Honeywell Process Solutions

SmartLine Wireless Transmitter

User’s manual

34-SW-25-01

Revision 2

October 2018

iii SmartLine Wireless User's Manual Revision 2

Notices and Trademarks

Copyright 2018 by Honeywell International Inc.

Revisions 2, October 2018

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied

warranties of merchantability and fitness for a particular purpose and makes no express warranties except as may

be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and

specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion PKS, and TotalPlant are registered trademarks of Honeywell International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell Process Solutions

1250 W Sam Houston Pkwy S

Houston, TX 77042

iv SmartLine Wireless User's Manual Revision 2

About This Document

This document describes preparation, operation and maintenance of the SmartLineTM Wireless Pressure

Transmitters. Mounting, installation and wiring are covered in other documents.

Honeywell does not recommend using devices for critical control where there is a single point of failure

or where single points of failure result in unsafe conditions. OneWireless is targeted at open loop

control, supervisory control, and controls that do not have environmental or safety consequences. As

with any process control solution, the end-user must weigh the risks and benefits to determine if the

products used are the right match for the application based on security, safety, and performance.

Additionally, it is up to the end-user to ensure that the control strategy sheds to a safe operating condition

if any crucial segment of the control solution fails.

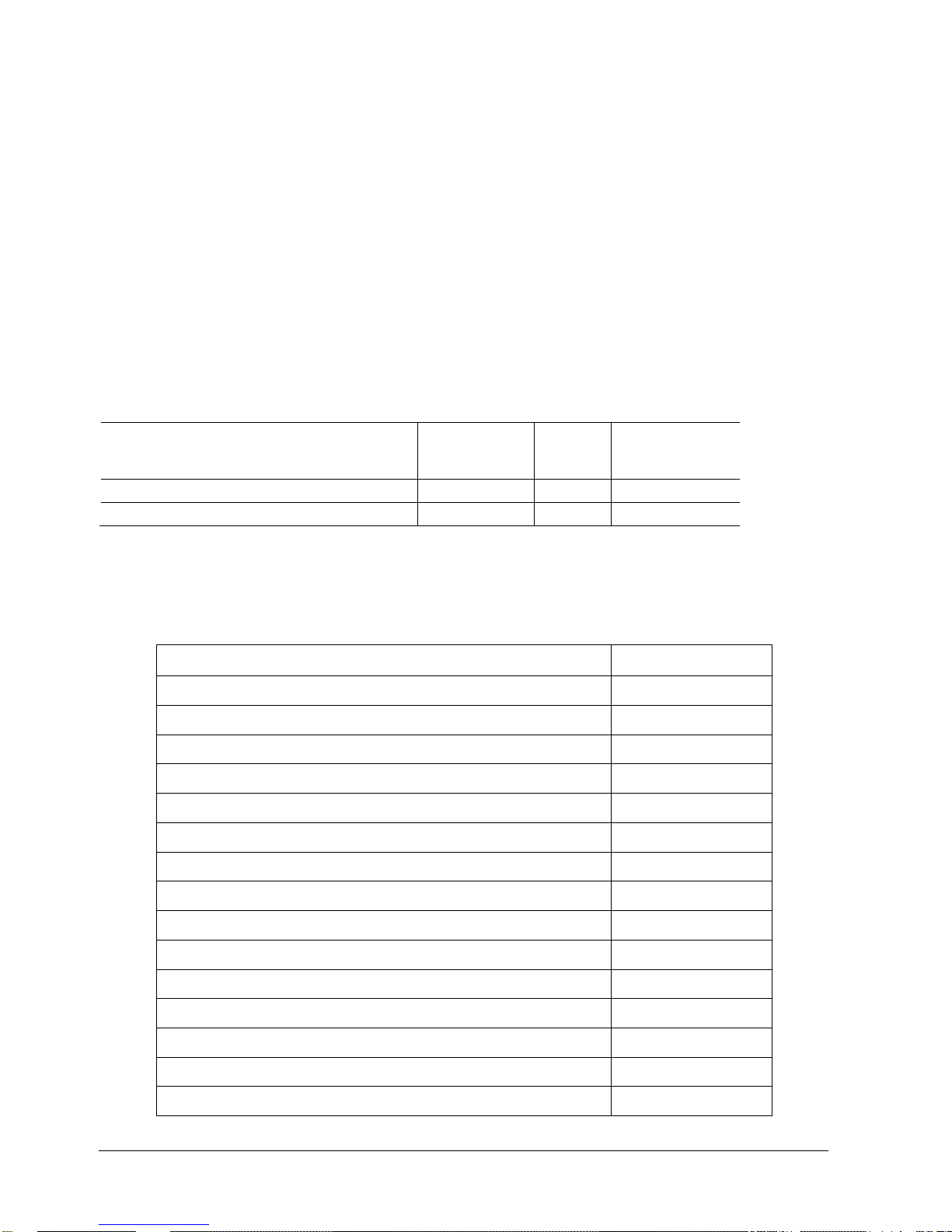

Revision Information

Document Name

SmartLine Wireless User's Manual

Document ID

(This document)

Revision

Number

Publication Date

1st Release

34-SW-25-01

1

September 2018

RoHS added

34-SW-25-01

2

October 2018

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

Document Title

Doc #

STDW800 Wireless Specification, Differential Transmitter

34-SW-03-01

STAW800 Wireless Specification, Absolute Transmitter

34-SW-03-02

STGW800 Wireless Specification, Gauge Transmitter

34-SW-03-03

STFW700_800 Wireless Specification, Flanged Transmitter

34-SW-03-04

STRW700_800 Wireless Specification, Remote Seal Transmitter

34-SW-03-05

STDW700 Wireless Specification, Differential Transmitter

34-SW-03-06

STAW700 Wireless Specification, Absolute Transmitter

34-SW-03-07

STGW700 Wireless Specification, Gauge Transmitter

34-SW-03-08

OneWireless R310 Release Notes

OWDOC-X252-en-310A

OneWireless R310 Migration Users Guide

OWDOC-X258-en-310

OneWireless R310 Field Device Access Point Users Guide

OWDOC-X256-en-310

OneWireless R310 Wireless Device Manager Users Guide

OWDOC-X254-en-310

OneWireless R300 Experion PKS Integration Guide

OWDOC-X259-en-300

OneWireless R300 Wireless LAN Controller Configuration Guide

OWDOC-X255-en-300

OneWireless R300 Network Planning an Installation Guide

OWDOC-X253-en-300

Revision 2 SmartLine Wireles User's Manual v

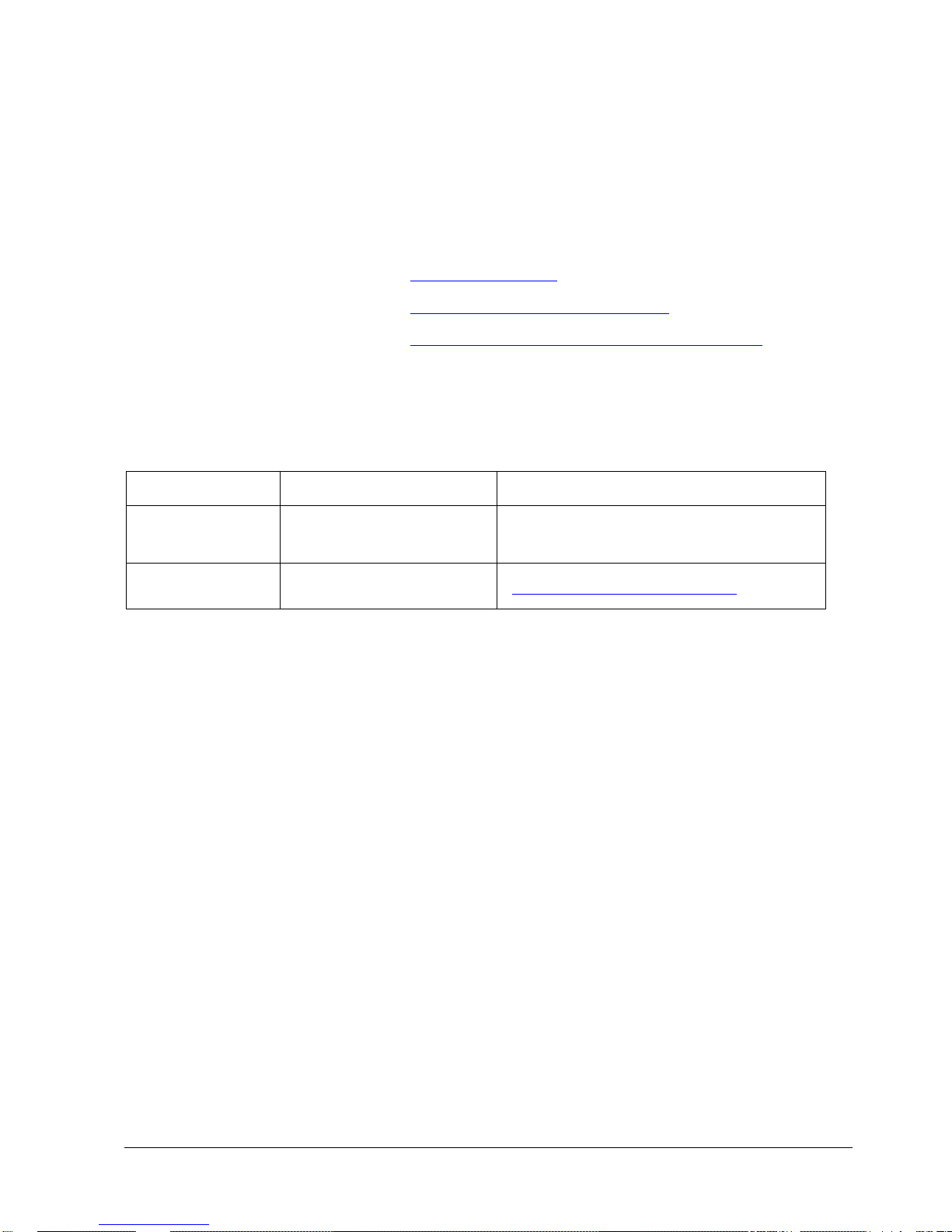

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, refer to the back page of this

manual or the appropriate Honeywell Support web site:

Honeywell Corporate www.honeywell.com

Honeywell Process Solutions https://www.honeywellprocess.com/*

Training Classes https://www.honeywellprocess.com/en-US/training

Telephone and Email Contacts

Area

Organization

Phone Number

United States and

Canada

Honeywell Inc.

