Honeywell S7800A Product Data

S7800A Keyboard Display Module

APPLICATION

The S7800A Keyboard Display Module (KDM) provides

first-out annunciation and system diagnosis using a two-row

by twenty-column readout. The KDM provides local or remote

annunciation of operation and fault information, remote reset,

report generation, burner control data and diagnostic

information. The KDM is part of the 7800 SERIES of

microprocessor-based burner controls for gas, oil, coal or

combination fuel single burner applications.

The 7800 SERIES is programmed to provide a level of safety,

functional capabilities and features beyond the capacity of

conventional controls.

7800 SERIES

PRODUCT DATA

FEATURES

• Application flexibility.

• Communication interface capability.

• Dependable, long-term operation provided by

microcomputer technology.

• First-out annunciation and system diagnostics

provided by a 2-row by 20-column display.

• First-out expanded annunciation with 24 limit and

interlock Light Emitting Diodes (LED).

• Local or remote annunciation of operation and

fault information.

• UL Class 4 rating when P/N 204718A,C NEMA 4 cover

is used.

Remote reset.

•

• Report generation.

• Burner controller data:

— Sequence status.

— Sequence time.

— Hold status.

— Lockout/alarm status.

— Flame signal strength.

— Expanded annunciator status.

— Total cycles of operation.

— Total hours of operation.

— Fault history of six most recent faults:

• Cycles of operation at time of fault.

• Expanded annunciator data at time of fault.

• Fault message and code.

• Hours of operation at time of fault.

• Sequence status at time of fault.

• Sequence time at time of fault.

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Wiring ............................................................................... 4

Troubleshooting ................................................................ 11

65-0090-4

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

— Diagnostic information:

• Device type.

•Flame amplifier type.

• Flame failure response time (FFRT).

•Manufacturing code.

•On-Off status of all digital inputs and

outputs.

•PREPURGE time selected.

•Software revision and version of 7800

SE RI ES

Relay Module and KDM.

•Status of configuration jumpers.

•Status of Run/Test Switch.

SPECIFICATIONS

Electrical Ratings:

Voltage and Frequency: 13 Vdc peak full wave rectified

(+20/-15%).

Power Dissipation: 7W maximum.

VA Consumption: 2 VA maximum.

Terminal Ratings:

Power: 13 Vdc peak full wave rectified.

Earth Ground.

Environmental Ratings:

Ambient Temperature Ranges:

Operating: -40°F (-40°C) to +140°F (+60°C).

Storage: -60°F (-51°C) to +150°F (+66°C).

Humidity: 85 percent relative humidity continuous,

noncondensing.

S7800A1050 Italian language display.

S7800A1068 Spanish language display.

S7800A1118 Japanese (Katakana) language display.

S7800A1126 Portuguese language display.

BURNER CONTROL

2-3/4

(69)

15/

32

(12)

1-15/16

(49)

29/32

(23)

SCROLL MODE

19/32

(15)

5/32 (4)

4-27/32 (123)

1-1/4

(32)

7/16 (11)

2-7/16 (62)

3-7/8 (99)

SAVE

4-3/32 (104)

1-1/32

(26)

13/

32

(11)

5/32

(4)

1/2

(13)

5/16

(8)

2-1/32

(52)

5/15

(8)

