Guide to Operation

Satellite XT R Version

Including Options:

Extractive Module XT

Pyrolyzer Module XT

Satellite XT R Version

toc-1

Table of Contents

Section 1 Basic Operation Page

1.1.............. Principle of Operation .................................................................................1-1

1.2............... Operating States ....................................................................................... 1-1

1.2.1 ............ Monitoring Mode ........................................................................................ 1-1

1.2.2 ............ Maintenance Mode ..................................................................................... 1-2

1.2.3 ............ Warning Condition ...................................................................................... 1-2

1.2.4 ............ Diagnostics ................................................................................................. 1-2

1.3............... Menu structure............................................................................................ 1-2

1.3.1 ............ Maintenance Menu ..................................................................................... 1-2

1.3.2 ............ Calibration Menu......................................................................................... 1-2

1.3.3 ............ Conguration Menu .................................................................................... 1-2

1.4............... Operational Elements ................................................................................. 1-3

1.4.1 ............ Keypad Functions....................................................................................... 1-3

1.4.2 ............ Graphic Display .......................................................................................... 1-3

1.5............... Technical Specications ............................................................................. 1-4

Section 2 Installation and Start-up

2.1............... General Guidelines..................................................................................... 2-1

2.2............... Standard Mounting ..................................................................................... 2-1

2.3............... Duct Mounting............................................................................................. 2-3

2.3.1 ............ Connecting the Sensor Extension to the Instrument .................................. 2-3

2.3.2 ............ Mounting the Sensor Extension to the Duct ............................................... 2-4

2.4............... Wiring.......................................................................................................... 2-5

2.5............... Initial Start-Up ............................................................................................. 2-7

Section 3 Main Menu

3.1............... The Main Menu Screens............................................................................. 3-1

3.2............... Main Menu - Monitoring.............................................................................. 3-2

3.3............... Main Menu - Maintenance .......................................................................... 3-3

3.4............... Main Menu - Calibration.............................................................................. 3-4

3.5............... Main Menu - Conguration ......................................................................... 3-5

Section 4 Mantenimiento

4.1............... Sensor Service ........................................................................................... 4-3

4.2............... Alarm Reset................................................................................................ 4-4

4.3............... Alarm/Warn Test......................................................................................... 4-4

4.4............... Device Infos ................................................................................................ 4-5

4.5............... Sensor Infos................................................................................................ 4-6

4.6............... Reset Device .............................................................................................. 4-8

4.7............... Service........................................................................................................ 4-8

Section 5 Calibration

5.1.............. Gas Calibration ........................................................................................... 5-2

5.1.1 ............ Zero Adjust ................................................................................................. 5-2

5.1.2 ............ Span Adjust ................................................................................................ 5-3

5.2............... Manual K-Factor ......................................................................................... 5-4

Satellite XT R Version

Section 6 Conguration Page

6.1............... Alarm Settings ............................................................................................6-3

6.1.1 ............ Alarm 1 .......................................................................................................6-4

6.1.2 ............ Alarm 2 .......................................................................................................6-7

6.2............... Language....................................................................................................6-8

6.3............... Date Format................................................................................................6-8

6.4............... Auto Selftest .............................................................................................. 6-9

6.5............... Security........................................................................................................6-9

6.6............... Password................................................................................................... 6-10

6.7............... Location ..................................................................................................... 6-10

6.8............... New Sensor Type ...................................................................................... 6-11

6.9............... Gas Name.................................................................................................. 6-11

6.10............. Relays........................................................................................................ 6-12

Section 7 Troubleshooting

7.1............... Warning and Fault Messages...................................................................... 7-1

7.1.1 ............ Warnings......................................................................................................7-1

7.1.2 ............ Faults ..........................................................................................................7-2

Section 8 Reference Information

8.1............... Sensor Order Information ........................................................................... 8-1

8.2............... Spares and Accessories............................................................................. 8-3

Section 9 Extractive Module XT - Option

9.1............... Principle of Operation ................................................................................. 9-1

9.2............... General Instructions.................................................................................... 9-1

9.3............... Safety Instructions ...................................................................................... 9-1

9.4............... Instrument Design....................................................................................... 9-2

9.5............... Mounting..................................................................................................... 9-4

9.6............... Tubing Connections.................................................................................... 9-4

9.7............... Sensor Replacement .................................................................................. 9-5

9.8............... Technical Specications ............................................................................. 9-6

Section 10 Pyrolyzer Module XT - Option

10.1............. Principle of Operation ............................................................................... 10-1

10.2............. General Instructions................................................................................... 10-1

10.3............. Safety Instructions ..................................................................................... 10-1

10.4............. Instrument Design...................................................................................... 10-2

10.5............. Mounting.................................................................................................... 10-3

10.6............. Tubing Connections................................................................................... 10-4

10.7............. Data Link.................................................................................................... 10-4

10.8............. Power Connection ..................................................................................... 10-4

10.9............. Technical specications............................................................................. 10-5

Table of Contents

toc-2

Satellite XT R Version

This section provides a basic understanding of the instrument and its operation.

1.1 Principle of Operation

The Satellite XT R Version is a generic gas monitoring instrument for the detection of a wide

range of hazardous gases. Power is supplied by a local 12 to 24 VDC power supply.

Target gas and measuring range depend on the type of sensor chosen. The sensor comes with

the specic data in its internal data memory.

The Satellite XT R Version provides 3 single-pole single-throw relays for activation of external

alarm devices. If the gas concentration exceeds the alarm levels, the instrument will activate

the appropriate alarm relay and display an according message. A relay will also be activated in

case of an instrument fault.

1.2 Operating States

There are four different operating states for the Satellite XT, Monitoring Mode, Maintenance

Mode, Warning Condition, and Diagnostics. Depending on the selected operating state, the

green status LED is either on, off, or ashing.

1.2.1 Monitoring Mode

The Monitoring Mode is the instrument’s standard operating mode. In the Monitoring Mode,

the instrument continuously monitors for hazardous gas concentrations and checks for alarm

levels and instrument faults.

The instrument’s self-diagnostics provides on-line preventive maintenance information

identifying electronics or sensor problems, e.g. a sensor selftest is performed every 24 hours.

The green LED located above the <set> key is on.

The settings for Alarm Level 1 and Alarm Level 2 are automatically loaded when installing the

sensor. Standard settings are 1x and 2x TLV (Threshold Limit Value) for the target gas. The

Alarm Setup function in the Conguration Menu allows the user to change the alarm levels

according to their specic requirements.

Whenever the concentration of the target gas exceeds the factory or user programmed alarm

levels, the instrument will document this concentration alarm condition on its LCD Display and

trigger the associated alarm relays.

1.2.1.1 Reset Alarms Function

Ex factory, Alarm 1 and Alarm 2 are preprogrammed “enabled” and “latching”. In the event of a

concentration alarm, the alarm indication with latching alarms will continue until the alarm is

manually acknowledged by pressing the <set> key. Alarm Reset is not possible, if the alarm

condition is still present.

1.2.1.2 Exiting the Monitoring Mode

Exiting the Monitoring Mode and entering the Maintenance Mode may be password protected.

To prevent the instrument from manipulations by unauthorized personnel, it is recommended to

enable this function (see Conguration Menu / Security Function).

- Password enabled:

Press the <esc> key to exit the Monitoring Mode and enter the password. The screen to enter

the password is shown for one minute. During this period the Monitoring Mode remains active

in the background. When the correct password has been entered, the instrument is in the

Maintenance Mode, it is not monitoring, and the green LED is off.

- Password disabled:

Press the <esc> key to exit the Monitoring Mode. The instrument is now in the Maintenance

Mode, the instrument is not monitoring, and the green LED is off.

Basic Operation - Section 1

1-1

Satellite XT R Version

1.2.2 Maintenance Mode

The Maintenance Mode indicates a complete absence of monitoring capability. The green status

LED is off. Depending on the conguration the fault relay will be activated.

1.2.3 Warning Condition

A warning condition indicates that the instrument requires some attention, but the instrument is still

able to monitor and operate as programmed.

The following will occur when the instrument detects a warning condition:

- the green status LED is ashing

- depending on the conguration the fault relay will be activated.

1.2.3.1 Reset Warning Condition

Press the <set> key to acknowledge and reset a Warning Condition.

Refer to Section 7, Troubleshooting for specic warnings.

1.2.4 Diagnostics

Instrument faults refer to a problem which prevents the instrument from operating properly and

interferes with the ability to monitor or document concentration alarms.

If the instrument has detected an instrument fault, the fault relay is activated. The green status LED

is off. The LCD display is ashing while indicating the specic fault message.

The instrument lists specic instrument responses to instrument faults. For information on the

various fault messages and instructions on how to correct a fault condition, please refer to

Section 7, Troubleshooting.

1.3 Menu structure

Besides the Monitoring Mode, there is also menu operation for the Satellite XT. Menu operation

comprises three groups of functions, maintenance, calibration, and conguration. A password

(if enabled) must be entered to exit the Monitoring Mode and to obtain access to the Main Menu.

