Honeywell S9240F1004 Installation Instructions Manual

®

S9240F1004 Modulating Hot Surface

Ignition Integrated Furnace Control

INSTALLATION INSTRUCTIONS

APPLICATION

The S9240F1004 Integrated Furnace Control (IFC) is

designed specifically to work with a Lennox G71MPP variable

firing rate, high efficiency furnace. It provides gas ignition,

safety shutoff, and variable speed fan control with multi-firing

rate gas heating and up to 2-stage electric cooling

applications.

FEATURES

The S9240F1004 provides the following features:

• Monitors a single stage or 2-stage conventional low

voltage thermostat for requests for heat, cool, or fan.

• Monitors an input provided for connection to a

thermostat with a dehumidification output or Harmony

III Zone Control.

• Provides three stage furnace input rate control when

operating with a conventional single stage thermostat.

• Provides 2-stage or modulating furnace input rate

control based on field selected option when operating

with a conventional 2-stage thermostat.

• Manages ignition of a main burner flame up to 400,000

BTU per hour using a 95 V hot surface igniter.

• Monitors the appliance pressure, limit, and rollout

switches and generate control actions as

programmed.

• Controls the 24 Vac Honeywell amplified gas/air gas

valve.

• Controls a 3-phase 120 Vac inducer motor (Fasco

Model 92B1 or other with identical voltage/frequency

curve) and blower assembly based on heat demand

and other parameters.

• Controls the Regal Beloit 3.0 ECM circulator motor and

blower based on defined appliance CFM profiles

and/or a discharge air sensor signal.

• Controls single stage or 2-stage cooling equipment.

The outdoor unit is controlled directly by the 24 Vac

conventional thermostat inputs. The IFC manages the

circulator speed based on cool demand and other

parameters.

• Controls a 120 Vac humidifier output and a 120 Vac

EAC output.

• Operates with 120 Vac single phase, 60 Hz power

supply.

• Uses a 7-segment LED display to communicate error

code and status information. A single on board button

is provided to generate the desired information

display.

• Provides field selectable DIP switches to select field

specific control operating parameters such as type of

thermostat, delay timings, and fan operating

parameters.

• Provides on-board jumpers that can be clipped to

permanently enable 2-stage cooling, heat pump

compatibility, dehumidification sequences, and define

appliance characteristics for field replacement

purposes.

• Provides Field Test Mode and Diagnostic Recall Mode

to assist the installation/service technician.

• Stores the 10 most recent error codes, which are

accessible by the service technician in Diagnostic

Recall Mode.

Automatic Ignition Systems

ANSI Z21.20

69-2088-01

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

SPECIFICATIONS

Electrical Ratings

Line Voltage Supply: 97-120 Vac, 58-62 Hz; single phase

(132 Vac and 62 Hz maximum)

Input Voltage: 18-24 Vac (30 Vac maximum)

Input Current: 500 mA (control only)

Current Draw: 0.5A Input Current plus valve load and

optional 24 VAC humidifier load at 24Vac

Igniter Current: 1.0A resistive at 95 Vac output

Induced Draft Blower: 33-110 Vac; 45-180 Hz; 1.1 A at

110 Vac 3-phase (full load)

Gas Valve: 1.5 A at 30 Vac; Inrush current 3.0 A at 30 Vac;

Inrush duration 16 ms

Line Voltage Humidifier: 1A resistive load maximum at

120 Vac

Electronic Air Cleaner: 1A resistive load maximum at

120 Vac

Gas Control: Honeywell VK8105R variable firing rate, 24 Vac

valve

Second Stage ON Delay: 7 or 12 minutes - when used with a

single stage thermostat (see Table 5 on page 8); default is

7 minutes

Third Stage ON Delay: 10 minutes - when used with a single

stage thermostat

Fan Delays:

Heat Fan ON Delay: 45 seconds

Heat Fan OFF Delay: 60, 90, 120, or 180 seconds; default

90 seconds; see Table 5 on page 8

Cool Fan ON Delay: 2 seconds plus selected Cooling Pro-

file; see Table 6 on page 9

Cool Fan OFF Delay: selected Cooling Profile; see Table 6

on page 9

Circulator Speeds:

Heat: various settings available; see Table 7 on page 10

Cool: low, medium-low, medium-high, and high speeds

available; see Table 6 on page 9

Fan - Thermostat “G”: low, medium-low, medium-high, and

high speeds available; see Table 5 on page 8

LED

The 7-segment LED communicates:

• System status

• Error codes

• Enables, via a pushbutton, alternate modes (Idle,

Diagnostic, and Field Test) of operation

Cooling Contactor: Any 24 Vac contactor rated at 1.0A or

less

Timings

Prepurge: 15 seconds

HSI Warm-up: 20 seconds

Trial for Ignition: 4 seconds

Ignition Stabilization Period: 10 seconds

Flame Failure Response Time: 2 seconds maximum

Gas Valve Sequence Period: 20 seconds

Postpurge: 20 seconds (15 seconds at current fire rate and 5

seconds at 40% fire rate)

