 40HP, AND 100HP AT 480V.

HEATER IS OPTIONAL ON ALL NEMA 3R PANELS. TRANSFORMER

ONLY REQUIRED ON 3R MODELS.

DISCONNECT PANEL HAS FUSED MAIN DISCONNECT.

DRIVE ONLY PANEL HAS WIRE TERMINALS. ON DRIVE

ONLY PANEL, CUSTOMER IS RESPONSIBLE FOR BRANCH

CIRCUIT AND SHORT CIRCUIT PROTECTION.

ALL WIRING: USE COPPER WIRE ONLY SUITABLE FOR MIN. 75 DEG. C, FIELD WIRING, NEC CLASS 1.

MOTOR AND FEEDER WIRE SIZE MUST BE IN ACCORDANCE WITH NEC.

FIELD WIRE

WIRE INSIDE C/PNL

OPTION

3

33

2

2

2

2

1

DIP SWITCHES

LOCATED BEHIND COVER,

RIGHT SIDE OF KEYPAD

RS485

A01

AI1

AI2

OFFON

VOLTAGECURRENT

VOLTAGECURRENT

VOLTAGECURRENT

M34226

1

21 3 4 5 6 7 8 9 10 11 12 1314 15 16 17 18 19

GND/AI1-: AI COMMON

GND/AI2-: AI COMMON

24V OUT: 24V AUXILLARY VOLTAGE

GND: I/O GROUND

DIN1: DIGITAL INPUT 1

DIN2: DIGITAL INPUT 2

DIN3: DIGITAL INPUT 3

24V OUT: 24V AUXILLARY VOLTAGE

GND: I/O GROUND

DIN4: DIGITAL INPUT 4

DIN5: DIGITAL INPUT 5

DIN6: DIGITAL INPUT 6

2122 23

RELAY OUTPUT 1

RELAY OUTPUT 2

SMART VFD

+10VREF: REFERANCE OUTPUT

AI1+: AI, VOLTAGE OR CURRENT

AI2+: AI, VOLTAGE OR CURRENT

CM: COMMON FOR DI1 - DI3

CM: COMMON FOR DI4 - DI6

AO+: ANALOG SIGNAL +OUT

AO-/GND: ANALOG OUTPUT COMMON

30

+24VIN: 24V AUXILLARY INPUT VOLTAGE

AB

RS485: NEGATIVE

RS485: POSITIVE

RO1/1 N.C.

RO1/2 CM

RO1/3 N.O.

24

RO2/1 N.C.

25

RO2/2 CM

26

RO2/3 N.O.

RO3/1 CM

32 33

RO3/2 N.O.

RELAY OUTPUT 2

RELAY OUTPUT 1

RELAY OUTPUT 3

GND

GND

W1

V1

U1

U2 V2

W2

Fig. 1. Frame 7, Fused Disconnect Wiring Diagrams

63-1374—01 2

M34225

ALL PANELS SHIPPED WITH VFD DEFAULT PROGRAMMING

PARAMETERS. SET DIP SWITCHES AS NEEDED.

IF CUSTOMER SAFETY INTERLOCK IS USED, REMOVE J1.

TS1, ENCLOSURE FAN1 STANDARD ON ALL NEMA 3R PANELS.

ENCLOSURE FAN2 ON 25HP AND LARGER AT 480V.

HEATER IS OPTIONAL ON ALL NEMA 3R PANELS.