M5002B

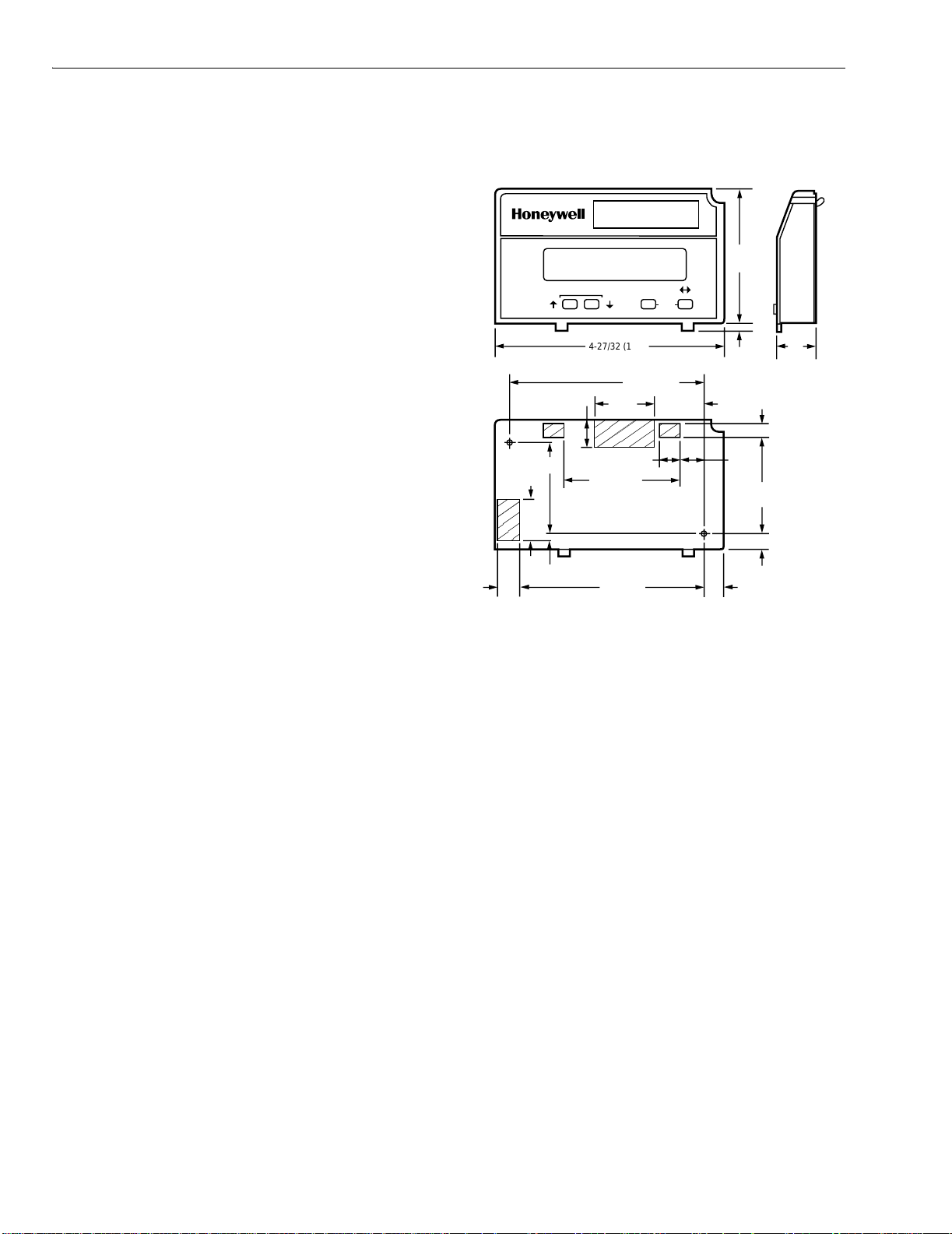

Fig. 1. Approximate dimensions of S7800 in in. (mm).

29/32

(23)

NOTE: UL Class 4 rating when P/N 204718A,C NEMA 4

Cover is used.

Approvals:

Underwriters Laboratories Inc. Listed:

File No. MP268, Guide No. MCCZ.

Vibration: 0.5G environment.

Canadian Standards Association Certified:

No. LR9S329-3.

Mechanical:

Dimensions: See Fig. 1.

Weight: 4 ounces (124 grams), unpacked.

Factory Mutual Approved: Report No. J.I.1V9A0.AF.

IRI: Acceptable.

Federal Communications Commission: Part 15,

Class B emissions.

Display: 40 character (2 rows by 20 columns).

EN60730: For compliance with remote KDM mounting

requirements, provide electrical insulation separation by

Languages:

S7800A1001 English language display.

S7800A1035 French language display.

insulation using double or reinforced insulation. Do this by:

Optically isolating the communication or remote reset lines

from the control cabinet, or provide physical separation

S7800A1043 German language display.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0090—4 2

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

from the communication or remote display cover assembly

(part number 204718A) or other suitable enclosure that

meets the IP40 class of protection.

Accessories:

203541 ControlBus 5-wire Electrical Connector.

S7810A1009 Data ControlBus Module™.

203765 Remote Display Mounting Bracket.

221818A 60 in. (1.5m) Extension Cable Assembly.

221818C 120 in. (3m) Extension Cable Assembly.

204718A NEMA 4 Cover Assembly for S7800A KDM.

204718B NEMA 1 Cover Assembly for S7800A KDM.

204718C NEMA 4 Cover Assembly for S7800A KDM with

reset button.

205321B Remote Display Flush Mount Kit.

INSTALLATION

WARNING

Electrical Shock Hazard.

Can cause severe injury or death.

Disconnect the power supply before beginning

installation to prevent electrical shock and equipment

damage. More than one power supply disconnect can

be involved.

Humidity

Install the S7800A where the relative humidity never reaches

the saturation point. The S7800 is designed to operate in a

maximum 85% RH continuous, noncondensing, moisture

environment.

Vibration

Do not install the S7800A where it can be subjected to

vibration in excess of 0.5G continuous maximum vibration.

Weather

The S7800A is not designed to be weather tight. If installed

outdoors, the S7800A must be protected by an approved

weather-tight enclosure such as the 204718A or 204718C

NEMA 4 Enclosure listed in Accessories.

