Page 1

Release 131

Safety Manager

Safety Manual

EP-SM.MAN.6283

Issue 4

10 July 2008

Page 2

Document Release Issue Date

EP-SM.MAN.6283 131 4 July 2008

Notice

This document contains Honeywell proprietary information. Information

contained herein is to be used solely for the purpose submitted, and no part of this

document or its contents shall be reproduced, published, or disclosed to a third

party without the express permission of Honeywell Safety Management Systems.

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

purpose and makes no express warranties except as may be stated in its written

agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential

damages. The information and specifications in this document are subject to

change without notice.

Copyright 2008 – Honeywell Safety Management Systems, a division of

Honeywell Aerospace B.V.

Honeywell trademarks

Experion PKS

U.S. registered trademarks of Honeywell International Inc.

®

, PlantScape®, SafeBrowse®, TotalPlant® and TDC 3000® are

Conventions

ii

Other trademarks

Microsoft and SQL Server are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Trademarks that appear in this document are used only to the benefit of the

trademark owner, with no intention of trademark infringement.

Symbols

The following symbols are used in Safety Manager documentation:

Attention

This symbol is used for information that emphasizes or supplements important points of

the main text.

Page 3

Tip

This symbol is used for useful, but not essential, suggestions.

Note

This symbol is used to emphasize or supplement important points of the main text.

Caution

This symbol warns of potential damage, such as corruption of the database.

Warning

This symbol warns of potentially hazardous situations, which, if not avoided, could result

in serious injury or death.

ESD

This symbol warns for danger of an electro-static discharge to which equipment may be

sensitive.

iii

Page 4

Fonts

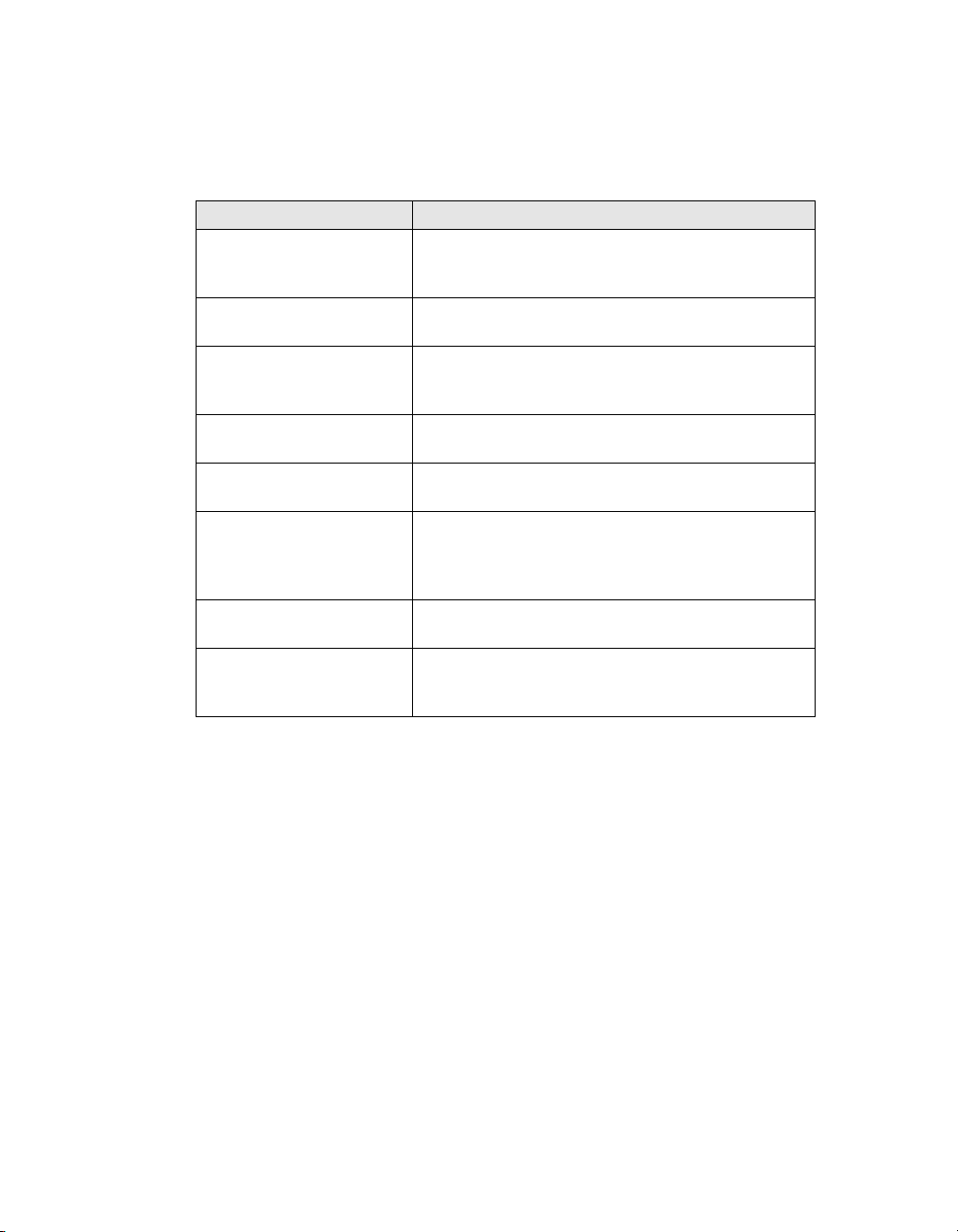

The following fonts are used in Safety Manager documentation:

Emphasis

• “... inform the reader on how to perform

the task in terms of...”

• “...see the Overview Guide”

Label

“The Advanced tab of the Properties

window has..”

Steps

Take the following steps:

1. Create a plant and set its properties.

2. ....

User Variable

..create the My Projects folder and

store the readme.txt file here.

..press the Tab key..

Next press Enter to..

Value

“Low is the fault reaction state for digital

inputs and digital outputs.”

Variable

“The syntax is: filename [-s] [-p]“

http://www.honeywellsms.com This font is used to identify a URL, directing

Emphasised text is used to:

• emphasise important words in the text,

• identify document titles.

This font is used to identify labels and titles

of (popup) windows.

Labels are used for Dialog box labels, menu

items, names of properties, and so on.

This font is used to identify steps.

Steps indicate the course of action that must

be adhered to, to achieve a certain goal.

This font is used to:

1. identify a user variable, a filename, an

object or view.

2. highlight the keys the user should press on

the keyboard.

User variable is a variable, an object or

a view that the reader can call-up to view or

to manipulate.

This font is used to indicate a value.

Value is a variable that the reader must

resolve by choosing a pre-defined state.

This font is used to identify a variable.

Variables are used in syntax and code

examples.

a reader to a website that can be referred to.

iv

Page 5

Contents

1The Safety Manual 1

Content of Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Basic skills and knowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Prerequisite skills. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety standards for Process & Equipment Under Control (PUC, EUC) . . . . . . . . . . . . . . . . . . . 4

Safety Integrity level (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Application design conform IEC 61131-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The IEC 61508 and IEC 61511 standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Architectural principle and standards of Safety Manager 9

Safety Manager basic architectures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dual Modular Redundant (DMR) architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Quadruple Modular Redundant (QMR) architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Watchdog architecture in mixed IO configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Standards compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Safety Manager fault detection and response 19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Diagnostic Test Interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FR state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Repair timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Shutdown at assertion of Safety Manager alarm markers . . . . . . . . . . . . . . . . . . . . . . . . 21

SM Controller faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

QPP faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

BKM faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PSU faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Communication faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SM IO faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Digital input faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Analog input faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Digital output faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Analog output faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Calculation errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety Manager Safety Manual v

Page 6

Contents

4 Safety Manager special functions 37

Unit shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Process units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configuration of unit shutdown (watchdog grouping) . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Unit shutdown outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Process outputs (safety related). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Application programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

On-line modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

SafeNet communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Protocol versus response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5 Special requirements for TUV-approved applications 47

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

F&G applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

vi Release 131, Issue 4

Page 7

The Safety Manual

Content of Safety Manual

The Safety Manual is a reference guide providing detailed information regarding

safety aspects in Safety Manager.

A reference guide is a Safety Manager related guide and does not describe tasks

in terms of how to perform the task in terms of steps to follow. A reference guide

can provide input to support decisions required to achieve a certain objective.

Guide subjects

Safety Manual

• “Architectural principle and standards of Safety Manager” on

page 9

• “Safety Manager fault detection and response” on page 19

• “Safety Manager special functions” on page 37

• “Special requirements for TUV-approved applications” on page 47

1

Safety Manager Safety Manual 1

Page 8

1 – The Safety Manual

References

The following guides may be required as reference materials:

Guide Description

The Overview Guide This guide describes the general knowledge required, the

The Planning and Design

Guide

The Installation and Upgrade

Guide

The Troubleshooting and

Maintenance Guide

The System Administration

Guide

The On-line Modification

Guide

The Hardware Reference This guide specifies the hardware components that build a

The Software Reference This guide specifies the software functions that build a

basic functions of, and the tasks related to Safety

Manager.

This guide describes the tasks related to planning and

designing a Safety Manager project.

This guide describes the tasks related to installing,

replacing and upgrading hardware and software as part of

a Safety Manager project.

This guide describes the tasks related to troubleshooting

and maintaining Safety Manager.

This guide describes the task related to administrating the

computer systems used in a Safety Manager project.

This guide describes the theory, steps and tasks related to

upgrading Safety Builder and embedded software and

modifying an application online in a redundant Safety

Manager.

Safety Manager project.

Safety Manager project and contains guidelines on how to

operate them.

2 Release 131, Issue 4

Page 9

Basic skills and knowledge

Before performing tasks related to Safety Manager you need to:

• Understand basic Safety Manager concepts as explained in the Overview

Guide and the Glossary.

