SmartPAC 2 Press Automation Control

®

with Wintriss WPC Clutch/Brake Control

includes optional DiPro PAC and ProCam PAC

®

®®

1126800 Rev. 1 September 2003

Tech Support Hotline 800-586-8324 8-5 EST

Wintriss

Wintriss Controls Group

100 Discovery Way

Acton MA 01720-3648 USA

Phone (978) 264-9550 (800) 586-8324

Fax (978) 263-2491

3

PRINTED IN USA DA70194

www.wintriss.com

Requirements You Must Meet

When Installing and Using the Wintriss Clutch/Brake Control

The Wintriss Clutch/Brake Control (WPC) is designed solely for controlling operation of part-revolution metal

stamping presses. Before installing or using WPC, be sure you understand and follow these requirements:

!

DANGER

FULL REVOLUTION MECHANICAL POWER PRESSES AND OTHER MACHINES CANNOT BE STOPPED

IN MID-STROKE OR MID-CYCLE

• DO NOT use WPC clutch/brake control on full-revolution clutched machinery or other equipment that cannot be

stopped at any point in its stroke or cycle.

• Use WPC clutch/brake control only on part-revolution clutched mechanical power presses as defined in OSHA

1910.217 (b) (7). Refer also to ANSI B11.1-2001 6.12.

• Use WPC clutch/brake control only on rotating machinery that can be stopped at any point in its stroke or cycle.

Failure to comply with these instructions will result in death or serious injury.

!

DANGER

IMPROPER SAFEGUARDING

• Ensure that the press on which WPC clutch/brake control is used meets all of the OSHA and ANSI regulations for

safeguarding press systems in installation and use. WPC is not in itself a safeguarding device. Honeywell takes no

responsibility for injury if safeguarding devices are not installed or working properly.

• Install any two-hand control used as a safety device at least the safety distance away from the hazardous area; safety

distance is defined in the OSHA and ANSI regulations. Verify at each shift change that any moveable two-hand control

used as a safety device is located at least the safety distance away from the hazardous area.

• Install any light curtain or curtains at least the safety distance away from the hazardous area; safety distance is defined

in the OSHA and ANSI regulations.

• Install other safeguarding devices as needed to ensure operator safety. Follow the machine guarding requirements of

OSHA standard 1910.217 and any other regulations and standards that apply. Test safeguarding devices for correct

installation and operation after installation and after any modification or repair.

• Ensure that guarding is properly installed to prevent access to the machine over, under or around any guarding device.

Failure to comply with these instructions will result in death or serious injury.

!

DANGER

MORE OPERATORS THAN OPERATOR STATIONS

• Ensure that there are the same number of active operator stations as there are operators, if the press is not equipped

with properly installed and operating light curtains.

• During setup, lockout/tagout the press if there are more operators than operator stations.

• Verify at every shift change that there are the same number of active operator stations as there are operators, if the

press is not equipped with properly installed and operating light curtains.

Failure to comply with these instructions will result in death or serious injury.

!

DANGER

NON-SAFETY OUTPUTS USED FOR SAFETY FUNCTIONS

Use auxiliary outputs and cam channels for non-safety functions only. They cannot protect personnel from a moving

hazard.

Failure to comply with these instructions will result in death or serious injury.

Read additional

!

DANGER

and

!

WARNING

notices on following page.

!

DANGER

IMPROPER INSTALLATION, USE OR MAINTENANCE

• Ensure that the machinery complies with OSHA regulations 1910.217 and ANSI B11.1-2001.

• Follow all procedures in this manual. Perform only the tests and repairs listed in this manual. Use only factory-supplied

replacement parts. Ensure that all safety procedures are followed during installation and operation of WPC.

• Wire and install WPC and other equipment according to the requirements of OSHA 1910.147 Control of Hazardous

Energy (Lockout/ Tagout).

• Lockout/Tagout the press during all installation, modification, repair or maintenance procedures.

• Ensure that the dual safety valve used on the press complies with OSHA 1910.217 (b) (7) (xi). Contact manufacturer to

verify compliance of your model.

• Ensure that any foot control complies with OSHA 1910.217 (b) (7) (x).

• Ensure that WPC clutch/brake control is installed, tested and repaired by qualified personnel.

• Wire, install and maintain WPC clutch/brake control in accordance with the applicable safety standards. Carry out all

inspection procedures in OSHA 1910.217

• Install and maintain your machine guarding system according to OSHA standard 1910.217, ANSI B11.1, ANSI B11.19

and any other regulations and standards that apply. Ensure that guarding is properly installed to prevent access to the

machine over, under or around any guarding device.

• Perform all installation verification and checkout tests after installation and after any modification or repair of the WPC

clutch/brake control. Correct any problems before using the press.

• Maintain all presses as stated in the applicable regulations. Honeywell takes no responsibility in cases where stopping

mechanisms of machinery or other devices are not maintained or do not meet the applicable regulations or standards.

• Ensure that supervisors, die-setters, maintenance persons, machine operators, foremen, and any others responsible

for operation of the machinery have read and understood all instructions for use of the WPC clutch/brake control.

• DO NOT use touch buttons for any safeguarding use.

Failure to comply with these instructions will result in death or serious injury.

x

!

WARNING

MACHINERY NOT CONFIGURED OR WORKING PROPERLY

• Ensure that the press on which WPC clutch/brake control is used meets the machine guarding requirements of OSHA

standard 1910.217 and any other regulations and standards that apply.

• DO NOT operate a press equipped with WPC clutch/brake control if the machine or any of its stopping mechanisms is

not in proper working order.

Failure to comply with these instructions could result in death or serious injury.

!

WARNING

OTHER EQUIPMENT CONTINUING TO OPERATE

• Ensure that all operators and other affected personnel know which equipment may continue to operate and which will

not. Equipment that operates with the machinery connected to WPC clutch/brake control may continue to operate after

the press has received a stop signal.

Failure to comply with these instructions could result in death or serious injury.

!

WARNING

ELECTRIC SHOCK HAZARD

• Turn off and disconnect power from WPC clutch/brake control, the press and any other machinery it is

connected to before making any wiring connections. This includes power to the press’s motor.

Failure to comply with these instructions could result in death or serious injury.