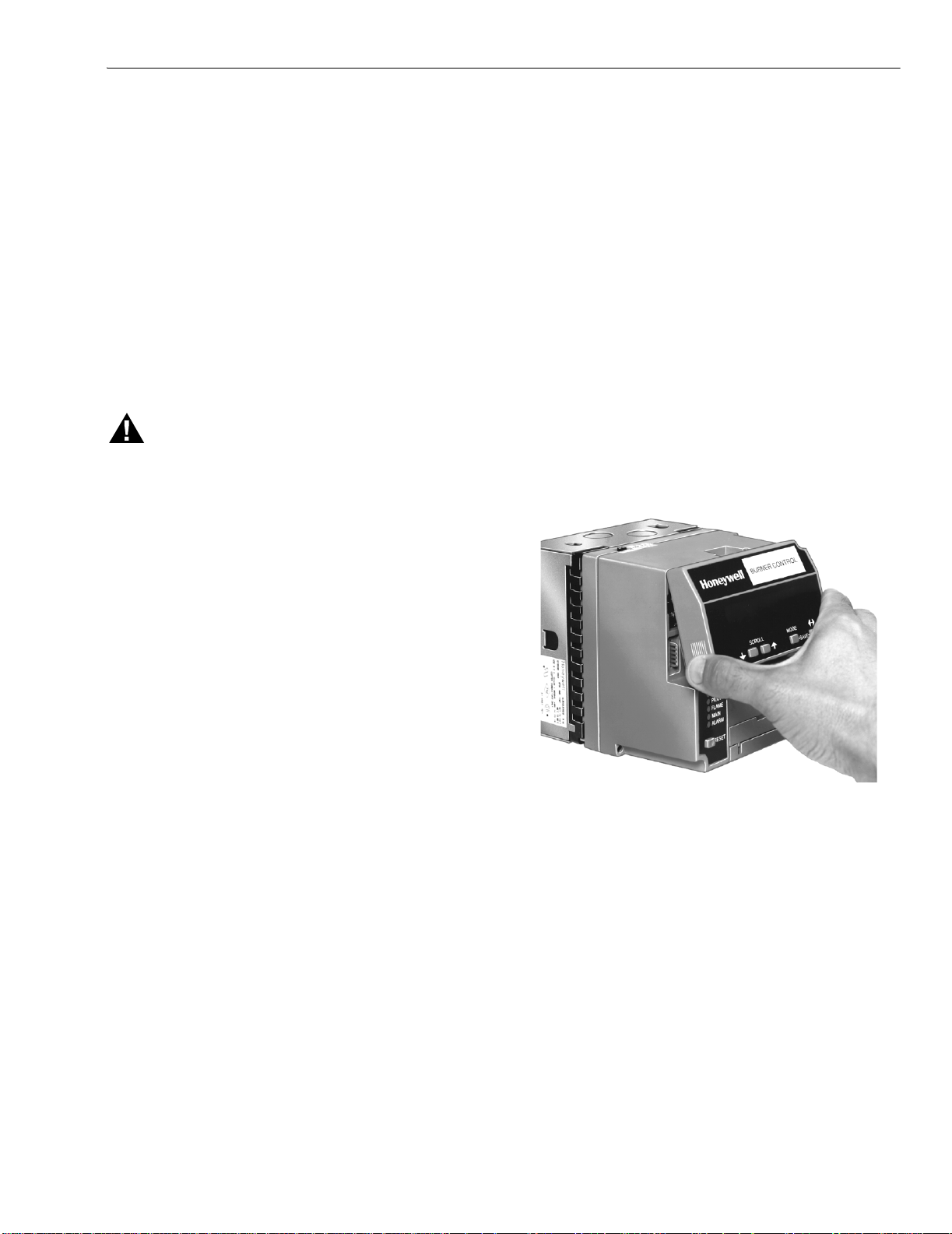

Mounting KDM on 7800 SERIES Relay Module.

1. Align the two interlocking ears of the KDM with the two

mating slots on the 7800 SERIES Relay Module. See

Fig. 2.

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and marked

on the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced, flame

safeguard service technician.

4. After installation is complete, check out the product

operation as provided in these instructions.

5. Be sure wiring complies with all applicable codes,

ordinances and regulations.

6. See Fig. 5, 6 and 7 for S7800A unique wiring

connections.

IMPORTANT

1.This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used

in accordance with the instructions, can cause

interference to radio communications. It has been

tested and found to comply with the limits for a Class

B computing device of Part 15 of FCC rules which

are designed to provided reasonable protection

against such interference when operated in a

commercial environment. Operation of this

equipment in a residential area can cause

interference, in which case, users, at their own

expense, can be required to take whatever

measures are required to correct this interference.

2.This digital apparatus does not exceed the Class B

limits for radio noise for digital apparatus set out in

the Radio Interference Regulations of the Canadian

Department of Communications.

Fig. 2. Keyboard display module mounting.

2. Insert the two interlocking ears into the two mating slots

and, with a hinge action, push on the lower corners of

the KDM to secure it to the 7800 SERIES Relay

Module.

3. Make sure the KDM is firmly in place.

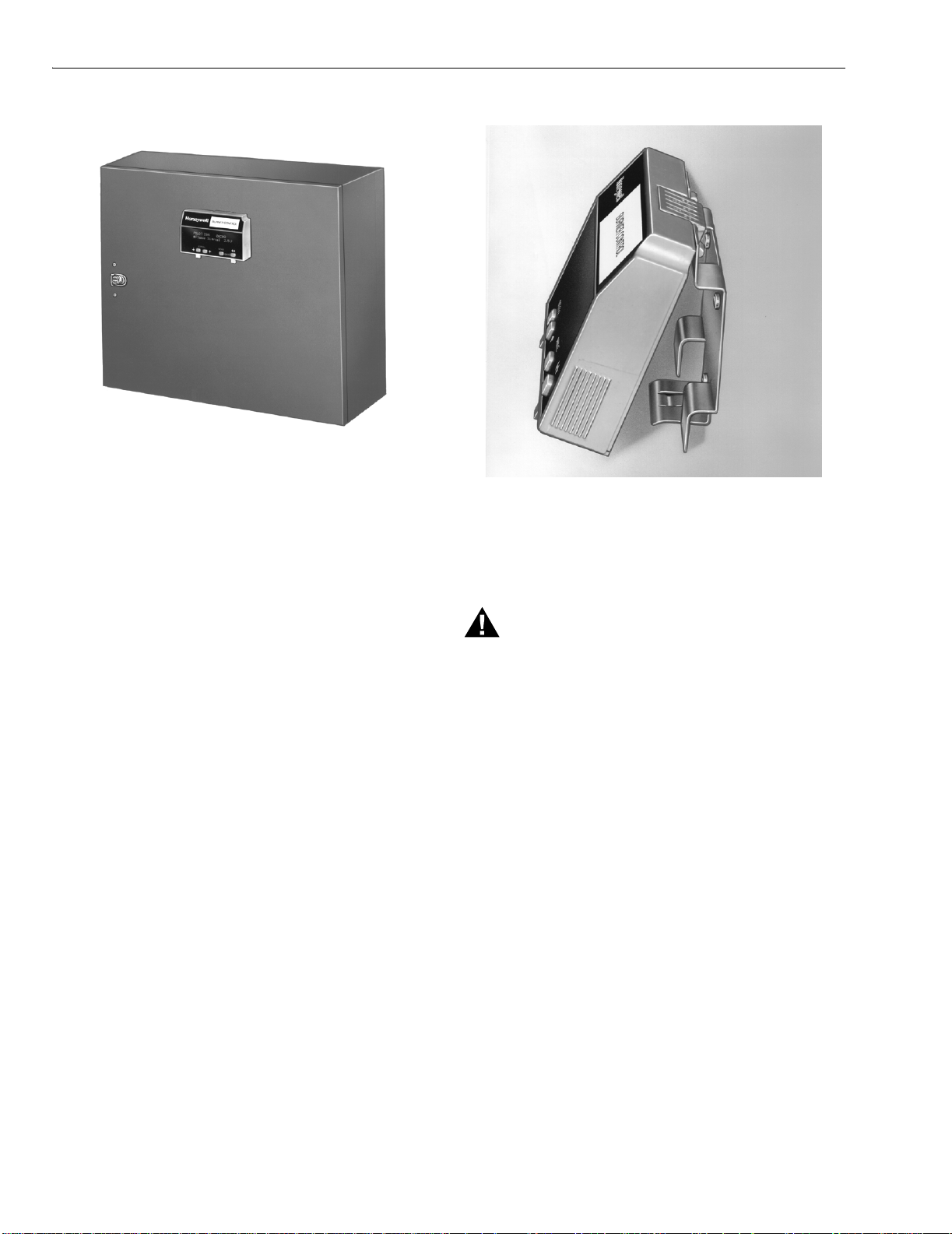

Remote Mounting KDM

The KDM can be mounted either on the face of a panel door

or on other remote locations. See Fig. 3. When mounting the

KDM on the face of a door panel, closely follow these

instructions:

3 65-0090—4

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

Door Panel Mounting

Fig. 3. Panel mounting of a keyboard display module.