• Have a thorough understanding of the Safety Manual.

• Have had appropriate training related to Safety Manager that certifies you for

your tasks (see the Planning and Design Guide).

Prerequisite skills

When you perform tasks related to Safety Manager, it is assumed that you have

appropriate knowledge of:

• Site procedures

• The hardware and software you are working with. These may i.e. be:

computers, printers, network components, Controller and Station software.

• Microsoft Windows operating systems.

• Programmable logic controllers (PLCs).

• Applicable safety standards for Process & Equipment Under Control.

• Application design conform IEC 61131-3.

• The IEC 61508 and IEC 61511 standards.

This guide assumes that you have a basic familiarity with the process(es)

connected to the equipment under control and that you have a complete

understanding of the hazard and risk analysis.

Basic skills and knowledge

Training

Most of the skills mentioned above can be achieved by appropriate training. For

more information, contact your Honeywell SMS representative or see:

• http://www.automationcollege.com.

Safety Manager Safety Manual 3

Page 10

1 – The Safety Manual

Safety standards for Process & Equipment Under Control (PUC, EUC)

Safety Integrity level (SIL)

The IEC 61508 standard specifies 4 levels of safety performance for safety

functions. These are called safety integrity levels. Safety integrity level 1 (SIL1)

is the lowest level of safety integrity, and safety integrity level 4 (SIL4) the

highest level. If the level is below SIL1, the IEC 61508 and IEC 61511 do not

apply.

Safety Manager can be used for processing multiple SIFs simultaneously

demanding a SIL1 up to and including SIL3.

To achieve the required safety integrity level for the E/E/PE safety-related

systems, an overall safety life cycle is adopted as the technical framework (as

defined in IEC 61508).

Application design conform IEC 61131-3

The IEC 61131 standard defines, as a minimum set, the basic programming

elements, syntactic and semantic rules for the most commonly used programming

languages, including graphical languages of:

• Ladder Diagram,

• Functional Block Diagram and,

• Textual languages of Instruction List and structured Text;

For more information see the IEC web site.

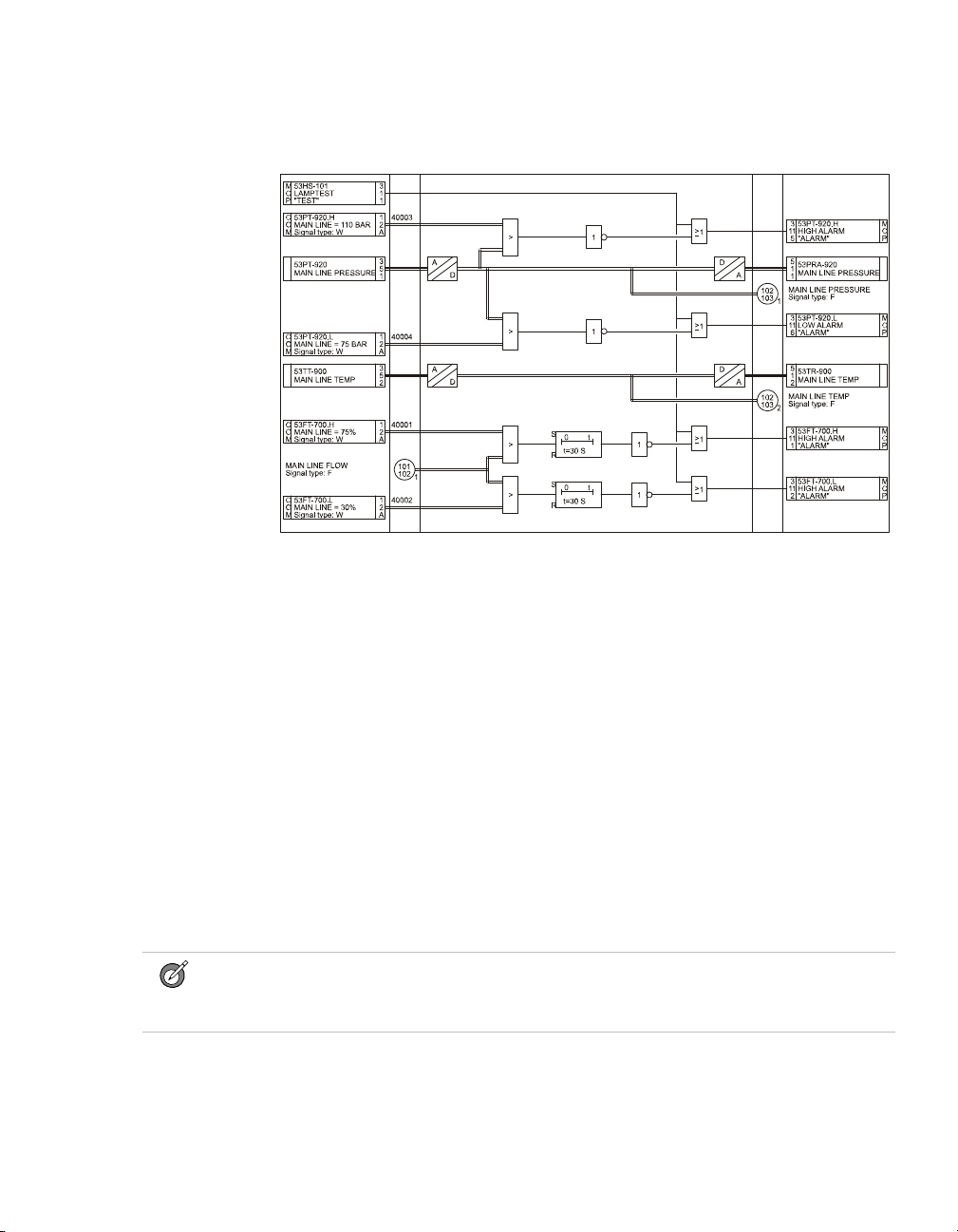

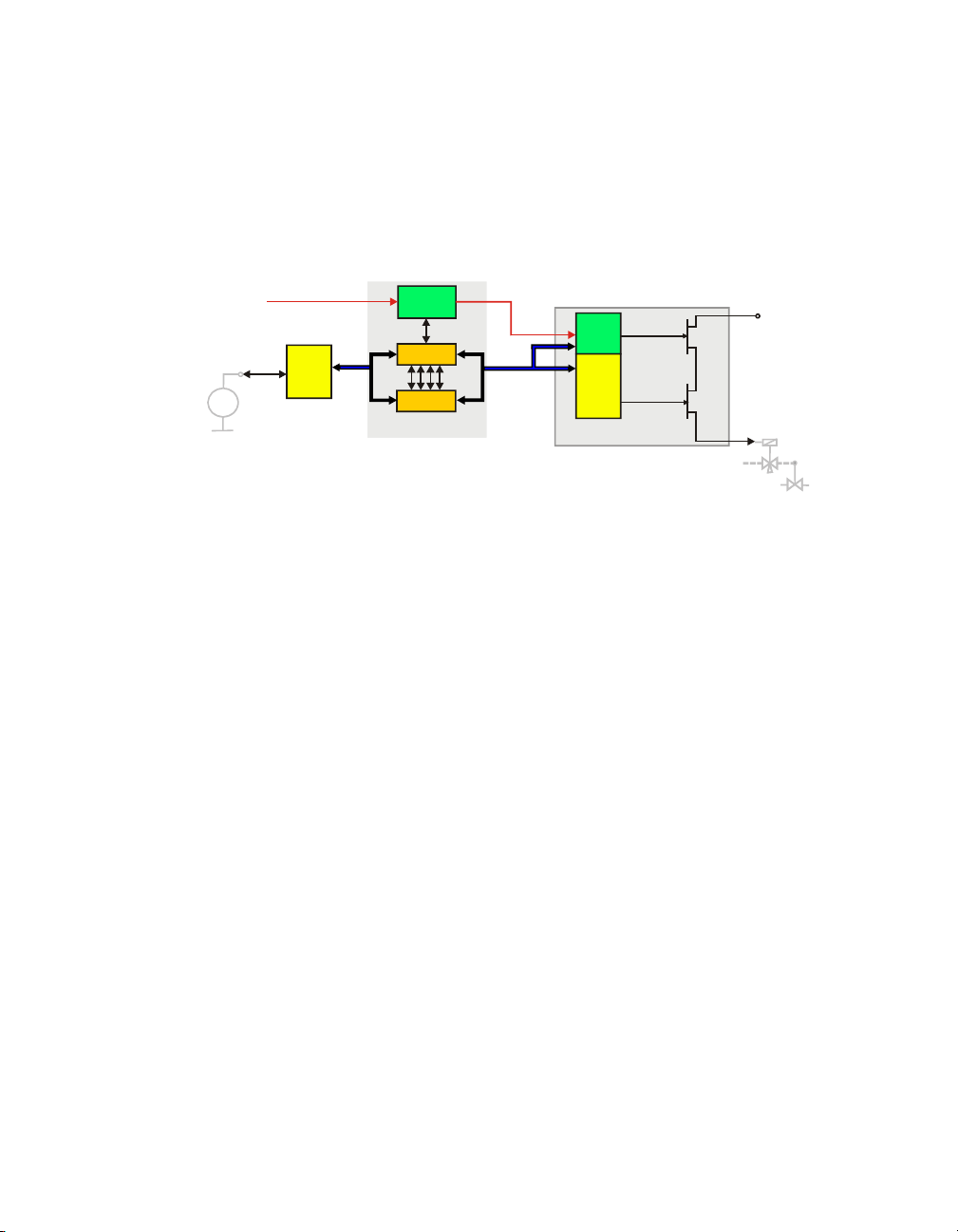

Figure 1 on page 5 shows how Safety Manager uses the graphical programming

method, based on Functional Block Diagram as defined by the IEC 61131-3.

