Honeywell S9200U1000 Installation Manual

69-2075-05

S9200U1000 Universal Hot Surface

Ignition Integrated Furnace Control

INSTALLATION INSTRUCTIONS

APPLICATION

The S9200U1000 Universal Integrated Furnace Control

is a combustion control used in single stage gas heating

and cooling appliances. Keyed wire harnesses allow the

S9200U1000 to replace most furnace controls and to be

applied to most heating and cooling single stage

appliances.

The S9200U1000 can be used with conventional

thermostats as well as the EnviraCOM™ enabled

VisionPRO IAQ and FocusPRO. The S9200U1000

Universal Integrated Furnace Control is intended for

residential natural or liquid propane fueled furnaces only.

The S9200U1000 EnvriaCOM™ communications

capability allows its use in twinning applications and

enables communication with local and remote diagnostic

devices such as the QuickLook hand held device

(QuickLook™ 72), EnviraLNK® web-based application

and the W8735D Telephone Access Module (TAM).

FEATURES

The S9200U1000 provides:

• Main burner ignition using a 120V hot surface

igniter.

• Flame rectification circuit to monitor flame

presence.

• Monitoring of system pressure switch, high

temperature limit, and rollout functions.

• Appliance operation/safety requirements

controlled via microprocessor.

• Control of a standard induction-type circulating

fan motor (based on appliance requirements), in

response to a conventional low voltage or

EnviraCOM™ thermostat.

• LED system status, performance and diagnostic

indication.

• Wire harnesses provided for simple replacement

of most IFCs and integration with most heating

and cooling appliances.

• Twinning capability.

• EnviraCOM™ communication capability to enable

local and/or remote system status, diagnostics,

troubleshooting, and HVAC system control.

SPECIFICATIONS

Line Voltage: Line 120V (97-132 Vac), 60 Hz

Low Voltage: Line 24V (19-30 Vac), 60 Hz

Current Draw: 0.5A Input Current @24 Vac, plus valve

load @ 24 Vac plus cooling contactor

Igniter Current: 5.0A resistive @ 132 Vac output

Thermostat Anticipator Setting: (Stage 1 only) 100mA

Prepurge: 30 seconds

HSI Warm-up: 17/27 or 30/30 seconds (1st/next trial)

depending on DIP switch S2 setting

Trial for Ignition: 4, 6, or 8 seconds depending on DIP

switch S2 setting

Postpurge: 15 seconds

Inter-trial Purge: 60 seconds

Auto Restart Delay: 60 minutes (after Soft Lockout)

Ignition Trials: Three; two retries if flame is not sensed

on the first trial

Flame Failure Response Time: 2 seconds maximum @

1A

LEDs: Three LEDs provide the following:

• A red LED provides system status and faults

• An amber LED provides flame status information

• A green LED provides information about the

EnviraCOM™ traffic

Wire harnesses:

• 12 pin, 3 x 4 connector, 7 inches; main harness

• 4-pin, 4 x 1 connector, 7 inches; igniter/inducer

harness

Fan Delays:

Heat Fan ON Delay: 30 or 60 seconds depending on

DIP switch S1 setting

Heat Fan OFF Delay: 60, 90, 120, or 180 seconds

depending on Dip Switch S1 setting

Cool Fan ON Delay: 5 seconds

Cool Fan OFF Delay: 0 or 60 seconds (depending on

DIP Switch S1 setting)

Gas Control: Any 24 Vac redundant, direct ignition gas

control rated at 1.5A or less; Honeywell

VR88345M4320 recommended

Cooling Contactor:

Any 24 Vac contactor rated at 1.0A or less

Induced Draft Blower:

2.2FLA/3.5LRA maximum @ 120 Vac

Circulator Load: 14.5FLA/25LRA maximum @ 120 Vac

Line Voltage Humidifier:

1A resistive load maximum @ 120 Vac

Electronic Air Cleaner:

1A resistive load maximum @ 120 Vac

Replaceable Fuse: 3.0 Amp, Automotive type

Operating Temperature: -40°F to 175°F (-40°C to 79°C)

Relative humidity: 0% to 95% non-condensing

Dimensions: See Fig. 1 on page 7

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

INSTALLATION AND CONFIGURATION OVERVIEW

The following is an overview of the steps required to

install and configure the S9200U1000 Integrated Furnace

Control:

1. Identify cross reference target using Table 1.

2. Remove old device and carefully identify and mark

any wiring. See “Replacement” on page 6.

3. Mount the S9200U1000 Integrated Furnace

Control. See “Replacement” on page 6.

4. Connect the wiring harnesses and make the wiring

connections. See “Wiring” on page 7.

5. Configure the field settings and safety timings. See

“Safety Timings, Field Settings, and Fixed

Parameters” beginning on page 11.