1.3.1 Maintenance Menu

This function covers the realtime service procedures required for a regular maintenance of the

instrument (e.g. sensor replacement).

1.3.2 Calibration Menu

Use the calibration function to dynamically calibrate the instrument with a known concentration of

the target gas or manually by entering a new correction K-Factor.

1.3.3 Conguration Menu

Use this function to congure the Satellite XT and to program instrument and monitoring

parameters to suit individual requirements.

! Note:

If the instrument was in the Monitoring Mode when last powered down,

it will automatically return to the Monitoring Mode when power is restored.

1-2

Basic Operation - Section 1

Satellite XT R Version

1-3

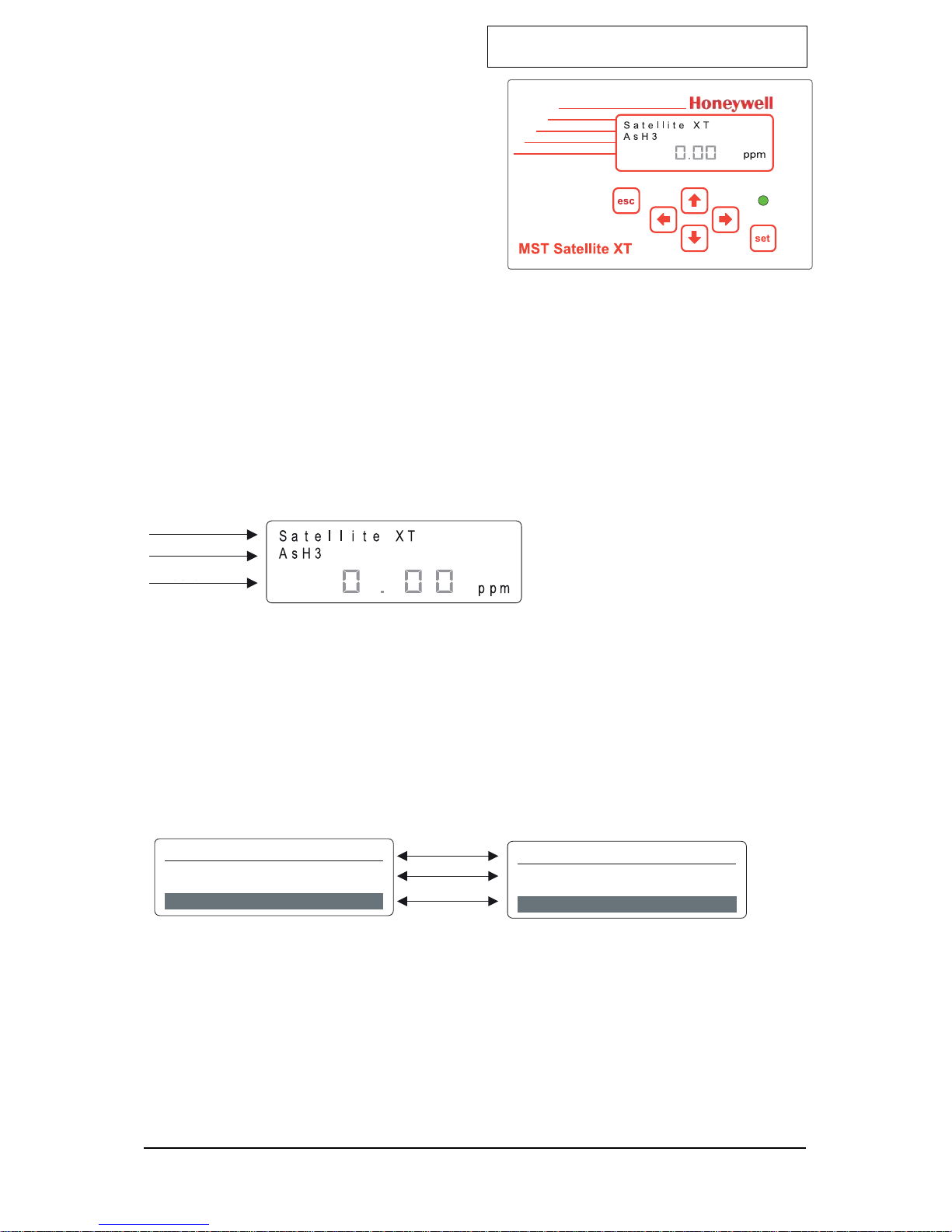

1.4 Operational Elements

Located at the front of the instrument is the

graphic display, the keypad consisting of six

keys, and above the Set Key the green status

LED.

1.4.1 Keypad Functions

o Escape Key <esc>

o Set Key <set>

o 4 Cursor Keys marked with an arrow,

<up>, <down>, <left>, <right>.

In the Maintenance, Calibration, and Conguration Menu, these keys provide the following functions:

To move forwards and backwards in the menus, use the cursor keys <down> and <up>. Select a

function by pressing the <set> key.

To enter text or gures, use the cursor keys <left> and <right> to reach the desired cursor position.

Use the cursor keys <up> and <down> to select the letter, gure, or sign you wish to enter. Bring the

cursor to the next position, select the next letter, gure, or sign. After entering the complete text, use

the <set> key to conrm the changes. If you do not want to save the changes, abort by pressing the

<esc> key.

1.4.2 Graphic Display

Depending on the operating mode the structure of the graphic display is different. Three

basic versions are illustrated and explained below. A detailed description is given in the

according sections.

Display Structure for Monitoring Mode

Line 1 offers the possibility to enter a user specic description, e.g. monitoring location

(max. 13 spaces; the name of the instrument is entered here when delivered).

Line 2 shows the name of the gas monitored.

Line 3 indicates the actual gas concentration and the concentration unit. Gas name and

concentration unit are data stored in the memory of the sensor installed.

Display Structure for Menu

Line 1 shows the actual position in the menu. In the left example the actual position is

Main Menu, in the right example it is the Sub-Menu Maintenance.

Line 2 shows one of the selection possibilities.

Line 3 shows the number of the selection possibility presently displayed and indicates also

the total of selection possibilities available in this menu.

M E N U

M A I N T E N A N C E

S E N S O R S E R V I C E

Línea 1

Línea 2

Línea 3

s ele c t : 2 o f 4

s ele c t : 1 o f 7

M A I N T E N A N C E

Basic Operation - Section 1

Line 1

Line 2

Line 3

Line 1

Line 2

Line 3

Satellite XT R Version

1.5 Technical Specications

Power Requirements

voltage 12 - 24 VDC (18 VDC minimum when using the Extractive Module)

consumption Max. 1.4 W

Wiring

power

2-wire shielded cable 2x0.5 mm2 / 20.4 AWG

(approx. 2 m delivered with instrument)

relay contacts

6-wire shielded cable 6x0.25 mm2 / 23 AWG

(approx. 3 m delivered with instrument)

Relay Outputs

contacts 3 x SPST (single-pole single-throw)

max. ratings 250 VAC / 30 VDC, 2 A

Graphic Display 122 x 32 dots with backlight

Status LED Green

Keypad 6 touch-sensitive membrane function keys

Physical Dimensions

size

145 x 95 x 50 mm (L x W x H)

5.7” x 3.7” x 2.0” (L x W x H)

weight

620 grams

22 ounces

Mounting

special mounting plate

(delivered with instrument)

Housing Protection Class IP 52 option: IP 65

EMC Directive 2004/108/EC

EN 50270

Operating Conditions

temperature

-20 °C ... +40 °C

-4 °F ... +104 °F

pressure 700 ... 1300 hPa

humidity 20 ... 90 % r.h.

Part Number

Satellite XT R 9602-0505

Satellite XT R, IP 65 9612-0505

1-4

Basic Operation - Section 1

Satellite XT R Version

2-1

Installation and Start-Up - Section 2

This section explains installation and initial start-up procedures.

2.1 General Guidelines

Please consider the aspects indicated below before locating the instrument.

The property of the target gas (lighter or heavier than air) must be considered. The

instrument should be mounted as close to the monitoring location as possible and should

be easily accessible for operation and maintenance. For narrow monitoring locations or

duct mounting a sensor extension with a standard length of 2m (6 feet) is available as an

option.

The optimum position to mount the instrument is in an upright position on a at surface.

If the instrument is used for ambient air monitoring, ensure that the sensor is facing

downwards. For personal monitoring applications the instrument should be mounted at

head level.

Ensure that the area immediately surrounding the instrument is free from objects that

might hinder free ow of air. The instrument should be installed away from any possible

liquid sources, extreme dust and dirt sources and should be protected against rain and

sunlight. An instrument version protection class IP 65 is available for outdoor applications.

A junction box is recommended to connect the instrument to external control systems.

A distance of 2 m (6 feet) must not be exceeded.

Regarding the power requirements and operating conditions, please follow the

specications indicated in Section 1, Technical Specications, for wiring instructions refer

to Section 2, Wiring.

The sensors should be stored in a cool, dry place when not in use.

