Page 1

34-00008EFS-01

S8910U3000

WARNING

UNIVERSAL HOT SURFACE IGNITION MODULE

INSTALLATION INSTRUCTIONS

Installation of this product must be performed by a trained and

qualified service technician.

APPLICATION

The S8910U Universal Hot Surface Ignition Module is

designed to provide easy field replacement for a wide range of

hot surface ignition modules manufactured by Honeywell,

Robertshaw and White-Rodgers. The S8910U Module

provides operating control of a direct ignition system using a

120 Vac hot surface igniter. The S8910U replaces existing

flame rectification type hot surface ignition modules with the

following characteristics:

• 120 Vac (up to 5A) timed warmup hot surface ignition

elements.

• Single rod (local sense) or dual rod (remote sense) hot

surface ignition.

• One or three ignition trials per call for heat.

• Four-second or seven-second ignition trials.

• Prepurge of 32 seconds or less.

• Up to 96 seconds between trial purge times (three-trial

mode only).

• Natural or LP gas.

The S8910U is not designed to replace:

• Intermittent pilot ignition controls.

• Direct spark ignition controls.

• Proven 120 Vac hot surface ignition controls.

• 24 Vac element hot surface ignition controls.

• 240 Vac input/120 Vac element hot surface ignition

controls.

• 120 Vac timed warmup hot surface ignition controls

— Ignition trial time shorter than four seconds.

— Ignition trial time longer than twelve seconds.

— Edge connectors rather than male quick-connects.

The S8910U package contains the S8910U control, and easyto-use instructions, and the accessories required to adapt the

existing hot surface ignition module. The accessory bag

assembly includes the White-Rodgers adapter, Robertshaw

ground lead, four 1/4 in. female .032 quick-connects, one 3/16

in. female .032 quick-connect, and nine wire labels. The

wiring labels are included to assure proper marking of the

wires attached to the existing module.

A complete list of the specific Honeywell and other modules

that the S8910U is designed to replace is provided in Tables 1

through 3.

NOTE: The S8910U is intended to replace only defective

ignition controls. The service technician should

make sure that the other parts of the appliance

and control system operate safely and reliably

before replacing the ignition control.

EXPLOSION HAZARD. CAN CAUSE INJURY OR

EQUIPMENT DAMAGE.

The S8910U can only be used for direct replacement.

Check Tables 1 through 3 before replacing an existing

hot surface module with the S8910U. If the existing

module is not listed, do not use the S8910U to replace

it. Always refer to the cross-reference table for proper

DIP switch settings.

Electrical Ratings:

Control Voltage: 24 V, 60 Hz.

Maximum Valve Contact Rating: 2 A.

Current Draw: 0.4 A plus valve load.

Hot Surface Igniter Voltage: 120 Vac, 60 Hz.

Contact Rating at 120 Vac: 5 A.

IMPORTANT

The S8910U is designed for 60 Hz applications.

Timings change by 20 percent in 50 Hz applications.

Hot Surface Igniter or Igniter-Sensor:

Norton Model 201 or 271 or equivalent.

NOTE: If an igniter other than a Norton Model 201 or 271

is used, the igniter must meet the following minimum specifications required over the life of the

igniter:

• Igniter must reach 1832 °F (1000 °C) within

the selected warm up time of 7, 17, 34 or

45 seconds with 102 Vac applied.

• Igniter must maintain at least 500M ohm

insulation resistance between the igniter

leadwires and the igniter mounting bracket.

• Igniter must not develop an insulating layer

on its surface (over time) that would prevent

flame sensing.

• Igniter surface area immersed in flame must

not exceed one-fourth of the grounded area

immersed in flame. This would prevent flame

sensing.

Page 2

S8910U3000

• Igniter current draw at 132 Vac must not

exceed 5A.

Sensor:

Separate sensor required for remote sensing applications.

Wiring:

Use existing appliance wiring. If repair or replacement of lead-

wires is required, follow instructions on appliance label.

Use included quick connect terminals and wiring adaptors

according to instructions.

Prepurge:

32 seconds.

Igniter Warmup:

7 (12), 17 (27), 34 or 45 seconds. Numbers in parenthesis

represent second and third trial for ignition timings.

Purge between Trials for Ignition:

96 seconds (32 second prepurge and 64 seconds interpurge).

Flame Failure Response Time:

1.5 seconds maximum.

Ignition Sequence:

The number of trials for ignition and trial time are determined

by selectable DIP switches.

Ambient Operating Temperature:

-40to+175°F (-40to+79°C).

Accessory Kit (Included):

• White-Rodgers adapter.

• Robertshaw ground lead.

• Four 1/4 in. female .032 quick-connects.

• One 3/16 in. female .032 quick-connect.

• Nine wire labels.

Approvals:

IAS Design Certified: Certification Report No. C2027002.

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifications. Also, this product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

The S8910U package contains the S8910U control, and easyto-use instructions, plus the accessories required to adapt the

existing hot surface ignition module. The accessory bag

assembly includes the White-Rodgers adapter, Robertshaw

ground lead, four 1/4 in. female .032 quick-connects, one 3/16

in. female .032 quick-connects, and nine wiring labels. The

wiring labels are included to assure proper marking of the

wires attached to the existing module.

A complete listing of the specific Honeywell and other

modules that the S8910U is designed to replace is provided in

Tables 1 through 3.

NOTE: The S8910U is intended to replace only defective

ignition controls. The service technician should

make sure that the other parts of the appliance

and control system operate safely and reliably

before replacing the ignition control.

Model Available:

S8910U Universal Hot Surface Ignition Module.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information,

or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1985 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

34-00008EFS—01 2

Page 3

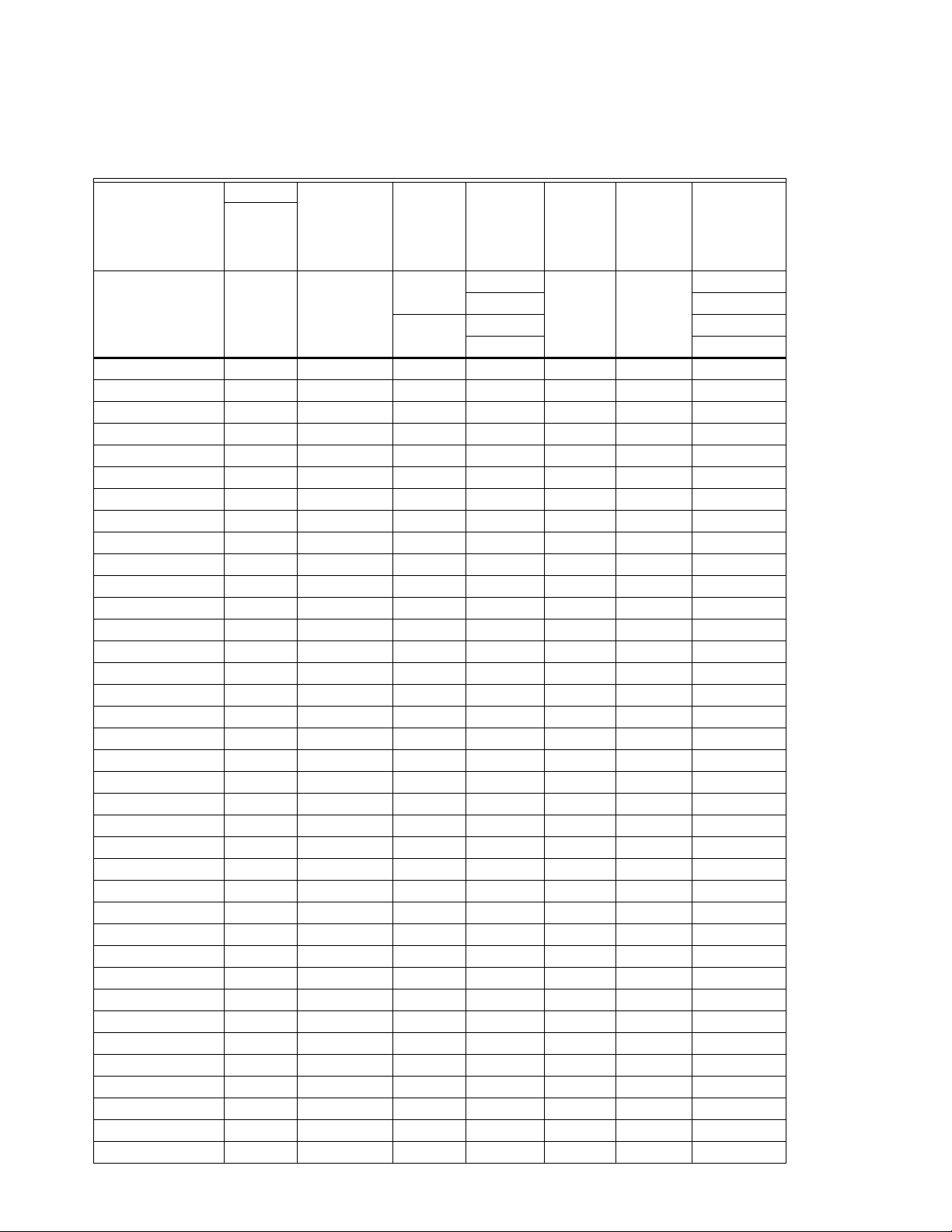

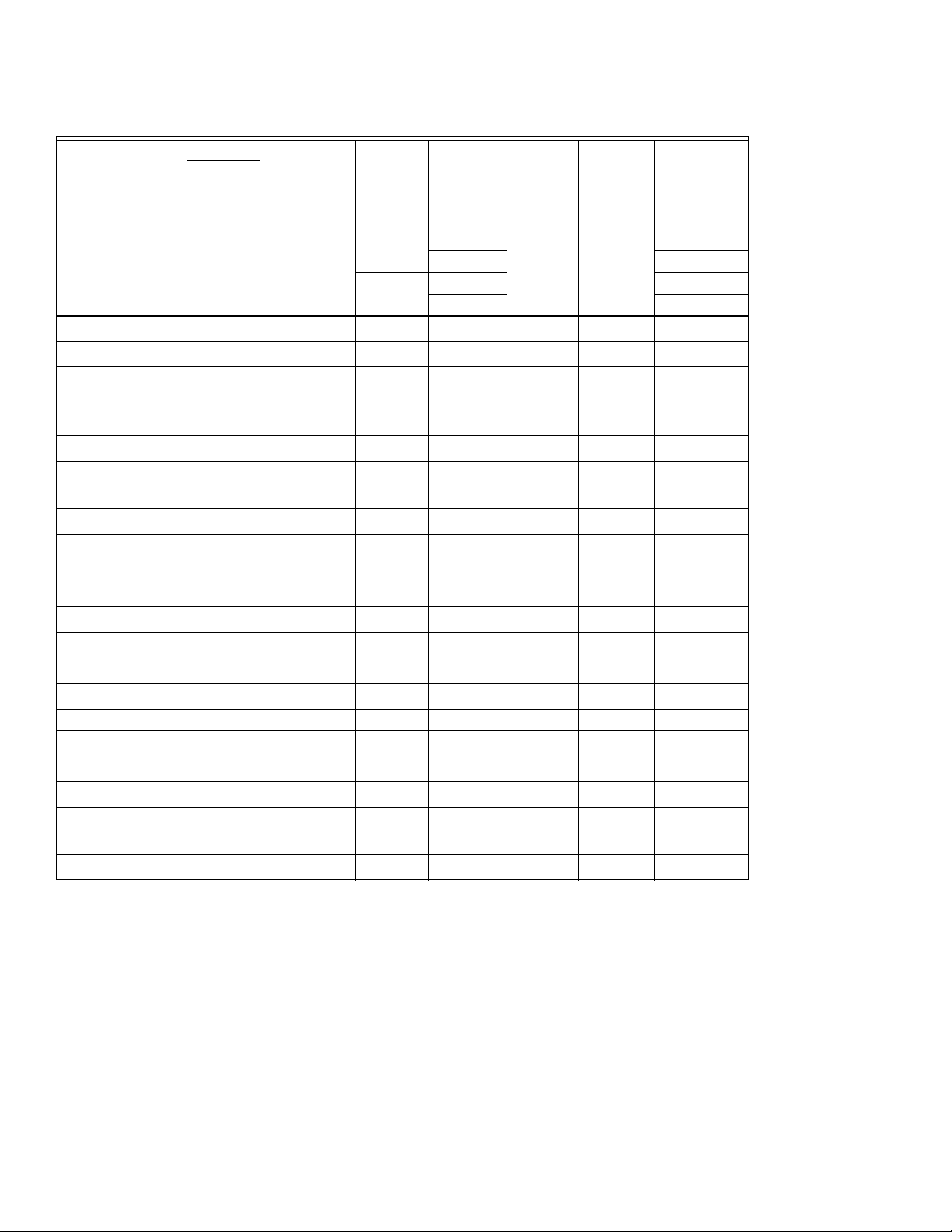

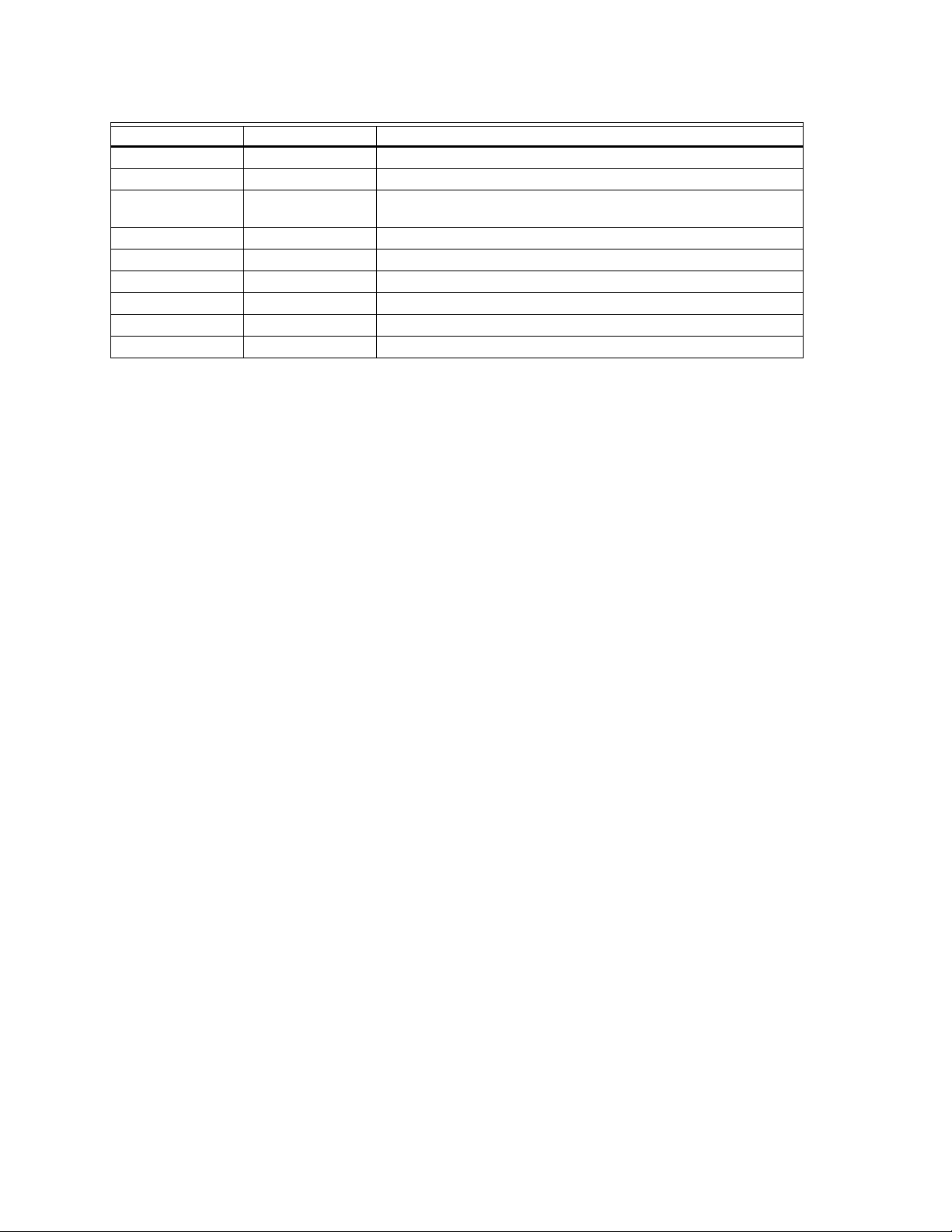

Table 1. White-Rodgers Control to Honeywell S8910U Cross Reference.