CROSS REFERENCE

IMPORTANT

Only use the S9200U1000 on 120 Vac

applications.

See Table 1 for the replacement details for other

manufacturers’ controls. See Table 2 for replacement

details for Trane controls.

69-2075—05 2

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

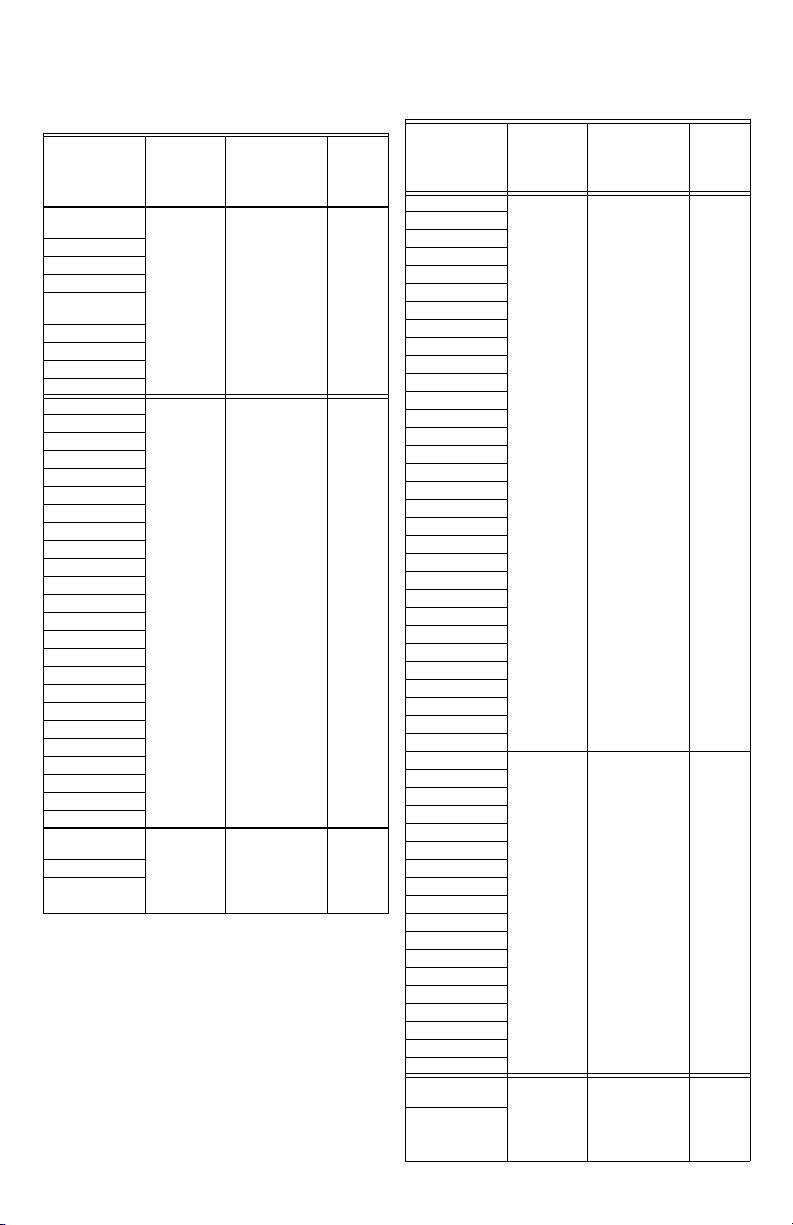

Table 1. S9200U1000 Replaces These Integrated

[Only use the S9200U1000 on 120 Vac applications.]

SKU Harness

United

Technologies

Furnace Controls.