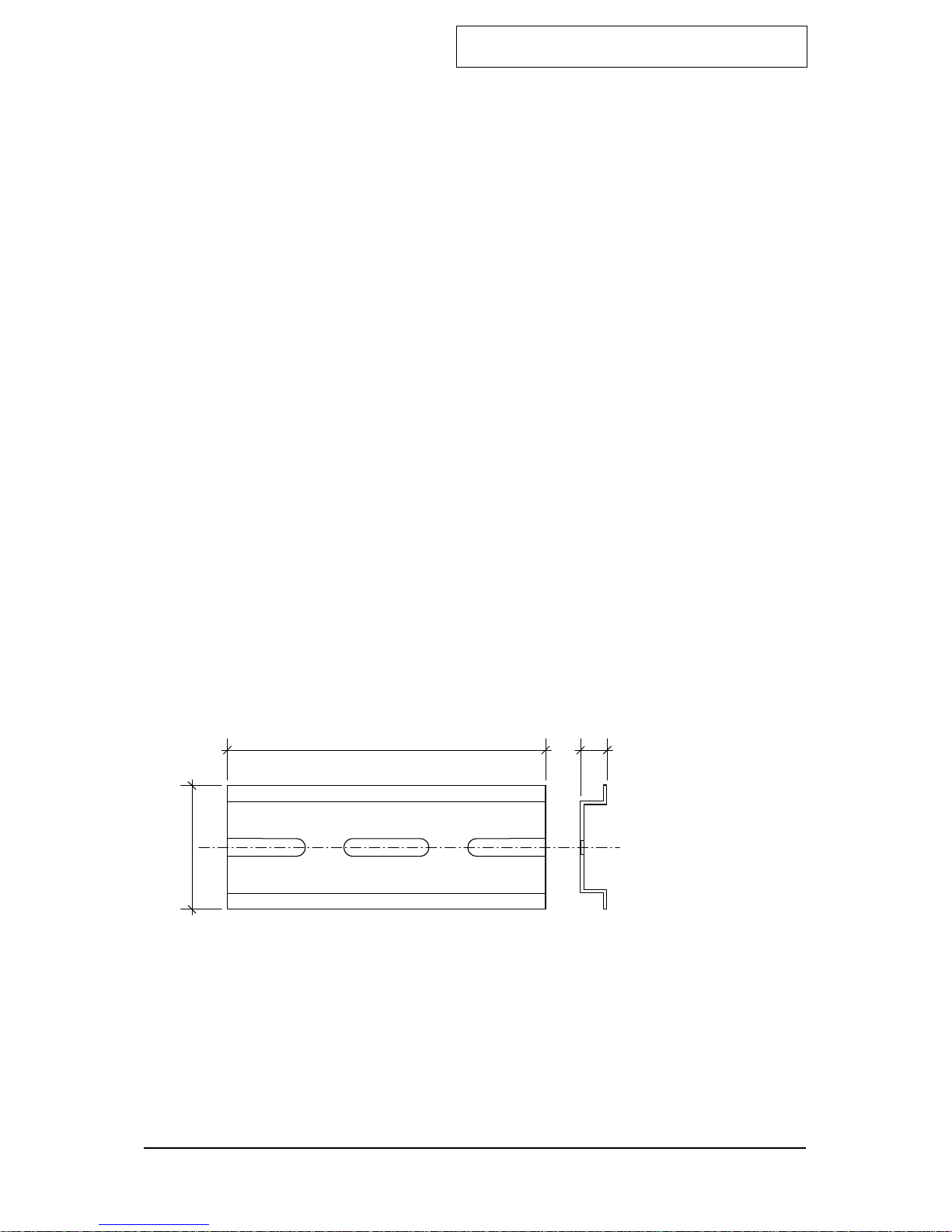

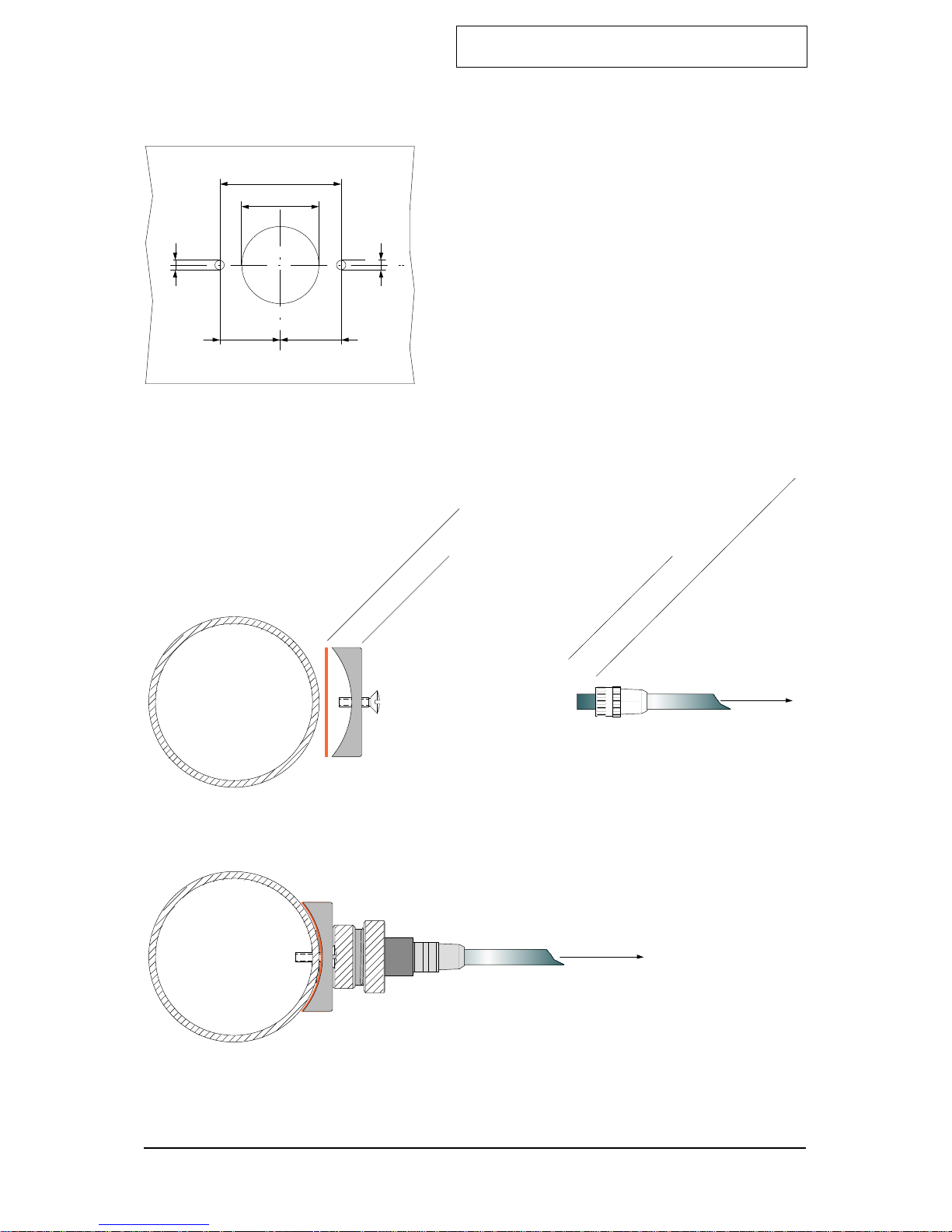

2.2 Standard Mounting

The instrument is designed for DIN–rail mounting. The mounting rail standard shipped with

each instrument is used for wall mounting. Mount the DIN–rail to a wall and fasten the

instrument with the sensor downwards and the display facing the front.

Attach the wires to the junction box according to the wiring diagram provided in the course

of this section.

Installation and Start-Up - Section 2

This section explains installation and initial start-up procedures.

Please consider the aspects indicated below before locating the instrument.

The property of the target gas (lighter or heavier than air) must be considered.

The instrument should be mounted as close to the monitoring location as possible and should be easily

accessible for operation and maintenance. For narrow monitoring locations or duct mounting a sensor

extension with a standard length of 2m (6 feet) is available as an option.

The optimum position to mount the instrument is in an upright position on a flat surface. If the instrument

is used for ambient air monitoring, ensure that the sensor is facing downwards. For personal monitoring

applications the instrument should be mounted at head level.

Ensure that the area immediately surrounding the instrument is free from objects that might hinder free

flow of air. The instrument should be installed away from any possible liquid sources, extreme dust and

dirt sources and should be protected against rain and sunlight. An instrument version protection class

IP 65 is available for outdoor applications.

A junction box is recommended to connect the instrument to external control systems. A distance of 2 m

(6 feet) must not be exceeded.

Regarding the power requirements and operating conditions, please follow the specifications indicated in

Section 1, Technical Specifications, for wiring instructions refer to Section 2, Wiring.

The sensors should be stored in a cool, dry place when not in use.

The instrument is designed for DIN–rail mounting. The mounting rail standard shipped with each

instrument is used for wall mounting. Mount the DIN–rail to a wall and fasten the instrument with the

sensor downwards and the display facing the front.

Attach the wires to the junction box according to the wiring diagram provided in the course of this

section.

