Honeywell SmartLine ST700 Installation Manual

SmartLine Pressure Transmitter ST 700 Basic

Quick Start Safety Installation Guide

34-ST-25-57, Revision 2, November 2018

March 2018 Quick Start Safety Installation Guide 1

This document provides descriptions and

procedures for the Quick Installation of

Honeywell’s ST 700 Basic SmartLine

Pressure Transmitter.

The ST 700 Basic SmartLine Pressure

Transmitter is available in a variety of

models for measuring Differential Pressure

(DP), Gauge Pressure (GP), and Absolute

Pressure (AP). For full details refer to the

manuals listed below for protocols, human

interface (HMI), Operation, Installation,

Configuration, Calibration, Maintenance,

Parts, Safety and Approvals etc. including

options.

Copyrights, Notices and Trademarks

Copyright 2018 by Honeywell

Revision 2, November 2018

Trademarks

SmartLine, ST 700 are U.S. registered

trademarks of Honeywell Inc.

HART® is trademark of the FieldComm

Group™

Table of Contents

Installation .................................................................................................................. 1

Mounting the Transmitter ........................................................................................... 1

Conduit Entry Plugs and Adapters ............................................................................. 3

Wiring Connections and Power Up ............................................................................ 4

Explosion-Proof Conduit Seal .................................................................................... 4

Trim the Transmitter ................................................................................................... 4

Set the Jumpers For HART ........................................................................................ 5

Configuration Guide ................................................................................................... 5

Appendix A. PRODUCT CERTIFICATIONS .............................................................. 5

Hazardous Locations Certifications ............................................................................ 7

Control Drawing ......................................................................................................... 8

Tables

Table 1 - Conduit Entry Plugs .................................................................................... 3

Table 2 - Conduit Adapters ........................................................................................ 3

Table 3 - Jumper Settings .......................................................................................... 5

Table 4 - Standard Display Menu ............................................................................... 5

Figures

Figure 1:Mounting Brackets ....................................................................................... 1

Figure 2: Angle Mounting Bracket .............................................................................. 1

Figure 3: LGP and LAP models.................................................................................. 2

Figure 4: Rotating Transmitter Housing ..................................................................... 2

Figure 5: Using level to mount transmitter .................................................................. 2

Figure 6: Flange mounting ......................................................................................... 2

Figure 7: Flush Mounting ........................................................................................... 3

Figure 8: Remote Seal mounting................................................................................ 3

Figure 9: Electronic Housing Conduit Entries ............................................................. 3

Figure 10: Two-wire power/current loop ..................................................................... 4

Figure 11: Terminal Block and Grounding Screw location ......................................... 4

Figure 12: Jumper Location HART ............................................................................ 5

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

Installation

Evaluate the site selected for the Transmitter installation with respect to the process

system design specifications and Honeywell’s published performance characteristics

for your particular model.

Temperature extremes can affect display quality. The display can become unreadable

at temperature extremes; however, this is only a temporary condition. The display will

again be readable when temperatures return to within operable limits.