Field Settings

Recommendation -

DIP Switch S1

Safety

Timing

Settings -

DIP Switch

S2

1012-925A

1012-925B

1012-925C

Rheem/ Robert

Shaw

62-24268-01

62-24268-02

50024568

Main Connector

50024566

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: ON

62-24268-03

695-200

Nordyne

624557

6245570

624557-0

624564

6245640

624591

624591A

624591-A

624591-B

624591-C

624591-D

624628

624628-0

6246310

50024568

Main Connector

50024565

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: OFF

624631-0

624631A

624631-A

624631-B

710128A

902378

902696

903106

CAR903106

United

Technologies

1012-955A

1012955A

50024568

Main Connector

50024565

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: OFF

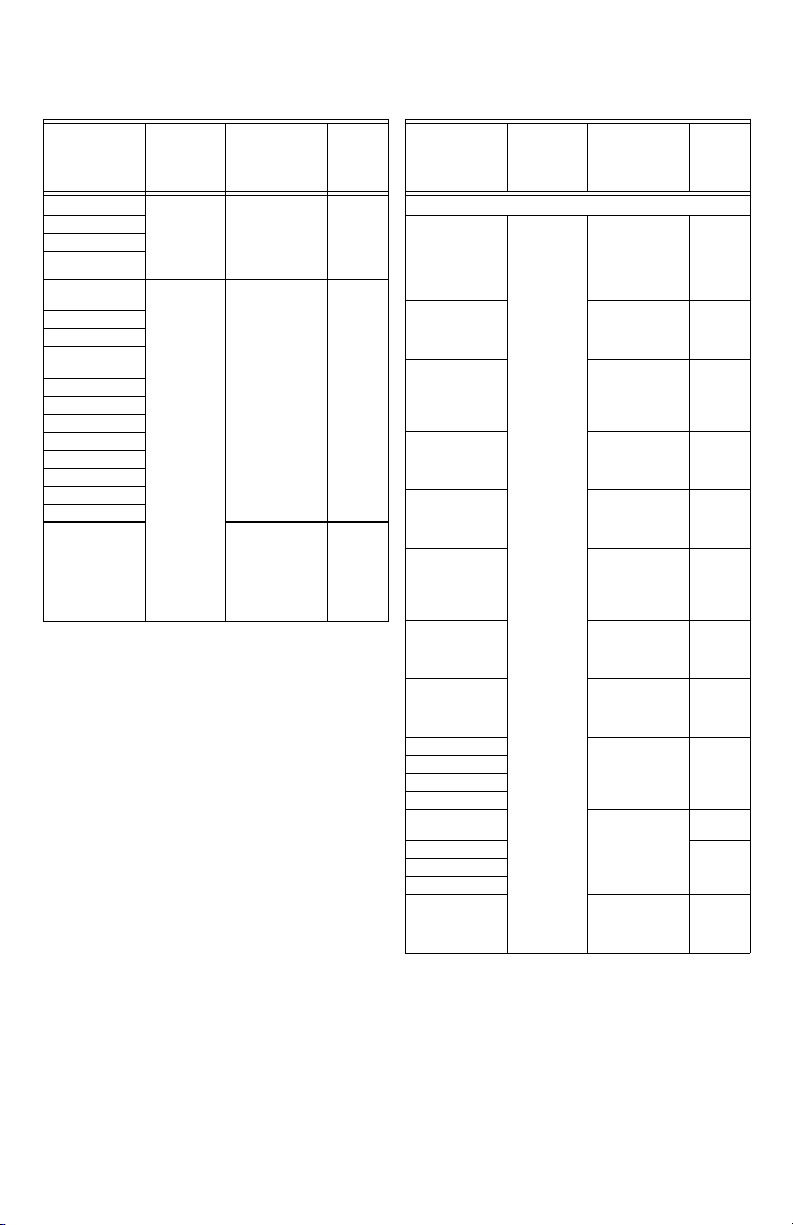

Table 1. S9200U1000 Replaces These Integrated

[Only use the S9200U1000 on 120 Vac applications.]

SKU Harness

Furnace Controls.

Field Settings

Recommendation -

DIP Switch S1

Safety

Timing

Settings -

DIP Switch

S2

Texas Instruments

6DT-1

6DT-2

61F3

Yor k

03100662000

031-00662-000

031-00662-700

031-01140-000

031-01140-001

031011140002

031-01140-002

031-01140-701

031-01140-702

031.01234.000

031-01234-700

031-01235-000

031-01235-700

Main Connector

not required.

50024561

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: OFF

SW2: ON

031-01250-000

031-01266-000

031-01267-00

031-01267-000

031-01267-001

031-01267-001A

031-01284-000

031-01933-000

031-01972-000

031-01973-000

031-02166-000

031-09166-000

031-09167-000

331-01933-000

331-01972-200

331-09167-000

43101972100

431-01972-100

CAR33101972200

CAR03101973000

CAR50A55843

G951ADB1401

G951ADB1401C

G951ADB-1401C

G951ADB1402

Main Connector

not required.

50024561

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: OFF

SW2: ON

G951ADB-1402

G951AEB-1403

P03101267001

P031-01267-001

PTH031011400-00

031-00662

United

Technologies

1012-83-9651B

Main Connector

not required.

