SUPER TRADELIN

E

S8910U Universal Hot

Surface Ignition Module

®

INSTALLATION INSTRUCTIONS

Installation Instructions for the Trained Service Technician.

APPLICATION

The SUPER TRADELINE® S8910U Universal Hot

Surface Ignition Module is designed to provide easy field

replacement for a wide range of hot surface ignition

modules manufactured by Honeywell, Robertshaw and

White-Rodgers. The S8910U Module provides operating

control of a direct ignition system using a 120 Vac hot

surface igniter. The S8910U replaces existing flame

rectification type hot surface ignition modules with the

following characteristics:

• 120 Vac (up to 5A) timed warmup hot surface ignition

elements.

• Single rod (local sense) or dual rod (remote sense) hot

surface ignition.

• One or three ignition trials per call for heat.

• Four-second or seven-second ignition trials.

• Prepurge of 32 seconds or less.

• Up to 96 seconds between trial purge times (three-trial

mode only).

• Natural or LP gas.

The S8910U is

• Intermittent pilot ignition controls.

• Direct spark ignition controls.

• Proven 120 Vac hot surface ignition controls.

• 24 Vac element hot surface ignition controls.

• 240 Vac input/120 Vac element hot surface ignition

controls.

• 120 Vac timed warmup hot surface ignition controls

with:

—Ignition trial time shorter than four seconds.

—Ignition trial time longer than twelve seconds.

—Edge connectors rather than male quick-connects.

The SUPER TRADELINE® S8910U package contains the

S8910U control, and easy-to-use instructions, and the

accessories required to adapt the existing hot surface

ignition module. The accessory bag assembly includes the

White-Rodgers adapter, Robertshaw ground lead, four

1/4 in. female .032 quick-connects, one 3/16 in. female

.032 quick-connect, four selection tabs and seven wire

labels. The wiring labels are included to assure proper

marking of the wires attached to the existing module.

A complete list of the specific Honeywell and other

modules that the SUPER TRADELINE

designed to replace is provided in Tables 1 through 3.

not

designed to replace:

®

S8910U is

NOTE: The S8910U is intended to replace only defective

ignition controls. The service technician should

make sure that the other parts of the appliance

and control system operate safely and reliably

before replacing the ignition control.

WARNING

EXPLOSION HAZARD. CAN CAUSE

INJURY OR EQUIPMENT DAMAGE.

The S8910U can only be used for direct replacement. Check Tables 1 through 3 before replacing

an existing hot surface module with the S8910U. If

the existing module is not listed, do not use the

S8910U to replace it. Always use the selection tab

specified in Tables 1 through 3 for the existing

module being replaced. Replacing with an unlisted

module or using a selection tab not specified can

result in appliance malfunction.

Electrical Ratings:

Control Voltage: 24V, 60 Hz.

Maximum Valve Contact Rating: 2A.

Current Draw: .4A plus valve load.

Hot Surface Igniter Voltage: 120 Vac, 60 Hz.

Contact Rating At 120 Vac: 5A.

IMPORTANT

Use the S8910U only in a 60 Hz system. Be sure

the system is not 50 Hz.

Hot Surface Igniter or Igniter-Sensor:

Norton Model 201 or 271 or equivalent.

NOTE: If an igniter other than a Norton Model 201 or 271

is used, the igniter must meet the following

minimum specifications required over the life of

the igniter:

• Igniter must reach 1832°F (1000°C) within

34 seconds with 102 Vac applied.

• Igniter must maintain at least 500M ohms

insulation resistance between the igniter

leadwires and the igniter mounting bracket.

• Igniter must not develop an insulating layer

on its surface (over time) that would prevent

flame sensing.

• Igniter surface area immersed in flame must

not exceed one-fourth of the grounded area

immersed in flame. This would prevent flame

sensing.

• Igniter current draw at 132 Vac must not

exceed 5A.

®U.S. Registered Trademark

Copyright © 1996 Honeywell Inc. • All Rights Reserved

X-XX UL

69-0845-2

S8910U UNIVERSAL HOT SURFACE IGNITION MODULE

Sensor:

A separate sensor is required for remote sensing applications.