4 Release 131, Issue 4

Page 11

Safety standards for Process & Equipment Under Control (PUC, EUC)

Figure 1 Example FLD layout

The IEC 61508 and IEC 61511 standards

SISs have been used for many years to perform safety instrumented functions e.g.

in chemical, petrochemical and gas plants. In order for instrumentation to be

effectively used for safety instrumented functions, it is essential that the

instrumentation meets certain minimum standards and performance levels.

To define the characteristics, main concepts and required performance levels,

standards IEC 61508 and IEC 61511 have been developed. The introduction of

Safety Integrity level (SIL) is one of the results of these standards.

This brief provides a short explanation of each standard. Detailed information

regarding IEC 61508 and 61511 can be found on the IEC web site

http://www.iec.org.

What standard to use?

Tip:

You can use the IEC 61508 as stand-alone standard for those sectors where a sector

specific standard does not exist.

Safety Manager Safety Manual 5

Page 12

1 – The Safety Manual

• If you are in the process sector and you are an owner/user, it is strongly

recommended that you pay attention to the IEC 61511 (ANSI/ISA 84.00.01).

For details see “IEC 61511, the standard for the process industry” on page 7.

• If you are in the process sector and you are a manufacturer, it is strongly

recommended that you pay attention to the IEC 61508. For details see “IEC

61508, the standard for all E/E/PE safety-related systems” on page 6.

• If you are in another sector, it is strongly recommended that you look for, and

use, your sector specific IEC standard for functional safety (if there is one). If

none exists, you can use the IEC 61508 instead. For details see “IEC 61508,

the standard for all E/E/PE safety-related systems” on page 6

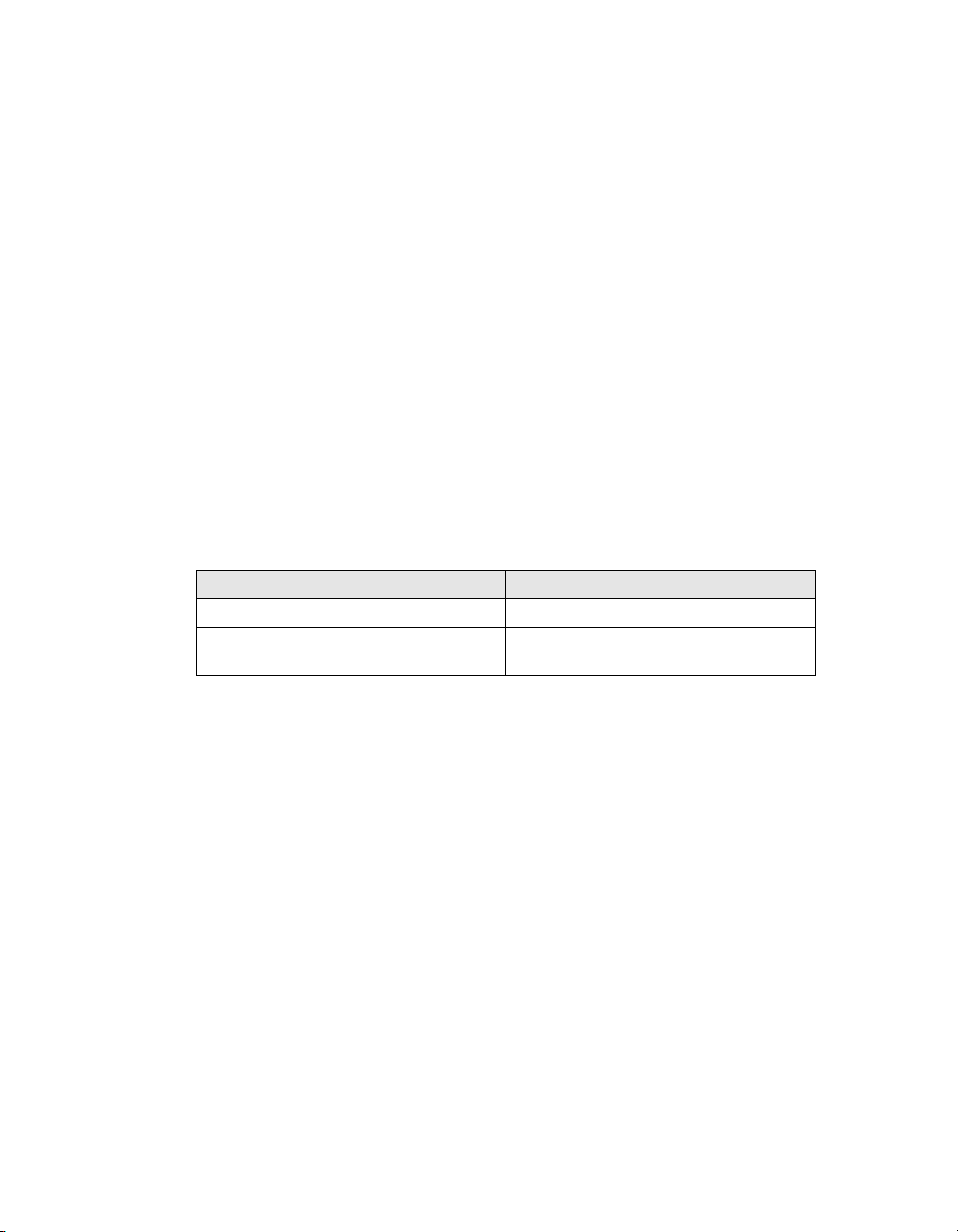

IEC 61508 and IEC 61511 terminology

This guide contains both IEC 61508 and IEC 61511 related terminology.

As the IEC 61511 sits within the framework of IEC 61508 most of the

terminology used may be interchanged. Table 1 on page 6 provides an overview

of the most common interchangeable terminology.

IEC 61508 terminology IEC 61511 terminology

safety function safety instrumented function

electrical/electronic/programmable

electronic (E/E/PE) safety-related system

Tab le 1 IEC 61508 versus IEC 61511 terminology

safety instrumented system (SIS)

IEC 61508, the standard for all E/E/PE safety-related systems

The IEC 61508 is called “Functional safety of

electrical/electronic/programmable electronic safety-related systems”

IEC 61508 covers all safety-related systems that are electrotechnical in nature

(i.e. electromechanical systems, solid-state electronic systems and

computer-based systems).

Generic standard

The standard is generic and is intended to provide guidance on how to develop

E/E/PE safety related devices as used in Safety Instrumented Systems (SIS).

The IEC 61508:

• serves as a basis for the development of sector standards (e.g. for the

machinery sector, the process sector, the nuclear sector, etc.).

• can serve as stand-alone standard for those sectors where a sector specific

standard does not exist.

6 Release 131, Issue 4

Page 13

Safety standards for Process & Equipment Under Control (PUC, EUC)

SIL

IEC 61508 details the design requirements for achieving the required Safety

Integrity Level (SIL).

The safety integrity requirements for each individual safety function may differ.

The safety function and SIL requirements are derived from the hazard analysis

and the risk assessment.

The higher the level of adapted safety integrity, the lower the likelihood of

dangerous failure of the SIS.

This standard also addresses the safety-related sensors and final elements

regardless of the technology used.

IEC 61511, the standard for the process industry

The IEC 61511 is called “Functional safety - Safety instrumented systems for the

process industry sector”. It is also referred to as the ANSI/ISA 84.00.01.

This standard addresses the application of SISs for the process industries. It

requires a process hazard and risk assessment to be carried out, to enable the

specification for SISs to be derived. In this standard a SIS includes all

components and subsystems necessary to carry out the safety instrumented

function from sensor(s) to final element(s).

The standard is intended to lead to a high level of consistency in underlying

principles, terminology and information within the process industries. This

should have both safety and economic benefits.

The IEC 61511 sits within the framework of IEC 61508.

Need to know more?

For more information regarding, or help on, implementing or determining, the

applied safety standards for your plant/process please contact your Honeywell

affiliate. Our Safety Consultants can help you to e.g.:

• perform a hazard risk analysis

• determine the SIL requirements

• design the Safety Instrumented System

• validate and verify the design

• train your local safety staff

Safety Manager Safety Manual 7

Page 14

1 – The Safety Manual

8 Release 131, Issue 4

Page 15

Architectural principle and standards of Safety Manager

Safety Manager basic architectures

Safety Manager can be configured for a number of architectures, each with its

own characteristics and typical Safety Instrumented Functions. Table 2 on page 9

provides an overview of the available architectures.

Tab le 2 Safety Manager architectures

Controller

configuration

Non-redundant

(DMR)

Redundant

(QMR)

IO configuration Remarks

Non-redundant DMR architecture;

• Non-redundant

• Redundant

• Redundant and non-redundant

2

Supports SIF for SIL1,

SIL2 and SIL3

applications.

QMR architecture;

Supports SIF for SIL1,

SIL2 and SIL3

applications.

Dual Modular Redundant (DMR) architecture

Typical applications of a DMR architecture are:

• Burner Management System

• Batch processing

• Machine protection

The Dual Modular Redundant (DMR) architecture provides 1oo2 voting in a

non-redundant system. The DMR architecture with 1oo2 voting is based on

dual-processor technology, and is characterized by a high level of self tests,

diagnostics and fault tolerance.

Safety Manager Safety Manual 9

Page 16

2 – Architectural principle and standards of Safety Manager

Processor

Processor

Watchdog

QPP Control Processor

SD

Input Interfaces Output Interfaces

Input

Module

Sensor

xx

yyy

Final Element

SMOD

Output

Module

The DMR architecture is realized with a non-redundant Controller. A

non-redundant architecture contains only one QPP (see Figure 2 on page 10),

which contains a redundant processor with 1oo2 voting between the processors

and memory.

Figure 2 Functional diagram: DMR architecture

In IO configurations, each path is primarily controlled by the Control Processor

and an independent switch (Secondary Means of De-energization, SMOD) which

is controlled by an independent watchdog.