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

Global Email

Support

Honeywell Process Solutions

hfs-tac-support@honeywell.com

vi SmartLine Wireless User's Manual Revision 2

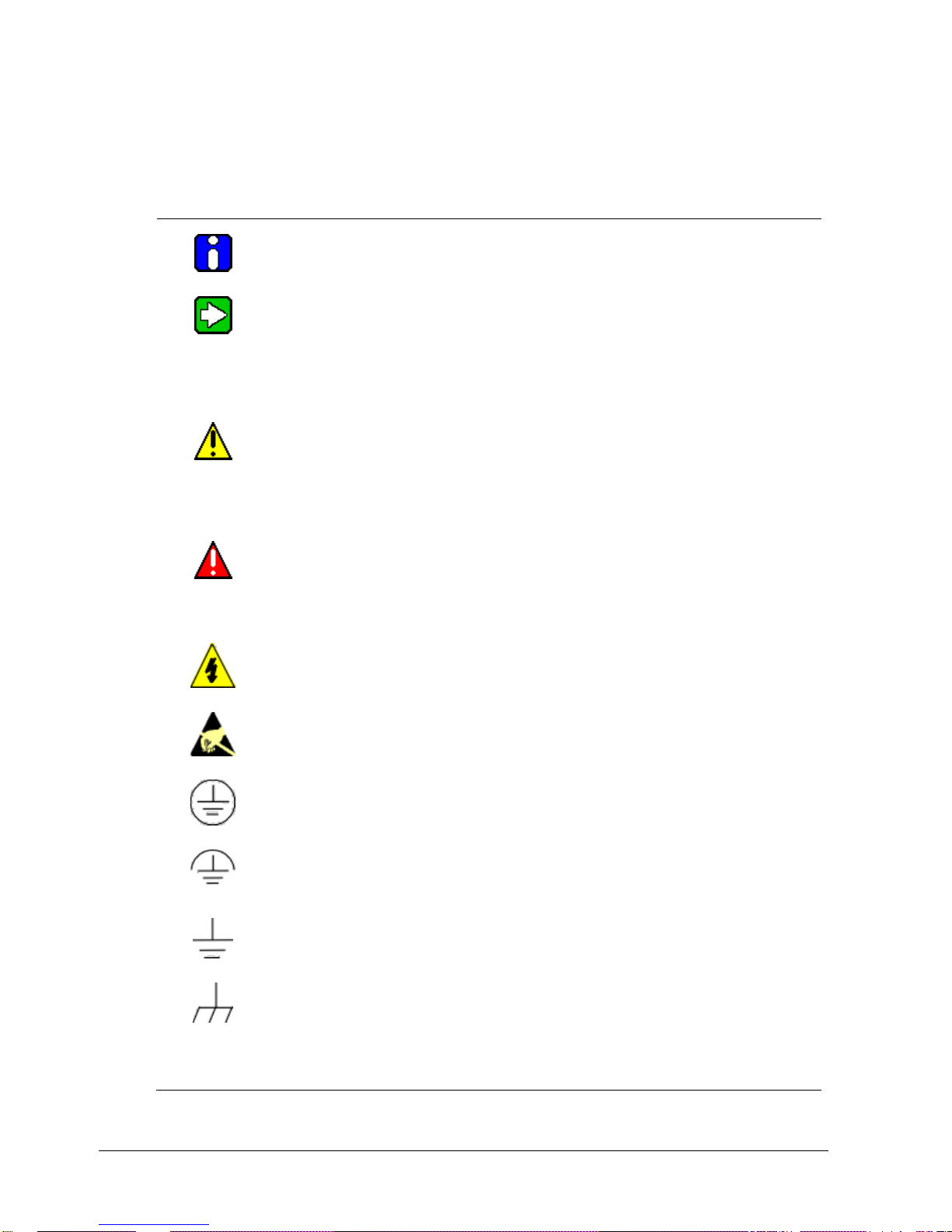

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol

Definition

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a task.

CAUTION

Indicates a situation which, if not avoided, may result in equipment or work (data) on

the system being damaged or lost, or may result in the inability to properly operate

the process.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

CAUTION symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in the

manual.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could

result in serious injury or death.

WARNING symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in the

manual.

WARNING, Risk of electrical shock: Potential shock hazard where HAZARDOUS

LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which equipment may be

sensitive. Observe precautions for handling electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to Protective Earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

Chassis Ground: Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

continued

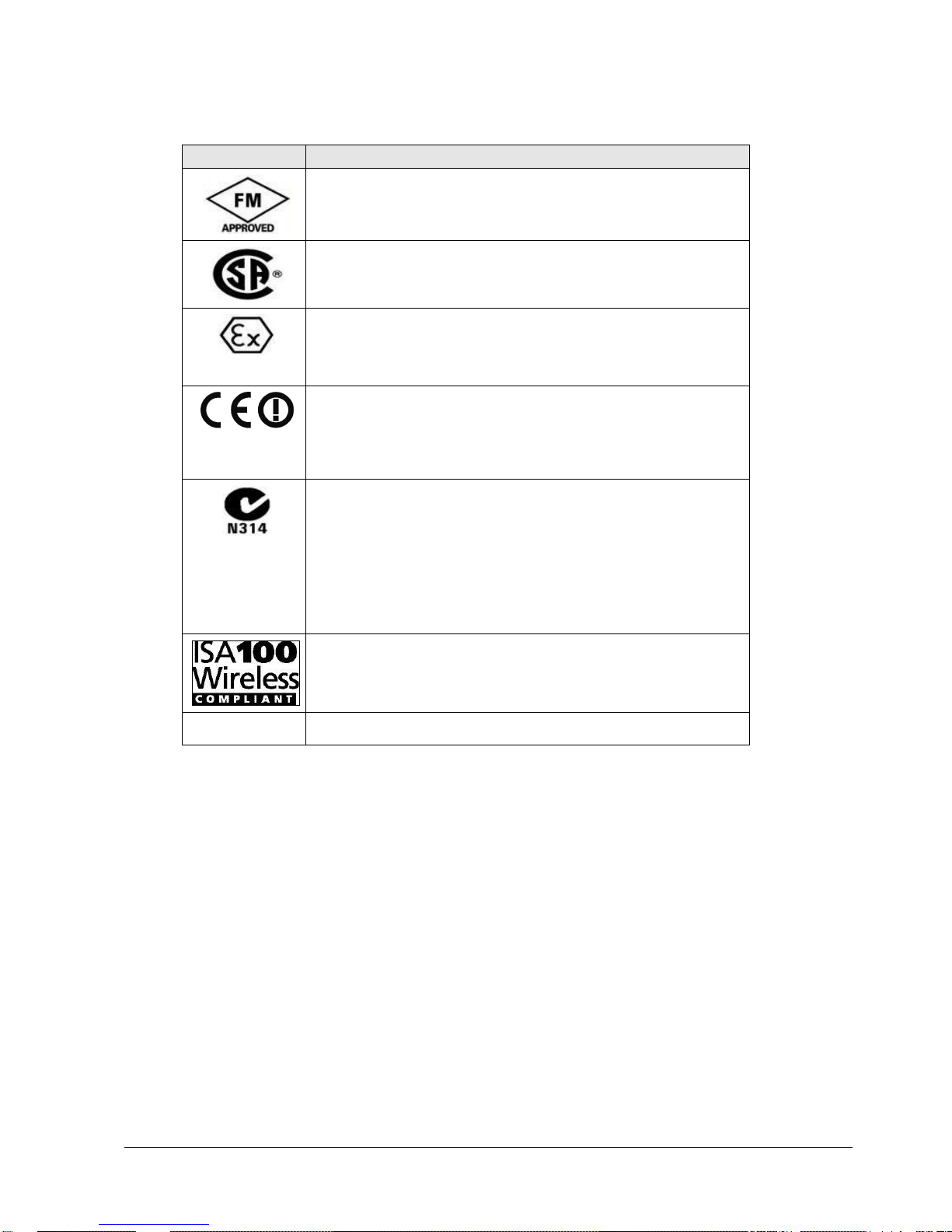

Revision 2 SmartLine Wireles User's Manual vii

Symbol

Description

The Factory Mutual® Approval mark means the equipment has

been rigorously tested and certified to FM standards for safety

and/or performance.

The Canadian Standards mark means the equipment has been

tested and meets applicable standards for safety and/or

performance.

The Ex mark means the equipment complies with the requirements

of the European standards that are harmonized with the 94/9/EC

Directive (ATEX Directive, named after the French "ATmosphere

EXplosible").

For radio equipment used in the European Union in accordance

with the Radio Equipment Directive (RED) and the CE Mark. The

alert sign must be used when a restriction on use (output power

limit by a country at certain frequencies) applies to the equipment

and must follow the CE marking.

The C-Tick mark is a certification trade mark registered to ACMA

(Australian Communications and Media Authority) in Australia under

the Trade Marks Act 1995 and to RSM in New Zealand under

section 47 of the NZ Trade Marks Act. The mark is only to be used

in accordance with conditions laid down by ACMA and RSM. This

mark is equal to the CE Mark used in the European Union.

