Honeywell SiXC2W Installation Manual

SiXC2W Convert to Wireless / Convert to Wireless

Quick Installation Guide

Guide d'installation rapide

The Honeywell SiXC2W is an eight zone hardwire t o wireless converter used with

controllers that support Honeywell’s SiX™ series devices. It is useful in retrofit 12volt security syste m applications where existing contact wiring was used. It uses

those existing wired contacts and convert s them to wireless.

FEATURES

• Provides 12-volts for devices such as motion detectors, glass breaks, etc.

NOTE: Only two devices may be powered using the auxiliary output on the

SiXC2W.

• Provides 24-hour battery backup (4-hour if external devices are connected).

NOTE: It immediately sends a power lo ss signal to the controller in the event

the power is lost.

• When no battery is connected, low battery message wil l send to control

panel.

When battery is connected, and if battery voltage drops below 3.6VDC, a low

battery message sends to the control panel.

When only the battery is connected, and if t he battery voltage 3.4 V, system

will shut down.

• Support one button calibration

• Automatic zone configuration

• Easy setup in three steps

• Cover tamper protection

IMPORTANT!

Not to be used for fire, heat, or carbon monoxide detectors.

The Honeywell SiXC2W is an eight zone hardwire t o wireless converter used with

controllers that support Honeywell’s SiX™ series devices. It is useful in retrofit 12-volt

security system applicat ions where existing contact wiring was used. It uses t hose

existing wired contacts and converts them to wireless

CARACTÉRISTIQUES

• Provides 12-volts for devices such as motion detectors, glass breaks, etc.

NOTE: Only two devices may be powered using the auxiliary output on the SiXC2W.

• Provides 24-hour battery backup. (4-hour if external devices are connected). NOTE:

It immediately sends a power loss signal to the controller in the event the power is

lost.

• When no battery is connected, low battery message will send to control pane l.

When battery is connected, and if battery voltage drops below 3.6VDC, a low battery

message sends to the control panel.

When only the battery is connected, and if the battery voltage 3.4 V, system will shut

down.

• Support one button calibration

• Automatic zone configuration

• Easy setup in three steps

• Cover tamper protection

IMPORTANT!

Not to be used for fire, heat, or carbon monoxide detectors.