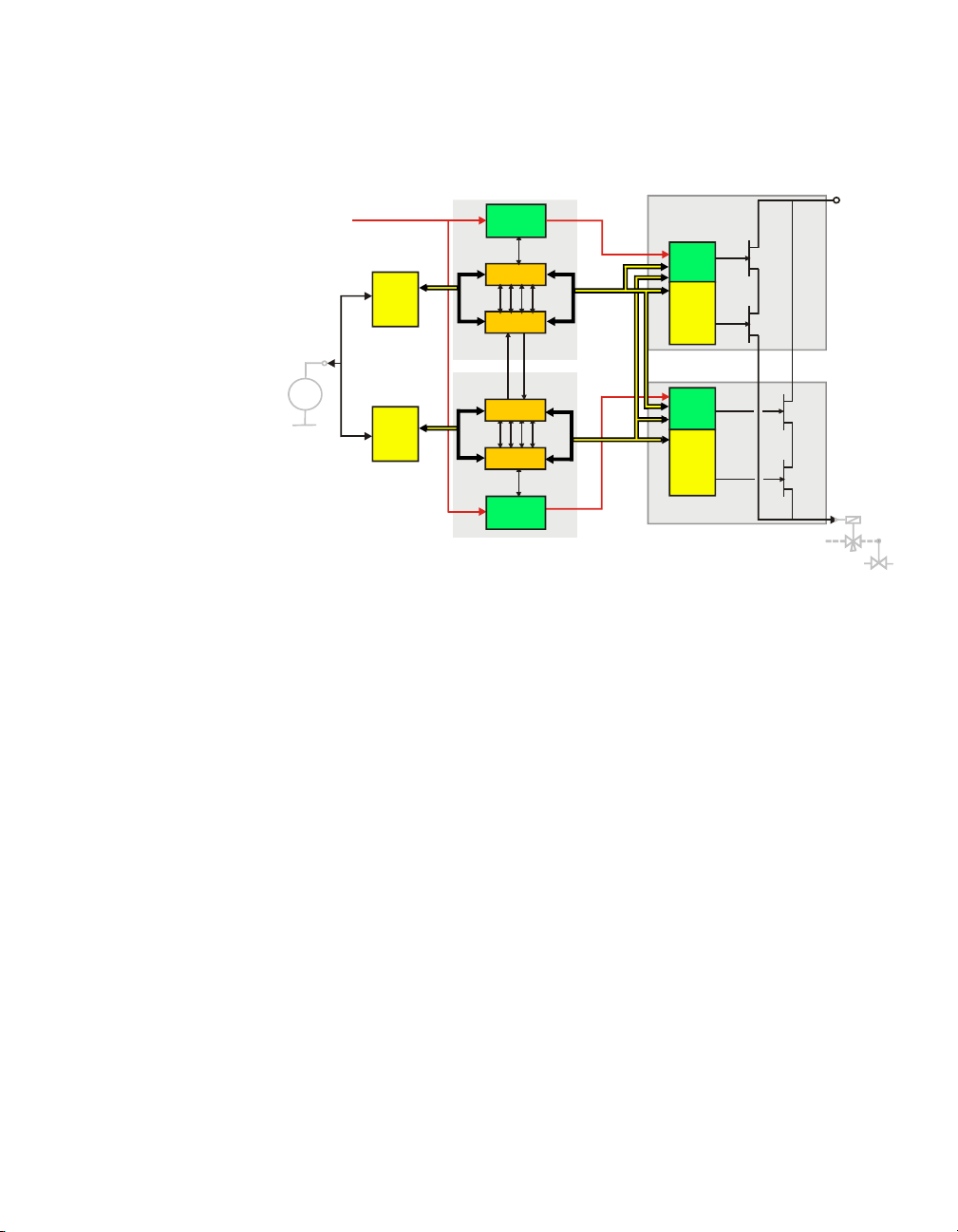

Quadruple Modular Redundant (QMR) architecture

Typical applications of a QMR architecture are:

• process safeguarding applications for which continues operation is essential.

The Quadruple Modular Redundant (QMR) architecture is based on 2oo4D

voting, dual-processor technology in each QPP. This means that it is characterized

by a ultimate level of self diagnostics and fault tolerance.

The QMR architecture is realized with a redundant Controller. This redundant

architecture contains two QPPs (see Figure 3 on page 11), which results in

quadruple redundancy making it dual fault tolerant for safety.

The 2oo4D voting is realized by combining 1oo2 voting of both CPUs and

memory in each QPP, and 1oo2D voting between the two QPPs. Voting takes

place on two levels: on a module level and between the QPPs.

10 Release 131, Issue 4

Page 17

Figure 3 Functional diagram: QMR architecture

Input

Module

Input

Module

Processor

Processor

Watchdog

QPP Control Processor 1

QPP Control Processor 2

SD

Input Interfaces

SMOD

Output

Module

Final Element

Output Interfaces

SMOD

Output

Module

Quad

Vot er

Processor

Processor

Watchdog

Sensor

xx

yyy

In redundant IO configurations, each path is controlled by one of the Control

Processors and an independent switch (Secondary Means of De-energization,

SMOD), which is controlled by the diagnostic software and an independent

watchdog.

Furthermore, each Control Processor is able to switch off the output channels of

the other Control Processor.

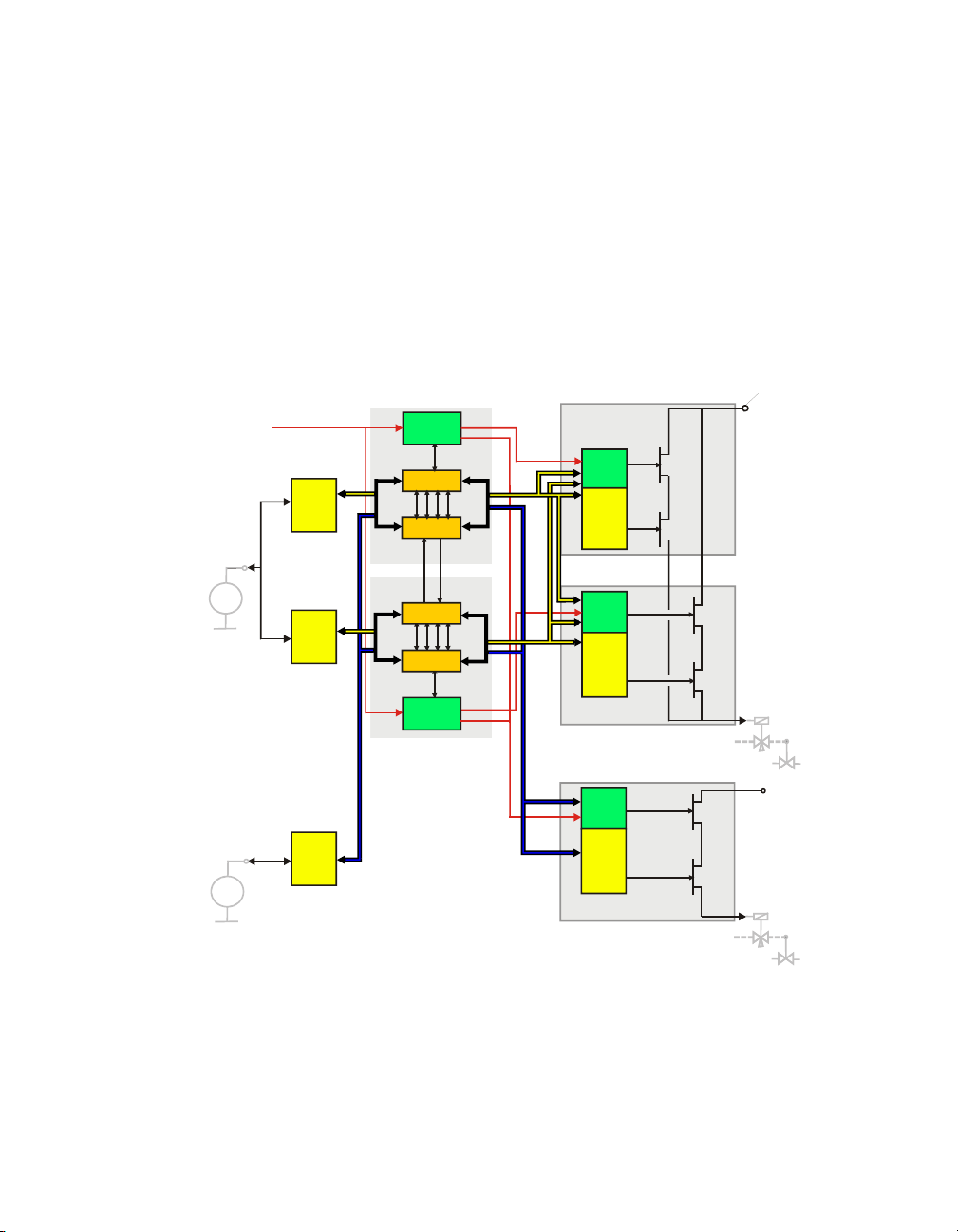

Watchdog architecture in mixed IO configurations

In a system with combined redundant and non redundant IO 3 watchdog lines are

active:

• WD1

This is the Watchdog line dedicated for Control Processor 1.

- De-energizes upon a safety related fault in Control Processor 1 or an

output module of Control Processor 1.

- When de-energized, Control Processor 1 and the related outputs are halted.

•WD2

This is the Watchdog line dedicated for Control Processor 2.

Safety Manager Safety Manual 11

Page 18

2 – Architectural principle and standards of Safety Manager

Input

Module

Input

Module

Processor

Processor

Watchdog

QPP Control Processor 1

QPP Control Processor 2

SD

Input Interfaces

SMOD

Output

Module

Final Element

Output Interfaces

SMOD

Output

Module

Quad

Vote r

Processor

Processor

Watchdog

Input

Module

Final Element

SMOD

Output

Module

Sensor

xx

yyy

Sensor

xx

yyy

- De-energizes upon a safety related fault in Control Processor 2 or an

output module of Control Processor 2.