The enforcement of the above requirements is beyond Honeywell’s ability to control. For proper WPC operation, it

is your responsibility to follow these requirements and any other requirements that may be specific to your

machinery.

Thank you for purchasing a Honeywell Wintriss Product. We appreciate your business and want to do

whatever we can to ensure your satisfaction. Wintriss products are built to stay on the job day after day,

and are backed by an ironclad guarantee, international standards approvals, and unbeatable support.

Whenever you need assistance or service, we back all our products with excellent spare parts inventories,

training programs, and prompt repair service. We would like to share with you a list of service options probably the largest number of service options offered in the industry.

•••• Technical Assistance

We offer a toll-free line for technical assistance. Call our Wintriss Tech Support Hotline at

1-800-586-TECH (8324) should you have any questions about your equipment. Our technical staff

is ready to assist you Monday through Friday, 8 a.m. to 5 p.m. EST. In many cases our experienced

technical staff can resolve your inquiry right over the phone.

•••• Return Authorization

Please call our “800” number for a return authorization (RA) number to return a product for repair.

Returned goods must arrive freight prepaid. In order to process your return quickly, we ask that you

provide us with the following pertinent information when you call: order number, order date,

shipping address, contact name and telephone number, and product type. The assigned RA number

should appear on all packages returning to Wintriss Controls Group to ensure prompt service. Please

be sure to carefully pack all returned items and ship to our Acton, MA location.

•••• Expedited Repair Program

Rush service providing 48 hour turn-around is available for most products upon request. A $50

Expedite Fee will be applied to our standard repair rate if the unit is not within its warranty period.

•••• Board Exchange Program

If your needs are urgent, you can take advantage of our Board Exchange (EX) program. The EX

program applies to SmartPAC, Wintriss Clutch/Brake Control (WPC), and all 1500 series products.

Call our “800” number between 8 a.m. to 5 p.m. EST and we will send a replacement to you

overnight. A fee does apply to this service. Contact Wintriss Tech Support at 800-586-8324 for

details.

•••• Service Center

Our major center for product service is located at our headquarters in Acton MA. If your equipment

requires repair, please contact us at 800-586-8324 to obtain a return authorization number.

Nationwide field service is also available. Contact the Wintriss Service Manager at

800-586-8324, ext. 1949 or Wintriss Tech Support group at 800-586- 8324.

•••• Product Training

We are also offer both product training and maintenance/troubleshooting courses at our Carol

Stream, IL and Acton, MA facilities. On-site training is available from the factory or through your

local Wintriss representative

•••• Restocking Charge

Returned goods are subject to a 20% restocking charge if returned for credit. The minimum charge

is $50, not to exceed $250 per item.

Whatever the product, we are committed to satisfying you with innovative engineering, quality

construction, reliable performance, and ongoing, helpful support. Call us whenever you need assistance.

Table of Contents

Chapter 1 – Introduction to SmartPAC 2 with WPC......................................... 1

SmartPAC 2................................................................................................................................................1

WPC and Control Reliability......................................................................................................................1

SmartPAC with WPC.................................................................................................................................2

How SmartPAC 2 with WPC Will Benefit Your Operation.......................................................................2

Standard features:...................................................................................................................................2

Optional Die Protection and Programmable Cam Switch Features: ......................................................3