Interpurge: 15 seconds

Auto Restart Delay: 60 minutes (after Soft Lockout)

Ignition Trials: Five total; four retries if flame is not sensed on

the first trial

Ignition Recycles: 4 total; 3 recycles if flame lost on first trial

Operating

Operating Temperature: -40°F to +175°F (-40°C to +79°C)

Storage Temperature: -40°F to +185°F (-40°C to +85°C)

Relative Humidity: 0% to 95% non condensing

Approvals

CSA

ANSI Z21.20

Second Stage Recognition Delay: 30 seconds (only on First

Call for High Fire on a Call for Heat)

69-2088—01 2

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings given in these instructions to make

sure the integrated furnace control is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out operation as

provided in these instructions.

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. The integrated furnace control can malfunction if it

gets wet, leading to accumulation of explosive gas.

— Never install where water can flood, drip or

condense on the IFC.

— Never try to use an integrated furnace control

that has been wet—replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not naturally vent upward.

— Do not operate electric switches, lights, or

appliances until you are sure the appliance area

is free of gas.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring or

making wiring connections to prevent electrical shock

or equipment damage.

CAUTION

Equipment Damage Hazard.

Water can cause equipment damage or

malfunction.

If the integrated furnace control must be mounted near

water or moisture, provide suitable waterproof

enclosure.

Location

The integrated furnace control is mounted on a panel within

the circulator compartment of the furnace. The location must

provide:

— Access to the field wiring terminals.

— Operating ambient temperatures between -40°F and 175°F

(-40°C and 79°C).

— Relative humidity below 95% non condensing.

— Protection from water, steam or corrosive chemicals that

are used to clean the appliance.

— Protection from dripping water, such as from an overfilled

humidifier or from condensation.

— Protection from dust or grease accumulation.

Mounting

The integrated furnace control is designed to snap into the

appliance mounting panel.