Mounting the Transmitter

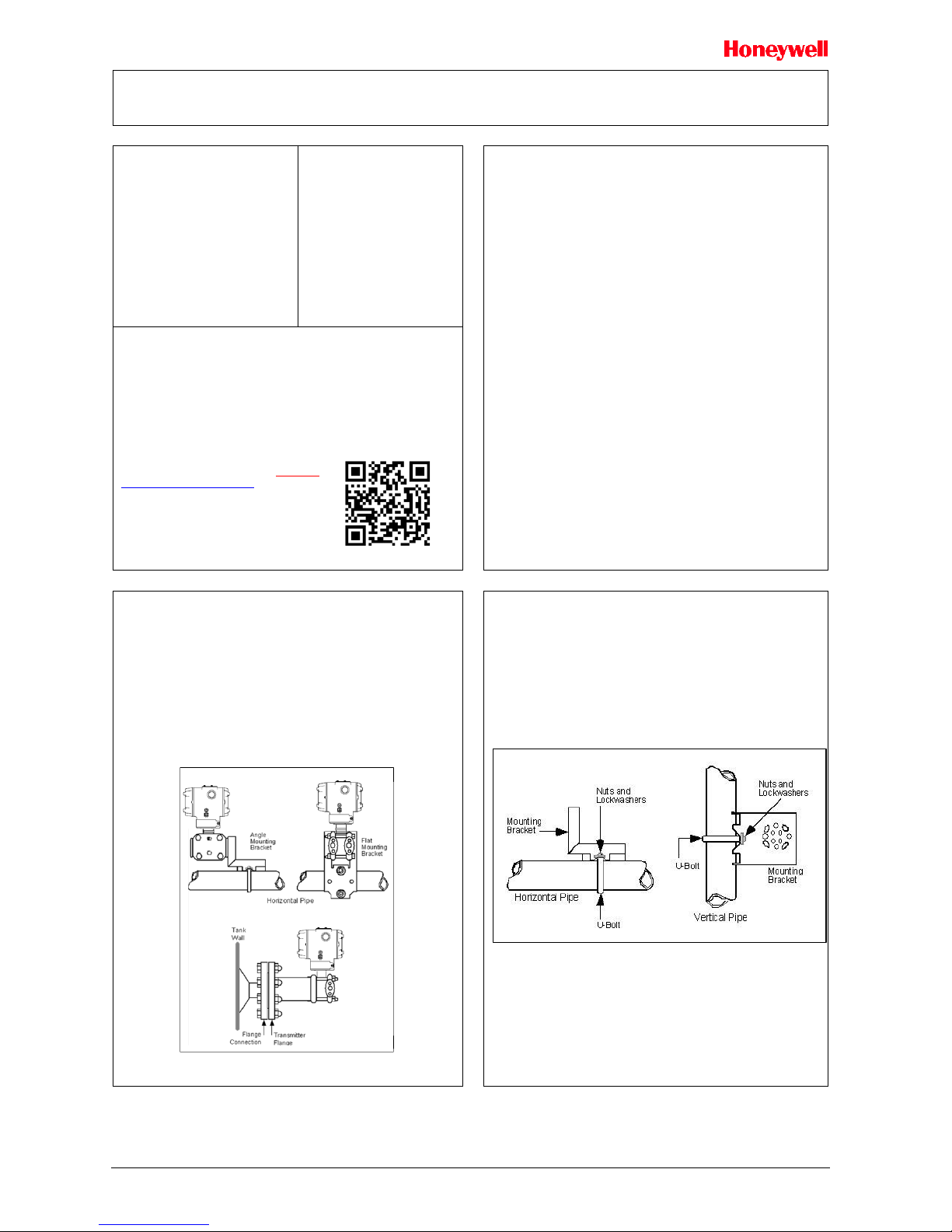

Transmitter models, except flush mounts and those with integral flanges, can be

attached to a two-inch (50 millimeter) vertical or horizontal pipe using Honeywell’s

optional angle or flat mounting bracket; alternately you can use your own bracket.

Flush-mount models are attached directly to a process pipe or tank by a one-inch

weld nipple. Models with integral flanges are supported by the flange connection.

Typical Bracket mounted and Flange Mounted Installations

Figure 1:Mounting Brackets

Bracket Mounting

Optional mounting bracket, see Figure 2

Existing mounting bracket, see Figure 3

Rotate the transmitter housing, see Figure 4

Level a transmitter with small absolute or differential pressure spans, see Figure 5

Optional Mounting Bracket

Position the bracket on a 2-inch (50.8mm) and install “U” bolt around pipe and

through holes in bracket. Secure with nuts and lock washers provided.

Figure 2 Example - Angle mounting bracket secured to horizontal or vertical pipe.