1. Select the location on the door panel for flush mounting.

2. Pay attention to the insertion dimensions of the two

KDM screws, two interlocking ears, and the two plug-in

connections to allow for sufficient clearance.

3. Use the KDM or Data ControlBus Module™ as a

template (Fig. 16) and mark the two screw locations,

interlocking ear locations and the two plug-in connector

locations.

4. Drill the pilot holes for the mounting screws.

5. Cut holes in the door panel for the interlocking ears and

the two plug-in connectors.

6. Mount the KDM, securing it with the two screws

provided in the KDM bag assembly.

Remote Display Mounting Bracket

Use the 203765 Remote Display Mounting Bracket when

mounting the KDM on a wall or remote location:

1. Use the 203765 Remote Display Mounting Bracket as a

template to mark the four screw locations.

2. Drill the pilot holes for the four mounting screws.

3. Mount the 203765 Remote Display Mounting Bracket by

securing the four no. 6 screws (M3.5 x 0.6). See Fig. 4.

4. Mount the KDM by aligning the two interlocking ears

with the two mating slots on the remote mounting

bracket.

5. Insert the two interlocking ears into the two mating slots.

6. Push on the lower corners of the KDM to secure it to the

remote mounting bracket.

7. Make sure the KDM is firmly in place.

Fig. 4. Remote mounting of a keyboard display module

using a 203765 Remote Display Mounting Bracket.

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury or death.

To prevent electrical shock and equipment damage,

disconnect the power supply from the main disconnect

before beginning installation. More than one

disconnect can be involved.