- When de-energized, Control Processor 2 and the related outputs are halted.

• WD3

This is the combined watchdog line, controlled by both Control Processors.

- De-energizes upon a safety related fault in a non redundant output.

- When de-energized, the non-redundant outputs are de-energized, but the

redundant outputs and the Control Processors remain operational.

Figure 4 Functional diagram: redundant Controller with redundant and non-redundant IO

12 Release 131, Issue 4

Page 19

Certification

The advantage of applying and complying to standards is obvious:

• International standards force companies to evaluate and develop their

• Products certified conform these international standards guarantee a certain

Since functional safety is the core of the Safety Manager design, the system has

been certified for use in safety applications all around the world. Safety Manager

has been developed specifically to comply with the IEC61508 functional safety

standards, and has been certified by TUV for use in SIL1 to SIL3 applications.

Safety Manager has also obtained certification in the United States for the UL

1998 and ANSI/ISA S84.01 standards.

For a full list of all these and other certifications see “Certification” on page 13.

Certification

Safety Manager has been certified to comply with the following standards:

Certification

products and processes according a consistent and uniform way.

degree of quality and product reliability that other products lack.

International Electrotechnical Commission (IEC) —

The design and development of Safety Manager are

compliant with IEC 61508 (as certified by TUV).

Instrument Society of America (ISA) — Certified to

fulfill the requirements laid down in ANSI/ISA S84.01.

CE compliance — Complies with CE directives

89/336/EEC (EMC) and 73/23/EEC (Low Voltage),

89/392/EEC (Machine Safety)

European Committee for Standardization — CEN,

CENELEC

Safety Manager Safety Manual 13

Page 20

2 – Architectural principle and standards of Safety Manager

TUV (Germany) — Certified to fulfill the requirements

of SIL3 safety equipment as defined in the following

documents: IEC61508, IEC60664-3, EN50156, EN 54-2,

EN50178, IEC 60068, IEC 61131-2, IEC 61131-3,

IEC60204.

Canadian Standards Association (CSA) — Complies

with the requirements of the following standards:

• CSA Standard C22.2 No. 0-M982 General

Requirements – Canadian Electrical Code, Part II;

• CSA Standard C22.2 No. 142-M1987 for Process

Control Equipment.

Underwriters Laboratories (UL) — Certified to fulfill

the requirements of UL 508, UL 991, UL 1998, and

ANSI/ISA S84.01.

Factory Mutual (FM) — Certified to fulfill the

requirements of FM 3611 and FM3600 (non-incentive

field wiring circuits for selected modules and installation

in Class 1 Div 2 environments).

14 Release 131, Issue 4

Page 21

Standards compliance

This subsection lists the standards Safety Manager complies with, and gives some

background information on the relevant CE marking (EMC directive and Low

Voltage directive).

Standard Title Remarks

IEC61508

(S84.01)

VDE 0116 (10/89) Electrical equipment of furnaces.

EN 54 part 2

(01/90)

EN 50081-2-1994 Electromagnetic compatibility –

EN 50082-2-1995 Electromagnetic compatibility –

IEC 61010-1-1993 Safety Requirements for Electrical

IEC 61131-2-1994 Programmable controllers. Part 2:

NFPA 72/2002 National Fire Alarm Code

NFPA 85/2001 Boiler and Combustions Systems

UL 1998 Safety-related software, first

UL 508 Industrial control equipment,

Functional safety of

electrical/electronic/

programmable electronic (E/E/PE)

safety-related systems.

(German title: Elektrische

Ausrüstung von

Feuerungsanlagen)

Components of automatic fire

detection systems, Introduction.

(German title: Bestandteile

automatischer

Brandmeldeanlagen)

Generic emission standard, Part 2:

Industrial environment.

Generic immunity standard, Part 2:

Industrial environment.

Equipment for Measurement,

Control and Laboratory Use, Part

1: General Requirements.

Equipment requirements and tests.

Handbook

Hazards Code

edition.

sixteenth edition.

Standards compliance

Table 3 Safety Manager compliance to standards

Underwriters Laboratories.

Underwriters Laboratories.

Safety Manager Safety Manual 15

Page 22

2 – Architectural principle and standards of Safety Manager

Tab le 3 Safety Manager compliance to standards

Standard Title Remarks

UL 991 Test for safety-related controls

employing solid-state devices,

second edition.

FM3600, FM 3611

Class I, Division 2,

Groups A, B, C &

D

Class II,

Division 2,

Groups F & G

CSA C22.2 Process control equipment.

IEC 60068-1 Basic environmental testing

IEC 60068-2-1 Cold test. 0°C (32°F); 16 hours; system in

IEC 60068-2-1 Cold test. –10°C (14°F); 16 hours; system

IEC 60068-2-2 Dry heat test. up to 65°C (149°F); 16 hours;

IEC 60068-2-3 Test Ca: damp heat, steady state. 21 days at +40°C (104°F), 93%

IEC 60068-2-3 Test Ca: damp heat, steady state. 96 hours at +40°C (104°F), 93%

IEC 60068-2-14 Test Na: change of temperature –

Electrical equipment for use in

• Class I, Division 2,

• Class II, Division 2, and

• Class III, Division 1 and 2,

hazardous locations.

Industrial products.

procedures.

withstand test.

Underwriters Laboratories.

Factory Mutual Research.

Applies to the field wiring

circuits of the following

modules:

SDI-1624, SAI-0410,

SAI-1620m, SDIL-1608 and

SAO-0220m, and installation of

the Controller in these

environments.

Canadian Standards Association

No. 142 (R1993).

operation; reduced power supply

voltage:

(–15%): U=20.4 Vdc or

(–10%): U=198 Vac.

in operation.

system in operation; increased

power supply voltage:

(+15%): U=27.6 Vdc or

(+10%): U=242 Vac.

relative humidity; function test

after cooling.

relative humidity; system in

operation.

–25°C—+55°C (–13°F—

+131°F), 12 hours, 95% relative

humidity, recovery time: max. 2

hours.

16 Release 131, Issue 4

Page 23

Table 3 Safety Manager compliance to standards

Standard Title Remarks

IEC 60068-2-30 Test Db variant 2: cyclic damp

heat test.

IEC 60068-2-6 Environmental testing – Part 2:

Tests – Test.

Fc: vibration (sinusoidal).

IEC 60068-2-27 Environmental testing – Part 2:

Tests – Test.

Ea: shock.

+25°C—+55°C (+77°F—

+131°F), 48 hours, 80-100%

relative humidity, recovery time:

1—2 hours.

Excitation: sine-shaped with

sliding frequency;

Frequency range: 10—150 Hz.

Loads:

• 10—57 Hz; 0.075 mm.

• 57—150 Hz; 1 G.

Duration: 10 cycles (20 sweeps)

per axis.

No. of axes: 3 (x, y, z).

Traverse rate: 1 oct/min in

operation.

Half sine shock.

2 shocks per 3 axes (6 in total).

Maximum acceleration: 15 G.

Shock duration: 11 ms.

Safety Manager in operation.

Standards compliance

Safety Manager Safety Manual 17

Page 24

2 – Architectural principle and standards of Safety Manager

18 Release 131, Issue 4

Page 25

Safety Manager fault detection and response

Introduction

The goal of fault detection and response is to detect and isolate any single fault

that affects the safety of the process under control, within a time frame that is

acceptable for the process.

Note:

There is always a diagnostic alarm available upon detection of a fault.

Diagnostic Test Interval

The Diagnostic Test interval (DTI) is the time in which detection and isolation of

faults takes place. The DTI must be set to a value that is acceptable for the

process, such as the Process Safety Time (PST). These values can be obtained

from hazard analysis reports.

3

FR state

The Fault Reaction (FR) state of each IO point is the predetermined state or action

the point assumes in case of faults.

• For normally energized safety related applications, like ESD applications, the

required predefined safe fault reaction state is de-energized or Low.

• For normally de-energized safety related applications, like FGS applications,

the required predefined safe fault reaction state for inputs is energized or

High / Top Scale.

Safety Manager Safety Manual 19

Page 26

3 – Safety Manager fault detection and response

Repair timer

Note:

The repair timer setting must be based on a hardware reliability analysis which includes

MTTR figures.

All configurations of Safety Manager are single fault tolerant towards faults that

affect safety: By using a secondary means Safety Manager is always able to bring

a process to safe state, regardless of the fault.

However, given some time, a second fault may occur. This second fault may then

disable the secondary means that keeps the process in a safe state.

To prevent such a scenario to develop, the system starts a repair timer if a

secondary means becomes vulnerable to faults. Once started, this configurable

timer counts down until the fault is repaired. If the timer is allowed to reach zero,

the Control Processor halts.

20 Release 131, Issue 4

Page 27

Shutdown at assertion of Safety Manager alarm markers

If the normal system response of Safety Manager is not enough when Safety

Manager detects a fault and more stringent system response is required, the Safety

Manager alarm markers can be used to shut down the system via the application.

Figure 5 on page 21 shows an example of how to shut down the system in case of

an IO compare error. An additional manual shutdown input is provided by which

the operator can initiate a shutdown by hand.

Figure 5 Diagram to shut down system in case of output compare error

If an IO compare error is detected or a manual shutdown is initiated, a

divide-by-zero is forced and Safety Manager shuts down. Other alarm markers

can be used in a similar way.

Note:

A manual shutdown can also be realized via the shutdown (SD) input of the

SM Controller.

With aid of the SD input a tested, hard wired connection can be used. The SD input is

accessible via the SD loop connector at the back of the CP chassis.

Breaking the SD loop causes all outputs to be de-activated!

Safety Manager Safety Manual 21

Page 28

3 – Safety Manager fault detection and response

SM Controller faults

Below topics provide an overview of detected Controller faults and the Controller

response to these faults.