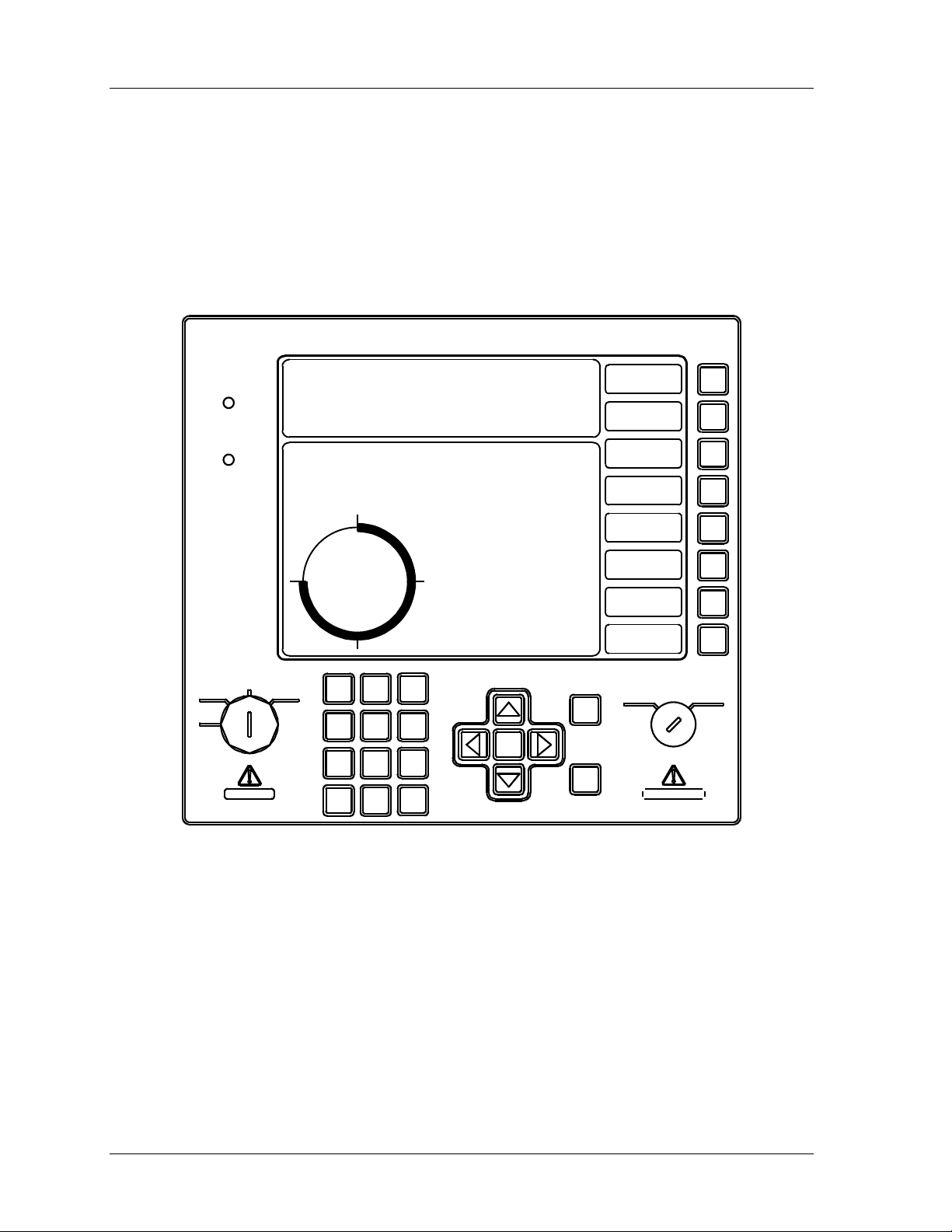

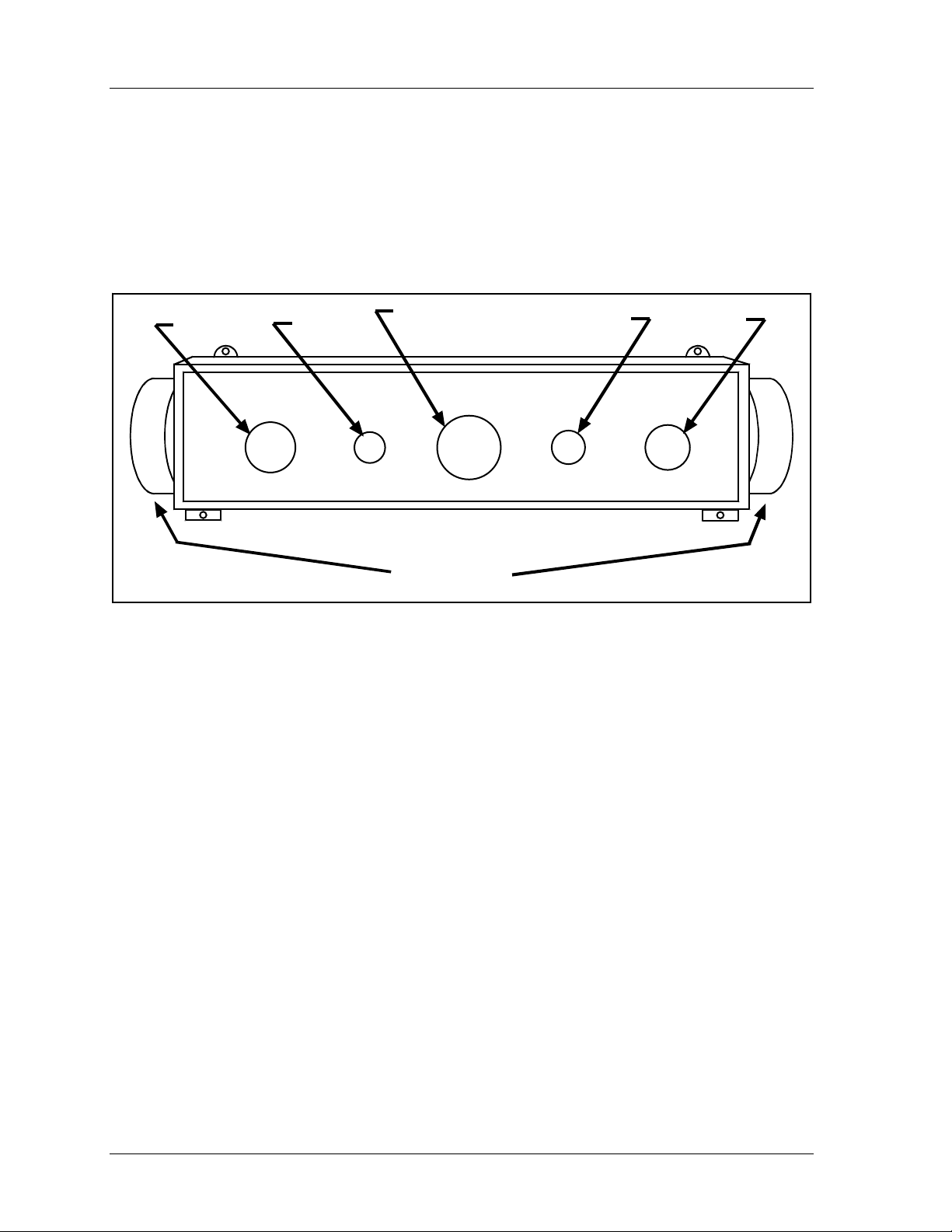

SmartPAC 2 Front Panel ............................................................................................................................4

System Components ...................................................................................................................................5

WPC Options..............................................................................................................................................7

How SmartPAC 2 Works............................................................................................................................8

Settings You Can Make on SmartPAC 2....................................................................................................9

Sensors Available for Optional DiProPAC...............................................................................................11

Understanding Sensor Terminology.........................................................................................................12

Normally Open, Normally Closed .......................................................................................................12

Ready signal.........................................................................................................................................12

Impedance............................................................................................................................................13

Sensor Types........................................................................................................................................13

Considerations for Setting Sensor Stop Type...........................................................................................18

ProCamPAC Programmable Cams (Optional) .........................................................................................18

SmartPAC 2's Three Modes of Operation ................................................................................................19

Specifications: SmartPAC 2 with WPC...................................................................................................20

Chapter 2 – Installing WPC and SmartPAC 2 .................................................23

Part 1 – Installation Overview ..................................................................................................................26

Before You Start.......................................................................................................................................26

The first step – Checking the Press...........................................................................................................27

Installation Guidelines..............................................................................................................................27

Overview of the Installation .....................................................................................................................30

How to Connect Wires to Terminal Block Connectors ............................................................................30

How to Terminate Cable Shields..............................................................................................................31

Part 2 – Install and Wire WPC .................................................................................................................32

Mounting the WPC Control Enclosure.....................................................................................................33

Install WPC Without Enclosure................................................................................................................34

Wiring the WPC .......................................................................................................................................35

Slide Adjust Considerations.................................................................................................................35

Connecting AC Wiring to WPC ...............................................................................................................35

Installing and Wiring Dual Safety Valve and Sensors for Clutch and Counterbalance Air Pressure.......37