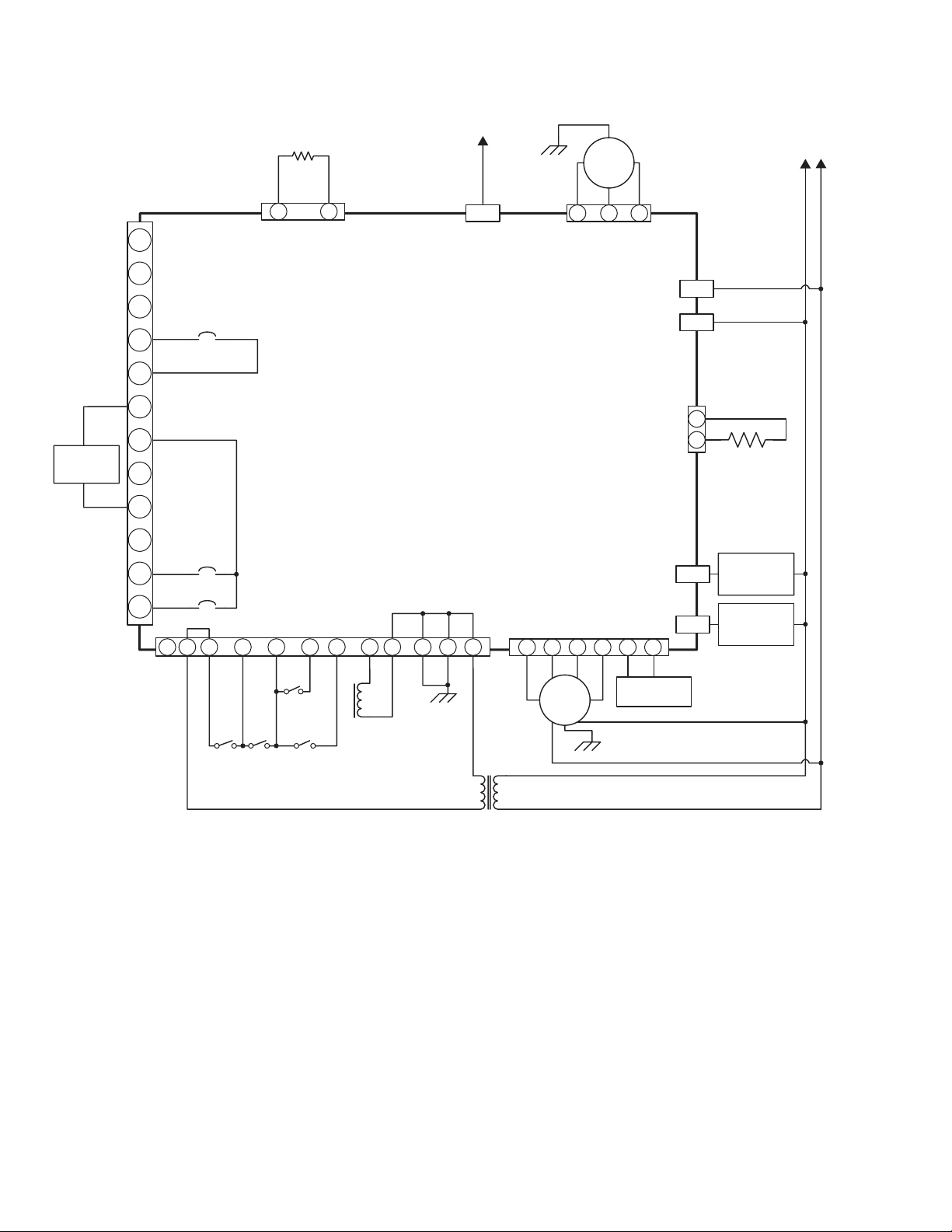

1. While holding the controller board with the thermostat

terminals (E7) at the bottom, insert the two left-side

hooks on the board into the holes in the mounting panel.

See Fig. 1 on page 5.

2. Press the board into the mounting panel’s right-side

holes until it snaps into place.

Wiring

Check the wiring diagrams furnished by the appliance

manufacturer, if available, for circuits differing from the

general hookup shown. Carefully follow any special

instructions affecting the general procedures outlined below.

All wiring must comply with local codes and ordinances.

See Table 1, Table 2, Table 3, and Fig. 1 beginning on page 4

for typical connections, but refer to furnace manufacturer

instructions, if available.

See Fig. 2 on page 6 for a typical wiring diagram.