N314 directly under the logo is Honeywell’s unique supplier

identification number.

The ISA100 Wireless Compliant logo indicates the device has

received ISA100.11a conformance certification and is registered

with the Wireless Compliance Institute, assuring device

interoperability.

CRN

Canadian Registration Number

ix SmartLine Wireless User's Manual Revision 2

Contents

Honeywell Process Solutions ................................................................................................................ iii

Symbol Definitions ..................................................................................................................................vi

1. INTRODUCTION .................................................................................................... 1

1.1 Purpose .......................................................................................................................................... 1

1.2 Scope .............................................................................................................................................. 1

1.3 OneWireless network overview ................................................................................................... 1

1.4 Security Considerations ............................................................................................................... 1

1.5 Licensing and License Keys for Anti-Aliasing Filter ................................................................. 1

1.6 About the transmitter .................................................................................................................... 2

1.7 Physical Characteristics ............................................................................................................... 4

2. PREPARATION AND QUICK START ................................................................... 6

2.1 Introduction ................................................................................................................................... 6

2.2 Set up the Network ........................................................................................................................ 6

2.3 Transmitter Quick Start ................................................................................................................ 6

3. INSTALLATION ..................................................................................................... 8

3.1 Installation Site Evaluation .......................................................................................................... 8

3.2 Maximum Working Pressure: ....................................................................................................... 8

3.3 Environmental Conditions: .......................................................................................................... 8

3.4 Transmitter Weights and Dimensions ......................................................................................... 9

Weights ..................................................................................................................................................................9

Dimensions ........................................................................................................................................................... 10

3.5 Installation drawing number tables ...........................................................................................14

3.6 Conduit / Cable Entries ...............................................................................................................15

Summary .............................................................................................................................................................. 15

3.7 Mounting Summary .....................................................................................................................16

3.8 Piping the SmartLine Wireless Transmitter .............................................................................23

3.9 Rotate transmitter housing ........................................................................................................27

3.10 Rotate display ..........................................................................................................................27

Tools required ...................................................................................................................................................... 27

Procedure ............................................................................................................................................................. 27

Display adjustment ............................................................................................................................................... 28

3.11 Antenna adjustment and mounting .......................................................................................29

Requirements ....................................................................................................................................................... 29

Integral antenna ................................................................................................................................................... 29

Contents

Telephone and Email Contacts

x SmartLine Wireless User's Manual Revision 2

3.12 Remote antenna .......................................................................................................................31

Outdoor installation warnings ............................................................................................................................... 31

Choosing a Mounting Location ............................................................................................................................. 32

Site Selection ....................................................................................................................................................... 32

Mounting the Antenna .......................................................................................................................................... 33

Directional mounting procedure ........................................................................................................................... 34

Omnidirectional mounting procedure ................................................................................................................... 35

Grounding the antenna ........................................................................................................................................ 36

4. START UP ........................................................................................................... 38

4.1 Battery Power Option..................................................................................................................38

Install/Replace batteries ....................................................................................................................................... 38

Battery Pack installation and replacement procedure .......................................................................................... 40

Battery Pack Test Terminals ................................................................................................................................ 40

4.2 24V Power Supply Option ..........................................................................................................41

24V Power Supply ............................................................................................................................................... 42

24V Power Supply Connection/Replacement Procedure ..................................................................................... 43

4.3 Grounding ....................................................................................................................................44

24V dc Power Supply Option (DC) System Diagram ........................................................................................... 44

4.4 Display sequence ........................................................................................................................45

4.5 Provisioning .................................................................................................................................45

4.6 Calibrating the transmitter .........................................................................................................46

Overview .............................................................................................................................................................. 46

Calibrate zero ....................................................................................................................................................... 46

Procedure for field calibration of Honeywell compound characterized SmartLine Wireless Transmitters ............ 47

5. FUNCTION BLOCKS ........................................................................................... 50

5.1 Introduction .................................................................................................................................50

5.2 Block description ........................................................................................................................50

Block types ........................................................................................................................................................... 50

Block diagram ...................................................................................................................................................... 50

6. OPERATION ........................................................................................................ 51

6.1 Overview ......................................................................................................................................51

Display modes ..................................................................................................................................................... 51

6.2 Transmitter connection status ...................................................................................................52

6.3 Transmitter PV display ...............................................................................................................54

PV status ................................................................ ................................ .............................................................. 57

6.4 Provisioning Device menus .......................................................................................................60

Overview .............................................................................................................................................................. 60

Main menu ........................................................................................................................................................... 60

Security and Node Deployment ........................................................................................................................... 60

De-provisioning .................................................................................................................................................... 62

Read Device Information ................................................................................................................................ ...... 62

Advanced Options ................................................................................................................................................ 64

Contents

Telephone and Email Contacts

Revision 2 SmartLine Wireles User's Manual xi

7. MAINTENANCE/REPAIR..................................................................................... 66

7.1 Introduction .................................................................................................................................66

7.2 Preventive maintenance .............................................................................................................66

7.3 Inspecting and cleaning barrier diaphragms ...........................................................................66

Tools required ...................................................................................................................................................... 66

Procedure ............................................................................................................................................................. 67

Torque ratings ...................................................................................................................................................... 69

7.4 Replacing Electronics Module ...................................................................................................70

Tools required ...................................................................................................................................................... 70

Procedure ............................................................................................................................................................. 70

7.5 Replacing batteries .....................................................................................................................71

When to replace ................................................................................................................................................... 71

7.6 Replacing 24V external power module .....................................................................................71

When to replace ................................................................................................................................................... 71

7.7 Replacing antenna ......................................................................................................................72

Tools required ...................................................................................................................................................... 72

Procedure ............................................................................................................................................................. 72

Antenna replacement procedure .......................................................................................................................... 73

8. PARTS ................................................................................................................. 75

7.8 Transmitter body .........................................................................................................................75

Mounting Brackets ................................................................................................................................................ 76

APPENDIX A - MODBUS ............................................................................................. 87

APPENDIX B - CERTIFICATIONS AND APPROVALS ............................................... 94

Hazardous location certifications .......................................................................................................................... 98

Battery ................................................................................................................................................................ 101

24V DC Supply ................................................................................................................................................... 101

B3. Conditions of Certification ..........................................................................................................102

FM Approval Specific Conditions of Use ............................................................................................................ 102

CSA, IECEx and ATEX Conditions of Certification ............................................................................................. 102

Apparatus Marked with Multiple Types of Protection .......................................................................................... 102

B4. Radio Compliance Information ...................................................................................................103

Radio Frequency (RF) statement ....................................................................................................................... 103

European Union restriction ................................................................................................................................. 103

Restriction .......................................................................................................................................................... 103

Japanese Restrictions ........................................................................................................................................ 104

FCC compliance statements .............................................................................................................................. 104

IC compliance statements .................................................................................................................................. 104

Contents

Tables

xii SmartLine Wireless User's Manual Revision 2

Tables

Table 3-1: Weights ..................................................................................................................... 9

Table 3-2: Drawing numbers for pressure transmitters ............................................................. 14

Table 3-3: Conduit entry plugs and cable glands for your transmitter. ...................................... 15

Table 3-4: Flange Mounting Guidelines .................................................................................... 22

Table 3-5: Remote Diaphragm Mounting Details ...................................................................... 23

Table 3-6: Suggested Connection Locations ............................................................................ 25

Table 4-1: Calibrate zero .......................................................................................................... 46

Table 4-2: Field calibration ....................................................................................................... 47

Table 5-1: Blocks...................................................................................................................... 50

Table 6-1: Transmitter connection status .................................................................................. 52

Table 6-2: Transmitter PV display ............................................................................................ 54

Table 6-3: SmartLine Wireless DP units ................................................................................... 54

Table 6-4: SmartLine Wireless Flow units ................................................................................ 56

Table 6-5: PV Status ................................................................................................................ 57

Table 6-6: Device status ........................................................................................................... 58

Table 6-7: Read Device Information ......................................................................................... 63

Table 6-8: Advanced Options ................................................................................................... 65

Table 7-1: Inspecting and Cleaning Barrier Diaphragms .......................................................... 67

Table 7-2: Head Bolt Torque Values ........................................................................................ 69

Table 7-3: Electronics module replacement .............................................................................. 70

Table 8-1: Transmitter Body Parts ............................................................................................ 75

Table 8-2: Angle and Flat Bracket Parts (Refer to Figure 8-1) .................................................. 77

Table 8-3: Transmitter Enclosure O-Ring Kit ............................................................................ 77

Table 8-4: Meter Body Parts ..................................................................................................... 77

Table 8-5: Models STDW810, 820, 825, 830 & 870 .................................................................. 78

Table 8-6: Parts for STGW830, 840, 870 and STAW822, 840 Transmitter Body ...................... 81

Table 8-7: Inline Gauge and Inline Atmospheric Meter Body Parts ........................................... 84

Table 8-8: Flange-Mounted Meter Body Parts .......................................................................... 84

Table 8-9: SmartLine Wireless Pressure – Modbus table ......................................................... 87

Table 8-10 SmartLine Wireless – Modbus table ....................................................................... 90

Contents

Figures

Revision 2 SmartLine Wireles User's Manual xiii

Figures

Figure 1-1 - SmartLine Wireless Transmitter Functional Diagram ............................................... 3

Figure 1-2 – SmartLine Wireless Transmitter Major Assemblies ................................................. 4

Figure 1-3– SmartLine Wireless Transmitter Electronics Housing Components .......................... 5

Figure 3-1: DP/DHGP Pressure transmitter dimensions unit mm/inch ................................ ....... 10

