Page 1

S8701/S8702 Direct Spark

Ignition Controls

INSTALLATION INSTRUCTIONS

APPLICATION

S8701 and S8702 Direct Spark Ignition Controls are

designed for use in commercial cooking and other gas

heating applications which require direct ignition and flame

safety control of gas burners. S8701/S8702 controls are

used to ignite the main burner(s), sense the flame and

control the gas valve in these applications, see Table 1.

Table 1. S8701/S8702 Models.

Model Flame Sense Trials for Ignition Spark/Sense Prepurge

S8701D remote 1 1 No

S8702D remote 1 2 No

S8702F remote 3

S8702K remote 1 2 Yes

S8702M remote 3

a

S8702 F and M models include an auto-reset from lockout after 1 hour.

Planning the Installation

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury,

or death.

Follow these warnings exactly:

1. Plan the installation as outlined below.

2. Plan for frequent maintenance as described in

the Maintenance section.

Review the following conditions that can apply to your

specific installation and take the precautionary steps

suggested.

Frequent Cycling

This control is designed for use on commercial cooking

appliances that typically cycle 400 times a day, year round.

Perform a monthly checkout.

Water or Steam Cleaning

If a control gets wet, replace it. If the appliance is likely to

be cleaned with water or steam, protect (cover) the control

and wiring from water or steam flow. Mount the control

high enough above the floor so it does not get wet during

normal cleaning procedures.

The S8701 is a single spark, single flame sense, direct

ignition control that is compatible with dual rod systems.

The S8702 is a dual spark, dual flame sense, direct

ignition control capable of igniting and sensing flame on

two separate gas burners that are fed by a single gas

valve. The S8702 is compatible with dual rod systems

only.

a

a

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never install

an appliance where water can drip on the control. In

addition, high ambient humidity can cause the control to

corrode and fail. If the appliance is in a humid atmosphere,

make sure air circulation around the control is adequate to

prevent condensation. Also, regularly check out the

system.

IMPORTANT

Always install a splash cover to protect the

control from water damage.

Corrosive Chemicals

Corrosive chemicals can attack the control, eventually

causing a failure. If chemicals are used for routine

cleaning, avoid contact with the control. Where chemicals

are suspended in air, as in some industrial or agricultural

applications, protect the control with an enclosure.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease can be a

problem, provide covers for the control to limit contamination.

2No

2 Yes

®U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • All Rights Reserved

69-1174

Page 2

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

Heat

Excessively high temperatures can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control, see Table

2. If the appliance operates at very high temperatures, use

insulation, shielding, and air circulation, as necessary, to

protect the control. Proper insulation or shielding should be

provided by the appliance manufacturer; verify proper air

circulation is maintained when the appliance is installed.

Table 2. S8701/S8702 Ambient Temperature Ratings.

Operation Ambient Temperature

50 Hz -40°F to 160°F

60 Hz -40°F to 175°F

Table 3. System Requirements.

Model

S8701/

S8702

a

Valve used must be designed for DSI application.

b

Separate spark igniter and flame sensor mounted on a

common bracket.

No.

Spark

Igniter

Flame

Sensor

Q347A Q354A

b

Q366

Valve Required

Honeywell VR8205

gas valves or

equivalent

a

INSTALLA TION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure it is suitable for your

application.

3. The installer must be a trained, experienced service

technician.

4. After installation is complete, check out system

operation.

IMPORTANT

If this is a replacement application, follow the

appliance manufacturer’s instructions, if available. The manufacturer usually provides wiring

diagrams, start-up and checkout instructions and

the service procedures for their system. If the

manufacturer’s instructions are not available, this

information may be used as a general guide.

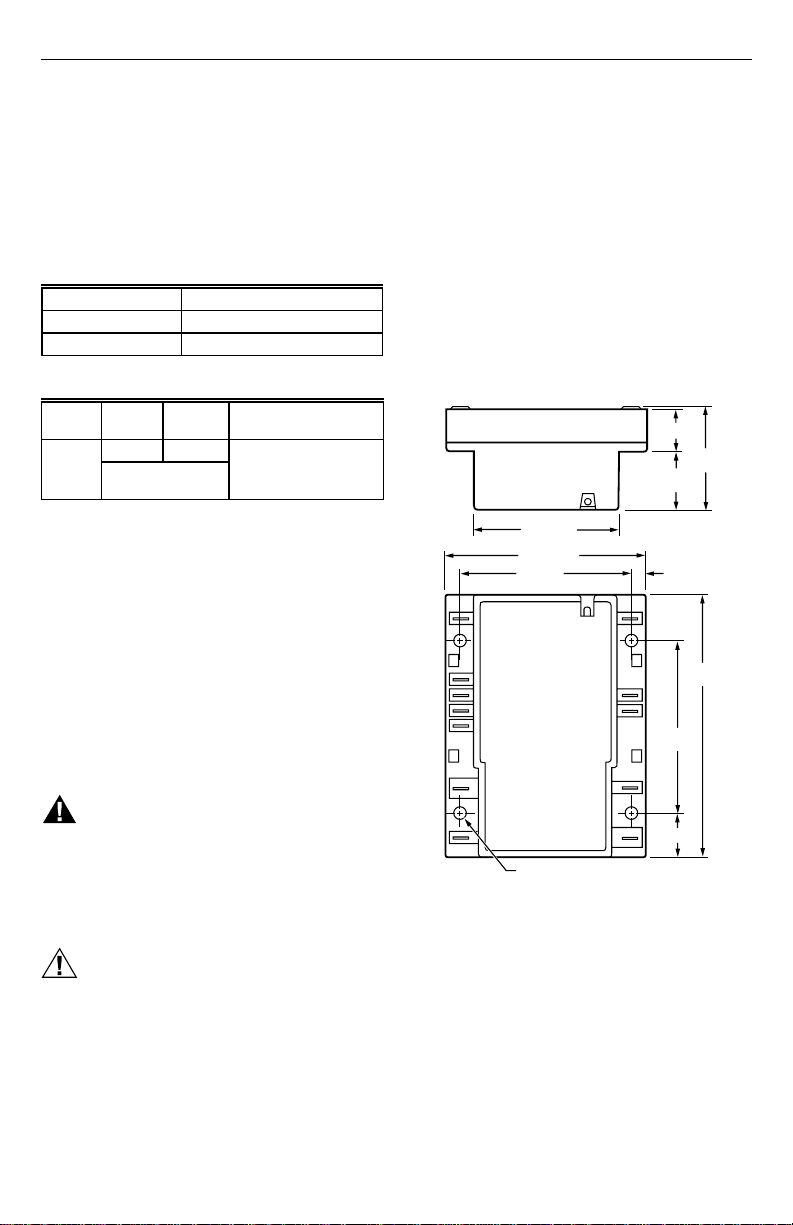

Mounting The S8701/S8702 Control

Select a location within 6 ft (1.8m) of the burner that will

permit a direct cable route to the spark igniter terminal.

Ready access to the terminals is necessary for wiring and

servicing. The S8701/S8702 control may be mounted in

any position. Use No. 6-32 machine screws or No. 8

sheetmetal screws 1 inch long for fastening. Fasten

securely. Do not exceed the ambient temperature rating

given in Table 2.