3

3

3

221

1

DIP SWITCHES

LOCATED BEHIND COVER,

RIGHT SIDE OF KEYPAD

RS485

A01

AI1

AI2

OFFON

VOLTAGECURRENT

VOLTAGECURRENT

VOLTAGECURRENT

U1

V1

W1

U2 V2 W2

21 3 4 5 6 7 8 9 10 11 12 13 14 15 1617 18 19

GND

GND

GND/AI1-: AI COMMON

GND/AI2-: AI COMMON

24V OUT: 24V AUXILLARY VOLTAGE

GND: I/O GROUND

DIN1: DIGITAL INPUT 1

DIN2: DIGITAL INPUT 2

DIN3: DIGITAL INPUT 3

24V OUT: 24V AUXILLARY VOLTAGE

GND: I/O GROUND

DIN4: DIGITAL INPUT 4

DIN5: DIGITAL INPUT 5

DIN6: DIGITAL INPUT 6

SMART VFD

+10VREF: REFERANCE OUTPUT

AI1+: AI, VOLTAGE OR CURRENT

AI2+: AI, VOLTAGE OR CURRENT

CM: COMMON FOR DI1 - DI3

CM: COMMON FOR DI4 - DI6

AO+: ANALOG SIGNAL +OUT

AO-/GND: ANALOG OUTPUT COMMON

30

+24VIN: 24V AUXILLARY INPUT VOLTAGE

2122 23AB

RS485: NEGATIVE

RS485: POSITIVE

RO1/1 N.C.

RO1/2 CM

RO1/3 N.O.

24

RO2/1 N.C.

25

RO2/2 CM

26

RO2/3 N.O.

RO3/1 CM

32 33

RO3/2 N.O.

RELAY OUTPUT 1

RELAY OUTPUT 2

RELAY OUTPUT 1

RELAY OUTPUT 2

RELAY OUTPUT 3

ALL WIRING: USE COPPER WIRE ONLY SUITABLE FOR MIN. 75 DEG. C, FIELD WIRING,

NEC CLASS 1.

MOTOR AND FEEDER WIRE SIZE MUST BE IN ACCORDANCE WITH NEC.

FIELD WIRE

WIRE INSIDE C/PNL

OPTION

SMARTVFD FRAME 7 WIRING DIAGRAMS AND DIMENSIONAL DRAWINGS

Fig. 2. Frame 7, 2 Contactor Wiring Diagram

3 63-1374—01

SMARTVFD FRAME 7 WIRING DIAGRAMS AND DIMENSIONAL DRAWINGS

M34045

DIS1

MAIN FUSED DISC.

FU1, FU2, FU3, CLASS J, TIME DELAY

VFD START COMMAND

VFD SPEED REFERENCE

USE 2 CONDUCTOR SHD,

TWISTED PAIR WIRE

GND SHD AT FIELD END

SHIELD

AI 0 - 10 VDC OR

4 - 20 mA

4 - 20 mA

AI 0 - 10 VDC OR

21 3 4 5 6 7 8 9 10 11 1213 14 15 16 17 18 19

GND/AI1-: AI COMMON

GND/AI2-: AI COMMON

24V OUT: 24V AUXILIARY VOLTAGE

GND: I/O GROUND

DIN1: DIGITAL INPUT 1

DIN2: DIGITAL INPUT 2

DIN3: DIGITAL INPUT 3

24V OUT: 24V AUXILIARY VOLTAGE

GND: I/O GROUND

DIN4: DIGITAL INPUT 4

DIN5: DIGITAL INPUT 5

DIN6: DIGITAL INPUT 6

2122 23

RELAY OUTPUT 1

RELAY OUTPUT 2

SMART VFD

+10VREF: REFERENCE OUTPUT

AI1+: AI, VOLTAGE OR CURRENT

AI2+: AI, VOLTAGE OR CURRENT

CM: COMMON FOR DI1 - DI3

CM: COMMON FOR DI4 - DI6

AO+: ANALOG SIGNAL +OUT

AO-/GND: ANALOG OUTPUT COMMON

30

+24VIN: 24V AUXILIARY INPUT VOLTAGE

AB

RS485: NEGATIVE

RS485: POSITIVE

RO1/1 N.C.

RO1/2 CM

RO1/3 N.O.

24

RO2/1 N.C.

25

RO2/2 CM

26

RO2/3 N.O.