QPP faults

Table 4 on page 22 provides an overview of faults that the Controller detects

related to the QPP and the response to these faults.

Tab le 4 Controller response to QPP faults

QPP faults Non redundant

related to diagnostics report includes CP

temperature monitoring

(set points user

configurable)

Memory QPP memory halt Controller halt CP none -continue

Execution execution time out of

Watchdog output shorted halt Controller halt CP none -continue

Watchdog faulty halt Controller halt CP none -continue

Bus drivers

Internal link

QPP module

secondary switch-off faulty halt Controller halt CP none -continue

high alarm or low alarm none -continue none -continue

high-high alarm or

low-low alarm

1 sensor faulty and temp.

more than 3 degrees from

shutdown limits

1 sensor faulty and temp.

less than 3 degrees from

shutdown limits

range / failure

error on logical sheet halt Controller

de-energized watchdog

line for redundant outputs

de-energized watchdog

line for non-redundant

outputs

Controller

response

halt Controller halt CP none -continue

none -continue none -continue

halt Controller halt CP none -continue

halt Controller halt CP none -continue

halt Controller halt CP none -continue

halt Controller de-energize non redundant outputs,

Redundant Controller response

X( faulty)

continue operation on redundant

outputs

CP

Y (not faulty)

22 Release 131, Issue 4

Page 29

Tab le 4 Controller response to QPP faults (continued)

SM Controller faults

QPP faults Non redundant

related to diagnostics report includes CP

repair timer

(user configurable)

software corrupted halt Controller halt CP none -continue

intervention QPP key switch to IDLE

synchronization QPP n.a. halt CP none -continue

time sync

(user configurable)

internal communication n.a. halt CP none -continue

running none -continue none -continue

expired halt Controller halt CP none -continue

position

Spurious watchdog

interrupt

safe state initiated

SD input de-energized halt Controller

system software halted CP does

base timer halt CP none -continue

IO compare error apply FR state

source unavailable switch to other

Controller

response

halt Controller halt CP none -continue

source

Redundant Controller response

X( faulty)

not start

switch to other source

CP

Y (not faulty)

none -continue

USI faults

Table 5 on page 24 provides an overview of detected faults in relation to the USI

and the response to these faults.

A fault in the USI also means that the communication channels of that USI are

down.

Safety Manager Safety Manual 23

Page 30

3 – Safety Manager fault detection and response

Tab le 5 Controller response to USI faults

USI faults Non redundant

related to diagnostics report

includes

Memory USI module apply FR state to

Execution

communication USI module

module faulty USI module

synchronization system software

software corrupted

* If values are not available via CPY apply FR state to affected COM & FSC inputs.

Controller

response

affected COM &

FSC inputs

Redundant Controller response

CP

X( faulty)

use values from

for affected

CP

Y

COM & FSC

*

inputs.

BKM faults

Table 6 on page 24 provides an overview of faults that can be detected in relation

to the BKM and the response to these faults.

Table 6 Controller response to BKM faults

BKM faults Non redundant

related to diagnostics report includes CP

key switch input compare error

(reset key switch)

input compare error

(force key switch)

module faulty BKM module none -continue none -continue

battery faulty / low none -continue none -continue

lifetime expired

transport switch

Controller

response

none -continue none -continue

Redundant Controller response

X( faulty)

CP

Y (not faulty)

none

CP

Y (not faulty)

PSU faults

Table 7 on page 25 provides an overview of faults that can be detected in relation

to the PSU and the response to these faults.

24 Release 131, Issue 4

Page 31

Table 7 Controller response to PSU faults

SM Controller faults

PSU faults Non redundant

related to diagnostics report includes CP

Controller

response

Redundant Controller response

X( faulty)

CP

Y (not faulty)

Voltage monitoring spurious watchdog interrupt halt Controller halt CP none -continue

module faulty PSU module

Communication faults

Note

Please note that a fault in the communication links may be caused by USI modules.

Table 9 on page 27 provides an overview of faults that can be detected in relation

to communication and the response to these faults.

Tab le 8 Controller response to communication faults

communication faults Non redundant

communication or

“shared CP”

Related to Diagnostic message

reports

broken link communication

wrong protocol assigned

fault

time-out

Controller

response

*

apply FR state to

COM & FSC inputs

of that channel

if channel belongs

to active clock

source, switch to

other clock source

too many data requests USI module faulty apply FR state to

COM & FSC inputs

of that USI

data mismatch between

****

inputs

compare error n.a. apply FR state

(SafeNet redundant)

data mismatch between

n.a. values received by CP2 prevail.

inputs****

(redundant Experion or

Modbus)

Redundant communication

Controller response

CP

X(faulty)

continue

communication via

healthy link

**

CP

Y(not faulty

none -continue

use values from

for affected

CP

Y

COM and FSC

***

inputs

Safety Manager Safety Manual 25

Page 32

3 – Safety Manager fault detection and response

* If the Controller is redundant, both CP channels respond the same.

** If no healthy link remains, apply FR state to the COM and FSC inputs allocated to that channel and/or switch to other

clock source.

*** If values are not available via CP

**** Inputs as in communication inputs of this SM Controller.

apply FR state to affected COM and FSC inputs.

Y

Communication time-out

If no communication with the external device is established within a predefined

time frame a communication time-out is generated.

A communication time-out always results in a communication failure.

Communication time-outs can be configured by the user.

If a device is connected to Safety Manager via a redundant communication link,

the fault detection applies to each link separately resulting in single-fault tolerant

communication.

26 Release 131, Issue 4

Page 33

SM IO faults

Tip:

For more information on repair timer settings or fault reaction states as referred to in these

topics, see “Introduction” on page 19.

These topics provide an overview of detected IO faults and the Controller

response to these faults.

Digital input faults

Table 9 on page 27 provides an overview of faults that can be detected in relation

to digital inputs and the response to these faults.

SM IO faults

Table 9 Controller response to digital input faults

Digital input faults Non redundant input

Related to Diagnostic message

reports

digital input loop

(line monitored)

loop power** power output to sensors

channel module faulty apply FR state use values from

module module faulty apply FR state use values from

compare

****

* If the Controller is redundant, both CPs respond the same.

** This fault is usually caused by an anomaly in the field, not by a defect of an input module.

*** If values are not available via CPY apply FR state to affected inputs.

**** Occurs when detecting a difference in the input values persists for more than 2 application cycli.

**

lead breakage apply FR state apply FR state

short circuit

shorted

input compare error apply FR state apply FR state

Controller response

apply FR state use values from

Redundant input, Controller response

*

CPX (faulty input) CPY (healthy input)

***

CP

Y

CPY***

CP

***

Y

none -continue

none -continue

none -continue

Safety Manager Safety Manual 27

Page 34

3 – Safety Manager fault detection and response

Analog input faults

Table 10 on page 28 provides an overview of faults that can be detected in

relation to analog inputs and the response to these faults.

Table 10 Controller response to analog input faults

Analog input faults Non redundant input

Related to Diagnostic message

Controller response

Redundant input, Controller response

*

CPX (faulty input) CPY (healthy input)

reports

analog input value below low transmitter

alarm level per range

none- continue for

0-20mA, 0-10V

bottom scale for

none- continue for 0-20mA, 0-10V

bottom scale for 4-20mA, 2-10V

4-20mA, 2-10V

above high transmitter

none- continue none- continue

alarm level all ranges

loop power

(SAI-1620m)

channel module faulty apply FR state use values from

External voltage

monitoring fault

none- continue none- continue

**

CP

Y

module module faulty apply FR state use values from

CP

Internal power down

compare

***

* If the Controller is redundant, both CPs respond the same.

** If values are not available via CPY apply FR state to affected inputs.

*** Occurs when detecting a deviation of >2% in the input values persists for more than 2 application cycles.

input compare error apply FR state apply FR state

Y***

Digital output faults

none- continue

none- continue

Table 11 on page 28 provides an overview of faults that can be detected in

relation to digital outputs and the response to these faults.

Tab le 11 Controller response to digital output faults

Digital output faults Non redundant output

Related to Diagnostic message

reports

digital output loop

**

current detected Apply FR state apply FR state

(line monitored)

default voting

28 Release 131, Issue 4

Controller response

Redundant output, Controller response

*

CPX (faulty output) CPY (healthy output)

Page 35

Tab le 11 Controller response to digital output faults (continued)

SM IO faults

Digital output faults Non redundant output

Related to Diagnostic message

Controller response

reports

digital output loop**

(line monitored)

current detected De-energize shorted

output(s).

1oo2D voting

digital output loop**

open loop none -continue none -continue

(line monitored)

digital output loop**

(other)

loop power

***

channel fault

(line monitored)

FR state = Low

channel fault

(other)

FR state = Low

channel fault

short circuit detected De-energize shorted

output(s).

external power down none -continue none -continue

module faulty De-energize outputs

on module & start

repair timer

module faulty De-energize outputs

on module & start

repair timer

module faulty none -continue none -continue

Other FR states

module fault

FR state = Low

module faulty De-energize outputs

on module & start

repair timer

module fault

module faulty none -continue none -continue

Other FR states

compare

****

output compare error apply FR state apply FR state

Redundant output, Controller response

*

CPX (faulty output) CPY (healthy output)

de-energize shorted output(s).

de-energize shorted output(s).

De-energize outputs on module & start

repair timer

De-energize outputs

none -continue

on module & start

repair timer

De-energize outputs

none -continue

on module & start

repair timer

* If the Controller is redundant, both CPs respond the same.

** This fault is usually caused by an anomaly in the field, not by a defect of an output module.

*** When this anomaly occurs on all modules in a watchdog group or a power group, it is not a defect of the output module.

**** Occurs when detecting a difference in the output values of a redundant SM Controller.

Analog output faults

Table 12 on page 30 provides an overview of faults that can be detected in

relation to analog outputs and the response to these faults.