3 69-2088—01

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

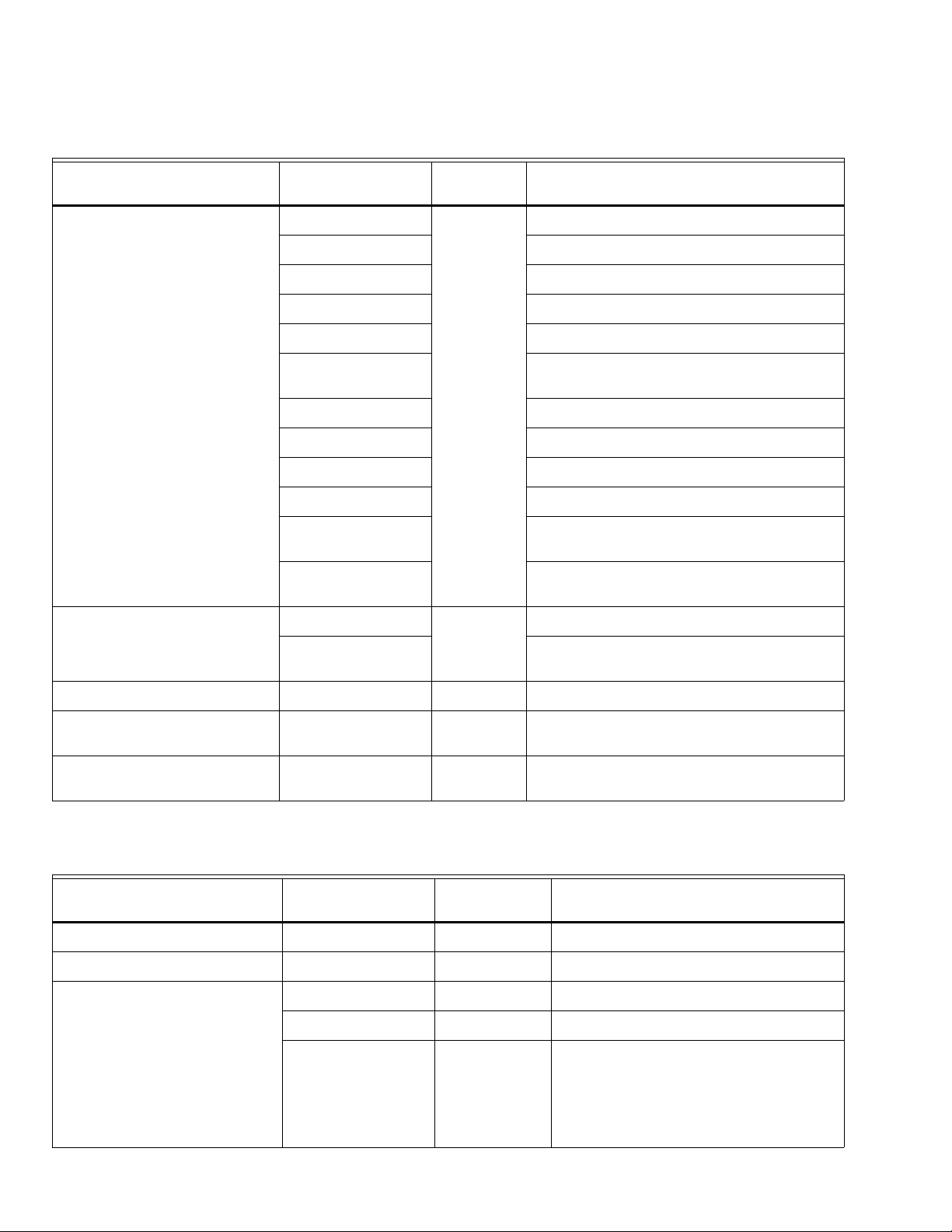

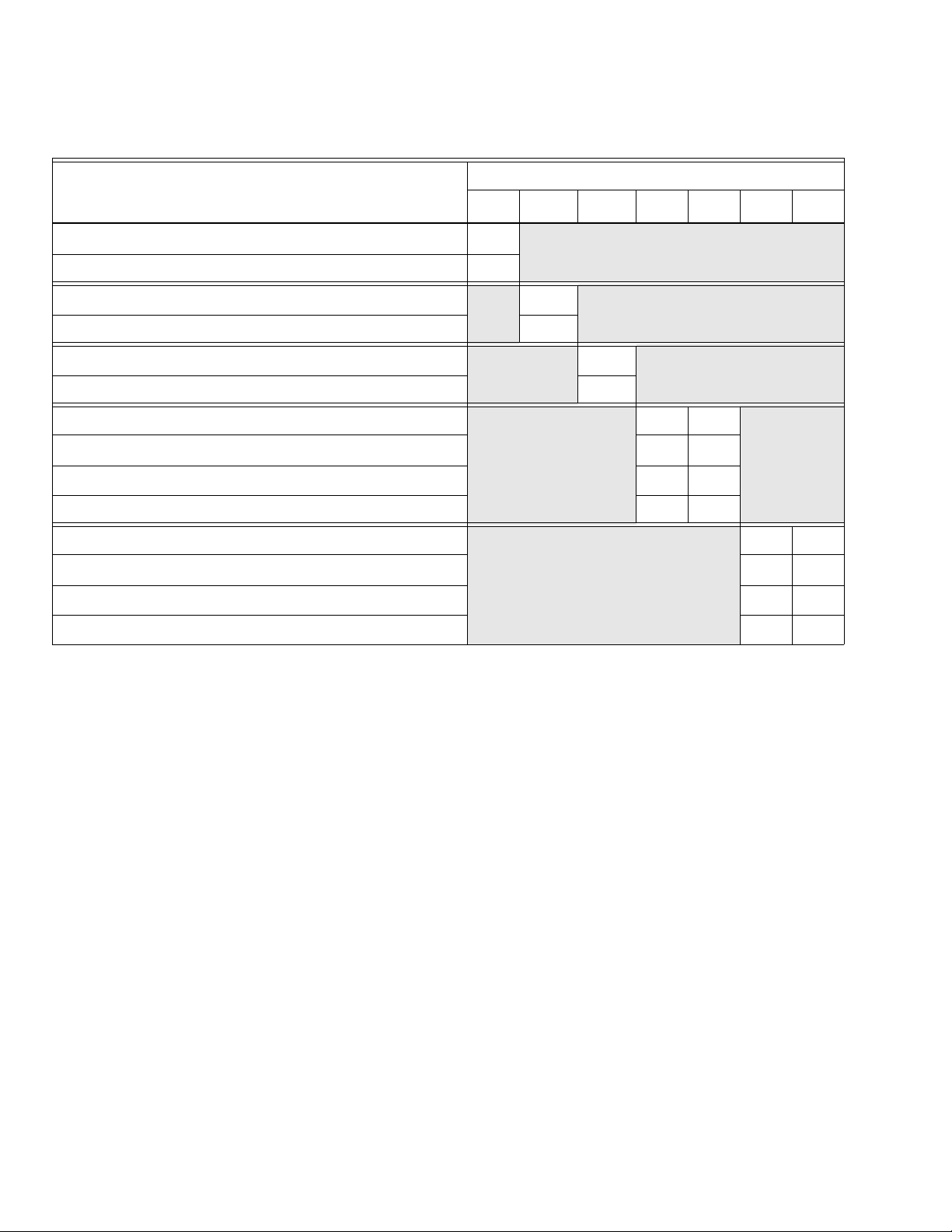

Table 1. Wiring Connections - Class 2 - Low Voltage.