RO3/1 CM

32 33

RO3/2 N.O.

RELAY OUTPUT 2

RELAY OUTPUT 1

RELAY OUTPUT 3

GND

GND

W1

V1

U1

U2 V2

W2

MOTORHPRPM

AMP

T2

T3

T1TB

TB

TB

L1 L2 L3

LINE VOLTAGE, 3 PHASE, 60 HZ

GND

T1 T2 T3

L1

L2

L3

T1

T2

T3

.51

DIC

L3

/1.41

L1

/1.41

T1

T2

T3

BC

L1

L2

L3

.57

L1

L2

L3

.57

T1

T2

T3

OL1

T2 T3T1

L2 L3L1

DOC

.53

M

VFDST

L3/1.40

L1/1.40

FU4

CLASS CC PRIMARY FUSE

1

2

FU5

CLASS CC

PRIMARY FUSE

2

2

2

1

1

1

1

1

250V, MIDGET

SECONDARY FUSE

FU6

CUSTOMER SUPPLIED

FREEZE/FIRE/SMOKE INTERLOCK

FFSI

SEE NOTE 2

TB

TB 3

J1

OFF

TEST

BYPASS

3

VFD

00X0

000X

000X

X000

4

9

6

SS1

SEE DETAIL “A”

SEE NOTE 1

5

.57

.53

DOC

BC

7

8

8

3

TB

TB

13

TS1

SEE NOTE 3

NOTE 1: ALL PANELS SHIPPED WITH VFD DEFAULT PROGRAMMING PARAMETERS.

SET DIP SWITCHES AS NEEDED, SEE DETAIL “B”

NOTE 2: IF CUSTOMER SAFETY INTERLOCK IS USED, REMOVE J1.

NOTE 3: TS1, ENCLOSURE FAN1 STD ON ALL NEM3R PNLS. ENCLOSURE FAN2,

ON 25HP & LARGER @ 480V. HEATER IS OPTIONAL ON ALL NEMA 3R PNLS.

ALL WIRING: USE COPPER WIRE ONLY SUITABLE FOR MIN. 75 DEG. C, FIELD WIRING, NEC CLASS 1.

MOTOR AND FEEDER WIRE SIZE MUST BE IN ACCORDANCE WITH NEC.

FIELD WIRE

WIRE INSIDE C/PNL

OPTION

.11

OL1

DOC

DIC

LT1

LT2

HEATER

BUILT IN T-STAT

SEE NOTE 3

FAN

BC

G

Y

X1 X2

A1 A2

A1 A2

A1 A2

X1 X2

TB

2

TB

2

BYPASS RUN

BYPASS

CONTACTOR

ENCLOSURE

HEATER

SEE NOTE 3

ENCLOSURE

CIRC FAN1

SEE NOTE 3

ENCLOSURE

CIRC FAN2

SEE NOTE 3

DRIVE OUTPUT

CONTACTOR

VFD RUN

DRIVE INPUT

CONTACTOR

2

CONTROL TRANSFORMER

T1

FAN

DIP SWITCHES

DETAIL “B”

RS485

ON OFF

CURRENT VOLTAGE

CURRENT

CURRENT

VOLTAGE

LOCATED BEHIND COVER,

RIGHT SIDE OF KEYPAD.

VOLTAGE

AO1

AI1

AI2

SS1 - FOUR POSITION SEL. SW.

DETAIL “A”

SEL SW POSITION

DIC

DE-ENERGIZED

DE-ENERGIZED

ENERGIZED

ENERGIZED

DE-ENERGIZED

DE-ENERGIZED

DE-ENERGIZED

DE-ENERGIZED

DE-ENERGIZED

DE-ENERGIZED

ENERGIZED

ENERGIZED

DOC BC

BYPASS

OFF

TEST

VFD

63-1374—01 4

Fig. 3. Frame 7, 3 Contactor Wiring Diagram

Loading...

Loading...