NOTES: This list is for reference only. Honeywell reserves the right to add or delete models at any time, based on new or

updated information.

S8910U

Remove

Between

Trial Purge

(sec)

Model Numbers

S8910U

Specifications

Black

Jumper

Local (L) or

Remote (R)

Sensing

— Local or

Remote

Lockout

Time

(sec)

Ignition

Trial s

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

3 96

7 1 NA

3 96

50E47-1 thru 9 Yes R 4 1 0 17 NA

50E47-10 thru 19 Yes R 4 1 0 45 NA

50E47-20 thru 29 Yes R 4 1 30 17 NA

50E47-30 thru 39 Yes R 4 1 30 45 NA

50E47-40 thru 49 Yes R 4 3 30 17 90

50E47-50 thru 59 Yes R 4 3 30 45 90

50E47-60 thru 69 Yes R 4 3 0 17 60

50E47-70 thru 79 Yes R 4 3 0 45 60

50E47-101 thru 109 Yes R 7 1 0 17 NA

50E47-110 thru 119 Yes R 7 1 0 45 NA

50E47-120 thru 129 Yes R 7 1 30 17 NA

50E47-130 thru 139 Yes R 7 1 30 45 NA

50E47-140 thru 149 Yes R 7 3 30 17 90

50E47-150 thru 159 Yes R 7 3 30 45 90

50E47-160 thru 169 Yes R 7 3 0 17 60

50E47-170 thru 179 Yes R 7 3 0 45 60

50E47-201 thru 209 Yes R 4 1 0 17 NA

50E47-210 thru 219 Yes R 4 1 0 45 NA

50E47-220 thru 229 Yes R 4 1 30 17 NA

50E47-230 thru 239 Yes R 4 1 30 45 NA

50E47-240 thru 249 Yes R 4 3 30 17 90

50E47-250 thru 259 Yes R 4 3 30 45 90

50E47-260 thru 269 Yes R 4 3 0 17 60

50E47-270 thru 279 Yes R 4 3 0 45 60

50E47-301 thru 309 Yes R 7 1 0 17 NA

50E47-310 thru 319 Yes R 7 1 0 45 NA

50E47-320 thru 329 Yes R 7 1 30 17 NA

50E47-330 thru 339 Yes R 7 1 30 45 NA

50E47-340 thru 349 Yes R 7 3 30 17 90

50E47-350 thru 359 Yes R 7 3 30 45 90

50E47-360 thru 369 Yes R 7 3 0 17 60

50E47-370 thru 379 Yes R 7 3 0 45 60

50F47-1 thru 9 Yes R 4 1 0 17 NA

50F47-10 thru 19 Yes R 4 1 0 45 NA

50F47-20 thru 29 Yes R 4 1 17 17 NA

50F47-30 thru 39 Yes R 4 1 17 45 NA

50F47-40 thru 49 Yes R 4 3 17 17 77

S8910U3000

3 34-00008EFS—01

Page 4

S8910U3000

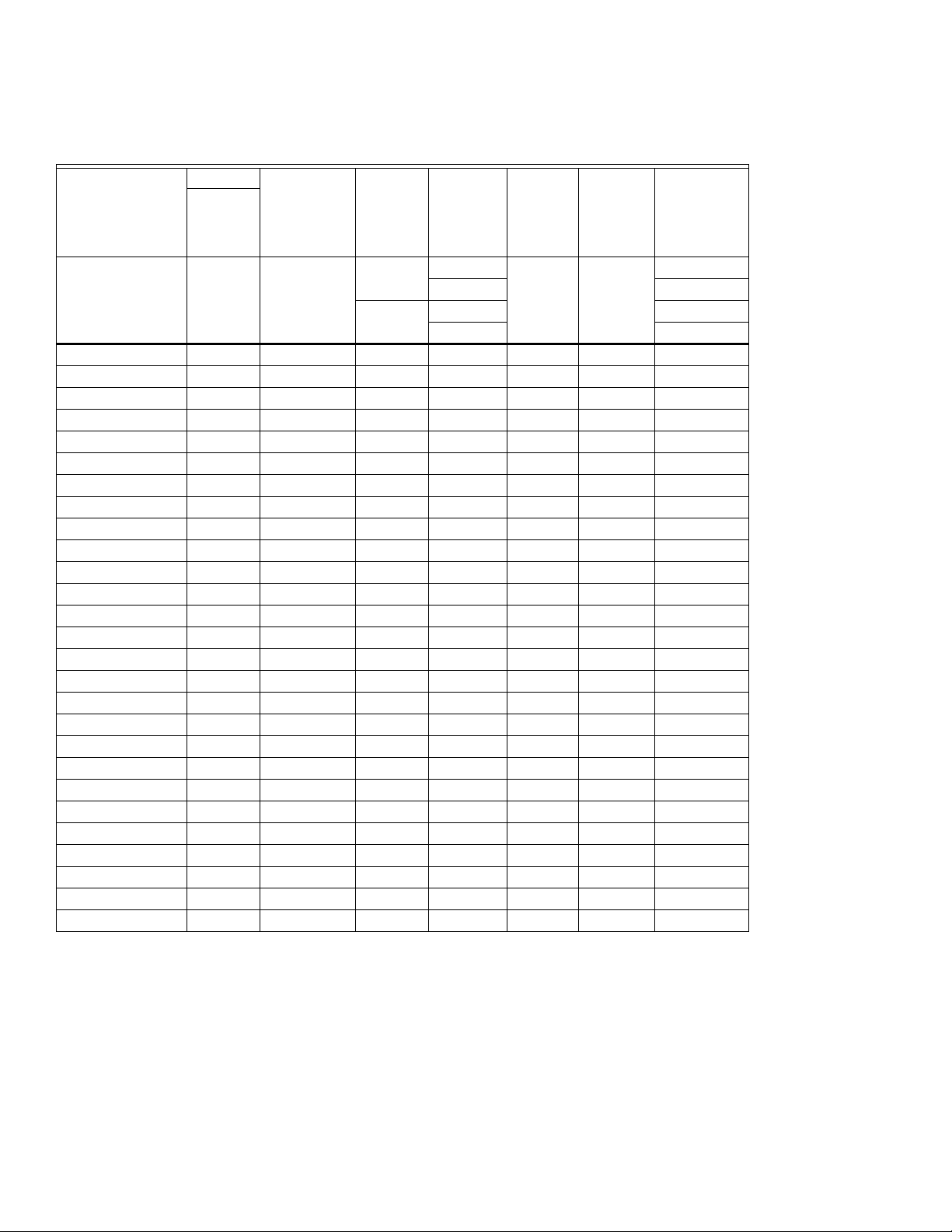

Table 1. White-Rodgers Control to Honeywell S8910U Cross Reference. (Continued)

NOTES: This list is for reference only. Honeywell reserves the right to add or delete models at any time, based on new or

updated information.

S8910U

Remove

Between

Trial Purge

(sec)

Model Numbers

S8910U

Specifications

Black

Jumper

Local (L) or

Remote (R)

Sensing

— Local or

Remote

Lockout

Time

(sec)

Ignition

Trial s

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

3 96

7 1 NA

3 96

50F47-50 thru 59 Yes R 4 3 17 45 77

50F47-60 thru 69 Yes R 4 3 0 17 60

50F47-70 thru 79 Yes R 4 3 0 45 60

50F47-101 thru 109 Yes R 7 1 0 17 NA

50F47-110 thru 119 Yes R 7 1 0 45 NA

50F47-120 thru 129 Yes R 7 1 17 17 NA

50F47-130 thru 139 Yes R 7 1 17 45 NA

50F47-140 thru 149 Yes R 7 3 17 17 77

50F47-150 thru 159 Yes R 7 3 17 45 77

50F47-160 thru 169 Yes R 7 3 0 17 60

50F47-170 thru 179 Yes R 7 3 0 45 60

50F47-201 thru 209 Yes R 4 1 0 17 NA

50F47-210 thru 219 Yes R 4 1 0 45 NA

50F47-220 thru 229 Yes R 4 1 17 17 NA

50F47-230 thru 239 Yes R 4 1 17 45 NA

50F47-240 thru 249 Yes R 4 3 17 17 77

50F47-250 thru 259 Yes R 4 3 17 45 77

50F47-260 thru 269 Yes R 4 3 0 17 60

50F47-270 thru 279 Yes R 4 3 0 45 60

50F47-301 thru 309 Yes R 7 1 0 17 NA

50F47-310 thru 319 Yes R 7 1 0 45 NA

50F47-320 thru 329 Yes R 7 1 17 17 NA

50F47-330 thru 339 Yes R 7 1 17 45 NA

50F47-340 thru 349 Yes R 7 3 17 17 77

50F47-350 thru 359 Yes R 7 3 17 45 77

50F47-360 thru 369 Yes R 7 3 0 17 60

50F47-370 thru 379 Yes R 7 3 0 45 60

34-00008EFS—01 4

Page 5

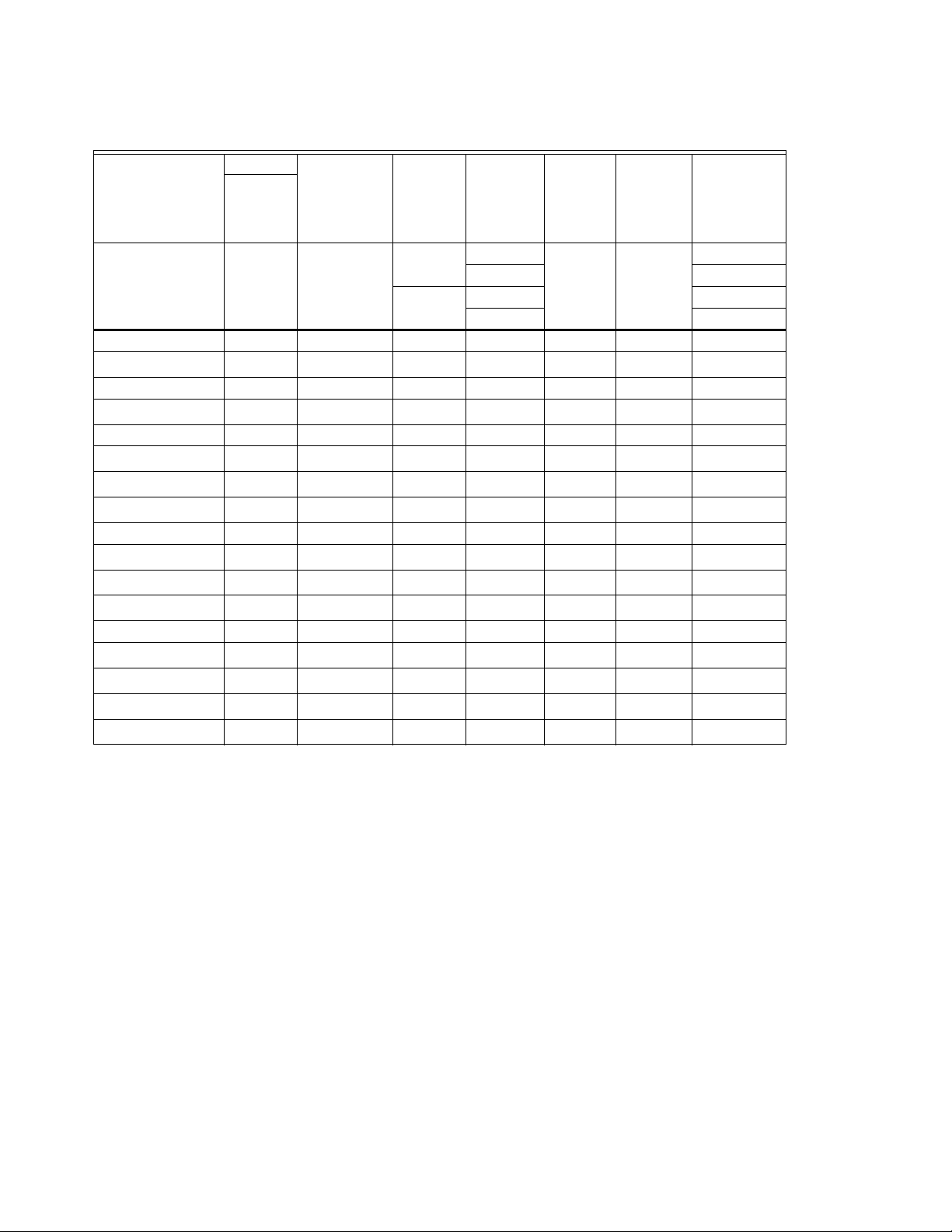

S8910U3000

Table 2. Robertshaw Control to Honeywell S8910U Cross Reference.

S8910U

Remove

Between

Trial Purge

(sec)

Model Numbers

S8910U

Specifications

Black

Jumper

Local (L) or

Remote (R)

Sensing

— Local or

Remote

Lockout

Time

(sec)

Ignition

Trial s

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

3 96

7 1 NA

3 96

HS780-17NL-104A No L 4 1 0 17 NA

HS780-17NL-108A No L

a

8

1 0 17 NA

HS780-17NL-304A No L 4 3 0 17 17

HS780-17NL-308A No L

8a

3 0 17 17

HS780-17NR-104A Yes R 4 1 0 17 NA

HS780-17NR-306A Yes R

HS780-17NR-308A Yes R

HS780-34NL-108A No L

6

8

8a

a

a

3 0 17 17

3 0 17 17

1 0 34 NA

HS780-34NL-304A No L 4 3 0 34 34

HS780-34NL-306A No L

HS780-34NL-308A No L

HS780-34NL-312A No L

6a

8a

12b

3 0 34 34

3 0 34 34

3 0 34 34

HS780-34NR-104A Yes R 4 1 0 34 NA

HS780-34NR-306A Yes R

HS780-34NR-308A Yes R

HS780-34NR-312A Yes R

HS780-34PL-308A No L

a

The S8910U and the original control lockout times are different. The S8910U lockout time is within the design tolerance lockout

12

6a

8a

8a

b

3 0 34 34

3 0 34 34

3 0 34 34

3 34 34 34

time of the original control.

b

The lockout time of the S8910U is shorter than the original control. Be sure to observe the appliance operation under a variety of

input conditions to assure reliable operation.

5 34-00008EFS—01

Page 6

S8910U3000

Table 3. Honeywell Control to Honeywell S8910U Cross Reference.

S8910U

Remove

Between

Trial Purge

(sec)

Model Numbers

S8910U

Specifications

Black

Jumper

Local (L) or

Remote (R)

Sensing

— Local or

Remote

Lockout

Time

(sec)

Ignition

Trial s

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

3 96

7 1 NA

3 96

S89C1004 No L

S89C1012 No L

6

6a

a

1 0 34 NA

1 0 34 NA

S89C1046 No L 4 1 0 34 NA

S89C1087 No L

6a

1 0 34 NA

S89C1103 No L 4 1 0 34 NA

S89D1002 Yes R

a

6

1 0 34 NA

S89G1005 No L 4 3 0 34 30

S89G1013 No L

S89G1021 No L

S89G1047 No L

6a

11

6

b

a

3 0 34 30

3 0 34 30

3 0 34 30

S89H1003 Yes R 4 3 0 34 30

11

6

6a

6a

6

a

b

3 0 34 30

3 0 34 30

1 0 34 NA

1 30 34 NA

a

1 30 34 NA

S89H1011 Yes R

S89H1029 Yes R

S89J1008 No L

S890C1007 No L

S890D1006 Yes R

S890G1003 No L 4 3 30 34 30

11

a

6

b

a

6

3 30 34 30

3 30 34 30

3 30 34 30

S890G1011 No L

S890G1029 No L

S890G1037 No L

S890H1002 Yes R 4 3 30 34 30

11

a

6

b

S890H1010 Yes R

S890H1028 Yes R

a

The S8910U and the original control lockout times are different. The S8910U lockout time is within the design tolerance

3 30 34 30

3 30 34 30

lockout time of the original control.

b

The lockout time of the S8910U is shorter than the original control. Be sure to observe the appliance operation under a

variety of input conditions to assure reliable operation.