Figure 3-2: DP/DHGP Pressure antenna dimensions unit mm/inch ........................................... 11

Figure 3-3: GP/AP Pressure transmitter dimensions unit mm/inch ............................................ 12

Figure 3-4: GP/AP Pressure antenna dimensions unit mm/inch ................................................ 13

Figure 3-5: Typical Bracket Mounted and Flange Mounted Installations .................................... 16

Figure 3-6: Angle Mounting Bracket Secured to a Horizontal or Vertical Pipe ........................... 17

Figure 3-7: – Inline Model Mounted to an Optional Bracket ....................................................... 18

Figure 3-8: Rotating the Electronic Housing .............................................................................. 18

Figure 3-9: Using a Spirit Balance to Level a Transmitter .......................................................... 20

Figure 3-10: Tank-Flange Mounted Transmitter ........................................................................ 21

Figure 3-11: Representative Remote Diaphragm Seal Transmitter Installation.......................... 22

Figure 3-12: Typical 3-Valve Manifold with Blow-Down Piping .................................................. 24

Figure 3-13: Flange Adapter Removal and Replacement .......................................................... 26

Figure 3-14: Rotating transmitter housing ................................................................................. 27

Figure 3-15: Display rotation ..................................................................................................... 28

Figure 3-16: Elbow antenna adjustment .................................................................................... 30

Figure 3-17: Directional antenna mounting ................................................................................ 35

Figure 3-18: Omnidirectional antenna mounting ........................................................................ 36

Figure 4-1: IS Battery Pack Installation ..................................................................................... 39

Figure 4-2: IS Battery Pack ................................................................................................ ....... 39

Figure 4-3: 24V Power Supply Installation ................................................................................. 41

Figure 4-4: 24V Power Supply Module ...................................................................................... 42

Figure 4-5: Power Supply 24V dc Option (DC) System Diagram ............................................... 44

Figure 5-1: Block Diagram......................................................................................................... 50

Figure 6-1: Main menu .............................................................................................................. 60

Figure 6-2: Security and Node Deployment ............................................................................... 61

Figure 6-3: Read Device Information ......................................................................................... 62

Figure 6-4: Advanced Options ................................................................................................... 64

Figure 7-1: Assembly of DP Transmitter Process Heads ........................................................... 68

Figure 7-2: STW Standard Transmitter - Head Bolt Tightening Sequence ................................. 68

Figure 7-3: Sensor module removal and replacement ............................................................... 71

Figure 7-4: Antenna replacement .............................................................................................. 74

Figure 8-1: Angle and Flat Bracket Parts ................................................................................... 76

Figure 8-2: Models STDW810, 820, 825, 830, & 870 ................................................................ 80

Figure 8-3: STGW830, 840, 870, and STAW822, 840 Transmitter Body .................................. 83

Figure 8-4: Inline Gauge and Inline Atmospheric Display Bodies .............................................. 84

Figure 8-5: Extended Flange Design ......................................................................................... 85

Figure 8-6: Pseudo Flange design ............................................................................................ 85

Figure 8-7: Flush Flange Design ............................................................................................... 86

Figure 8-8: Remote Seal Diaphragm ......................................................................................... 86

xiv SmartLine Wireless User's Manual Revision 2

1. Introduction

1.1. Purpose

Revision 2 SmartLine Wireles User's Manual 1

1. Introduction

1.1 Purpose

This manual describes the Honeywell SmartLine Wireless Transmitter function, operation and

maintenance.

1.2 Scope

The manual includes:

Details of topics that relate uniquely to the Honeywell SmartLine Wireless Transmitter

1.3 OneWireless network overview

OneWireless is an all digital, two-way communication mesh network that interconnects industrial

field sensors to a central system.

OneWireless has defined standards to which field devices and operator stations communicate

with one another. The communications protocol is built as an "open system" to allow all field

devices and equipment that are built to OneWireless standard to be integrated into a system,

regardless of the device manufacturer. This interoperability of devices using OneWireless

technology is to become an industry standard for automation systems.

1.4 Security Considerations

Honeywell OneWireless Transmitters conform to the security features provided by compliance to

the ISA100.11a standard for both stack and device interoperability and security. The security

aspects of the ISA100.11a standard include multi-level authentication for endpoint validation,

data privacy consisting of network and end to end encryption, network diversity using spread

spectrum technology and time slot allocation, and data integrity using quality and latency

attributes.

For assure availability, the placement of Wireless transmitters and other wireless network

components should consider signal quality under various environmental conditions. Signal

quality can be monitored by inspection of the Receive Signal Strength Indicator (RSSI) and

Receive Signal Quality Indications (RSQI). The RSSI and RQSI for mesh links can be viewed on

the OneWireless Wireless Device Manager (WDM) network display.

Physical security of the transmitter relies on restricting access to the transmitter and related

network components to only authorized personal.

1.5 Licensing and License Keys for Anti-Aliasing Filter

This option enables the Anti-Alias filter which attenuates the higher frequencies and helps to

prevent aliasing components from being sampled.

License Keys can be purchased from Honeywell to Activate the Anti-Aliasing Filter Feature.

To Order Contact Honeywell and Provide the Device ID value for the transmitter you want to

buy the feature for. The Device ID can be found under “Device Vendor Parameters” in the WDM

interface.

1. Introduction

1.6. About the transmitter

2 SmartLine Wireless User's Manual Revision 2

1.6 About the transmitter

The SmartLine Wireless Transmitter is furnished with an ISA100.11a-compliant wireless

interface to operate in a compatible distributed ISA100.11a wireless system. The transmitter will

interoperate with any ISA100.11a wireless network.

The transmitter includes ISA100.11a-compliant electronics for operating in a 2.4 GHz wireless

network. It features function block architecture and instantiable input channels.

The SmartLine Wireless Transmitter comes in a variety of models for measurement applications

involving one of these basic types of pressure:

Differential pressure

Gauge pressure

Absolute pressure

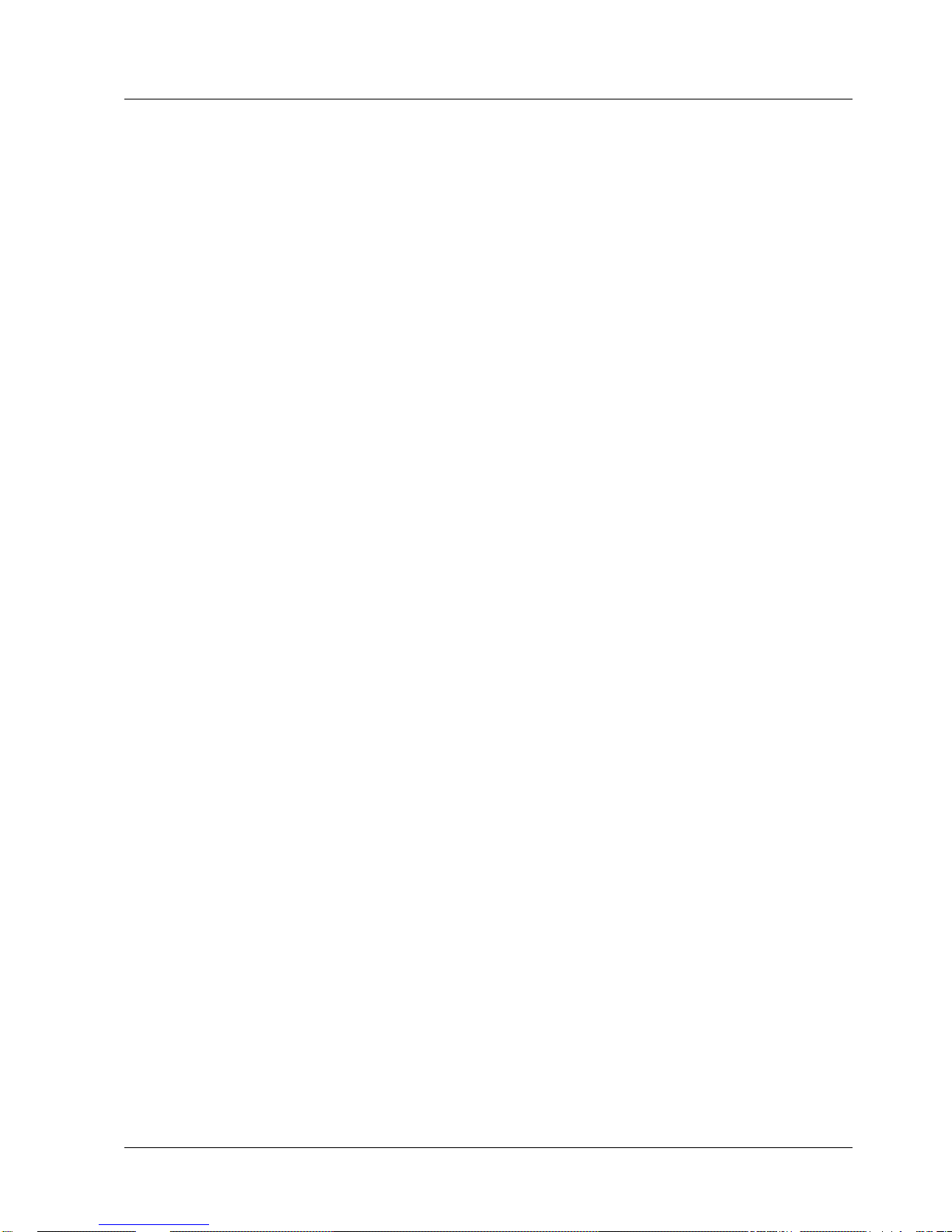

The transmitter measures the process pressure and transmits the measured value as a digital

output signal in user-configured engineering units. Its major components are an electronics

housing and a meter body as shown in Figure 1-1 (a typical differential pressure model

transmitter).