Terminal Type Connection/Label

12-position screw terminal block

(#5 screw)

4-position screw terminal block

(#5 screw)

Board label

(see Fig. 1) Connects S9240F to:

W1

Thermostat 1st stage heat input

W2 Thermostat 2nd stage heat input

G Thermostat continuous fan input

Y2 Thermostat 2nd stage cool input

Y1 Thermostat 1st stage cool input

C 24 Volt ground (connected to transformer and

chassis ground)

R 24 Volt hot

E7

DH Not used

H - (optional) If used: 24V humidifier output

L Not used

O - (optional) If used: Thermostat signal to heat pump

reversing valve input

DS - (optional) If used: Thermostat Dehumidification or

Harmony Zoning input

Outdoor Sensor

Discharge Air Sensor

E4

Not used

If used: Discharge air sensor

- (optional)

Straight Spade Quick Connect Flame Sense E42 Flame signal input

12-pin connector (male terminals) Main Harness J2 Main valve, pressure switches, rollout, limit,

chassis ground, and 24 Vac

6-pin connector (male terminals) Circulator Motor P79 Motor serial control interface and furnace size

select input

Table 2. Wiring Connections - Class 1 - Line Voltage.

Board label

Terminal Type Connection/Label

(see Fig. 1) Connects S9240F to:

2 pin connector (male terminals) Igniter P77 – HSI Igniter interface

3-pin connector (male terminals) CAI Connector J3 – CAI 3-phase AC power

Straight Spade Quick-connect Humidifier HUM Humidifier 120 Vac output

EAC EAC Electronic air cleaner 120 Vac output

Neutrals E36, E37,

E38, E39,

and E40

Any neutral connector can be used for:

• 120 Vac Input neutral

• Transformer neutral

• Electronic air cleaner neutral

• Circulator neutral

• Humidifier neutral

69-2088—01 4

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

.

Table 3. Jumpers.

Jumper

(see Fig. 1) Action:

W915 - 2-Stage Compressor W915 UNCUT: Single stage compressor (factory default)

CUT: 2-stage compressor

W951 - Heat Pump W951 UNCUT: Compressor heating disabled (factory default)

CUT: Compressor heating enabled

W914 - Dehumidifier or Harmony III W914 UNCUT: Harmony III and dehumidifying operation disabled

(factory default)

CUT: Harmony III and dehumidifying operation enabled

Board label

SIDE HOOK (X2)

PANEL MOUNTING

FOR

W1

W2

G

Y2

E7

Y1

C

R

DH

50029412-001 Rev. A

H

L

TEMPERATURE SENSORS – E4

OUTDOOR

EQUIPMENT

RCI –I +

INDOOR

EQUIPMENT

RCI –I +

W1 W2 G Y2 Y1 DH H O DSC

LR

W914

DEHUM

OR

HARMONY

W951

HEAT

PUMP

COMPR

2 STAGE

I –

W915

I+

P80

SELECTION

CUT FOR

OPTION

3

6

9

12

1

S3

AIR SENSOR

DISCHARGE

15 17

19

1

4

7

10

SENSOR

OUTDOOR

1614 18

S2 S1 PUSH BUTTON E42 – FLAME SENSE

LED

ON ON

3

6

ON

8

10

119

12

13

1234567

R

EAC HUM

1

4

R

L1

SENSE

FLAME

3

1

HSI

2

J3 – CAI

1

NEUTRALS

W914

DEHUM

OR

HARMONY

W951

HEAT

PUMP

W915

2-STAGE

COMPR

J2

MAIN

HARNESS

P79

CIRCULATOR

MOTOR

HARNESS

HUMEAC

L1

P77

HSI

NEUTRALS

E36, E37, E38, E39, AND E40

FACTORY USE ONLY.1

Fig. 1. Typical wiring connections and component locations for S9240F1004 Integrated Furnace Control

(minor components removed for clarity).

5 69-2088—01

M28148

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

24V

HUMIDIFIER

(OPTIONAL)

W1

W2

Y2

Y1

DH

DS

DISCHARGE AIR SENSOR

(OPTIONAL)

21

E4

G

W915

C

E7

R

H

L

O

W951

W914

3511 6 1218472109

J2

FLAME ROD

FLAME SENSE

P79

312 4

3 PHASE COMBUSTION

AIR INDUCER

M

213

J3

P77

56

L1

L2

1

2

HUM

EAC

95V HSI

LINE VOLTAGE

HUMIDIFIER

(OPTIONAL)

ELECTRONIC

AIR CLEANER

(OPTIONAL)

120 V / 60 HZ

AC MAINS

L2 L1

FURNACE SIZE

IDENTIFIER

ROLLOUT

SWITCH

HIGH

LIMIT

SWITCH

HIGH

PRESSURE

SWITCH

LOW

PRESSURE

SWITCH

MAIN

VALV E

24 VAC

REGAL

BELOIT

ECM 3.0

INDOOR

AIR BLOWER

M

Fig. 2. Typical wiring diagram for S9240F1004 Integrated Furnace Control.