13/16 (21)

2

(50)

1-1/8

(29)

2-13/16 (72)

3-15/16 (100)

3-3/8 (86)

5/17 (7)

3-3/8

(86)

5-3/16

(130)

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

If a new gas control is to be installed, turn off gas

supply before starting installation.

Be sure to conduct a gas leak test after the control

is installed.

CA UTION

Electric Shock Hazard.

Can cause personal injury or equipment

damage.

Disconnect power supply before wiring.

69-1174

7/8 (23)

3/16 (4)

M16233

Fig. 1. S8701/S8702 Dimensions.

Mounting Auxiliary Controls

Mount the spark igniter, flame sensor, temperature control,

transformer, gas control and any other auxiliary controls

according to the manufacturer’s instructions.

NOTE: The S8701 and S8702 installations require a 24V

transformer rated to handle both the S8701/

S8702 current and the gas valve current. Table 4

shows the transformer rating necessary for

various loads.

2

Page 3

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

Table 4. Transformer Ratings for S8701/S8702 and

Dual Valve Combination Gas Controls.

Minimum VA

Rating (24V

transformer)

Total Valve

Current

(in amperes)

S8701/S8702

(in amperes)

20 up to 0.6 0.15

30 0.6 to 1.0 0.15

40 1.0 to 1.4 0.15

55 1.4 to 2.0 0.15

Wiring

General Precautions

1. Check the wiring diagram furnished by the

heating appliance manufacturer, if available, for

circuits different from the ones shown. Carefully

follow any special instructions affecting the general

procedures outlined below.

2. All wiring must comply with applicable electrical

codes and ordinances.

3. Disconnect the power supply before wiring to

prevent electrical shock or equipment damage.

4. If installing a separate Q345A flame sensor, the

sensor leadwire should be kept as short as possible

and should not be allowed to rest against grounded

metal surfaces.

5. A common ground is required for the S8701/S8702,

the spark igniter and the main burner. The 24V

(GND) terminal does not internally ground the

transformer. The 24 V (GND) terminal must be

grounded to the equipment chassis separately. Any

auxiliary controls or limits must not be in the

grounded leg.

6. Ignition cable should not touch any metal surface or

current carrying wires. It must not be more than 6 ft

(1.8m) long.

7. Do not short valve terminals as this may damage the

temperature controller, the transformer or the

S8701/S8702.

Table 5. Recommended Ignition Cable.

Temperature

RMS

Cable Type

Voltage Rating

UL Style 3257 10,000 482 250

Rating

°F °C

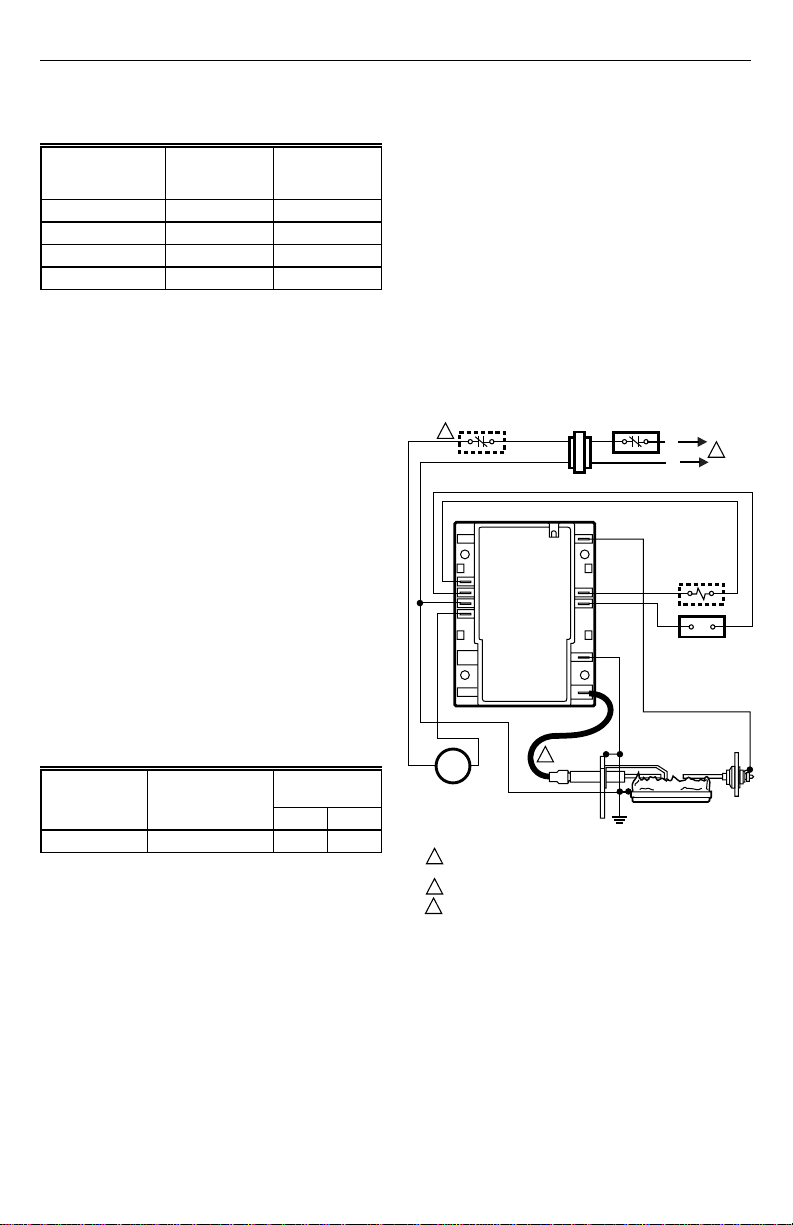

Wiring the S8701/S8702 Control

1. Connect system components to the S8701/S8702

terminals as shown in the wiring diagrams, Figs. 2

and 3. Refer to the appliance manufacturer’s

instructions for wiring any other auxiliary controls.

2. Adjust temperature control heat anticipator to match

system current draw. The current draw equals the

total current required for the S8701 or S8702

(0.15A) plus the gas valve and all other 24 V control

loads (vent dampers, prepurge relays, etc.). Gas

valve must be designed for the DSI application.

NOTE: Use only recommended ignition cable (see

Table 5) to connect the S8701/S8702 with the

spark igniter. Cable must not run in continuous

contact with a metal surface or spark voltage

will be greatly reduced; use ceramic standoff

brackets if necessary. Cable length must not

exceed 6 ft (1.8m).

2

S8701D CONTROL MODULE

GND

VALVE (GND)

24 Vac (GND)

24 Vac

BURNER

TEMPERATURE

CONTOLLER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 6 FT. (1.8 M) OR LESS.

TRANSFORMER

FLAME

SENSE

ALARM

VALVE

(GND)

SPARK

3

LIMIT CONTROLLER

Q347

SPARK

IGNITER

IGNITER AND

BURNER GROUND

L1

(HOT)

L2

ALARM, IF USED

ANY COMBINATION

GAS CONTROL

2.0A MAX.