The SmartLine Wireless transmits its output in a digital OneWireless protocol format for direct

digital communications with systems.

The Process Variable (PV) is available for monitoring and alarm purposes. Available PV update

rates: 0.5, 1, 5, 10, 30 seconds, 1, 5, 15, 30 minutes and 1 hour are set on the OneWireless User

Interface. Slower update rates extend battery life. The meter body temperature is also available as

a secondary variable for monitoring. Figure 1-1 shows a block diagram of the SmartLine

Wireless Transmitter’s operating functions.

The SmartLine Wireless DP model type is capable of measuring mass flow and volumetric flow.

When minimum and maximum flow rate values are configured as PV scale 0% and 100% values

at given PV units of measure, and the respective DP values at those limits are configured as the

calibration scale 0% and 100% values, the PV value becomes a flow rate in the selected units of

measure. Minimum and maximum flow rate data at given DP values is either provided on or

with orifice plates, or is commonly available according to orifice plate size.

1. Introduction

1.6. About the transmitter

Revision 2 SmartLine Wireles User's Manual 3

Figure 1-1 - SmartLine Wireless Transmitter Functional Diagram

1. Introduction

1.7. Physical Characteristics

4 SmartLine Wireless User's Manual Revision 2

1.7 Physical Characteristics

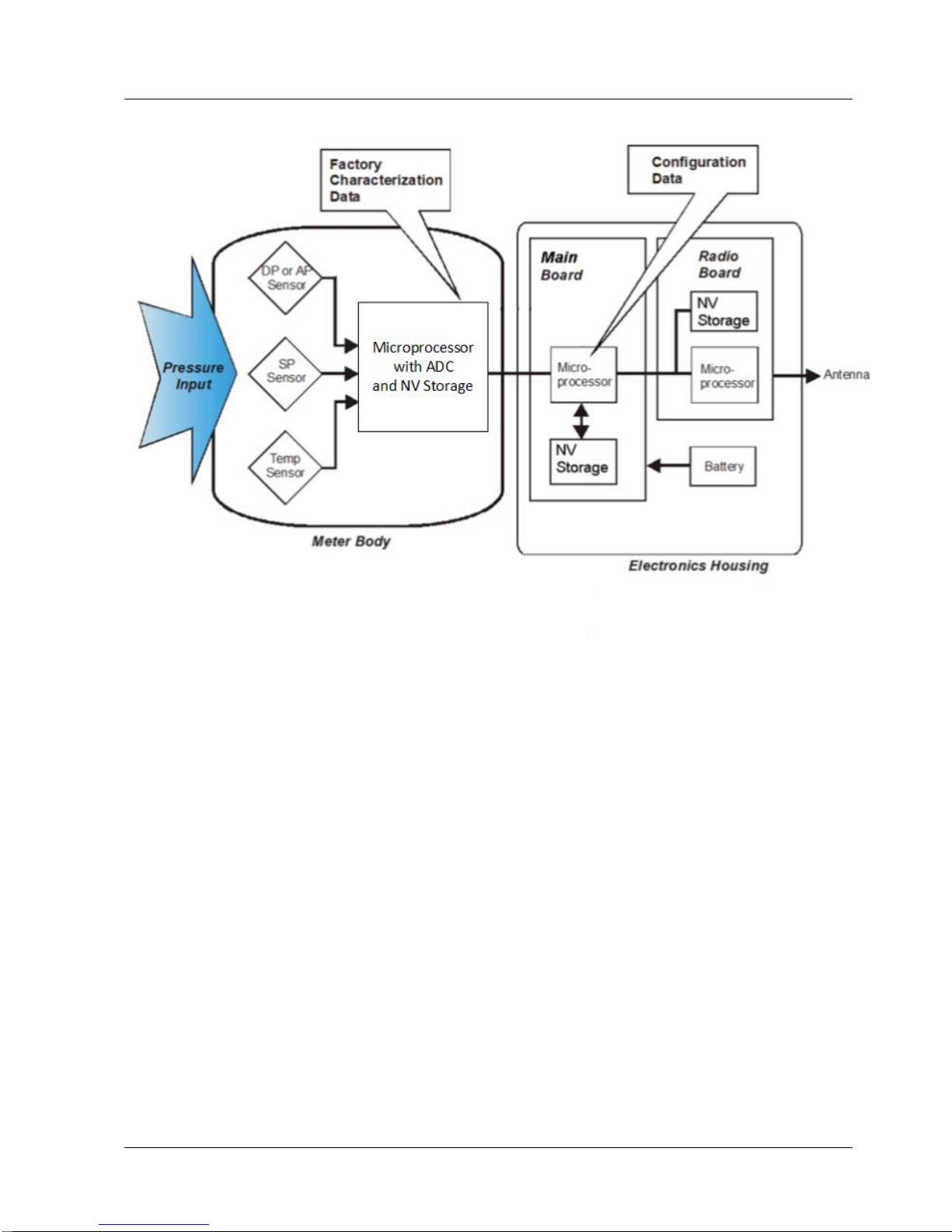

As shown in Figure 1-2, the SmartLine Wireless transmitter is packaged in two major assemblies: the

Electronics Housing and the meter body. The elements in the Electronic Housing respond to IR

commands and execute the software and protocol for the different pressure measurement types.

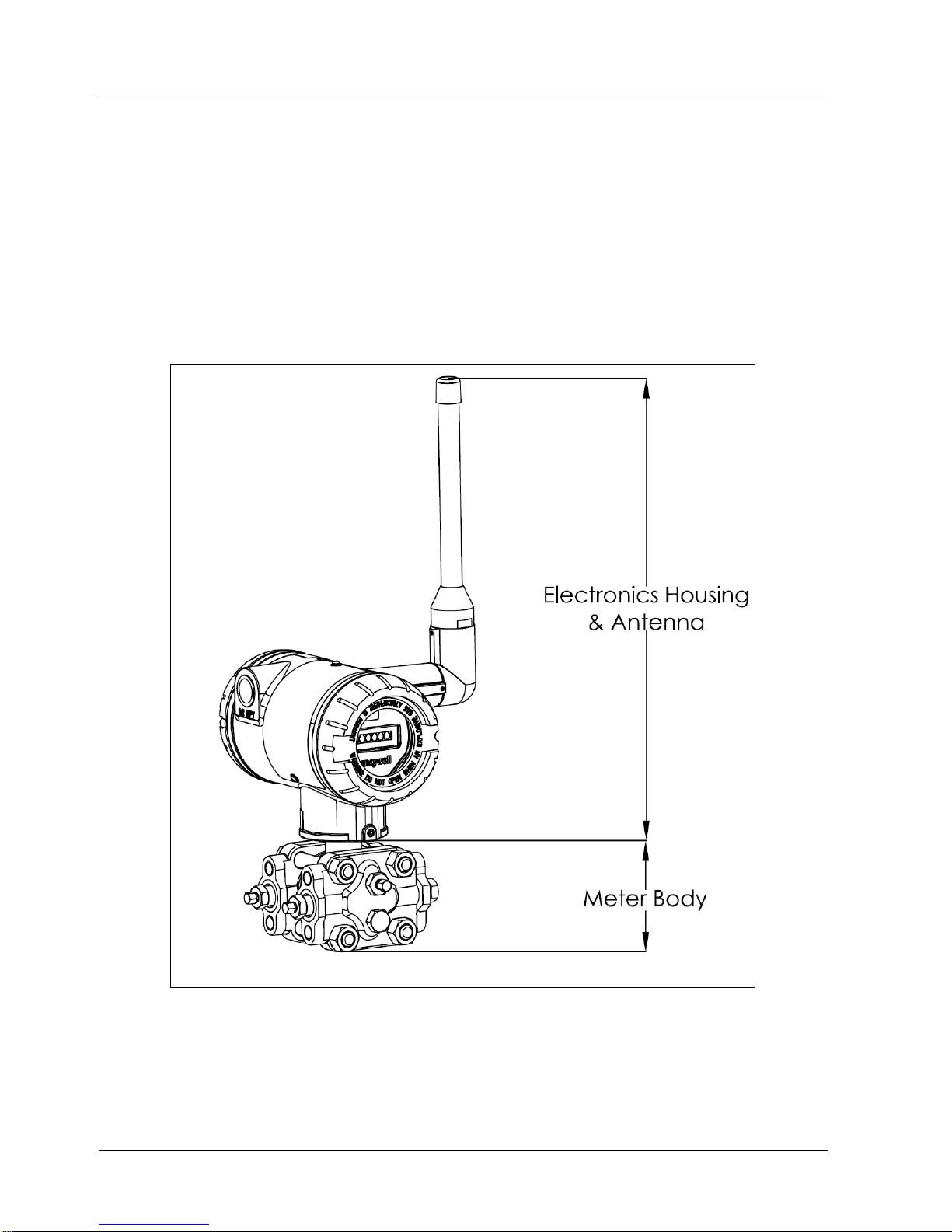

Figure 1-3 shows the assemblies in the Electronics Housing.

The meter body provides connection to a process system. Several physical interface configurations are

available, as determined by the mounting and mechanical connections, all of which are described in the

Installation section of this manual.

Figure 1-2 – SmartLine Wireless Transmitter Major Assemblies

1. Introduction

1.7. Physical Characteristics

Revision 2 SmartLine Wireles User's Manual 5

Figure 1-3– SmartLine Wireless Transmitter Electronics Housing Components

2. Preparation and Quick Start

2.1. Introduction

6 SmartLine Wireless User's Manual Revision 2

2. Preparation and Quick Start

2.1 Introduction

This section is useful if you are unfamiliar with the SmartLine Wireless transmitter, want a quick

start list, or if you want to configure and test your transmitter in an office environment before

installing it in its final location.