50024561

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: OFF

SW2: ON

3 69-2075—05

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

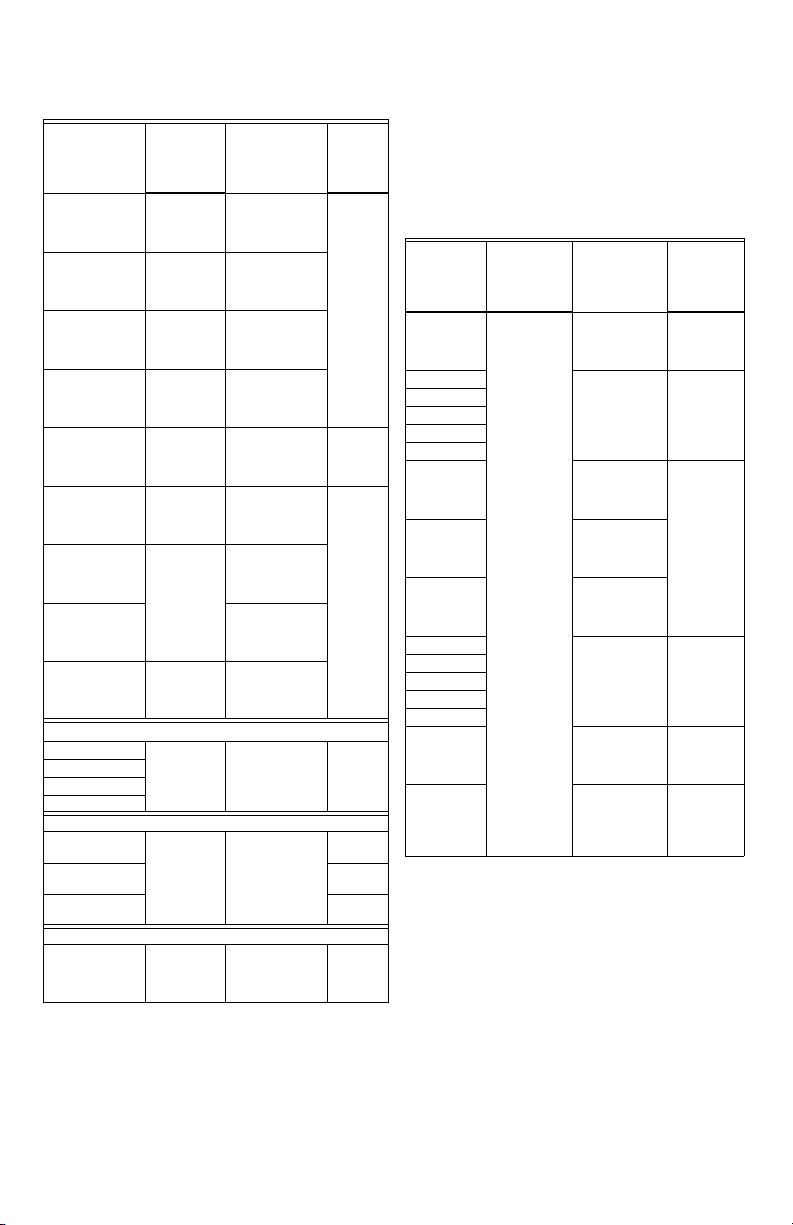

Table 1. S9200U1000 Replaces These Integrated

[Only use the S9200U1000 on 120 Vac applications.]

SKU Harness

1

Goodman

1809913

B1809913

B18099-13

United

Technologies

Furnace Controls.

Recommendation -

50026393

Main Connector

50026446

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

Field Settings

DIP Switch S1

Safety

Timing

Settings -

DIP Switch

S2

SW1: OFF

SW2: ON

1012933D

1012-933D

1012-83-

9336AHSC1

1012-83-9337A

Texas Instruments

41F-5

White Rodgers

50T35730

50T35-730

50T35743

50026393

Main Connector

50026446

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: OFF

SW2: ON

50T35-743

ICM280

SW1-SW4:

Check control Field

Settings

before setting.

SW1-SW2:

Check

control

Safety

Timings

before

setting.

Table 1. S9200U1000 Replaces These Integrated

[Only use the S9200U1000 on 120 Vac applications.]

SKU Harness

White Rodgers

50A55-843 Universal

50A55-286 SW1: ON

50A50-143 SW1: ON

50A55-241 SW1: ON

50A50-286 SW1: ON

50A50-438 SW1: Check

50A50-209 SW1: ON

50A50-230 SW1: ON

50A50-205

50A50-206

50A50-207

50A50-288

50A50-142

50A50-110

50A50-111

50A50-112

50A55-120 SW1: OFF

Furnace Controls.

1

50024561

Inducer & HSI

Connector

Field Settings

Recommendation -

DIP Switch S1

SW1: Check

Settings

SW2: Check

Settings

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW2: Check

Settings

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3: ON

SW4: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

Settings

SW2: ON

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3: ON

SW4: ON

SW2: OFF

SW3: ON

SW4: ON

SW1: ON

SW2: OFF

SW3: ON

SW4: OFF

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3: ON

SW4: OFF

Safety

Timing

Settings -

DIP Switch

S2

SW1: OFF

SW2: OFF

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: OFF

SW1: OFF

SW2: ON

SW1: OFF

SW2: OFF

69-2075—05 4

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

Table 1. S9200U1000 Replaces These Integrated

[Only use the S9200U1000 on 120 Vac applications.]