34-00008EFS—01 6

Page 7

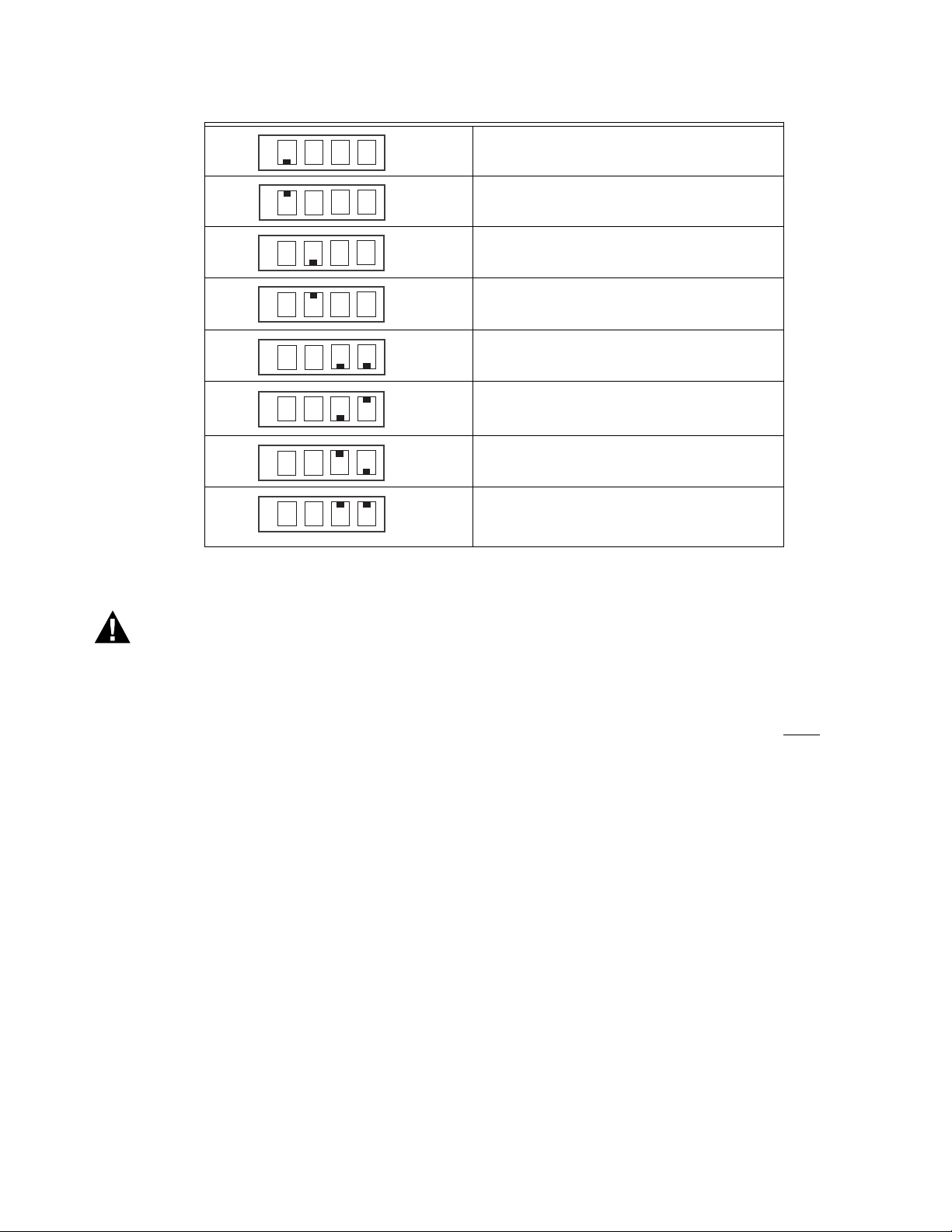

Table 4. DIP switch configuration.

WARNING

ON

1

2

3

4

ON

1

2

3

4

ON

1

2

3

4

ON

1

2

3

4

ON

1

2

3

4

ON

1

2

3

4

ON

1

2

3

4

ON

1

2

3

4

M35557

Trial count = 1 try

Trial count = 3 tries

Trial for ignition period = 4 seconds

Trial for ignition period = 7 seconds

Igniter warm-up time = 34 seconds

Igniter warm-up time = 45 seconds

S8910U3000

REVIEW THE INSTALLATION

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

Follow these warnings exactly:

1. Review the installation as outlined in this section.

2. Plan for frequent maintenance as described in the

Maintenance section.

When hot surface ignition systems are used on central heating

equipment in barns, greenhouses, and commercial properties

and on heating appliances such as commercial cookers,

agricultural equipment, industrial heating equipment and pool

heaters, heavy demands are made on the controls. Special

steps may be required to prevent nuisance shut-downs and

control failure due to frequent cycling, and severe

environmental conditions related to moisture, corrosive

chemicals, dust or excessive heat. These applications require

Honeywell Home and Building Control Engineering review;

contact your Honeywell Sales Representative for assistance.

Review the following conditions that can apply to your specific

installation and take the precautionary steps suggested.

Frequent Cycling

These controls are designed for use on appliances that

typically cycle only three to four times an hour during the

heating season. In year-around applications with greater

cycling rates, the control can wear out more quickly. Perform a

monthly checkout.

Igniter warm-up time = 17 seconds

(27 seconds 2

nd

and 3rd trial)

Igniter warm-up time = 7 seconds

(12 seconds 2

nd

and 3rd trial)

Water or Steam Cleaning

If a module or gas control gets wet, replace it. If the appliance

is likely to be cleaned with water or steam, cover the controls

and wiring to protect from water or steam flow. Mount the

controls high enough above the bottom of the cabinet to avoid

getting wet during normal cleaning procedures. A NEMA 4

enclosure is recommended for the ignition module.

High Humidity or Dripping Water

Dripping water can cause the module to fail. Never install an

appliance where water can drip on the controls.

In addition, high ambient humidity can cause the gas control to

corrode and fail.

If the appliance is in a humid atmosphere, make sure air

circulation around the controls is adequate to prevent

condensation. Also, regularly check out the system. A NEMA 4

enclosure is recommended for the ignition module.

Corrosive Chemicals

Corrosive chemicals can attack the module and gas control,

eventually causing a failure. If chemicals are used for routine

cleaning, avoid contact with the controls. Where chemicals are

suspended in air, as in some industrial or agricultural

applications, A NEMA 4 enclosure is recommended for the

ignition module.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause controls to

malfunction. Where dust or grease can be a problem, provide

covers for the module and the gas control to limit

contamination. A NEMA 4 enclosure is recommended for the

ignition module.

7 34-00008EFS—01

Page 8

S8910U3000

WARNING

CAUTION

Heat

Excessively high temperatures can damage controls. Make

sure the maximum ambient temperature at the control does not

exceed the rating of the control. If the appliance operates at

very high temperatures, use insulation, shielding, and air

circulation, as necessary, to protect the controls. Proper

insulation or shielding should be provided by the appliance

manufacturer; verify proper air circulation is maintained when

the appliance is installed.

INSTALLATION

When Installing this Ignition System...

1. Read these instructions carefully. Failure to follow them

could damage the components or cause a hazardous

condition.

2. Check Tables 1, 2, and 3 to confirm that the S8910U is a

direct replacement for the existing module.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out component and

appliance operation as provided in these instructions.

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

1. If the ignition module gets wet, it can malfunction,

leading to accumulation of explosive gas.

— Never install where water can flood, drip or

condense on the module.

— Never use a module that has been wet.

Replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and can not vent upward naturally.

— Do not light pilot or operate electric switches,

lights or appliances until you are sure the

appliance area is free of gas.

3. Do not attempt to disassemble or clean the module.

Improper reassembly and cleaning can cause

unreliable operation.

1. Disconnect the power supply before beginning

wiring to prevent electrical shock or equipment

damage.

2. If a new gas control is to be installed, turn off the

gas supply before starting the installation. Conduct

a Gas Leak Test according to the gas control

manufacturer instructions after the gas control is

installed.

3. If a module must be mounted where it can be

exposed to moisture or water, provide a suitable

waterproof enclosure.

4. Using the wire labels provided, label all wires

before disconnecting. Wiring errors can cause

improper appliance operation and create

dangerous conditions such as bypassing safety

features.

Perform Preinstallation Safety Inspection

A preinstallation safety check of the appliance and venting

system must be done before the replacement module is

installed. If a condition is detected that could result in unsafe

operation, shut off the appliance and advise the owner of the

unsafe condition. Correct any potentially unsafe condition

before proceeding with the installation.

Remove Old Module

Disconnect power supply before doing any work on the unit.

Disconnect and tag the wires from the old module using the

wire labels provided. Remove the old module from its mounting

location.

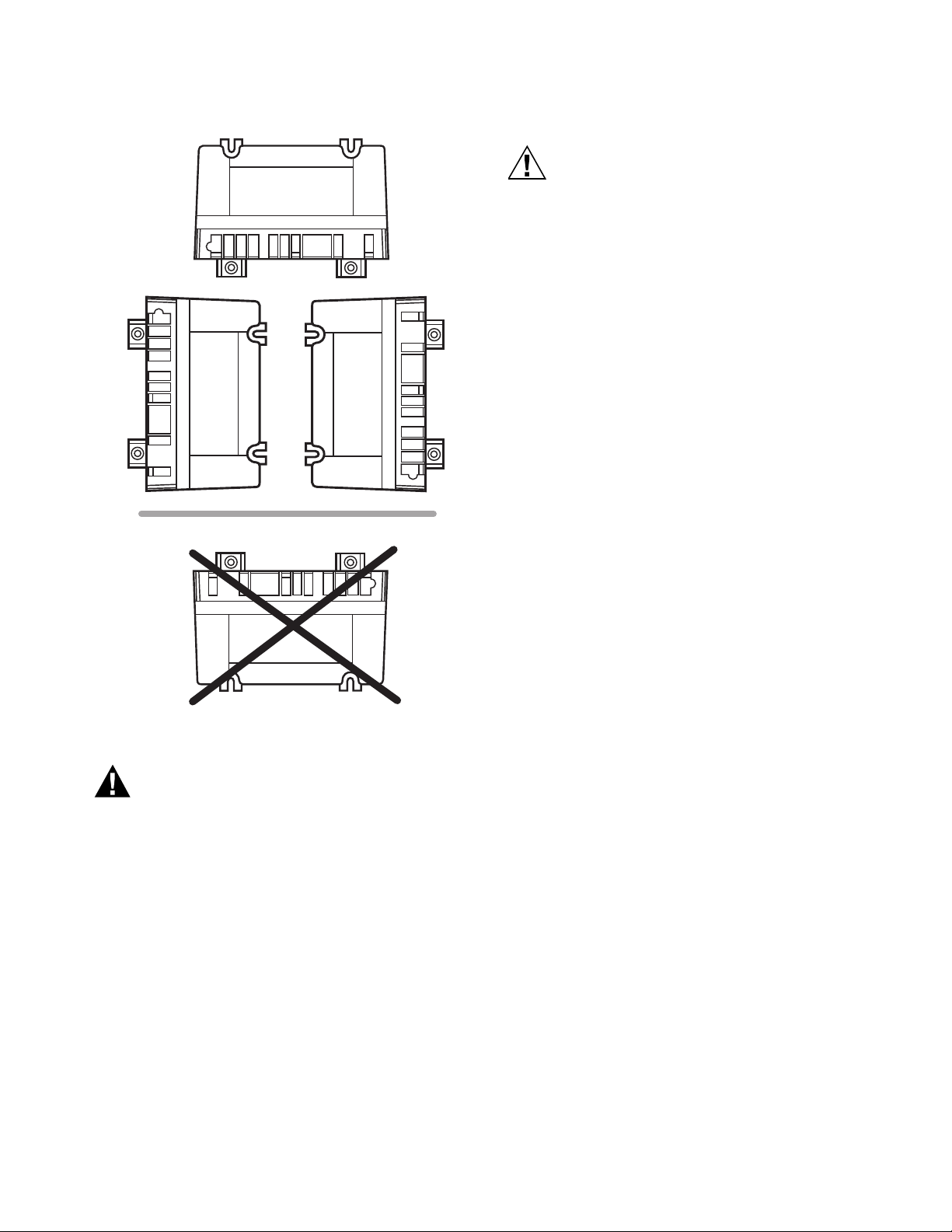

Mount New Ignition Module

Mount the S8910U Module in the same location as the old

module. Protect the module from exposure to water, moisture,

corrosive chemicals and excessive dust and grease. Assure

that ambient temperature at the module is within the range

listed in the Application section.

Mount the module with the terminals down to protect from

dripping water and dust. The module can also be mounted with

terminals on either side. Do not mount with the terminals

pointing up. Refer to Fig. 1 for mounting recommendations.

When it is necessary to drill new mounting holes, use the

S8910U as a template to mark the mounting hole pattern. Drill

new holes as required. Fasten securely with four No. 6-32

machine or No. 8 sheet metal screws.

34-00008EFS—01 8

Page 9

WARNING

CAUTION

TERMINALS FACING DOWN

TERMINALS FACING LEFT TERMINALS FACING RIGHT

MOUNT IN ONE OF THESE POSITIONS

DO NOT MOUNT

WITH TERMINALS FACING UP

M2647A

Fig. 1. Module mounting recommendations.

EXPLOSION HAZARD. CAN CAUSE

INJURY OR EQUIPMENT DAMAGE.

Only trained professional gas appliance service

technicians should install and check out the S8910U.

S8910U3000

Wire the Module

1. Check the wiring diagram furnished by the

appliance manufacturer, if available, and compare

with Table 5. Carefully follow any special

instructions affecting the general procedures

outlined in this section.

2. Disconnect the power supply before making wiring

connections to prevent electrical shock or

equipment damage.

IMPORTANT

1. Be sure all wiring complies with applicable electrical

codes and ordinances.

2. Hot surface igniter leadwires should not be allowed to

rest against grounded metal surfaces.

3. A common ground is required for the S8910U and the

main burner. The 24V (GND) terminal internally

grounds one side of the transformer. Any auxiliary

controls or limits must not be in the grounded leg. In

addition, the appliance should be earth-grounded.

4. Make sure the transformer has adequate VA. The

ignition module requires 0.4A at 24 Vac. Add the current draws of all other devices in the control circuit,

including the pilot and main valves in the gas control,

and multiply by 24 to determine the total VA requirement of these components. Add this total to 9.6 VA

(for the ignition module). The result is the minimum

transformer VA rating. Use a Class II transformer

when replacement is required.

5. Check that L1 (hot) and L2 (neutral) are wired to the

proper terminals.

1. Connect the wires to the S8910U Ignition Module as

shown in Table 5. Make sure that adequate system

ground is provided as indicated in the wiring table. See

Fig. 2 through 4. Where a change in quick-connect is

required, cut off the original quick-connect, strip the leadwire and firmly crimp in place the proper quick-connect

supplied.

2. Verify the thermostat anticipator setting as explained in

the preceding IMPORTANT, item 4.

Selectable DIP switches allow the ignition module to be

customized for the appropriate trial count, trial for

ignition period, and igniter warm-up time. Use only the

appropriate DIP switch configuration as given in Table 4

on page 7. Refer to Tables 1, 2, and 3 for appropriate

number of ignition trials, warm-up, prepurge and

between trial prepurge timings.

Improper DIP switch configuration can result in

appliance malfunction.

9 34-00008EFS—01

Page 10

S8910U3000

Table 5. Replacement Wiring Terminals.

