7800 SERIES

s

S7830

Expanded Annunciator

APPLICATION

The S7830 Expanded Annunciator is an enhancement module

for use with 7800 SERIES Relay Modules. The S7830 is a

microprocessor-based device designed to monitor the status

of a series string of limit, control, and interlock contacts for a

commercial or industrial burner. The S7830 acts as a system

monitor and enhances fault and status messages of the 7800

SERIES burner control.

PRODUCT DATA

FEATURES

• 26 status light emitting diodes (LED).

• Front panel LED array, arranged in a pattern to clearly

indicate the flow of line voltage through the string of

limits, controls and interlocks.

• Selectable current and first-out LED array display

status.

• Power and proper operation indicating LED.

• Common Universal Mounting Subbase (Q7800A or B).

• 21 monitored contact points.

• Access for external electrical voltage checks.

• Communication interface capability.

• Capable of programmable limit or interlock messages

using the S7800A1142 Keyboard Display Module

(KDM).

• Open Lockout interlocks are indicated with a flashing

status LED when used with Relay Module Models with

Lockout Interlock feature.

• Hold messages displayed on the KDM are enhanced

with the Expanded Annuciator terminal description

information that is causing the hold (low water cutoff

for example).

• LED operational test.

• 36 additional 7800 SERIES fault and hold messages.

Content

pplication ........................................................................ 1

eatures ........................................................................... 1

pecifications ................................................................... 2

rdering Information ......................................................... 2

rincipal Technical Features ............................................ 4

nstallation ........................................................................ 4

iring ............................................................................... 5

peration ......................................................................... 9

65-0101-03

7800 SERIES S7830 EXPANDED ANNUNCIATOR

SPECIFICATIONS

Electrical Ratings:

Voltage and Frequency: 120 Vac (+10%/-15%), 50/60 Hz

(±10%)

Power Dissipation: 4.6W maximum.

Terminal ratings: See Table 1.

.