Wiring:

Use the existing appliance wiring. If repair or replacement

of leadwires is required, follow the instructions on the

appliance label. Use the included quick-connect terminals

according to the instructions.

Prepurge:

32 seconds.

Igniter Warmup:

34 seconds.

Between Trial Purge:

96 seconds (three trial mode only).

Flame Failure Response Time:

1.5 seconds maximum.

Ignition Sequence:

The number of trials for ignition and trial time are determined by the selection tab. See Table 1. If a selection tab

is not installed, the module will operate at four seconds

trial time and one ignition trial.

Ambient Operating Temperature:

-40°F to +175°F (-40°C to +79°C).

Accessory Bag Assembly:

• White-Rodgers adapter.

• Robertshaw ground lead.

• Four 1/4 in. female .032 quick-connects.

• One 3/16 in. female .032 quick-connect.

• Four selection tabs.

• Seven wire labels.

Approval Bodies:

IAS Design Certified: Certification Report No. C2027002.

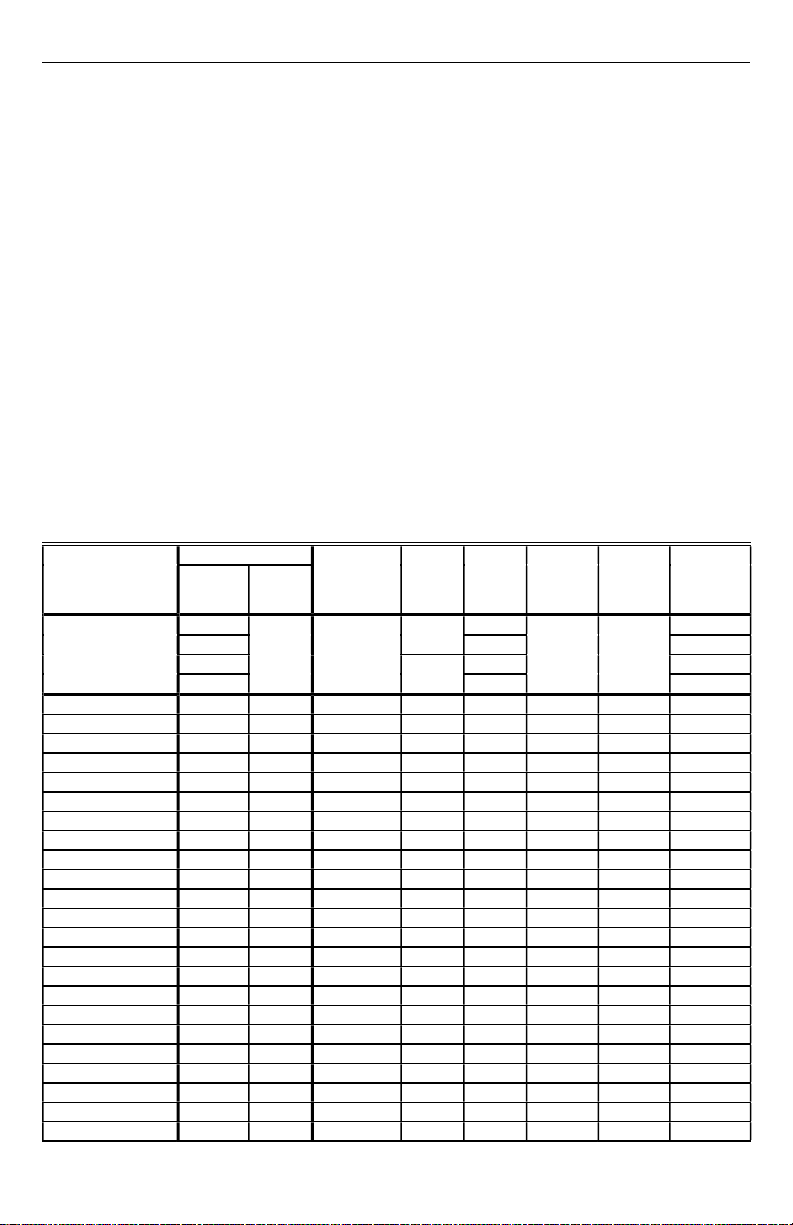

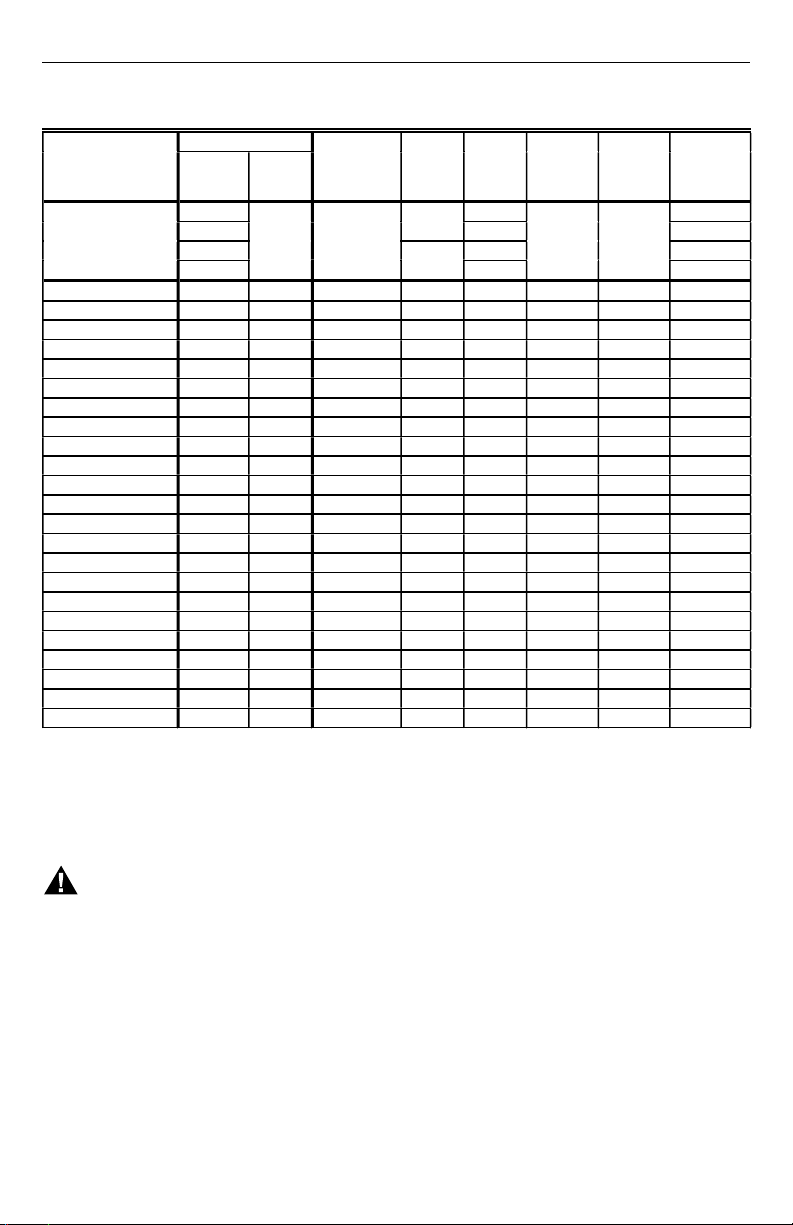

Table 1. White-Rodgers Control to Honeywell S8910U Cross Reference.

NOTES: This list is for reference only. Honeywell reserves the right to add or delete models at any time, based on new or

updated information.

White-Rodgers product information was obtained from the 1991 White-Rodgers Product Catalog (R3700).

S8910U

Model

Numbers

S8910U

Specifications

Tab

Remove

Jumper

Selection

A—

B

Black

Local (L) or

Remote (R)

Sensing

Local or

Remote

Lockout

Time

(sec)

Ignition

Trials

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

396

Between

Trial Purge

(sec)