90,0

35,0

7,5

Mounting rail standard (P/N 9602.0050.10.03)

Satellite XT R Version

2-2

Installation and Start-Up - Section 2

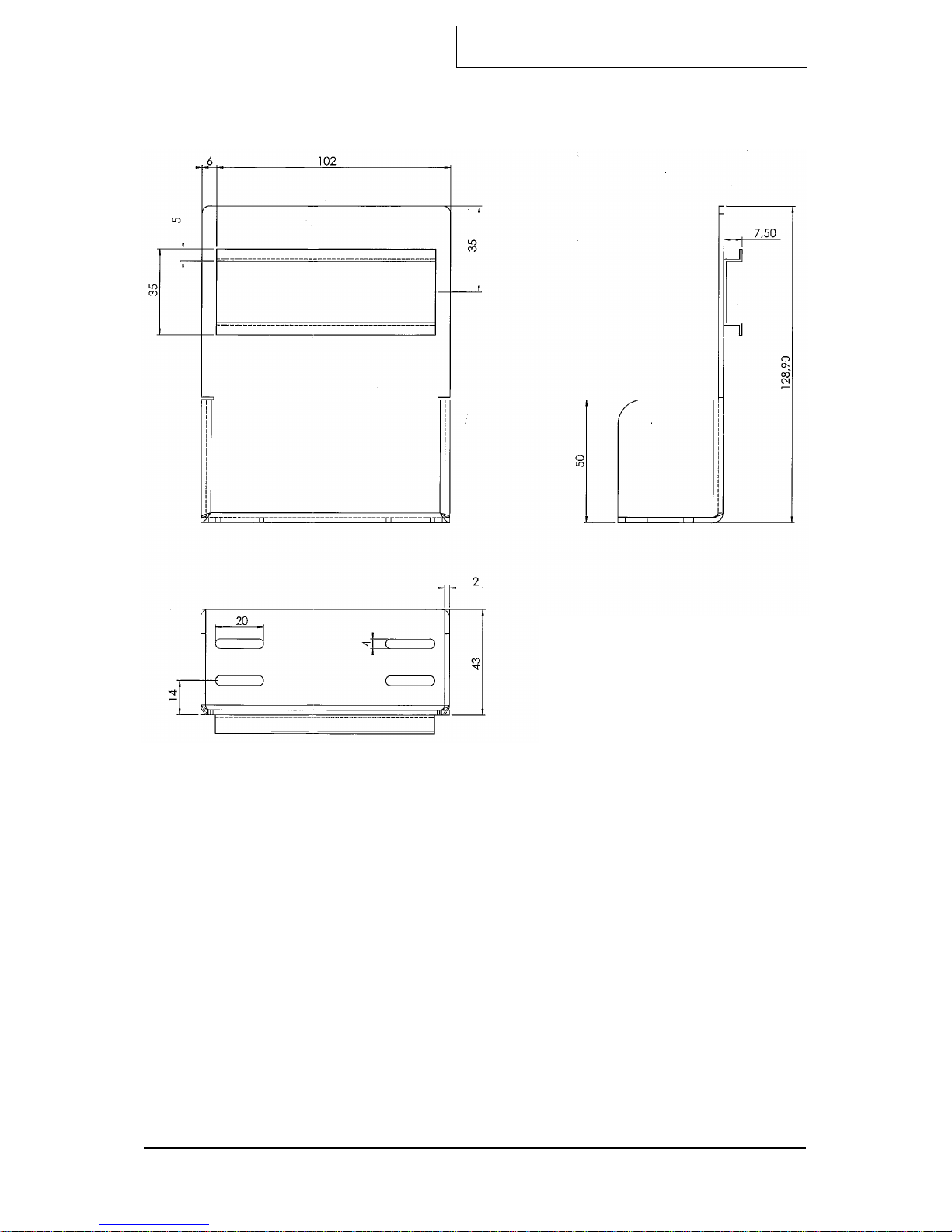

For applications where wall mounting is not possible, an L-shaped mounting plate with DIN–rail is

available as an option.

Optional L-shaped mounting plate with DIN–rail (P/N 9602.0051.10.02)

! Note:

Do not apply power until system is ready for start-up!

Satellite XT R Version

2-3

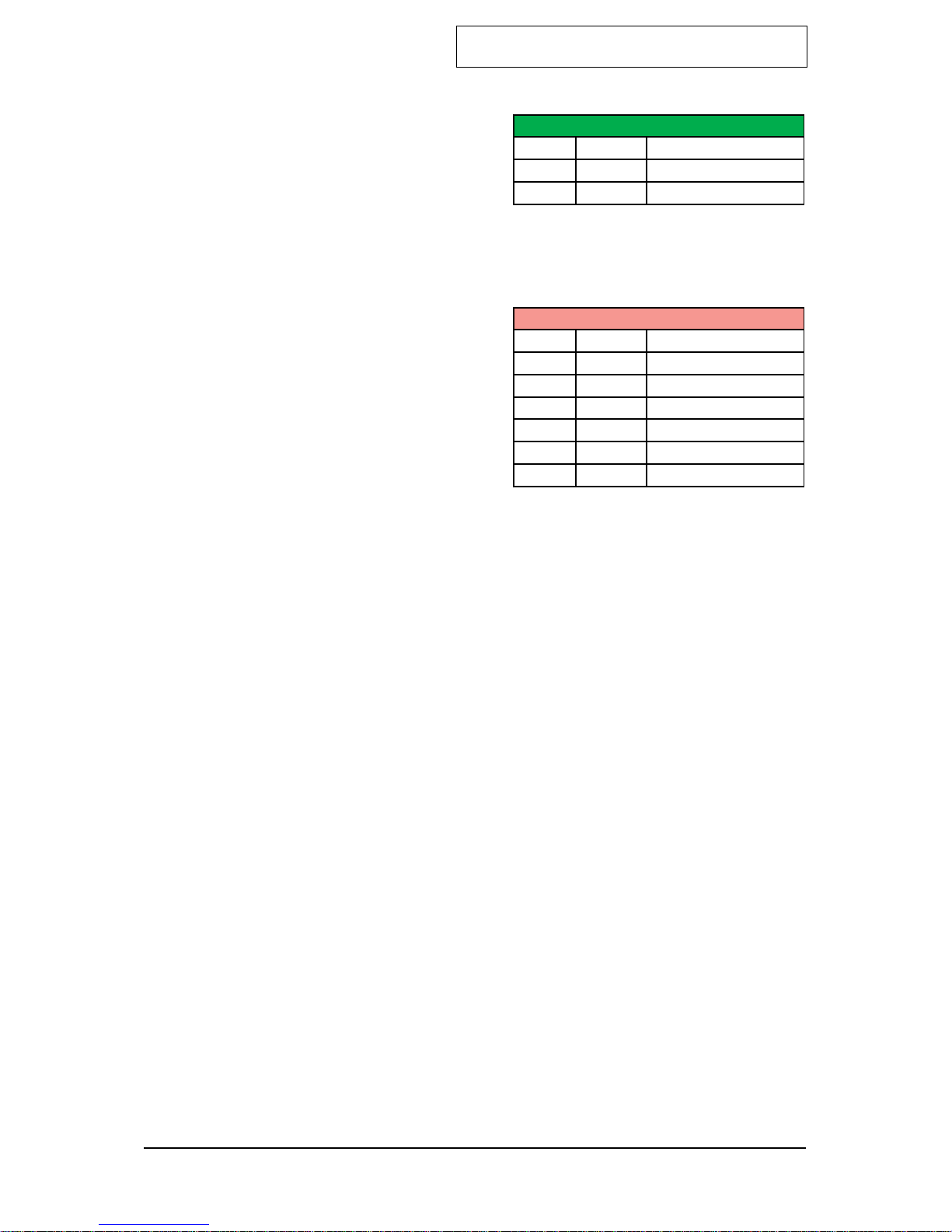

2.3 Duct Mounting

Observe the guidelines for installation of the instrument. For assembly and installation of

the sensor extension see the schematics below and overleaf.

2.3.1 Connecting the Sensor Extension to the Instrument

1. Connect the Socket (A) to the plug in the sensor compartment located at the bottom of

the Satellite XT. The groove of the Socket must face to the front.

2. Screw in the Internal Cap (B) and fasten it hand-tight.

3. Insert the Sensor Housing (C) with the nose of the Bayonet Catch facing to the front.

Lock the Bayonet Catch with a quarter-turn right.