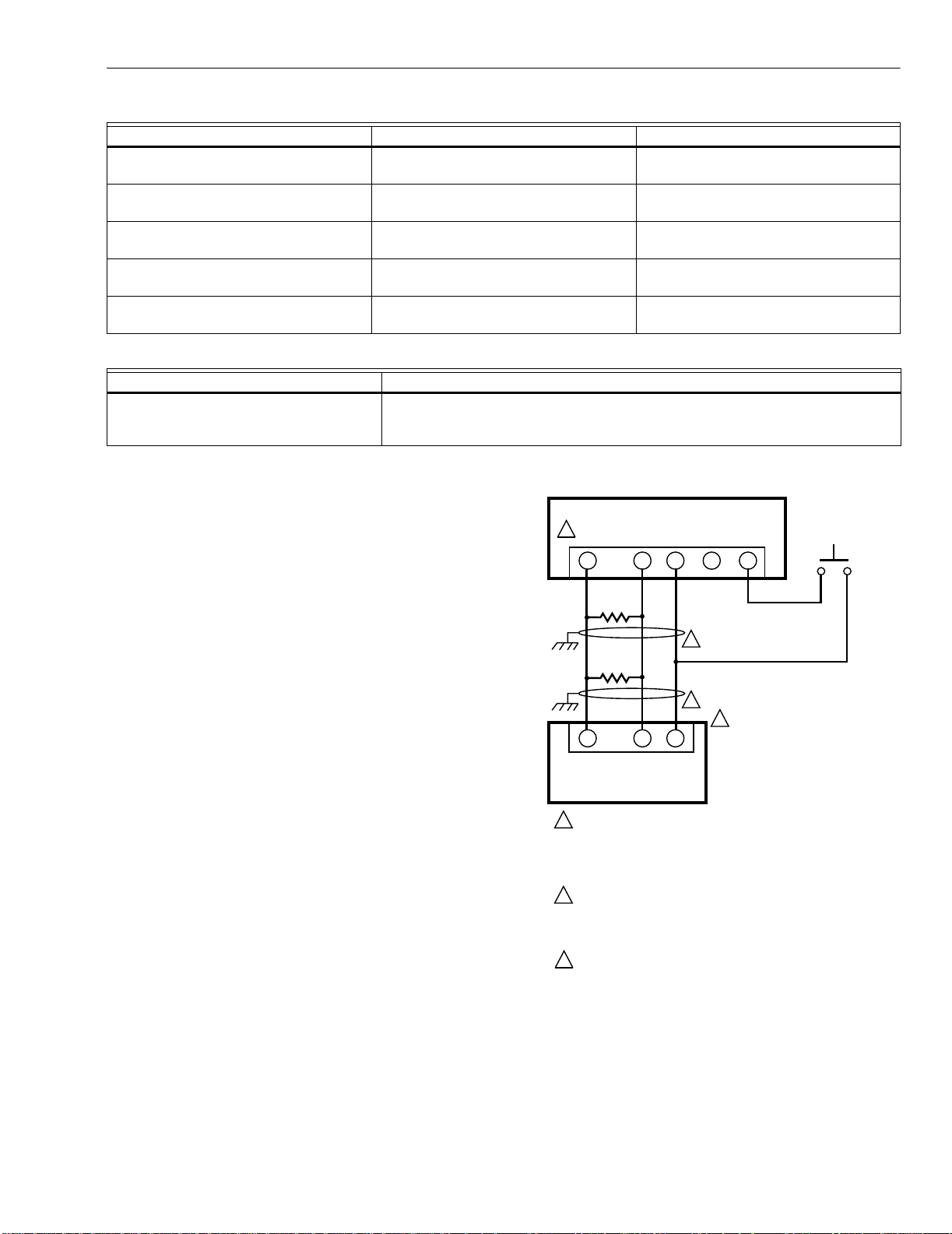

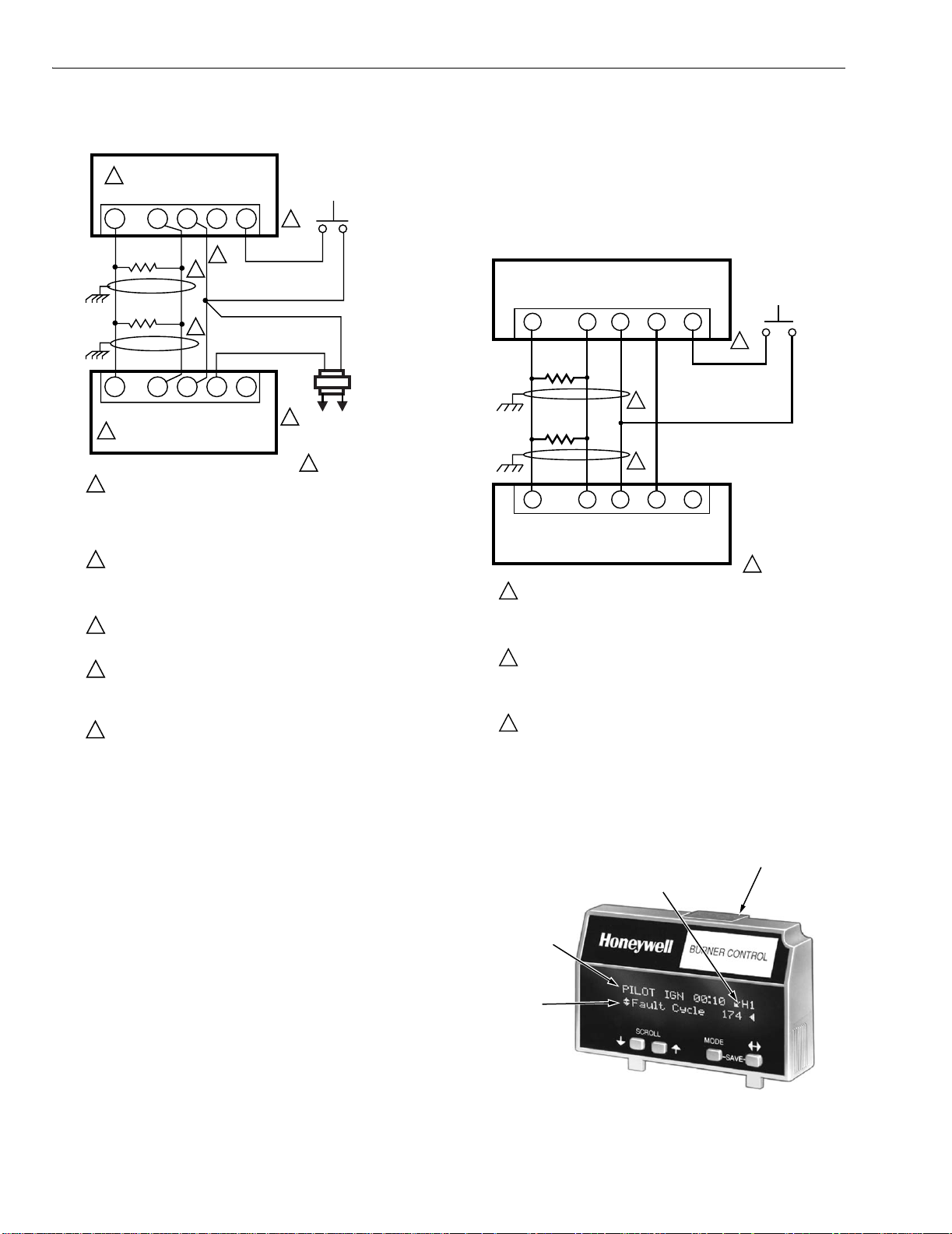

1. Refer to Fig. 5, 6, and 7 for proper wiring.

2. Make sure all wiring complies with all applicable

electrical codes, ordinances and regulations.

3. For recommended wire size and type, see Table 1.

4. For Recommended grounding practices, see Table 2.

5. For KDM: The KDM is powered from a low voltage,

energy-limited source. It can be mounted outside of a

control panel if it is protected from mechanical damage.

NOTE: A 13 Vdc power supply must be used any time more

than one KDM is used. A maximum of two KDM,

Data ControlBus Modules™ or S7810B Multi-Drop

Switch Modules are allowed in any combination.

65-0090—4 4

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

N

Table 1. Recommended Wire Size and Part Number.

Application Recommended Wire Size Recommended Part Number

Keyboard Display Module 22 AWG two-wire twisted pair with

ground, or five-wire.

Data ControlBus™ Module 22 AWG two-wire twisted pair with

ground, or five-wire.

Remote Reset Module 22 AWG two-wire twisted pair, insulated

for low voltage.

Communications Interface ControlBus

Module™

13 Vdc full wave rectified transformer

power input.

22 AWG two-wire twisted pair with

ground.

18 AWG wire, insulated for voltages and

temperatures for given applications.

Table 2. Recommended Grounding Practices.

Ground Type Recommended Practice

Signal ground (KDM, Data ControlBus™

Module, Communications Interface

Use the shield of the signal wire to ground the device to the signal ground terminals

[3(c)] of each device. Connect the shield at both ends of the daisy chain to ground.

ControlBus Module™).

6. Recommended wire routing:

a. ControlBus:

(1) Do not route the ControlBus cable in conduits

S7800 KEYBOARD DISPLAY MODULE

(MOUNTED ON 7800 SERIES RELAY MODULE)

that carry line voltage circuits.

(2) Avoid routing the ControlBus cable close to

ignition transformer leadwires.

(3) Route the ControlBus cable outside of conduit if

properly supported and protected from damage.

3

A

1

b. Remote Reset:

(1) Do not run high voltage ignition transformer

wires in the same conduit with the Remote Reset

120 OHM

RESISTOR

wiring.

(2) Do not route Remote Reset wires in conduit with

line voltage circuits.