C71NA

D396

50E47-1 thru 9 A Yes R 4 1 0 17 NA

50E47-10 thru 19 A Yes R 4 1 0 45 NA

50E47-20 thru 29 A Yes R 4 1 30 17 NA

50E47-30 thru 39 A Yes R 4 1 30 45 NA

50E47-40 thru 49 B Yes R 4 3 30 17 90

50E47-50 thru 59 B Yes R 4 3 30 45 90

50E47-60 thru 69 B Yes R 4 3 0 17 60

50E47-70 thru 79 B Yes R 4 3 0 45 60

50E47-101 thru 109 C Yes R 7 1 0 17 NA

50E47-110 thru 119 C Yes R 7 1 0 45 NA

50E47-120 thru 129 C Yes R 7 1 30 17 NA

50E47-130 thru 139 C Yes R 7 1 30 45 NA

50E47-140 thru 149 D Yes R 7 3 30 17 90

50E47-150 thru 159 D Yes R 7 3 30 45 90

50E47-160 thru 169 D Yes R 7 3 0 17 60

50E47-170 thru 179 D Yes R 7 3 0 45 60

50E47-201 thru 209 A Yes R 4 1 0 17 NA

50E47-210 thru 219 A Yes R 4 1 0 45 NA

50E47-220 thru 229 A Yes R 4 1 30 17 NA

50E47-230 thru 239 A Yes R 4 1 30 45 NA

50E47-240 thru 249 B Yes R 4 3 30 17 90

50E47-250 thru 259 B Yes R 4 3 30 45 90

50E47-260 thru 269 B Yes R 4 3 0 17 60

continued

69-0845—2

2

S8910U UNIVERSAL HOT SURFACE IGNITION MODULE

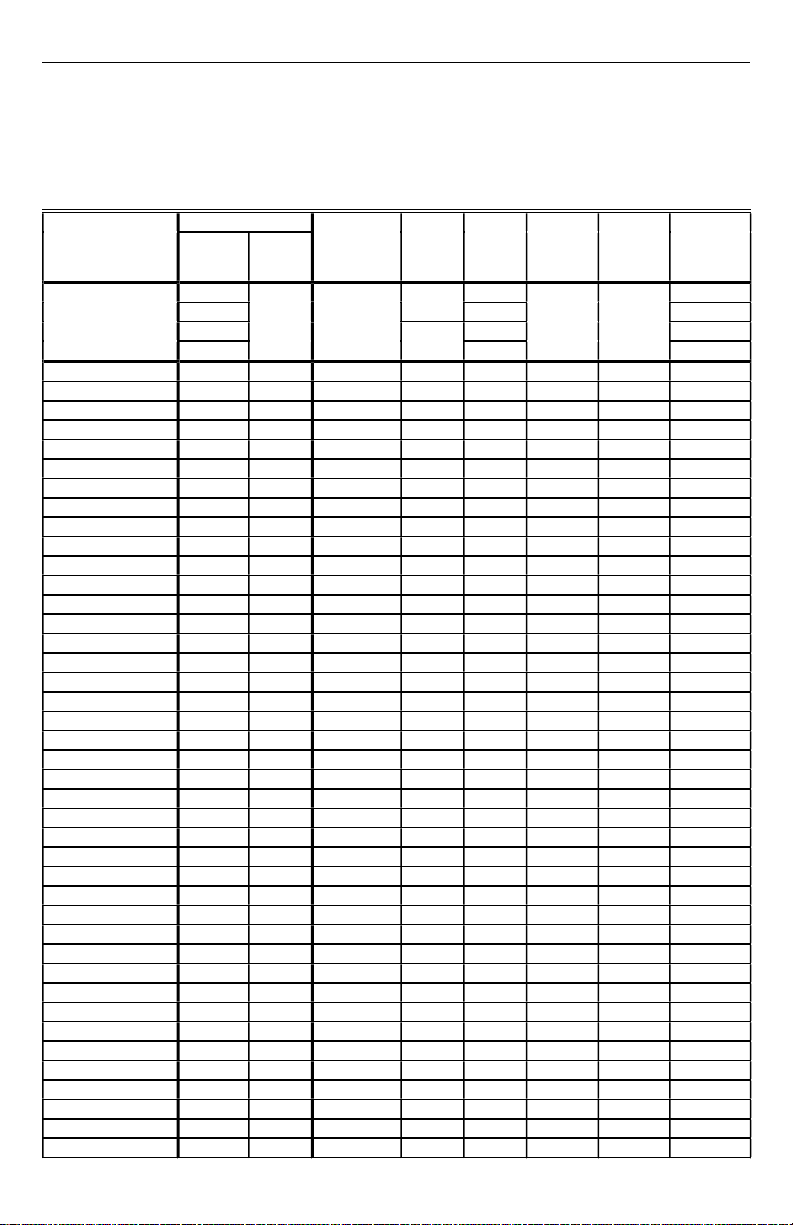

Table 1. White-Rodgers Control to Honeywell S8910U Cross Reference (Continued).