1

2

3

A

B

C

D

A Socket with Groove

B Internal Cap

C Sensor Housing with Bayonet Catch

D Extension Cable to the Sensor

Installation and Start-Up - Section 2

Satellite XT R Version

2-4

2.3.2 Mounting the Sensor Extension to the Duct

Duct

*) Duct Mounting Saddle Assembly various types

available, see spare parts list, Section 8,

Reference Information

5,2cm

3,3cm

2,6cm 2,6cm

0,4cm

0,4cm

Duct

Satellite XT

Duct

Duct Mounting Saddle *)

9902.0080.40.00 Silicon Sealing

Sensor Extension

9902.0004.40.01 Milled Nut

Sensor

Satellite XT

Installation and Start-Up - Section 2

Satellite XT R Version

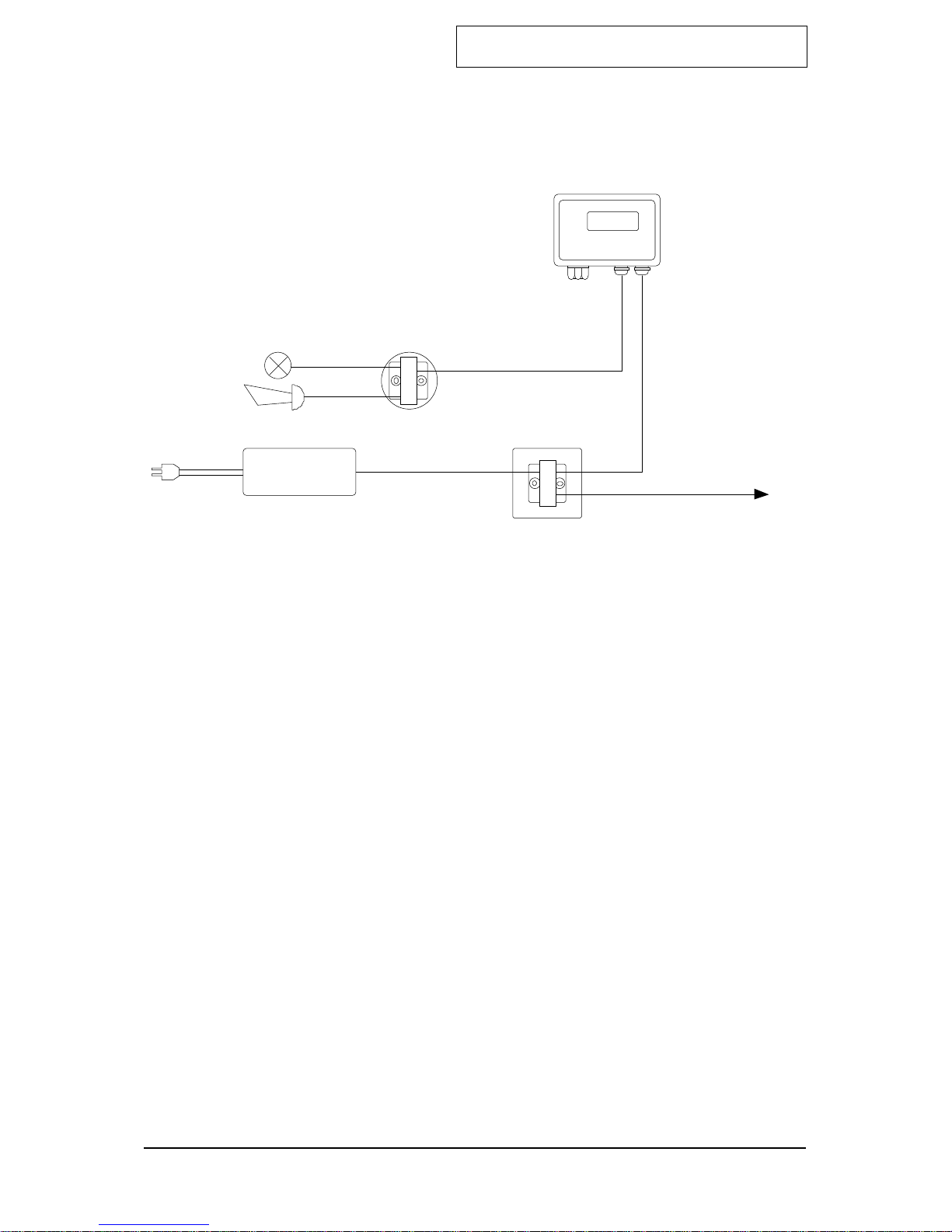

2.4 Wiring

There are two permanently attached cables extending

from the bottom of the instrument, a 2-wire shielded

cable with a length of 2 meters and a 6wire shielded cable with a length of 3 meters.

The 2-wire shielded cable is required to power the

instrument. The open end of the cable should be

terminated in a junction box.

The 6-wire shielded cable provides a pair of

connections for each of the 3 internal relays for

activation of visual or audible external alarm devices.

Power Supply Connections

P+ White Power +

P– Brown Power -

S Shield cable shield

Relay Contacts

1 White Alarm 1 Relay

1 Brown Alarm 1 Relay

2 Green Alarm 2 Relay

2 Yellow Alarm 2 Relay

3 Grey Fault Relay

3 Pink Fault Relay

S Shield Cable shield

Note:

All wiring for the Satellite XT and its related equipment must be in compliance with any local

electrical and re codes. The Satellite XT wiring must be kept away from any high power lines.

All shielding for the wiring must be connected together and grounded at only one point in the

system.

2-5

Installation and Start-Up - Section 2

Satellite XT R Version

2-wire shielded cable

2-wire shielded cable

2 m provided with instrument

230 / 115 VAC

2-wire shielded cable

to additional control devices

Junction Box

Satellite XT R

6-wire shielded cable

3 m provided with instrument

Junction Box

Power Supply

24 VDC

2-6

Wiring Diagram Satellite XT R - Basic Conguration

Installation and Start-Up - Section 2

Satellite XT R Version

2-7

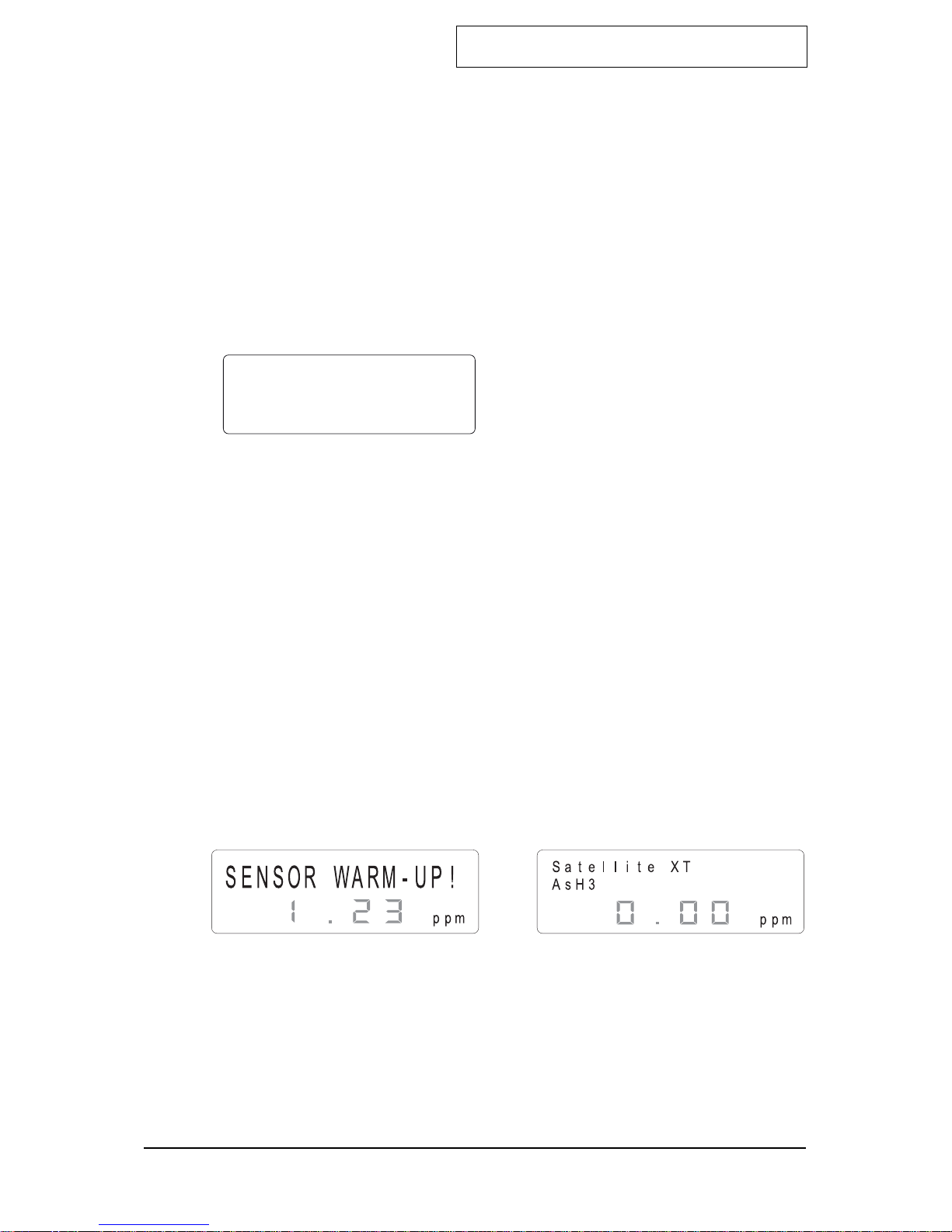

2.5 Initial Start-Up

When wiring is completed, a sensor must be assigned to each instrument. Every sensor is

gas calibrated and these sensor specic calibration parameters are stored in its integrated

data memory. Make sure to use only sensors designed for use with the Satellite XT.