7. Maximum wire lengths:

120 OHM

RESISTOR

a. KDM: The maximum length interconnecting wire is

4000 ft (1219m).

b. Remote Reset leadwires: The maximum length wire

is 1000 ft (300m) to a Remote Reset push-button.

8. Install all electrical connectors.

9. Restore power to the panel.

1

A

Belden 8723 shielded cable or equivalent.

Belden 8723 shielded cable or equivalent.

—

Belden 8723 shielded cable or equivalent.

TTW60C, THW75C, THHN90C

MOMENTARY

PUSH BUTTO

B

C (GND)

23

1

1

23

B

C

RESET

+13 VDC

4

5

2

QS7800 COMMUNICATIONS

INTERFACE CONTROLBUS

MODULE, MOUNTED IN

Q7700 COMMUNICATIONS

INTERFACE MODULE

SWITCH

THREE WIRE SHIELDED CABLE MAY BE REQUIRED. TWO 120

1

OHM TERMINATING RESISTORS ARE REQUIRED FOR

CONNECTIONS OVER 100 FEET (30 METERS). CABLE SHIELD

MUST BE TERMINATED TO EARTH GROUND AT BOTH ENDS.

IF SHIELDED CABLE IS NOT USED, TWISTED PAIR

WIRE MUST BE USED.

2

WHEN CONNECTING THE KEYBOARD DISPLAY MODULE, DATA

CONTROLBUS MODULE“, OR REMOTE RESET MODULE

EXTERNAL FROM THE CONTROL CABINET, APPROPRIATE

MEASURES MUST BE TAKEN TO MEET EN60730 SAFETY

LOW VOLTAGE REQUIREMENTS (SEE APPROVALS).

TERMINALS OF 203541 5-WIRE CONNECTOR.

3

M1990F

Fig. 5. Wiring the keyboard display module.

5 65-0090—4

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

,

N

S

M

P

M

sequence status information. It also replaces a selectable

S7800 KEYBOARD DISPLAY MODULE

(MOUNTED ON 7800 SERIES RELAY MODULE)

message after 60 seconds if it or a lockout message is

available. The 7800 SERIES Relay Module LED provide

positive visual indication of the Relay Module sequence. The

5

A

B

C (GND)

23 54

1

120 OHM

RESISTOR

120 OHM

RESISTOR

1

A

5

S7800 REMOTE KEYBOARD DISPLAY MODULE

1

THREE WIRE SHIELDED CABLE MAY BE REQUIRED. TWO

120 OHM TERMINATING RESISTORS ARE REQUIRED FOR

CONNECTING OVER 100 FEET [30 METERS]. CABLE SHIELD

MUST BE TERMINATED TO EARTH GROUND AT BOTH ENDS.

IF SHIELDED CABLE IS NOT USED, TWISTED PAIR WIRE

MUST BE USED.

2

WHEN CONNECTING THE KEYBOARD DISPLAY MODULE DATA

CONTROLBUS MODULE“, OR REMOTE RESET MODULE

EXTERNAL FROM THE CONTROL CABINET, APPROPRIATE

MEASURES MUST BE TAKEN TO MEET EN60730 SAFETY

LOW VOLTAGE REQUIREMENTS (SEE APPROVALS).

3

7800 SERIES RELAY MODULE CAN SUPPORT ONE S7800

KEYBOARD DISPLAY MODULE. A 13 Vdc POWER SUPPLY

IS REQUIRED FOR EACH ADDITIONAL DISPLAY.

4

UP TO 36 S7800 KEYBOARD DISPLAYS CAN BE CONNECTED

TO A SINGLE 7800 RELAY MODULE NOT TO EXCEED

4000 FEET (1219M) TOTAL LEADWIRE RUN. DAISY CHAIN 1 TO 1

2 TO 2, 3 TO 3 AND PROVIDE 13 Vdc POWER SUPPLY FOR

EACH S7800 DISPLAY.

5

TERMINALS OF 203541 5-WIRE CONNECTOR.

1

1

23 54

B

C (GND)

+13 VDC

2

+13 VDC

RESET

RESET

Fig. 6. Wiring for multiple keyboard display modules.

MOMENTARY

PUSHBUTTON

SWITCH

3

4

2

L1

(HOT)

L2

13 Vdc

POWER

SUPPLY

M5006G

LED is energized simultaneously with the correct sequence

description.

S7810 DATA CONTROLBUS MODULE™

(MOUNTED ON 7800 SERIES RELAY MODULE)

MOMENTARY

PUSH BUTTO

A

1

120 OHM

RESISTOR

120 OHM

RESISTOR

1

A

7800 REMOTE KEYBOARD DISPLAY MODULE

THREE WIRE SHIELDED CABLE MAY BE REQUIRED. TWO 120

1

OHM TERMINATING RESISTORS ARE REQUIRED FOR

CONNECTIONS OVER 100 FEET. CABLE SHIELD MUST BE

TERMINATED TO EARTH GROUND AT BOTH ENDS. IF SHIELDED

CABLE IS NOT USED, TWISTED PAIR WIRE MUST BE USED.

2

WHEN CONNECTING THE KEYBOARD DISPLAY MODULE DATA

CONTROLBUS MODULE™, OR REMOTE RESET MODULE

EXTERNAL FROM THE CONTROL CABINET, APPROPRIATE

MEASURES MUST BE TAKEN TO MEET EN60730 SAFETY

LOW VOLTAGE REQUIREMENTS (SEE APPROVALS).

3

221818A OR C EXTENSION CAN BE USED IN PLACE OF THE

S7810 DATA CONTROLBUS MODULE™ IF DISPLAY IS TO

A CABINET DOOR.

B

C (GND)

23

1

1

23

B

C (GND)

+13 VDC

4

4

+13 VDC

RESET

5

5

RESET

SWITCH

3

2

M5285C

Fig. 7. Wiring keyboard display module

for remote mounting.