Replacement Control Original Control

S8910U

Terminal Function

Terminal

Burner Ground Connection GND (BURNER)

Tranformer Secondary

24V (GND)

(unswitched leg)

Main Valve Common VALVE (GND)

Honeywell

S89/S890 Terminal

GND (BURNER)

24V (GND)

VALVE (GND)

a

a

White Rodgers

50E/F47 Terminal

a

MVa (next to TR

Robertshaw

HS780 Terminal

GND

TR (GND CLIP)

TR GND

—

terminal)

Transformer Secondary

24V

(switched leg)

Main Valve Operator VALVE VALVE

e

120 Vac Neutral Leg Power Supply

L2 120V NEUTRAL

L2 120V NEUTRAL — L2

120 Vac Hot Leg Power Supply L1 120V HOT L1 120V HOT

Hot Surface Igniter Element

HSI 120V NEUTRAL

e

Hot Surface Igniter Element HSI 120V HOT HSI 120V

Flame Sensor

a

Remove quick-connect and replace with the included 1/4 in. quick-connect.

b

Use green adapter cable (provided) to connect S8910U GND (BURNER) terminal to chassis ground.

c

Do not use the S8910U VALVE (GND) terminal. VALVE (GND) and 24V (GND) are interconnected in the appliance wiring.

d

Remove quick-connect and replace with the included 3/16 in. quick-connect.

e

Do not use this terminal if model being replaced does not have 120V neutral power supply connection.

f

Use the black wire on the included adapter cable.

g

Use the orange wire on the included adapter cable.

h

On remote sense models, remove jumper quick-connect from S8910U sense terminal, cut jumper wire at circuit board and

SENSEh SEN

24V

a

TH TH

MV

L

d

f

VALVE

L1

HSI 120V — IGN

g

IGN

h

FP

i

IGN

RS

discard. On local sense models, leave black jumper connected.

i

Remove jumper from S8910U sense terminal, cut jumper wire at circuit board and discard.

b

c

d

h

34-00008EFS—01 10

Page 11

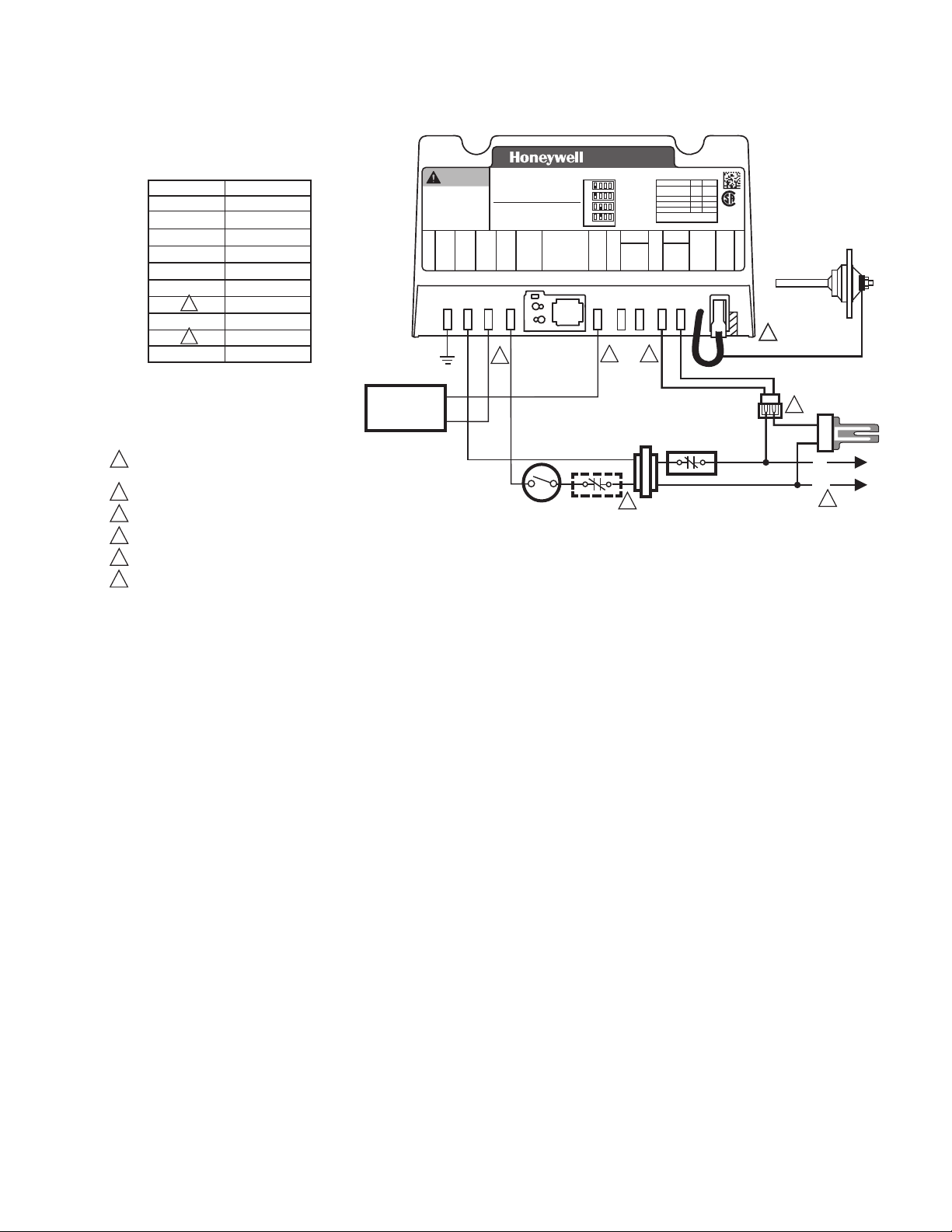

S8910U HOT SURFACE IGNITER CONTROL

TERMINAL CROSS

REFERENCE

S8910U

GND(BURNER)

24V (GND)

VALVE (GND)

24V

VALVE

L2

L1

4

HSI

4

HSI

SENSE

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. MAKE SURE L1 AND L2 ARE NOT REVERSED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

3

REMOVE JUMPER QUICK-CONNECT FROM S8910U. CUT WIRE AT CIRCUIT BOARD AND DISCARD.

USE ADAPTER PLUG WITH BLACK AND ORANGE WIRES (SUPPLIED).

4

CUT 3/16 IN. QUICK-CONNECT OFF WIRE AND REPLACE WITH 1/4 IN. QUICK-CONNECT (SUPPLIED).

5

CUT 3/16 IN. QUICK-CONNECT OFF WIRE AND REPLACE WITH 3/16 IN. QUICK-CONNECT (SUPPLIED).

6

50E/F47

GND

TR

MV

(NEXT TO TR)

TH

MV

—

L

—

IGN

FP

COMBINATION

GAS CONTROL

Explosion Hazard.

serious injury or death.

Disconnect power before servicing. This device can malfunction if it gets wet. Never

try to use a device that has

been wet -- replace it.

BURNER

GROUND

WARNING

BURNER

MV

MV

(GND)

Can cause

(GND)

24V

VALVE

S8910U Hot Surface Ignition

Input Voltages = 120 & 24 VAC, 60 Hz

HSI = 120V, 5A max.

Valve = 24V, 2A max.

Total 24V Load = 0.4 + valve load

U.S. Patent 8,085,521

Prepurge Time = 32 Sec.

Igniter Warm Up Time = See Inst. Sh. 34-00008

Ignition Trial Time - See Selection Tab

Number of Trials - See Selection Tab

Between Trial Time - 96 Sec.

See

LED

States

(GND)

TH-W

5

THERMOSTAT OR

CONTROLLER

NOTE: ALWAYS apply

this control as instructed

in Instruction Sheet

34-00008

SYSTEM SETUP

LED

Golden Valley, MN 55422

Assembled in Mexico

Selection Tab

Trial count

ON

OFF

= 1 try (default)

Trial count

ON

OFF

= 3 tries

Trial for ign. period

ON

OFF

= 4 seconds (default)

Trial for ign. period

ON

OFF

= 7 seconds

132

4

120 VAC

NEUTRAL

VALVE

6

2

HSI

L2

4

LED States

Control Status Color Pattern

Device damaged- Red Steady

replace control

Ignition lockout Red Blink

Normal operation Green Steady

Weak flame signal Green Blink

See Instruction Sheet 34-00008

for additional states

32304204-001 Rev. A

120 VAC

See

HOT

Instructions

for

Single/Dual

Rod

L1

HSI

Applications

ORANGE

BLACK

LIMIT

CONTROLLER

®

CUS

AUTO

IGNITION

SYSTEMS

ANSI Z21.20

SENSE

ADAPTER

3

S8910U3000

FLAME

SENSOR

HOT SURFACE

IGNITER

4

L1

(HOT)

L2

1

M8528E

Fig. 2. Typical hookup when S8910U replaces White-Rodgers 50E/F47.

11 34-00008EFS—01

Page 12

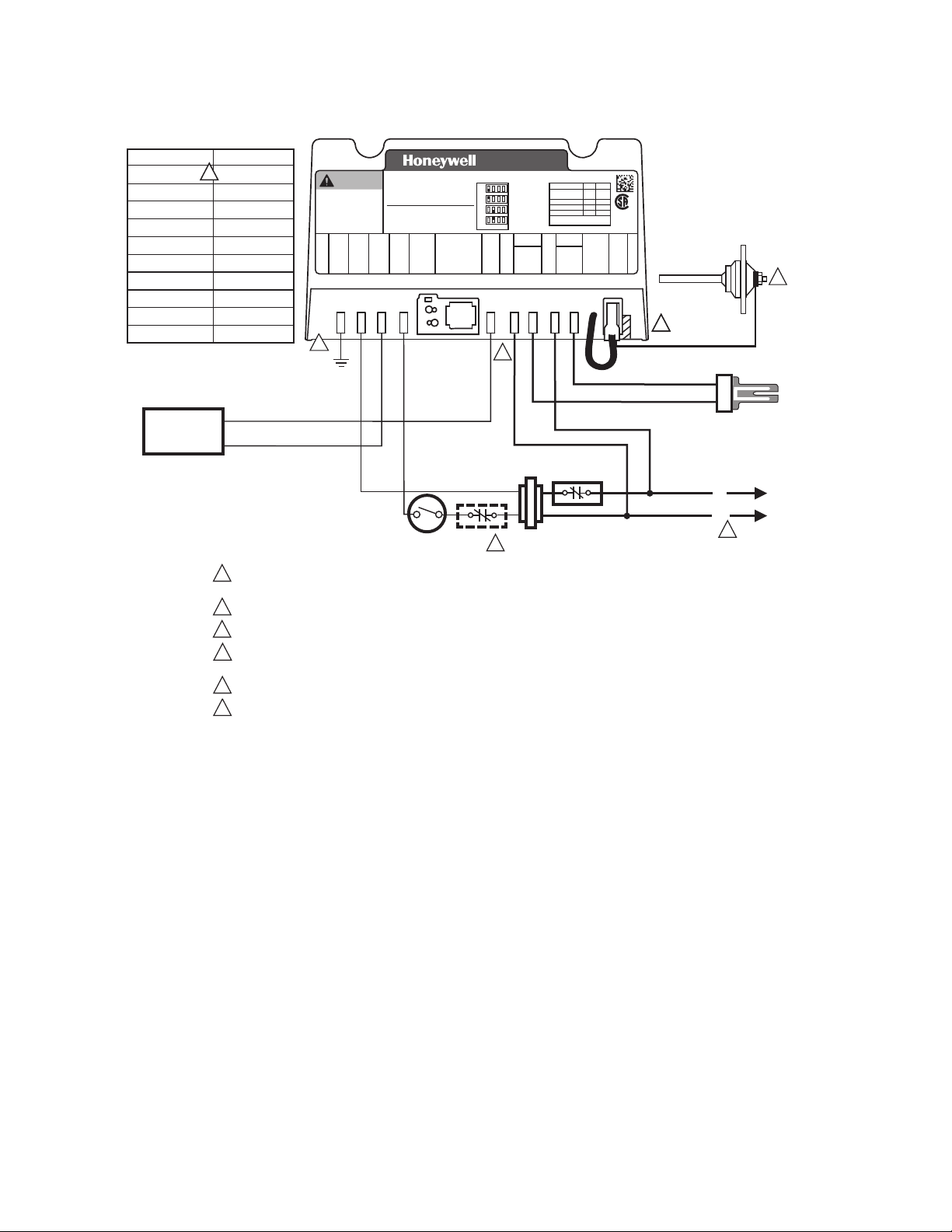

S8910U3000

WARNING

Golden Valley, MN 55422

Assembled in Mexico

Explosion Hazard.

Can cause

serious injury or death.

Disconnect power before servicing. This device can malfunction if it gets wet. Never

try to use a device that has

been wet -- replace it.

Input Voltages = 120 & 24 VAC, 60 Hz

HSI = 120V, 5A max.

Valve = 24V, 2A max.

Total 24V Load = 0.4 + valve load

U.S. Patent 8,085,521

S8910U Hot Surface Ignition

Prepurge Time = 32 Sec.

Igniter Warm Up Time = See Inst. Sh. 34-00008

Ignition Trial Time - See Selection Tab

Number of Trials - See Selection Tab

Between Trial Time - 96 Sec.

(GND)

(GND)

(GND)

BURNER

24V

VALVE

TH-W

LED

SYSTEM SETUP

VALVE

L2

HSI

L1

HSI

SENSE

NOTE: ALWAYS apply

this control as instructed

in Instruction Sheet

34-00008

32304204-001 Rev. A

120 VAC

NEUTRAL

120 VAC

HOT

See

Instructions

for

Single/Dual

Rod

Applications

See

LED

States

®

CUS

AUTO

IGNITION

SYSTEMS

ANSI Z21.20

Selection Tab

ON

OFF

132

ON

OFF

ON

OFF

ON

OFF

Trial for ign. period

= 7 seconds

Trial for ign. period

= 4 seconds (default)

Trial count

= 3 tries

4

Trial count

= 1 try (default)

Control Status Color Pattern

Device damaged- Red Steady

replace control

Ignition lockout Red Blink

Normal operation Green Steady

Weak flame signal Green Blink

See Instruction Sheet 34-00008

for additional states

LED States

MV

MV

L1

(HOT)

L2

1

3

2

1

2

3

4

4

5

6

COMBINATION

GAS CONTROL

S8910U HOT SURFACE IGNITER CONTROL

HOT

SURFACE

IGNITER

FLAME

SENSOR

LIMIT

CONTROLLER

THERMOSTAT OR

CONTROLLER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

MAKE SURE L1 AND L2 ARE NOT REVERSED.

ALTERNATE LIMIT CONTROLLER LOCATION.

SENSE ROD WILL BE PRESENT IF REMOTE SENSE HS780 MODEL. SEE TABLE 2.

WHEN HS780 IS A REMOTE SENSE MODEL, REMOVE JUMPER QUICK-CONNECT FROM S8910U. CUT WIRE AT CIRCUIT

BOARD AND DISCARD. CONNECT FLAME ROD LEAD WIRE TO SENSE. SEE TABLE 2.

CUT 1/4 IN. QUICK-CONNECT OFF WIRE AND REPLACE WITH 3/16 IN. QUICK-CONNECT (SUPPLIED).

USE GREEN GROUND ADAPTER (SUPPLIED) TO CONNECT S8910U GND (BURNER) TO APPLIANCE CHASSIS.

BURNER

GROUND

M8529E

5

6

4

HS780

TR (GND CLIP)

GND

—

TH

VALVE

L2

L1

IGN

IGN

RS

4

4

TERMINAL CROSS

REFERENCE

S8910U

GND(BURNER)

24V (GND)

VALVE (GND)

24V

VALVE

L2

L1

HSI

HSI

SENSE

6

34-00008EFS—01 12

Fig. 3. Typical hookup when S8910U replaces Robertshaw HS780.