Figure 2: Angle Mounting Bracket

November 2018 Quick Start Installation Guide 2

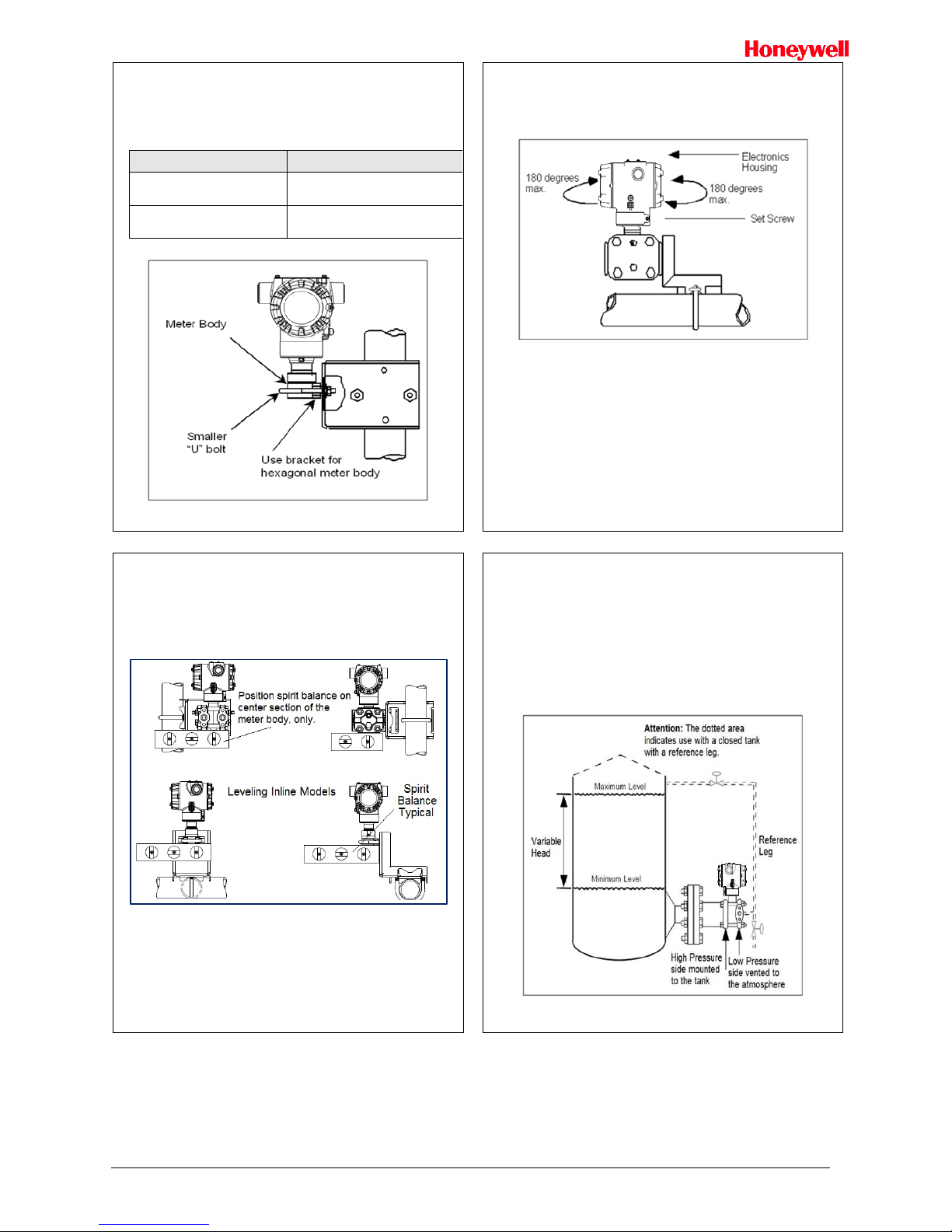

Existing Mounting Bracket

Align appropriate mounting holes in transmitter with holes in bracket and secure with

bolts and washers provided.

Note: If the meter body is hexagonal, you must use the additional bracket supplied.

If meter body is round, discard the bracket.

Example – LGP model transmitter mounted to optional angle mounting bracket.

If Transmitter is….

Then….

DP, Dual Head GP, Dual Head AP

and DP Remote Seals.

Use alternate mounting holes in end of

heads.

In-line GP and AP (LGP model) or

GP/AP Remote Seal

Use smaller “U” bolt provided to attach

meter body to bracket. See Figure 3.

Figure 3: LGP and LAP models

Rotating Transmitter Housing

Loosen set screw on outside neck of transmitter one full turn. Rotate Transmitter

housing in maximum of 180 degree increment in left or right direction from center to

position you require and tighten set screw (1.46 to 1.68Nm/13 to 15lb-in).

Figure 4 Example – Rotating Transmitter Housing.

Figure 4: Rotating Transmitter Housing

Leveling Transmitters with Small Absolute or Differential Pressure

Spans

Mounting position of these transmitters is critical due to the smaller transmitter spans.

To minimize these positional effects on calibration (zero shift), take the appropriate

mounting precautions that follow for the given transmitter model.

See Figure 5 for suggestions on how to level the transmitter using a spirit balance.