KDM Display

The first line of the KDM display provides current status of the

burner sequence (STANDBY, PURGE, PILOT IGN, MAIN

IGN, RUN and POSTPURGE), timing information (PURGE,

PILOT IGN, MAIN IGN and POSTPURGE) in minutes and

seconds, hold information (PURGE HOLD), and lockout

DI = DIAGNOSTICS

H1 = HISTORY

EA = EXPANDED ANNUNCIATOR

information (Lockout, Fault Code, Message and Sequence),

see Fig. 8. The extreme right side of the first line will be either

blank or will show a small arrow pointing to the second line

followed by a two-letter code (DI—Diagnostic Information,

Hn—Fault History Information (where n equals the number of

the fault), and EA—Expanded Annunciator). When the arrow

and two-letter code are displayed, it indicates the second line

is showing a selectable message submenu. The second line

SEQUENCE

STATUS

ELECTABLE

ESSAGE OR

REEMPTIVE

ESSAGE

will display selectable or preemptive messages. A selectable

message supplies information for flame strength, system

status indication, system or self-diagnostics and

troubleshooting. A preemptive message has parentheses

around the message and supplies a detailed message to

support the sequence status information. A preemptive

message can also be a lockout message. A preemptive

message replaces a selectable message to support the

Fig. 8. S7800 Keyboard Display Module.

FIVE WIRE CONNECTOR FOR

COMMUNICATIONS, REMOTE KEYBOARD

DISPLAY AND REMOTE RESET

M7412

65-0090—4 6

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

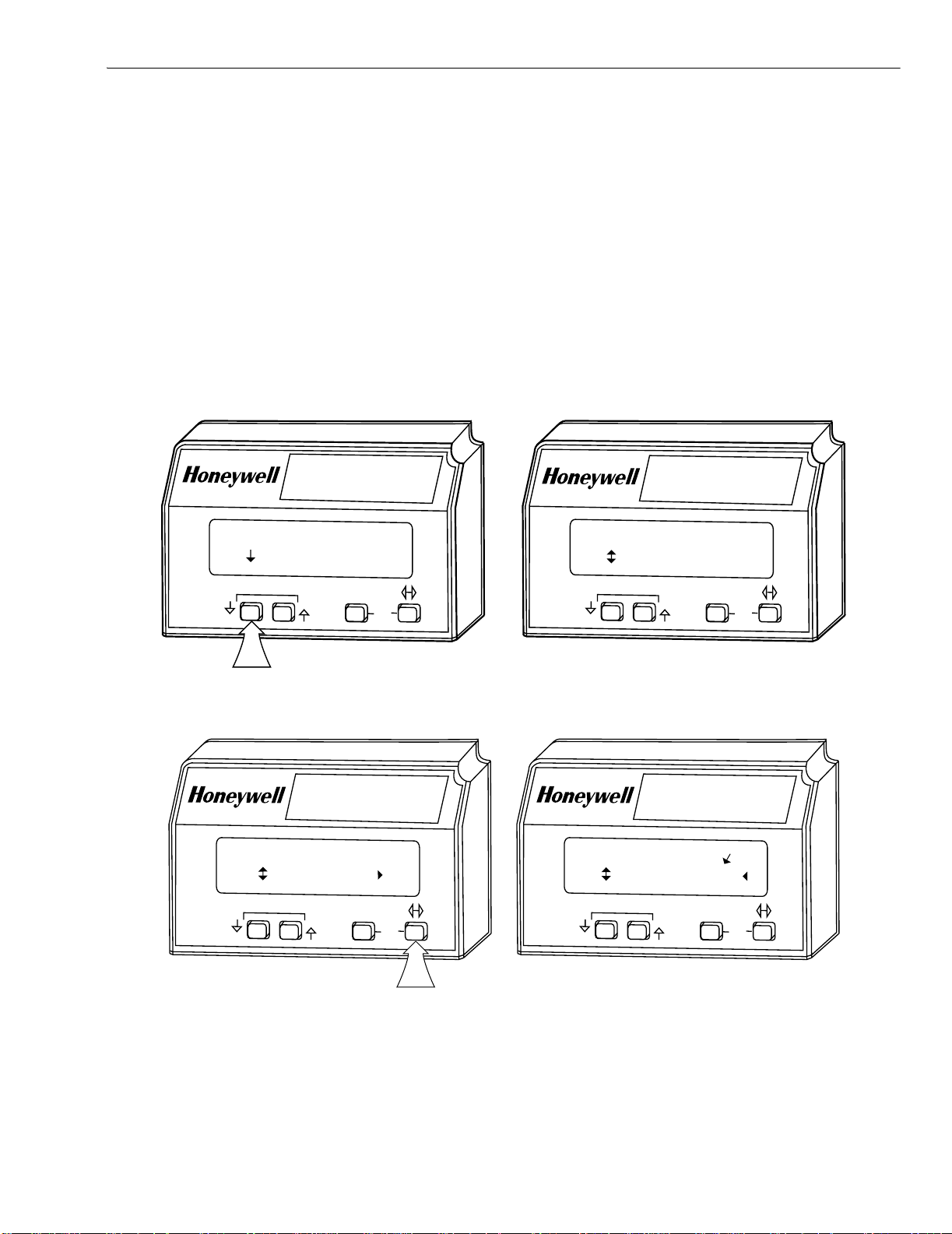

Keyboard Functions

The keyboard contains four push-buttons with separate

functions (SCROLL-down, SCROLL-up, MODE, and

CHANGE-LEVEL). The MODE and CHANGE-LEVEL, when

pressed together, provide a SAVE function.

1. SCROLL down-up push-buttons (↕). See Fig. 9. The

SCROLL down-up push-buttons (↕) are used to scroll

through the selectable messages. The double-headed

arrow (↕), which is located in the lower left position of

the second line of the display, represents the SCROLL

down-up push-buttons. The SCROLL down-up pushbuttons (↕) can be pressed to display the selectable

messages one at a time or held down to scroll through

the selectable messages at the rate of two per second.

BURNER CONTROL

RUN

Total Cycles 333

When the last item of the selectable message is viewed,

the display wraps around and displays the first

selectable message again.