Safety Manager Safety Manual 29

Page 36

3 – Safety Manager fault detection and response

Table 12 Controller response to analog output faults

Analog output faults Non redundant output

Related to Diagnostic message

reports

analog output calculation error halt Controller halt Controller

analog output loop open loop De-energize outputs

channel fault

FR state = 0 mA

channel fault

Other FR states

module fault

FR state = 0 mA

module fault

Other FR states

compare

**

* If the Controller is redundant, both CPs respond the same.

** Occurs when detecting a difference in the output values of a redundant SM Controller.

module faulty De-energize outputs

module faulty none -continue none -continue

module faulty De-energize outputs

module faulty none -continue none -continue

output compare error Apply FR state Apply FR state

Controller response

on module & start

repair timer

on module & start

repair timer

on module & start

repair timer

Redundant output, Controller response

*

CPX (faulty output) CPY (healthy output)

none -continue

De-energize outputs

on module & start

repair timer

De-energize outputs

on module & start

repair timer

IO compare errors and system response

none -continue

none -continue

Note

Because of the high level of self-testing and fault-handling by Safety Manager, the actual

occurrence of a compare error is very unlikely.

For proper operation both Control Processors of a redundant system must have

identical IO values at the beginning and at the end of each application cycle.

An IO compare error is generated as soon as the Controller detects a difference

between the IO values of CP1 and CP2.

The Controller responds towards IO compare errors by applying the fault reaction

state to the faulty IO.

Note

A Controller does not automatically shut-down upon detection of IO compare error.

30 Release 131, Issue 4

Page 37

Table 13 on page 31 shows the relation between Input and output compare faults,

alarm markers and Controller response.

Tab le 13 Controller response to IO compare faults

IO compare error

Related to redun

digital inputs N.A. a persisting difference for more than 2

analog inputs N.A. a deviation of >2% for more than 2

digital

outputs

analog

outputs

Occurs when detecting Controller

dancy

application cycles

application cycles.

N.A. a difference between outputs

N.A.

Compare error detection and synchronization

Input compare errors

Input compare error detection applies to all hardware inputs.

Differences in the input status read should be momentary. Persisting differences

could be the result of detected hardware faults. In that case, the faulty input

channel is reported in the diagnostics, and both Control Processors use the

process value read from the healthy input channel.

A persisting difference in status of an input while no faults are detected at the

accessory hardware channels leads to an input compare error.

SM IO faults

response

apply FR

state

Output compare errors

An output compare error applies to all hardware outputs.

In configurations with a redundant Controller, both Control Processors will

continuously have an identical application status, resulting in identical process

outputs.

An output compare error is detected if there is a difference between the Control

Processors with respect to:

• the calculated application output values for hardware outputs (AO/DO) or

• the actual application values sent to hardware outputs (AO/DO) or

communication outputs (DO, BO) to another Safety Manager.

communication outputs (DO, BO) to another Safety Manager.

Safety Manager Safety Manual 31

Page 38

3 – Safety Manager fault detection and response

If outputs are no longer synchronized an Output Compare error is generated.

Input synchronization algorithm

In configurations with a redundant Controller, the process inputs are scanned

every application program cycle by both Control Processors.

Each Control Processor executes the application cycle independently of the other.

It is therefore essential that they use identical values for the process inputs.

There is no problem if the process inputs are stable. However, if an input value

changes when the Control Processors read the value, both Control Processors

could read a different value. In such cases, an identical input value in the

Controller is obtained via input synchronization.

If inputs are no longer synchronized, the signal value freezes to the last known

synchronized state and a synchronization timer -equal to two application cyclesis started. This state is maintained until:

• a synchronized state is obtained or

• the synchronization timer runs out.

If a synchronized state is not achieved within two application cycles the fault

reaction is activated and an Input Compare error is generated.

If a synchronized state is achieved within two application cycles the

synchronization timer is reset.

Synchronization algorithms are used for digital and analog inputs.

Digital input synchronization

A digital input compare error is detected if the inputs of both Control Processors

are stable but different (for example Control Processor 1 continuously ‘0’,

Control Processor 2 continuously ‘1’), for the duration of two application cycles.

The input compare error detection algorithm puts the following demands on the

dynamic nature of the digital process inputs:

1. If an input state changes, it must become stable again within two application

cycles.

2. The frequency of continuously changing inputs must be less than two

application cycles.

Analog input synchronization

For analog inputs, the synchronized value is the mean value of the input values.

An input compare error is detected if the input values differ more than 2% of the

full scale for the duration of the configured Diagnostic Test Interval.

32 Release 131, Issue 4

Page 39

SM IO faults

The input compare error detection algorithm puts the following demands on the

dynamic nature of the analog process inputs:

1. For inputs allocated on a redundant module (type SAI-0410 or SAI-1620m),

the slope steepness must be less than 125 mA/s.

2. For inputs allocated on a non-redundant module (type SAI-1620m), the slope

steepness must be less than 20 mA/s

.

Caution

Analog input compare errors may, for example, occur when calibrating smart transmitters

using hand-held terminals. Refer to the Troubleshooting and Maintenance Guide for

details on calibrating smart transmitters that are connected to Safety Manager analog

inputs.

Safety Manager Safety Manual 33

Page 40

3 – Safety Manager fault detection and response

Calculation errors

Caution

Safety Manager stops if a calculation error occurs.

Calculation errors may occur in the application program.

Calculation errors occur if:

• The calculated value of an analog output is outside the specified range.

• The square root of a negative number is taken.

• A logarithm function is loaded with a negative value or zero

• A divide-by-zero occurs.

• An overflow occurs during a calculation.

• The value for a counter is outside the specified range.

Calculation errors reflect an incorrect design of the application program for the

intended function. Once a calculation error occurs for a specific process point, a

correct result of successive calculations based on this point cannot be guaranteed.

Guidelines on how to avoid calculation errors in the Safety Manager application

are presented below.

Preventing calculation errors

Calculation errors can be prevented as follows:

• Overall process design.

• Inclusion of Safety Manager diagnostic data.

• Validation of signals in the Functional Logic Diagrams (FLDs).

• Exception handling during the actual calculation.

Prevention by design

In line with good software engineering practice, as promoted by IEC 61508,

calculation errors should be avoided by design. This means that an application

should be designed in such a way that the operands of a symbol in the FLDs can

never get an invalid value. The design approach starts with making sure that input

values as obtained from the process remain within a predefined range. This

approach ensures that the derived values are also valid for successive operations.

34 Release 131, Issue 4

Page 41

Sometimes, however, it cannot be guaranteed that an input value remains within a

Transmitter

Transmitter

Validated

input value

Alarm/

Annunciation

Process

value

predefined range which is valid for all functions. For example, a signal derived

from a reverse-acting, non-linear 4-20 mA transmitter which has been configured

for a zero top scale in the application domain could become negative if the

transmitter fails and delivers a signal beyond 20 mA. If the signal is then

linearized through a square-root function, a system stop occurs (square root of

negative number).

Preventive measures

If a valid input value cannot be guaranteed, preventive measures must be built

into the design. A comparison function can be used as an indicator that the

transmitter value has left its normal operational band and that the calculation

should not be done. The alarm signal is used to implement a corrective action and

to indicate the exception to the operator (see Figure 7 on page 35).

Calculation errors

Figure 6 Intended square-root function

Figure 7 Square-root function with validated input value

If diagnostics are not available (e.g. for 0-20 mA transmitters), it is necessary to

implement range checking in the application. The result of the range check is

again used for the implementation of corrective actions.

Tip

Range checking is also useful to define the boundaries of analog outputs 0(4)-20mA, thus

preventing a system shutdown due to driving values that exceed the boundaries.

Safety Manager Safety Manual 35

Page 42

3 – Safety Manager fault detection and response

Transmitter

Function block

Alarm/

Annunciation

Process

value

An important advantage of input validation is that it can be implemented for input

values of which the validity cannot be guaranteed. Furthermore, the invalid input

can be exactly identified. This allows the implementation of effective correction

strategies of only the affected part of the process.

Common function block

A last option is to create a common function block, e.g. square root. The function

block validates the operand(s) and only performs the intended function if the

operands are valid. Otherwise a predefined value is returned. An additional

function block output should be provided which indicates if the calculation result

is valid or not. This output signal can be used for the implementation of corrective

actions in the application (see Figure 8 on page 36).

Figure 8 Square-root function with validity check in function block

36 Release 131, Issue 4

Page 43

Safety Manager special functions

Unit shutdown

Process units

If a process can be divided into independent process units, the overall process

availability can be increased by a separate shutdown of the units within Safety

Manager. In this way, whenever a fault is detected in the hardware of a process

unit, only the affected unit needs to be shut down, while the other parts of the

process remain unaffected.

Configuration of unit shutdown (watchdog grouping)

This subsection covers the required configuration, application programming and

wiring to achieve shutdown per process unit.

Figure 9 on page 38 shows a standard wiring diagram for unit shutdown of three

separate process units.

4

Safety Manager Safety Manual 37

Page 44

4 – Safety Manager special functions

Safety Manager

9236295192362951

Watchdog signal

Relay Relay Relay

Safe

"Relay-controlling"

Digital

Output module

Safe "Process”

Digital Output modules

For each process unit, a relay is used to connect the watchdog signal of the unit

output to the process Safety Manager watchdog. The relays are controlled via

outputs of Safety Manager: the unit shutdown outputs. In normal operation, all

relays are activated. If a fault is detected in a process unit, the corresponding relay

is deactivated, which results in a shutdown of the relevant unit.

The unit relays must meet the requirements of DIN VDE 0116, part 8.7.4.5 and

8.7.4.6 of October 1989, i.e.:

1. Mechanical reliability > 3 ∗ 10

2. Contacts protected (for example fuses, series resistors, etc.) at 0.6 ∗ nominal

contact current.

3. Electrical reliability > 2.5 ∗ 10

Tip

The relay output FTA TSRO-0824 complies to these requirements.