NOTES: This list is for reference only. Honeywell reserves the right to add or delete models at any time, based on new or

updated information.

White-Rodgers product information was obtained from the 1991 White-Rodgers Product Catalog (R3700).

S8910U

Model

Numbers

S8910U

Specifications

Tab

Remove

Jumper

Selection

A—

B

Black

Local (L) or

Remote (R)

Sensing

Local or

Remote

Lockout

Time

(sec)

Ignition

Trials

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

396

Between

Trial Purge

(sec)

C71NA

D396

50E47-270 thru 279 B Yes R 4 3 0 45 60

50E47-301 thru 309 C Yes R 7 1 0 17 NA

50E47-310 thru 319 C Yes R 7 1 0 45 NA

50E47-320 thru 329 C Yes R 7 1 30 17 NA

50E47-330 thru 339 C Yes R 7 1 30 45 NA

50E47-340 thru 349 D Yes R 7 3 30 17 90

50E47-350 thru 359 D Yes R 7 3 30 45 90

50E47-360 thru 369 D Yes R 7 3 0 17 60

50E47-370 thru 379 D Yes R 7 3 0 45 60

50F47-1 thru 9 A Yes R 4 1 0 17 NA

50F47-10 thru 19 A Yes R 4 1 0 45 NA

50F47-20 thru 29 A Yes R 4 1 17 17 NA

50F47-30 thru 39 A Yes R 4 1 17 45 NA

50F47-40 thru 49 B Yes R 4 3 17 17 77

50F47-50 thru 59 B Yes R 4 3 17 45 77

50F47-60 thru 69 B Yes R 4 3 0 17 60

50F47-70 thru 79 B Yes R 4 3 0 45 60

50F47-101 thru 109 C Yes R 7 1 0 17 NA

50F47-110 thru 119 C Yes R 7 1 0 45 NA

50F47-120 thru 129 C Yes R 7 1 17 17 NA

50F47-130 thru 139 C Yes R 7 1 17 45 NA

50F47-140 thru 149 D Yes R 7 3 17 17 77

50F47-150 thru 159 D Yes R 7 3 17 45 77

50F47-160 thru 169 D Yes R 7 3 0 17 60

50F47-170 thru 179 D Yes R 7 3 0 45 60

50F47-201 thru 209 A Yes R 4 1 0 17 NA

50F47-210 thru 219 A Yes R 4 1 0 45 NA

50F47-220 thru 229 A Yes R 4 1 17 17 NA

50F47-230 thru 239 A Yes R 4 1 17 45 NA