2. CHANGE-LEVEL push-button (

↔), see Fig. 10. The

CHANGE-LEVEL push-button is used to change

between the first hierarchy of selectable messages to a

subset of selectable messages. The CHANGE-LEVEL

push-button can also be used to change from a subset

message to a first level selectable message. The

symbol (<), located on the second line in the lower right

corner of the display, represents a subset of selectable

messages.

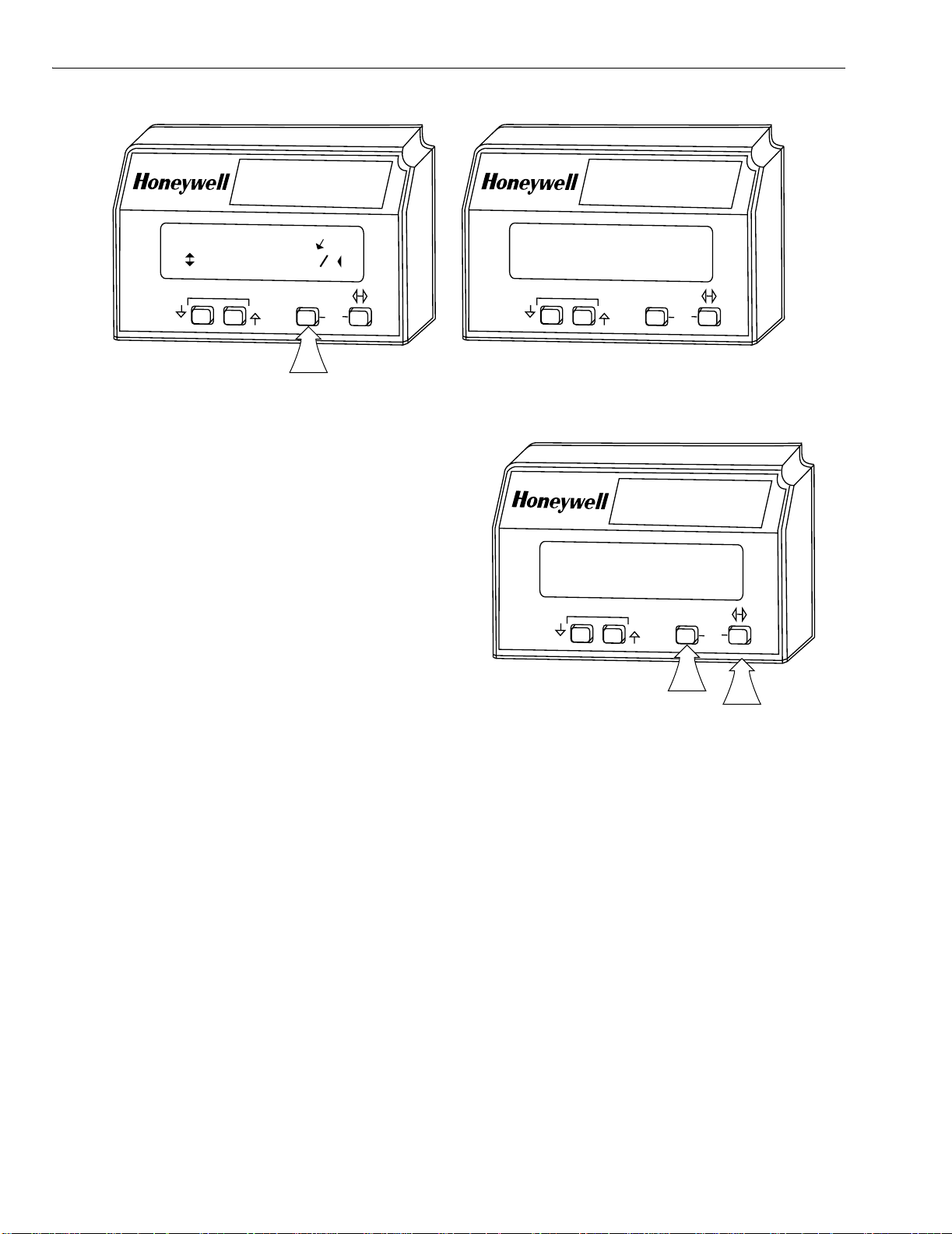

3. MODE push-button, see Fig. 11. Use the MODE

push-button to instantaneously switch the display from a

second-line selectable message to a second-line

preempted message. The sixty second time-out

function can also be used for this task. The MODE

push-button only works if there is a second-line

preempted message or a lockout message.

BURNER CONTROL

RUN

Total Hours 1332

SCROLL

MODE

BURNER CONTROL

PILOT IGN 00:05

Fault History

SCROLL

MODE

Fig. 10. CHANGE-LEVEL (

SAVE

Fig. 9. SCROLL (↕

SAVE

SCROLL

) push-button function.

PILOT IGN 00:10 H1

Fault Cycle 174

SCROLL

↔) push-button function.

MODE

SAVE

M1932A

BURNER CONTROL

MODE

SAVE

M1933A

7 65-0090—4

7800 SERIES S7800A KEYBOARD DISPLAY MODULE

A

BURNER CONTROL

LOCKOUT 17 DI

Main Valve T9 = O

SCROLL

MODE

SAVE

Fig. 11. MODE push-button function.

4. SAVE function, see Fig. 12. The SAVE function enables

users to identify the selectable message they want to

view upon power restoration. The second line

selectable message are restored to the most recently

saved selection when power returns. The SAVE

function is performed is by pressing and holding the

MODE key and then pressing the CHANGE-LEVEL key

(´). The second line of the display briefly notes

“…SAVING…” to confirm the keys were pressed.

Selectable Messages

For the second line display, two-level hierarchy, see Table 3.

The display values are as follows:

BURNER CONTROL

LOCKOUT 17

*Main Flame Fail*

SCROLL

MODE

BURNER CONTROL

PURGE 00:30

... SAVING ...

SCROLL

SAVE

M1934C

MODE

SAVE

n represents a numbered value.

T represents the terminal number.

x represents the suffix letter of the Relay Module.

M1935

Fig. 12. SAVE function.

Table 3. Selectable Messages.

65-0090—4 8

Loading...

Loading...