2.2 Set up the Network

Refer to the One Wireless Device Manager User Guide and Field Device Access Point User

Guide to setup the gateway, wireless device manager (WDM) and the access points (FDAP).

See References.

Ensure you have access to the WDM through the browser interface.

2.3 Transmitter Quick Start

1. INSTALL. If desired, mount or install the transmitter. If setting up in an office environment

for test, place the transmitter securely on a work surface.

2. ANTENNA. The transmitter can be supplied with an integral 4dBi antenna. If the transmitter

is equipped with a remote mount antenna connection, connect the antenna with a RF cable.

The transmitter remote mount and antennas utilize N-type connectors.

3. POWER up the transmitter.

Remove the end cap, opposite the LCD display, to connect power. Ensure the internal power

cable is connected to the battery pack or 24V supply module as applicable.

a. Battery Operated transmitters require two 3.6 V D-Size lithium thionyl chloride

batteries. See section 4.1 for specific battery requirements.

b. Line powered transmitters with the power supply option require 24V DC connected

to the input connector P3. See section 4.2 for details.

Once powered, verify that the transmitter LCD is functioning. If the LCD is blank, check the

power connections, and batteries as applicable.

4. PROVISION the transmitter to the network

a. Over The Air (OTA) provisioning can be done using the WDM interface.

i. Enable OTA provisioning on the access point closest to the transmitter.

On the WDM interface, select the access point, then on the property panel

expand and “Device Management” and under Over the Air Provisioning

press “Enable for 60 Minutes”

ii. Select the transmitter in the selection panel

iii. Press the provisioning green “Accept” check mark button

b. Handheld provisioning can be done through the IR port with a Handheld Provisioning

Device such as MCT404

2. Preparation and Quick Start

2.3. Transmitter Quick Start

Revision 2 SmartLine Wireles User's Manual 7

See section 4.5 for further provisioning details. This step may take several minutes,

depending on your network.

5. VERIFY that the transmitter appears in the wireless network, and is transmitting PVs. This

step may take several minutes, depending on your network.

a. Drag the transmitter icon from the selection panel to the map (optional)

b. Load the DD file (if not done previously)

i. Select the transmitter.

ii. Press the maintenance “Templates” button.

iii. Press “Load DD File”, and select the DD .zip file.

iv. Refresh the browser to re-load the WDM web interface. This will require to

log in again.

c. Activate the channel

i. Select the transmitter channel to activate

ii. Press the Channel green “Activate” button

d. Configure the transmitter as desired using the property panel

i. Tag Name, Description, Display Tag, Routing assignment, Publication

frequency, Publication attributes, etc.

ii. Ensure the press “Apply” after the changes, and wait for the changes to take

effect.

e. Configure the channel as desired using the property panel.

i. Name, Description, Process limits, Process Scale, etc.

ii. Ensure to press “Apply” after the changes, and wait for the changes to take

effect.

6. INSTALL. If not done already, once the transmitter is verified to be functioning as expected,

it can be powered off and installed in the field. The provisioning key will remain.

7. CALIBRATE. If required, calibration should only be done after the transmitter is installed in

its final location. See section 4.6.

3. Installation

3.1. Installation Site Evaluation

8 SmartLine Wireless User's Manual Revision 2

3. Installation

3.1 Installation Site Evaluation

Evaluate the site selected for the SmartLine Wireless Transmitter installation with respect to the

process system design specifications and Honeywell’s published performance characteristics for

your particular model. Some parameters that you may want to include in your site evaluation are:

Environmental Conditions:

o Ambient Temperature

o Relative Humidity

Potential Noise Sources:

o Radio Frequency Interference (RFI)

o Electromagnetic Interference (EMI)

Vibration Sources

o Pumps

o Motorized System Devices (e.g., pumps)

o Valve Cavitation

Process Parameters

o Temperature

o Maximum Pressure Rating

3.2 Maximum Working Pressure:

Refer to the applicable specification sheets in References

3.3 Environmental Conditions:

Refer to the specification sheet for performance considerations, see References

The transmitter operates with an ambient temperature of -40 oC to +85 oC. If installed in a

hazardous environment, the maximum ambient temperature may be limited. Refer to the control

drawing and the markings on the transmitter nameplate.

The process fluid temperature at the meter body operates from -40 oC to +125 oC.

Ambient humidity limits are 0 to 100% relative humidity.

The transmitter may be installed indoors or outdoors, with pollution degree 4. The enclosure is

rated Type 4X, IP66 / IP67.

The transmitter operates up to an altitude of 2,000 m.

Entry plugs/glands rated for the installation environment are required to be installed on the

transmitter.

3. Installation

3.4. Transmitter Weights and Dimensions

Revision 2 SmartLine Wireles User's Manual 9

3.4 Transmitter Weights and Dimensions

Weights

Table 3-1: Weights

Transmitter

Model

Weight

STDW7xx

STDW8xx

STGW7x0

STGW8x0

STRW7xD

STRW8xD

11 lbs (5 kg)

STAW7xL

STAW8xL

STRW7xA

STRW8xA

STRW7xG

STRW8xG

STGW7xL

STGW8xL

7 lbs (3.2 kg)

STFW7xF

STFW8xF

17 lbs (7.7 kg) for 2” 150# flanged head

21 lbs (9.5 kg) for 3” 150# flanged head

STFW7xx

STFW8xx

23 to 36 lbs (10.5 kg to 16.4 kg) depending on flange size

Note: Add 8.0 pounds (3.6 kg) to any model equipped with the stainless-steel housing option

(Model Selection Guide Table IV selections M or N)

For Flange and Remote Seal transmitter dimensions, obtain appropriate installation drawing

using Installation drawing number tables in section 3, as a guide.