Q354 FLAME

SENSOR

BURNER

Fig. 2. S8701 Wiring Diagram.

1

M16232A

3

69-1174

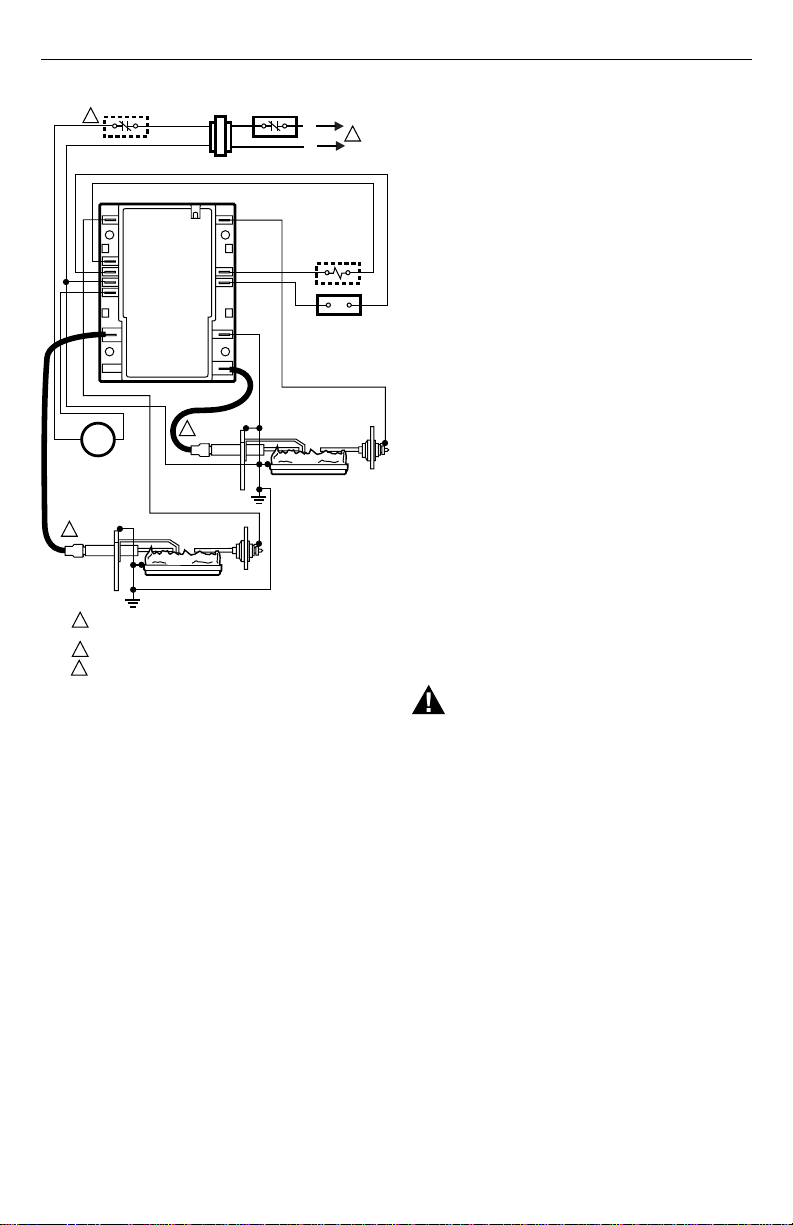

Page 4

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

TRANSFORMER

ALARM

VALVE

(GND)

3

Q354 FLAME

SENSOR

LIMIT CONTROLLER

ALARM, IF USED

ANY COMBINATION

GAS CONTROL

2.0A MAX.

Q347

SPARK

IGNITER

BURNER

IGNITER AND

BURNER GROUND

L1

(HOT)

L2

1

Q354 FLAME

SENSOR

M16267A

2

S8702D CONTROL MODULE

SENSE 2

SENSE 1

GND

VALVE (GND)

24 Vac (GND)

24 Vac

BURNER

SPARK 2

SPARK 1

TEMPERATURE

CONTOLLER

3

Q347 SPARK

IGNITER

BURNER

IGNITER AND

1

2

3

BURNER GROUND

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 6 FT. (1.8 M) OR LESS.

Fig. 3. S8702 Wiring Diagram.

Grounding the S8701/S8702 Spark Igniter and

Main Burner

For the system to operate properly, spark igniter, flame

sensor bracket, the burner (GND) terminal on the 24V

(GND) terminal, and the S8701/S8702 control must share

a common ground with the main burner. Use thermoplastic

insulated wire with a minimum rating of 105°C (221°F) for

the ground wire; asbestos insulation is not acceptable. If

necessary, use a shield to protect the wire from radiant

heat generated by the burner.

IMPORTANT

Use moisture resistant 18 AWG wire rated for

continuous duty up to 105

tions must be clean and tight.

Connect the ground wire as follows:

1. Fit one end of the ground wire with a female 1/4 in.

quick-connect terminal and connect it to the male

quick connect GND (Burner) terminal on the S8701/

S8702 control.

2. Strip the other end of the GND (Burner) wire and

fasten it under the igniter bracket mounting screw. If

necessary, use a shield to protect the wire from

radiant heat. The burner serves as the common

grounding area.

°

C (221°F). Connec-

3. Fit one end of another ground wire with a female 1/4

in. quick connect terminal and connect it to the male

quick connect 24V (GND) terminal on the S8701/

S8702 control.

4. Strip the other end of the 24V (GND) wire and fasten

it to the burner ground.

5. If used with a separate flame sensor, make sure the

bracket is connected to the burner ground.

NOTE: It is not necessary that the burner is earth

grounded.

ST ARTUP AND CHECKOUT

The following start-up and checkout procedures are basic

to all S8701 and S8702 control modules. If this is a

replacement application, refer to the specific instructions

provided by the heating appliance manufacturer (if

available). Also, since the auxiliary controls used on any

DSI system may differ, refer to the manufacturer’s

instructions for start-up and checkout procedures for other

system components.

NOTE: If one of the system components fail, the S8701/

S8702 will either not operate or it will go into

safety lockout (depending on the type of failure).

If the system does not perform as outlined in

Start System and Check Trial for Ignition steps

below, refer to the SERVICE section to determine the cause.

Gas Leak Test

If the gas control has been replaced as a part of the S8701

or S8702 installation, perform the following test for gas

leaks.

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

To avoid possible explosion or fire, perform Gas

Leak Test.

With the main burner in operation, paint the pipe joints and

valve gasket with a rich soap and water solution. Bubbles

indicate a gas leak. To stop leak, tighten joints and screws or

replace the gasket. Never use a flame to check for gas leaks.

START SYSTEM

1. Turn on the power and the gas supply.

Set the temperature control to request heat and

watch for a spark at the igniter (S8701D, S8702D

models have no delay on start-up. S8702K and M

models have a predetermined delay on start-up for

prepurge.). Time the length of the spark operation; it

must be within the Trial for Ignition (TFI) timing

period (see Table 6).