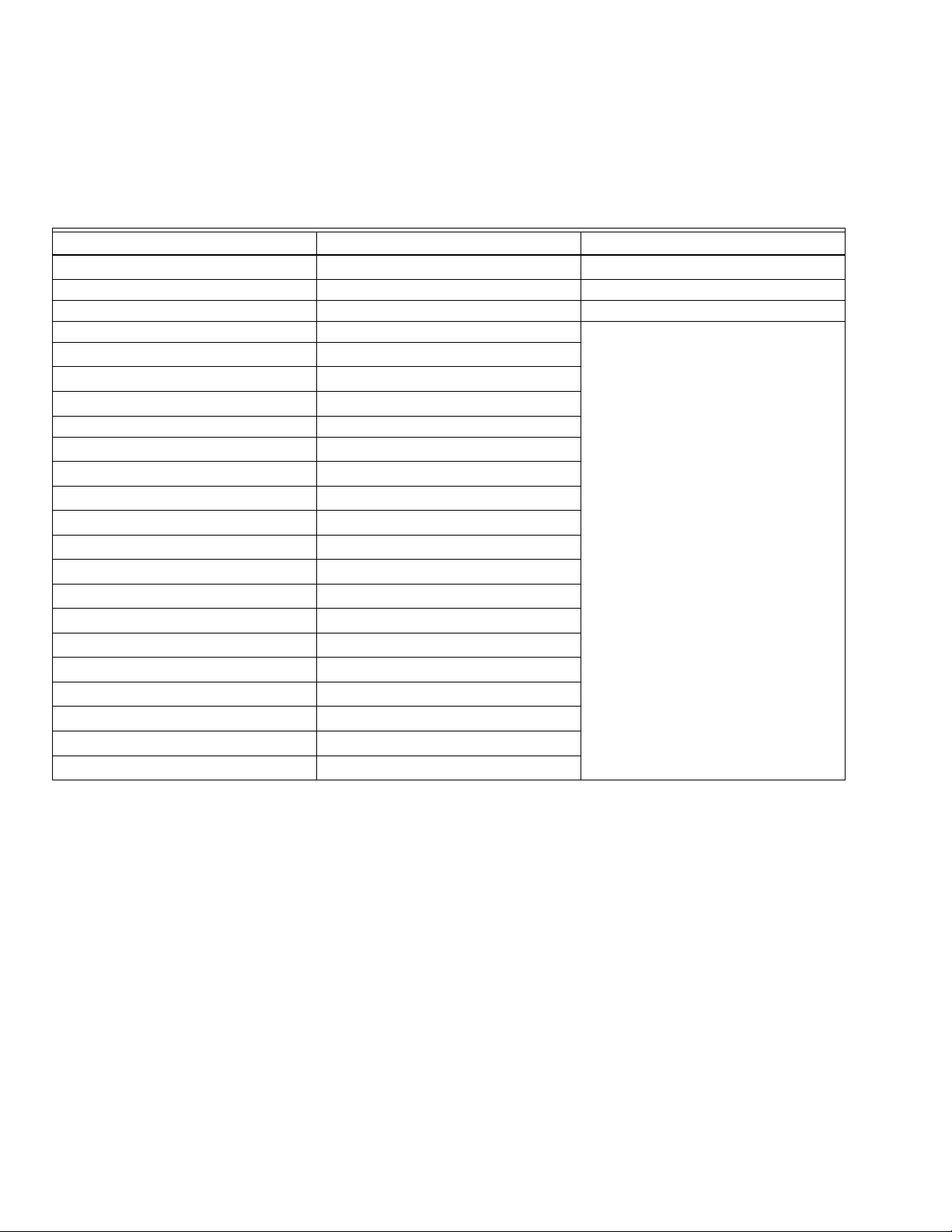

Table 1. Terminal Ratings

Terminal Number Description

1

Earth Ground

a

b

Rating

—

2 Input Line Voltage (Neutral)

3 Input Line Voltage (Hot) 120 Vac, +10%/-15%.

4 Main Valve Proof of Closure 120 Vac, +10%/-15%, 2 mA.

5

6

7

Burner Switch

Operating Control

Auxiliary Limit # 1

b

b

b

8 Auxiliary Limit # 2

9

10

11

12

13

14

15

16

17

18

19

20

21

22

a

The S7830 must have an earth ground providing a connection between the subbase and the control panel or equipment. The earth

Low Water Cutoff

High Limit

Auxiliary Limit # 4

Oil Select Switch

High Oil Pressure

Low Oil Pressure

High Oil Temperature

Low Oil Temperature

Gas Select Switch

High Gas Pressure

Low Gas Pressure or Atomizing Switch

Air Flow Switch

Auxiliary Interlock # 4

Auxiliary Interlock # 5

b

b

b

b

b

b

b

b

b

b

b

b

b

b

ground must be capable of conducting the current to blow a 15A fuse (or breaker) in the event of an internal short circuit. the S7830

needs a low impedance ground connection to the equipment frame that, in turn, needs a low impedance connection to earth ground.

For a ground path to be low impedance at RF frequencies, the connection must be made with minimum length conductors that have

maximum surface areas. Wide straps or brackets, rather than leadwires, are preferred. Be careful to verify that the mechanically

tightened joints along the ground path, such as pipe or conduit threads or surfaces held together with fasteners, are free of

nonconductive coatings and are protected against mating surface corrosion.

b

The S7800A1142 Keyboard Display Module can change the default description.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0101—03 2

7800 SERIES S7830 EXPANDED ANNUNCIATOR

Environmental Ratings:\

Ambient Temperature Range:

Operating: -40°F to +140°F (-40°C to +60°C).

Storage: -40°F to +150°F (-40°C to +66°C).

Humidity: 85% continuous, noncondensing.

Vibration: 0.5 G environment.