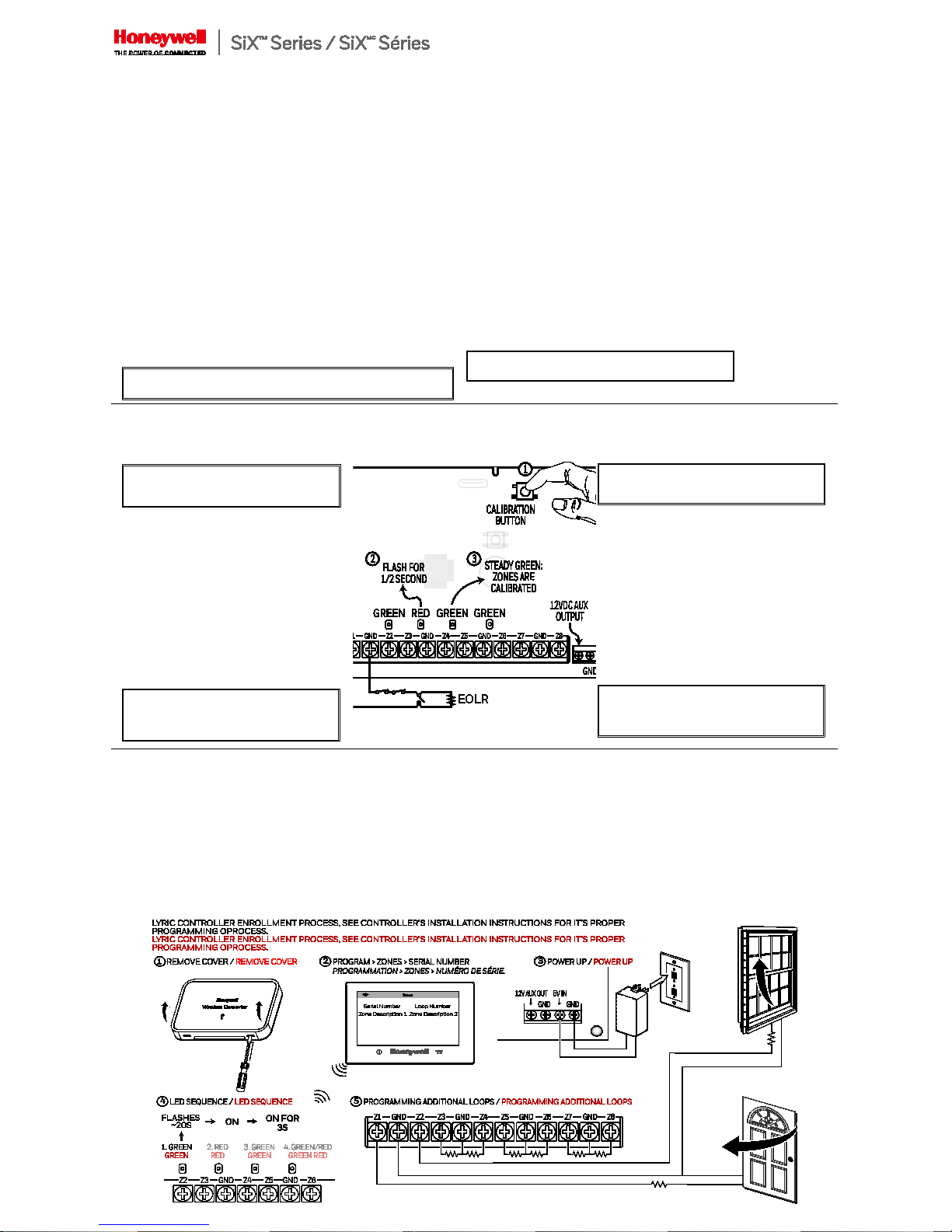

CALIBRATING CALIBRATING

The calibration process enables the SiXC2W to learn

what zones are to be active and what value EO L resistors

are used.

IMPORTANT!

Unused zones that are open ARE NOT

recognized and reported.

1. Ensure all zones are connecte d and not faulted.

2. On the SiXC2W, press and release the to p middle

button.

3. Indicator LED #2 will flash Red for 1 /2 second; then

LED #3 turns steady Green.

4. Calibration is in process

5. DONE. The SiXC2W is calibrated and ready to enro ll

in the control panel.

NOTES:

• If the SiXC2W loses both AC and battery backup

power, the zone calibration data is ret ained.

• If there is an existing resis tor, it MUST have a value

between 1K and 10K.The unit comes with eight (8)

2.2K resistors for zones that don’t have one.

IMPORTANT!

Once the SiXC2W is calibrate, any change in

the zone resistance the module must be

re-calibrated.

The calibration process enables the SiXC2W to learn

what zones are to be active and what value EO L

resistors are used.

IMPORTANT!

Unused zones that are open ARE NOT

recognized and reported

1. Ensure all zones are connecte d and not faulted.

2. On the SiXC2W, press and release the t op middle

button.

3. Indicator LED #2 will flash Red for 1 /2 second;

then LED #3 turns steady Green.

4. Calibration is in process

5. DONE. The SiXC2W is calibrated and ready to

enroll in the control panel .

NOTES:

• If the SiXC2W loses both AC and battery backup

power, the zone calibration data is ret ained.

• If there is an existing re sistor, it MUST have a value

between 1K and 10K.The unit comes with eight (8)

2.2K resistors for zones that don’t have one.

IMPORTANT!

Once the SiXC2W is calibrate, any change in the

zone resistance the module must be

re-calibrated.

ENROLLING / ENROLLING

Lyric Control

Lyric Controller Enrollment Process, See Controller’s installation instructions for its

proper programming process.