2. Check that the system starts as follows: Spark turns

on, gas valve opens at once, and burner ignites after

gas reaches main burner. Once burner flame is

established, spark igniter cuts off. For S8702

models; flame must be established on both burners

for spark igniters to turn off.

69-1174

4

Page 5

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

NOTE: If the gas control has been replaced or serviced,

lightoff may not be satisfactory until air has been

purged from the gas line or the gas input and

combustion air have been adjusted (see

manufacturer’s instructions).

Table 6. Trial for Ignition Periods for the S8701/S8702.

Specified Trial for

Ignition (TFI) (stamped

Model

S8701;

S8702

Check Trial for Ignition

1. Check device label on control to determine correct

Trial for Ignition time.

2. With the system power off and the thermostat or

temperature control set to call for heat, manually

shut off the gas supply.

3. Turn power on to energize the S8701/S8702,

immediately start timing when the gas valve turns

on.

4. Determine the number of seconds to drop-out of the

gas valve. It should not exceed the trial for ignition

time shown in Table 6.

5. After spark cutoff, manually reopen gas supply cock.

No gas should flow to the main burner.

6. Reset system as described below.

on control)

4.6 sec

6.6 sec

11.6 sec

21.6 sec

Trial for

Ignition Should

Not Exceed

5.05 sec

7.25 sec

12.75 sec

23.75 sec

Resetting S8701 and S8702 After Safety

Lockout

If the control goes into safety lockout, it will remain locked

out for D and K models, until the system is reset.

To reset the system:

Adjust the temperature control setting to below room

temperature, wait 5 seconds, and move the temperature

control setting up to request heat or remove 24V power

and reapply. Normal ignition should occur as described in

Start System section.

NOTE: F and M models have the 3 retry feature for Trial

for Ignition with 30 second interpurge between

TFI periods. Safety lockout on the F and M

models occurs after the 3rd TFI period if flame is

not sensed. F and M models also automatically

reset after one (1) hour in lockout.

CHECKOUT

Start the system and observe operation through at least

one complete cycle to make certain all controls are

operating safely.

Sequence of Operation

The S8701/S8702 controls perform the following basic

functions:

• Supplies power to the electronic pulse-generator

circuit for the spark igniter (14,000 volts, open circuit).

• Allows up to 23.75 seconds (maximum) for ignition

and 1 or 3 trials before system safety lockout occurs

(see Table 4).

• Senses burner flame for safe lighting (2 burners for

S8702).

• Shuts off spark after burner is lit.

The S8701 and S8702 are powered by a 24 Vac transformer and activated when the temperature control

requests heat.

Operation is as follows:

When the S8701/S8702 control is activated by the

temperature control’s request for heat, S8701/S8702

controls perform a safe-start check that determines proper

operation of the control before beginning the normal

sequence of operation. Once the Safe Start Check

operation passes, the control turns on the spark circuit and

at the same time, the S8701/S8702 opens the gas

control’s main valves, which allows gas to flow to the main

burner.

Power is supplied to the generator until:

• The main burner(s) lights and the flame sensor

current reaches 1.0 µA, or

• The ignition activation period ends

If the main burner lights, a flame sensing circuit is completed through the flame to the burner head to ground.

This current flow sets the Trial for Ignition timer to the reset

(normal) condition and interrupts the spark ignition circuit

(flame sense must occur on both burners on a S8702).

Should the current flow be interrupted, i.e., flame out

condition, the trial for ignition period begins again.

The S8701/S8702 will keep the gas control main valve

open as long as there is a request for heat and flame

current through the flame sensing circuit. If, however, the

trial for ignition timing period ends before the main burner

lights or the flame sensor establishes enough current, the

system will go into safety lockout or interpurge if the

control is an F or M model.

When the system goes into safety lockout, power to the

spark generator is interrupted, the power to the gas valve

is interrupted and the alarm circuit is completed and the

LED is steady on. The system will stay locked out until it is

reset by moving the temperature control setpoint to below

room temperature, no request for heat, for 5 seconds.

Then, re-energize the system by moving the temperature

control setpoint 5°F (3°C) above room temperature. Or,

remove 24 Vac power to the control then reapply.

NOTE: F and M models will automatically reset from

lockout after one (1) hour.

5

69-1174

Page 6

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

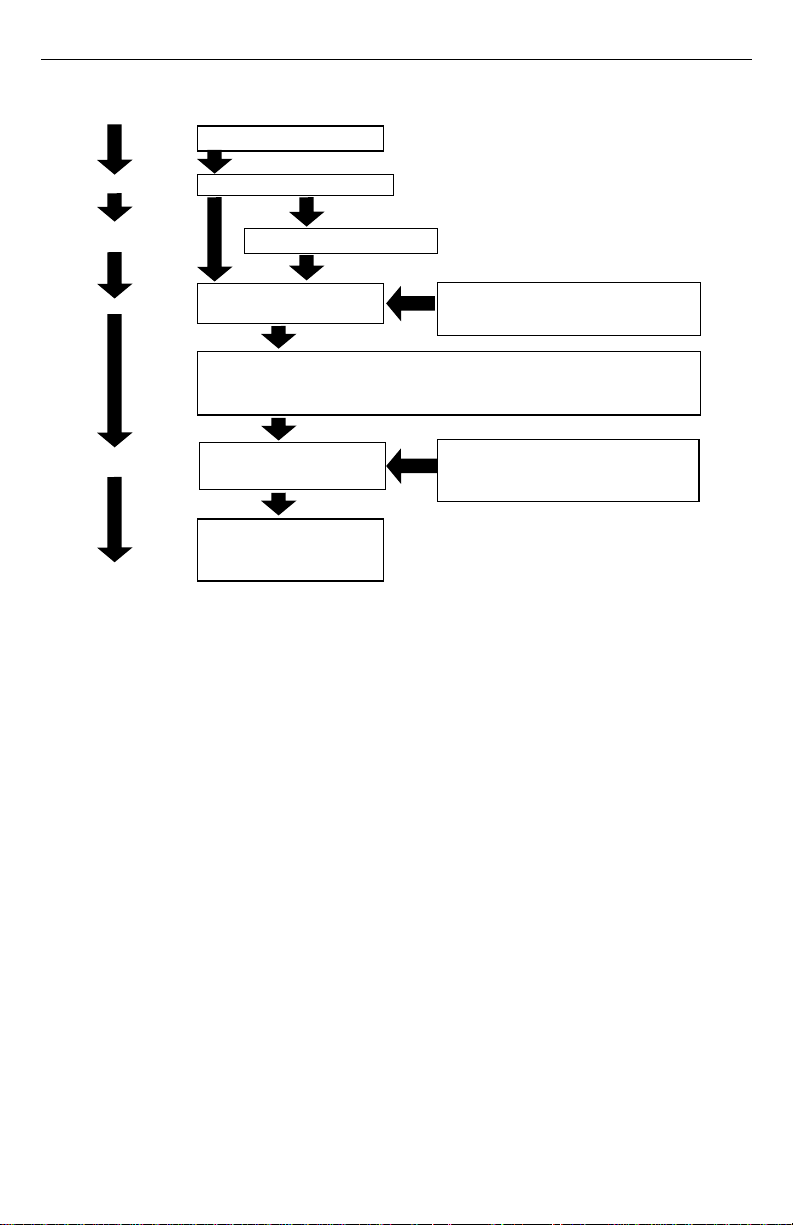

START

THERMOSTAT CALLS FOR HEAT

SAFE START CHECK

PREPURGE

(J AND K MODELS ONLY)

TRIAL FOR IGNITION

MAIN BURNER

OPERATION

END

Fig. 4. S8701/S8702 Sequence of Operation for 1 Trial Models (B, D, J, and K Models).