3. Installation

3.4. Transmitter Weights and Dimensions

10 SmartLine Wireless User's Manual Revision 2

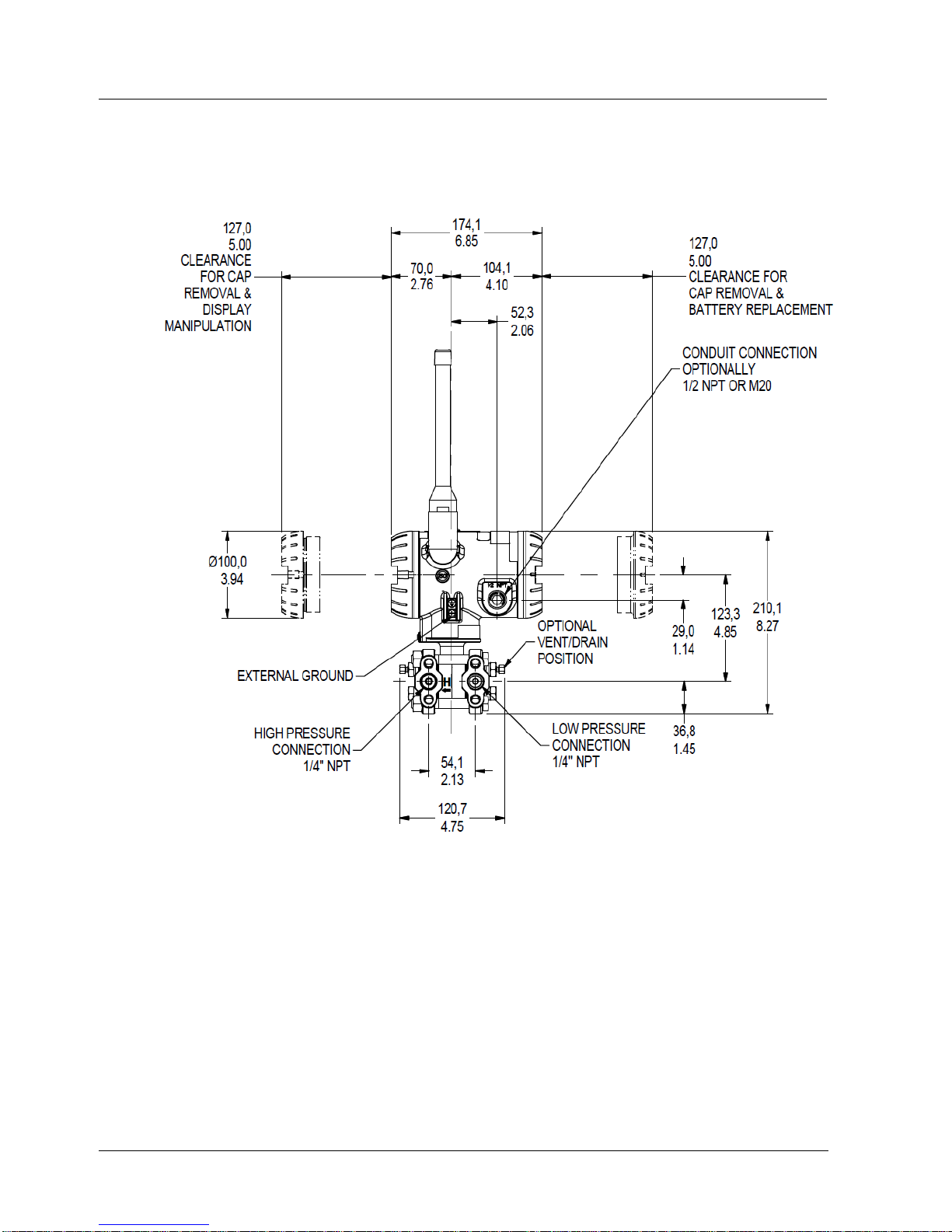

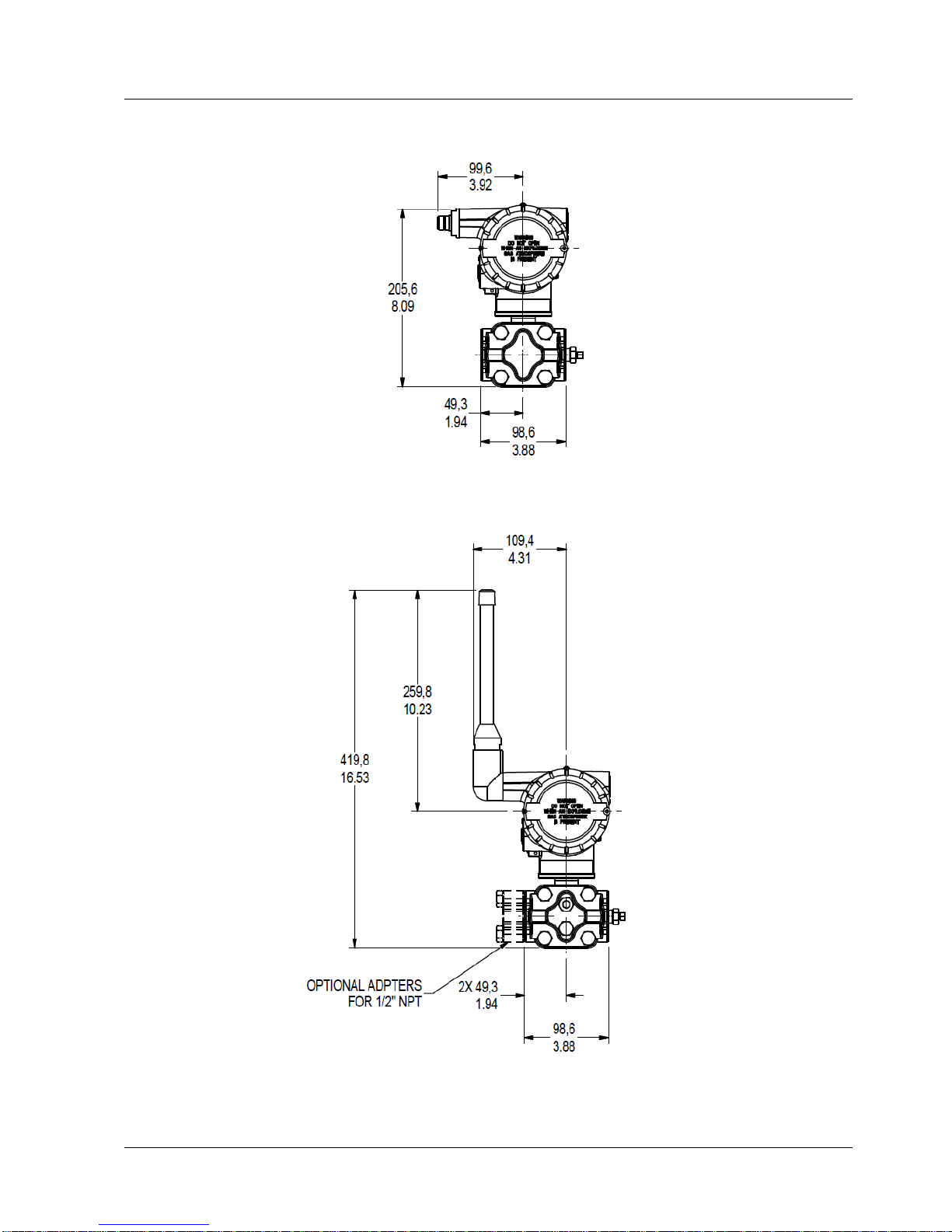

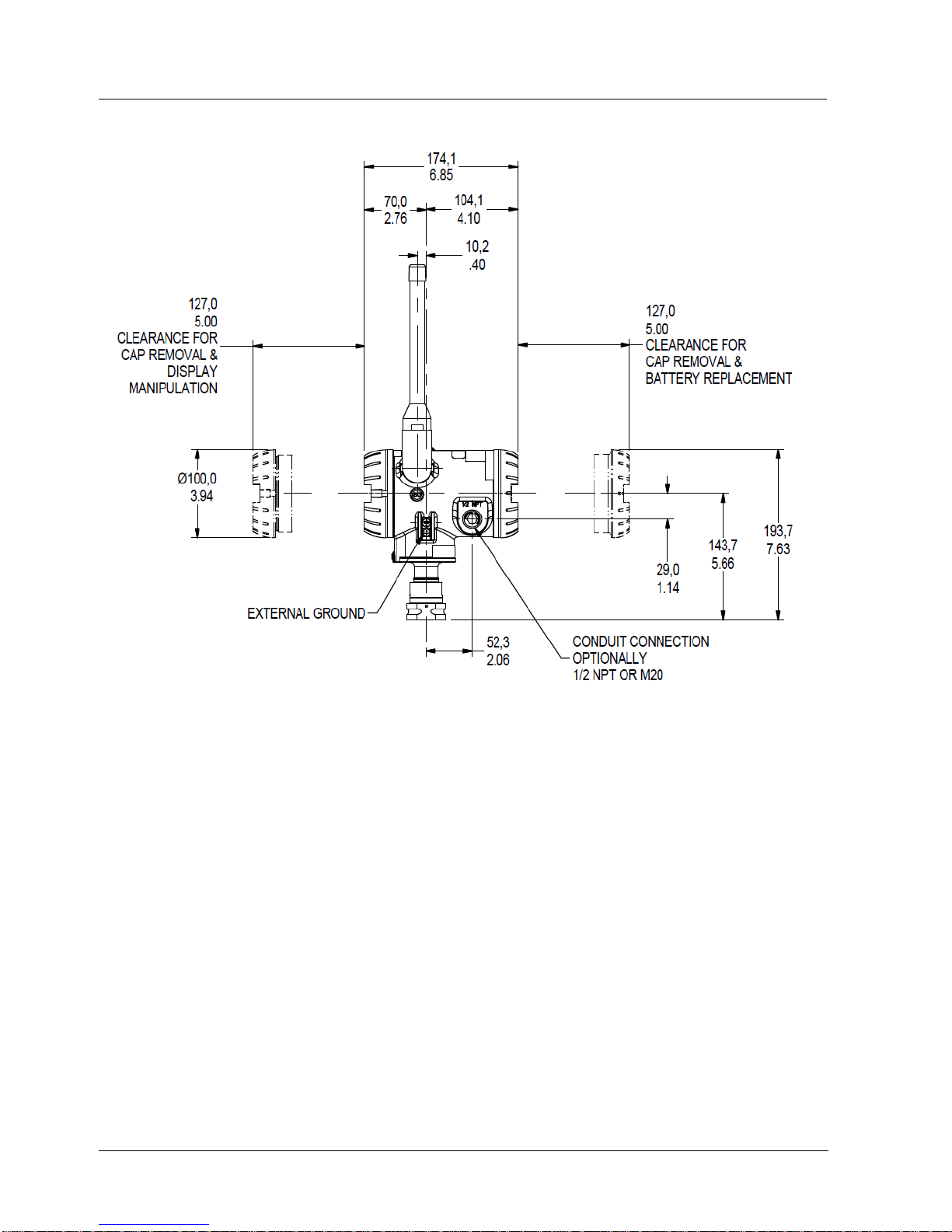

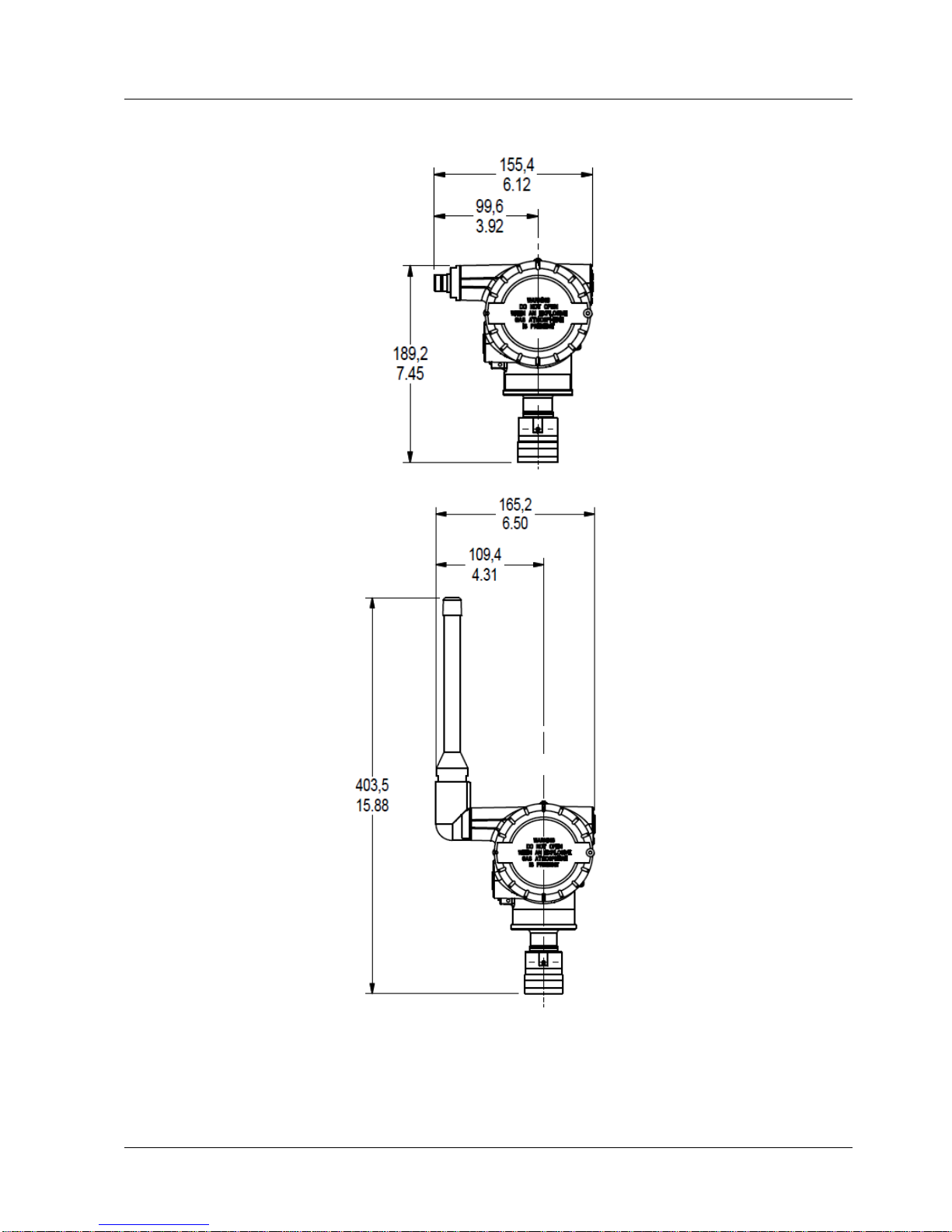

Dimensions

Figure 3-1: DP/DHGP Pressure transmitter dimensions unit mm/inch

3. Installation

3.4. Transmitter Weights and Dimensions

Revision 2 SmartLine Wireles User's Manual 11

Figure 3-2: DP/DHGP Pressure antenna dimensions unit mm/inch

3. Installation

3.4. Transmitter Weights and Dimensions

12 SmartLine Wireless User's Manual Revision 2

Figure 3-3: GP/AP Pressure transmitter dimensions unit mm/inch

3. Installation

3.4. Transmitter Weights and Dimensions

Revision 2 SmartLine Wireles User's Manual 13

Figure 3-4: GP/AP Pressure antenna dimensions unit mm/inch

3. Installation

3.5. Installation drawing number tables

14 SmartLine Wireless User's Manual Revision 2

3.5 Installation drawing number tables

If an installation drawing from the table below is required, please contact your local Honeywell

representative. Refer to Honeywell drawing numbers in Table 3-2 for detailed dimensions.

Abbreviated overall dimensions are also shown on the Specification Sheets for the transmitter

models, see References

This section assumes that the mounting dimensions have already been taken into account and the

mounting area can accommodate the Transmitter.

Table 3-2: Drawing numbers for pressure transmitters

DRAWING

DRAWING

NUMBER

INSTALLATION DRAWING STW700/800 PRESSURE, DP, SMV, DHGP, AND

DHAP

50136136

INSTALLATION DRAWING STW700/800 PRESSURE, INLINE (LAP AND LGP)

50136137

INSTALLATION DRAWING STW700/800 PRESSURE PSEUDO FLANGE

50136138

INSTALLATION DRAWING STW700/800 PRESSURE EXTENDED AND

FLUSH FLANGE

50136139

INSTALLATION DRAWING STW700/800 PRESSURE DP, DHGP AND DHAP

REMOTE SEAL

50136140

INSTALLATION DRAWING STW700/800 PRESSURE INLINE (LGP AND LAP)

REMOTE SEAL

50136141

INSTALLATION DRAWING STW700/800 PRESSURE PULP AND PAPER

50136142

INSTALLATION INSTRUCTIONS STW700/800 PRESSURE ANGLE