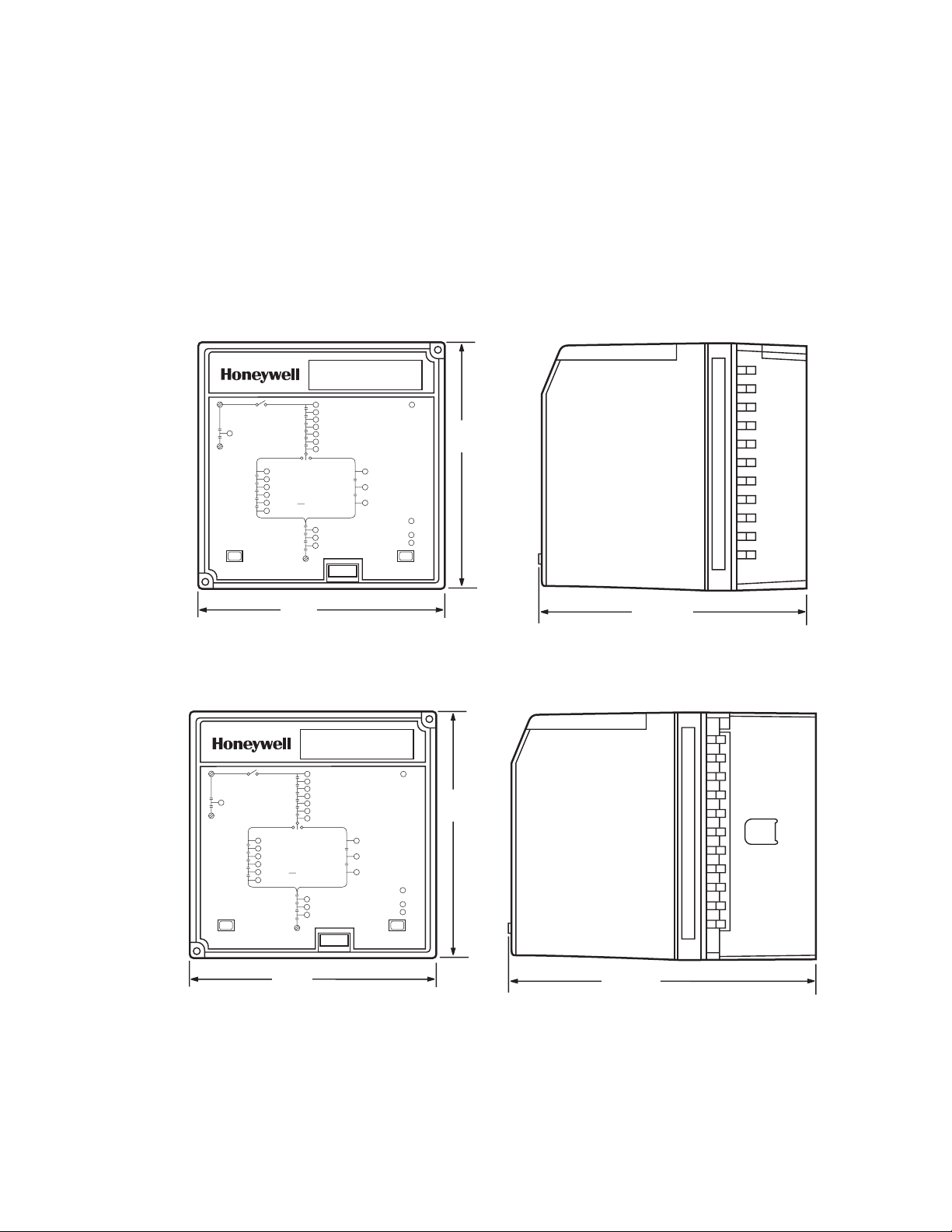

Dimensions: See Fig. 1 and 2.

Weight: 1 lb, 6 oz (0.624 kilogram), unpacked.

Approvals:

Underwriters Laboratories Inc. Listed: File No. MH17367,

Guide No. MJAT.

EXPANDED ANNUNCIATOR

Gas Select

High Gas Pressure

Low Gas Pressure

System Lockout

c

Power

First Out

Current

Select

L1

Proof of Closure

Preignition Interlocks

Reset

Fuel Selection

Oil Select

High Oil Pressure

Low Oil Pressure

High Oil Temperature

Low Oil Temperature

Atomizing Switch

Interlocks

Burner Switch

Operating Control

Auxiliary Limit 1

Auxiliary Limit 2

Low Water Cutoff

High Limit

Atomizing Limit 3

Airflow Switch

Auxiliary Interlock 4

Auxiliary Interlock 5

b

a

5

(127)

Canadian Standards Association certified: LR95329.

Factory Mutual Approved.

IRI Acceptable.

Federal Communications Commission: Part 15, Class B

Emissions.

Required Components;

Q7800A or Q7800B universal Wiring Subbase.

RM7800 SERIES Relay Module.

S7800 Keyboard Display Module or S7810 Data ControlBus™

Module.