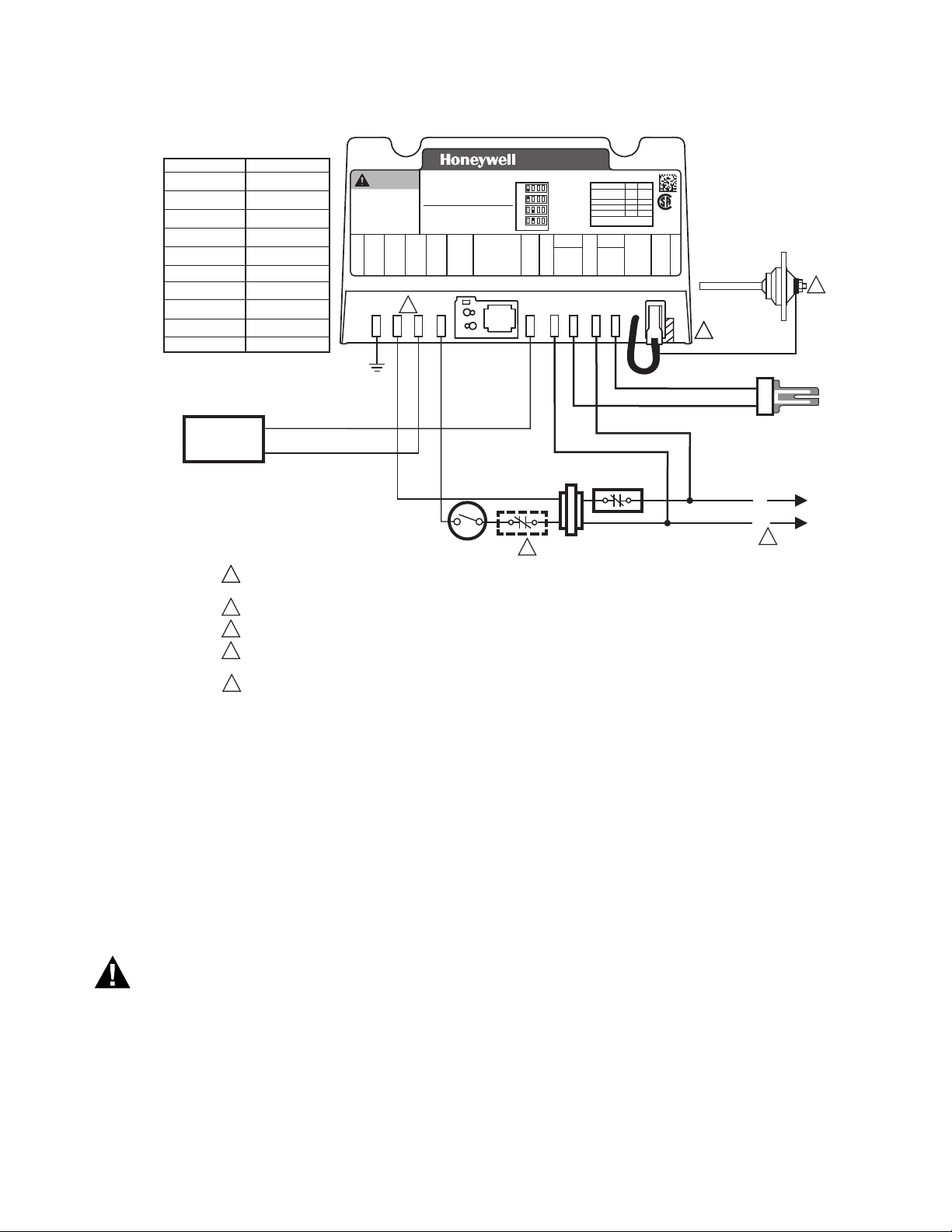

Page 13

S8910U3000

WARNING

TERMINAL CROSS

REFERENCE

S8910U

GND(BURNER)

24V (GND)

VALVE (GND)

24V

VALVE

L2

L1

HSI

HSI

SENSE

COMBINATION

GAS CONTROL

S8910U HOT SURFACE IGNITER CONTROL

Golden Valley, MN 55422

34-00008

Assembled in Mexico

Selection Tab

ON

OFF

ON

OFF

ON

OFF

ON

OFF

132

4

VALVE

Trial count

= 1 try (default)

Trial count

= 3 tries

Trial for ign. period

= 4 seconds (default)

Trial for ign. period

= 7 seconds

120 VAC

NEUTRAL

HSI

L2

LED States

Control Status Color Pattern

Device damaged- Red Steady

replace control

Ignition lockout Red Blink

Normal operation Green Steady

Weak flame signal Green Blink

See Instruction Sheet 34-00008

for additional states

120 VAC

See

HOT

Instructions

for

Single/Dual

Rod

L1

HSI

Applications

CUS

AUTO

IGNITION

SYSTEMS

ANSI Z21.20

32304204-001 Rev. A

SENSE

®

FLAME

SENSOR

S89/S890

GND (BURNER)

24V (GND)

VALVE (GND)

24V

VALVE

L2

WARNING

Explosion Hazard.

Can cause

serious injury or death.

Disconnect power before servicing. This device can malfunction if it gets wet. Never

try to use a device that has

been wet -- replace it.

(GND)

(GND)

BURNER

24V

S8910U Hot Surface Ignition

Input Voltages = 120 & 24 VAC, 60 Hz

HSI = 120V, 5A max.

Valve = 24V, 2A max.

Total 24V Load = 0.4 + valve load

U.S. Patent 8,085,521

Prepurge Time = 32 Sec.

Igniter Warm Up Time = See Inst. Sh. 34-00008

Ignition Trial Time - See Selection Tab

Number of Trials - See Selection Tab

Between Trial Time - 96 Sec.

VALVE

(GND)

TH-W

NOTE: ALWAYS apply

See

LED

this control as instructed

States

SYSTEM SETUP

LED

in Instruction Sheet

L1

HSI

HSI

5

4

4

SEN

BURNER

GROUND

MV

MV

LIMIT

CONTROLLER

THERMOSTAT OR

CONTROLLER

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

MAKE SURE L1 AND L2 ARE NOT REVERSED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

SENSE ROD WILL BE PRESENT IF REMOTE SENSE S89/S890 MODEL. SEE TABLE 3.

3

WHEN S89/S890 IS A REMOTE SENSE MODEL, REMOVE JUMPER QUICK-CONNECT FROM S8910U. CUT WIRE AT CIRCUIT

4

BOARD AND DISCARD. CONNECT FLAME ROD LEAD WIRE TO SENSE. SEE TABLE 3.

CUT QUICK-CONNECTS OFF WIRES AND REPLACE WITH 1/4 IN. QUICK-CONNECTS (PROVIDED).

5

2

HOT

SURFACE

IGNITER

L1

(HOT)

L2

1

3

M8530E

Fig. 4. Typical hookup when S8910U replaces Honeywell S89/S890.

STARTUP AND CHECKOUT

Check out the gas control system:

• At initial installation of the appliance.

• As part of regular maintenance procedures.

• At maintenance intervals determined by the application.

• As the first step in troubleshooting.

• Any time work is done on the system.

Determine maintenance frequency individually for each

application; see Maintenance section.

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

1. If you smell gas or suspect a gas leak, turn off gas

at the manual service valve and evacuate the

building. Do not try to light any appliance; do not

touch any electrical switch or telephone in the

building until you are sure no spilled gas remains.

2. Perform a gas leak test, as described in Steps 1

and 6 in the Startup and Checkout section, for initial

installation and any time work is done involving the

gas piping.

Step 1: Perform visual inspection.

a. With power off, make sure all wiring connections are

clean and tight.

b. Turn on the power to the appliance and the S8910U.

c. Open the manual shutoff valves in the gas line to the

appliance.

d. Test for a gas leak upstream of the gas control if the

piping has been disturbed.

GAS LEAK TEST: Paint gas control gasket edges and all pipe

connections upstream of the gas control with a rich soap and

water solution. Bubbles indicate gas leaks. Tighten the joints

and screws or replace the component to stop a gas leak.

Recheck with soap and water solution.

13 34-00008EFS—01

Page 14

S8910U3000

WARNING

Step 2: Verify control system ground.

The ignition module must share a common ground with the

main burner. The burner serves as the common grounding

area to assure reliable flame detection. If there is not good

metal-to-metal contact between the burner and ground, run a

lead from the burner to ground.

Step 3: Review normal operating sequence and module

specifications. See Operation and Application sections.

Step 4: Reset the ignition module.

a. Turn the thermostat or controller to the lowest setting.

b. Turn on the system power.

c. Wait one minute.

As you do Steps 5 and 6, watch for points where operation

deviates from normal. Refer to Troubleshooting section to

correct the problem.

Step 5: Check the safety lockout operation.

a. Turn off the gas supply.

b. Set the thermostat or controller above the room

temperature to call for heat.

c. Watch for igniter warmup following prepurge. Igniter

starts to glow several seconds after it is powered.

d. Time the length of time gas control is energized; measure

the time by connecting a voltmeter across the gas valve

terminals.

e. When configuring control for three ignition trials, watch for

the start of the 96-second between trial purge, followed

by a configured igniter warmup period and a second try

for ignition. After a third purge, warmup, and trial for

ignition sequence, the S8910U should lock out. The LED

displays a brief red flash. Refer to Table 6 for a complete

list of LED codes.

f. Open the manual gas control knob and make sure no gas

is flowing to the burner.

g. Set the thermostat below the room temperature and wait

one minute before continuing.

Step 6: Check normal operation.

a. Set the thermostat or the controller above the room

temperature to call for heat.

b. Observe the lightoff sequence and make sure the main

burner lights smoothly without flashback.

c. Make sure the burner operates smoothly without floating,

lifting, or flame rollout to the furnace vestibule or heat

buildup in the vestibule.

d. Test for a gas leak downstream of the gas control if the

piping has been disturbed.

f. Turn the thermostat or controller below the room

temperature. Make sure the main burner and the pilot

flames go out.

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

Improper location of the 120 Vac hot surface igniter or

any flame sensing rod can result in appliance

malfunction.

1. Never attempt to relocate the 120 Vac hot surface

igniter or the flame sensing rod from the original

position established by the appliance manufacturer.

2. Be sure the 120 Vac hot surface igniter or the flame

sensing rod is replaced in exactly the original

position after removal for inspection, service or

replacement.

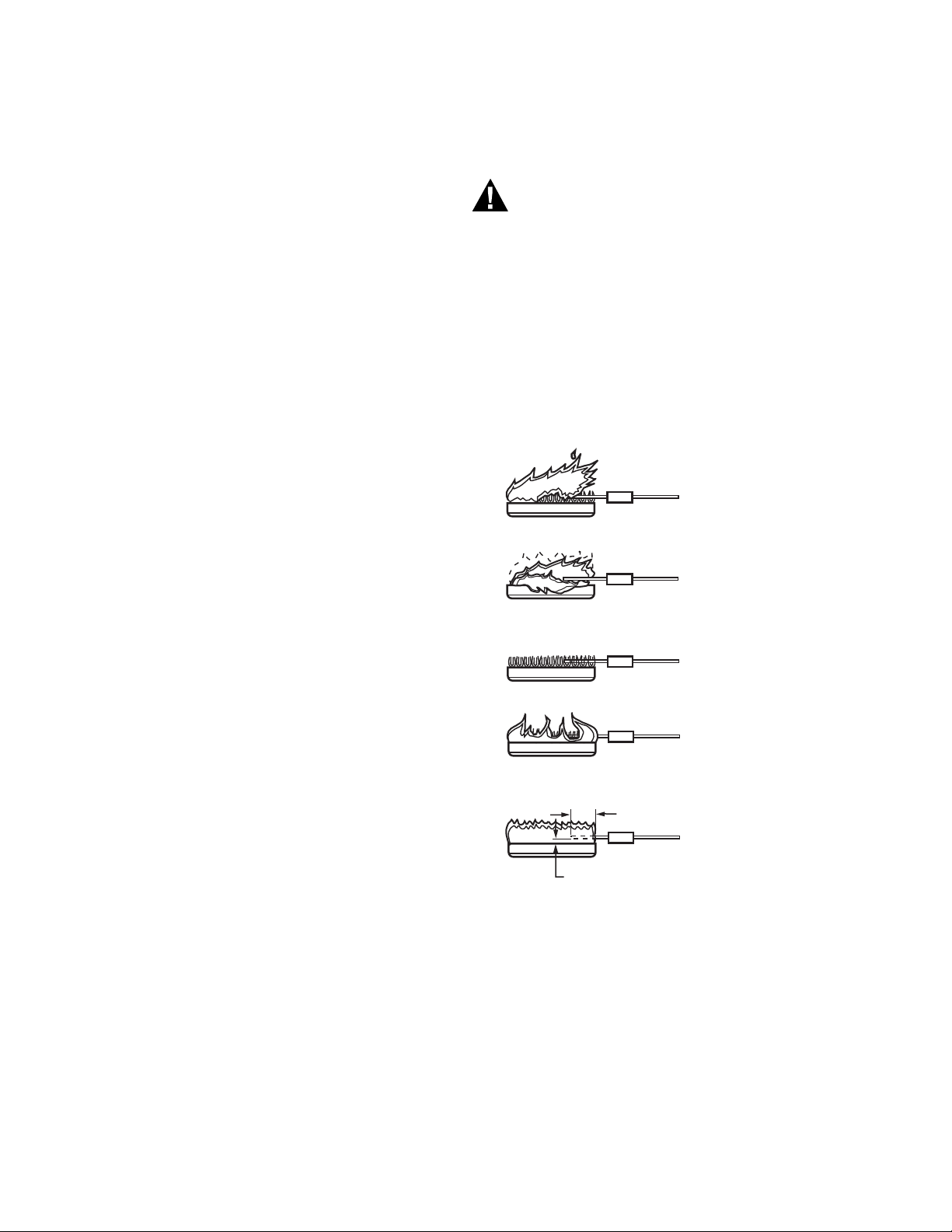

CHECK BURNER FLAME CONDITION

NOISY

LIFTING

FLAME

BURNER

1/4 TO 1/2 IN. (6 TO 13 MM)

WAVING

FLAME

SMALL

BLUE

FLAME

LAZY

YELLOW

FLAME

GOOD

RECTIFYING

FLAME

3/4 TO 1 IN. (19 TO 25 MM)

CHECK FOR:

• HIGH GAS PRESSURE

• EXCESS PRIMARY AIR

OR DRAFT

CHECK FOR:

• POOR DRAFT

• EXCESS DRAFT

• HIGH VELOCITY OR

SECONDARY AIR

INSTALL SHIELD IF NECESSARY

CHECK FOR:

• CLOGGED PORTS OR

ORIFICE FILTER

• WRONG SIZE ORIFICE

CHECK FOR LACK OF

AIR FROM:

• DIRTY PRIMARY

AIR OPENING

• LARGE PORTS

OR ORIFICES

Fig. 5. Check burner flame condition.

OPERATION

M8446B

GAS LEAK TEST: Paint the gas control gasket edges and all

pipe connections downstream of the gas control with a rich

soap and water solution. Bubbles indicate a gas leak. Tighten

the joints and screws or replace the component to stop a gas

leak. Recheck with soap and water solution.

e. Check the burner flame condition. The igniter-sensor or

sensor must be constantly immersed in flame. Check the

burner flame condition as shown in Fig. 5. Do not relocate

the hot surface igniter or flame rod.