For Lyric Gateway

Use AlarmNet 360™ to enroll and program this sensor.

For Other Controls

For other controls that support SiX series device s, see the controller’s installation app for

details

NOTE: Once enrolled in a system, the SiXC2W cannot be used with another co ntroller

until it is removed from the current controller. See the Controller’s instructions

for details.

Lyric Control

Lyric Controller Enrollment Process, See Controller’s installation instructions for it’s

proper programming process.

For Lyric Gateway

Use AlarmNet 360™ to enroll and program this sensor.

For Other Controls

For other controls that support SiX series device s, see the controller’s installation app for

details

NOTE: Once enrolled in a system, the SiXC2W cannot be used with another co ntroller

until it is removed from the current controller. See the Controller’s instructions

for details.

2018 Honeywell International Inc. Honeywell and is a registered

trademark of Honeywell International Inc.

All other trademar ks are the properties of their respective owners. All

rights reserved.

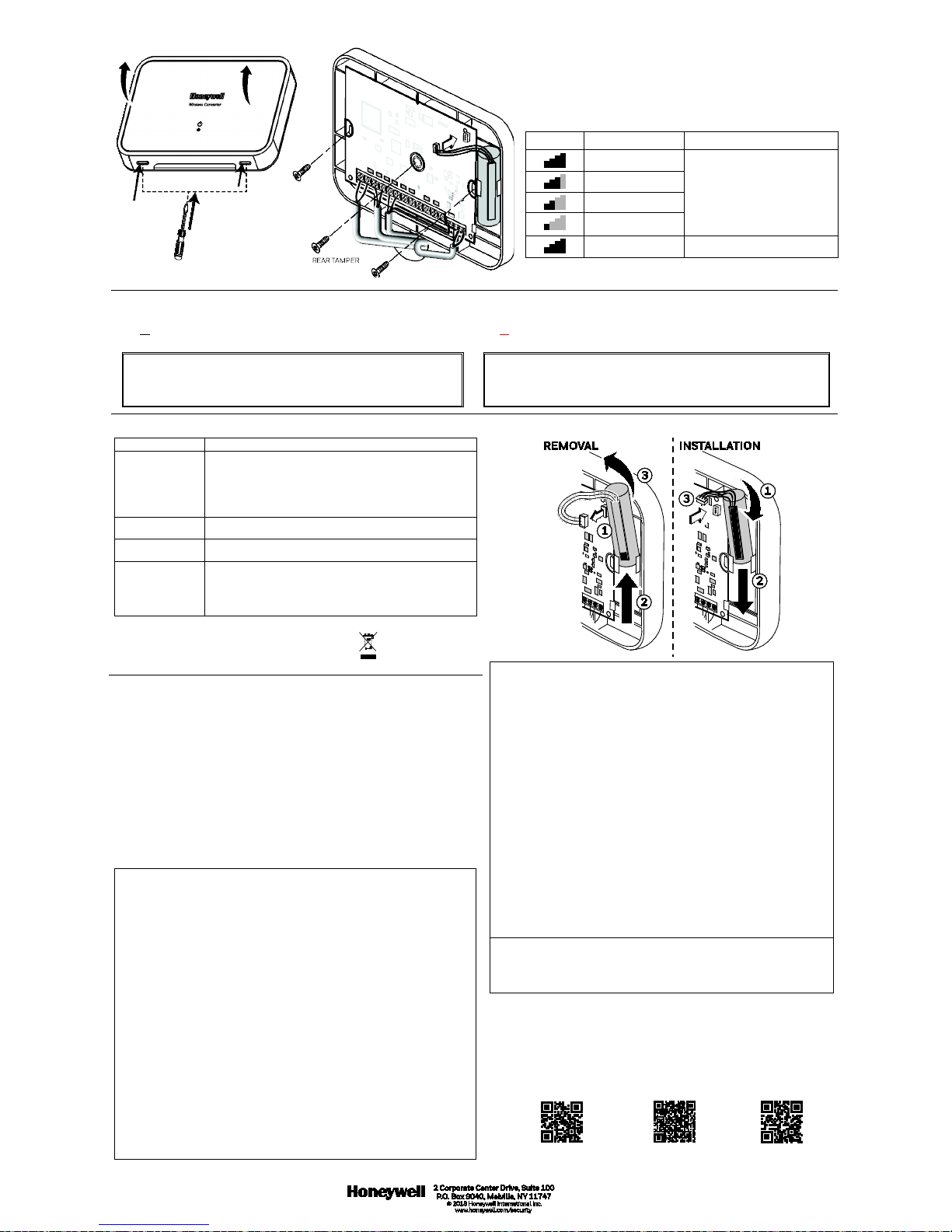

MOUNTING / MONTAGE

Signal strength:

• Rang of 1-4 bars (green), should be a minimum 1 green bar for

the zone being programmed.

• Four Red Bards indicate poor signal strength; the device should

be relocated.

• See the controller’s instruction for bar indication signal

strength values.

Icon Description Signal Strength

4 Green Bars

Good

3 Green Bars

2 Green Bars

1 Green Bar

4 Red Bars Relocate

TAMPER/LOW BATTERY REPORTING TAMPER/LOW BATTERY REPORTING

The SiXC2W reports this condition to the control. If a low battery or tamper condition

exists all zones used on the module shows a trouble on the control.

IMPORTANT:

The first battery test occurs 1 hour after power up. To quickly verify a good

backup battery, unplug and then plug back in the power supply; the system

will perform a battery test within 1 minute.

The SiXC2W reports this condition to the control. If a low battery or tamper condition

exists all zones used on the module shows a trouble on the control.