Dual Safety Valve ................................................................................................................................37

Air Pressure Sensors or Switches.........................................................................................................38

Install the Resolver ...................................................................................................................................41

Mounting and Wiring the Resolver......................................................................................................42

If You Replace Your Resolver.............................................................................................................43

Table of Contents page i

SmartPAC 2 with WPC Integration 1126700

1126800 SmartPAC 2 with WPC Integration

Chapter 2 – Installing WPC and SmartPAC 2, continued

Install the Overrun Limit Sensor Magnetic Switch...................................................................................44

Planning Your Overrun Sensor Installation .........................................................................................45

Mounting the Overrun Sensor Magnetic Switch..................................................................................45

Wiring the Overrun Sensor Magnetic Switch ......................................................................................46

Mounting and Wiring the Operator Station and Light Curtain(s).............................................................47

Using a Light Curtain on Your Press ...................................................................................................49

Mounting the Operator Station if You Do Not Use Light Curtains......................................................50

Using Two Light Curtains on Your Press ............................................................................................50

Connecting Other Wintriss Products to WPC...........................................................................................50

Wiring WPC User Inputs..........................................................................................................................52

Part 3 – Install and Wire WPC Options....................................................................................................55

Wiring Lockout Relay (Optional).............................................................................................................55

Wiring a Remote Reset Switch (Optional) ...............................................................................................56

Wiring Operator Mode Outputs (Optional) ..............................................................................................56

Wiring Foot Switch (Optional).................................................................................................................57

Installing One-hand Control (Optional)....................................................................................................58

Mounting One-hand Control Switch....................................................................................................58

“Light Curtain Break” Mode................................................................................................................60

Wiring One-hand Control to WPC.......................................................................................................61

Wiring Automatic Single Stroke/External Trip ........................................................................................62

Wiring Continuous on Demand ................................................................................................................62

Installing Multiple Operator Stations........................................................................................................63

Auxiliary Outputs (Optional)....................................................................................................................64

Wiring Auxiliary 1 Output (Optional)..................................................................................................64

Wiring Auxiliary 2 Output (Optional)..................................................................................................65

Wiring Auxiliary 3 Output (Optional)..................................................................................................66

Wire a Keylock Switch to Prevent Changes to WPC Settings in Program and Run (Optional)...............66

Installing Flywheel Speed Sensor (Optional Hardware Required)...........................................................67

Mounting and Wiring the Bar Control Enclosure (Optional) ...................................................................68

Part 4 – Install and Wire SmartPAC.........................................................................................................69

SmartPAC 2 the First Step—Checking the Press .....................................................................................69

Installing SmartPAC 2 Enclosure.............................................................................................................70

Installing SmartPAC 2 as a Panel Mount..................................................................................................72

Standard Enclosure Versus Optional Panel Mount ..............................................................................72

Preparation for Mounting SmartPAC 2 Using Your Enclosure ...........................................................72

Wiring between WPC and SmartPAC ......................................................................................................74

Connecting WPC’s Resolver to SmartPAC .........................................................................................74

Connecting Communications Between SmartPAC 2 and WPC...........................................................75

Connecting AC Wiring Between WPC and SmartPAC 2.........................................................................76

Connect Stop Circuits and Input Check Circuit to SmartPAC 2...............................................................77

Setting Input Check Voltage Switch ....................................................................................................77

Connecting SmartPAC 2 to a Network.....................................................................................................79

Part 5 – Install SmartPAC Options...........................................................................................................80

Adding or Upgrading ProCamPAC or DiProPAC....................................................................................80

page ii Table of Contents

SmartPAC 2 with WPC Integration 1126800

Chapter 2 – Installing WPC and SmartPAC 2, continued

Connecting Programmable Cam Channels...............................................................................................83

Making the Connections ......................................................................................................................83

Connecting DiPro Sensor Interface to SmartPAC 2.................................................................................90

Installing the DiPro Remote Connection Box ..........................................................................................92

Set Up High Speed Version of SmartPAC 2 with WPC (Optional) .........................................................94

Wiring Setup Mode Circuit ......................................................................................................................94

Wiring a Sensor-Disabled Output (Optional) ...........................................................................................94

Part 6 – Set Up SmartPAC 2 with WPC...................................................................................................95

Turn On Power to SmartPAC 2 and WPC................................................................................................96

Problems at Startup...................................................................................................................................98

Verify Proper Installation of ProCamPAC and/or DiProPAC Options ..................................................100

Initialize Press Parameters......................................................................................................................101

Create and Load a Test Tool Number.....................................................................................................103

Check and Set Direction of Resolver Rotation.......................................................................................104

Zero the Resolver....................................................................................................................................105

Set Top Stop Angle and Install Overrun Magnet....................................................................................107

Check Top Stop After You Change Top Stop Angle.........................................................................115

Prepare to Install Magnet for Overrun Limit Sensor..........................................................................116

Install Magnet for Overrun Sensor.....................................................................................................125

Check the ON and OFF Time of the Overrun Sensor.............................................................................126

Part 7 – Perform Checkout Tests ............................................................................................................127

WPC Power Supply Test ........................................................................................................................129

Check Safeguarding Devices..................................................................................................................130

Check Dual Safety Valve (DSV) Wiring................................................................................................132

Check the Emergency-Stop Circuit ........................................................................................................134

Check the Top Stop Circuit ....................................................................................................................135

System Static Test ..................................................................................................................................136

Anti-tiedown Test...................................................................................................................................138

Anti-repeat Test ......................................................................................................................................139

Shadow Light Curtain Test.....................................................................................................................140

Single Stroke Mode Test with Light Curtain..........................................................................................142

Single Stroke Mode Test Without Light Curtain(s)................................................................................145

Continuous Mode Test with Light Curtain.............................................................................................147

Continuous Mode Test Without Light Curtain(s)...................................................................................149

Foot Switch Test (with Optional Foot Switch).......................................................................................151

One-hand Control SwitchTests (with Optional One-hand Control) .......................................................153

Test for One-hand Control with “Light Curtain Break” Mode ..........................................................154

Test for One-hand Control Without “Light Curtain Break” Mode ....................................................155

Bar Mode Control Test – Optional.........................................................................................................156

User Inputs Test......................................................................................................................................157