SKU Harness

50A50-113 SW1: ON

50A50-295 SW1: ON

50A50-296 SW1: ON

50A50-408 SW1: OFF

50A50-241

50A55-143

50A55-288

50A50-285 SW1: OFF

50A55-285

1

Amana

10207701

10207702

10207703

10207710

ICP

1010806

1380-686 SW1: OFF

1380-699 SW1: OFF

Lennox

1214201

1

Wiring harness # 50031795 should be used if the control

being replaced has a 2-pin inducer/igniter connector

instead of a 4-pin inducer/igniter connector.

Furnace Controls.

Recommendation -

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3: ON

SW4: OFF

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3 & SW4: 60/90/

120/180

50024561

Inducer & HSI

Connector

50031795

50024561

Inducer & HSI

Connector

50031795

50024561

Inducer & HSI

Connector

50024561

Inducer & HSI

Connector

50024561

Inducer & HSI

Connector

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: 30/60

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW2: OFF

SW3: ON

SW4: OFF

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: OFF

SW3: ON

SW4: OFF

SW1: ON

SW2: OFF

SW3 & SW4: 60/90/

120/180

SW1: ON

SW2: OFF

SW3: ON

SW4: OFF

Field Settings

DIP Switch S1

Safety

Timing

Settings -

DIP Switch

S2

SW1: OFF

SW2: ON

SW1: OFF

SW2: ON

SW1: OFF

SW2: OFF

SW1: OFF

SW2: ON

SW1: OFF

SW2: OFF

SW2: ON

SW2: ON

SW1: OFF

SW2: OFF

NOTE: To replace controls in Table 2, a jumper (not

provided) may be required to short out the

rollout switch on the main 12-pin connector

plug from the furnace. The rollout switch is

located between pins 5 and 11 on the 12-pin

connector. Refer to Table 3 and Fig. 2 on

page 7.

Table 2. Replacing Additional Controls.

[Only use the S9200U1000 on 120 Vac applications.]

Safety

Field Settings

Recommendatio

n - DIP Switch

SKU Harness

D330927P01

D330930P01

D330934P01

D340035P01

D340354P01

D340774P01

D341235P01 SW1: ON

50A50-571 SW1: ON

50024561

50A55-571 SW1: OFF

50A50-473

50A50-474

50A50-405

50A50-406

50A50-471

50A55-474 SW1: OFF

50A55-438 SW1: Check

Inducer & HSI

Connector

S1

SW1: ON

SW2: OFF

SW3 & SW4: 60/

90/120/180

SW1: OFF

SW2: OFF

SW3 & SW4: 60/

90/120/180

SW2: OFF

SW3: ON

SW4: OFF

SW2: OFF

SW3 & SW4: 60/

90/120/180

SW2: OFF

SW3: ON

SW4: OFF

SW1: OFF

SW2: OFF

SW3 & SW4: 60/

90/120/180

SW2: OFF

SW3: ON

SW4: OFF

Settings

SW2: OFF

SW3 & SW4: 60/

90/120/180

Timing

Settings -

DIP Switch

S2

SW1: OFF

SW2: OFF

SW1: OFF

SW2: ON

SW1: OFF

SW2: OFF

SW1: OFF

SW2: ON

SW1: OFF

SW2: OFF

SW1: OFF

SW2: OFF

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in these instructions to

make sure the integrated furnace control is suitable

for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out operation

as provided in these instructions.

5 69-2075—05

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

WARNING

WARNING

CAUTION

Replacement

To replace the existing furnace control:

Fire or Explosion Hazard.

Can cause severe injury, property damage, or

death.

1. The integrated furnace control can malfunction

if it gets wet, leading to accumulation of

explosive gas.

— Never install where water can flood, drip or

condense on the control.

— Never try to use an integrated furnace control

that has been wet—replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not naturally vent upward.

— Do not operate electric switches, lights, or

appliances until you are sure the appliance

area is free of gas.

Electrical Shock Hazard.

Can cause severe injury, property damage, or

death.

1. Make sure to turn power off to the furnace.

Failure to do this may result in electrical shock

or equipment damage

2. Disconnect power supply before beginning

wiring or making wiring connections to prevent

electrical shock or equipment damage.

Equipment Damage Hazard.

Water can cause equipment damage or

malfunction.

If furnace control must be mounted near water or

moisture, provide suitable waterproof enclosure.

Replacing An Existing Furnace Control

Location

In most cases the integrated furnace control is mounted

on a panel within the circulator compartment of the

furnace. The location must provide:

— Access to the field wiring terminals.

— Operating ambient temperatures between -40°F and

175°F (-40°C and 79°C).

— Relative humidity below 95% non-condensing.