IMPORTANT:

The first battery test occurs 1 hour after power up. To quickly verify a good

backup battery, unplug and t hen plug back in the power supply; the system will

perform a battery test within 1 minute.

LED INDICATIONS

LED # / LED #

Functions / Functions

1 (Green / Green) Blinks once upon RF signal transmission ( HW zone

trigger/tamper and/or a fault me ssage), slow blink for a cover

tamper, quick blinks for enrollment or deletion / Blinks once

upon RF signal transmission (HW zone t rigger/tamper and/or a

fault message), slow blink for a cover tamper, quick blinks for

enrollment or deletion

2 (Red / Red)

Blinks 1s / 1s off when module needs cal ibrating / Blinks 1s /

1s off when module needs calibrating

3 (Green / Green)

Steady on when the module has been calibrate d. / Steady on

when the module has been calibrated.

4 (Green and Red /

Green and Red)

Green: 5VDC Power from the plug-in transformer is present

Red (blinking 1sec on / 1 sec off): Running on battery, DC

power not present. / Green: 5VDC Power from the plug-in

transformer is present Red (blinking 1sec on / 1 sec off):

Running on battery, DC power not present .

Approval Listings / Approbation s Homologations:

FCC / IC - ETL Listed to UL268 & 521

cETL Listed to ULC S530 & S531

Other Standards / Autres normes : RoHS

BATTERY REMOVAL AND INSTALLATION

Caution:

The batteries used in this device may present a fir e or chemical burn

hazard if mistreated. Do not rechar ge, disassemble, heat above 212°F

(100°C) or dispose of in fire. Use Panasonic CR123A or DURACELL DL123,

DL 123A Lithium batteries. Use of other batteries may present a risk of fire or

explosion. Keep used batteries away from children. Dispose of used batteries

properly.

Remove old batteries. Wait 10 s econds and then replace with four new

batteries. To avoid a low battery indication when installing new batteries, both

batteries must be installed within 15 se conds of installing the first one. Any

low battery condition that may have occu rred should clear when the back

plate is installed.