To perform a Zero Trim after leveling, refer to Trim the Transmitter on page 4.

Figure 5: Using level to mount transmitter

For transmitter models STA725 and STA72S you must ensure that the transmitter is

vertical when mounting it. You do this by leveling the transmitter side-to-side and

front-to-back.

Mount transmitter vertically to assure best accuracy. Position the spirit balance on the

pressure connection surface of AP body.

Flange Mounting

To mount a flange mounted transmitter model, bolt the transmitter’s flange to the flange

pipe on the wall of the tank.

On insulated tanks, remove enough insulation to accommodate the flange extension.

It is the End User’s responsibility to provide a flange gasket and mounting hardware that

are suitable for the transmitter’s service condition.

To prevent degradation of performance in Flush-Mounted Flanged Transmitters,

exercise care to ensure that the internal diameter of the flange gasket does not obstruct

the sensing diaphragm.

To prevent degradation of performance in Extended Mount Flanged Transmitters,

ensure that there is sufficient clearance in front of the sensing diaphragm body.

Figure 6: Flange mounting

November 2018 Quick Start Installation Guide 3

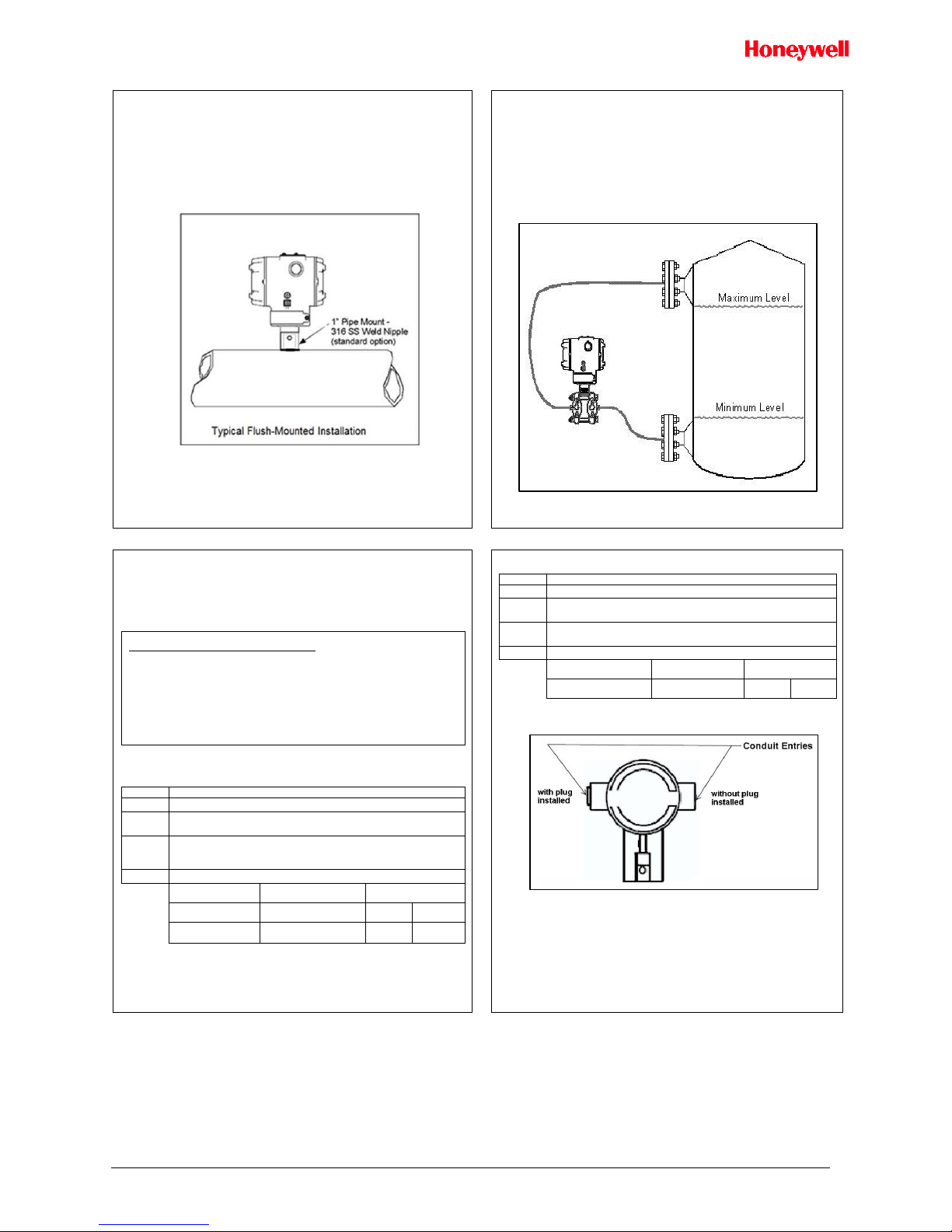

Flush Mounting

To mount a flush mounted transmitter model, cut a hole for a 1-inch standard pipe in the

tank or pipe where the transmitter is to be mounted. See Figure 7.

Weld the 1-inch mounting sleeve to the wall of the tank or to the hole cut on the pipe.

Insert the meter body of the transmitter into the mounting sleeve and secure with the

locking bolt. Tighten the bolt to a torque of 6.4Nm ±0.30Nm [4.7ft.-lbs. ±0.2ft.-lbs.]

Once the transmitter is mounted, the transmitter housing can be rotated to the desired

position. See Figure 7.

Figure 7: Flush Mounting

Remote Seal Mounting

Mount the transmitter at a remote distance determined by length of capillary tubing.

Note: The combination of tank vacuum and high pressure capillary head effect should

not exceed 9psi (300mm Hg) absolute.

On insulated tanks, remove enough insulation to accommodate the mounting sleeve.

Figure 8 Example – Typical Remote Seal Transmitter installation.

Note: For Sanitary 3-A installations, only mount the transmitter outside of the NonProduct Contact area where incidental contact with the process material is unlikely,