50F47-240 thru 249 B Yes R 4 3 17 17 77

50F47-250 thru 259 B Yes R 4 3 17 45 77

50F47-260 thru 269 B Yes R 4 3 0 17 60

50F47-270 thru 279 B Yes R 4 3 0 45 60

50F47-301 thru 309 C Yes R 7 1 0 17 NA

50F47-310 thru 319 C Yes R 7 1 0 45 NA

50F47-320 thru 329 C Yes R 7 1 17 17 NA

50F47-330 thru 339 C Yes R 7 1 17 45 NA

50F47-340 thru 349 D Yes R 7 3 17 17 77

50F47-350 thru 359 D Yes R 7 3 17 45 77

50F47-360 thru 369 D Yes R 7 3 0 17 60

50F47-370 thru 379 D Yes R 7 3 0 45 60

3

69-0845—2

S8910U UNIVERSAL HOT SURFACE IGNITION MODULE

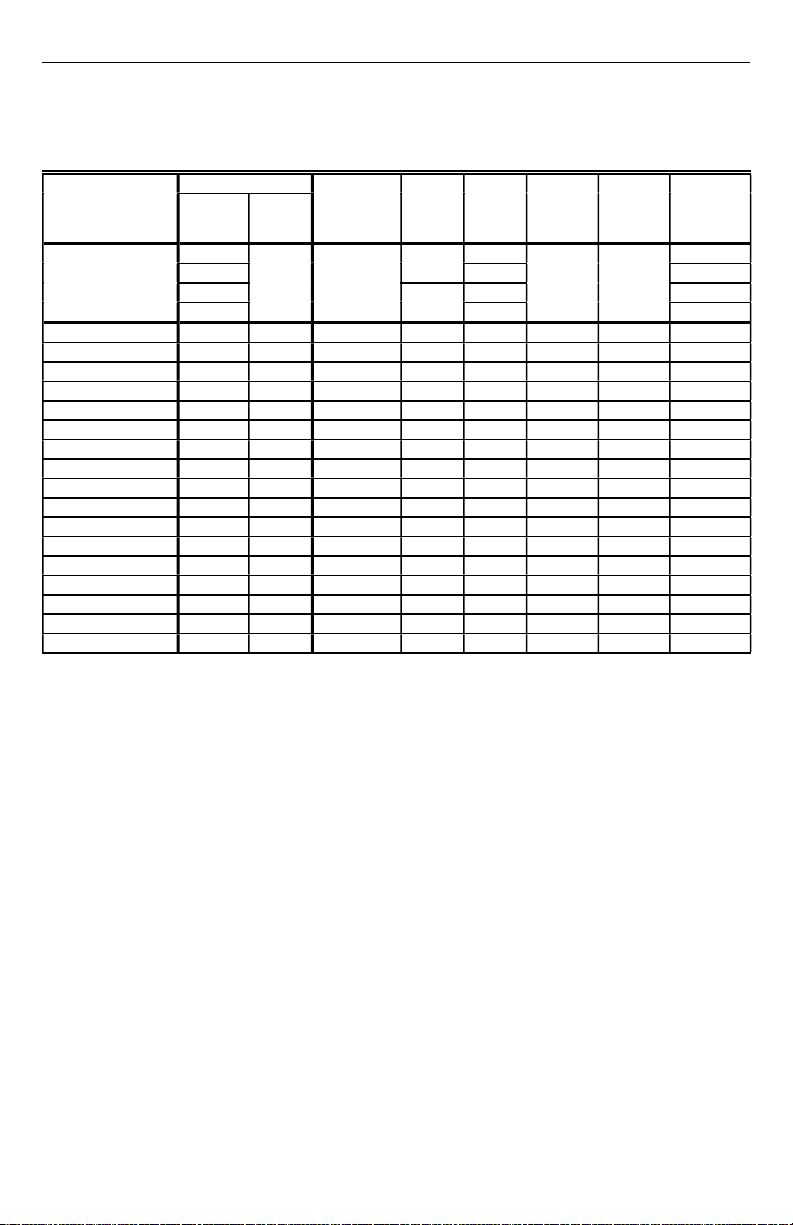

Table 2. Robertshaw Control to Honeywell S8910U Cross Reference.

NOTE: Robertshaw product information was obtained from the 1993-1994 Robertshaw Uni-Line Catalog (2–064).

S8910U

Model

Numbers

S8910U

Specifications

Selection

Remove

Tab

Jumper

A—

B

C71NA

D396

HS780-17NL-104A A No L 4 1 0 17 NA

HS780-17NL-108A C No L 8

HS780-17NL-304A B No L 4 3 0 17 17

HS780-17NL-308A D No L 8

HS780-17NR-104A A Yes R 4 1 0 17 NA

HS780-17NR-306A D Yes R 6

HS780-17NR-308A D Yes R 8

HS780-34NL-108A C No L 8

HS780-34NL-304A B No L 4 3 0 34 34

HS780-34NL-306A D No L 6

HS780-34NL-308A D No L 8

HS780-34NL-312A D No L 12

HS780-34NR-104A A Yes R 4 1 0 34 NA

HS780-34NR-306A D Yes R 6

HS780-34NR-308A D Yes R 8

HS780-34NR-312A D Yes R 12

HS780-34PL-308A D No L 8

a

The S8910U and the original control lockout times are different. The S8910U lockout time is within the design tolerance

lockout time of the original control.

b

The lockout time of the S8910U is shorter than the original control. Be sure to observe the appliance operation under a

variety of input conditions to assure reliable operation.