Mise en garde : Les piles utilis ées dans ce dispositif peuvent présenter des

risques d'incendie ou de br ûlure chimique si elles sont mal traitées. Ne

rechargez pas, ne désassemblez pas, ne faites pas chauffer et ne jet ez pas au

feu les piles à plus de 100 °C (212 °F). Utilisez des piles au lithium

Panasonic CR123A ou DURACELL DL123, DL 123A. L'utilisation d'autres

types de piles peut présenter des risques de feu ou d'explosion. Gardez les

vieilles piles hors de la portée des enfants. Débarrassez-vous des batteries

utilisées de façon appropriée.

Retirez les vieilles piles. Attendez 10 secondes et remplacer-les par quatre

nouvelles piles. Pour éviter une indication de piles faibles lorsque vous

installez de nouvelles piles, les dos (2) piles doivent être installées en deçà de

15 secondes après l'installation de la première. Toute condition de pilles

faibles qui aurait pu se pro duire devrait être rétablie une fois la plaque arrière

installée.

REFER TO THE INSTALLATION INSTRUCTIONS FOR THE CONTROL WITH

WHICH THIS DEVICE IS USED, FOR DETAILS REGARDING LIMITATIONS OF

THE ENTIRE ALARM SYSTEM.

POUR LES LIMITES DU SYSTÈME D’ALARME AU COMPLET, REPORTEZ-

VOUS AU GUIDE D’INSTALLATION DU PANNEAU DE COMMANDE

See Honeywell Installation Guide P/N

800-24139–

https://mywebtech.honeywell.com/.

Voir les instructions d'installation

complètes 800-24139-

https://mywebtech.honeywell.co m/.

Support / Pour de l’assistance e n ligne, visitez :

https://mywebtech.honeywell.com/

U.S. warranty / U.S. garantie: www.ho neywell.com/security/hsc/resources /wa

For patent info, see: / Pour des informations sur les brevets, voir :

www.honeywell.com/pate nts

MyWebTech

Warranty / Garantie

Patents / brevets

FEDERAL COMMUNICATIONS COMMISSION & INDUSTRY CANADA

STATEMENTS

The user shall not make any changes or modifications to the equipment unless

authorized by the Installation Inst ructions or User's Manual. Unauthorized changes

or modifications could void the user's authority to operate the equipment.

FCC / IC STATEMENT This device complies with Part 15 of the FCC Rules, and

Industry Canada’s license-exempt RSSs. Operation is subject to the following two

conditions: (1) This device may not cause harmf ul interference, and (2) This device

must accept any interference rece ived, including interference that may cause

undesired operation.

Cet appareil est conforme à la part ie 15 des règles de la FCC et exempt de licence

RSS d’Industrie Canada. Son fonctionnement es t soumis aux conditions suivantes:

(1) Cet appareil ne doit pas causer d’inter férences nuisibles. (2) Cet appareil doit

accepter toute interférence reçue y compris les interférences causant une

réception indésirable.

SPECIFICATIONS / SPÉCIFICATIONS:

Voltage

Transformer Part # ................................... 300-10259

Input Voltage ............................................... 100 ~ 240VAC, 50 ~60 Hz

Operating Voltage ..................................... 5VDC

Maximum Transformer Distance ...... 9.8ft. (3m)

Voltage Output ........................................... 12VDC @ 100mA (Up to three sets of 20–24

gauge wiring)

Battery/ Pile ................................................. P/N 300-10342

Environmental

Operating Temp ......................................... 14

F (-10C) to 140F (60C)

NOTE: Charging the lithium battery stops

when temperature is below 32F

(0C)

Relative Humidity ...................................... 95%, Non-condensing / 95% max. sans

condensation

Physical

Dimensions .................................................. Length 7.0 in (178 mm) x

Width 4.5 in (114 mm) x

Depth 1.5 in (38mm)

Mounting Hardware ................................. Double stick tape and screws

Zone Resistance ......................................... 1K to 10K Ohm EOL Resistors

Zone Wiring .................................................. 1,000ft (Each Zone)

Radio Frequency

Transmission Range ................................ 300ft (91.5m)

Loading...

Loading...