Ex factory the instruments are shipped either uncongured or already precongured

according to the customer’s specications.

If the instruments are precongured, a certain sensor, which can be identied by its serial

number printed on the packaging and the sensor label, is assigned and documented to

one particular instrument. These data are stated in the test certicate provided with the

shipment.

Switch on power supply. If no sensor is tted, the display of the instrument shows the

below message.

---- F A U L T ----

N O S E N S O R !

For applications without sensor extension open the bayonet catch of the sensor housing

located on bottom of the instrument with a quarter-turn left and remove the sensor housing.

For applications with sensor extension hold the plastic tting at the duct side with two ngers

and unscrew the metal tting.

Take the assigned sensor out of the packaging. Remove shorting strap or wire link placed in

the sensor plug before inserting it into the instrument. Not all sensors will feature this strap or

link.

Caution: Failure to remove the shorting strap or wire link may result in damage to

the Satellite.

For applications without sensor extension insert the sensor into the instrument’s sensor

compartment with the arrow printed on the sensor label facing upwards and to the front. Fit

sensor housing by fastening the bayonet catch with a quarter-turn right.

For applications with sensor extension insert the sensor into the socket inside the metal

tting, properly aligning notch, groove, and arrow printed on the sensor label.

A sensor warm-up is performed and the graphic display shows the according screen until the

displayed value is zero.

This does not apply for oxygen sensors. The warm-up time required depends on the type of

sensor installed. The instrument is in the Maintenance Mode and the green LED is off.

As soon as the displayed value reads zero, the instrument automatically switches to the

Monitoring Mode. The graphic display shows the according screen, the green status LED

is on, the instrument is monitoring.

! Note:

If the instrument does not perform as described above and a fault message is

shown, please refer to Section 7, Troubleshooting.

! Instruments with OXYGEN sensors:

Span Adjustment must be performed prior to start-up. It is recommended to repeat

Span Adjustment every 4 to 6 weeks. For details refer to Section 5, Calibration.

Installation and Start-Up - Section 2

Satellite XT R Version

2-8

Installation and Start-Up - Section 2

Satellite XT R Version

3-1

Main Menu - Section 3

This section explains the different monitoring conditions and the Sub-Menus available

under the Main Menu.

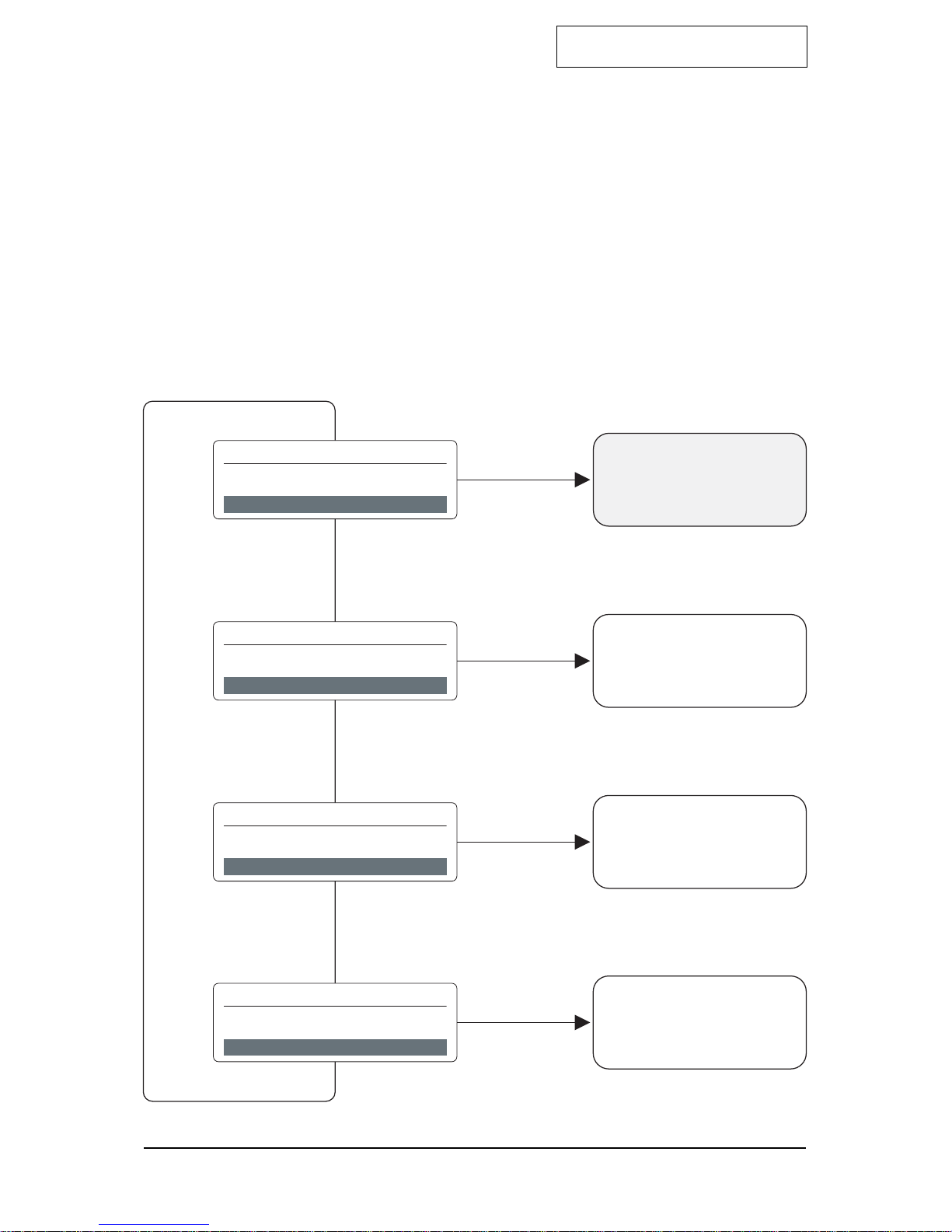

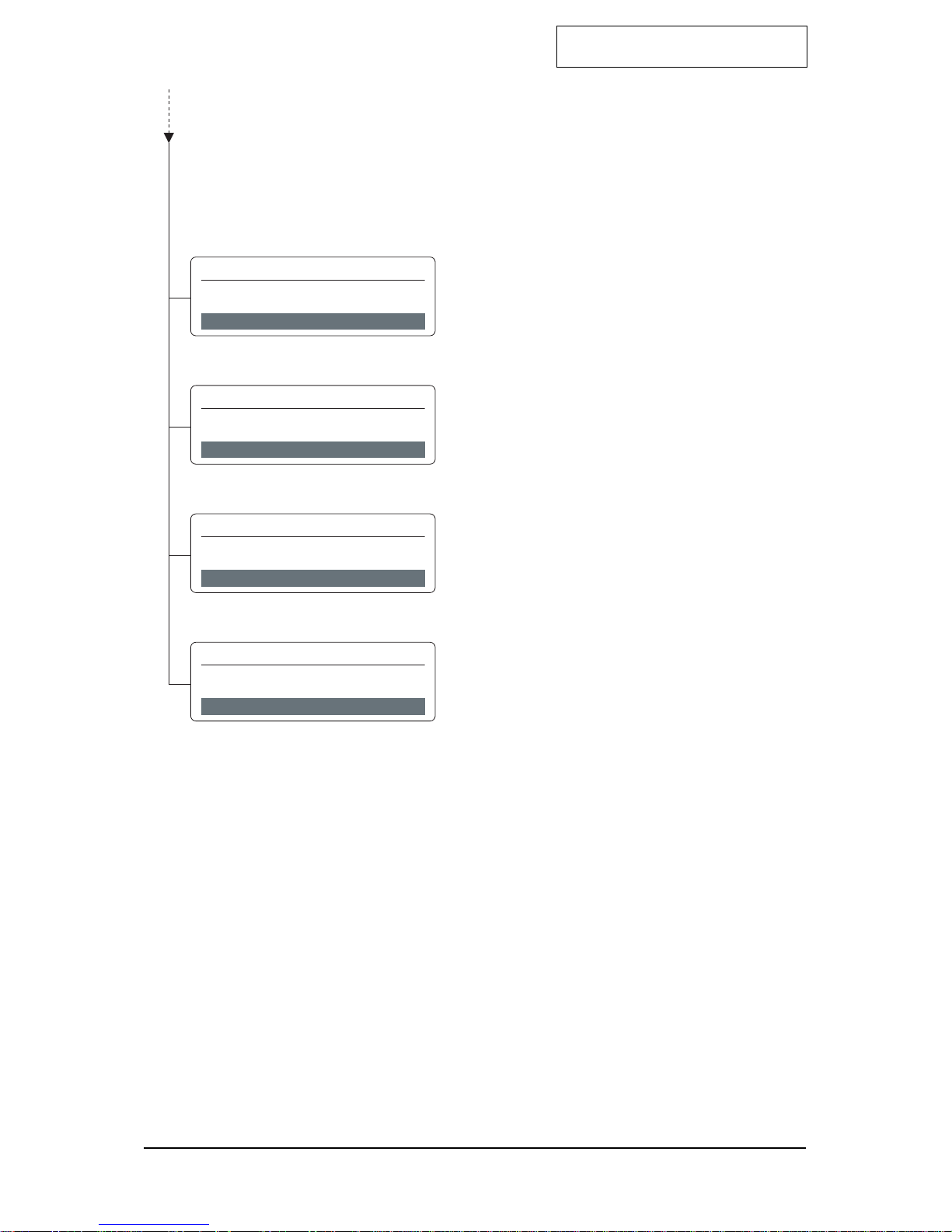

3.1 The Main Menu Screens

When the <esc> key is pressed, the instrument will leave the Monitoring Mode and go

to the Main Menu. The instrument is now in the Maintenance Mode and the green LED

is off.