M28147

69-2088—01 6

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

SETTINGS AND ADJUSTMENTS

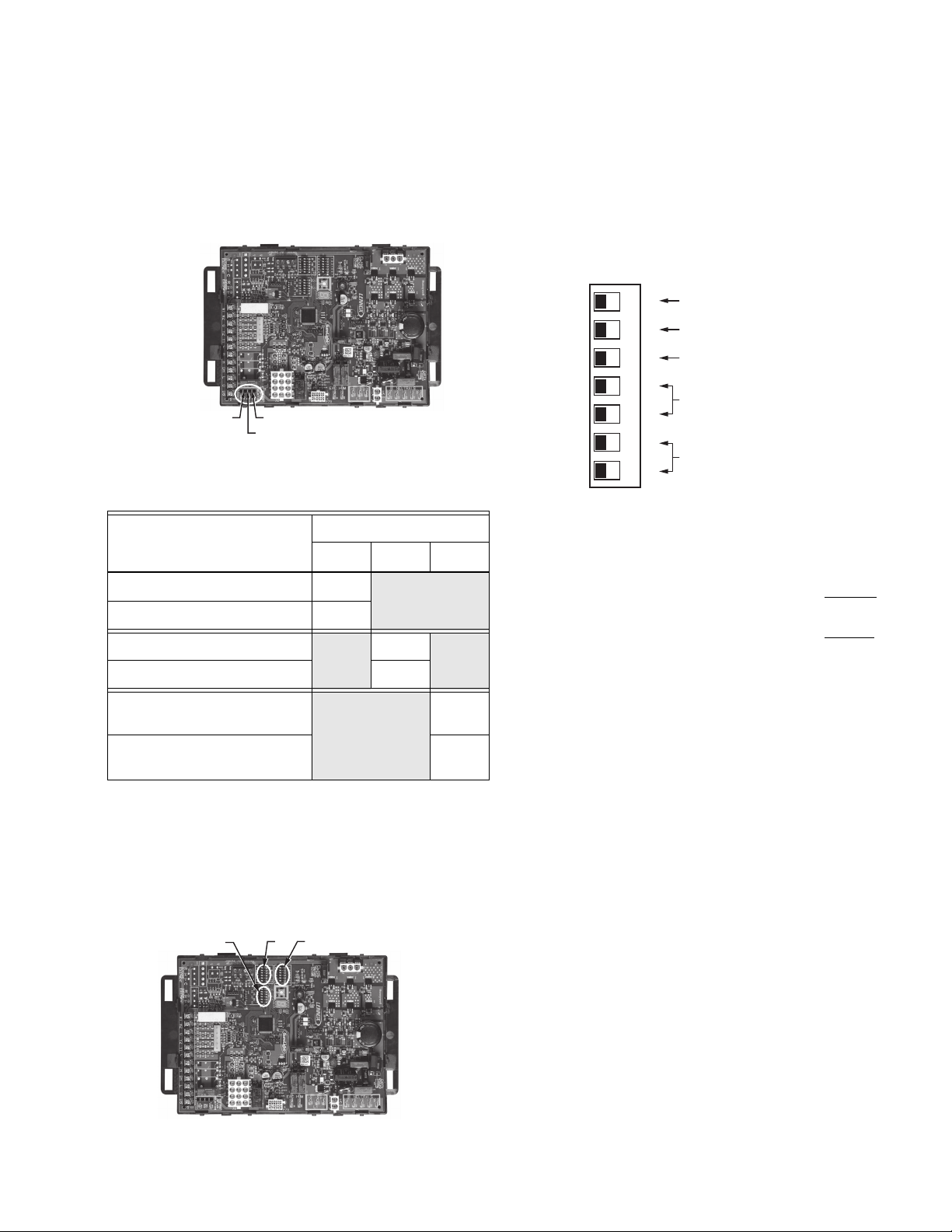

Jumpers

Three jumpers are located on the S9240 board. The jumpers

are all ON (uncut) from the factory. To change any jumper, first

disconnect the power, then cut the desired jumper.