SAFE START CHECK. LED BLINKS RAPIDLY.

PREPURGE - J & K MODELS ONLY

SPARK GENERATOR POWERED

MAIN VALVE OPERATORS OPEN.

IF FLAME CURRENT SENSED:

(MUST BE SENSED AT BOTH

BURNERS ON S8702)

SPARK GENERATOR IS SHUT OFF.

LOCKOUT TIMER IS RESET.

MAIN BURNER OPERATION

UNIT MONITORS BURNER

FLAME CURRENT.

TEMPERATURE CONTROLLER

IS SATISFIED.

POWER TO UNIT IS INTERRUPTED.

VALVES CLOSE.

MAIN BURNER(S) ARE OFF.

NOTES: B, D, J, AND K MODELS GO THROUGH ONE (1) TRIAL FOR IGNITION PERIOD BEFORE LOCKOUT.

LOCKOUT = VALVE CLOSED PLUS SPARK OFF PLUS ALARM ACTIVATED PLUS LED ON STEADY.

IF NO SPARK, B, D, J, AND K MODELS GO INTO LOCKOUT

AFTER ONE (1) TRIAL FOR IGNITION PERIOD.

ALARM CIRCUIT IS ACTIVATED.

LED IS ON STEADY. SYSTEM MUST BE RESET.

IF FLAME CURRENT IS NOT SENSED:

B, D, J, AND K MODELS GO INTO LOCKOUT

AFTER ONE (1)TRIAL FOR IGNITION PERIOD.

LED IN ON. SYSTEM MUST BE RESET.

LOSS OF FLAME

SPARK GENERATOR IS POWERED.

B, D, J, AND K MODELS GO INTO LOCKOUT AFTER

ONE (1) TRIAL FOR IGNITION PERIOD. LED IS ON STEADY.

SYSTEM MUST BE RESET.

DURING NORMAL OPERATION LED BLINKS ONCE PER SECOND.

M18058

69-1174

6

Page 7

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

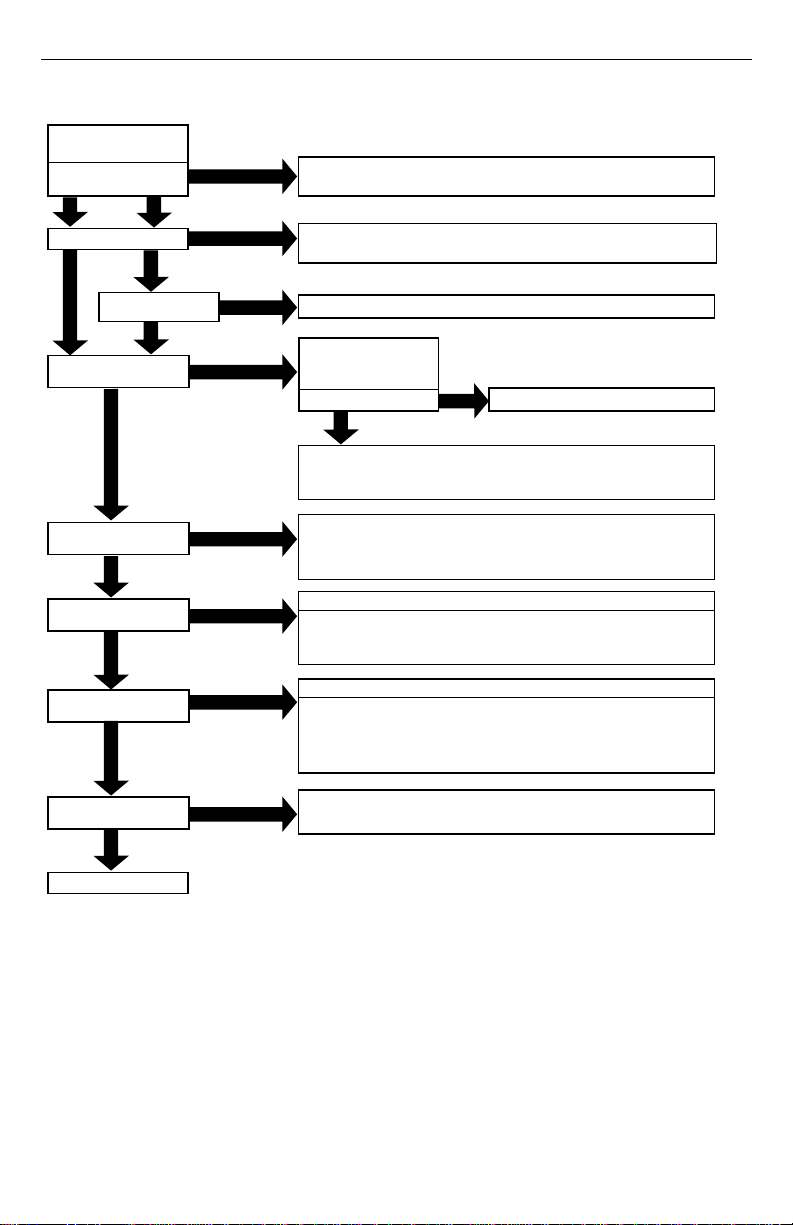

START

SAFE START CHECK

PREPURGE

(L AND M MODELS ONLY)

TRIAL FOR IGNITION

MAIN BURNER

OPERATION

END

Fig. 5. S8701/S8702 Sequence of Operation for Retry Models (E, F, L and M Models).

THERMOSTAT CALLS FOR HEAT

SAFE START CHECK. LED BLINKS RAPIDLY.

PREPURGE - L & M MODELS ONLY

INTERPURGE

IF NO SPARK, E, F, L, AND M MODELS GO INTO LOCKOUT

SPARK GENERATOR POWERED

MAIN VALVE OPERATORS OPEN.

IF FLAME CURRENT SENSED:

(MUST BE SENSED AT BOTH

BURNERS ON S8702)

SPARK GENERATOR IS SHUT OFF.

LOCKOUT TIMER IS RESET.

MAIN BURNER OPERATION

UNIT MONITORS BURNER

FLAME CURRENT.

TEMPERATURE CONTROLLER

IS SATISFIED.

POWER TO UNIT IS INTERRUPTED.

VALVES CLOSE.

MAIN BURNER(S) ARE OFF.

NOTES: E, F, L, AND M MODELS GO THROUGH THREE (3) TRIAL FOR IGNITION PERIODS WITH A 30 SECOND INTERPURGE

PERIOD BETWEEN TRIAL FOR IGNITION PERIODS BEFORE LOCKOUT AND THEN RETRY AUTOMATICALLY

AFTER ONE (1) HOUR.