Press the cursor keys <up> or <down> to move forwards and backwards in the Main

Menu.

Press the <set> key to select a Sub-Menu. Press the <esc> key to go back to the Main

Menu.

To return to the Monitoring Mode, go to the menu ‘MONITORING’ and press <set> to

select. The display shows the monitoring screen again and the illuminated green LED

indicates, that the instrument is in the Monitoring Mode.

s ele c t : 1 o f 4

M O N I T O RIN G

M E N U

s ele c t : 2 o f 4

M A I N T E N A N C E

M E N U

s ele c t : 3 o f 4

C A L I B R A T I O N

M E N U

s ele c t : 4 o f 4

CON F I G U R A T I O N

M E N U

Monitoring Mode

Sub-Menus

Sub-Menus

Sub-Menus

Satellite XT R Version

3-2

Main Menu - Section 3

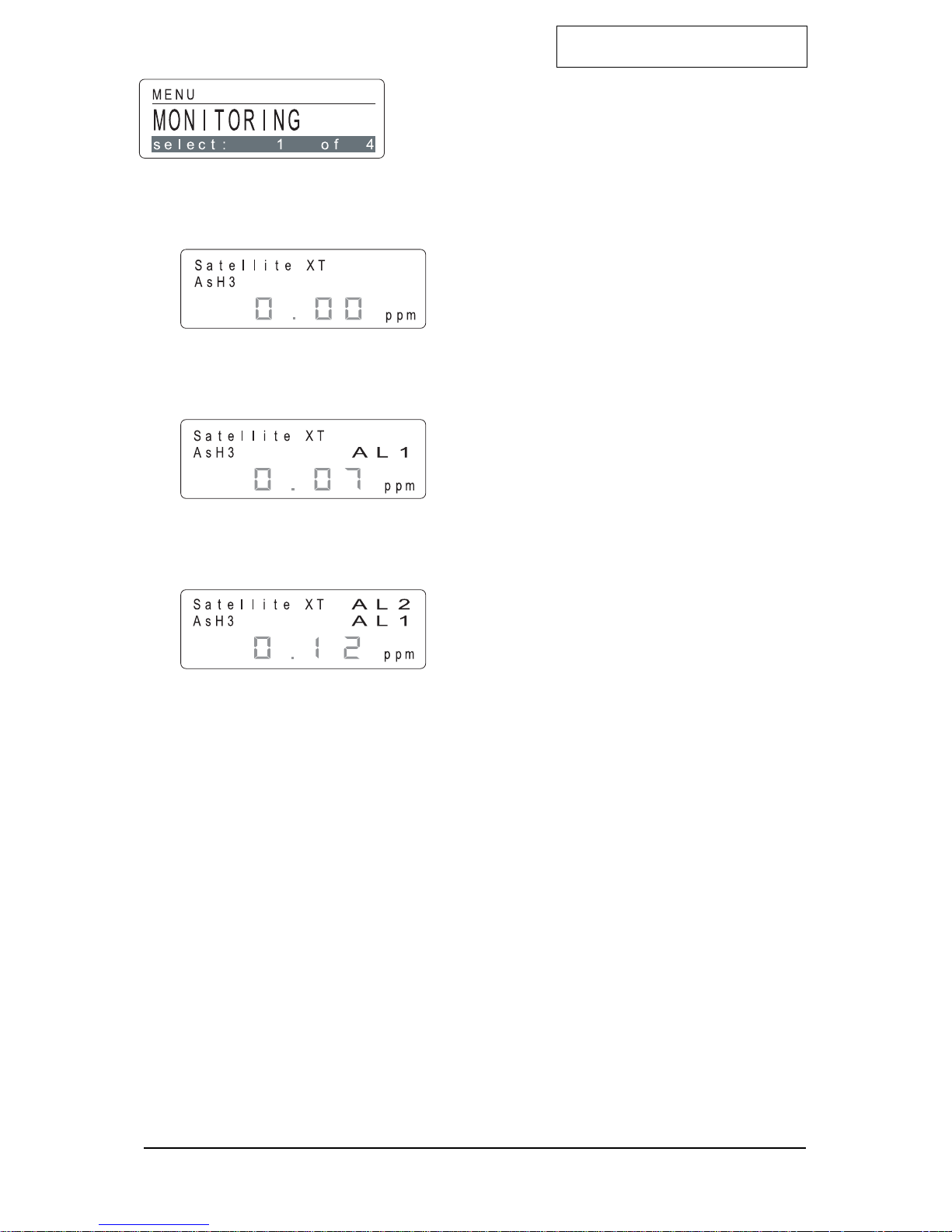

Main Menu - Monitoring

The instrument is in the operating mode

Maintenance and the green LED is off.

Press the cursor keys <up> or <down> to move

forwards and backwards in the Main Menu.

Press the <set> key to enter the Monitoring Mode.

<Normal Condition>

This screen and the illuminated green LED indicate

that the instrument is in the Monitoring Mode and is

operating properly.

<Alarm 1 Condition>

This screen shows that Alarm Level 1 has

been exceeded and that there is an actual gas

concentration of 0.07 ppm AsH3.

(f.i. Alarm 1 set at 0.05 ppm AsH3)

<Alarm 2 Condition>

This screen shows that Alarm Level 2 has been

exceeded and that there is an actual gas concentration

of 0.12 ppm AsH3.

(f.i. Alarm 2 set at 0.10 ppm AsH3)