W915 - 2 STAGE COMPRW914 - DEHUM/HARMONY

W951 - HEAT PUMP

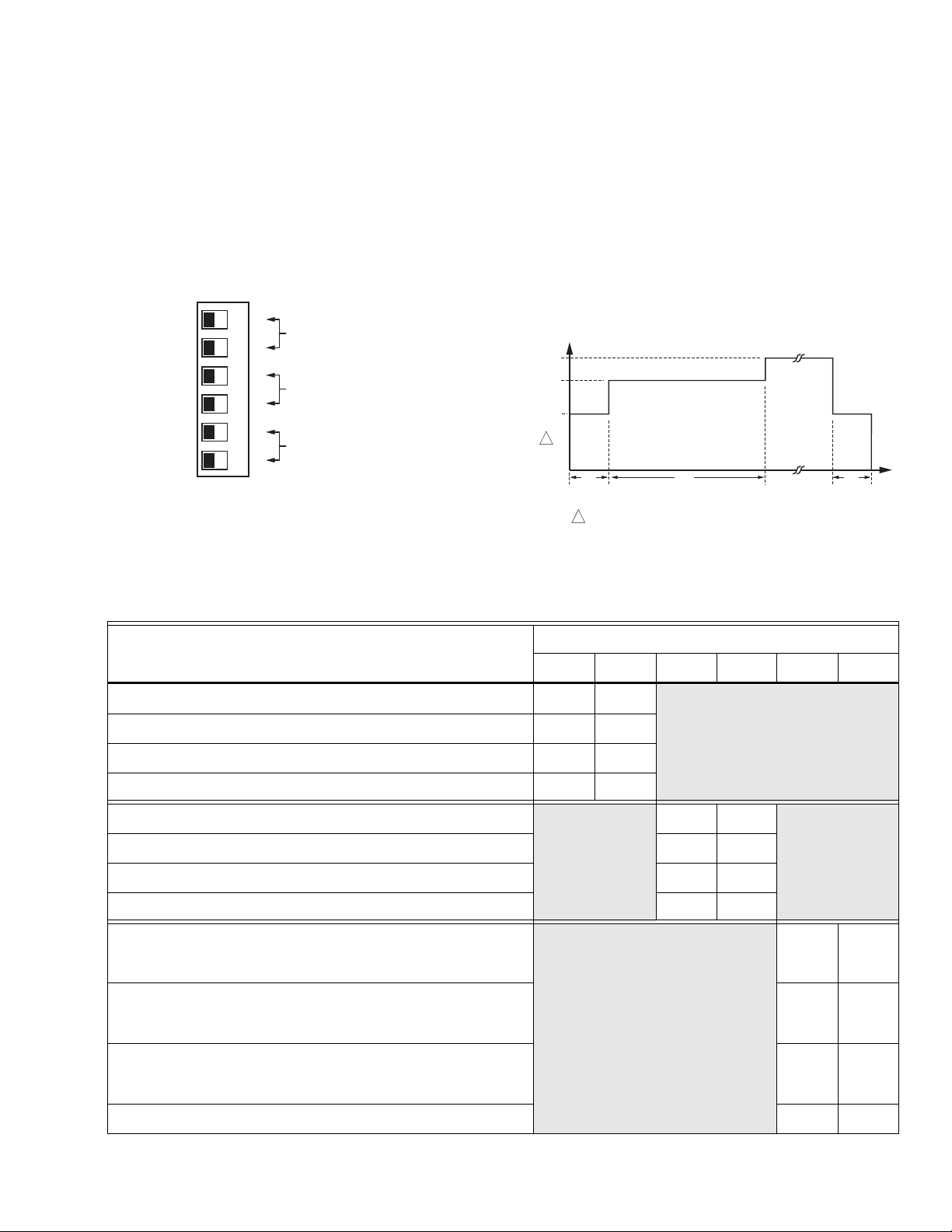

Fig. 3. Jumper locations.

Table 4. Jumper Conditions - Defaults in Bold.

Jumper

Description

W915 W951 W914

Single stage compressor Uncut

2-stage compressor Cut

Disable compressor heating

Uncut

Enable compressor heating Cut

M28149

DIP Switch S1 Settings

Five parameters may be set with this 7-position DIP switch.

Refer to Fig. 4 for location of DIP switch S1.

The default factory settings (all OFF) are shown in Fig. 5 and

indicated in Bold in Table 5 on page 8.

To change any setting, first disconnect the power, then set

SW1 through SW7 according to Table 5 on page 8.

.

DIP SWITCH S1

Fig. 5. DIP Switch S1 - shown with factory default

SW1: STAGE SELECTION

The stage selection is factory-set (OFF) to a 2-stage

thermostat with the 2nd and 3rd stage On Delays disabled

The ON position configures the IFC for a single stage

thermostat with the 2nd and 3rd stage On Delays enabled

NOTE: Selection of the single stage position (ON) allows

three stage operation with a single stage thermostat.

ON

12 43576

SINGLE OR 2-STAGE THERMOSTAT

SELECTION

CONVENTIONAL 2-STAGE OR

LENNOX MODULATING SEQUENCE

2ND STAGE ON DELAY

HEAT FAN OFF DELAY

FAN SPEED - THERMOSTAT “G”

settings; all OFF.

M28151

.

.

Disable Harmony III and

Uncut

dehumidifying operation

Enable Harmony III and

Cut

dehumidifying operation

DIP Switches

There are three DIP switch blocks on the S9240F (see Fig. 4):

• S1 – see “DIP Switch S1 Settings”

• S2 – see “DIP Switch S2 Settings – Cooling Airflow” on

page 9.

• S3 – see “DIP Switch S3 Settings – Heating Airflow” on

page 10.

S3 S1

Fig. 4. DIP Switch locations (S1, S2, and S3).