Figure 9 Wiring diagram for unit shutdown

6

switches.

5

switches.

38 Release 131, Issue 4

Page 45

Unit shutdown outputs

The unit shutdown outputs must:

• Be allocated on safe modules (such as a SDO-0824 or SDOL-0424 module)

• Have their fault reaction state set to Low.

This guarantees that Safety Manager directs the process to its safe state if a

fault occurs which affects this output.

• Have set the power-up status of the unit shutdown output to ON.

This allows a correct start-up of Safety Manager with activated unit relays.

For optimal availability it is recommended that unit shutdown outputs are

allocated to redundant output modules.

Process outputs (safety related)

The process outputs must be allocated to a Safety Manager output module of the

type:

•SDO-0824

• SAO-0220m

•SDO-04110

•SDO-0448

•SDO-0424

• SDOL-0424

• SDOL-0448

To allow the programming of the response via the application, the fault reaction

of these outputs must be set to Appl. This disables the automatic response of

Safety Manager in case a fault occurs at safety-related output modules.

Application programming

To realize unit shutdown in the functional logic diagrams, all diagnostic inputs

related to output modules of each process unit are connected to an AND gate.

Safety-related digital output module

(24 Vdc, 0.55 A, 8 channels)

Safety-related analog output module

(0(4)-20 mA, 2 channels)

Safety-related digital output module

(110 Vdc, 0.32 A, 4 channels)

Safety-related digital output module

(48 Vdc, 0.75 A, 4 channels)

Safety-related digital output module

(24 Vdc, 2 A, 4 channels)

Safety-related loop-monitored digital output module

(24 Vdc, 1 A, 4 channels)

Safety-related loop-monitored digital output module

(48 Vdc, 0.5A, 4 channels

Safety Manager Safety Manual 39

Page 46

4 – Safety Manager special functions

Figure 10 on page 40 shows how the output signal of the AND gate is connected

to the unit shutdown.

As long as all diagnostic inputs are “healthy”, they are High, the unit shutdown

output is High and the unit relay is activated (relay contact closed).

If a diagnostic input of an output channel in the unit becomes “unhealthy”, the

corresponding unit shutdown output becomes Low and the unit relay is

deactivated (relay contact open).

Figure 10 Functional logic diagram of unit shutdown

A defective output channel can be switched-off in accordance with the normal

Safety Manager response for safety-related signals. To switch off a defective

output channel, the calculated application output and the channel diagnostic input

must be supplied to the output channel via an AND gate.

The Safety Manager FaultReset alarm marker is connected to all unit

shutdown outputs via an OR gate. When an error is detected and repaired in a

unit, the unit may be restarted using the FaultReset alarm marker.

The minimum and maximum time the unit output is enabled by the

FaultReset is limited to ensure that the FaultReset is detected by the

output. The pulse length (typically set at 800 ms) may not exceed the Diagnostic

Test Interval.

40 Release 131, Issue 4

Page 47

On-line modification

Tip:

Detailed information about On-line modification can be found in On-line Modification

Guide

Introduction

On-line modification (OLM) is a Safety Manager option which allows you to

modify the application software, embedded system software and the Safety

Manager hardware configuration of systems with a redundant Controller while

the system remains operational.

During the on-line modification, the changes are implemented in the Control

Processors one by one. While one Control Processor is being modified, the other

Control Processor continues safeguarding the process.

The engineer executing the OLM is guided through the OLM procedure step by

step by Controller Management which is integrated in the Safety Builder.

On-line modification

Compatibility check

During the modification, Safety Manager performs a compatibility check of the

application-related data, to guarantee a safe changeover from the existing

configuration to the new configuration. The system reports all application

changes in a detailed report in the Extended Diagnostics.

The user is expected to verify each reported change before starting up the system.

When modifications are implemented in an application, only a functional logic

test of the modified functions is required by, for example, TUV. This must be

done when the final verification of the implemented changes is obtained via the

built-in sheet difference report in Controller Management diagnostics.

Safety Manager networks

If a system has been integrated into a Safety Manager communication network

(SafeNet), it performs a compatibility check for all connected systems.

If it detects inconsistencies or if the check of a specific system cannot be

completed for some reason, an error message is generated in the extended

diagnostics. In case such an error occurs, no data will be exchanged with that

system. The communication can only be established after a successful completion

of the compatibility check by any of the Safety Managers that can communicate

with each other, initiated via a QPP reset.

Safety Manager Safety Manual 41

Page 48

4 – Safety Manager special functions

SafeNet communication

Safety Managers can be connected together to form safety-related networks. The

protocol used for this network is called SafeNet.

SafeNet is available to Safety Managers for:

• Distributed processing

• Sharing safe data for joint SIS related tasks.

• SIL3, TUV approved, communication.

• Remote load

Networks

Attention:

USIs running 3

USI outages and communication shutdown.

If communication overflow is a potential risk, we recommend to allocate all SafeNet links

on dedicated USIs (not running vulnerable 3

rd

party protocols may be vulnerable to communication overflow, causing

rd

party protocols).

Data that is transferred between Safety Managers is represented in function logic

diagrams as IO symbols with the location FSC. Points with location FSC can be

of type DI or DO (markers), BI or BO (registers), and may be configured for safe

and non-safe functions.

Protocol versus response time

The response time between Node ID and logical Peer ID depends on:

• the application program cycle time of the Node ID and Peer ID system in the

logical link.

• the delay caused by the data layer protocol of the physical links.

Response time and time-out time are related.

The minimum time-out depends on the system application cycle and the type of

communication link.

The time-out time you set must be larger than the maximum response time.

The response time to a communication request highly depends on the actual states

of both Node ID and Peer ID system at the time of the request.

42 Release 131, Issue 4

Page 49

The maximum response time equals the sum of:

• the application cycle time of the Node ID plus

• the application cycle time of the Peer ID plus

• the expected communication delay.

The Node ID periodically sends data to the Peer ID systems and initiates a request

for data from the Peer IDs. A correct answer must be provided for within the

time-out period; when not received in time, the link is regarded faulty.

A new data transmission and request for a Peer ID are initiated after the Peer ID

reply to the previous request has been received. This could be equal to the

time-out time, but usually it is shorter.

SafeNet time-out time

All systems within the network monitor the operation of a communication link by

means of a time-out.

• The time-out can be set for each individual logical link and must be chosen

• The time-out time set must be at least 2x the calculated response time.

SafeNet communication

such that it stays within the Process Safety Time (PST) for the Safety

Instrumented Functions (SIFs) involved.

Ethernet communication

When communicating via Ethernet you should be aware of the following:

• “Ethernet communication risks” on page 43

• “Ethernet bandwidth and response time calculation” on page 44

Ethernet communication risks

Attention:

USIs running 3

USI outages and communication shutdown.

If communication overflow is a potential risk, we recommend to allocate all SafeNet links

on dedicated USIs (not running vulnerable 3

When devices communicate via an Ethernet based local area network (LAN),

their information is contained and sent in packets. This is no different when using

SafeNet through Ethernet. However, Ethernet has far less timing restrictions and,

when sending SafeNet packets together with other application packets, some

packets may suffer critical delay or get lost if a network gets congested.

rd

party protocols may be vulnerable to communication overflow, causing

rd

party protocols).

Safety Manager Safety Manual 43

Page 50

4 – Safety Manager special functions

Packet losses and network congestion may occur if e.g.:

• several devices start transmitting packets at the same time and/or,

• a single device generates a peak in network traffic,

Attention:

1. Risks are involved when using SafeNet on an insecure, open or shared Ethernet,

where downtime, delays, loss and/or access to packets can be caused by other devices

on the LAN.

Such risks can be caused by office computers, network printers, servers and open

access points (such as wifi access points, WAN routers, etc.)

2. Viruses and applications such as MSN Messenger may affect SafeNet reliability when

active on the same Ethernet.

When the Ethernet is dedicated to a single Safenet, issues do not take place:

• No single SafeNet configuration can cause a 100MB Ethernet to operate at its

maximum capacity (Safety Builder checks this in the configuration stage).

Packets are vulnerable to modifications or alterations when accessed by external

systems: Applications running on these systems could (deliberately or via a virus

infection) intercept, delay and/or alter packets.

Ethernet bandwidth and response time calculation

Please consult the release notes issued with your Safety Builder software for ways

to determine bandwidth and response time.

Conventional serial communication

Please consult the release notes issued with your Safety Builder software for ways

to determine bandwidth and response time.

Reset

The reset function is a means to allow Safety Manager to recover from an

abnormal state. (Running fault free is the normal operating state.)

Safety related resets allow the recovery from all fault types whereas non safety

related resets allow the recovery of non safety related faults only.

Safety related resets can be given via the reset key switch, via the Remote

Reset button in Safety Builder (after enabling in the configuration) and by

SM Controllers, initiating a safety related reset command via SafeNet.

44 Release 131, Issue 4

Page 51

System response towards a safety related reset

The response to a safety related reset action depends on the QPP state of the

Control Processor. The following QPP states make the Control Processor respond

to a reset:

1. Running

The Control Processor is running without faults.

Initiating a reset will have no effect on the SM Controller state.

2. Running with Flt

The Control Processor is running with faults.

Initiating a reset will move the faults logged in the actual fault database to the

historical fault database (clearing the actual faults database) and log the reset.

3. CPReady (after startup or after recovering from a fault)

(Both Control Processors contain the same application.)

Initiating a reset, with a QPP in CPReady and identical applications residing

in CP1 and CP2, will start the application in the ready QPP.

4. CPReady (during an OLM procedure)

(Both Control Processors contain different applications.)

Initiating a reset with a QPP in CPReady and different applications in the

Control Processors (OLM) will cause an application switch-over from the

running Control Processor to the ready (idle) Control Processor.

5. Halt with Flt (during an OLM procedure)

(Both Control Processors contain different applications.)