LOCKOUT = VALVE CLOSED PLUS SPARK OFF PLUS ALARM ACTIVATED PLUS LED ON STEADY PLUS

ONE (1) HOUR AUTO RESET TIMER ACTIVATED

AFTER THREE (3) TRIAL FOR IGNITION PERIODS.

ALARM CIRCUIT IS ACTIVATED. LED

IS ON STEADY. SYSTEM WILL AUTOMATICALLY

RETRY AFTER ONE (1) HOUR.

IF FLAME CURRENT IS NOT SENSED:

SPARK GENERATOR AND MAIN VALVE OFF. GO TO

INTERPURGE. E, F, L AND M MODELS GO INTO LOCKOUT

AFTER THREE (3) TRIAL FOR IGNITION PERIODS. SYSTEM

WILL AUTOMATICALLY RETRY AFTER ONE (1) HOUR.

LED IS ON STEADY.

LOSS OF FLAME

SPARK GENERATOR IS POWERED.

E, F, L, AND M MODELS GO INTO LOCKOUT AFTER THREE (3)

TRIAL FOR IGNITION PERIODS. LED IS ON STEADY.

SYSTEM WILL AUTOMATICALLY RETRY AFTER ONE (1) HOUR.

DURING NORMAL OPERATION LED BLINKS ONCE PER SECOND.

M18057

SERVICE

IMPORTANT

1. Only persons trained and experienced in DSI

systems should service this equipment.

2. If a condition exists that causes the S8701 or

S8702 control to go into safety lockout, meter

readings must be taken quickly after restart—

within the Trial-for-Ignition period.

3. Always de-energize the system for at least 5

seconds before recycling for further tests.

4. Always turn off gas supply before performing

ignition checks.

5. S8701 and S8702 control cannot be repaired. If

the troubleshooting procedure indicates a

malfunction in the S8701 or S8702, it must be

replaced.

6. The following service procedures are for the

S8701/S8702 and basic DSI systems. On all

installations, refer to the appliance

manufacturer’s service instructions.

Preliminary Check

The following checks should be made before troubleshooting the system.

1. Check for power to the heating appliance and the

S8701 or S8702. Voltage to the control should be

between 20.5 and 28.5 Vac when in run mode.

2. Make certain that the manual shut-off valve in the

supply line and the gas cock knob on the combination gas control valve are open.

3. Make certain that all wiring connections are clean

and tight.

4. Make certain that the S8701 or S8702 is not in

safety lockout. De-energize the system by moving

the temperature control setpoint below room

temperature or by removing the 24 Vac power to the

S8701/S8702 control. Wait at least 5 seconds and

reenergize the system by moving the thermostat or

temperature control setpoint 5°F (3°C) above room

temperature. Return setpoint to normal temperature

setting or by re-applying 24 Vac power to the S8701/

S8702 control.

5. Check ceramic insulator on flame sensor, spark

igniter or igniter/sensor. A cracked insulator will

allow current to leak to ground. Replace device if

insulator is cracked.

7

69-1174

Page 8

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

6. Check the flame sensor and its mounting bracket.

Correct the position if bent out of shape.

7. Review the S8701/S8702 normal sequence of

operation. See START SYSTEM section.

S8701/S8702 COMPONENT CHECKS

Spark Ignition Circuit

The step-up transformer in the S8701/S8702 provides

spark ignition at 14,000 volts (open circuit). To check the

spark ignition circuit, proceed as follows:

1. Shut off gas supply to the gas control.

2. Disconnect the ignition cable at the S8701 or both

S8702 spark terminals to isolate the circuit from the

spark igniter or igniter sensor. Prepare a short

jumper lead, using heavily insulated wire such as

ignition cable.

WARNING

High Voltage.

Can cause personal injury or death.

To prevent electric shock, do not allow fingers to

touch either the stripped end of the jumper or the

stud terminal.

3. Perform this test immediately upon energizing the

system, before the S8701 or S8702 goes into

lockout and interrupts the spark circuit. Touch one

end jumper firmly to the S8701/S8702 GND

terminal. Do not remove the existing ground lead.

Slowly move the other end of the jumper wire toward

the spark terminal on the control to establish a

spark. Pull the wire away from the spark terminal

and note the length of the gap at which spark

discontinues.

4. A spark length of 1/8 inch (3 mm) or more indicates

satisfactory voltage output. If no arc can be established or the maximum spark is less than 1/8 inch

(3 mm), and power to the S8701 or S8702 input

terminals was proved, replace the S8701/S8702.

Ignition Cable

Check the electrical continuity of the ignition cable and

make certain the cable is not in contact with metal

surfaces. The total cable length should not exceed 6 ft

(1.8 m). Check connection to the spark terminal on the

S8701/S8702 and the boot connection to the igniter/

sensor. Make certain they are clean and tight.

Grounding Connections

A common ground is required for the burner, spark igniter

or igniter sensor mounting bracket, the 24 Vac (GND)

terminal and the GND (burner) terminal of the S8701/

S8702. If ground is poor or erratic, safety shutdown may

occur occasionally even though operation is normal at time

of checkout. Therefore, if nuisance shutdowns have been

reported, be sure to check ground connections.

Electrical ground connections at the spark igniter or igniter

sensor and the S8701/S8702 must be clean and tight. If

leadwire is damaged or deteriorated, use only a no. 14 to

18 gauge, moisture resistant, thermoplastic insulated wire

with the 105°C (221°F) minimum rating as a replacement.

Flame Sensor Circuit

The S8701 and S8702 provide ac power to the flame

sensor which the burner flame rectifies to direct current. If

the flame signal is less than 1.0 µA dc, the system will

lockout.