Cam Channels Test (Optional – with ProCamPAC)...............................................................................157

Checkout Tests Complete.......................................................................................................................157

Part 8 – PC Board Illustrations and Wiring Tables.................................................................................158

Table of Contents page iii

1126800 SmartPAC 2 with WPC Integration

Chapter 3 – SmartPAC 2 Keyboard, Displays and Operating Modes .........171

Comparing SmartPAC 2 with Original SmartPAC.................................................................................173

SmartPAC 2 Keyboard ...........................................................................................................................174

Number Keys .....................................................................................................................................176

Clear Key ...........................................................................................................................................177

Help Key ............................................................................................................................................178

Cursor Keys........................................................................................................................................179

ENTER and RESET Keys..................................................................................................................181

Program/Run Key Switch...................................................................................................................183

Function Keys ....................................................................................................................................184

Hot Keys ............................................................................................................................................185

SmartPAC 2 Display...............................................................................................................................186

Selecting an Item on a Display...........................................................................................................187

The Three Operating Modes of SmartPAC 2..........................................................................................188

Initialization Mode..................................................................................................................................190

Program Mode ........................................................................................................................................192

Run Mode ...............................................................................................................................................194

Using Cursor Keys to Set Timing...........................................................................................................195

Screen Capture........................................................................................................................................199

Chapter 4 – SmartPAC 2 with WPC Initialization Mode................................201

SmartPAC 2 and Original SmartPAC.....................................................................................................202

How to Enter and Exit Initialization Mode.............................................................................................203

Initialize Press Parameters ......................................................................................................................204

RESOLVER ZERO ................................................................................................................................204

POSITION SENSOR..............................................................................................................................205

Position Sensor Mode ........................................................................................................................205

Resolver Motion Mode (Normal Motion – Link Motion)..................................................................206

Tool Number Mode............................................................................................................................206

Counter Setup Mode ..........................................................................................................................208

INSTALLED OPTIONS.........................................................................................................................209

PRESS NAME........................................................................................................................................210

SELECT CAM NAMES (Optional) .......................................................................................................211

AUTO ADVANCE and Slow RPM .......................................................................................................213

Setting Auto Advance Constant and Slow RPM................................................................................214

SET GLOBAL CAMS (Optional) ..........................................................................................................216

CUSTOM SENSOR NAMES (Optional)..............................................................................................218

SENSOR ENABLE MODE (Optional) ..................................................................................................219

Enabling Sensors................................................................................................................................219

Enabling or Disabling Setup Mode.........................................................................................................220

TOOL INFORMATION (Optional) .......................................................................................................221

PRESS CONTROL.................................................................................................................................225

User Interlocks ...................................................................................................................................225

Press Parameters.................................................................................................................................229

Stop Limit ..........................................................................................................................................230

Stopping Time and Stop Time Limit..................................................................................................230

Setting Stop Time Limit at Press Parameters.....................................................................................232

page iv Table of Contents

SmartPAC 2 with WPC Integration 1126800

Chapter 4 – SmartPAC 2 with WPC Initialization Mode, continued

PRESS CONTROL, continued

Setting the Start Time Limit at Press Parameters...............................................................................234

Using Auto Carry-up ..............................................................................................................................235

Setting Auto Carry-up Angle .............................................................................................................236

Setting Micro-Inch Time and Angle (Optional) .....................................................................................236

Setting Clutch and Counterbalance Air Pressure Limits ........................................................................238

Setting Shutdown and Flywheel Timer Limits (Optional).................................................................239

Setting the ACTS Angle (Optional)...................................................................................................240

Initialize Parameters...........................................................................................................................241

Press Options .....................................................................................................................................241

Setting Switches.................................................................................................................................242

Operator Mode Settings on Press Control Option Switch Screen......................................................249

Input Status ........................................................................................................................................250

SECURITY ACCESS.............................................................................................................................251

Selecting Security Access Options.....................................................................................................254

Reset Mode ........................................................................................................................................255

Changing Passwords ..........................................................................................................................255

Additional Security.................................................................................................................................257

PACNET.................................................................................................................................................258

SETUP NETWORK ...............................................................................................................................259

E-MAIL FUNCTION ........................................................................................................................259

SMARTVIEW FUNCTION ..............................................................................................................260

SETUP E-MAIL ................................................................................................................................260

CHANGE NETWORK SETTINGS ..................................................................................................262

PRESS TYPE.....................................................................................................................................263

DIAGNOSTICS......................................................................................................................................263

COMMUNICATIONS.......................................................................................................................264

SET CLOCK......................................................................................................................................266

UPDATE FIRMWARE .....................................................................................................................266

SAVE TO USB DISK........................................................................................................................267

Using SmartPAC 2 with a Link-motion Press........................................................................................268

Setting Link Motion...........................................................................................................................268

Using a Servofeed Interface with Link Motion..................................................................................269

Using a Computer Keyboard to Enter Names.........................................................................................270

Chapter 5 – SmartPAC 2 with WPC Program Mode ..................................... 273

SmartPAC 2 and Original SmartPAC.....................................................................................................274

Entering and Exiting Program Mode......................................................................................................275

TOOL MANAGER ................................................................................................................................276

Load an Existing Tool........................................................................................................................278

Delete a Tool......................................................................................................................................279

Tool Template....................................................................................................................................280

Create a New Tool .............................................................................................................................281

Copy an Existing Tool .......................................................................................................................282

Change Settings for an Existing Tool ................................................................................................282

Table of Contents page v

1126800 SmartPAC 2 with WPC Integration

Chapter 5 – SmartPAC 2 with WPC Program Mode, continued

Tool Program Menu................................................................................................................................285

TOOL NAME or TOOL ID ...............................................................................................................286

COUNTERS.......................................................................................................................................286

Setting or Clearing the Counter Presets..............................................................................................287

Setting or Clearing the Counter Values..............................................................................................288

Clearing the Total Hits Preset Message..............................................................................................288

Setting Counter Mode ........................................................................................................................288

Setting Parts/Stroke or Strokes/Part ...................................................................................................290

DIE PROTECTION................................................................................................................................292

Setting "Auto Enable by Tool" Counter Value ..................................................................................292

Naming the Sensor .............................................................................................................................294