— Protection from water, steam or corrosive chemicals

that are used to clean the appliance.

— Protection from dripping water, such as from an

overfilled humidifier or from condensation.

— Protection from dust or grease accumulation.

IMPORTANT

Be sure to identify the safety timings on the

existing furnace control before any wires are

disconnected. If this information is unavailable,

check with the furnace manufacturer for

recommended settings.

1. Remove the access panel to gain access to the

furnace control.

2. Unclip the wiring harness from the furnace control

and identify/mark all wires not connected to a wiring

plug.

3. Once the furnace control is free from all wiring,

either unclip or unscrew the furnace control from

the base plate.

4. Select the location within the appliance most

suitable so that all existing cables or required

harnesses will reach without straining either the

cables or the plugs. We recommend mounting the

S9200U1000 in the same location as the old

furnace control, if possible. Ambient temperature at

the S9200U1000 must be within the control

specifications.

5. The S9200U1000 can be mounted vertically in any

orientation. See Fig. 4 on page 9 for typical

mounting orientation.

6. Secure the board to the mounting panel base plate

with the two sheet metal screws inserted through

the eyelets located on the edges of the board. See

Fig. 1 on page 7.

7. From Table 1 on page 3, identify the wiring

harness(es) required for the quick installation of the

S9200U1000. The provided wiring harness

adapters are intended to connect to the existing

wiring harness. See Table 3 on page 7 and Table 4

on page 8 for pin-out information for the provided

wiring harnesses.

8. Connect the appropriate end of the wiring harness

to the 12-pin plug on the S9200U1000 (if required)

and the other end to the existing wiring plug

(previously removed from the existing furnace

control). Connect the appropriate igniter/inducer

harness (if required) to the 4 pin plug and the other

end to either the existing plug or spade connectors

(previously removed from the existing furnace

control).

IMPORTANT

The provided wiring harnesses are keyed. Do

not force the connection if the plug on the harness and receptacle on the S9200U1000 do not

easily snap closed.

9. Connect the quick-connect cables to the

appropriate contacts on the S9200U1000

10. Set the Safety timings as required using switch S2.

Refer to Table 10 on page 12 for switch setting

information.

11. Set the field selectable timings as required using

switch S1. Refer to Table 9 on page 11 for setting

information.

12. Review the connections to insure no wiring is loose

and there is a proper earth ground to the appliance

chassis.

13. Turn power ON to the appliance. See “Checkout” on

page 13 and the control sequence diagrams, Fig. 9Fig. 11 beginning on page 17.