Black

Local (L) or

Remote (R)

Sensing

Local or

Remote

Lockout

Time

(sec)

Ignition

Trials

PrePurge

(sec)

Igniter

Warmup

(sec)

4 1 32 34 NA

396

a

1017NA

a

3 0 17 17

a

3 0 17 17

a

3 0 17 17

a

1034NA

a

3 0 34 34

a

3 0 34 34

b

3 0 34 34

a

3 0 34 34

a

3 0 34 34

b

3 0 34 34

a

33434 34

Between

Trial Purge

(sec)

69-0845—2

4

S8910U UNIVERSAL HOT SURFACE IGNITION MODULE

Table 3. Honeywell Control to Honeywell S8910U Cross Reference.

S8910U

Model

Numbers

S8910U

Specifications

S89C1004 C No L 6

S89C1012 C No L 6

S89C1046 A No L 4 1 0 34 NA

S89C1087 C No L 6

S89C1103 A No L 4 1 0 34 NA

S89D1002 C Yes R 6

S89G1005 B No L 4 3 0 34 30

S89G1013 D No L 6

S89G1021 D No L 11

S89G1047 D No L 6

S89H1003 B Yes R 4 3 0 34 30

S89H1011 D Yes R 6

S89H1029 D Yes R 11

S89J1008 C No L 6

S890C1007 C No L 6

S890D1006 C Yes R 6

S890G1003 B No L 4 3 30 34 30

S890G1011 D No L 6

S890G1029 D No L 11

S890G1037 D No L 6

S890H1002 B Yes R 4 3 30 34 30

S890H1010 D Yes R 6

S890H1028 D Yes R 11

a

The S8910U and the original control lockout times are different. The S8910U lockout time is within the design tolerance

lockout time of the original control.

b

The lockout time of the S8910U is shorter than the original control. Be sure to observe the appliance operation under a

variety of input conditions to assure reliable operation.

Selection

Remove

Tab

Jumper

A—

B

C71NA

D396

Black

Local (L) or

Remote (R)

Sensing

Local or

Remote

Lockout

Time

Ignition

(sec)

4 1 32 34 NA

a

a

a

a

a

b

a

a

b

a

a

a

a

b

a

a

b

PrePurge

Trials

(sec)

396

1034NA

1034NA

1034NA

1034NA

3 0 34 30

3 0 34 30

3 0 34 30

3 0 34 30

3 0 34 30

1034NA

13034NA

13034NA

33034 30

33034 30

33034 30

33034 30

33034 30

Igniter

Warmup

(sec)

Between

Trial Purge

(sec)

REVIEW THE INSTALLATION

WARNING

FIRE OR EXPLOSION HAZARD.

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Follow these warnings exactly:

1. Review the installation as outlined in this

section.

2. Plan for frequent maintenance as described in

the Maintenance section.

When hot surface ignition systems are used on central

heating equipment in barns, greenhouses, and commercial

properties and on heating appliances such as commercial

cookers, agricultural equipment, industrial heating

equipment and pool heaters, heavy demands are made on

the controls. Special steps can be required to prevent

nuisance shutdowns and control failure due to frequent

cycling, severe environmental conditions related to

moisture, corrosive chemicals, dust or excessive heat.

These applications require Honeywell Home and Building

Control Engineering review; contact your Honeywell Sales

Representative for assistance.

Review the following conditions that can apply to your

specific installation and take the precautionary steps

suggested.

Frequent Cycling

These controls are designed for use on appliances that

typically cycle only three to four times an hour during the

heating season. In year-round applications with greater

cycling rates, the control can wear out more quickly.

Perform a monthly checkout.

Water or Steam Cleaning

If a module or gas control gets wet, replace it. If the

appliance is likely to be cleaned with water or steam, cover

the controls and wiring to protect from water or steam flow.

5

69-0845—2

Loading...

Loading...