Setting the "Auto Enable by Sensor and Tool" Counter Value..........................................................294

Setting Sensor Type ...........................................................................................................................295

Setting Stop Type...............................................................................................................................296

Setting the Ready Signal for a Green Sensor .....................................................................................297

Setting the Other Sensors for the Tool ...............................................................................................299

Going Back to the Main Programming Menu....................................................................................299

CAM SWITCH.......................................................................................................................................302

View Global Cams .............................................................................................................................304

View Cam Summary..........................................................................................................................305

Make an ON/OFF Setting for a Channel............................................................................................305

Multiple ON/OFFs for Cam Channels ...............................................................................................307

Selecting a Channel and Making a Timed Output Setting .................................................................309

Selecting a Channel and Making an Auto Advance Setting...............................................................311

Setting DSV ON Channel Timing......................................................................................................312

Set Other Channels for the Tool.........................................................................................................313

Delete Channel Settings .....................................................................................................................313

PRESS CONTROL.................................................................................................................................314

TOOL INFORMATION.........................................................................................................................315

SENSOR ENABLE/DISABLE & STATUS ..........................................................................................317

Controlling Which Sensors SmartPAC 2 Monitors............................................................................317

Enable or Disable All Sensors............................................................................................................318

Turn a Sensor OFF or ON..................................................................................................................318

RECALCULATE SETPOINTS (Optional)............................................................................................319

Chapter 6 – SmartPAC 2 with WPC Run Mode .............................................321

About Run Mode ....................................................................................................................................322

What you can and cannot do in Run mode.........................................................................................322

Why Some Tasks Are Duplicated in Each Mode...............................................................................322

Locking Run mode.............................................................................................................................322

Interrupted Stroke...............................................................................................................................322

Hot Keys ............................................................................................................................................323

SmartPAC 2 and Original SmartPAC.....................................................................................................324

Part 1 – Using SmartPAC 2 in Run Mode..............................................................................................325

How to Enter and Exit Run Mode...........................................................................................................325

Load A Tool Number Before Switching to Run Mode...........................................................................325

page vi Table of Contents

SmartPAC 2 with WPC Integration 1126800

Chapter 6 – SmartPAC 2 with WPC Run Mode, continued

Settings Locked in Run Mode, or Password Required ...........................................................................326

How to Use Hot Keys.............................................................................................................................327

Toggle Hot Keys ................................................................................................................................327

How to Program a Hot Key................................................................................................................328

How to Delete a Hot Key...................................................................................................................328

Main Run Menu......................................................................................................................................329

DISABLE (ENABLE) SENSORS (Optional)........................................................................................330

Setup Mode Message .........................................................................................................................331

COUNTERS ...........................................................................................................................................332

DIE PROTECTION (Optional) ..............................................................................................................333

Adjusting the Ready Signal for Green Sensors..................................................................................334

View Sensor Summary.......................................................................................................................337

Show Sensor Status............................................................................................................................338

CAM SWITCH (Optional) ....................................................................................................................340

View Cam Timing..............................................................................................................................341

View Global Cam Summary..............................................................................................................343

View Cam Summary..........................................................................................................................344

BRAKE MONITOR...............................................................................................................................345

Setting Stop Time, Stop Angle, and Start Time.................................................................................345

Start Time...........................................................................................................................................345

Stopping Angle ..................................................................................................................................346

Brake Warning...................................................................................................................................346

Performing the 90° Stop-Time Test...................................................................................................346

Calculating the Safety Distance .........................................................................................................348

PRESS CONTROL.................................................................................................................................353

Adjusting Top Stop Angle, Press Speed Limits, Counterbalance Setpoint, Main System Air Limit.353

Show Overrun Angles........................................................................................................................354

Viewing Actual Counterbalance and Main Air Pressure Limits (Optional).......................................354

TOOL INFORMATION (Optional) .......................................................................................................355

ERROR LOG..........................................................................................................................................356

LOAD NEW TOOL ...............................................................................................................................357

Load Next Tool Number (Available Only with PACNet Software) ..................................................357

Select a Tool to Load .........................................................................................................................359

MESSAGING.........................................................................................................................................361

Send E-mail to Wintriss Tech Support...............................................................................................362

TOGGLE HOT KEYS............................................................................................................................363

Part 2 – Operating the Press....................................................................................................................364

Interrupted Stroke...................................................................................................................................364

Mode Select Menu..................................................................................................................................365

Operating the Press in INCH mode ........................................................................................................366

Three Ways You Can Operate the Press in INCH Mode...................................................................366

Operating the Press in Single Stroke Mode............................................................................................368

One-hand Operation, Single Stroke Mode .........................................................................................369

Two-hand Operation, Single Stroke Mode ........................................................................................370

Foot Operation, Single Stroke Mode..................................................................................................372

Table of Contents page vii

1126800 SmartPAC 2 with WPC Integration

Chapter 6 – SmartPAC 2 with WPC Run Mode, continued

Operating the Press in Automatic Single Stroke Mode ..........................................................................373

Setting Prior Act Timing for Automatic Single Stroke ......................................................................374

Automatic Single Stroke Operating Instructions................................................................................374

Operating the Press in Continuous Mode ...............................................................................................375

Two-hand Operation, Continuous Mode............................................................................................375

Foot Operation, Continuous Mode.....................................................................................................376

Operating the Press in Continuous On Demand Mode...........................................................................377

Using One-hand Control.........................................................................................................................378

"Light Curtain Break" Mode..............................................................................................................378

Operating the Press Using One-hand Control ....................................................................................379

Operating the Press in BAR Mode..........................................................................................................380

Multiple Operator Stations......................................................................................................................380

Chapter 7 – SmartPAC 2 with WPC Fault Messages and Troubleshooting383

SmartPAC 2 and Original SmartPAC.....................................................................................................384

What Happens When You Get a Fault Message ................................................................................385

How to Clear the Fault Message from the Display ............................................................................385

Status Code #10 ......................................................................................................................................386

Interrupted Stroke ...................................................................................................................................386

Lockout...................................................................................................................................................387

Brake Monitor Brake Warning ...............................................................................................................388

Brake Monitor - Stop Time Exceeded* ..................................................................................................388

Customized Status Codes........................................................................................................................390