34-00008EFS—01 14

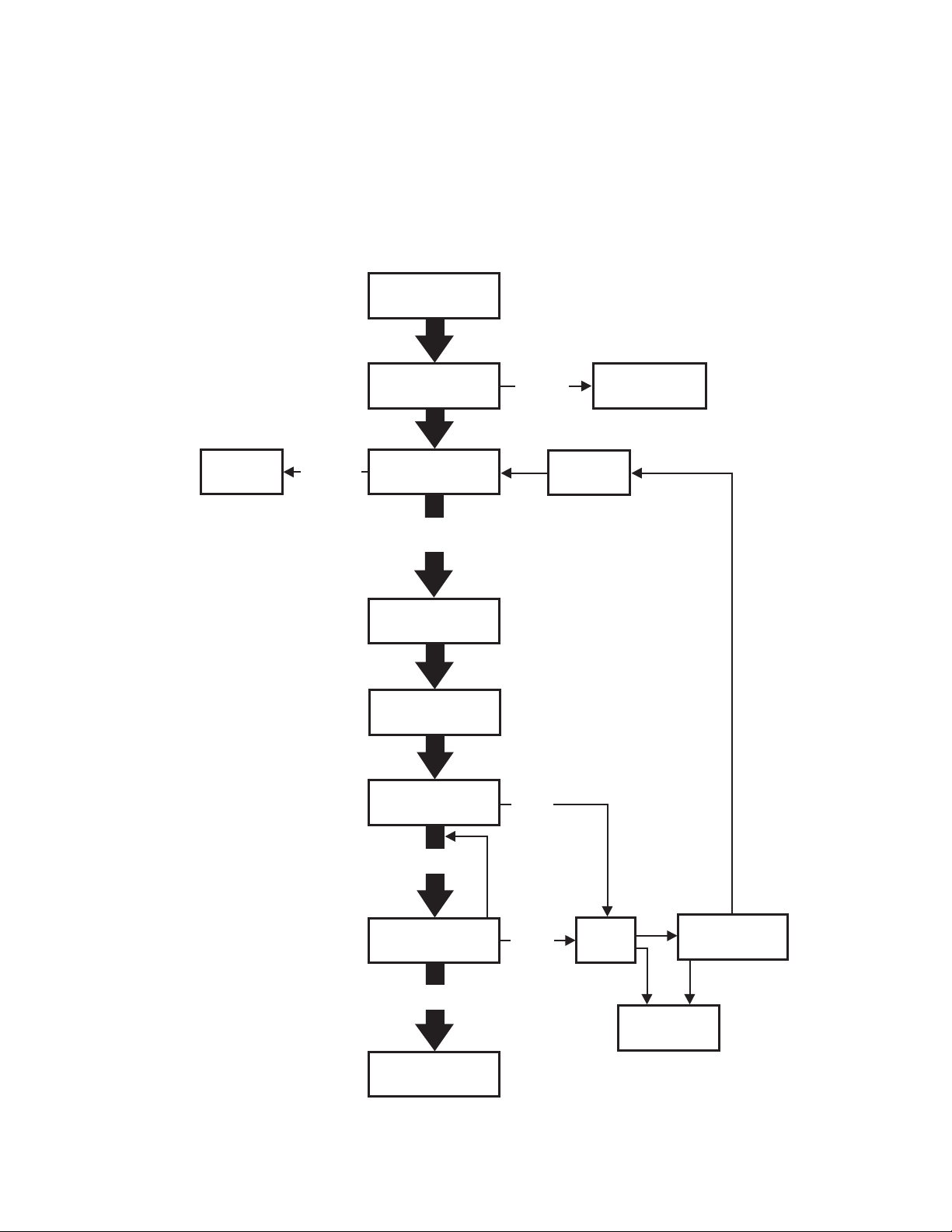

The S8910U is a direct ignition control used with 120 Vac timed

warmup hot surface igniter. The control provides operating

control and shuts off all gas flow on ignition failure or loss of

main burner flame in central heat furnaces and other heating

appliances.

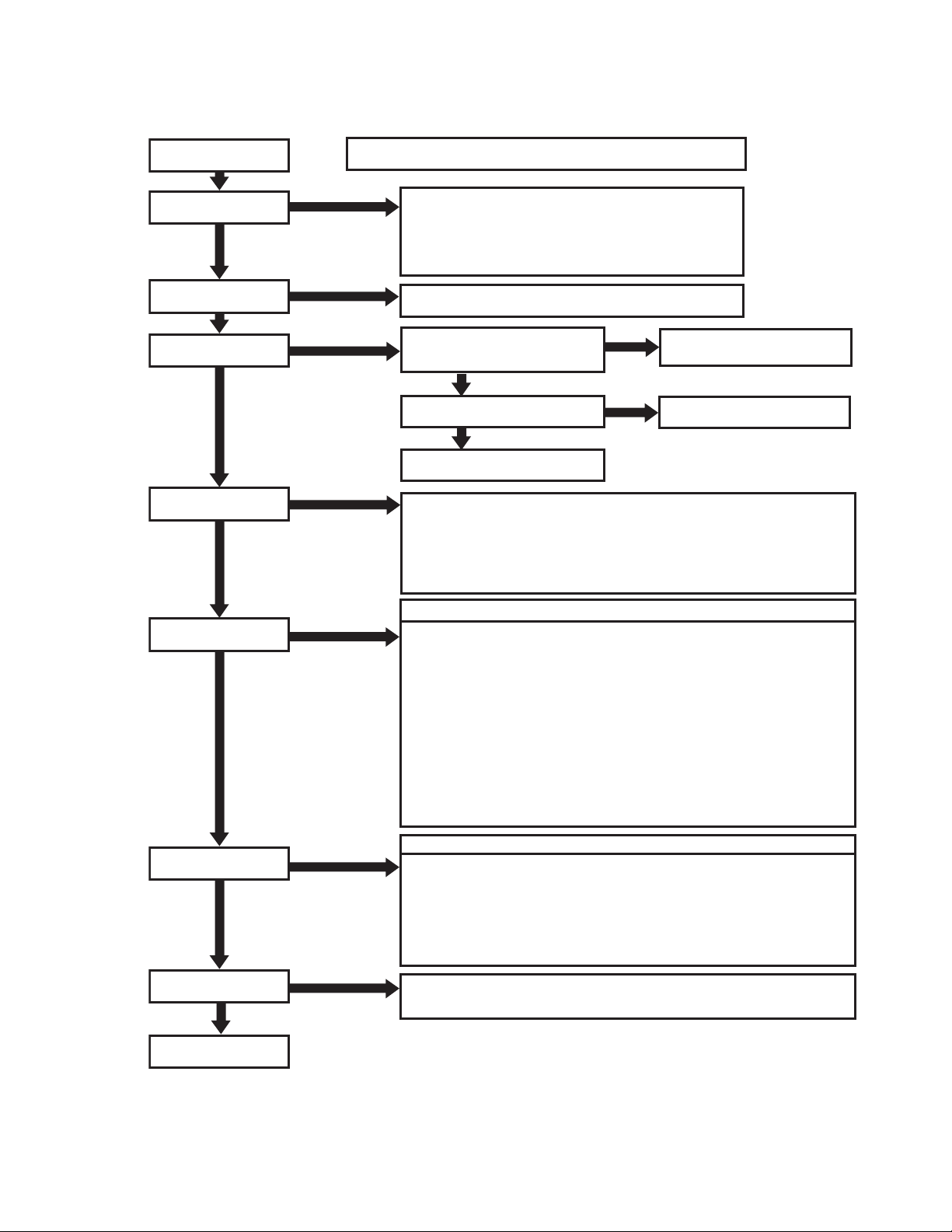

Module operation is in three phases—prepurge/igniter

warmup, trial for ignition and burner operation. The S8910U

provides one or three trials for ignition, depending on the DIP

switch configuration. Fig. 6 shows the normal operating

sequence.

Page 15

S8910U3000

Purge/Prepurge

When the S8910U is used in a fan-assisted combustion

system, the combustion air blower starts on a call for heat from

the thermostat. On proof of airflow, the air proving switch

closes and energizes the S8910U. When the S8910U is used

in an atmospheric system, the call for heat energizes the

module.

CALL FOR HEAT (24V

TERMINAL POWERED)

INITIALIZATION CHECKS

SYSTEM WILL

NOT START

FLAME

SIMULATING

FAILURE

PREPURGE (32 SEC)

NO FLAME

SIMULATING

FAILURE

In either case, the S8910U first initiates a 32-second delay to

allow system prepurge.

Igniter Warmup

After prepurge, the S8910U energizes the igniter to start the

igniter warmup. The module energizes the hot surface igniter

for the selected warmup period; the gas control is closed

during this period.

WELDED

RELAYS

DETECTED

DEVICE LOCKED

(REPLACE CONTROL)

INTERPURGE

(64 SEC)

IGNITER WARMS UP (7

(12), 17 (27), 34 OR 45 SEC)

GAS CONTROL OPENS

FOR TIMED TRIAL

FOR IGNITION.

IGNITER OFF;

FLAME SENSING BEGINS.

FLAME

PRESENT

GAS CONTROL STAYS

OPEN (MAIN BURNER

RUNS).

CALL FOR HEAT

IS SATISFIED.

NO

FLAME

FLAME

FAILURE

GAS

CONTROL

CLOSES

ONE

TRIAL

THREE

TRIALS

HOW MANY IGNITION

TRIALS COMPLETED

THIS CALL FOR HEAT?

THREE

LOCKOUT OCCURS.

SYSTEM MUST BE

RESET.

LESS

THAN

THREE

GAS CONTROL CLOSES

(MAIN BURNER OFF).

Fig. 6. S8910U normal operating sequence.

15 34-00008EFS—01

M35558

Page 16

S8910U3000

WARNING

Trial for Ignition

At the end of the warmup period, the gas control opens for the

ignition trial time determined by the DIP switch configuration.

The hot surface igniter stays powered for an ignition activation

period of two seconds if the four second trial time is used or

five seconds if the seven second trial time is used. The igniter

turns off after the ignition activation period. Near the end of the

ignition trial time, the flame rectification sensing circuit

determines if the main burner flame is present. If so, the gas

control remains open and the burner operation phase begins.

Burner Operation

When the main burner is lit, a flame rectification circuit is

completed between the flame sensor (igniter on local sense

systems or flame rod on remote sense systems) and the main

burner (burner ground). The S8910U flame sensing circuit

detects the flame current and holds open the gas control. The

main flame is monitored continuously during the call for heat.

Safety Shutdown

One Trial

If flame is not sensed by the end of the timed trial for ignition,

the gas control closes and the module locks out. It must be

manually reset by removing power or setting the thermostat

below the room temperature for at least 30 seconds.

MAINTENANCE

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

Do not attempt to take apart the module or to clean it.

Improper assembly and cleaning can cause unreliable

operation.

Regular preventive maintenance is important in applications

that place a heavy load on system controls such as those used

in the commercial cooking and agricultural and industrial

industries because:

• In many such applications, particularly commercial cooking,

the equipment operates 100,000 to 200,000 cycles per

year. This heavy cycling can wear out the gas control in one

to two years.

• Exposure to water, dirt, chemicals and heat can damage the

gas control and shut down the control system. A NEMA 4

enclosure can reduce exposure to environmental contaminants.

The maintenance program should include regular checkout of

the system as outlined in the Startup and Checkout section,

and checkout of the control system as described in the

appliance manufacturer literature.

If the burner lights and flame is proved but goes out during the

run cycle, the gas control closes and the module locks out. It

must be manually reset by removing power or setting the

thermostat below the room temperature for at least 30

seconds.

Three Trial

If flame is not sensed by the end of the first timed trial for

ignition, the gas control closes and the module initiates a

second 96 seconds between trial purge cycle, followed by

igniter warmup and a second trial for ignition. If flame is not

established, the between trial purge, warmup, trial for ignition

cycle is repeated a third time. If flame is still not established

following the third trial, the gas control closes and the module

locks out. It must be manually reset by removing power or

setting the thermostat below the room temperature for at least

30 seconds.

If the burner goes out during the run cycle, the gas control

closes and the module checks for the number of ignition trials

performed during the current call for heat. If the number is less

than three, the module initiates a between trial purge, warmup

and trial for ignition. After the third trial during a single call for

heat, the module locks out. The module must be manually

reset following the lockout.

Maintenance frequency must be determined individually for

each application. Some considerations are:

• Cycling frequency. Appliances that may cycle 20,000 times

annually should be checked monthly.

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before the

next use.

• Consequence of unexpected shutdown. Where the cost of

an unexpected shutdown would be high, the system should

be checked more often.

• Dusty, wet, or corrosive environment. Because these

environments can cause the gas control to deteriorate more

rapidly, the system should be checked more often.

Any control should be replaced if it does not perform properly

on checkout or troubleshooting. In addition, replace any

module if it is wet or looks like it has ever been wet. Protective

enclosures, as described in the Planning the Installation

section, are recommended regardless of checkout frequency.

TROUBLESHOOTING

IMPORTANT

1. The following service procedures are provided as a

general guide. Follow the appliance manufacturer

service instructions if available.

2. Meter readings between gas control and ignition

module must be taken within the trial for ignition

period. Once the ignition module shuts off, wait for

retry or reset at the thermostat.

3. If any component does not function properly, make

sure it is correctly installed and wired before replacing

it.

34-00008EFS—01 16

Page 17

S8910U3000

4. The ignition module cannot be repaired. If it malfunctions, replace it.

5. Only trained, experienced service technicians should

service hot surface ignition systems.

6. After servicing, verify proper system operation.

Perform the checkout steps in the Startup and Checkout

section as the first step in troubleshooting. Then check the

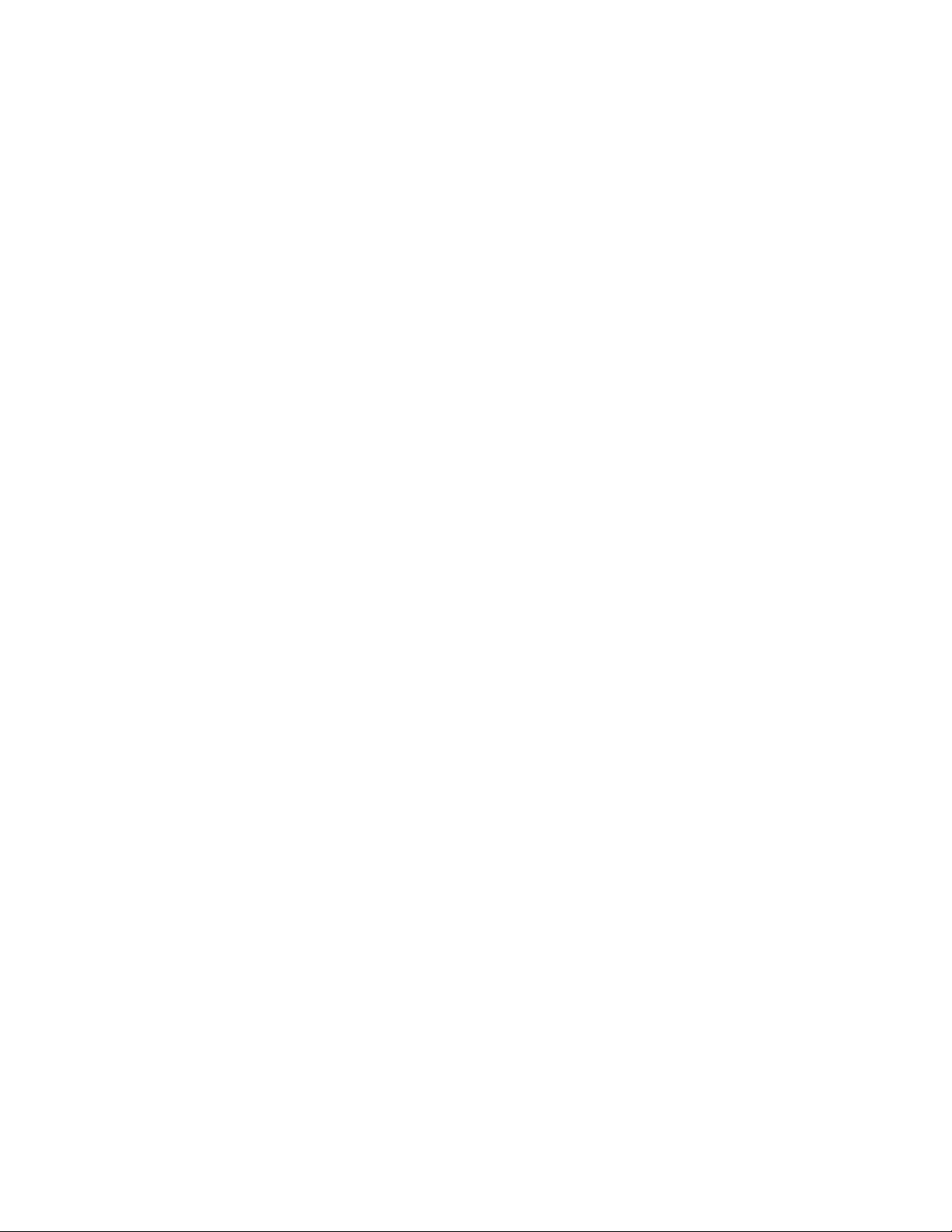

troubleshooting sequence (Fig. 7) to determine the exact the

cause of the problem.

After troubleshooting, perform the checkout procedure again to

be sure the system is operating normally.

Status LED Used to Troubleshoot

The LED can be used to check the appliance status. A

description of the LED signals follows. Refer to Table 6 on

page 18 for a complete list of LED codes.

IMPORTANT

The LED displays system status for the current call for

heat. When the call for heat is interrupted (thermostat

satisfied or system power switched off), the LED goes

off and the status information is lost.

• A steady green LED indicates the normal operating mode

during a call for heat (24 V terminal is powered). The

system can be in any of the normal operating modes

including prepurge, warmup, ignition trial, between trial

purge, or normal run.