69-2075—05 6

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

WARNING

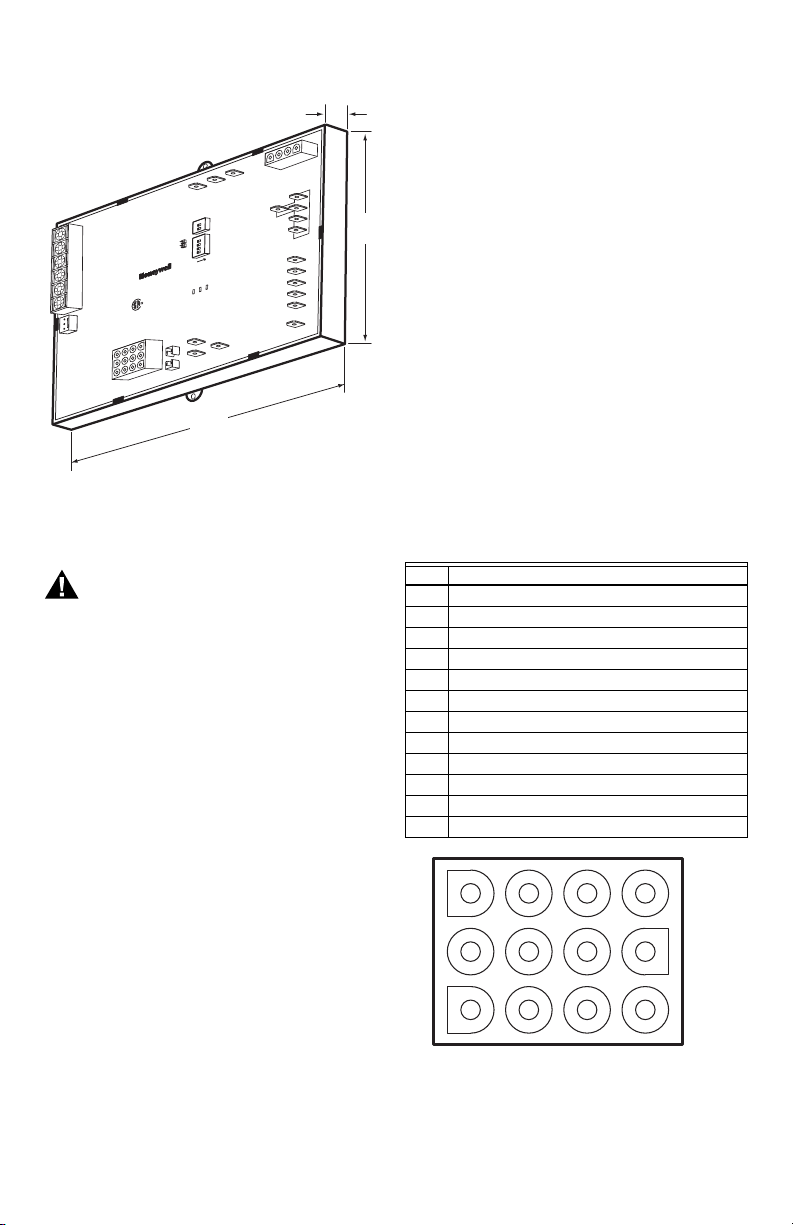

1 1/2

(38)

4 1/8

(105)

6 1/8

(156)

M24905

Fig. 1. S9200U1000 dimensions in inches and (mm).

Wiring

Fire or Explosion Hazard.

Can cause severe injury, property damage, or

death.

Make sure the proper wiring harness is used.

Check the cross reference tables (Table 1 on

page 3) and review the appliance wiring

schematic.

The S9200U1000 is intended to connect to the appliance

with the aid of wiring harnesses. Carefully review the

wiring harness selection table for the correct wiring

harnesses. See Table 1 on page 3.

Check the wiring diagram (Fig. 4 on page 9) and the

diagram furnished by the appliance manufacturer for all

terminal designations. Table 5 and Table 6 beginning on

page 8 describe the wiring connections for Class 2 and

Class 1 installations.

Typical wiring connections are shown in Fig. 5 on

page 10.

Check the wiring diagrams furnished by the appliance

manufacturer, if available, for circuits that differ from the

general hookup shown. Carefully follow any special

instructions affecting the general procedures outlined

below.

All wiring must comply with local codes and ordinances.

See “Wiring Harnesses” for the main and igniter/inducer

harness plug connections and details.

See “Wiring Connections” on page 8 for wiring

connections, but also refer to furnace manufacturer

instructions, if available.

NOTE: The Safety Timing jumper is described in Table 7

on page 11.

IMPORTANT

The common ground required for the

S9200U1000 and the main burner must be supplied through the plug connected to the Main

Harness (12-pin connector) receptacle on the

board.

Wiring Harnesses

The following describes the main and igniter/inducer

harness connections.

MAIN HARNESS PLUG CONNECTIONS

The following describes the harness plug connectors for

the main harness. See Table 3 and Fig. 2.

IMPORTANT

The common ground required for the

S9200U1000 and the main burner must be supplied through the plug connected to the Main

Harness (12-pin connector) receptacle on the

board.

Table 3. Main Harness Plug Connector 12-pin

Pin # Function

1High Limit Out

2 Flame Sense - Flame Signal Input (90 Vac, current limited)

324 Vac Hot

4 Not Used

5 Rollout Switch Out

624 Vac Common

7 High Limit In + Pressure Switch Out

8 Chassis Ground

9 Main Valve Common

10 Pressure Switch In

11 Rollout Switch In

12 Main Valve

.

Fig. 2. S9200U1000 Main harness plug configuration.

(Class 2, Low Voltage).