Description of Status Codes and How to Correct ...................................................................................390

Messages Displayed Due to Press Control Problems .............................................................................391

Resolver faults....................................................................................................................................392

Operational faults...............................................................................................................................393

Inter-processor failures.......................................................................................................................397

Input buffer test failures.....................................................................................................................397

Air pressure limits exceeded ..............................................................................................................398

Component failures ............................................................................................................................399

Customized Status Codes...................................................................................................................400

Light Curtain faults ............................................................................................................................402

Emergency stop circuit driver failure.................................................................................................404

Top stop circuit driver failure.............................................................................................................404

DSV Interface and Lockout relay failures..........................................................................................405

Loss of rotation ..................................................................................................................................406

Internal timing input failures..............................................................................................................406

Top Stop and Overrun Setting Faults.................................................................................................407

Overrun Limit Switch Fault ...............................................................................................................407

Overrun Limit Switch Test Angle Fault.............................................................................................408

Overrun Limit Switch Setting Fault ...................................................................................................408

Internal memory failures....................................................................................................................409

Messages Displayed for Equipment or Brake Monitor Problems ......................................................409

Messages displayed for programming problems................................................................................412

Messages Displayed When a Sensor Signals a Fault .........................................................................414

page viii Table of Contents

SmartPAC 2 with WPC Integration 1126800

Chapter 7 – SmartPAC 2 with WPC Fault Messages and Troubleshooting,

continued

Messages Displayed Due to Press Control Problems, continued

Miscellaneous Fault messages ...........................................................................................................416

Error Log ................................................................................................................................................418

E-mail Error Log and Other Information to Wintriss Tech Support..................................................419

Using the WPC Input Status Display......................................................................................................420

Install Revised Firmware into WPC.......................................................................................................423

Appendix A – OSHA Regulations and ANSI Standards...............................427

Section 1 OSHA Regulation 1910.217..................................................................................................427

Section 2 ANSI Standards for Presence-sensing Devices.....................................................................431

Appendix B – SmartPAC Preventive Maintenance (PM) Monitor (Optional)437

Comparison with Traditional Preventive Maintenance......................................................................437

How the PM Monitor Works..............................................................................................................438

Examples of How to Use the PM Monitor.........................................................................................438

SmartPAC 2 and Original SmartPAC.....................................................................................................440

Installing the PM Monitor ......................................................................................................................441

For New Systems from the Factory....................................................................................................441

For Existing Systems .........................................................................................................................441

Using the PM Monitor in Initialization Mode ........................................................................................441

How to Get into SmartPAC Initialization and PM Monitor...............................................................441

Initializing the PM Monitor ...............................................................................................................443

Assigning a New PM Password Number...........................................................................................445

Select PM Item Names.......................................................................................................................446

Using the PM Monitor in Run mode ......................................................................................................450

How to Get into SmartPAC Run mode ..............................................................................................450

A Tool Number Must Be Loaded Before Switching to Run Mode....................................................450

Viewing and modifying PM Alerts....................................................................................................451

Appendix C – Update SmartPAC 2 Firmware ...............................................453

Appendix D – SmartView Remote Viewing and E-mail Setup .....................455

Appendix E – Upgrade from Original SmartPAC to SmartPAC 2................ 457

Appendix F – Replacing SmartPAC 2 PC Board ..........................................459

Glossary of Terms ..........................................................................................461

Index ................................................................................................................471

Table of Contents page ix

1126800 SmartPAC 2 with WPC Integration

Wintriss User Manuals

SmartPAC2 with WPC Setup Sheet

ProCamPAC Cam Switch Setup Sheet Channels 1 - 8

ProCamPAC Cam Switch Setup Sheet Channels 9 – 16

DiProPAC Setup Sheet

Press Parameters Setup Sheet

Figures and Table at End of Manual

Figure A. SmartPAC 2 PC Board Illustration

Figure B. WPC LED Map

Table A. Wintriss Clutch/Brake Control (WPC) Connector Pinouts

Figure 1. Wintriss Clutch/Brake Control and SmartPAC 2 System Wiring

Figure 2. Wintriss Clutch/Brake Control Operator Station A Wiring

Figure 3. Wintriss Clutch/Brake Control External Wiring

Figure 4. Wintriss Clutch/Brake Control Shadow V & Herion XSV DSV Wiring

Figure 5. Wintriss Clutch/Brake Control Dual Operator Station Wiring

Figure 6. Wintriss Clutch/Brake Control, Shadow V & Ross EP DSV Wiring

Figure 7. Stop/Start Motor Control Station Wiring with Lockout

Figure 8. Wintriss Clutch/Brake Control OEM Operator Station with Separate One

Hand Control

Figure 9. WPC with Separate One-hand Control Wiring

Figure 10. DiProPAC with DSI 2 Wiring Diagram

Figure 11. DiProPAC with RCB Wiring Diagram

Figure 12. ProCamPAC 16 to Cam Output Wiring Diagram

Figure 13. SmartPAC 2 Loopback Wiring Connections

Figure 14. Cross-checked User Interlocks with Honeywell Interlocks

Figure 15. Wintriss Clutch/Brake Control Shadow VI and Herion XSZ DSV Wiring

Figure 16. Wintriss Clutch/Brake Control Integrated Shadow VI Wiring

page x Table of Contents

SmartPAC 2 with WPC Integration 1126800

List of Figures and Tables

Figure 1 - 1 SmartPAC 2 Front Panel...................................................................................................................4

Figure 1 - 2. Illustration of Operator Station .........................................................................................................6

Figure 1 - 3. How SmartPAC 2 Interprets Signals From a “Green” Sensor ....................................................... 14

Figure 1 - 4. How SmartPAC 2 Interprets Signals From a Sensor Set to "Green Quick Check" ........................15

Figure 1 - 5. How SmartPAC 2 Interprets Signals From a Sensor Set to "Green Constant" ............................... 16

Figure 2 - 1. Installation Overview......................................................................................................................29

Figure 2 - 2. Attaching Wires to Connector.........................................................................................................31

Figure 2 - 3. Connecting Shield Drain Wire to Ground Stud ..............................................................................31

Figure 2 - 4. WPC Mounting Dimensions...........................................................................................................33