• An intermittant red flash, and two, three, or four yellow

flashes indicate a lockout mode. Refer to Table 6 for a

complete list of LED codes. The most probable cause is the

main burner failing to light or failure to detect the flame. Run

the appliance through a call for heat and if the burner does

not light, check the:

— gas supply

— input voltage

— hot surface igniter

— gas control

— wiring

If the main burner lights, but goes out at the end of ignition trial,

check the:

— igniter/sensor

— flame rod

— burner ground connections

— wiring

• Intermittant green flashes indicates the flame rectification

signal is weak. The most probable causes are:

— contaminated or mislocated igniter/sensor or flame rod

— poor flame sense leadwire insulation or connections

— poor gas pressure

If the flame rectification signal is strong when the

appliance lights, but weak while heat is being delivered, check

for overheating of the igniter/sensor, flame rod ceramic or

flame sense leadwires.

• Four yellow flashes indicate an internal error. The most

probable cause is an S8910U logic failure. Start a new call

for heat and if the four-flash signal returns wait 1 to 2 hours

and repeat the last step. If the four-flash signal returns

again, replace the S8910U.

• A steady red LED indicates a device lockout due to a

detected welded gas valve relay. Replace the control.

Ignition System Checks

Step 1: Check igniter wire harness.

Make sure:

a. Ignition cable does not run in contact with any metal

surfaces.

b. Connections to the ignition module and to the igniter or

igniter-sensor are clean and tight.

c. Ignition cable provides good electrical continuity.

Step 2: Check ignition system grounding. Nuisance shutdowns

are often caused by a poor or erratic ground.

a. A common ground is required for the module, igniter,

flame sensor and main burner.

• Check for good metal-to-metal contact between the

igniter bracket and the main burner.

• Check the ground path from the GND (BURNER)

terminal on the module to the main burner. Make sure

connections are clean and tight. If the wire is

damaged or deteriorated, replace it by following the

appliance manufacturer instructions. A temporary

leadwire connection between the GND (BURNER)

terminal and the main burner can help confirm a

ground path problem.

• Check the temperature at the igniter ceramic or flame

sensor insulator. Excessive temperature permits

leakage to ground. Contact the appliance

manufacturer if the temperature exceeds rating of

igniter or sensor.

• If flame sensor or bracket is bent out of position,

restore to the correct position.

• Replace the igniter and sensor or igniter-sensor with

an identical unit if the insulator is cracked.

Step 3: Check the flame sensing circuit.

a. Make sure the burner flame is capable of providing a

good rectification signal. See Fig. 5.

b. Make sure about 3/4 to 1 in. of the flame sensor or igniter-

sensor is continuously immersed in the flame for the best

flame signal. See Fig. 5.

c. Check for excessive (above 1000 °F [538 °C])

temperature at the ceramic insulator on the flame sensor.

Excessive temperature can cause a short to ground.

d. Check for cracked igniter-sensor or sensor ceramic

insulator, which can cause short to ground, and replace

unit if necessary.

• Make sure electrical connections are clean and tight.

Replace damaged wire with moisture-resistant No. 18

wire rated for continuous duty up to 221 °F (105 °C).

e. If the igniter is other than a Norton 201 or 271, make sure

it meets the following specifications:

• Igniter must reach 1832 °F (1000 °C) within the

selected warm up time of 7, 17, 34 or 45 seconds

with 102 Vac applied.

• Igniter must maintain at least 500M ohm insulation

resistance between the igniter leadwires and the

igniter mounting bracket.

• Igniter must not develop an insulating layer on its

surface (over time) that would prevent flame sensing.

• Igniter surface area immersed in flame must not

exceed one-fourth of the grounded area immersed in

flame. This would prevent flame sensing.

• Igniter current draw at 132 Vac must not exceed 5 A.

17 34-00008EFS—01

Page 18

S8910U3000

Red Steady Device locked - detected welded gas valve relay. Replace control

Red Intermittent blink Hard lockout - exceeded maximum number of retries

Yellow Steady Soft lockout - gas valve failure or 8 consecutive recoverable lockouts:

Yellow 1 Flame detected out of sequence.

Yellow 2 Recoverable lockout - Low input voltage detected.

Yellow 3 Recoverable lockout - AC line frequency out of acceptable range.

Yellow 4 Recoverable lockout - Internal error.

Green Steady Normal sequence and operation.

Green Intermittent blink Normal sequence and operation, weak flame detected.

Table 6. LED codes.

Color Flash Code Status

the unit will wait 1 hour before next ignition attempt.

34-00008EFS—01 18

Page 19

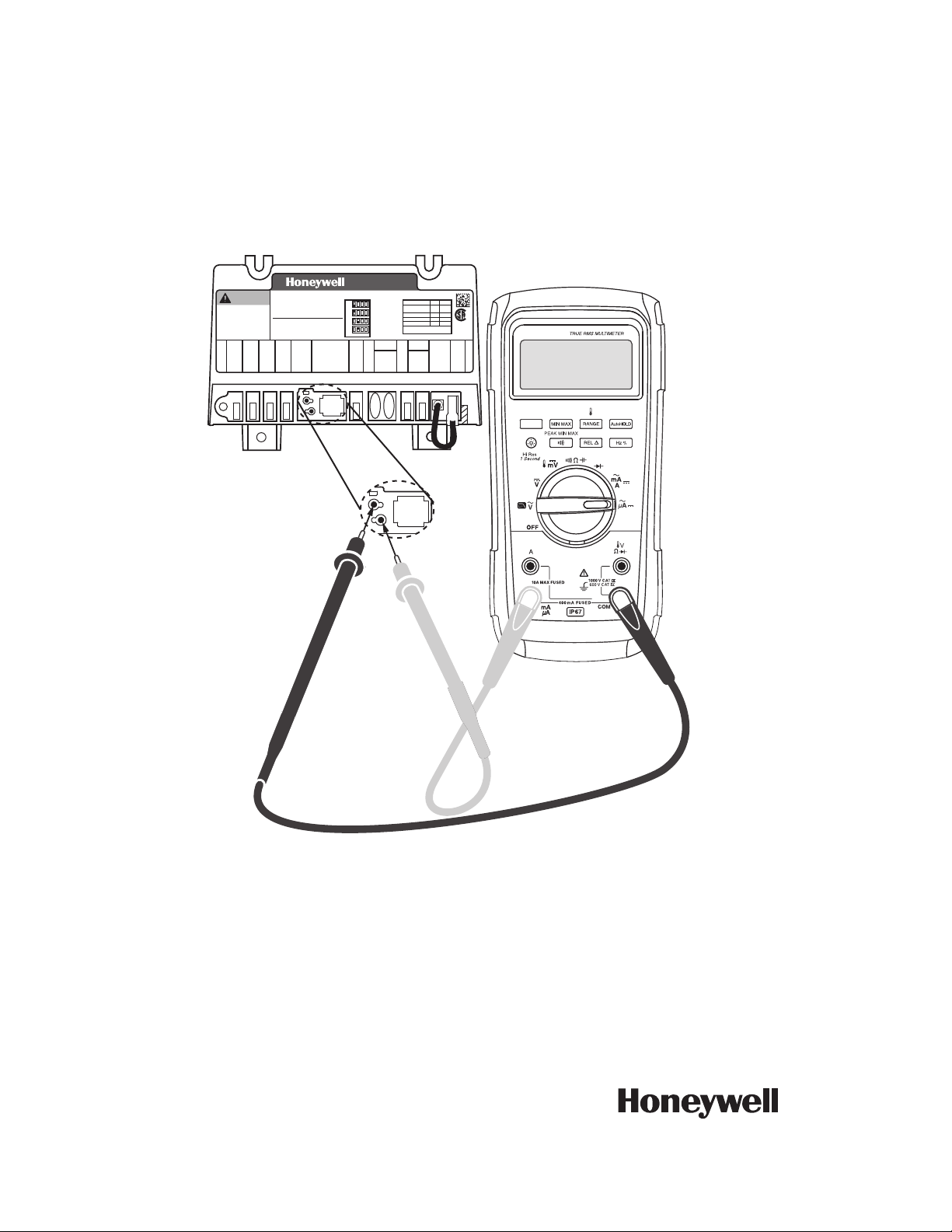

CONFIRM THAT 120V HOT LEAD

CONNECTS TO L1, AND 120V NEUTRAL

LEAD CONNECTS TO L2.

M8531B

NO

NO

NO

NO

NO

NO

YES

YES

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

START

TURN THERMOSTAT TO

CALL FOR HEAT

DOES S8910U GET POWER

(24 VAC NOMINAL)?

30 SECOND MINIMUM

PURGE

IGNITER WARMS UP AND

GLOWS RED

REPEAT PROCEDURE UNTIL TROUBLE-FREE OPERATION IS OBTAINED.

SYSTEM RUNS UNTIL CALL

FOR HEAT ENDS

CALL FOR HEAT ENDS,

SYSTEM SHUTS OFF

TROUBLESHOOTING ENDS

••CHECK FOR PROPER TEMPERATURE CONTROLLER OPERATION.

REMOVE VALVE LEAD AT S8910U; IF VALVE CLOSES, RECHECK TEMPERATURE CONTROLLER

AND WIRING; IF NOT, REPLACE GAS CONTROL.

NOTE: IF S8910U GOES INTO LOCKOUT, RESET SYSTEM.

CHECK CONTINUITY OF GROUND WIRE.

NOTE: IF GROUND IS POOR OR ERRATIC, SHUTDOWNS CAN OCCUR OCCASIONALLY

EVEN THOUGH OPERATION IS NORMAL AT THE TIME OF CHECKOUT.

CHECK FOR EXCESSIVE HEAT AT IGNITER OR FLAME ROD CERAMIC BASE

(TEMPERATURE ABOVE 1000F (538C) CAUSES SHORT TO GROUND).

IF CHECKS ARE OKAY, REPLACE S8910U MODULE.

NOTE: SYSTEM FAILURE DURING A RUN CYCLE HAS A LOW PROBABILITY OF

BEING THE S8910U.

•

•

•

MAIN BURNER REMAINS

POWERED AND LIT

MAIN BURNER LIGHTS

CHECK FOR 120 VAC ACROSS HOT

SURFACE IGNITER TERMINALS.

NOTE: IF S8910U GOES INTO LOCKOUT, RESET SYSTEM.

CHECK CONTINUITY OF GROUND WIRE AND GROUND PATH FROM MAIN BURNER TO

GND (BURNER) TERMINAL OF S8910U.

CONFIRM THAT 120 VAC HOT LEAD IS CONNECTED TO L1 AND 120 VAC NEUTRAL LEAD

IS CONNECTED TO L2.

CHECK THAT BURNER FLAME COVERS IGNITER/SENSOR OR SENSOR.

CHECK INSULATION ON IGNITER/SENSOR LEADS.

CHECK IGNITER/SENSOR OR FLAME ROD FOR CONTAMINATION OR DAMAGE. REPLACE,

IF NECESSARY.

CHECK INSULATION ON SENSOR LEADS AND CHECK SENSOR POSITION.

IF CHECKS ARE OK, REPLACE S8910U MODULE.

NOTE: SYSTEM FAILURE AFTER MAIN FLAME LIGHTS HAS A LOW PROBABILITY

OF BEING THE S8910U.

•

•

•

•

•

•

CHECK FOR 24 VAC ACROSS VALVE TERMINALS ON S8910U DURING TRIAL FOR IGNITION

TIMING. IF NO VOLTAGE, REPLACE S8910U.

CHECK ELECTRICAL CONNECTIONS BETWEEN S8910U AND GAS CONTROL.

IF OK, REPLACE GAS CONTROL.

CHECK IGNITER POSITION.

CHECK GAS PRESSURE TO MAIN BURNER.

•

•

•

•

REPLACE S8910U.

CHECK AND CORRECT WIRING FUSE

OR CIRCUIT BREAKER.

CHECK WIRES TO IGNITER.

IF OK, REPLACE IGNITER.

CHECK AIR PROVING SWITCH.

REPLACE S8910U.

•

•

CHECK LINE VOLTAGE POWER.

CHECK LOW VOLTAGE TRANSFORMER.

CHECK LIMIT CONTROLLER.

CHECK AIR PROVING SWITCH (IF USED).

CHECK THERMOSTAT.

CHECK WIRING.

•

•

•

•

•

•

NOTE: BEFORE TROUBLESHOOTING, BECOME FAMILIAR WITH STARTUP

AND CHECKOUT PROCEDURES.

S8910U3000

Fig. 7. S8910U troubleshooting sequence.

19 34-00008EFS—01

Page 20

S8910U3000

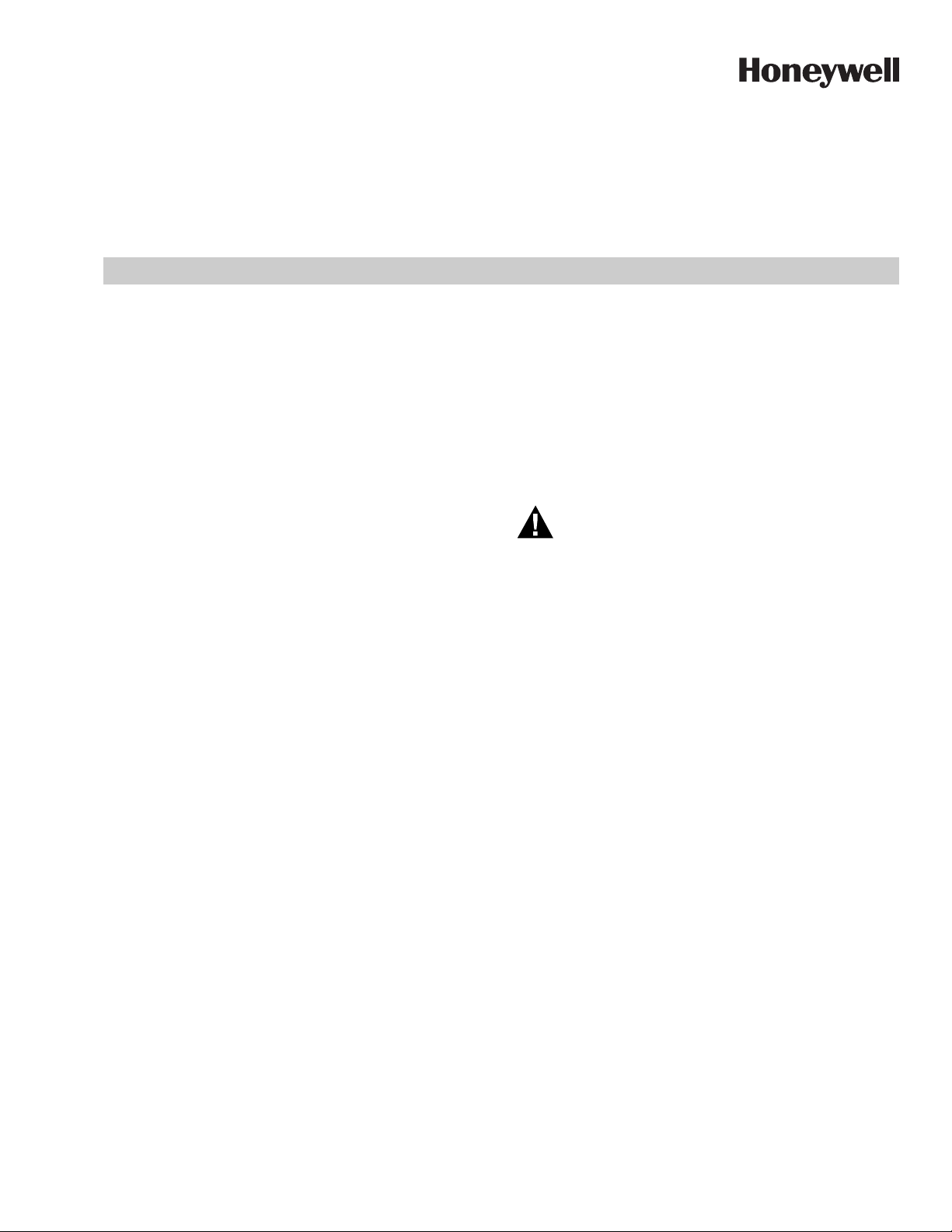

Flame Current Measurement

Flame current of the device can be meaured using a standard

micro-ammeter by simply inserting the meter probes into the

holes labeled FLAME CURRENT, as shown in Fig. 8.

— Flame current must be measured with valve lit.

— Set meter to DC μAmp scale.