Accessories:

S7810M Modbus™ Module.

12

13

14

15

16

17

20 19 18

21

22

5 (127)

5-5/16 (135)

M5182

Fig. 1. Mounting dimensions of S7830 Expanded Annunciator and Q7800A Wiring Subbase in in. (mm).

EXPANDED ANNUNCIATOR

L1

Proof of Closure

Preignition Interlocks

Reset

Fuel Selection

Oil Select

High Oil Pressure

Low Oil Pressure

High Oil Temperature

Low Oil Temperature

Atomizing Switch

Interlocks

5 (127)

Burner Switch

Operating Control

Auxiliary Limit 1

Auxiliary Limit 2

Low Water Cutoff

High Limit

Atomizing imit 3

Airflow Switch

Auxiliary Interlock 4

Auxiliary Interlock 5

a b c

Power

Gas Select

High Gas Pressure

Low Gas Pressure

System Lockout

First Out

Current

Select

5

(127)

22 21 20 19 18 17 16 15 14 13 12

6-9/64 (156)

M5183

Fig. 2. Mounting dimensions of S7830 Expanded Annunciator and Q7800B Wiring Subbase in in. (mm).

3 65-0101—03

7800 SERIES S7830 EXPANDED ANNUNCIATOR

PRINCIPAL TECHNICAL FEATURES

The S7830 Expanded Annunciator is an enhancement

module for use with 7800 SERIES Relay Modules. The S7830

is a microprocessor-based device designed to monitor the

status of a series string of limit, control and interlock contacts

for a commercial or industrial burner. The S7830 acts as a

system monitor and enhances fault and status messages for

the 7800 SERIES burner control.

ControlBus Communications

The S7830 provides interfaces with the 7800 SERIES Relay

module through a three-wire RS-485 interface. Using this

communications bus, the S7830 provides additional first-out

annunciation, burner hold, and current status information for

the control, limit and interlock string of the burner equipment.

LED Array

The S7830 provides visual indication of the status of the

burner equipment control, limit and interlock string. The string

of contact and switch points are individually identified with a

colored LED. When power is present at the contact point, the

LED is lighted. When the contact point is de-energized, the

LED is dark. If the contact or switch is identified as the first-out

annunciation point, the LED flashes if the RM78X0L,

RM7838B,C with the Lockout Feature is used or if the feature

is enabled (RM7895, 6, 7, or 8 with JR2 configuration resistor

removed).

Opto-Isolator Coupling

The S7830 uses opto-isolators to monitor the limit string and

couple the line voltage input to the microprocessor. An optoisolator allows a microprocessor to determine the status of

line voltage at control, limit or interlock switch points. Using

this capability, the microprocessor is able to determine the

current as well as first-out status of 23 digital points, each

representing specific burner control, limit or interlock switches.

INSTALLATION

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Verification of safety requirements must be performed

each time a control is installed on a burner to prevent

possible hazardous burner operation.

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced flame

safeguard technician.

4. After installation is complete, check out the product

operation as provided in these instruction.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment

damage.

1. Disconnect the power supply before beginning

installation to prevent electrical shock and

equipment damage. More than one power supply

disconnect can be involved.

2. Wiring connections for the S7830 are unique;

therefore, refer to Fig. 3, 4, 5 for proper subbase

wiring.

3. Wiring must comply with all applicable codes,

ordinances and regulations.

4. Wiring must comply with NEC Class 1 (Line

Voltage) wiring.

5. The S7830 should not interfere with the proper

safety operation of the controls, limits and interlocks

it is monitoring. After installation, check each

control, limit and interlock to ensure that it is

operating properly. DO NOT PLACE JUMPER

WIRES ACROSS THE INSTALLATION

CONTROLS, LIMITS AND INTERLOCKS.

65-0101—03 4

7800 SERIES S7830 EXPANDED ANNUNCIATOR

IMPORTANT

1. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used

in accordance with these instructions, may cause

interference for radio communications. It has been

tested and found to comply with the limits of a Class

B computing device of part 15 of FCC rules, which

are designed to provide reasonable protection

against such interference when operated in a

commercial environment. Operation of this

equipment in a residential area may cause

interference; in which case, the user, at their own

expense, may be required to take whatever

measures are required to correct this interference.