S2

M28150

SW2: SEQUENCE

The sequence is factory-set (OFF) to respond to a thermostat

as dictated by the SW1 selection.

The ON position configures the IFC for the Lennox modulating

firing state sequence with 2-stage thermostat.

NOTE: SW2 position is ignored if SW1 is ON.

SW3: 2ND STAGE ON DELAY

The On Delay timing applies to systems configured only with

single stage thermostats. It is the length of time operating in

normal low fire mode before switching to high fire mode. The

timing is factory-set (OFF) to 7 minutes.

The ON position configures the 2nd stage On Delay for 12

minutes.

NOTE: SW3 position is ignored if SW1 is OFF.

SW4-5: HEAT FAN OFF DELAY

The Heat Fan Off Delay is the period between the loss of

supervised main burner flame after the call for heat has ended

and the deactivation of the blower motor at the low heat

speed. The timing is factory-set (all OFF) to 90 seconds. See

Table 5 on page 8 for other timing settings.

SW6-7: FAN SPEED – THERMOSTAT “G”

The fan speed is factory-set (all OFF) to Medium-low. See

Table 5 on page 8 for other speed settings.

7 69-2088—01

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

Table 5. DIP Switch S1 Settings - Defaults in Bold.

Individual Switches

a

Description

SW1 SW2

SW3bSW4 SW5 SW6 SW7

2-Stage Thermostat: 2nd and 3rd stage On Delay disabled

OFF

Single Stage Thermostat: 2nd and 3rd stage On Delay enabled ON

Conventional 2-stage sequence with 2-stage thermostat

OFF

Lennox modulating sequence with 2-stage thermostat ON

2nd Stage On Delay - 7 minutes

OFF

2nd Stage On Delay - 12 minutes ON

Heat Fan Off Delay - 60 seconds

Heat Fan Off Delay - 90 seconds

OFF ON

OFF OFF

Heat Fan Off Delay - 120 seconds ON OFF

Heat Fan Off Delay - 180 seconds ON ON

Low fan speed (fan only operation)

Medium-low fan speed (fan only operation)

OFF ON

OFF OFF

Medium-high fan speed (fan only operation) ON OFF

High fan speed (fan only operation) ON ON

a

Switch 2 is ignored if switch 1 is in the ON position.

b

Switch 3 is ignored if switch 1 is in the OFF position.

69-2088—01 8

S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

DIP Switch S2 Settings – Cooling Airflow

DIP Switch S2 is used to adjust the cooling speed and profile.

Refer to Fig. 4 on page 7 for location of DIP switch S2.

The default factory settings (all OFF) are shown in Fig. 6 and

indicated in Bold in Table 6.

To change any setting, first disconnect the power, then set

SW8 through SW13 according to Table 6.

.

Fig. 6. DIP Switch S2 - shown with factory default

DIP SWITCH S2

ON

89 1110 12 13

settings; all OFF.

COOL SPEED

COOL SPEED ADJUSTMENT

COOLING PROFILE

M28152

SW8-9: COOLING FAN SPEED

The fan speed during cooling is factory-set to High.

SW10-11: COOLING FAN SPEED ADJUSTMENT (CFM)

The fan CFM during cooling is factory-set to normal (Base

Tap).

SW12-13: COOLING PROFILE

The fan profile during cooling is factory-set to 30 seconds at

50%, 7.5 minutes at 82%, run at 100%, and with a 30 second

Off delay at 50%. Fig. 7 illustrates the factory-set cooling

profile. The fan speed ramps up and down during speed

changes.

.

100%

F

A

82%

N

S

P

50%

E

E

1

D

30

FAN SPEED AS A PERCENT OF MAXIMUM.

1

450

TIME (SECONDS)

30

M28161

Fig. 7. Fan cooling speed ramp up and ramp down profile

(factory default shown).

Table 6. DIP Switch S2 Settings – Cooling Airflow.

Individual Switches

Description

High Cool Speed (circulator)

SW8 SW9 SW10 SW11 SW12 SW13

OFF OFF

Medium-low Cool Speed (circulator) OFF ON

Medium-high Cool Speed (circulator) ON OFF

Low Cool Speed (circulator) ON ON

Normal CFM - Base tap

OFF OFF

Decrease Cool speed CFM by 10% OFF ON

Increase Cool speed CFM 10% ON OFF

ECM Test Mode (motor slew rates disabled) ON ON

Cooling Profile -

On: 30 seconds at 50%, 7.5 minutes at 82%, then run at 100%

Off: 30 second Off Delay at 50%

Cooling Profile -

On: No On Delay (run at 100%)

Off: 60 second Off Delay at 100%

OFF OFF

OFF ON

Cooling Profile -

On: 7.5 minutes at 82%, then run at 100%

ON OFF

Off: no Off Delay

Cooling Profile - no On or Off Delays ON ON

9 69-2088—01

Loading...

Loading...