— Ensure meter leads are positioned correctly [+/-].

S8910U HOT SURFACE IGNITER CONTROL

Golden Valley, MN 55422

NOTE: ALWAYS apply

this control as instructed

in Instruction Sheet

34-00008

SYSTEM SETUP

Assembled in Mexico

Selection Tab

ON

OFF

ON

OFF

ON

OFF

ON

OFF

132

4

VALVE

Trial count

= 1 try (default)

Trial count

= 3 tries

Trial for ign. period

= 4 seconds (default)

Trial for ign. period

= 7 seconds

120 VAC

NEUTRAL

L2

LED States

Control Status Color Pattern

Device damaged- Red Steady

replace control

Ignition lockout Red Blink

Normal operation Green Steady

Weak flame signal Green Blink

See Instruction Sheet 34-00008

for additional states

120 VAC

HOT

HSI

L1

WARNING

Can cause

Explosion Hazard.

serious injury or death.

Disconnect power before servicing. This device can malfunction if it gets wet. Never

try to use a device that has

been wet -- replace it.

(GND)

BURNER

24V

S8910U Hot Surface Ignition

Input Voltages = 120 & 24 VAC, 60 Hz

HSI = 120V, 5A max.

Valve = 24V, 2A max.

Total 24V Load = 0.4 + valve load

U.S. Patent 8,085,521

Prepurge Time = 32 Sec.

Igniter Warm Up Time = See Inst. Sh. 34-00008

Ignition Trial Time - See Selection Tab

Number of Trials - See Selection Tab

Between Trial Time - 96 Sec.

See

LED

States

VALVE

(GND)

(GND)

TH-W

LED

Recommended Minimum Flame Current:

• Must read steady 1 μAmp DC minimum.

• Flame current should be 2 μAmp or greater for reliable

appliance operation.

®

CUS

AUTO

IGNITION

SYSTEMS

ANSI Z21.20

32304204-001 Rev. A

HSI

See

Instructions

Single/Dual

Rod

Applications

for

SENSE

002.3

DC

µA

Fig. 8. Measuring flame current with micro-ammeter.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2015 Honeywell International Inc.

34-00008EFS—01 M.S. 06-15

Printed in United States

M31283A

Page 21

S8910U3000

AVERTISSEMENT

MODULE D'ALLUMAGE PAR INCANDESCENCE UNIVERSEL

NOTICE D’INSTALLATION

L'installation de ce produit doit être réalisée par un technicien

d'entretien formé et qualifié.

APPLICATION

Le module d'allumage par incandescence universel S8910U

est conçu pour remplacer facilement un vaste éventail de

modules d'allumage par incandescence fabriqués par

Honeywell, Robertshaw et White-Rodgers. Le module

S8910U contrôle le fonctionnement d'un système à allumage

direct faisant appel à un allumeur par incandescence de 120

V c.a. Le modèle S8910U remplace les modules d’allumage à

veilleuse intermittente et redressement de flamme existants

par les caractéristiques suivantes :

• Éléments d'allumage par incandescence à réchauffage

temporisé 120 V c.a. (jusqu'à 5 A).

• Allumage par incandescence à électrode unique (détection

locale) ou à deux électrodes (détection à distance).

• Un ou trois essais d'allumage par appel de chaleur.

• Essais d'allumage de quatre secondes ou sept secondes.

• Prébalayage de 32 secondes ou moins.

• Durées de balayage entre essais jusqu'à 96 secondes

(mode trois essais uniquement).

• Gaz naturel ou GPL.

Le modèle S8910U n'est pas destiné à remplacer les

systèmes suivants :

• Modules d'allumage à veilleuse intermittente.

• Modules d'allumage à étincelles direct.

• Modules d'allumage par incandescence 120 V c.a. avec

vérification.

• Modules d'allumage par incandescence avec élément

24 V c.a.

• Modules d'allumage par incandescence entrée 240 V c.a./

avec élément. 120 V c.a.

• Modules d'allumage par incandescence 120 V c.a. à

réchauffage temporisé de 120 V c.a

— Temps d'essai d'allumage inférieur à quatre secondes.

—

Temps d'essai d'allumage supérieur à douze secondes

— Connecteurs plats au lieu de connecteurs rapides

mâles.

Le système S8910U contient le contrôleur S8910U, un mode

d'emploi simple et les accessoires requis pour assurer la

compatibilité avec le module d'allumage par incandescence

existant. Le sac des accessoires comprend un adaptateur

White-Rodgers, un fil de terre Robertshaw, quatre

connecteurs rapides 0,032 femelles 1/4 po, un connecteur

rapide 0,032 femelle 3/16 po et neuf étiquettes de câblage.

Les étiquettes de câblage sont incluses pour permettre un

marquage adéquat des fils attachés au module existant.

Une liste complète des modules Honeywell et d’autres

marques pouvant être remplacés par le modèle S8910U est

fournie dans les Tableaux 1 à 3.

REMARQUE :Le modèle S8910U est destiné à remplacer

Caractéristiques électriques :

Tension du contrôleur : 24 V, 60 Hz.

Intensité maximale des contacts de vanne : 2 A.

Appel de courant : 0,4 A plus charge de la vanne.

Tension de l'allumeur par incandescence : 120 V c.a., 60 Hz.

Tension nominale des contacts à 120 V c.a.: 5 A.

IMPORTANT

Le modèle S8910U est conçu pour les applications de

60 Hz. Les temporisations varient de 20 % pour les applications de 50 Hz.

Allumeur par incandescence ou allumeur-capteur :

.

Modèle Norton 201 ou 271 ou équivalent.

REMARQUE : Si un allumeur autre que le modèle Norton

les contrôleurs d'allumage défectueux

uniquement. Le technicien d'entretien doit

s'assurer que les autres composants de

l'appareil et du système de contrôle

fonctionnent correctement et de manière

fiable avant de remplacer le contrôleur

d'allumage.

RISQUE D’EXPLOSION. PEUT CAUSER DES

BLESSURES ET DES DOMMAGES MATÉRIELS.

Le modèle S8910U ne peut être utilisé que pour un

remplacement direct. Consulter les Tableaux 1 à 3

avant de remplacer un module par incandescence

existant par le modèle S8910U. Si le module existant

n'est pas répertorié, ne pas utiliser le modèle S8910U

pour le remplacer. Toujours consulter le tableau des

correspondances pour assurer un réglage correct des

commutateurs DIP.

201 ou 271 est utilisé, il doit être conforme

aux caractéristiques minimales suivantes

requises pour toute la durée d'utilisation de

l'allumeur

• L'allumeur doit atteindre 1000 °C (1832 °F)

dans la période de réchauffage sélectionnée

de 7, 17, 34 ou 45 secondes à 102 V c.a.

Page 22

S8910U3000

• L'allumeur doit maintenir une résistance

d'isolement d'au moins 500 M ohms entre les

fils de l'allumeur et le support de montage de

l'allumeur.

• L'allumeur ne doit pas développer une

couche d'isolement sur sa surface (au fil du

temps) qui empêcherait la détection de

flamme.

• La superficie de l'allumeur immergée dans la

flamme ne doit pas dépasser un quart de la

superficie à la terre immergée dans la

flamme. Cela empêcherait la détection de

flamme.

• L'appel de courant de l'allumeur à 132 V c.a.

ne doit pas dépasser 5 A.

Capteur :

Un capteur séparé est requis pour les applications de

détection à distance.

Câblage :

Utiliser le câblage existant de l'appareil. Si le câblage doit être

réparé ou remplacé, suivre les instructions fournies sur

l'étiquette de l'appareil. Utiliser les bornes de connexion

rapide et les adaptateurs de câblage fournis conformément

aux instructions.

Prébalayage :

32 secondes.

Réchauffage de l'allumeur :

7 (12), 17 (27), 34 ou 45 secondes. Les chiffres entre

parenthèses représentent le 2e et le 3e essai des

temporisations d'allumage.

Balayage entre les essais d'allumage :

96 secondes (prébalayage 32 secondes et interbalayage

64 secondes).

Temps de réponse en cas d’extinction de la flamme :

1,5 s maximum.

Séquence d'allumage :

Le nombre d’essais pour l’allumage et la durée des essais

sont déterminés par les commutateurs DIP sélectionnables.

Température de fonctionnement ambiante :

-40 à +79 °C (-40 à +175 °F).

Nécessaire d’accessoires (inclus) :

• Adaptateur White-Rodgers.

• Fil de terre Robertshaw.

• Quatre connecteurs rapides 0,032 femelles 1/4 po.

• Un connecteur rapide 0,032 femelles 3/16 po.

• Neuf étiquettes de câblage.

Homologations :

Conception certifiée IAS : rapport de certification n°

C2027002.

IMPORTANT

Les spécifications indiquées dans cette publication

n’incluent pas les tolérances de fabrication normales.

En conséquence, cette unité peut ne pas

correspondre exactement aux spécifications

indiquées. En outre, ce produit est testé et étalonné

dans des conditions strictement contrôlées, et des

différences de performance mineures peuvent avoir

lieu si ces conditions sont différentes.

Le système S8910U contient le contrôleur S8910U, un mode

d'emploi simple et les accessoires requis pour assurer la

compatibilité avec le module d'allumage par incandescence

existant. Le sac des accessoires comprend un adaptateur

White-Rodgers, un fil de terre Robertshaw, quatre

connecteurs rapides 0,032 femelles 1/4 po, un connecteur

rapide 0,032 femelle 3/16 po et neuf étiquettes de câblage.

Les étiquettes de câblage sont incluses pour permettre un

marquage adéquat des fils attachés au module existant.

Une liste complète des modules Honeywell et d’autres

marques pouvant être remplacés par le modèle S8910U est

fournie dans les Tableaux 1 à 3

REMARQUE : Le modèle S8910U est destiné à remplacer

les contrôleurs d'allumage défectueux

uniquement. Le technicien d'entretien doit

s'assurer que les autres composants de

l'appareil et du système de contrôle fonctionnent correctement et de manière fiable avant

de remplacer le contrôleur d'allumage.

Modèle disponible :

Module d’allumage à incandescence universel S8910U.

RENSEIGNEMENTS POUR LA COMMANDE

Lors de l’achat de pièces de rechange ou de modernisation auprès de votre grossiste ou distributeur TRADELINE®, consultez le

catalogue ou les documents relatifs aux tarifs TRADELINE® pour les références de commande complètes. Pour toute question, ou

pour obtenir des renseignements supplémentaires ou adresser des remarques concernant les produits ou services, veuillez écrire ou

téléphoner :

1.

Au bureau local de vente de produits de combustion et environnementaux Honeywell (dans les pages blanches de l’annuaire).

2. Honeywell Customer Care

1985 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

Bureaux de vente et après-vente internationaux dans toutes les principales villes du monde. Fabrication en Allemagne, en Belgique, au

Canada, en Chine, aux États-Unis, en Hongrie, en Italie, au Mexique, aux Pays-Bas, dans la République tchèque et au Royaume-Uni.

34-00008EFS—01 2

Page 23

S8910U3000

Tableau 1. Correspondances entre le contrôleur White-Rodgers et le modèle S8910U de Honeywell.

REMARQUES : Cette liste est fournie pour référence uniquement. Honeywell se réserve le droit d'ajouter ou de supprimer des modèles à

tout moment en fonction d'informations nouvelles ou mises à jour.

S8910U

Numéros de

modèle

S8910U

Spécifications

Retrait du

cavalier

noir

Détection

locale (L) ou à

distance (R)

— Locale ou à

distance

Temps de

verrouillage

(s)

Essais

d’allumage

Prébalayage

(s)

Réchauffage

de l'allumeur

(s)

Balayage

entre essais

(s)

4 1 32 34 S/O

3 96

7 1 S/O

3 96

50E47-1 à 9 Oui R 4 1 0 17 S/O

50E47-10 à 19 Oui R 4 1 0 45 S/O

50E47-20 à 29 Oui R 4 1 30 17 S/O

50E47-30 à 39 Oui R 4 1 30 45 S/O

50E47-40 à 49 Oui R 4 3 30 17 90

50E47-50 à 59 Oui R 4 3 30 45 90

50E47-60 à 69 Oui R 4 3 0 17 60

50E47-70 à 79 Oui R 4 3 0 45 60

50E47-101 à 109 Oui R 7 1 0 17 S/O

50E47-110 à 119 Oui R 7 1 0 45 S/O

50E47-120 à 129 Oui R 7 1 30 17 S/O

50E47-130 à 139 Oui R 7 1 30 45 S/O

50E47-140 à 149 Oui R 7 3 30 17 90

50E47-150 à 159 Oui R 7 3 30 45 90

50E47-160 à 169 Oui R 7 3 0 17 60

50E47-170 à 179 Oui R 7 3 0 45 60

50E47-201 à 209 Oui R 4 1 0 17 S/O

50E47-210 à 219 Oui R 4 1 0 45 S/O

50E47-220 à 229 Oui R 4 1 30 17 S/O

50E47-230 à 239 Oui R 4 1 30 45 S/O

50E47-240 à 249 Oui R 4 3 30 17 90

50E47-250 à 259 Oui R 4 3 30 45 90

50E47-260 à 269 Oui R 4 3 0 17 60

50E47-270 à 279 Oui R 4 3 0 45 60

50E47-301 à 309 Oui R 7 1 0 17 S/O

50E47-310 à 319 Oui R 7 1 0 45 S/O

50E47-320 à 329 Oui R 7 1 30 17 S/O

50E47-330 à 339 Oui R 7 1 30 45 S/O

50E47-340 à 349 Oui R 7 3 30 17 90

50E47-350 à 359 Oui R 7 3 30 45 90

50E47-360 à 369 Oui R 7 3 0 17 60

50E47-370 à 379 Oui R 7 3 0 45 60

50F47-1 à 9 Oui R 4 1 0 17 S/O

50F47-10 à 19 Oui R 4 1 0 45 S/O

50F47-20 à 29 Oui R 4 1 17 17 S/O

50F47-30 à 39 Oui R 4 1 17 45 S/O

50F47-40 à 49 Oui R 4 3 17 17 77

50F47-50 à 59 Oui R 4 3 17 45 77

3 34-00008EFS—01

Page 24

S8910U3000

Tableau 1. Correspondances entre le contrôleur White-Rodgers et le modèle S8910U de Honeywell. (suite)

REMARQUES : Cette liste est fournie pour référence uniquement. Honeywell se réserve le droit d'ajouter ou de supprimer des modèles à

tout moment en fonction d'informations nouvelles ou mises à jour.

S8910U

Numéros de

modèle

S8910U

Spécifications

Retrait du

cavalier

noir

Détection

locale (L) ou à

distance (R)

— Locale ou à

distance

Temps de

verrouillage

(s)

Essais

d’allumage

Prébalayage

(s)

Réchauffage

de l'allumeur

(s)

Balayage

entre essais

(s)

4 1 32 34 S/O

3 96

7 1 S/O

3 96

50F47-60 à 69 Oui R 4 3 0 17 60

50F47-70 à 79 Oui R 4 3 0 45 60

50F47-101 à 109 Oui R 7 1 0 17 S/O

50F47-110 à 119 Oui R 7 1 0 45 S/O

50F47-120 à 129 Oui R 7 1 17 17 S/O

50F47-130 à 139 Oui R 7 1 17 45 S/O

50F47-140 à 149 Oui R 7 3 17 17 77

50F47-150 à 159 Oui R 7 3 17 45 77

50F47-160 à 169 Oui R 7 3 0 17 60

50F47-170 à 179 Oui R 7 3 0 45 60

50F47-201 à 209 Oui R 4 1 0 17 S/O

50F47-210 à 219 Oui R 4 1 0 45 S/O

50F47-220 à 229 Oui R 4 1 17 17 S/O

50F47-230 à 239 Oui R 4 1 17 45 S/O

50F47-240 à 249 Oui R 4 3 17 17 77

50F47-250 à 259 Oui R 4 3 17 45 77

50F47-260 à 269 Oui R 4 3 0 17 60

50F47-270 à 279 Oui R 4 3 0 45 60

50F47-301 à 309 Oui R 7 1 0 17 S/O

50F47-310 à 319 Oui R 7 1 0 45 S/O

50F47-320 à 329 Oui R 7 1 17 17 S/O

50F47-330 à 339 Oui R 7 1 17 45 S/O