1 4 7 10

2 5 8 11

3 6 9 12

M24906

7 69-2075—05

S9200U1000 UNIVERSAL HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

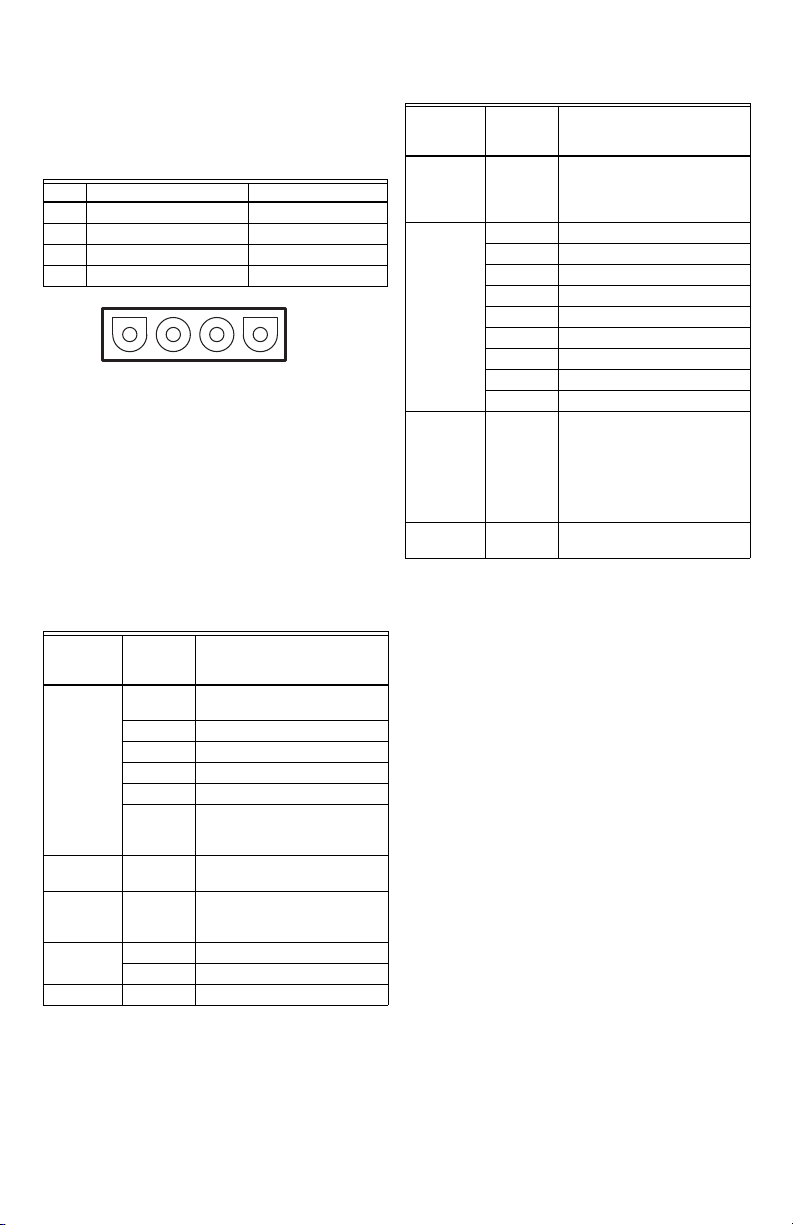

IGNITER/INDUCER HARNESS PLUG CONNECTIONS

The following describes the harness plug connectors for

the igniter/inducer. See Table 4 and Fig. 3.

Table 4. Igniter/Inducer Harness Plug Connector 4-pin

(Class 1, Line Voltage).

Pin # Reference Lettering Function

1 IND-HOT Inducer 120 Vac

2 IGN-HOT Igniter 120 Vac

3 IND-NEUTRAL Inducer Neutral

4 IGN-NEUTRAL Igniter Neutral

.

4 3 2 1

Fig. 3. S9200U1000 Igniter/Inducer harness plug

configuration.

M24907

Wiring Connections

Table 5 describes the wiring connections for Class 2

voltages.

Table 6 describes the wiring connections for Class 1

voltages.

See Fig. 5 on page 10 for wiring connection locations on

the board.

Table 5. Wiring Connections (Class 2, Low Voltage).

Connection

Ter mi nal Typ e

6-position

screw terminal

(#5 screw)

Polarized 3-pin

connector

12-pin

connector

Straight Spade

Quick-connect

Fuse Block Fuse Fuse - Automotive Type - 3.0 Amps

(see Fig. 4

on page 9) Connects S9200U1000 to:

D/1 (optional) EnviraCOM™ data connection (if

used)

C/3 24 volt ground

R/2 24 volt hot - Thermostat

W Thermostat heat input

G Thermostat continuous fan input

Y Thermostat cool input / cooling

contactor output for EnviraCOM™

thermostats

E-COM EnviraCOM™ diagnostic or

communications device

Main

See Table 3 on page 7

Harness

Connector

24 Vac Transformer - 24 Vac

COM Transformer - Common

.

Table 6. Wiring Connections (Class 1, Line Voltage).

Connection

Ter mi nal Typ e

4-pin

connector

(male

terminals)

Straight Spade

Quick-connect

(see Fig. 4

on page 9) Connects S9200U1000 to:

Igniter-

See Table 4

Inducer

Harness

Connector

COOL Circulator cool speed output

EAC Electronic Air Cleaner 120 Vac output

HEAT Circulator heat speed output

CONT Continuous circulation

XFMR Transformer 120 Vac output

L1 Line 120 Vac hot power supply

HUM Humidifier 120 Vac output

PARK Circulator Motor Park 120 Vac input

PARK Circulator Motor Park 120 Vac input

Straight Spade

Quick-connect

Straight Spade

Quick-connect

Neutrals Any neutral connector can be used

for:

• 120 Vac Input neutral

• Transformer neutral

• Electronic air cleaner neutral

• Circulator neutral

• Humidifier neutral

Flame Flame Sense - Signal input (90 Vac,

current limited)

69-2075—05 8

Loading...

Loading...