Figure 2 - 5. Mounting dimensions for Non-enclosure WPC..............................................................................34

Figure 2 - 6. Setting Voltage Selector Switch .....................................................................................................36

Figure 2 - 7. Resolver ..........................................................................................................................................42

Figure 2 - 8. Overrun Sensor Magnetic Switch Installation Example ..................................................................44

Figure 2 - 9. Operator Station, Side Buttons........................................................................................................48

Figure 2 - 10. Operator Station, Top Buttons......................................................................................................49

Table 2 - 1. User Inputs (Interlocks), SmartPAC with WPC............................................................................... 54

Figure 2 - 11. One Way to Wire WPC Operator Mode Outputs..........................................................................56

Figure 2 - 12. One-hand Control Switch Dimensions..........................................................................................59

Figure 2 - 13. One-hand Control Switch Base, Showing Mounting Holes.......................................................... 60

Figure 2 - 14. Wiring Connections in One-hand Control Switch ........................................................................60

Figure 2 - 15. Multiple Operator Station Configurations ....................................................................................63

Figure 2 - 16. Installing the LMCS and Magnets ................................................................................................67

Figure 2 - 17. Bar Control Enclosure Mounting Dimensions..............................................................................68

Figure 2 - 18. SmartPAC 2 Mounting Dimensions, Enclosure............................................................................71

Figure 2 - 19. SmartPAC 2 Mounting and Cutout Dimensions, Panel Mount.....................................................73

Table 2 - 2. Resolver Wiring on SmartPAC 2 .....................................................................................................75

Figure 2 - 20. Wiring AC to SmartPAC 2, Top Right Inside Enclosure..............................................................76

Figure 2 - 22. Input check switch (S101) ............................................................................................................78

Table 2 - 3. Wiring to Input Check and Stop Circuits .........................................................................................78

Figure 2 - 23. ProCamPAC Output Assembly.....................................................................................................85

Figure 2 - 24. Cam Outputs Board ......................................................................................................................86

Table 2 - 4. ProCamPAC to Cam Output Assembly TB301, Cams 1-8..............................................................87

Table 2 - 5. ProCamPAC to Cam Output Assembly TB301, Cams 9-16............................................................87

Table 2 - 6. Making Connections to Relays.........................................................................................................88

Figure 2 - 25. Connector TB302 and TB303 for Wiring Relays to Equipment...................................................88

Figure 2 - 26. How to Connect Suppressors Across the Load .............................................................................89

Table 2 - 7. SmartPAC 2 to DSI 2 DiPro Sensor Interface, Sensors 1-8.............................................................91

Table 2 - 8. SmartPAC 2 to DSI 2 DiPro Sensor Interface, Sensors 9-16...........................................................91

Figure 2 - 27. DiPro Remote Connection Box for Sensors..................................................................................92

Table 2 - 9. DiPro RCB to SmartPAC 2.............................................................................................................. 93

Table 2 - 10. DiPro RCB to SmartPAC 2 (continued).........................................................................................93

Figure 2 - 28. SmartPAC 2 Startup Screen..........................................................................................................96

Figure 2 - 29. Main Program Menu..................................................................................................................... 97

Figure 2 - 30. SmartPAC 2 Main Initialization Menu .........................................................................................97

Figure 2 - 31. List of Installed Options..............................................................................................................100

Figure 2 - 32. WPC Initialization Menu ............................................................................................................102

Figure 2 - 33. "Press Parameters" Display in SmartPAC's Initialization Mode.................................................102

Figure 2 - 34. Initialize Parameters Warning Message......................................................................................102

Figure 2 - 35. “Resolver Zero” Screen ..............................................................................................................106

Table 2 - 11. Top Stop Angle 240

Table 2 - 12. Top Stop Angle bet. 241

Table 2 - 13. Top Stop Angle bet. 271

Table 2 - 14. Top Stop Angle 301

Figure 2 - 36. Installing Magnet for Overrun Sensor.........................................................................................125

° or less: Mounting Overrun Magnet ..........................................................117

° and 270° : Mounting Overrun Magnet................................................119

° and 300° : Mounting Overrun Magnet.................................................121

° or Greater: Mounting Overrun Magnet ....................................................123

Table of Contents page xi

1126800 SmartPAC 2 with WPC Integration

List of Figures and Tables

Figure 2 - 37. WPC Processor Board Layout ....................................................................................................159

Figure 2 - 38. WPC Power Supply Board Layout..............................................................................................160

Figure 2 - 39. WPC Serial Interface Board Layout............................................................................................161

Figure 2 - 40. SmartPAC 2 Board, Location of Components ............................................................................162

Figure 2 - 41. DiProPAC Boards, Location of Components..............................................................................163

Figure 2 - 42. ProCamPAC Boards, Location of Important Components .........................................................164

Figure 2 - 43. ProCamPAC and DiProPAC Boards Installed on SmartPAC 2 Board.......................................165

Table 2 - 15. WPC Wiring: Resolver................................................................................................................166

Table 2 - 16. WPC Wiring: Power Supply Connectors ...................................................................................166

Table 2 - 17. SmartPAC 2 Wiring: Resolver (TB101) ....................................................................................166

Table 2 - 18. SmartPAC 2 Wiring: Input Check and Stop Circuits (TB102) ..................................................167

Table 2 - 19. SmartPAC 2 Wiring: SFI Port (1) and Module Port (2) (TB103) ...............................................167

Table 2 - 20. SmartPAC 2 Wiring: Special Port (3) and PACNet Port (4) (TB104) ........................................168

Table 2 - 21. SmartPAC 2 Wiring: Spare 1 Port (5) and WPC Port (6) (TB105)............................................168

Table 2 - 22. SmartPAC 2 Wiring: Spare 3 Port (7) and Spare 4 Port (8) (TB106) ........................................169

Table 2 - 23. SmartPAC 2 Wiring: Aux I/O (TB107) ......................................................................................169

Figure 3 - 1. Front Panel, SmartPAC 2 with WPC Integration..........................................................................171

Figure 3 - 2. Differences Between SmartPAC 2 and Original SmartPAC.........................................................173

Figure 3 - 3. SmartPAC 2 Keyboard..................................................................................................................174

Figure 3 - 4. Stroke Select Key Switch...............................................................................................................175