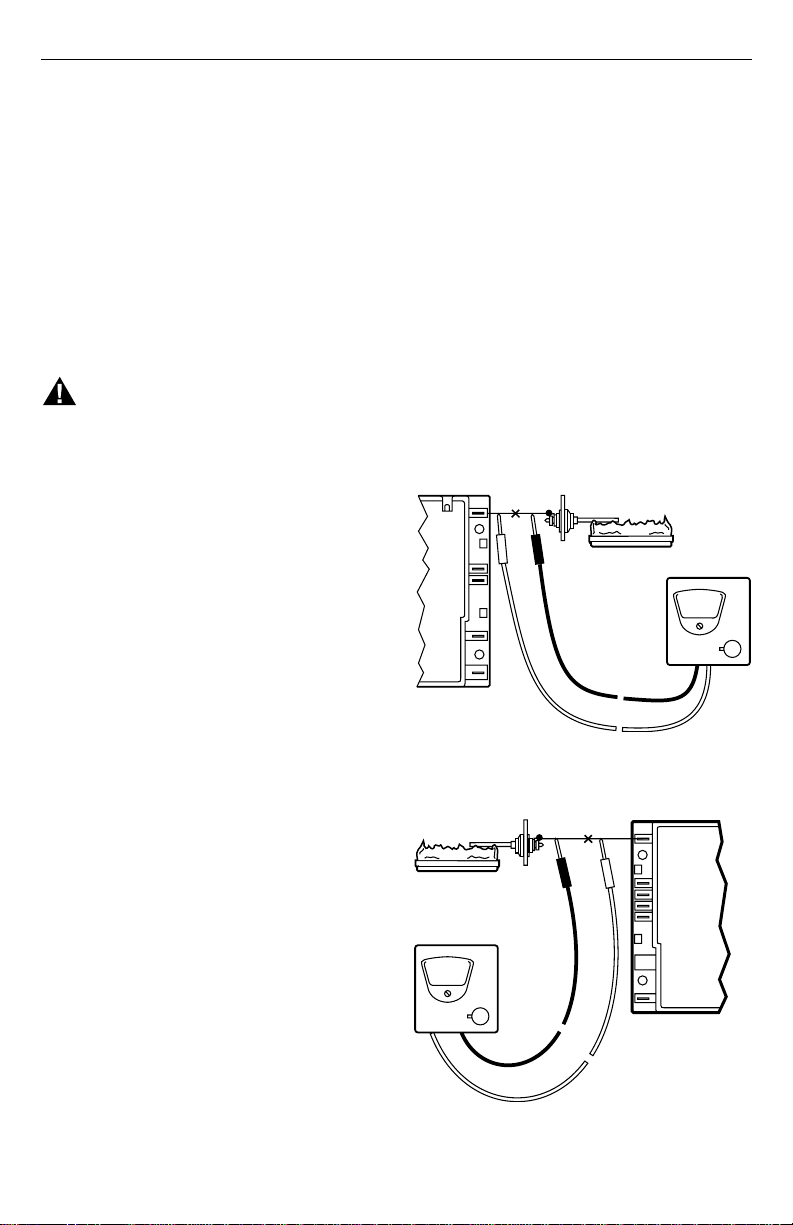

Check the flame sensing current from the sensor to the

S8701/S8702 control as follows:

1. Connect a meter (dc microammeter scale) in series

with the flame signal wire as shown in figures 4 and

5. Use the Honeywell W136A test meter or equivalent. Disconnect the flame sense wire from the

sense terminal on the control. Connect the red

(positive) meter lead to the flame sense terminal on

the control. Connect the black (negative) meter lead

to the flame sense wire that goes to the flame rod.

2. Restart the system and read the meter. The flame

sensor current must be at least 1.0 µA and steady.

If the reading is less than 1.0 µA or unsteady , see

LOW OR UNSTEADY FLAME CURRENT section,

below. If flame is present at sensor and a reading of

0 µA is obtained, check for a secondary ground

connection to the 24 V (GND) terminal.

FLAME

SENSOR

SENSE

BURNER

ALARM

VALVE

(GND)

SPARK

1.2 µA dc MINIMUM (AND STEADY)

MULTIPURPOSE

METER

BLACK (–)

RED (+)

M16236A

Fig. 6. S8701 Flame Current Measurement.

FLAME

SENSOR

BURNER

1.2 µA dc MINIMUM

(AND STEADY)

MULTIPURPOSE METER

BLACK (–)

RED (+)

Fig. 7. S8702 Flame Current Measurement.

(See also S8701 Fig. 4).

SENSE 2

GND

VALVE (GND)

24 Vac (GND)

24 Vac

BURNER

(GND)

M16268A

69-1174

8

Page 9

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

Low or Unsteady Flame Current

If the current to the S8701/S8702 is less than 1.0 µA or is

unsteady, check the burner flame, flame sensor location

and electrical connections as follows:

Burner Flame

The flame sensor must be constantly immersed in flame.

Check burner flame conditions as shown in Fig. 8.

Flame Sensor

The flame signal is best when about 1 inch. (25 mm) of

flame rod is immersed in the burner flame. A bent flame

rod, bent mounting bracket or cracked ceramic insulator

can affect flame signal. Replace flame sensor if necessary.

Electrical Connections and Shorts

Connections at the flame sensor must be clean and tight. If

wiring needs replacement, use moisture resistant no. 18

AWG wire rated for continuous duty up to 105°C (221°F).

CHECK BURNER FLAME CONDITION

BURNER

NOISY LIFTING FLAME

WAVING FLAME

SMALL BLUE FLAME

LAZY YELLOW FLAME

GOOD RECTIFYING FLAME

1 IN. (25.4 MM)

CHECK FOR:

• HIGH GAS PRESSURE

• EXCESS PRIMARY AIR

OR DRAFT

CHECK FOR:

• POOR DRAFT

• EXCESS DRAFT

• HIGH VELOCITY OR

SECONDARY AIR

INSTALL SHIELD IF NECESSARY.

CHECK FOR:

• CLOGGED PORTS OR

ORIFICE FILTER

• WRONG SIZE ORIFICE

CHECK FOR

LACK OF AIR FROM:

• DIRTY PRIMARY

AIR OPENING

• LARGE PORTS

OR ORIFICES

Checkout After Service

Perform the following steps before leaving the job (described in the CHECKOUT section).

• START SYSTEM

• TRIAL FOR IGNITION PERIOD CHECK

• SAFETY LOCKOUT RESET

Also perform any other checks recommended by the

heating appliance manufacturer if system components

other than the S8701 or S8702 were serviced.