2. This digital apparatus does not exceed the Class B

limits for radio noise, set out in the Radio Interference Regulations of the Canadian Department of

Communications.

3. If a control, limit or interlock is not used with the

installation, a jumper must be installed in the S7830

wiring subbase. DO NOT PLACE JUMPER WIRES

ACROSS THE INSTALLATION CONTROL, LIMITS

AND INTERLOCKS. For example, if Auxiliary Limit #

1(Aux Limit#1) is not used, place a jumper wire

between terminals 6 and 7 on the S7830 wiring

subbase.

4. For straight gas burner applications, the oil limit and

interlock inputs DO NOT need to be jumpered.

5. For straight oil burner applications, the gas limit and

interlock inputs DO NOT need to be jumpered.

6. For combination gas-oil burner applications, a

double pole, double throw (dpdt) fuel select switch is

required. See Fig. 3.

7. For communications ControlBus connections in

excess of 100 feet (30 meters), a 120 ohm, 1/4 watt

minimum, termination resistor may be required

across terminals 1(a) and 2(b) of the electrical connectors. Cable shield must be terminated to ground

at both ends. If shielded cable is NOT used, use

three-wire twisted cable.

8. The 7800 SERIES Relay Module control point can

be tied into the S7830:

• For dual fuel burners, from terminals 6 to 11,

inclusive.

• For single fuel burners, from terminals 6 to 9,

inclusive.

Humidity

Install the S7830 where the relative humidity never reaches

the saturation point. The S7830 is designed to operate in a

maximum 85% relative humidity, continuous, noncondensing,

moisture environment. Condensing moisture can cause

erratic operation.

Vibration

Do not install the S7830 where it could be subjected to

vibration in excess of 0.5G continuous, maximum.

Weather

The S7830 is not designed to be weather tight. If installed

outdoors, the S7830 must be protected by a weather-tight,

NEMA 4, enclosure.Mounting Wiring Subbase

NOTE: For installation dimensions, see Fig. 1 or 2.

1. Mount the subbase in any position except horizontally

with the bifurcated subbase contacts pointed down (on

the row F). A vertical mounting position is recommended. Any other position decreases the maximum

ambient temperature rating.

2. Select a location on a wall, burner surface, or within an

electrical control panel. Be sure to allow adequate

clearance for electrical voltage probe tests, electrical

field connections, and wiring of the RS-485 ControlBus

to the 7800 SERIES Relay Module. The S7830 must be

within 1000 feet (305 meters) of the 7800 SERIES

Relay Module for proper communication of first-out

annunciation and current burner status information.

3. Use the back of the subbase as a template to mark the

four screw locations and drill pilot holes.

4. Insert four No. 6 screws for mounting, and tighten

securely.

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect the power supply from the main

disconnect before beginning installation to prevent

electrical shock and equipment damage. More than

one disconnect can be required.

1. Refer to Fig. 3 for proper subbase wiring. The system

wiring must follow the order shown in Fig. 3.

NOTE: With the S7800A1142 Keyboard Display Module, you

can name the limits and interlocks to match your

system.

2. All wiring must comply with all appropriate electrical

codes, ordinances and regulations. Wiring, where

required, must comply with NEC Class 1 (Line Voltage).

3. Recommended wire size and type:

a. Line Voltage:

(1) Use No. 14, 16 or 18 gauge (TTW60C or

THW75C or THHN90C), 600 volt insulation for

all line voltage terminals.

b. RS-485 ControlBus:

(1) Use three-wire twisted cable. Some installations

may require shielded cable; use Belden 8771 or

equivalent. For connections in excess of 100

feet (30 meters), a 120 ohm, 1/4 watt minimum,

termination resistor may be placed across

terminals 1(a) and 2(b) of the electrical

connectors.

4. Recommended grounding practices:

a. The earth ground provides for a connection between

the wiring subbase and the control panel or the

equipment. The earth ground wire must be capable

of conducting the current to blow the 15A type SC

fast blow fuse (or breaker) in the event of an internal

short circuit.

b. The S7830 needs a low impedance ground

connection to the equipment frame which, in turn,

needs a low impedance ground connection to earth

ground. For a ground path to be low impedance at

RF frequencies, the connection must be made with

minimum length conductors that have a maximum

5 65-0101—03

Loading...

Loading...