Satellite XT R Version

s ele c t : 1 o f 7

M A I N T E N A N C E

S E N S ORS E R V I C E

s ele c t : 2 o f 7

M A I N T E N A N C E

A L A RM R ESE T

s ele c t : 4 o f 7

M A I N T E N A N C E

D E V I C E I N F O S

s ele c t : 5 o f 7

M A I N T E N A N C E

S E N S ORI N F O S

s ele c t : 6 o f 7

M A I N T E N A N C E

R ESE T D E V I C E

s ele c t : 7 o f 7

M A I N T E N A N C E

S E R V I C E

M A I N T E N A N C E

s ele c t : 2 o f 4

M E N U

s ele c t : 3 o f 7

M A I N T E N A N C E

A L A RM /WA R N T E S T

3-3

Main Menu - Section 3

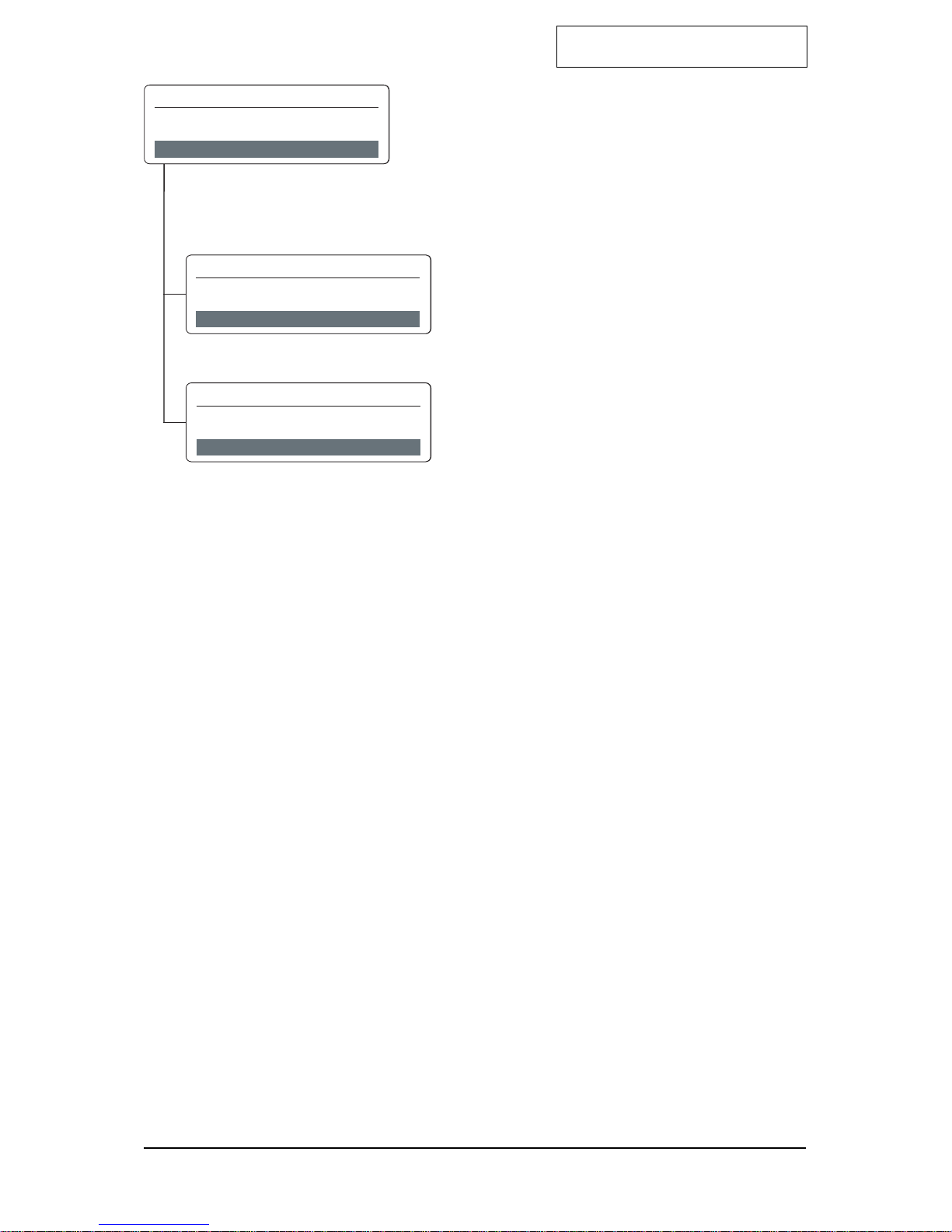

Main Menu - Maintenance

The instrument is in the Maintenance Mode and the

green LED is off.

Press the cursor keys <up> or <down> to move

forwards and backwards in the Main Menu.

To select a Sub-Menu, press the <set> key to enter.

Sub-Menus - Maintenance

Sensor Service

screen 1 of 7

Alarm Reset

screen 2 of 7

Alarm/Warn Test

screen 3 of 7

Device Infos

screen 4 of 7

Sensor Infos

screen 5 of 7

Reset Device

screen 6 of 7

Service

screen 7 of 7

Satellite XT R Version

3-4

Main Menu - Section 3

Main Menu - Calibration

The instrument is in the Maintenance Mode and

the green LED is off. Press the cursor keys <up> or

<down> to move forwards and backwards in the Main

Menu.

To select a Sub-Menu, press the <set> key to enter.

Sub menus - Calibration

Gas Calibration

screen 1 of 2

Manual K-Factor

screen 2 of 2

C A L I B R A T I O N

s ele c t : 3 o f 4

M E N U

s ele c t : 1 o f 2

C A L I B R A T I O N

G A S C A L I B R A T I O N

s ele c t : 2 o f 2

C A L I B R A T I O N

M A N U A L K - F A C T O R

C A L I B R A T I O N

s ele c t : 3 o f 4

M E N U

s ele c t : 1 o f 2

C A L I B R A T I O N

G A S C A L I B R A T I O N

s ele c t : 2 o f 2

C A L I B R A T I O N

M A N U A L K - F A C T O R

Satellite XT R Version

3-5

Main Menu - Section 3

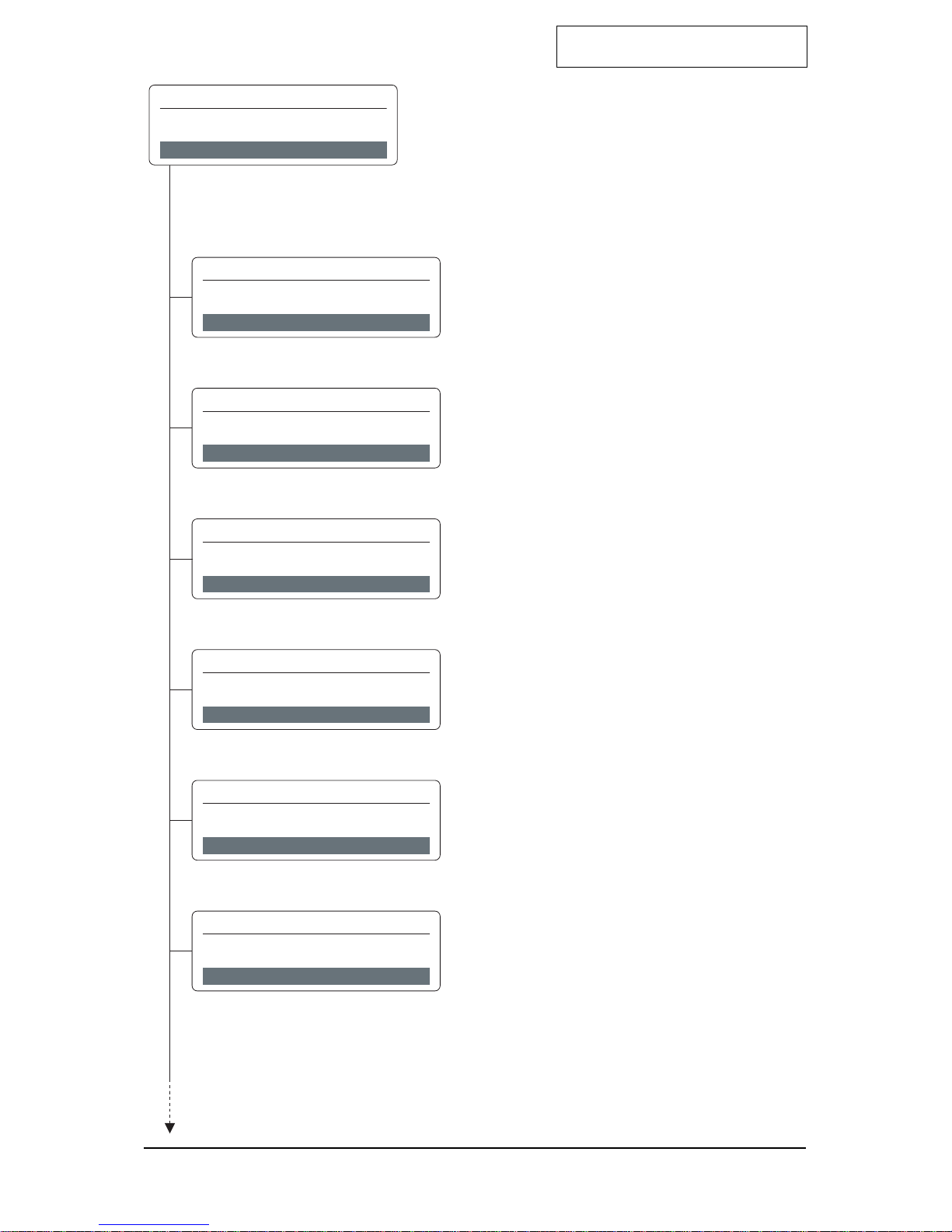

Main Menu - Conguration

The instrument is in the Maintenance Mode and the

green LED is off.

Press the cursor keys <up> or <down> to move

forwards and backwards in the Main Menu.

To select a Sub-Menu, press the <set> key to enter.

Sub Menus - Conguration

Alarm Settings

screen 1 of 10

Language

screen 2 of 10

Date Format

screen 3 of 10

Auto Selftest

screen 4 of 10

! This function is not available with instruments

using oxygen sensors.

Security

screen 5 of 10

Password

screen 6 of 10

s ele c t : 1 o f 1 0

CON F I G U R A T I O N

ALA R M S E T T I N G S

s ele c t : 2 o f 1 0

CON F I G U R A T I O N

L A NGU AGE

s ele c t : 3 o f 1 0

CON F I G U R A T I O N

D ATE F O R M A T

s ele c t : 4 o f 1 0

CON F I G U R A T I O N

A U T O S E L F T E S T

s ele c t : 5 o f 1 0

CON F I G U R A T I O N

S E CUR I T Y

s ele c t : 6 o f 1 0

CON F I G U R A T I O N

PASSWO R D

CON F I G U R A T I O N

s ele c t : 4 o f 4

M E N U

continued

Continued

Satellite XT R Version

3-6

Main Menu - Section 3

Main Menu - Conguration

Sub menus - Conguration

Location

screen 7 of 10

New Sensor Type

screen 8 of 10

Gas Name

screen 9 of 10

Relays

screen 10 of 10

s ele c t : 7 o f 1 0

CON F I G U R A T I O N

L O C A T I O N

continued

s ele c t : 8 o f 1 0

CON F I G U R A T I O N

N EWS E N S O R T YPE

s ele c t : 9 o f 1 0

CON F I G U R A T I O N

G A S N AME

s ele c t : 1 0 o f 1 0

CON F I G U R A T I O N

R E L AYS

Continued

Loading...

Loading...