MOUNTING BRACKET

50136143

INSTALLATION INSTRUCTIONS STW700/800 PRESSURE FLAT MOUNTING

BRACKET

50136144

3. Installation

3.6. Conduit / Cable Entries

Revision 2 SmartLine Wireles User's Manual 15

3.6 Conduit / Cable Entries

NOTICE

THIS PRODUCT IS SUPPLIED WITH PLASTIC DUST PLUGS IN THE

CONDUIT/CABLE GLAND ENTRIES. IT IS THE USERS

RESPONSIBILITY TO PROVIDE CABLE GLANDS, ADAPTORS AND/OR

BLANKING PLUGS SUITABLE FOR THE ENVIRONMENT IN WHICH THIS

PRODUCT IS INSTALLED. WHEN INSTALLED IN A HAZARDOUS

LOCATION THE CABLE GLANDS, ADAPTORS AND/OR BLANKING

PLUGS SHALL ADDITIONALLY BE SUITABLE FOR THE HAZARDOUS

LOCATION, THE PRODUCT CERTIFICATION AND ACCEPTABLE TO

THE AUTHORITY HAVING JURISDICTION FOR THE INSTALLATION

Summary

Table 3-3: Conduit entry plugs and cable glands for your transmitter.

Factory Part

No.

Description

Environmental

rating

Ambient

Hazardous Location

Certification

50000547-001

M20 Conduit

Plug

IP66-68, 4X,

6P

–40 – 85ºC

–40 – 185ºF

ATEX EEx de IIC

50021832-002

½ NPT Conduit

Plug

IP66-68, 4/4X,

6/6P

–40 – 85ºC

–40 – 185ºF

ATEX EEx d IIC;

CSAcus CL I, Zone 1, Ex/AEx d

IIC; CL I, Div 1 & 2, GP ABCD;

CL II, Div 1 & 2, GP EFG; CL III,

Div 1 & 2

50023232-001

M20 Cable

Gland

IP68

–40 – 100ºC

–40 – 212ºF

-----------------------------------

50023212-001

½ NPT Cable

Gland

IP68

–40 – 100ºC

–40 – 212ºF

-----------------------------------

Note: Torque conduit entry plugs, cable glands, or adapters to 32 Nm (24 lb-ft).

3. Installation

3.7. Mounting Summary

16 SmartLine Wireless User's Manual Revision 2

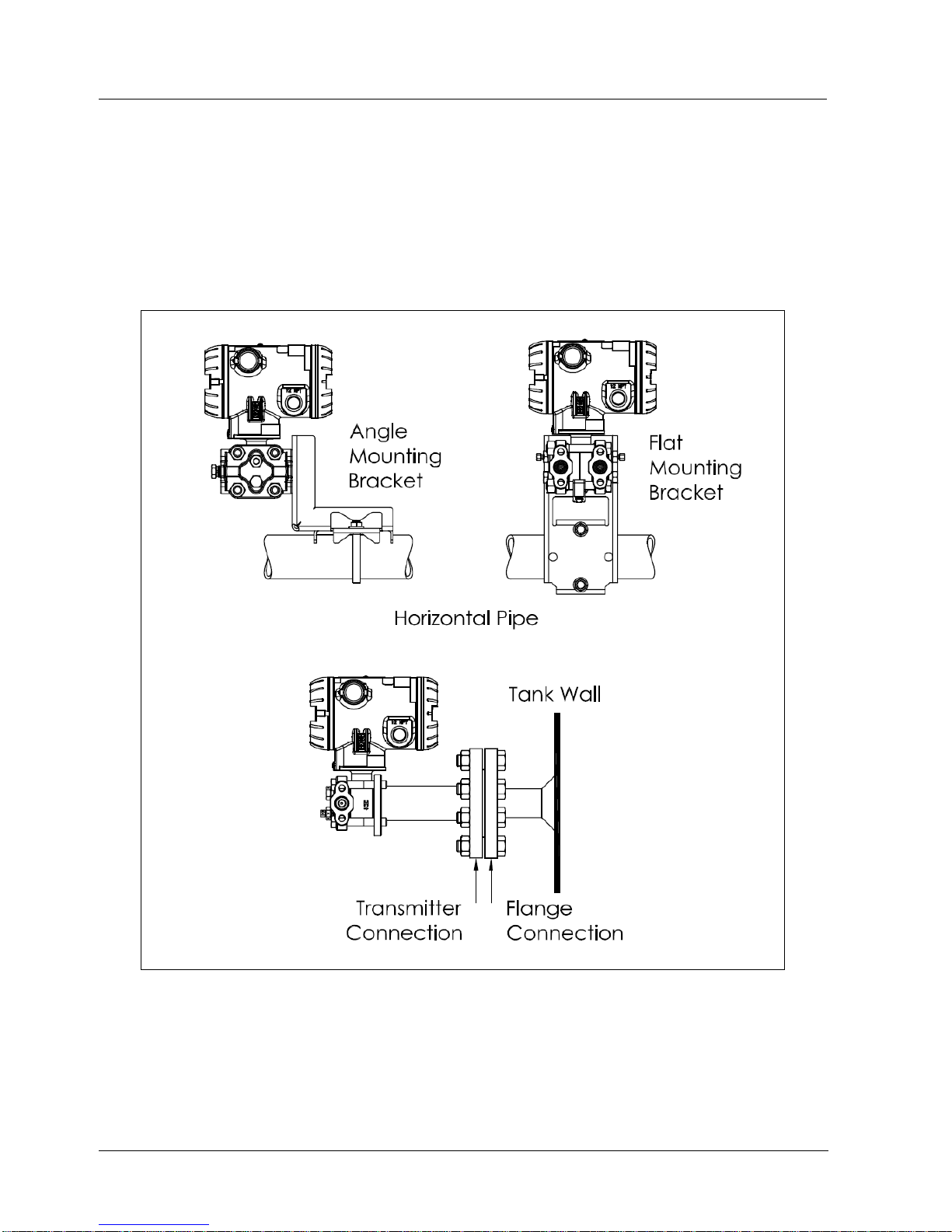

3.7 Mounting Summary

Transmitter models, except those with integral flanges, can be attached to a two-inch (50 millimeter)

vertical or horizontal pipe using Honeywell’s optional angle or flat mounting bracket; alternately you can

use your own bracket. Models with integral flanges are supported by the flange connection.

Figure 3-5 shows typical bracket-mounted and flange-mounted transmitter installations.

Figure 3-5: Typical Bracket Mounted and Flange Mounted Installations

Loading...

Loading...