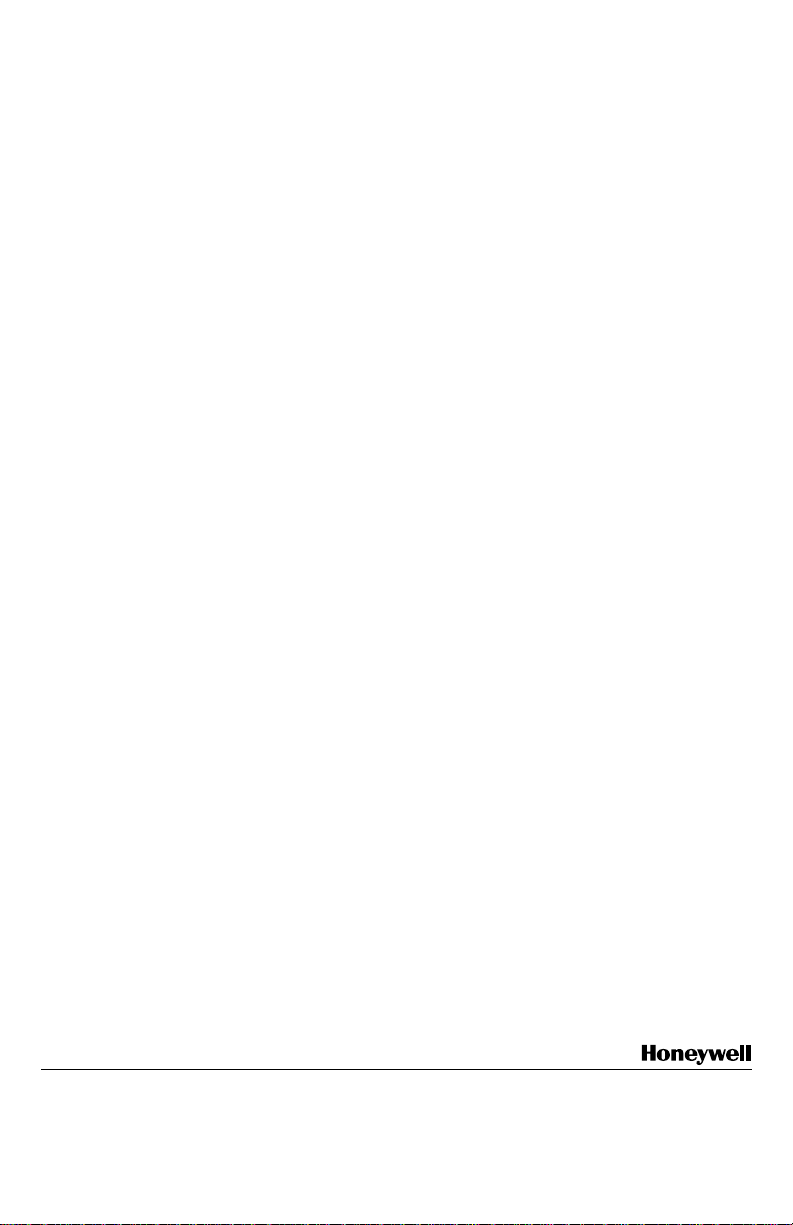

TROUBLESHOOTING GUIDE

Start the system by setting the thermostat or temperature

control to call for heat. Observe the system response and

establish the type of malfunction or deviation from normal

operation by using the troubleshooting guide. After any

maintenance or repair, the troubleshooting sequence

should be repeated until normal system operation is

obtained.

1/4 TO 1/2 IN. (6.4 TO 12.7 MM)

M18055

Fig. 8. Check Burner Flame Conditions.

9

69-1174

Page 10

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

START

TURN THERMOSTAT TO

CALL FOR HEAT

TURN GAS SUPPLY OFF.

POWER TO UNIT

(24 VAC NOMINAL)

YES YES

SAFE START CHECK OK.

SPARK ACROSS IGNITER OR

IGNITER/SENSOR GAP.

YES

J, K, L, AND M MODELS

PREPURGE DELAY.

YES

YES

MAIN BURNER(S) LIGHTS

YES

SPARK STOPS WHEN

BURNER IS LIT

YES

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS

YES

NOTE: BEFORE TROUBLESHOOTING, FAMILIARIZE YOURSELF

WITH THE START-UP AND CHECKOUT PROCEDURE.

NO

NO

NO

NO

NO

NO

NO

CHECK LINE VOLTAGE POWER, LOW VOLTAGE TRANSFORMER, LIMIT CONTROLLERS,

THERMOSTATS AND WIRING. ALSO, AIR PROVING SWITCH ON PREPURGE

SYSTEMS (SEE FIGS. 4 AND 5).

UNIT LOCKS OUT ON POWER UP. CHECK FOR FLAME AT EACH BURNER. IF FLAME

IS PRESENT, SHUT OFF GAS SUPPLY AND REPLACE GAS CONTROL. IF NOT, REPLACE

IGNITION CONTROL.

NO PREPURGE DELAY. REPLACE J, K, L, OR M UNIT.

• TURN OFF GAS SUPPLY.

• PULL IGNITION LEAD

AND CHECK SPARK AT

SPARK TERMINALS.

SPARK OKAY?

YES

• CHECK IGNITION CABLE, BURNER GROUND WIRING, CERAMIC INSULATOR AND GAP,

AND CORRECT.

• CHECK BOOT OF THE IGNITION CABLE FOR SIGNS OF MELTING OR BUCKLING. TAKE

PROTECTIVE ACTION TO SHIELD CABLE AND BOOT FROM EXCESSIVE TEMPERATURES.

• CHECK FOR 24 VAC ACROSS VALVE AND VALVE TERMINALS DURING TRIAL FOR

IGNITION PERIOD. IF NO VOLTAGE, REPLACE UNIT.

• Q347, Q354 OR Q366 MAY BE OUT OF POSITION.

• CHECK ELECTRICAL CONNECTIONS BETWEEN UNIT AND GAS CONTROL. IF OKAY,

REPLACE GAS CONTROL.

NOTE: IF UNIT GOES INTO LOCKOUT, RESET SYSTEM.

• CHECK CONTINUITY OF SENSOR CABLE(S) AND BURNER GROUND WIRES.

• CHECK THAT BURNER FLAME COVERS ALL ELECTRODES (ON BOTH BURNERS IF S8702).

• CHECK 24V GROUND CONNECTION TO BURNER.

• IF CHECKS ARE OKAY, REPLACE UNIT.

NOTE: IF UNIT GOES INTO LOCKOUT, RESET SYSTEM.

• CHECK CONTINUITY OF SENSOR CABLE(S) AND GROUND WIRES.

NOTE: IF GROUND IS POOR OR ERRATIC, SHUTDOWNS MAY OCCUR OCCASIONALLY

EVEN THOUGH OPERATION IS NORMAL AT TIME OF CHECKOUT.

• CHECK FOR EXCESSIVE HEAT AT SENSOR INSULATOR(S)

(TEMPERATURE ABOVE 1000 °F (538 °C) CAUSES SHORT TO GROUND).

• IF CHECKS ARE OKAY, REPLACE UNIT.

NO

REPLACE UNIT

CALL FOR HEAT ENDS:

SYSTEM SHUTS OFF

YES

TROUBLESHOOTING ENDS

69-1174

NO

• CHECK FOR PROPER TEMPERATURE CONTROLLER OPERATION.

• REMOVE VALVE LEAD AR UNIT; IF VALVE CLOSES, RECHECK TEMPERATURE

CONTROLLER AND WIRING; IF NOT, REPLACE GAS CONTROL.

REPEAT PROCEDURE UNTIL TROUBLE FREE OPERATION IS OBTAINED.

NOTES: B, D, J, AND K MODELS GO THROUGH ONE (1) TRIAL FOR IGNITION PERIOD BEFORE LOCKOUT.

E, F, L, AND M MODELS GO THROUGH THREE (3) TRIAL FOR IGNITION PERIODS WITH A 30 SECOND

INTERPURGE PERIOD BETWEEN TRIAL FOR IGNITION PERIODS BEFORE LOCKOUT AND THEN RETRY AUTOMATICALLY

AFTER ONE (1) HOUR.

LOCKOUT = VALVE CLOSED PLUS SPARK OFF PLUS ALARM ACTIVATED PLUS LED ON STEADY.

S8702 MODELS SPARK AND SENSE FLAME ON TWO SEPARATE BURNERS.

FLAME MUST BE SENSED ON BOTH BURNERS DURING TRIAL FOR IGNITION ON THE UNIT WILL LOCKOUT.

Fig. 9. S8701/S8702 Direct Spark Ignition System Troubleshooting Guide

10

M18059

Page 11

S8701/S8702 DIRECT SPARK IGNITION CONTROLS

11

69-1174

Page 12

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

69-1174 L.C. 4-99 Printed in Mexico

www.honeywell.com

Loading...

Loading...