use a minimum capillary length of 1.5m (5ft.)

Figure 8: Remote Seal mounting

Conduit Entry Plugs and Adapters

Procedures

It is the User/Installer’s responsibility to install the Transmitters in accordance with

national and local code requirements. Conduit entry plugs and adapters shall be

suitable for the environment, shall be certified for the hazardous location when required

and acceptable to the authority having jurisdiction for the plant.

CONDUIT ENTRY PRECAUTIONARY NOTICE

THE CONDUIT/CABLE GLAND ENTRIES OF THIS PRODUCT ARE SUPPLIED

WITH PLASTIC DUST CAPS WHICH ARE NOT TO BE USED IN SERVICE.

IT IS THE USER’S RESPONSIBILITY TO REPLACE THE DUST CAPS WITH

CABLE GLANDS, ADAPTORS AND/OR BLANKING PLUGS WHICH ARE

SUITABLE FOR THE ENVIRONMENT INTO WHICH THIS PRODUCT WILL BE

INSTALLED. THIS INCLUDES ENSURING COMPLIANCE WITH HAZARDOUS

LOCATION REQUIREMENTS AND REQUIREMENTS OF OTHER GOVERNING

AUTHORITIES AS APPLICABLE.

Use the following procedures for installation:

Table 1 - Conduit Entry Plugs

Step

Action

1

Remove the protective plastic cap from the threaded conduit entry.

2

To ensure the environmental ingress protection rating on tapered

threads (NPT), a non-hardening thread sealant may be used.

3

Thread the appropriate size conduit plug (M20 or ½” NPT) into the

conduit entry opening. Do not install conduit entry plugs in conduit entry

openings if adapters or reducers will be used.

4

Tighten adapters according to the following table.

Description

Tool

Torque

M20 Conduit Entry

10mm Hex Wrench

32Nm

24Lb-ft

½” NPT Conduit

Entry

10mm Hex Wrench

32Nm

24Lb-ft

Table 2 - Conduit Adapters

Step

Action

1

Remove the protective plastic cap from the threaded conduit entry.

2

To ensure the environmental ingress rating on tapered threads (NPT),

a non-hardening thread sealant may be used.

3

Thread the appropriate size adapter (M20 or ½ NPT) into the conduit

entry opening

4

Tighten adapters according to the following table.

Description

Tool

Torque

½ to ¾ NPT Adapter

1 ¼” Wrench

32Nm

24Lb-ft

Figure 9: Electronic Housing Conduit Entries

Note. No plugs come installed in the housings. All housings come with temporary

plastic dust protectors (red) installed and are not certified for use in any installation

Loading...

Loading...